Patents

Literature

131results about How to "Centralized processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

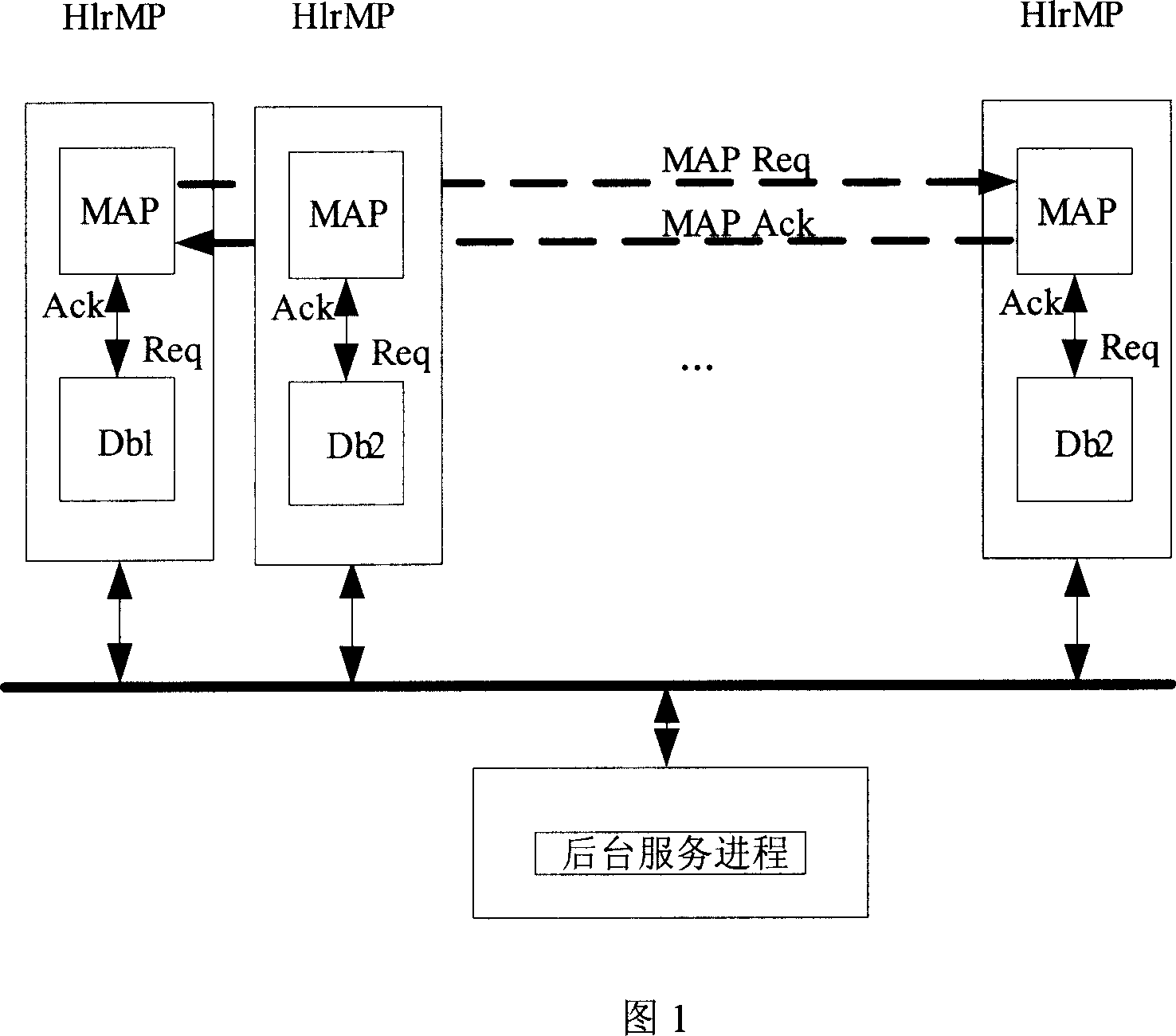

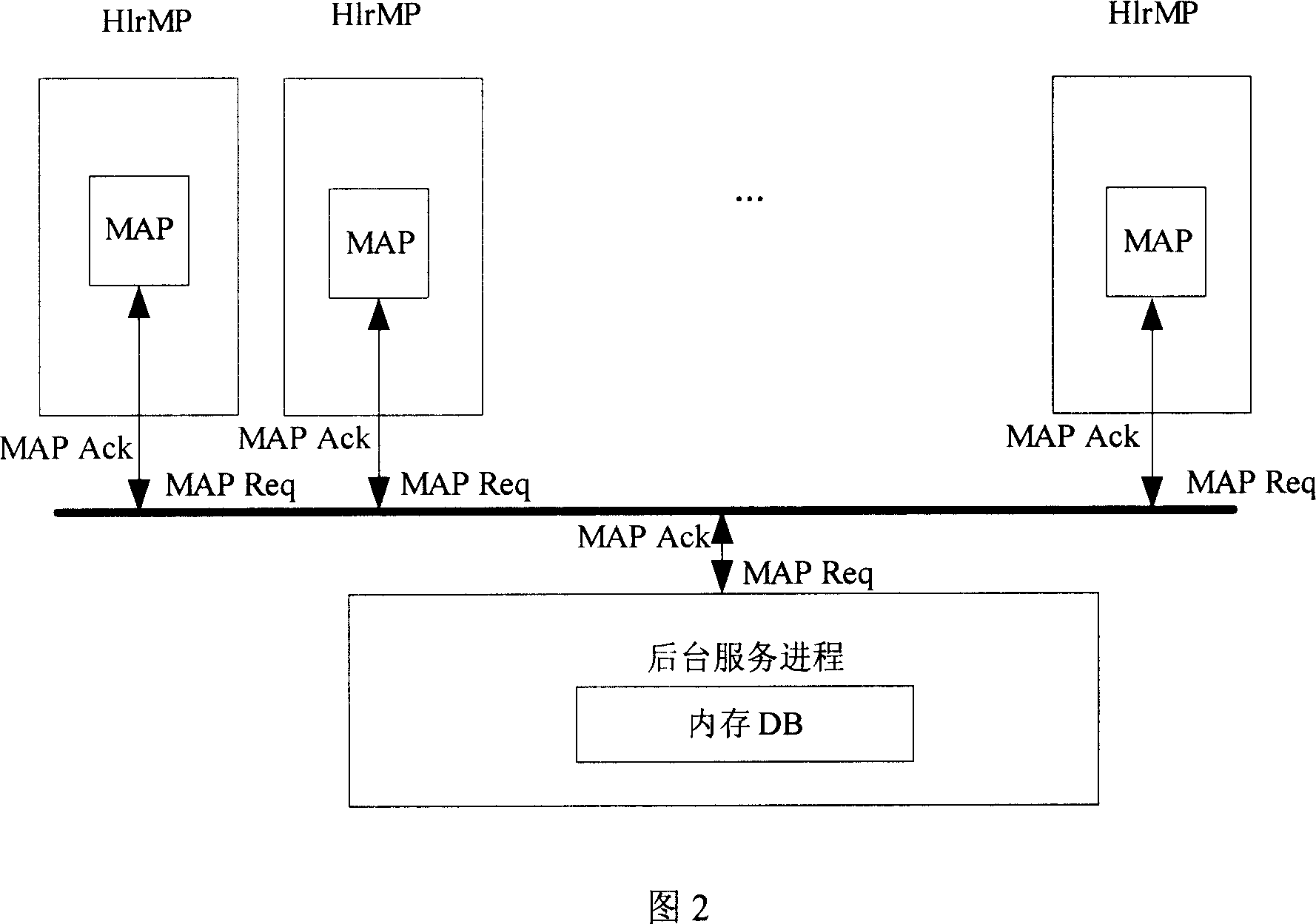

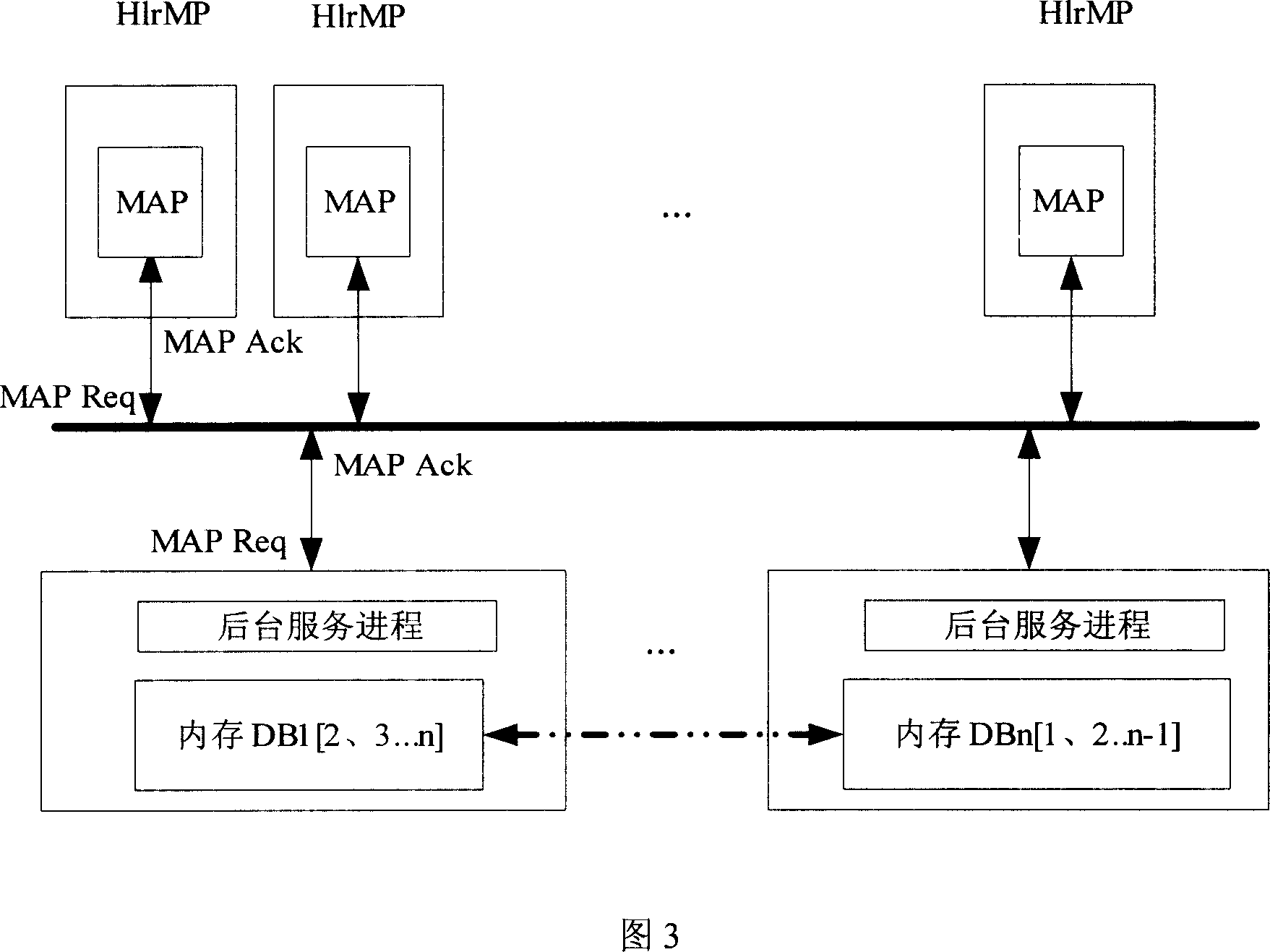

Method for implementing distributed HLR memory database

InactiveCN1992953ACentralized processingRealize online upgradeRadio/inductive link selection arrangementsSpecial data processing applicationsIn-memory databaseDatabase server

The invention relates to a method for realizing distributed HLR memory database, wherein it comprises that: a, dividing the data of HLR memory database into different types, defining different memory database servers; b, distributing the database servers on the nodes; c, defining data dictionary for each type of memory database server; d, building memory database; e, server via relative dictionary loads data into memory list; f, building local access interface and remote access interface for the list of memory database server, while the local interface is used to access into the list on local node, and the remote interface is used to access the list on the main server; g, the modification on the memory database list is distributed by the main server to other backup nodes to be synchronously refreshed. The invention can improve the capacity and property of HLR memory database.

Owner:ZTE CORP

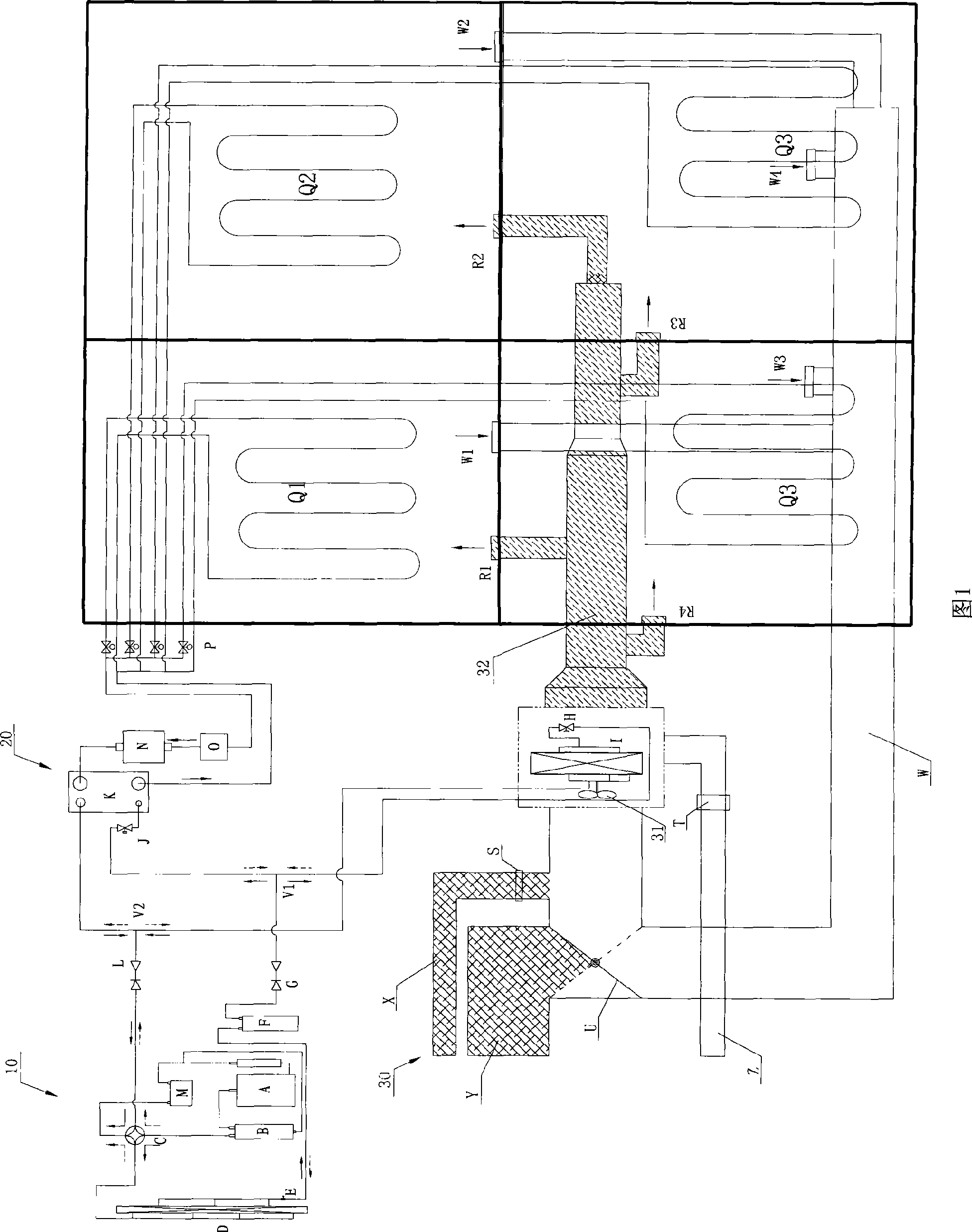

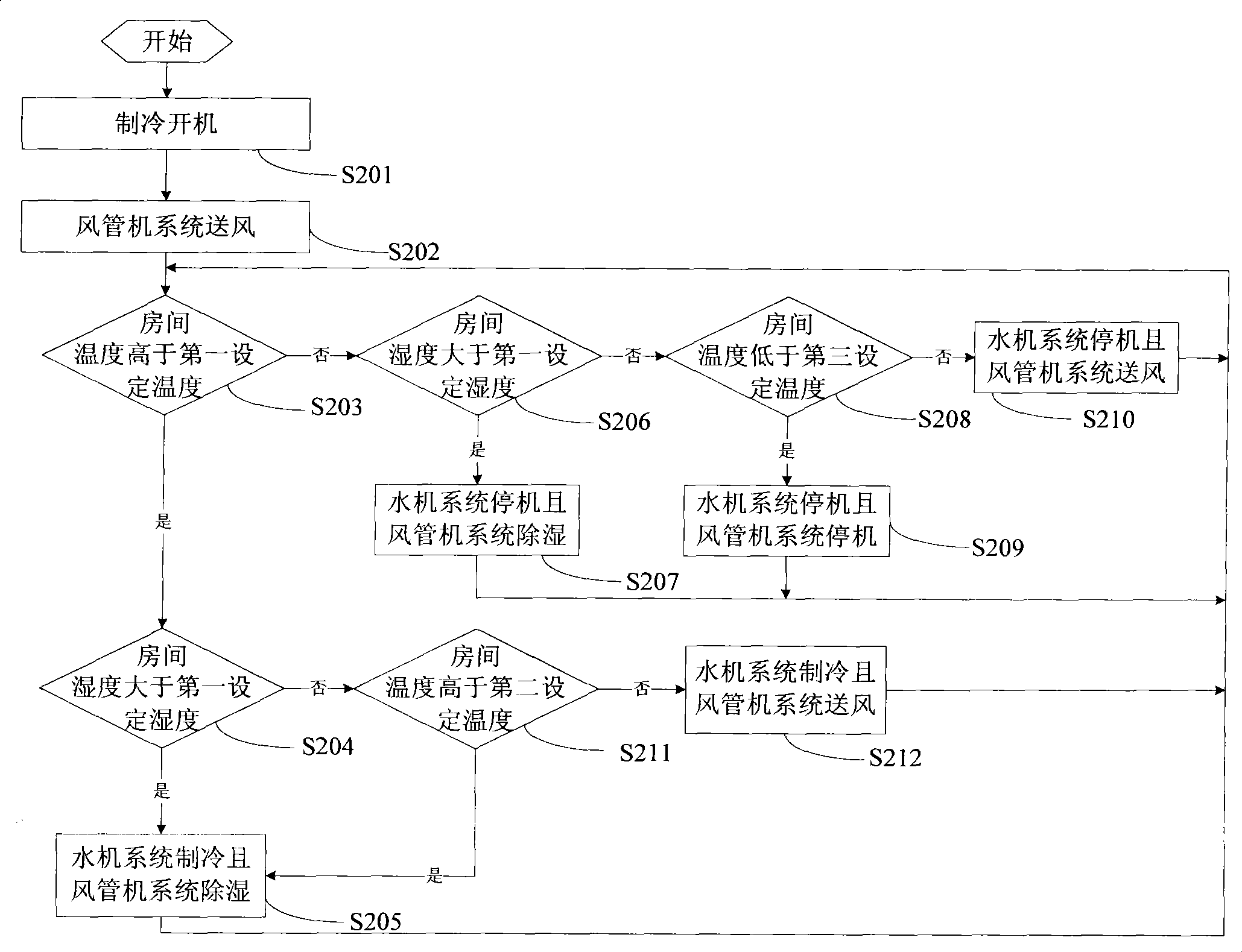

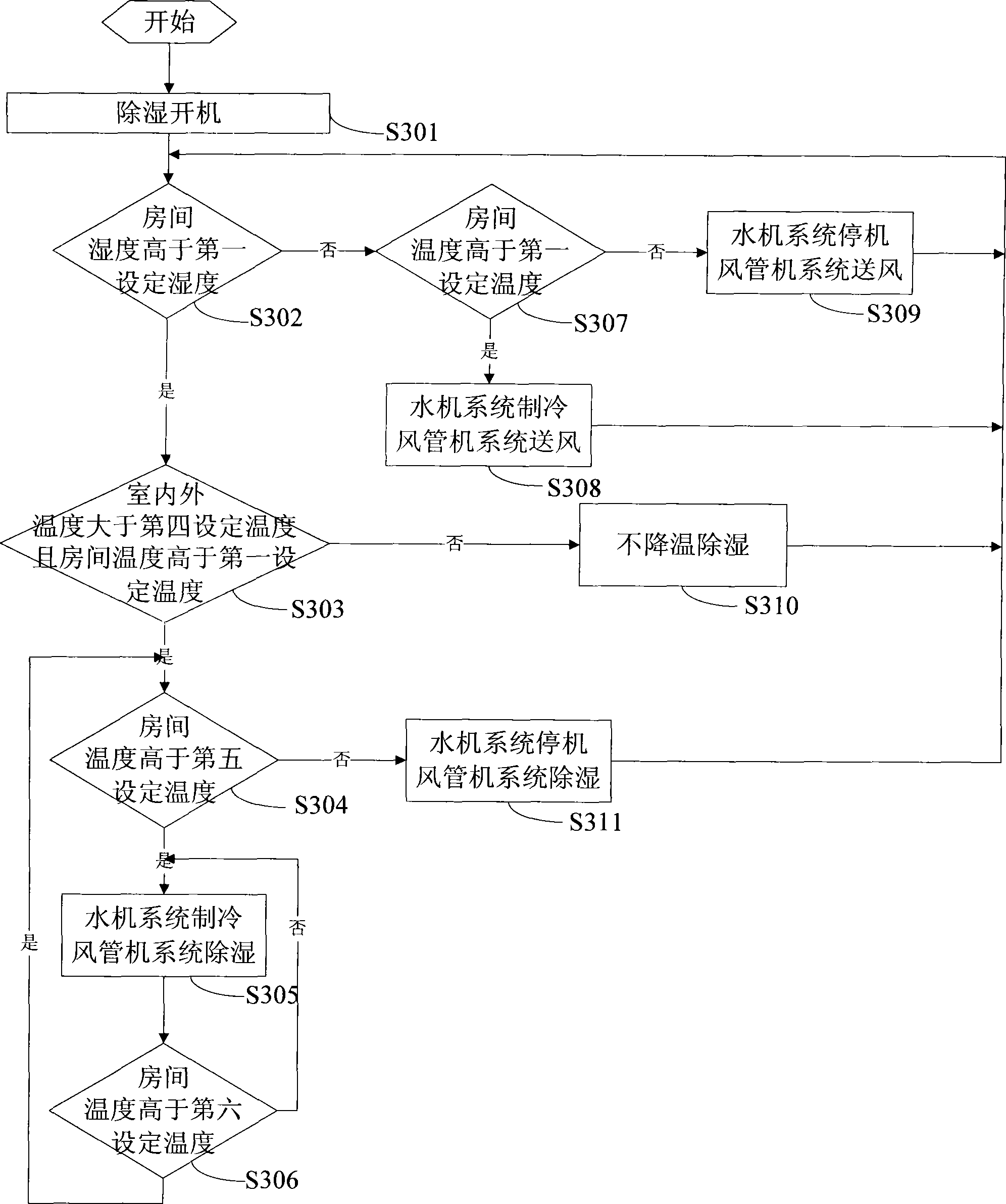

Air conditioner system for independently controlling temperature and humidity and refrigeration/dehumidification method

InactiveCN101363648AAchieve independent controlImprove comfortMechanical apparatusSpace heating and ventilation safety systemsWater circulationProcess engineering

The invention provides an air conditioning system which independently controls temperature and humidity and a refrigeration / dehumidifying method. A cooling media circulation system, a water circulation system and an air supply system of an air duct machine are assembled to realize independent control of the temperature and the humidity, thus greatly improving comfort of a user and realizing energy saving.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

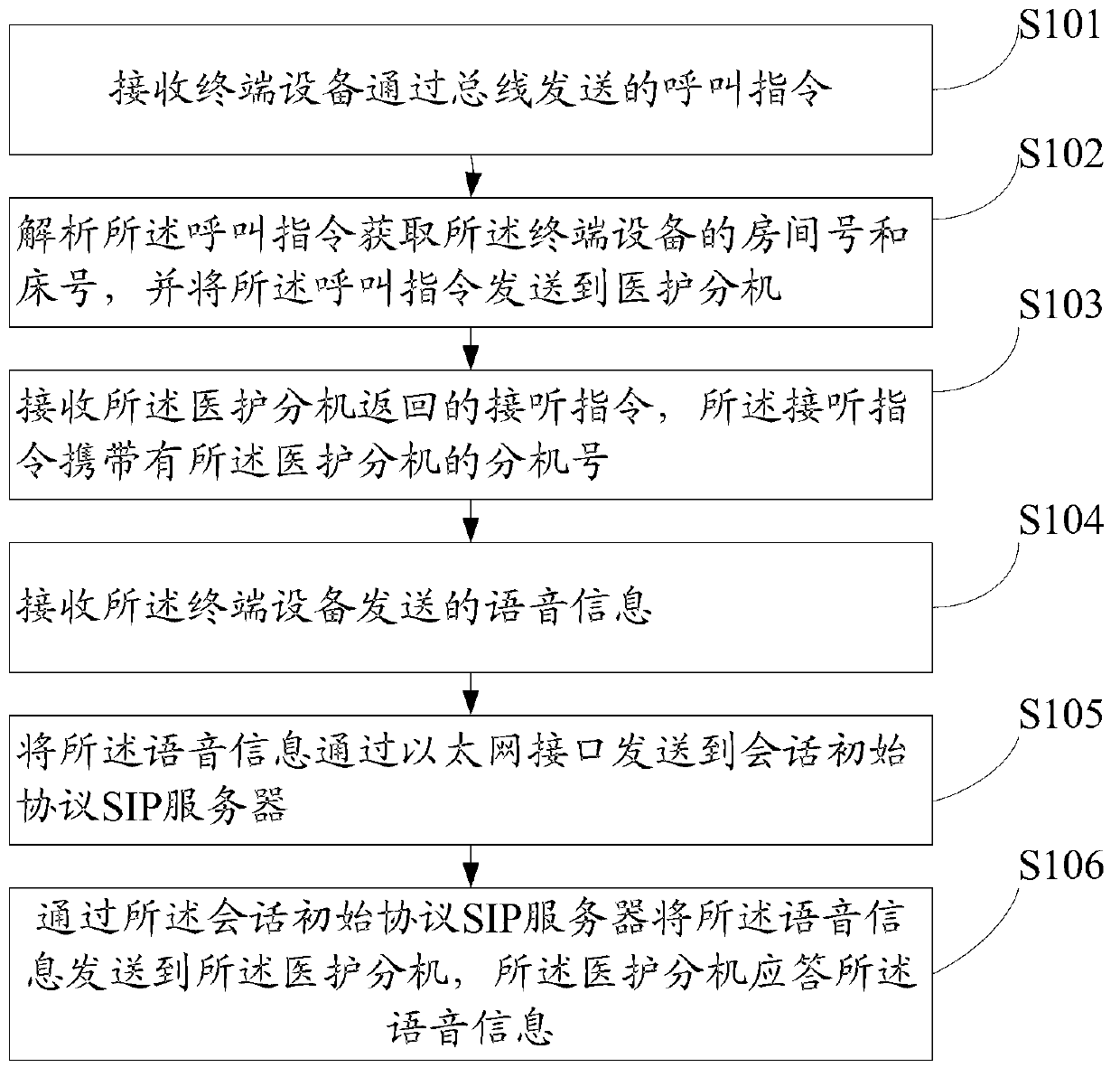

Nursing call gateway implementation method

ActiveCN103220439ARealize linkageCentralized processingInterconnection arrangementsTerminal equipmentComputer terminal

The invention discloses a nursing call gateway implementation method. The method includes the steps of receiving a call instruction sent by terminal equipment through a bus, analyzing the call instruction to obtain a room number and a bed number of the terminal equipment, sending the call instruction to a medical extension, receiving an answer instruction returned by the medical extension, wherein the answer instruction carries an extension number of the medical extension, receiving voice information sent by the terminal equipment, sending the voice information to a conversation initial protocol SIP server through an Ethernet port, and sending the voice information to the medical extension through the conversation initial protocol SIP server, wherein the medical extension answers the voice information. The method realizes application of a simulated voice system of a hospital calling system on the Ethernet, achieves concentrated processing for voice call requests of all wards, and improves work efficiency and work quality of medical staff.

