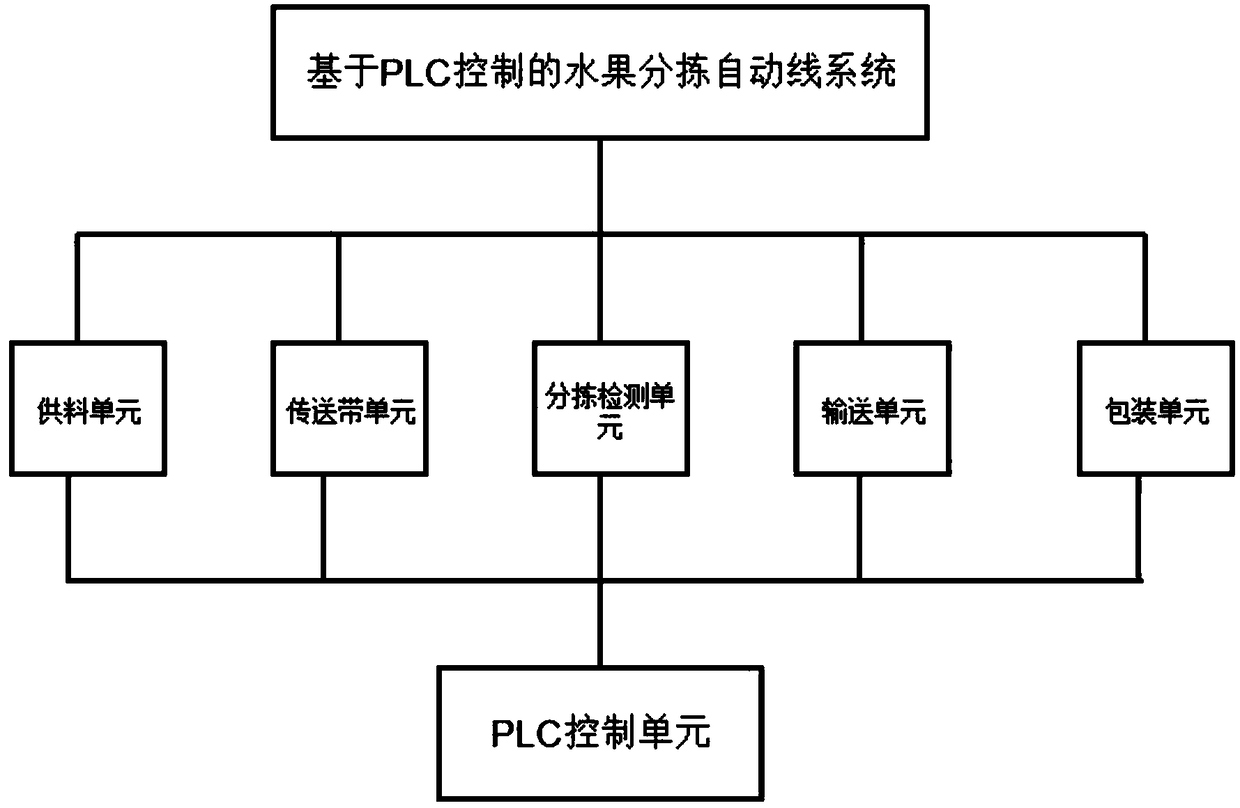

Fruit sorting automatic line system based on PLC control

An automatic line and fruit technology, applied in sorting and other directions, can solve the problems of single sorting specifications, no fruit sorting, and general sorting effect, and achieve the effect of improving the level of automation, reducing labor costs, and avoiding fruit damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is further described in detail through specific implementation methods:

