Patents

Literature

1763results about How to "Not easy to move" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

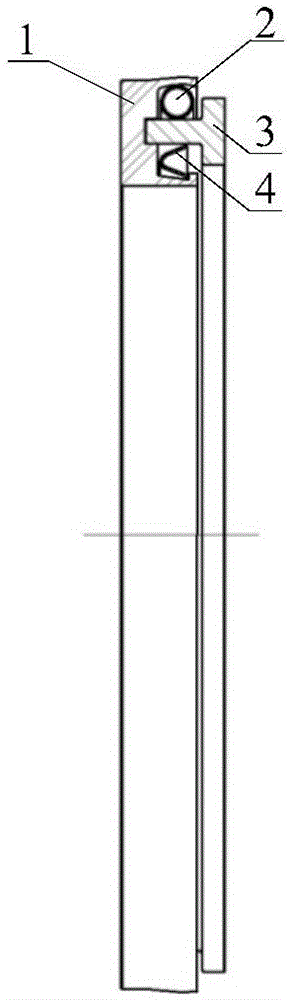

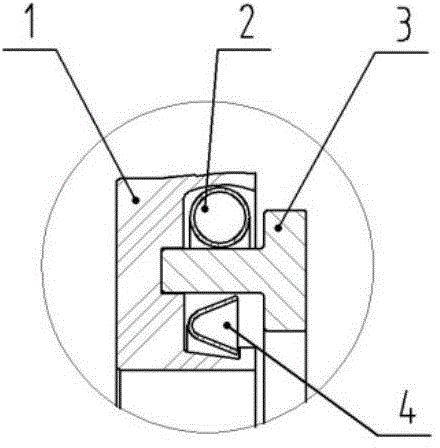

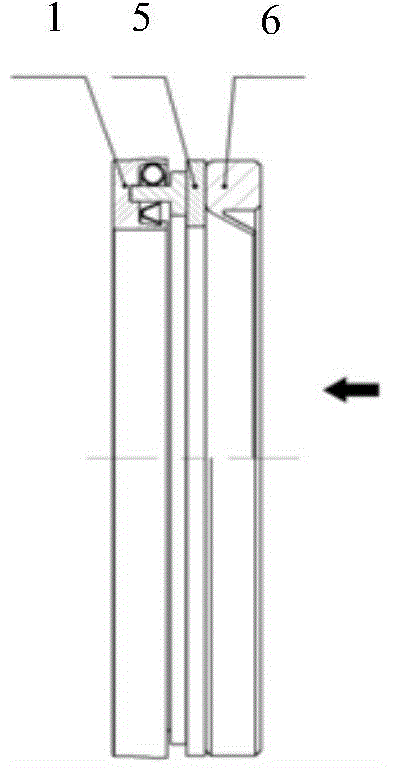

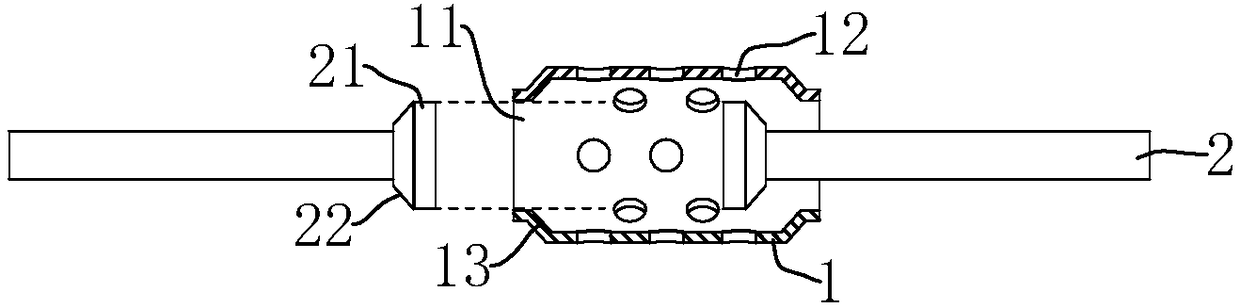

Sealing device and sealing ring thereof

InactiveCN104595493AClose contactAvoid deformationEngine sealsPositive displacement pump componentsEngineeringHigh pressure

The invention discloses a sealing ring, which comprises a base body, a first elastic element and a support element used for supporting, wherein the base body is provided with a groove, the support element is fixedly arranged in the groove, the first elastic element is arranged between the support element and the inner side wall of the groove in a clamping way, and in addition, the first elastic element exerts the force in the direction towards the axis center when receiving the impact by fluid. When the sealing ring provided by the invention is adopted, and when the sealing ring receives the impact by the fluid, on one hand, the base body has a certain impact resistance effect on the fluid, and on the other hand, the elastic element receives the impact effect of the fluid and exerts the force in the direction towards the axis center on the base body, so that the contact of the base body and the part passing through the shaft hole is tighter, so that a good sealing effect is achieved. Therefore the sealing ring has the excellent high-pressure fluid dynamic sealing performance, and in addition, the service life is long. The invention also discloses a sealing device comprising the sealing ring.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

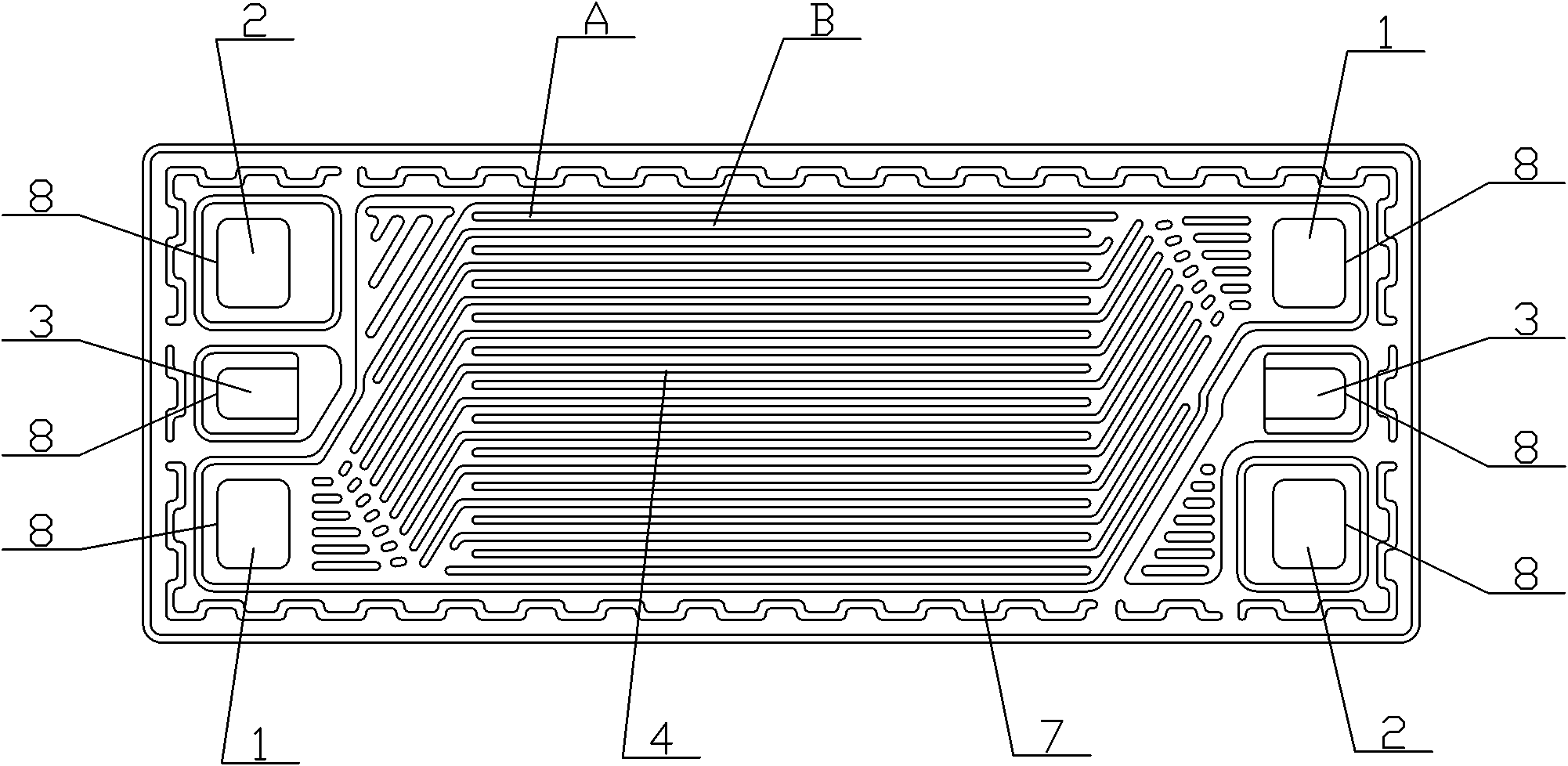

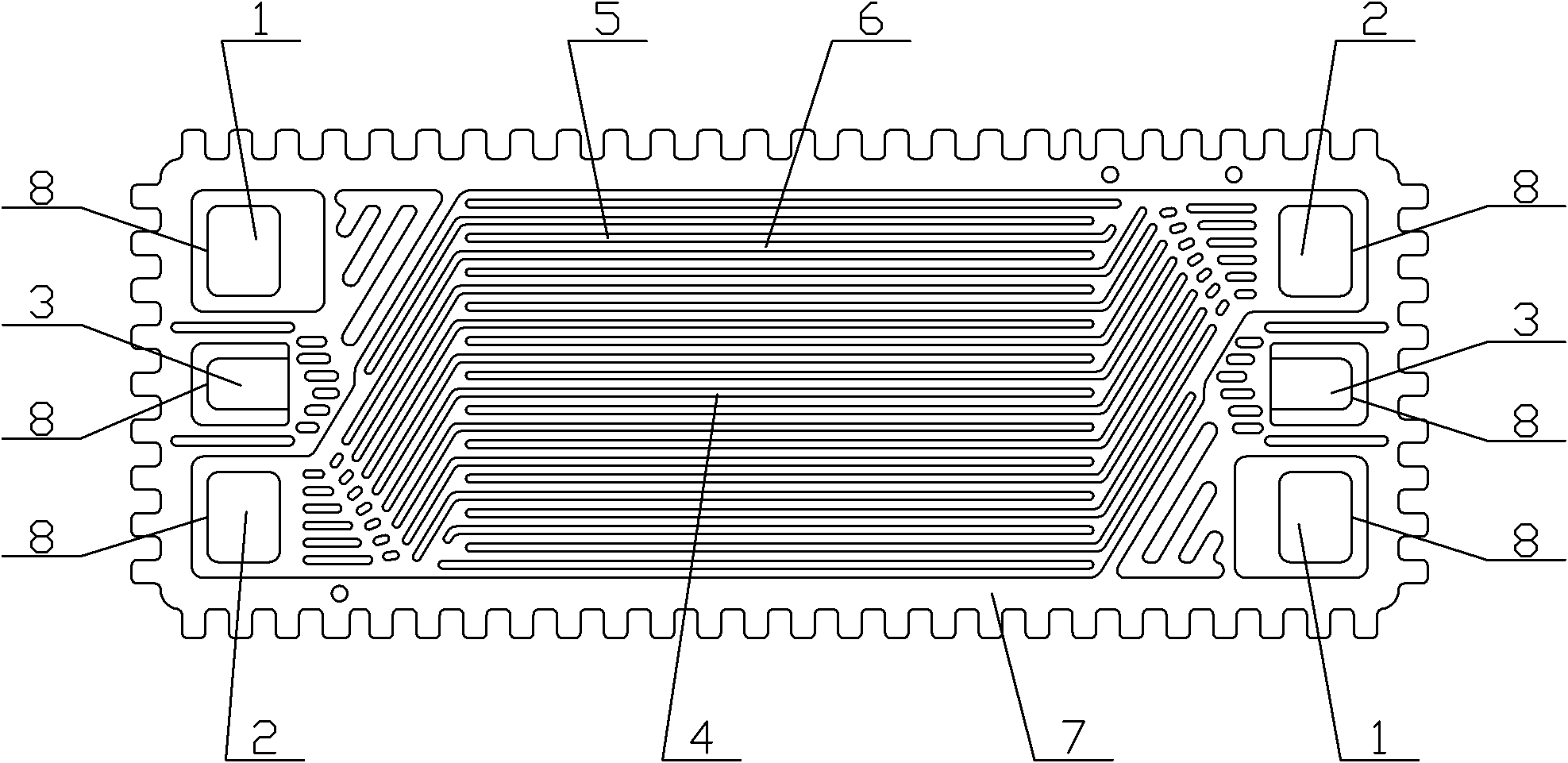

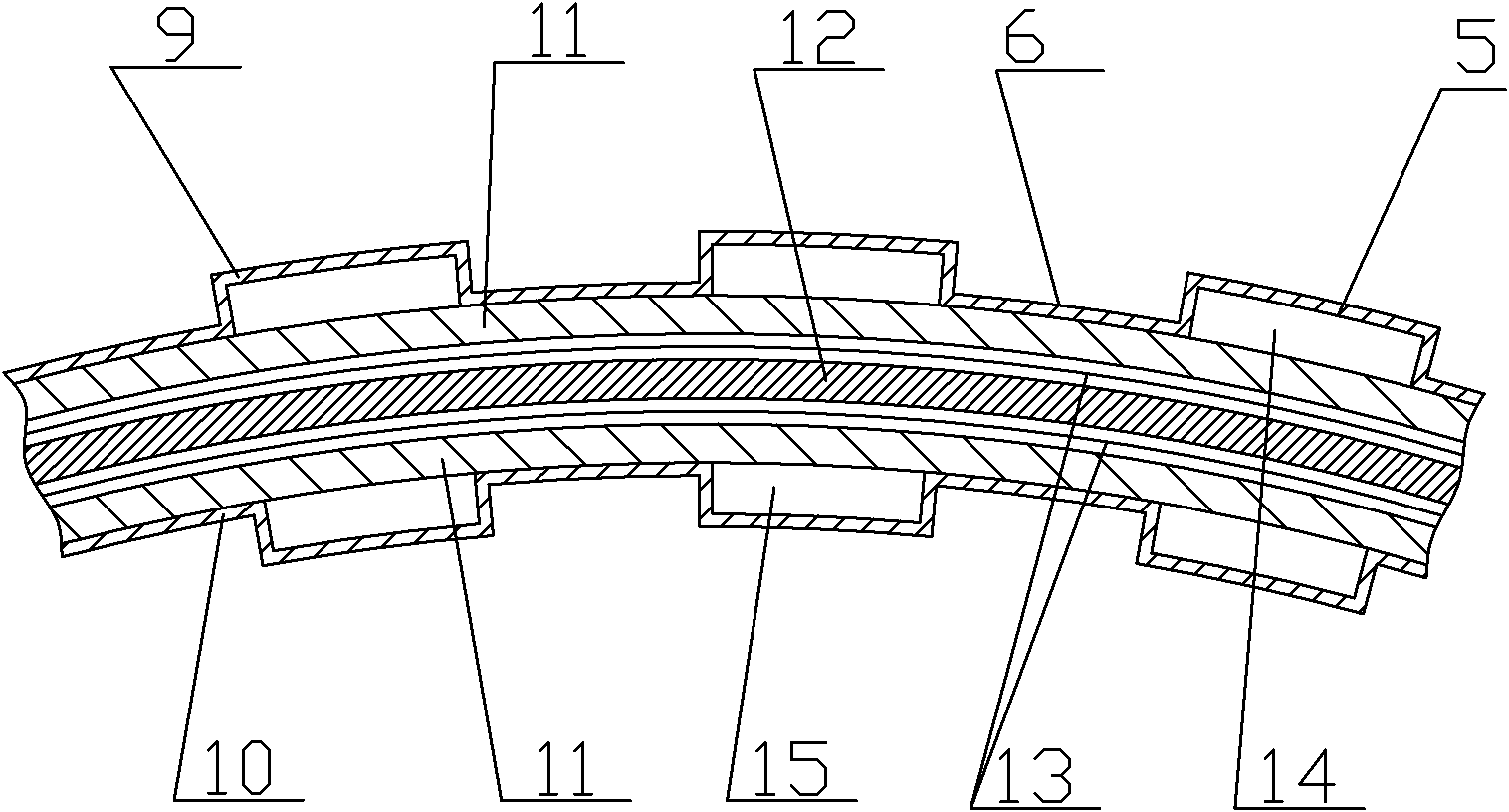

Metallic bipolar plate of proton exchange membrane fuel cell and single cell and electric stack formed by same

ActiveCN101937997AIncrease contactReduce reaction efficiencyFuel cells groupingCell electrodesInternal resistanceEngineering

The invention discloses a metallic bipolar plate of a proton exchange membrane fuel cell and a single cell and an electric stack formed by the same. The metallic bipolar plate is a non-planar arc plate with certain curvature, and is formed by relatively combining a cathode monopolar plate and an anode monopolar plate which are made of metal sheets; cathode and anode cavities, cooling medium cavities, flow field area grooves and lug bosses of the two plates have mutual corresponding convex-concave shapes and form a fuel gas passage, an oxidant gas passage and a cooling medium passage respectively; and a membrane electrode and single bipolar plate can be combined into single fuel cell, and a plurality of single cells can be superposed and connected to form the electric stack. Compared with a common metallic bipolar plate, the bipolar plate has better mechanical property, is not easy to deform or dislocated after assembly, and has high stability; and because the contact between the bipolar plate and a diffusion layer of the membrane electrode is good, the internal resistance is low, the energy consumption is low, and the formed electric stack can provide higher output voltage and higher output power.

Owner:WUHAN UNIV OF TECH

Antiseptic wearable coat and coating method thereof

ActiveCN101191225ATo achieve the purpose of corrosion resistance and wear resistanceEasy to operateMetallic material coating processesRheniumThermal spraying

The invention discloses a corrosion and abrasion resistant coating and a coating method thereof, comprising: firstly, weight percentage of compositions of coating materials adopted is that: carbon: less than or equal to 0.5 percent; chromium: 16 to 26 percent; nickel: 3.5 to 9.5 percent; molybdenum: 1.0 to 4.0 percent; boron: 0.5 to 4.5 percent; silicon: 0.5 to 4.5 percent; copper: 1.0 to 4.0 percent; manganese: 0 to 2.0 percent; rare earth - rhenium: 0.01 to 1.5 percent; the residual is ferrum and inevitable impurities; secondly, pretreatment of the surface of a metallic matrix reaches technological demand; thirdly, thermal spraying is adopted on the matrix surface; a plurality of air cooling nozzles surrounding a spray gun which are in parallel with spraying flame velocity are arranged on the spray gun; travel rate of the spray gun is 150 to 400 millimeters per second; surface temperature of workpieces is controlled to be less than 150 DEG C; an amorphous stainless steel protective coating is formed on the matrix surface finally; fourthly, sundries on the coating surface are cleaned, and the coating is performed sealing treatment. The invention solves the protective problem of erosion-corrosion under the condition of acid humid environment and that Cl<-> ions and dust particles exist.

Owner:BAOSHAN IRON & STEEL CO LTD

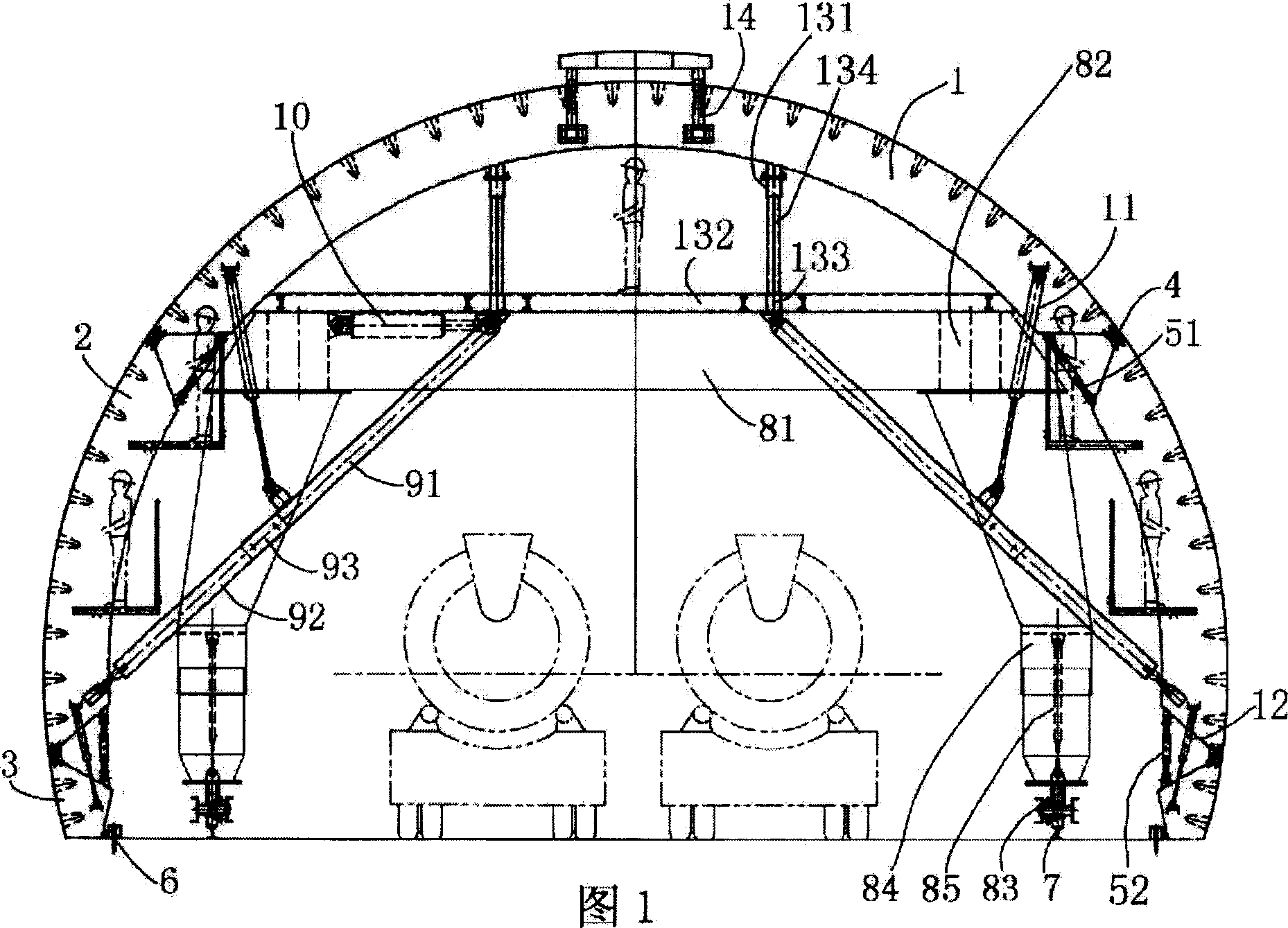

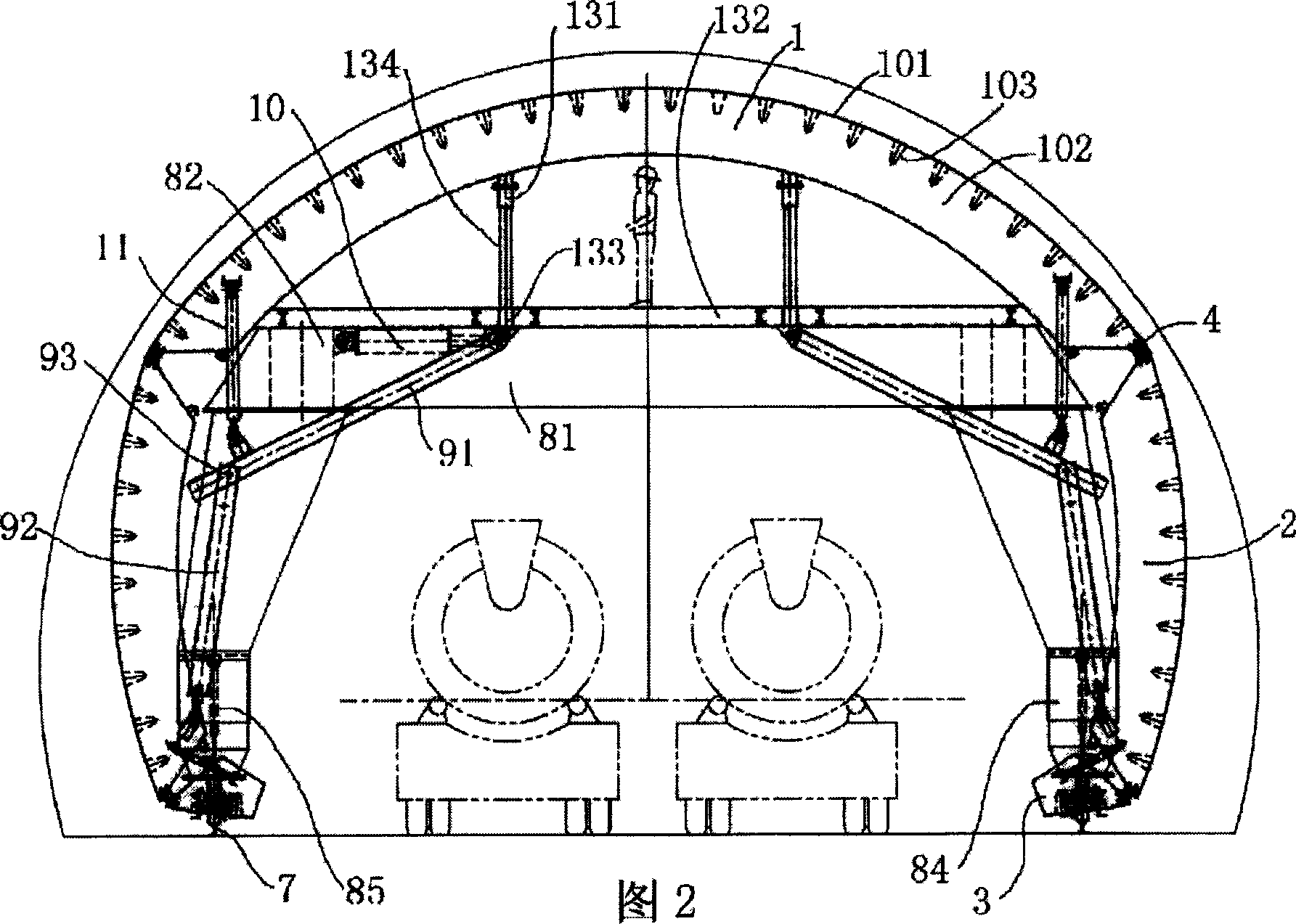

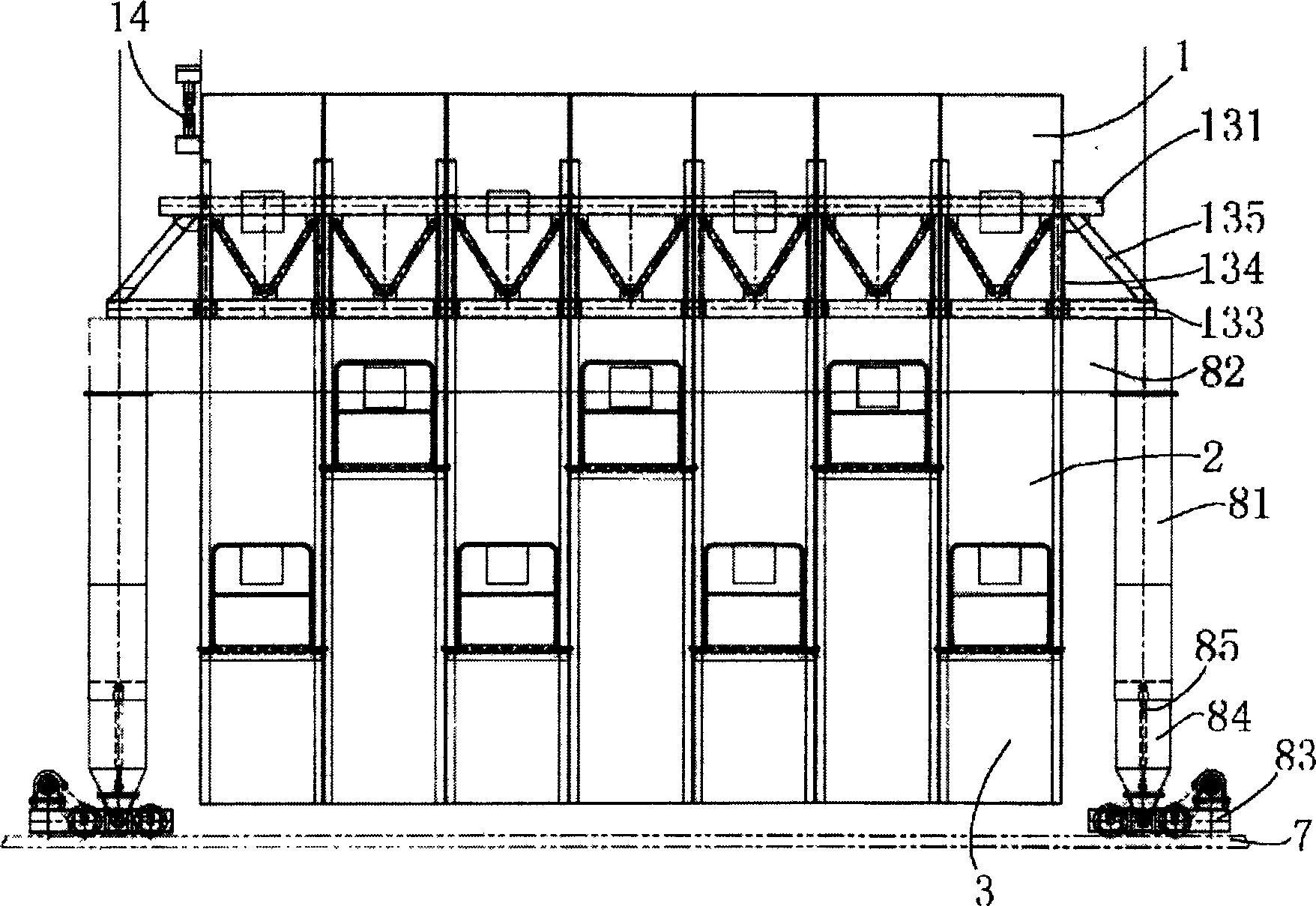

Tunnel lining trolley

InactiveCN1851233AFrame widthIncrease stiffnessUnderground chambersTunnel liningEngineeringMechanical engineering

The invention is a tunnel lining carrier, where a group of templates comprises top plate, two side templates and two bottom templates, the cross sections at the interfaces between the top template and the two side templates and between the two side templates and the two bottom templates are horn-shaped, and their outer edges are hinged with flat top hinge and their inner edges are connected with regulating screws; a template bracket comprises top longitudinal beam, cross beam, bottom longitudinal beam, column and inclined strut. And the carrier comprises door frame, girder summer and moving system; folding supports arms are connected between the bottom surface of the crossbeam and the bottom ends of the two side templates, side moving hydraulic oil cylinder is connected between the bottom longitudinal beam and the girder summer, expanding hydraulic oil cylinders are connected between the large arms of the folding support arms and the two bottom ends of the top template, and opening hydraulic oil cylinders are connected in the horn-shaped positions between the side and bottom templates.

