Weld joint grinding device for automobile welding part production and using method thereof

A technology for parts and automobiles, which is applied in the field of welding seam grinding devices for the production of automobile welding parts, can solve the problems of low operation efficiency and increase the labor intensity of staff, so as to improve work efficiency, grinding efficiency, and grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

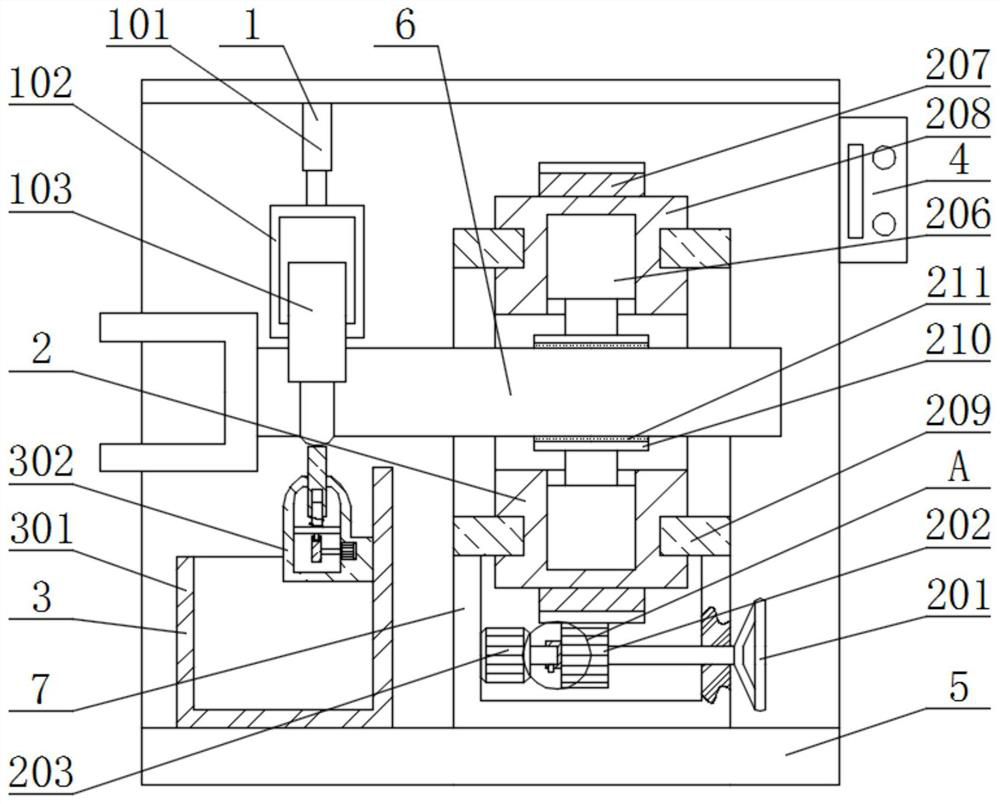

[0028] see Figure 1-6 , the present invention provides a technical solution:

