Butterfly-shaped wave-resistance plate structure of tank semi-trailer

A technology of anti-wave board and semi-trailer, which is applied in the direction of container, packaging, transportation and packaging, etc. It can solve the problems of weak strength of anti-wave board, deformation of tank body, cracking of tank body, etc., and achieve good sealing and improve anti-wave effect, not easy to deform and crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

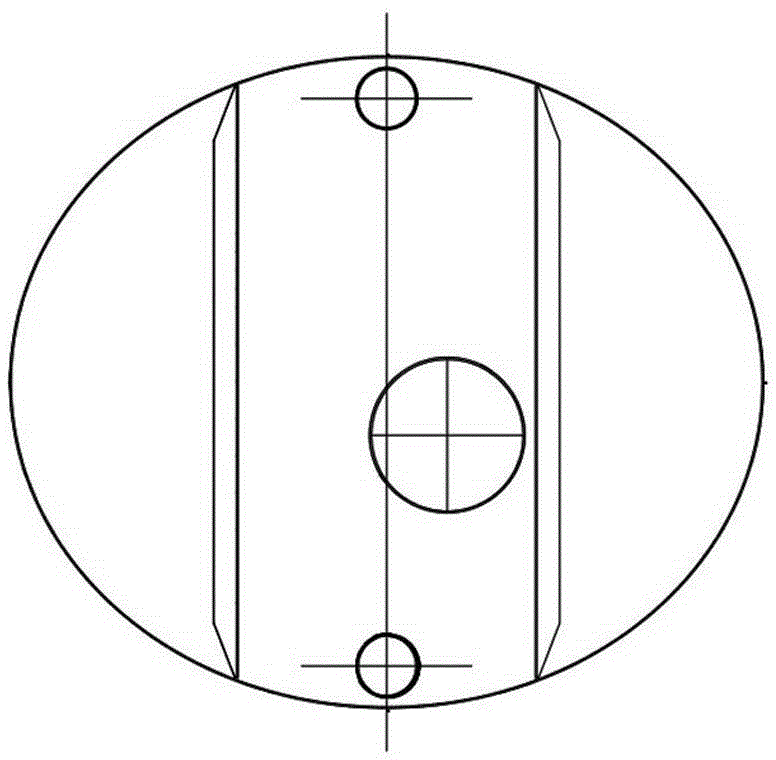

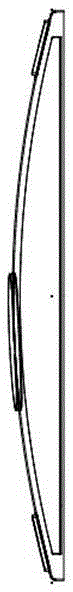

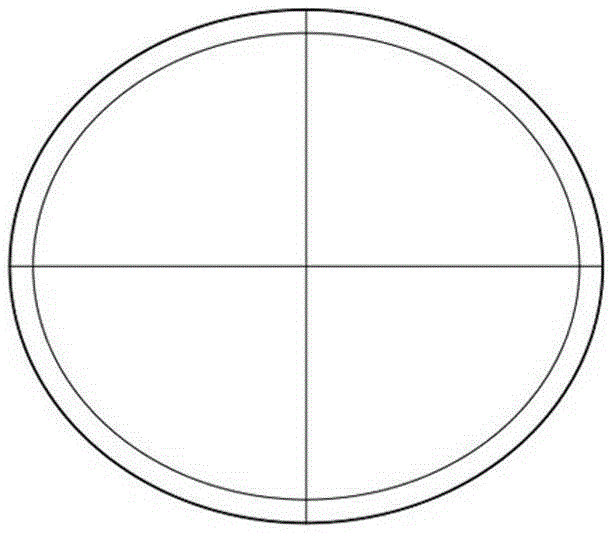

[0014] Embodiments provided by the present invention are described in further detail in conjunction with the accompanying drawings:

[0015] Such as Figure 1-5 As shown, a butterfly-shaped anti-wave plate structure for a semi-trailer tanker includes a butterfly-shaped anti-wave plate 1 and a butterfly-shaped reinforcing ring 2. The butterfly-shaped reinforcing ring 2 is welded on the butterfly-shaped anti-wave plate 1, and the butterfly-shaped anti-wave plate 1 and the butterfly-shaped reinforcing ring 2 are respectively welded to the inside of the tank body of the semi-trailer.

[0016] Preferably, the cross-sectional structure of the butterfly-shaped anti-wave plate 1 is an arcuate structure.

[0017] Preferably, the butterfly-shaped reinforcing ring 2 is an annular structure.

[0018] The invention adopts the tank body of the butterfly-shaped anti-wave plate structure to further improve the anti-wave effect of the anti-wave plate, and can realize double-sided welding at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com