Owner:杨秋利

Soil modifying agent, manufacturing and use method thereof

ActiveCN1876759AWide range of raw materialsEasy to operateOrganic fertilisersSoil conditioning compositionsOrganic fertilizerSoil conditioner

The invention relates the soil conditioner, comprising the following steps: using porous inorganic matter as raw material, adding 3wt%-50wt% forming agent and 0.1-50wt% activating agent, granulating, and getting the product. The soil conditioner can modify soil physicochemistry deseription; it can be mixed with inorganic or organic fertilizer. It also can be used as carrier to product microbe soil conditioner. It is mixed with organic matter to product organic fertilizer which contains high nitrogen content.

Owner:王培武

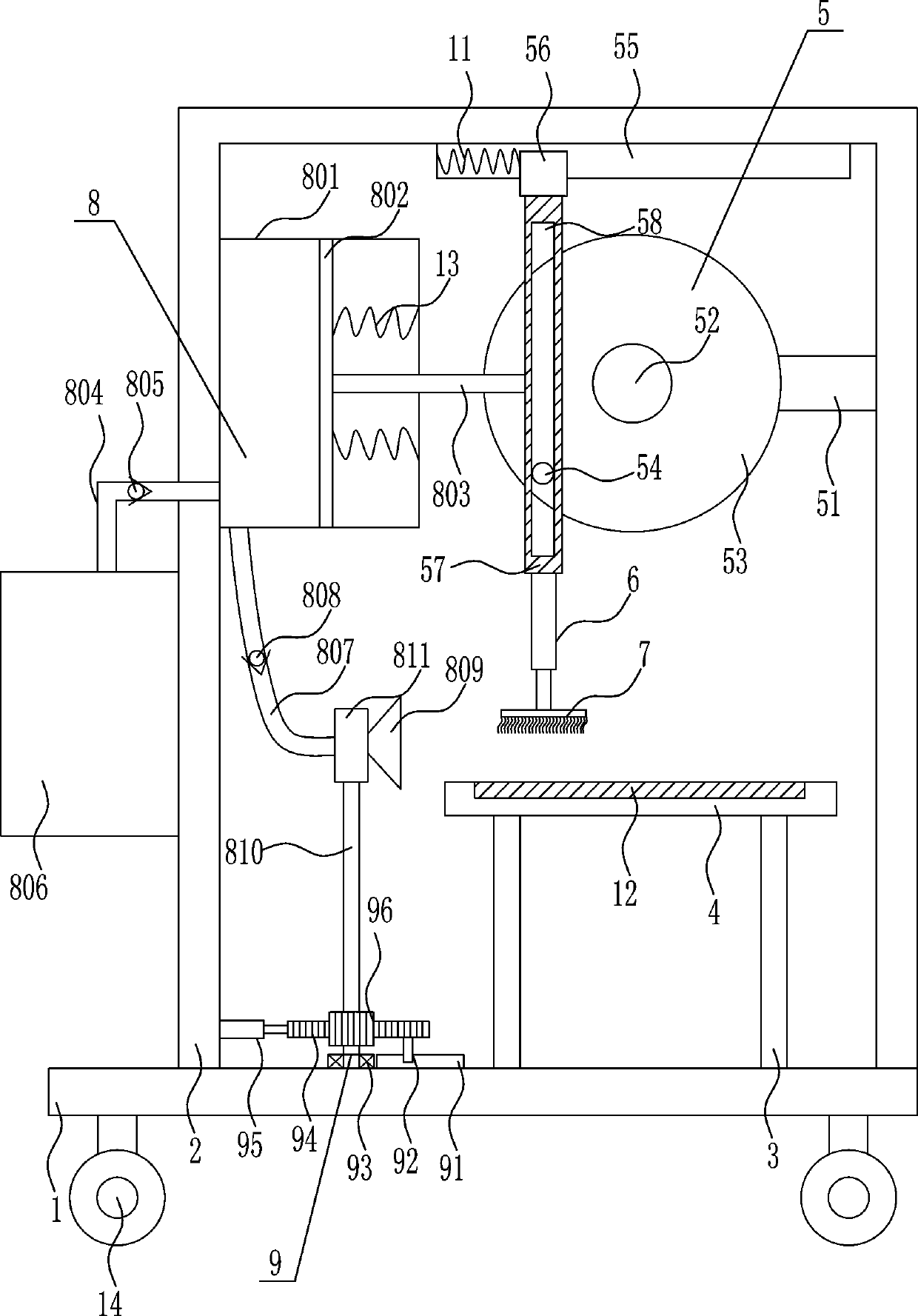

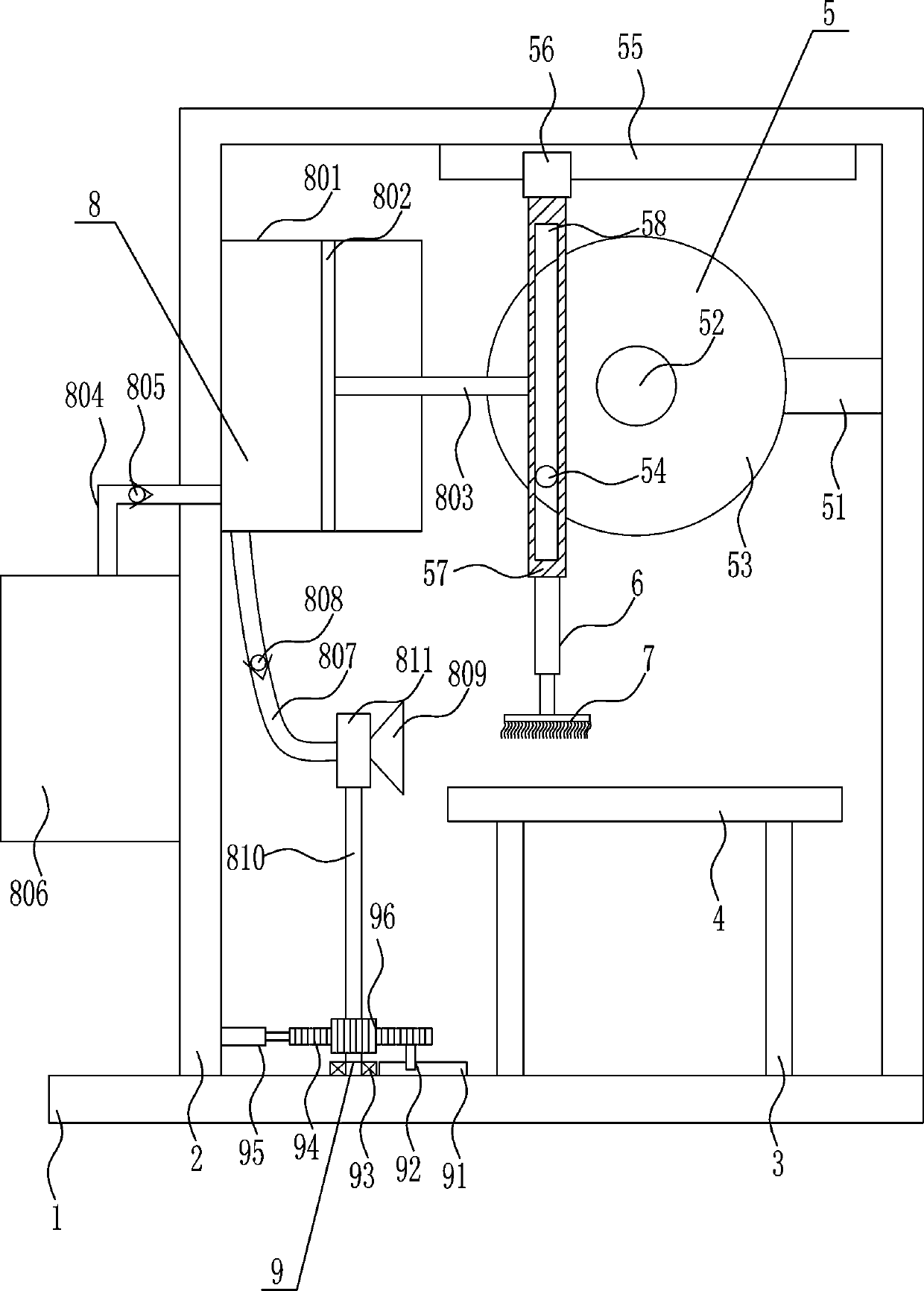

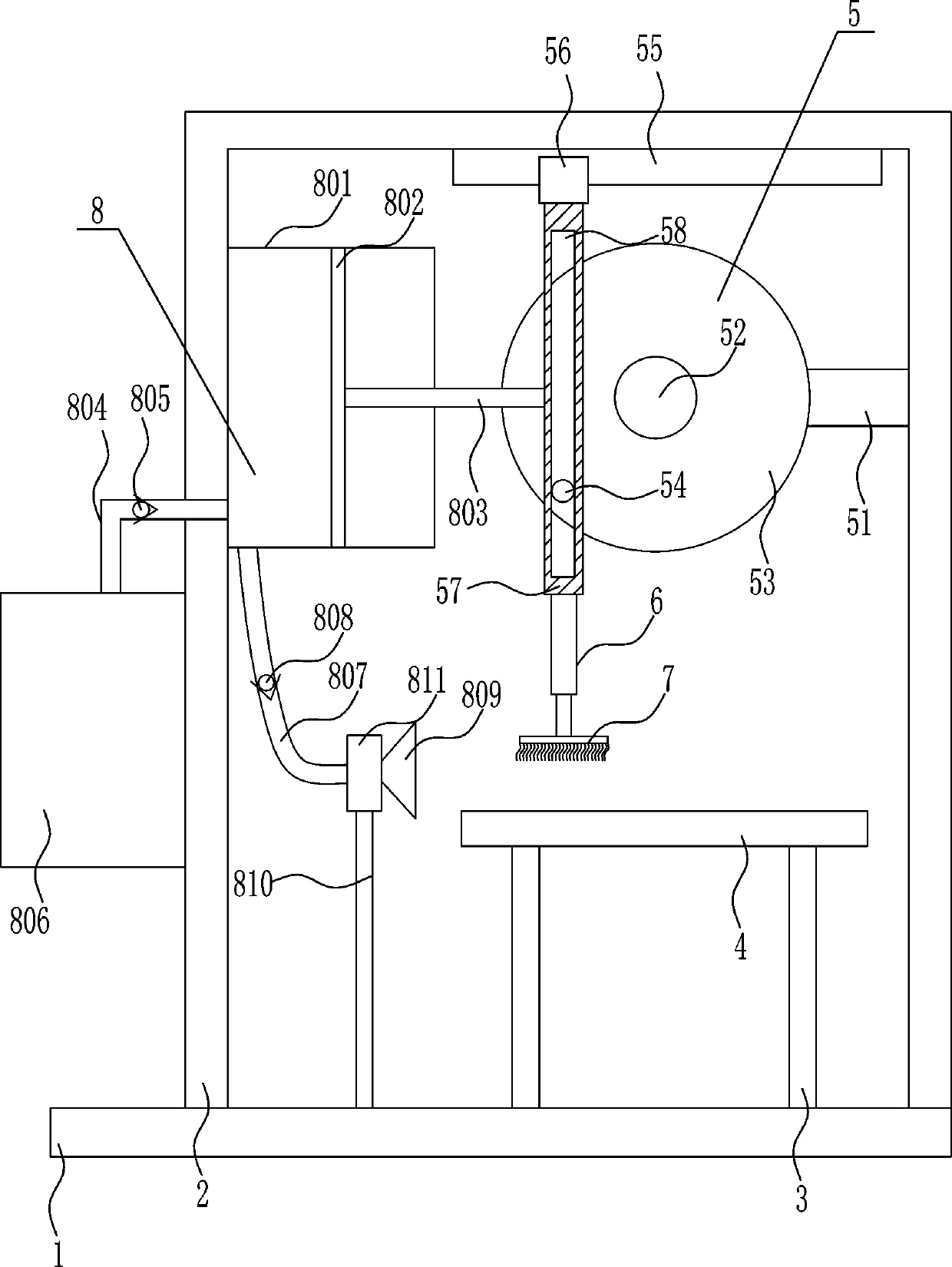

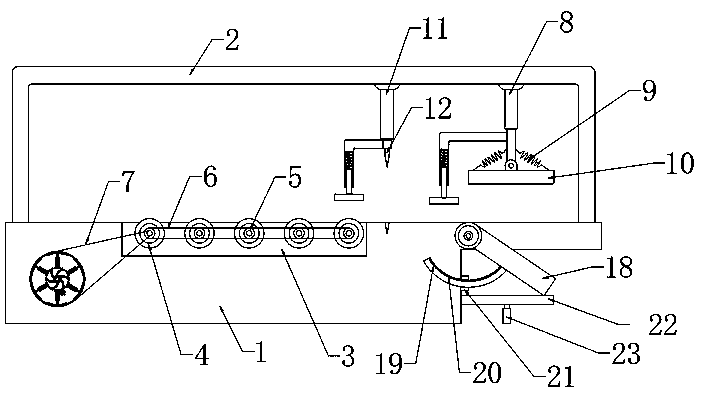

Dust removing plant for production of circuit switch

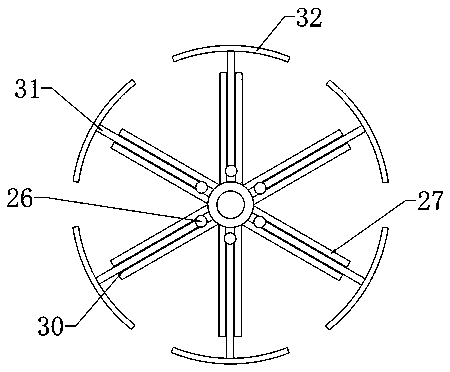

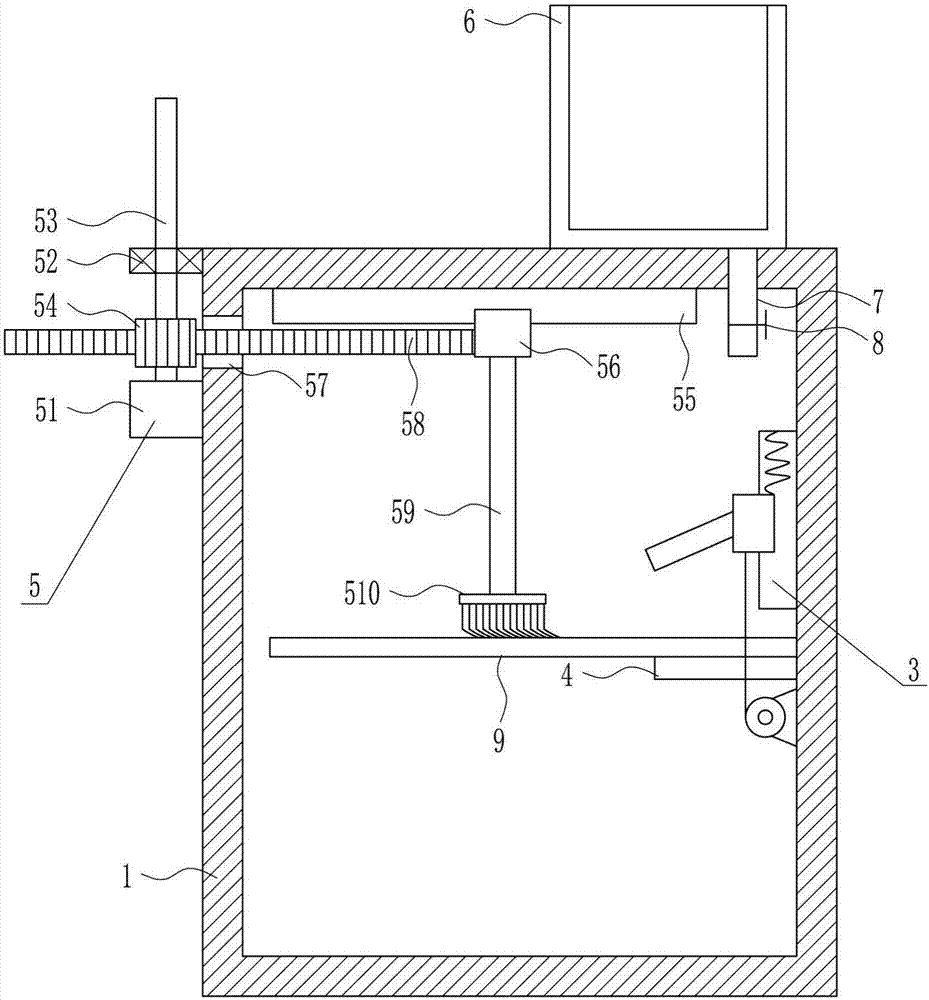

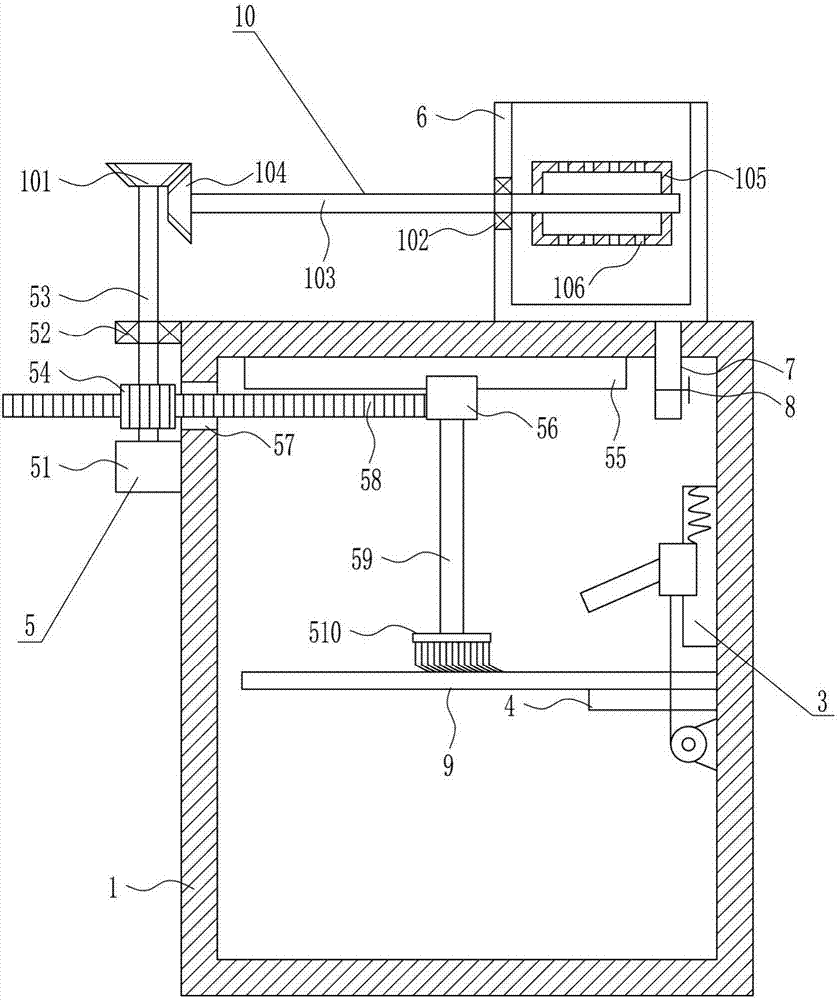

InactiveCN107694977ANot easy to moveImprove dust removal efficiencyDirt cleaningCleaning using toolsEngineering

The invention relates to a dust removing plant of a circuit switch, and particularly relates to a dust removing plant for production of a circuit switch. The technical problem to be solved is to provide the dust removing plant for production of the circuit switch, which is high in dust removing efficiency, and can treat dust in the process of removing dust, and is not easy to move the circuit switch. For solving the technical problem, the dust removing plant for production of the circuit switch is provided. The dust removing plant comprises a bottom plate, a n-shaped frame, a first supportingrod, a placing plate, and others; the top part of the bottom plate is provided with the n-shaped frame, and the upper part of the inner right side of the n-shaped frame is provided with a driving mechanism; the bottom part of the driving mechanism is provided with an air cylinder, and the bottom end of the air cylinder is connected with a soft brush; the upper part of the left side of the n-shapedframe is provided with a dust removing mechanism. The a dust removing plant reaches the effect that the dust removing efficiency is high, the dust can be treated in the process of removing dust and the circuit switch is not easy to move. Through the driving mechanism, the soft brush is driven to remove dust on the circuit switch; the dust is treated by the dust collecting mechanism, and the circuit switch is clamped by the clamping mechanism; the dust removing plant is not easy to slip.

