Intelligent fixture switching system

A technology for switching systems and fixtures, applied in the direction of manufacturing tools, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of high processing and installation precision, high manufacturing cost, and low production efficiency, so as to improve production efficiency and reduce production cost , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

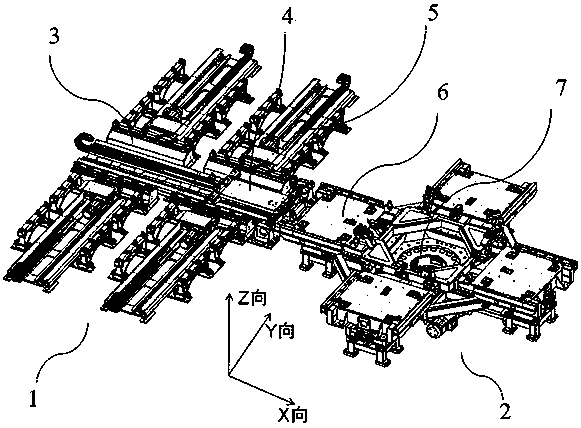

[0030] In a preferred embodiment of the present invention, an intelligent fixture switching system is provided, please refer to figure 1 As shown, it includes a warehouse location 1 and a turntable 2, wherein the warehouse location includes a Z-direction lifting device 3, an X-direction transfer platform 4 and a Y-direction storage location 5; the turntable 2 includes a plurality of switching platforms 6 and The turntable drive 7; the motor drive part of the storage location 1 is controlled by the robot system, the storage location 1 is docked with a switching platform 6, and the remaining switching platforms 7 continue to work.

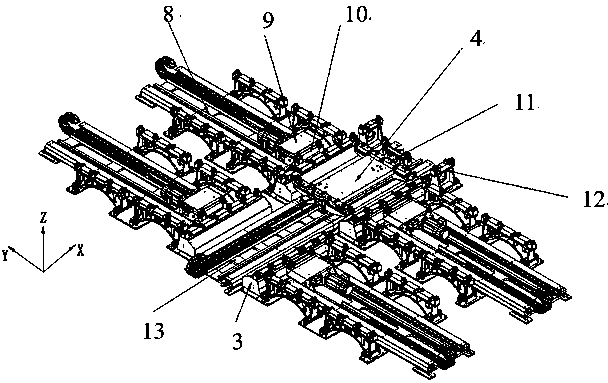

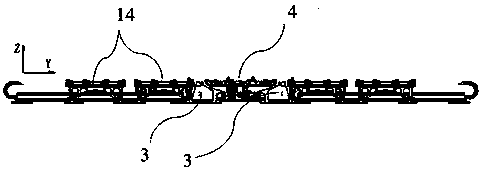

[0031] see figure 2 , image 3 and Figure 4 , this clamp switching storage system for flexible production lines includes X-direction rails 13, X-direction transfer platforms 4, Y-direction storage locations 5, Z-direction lifting devices 3 and robot control systems. The robot control system connects the servo motors of the X-direction transfer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com