Owner:北京鑫丰南格科技股份有限公司

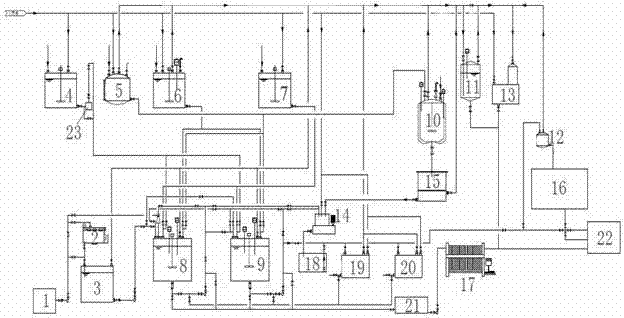

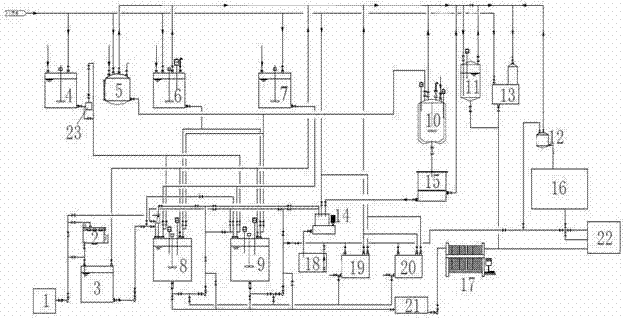

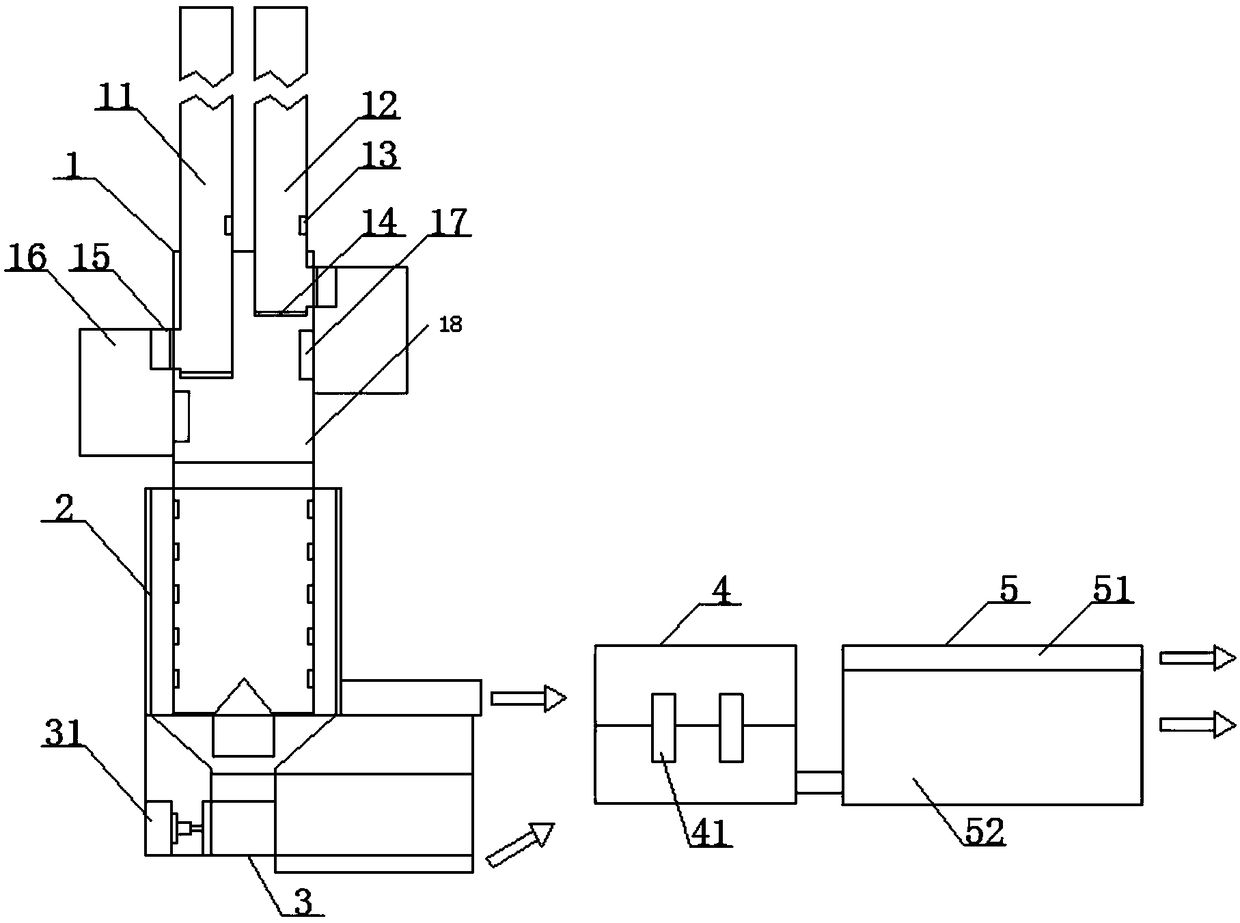

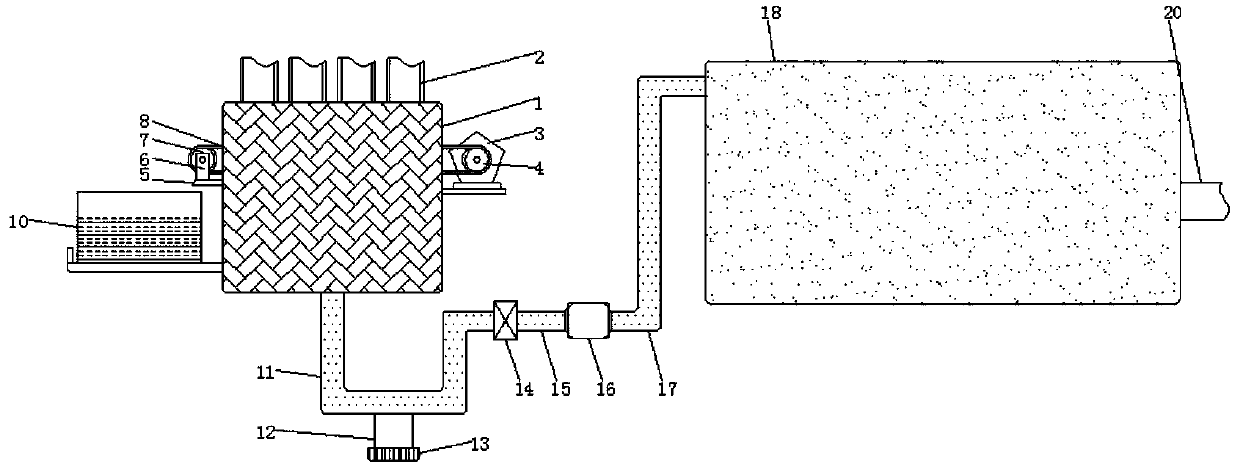

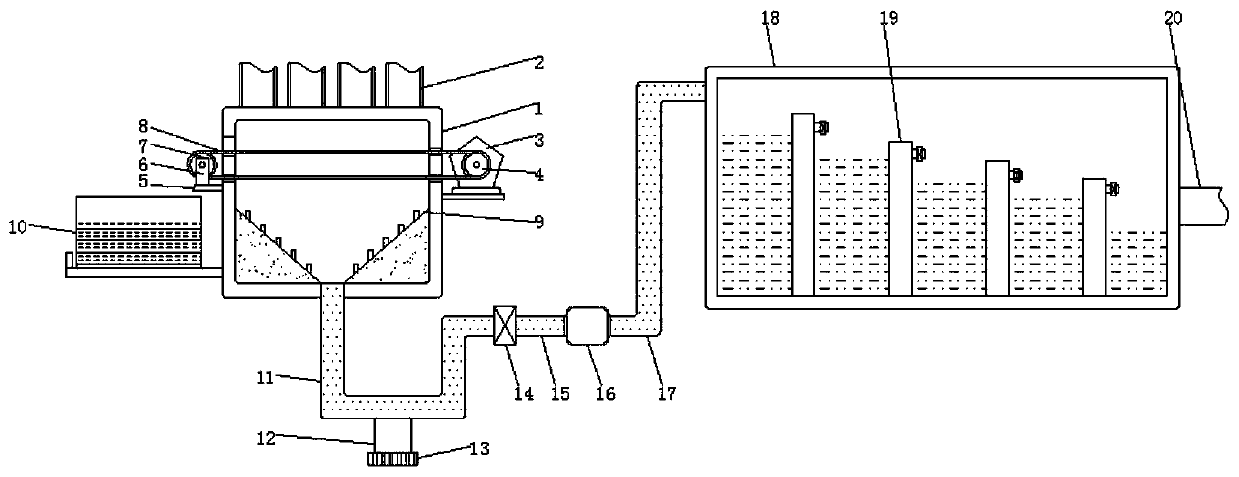

Physicochemical comprehensive treatment system for dangerous waste liquid

InactiveCN102344214AAvoid running, dripping and leakingReduce processing operating costsMultistage water/sewage treatmentLiquid wastePaper tape

The invention discloses a physicochemical comprehensive treatment system for a dangerous waste liquid. The system comprises a waste liquid storage tank, a paper tape filter, a quenching and tempering groove, four reagent grooves, three reaction vessels with stirrers, a tail gas absorption groove, a buffer tank, a water injection vacuum set, a centrifuge, a suction filtration groove, a membrane processor, a filter press, a filtrate collection pool, two waste liquid intermediate grooves, a sludge collection pool and a wastewater regulating pool. Each processing unit of the invention can be switched and combined flexibly so as to be adapted to various physicochemical comprehensive treatments of a dangerous waste liquid, such as acid-base neutralization, coagulation sedimentation, redox, desalination, solid-liquid separating and tail gas purifying treatment etc. Under the condition of satisfying the technical requirements of waste liquid treatment, the system of the invention can reduce repeated treatment facility construction and investment. Under the premise of ensuring a good treatment effect, the system provided in the invention reduces human consumption, material consumption and energy consumption, and reduces the treatment operation cost of per unit of waste amount. The escaping and leaking phenomena common in present waste liquid treatment processes can be avoided, and secondary pollution to the environment as well as damage to people can be eradicated.

Owner:ZHEJIANG UNIV

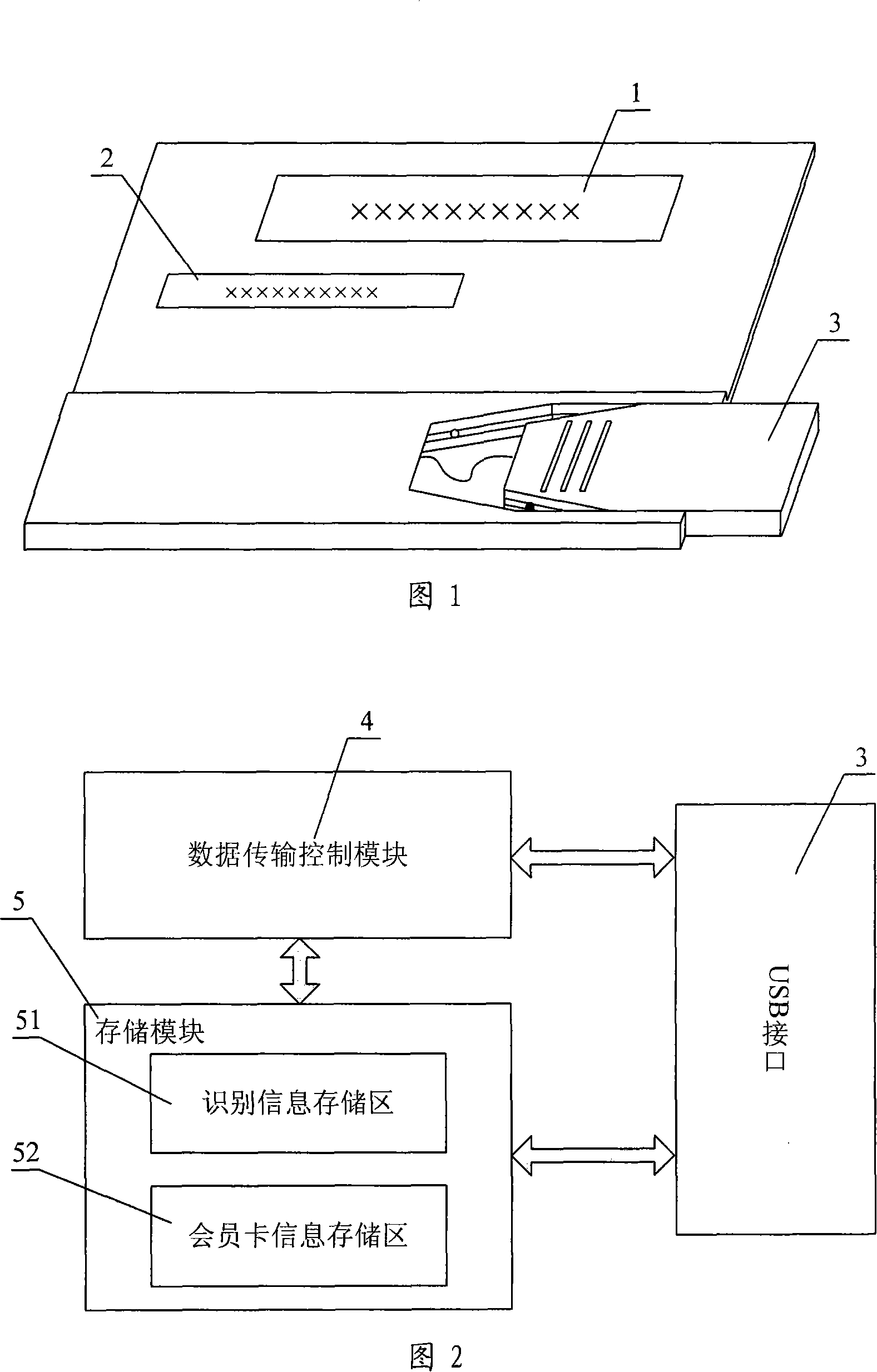

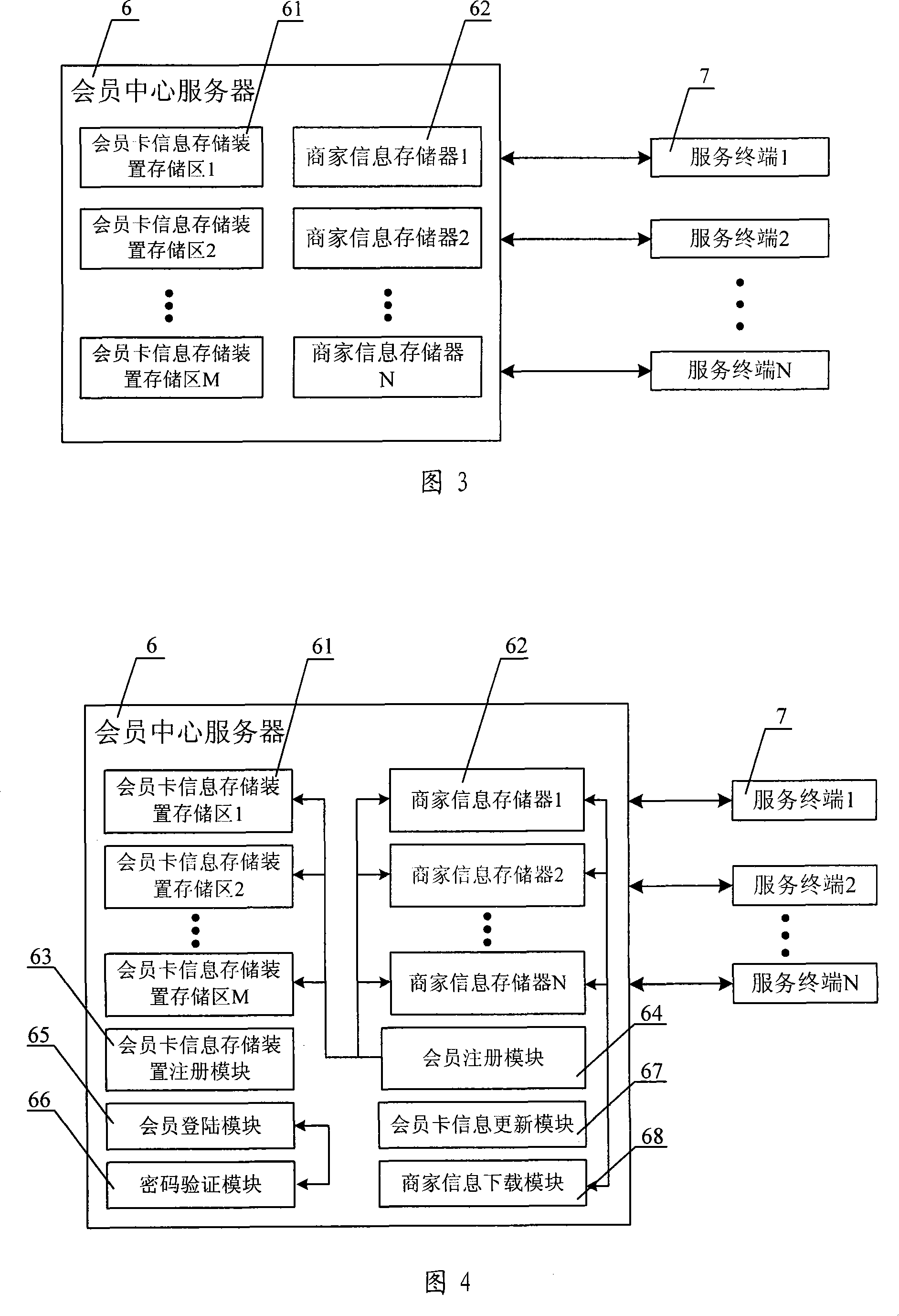

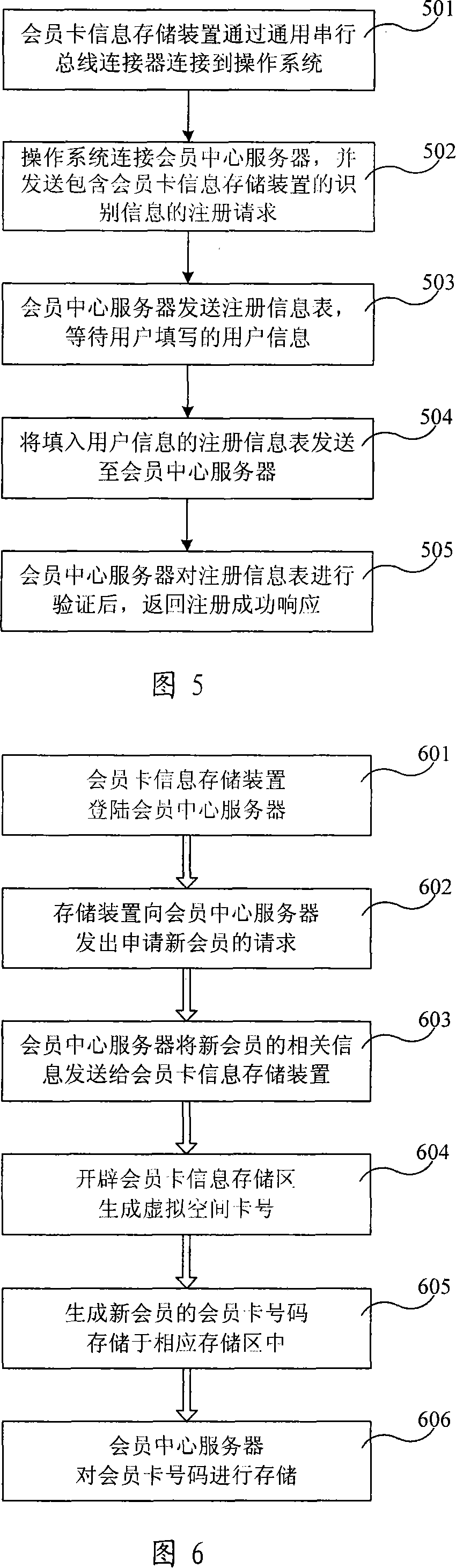

Multiuser member card management system

InactiveCN101114356AReduce consumptionCentralized processingResourcesMarketingLibrary scienceManagement system

The invention relates to a management system of multi-user membership cards and comprises a membership center server and a plurality of serving terminals which are connected with the membership center server, wherein, the membership center server comprises a plurality of storage sections of membership card information storage devices and a plurality of information storage sections of trade companies which are used for storing the information of the membership card information storage devices and each trade company; the serving terminals are used by the trade companies to search information in the correspondent information storage sections of trade companies and to update the information of trade companies. The invention realizes that the user terminals having the membership cards can download and update all information of any member optionally without being limited by the card issuers; the serving terminals of the trade companies can develop members independently based on the own requirements without being affected by other trade companies and keep the own independence.

Owner:TAIGUEN TECH SHEN_ZHEN

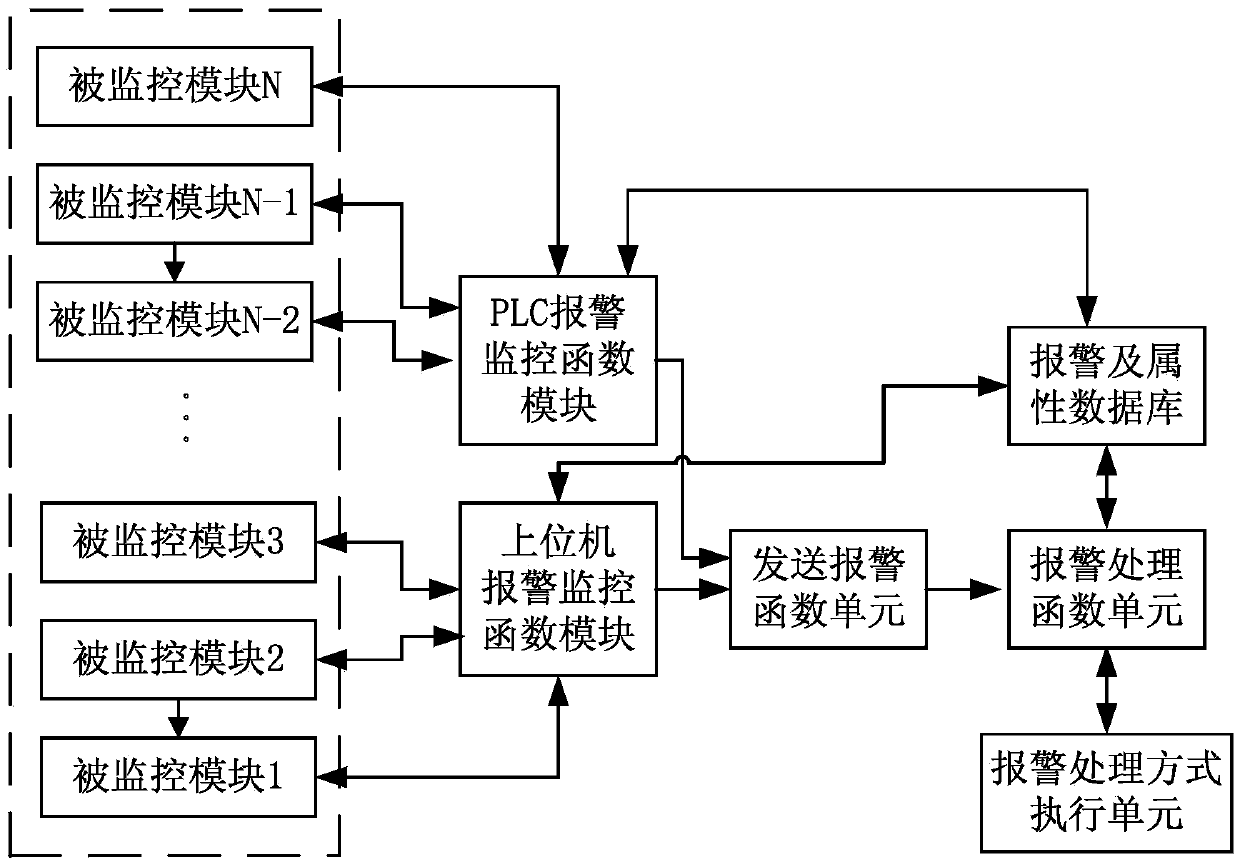

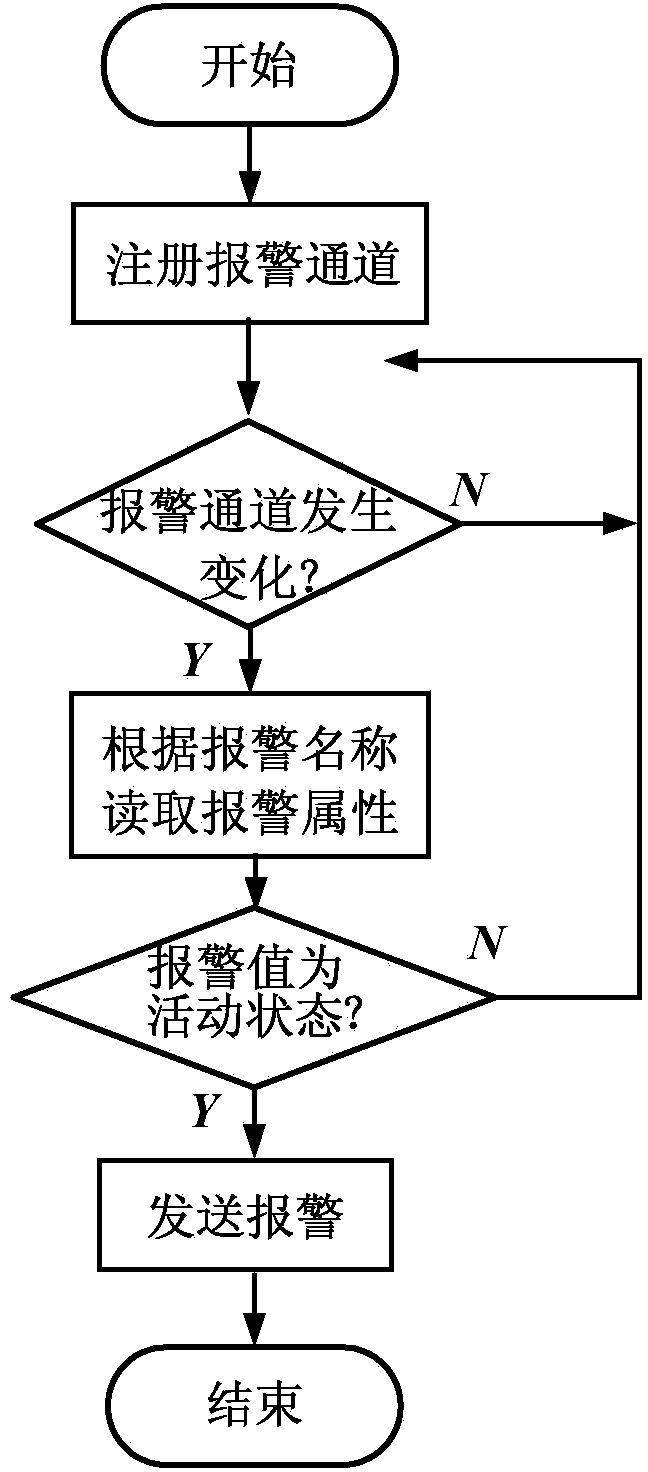

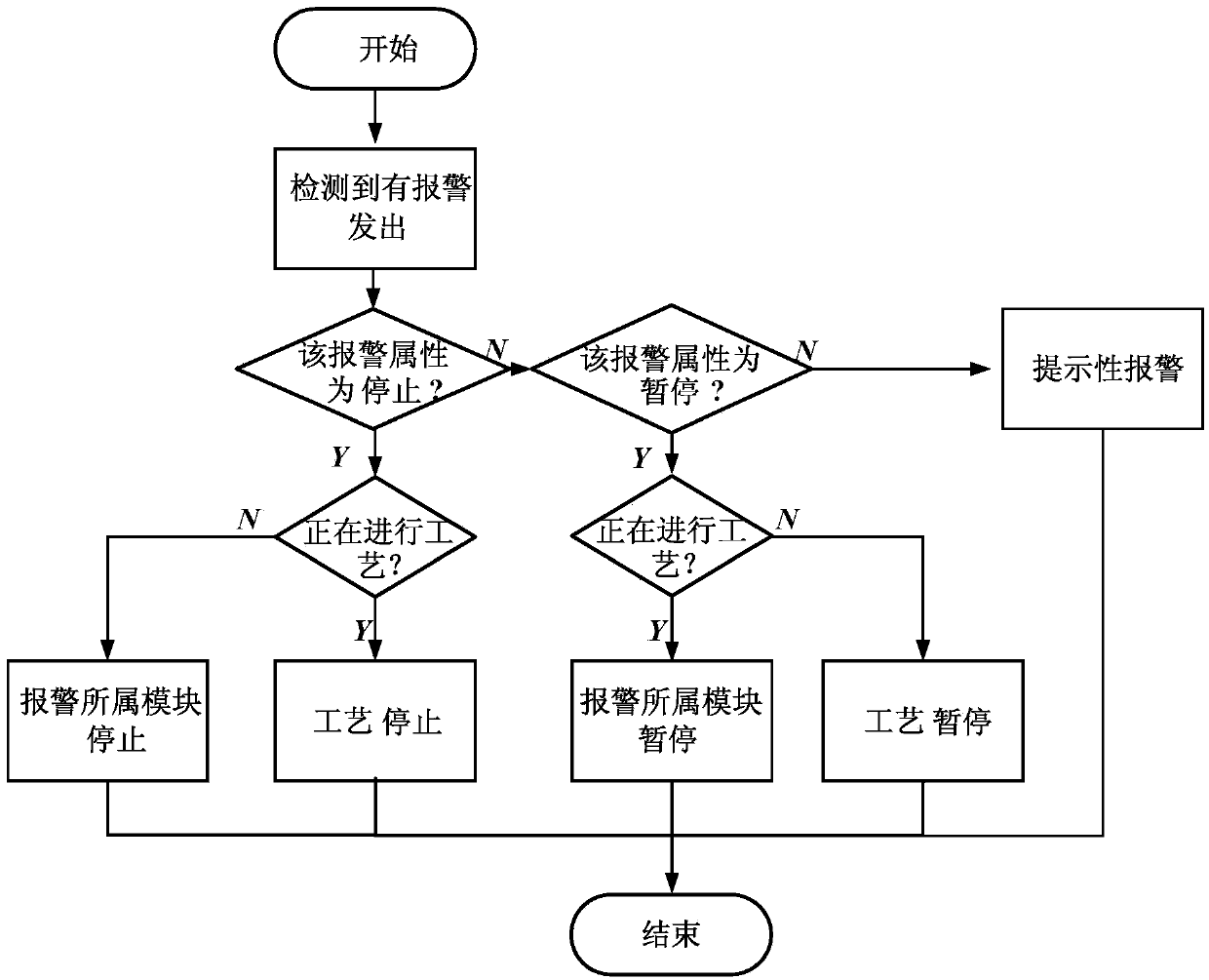

Method for alarm centralized processing for semiconductor processing device

ActiveCN103809577ACentralized processingEasy to manageTotal factory controlProgramme total factory controlReal-time computingSemiconductor