Owner:南昌安润科技有限公司

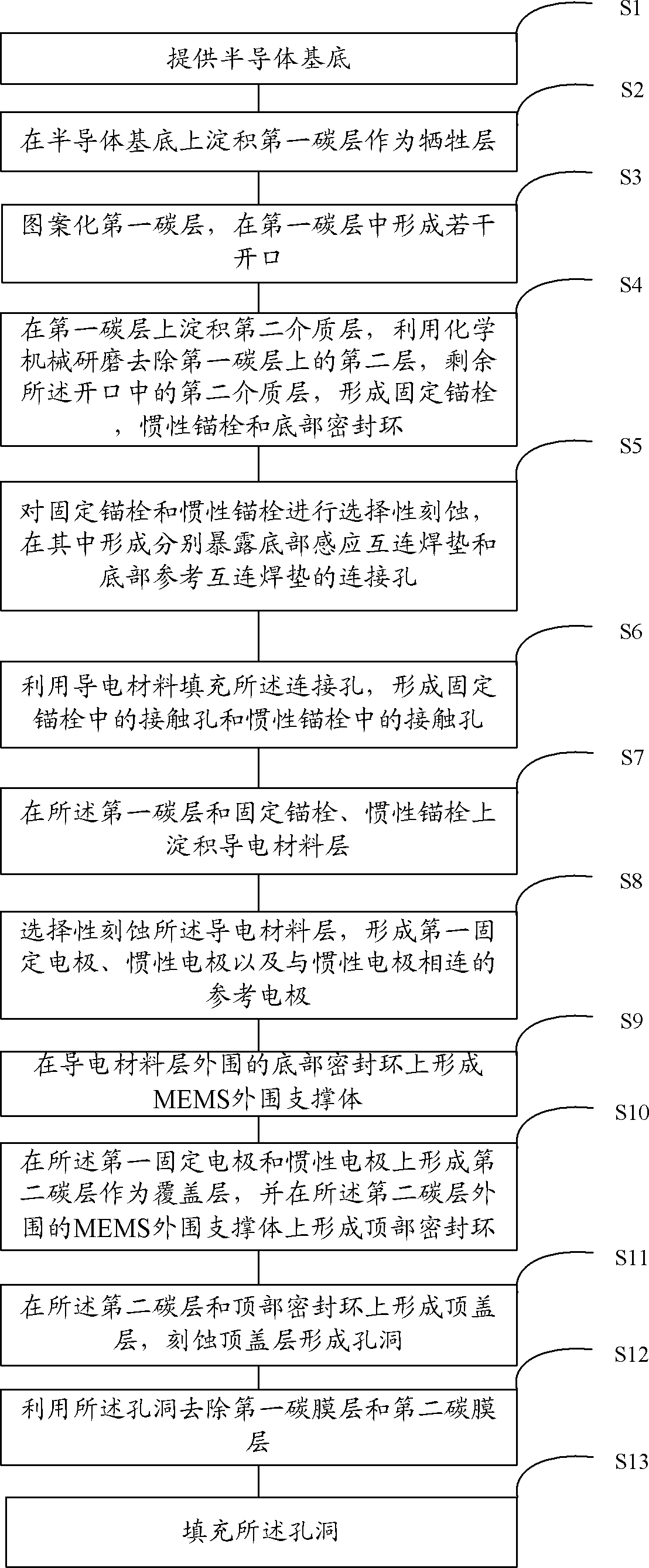

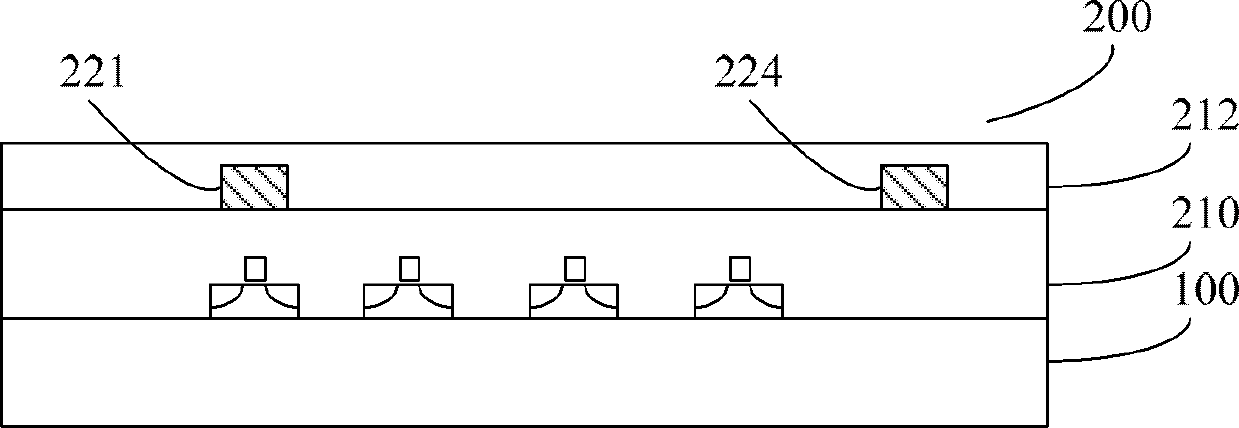

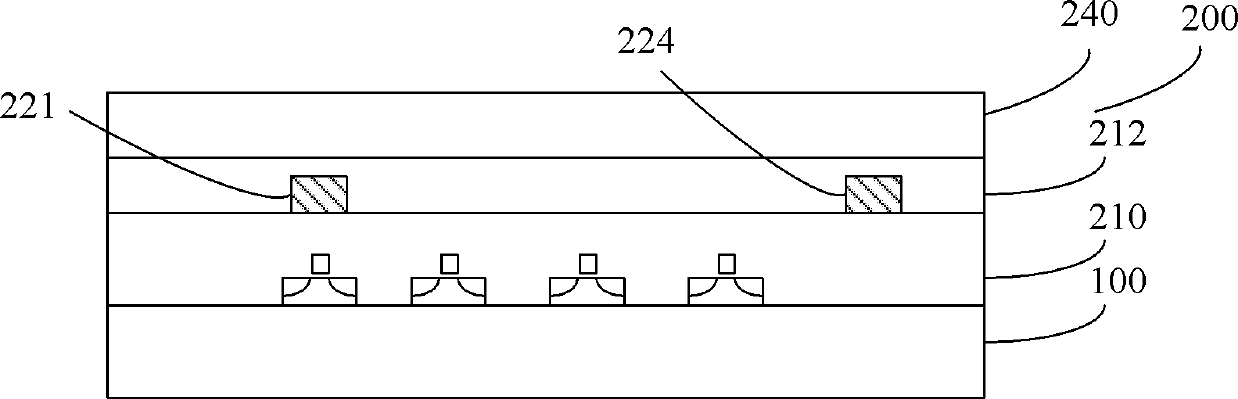

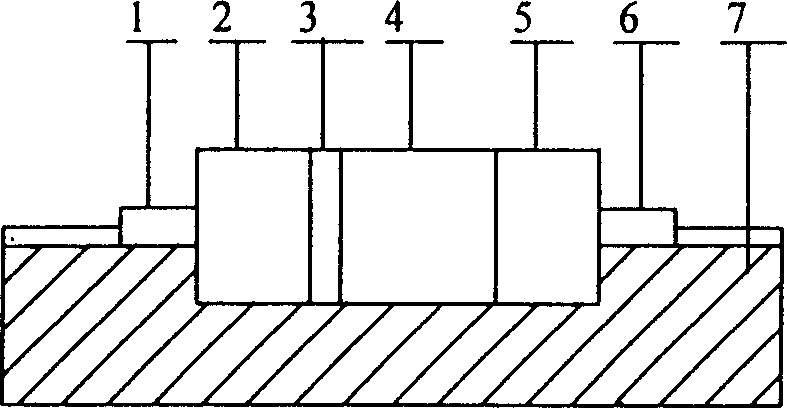

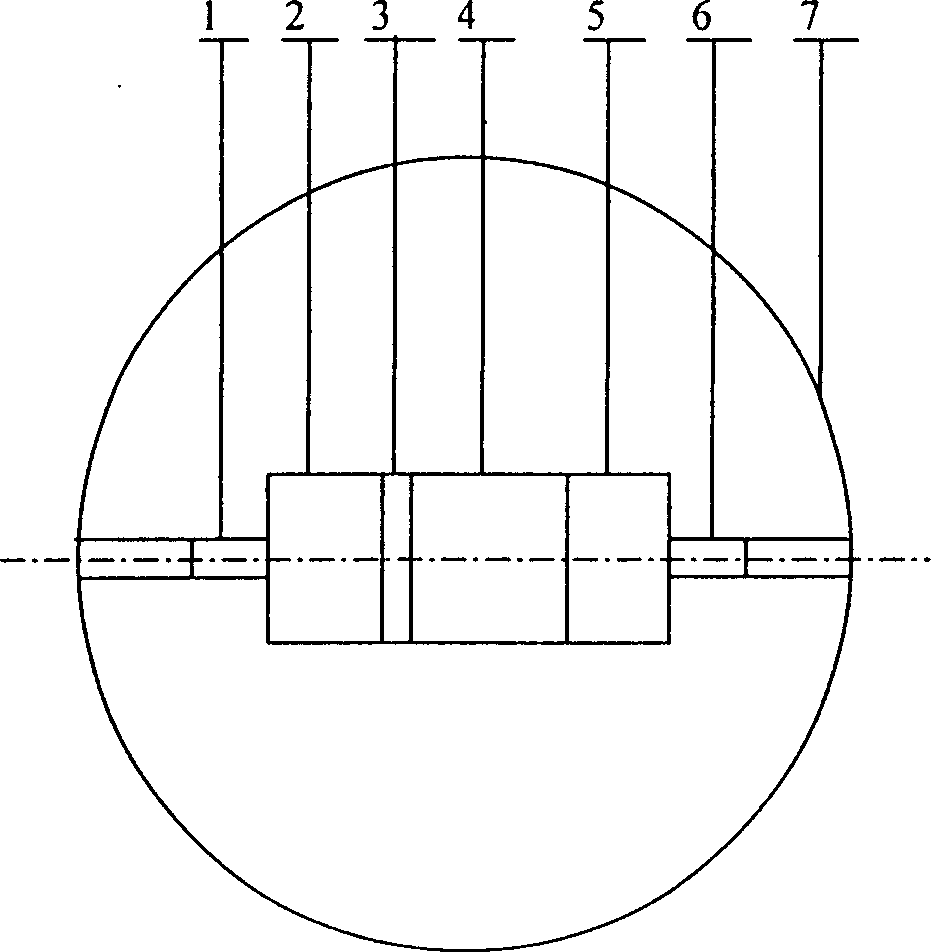

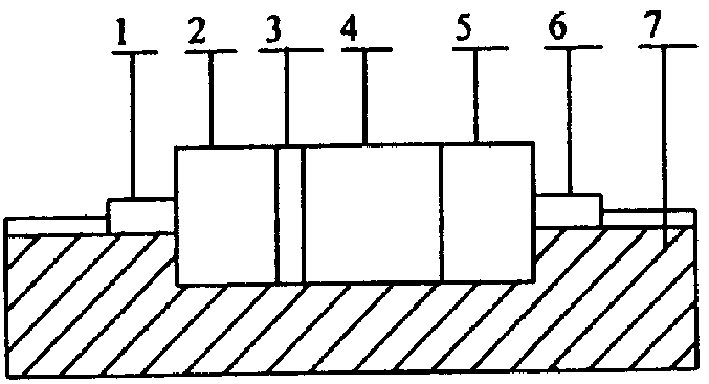

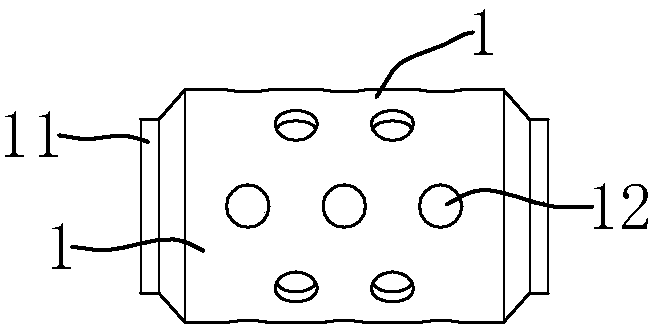

Method for manufacturing MEMS (Micro Electro Mechanical System) and MEMS inertial sensor

ActiveCN103373698ANot easy to moveMovement doesn't happen easilyDecorative surface effectsAcceleration measurementCapacitanceCarbon layer

The invention provides a method for manufacturing a MEMS (Micro Electro Mechanical System) and an MEMS inertial sensor. The method comprises the steps of depositing a first carbon layer serving as a sacrificial layer on a semiconductor substrate; patterning the first carbon layer and forming a fixed anchor bolt, an inertial anchor bolt and a bottom sealing ring; forming a contact plug in the fixed anchor bolt and a contact plug in the inertial anchor bolt; forming a first fixed electrode, an inertial electrode and a connection electrode connected with the inertial electrode on the first carbon layer, the fixed anchor bolt and the inertial anchor bolt, wherein the first fixed electrode and the inertial electrode form a pair of capacitors; forming second carbon layers serving as covering layers on the first fixed electrode and the inertial electrode; and forming top cover layers on the second carbon layers and a top sealing ring. According to the inertial sensor provided by the invention, under the action of the inertial force, only the inertial electrode moves and the fixed electrode can not move or vibrate, so that the accuracy of the inertial sensor is improved.

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

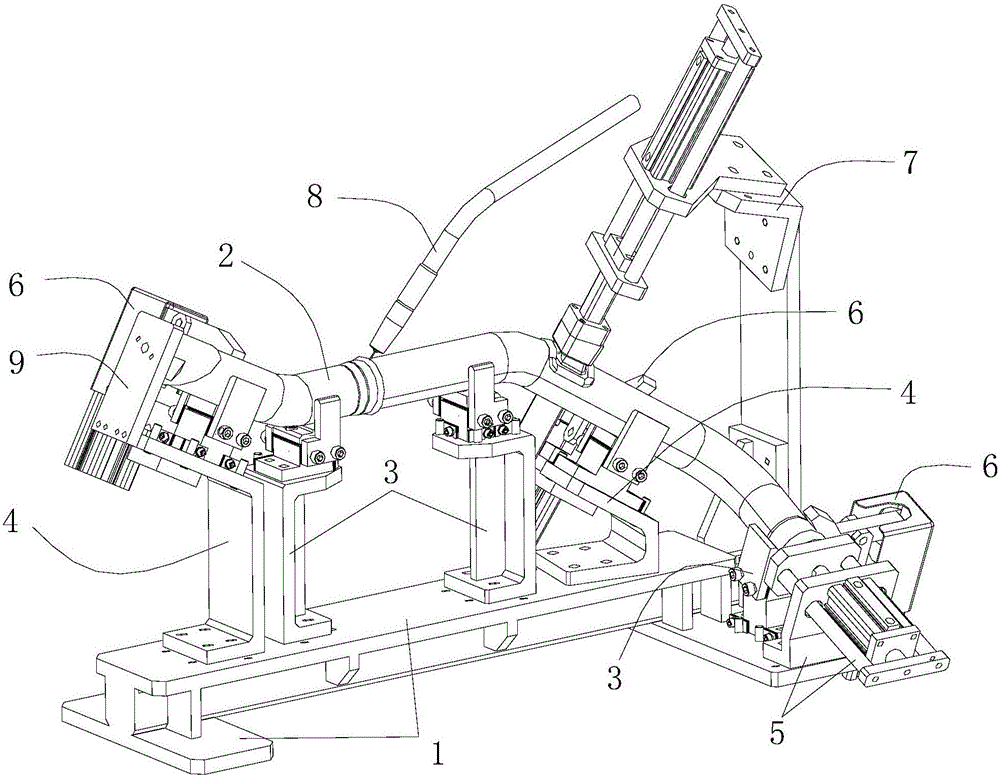

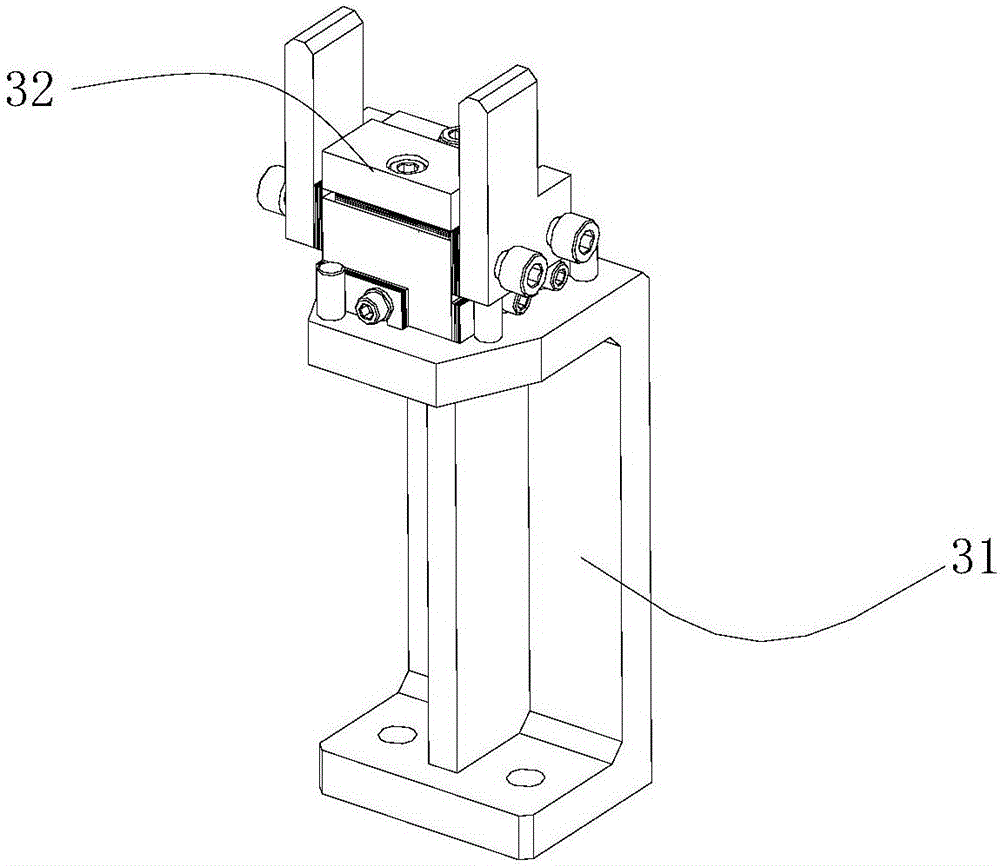

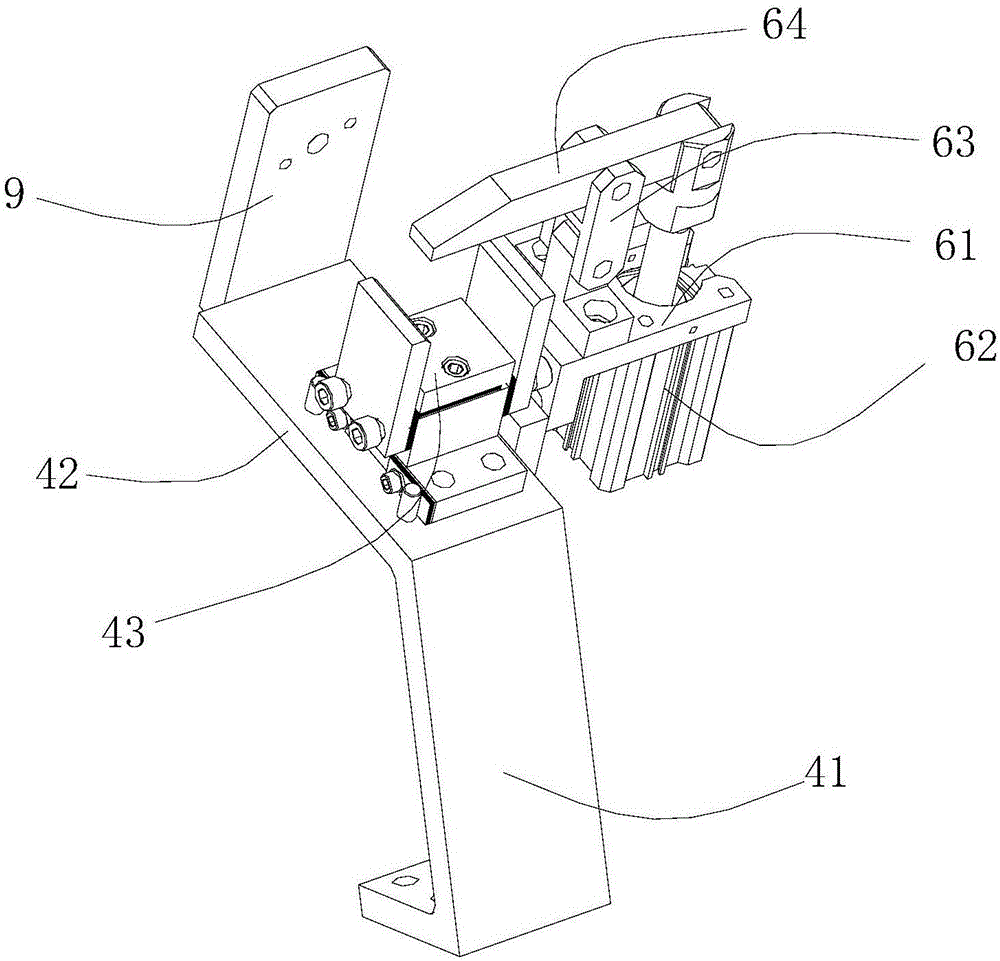

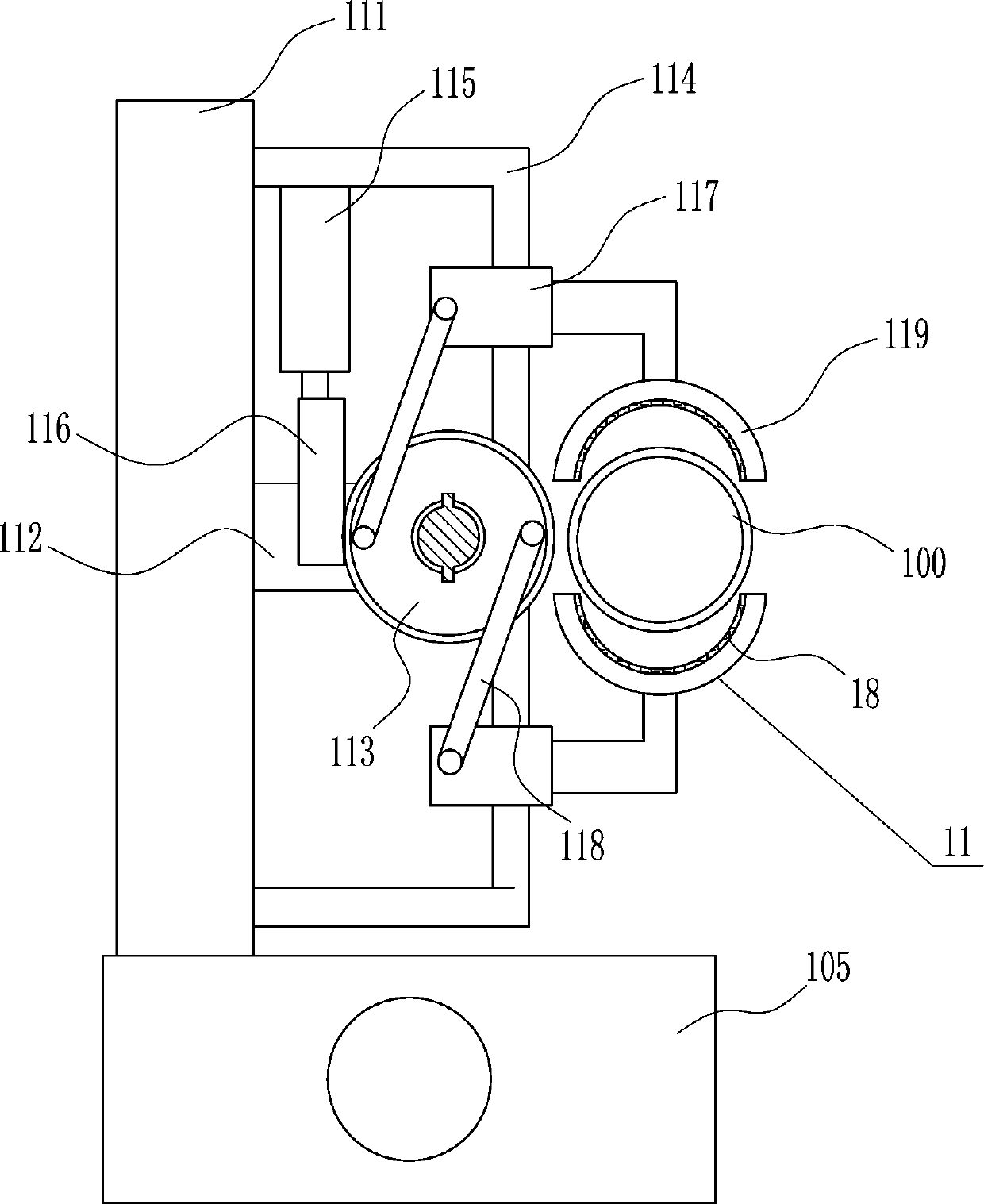

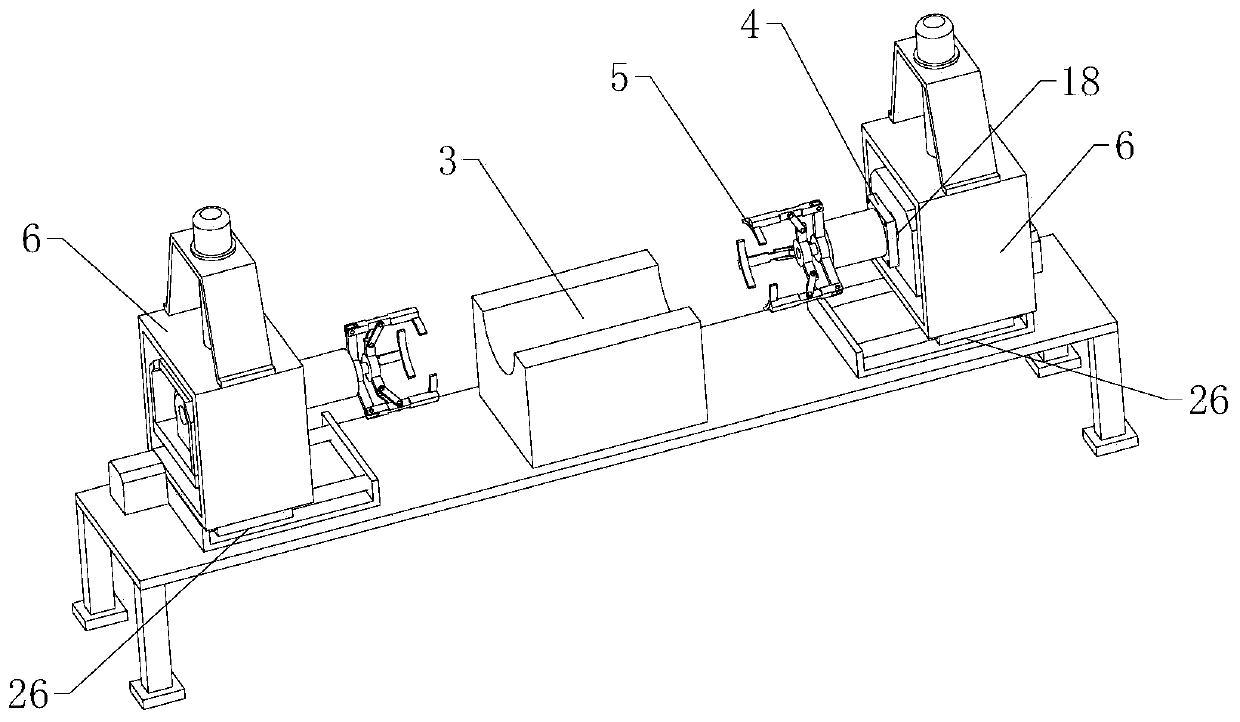

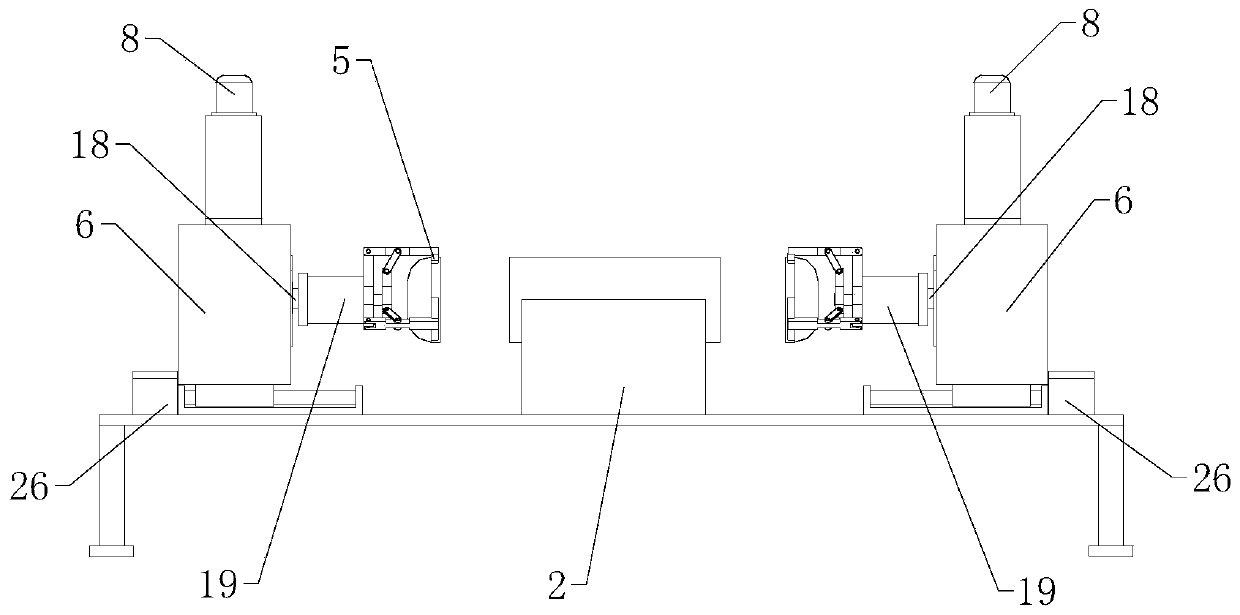

Welding device for special-shaped bent pipe

ActiveCN106514106APrecise positioningNot easy to moveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding device for a special-shaped bent pipe. The special-shaped bent pipe is installed on a working platform. The special-shaped bent pipe comprises a plurality of horizontal sections and a plurality of oblique sections. The horizontal sections are parallel to the working platform. An included angle is formed between each oblique section and the working platform. The welding device for the special-shaped bent pipe comprises at least one first supporting mechanism used for supporting the horizontal sections, at least one second supporting mechanism for supporting the oblique sections, a limiting mechanism used for limiting the movable end of the special-shaped bent pipe, at least one first clamping mechanism for clamping the special-shaped bent pipe, and a second clamping mechanism for clamping the middle portion of the special-shaped bent pipe. The welding device is simple in structure, the special-shaped bent pipe is clamped and positioned, looseness and displacement are not likely to happen, the welding precision of the special-shaped bent pipe is effectively guaranteed, welding application of a welding machine is facilitated, the welding and assembling efficiency is improved, welding errors are reduced, and the welding quality of products is improved.

