Installation method of underground concrete wall formwork of row pile supporting structure

An installation method and technology for concrete walls, applied in sheet pile walls, excavation, underwater structures, etc., can solve problems such as difficulty in ensuring the strength, rigidity and stability of the formwork system, formwork deformation, and affecting project quality. It is not easy to achieve Effect of Formwork Deformation, Stiffness and Stability Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further illustrated below by specific examples.

[0031] A method for installing concrete pouring formwork for underground structures; its feature is: comprising

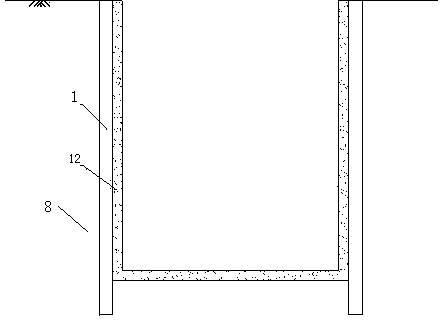

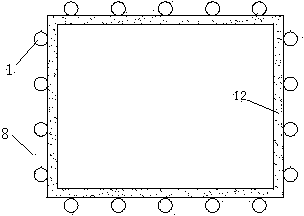

[0032] Step 1, such as figure 1 , figure 2 As shown, retaining piles 1 are arranged on the soil body 8 on the side of the foundation pit according to a certain interval;

[0033] Step 2, foundation pit excavation;

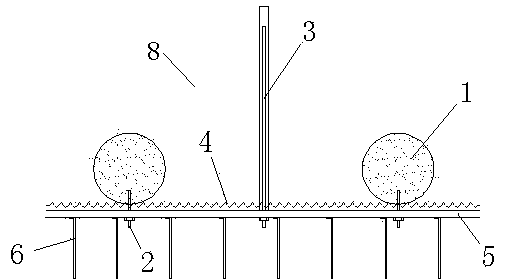

[0034] Step 3, if image 3 As shown, the reinforcement bolts 2 are vertically spaced on each enclosure pile 1, and the anchor bolts 3 are vertically spaced in the side soil 8;

[0035] Step 4, such as Figure 4 , Figure 5 As shown, cover the steel wire mesh 4 on the side soil body 8, and use the reinforcement bolt 2 and the pull anchor bolt 3 to compress it;

[0036] Step 5, such as image 3 , Figure 7 As shown, the ring beam 5 is continuously arranged in the horizontal direction, and the ring beam 5 is respectively connected with the surrounding protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com