A method for alarm centralized processing for a semiconductor processing device comprises the steps of adopting a database to set and store all alarms and attributes of the alarms, and enabling the attributes to comprise alarm number attributes, alarm name attributes, alarm level attributes, alarm constraint attributes, alarm processing mode attributes, PLC alarm channel addresses, attributes of monitored modules where the alarms are located and / or alarm recovery attributes; reading all the alarms and the attributes of the alarms in the database and registering PLC alarm monitoring; if alarm events occur in a PLC part, entering a PLC alarm monitoring function module to read associated attributes of the alarm events, calling alarm sending functions and giving an alarm to an upper computer; if alarm events occur in the upper computer, entering upper computer alarm monitoring functions to read associated attributes of the alarm events, calling the alarm sending functions and giving an alarm; finally, selecting a corresponding alarm recovery mode to perform alarm processing according to the processing mode attributes of the alarms in the database corresponding to alarm processing functions.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

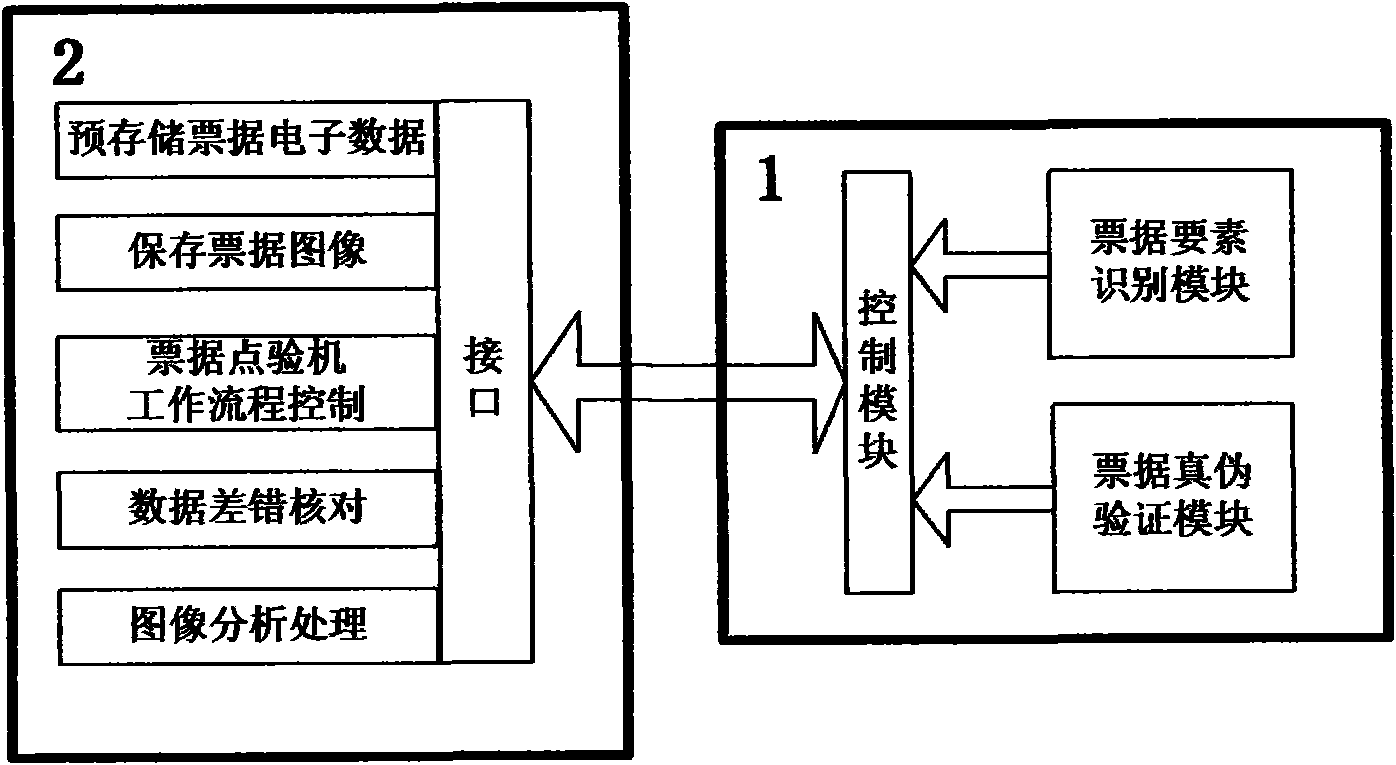

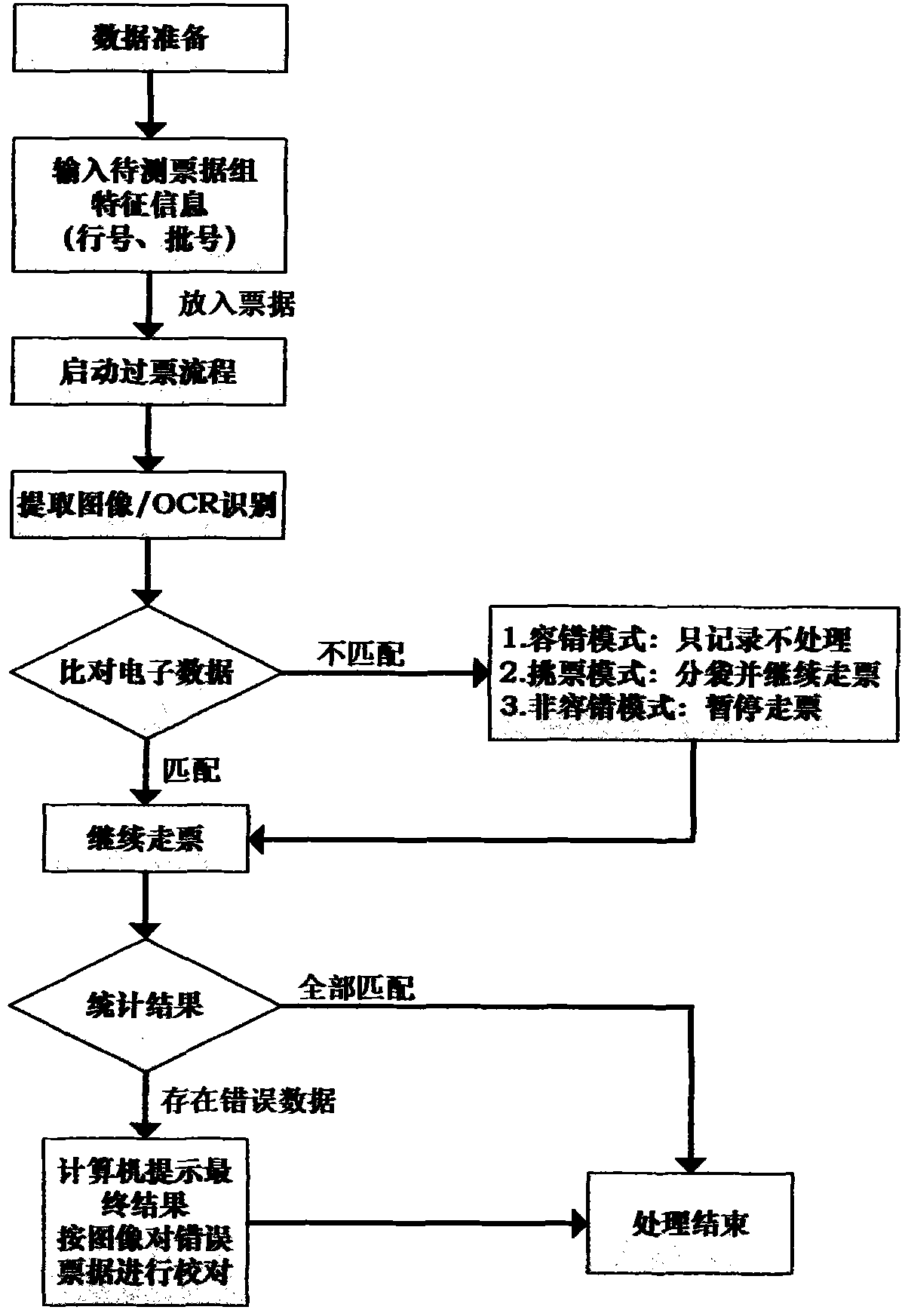

Bill currency count machine system and method

InactiveCN102096960AHigh degree of automationRealize fully automated inventoryPaper-money testing devicesCounting objects on conveyorsMachining systemComputer science

The invention discloses a processing method of an automatic processing system for bill certificates. The system can automatically count and check the bill certificates and also has the functions of bill counterfeiting, bill characteristic zone shooting, automatic identification and ticket picking. The product is mainly used for bank systems, and is especially suitable for intensively processing bill exchange business and processing bill subsequent supervision business, and the degree of electronization and automation is high.

Owner:万程

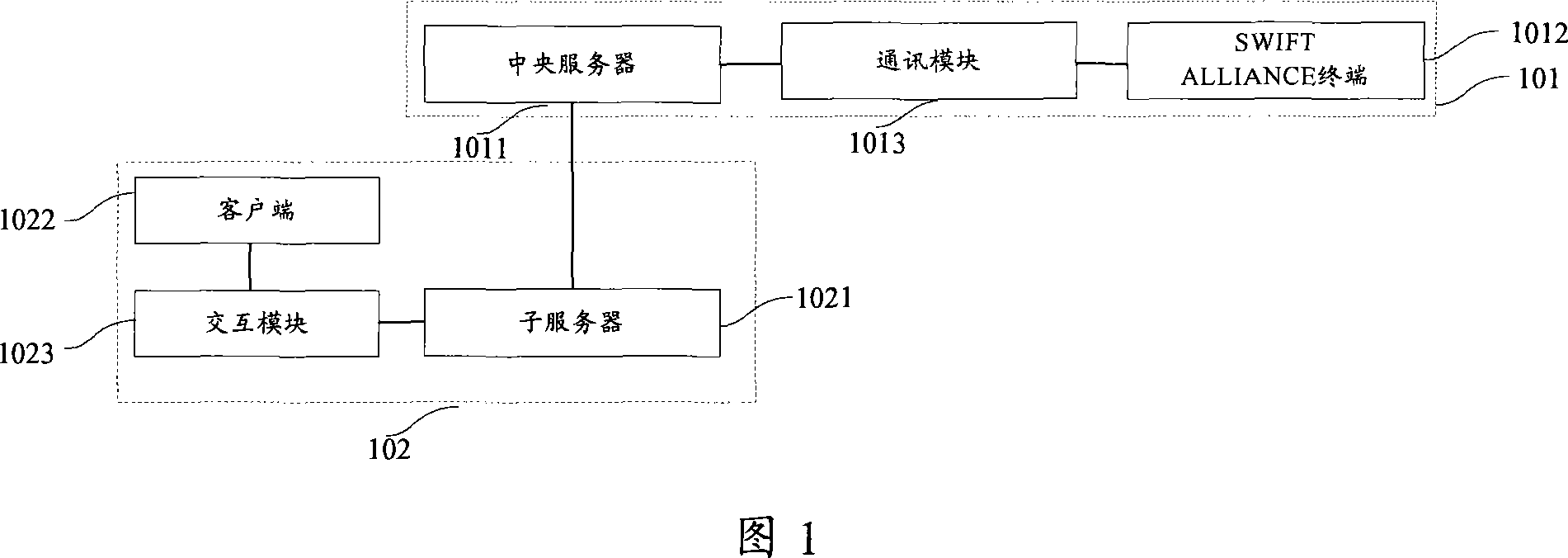

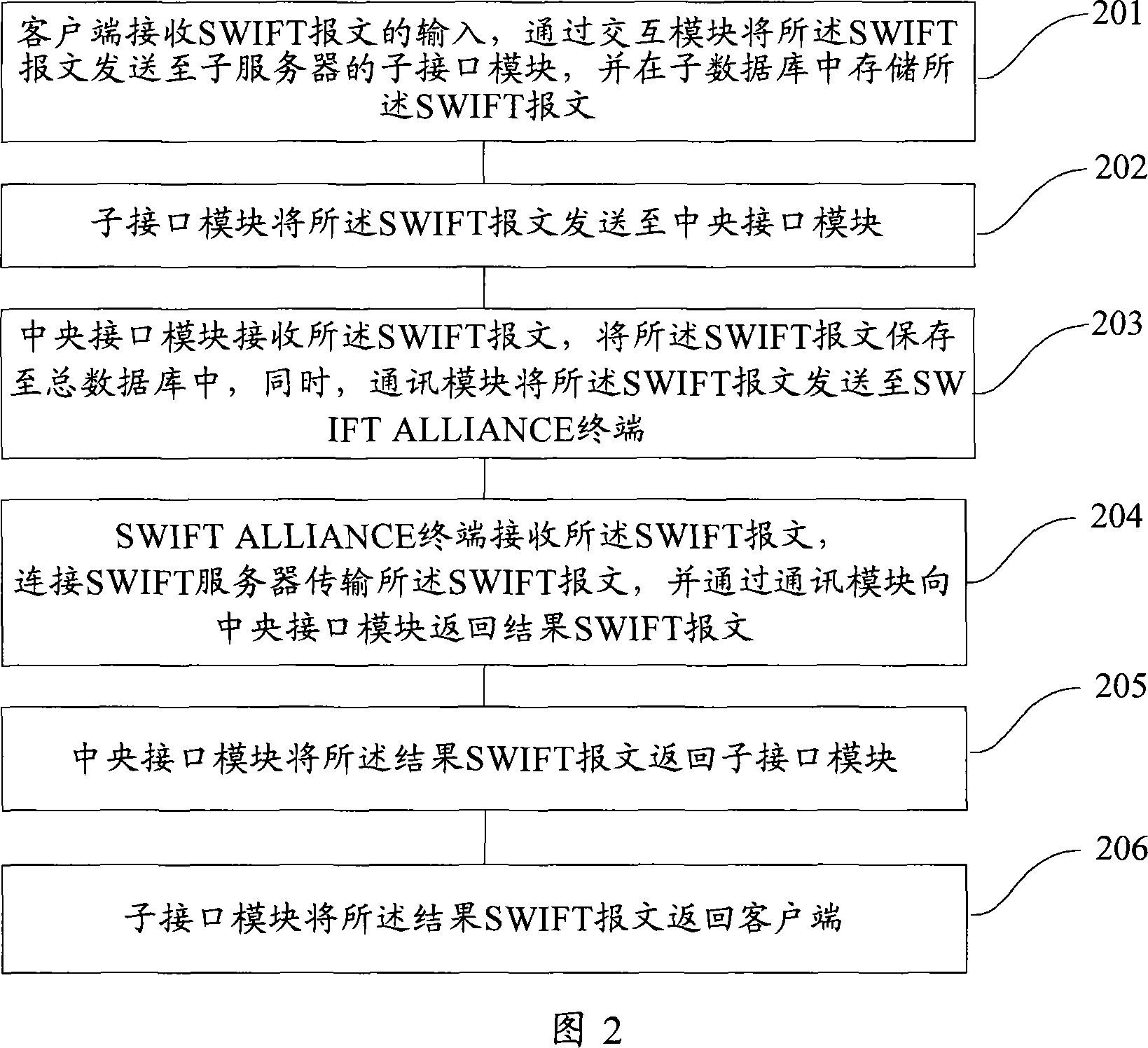

System for processing SWIFT message

ActiveCN101075967ALow costReal-time sending and receivingData switching networksSecuring communicationClient-sideHandling system

The system comprises: a central system comprising a central server, a SWIFT ALLIANCE and a communication module; and a slave system comprising a slave server, at least one client side and an interaction module. The invention effectively reduces the cost by creating a slave system and a central system so as to change the currently-used technical solution where each branch respectively set up the terminal.

Owner:CHINA CONSTRUCTION BANK

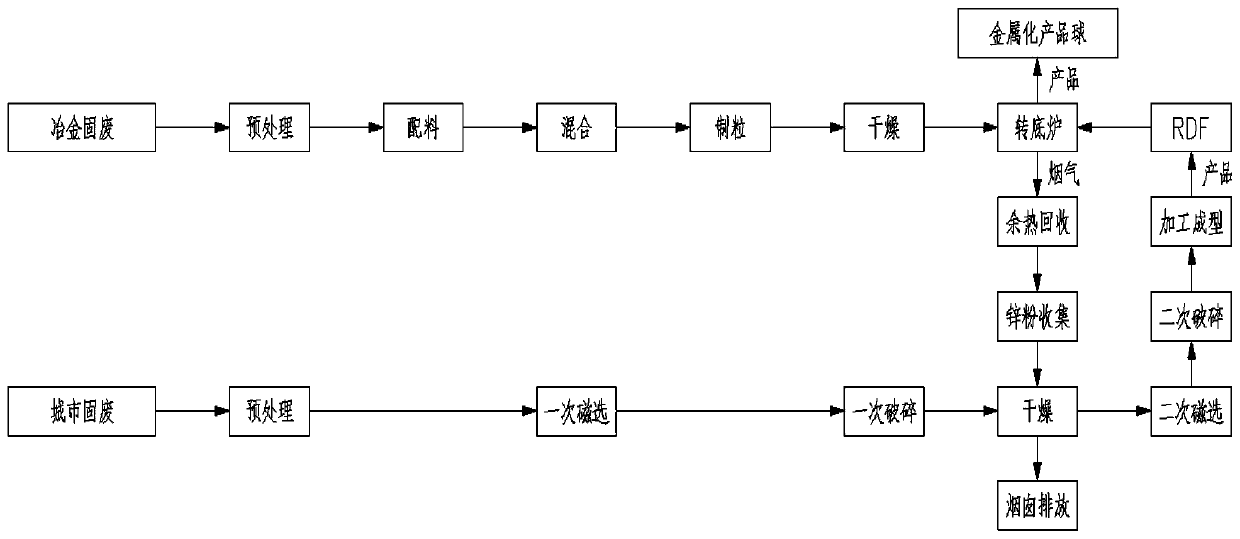

Urban solid waste and metallurgical solid waste combined treatment process

InactiveCN110157897ACentralized processingEfficient use ofBiofuelsSolid fuelsRefuse-derived fuelFlue gas

The invention belongs to the field of waste treatment, and relates to an urban solid waste and metallurgical solid waste combined treatment process. The urban solid waste treatment process comprises crushing, sorting, drying and processing and forming so as to form refuse derived fuel; the metallurgical solid waste treatment process comprises the steps of burdening, mixing, granulating, drying andhigh-temperature roasting in a rotary hearth furnace so as to form a metalized product ball; and the urban solid waste and metallurgical solid waste combined treatment process comprises the steps that the waste derived fuel which is finally formed in the urban solid waste treatment process is used for high-temperature heat supply of the rotary hearth furnace for treating metallurgical solid waste, and meanwhile, the flue gas which is roasted in the rotary hearth furnace in the metallurgical solid waste treatment process is treated, and after the flue gas is treated, the flue gas is used for drying the waste derived fuel in the preparation process of the urban solid waste process. According to the combined treatment process, energy is saved, centralized treatment of the solid waste can berealized, overall planning can be realized, the urban solid waste treatment process and the metallurgical solid waste treatment process are supplemented each other, resources are shared, and the construction cost and the operation cost are saved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