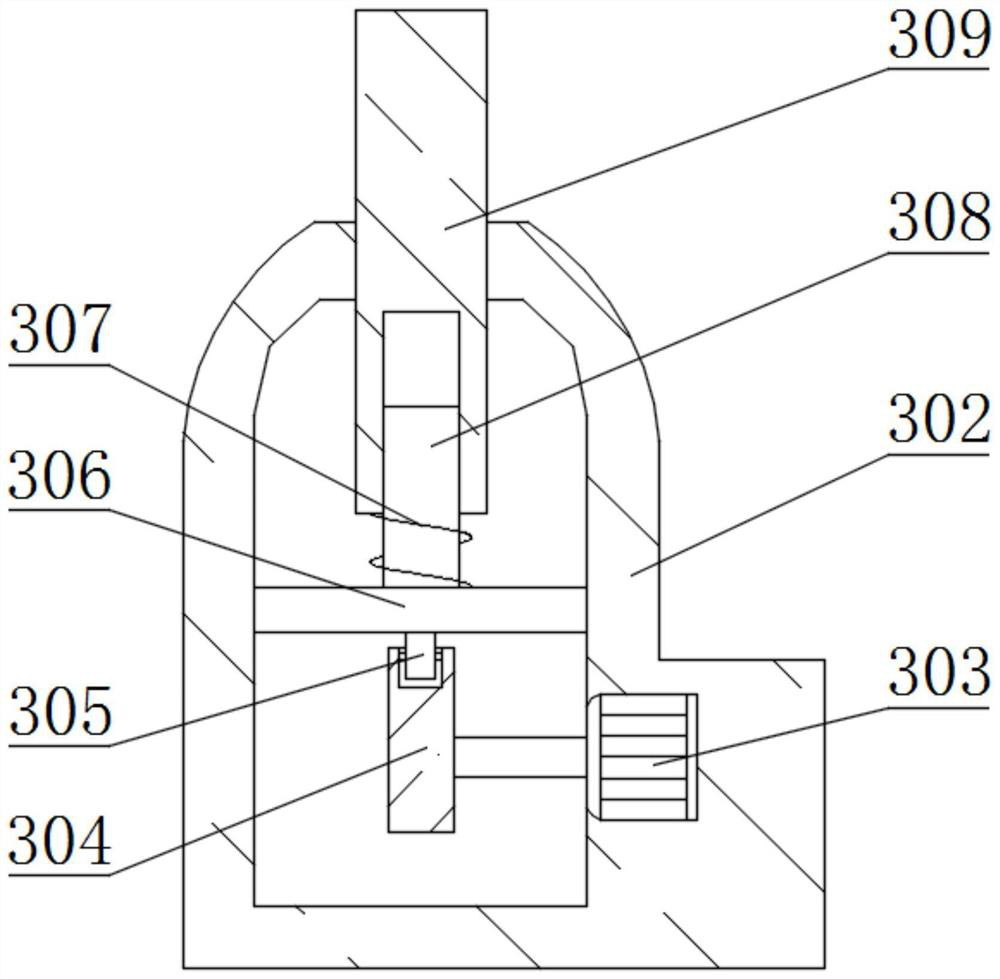

[0029] A welding seam grinding device for the production of automobile welding parts and its use method, including a base 5 and a controller 4, the right end of the base 5 is fixedly connected with the controller 4, and the inner side of the bottom end of the base 5 is fixedly connected with a support seat 7, which supports One end of the seat 7 is fixedly connected with the adjusting device 2, the inner side of the adjusting device 2 is provided with a transmission shaft 6, the inner side of the top of the base 5 is fixedly connected with a grinding device 1, and the grinding device 1 is attached to the transmission shaft 6, and the lower part of the transmission shaft 6 A welding slag processing device 3 is arranged on the side, and the welding slag processing device 3 is fixedly connected with the base 5. The grinding device 1 includes a first electric telescopic rod 101, a fixed frame 102, a gr...

Embodiment 2

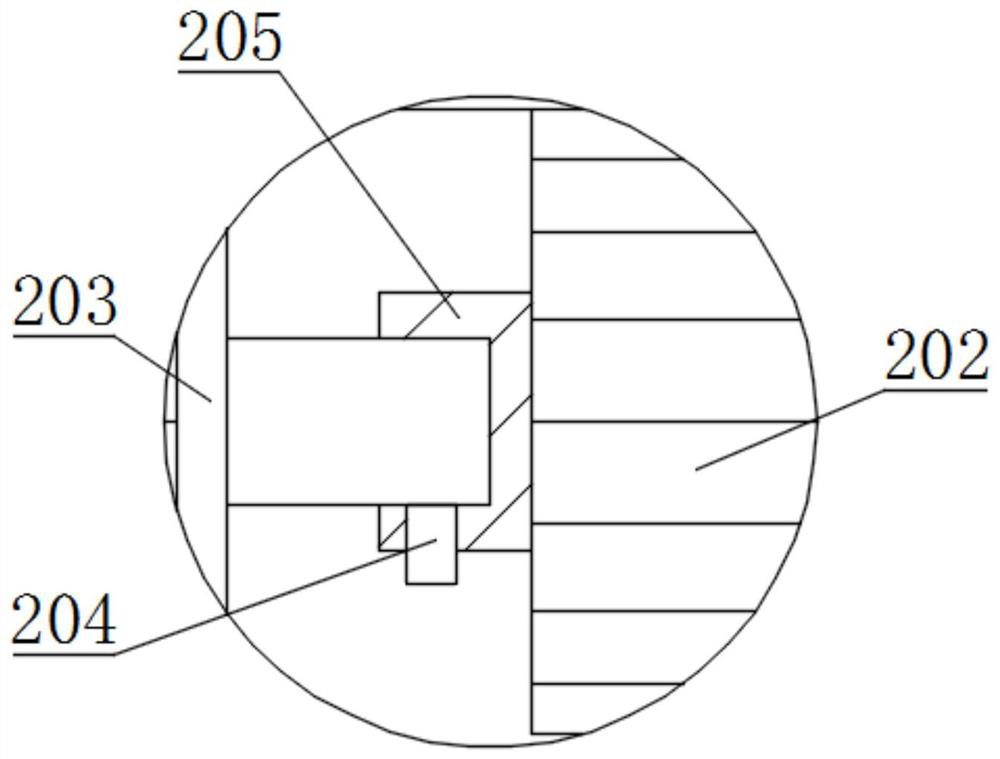

[0036] Embodiment 2 and Embodiment 1 will not go into details. The difference is that when manual operation is required through the hand wheel 201, the staff turns the locking screw 204 counterclockwise so that the locking screw 204 does not contact the card holder 205, Then the staff pulls the gear 202 to the right through the hand wheel 201, so that the gear 202 is separated from the end of the main shaft of the second motor 203 with the deck 205, and then the staff rotates the gear 202 through the hand wheel 201, so that the gear 202 passes through the gear ring 207 rotates with swivel 208.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com