Owner:景和智能制造(广东)有限公司

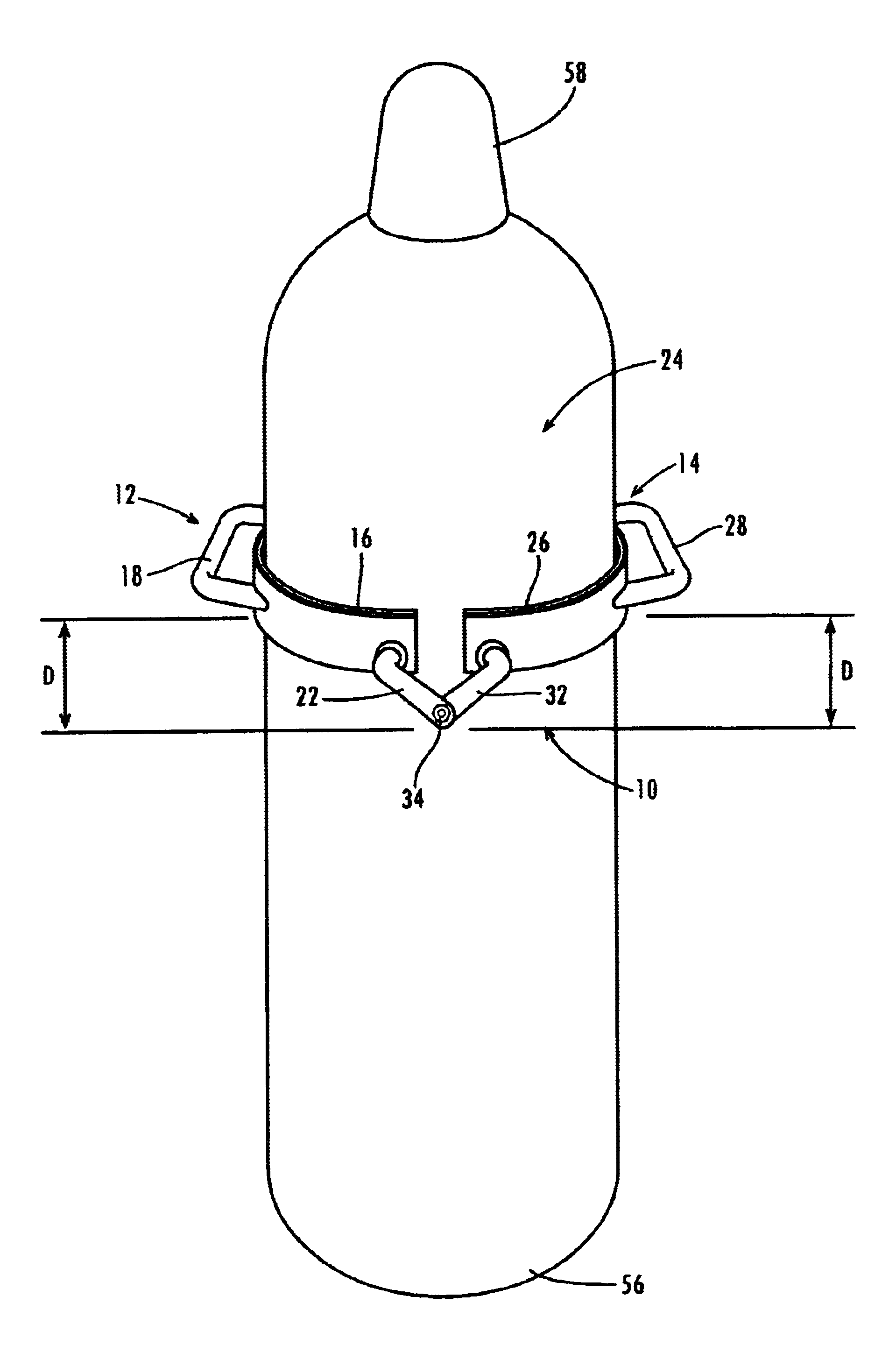

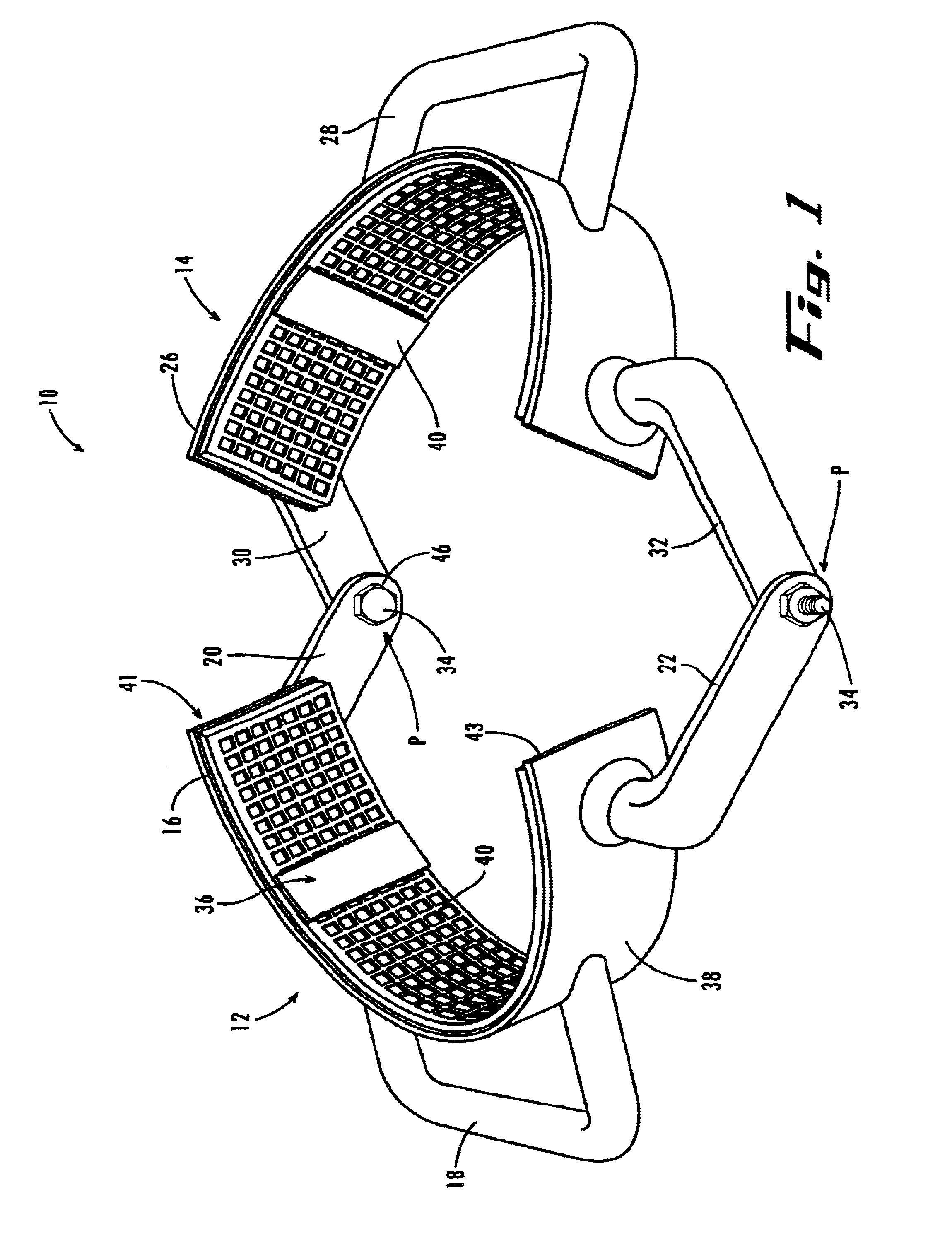

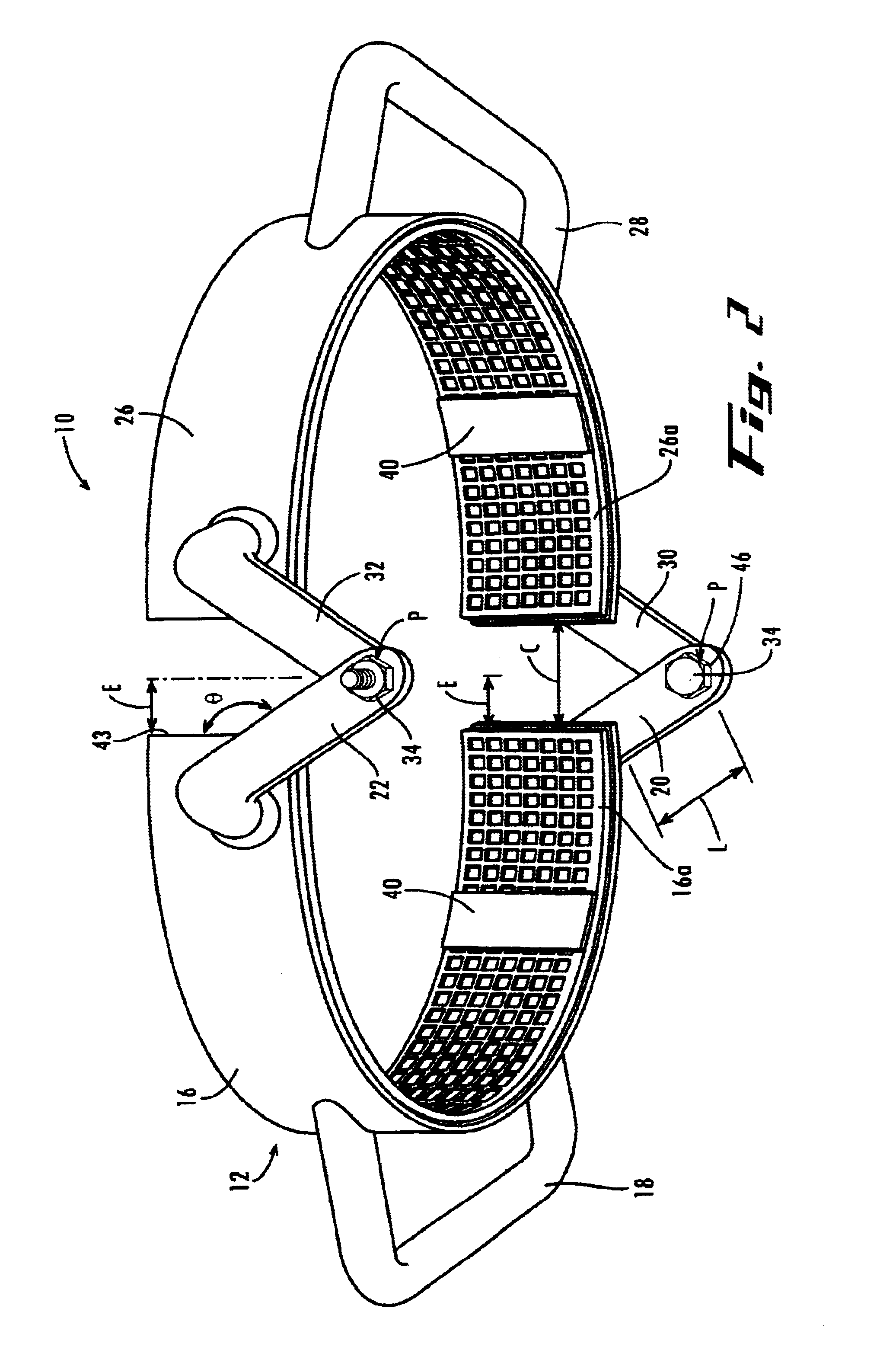

Device for lifting gas cylinders

InactiveUS6840556B1Difficult to liftNot easy to moveKitchen equipmentManual conveyance devicesGas cylinderLifting gas

A device for maneuvering cylinders having first and second semi-circular lifting members hingedly connected to one another by first and second hinge members. The lifting members are urged toward one another and the cylinder to frictionally secure the lifting members against the cylinder for maneuvering of the cylinder. First and second free ends of the first lifting member are maintained in a spaced apart relationship relative to first and second free ends of the second lifting member corresponding to a desired gap distance, and the first and second hinge members of each lifting member each define a hinge point located a desired hinge distance vertically spaced from free edges of each of the lifting members, such that the ratio of the gap distance to the hinge distance is at least about 1.25.