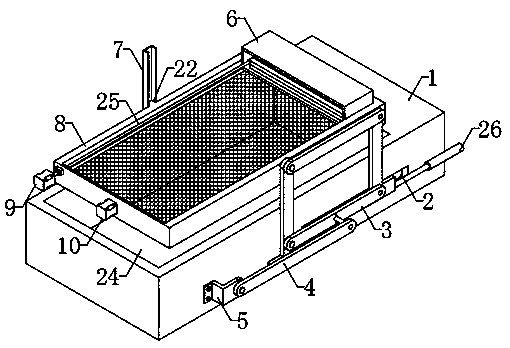

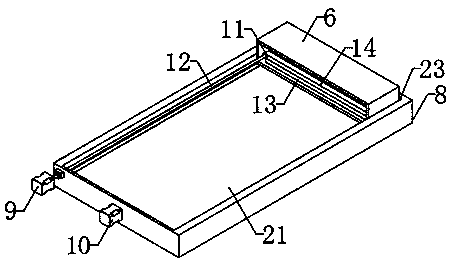

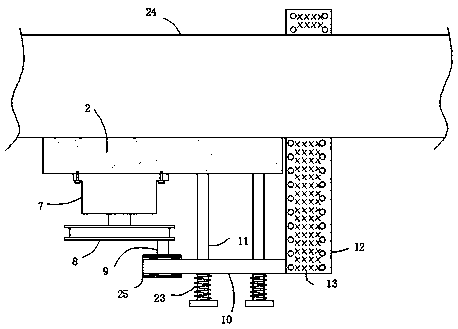

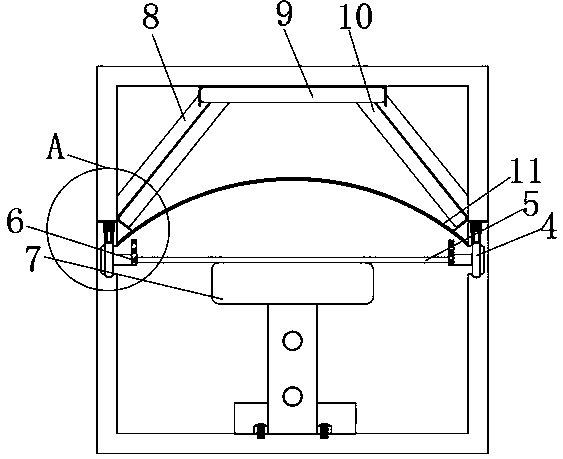

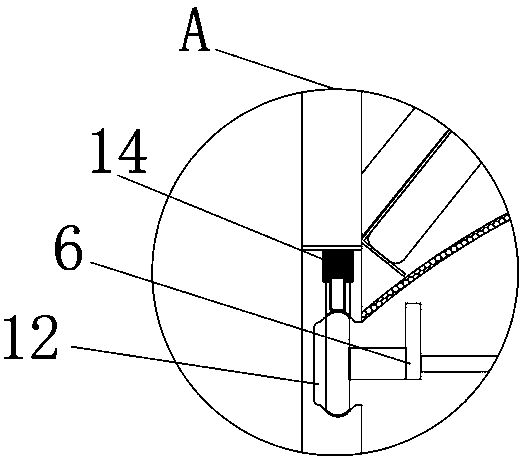

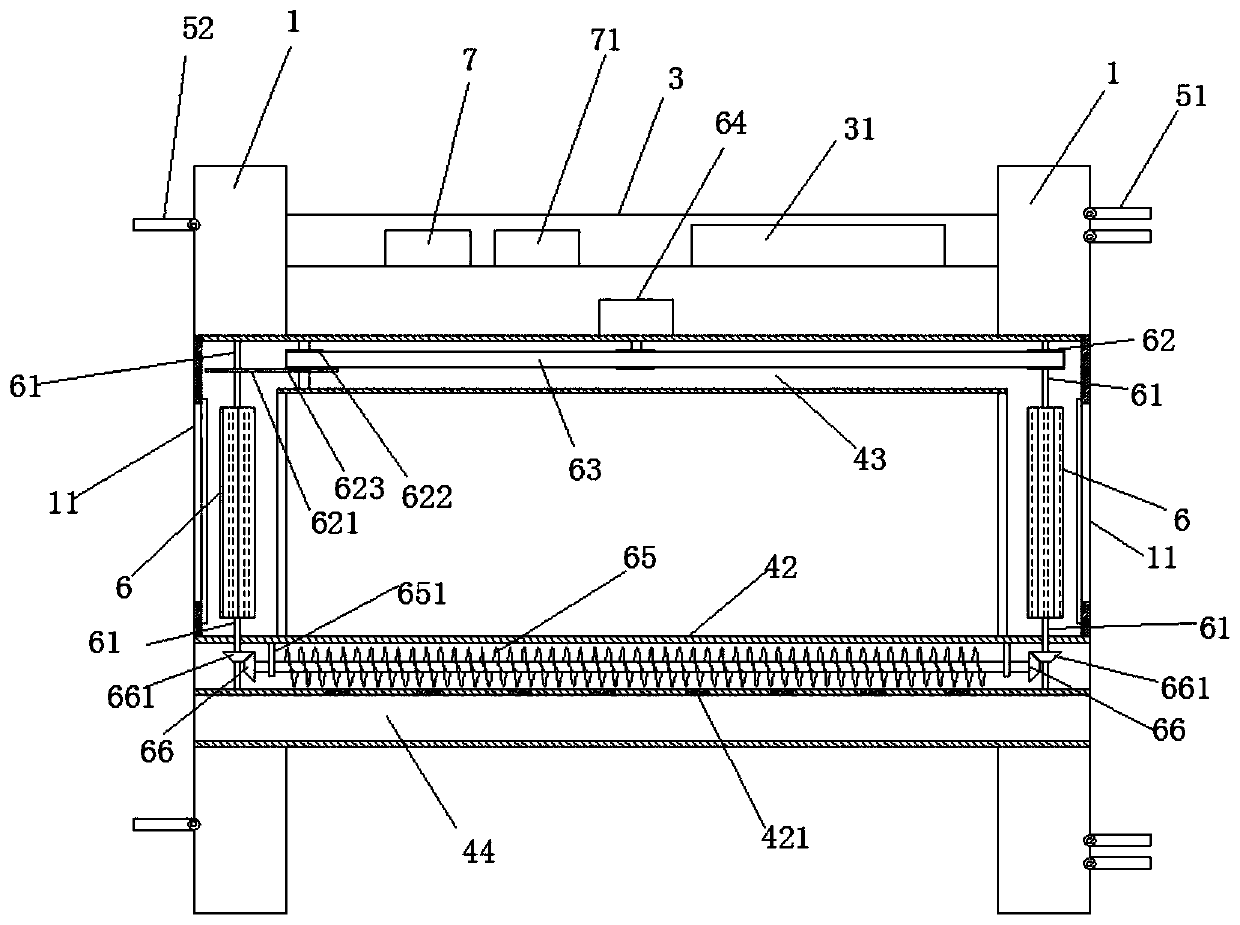

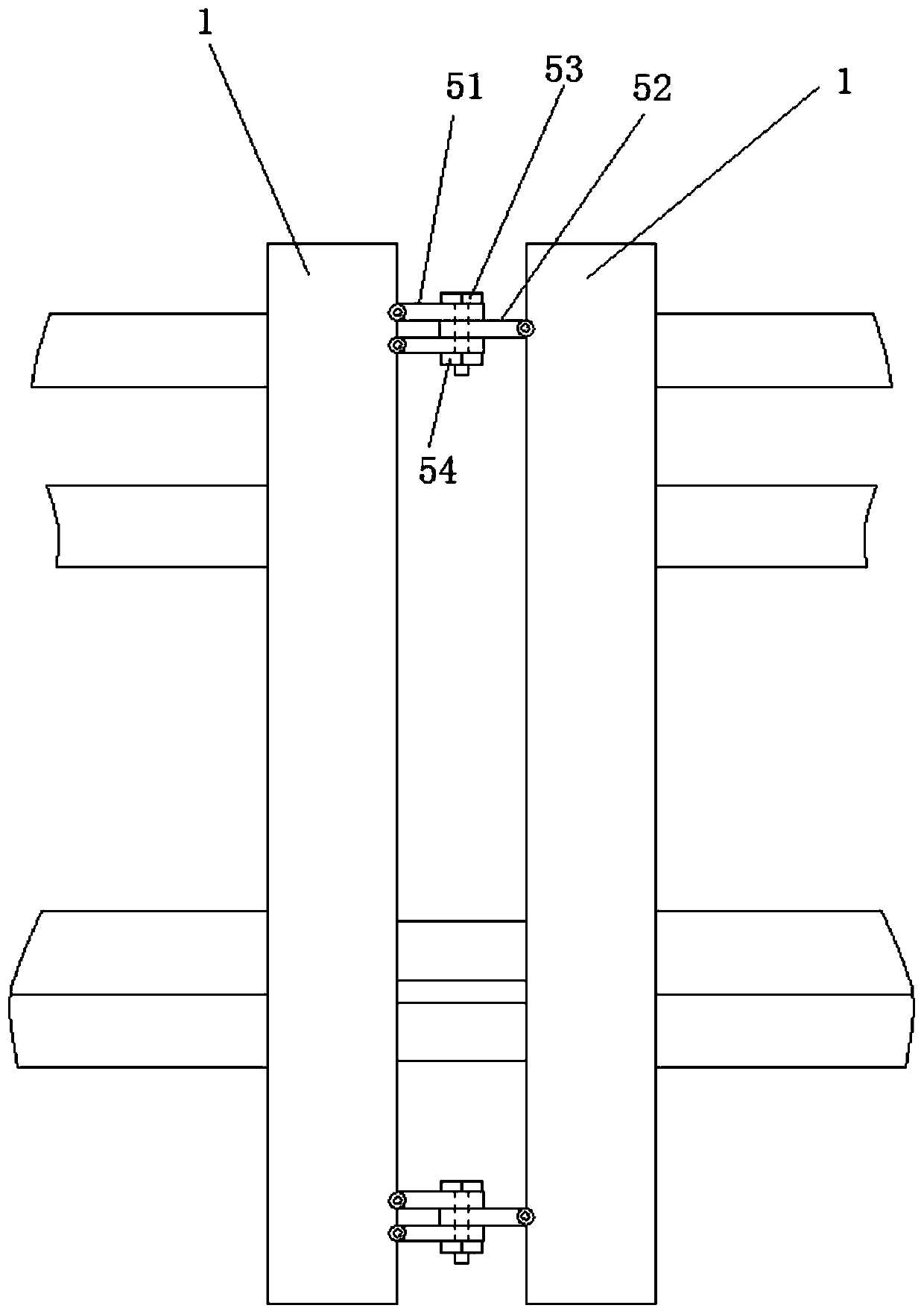

Tea dust separation device for tea production

ActiveCN110813516AReduce workloadImprove separation efficiencyWet separationProcess engineeringMechanical engineering

The invention discloses a tea dust separation device for tea production. The device comprises a worktable, wherein lifting mechanisms are arranged on two sides of the worktable; a production pool is arranged in the middle of the top end of the worktable; a chute is formed at one end of each of two sides of the worktable, and connecting seats are fixed at the other ends of two sides of the worktable. According to the tea dust separation device for tea production, the lifting mechanisms are arranged, a filter plate is sent into the production pool back and forth, and can separate tea dust on thesurface of the production pool continuously, so that the workload of workers can be reduced, the tea dust separation efficiency is improved, and working efficiency is increased; a driving scraper mechanism is arranged at the top of a frame plate, a scraper is driven to scrape the tea dust while a screw rotates, the scraped tea dust is sent into a collecting box, and centralized treatment is achieved.

Owner:HUNAN GUDONGCHUN TEA IND

Device for rapidly measuring hydrogen at plurality of points after containment accident of nuclear power plant and realization method of device

ActiveCN105513654AAvoid poisoningAvoid humidityNuclear energy generationNuclear monitoringHydrogen concentrationFast measurement

The invention discloses a device for rapidly measuring hydrogen at a plurality of points after a containment accident of a nuclear power plant. The device comprises a sample gas sampling probe, a water vapor and hydrogen concentration measuring device, a first buffering gas tank and a sample gas pressurizing and recycling device, wherein the sample gas sampling probe is used for sampling sample gas in a containment of the nuclear power plant and removing gas sol and liquid-state water in the sample gas; the water vapor and hydrogen concentration measuring device is used for measuring concentrations of water vapor and hydrogen in the sample gas respectively and removing the water vapor; the first buffering gas tank is used for temporarily storing the sample gas without the water vapor and stabilizing a gas flow; and the sample gas pressurizing and recycling device is used for pressurizing the sample gas in the first buffering gas tank and then conveying the sample gas back into the containment of the nuclear power plant. The device can be used for accurately and rapidly measuring the concentrations of the water vapor and the hydrogen in the containment of the nuclear power plant, and provides reliable guarantees for real-time monitoring of the hydrogen concentration in a severe environment under an emergency condition.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +2

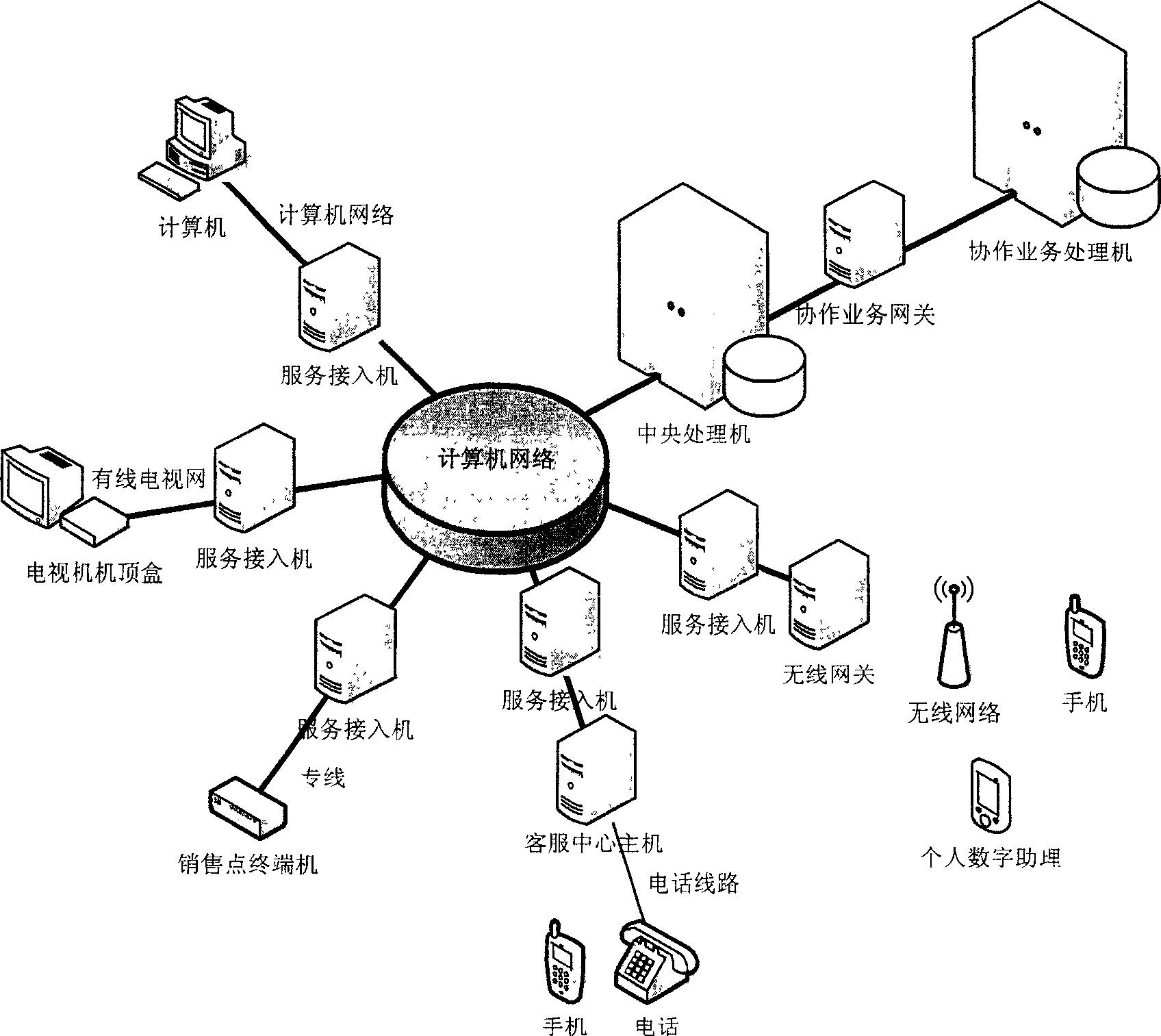

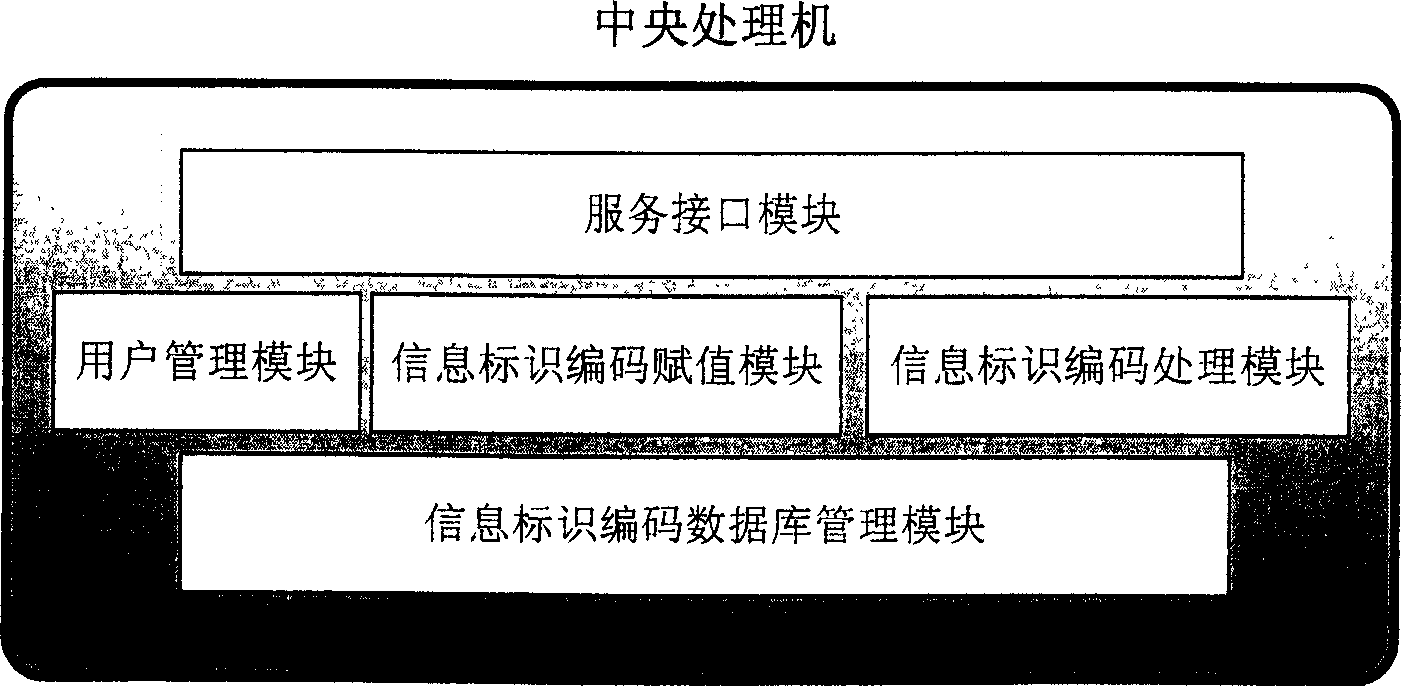

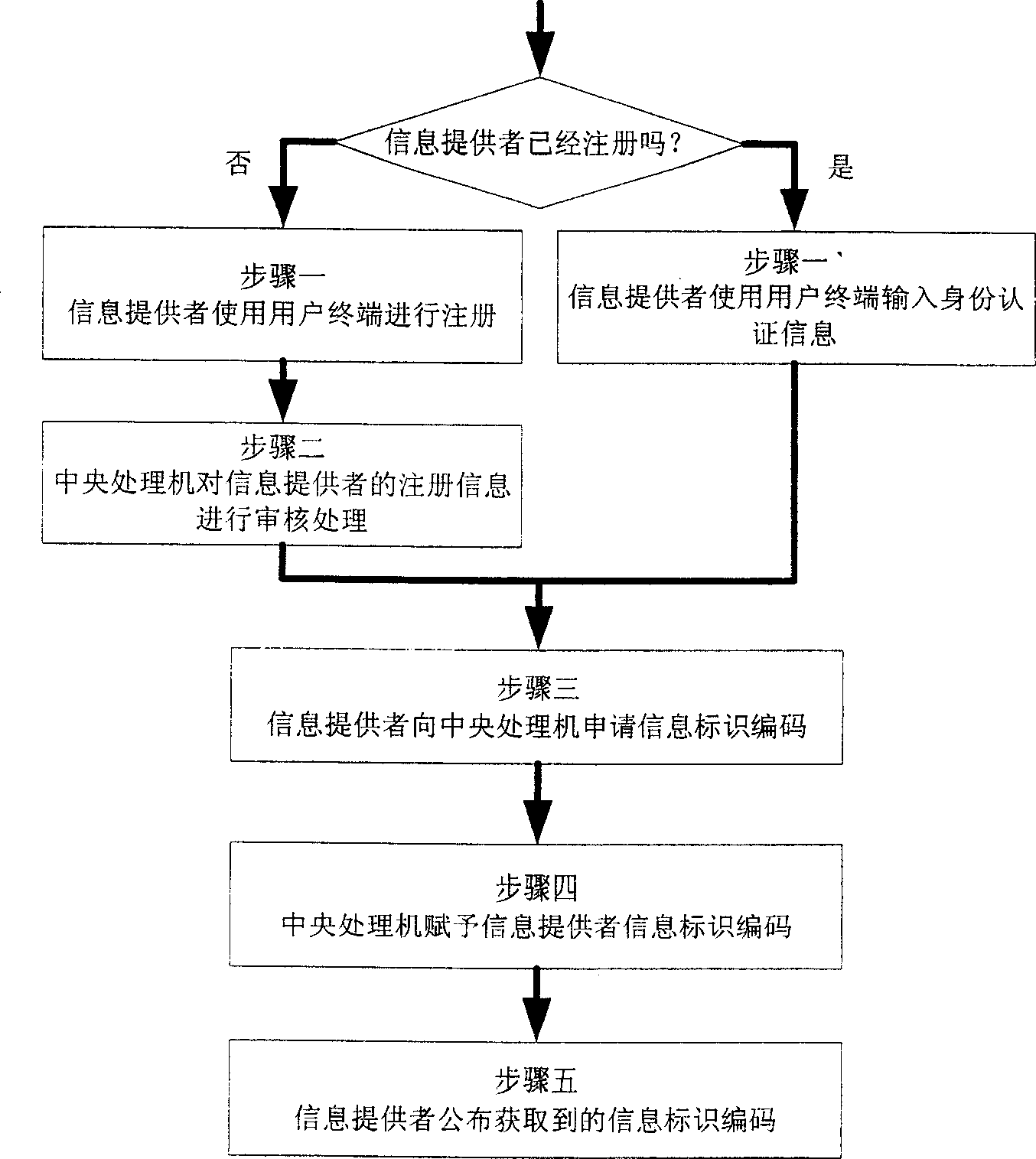

Information collection, transmission, process system and method based on uniform information identification codes

InactiveCN1760910AReduce complexityCentralized processingTransmissionCommerceProcess systemsSystem capacity

The system and method is applicable between commodities or service providers and users. Using uniform information identification codes, the invention unifies technical specification, data transmission format and data processing technique highly. Based on the unified base, electronic business system of containing commodities or services with unified technical standard can be built up so as to realize each business terminals possible to be connected to network. The uniform information identification codes can compress data quanitity needed to transmit in electronic business. Advantages are: reducing complexity of operation for users, reducing memory capacity and data quanitity to be processed by system host, extending system capacity and quanitity of usersí» terminals, and lowering cost for operating the system.

Owner:BEIJING YIFUJINCHUAN TECH

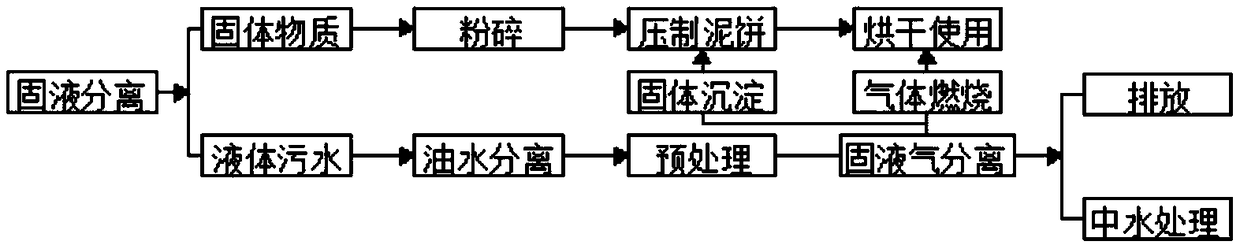

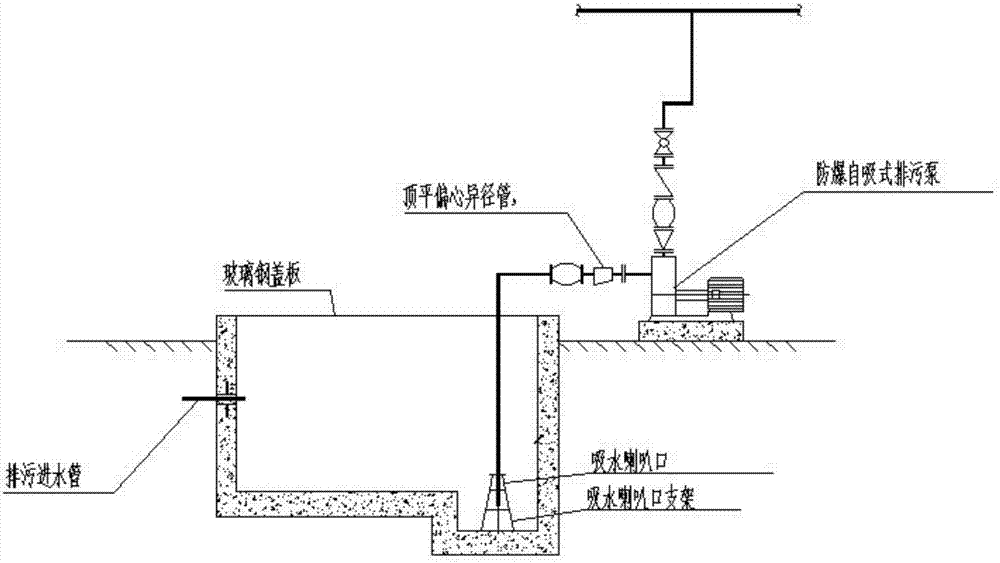

Tall building kitchen sewage treatment method and integrated treatment device

InactiveCN109502839ASolve split processingEfficient handling of processing requirementsFatty/oily/floating substances removal devicesTransportation and packagingWater dischargeSludge

The invention discloses a tall building kitchen sewage treatment method and an integrated treatment device, wherein the tall building kitchen sewage treatment method comprises the following steps of (1) respectively conveying high floor kitchen sewage and low floor kitchen sewage into a water discharge chamber of a sewage discharge system through pipelines; (2) separating liquid and solid througha solid-liquid separation device; conveying the separated sewage liquid into an oil-water separation pool for oil-water separation; (3) conveying liquid after the oil-water separation into a pretreatment pool; respectively collecting the sludge and composite gas in the pretreatment mechanism; performing standard reaching discharge or repeated utilization on the treated sewage; (4) crushing the solid after the separation by the solid-liquid separation device through a crushing device; compressing the crushed solid and the sludge in the pretreated pool through a press filtering device ; (5) drying the compressed solid in a drying box to be used or buried. The method provided by the invention solves the problem to achieve the effects that the existing tall building kitchen sewage is integrally treated, so that solid-liquid separation and respective treatment are convenient.

