Tall building kitchen sewage treatment method and integrated treatment device

A sewage treatment method and high-rise building technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc. Inconvenience and other problems, to achieve the effect of facilitating landfill treatment or combustion treatment, improving the treatment effect, and improving the transport and storage environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

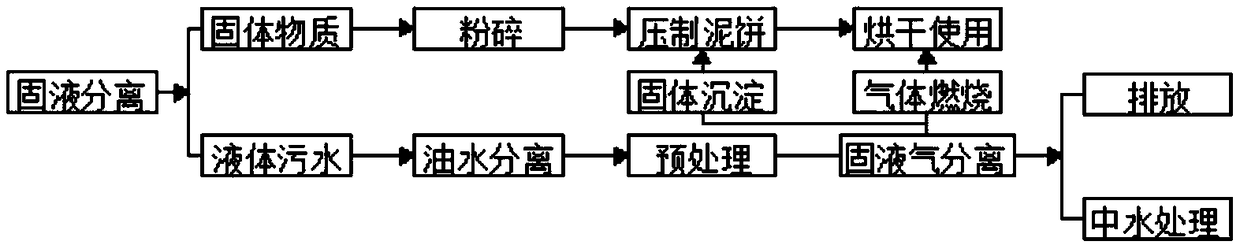

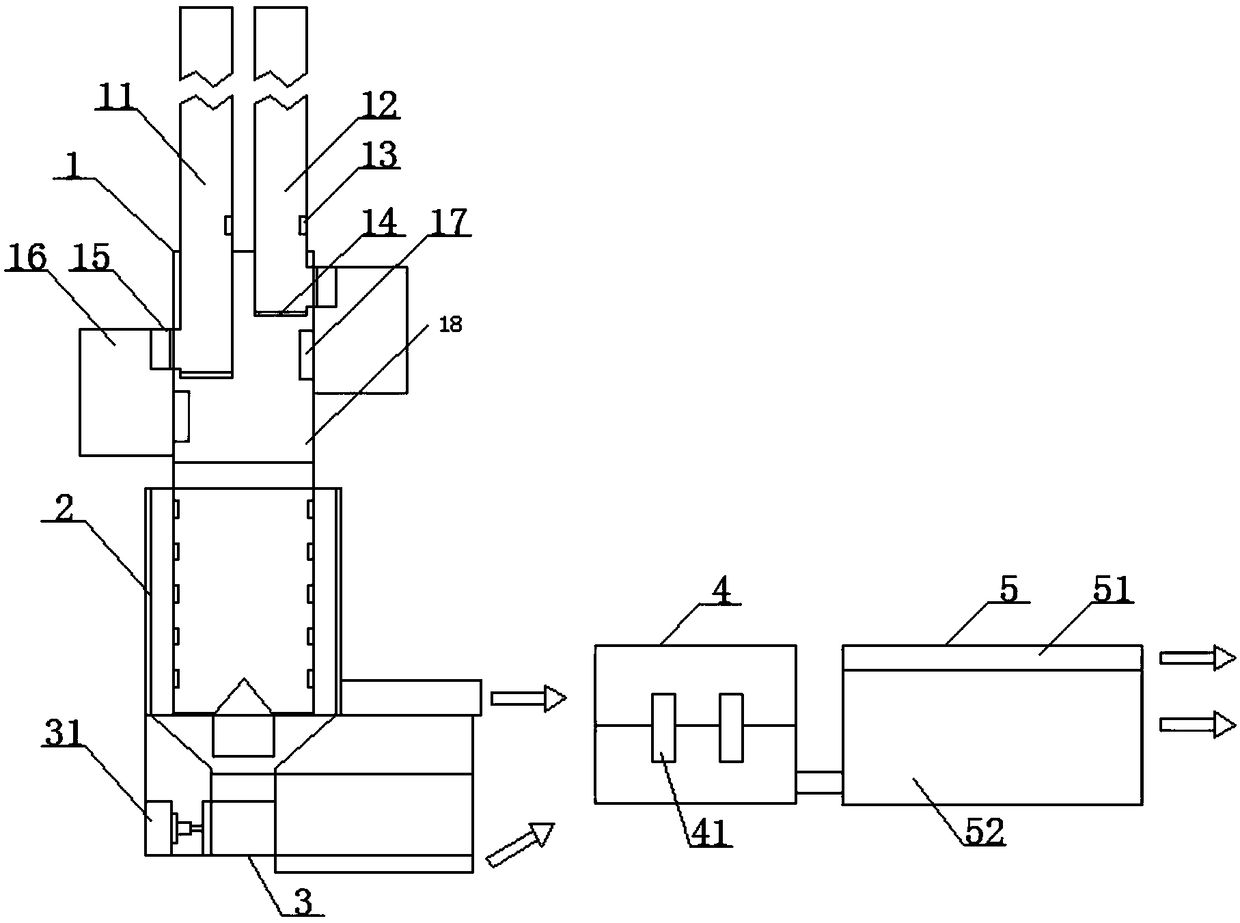

[0043] refer to figure 1 Shown, a kind of high-rise building kitchen sewage treatment method comprises the steps:

