Patents

Literature

164results about How to "Improve sorting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

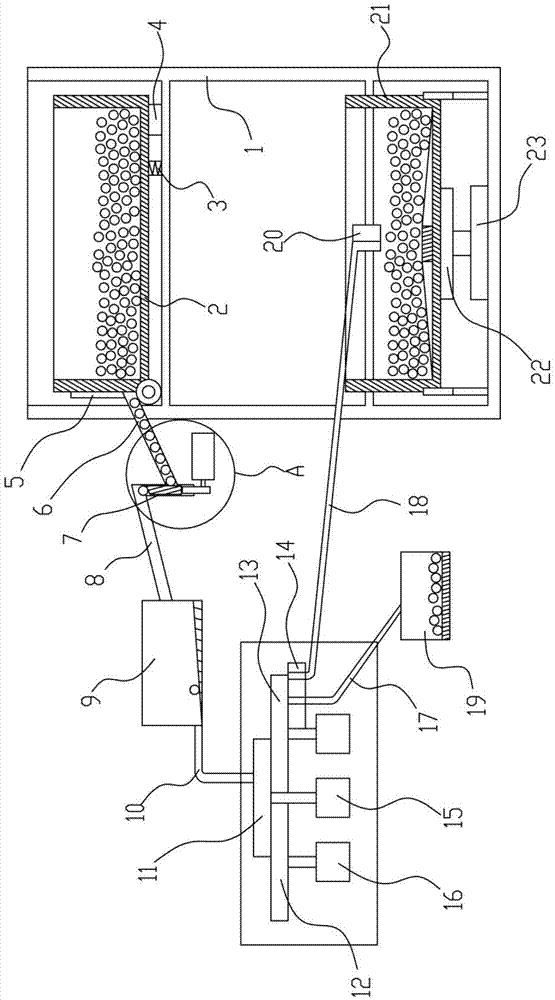

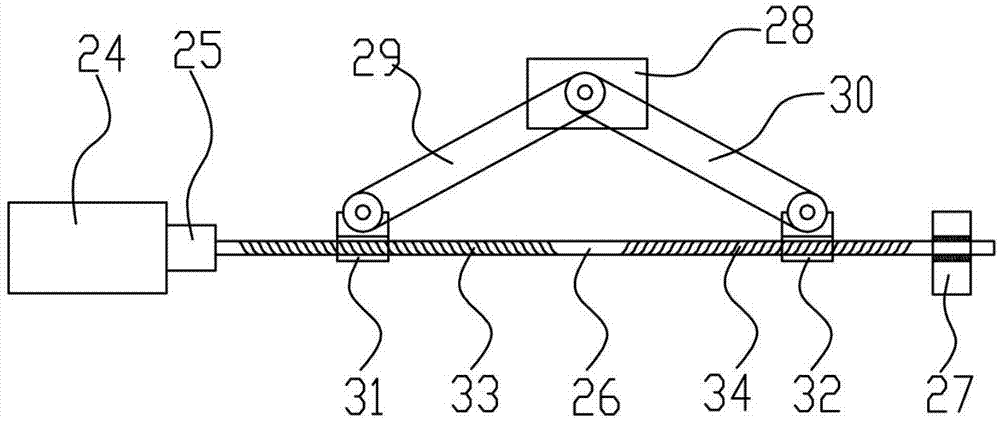

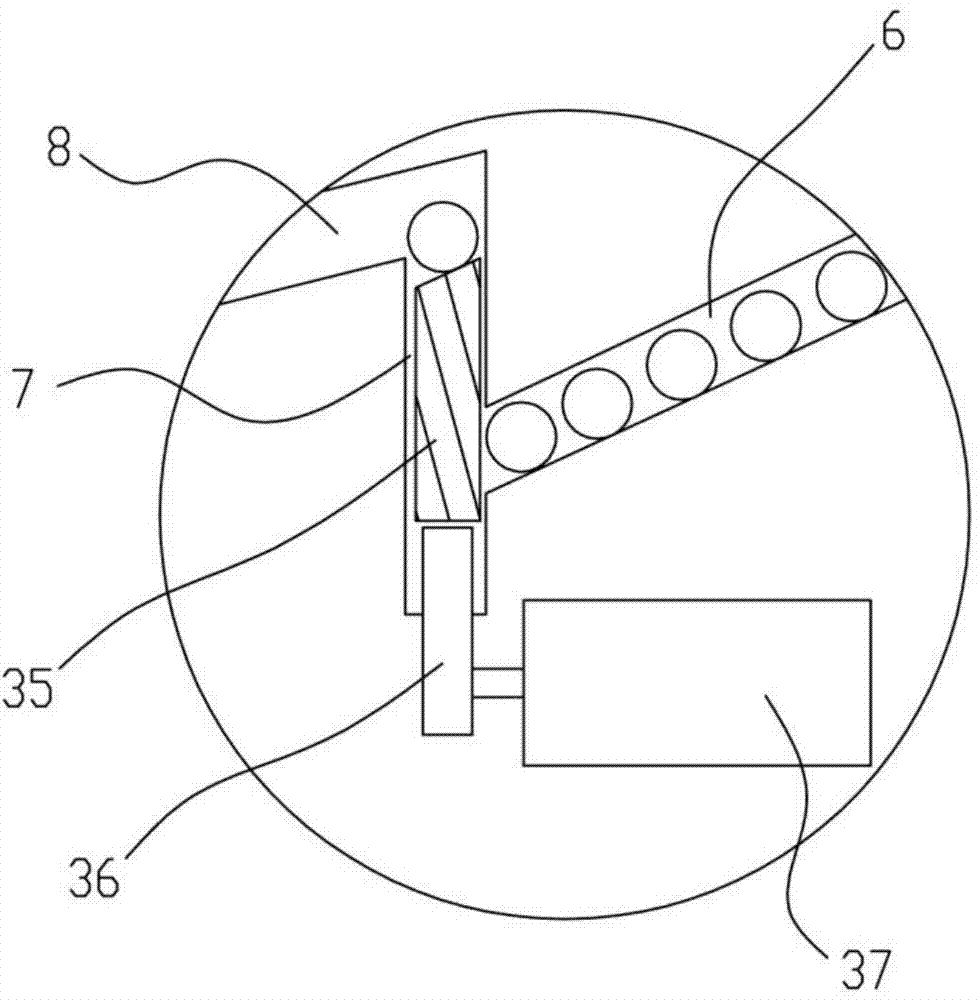

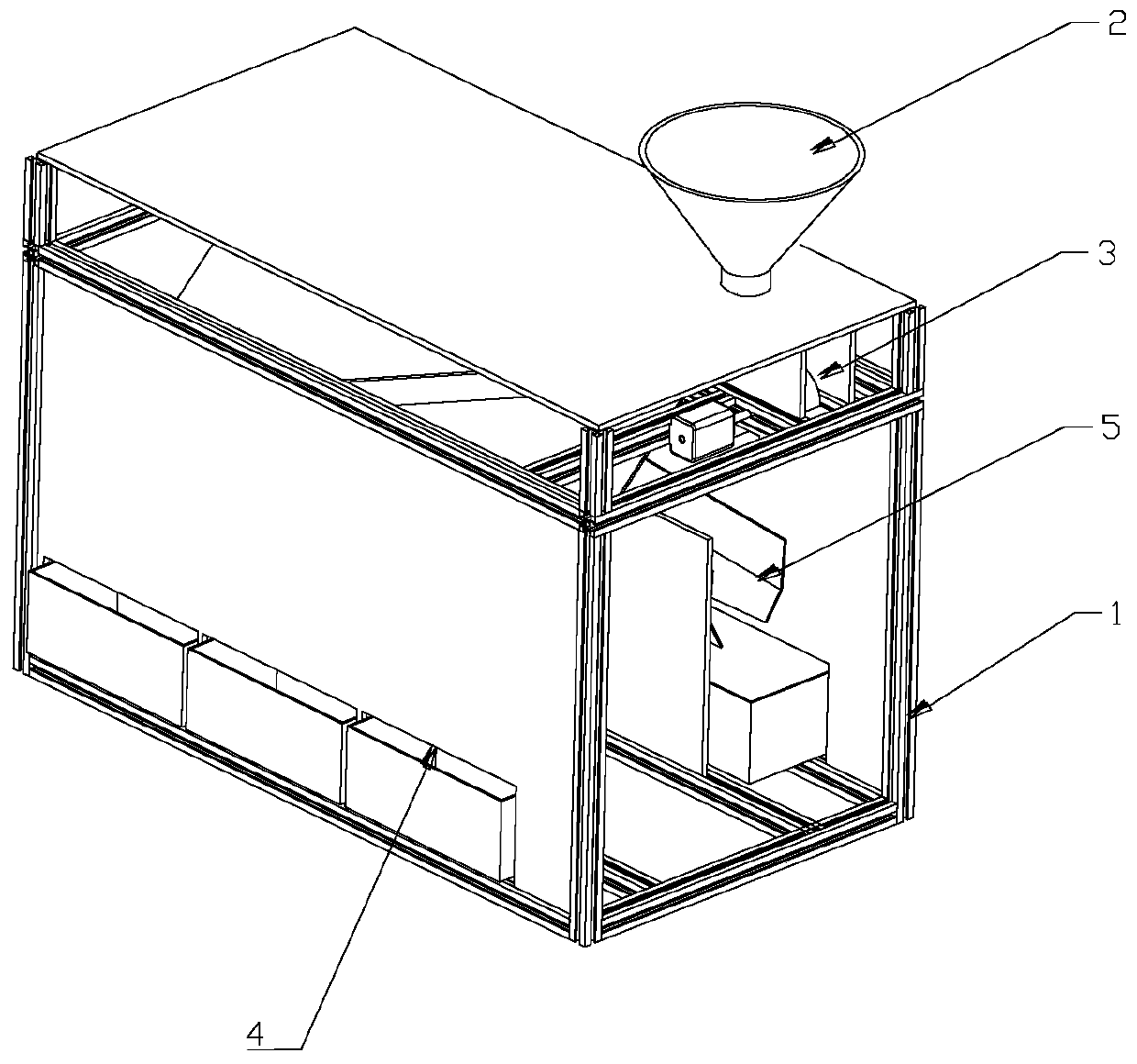

Automatic steel ball sorting device

The invention discloses an automatic steel ball sorting device, which comprises a frame, a loading bucket, a discharging bucket, a waste ball cabin, a quantitative ball supply device, a feeding box, a detection device and a control device, wherein the lower end of the loading bucket is provided with a gravity sensor; one side of the loading bucket is hinged to the frame; a single-side elevating device is arranged on the other side of the loading bucket; the loading bucket is connected with the quantitative ball supply device and the feeding box through a loading channel; the feeding box is connected with the detection device through a feeding channel; the detection device is connected with the waste ball cabin and the discharging bucket respectively through a discharging channel; a distance sensor is arranged above the discharging bucket; the lower end of the discharging bucket is provided with a horizontal elevating device. The automatic steel ball sorting device has the advantages of no need of manual attendance for a long time, lower processing cost, constant loading frequency, higher sorting efficiency and avoidance of secondary defects caused by falling of steel balls into the discharging bucket.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