Owner:金煊策

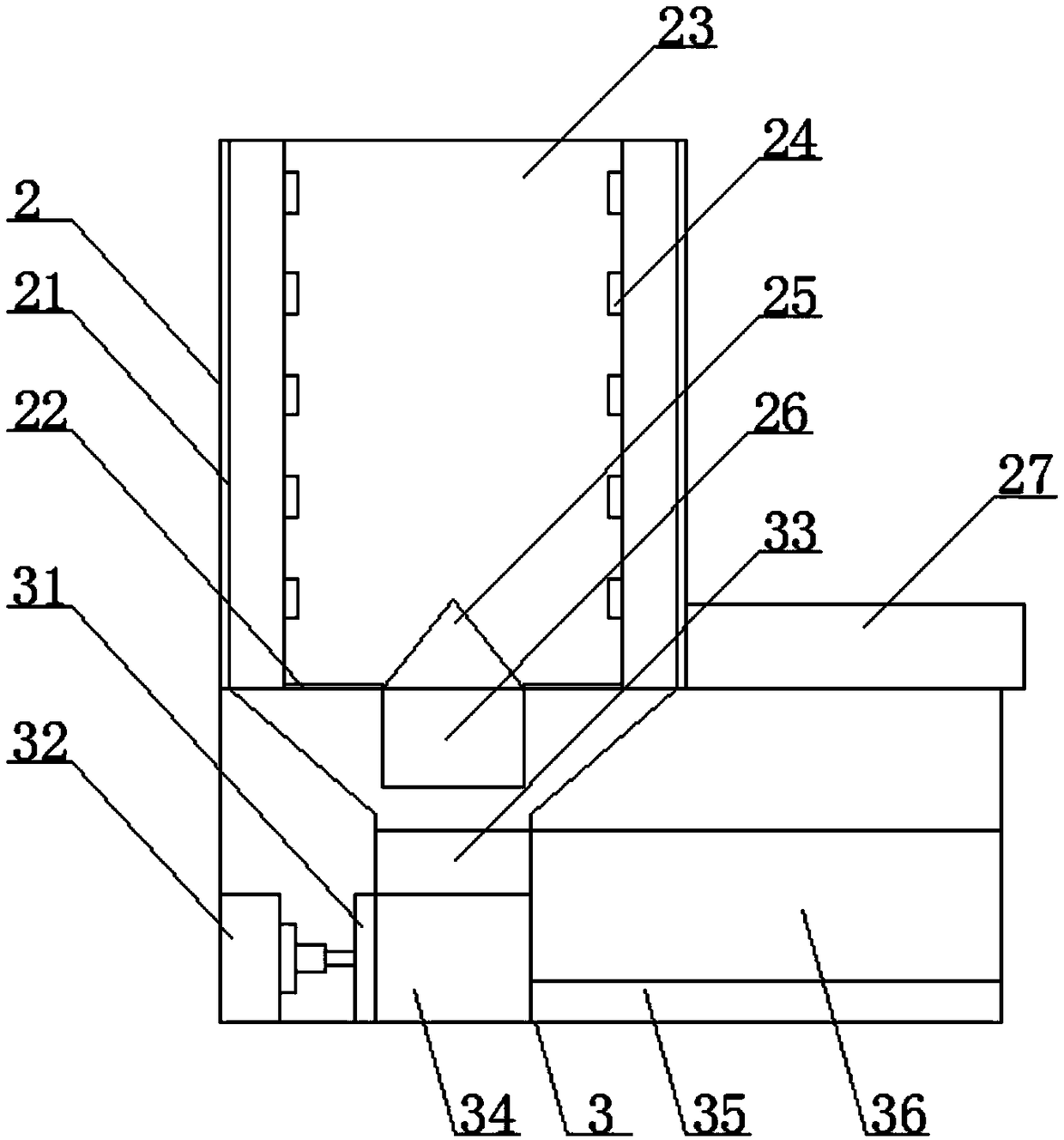

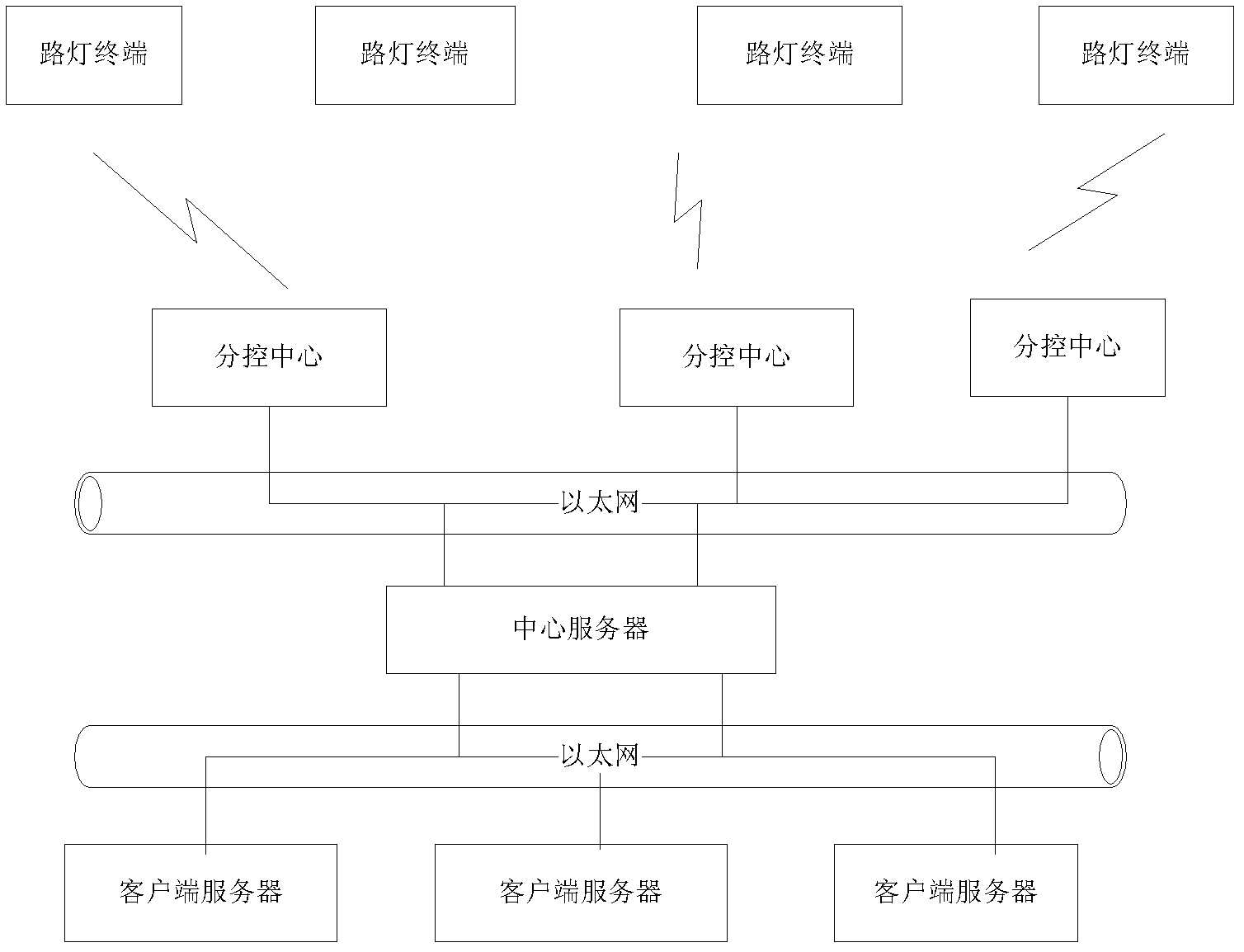

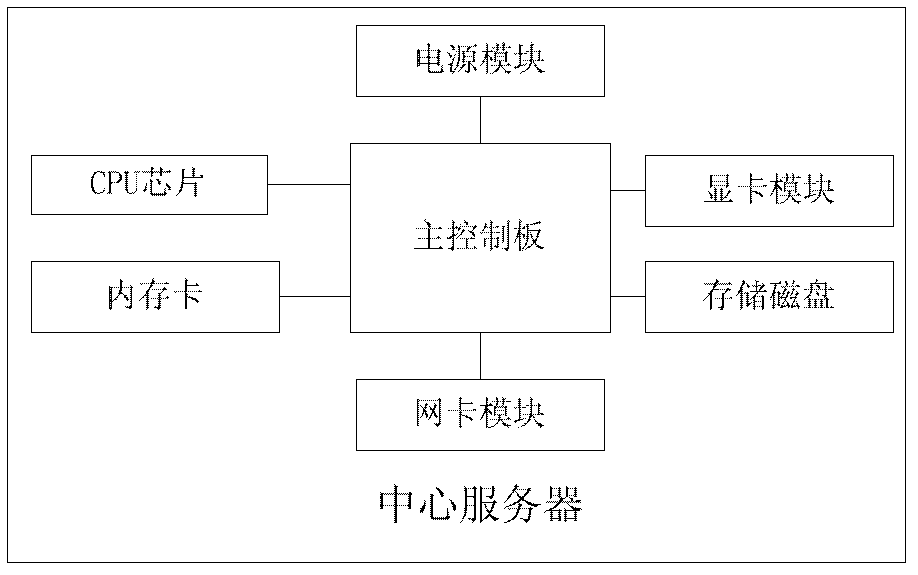

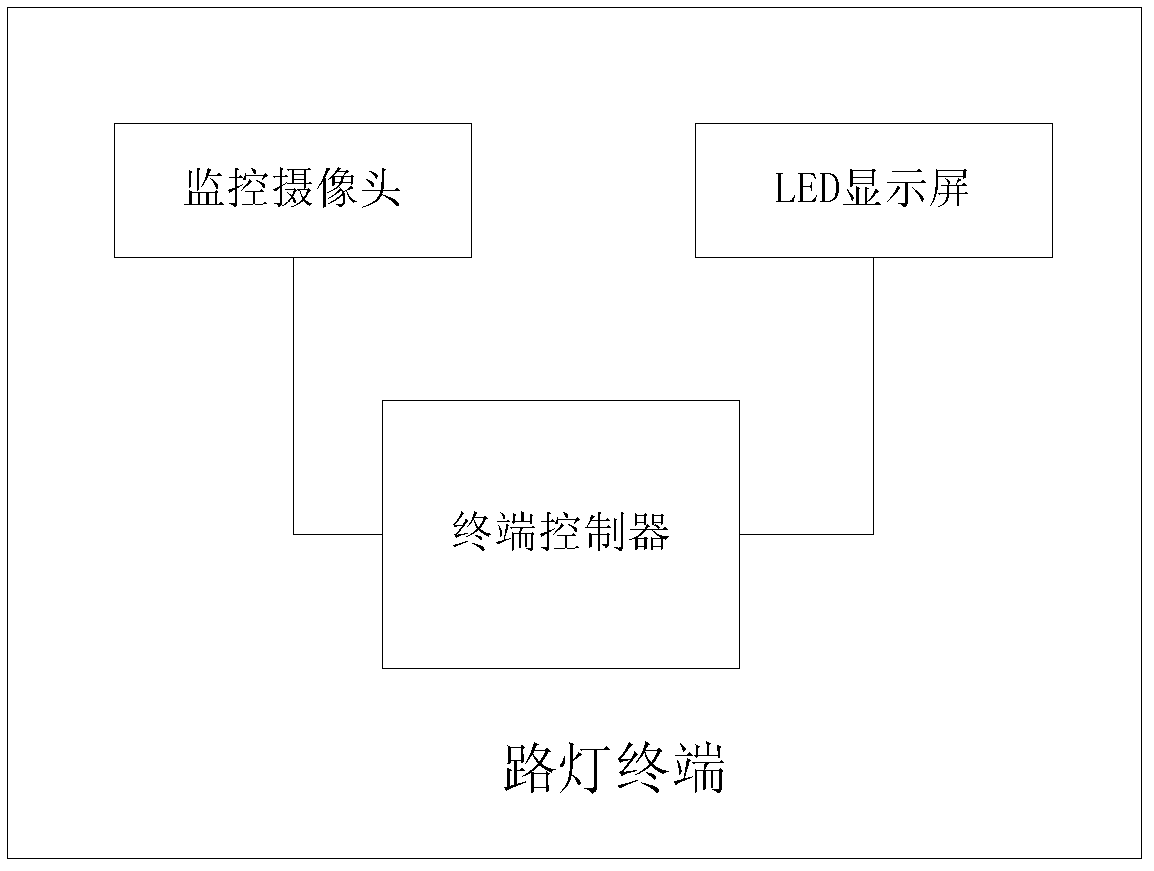

Street lamp multimedia directing and monitoring system

ActiveCN102385827ARealize remote synchronous processingCentralized processingAdvertisingClosed circuit television systemsReal-time computingLED display

The invention discloses a street lamp multimedia directing and monitoring system which comprises a client server, a central server, a distributed control center and a street lamp terminal. For the street lamp multimedia directing and monitoring system in the embodiment of the invention, the central server is used as the core to establish the Ethernet connection relation between a client and the distributed control center, so that the monitoring range is enlarged, the stable transmission and safety of data are ensured and all departments are more convenient to cooperatively operate. Moreover, a microprocessor is adopted at the street lamp terminal to manage and control contents played by an LED (light-emitting diode) display screen, and the remote connection between the distributed controlcenter and the street lamp terminal is established, so that a video, an advertising or notification information of a user is displayed on the LED display screen of the street lamp terminal at the first time, and thus, the advertising, alarm and broadcasting integrated function of the street lamp terminal is realized and a great amount of human resources for replacing the contents on the information display screen are saved.

