Waste lithium battery sorting and recycling equipment

A technology for waste lithium batteries and recycling equipment, which is applied in battery recycling, waste collector recycling, recycling technology, etc., and can solve the problems of weak two-stage crushing linkage, damage to coarse crushing sorter, and low energy utilization rate. , to achieve the effects of avoiding clogging, high energy utilization rate and improving crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

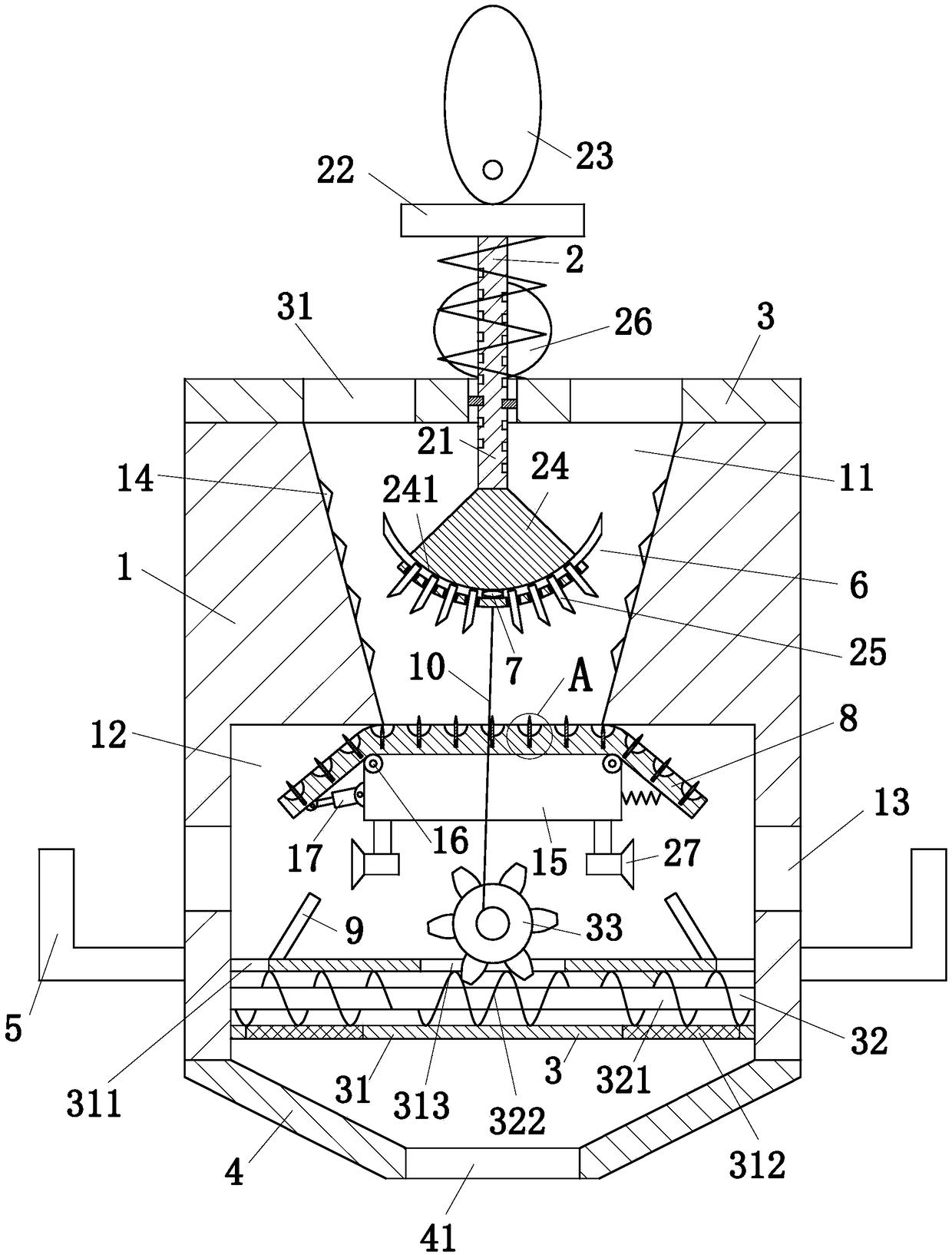

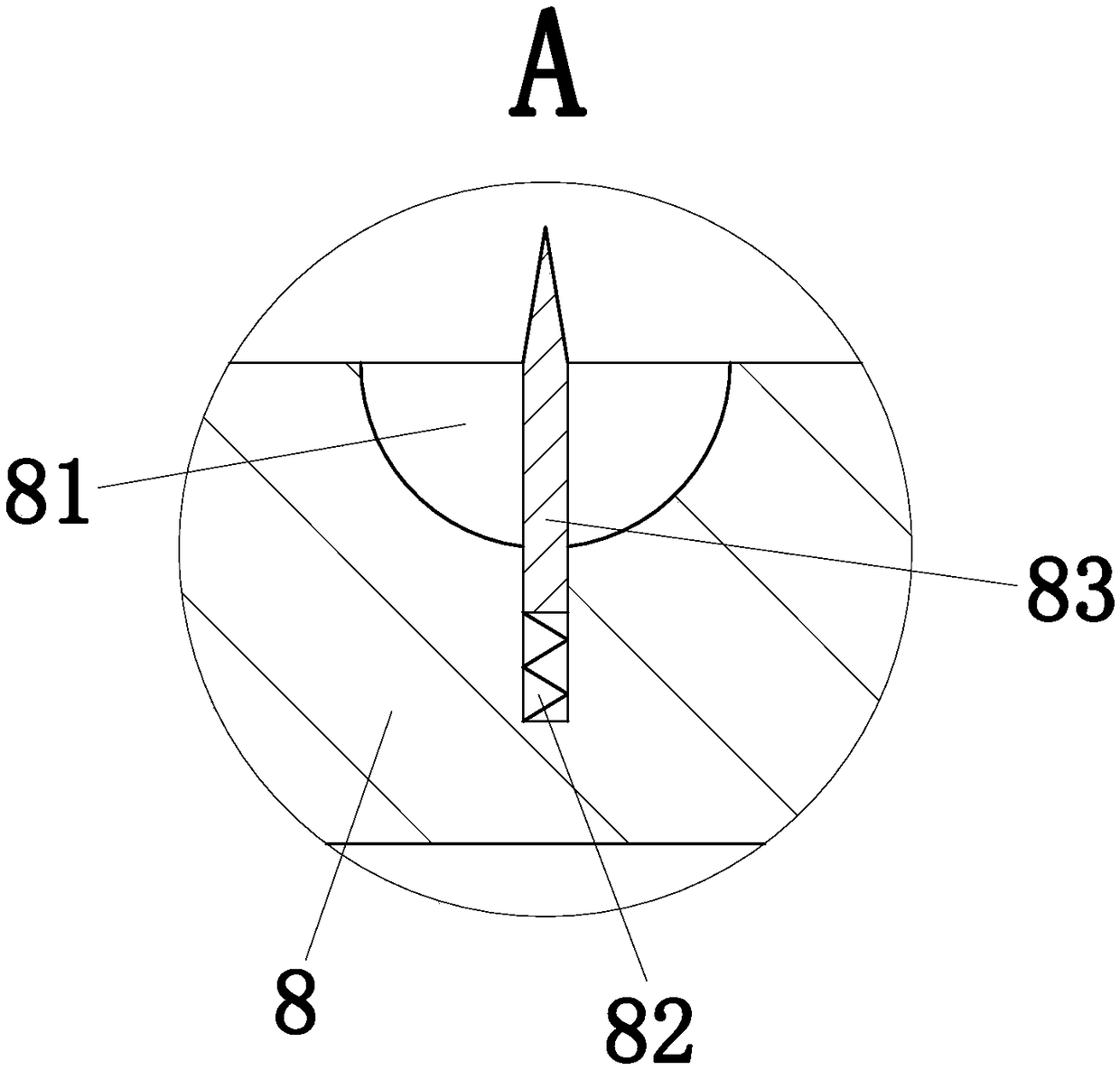

[0020] use figure 1 with figure 2 A device for sorting and recovering waste lithium batteries according to an embodiment of the present invention is described as follows.

[0021] Such as figure 1 As shown, a waste lithium battery sorting and recycling device according to the present invention includes a box body 1, a primary sorting unit 2 and a secondary sorting unit 3, and a circular frustum-shaped Groove 11, the size of the upper end of the frustum-shaped groove 11 is large and the size of the lower end is small. The middle position of the lower surface of the box body 1 is provided with a rectangular groove 12, and the box body 1 is provided with a filter hole between the truncated-shaped groove 11 and the rectangular groove 12 , a cover plate 3 is arranged above the box body 1, a collection bucket 4 is provided at the bottom of the box body 1, and a discharge port 41 is provided at the bottom of the collection bucket 4; , the feed port 31 communicates with the frustu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com