Numerical control milling machine

A technology for CNC milling machines and machine tools, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. Efficiency, the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

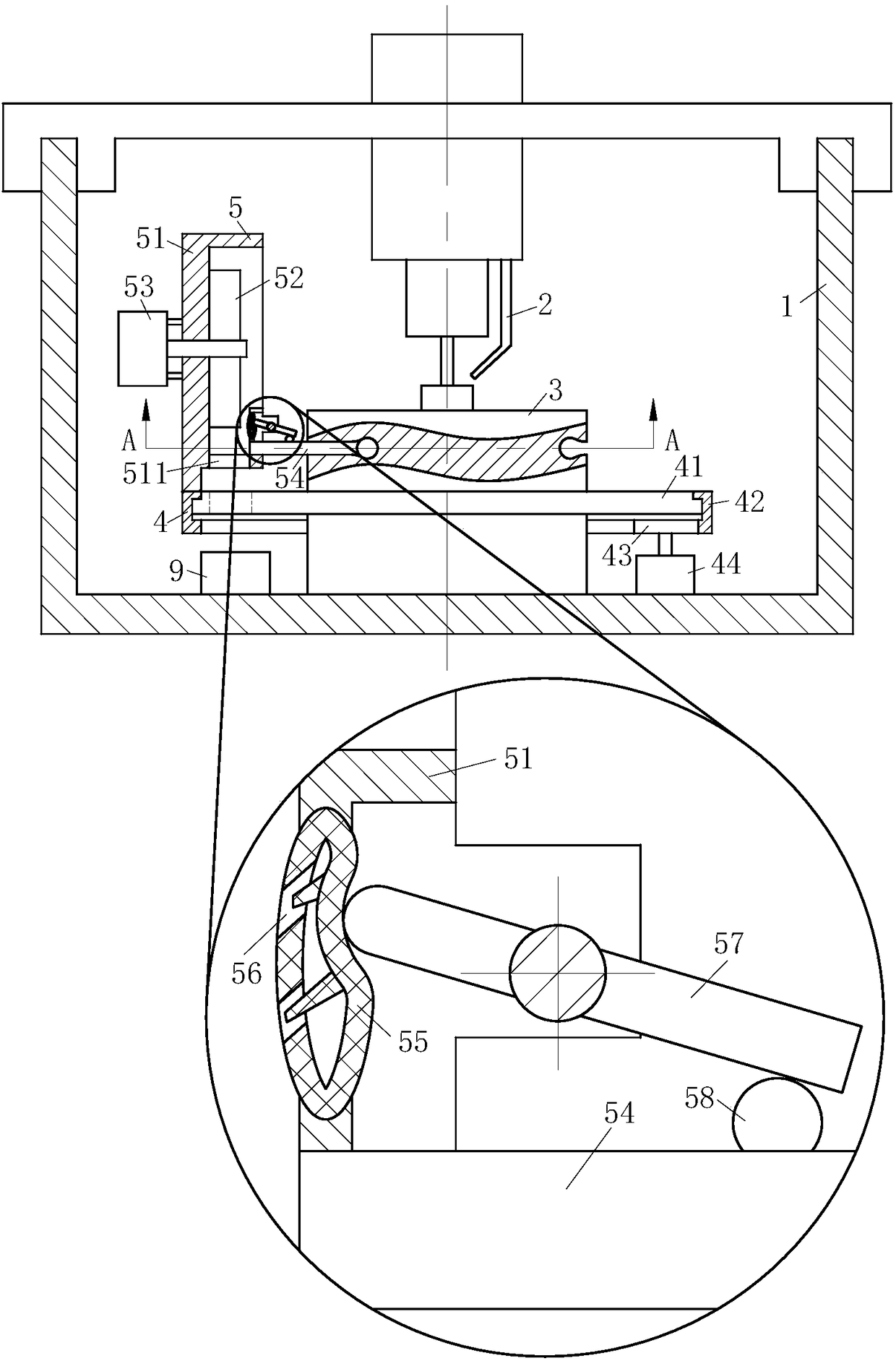

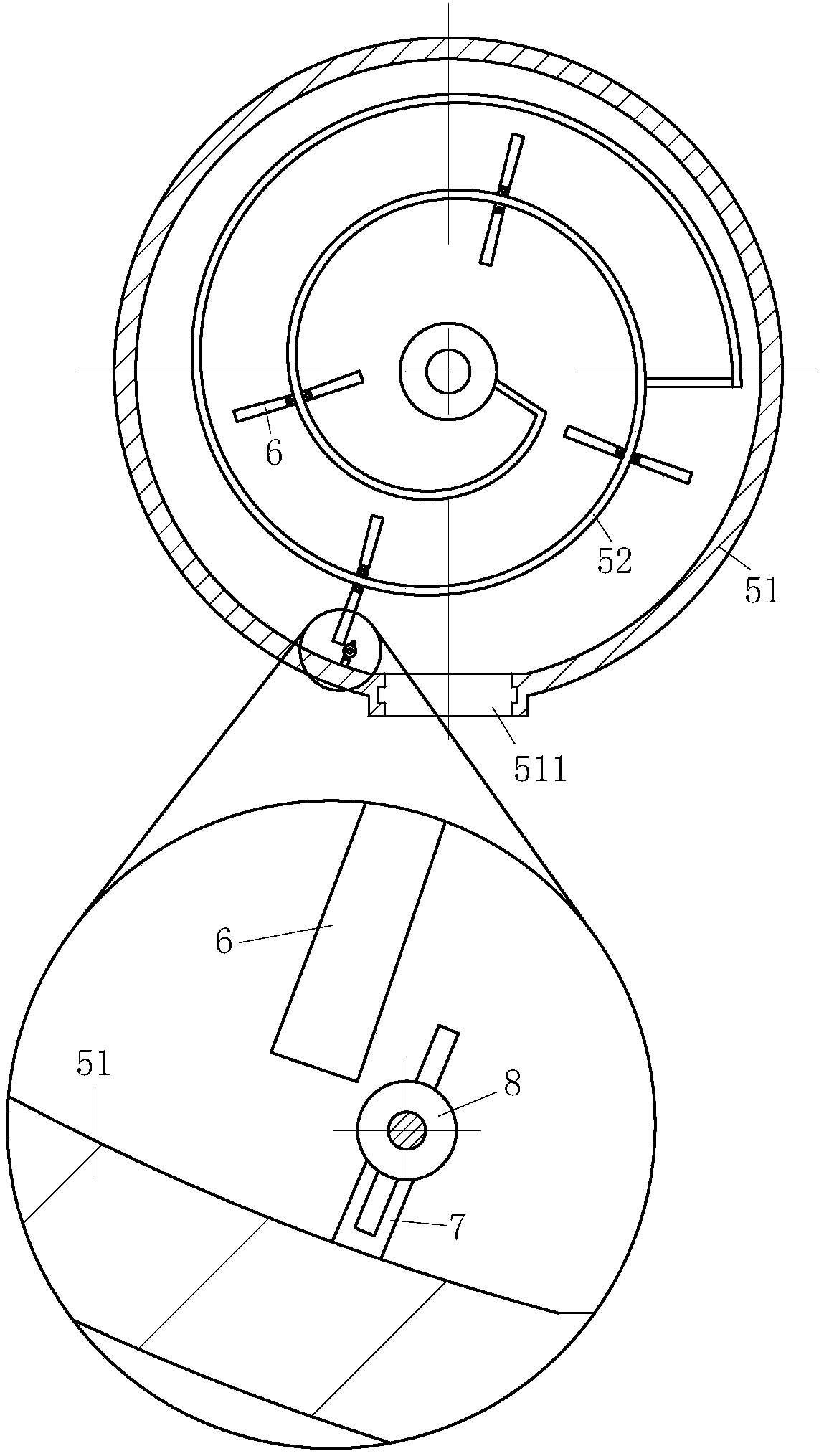

[0027] As an embodiment of the present invention, an airbag 55 is fixedly installed at the lower end of the collection box 51; one side of the airbag 55 is provided with a group of air holes 56 facing the chip discharge port 511; The rotating plate 57 in the collection box 51; the middle part of the upper surface of the closing plate 54 is provided with a protrusion 58; the movement of the protrusion 58 makes the rotating plate 57 rotate, and the rotating plate 57 rotates and squeezes the air bag 55 to form an air flow; When the plate 54 moves, the bump 58 pushes the rotating plate 57 to rotate, and the rotating plate 57 rotates and squeezes the air bag 55 to form an air flow; the cutting chips on the closing plate 54 are cleaned by using the air flow to improve the cleaning efficiency.

[0028]As an embodiment of the present invention, the inner wall of the other side of the airbag 55 corresponding to the air hole 56 is provided with a conical protrusion 59; the protrusion 59 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com