Owner:肇庆全商联盟信息科技有限公司

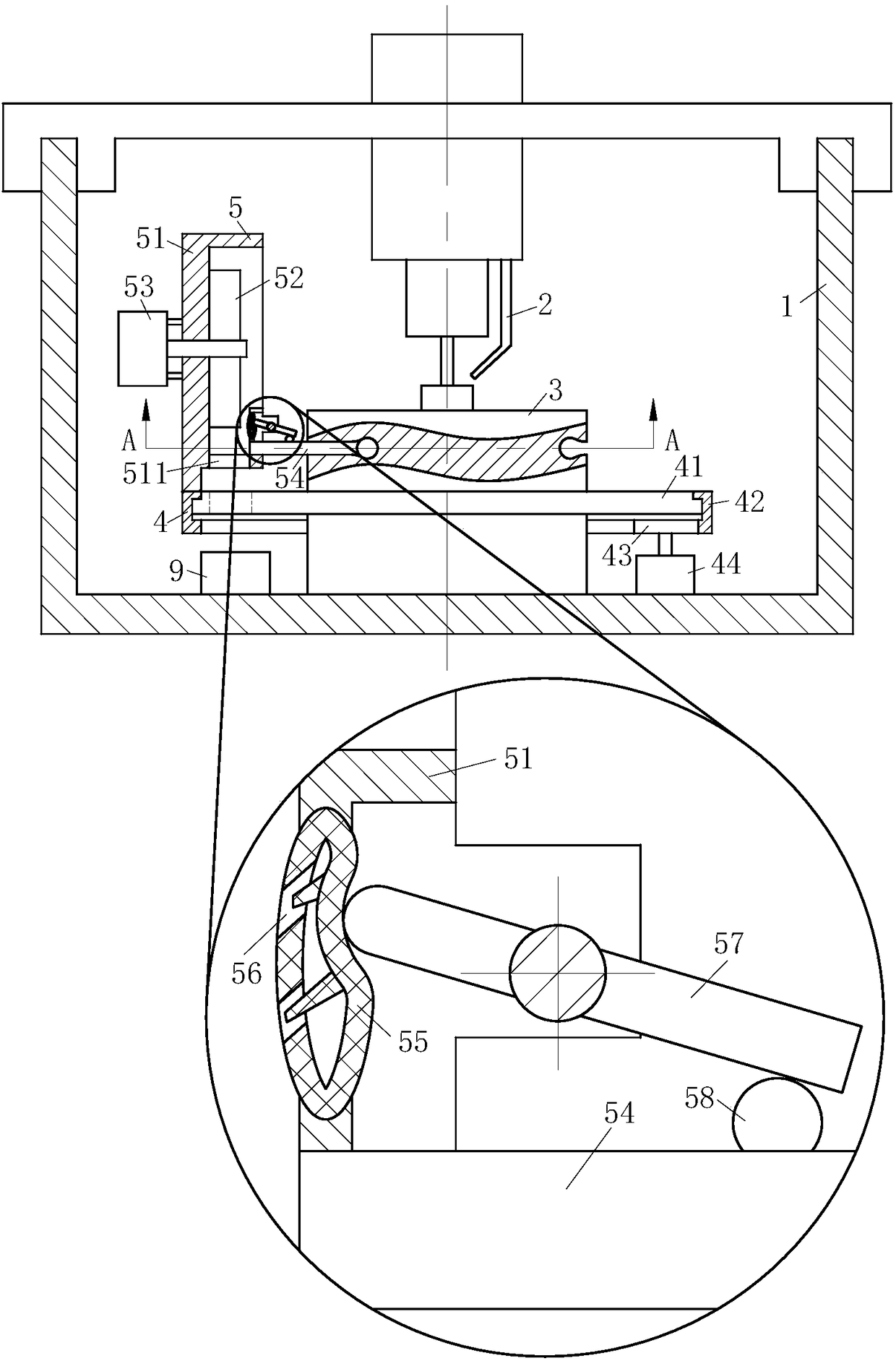

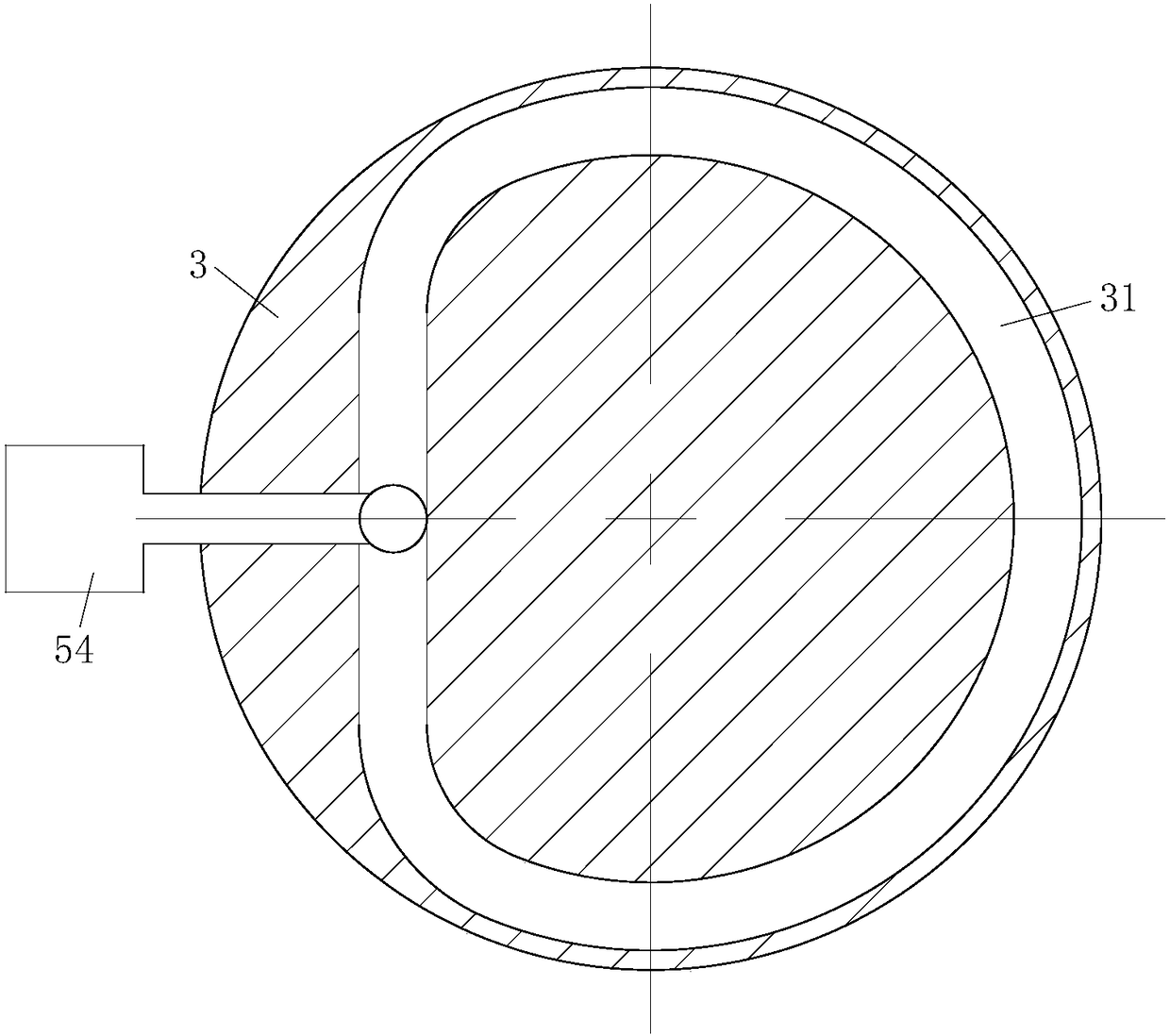

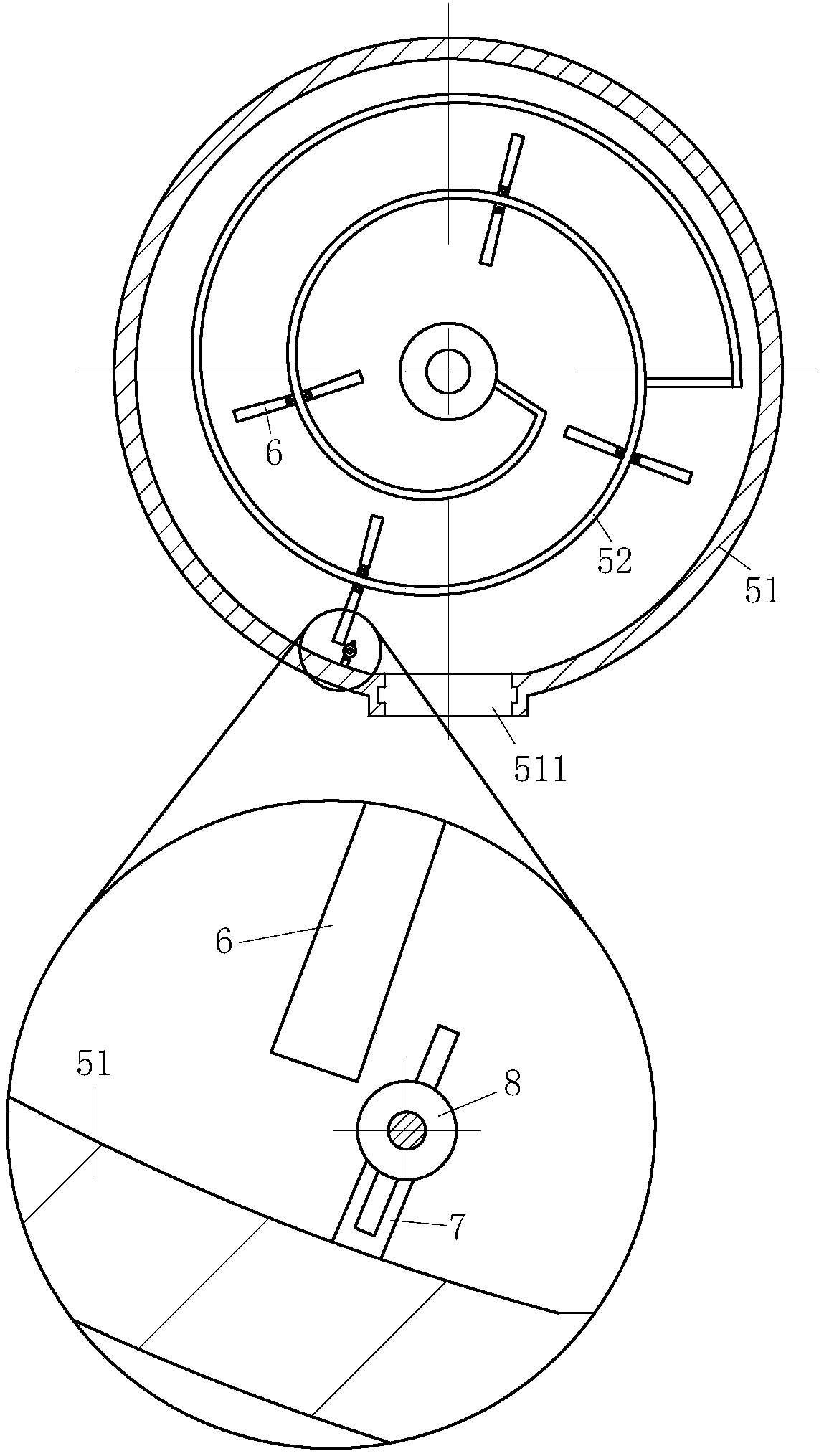

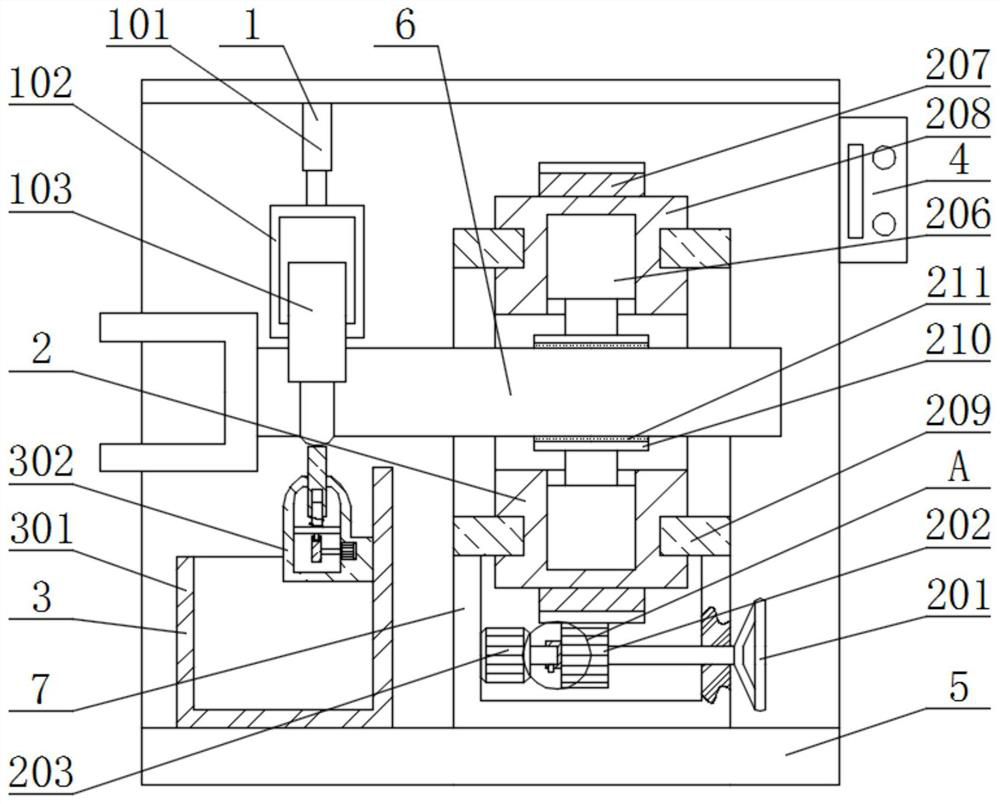

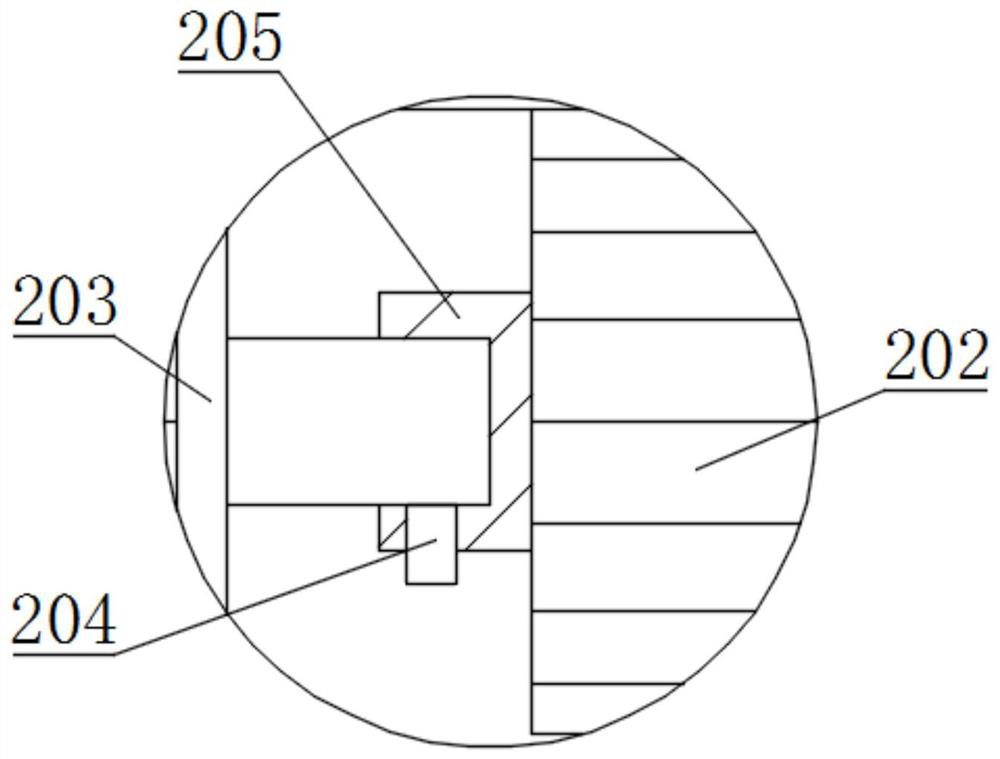

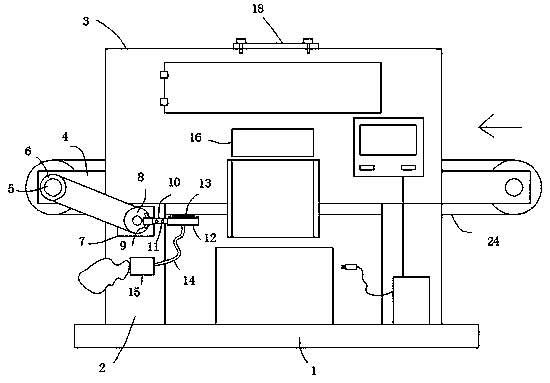

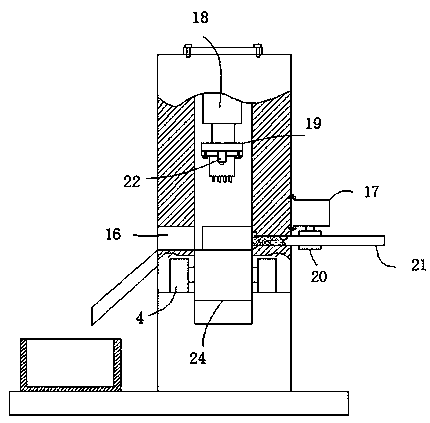

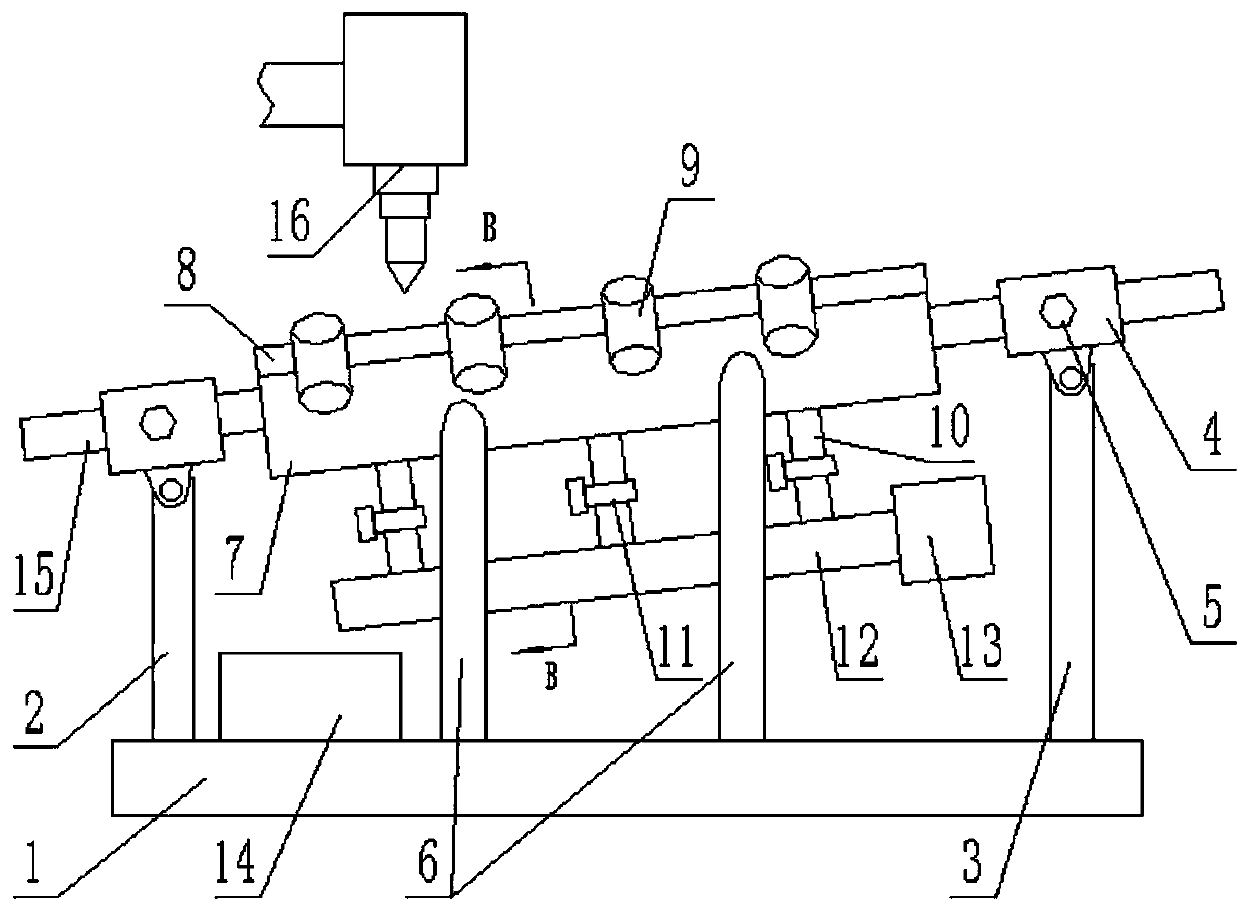

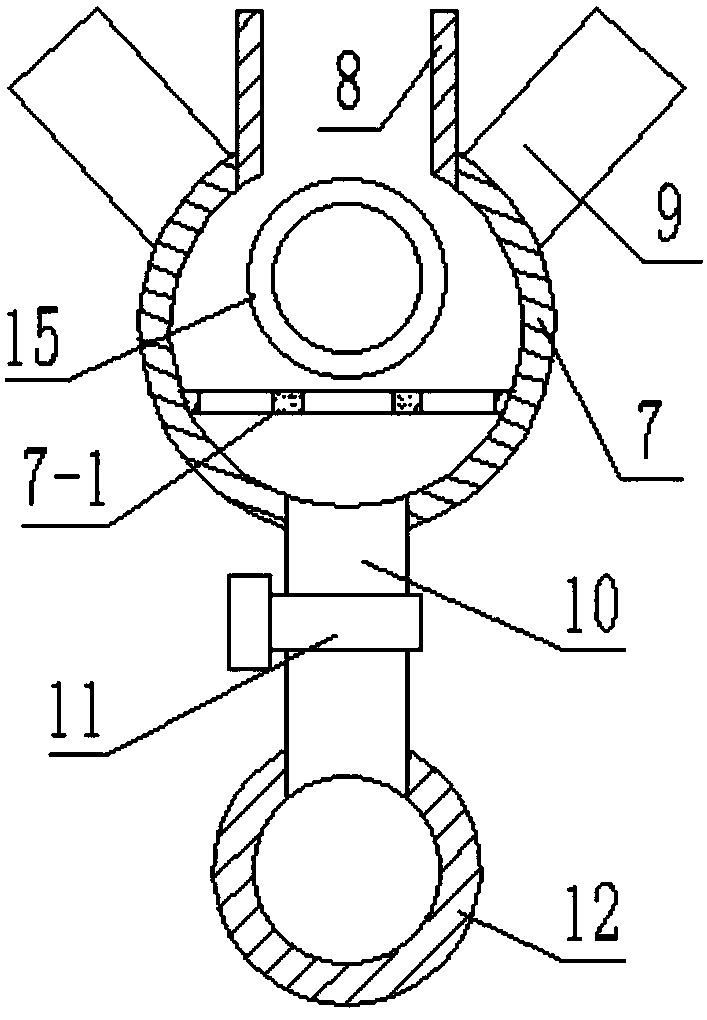

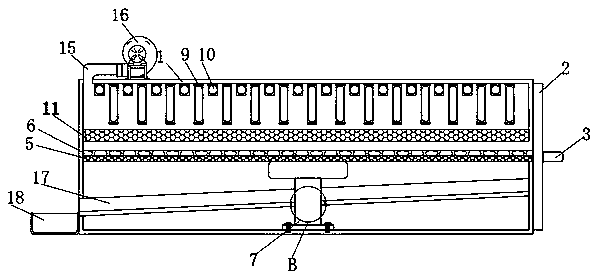

Numerical control milling machine

InactiveCN108544291AImprove processing efficiencyCentralized processingMaintainance and safety accessoriesNumerical controlSlag

The invention belongs to the technical field of milling machine equipment, and particularly relates to a numerical control milling machine. The numerical control milling machine comprises a machine tool, a gas pipe, a worktable, a driving module and a slag discharging module, wherein the worktable is cylindrical; the driving module is arranged on the outer circle of the worktable; the slag discharging module is slidably arranged on the outer circle of the worktable and is fixedly connected to one side of the driving module; the slag discharging module comprises a collection box, a spiral plate, a rotation motor, a closing plate and a slag collection box; the driving module is used for driving the slag discharging module to rotate around the worktable; and during machining, for different working conditions where directions of cutting slags blown out by the air pipe are different, the collection box rotate around the worktable through the driving module, so that the milling machine is applicable to reception and processing work of cutting slags in different directions. According to the numerical control milling machine, the slag discharging module is arranged, so that the cutting slags of the machine tool is collectively treated; the driving module is matched with the slag discharging module, so that the cutting slags in different directions are cleaned according to different working conditions; and treating efficiency of the cutting slags is improved.

Owner:陈壮壮

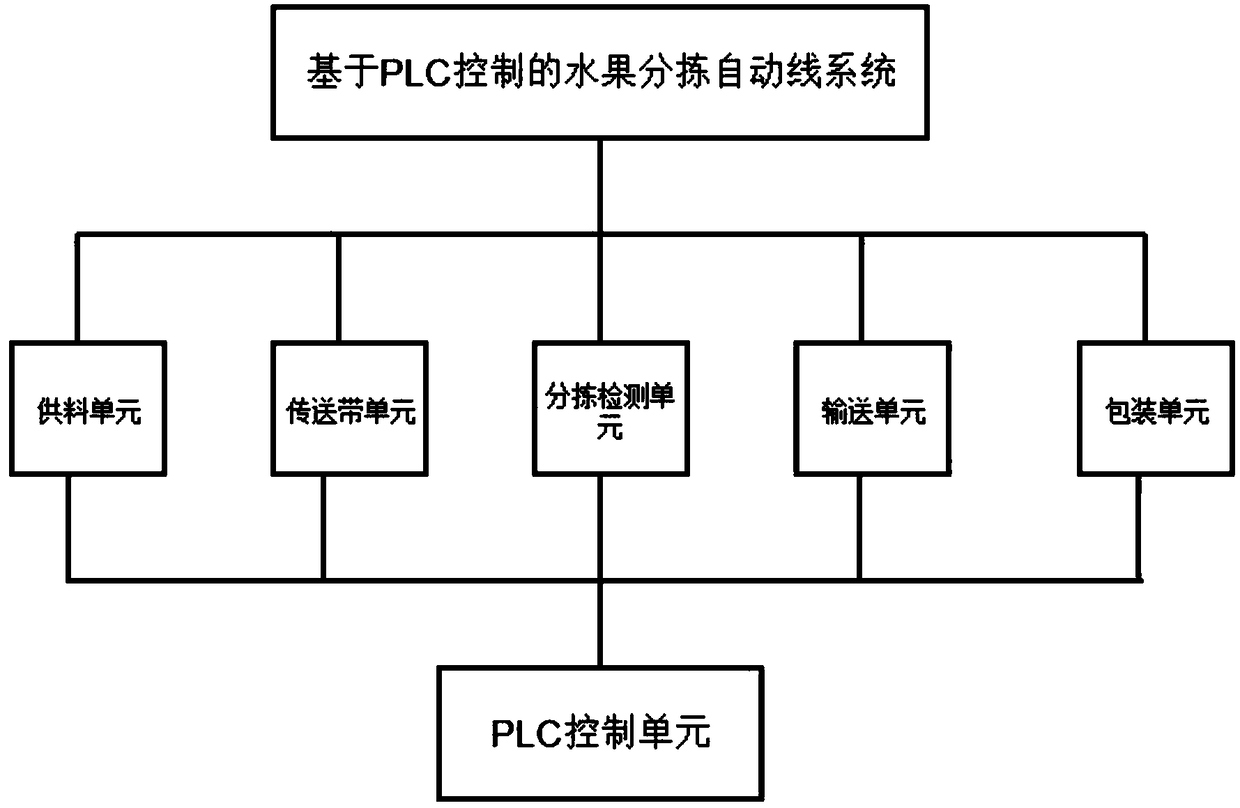

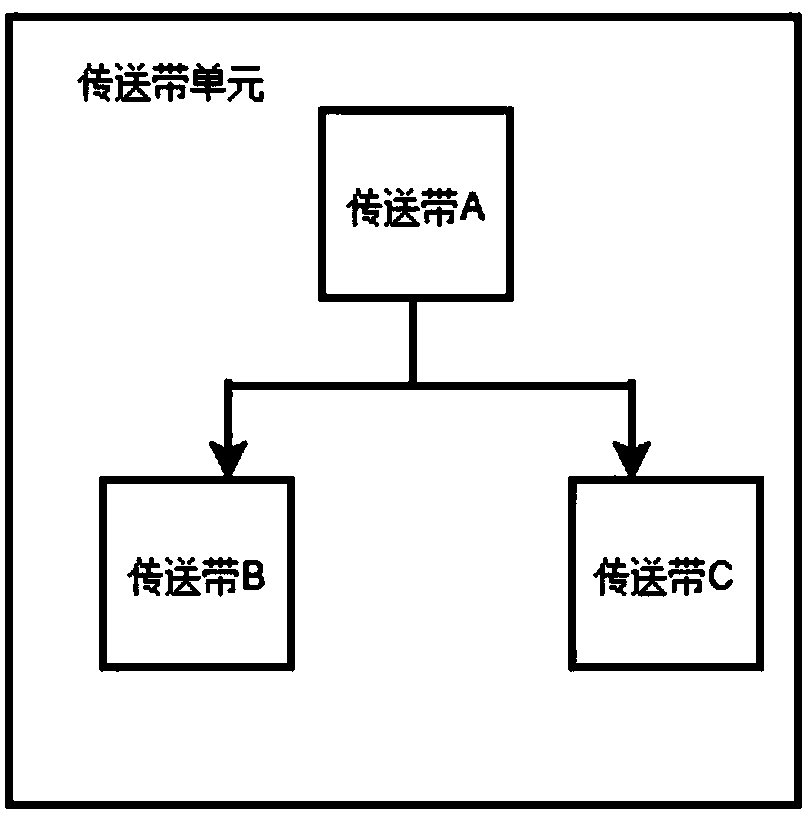

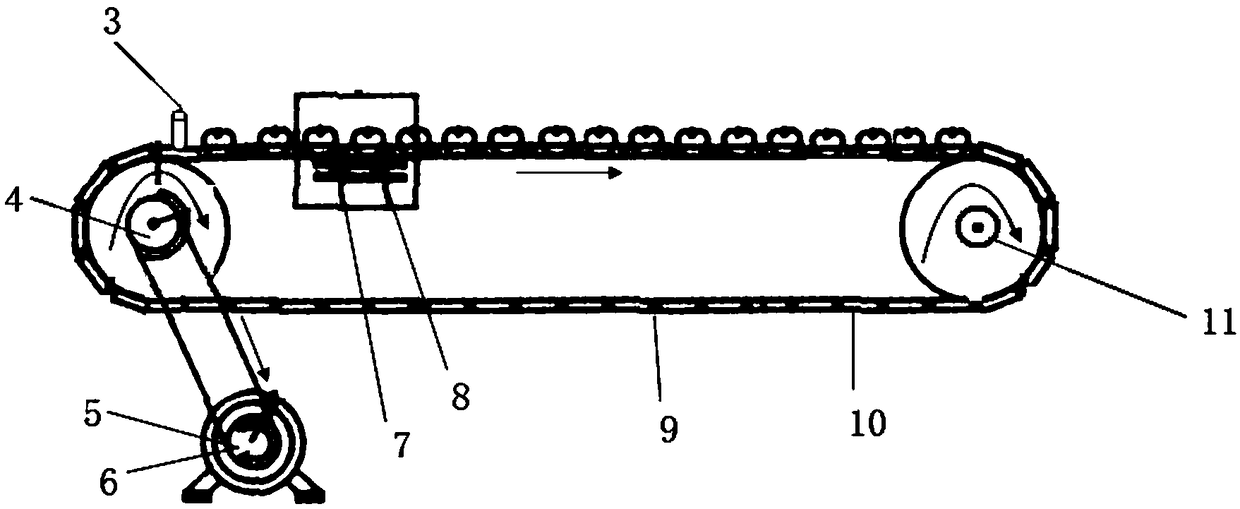

Fruit sorting automatic line system based on PLC control

PendingCN108855974AImprove fine sortingMeet different sorting requirementsSortingComputer moduleConveyor belt

The invention relates to the technical field of fruit and vegetable sorting, in particular to a fruit sorting automatic line system based on PLC control. The fruit sorting automatic line system comprises a conveyor belt unit, a sorting detection unit, a conveying unit and a PLC control unit, wherein the conveyor belt unit comprises multiple groups of conveying belts and is used for transporting fruits; the sorting detection unit comprises various types of detection modules; each group of conveyor belt is at least provided with one detection module according to the types of fruits needed to besorted; each detection module is used for detecting sorting level of the fruits on the conveyor belts; the conveying unit comprises a plurality of manipulators; each group of conveyor belt is at leastprovided with one manipulator; the conveying unit is used for grabbing and conveying the fruits on the conveyor belts under the control of the PLC control unit. According to the scheme, by automatically sorting and detecting multiple qualities and types of the fruits, fine sorting and sorting quality of the fruits are improved.

Owner:阜阳职业技术学院

Weld joint grinding device for automobile welding part production and using method thereof

InactiveCN112139928AAchieve tensionStable jobGrinding carriagesGrinding drivesDrive shaftElectric machinery

Owner:HEFEI CHANGQING MACHINERY

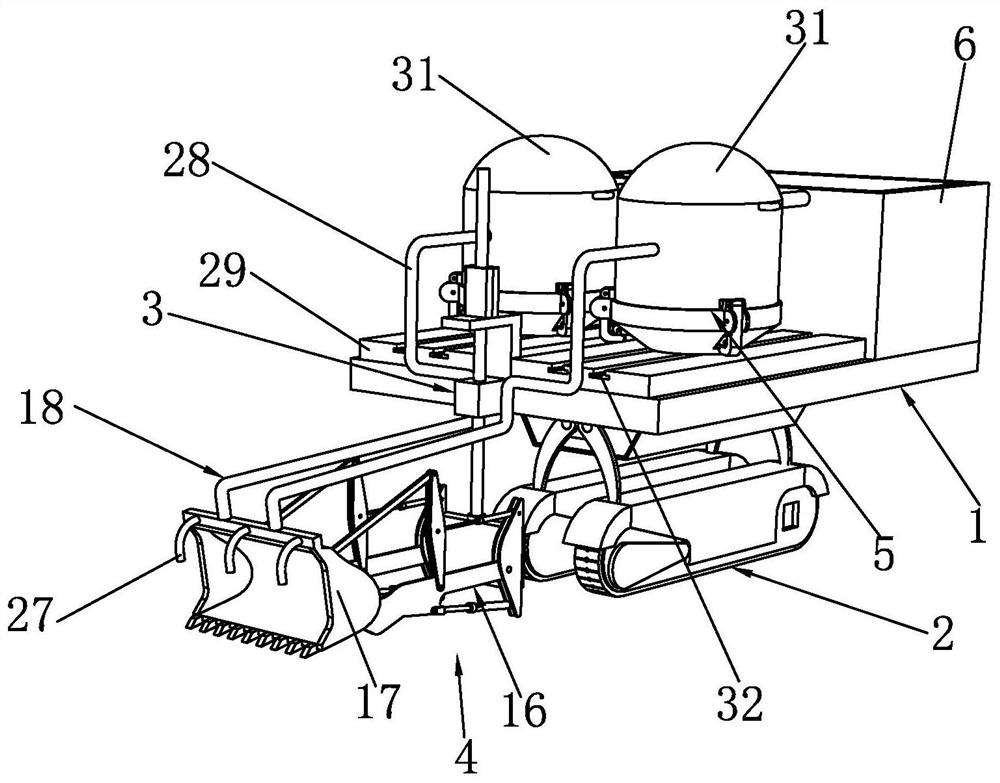

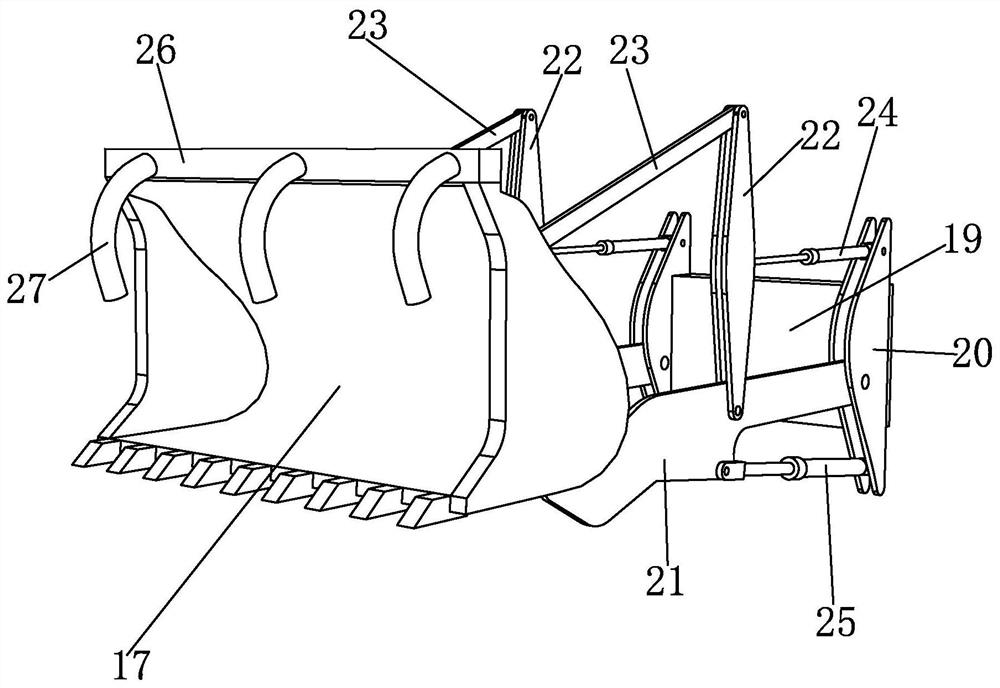

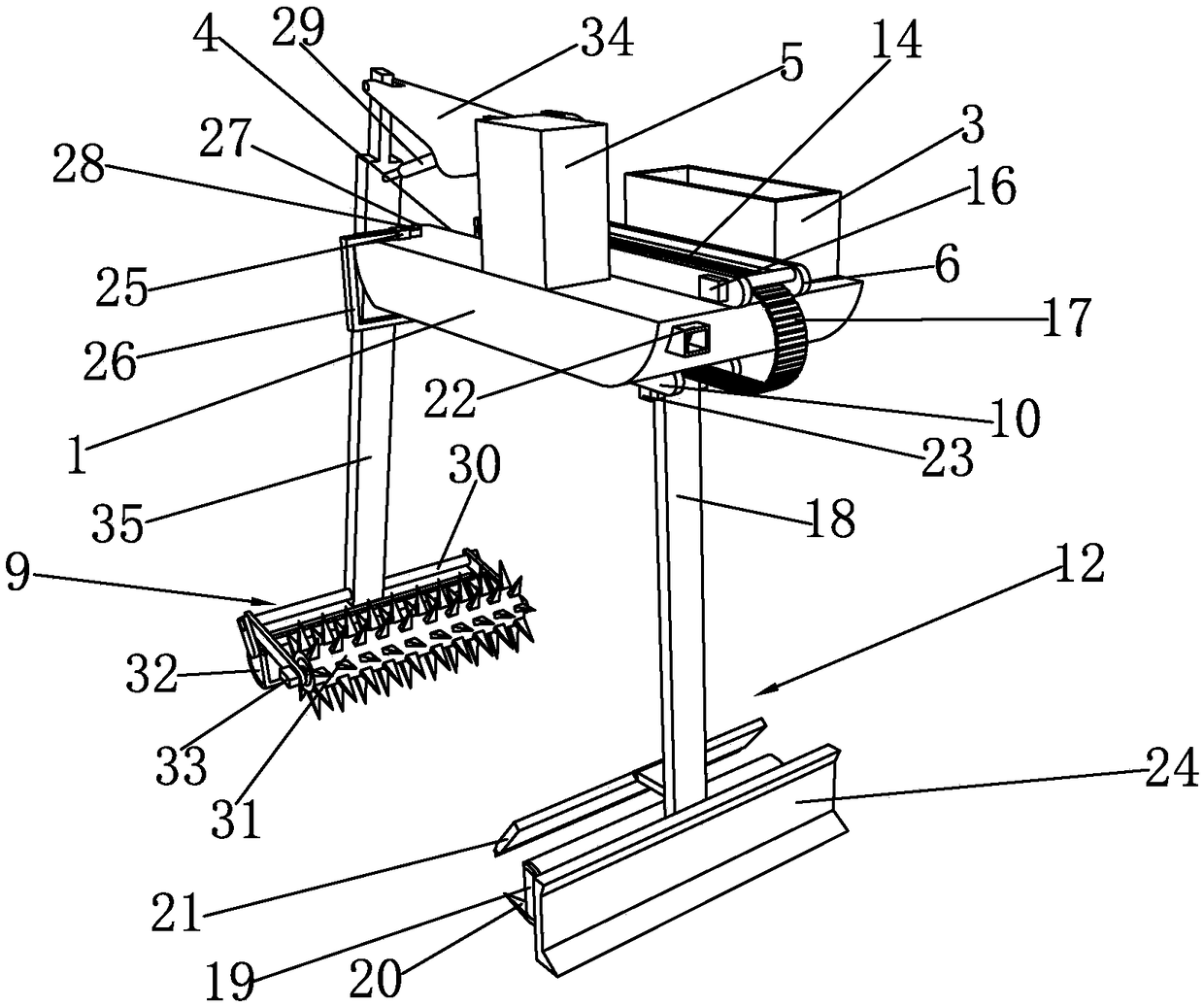

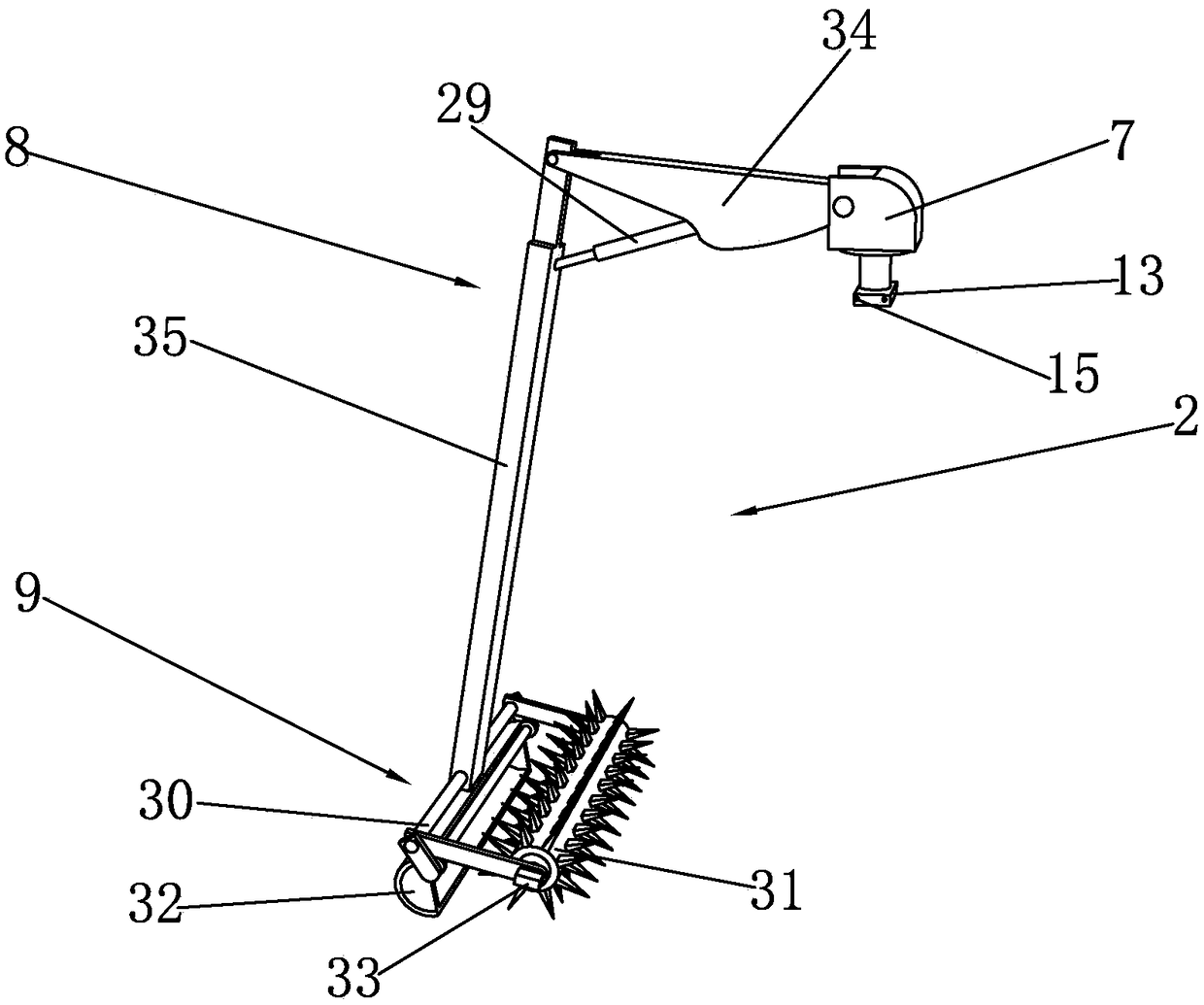

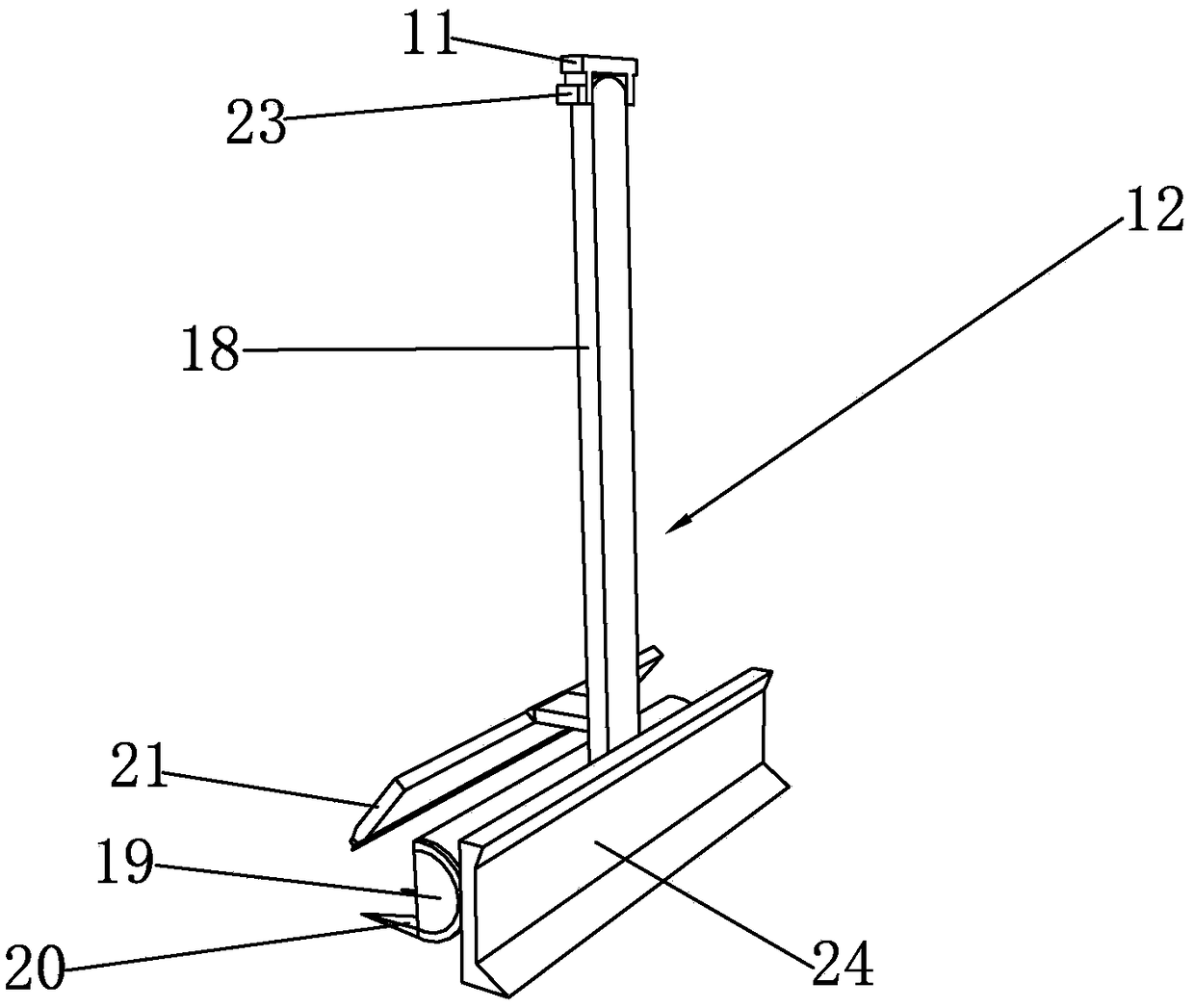

Plain river bottom silt clearing device and clearing method thereof

PendingCN112726716AEnsure balanceEasy to dredgeMechanical machines/dredgersRiver routingEnvironmental engineering