Owner:CATLETT LARRY K

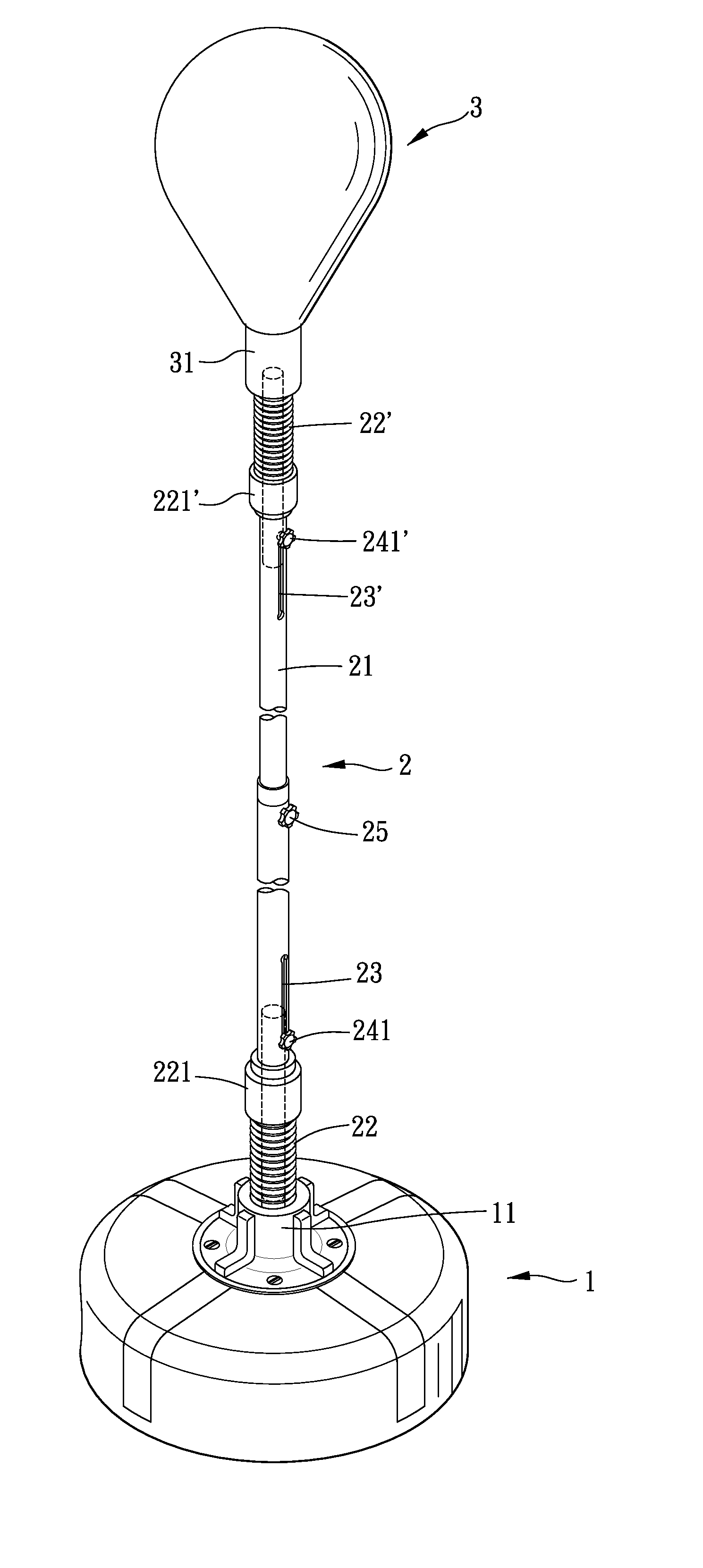

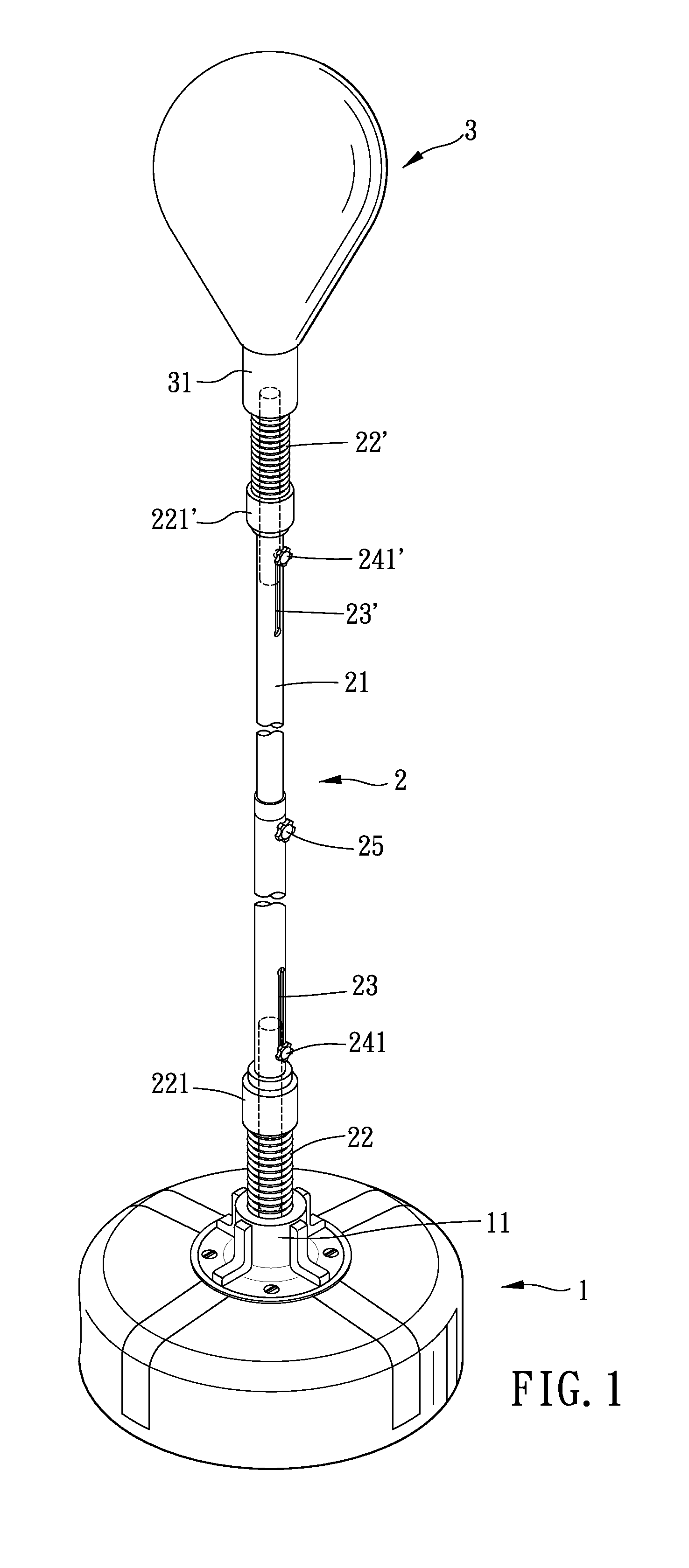

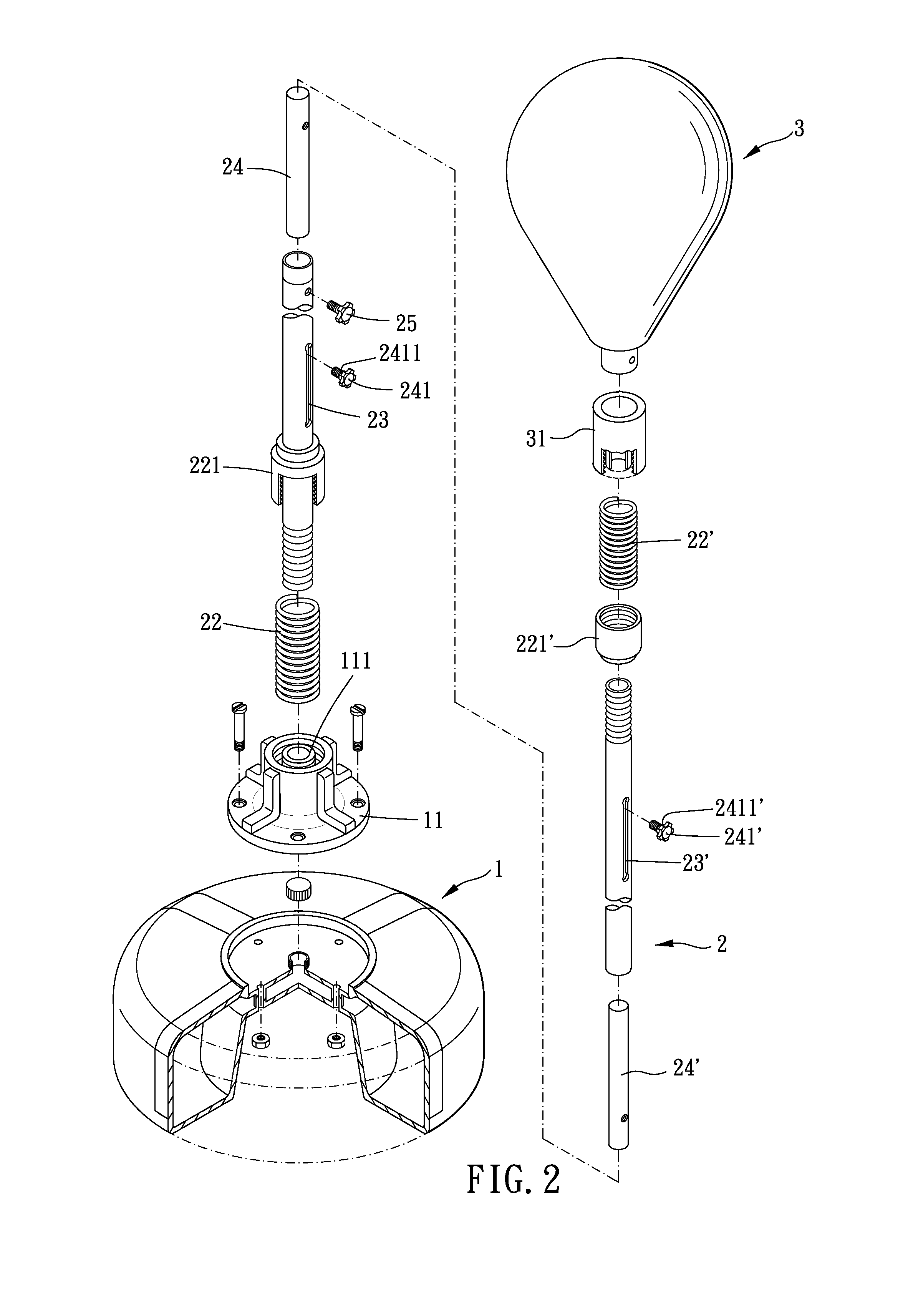

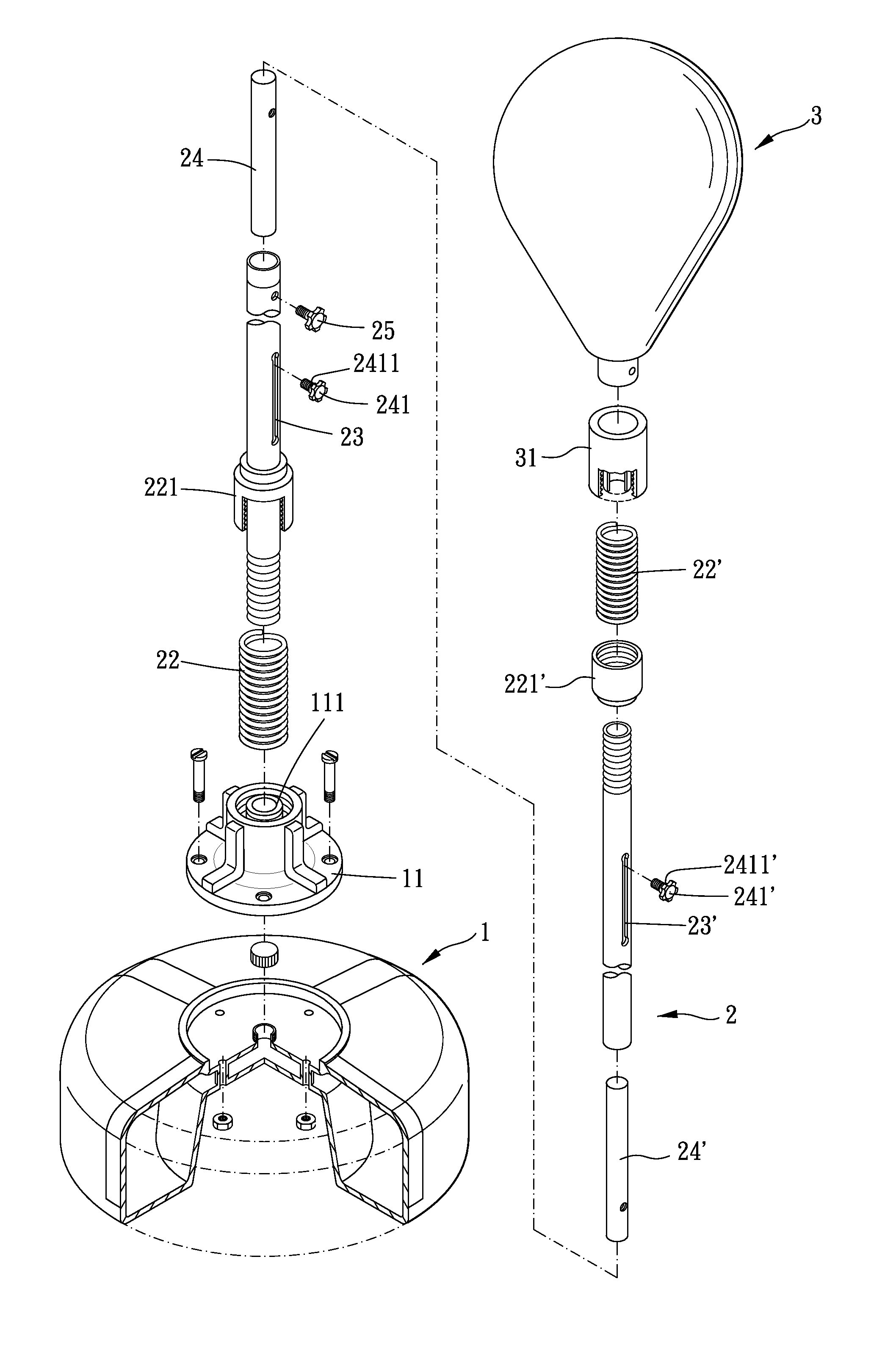

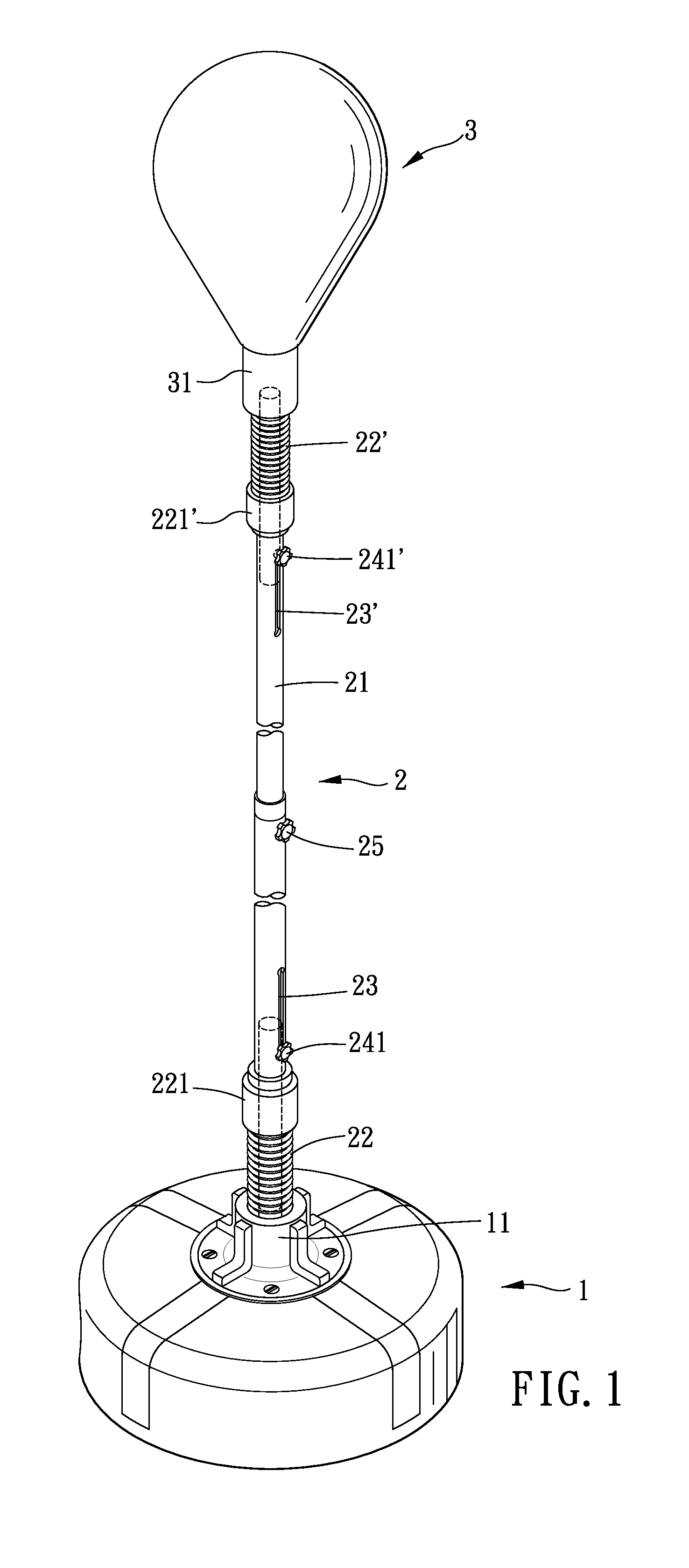

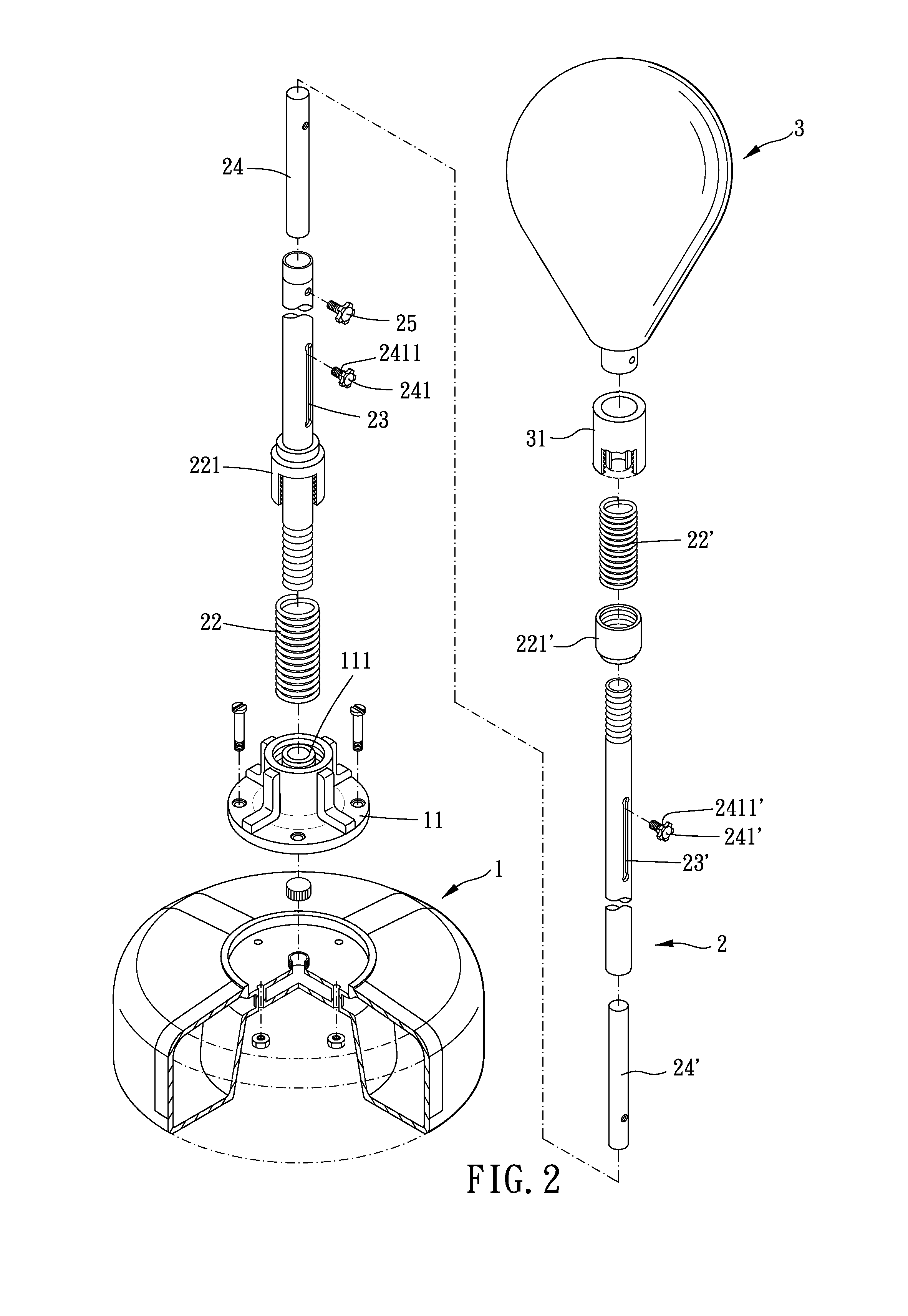

Boxing training device

Owner:CHEN TINA

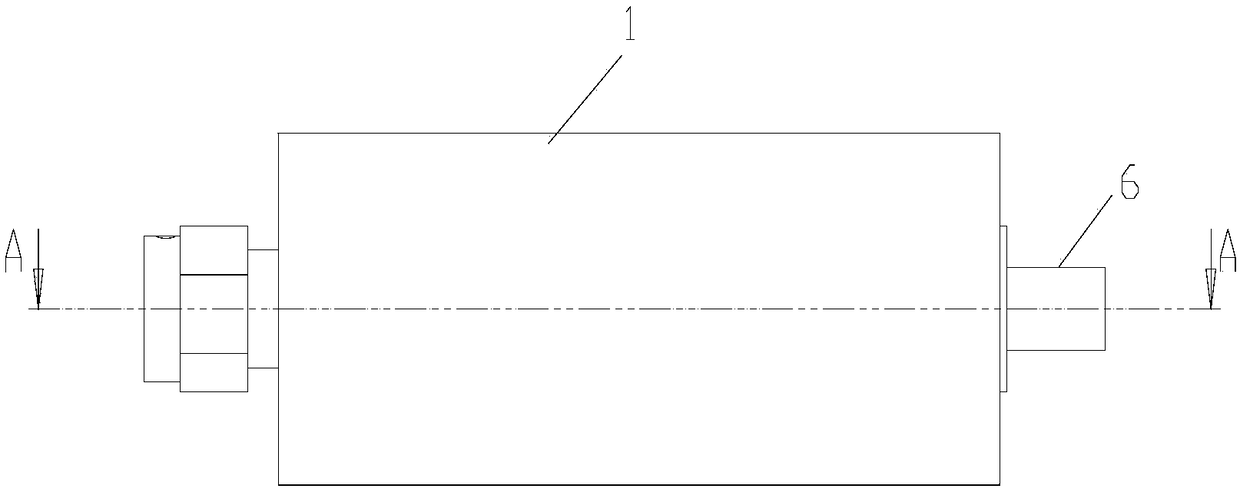

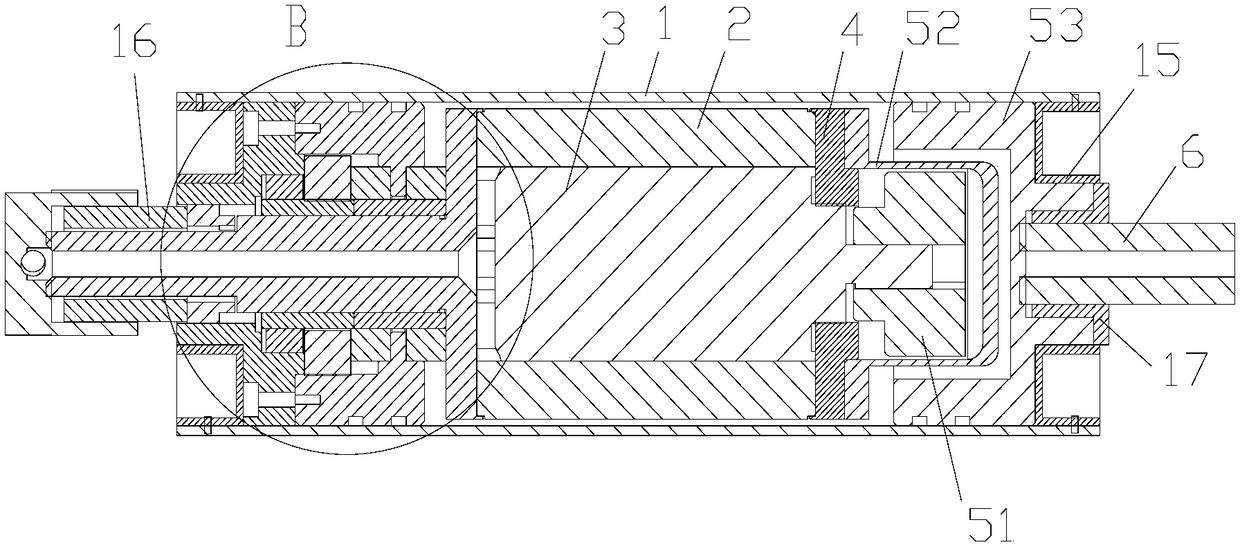

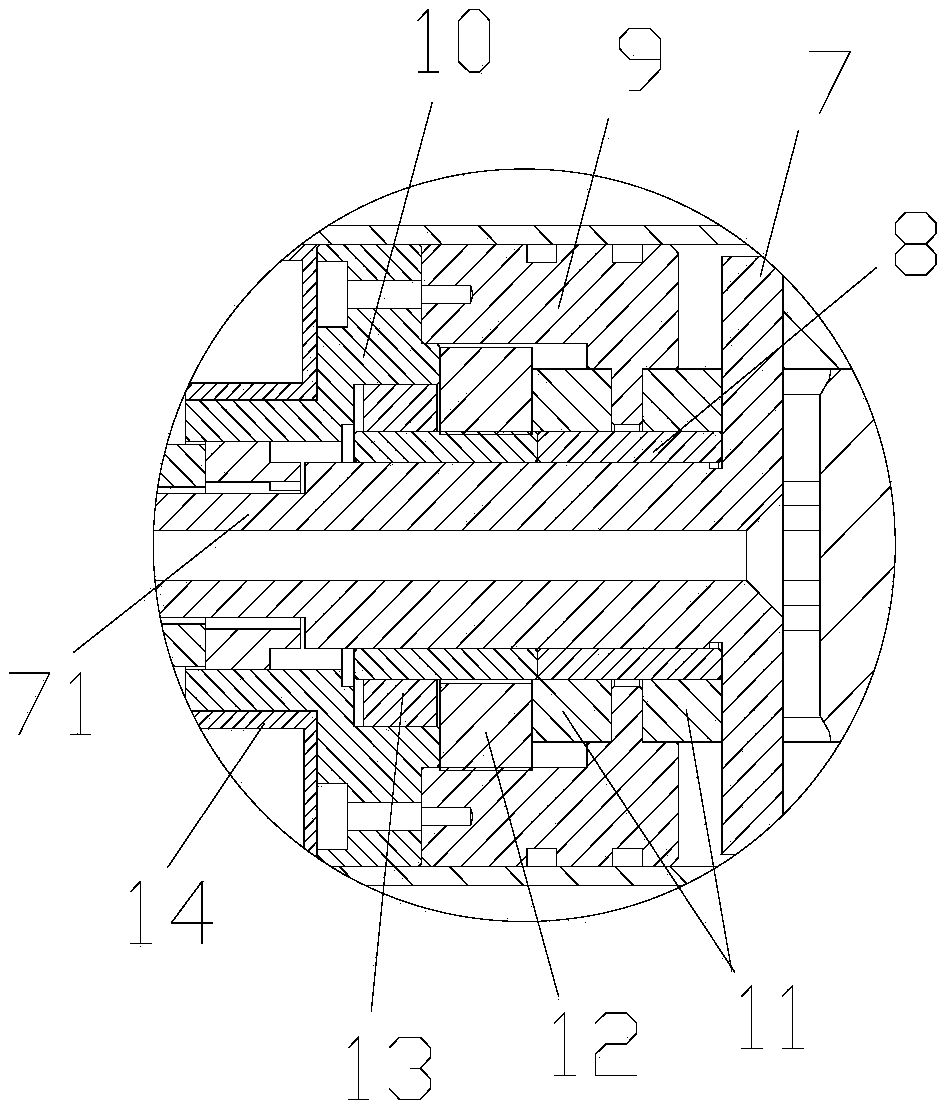

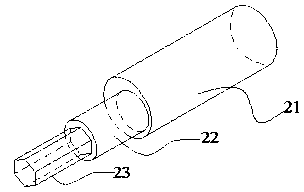

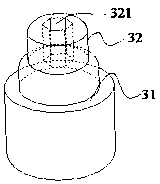

Driving roller

ActiveCN108506636AGood waterproof performanceIncrease contact areaEngine sealsShaftsPropellerEngineering

The invention discloses a driving roller. The driving roller comprises an outer cylinder and an inner cylinder arranged inside the outer cylinder, a motor is fixedly arranged inside the inner cylinder, the output shaft of the motor sleeves with a first rotating piece, and the outer peripheral surface of the first rotating piece is fixedly connected with the inner wall of the outer cylinder in a sealing mode; and the other end of the inner cylinder is provided with a second connecting piece, and the inner cylinder and the outer cylinder are rotationally connected together through the second connecting piece, wherein the second connecting piece is hermetically connected with the inner cylinder and the outer cylinder correspondingly. The driving roller has the beneficial effects that the motor is fixedly arranged inside the inner cylinder in a sealing mode, so that the waterproof performance is good; the inner cylinder and the outer cylinder are enabled to be connected rotationally through the first connecting piece and the second connecting piece, the outer cylinder is sleeved with the shell with spiral blades, when the roller of the robot is in contact with the inner wall or the sludge of the pipeline, friction is carried out by rotating of a spiral roller to the inner wall of the pipeline or the sludge to drive the pipeline robot to move forward, so that the contact area is large, and slipping is avoided; and when the roller of the robot is suspended in water, the spiral roller is equivalent to a propeller, the spiral roller rotates to be drained away water backwards and drives the pipeline robot to move forwards.

Owner:南京管科智能科技有限公司

Optical fibre electric field sensor

InactiveCN1419129AFix stabilityAddressing Structural StabilityVoltage/current isolationElectrostatic field measurementsFiberElectric field sensor

The invention is a fiber-optical electric-field sensor namely a photoelectric measuring device, based on electrooptic effecct to measure electric field, including collimation lens, polarizer, lambda / 4 wave piece, electrooptic crystal, polarization detector and coupler lens in order placed in light path. Each optical cell is inserted on organic glass basic body with the flute matching the shape and order of the optical cells, and the optical cells are felted one another and the cells and the glass are also felted by optical glue. The link and test of light-path system is convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

Necking type steel bar connecting sleeve, connecting structure thereof and installing method of connecting structure

PendingCN108316562AImprove corrosion resistanceImprove connection strengthBuilding reinforcementsArchitectural engineeringRebar

The invention discloses a necking type steel bar connecting sleeve, a connecting structure thereof and an installing method of the connecting structure. The necking type steel bar connecting sleeve comprises a sleeve body and a connecting steel bar, wherein grouting holes are formed in the sleeve body; two ends of the necking type steel bar connecting sleeve are fixedly connected with necking openings; the end part of the connecting steel bar is fixedly connected with an enlarging head; the enlarging head can be inserted to the inner part of the sleeve body through the necking openings; two ends of the sleeve body are respectively arranged on the connecting steel bar in a sleeving way; concrete can be formed through solidification after concreting; the necking openings can limit the concrete and the enlarging head to move towards direction of pulling out sleeve; the enlarging head can be fixed to the inner part of the sleeve body by the concrete; the connecting steel bar and the sleevebody can be fixedly connected; one end, which is far away from the sleeve body, of the connecting steel bar is fixed to the inner part of a prefabricated slab required to be connected in a pre-embedded way; two prefabricated slabs can be connected; installation of the sleeve body is simple and convenient, the cost is low, and the connecting strength is high.

Owner:李藏柱

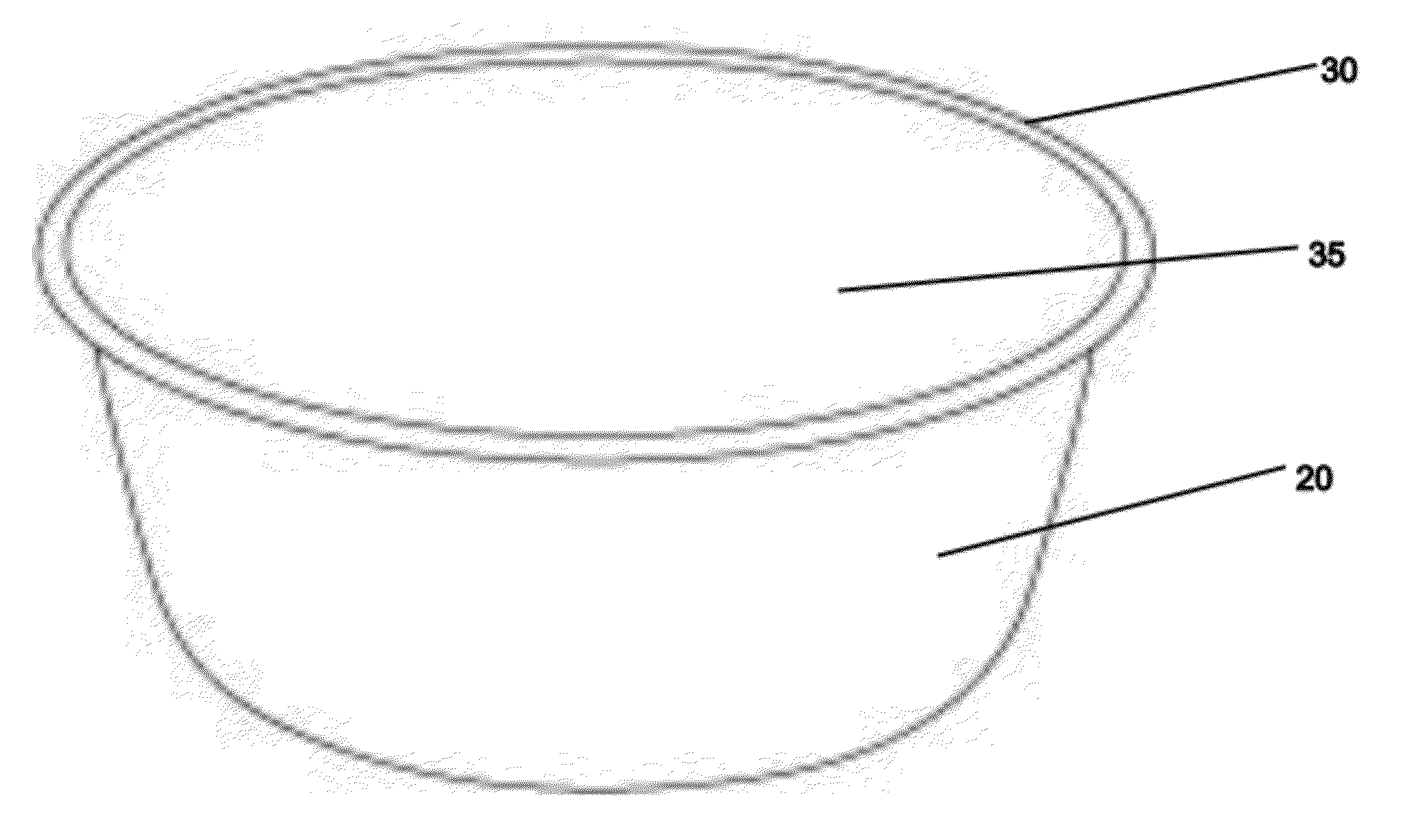

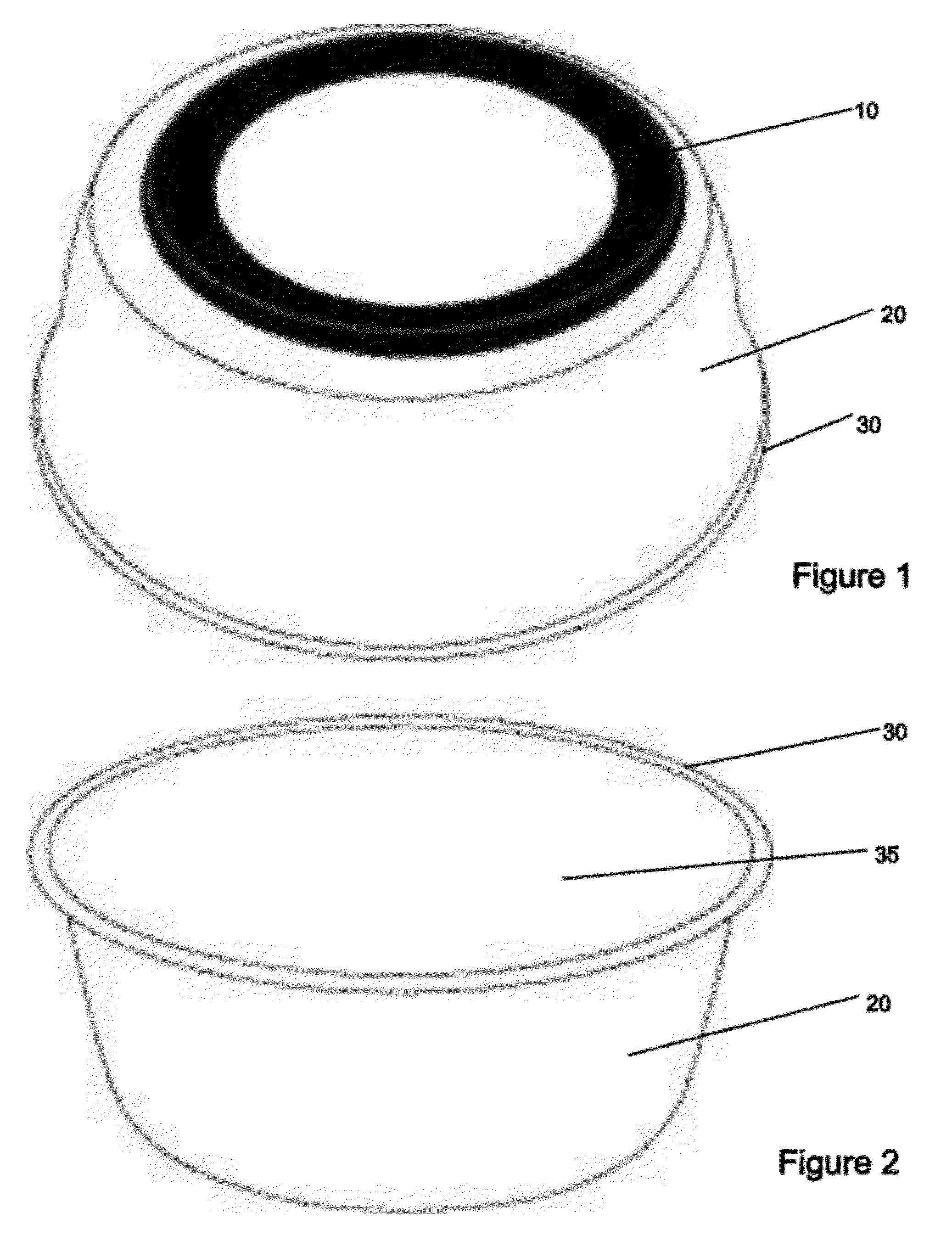

Non-skid double-layer pet bowl and a method of fabricating the same

ActiveUS20120285388A1Not easy to relative displacementNot easy to moveAnimal watering devicesMetal rolling stand detailsEngineeringMetal

The present invention provides a non-skid double-layer pet bowl for feeding animals and also provides a method of fabricating the said bowl. The bowl has an anti-skid bottom, so that the bowl does not move when the animal is eating or drinking from it. Another feature of the bowl is that materials, plastic and metal can be detached from each other. The plastic bowl is on the outside and is printed with various prints to make it attractive. Only this outer plastic bowl can be changed by removing it, in case of any damage or to obtain a different pattern.When detached, both the bowls can be used separately also, as double diner, that is one for feeding and the other one for drinking water for animal.The present invention also provides a method of fabricating the non-skid pet bowl. The bowls of the present invention are easy to fabricate, attractive in appearance and cost-effective.

Owner:PADIA ASHISH

Portable charging apparatus

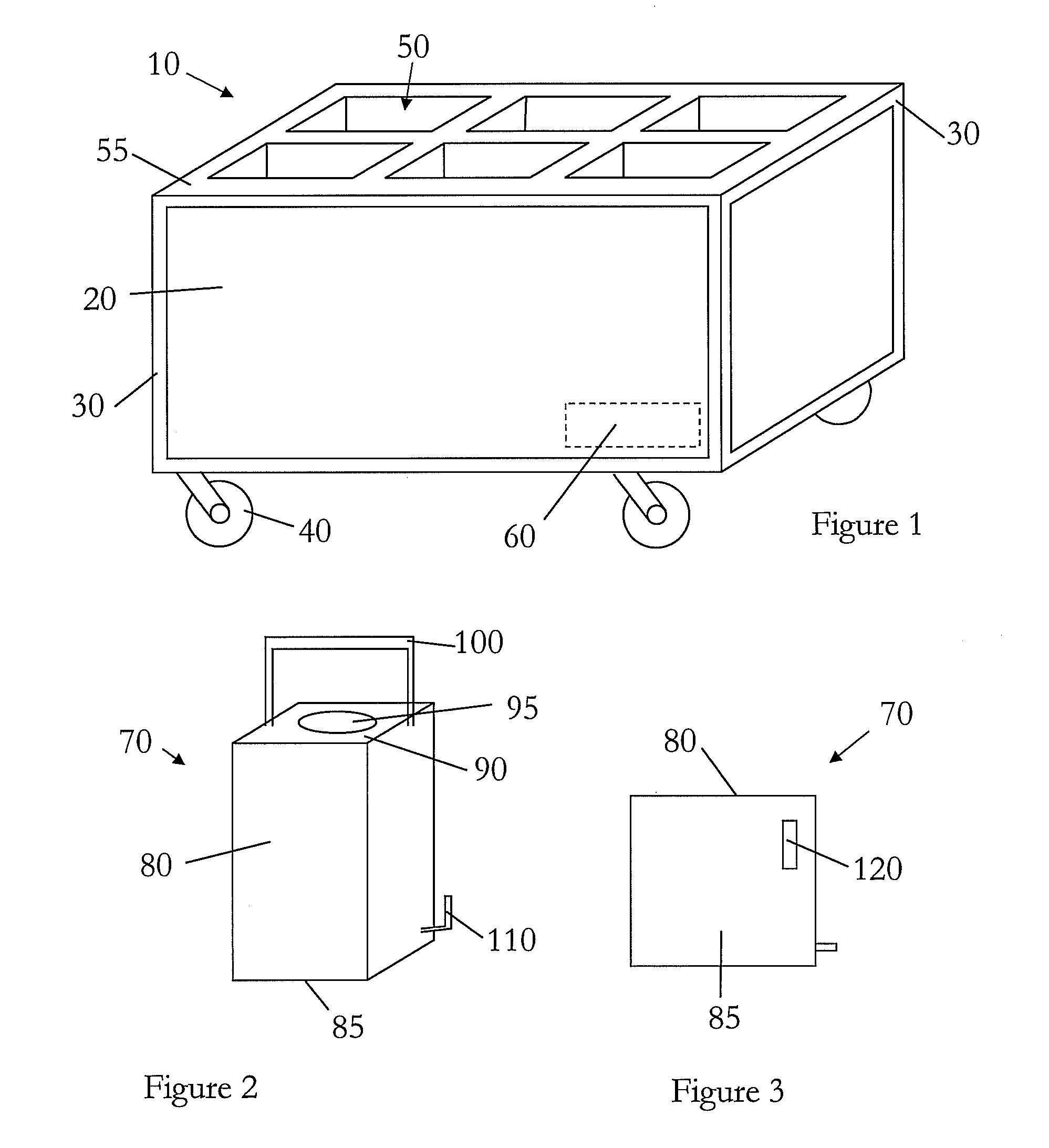

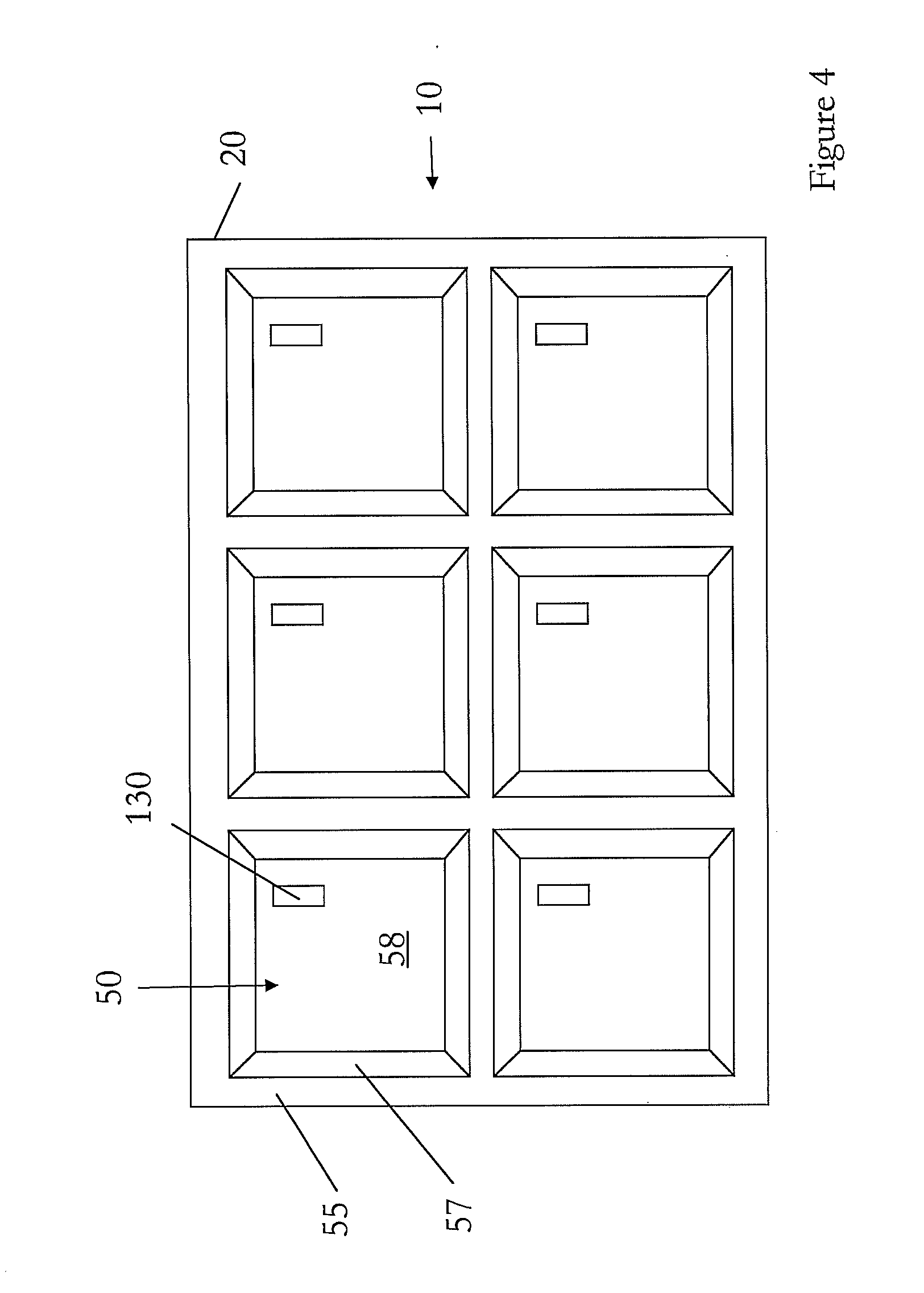

ActiveUS20110062911A1Easy to moveNot easy to moveWith electric batteriesMobile unit charging stationsElectricityElectrical battery

A portable charging apparatus for electrically charging one or more portable battery operated light units, comprising a container having one or more receiving means for receiving one or more portable battery operated light units, electricity supply connection means for electrically connecting with the one or more portable battery operated light units, and electricity supply regulating means.

