Digital intelligent rope guiding device

An intelligent technology of a rope arranging device, which is applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of large double-headed screw wear, high cost and price, manual reversing, etc., and achieves improved reliability, simple structure, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

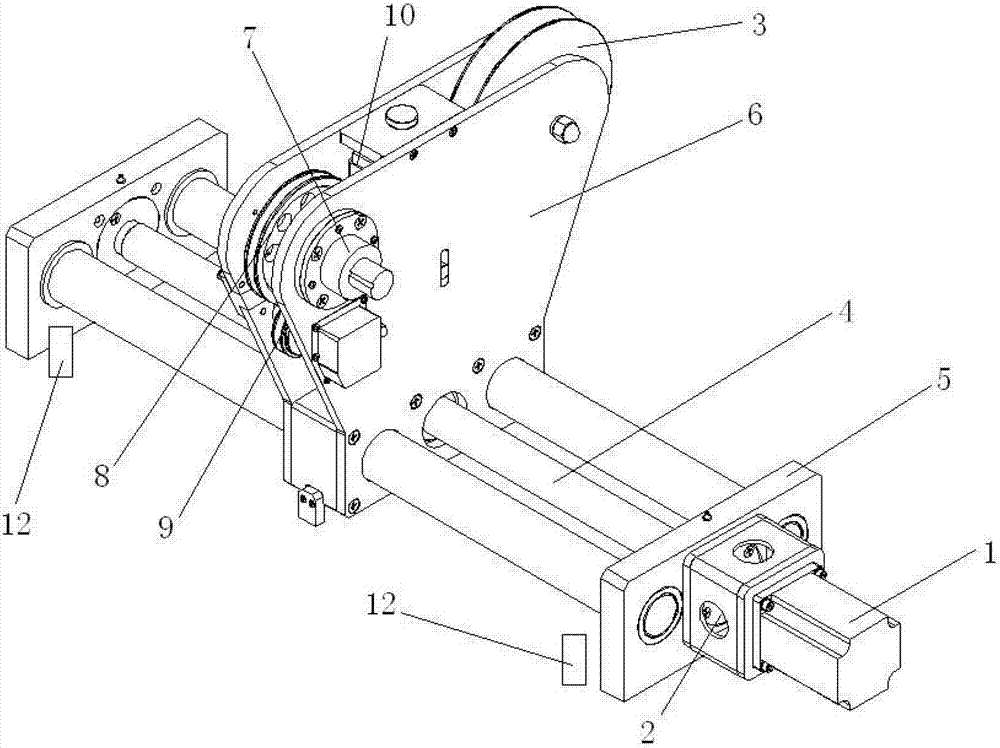

[0023] This embodiment describes a digital intelligent rope rower, its overall structure is as follows figure 1 As shown, it includes a stepper motor 1, a coupling 2, a lead screw 4, a guide wheel 3, a metering wheel 8, a rotary encoder 7 and a body 6, and the stepper motor 1 is connected to the lead screw 4 through a coupling 2. The lead screw 4 is fixed between two parallel lead screw support plates 5, and position sensors 12 are respectively provided at both ends of the lead screw 4 of the described rope arranging device for detecting the position of the rope arranging device fuselage 6.

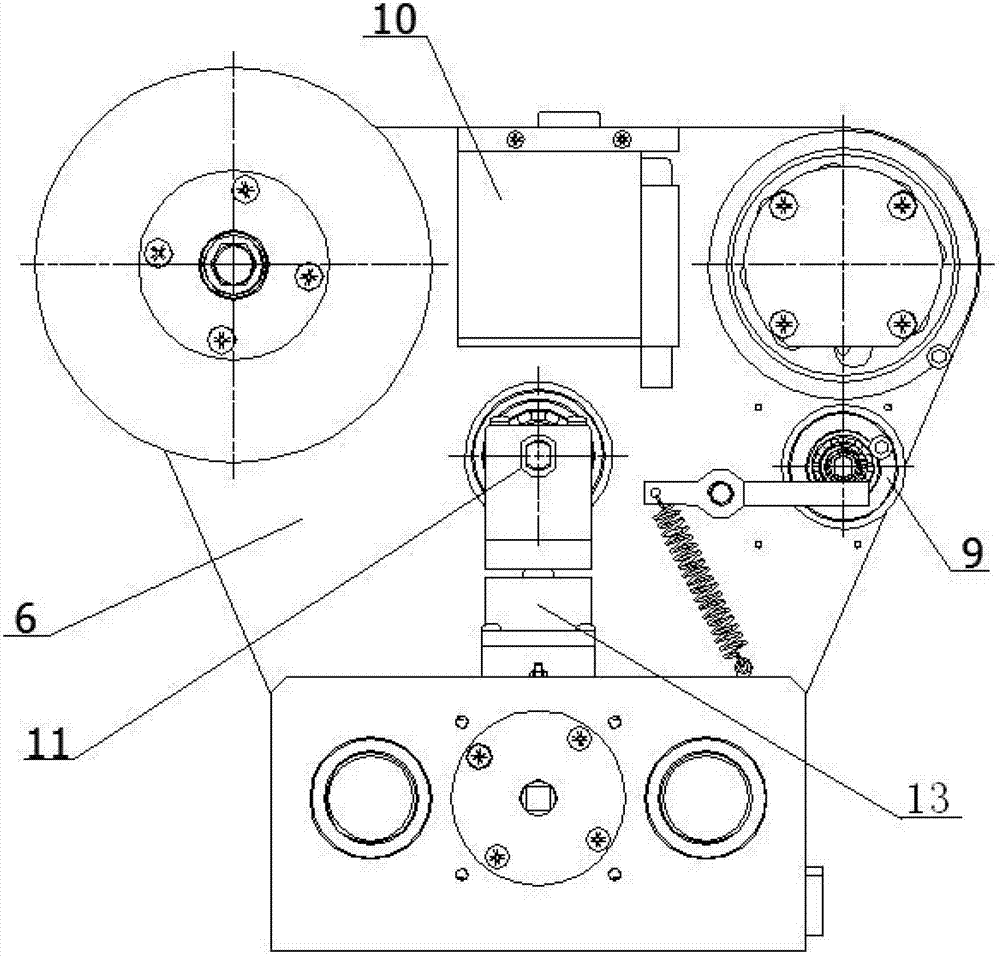

[0024] The fuselage 6 is arranged on the leading screw 4 and the fuselage 6 can move left and right along the leading screw 4. The structure of the fuselage 6 and its upper components is as follows: figure 2 As shown, the guide wheel 3 and the metering wheel 8 are arranged on the two vertices of the fuselage 6 parallel to each other, the rotary encoder 7 is connected with the metering wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com