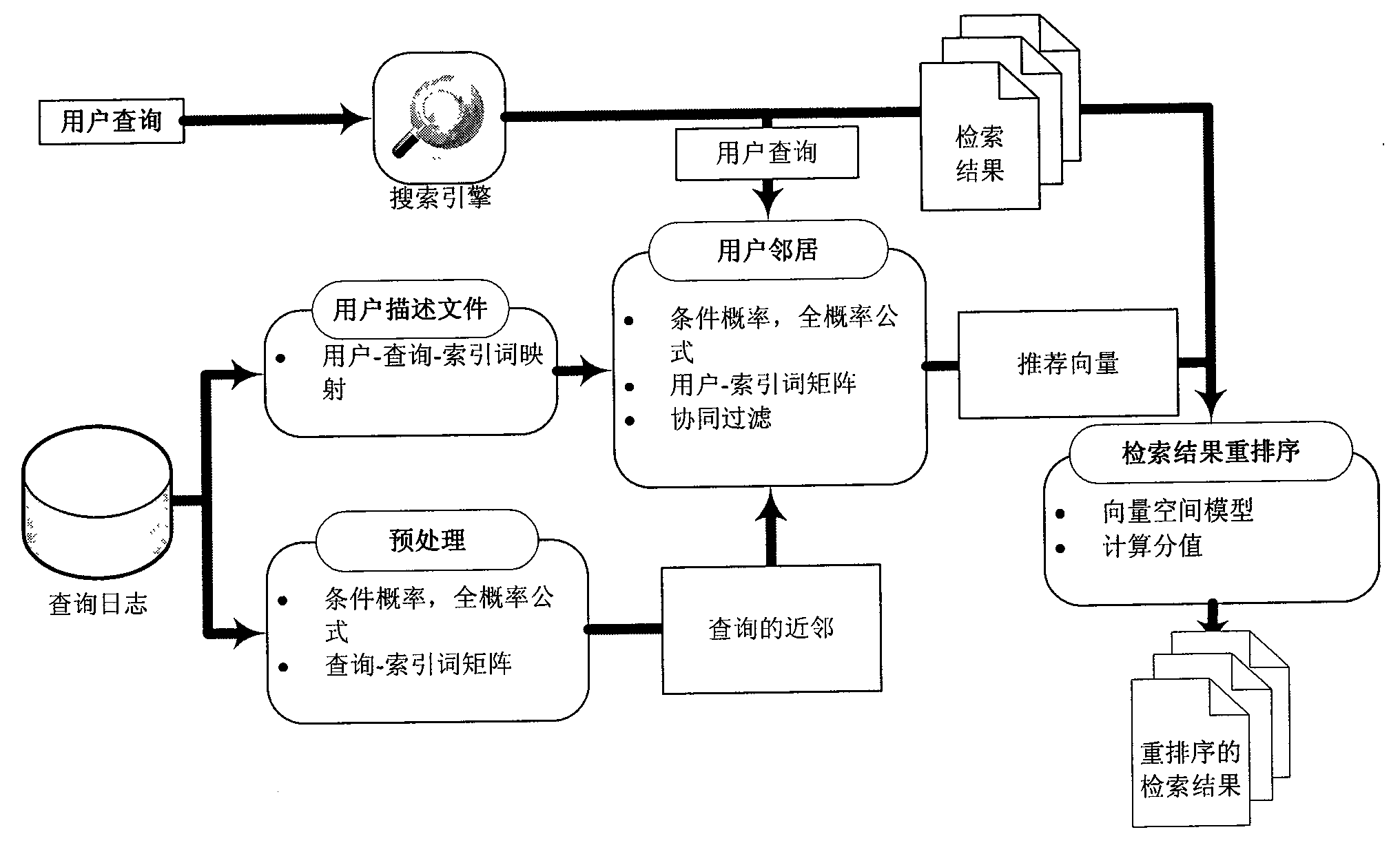

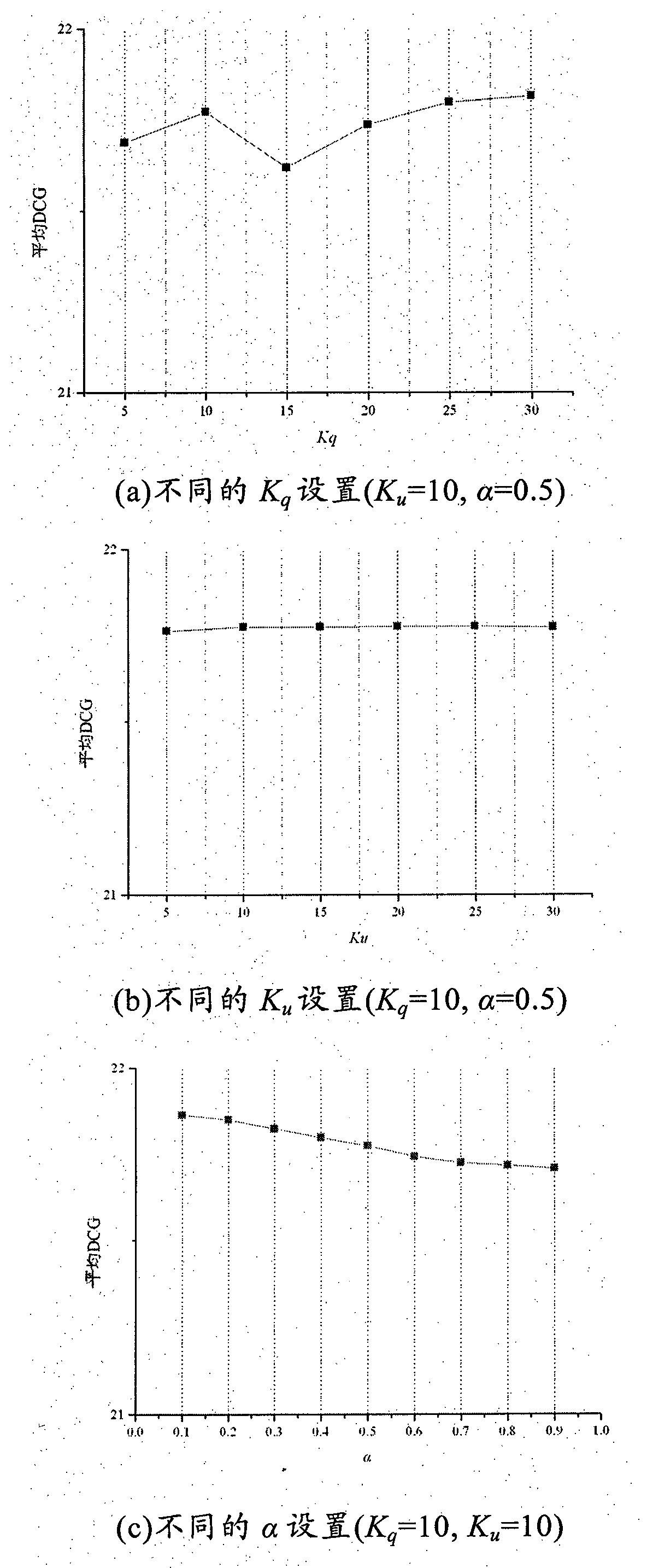

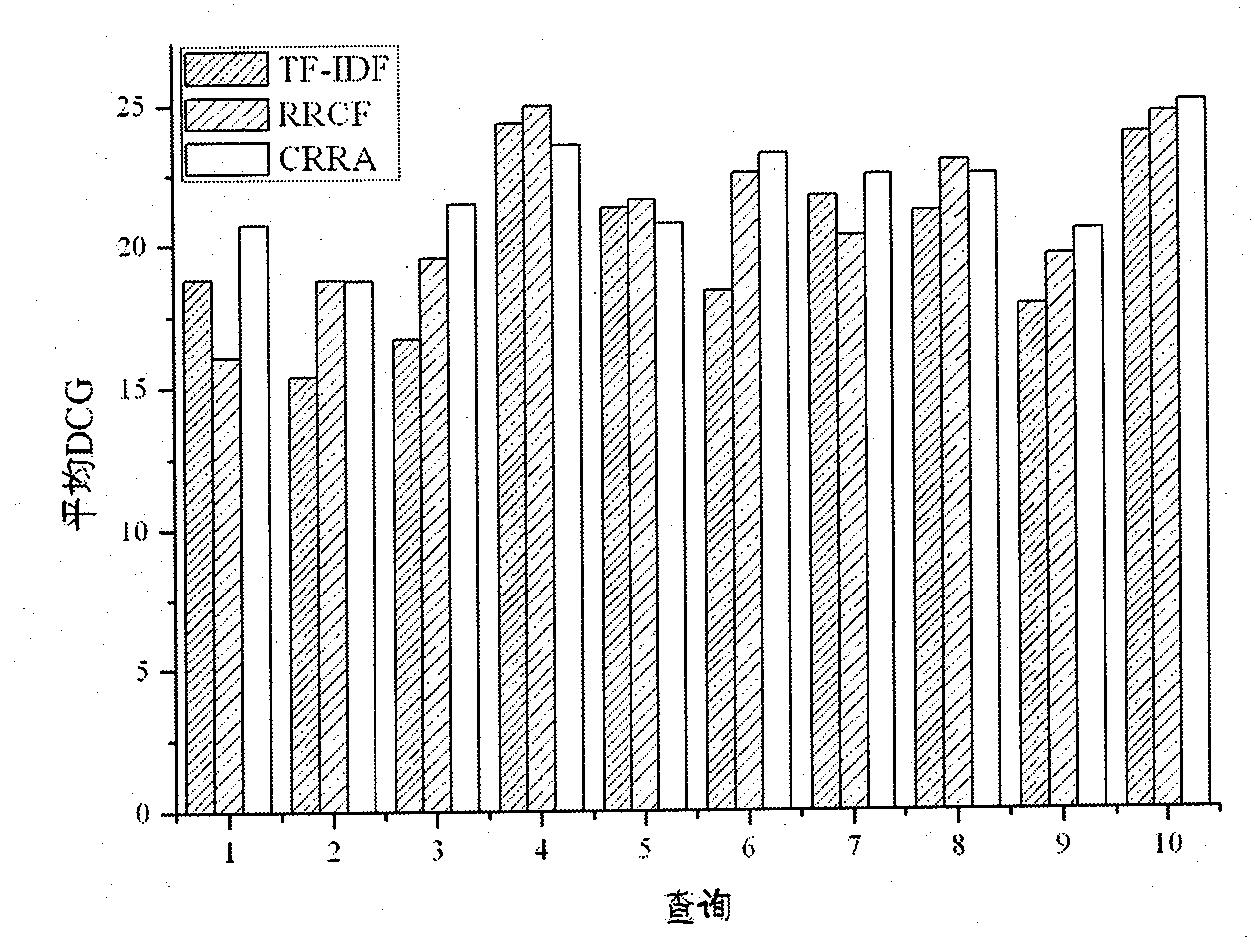

Coordinate search method used for reordering search results

InactiveCN101556603AHigh internal similarityImprove sorting qualitySpecial data processing applicationsWeb search engineRetrieval result

The invention provides a coordinate search method used for reordering search results. The method mainly aims at improving the ordering quality of search results by combining the search experience of users who have the same search intention. The method comprises four stages of pretreatment stage, user interest learning stage, community calculating stage and ordering score calculating stage. Beginning from query logs of a Web search engine, the method analyzes the search activity of users and establishes a relational matrix taken as a potential knowledge base for inquiring a characteristic word in the pretreatment stage, then learns the interest model of each user from the segment of inquiry session of users, integrates the interest models and potential knowledge bases of users, dynamically calculates the composition range of communities, and finally endows the search experience of community members with different weights according to the similarity between all members and activity users so as to regulate the sequence of search results and improve ordering quality.