Owner:GLOBAL DESIGN SOLUTIONS

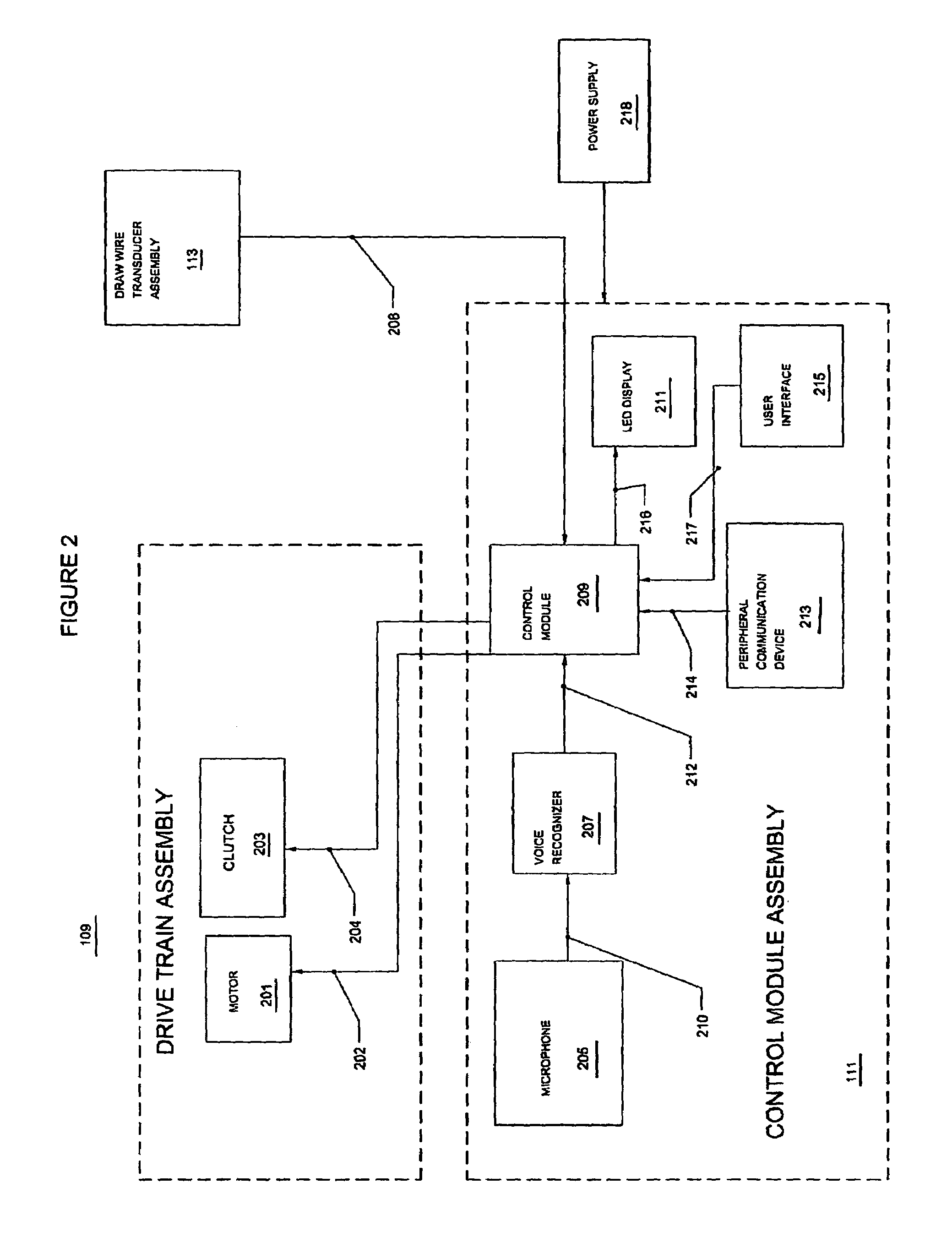

Automatic door control system

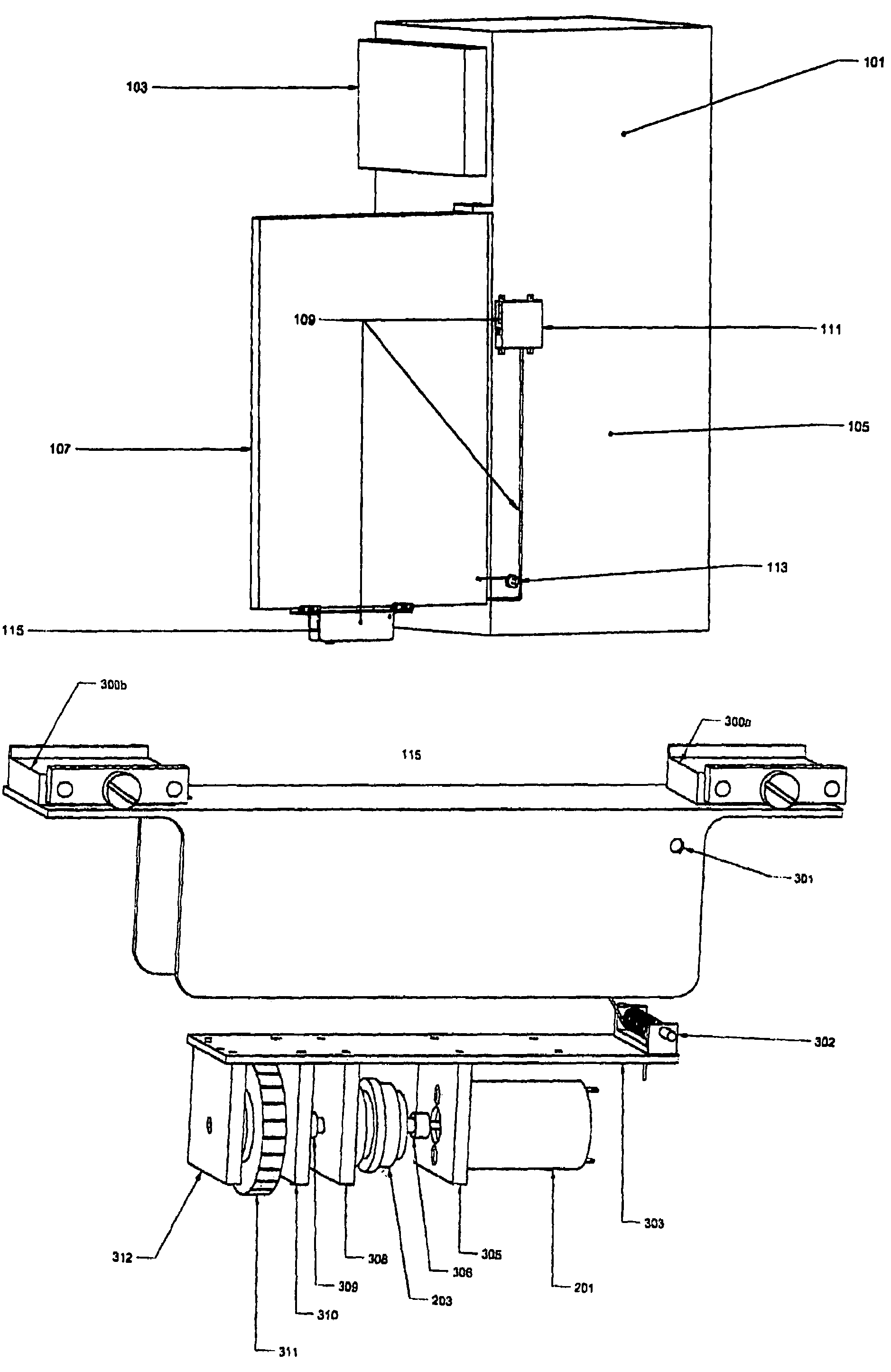

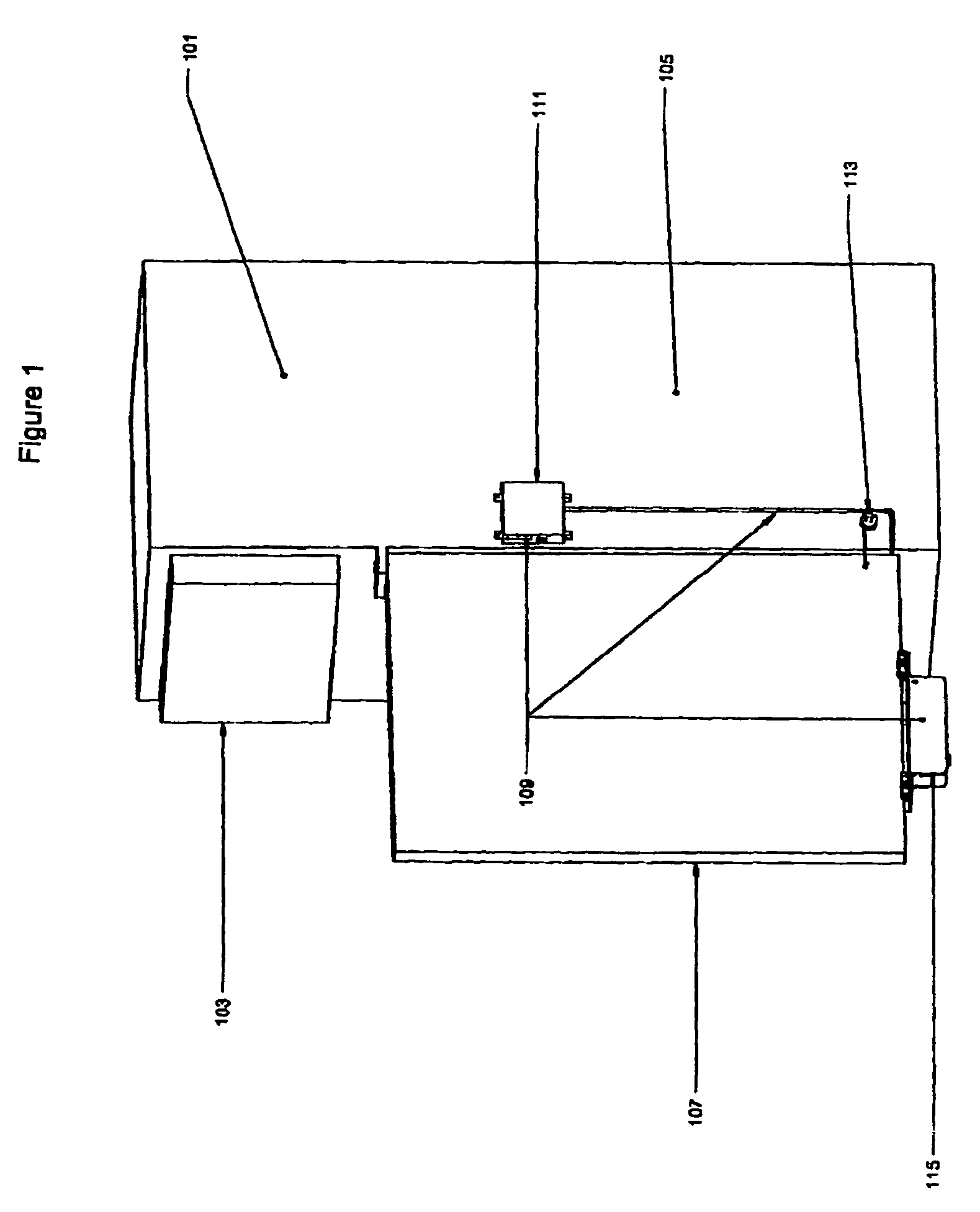

InactiveUS7213369B2Not easy to moveEasy to moveDomestic cooling apparatusLighting and heating apparatusControl systemAutomotive engineering

The present invention provides an automatic door control system that includes a door, a control module assembly, and a drive train assembly. The control module assembly is coupled to the door. The drive train assembly is coupled to the control module assembly, where the drive train assembly is configured to receive a signal from the control module assembly to easily move the door, where the drive train assembly exerts a force to move the door.

Owner:FREEMAN BRIAN

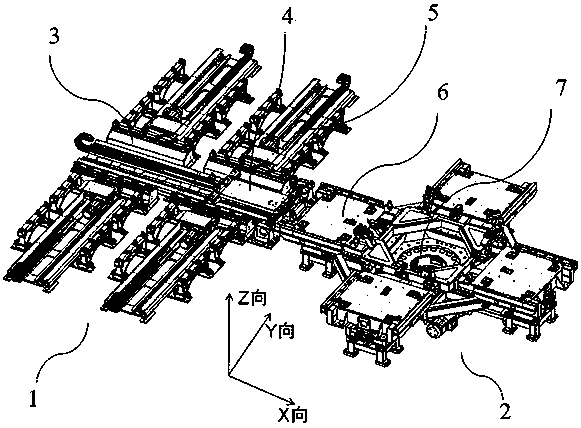

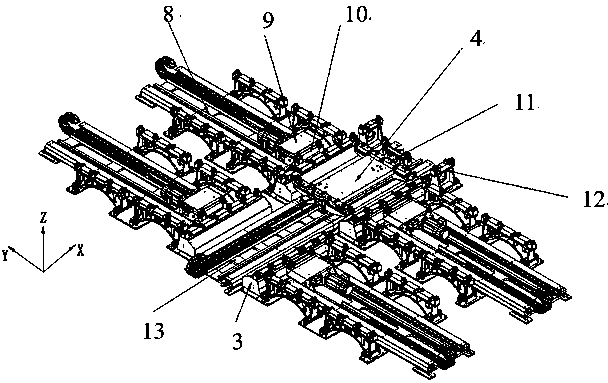

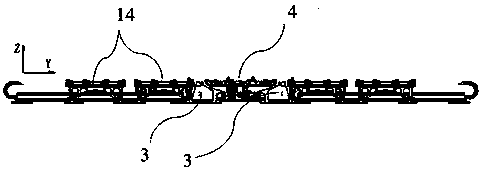

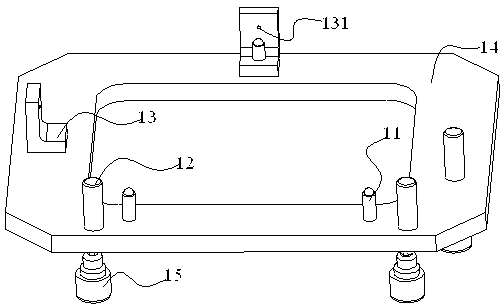

Intelligent fixture switching system

PendingCN107931937ARealize linkageShort switching timeWelding/cutting auxillary devicesAuxillary welding devicesIntelligent lightingRobotic systems

The invention provides an intelligent fixture switching system. The system comprises a storage location and a rotating table and is characterized in that the storage location comprises Z-direction lifting devices, an X-direction transferring platform and Y-direction storage locations; the rotating table comprises a plurality of switching platforms and a rotating table driver; a motor driving partof the storage location is controlled by the robot system; the storage location is docked with one of the switching platforms; and the other switching platforms continuously work. Compared with the prior art, the system provided by the invention has the advantages that the system is based on robot control and used for conveying, storing and switching fixtures to cooperate with an industrial robotfor grasping, welding and painting; the mechanical structure is flexible and the intelligent flexible production can be realized in combination with intelligent control; and therefore, the requirements for the universality, the automation and the intelligent switching of the fixtures are met, the production efficiency is greatly increased and the production cost is effectively reduced.

Owner:SHANGAHI SHOW KYOEL AUTOMOTIVE EQUIP +1

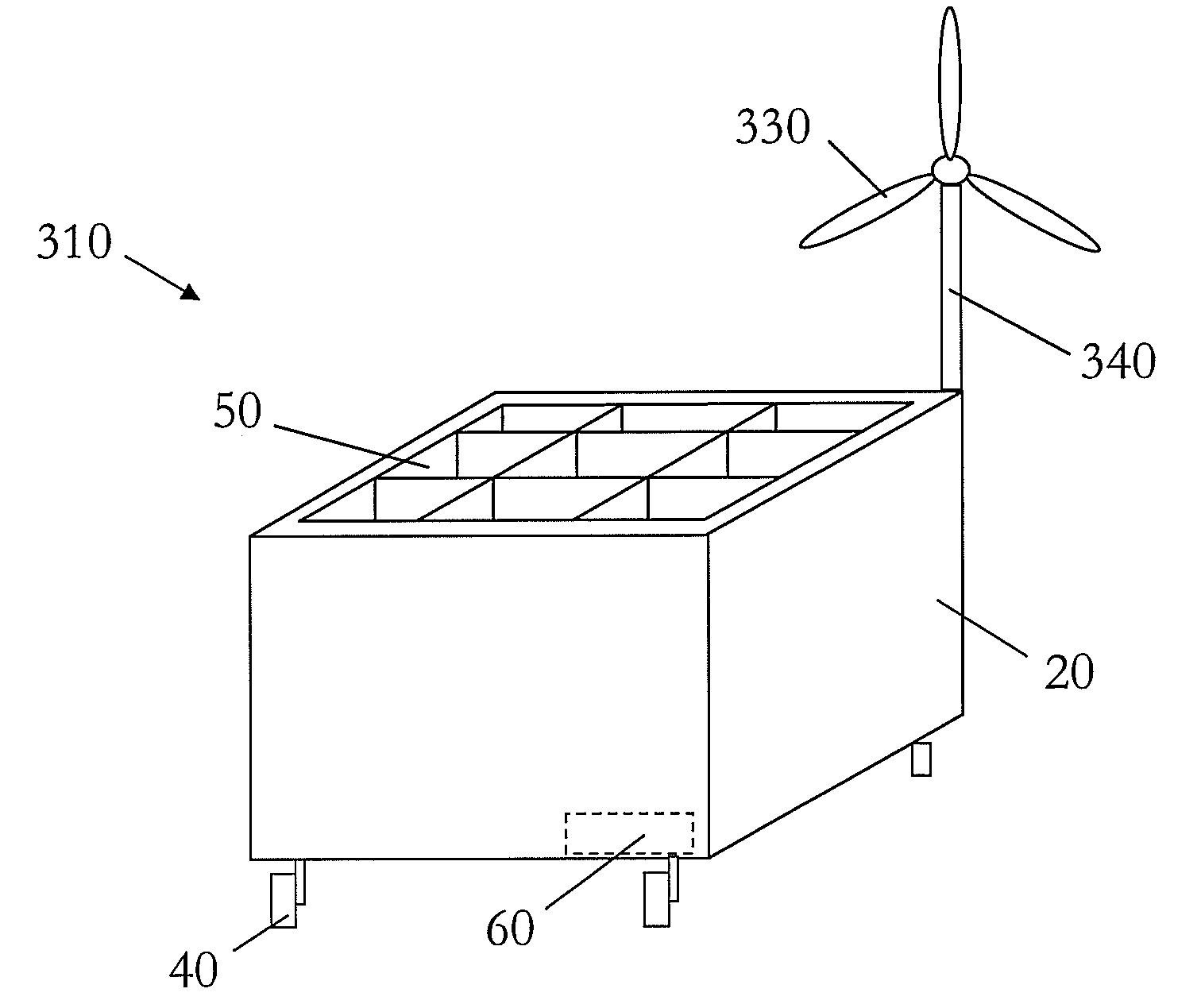

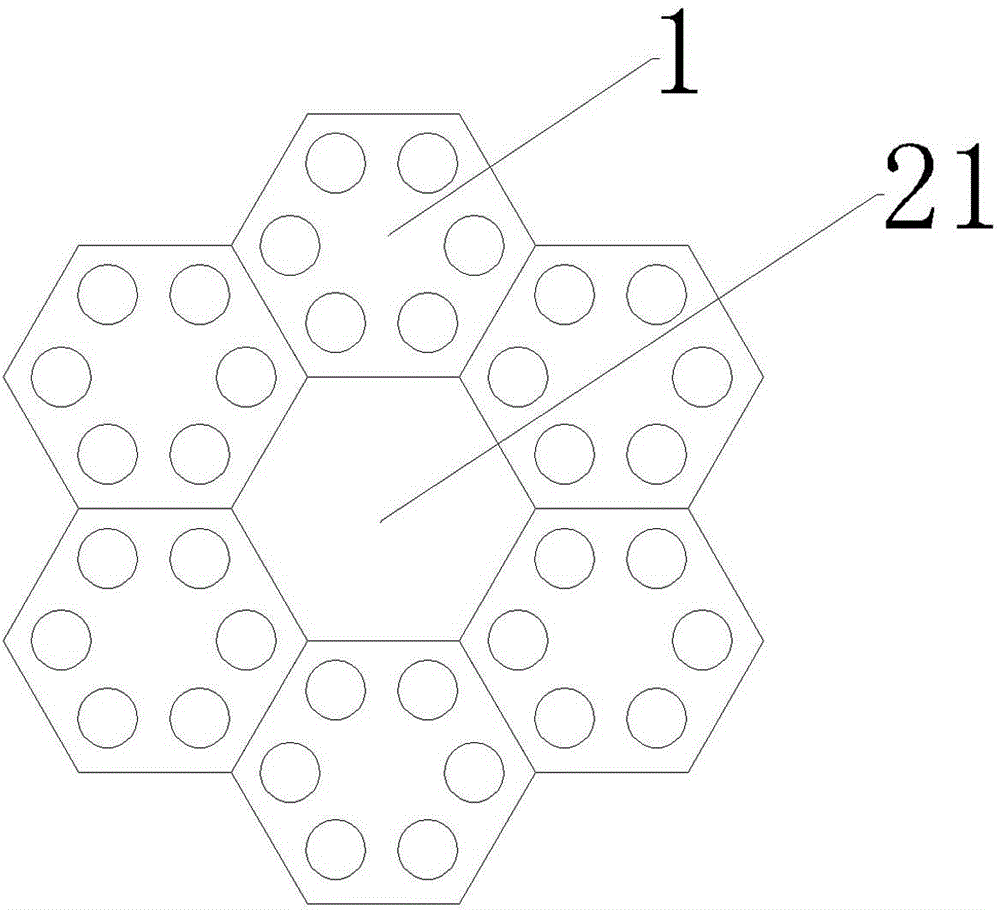

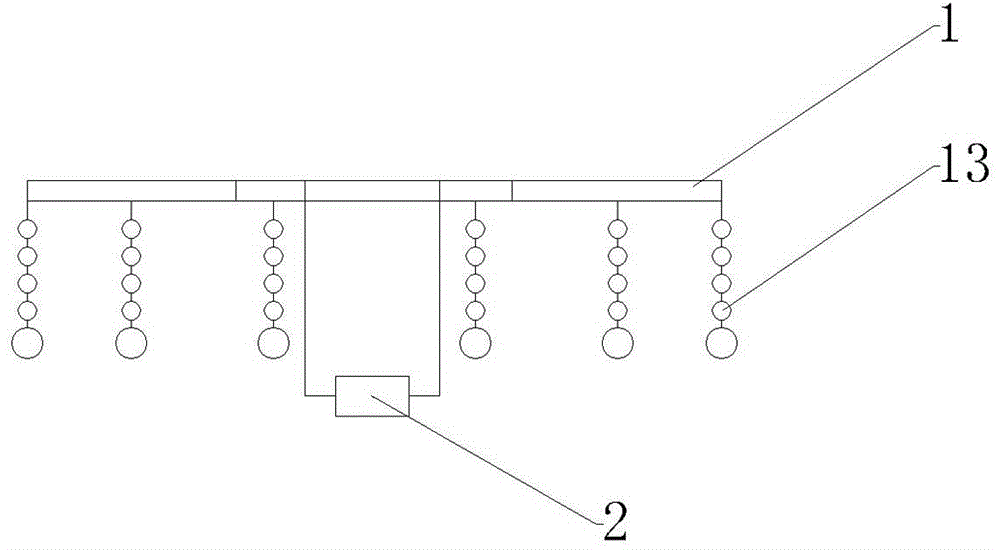

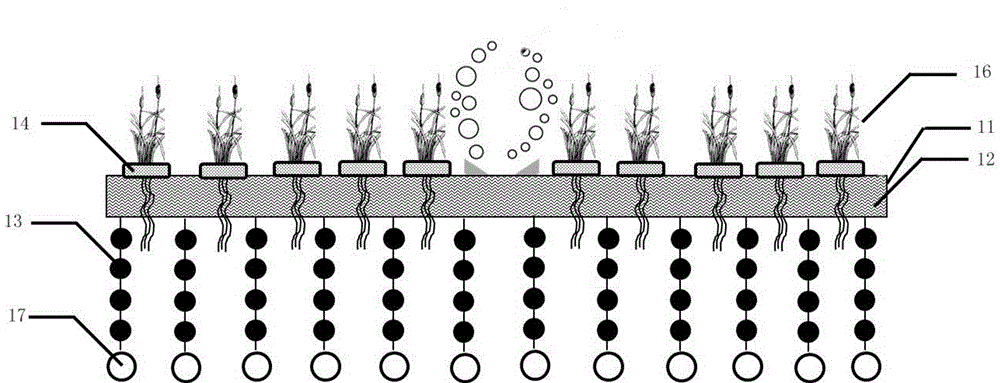

Novel combined bio-floating bed

InactiveCN104671417ASuitable for attachment growthRealize mandatory purificationTreatment with aerobic and anaerobic processesAquatic ecosystemWater source

The invention relates to a treatment device for a eutrophic water body, in particular to a combined bio-floating bed. The bio-floating bed comprises a bed body which is formed by connecting a plurality of floating bed single bodies and an aeration cavity in the bed body, wherein an aeration device is arranged in the aeration cavity. According to the combined bio-floating bed, a minitype aquatic ecosystem is built through increasing dissolved oxygen in the water body, introducing aquatic plants and increasing population and quantity of microorganism, nitrogen and phosphorus nutrients in the eutrophic water body in an urban landscape can be stably and effectively removed, and a new process is provided for water quality preservation in the northern urban landscape water body which takes tail water of an urban sewage treatment plant as the main nourishment source.

Owner:HEBEI PROVINCIAL ENVIRONMENTAL SCI RES

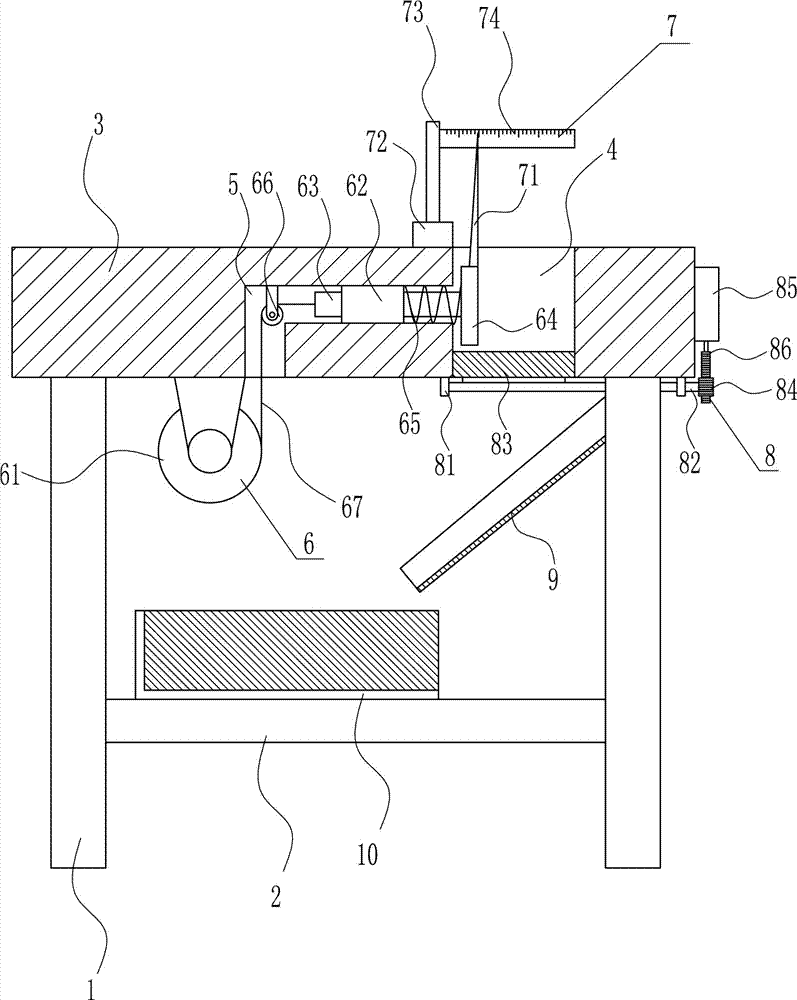

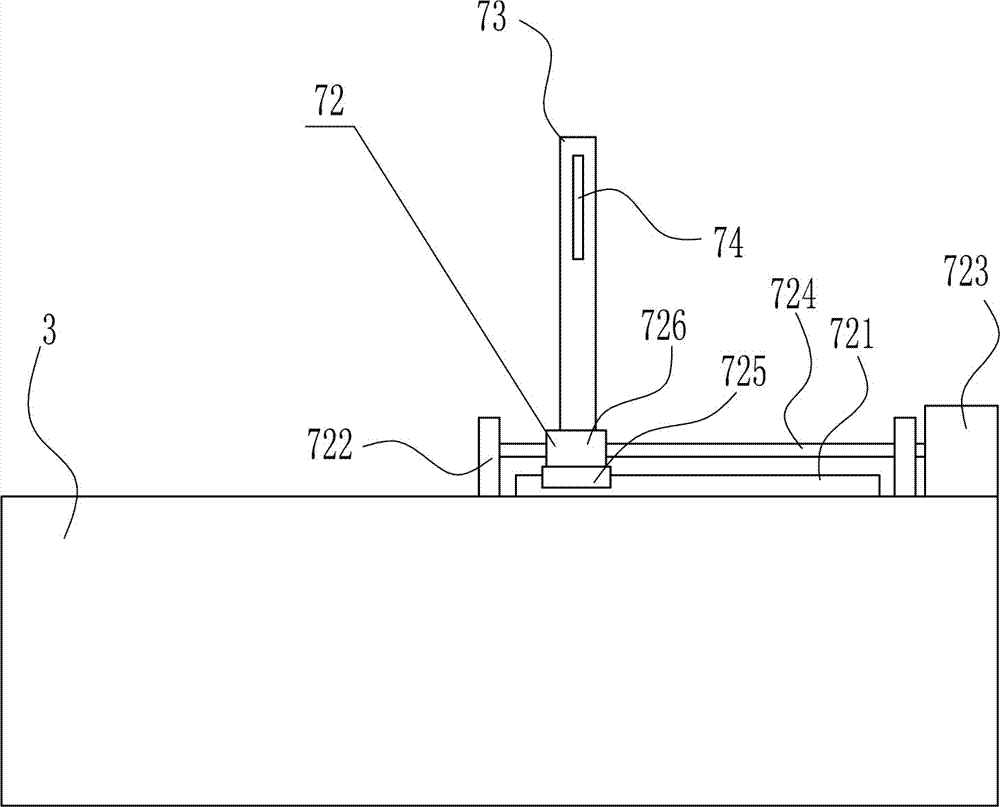

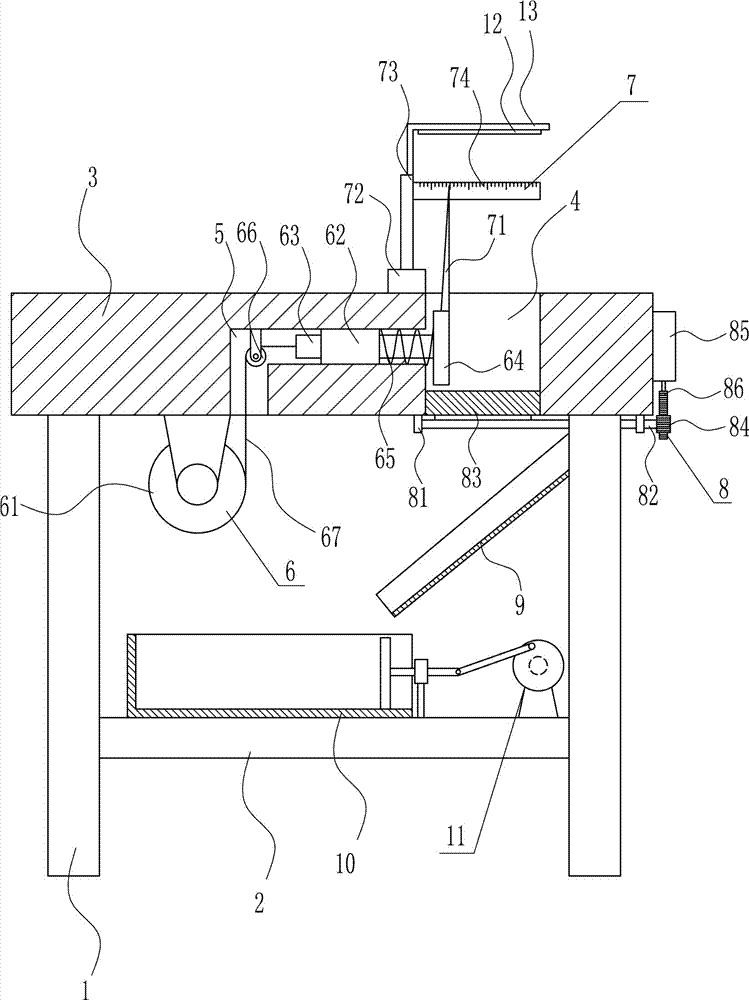

Fixing device for air conditioner copper pipe fusion welding

PendingCN107790848ANot easy to moveAdjust the angle of weldingMetal working apparatusGas flame welding apparatusButt jointArchitectural engineering