The invention discloses a plain river bottom silt clearing device and a clearing method thereof. The plain river bottom silt clearing device comprises a boat, wherein a driving device is arranged at the bottom of the boat, a lifting assembly is arranged at the front side of the boat, a clearing assembly is slidingly connected with the side, away from the boat, of the lifting assembly, a storage device is arranged at the front side of the top surface of the boat, a balance weight water tank is arranged at the rear side of the top surface of the boat, the storage device communicates with the balance weight water tank, and the clearing assembly communicates with the storage device. The method comprises the following steps: (1) conducting preparation before desilting; (2) stacking silt centralizedly; (3) conducting desilting; (4) storing the silt; and (5) conducting desilting on residual desilting points. According to the plain river bottom silt clearing device and the clearing method thereof, through the clearing assembly, river bottom silt at different depths can be cleared, the clearing assembly is used for clearing the silt at the river bottoms, meanwhile, the silt at the river bottoms is transported into the storage device, the silt placed in the storage device naturally sinks, and river water located above the storage device is transported into the balance weight water tank at the rear end of the boat, so that balance of the boat is guaranteed.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

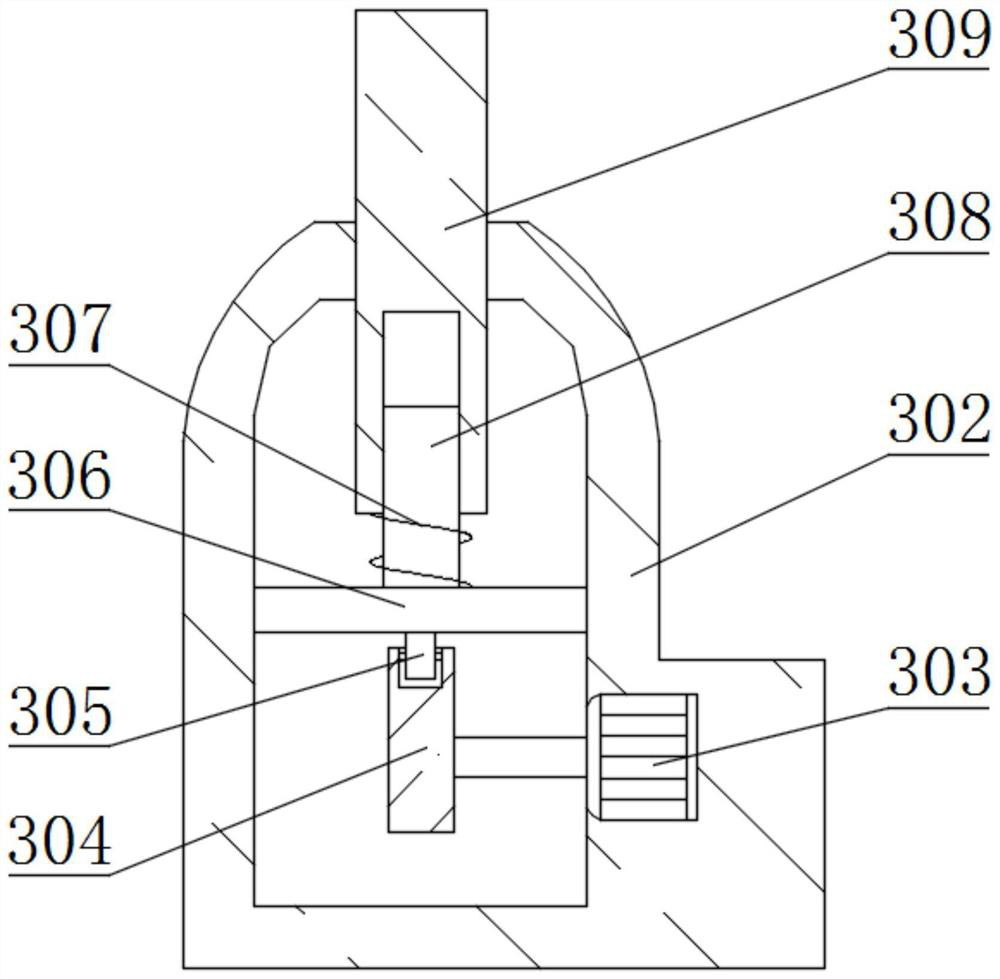

Desilting device for reservoir and desilting method thereof

The invention discloses a desilting device for a reservoir and a desilting method of the desilting device. The desilting device for the reservoir comprises a boat body, an operating device and a siltbox, wherein the silt box is arranged on the boat surface of the boat body, the operating device is arranged at the end of the boat body, an opening is formed in the end of the boat body, an operatingroom is arranged on the boat body, the boat surface of the boat body is provided with a first slide rail, and the operating device is in sliding connection with the first slide rail; and the operating device comprises a rotary platform, a connecting piece and a desilting structure, wherein the rotary platform is rotationally connected with the connecting piece, the desilting structure is arrangedat the bottom of the connecting piece, a second slide rail is arranged on the bottom surface of the boat body, a base is slidably connected in the second slide rail, and a pushing structure is arranged on the base. The desilting method of the desilting device for the reservoir comprises the following steps of (a) preparing before desilting; (b) desilting at a first desilting position; (c) desilting at the rest desilting positions; and (d) recovering the tools. According to the desilting device for the reservoir and the desilting method of the desilting device for the reservoir, the silt at the bottom of the water is concentrated in one area for centralized desilting, so that the operation is simple and fast, the desilting time and the resources are saved, and the desilting efficiency is high.

Owner:浙江景昌建设有限公司

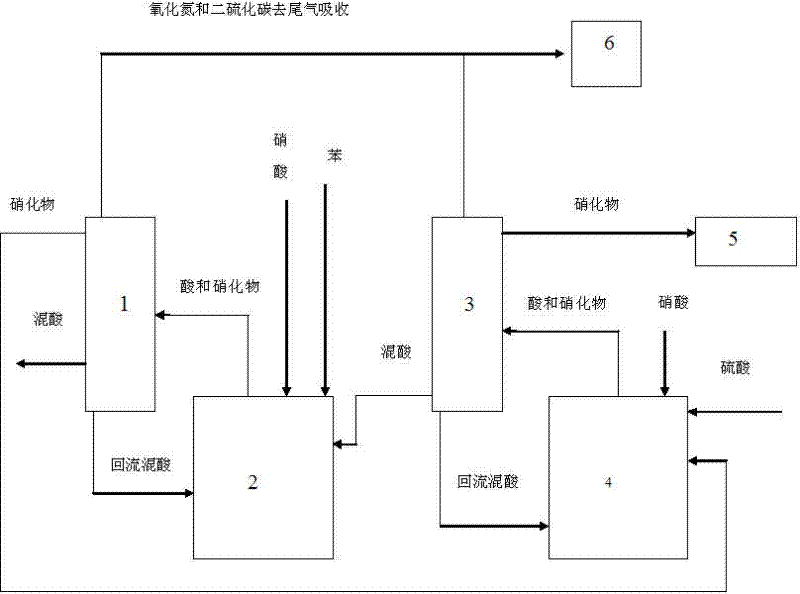

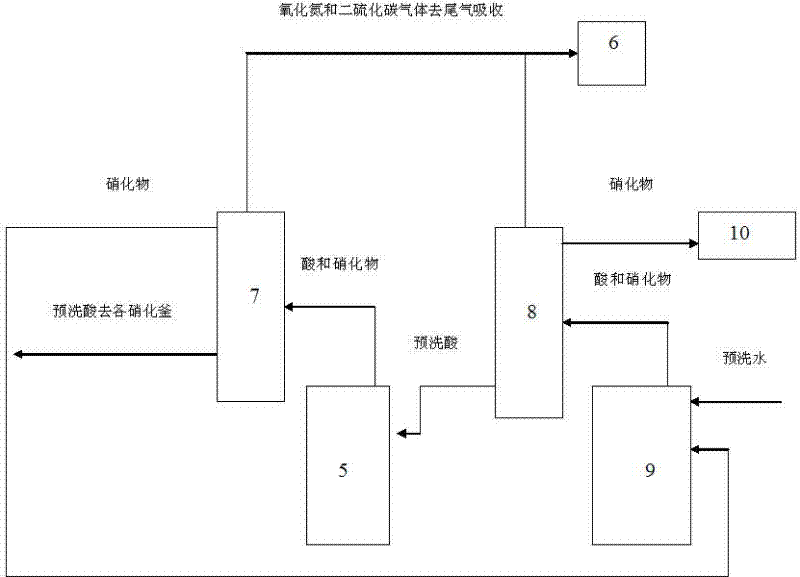

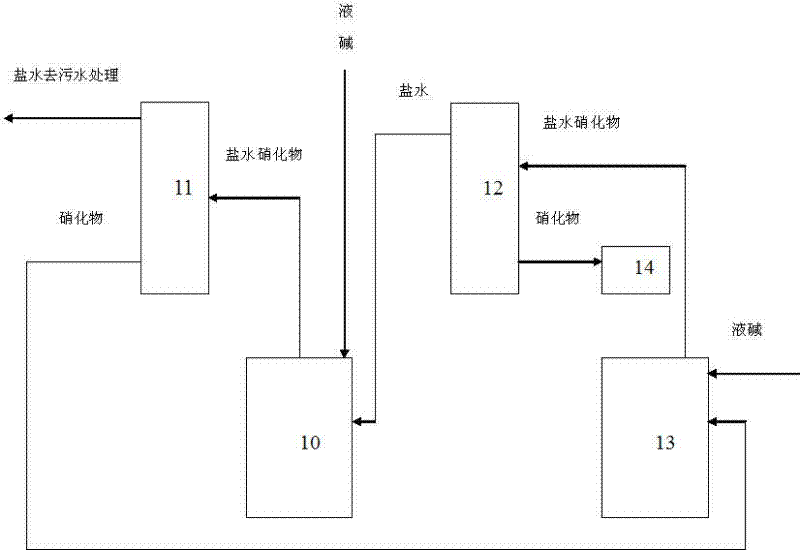

Device and method for continuously producing mixed dinitrobenzene by using coking benzene

ActiveCN102311347AReduce desulfurization costHigh reaction conversion rateNitro compound preparationNitrationPre washing

The invention discloses a device and method for continuously producing mixed dinitrobenzenes by using coking benzene. The production device is composed of nitrating kettles, pre-washing kettles, neutralization kettles and washing kettles which are reversely connected in series, wherein the number of the nitrating kettles is 5-7, the number of the pre-washing kettles is 1-2, the number of the neutralization kettles is 2-4, the number of the washing kettles is 2-4, and an oil-water separator is connected in front of each kettle. The method disclosed by the invention comprises the following steps: nitrating coking benzene into dinitrobenzene in the nitrating kettles by using mixed acid consisting of sulfuric acid and nitric acid, and simultaneously carrying out ring-opening oxidation on thiophene so as to obtain carbon disulfide; then, sequentially processing a mixture by using the pre-washing kettles, the neutralization kettles and the washing kettles so as to obtain hetero-dinitrobenzene. In the invention, based on the characteristics of a benzene nitration process and the reaction characteristics of thiophene and the mixed acid, the mixed dinitrobenzene production process is a reverse continuous nitration process; the sulfur-free mixed dinitrobenzene is produced directly by using coking benzene, therefore, the energy consumption and material consumption of the traditional coking benzene desulfurization process are reduuced; because the step of pre-desulfurization is not required, the desulfurization cost is low, and the nitrification is safe; meanwhile, because the whole system is in reverse series connection, the conversion rate of the nitration reaction is high, the consumption of the sulfuric acid is low, and less wastewater is generated.

Owner:JIANGSU KESHENG CHEM EQUIP ENG

Electronic product testing production line and testing method thereof

The invention discloses an electronic product testing production line and a testing method thereof. Aiming at the problems that the manual testing efficiency for existing electronic products is slow,a use effect is not good enough, and the products are easy to pollute by dust on a conveyor belt, the invention provides the following scheme that the electronic product testing production line comprises a base, wherein two opposite installation frames are fixed onto the base; a main case is fixed between the upper ends of the two installation frames; an inlet and an outlet are formed in the leftside and the right side of the main case; a waste parts outlet is formed in the front surface of the main case; a group of fixed blocks is fixed to the each of the left side and the right side of themain case; rotary shafts are rotatably connected onto the two groups of fixed blocks; driven pulleys are fixed to one ends of the rotary shafts; and belt rollers are fixed to the other ends of the rotary shafts. According to the electronic product testing production line and the testing method thereof provided by the invention, a product automatic testing production line can be formed, so that theproduct testing efficiency is improved, the worker burden is reduced, and meanwhile, the cost is reduced; and in addition, ash removal work can be automatically carried out on the conveyor belt, so that dust on the conveyor belt is effectively prevented from polluting products.

Owner:PUTIAN UNIV

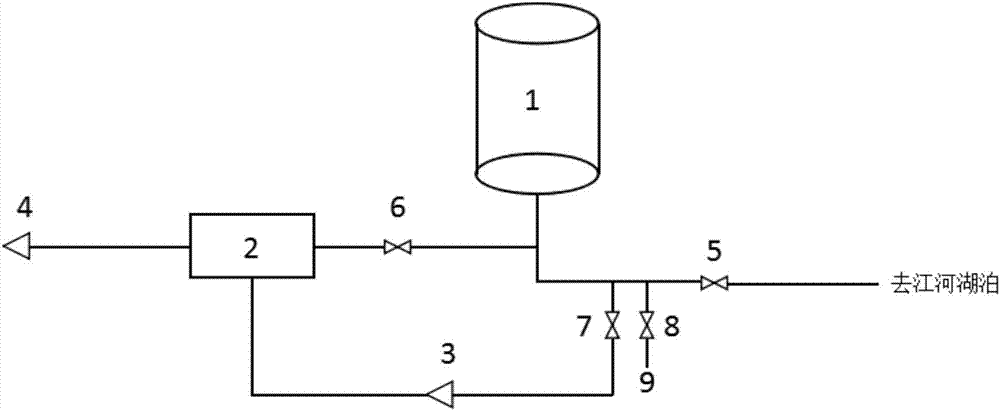

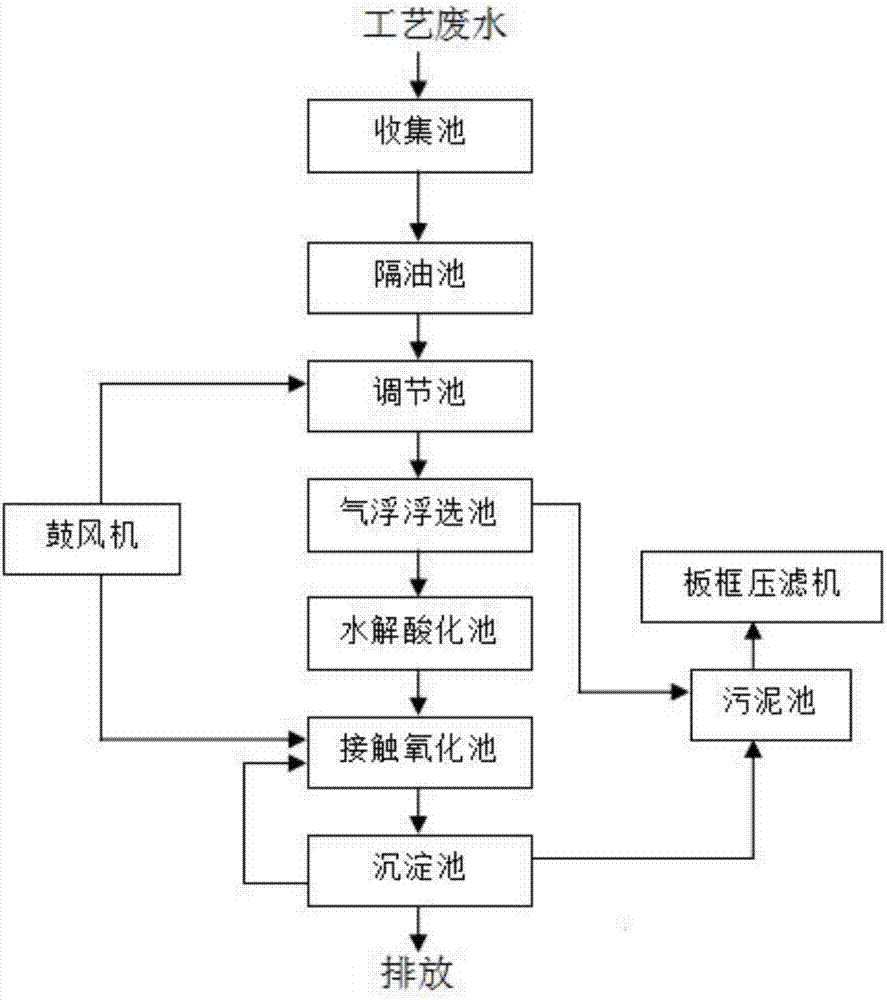

Novel sewage collection system and novel sewage treatment system

InactiveCN107352748ACentralized processingMeet emission standardsMultistage water/sewage treatmentTreatment involving sedimentationCollection systemEmission standard

The invention provides a novel sewage collection system. The novel sewage collection system comprises a storage tank, a water collection pit, a first pump body, a second pump body and a liquid discharging opening. The invention further provides a novel sewage treatment system; the novel sewage treatment system is mainly composed of treatment equipment including a collection tank, an oil separation tank, a regulation tank, an air-floating flotation tank, a hydrolytic acidification tank, a contact oxidization tank, a sedimentation tank, a discharging water tank, a sludge tank, a plate-and-frame filter press, an air blower and the like. The novel sewage collection system and the novel sewage treatment system, provided by the invention, have the following beneficial effects that the novel sewage collection system can be used for treating rainwater and sewage respectively, centralized treatment of the sewage can be realized and the rainwater is directly discharged; the novel sewage treatment system can be adaptive to sewage treatment with different pollution sources so that the treated sewage reaches emission standards.

Owner:江苏海企化工仓储股份有限公司

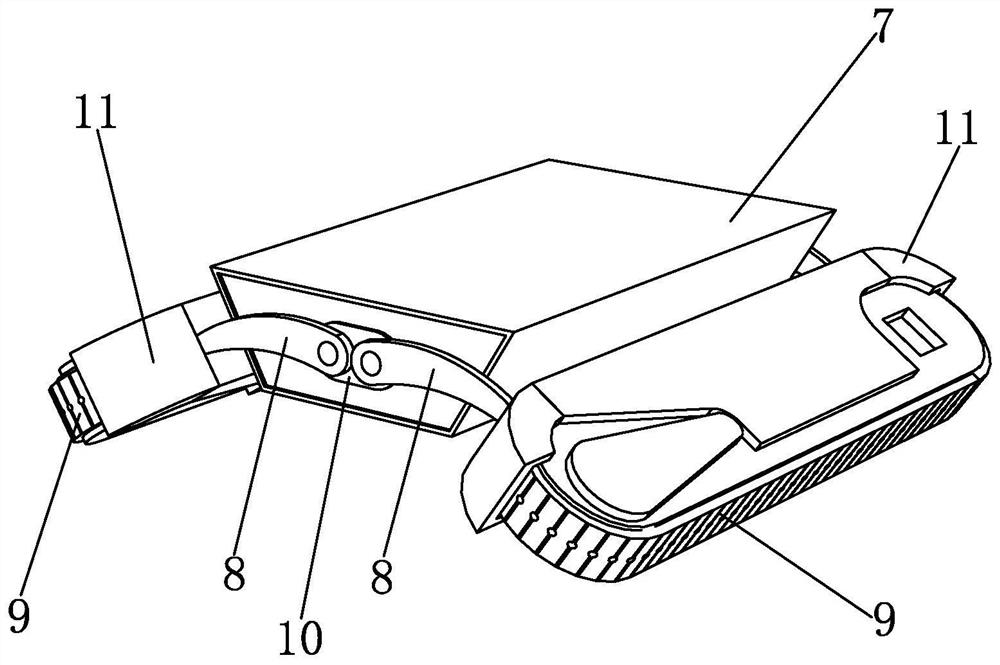

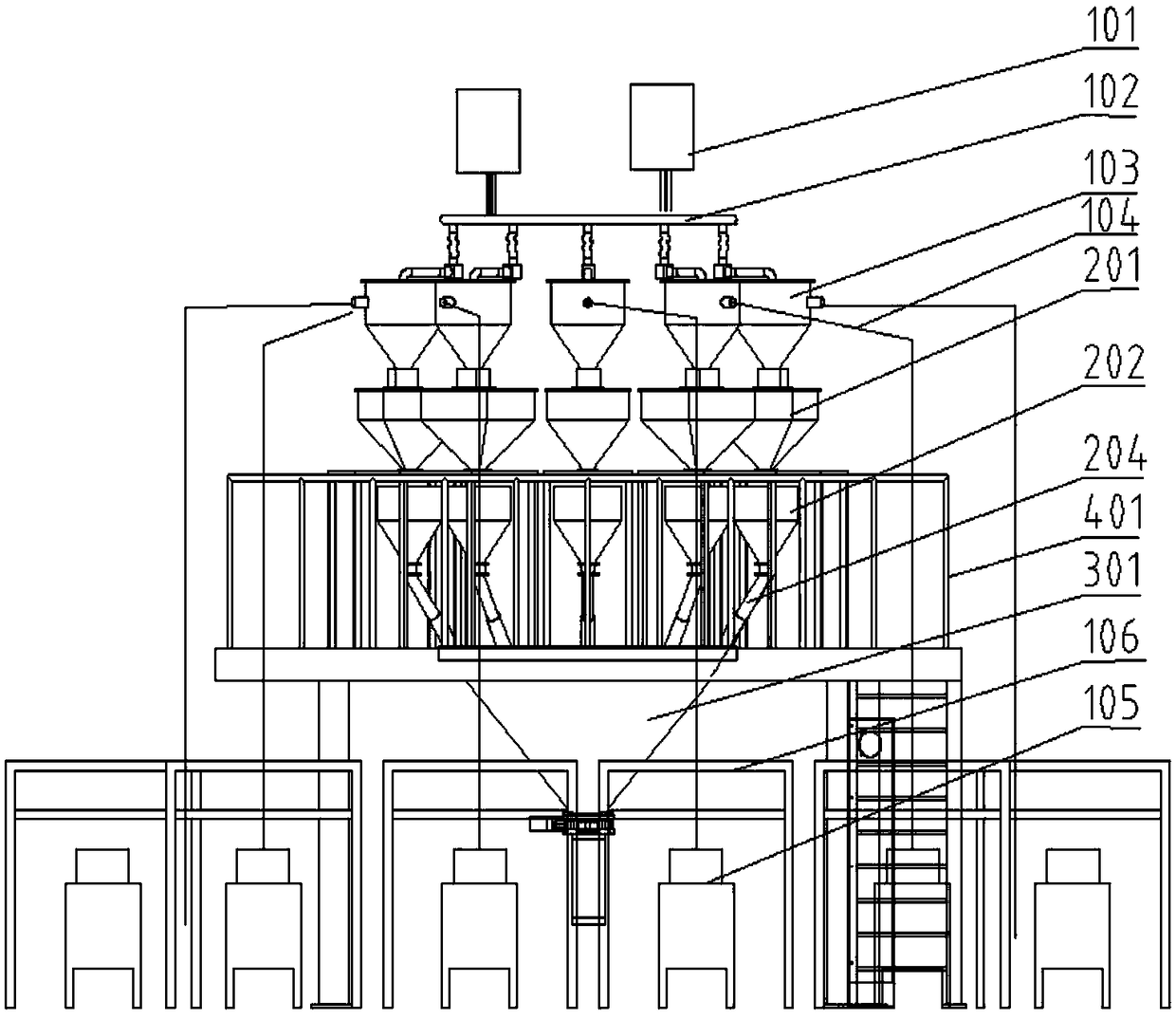

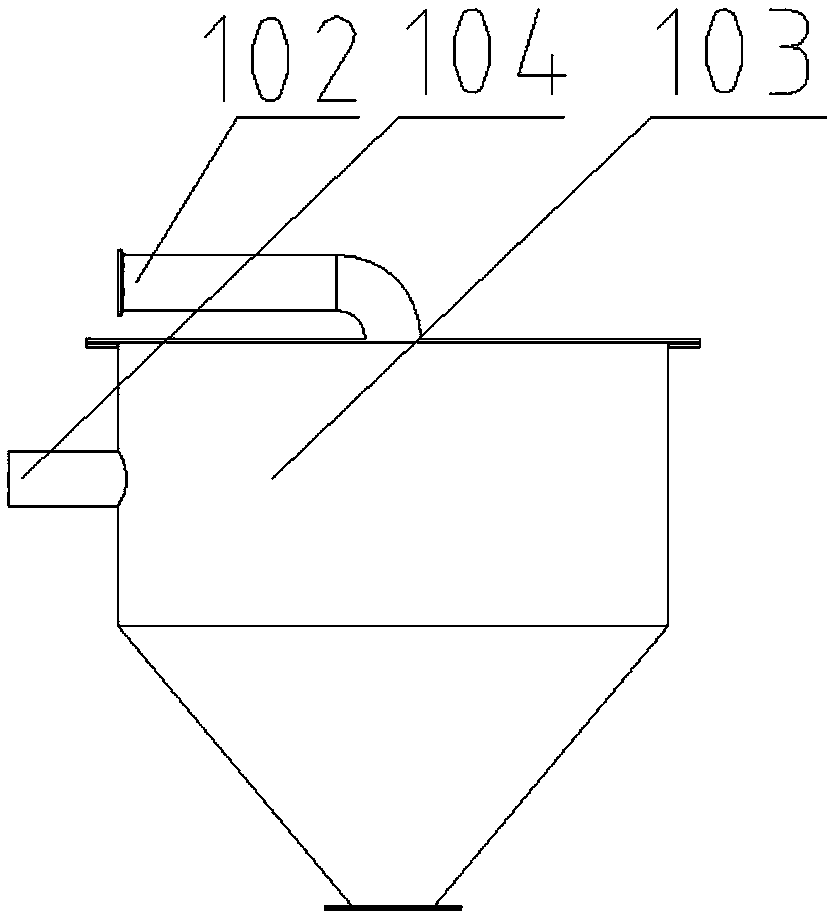

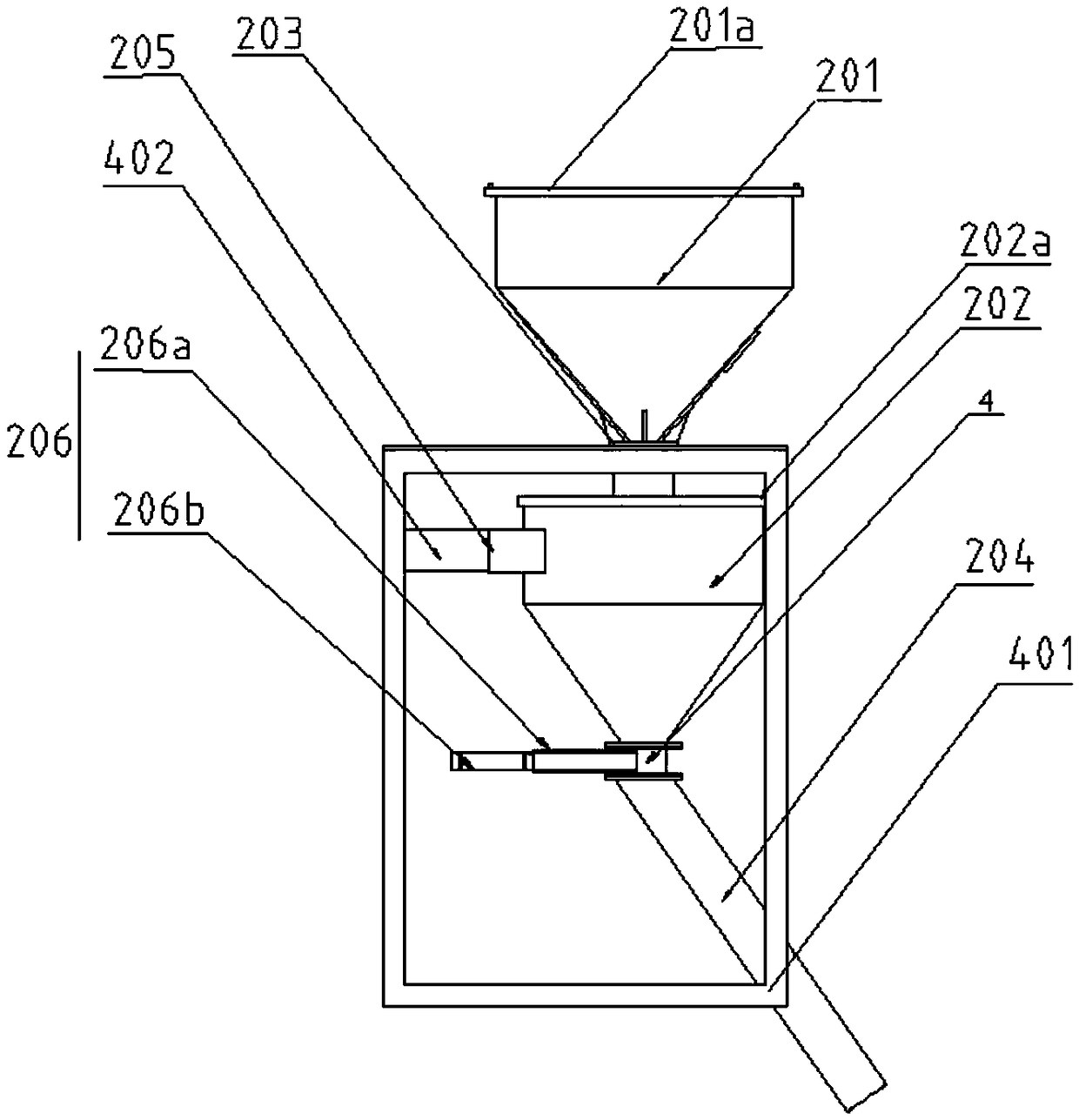

Color masterbatch automatic feeding equipment and feeding process

PendingCN109110505ACentralized processingImplement closed inputLarge containersBulk conveyorsVacuum pumpingMasterbatch