Owner:BEIHANG UNIV

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

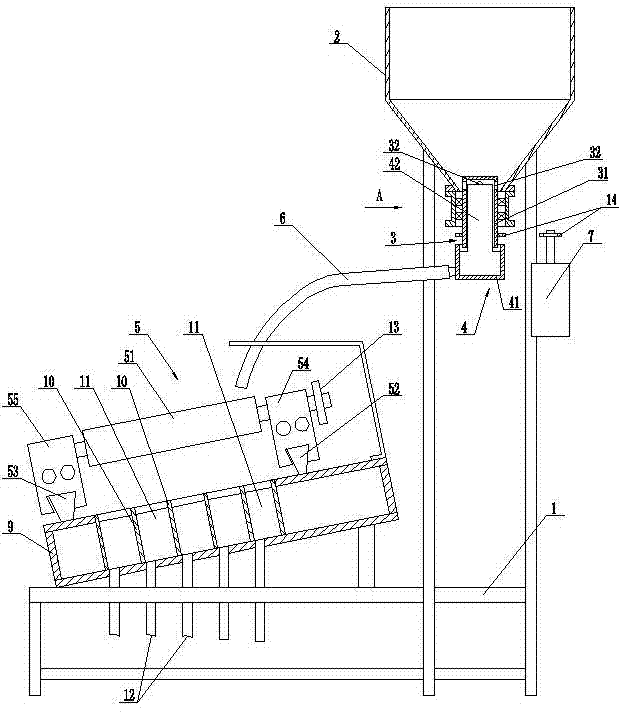

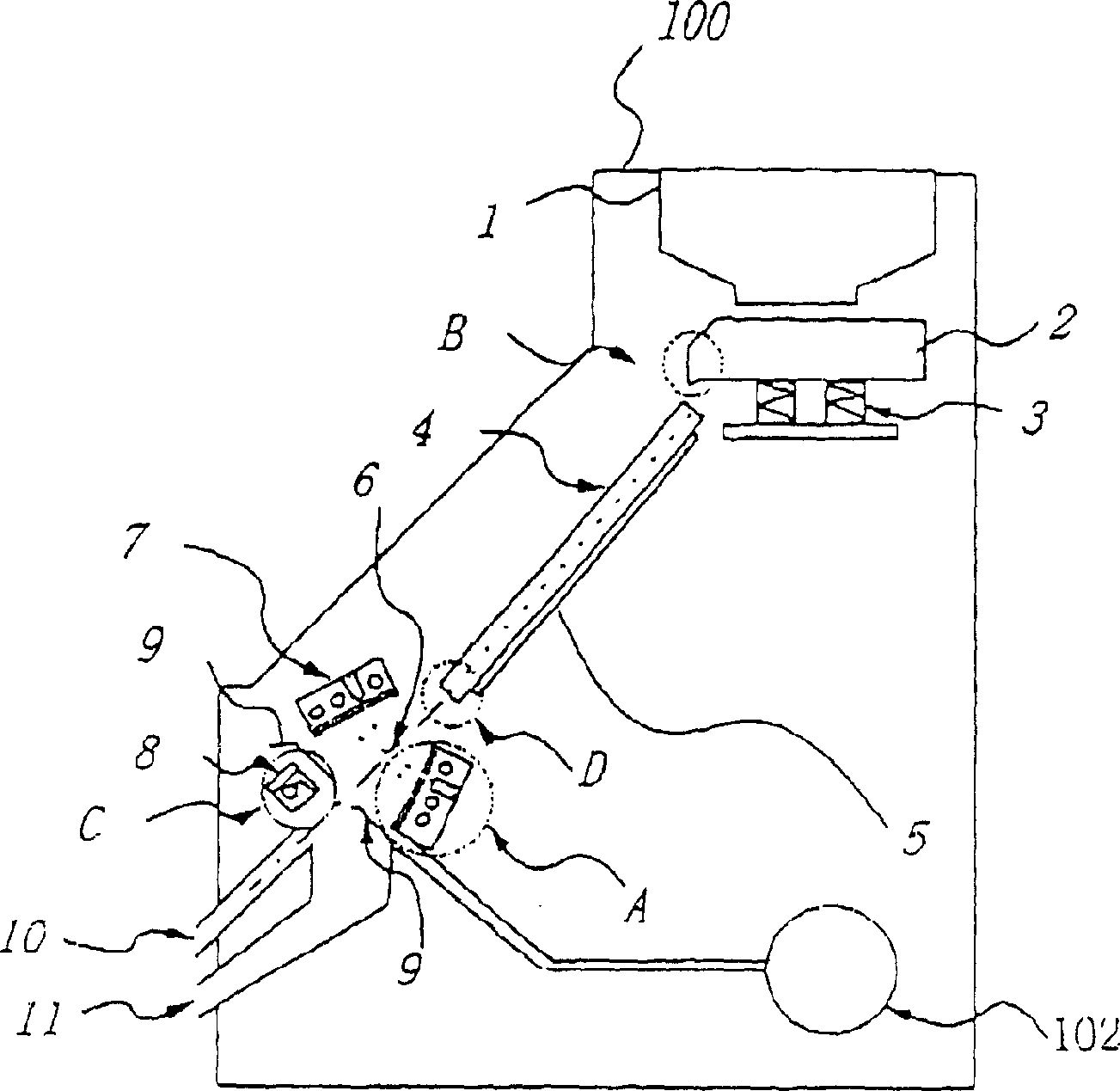

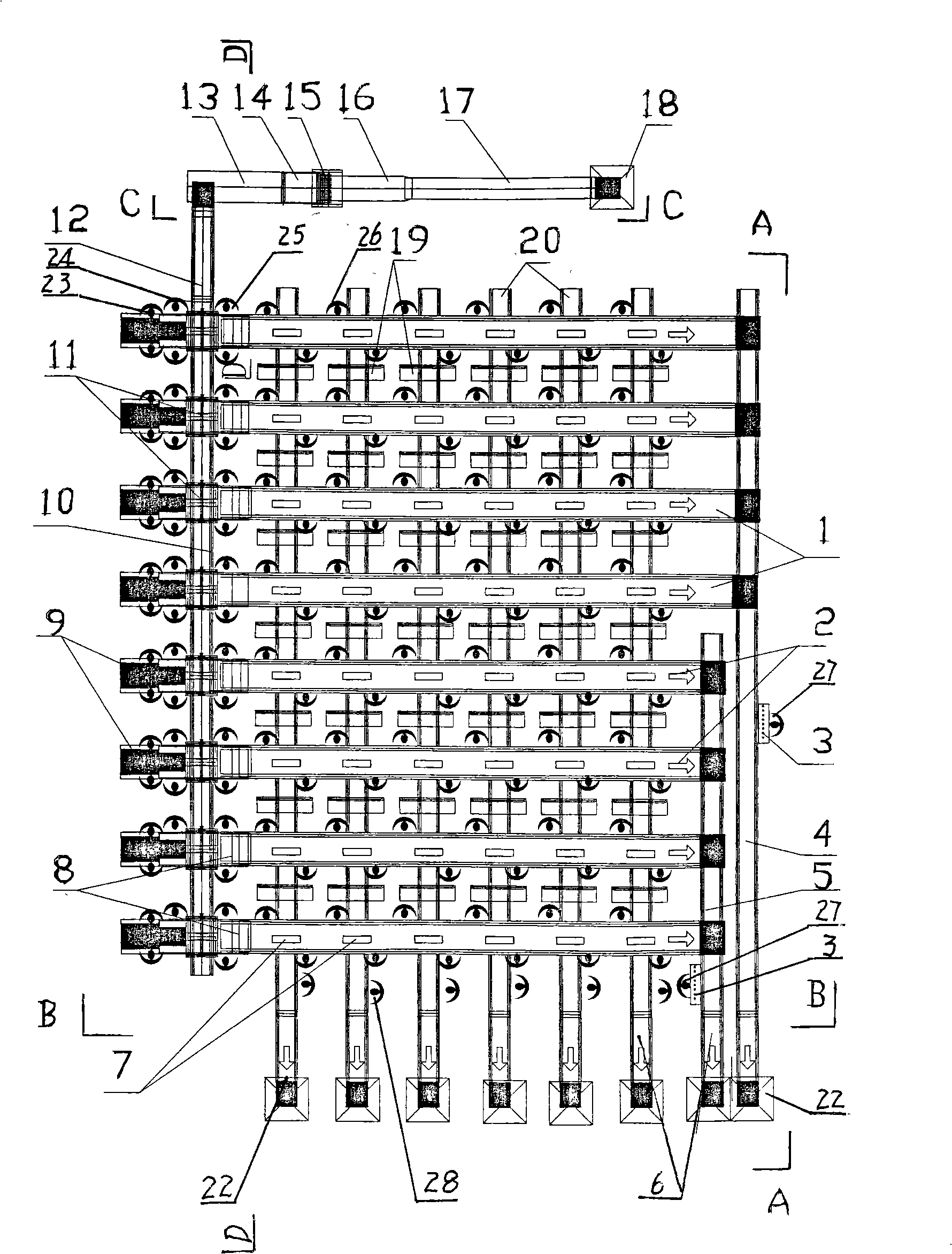

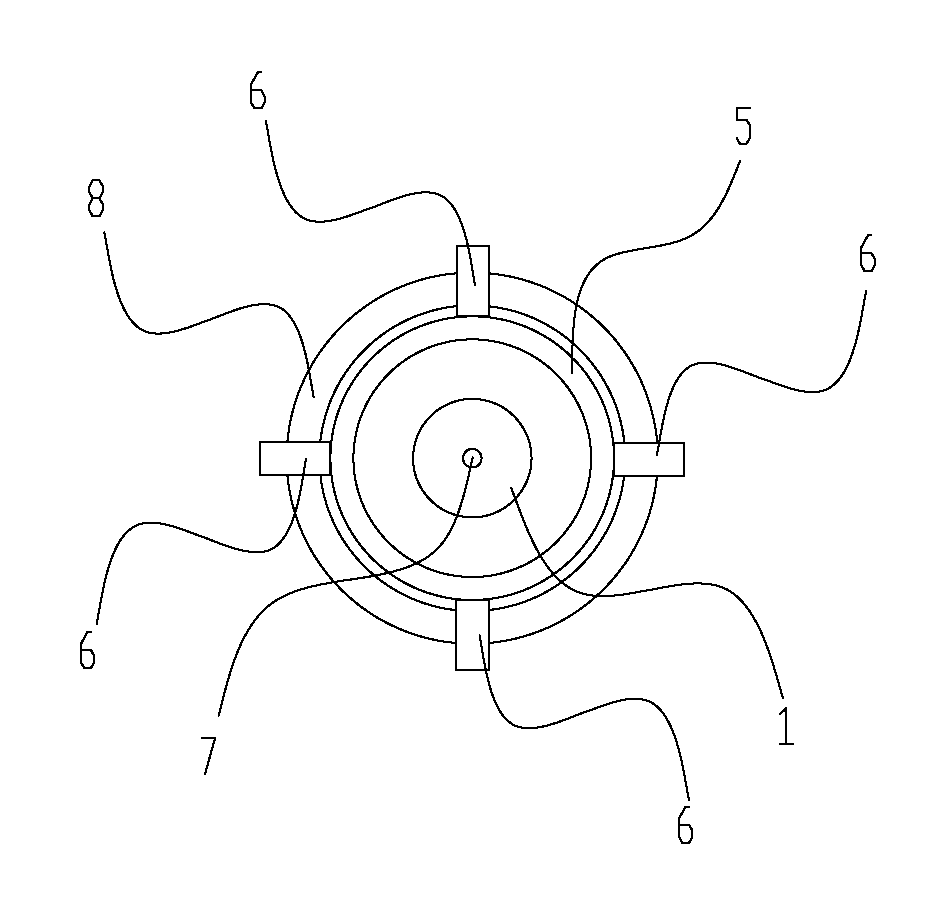

Granular material optical color sorter

InactiveCN101279321AOvercoming the problem of low yieldIncrease productionSortingControl systemEngineering

The invention relates to a grain material optical color selector which comprises a discharge chute, an image collecting system, a blowing system as well as an information treating control system. The observing area of the image collecting system is arranged on a material moving track limited by the discharge chute; the information treating control system is respectively connected with the image collecting system and the blowing system in a signaling way used for identifying the grains with different colors according the image digital signals of the image collecting system and controlling the blowing system to carry out corresponding blowing actions. The blowing system is provided with a plurality of blowing nozzles; the blowing path of each blowing nozzle passes through the material moving track limited by the discharge chute; the crossing position of the blowing paths and the material moving track is arranged below the observing area of the image collecting system. The image collecting system preferentially selects a CCD camera of area array CCD imaging or linear array CCD imaging. The color selector has large treating amount, simple structure and accurate judgment to the grains with different colors, which can automatically remove the grains with different colors in the material and is mainly used for sorting the grain materials, such as rice, etc.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