Owner:周亮

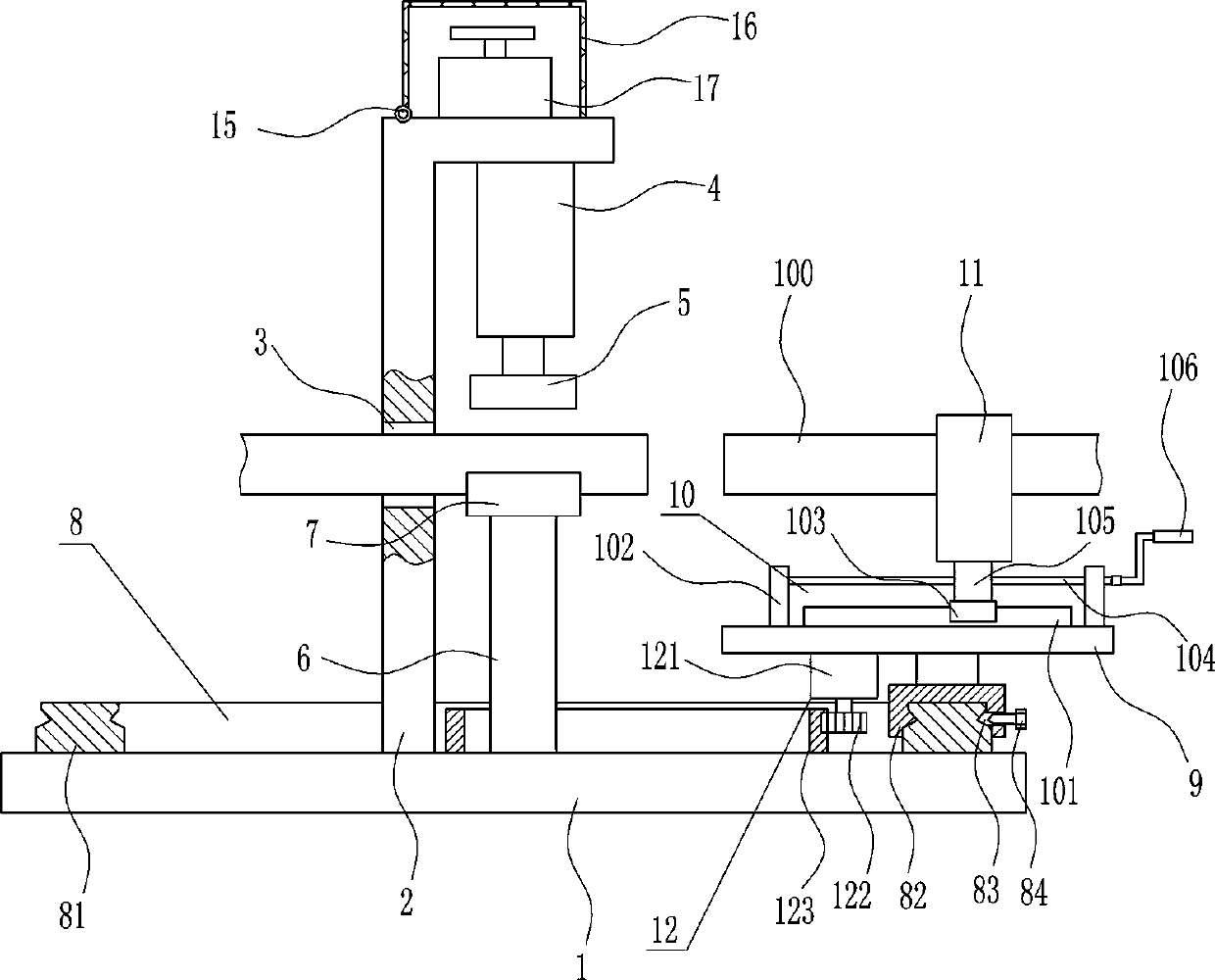

Reshaping device for metal steel processing

ActiveCN111545604ANot easy to moveGuaranteed stabilityMetal-working feeding devicesPositioning devicesElectric machineGear wheel

The invention discloses a reshaping device for metal steel processing. The reshaping device for metal steel processing comprises a workbench. A support is fixedly connected to the workbench. An installation groove is formed in the upper end of the workbench, multiple conveying rollers are connected with the interior of the installation groove in a rotating mode, and a transmission mechanism is arranged among the multiple conveying rollers. A driving motor is installed on the front side of the workbench, a first gear is fixedly connected with the output end of the driving motor, a second gear is installed on the workbench, and the second gear and the first gear mesh with each other. An adjusting mechanism is fixedly connected to the second gear, the adjusting mechanism and the second gear are coaxial, and the adjusting mechanism and the transmission mechanism are connected with each other through a transmission belt. The reshaping device for metal steel processing is reasonable in structure, cutters can be bent into a whole, and therefore the steel plate bending efficiency is greatly improved, the labor workload of a worker is also reduced, steel plates can be subjected to adjustable equal-length cutting operation, the practicability is high, the steel plate bending angle can also be adjusted, and the function is powerful.

Owner:浙江星筑科技有限公司

Quick cleaning device for testing equipment

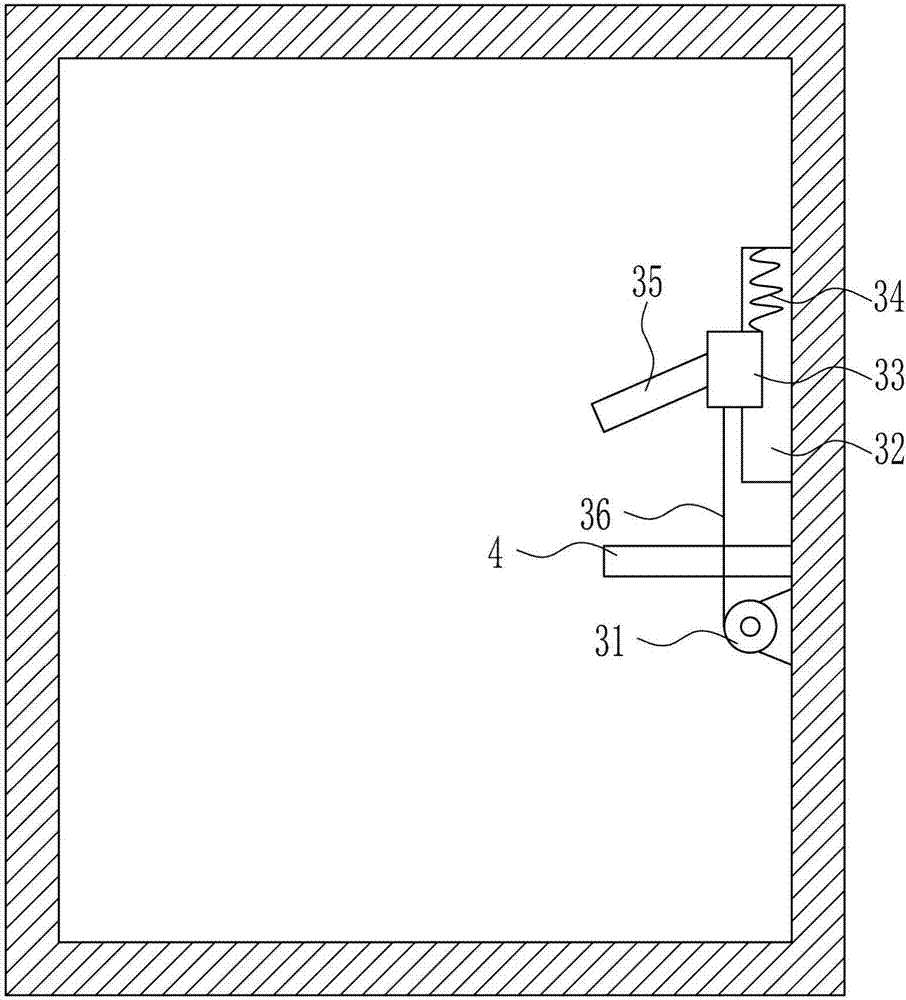

InactiveCN107362992AReduce resistanceStir wellCleaning using toolsCleaning using liquidsEngineeringUltimate tensile strength

The invention relates to a cleaning device for testing equipment, in particular to a quick cleaning device for the testing equipment. The technical problem to be solved is to provide the quick cleaning device which is used for the testing equipment and is high in cleaning speed, clear to clean and small in labor intensity. To solve the technical problem, the quick cleaning device for the testing equipment is provided. The quick cleaning device comprises a cleaning box and the like. A fixing device is arranged on the right side face of the cleaning box. A containing plate is arranged on the lower portion of the right side face of the cleaning box and horizontally arranged. The right side face of the containing plate is connected with the right side face in the cleaning box in a bolt connecting manner. A cleaning device body is arranged on the top of the cleaning box. Cleaning components of the cleaning device body are located in the cleaning box. According to the quick cleaning device for the testing equipment, a caliper rule is cleaned after being fixed, and the cleaning effect is good; and through the contact of contact wheels and the caliper rule, the contact strength of the caliper rule and a hairbrush is increased, and the effects of the high cleaning speed, clear cleaning and small labor intensity are achieved.

Owner:CHINA JILIANG UNIV

Boxing training device

ActiveUS8641583B2Easy to useAvoid easy disassemblySpace saving gamesMuscle exercising devicesEngineering

Owner:CHEN TINA

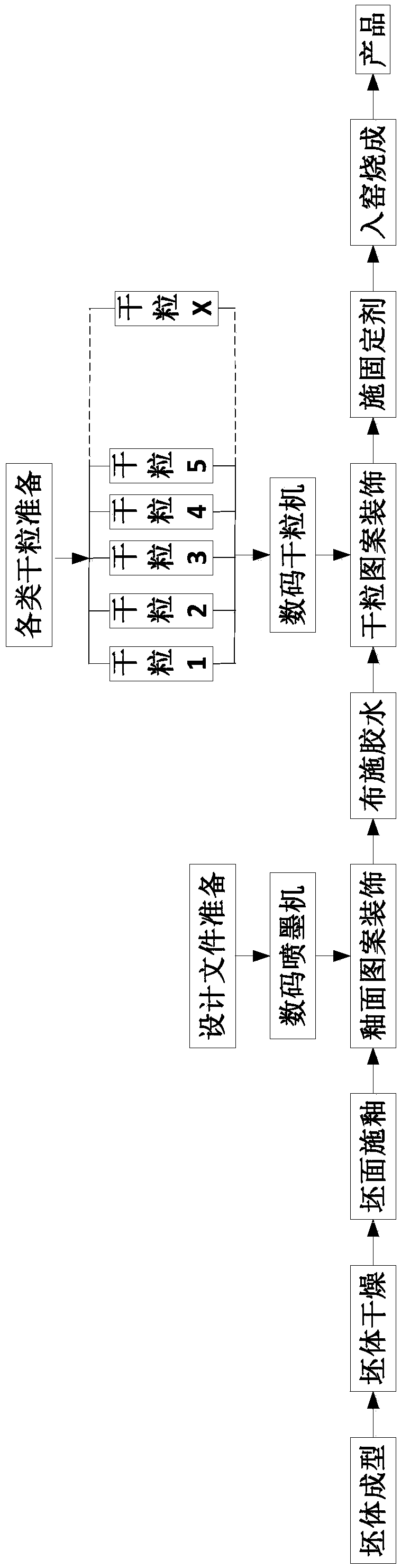

A plurality of dry granular ceramic tiles capable of being simultaneously distributed and applied, preparation method and control method thereof

The invention relates to a plurality of dry granular ceramic tiles which can be simultaneously distributed and applied, a preparation method and a control method thereof. The dry granular ceramic tileis composed of a green body layer, a surface glaze layer, a decoration layer, a glue layer, a dry granular layer and a fixing agent layer which are sequentially compounded. The preparation method comprises the following steps: (1) preparing a green body, and arranging a pattern decoration layer on the green body; (2) applying glue on the surface of the pattern decoration layer to form a glue layer; (3) arranging a plurality of dry granular on the surface of the glue layer through dry particle equipment to form a dry granular layer; (4) spraying a fixing agent on the surface of the dry granular layer; and (5) firing in a kiln. The control method mainly comprises the following steps: (1) preparing a design document; (2) the design document carrying out glaze pattern decoration through a digital ink jet machine; (3) applying glue; and (4) inputting preset parameters, patterns and quantity into a digital dry granular machine, wherein the digital dry granular machine simultaneously controls the dry granular distribution amount and distribution effect of a plurality of kinds of dry granular, and those dry granular can simultaneously distribute and apply the dry granular pattern decoration through the digital dry granular machine.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

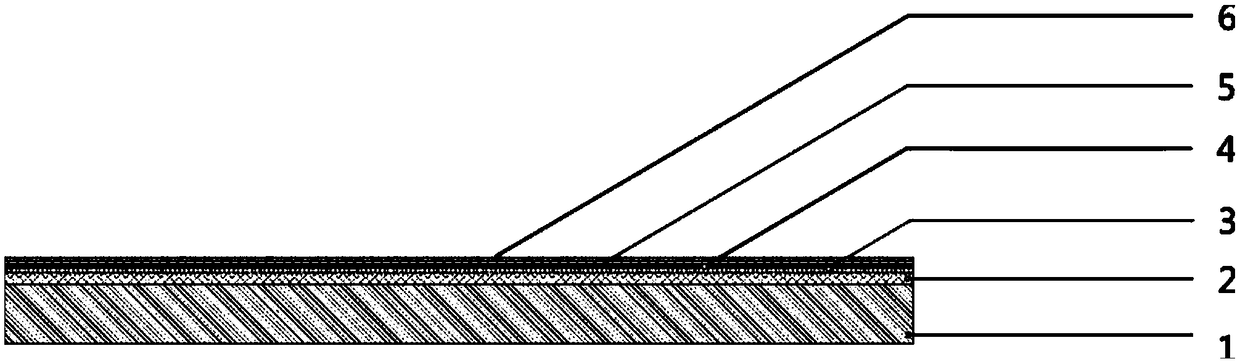

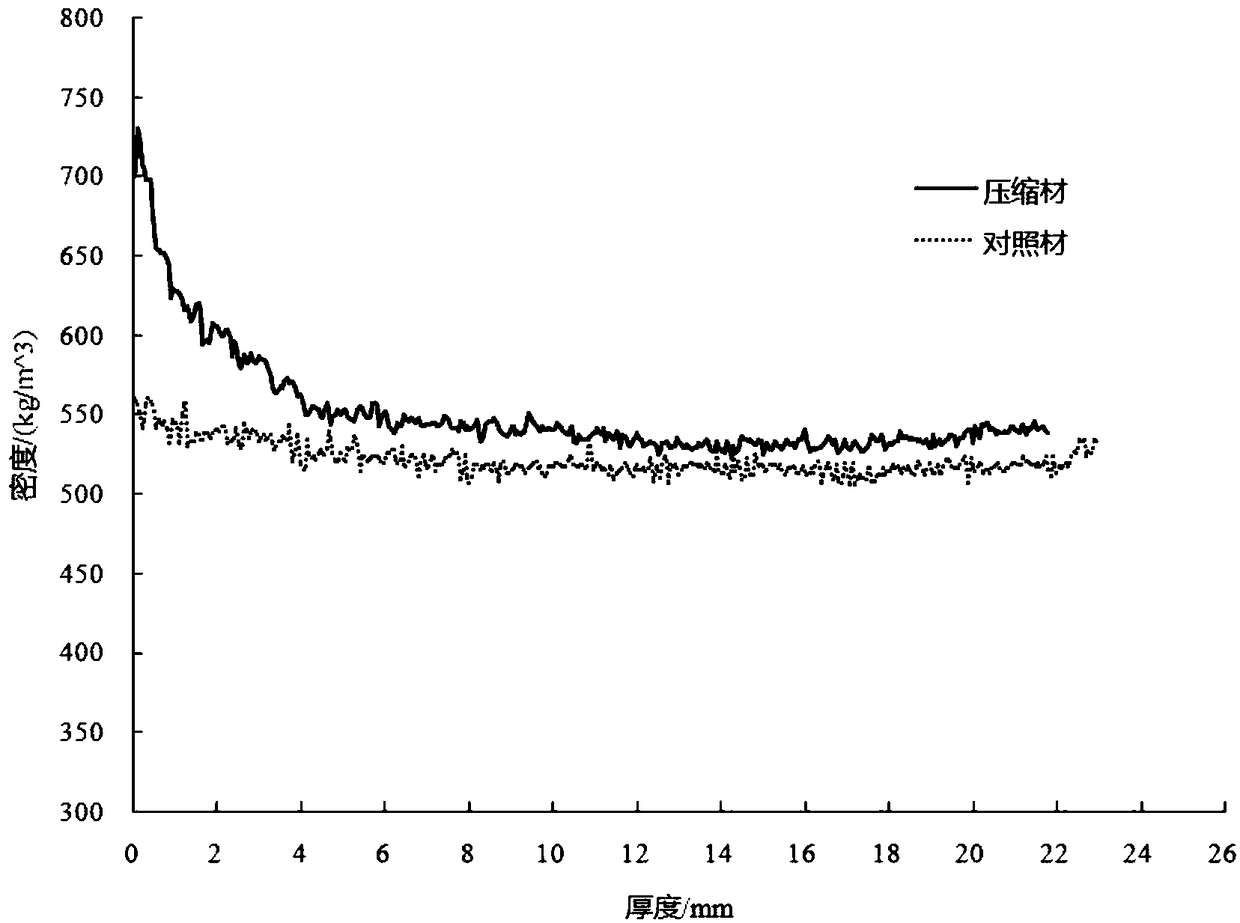

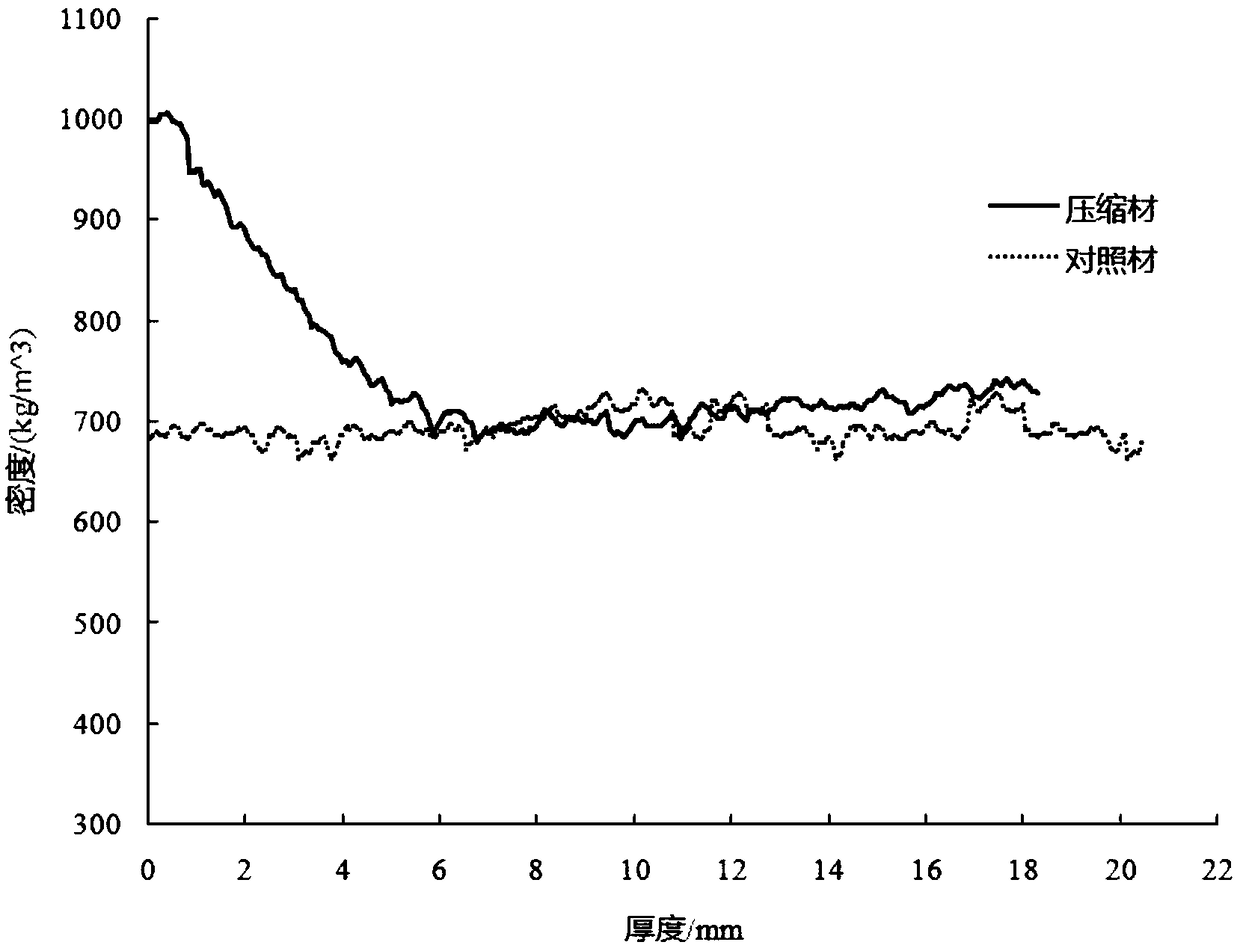

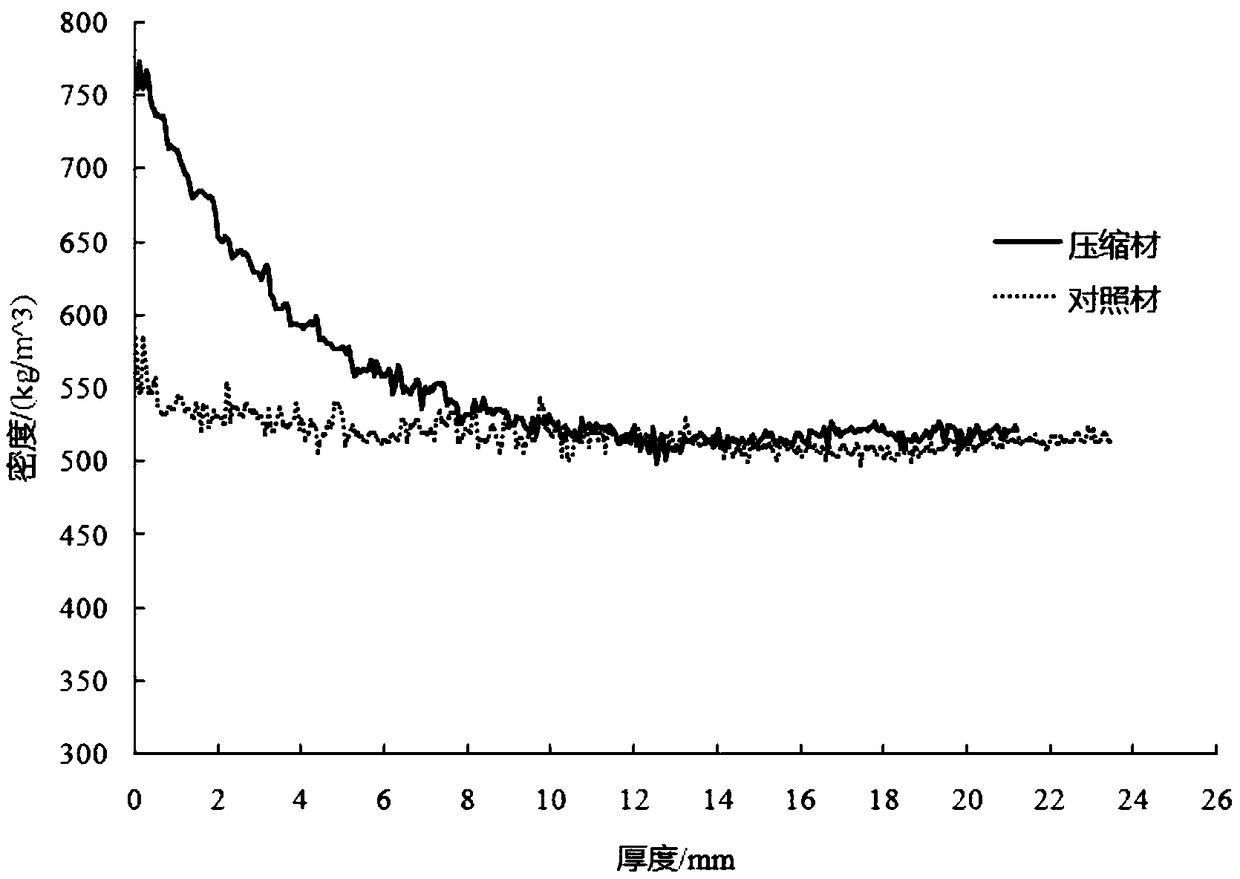

Single-side surface layer compressed wood and preparation method thereof

InactiveCN108582378ANot easy to movePrevent movementLayered product treatmentWood compressionSurface layerWood fibre

The invention discloses a single-side surface layer compressed wood and a preparation method thereof. The single-side surface layer compressed wood comprises a peak density layer, a dense layer and awood original density layer, wherein the connection between the peak density layer, the dense layer and the wood original density layer is a natural connection of wood fibers of the wood; the preparation method of the single-side surface layer compressed wood comprises the following steps that a hot pressing plate on a press machine is heated to 150-220 DEG C, and the wood is laid on a cold pressing plate after the wood is dried; the upper surface of the hot pressing plate and the upper surface of the wood are in contact and pre-heating; under the pressure of 6-15 Mpa, the pressure is maintained after the wood is compressed to the required thickness; at the temperature of 150-220 DEG C, the pressure is maintained after reducing the pressure to 1-3 Mpa; and the single-side layer compressedwood and the preparation method thereof is obtained after unloading. According to the single-side surface layer compressed wood and the preparation method thereof, the problem of single-side compressed wood tile bending deformation is solved by utilizing a temperature difference method, the single-side surface layer compression of the wood is realized, the production time is short, the energy consumption is low, the operation is simple and convenient, chemical drugs do not need to be added in the treatment process, and the method has the advantages of being efficient, environmentally friendlyand the like; and the hardness, the flatness, the production efficiency and the percent of pass of the surface of the compressed wood are effectively improved.