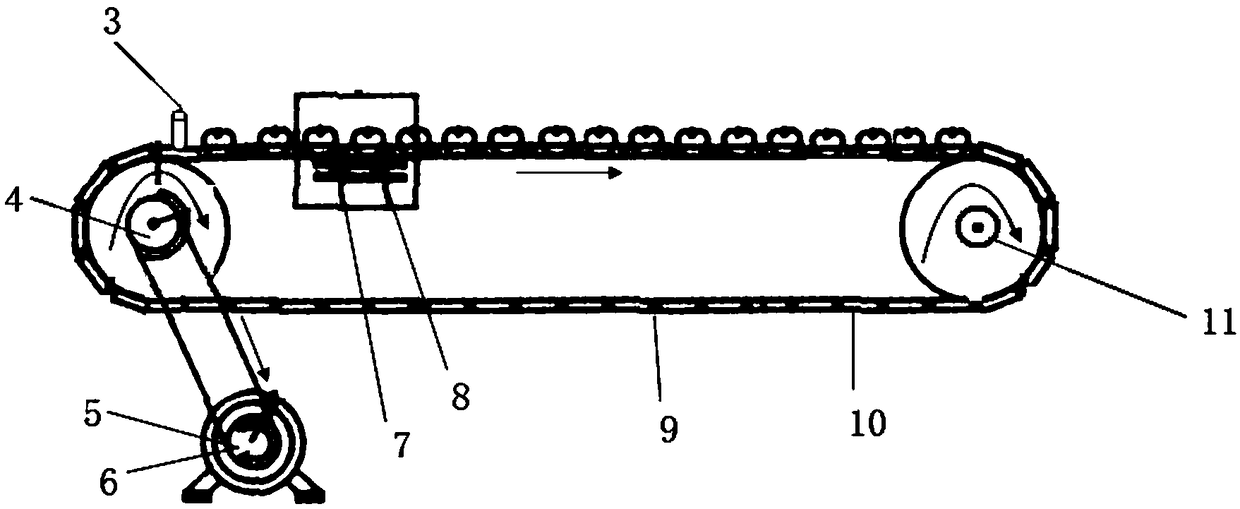

[0039]The reference signs in the drawings of the description include: feeding chute conveyor belt 1, roller 2, photoelectric sensor 3, driven sprocket 4, three-phase asynchronous motor 5, power output sprocket 6, weighing detection module 7, weighing Platform 8, conveyor chain 9, fruit tray mechanism 10, conveyor sprocket 11, fruit tray 12, tray bracket 13, accessories 14, support plate 15, support plate bracket 16, limit iron bar 17, steel ball 18, base plate 19, Guide rail slider 20, sliding plate 21, timing belt 22, first bracket 23, crawler belt 24, servo motor 25, vacuum suction cup 26, vacuum suction cup cylinder 27, arm telescopic cylinder 28, swing cylinder 29, lifting cylinder 30, linear guide rail 31 , the second bracket 32, and the infrared detection module 33.

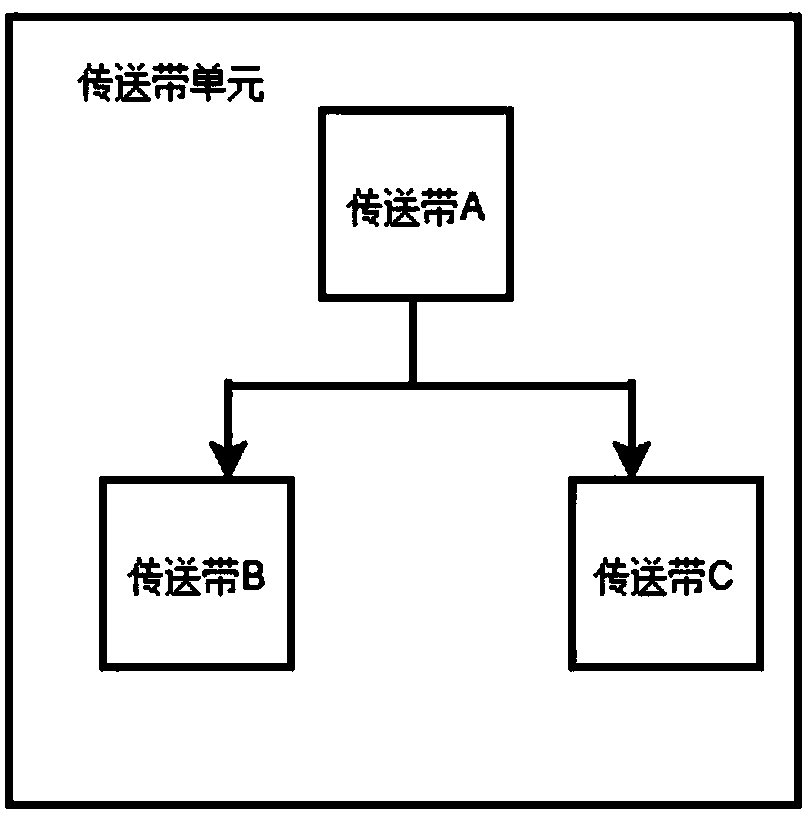

[0040] The embodiment is basically as attached figure 1 As shown, the fruit sorting automatic line system bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com