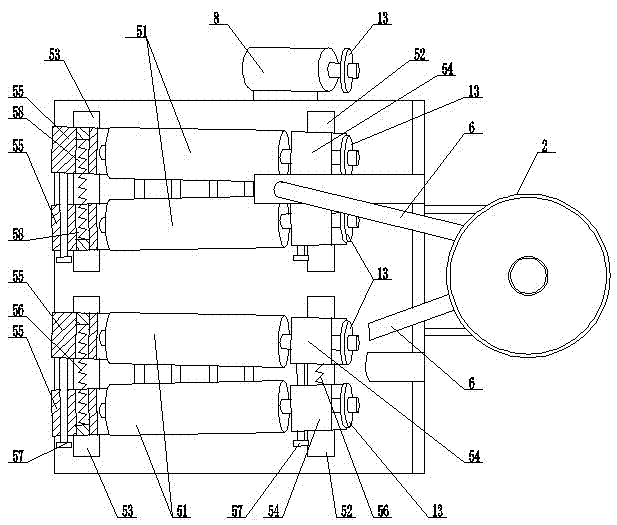

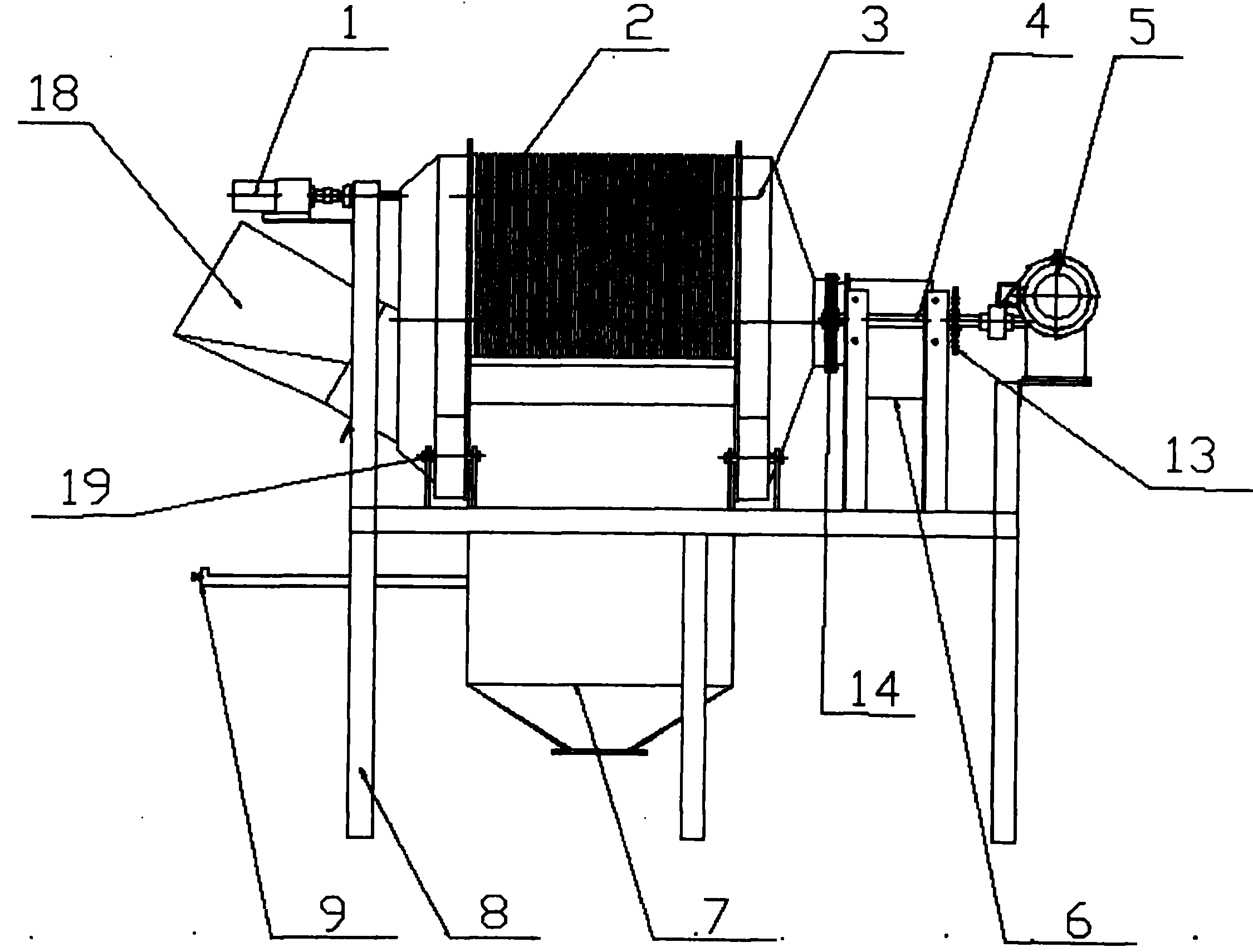

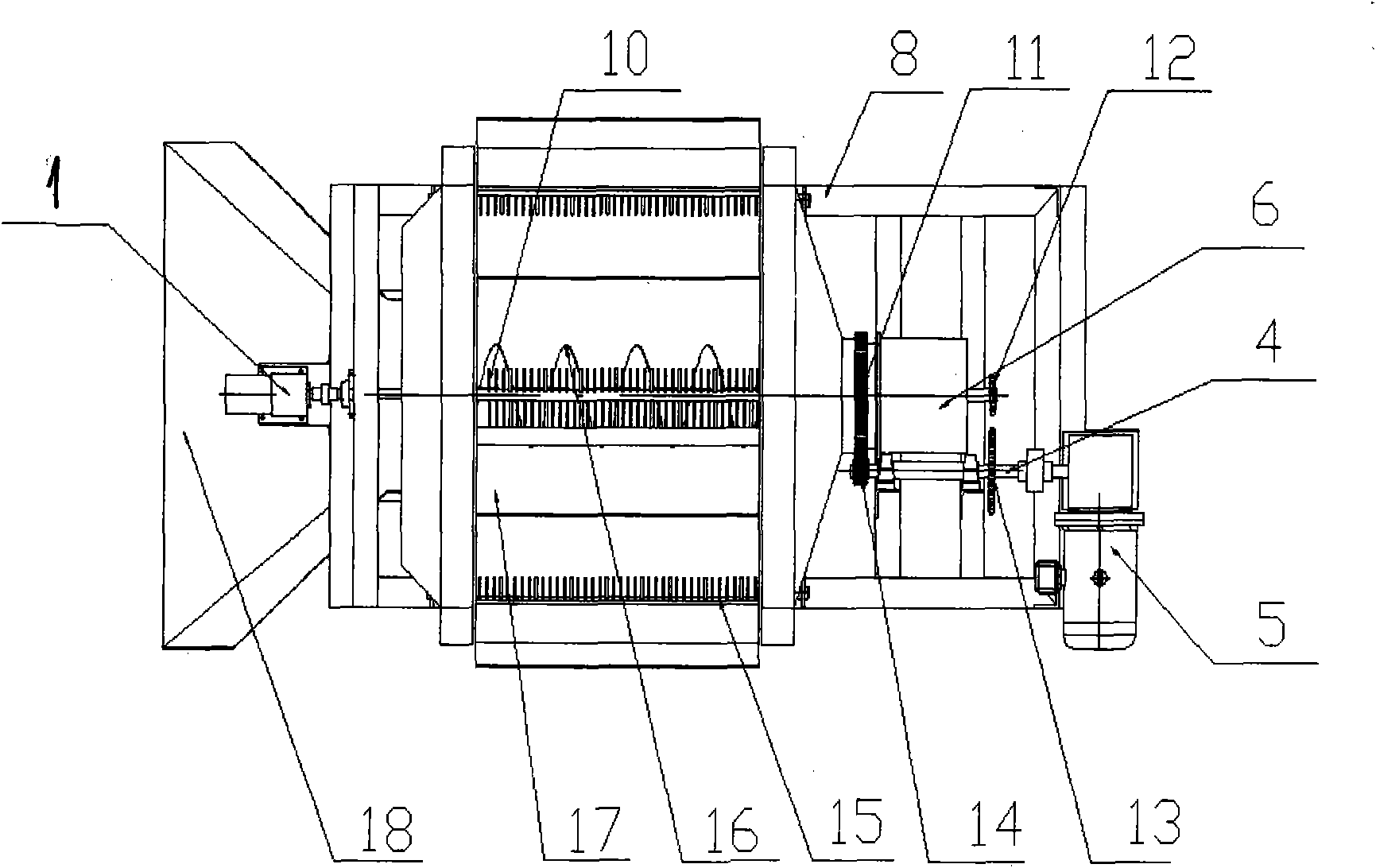

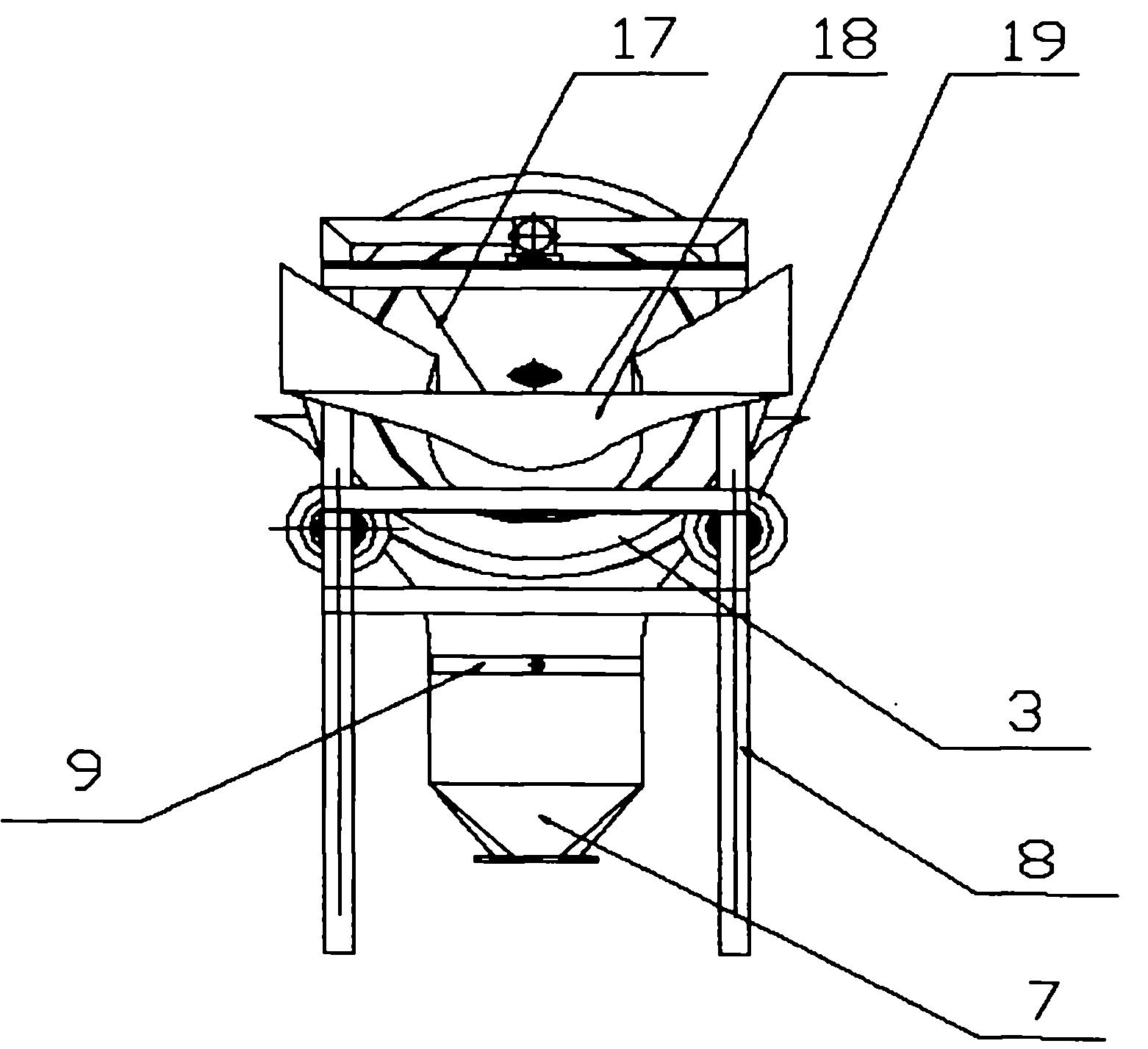

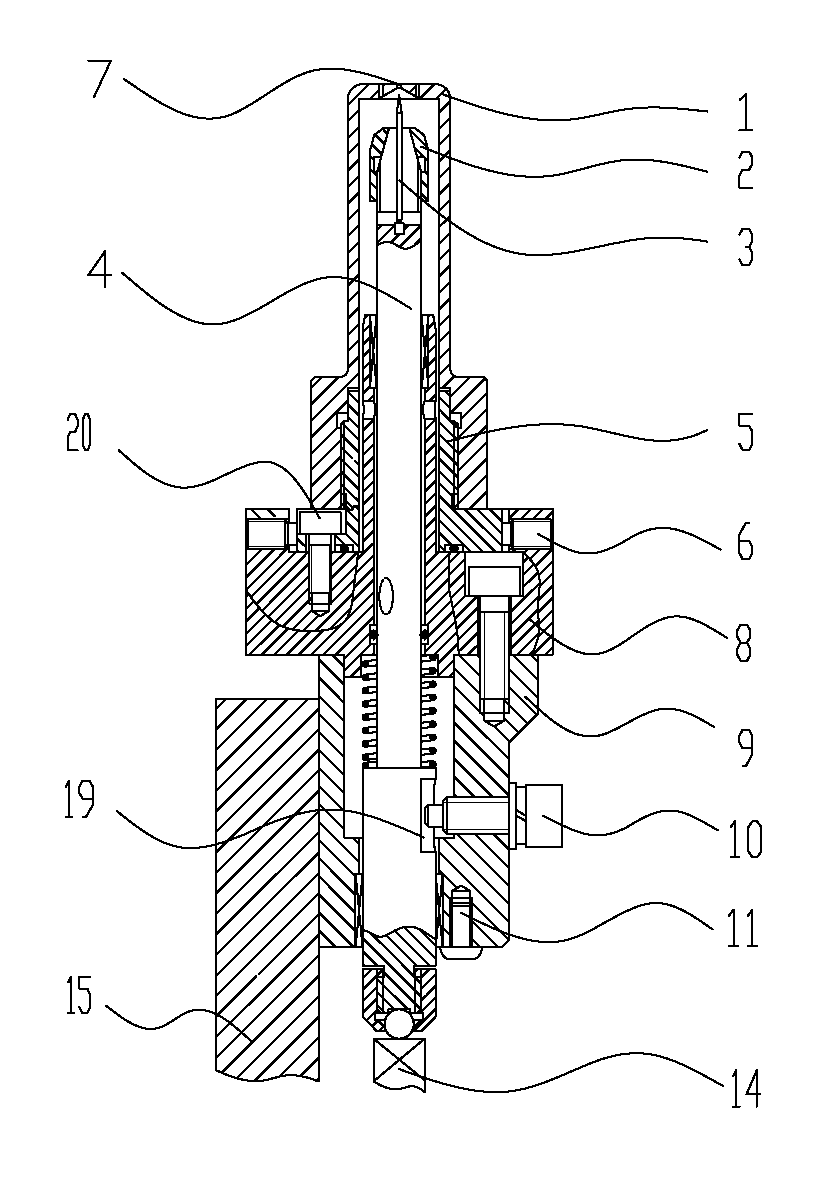

Steel ball sorting machine

The invention discloses a steel ball sorting machine. The steel ball sorting machine comprises a hopper, a rotary type ball taking device, a steel ball distributing device and at least one group of steel ball sorting devices, wherein the hopper is arranged on a stander, the rotary type ball taking device is arranged at the bottom of the hopper, the steel ball sorting devices are arranged on the stander, and steel ball delivery pipes are connected on the steel ball distributing device; the rotary type ball taking device and the steel ball sorting devices are respectively driven by a ball taking power device and a sorting power device, each steel ball sorting device comprises two rotating rollers, one ends (close to the steel ball delivery pipes) of the rotating rollers are high and the other ends of the rotating rollers are low, the two rotating rollers are both connected with the sorting power device in a power manner, two ends of each rotating roller are respectively and rotatably connected on two slide blocks capable of sliding on the stander, and gap adjusting devices capable of adjusting the size of a gap between the two rotating rollers are arranged on the two slide blocks at the same end; and a ball receiving groove is formed below the steel ball sorting devices, a plurality of ball receiving regions sequentially arrayed along the length directions of the rotating rollers are arranged in the ball receiving groove. The steel ball sorting machine is simple in structure, high in production efficiency, high in sorting quality and good in sorting effect.