Owner:SOUTH CHINA AGRI UNIV

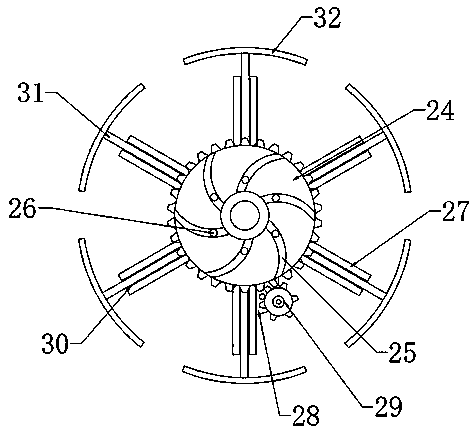

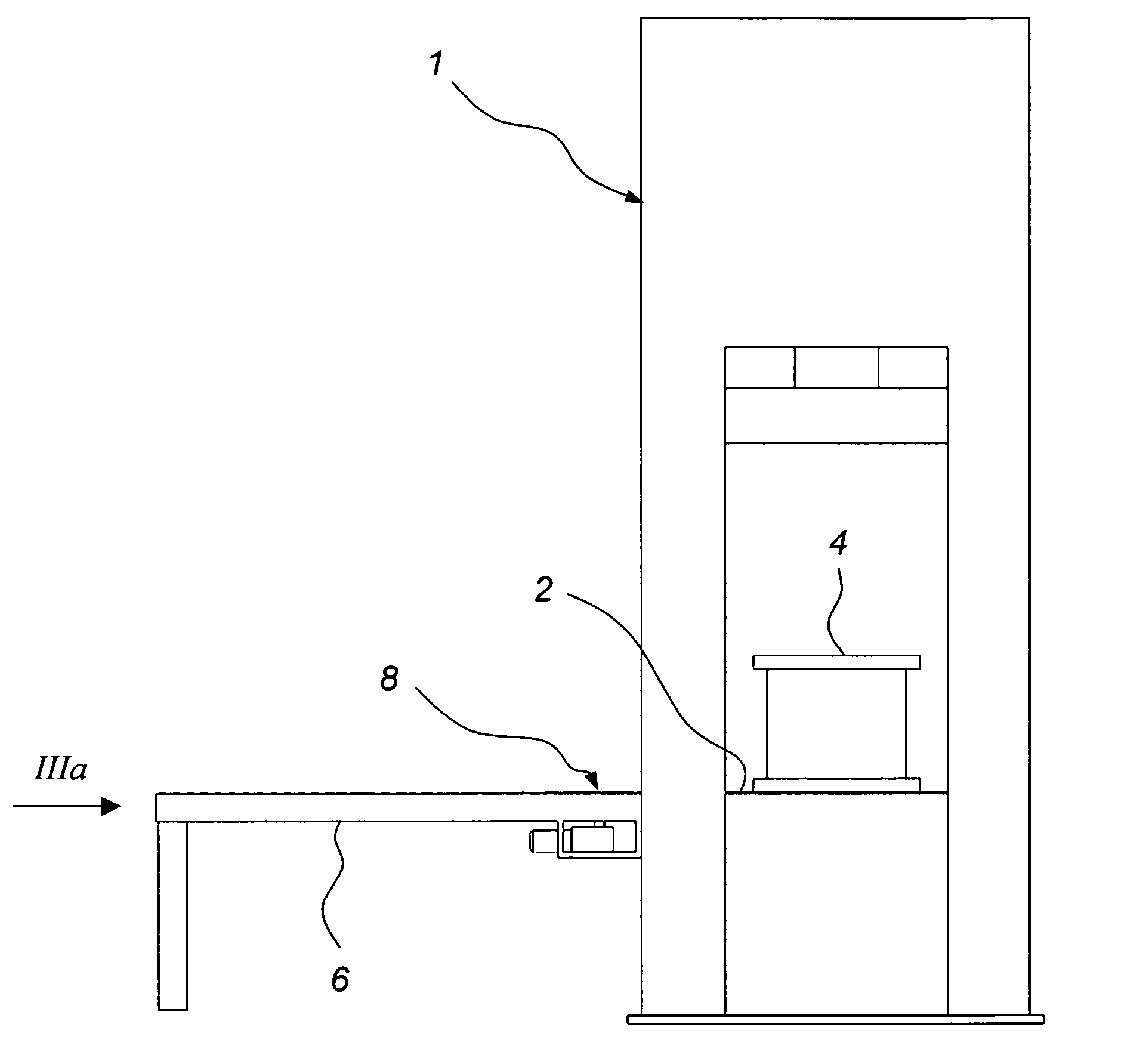

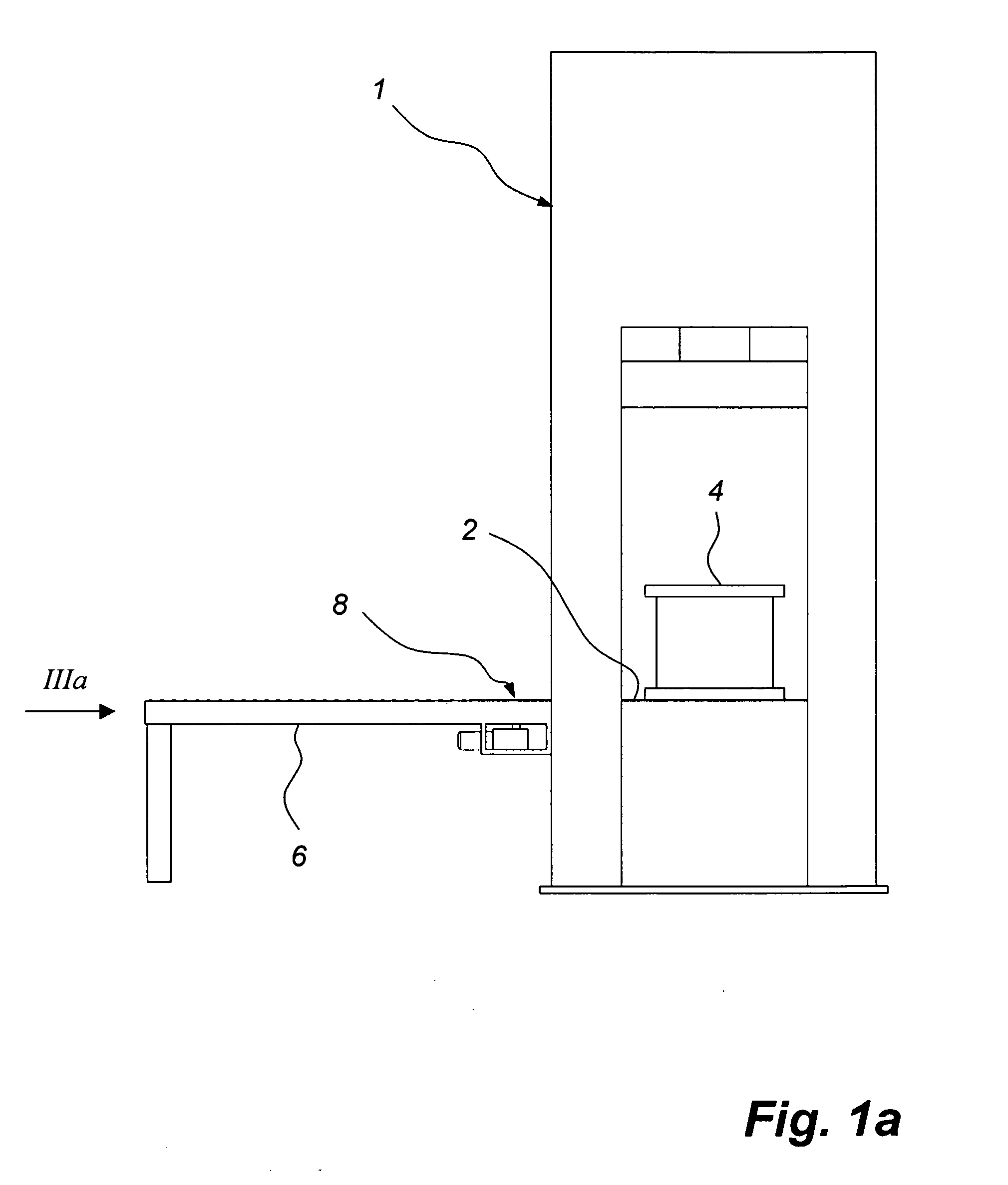

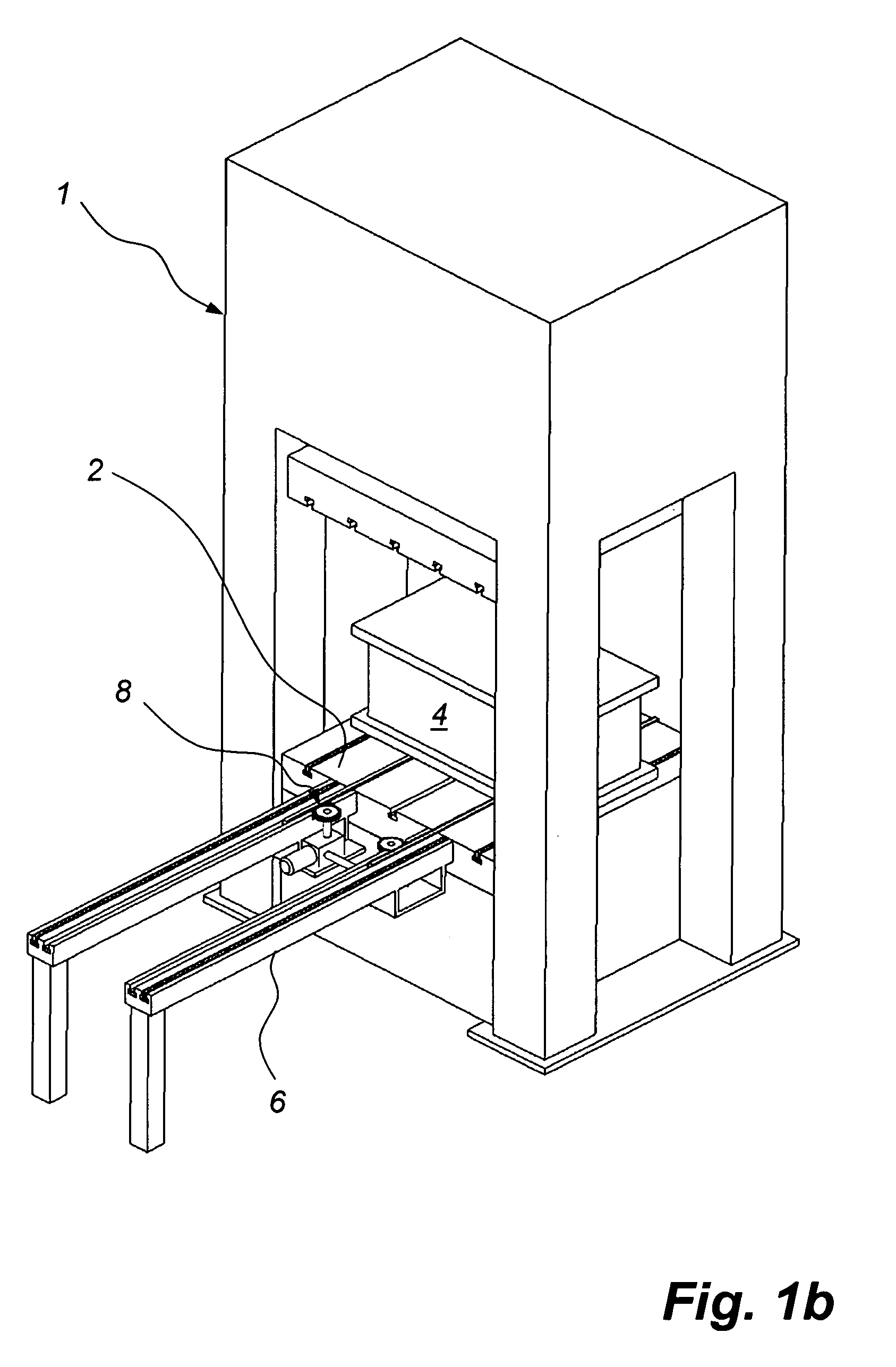

Device for moving die tools and moulds in a press

InactiveUS20060223687A1Protection from damageInjury is also causedTool changing apparatusForging/hammering/pressing machinesGear wheelEngineering

A device for moving objects ( 4 ) to and from the table ( 2 ) of a press ( 1 ) comprises a bar ( 24 ) being vertically movable, by means of inflating a bag ( 10 ), from a first position in which an upper surface ( 26 ) of the bar ( 24 ) is located below the upper surface ( 16 ) of the table ( 2 ) to a second position in which the upper surface ( 26 ) of the bar ( 24 ) is located above the upper surface ( 16 ) of the table ( 2 ). The bar ( 24 ) is adapted to slide horizontally in its longitudinal direction and is provided with gear teeth ( 28 ). A gear wheel ( 32 ), engaging the gear teeth ( 28 ) of the bar ( 24 ), is adapted to move the bar ( 24 ) in the horizontal direction along the slot ( 14 ) when the bar ( 24 ) is in its second position and thus to move an object ( 4 ) resting on the upper surface ( 26 ) of the bar ( 24 ).

Owner:HEDIN LAGAN

Electric objective table

Owner:KUN SHAN POWER STENCIL

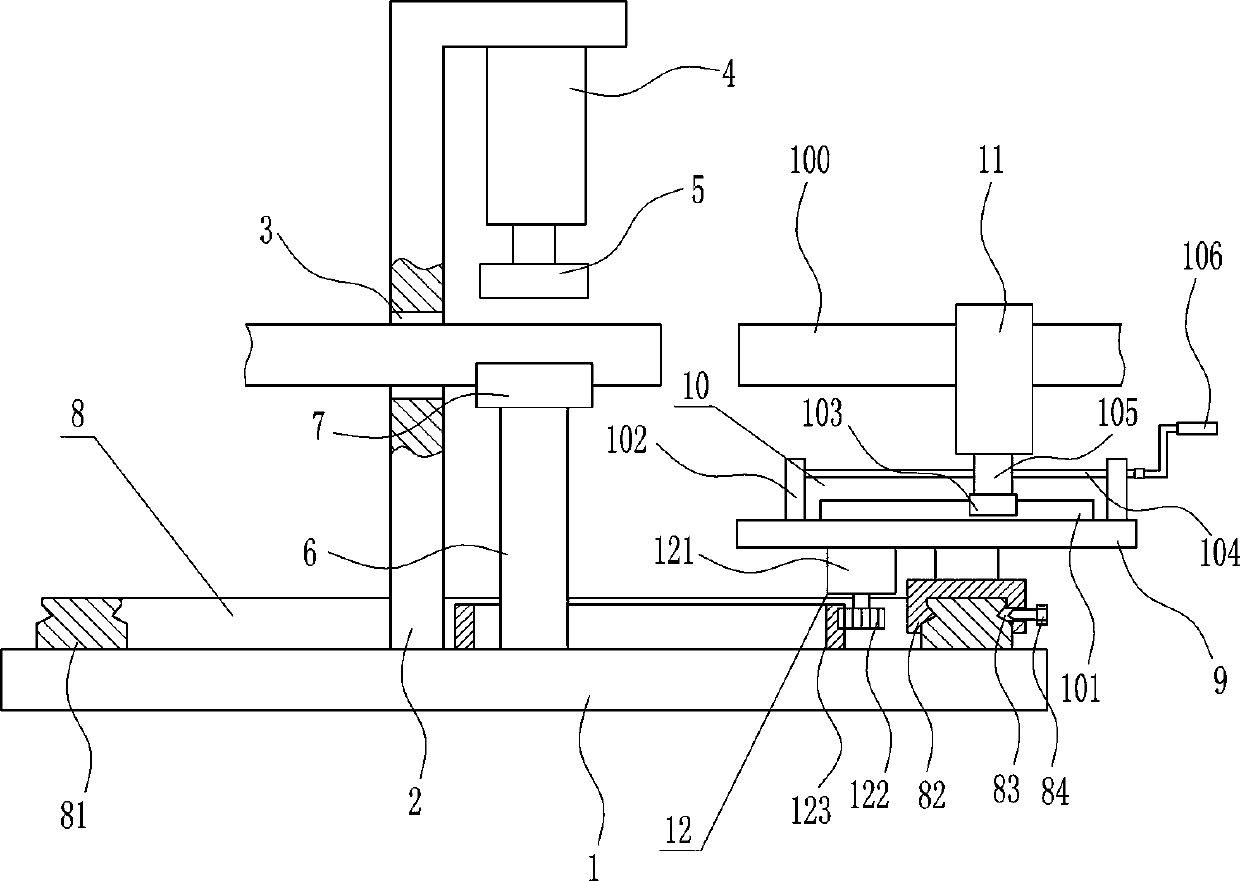

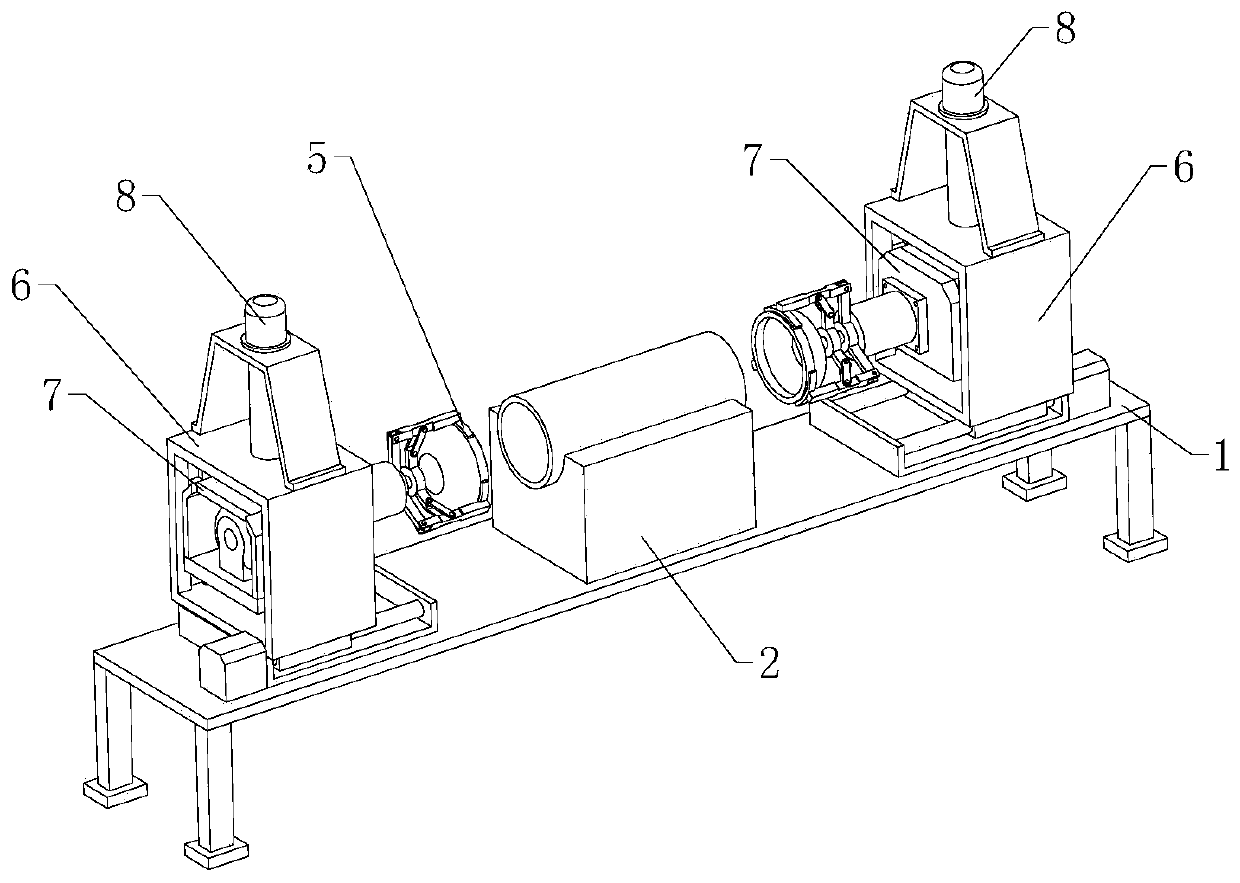

Improved end cover welding tool for barrel

InactiveCN110757085ANot easy to moveScratch protectionWelding/cutting auxillary devicesAuxillary welding devicesMachiningPhysics

The invention relates to the technical field of end cover machining, in particular to an improved end cover welding tool for a barrel. The tool comprises a machining table and a barrel support, and further comprises two positioning adjustment stepping mechanisms, wherein the barrel support is fixedly mounted at the center of the top of the machining table, the barrel support is provided with an arc-shaped accommodating groove capable of accommodating the barrel, and the two positioning adjustment stepping mechanisms are arranged at the two ends of the barrel support correspondingly; and each positioning adjustment stepping mechanism comprises a height adjusting assembly, a rotating assembly, a positioning clamping assembly, and a horizontal moving assembly, each horizontal moving assemblyis fixedly mounted on the machining table, each height adjusting assembly is located above the corresponding horizontal moving assembly, the bottom of each height adjusting assembly is fixedly connected with the working end of the corresponding horizontal moving assembly, and each rotating assembly is located inside the corresponding height adjusting assembly. Each end cover needing to be welded can be stably clamped by the device, the height of each end cover can be adjusted, and the accuracy of welding between each end cover and the barrel is improved.

Owner:丽水市莲都区贝亿乐信息技术服务有限责任公司

Automobile brake disc thickness detection apparatus

InactiveCN107388933AEasy to fixNot easy to moveMechanical thickness measurementsEngineeringBrake pad

The invention relates to a detection apparatus, and especially relates to an automobile brake disc thickness detection apparatus. The technological problem to be solved by the invention is to provide an automobile brake disc thickness detection apparatus which is convenient to operate, is high in detection efficiency and is high in detection accuracy during the automobile brake disc thickness detection process. The automobile brake disc thickness detection apparatus includes a support frame and the like, wherein the lower part of the support frame is horizontally connected with a horizontal support; the top of the support frame is horizontally connected with a detection table; a detection groove is formed in the right side of the detection table; a mounting groove is formed in the detection table at the left side of the detection groove; the mounting groove is L-shaped, and is communicated with the detection groove; a fixing device is arranged in the mounting groove; and a discharge device is arranged below the detection groove. The automobile brake disc thickness detection apparatus can preferably fix a brake disc through the fixing device, and achieves the effect of convenient operation, high detection efficiency and high detection accuracy during the automobile brake disc thickness detection process.

Owner:谢剑和

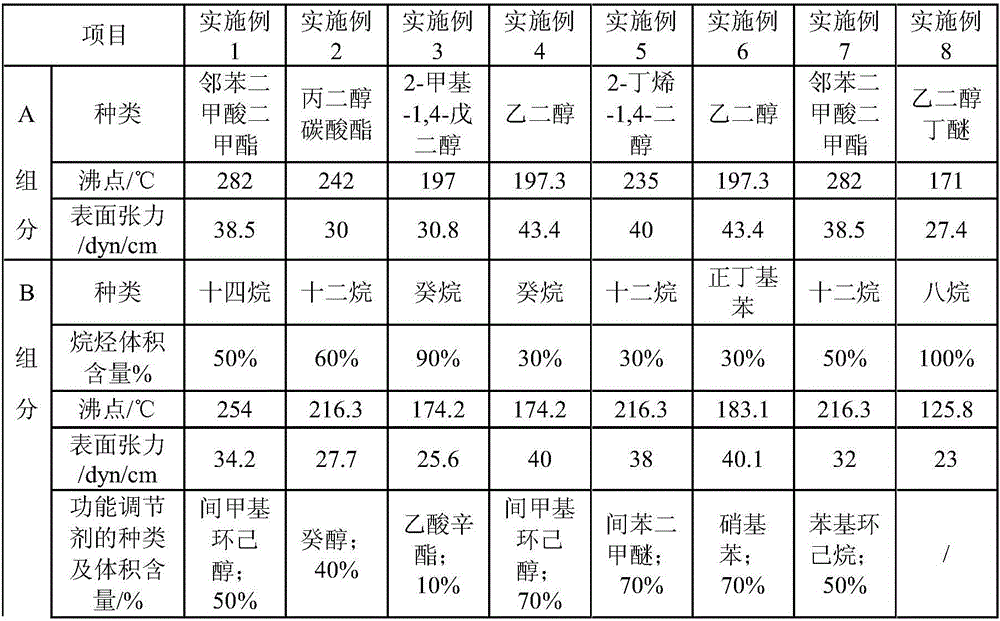

Ink formula, photoelectric device and preparation method for functional layer of photoelectric device

ActiveCN107177239AReduce solubilityEvenly distributedSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityBoiling point

The invention provides an ink formula, a photoelectric device and a preparation method for the functional layer of the photoelectric device. The ink comprises a component A and a component B, wherein the component A comprises first liquid; the component B comprises second liquid and functional materials dispersed in the second liquid; the boiling point of the first liquid is higher than the boiling point of the second liquid by at least ten DEG C; the first liquid and the second liquid do not mutually dissolve; the solubility of the functional materials in the second liquid is higher than or equal to 1g, and the solubility of the functional materials in the first liquid is less than or equal to 0.05g; the density of the first liquid is greater than the density of the second liquid; the range of a ratio of the surface tension of the first liquid to the surface tension of the second liquid is 0.8-1.2; the second liquid is volatilized earlier than the first liquid; along with the volatilization of the second liquid, two parallel interfaces are formed between the component B and external atmosphere as well as the component A; along with the volatilization of the first liquid, solids which are evenly dispersed on the interface form an even film layer on a matrix so as to solve the problem of unevenness in film formation.

Owner:NANJING TECH CORP LTD

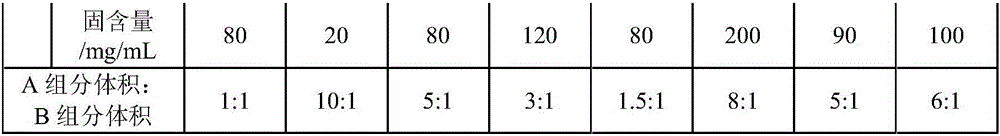

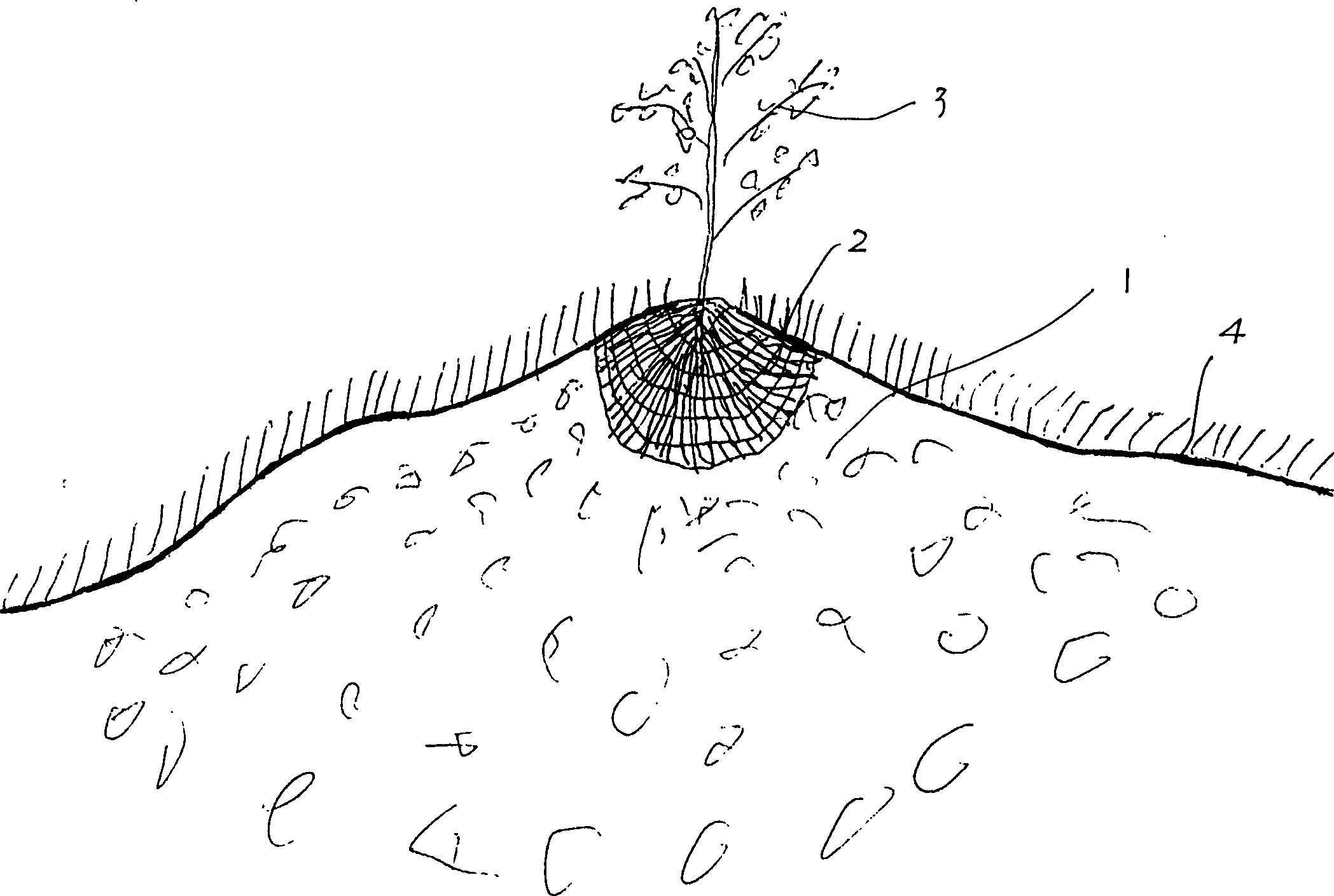

Method for sand-fixing, water preserving, planting grass and tree afforestation desert

InactiveCN1781353AImprove the ecological environmentImprove survival ratePlant protectionSoil-working methodsSoil scienceSandhill

The method of afforesting desert includes spreading simulating grass onto the surface of desert, measuring underground water content and obtaining water containing soil, digging planting hole in the high part of sand hill, packing water containing soil inside film bag with cracks and setting inside the planting hole and planting grass or tree seedling in the film bag. The present invention spreads simulating grass to inhibit sand flying, plants in the high part of sand hill to absorb evaporated underground water, packs soil to avoid loss, and sucks underground water with water sucking nail, so as to utilize underground water fully in afforesting desert and reduce needed post-management.

Owner:林廷勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com