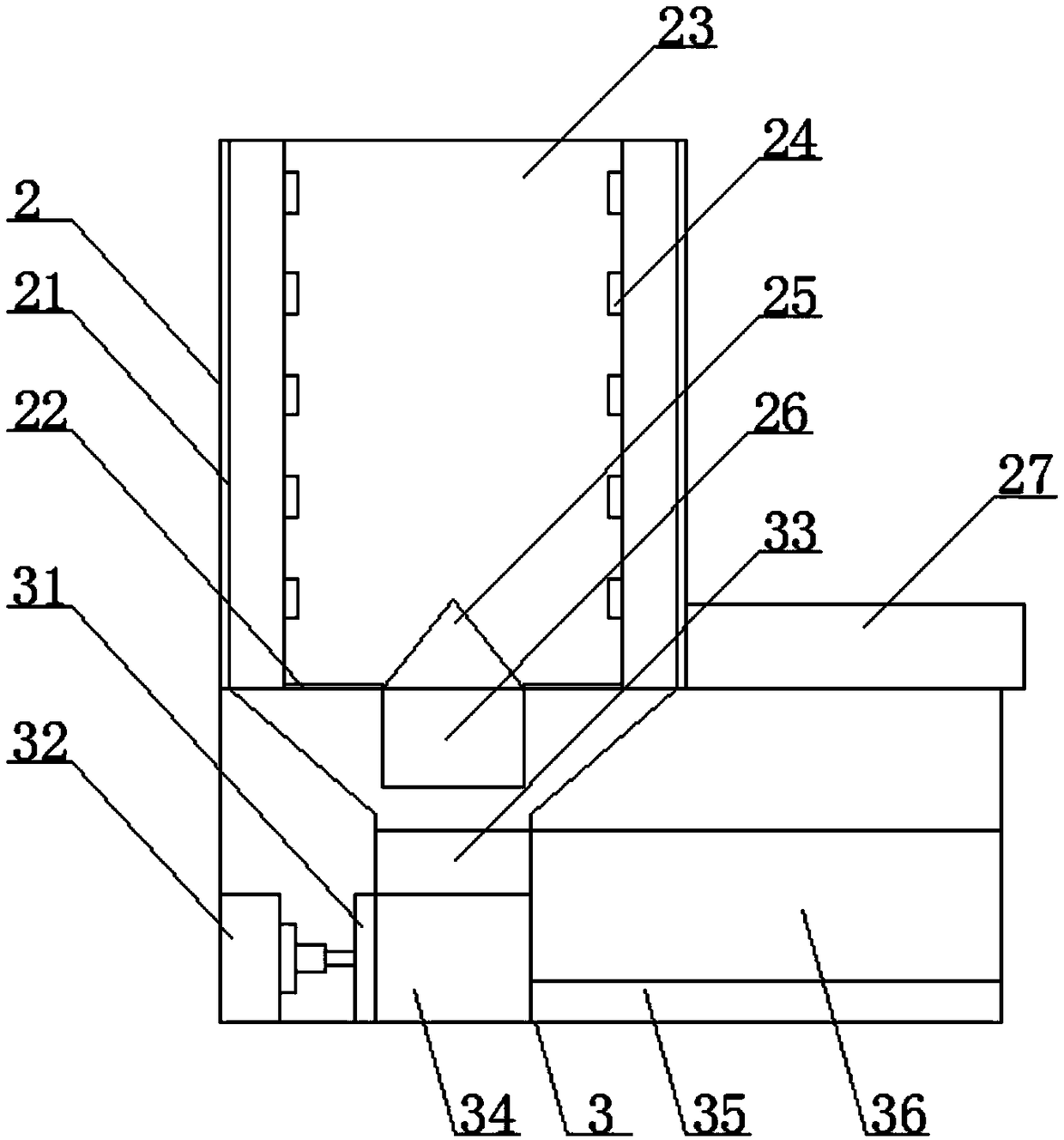

[0044] 1) The high-level kitchen sewage and the low-level kitchen sewage are transported to the drainage chamber of the sewage drainage system through pipelines;

[0045] 2) The liquid and solid are separated by the solid-liquid separation device, and the separated sewage liquid is transported to the oil-water separation tank for oil-water separation;

[0046] 3) The liquid after oil-water separation is transported to the pretreatment tank, and the sludge and compound gas in the pretreatment mechanism are collected separately, and the treated sewage is discharged or reused up to standard;

[0047] 4) The separated solid after the solid-liquid separation device is crushed by the crushing device, and the crushed solid and the sludge in the pretreatment tank are compressed by the filter press device;

[0048] 5) The compressed solid blocks are dried in a drying ov...

Embodiment 2

[0051] The high-rise building kitchen sewage treatment method of the present embodiment differs from Embodiment 1 in that: for buildings higher than 10 floors, drain pipes or drains into the lifting system are arranged separately in the kitchen sewage pipes of the low floors; higher than 20 floors For the buildings above the ground to the 3rd-4th floor, separate management and discharge are required. Ventilation pipes are required to discharge the corresponding kitchen sewage into the corresponding pipes according to different building heights to avoid the backflow of sewage and cause damage to the interior of low-rise buildings. .

Embodiment 3

[0053] The difference between the high-rise building kitchen sewage treatment method of this embodiment and Embodiment 1 is that the gas generated in the pretreatment mechanism is discharged into the combustion system of the drying box through the gas collector for combustion, and the gas after combustion is purified and treated Exhausted into the external air, on the basis of the technology in Example 1, the waste gas and biogas generated in the corresponding sewage treatment are burned in the burner and then purified and discharged into the external air. On the one hand, the waste gas can be reused to avoid accumulation. On the other hand, the corresponding exhaust gas can be treated centrally to reduce emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com