Owner:WULIAN DADI PRECISION STEEL BALL CO LTD

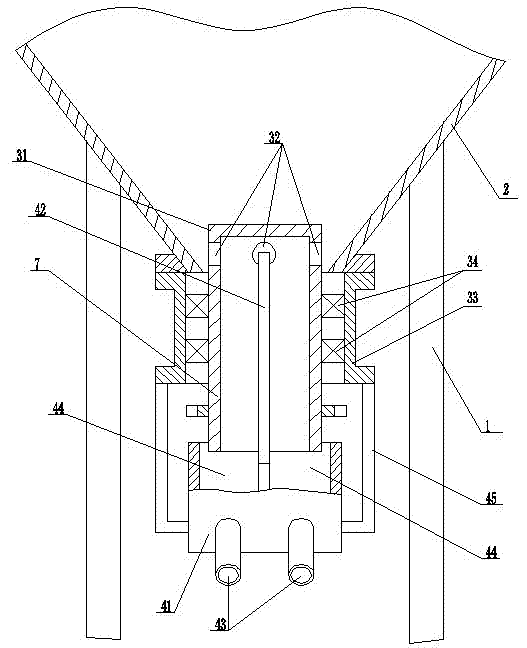

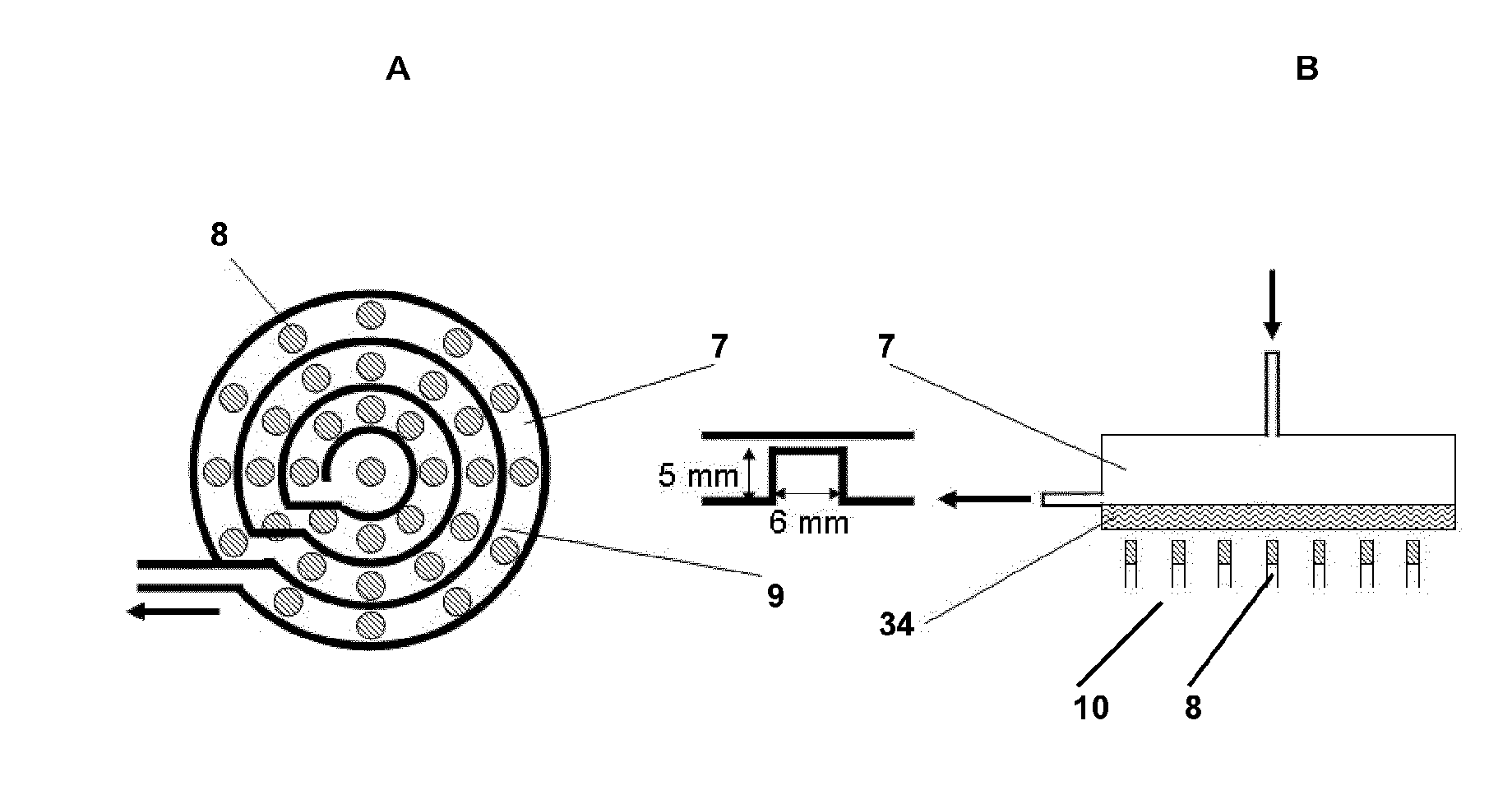

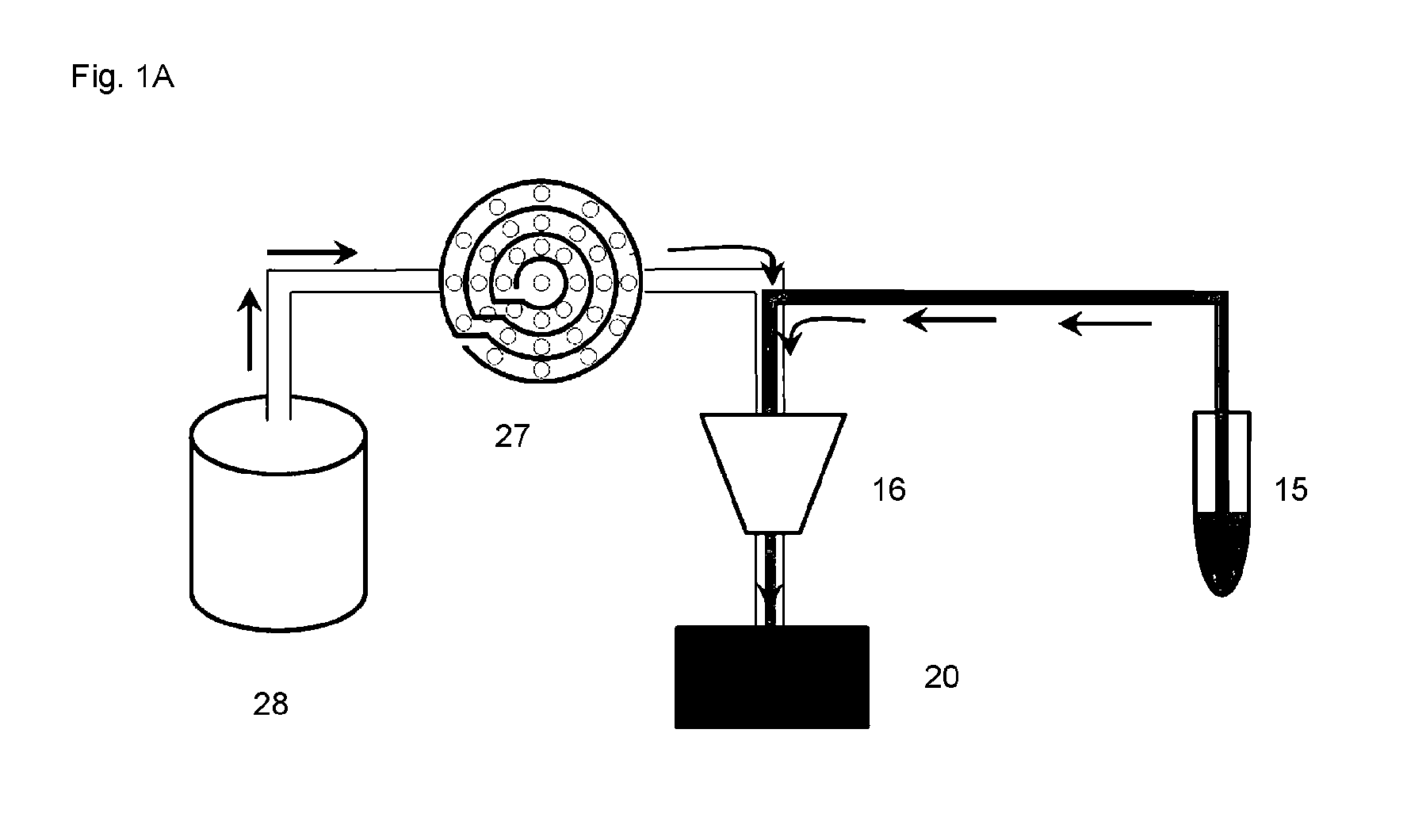

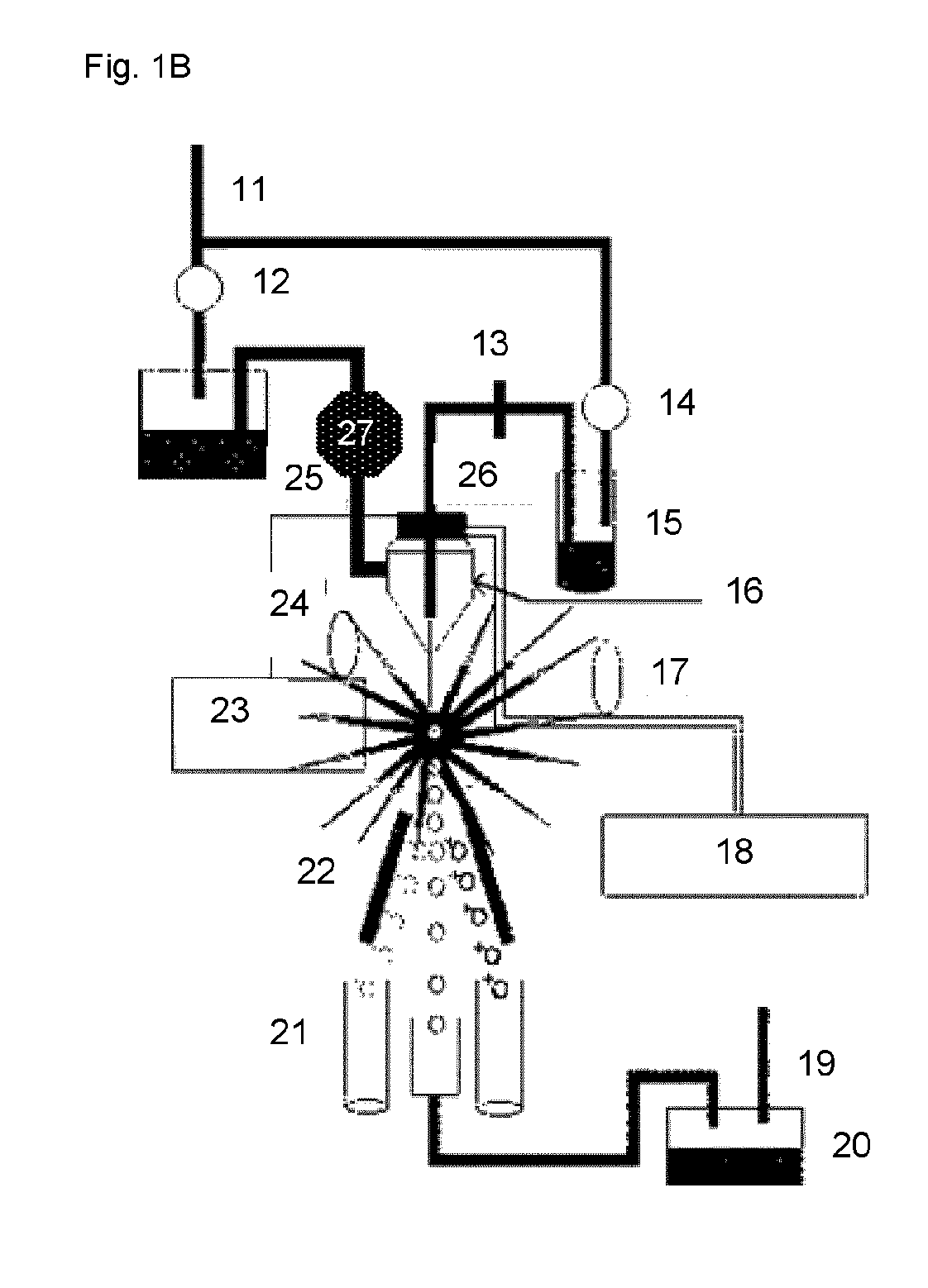

Flow cytometer disinfection module

ActiveUS20140050612A1Easily be attached to existing cytometerDamaging microorganismScattering properties measurementsMaterial analysis by transmitting radiationMedicineLight source

A flow cytometer disinfection module is useful for disinfecting a sheath fluid in a flow cytometer. The module includes a flow cell and at least one UV-C and / or UV-B light source. The UV-C and / or UV-B light source is disposed about the cell and irradiates a sheath fluid passing through the cell