The invention discloses color masterbatch automatic feeding equipment and a feeding process, the equipment comprises a feedstock feeding device, a weight-increasing type feeding device, a gathering device and a control device, wherein the feedstock feeding device adopts a vacuum pumping mode to carry out feeding and supplementing, the weight-increasing type feeding device distributes materials tothe same material distribution point through mutually independent weighting warehouses arranged in a ring, so that the feeding efficiency is increased. The weighting mode of the weighting warehouse isthat an industrial control computer controls an opening amount of an outlet valve according to an input material addition amount to make the material fall from the storage bin into the weighing warehouse in a fast-adding-slow-supplying manner, and the weighing is more accurate. The equipment can realize material centered processing, closed input, and prevention of dust and feedstock pollution ofthe workshops. In order to ensure the continuity and reliability of the system operation, the system adopts the industrial control computer, a MES system device connected with the industrial control computer and interacting with the industrial control computer and a human-computer interface, which reduces manual participation and greatly improves the quality of products.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

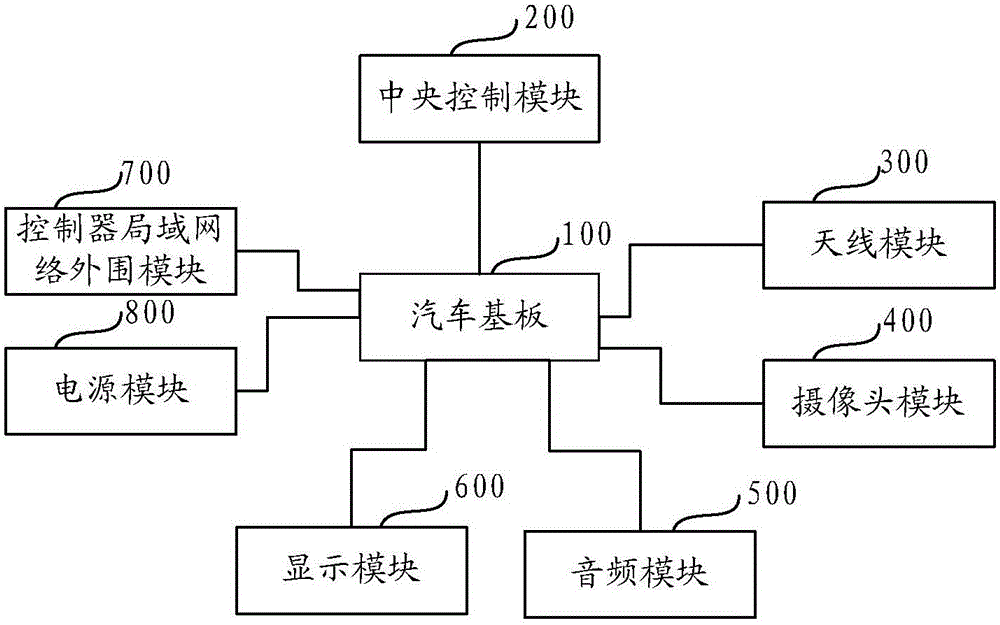

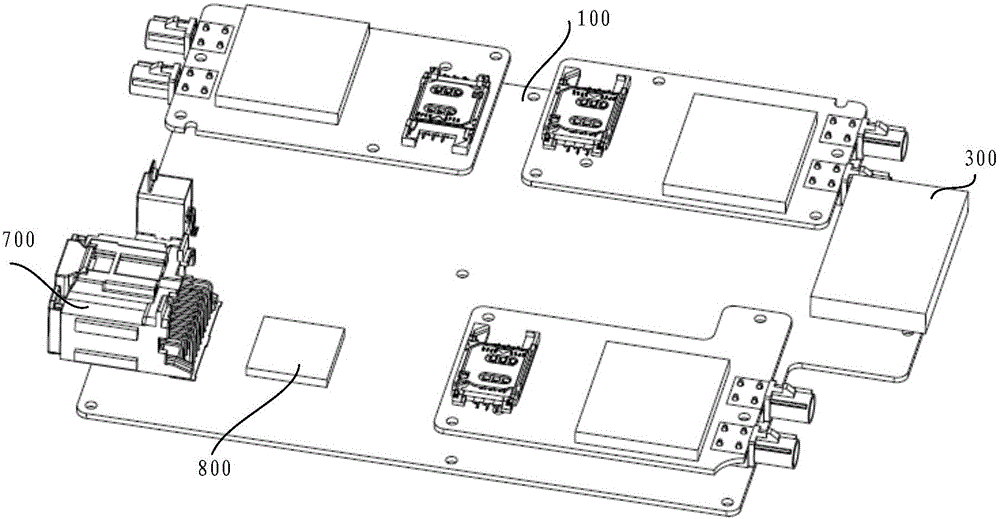

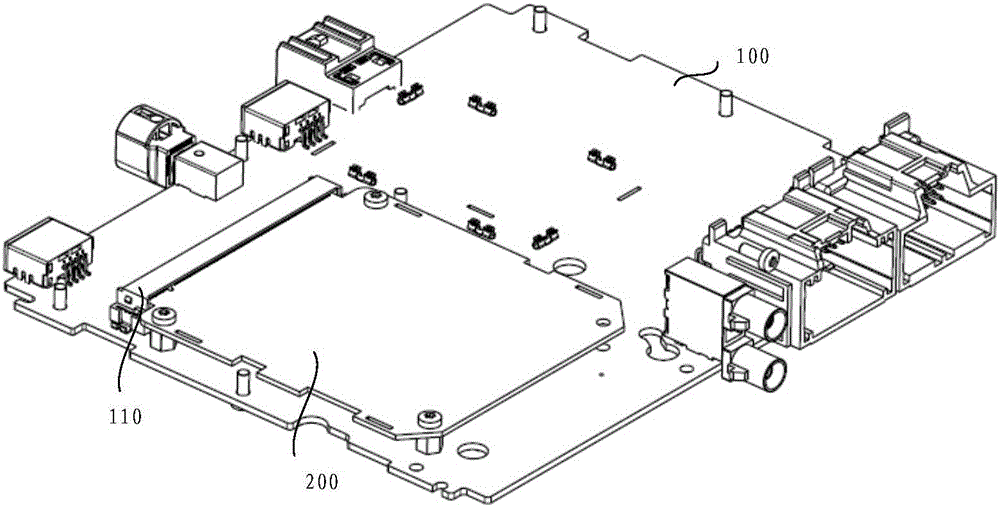

Automobile hardware modularization device

InactiveCN105818761AReduce the problem of difficult updateSimple structureElectric/fluid circuitModularityHardware modules

The embodiment of the invention discloses an automobile hardware modularization device and belongs to the field of intelligent automobiles. The automobile hardware modularization device comprises an automobile substrate and multiple hardware function modules applied to the automobile substrate. The automobile substrate comprises a master control circuit of the multiple hardware function modules and multiple hardware connecting interfaces. The multiple hardware connecting interfaces of the automobile substrate are connected with the multiple hardware function modules through preset connectors. By the adoption of the embodiment of the automobile hardware modularization device, multiple pieces of function hardware of an automobile are modularized according to functions, the modularized hardware modules are connected with the automobile substrate through the preset connectors, the automobile hardware modularization device is simple in structure and easy to operate, and meanwhile the problem that existing hardware is difficult to update due to the limitations of factors such as interfaces and shapes of the existing hardware is solved.

Owner:LETV HLDG BEIJING CO LTD +1

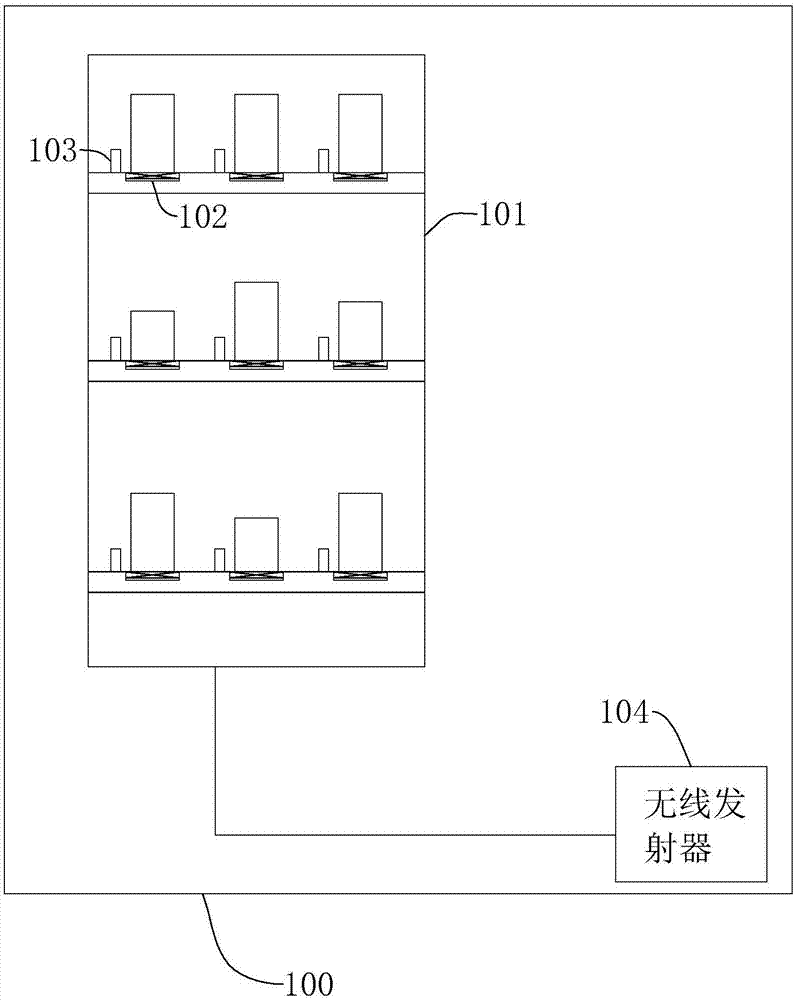

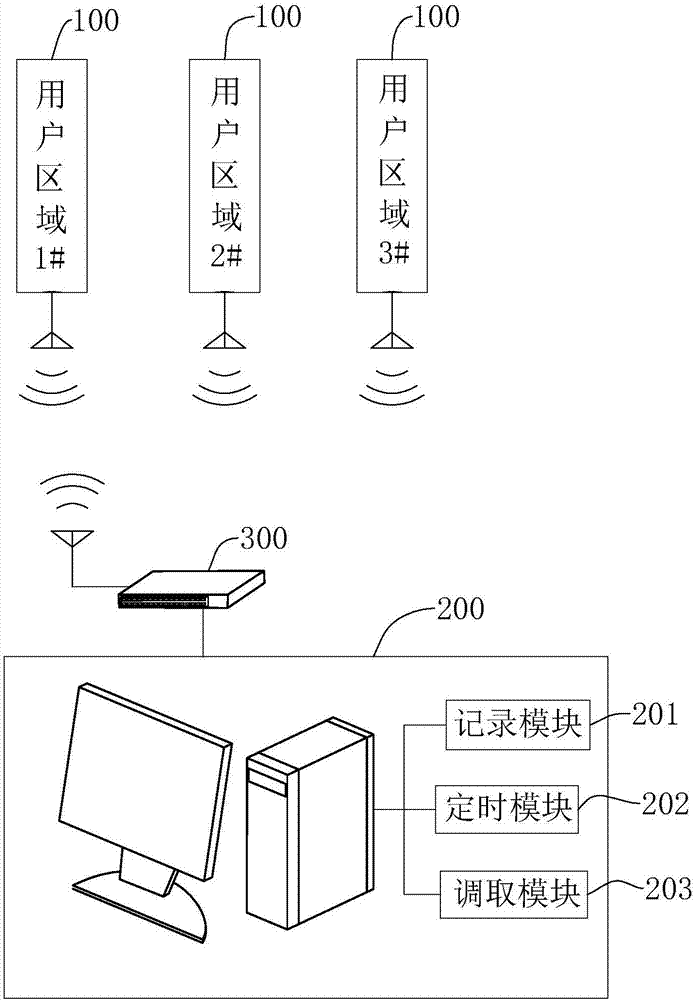

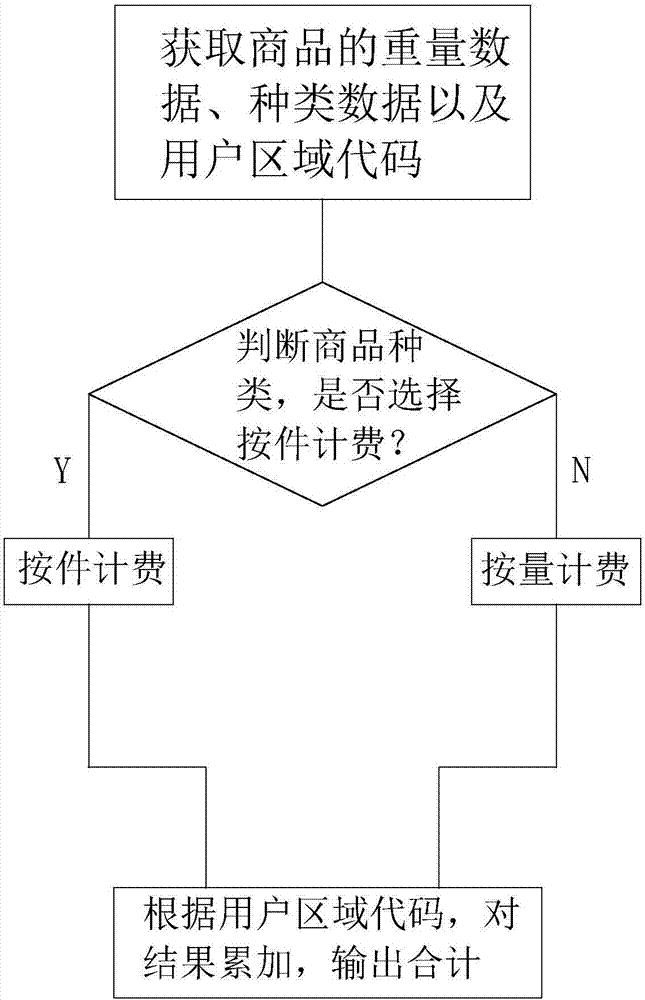

Commodity charging system and method

InactiveCN106980885ATimely feedbackImprove checkout efficiencyCo-operative working arrangementsSpecial purpose weighing apparatusComputer engineeringBilling system

The present invention discloses a commodity charging system and a method, wherein the high-efficient charging purpose is realized. Meanwhile, the problem in the prior art that commodities are dispersed so as to be difficultly charged or monitored can be solved. According to the technical scheme of the invention, a user region is monitored, and then the weight data and the type data of commodities and the code of the user region are collected. The above information is sent to a merchant terminal. Through the merchant terminal, commodities are charged.

Owner:杭州竞立智能科技有限公司

Building steel pipe punching chip collecting device easy to clean

InactiveCN108098443AGood effectQuality improvementPositioning apparatusMaintainance and safety accessoriesPunchingArchitectural engineering

The invention discloses a building steel pipe punching chip collecting device easy to clean. The device comprises a base; a first support rod is fixed on one side of the upper surface of the base; a second support rod is fixed on the other side of the upper surface of the base; fixed sleeves are hinged to the top ends of the first support rod and the second support rod, and are provided with locking screws; an arc shell with a top opening is arranged at the top of the base; baffle plates are arranged on the two side edges of the top opening of the arc shell; the bottom of the arc shell is fixedly connected with the base through multiple fixed rods arranged in parallel; a hole plate is axially fixed in the arc shell; multiple connecting pipes, communicating with the arc shell, are uniformlyarranged at the bottom of the arc shell; the other ends of the connecting pipes are connected with a collecting cylinder; the collecting cylinder communicates with each connecting pipe; a second airblower is mounted at one end of the collecting cylinder; and a storage box is arranged in an outlet at the other end of the collecting cylinder.

Owner:XI'AN POLYTECHNIC UNIVERSITY

High efficient draining-drying device for vegetable dehydration

PendingCN109527618AAvoid damage to internal partsRealize drying operationFood treatmentDehydrationPulp and paper industry

The invention relates to the technical field of vegetable draining-drying devices, and discloses a high efficient draining-drying device for vegetable dehydration. The device comprises a draining-baking apparatus, a bin gate, a handle, a first chute, a suction pipe, an exhaust fan, a second chute, and a residue collecting box. The bin gate is arranged on the right surface of the draining-baking apparatus; the handle is fixedly connected to the right surface of the bin gate; the exhaust fan is fixedly connected to the left side of the top of the draining-baking apparatus; the suction opening ofthe exhaust fan is fixedly connected to the suction pipe; and the end, which is far away from the suction opening of the exhaust fan, is communicated with the interior of the draining-baking apparatus. The provided high efficient draining-drying device has the advantages that through the vibration of a pneumatic vibrator and a structure with crossed first baking lamp and second baking lamp, vegetables can be dried from all directions, all parts of vegetables are fully dried, and repeated drying is avoided.

Owner:JIANGSU NATURAL FOOD

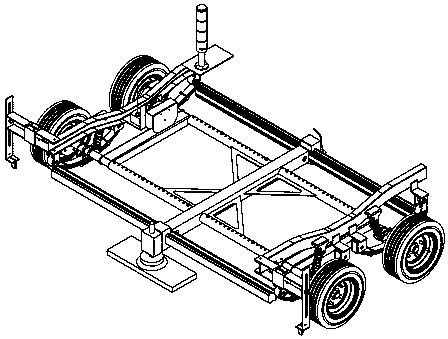

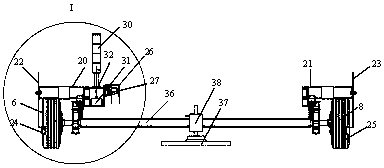

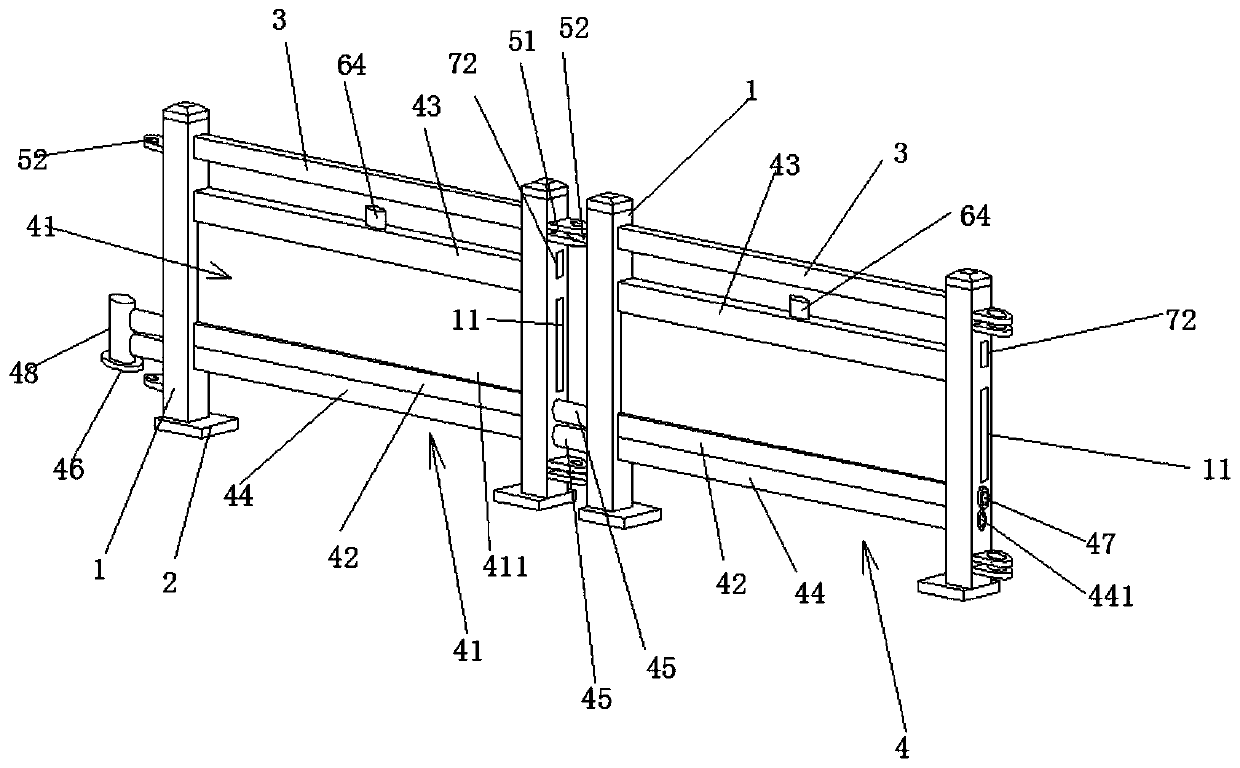

Paving construction pavement cleanliness detection method

The invention discloses a paving construction pavement cleanliness detection method. The cleanliness detection device is used for detection; the cleanliness detection device comprises a chassis main beam, left, right, front and rear arm pipes, left, right, front and rear wheels, a left fixing arm, a right fixing arm, left, right, front and rear damping plate springs, a left shock absorber, a rightshock absorber, a front shock absorber, a rear shock absorber, a left photoelectric sensor position adjustable bracket, a right photoelectric sensor position adjustable bracket, a laser correlation photoelectric emission sensor, a laser correlation photoelectric receiving sensor, a laser measurement sensor mounting bracket, a laser measurement sensor, an infrared temperature sensor bracket, an infrared temperature sensor, a warning lamp, a data processing center, a data transmission antenna and a pull rod pin. The laser correlation photoelectric transmitting and receiving sensors are fixed atthe bottom end of the photoelectric sensor position adjustable brackets through bolts. The laser correlation photoelectric emission sensor and the laser correlation photoelectric receiving sensor arebilaterally symmetrical, are kept on the same straight line and are kept close to the road surface.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Waste water filtering and recycling device for construction site

The invention relates to the technical field of environmental protection, and discloses a water filtering and recycling device for a construction site. The water filtering and recycling device for theconstruction site comprises a filter box, wherein a water inlet pipe is fixedly arranged at the top of the filter box; a motor is fixedly arranged on the right side of the filter box; a driving wheelis fixedly arranged at an output shaft of the motor; a base is fixedly arranged on the left side of the filter box; two supporting rods are fixedly arranged at the top of the base; the sides, opposite to each other, of the two supporting rods are movably connected with a driven wheel through a rotating shaft; and a conveying belt which penetrates through and extends to the left side of the filterbox and is in transmission connection with the driven wheel sleeves the driving wheel. The problems that most of the sewage at the construction site is directly discharged at present, no further treatment is carried out on the sewage at the construction site, if the sewage is not treated at the construction site, the sewage has certain influence on the nature and the living environment of people,water resources are very wasted, and environmental protection is not facilitated are solved.

Owner:CHINA CONSTR FOURTH ENG DIV

Movable electrostatic dust collection device

PendingCN110813537AImprove removal abilityAvoid flying againVapor flow controlElectric supply techniquesPhysicsElectrostatic adsorption

The invention relates to the technical field of dust collection devices, and particularly relates to movable electrostatic dust collection device which comprises frame bodies. Each frame body comprises a stand column, a base and a handrail. Each stand column is of a hollow structure. Through air openings are formed in the opposite sides of the two stand columns. An electrostatic adsorption mechanism is further arranged between the two stand columns. The electrostatic adsorption mechanism comprises an adsorption plate, a dust suction groove and a shielding groove. The adsorption plate comprisesinsulating plates and charge plates. One face of each of the two charge plates are fixedly connected with the opposite face of each of the two insulating plates. A battery is fixedly arranged in thehandrail and is electrically connected with the charge plates. The dust suction groove is located in the bottom of the adsorption plate. The shielding groove is located in the top of the adsorption plate. Connecting mechanisms are arranged on the sides, opposite to each other, of the two stand columns, so that multiple frame bodies can be spliced in pairs through the connecting mechanisms. According to the invention, dust in air can be adsorbed to handrails, so that dust pollution can be reduced.

Owner:GUANGXI UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com