Owner:DEUT RHEUMA FORSCHUNGSZENT BERLIN +1

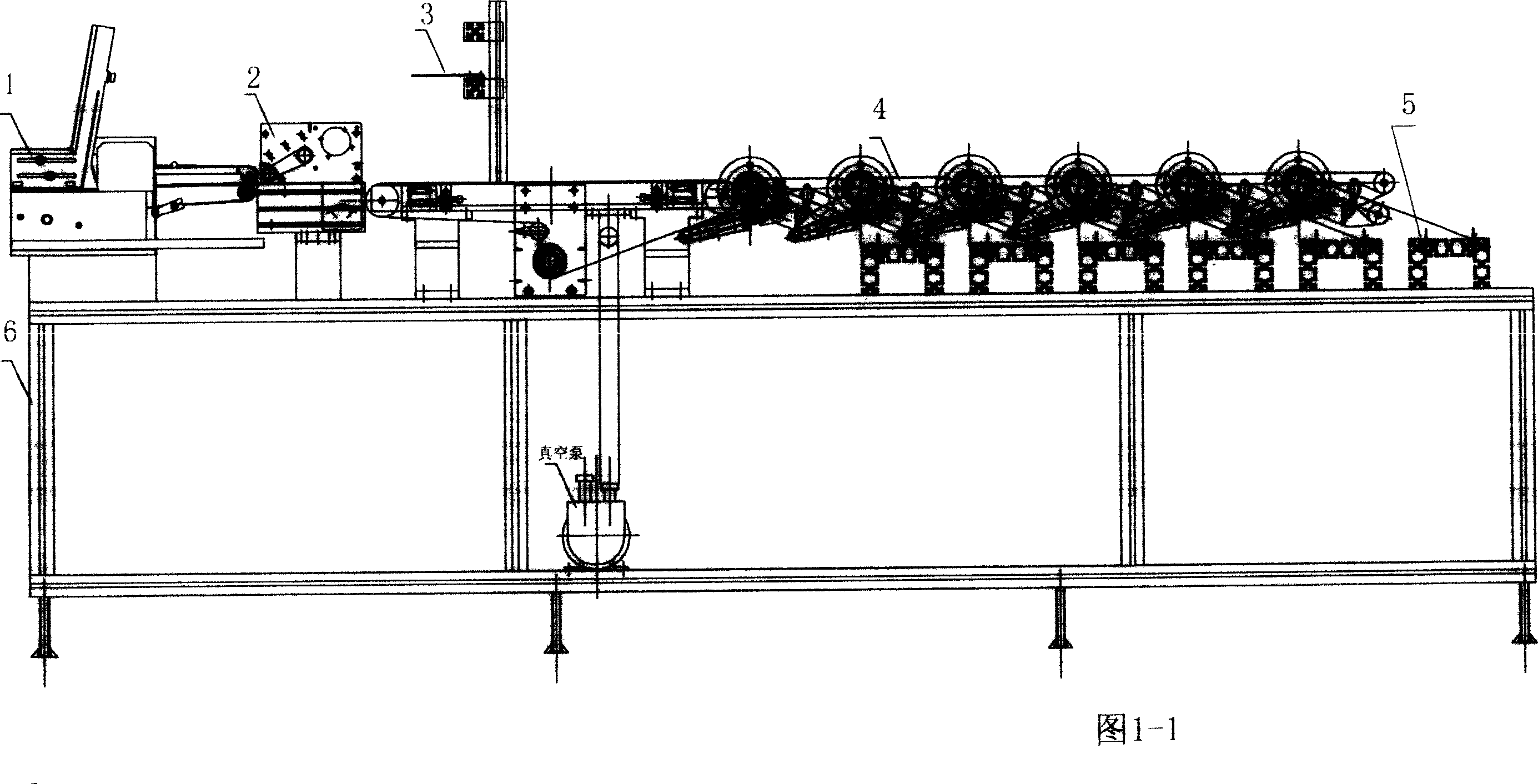

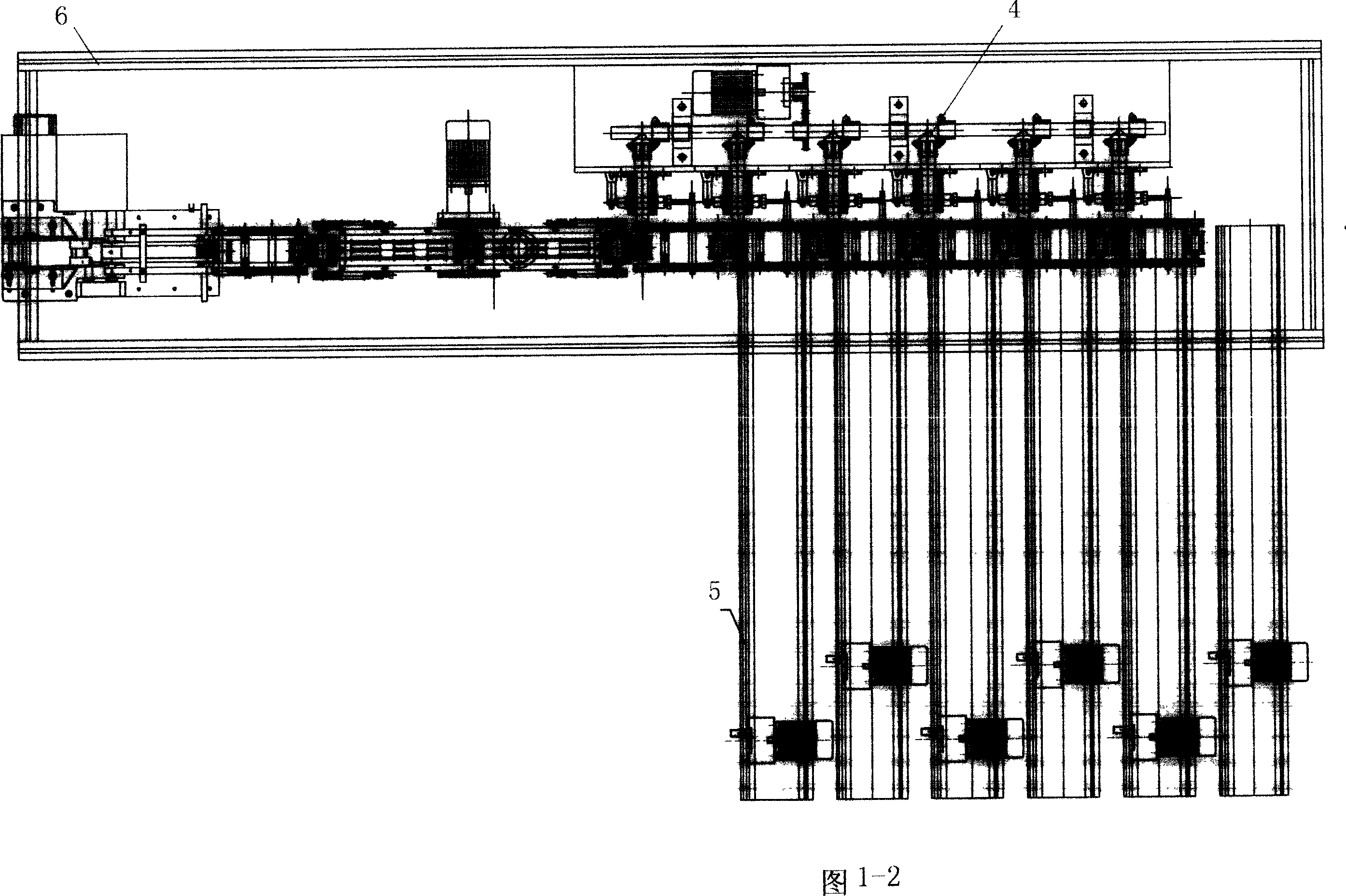

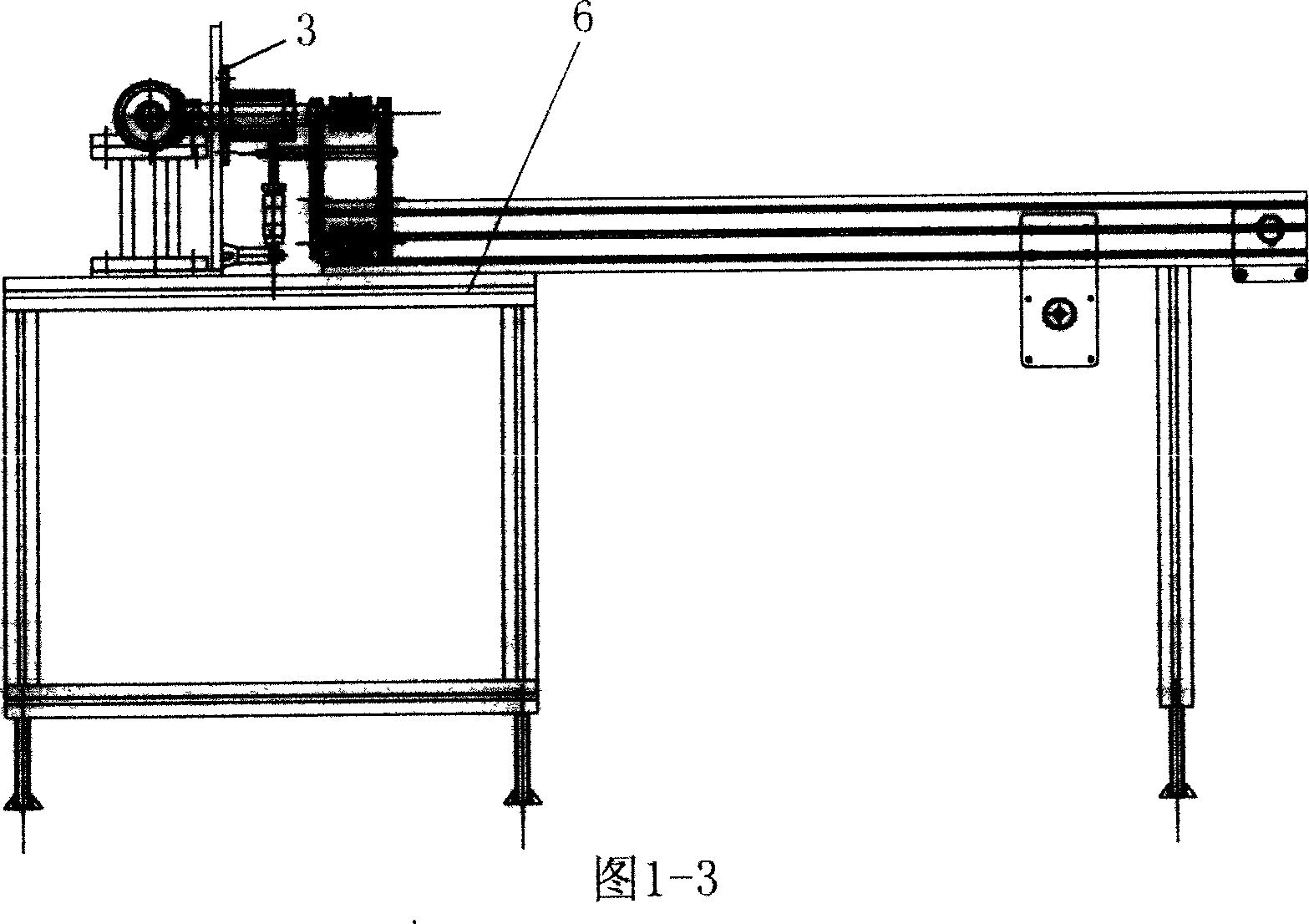

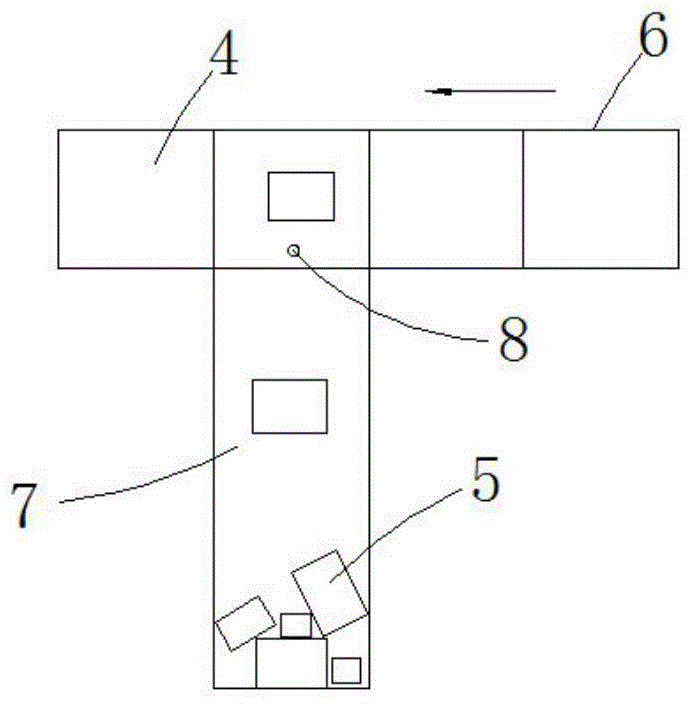

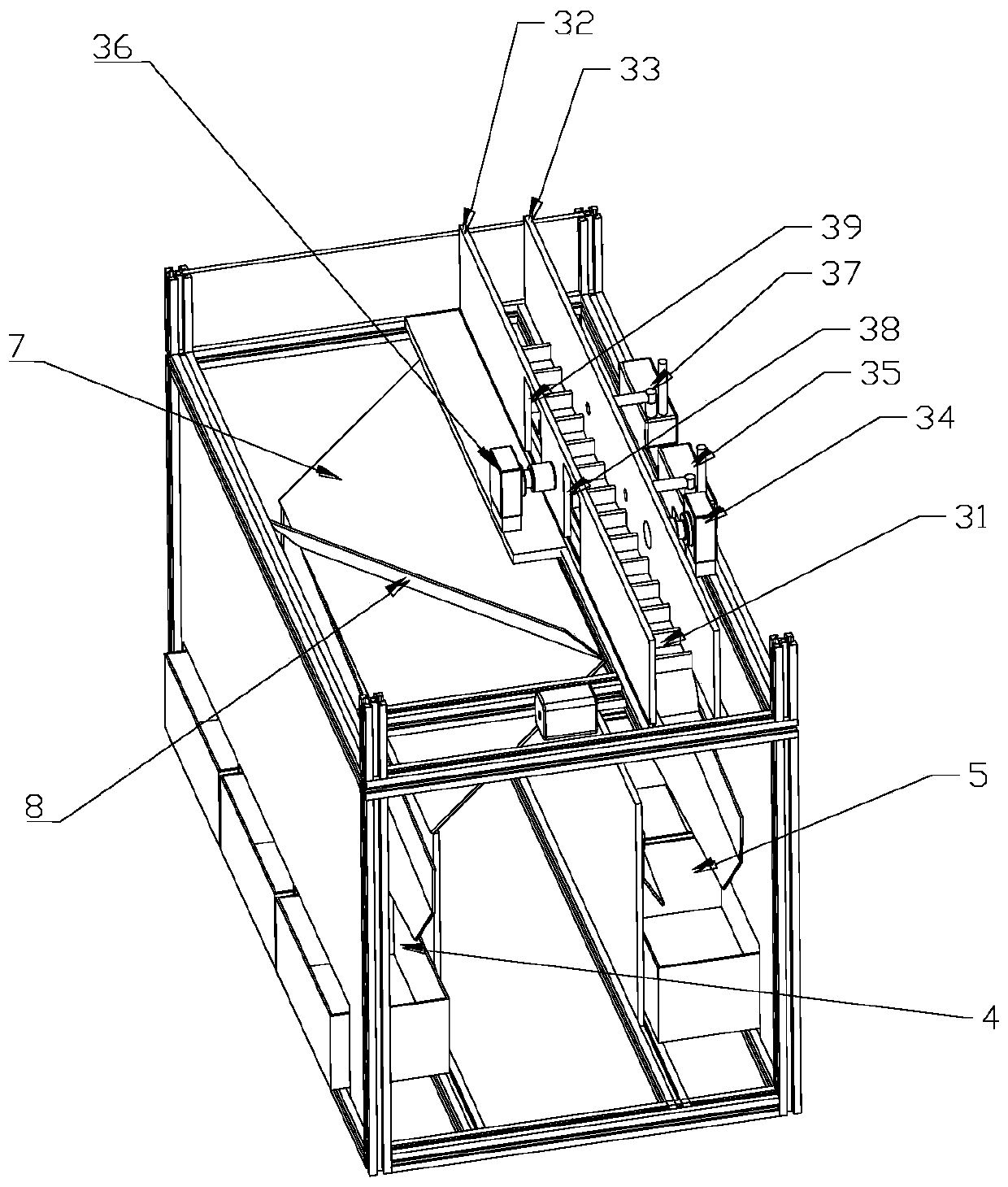

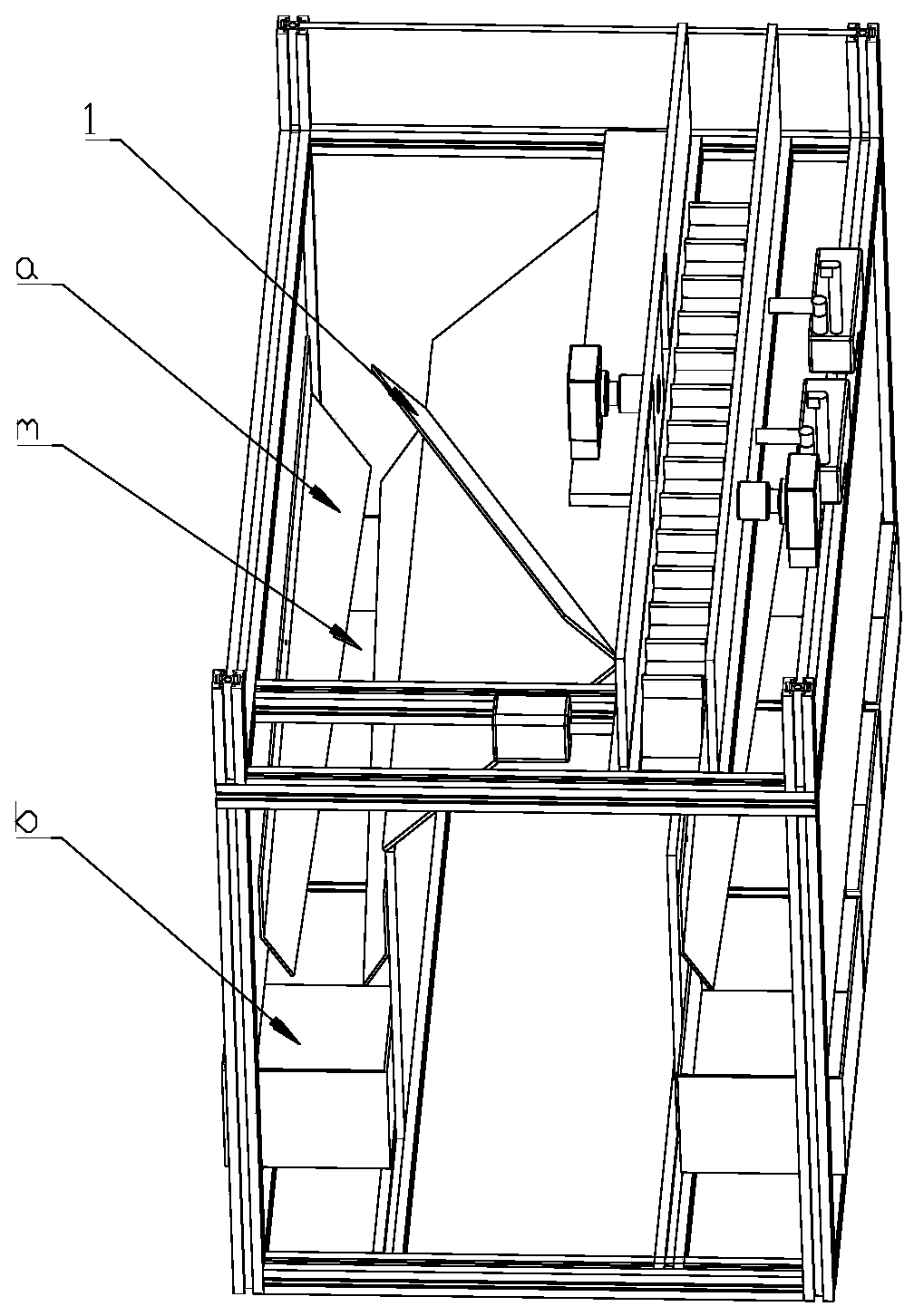

Extensible inspection production equipment for smart cards

InactiveCN101049595AImprove sorting efficiencyGood sorting qualitySortingProduction lineHigh volume manufacturing

An apparatus for sorting the intelligent cards with same size but different patterns is composed of a machine frame, a card feeder for feeding said intelligent cards one by one, a duplicate card rejecting unit, a pattern quality tester for testing the quality of the pattern on each card, a card sorting unit for sorting the cards according to their patterns, and a card receiver for receiving the sorted cards and stacking them.

Owner:GUANGZHOU SANTUO IDENTIFICATION TECH CO LTD

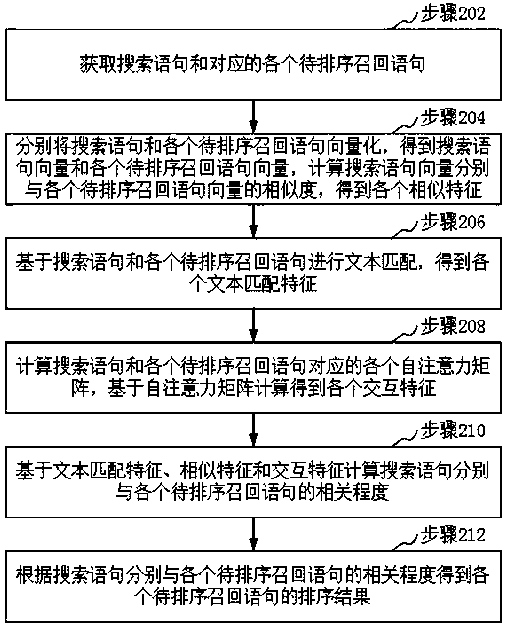

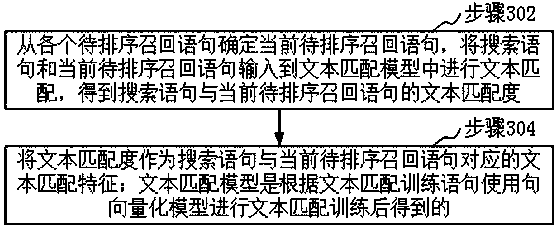

Search sorting method and device, computer equipment and storage medium

ActiveCN111538908AHigh precisionImprove sorting qualityCharacter and pattern recognitionNatural language data processingTheoretical computer scienceEngineering

The invention relates to a search sorting method and device, computer equipment and a storage medium. The method comprises the steps of obtaining a search statement and corresponding to-be-sorted recall statements; vectorizing the search statement and each to-be-sorted recall statement to obtain a search statement vector and each to-be-sorted recall statement vector, and calculating the similaritybetween the search statement vector and each to-be-sorted recall statement vector to obtain each similar feature; performing text matching based on the search statement and each to-be-sorted recall statement to obtain each text matching feature; calculating each self-attention matrix corresponding to the search statement and each to-be-sorted recall statement, and performing calculation based onthe self-attention matrixes to obtain each interaction feature; based on the text matching features, the similarity features and the interaction features, calculating the correlation degree between the search statement and each to-be-sorted recall statement; and obtaining a sorting result of each to-be-sorted recall statement according to the correlation degree. By adopting the method, the accuracy of the sorting result can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

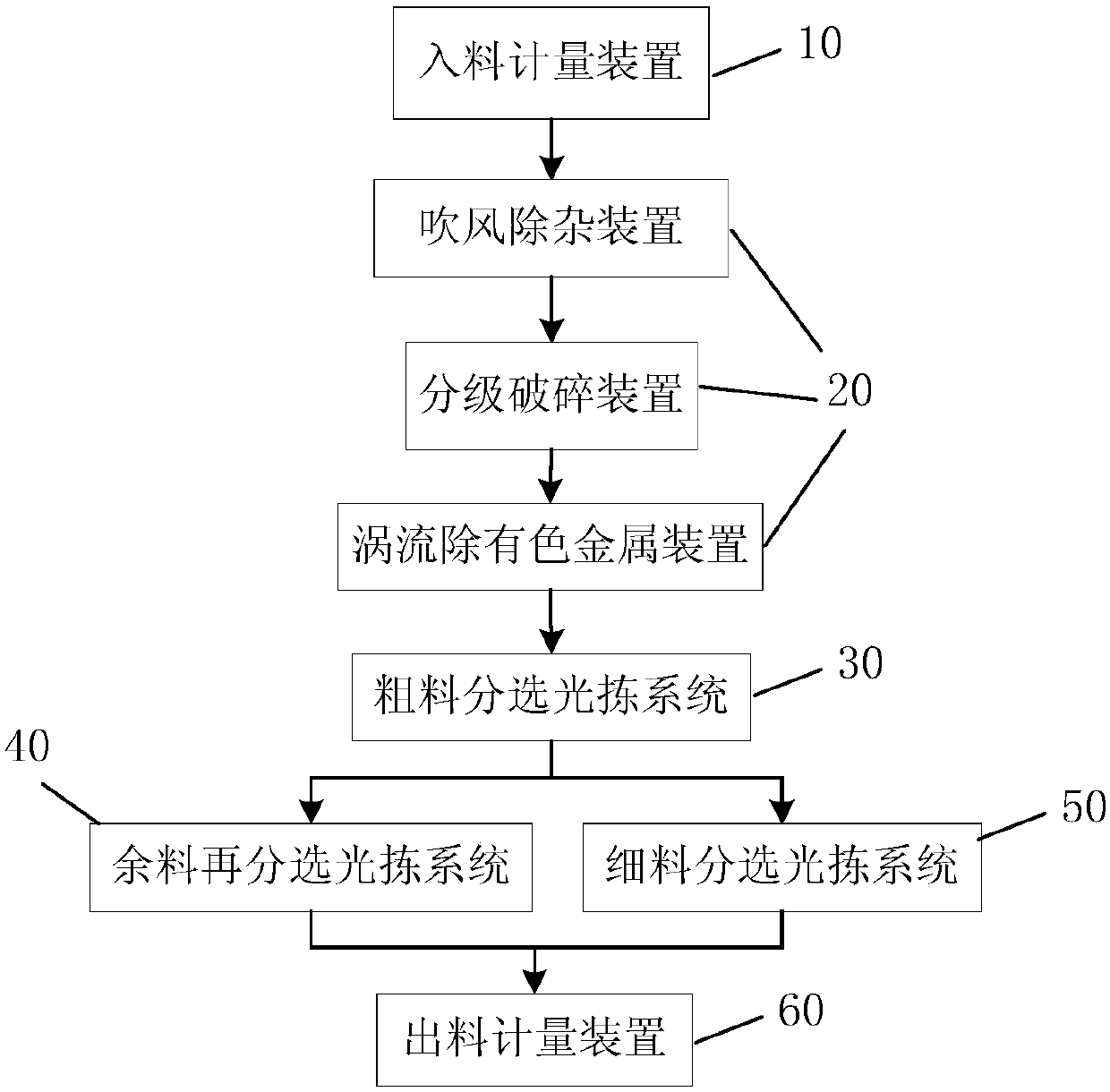

Automatic waste glass sorting system and control method thereof

ActiveCN107755410AImprove sorting qualityImprove sorting efficiencySievingGas current separationNonferrous metalProcess engineering

The invention discloses an automatic waste glass sorting system and a control method thereof. The automatic waste glass sorting system comprises a feed metering device, a crushing and impurity removing system, a coarse waste optical sorting system, a residue optical sorting system, a fine waste separating and sorting system and a discharge metering device which are connected in sequence, wherein the crushing and impurity removing system comprises a graded crushing device; a graded vibrating screen in the graded crushing device separates materials and transports the material to the graded crushing device; a winnowing impurity removal device is arranged at the front end of the graded crushing device; a vortex nonferrous metal removing device is arranged at the rear end of the graded crushingdevice; the coarse waste optical sorting system is used for classifying the impurity-removed materials according to different particle specifications and respectively feeding the classified materialsto the residue optical sorting system or the fine waste separating and sorting system respectively; and a label removing machine is arranged between the coarse waste optical sorting system and the residue optical sorting system. According to the automatic waste glass sorting system disclosed by the invention, multiple different specifications can be subdivided, all the impurities and sundries canbe removed, the sorting quality is greatly improved, and the sorting efficiency and capacity are improved.

Owner:上海燕龙基再生资源利用有限公司

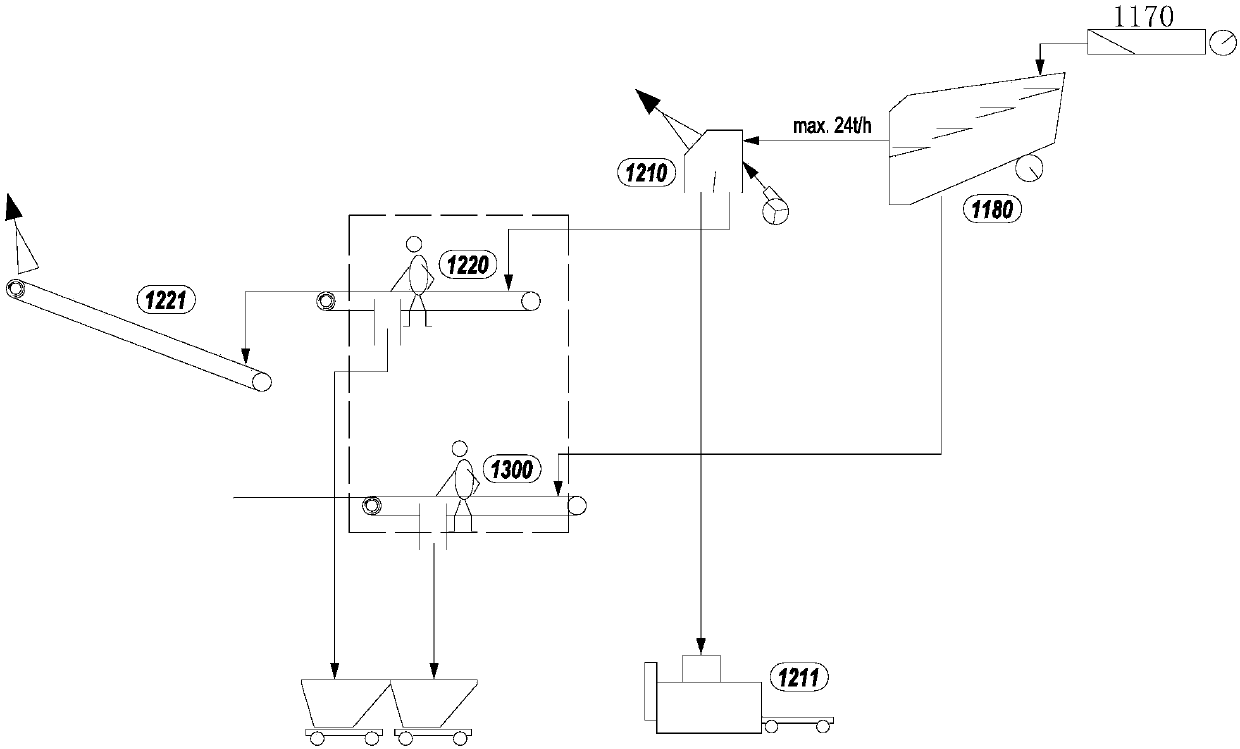

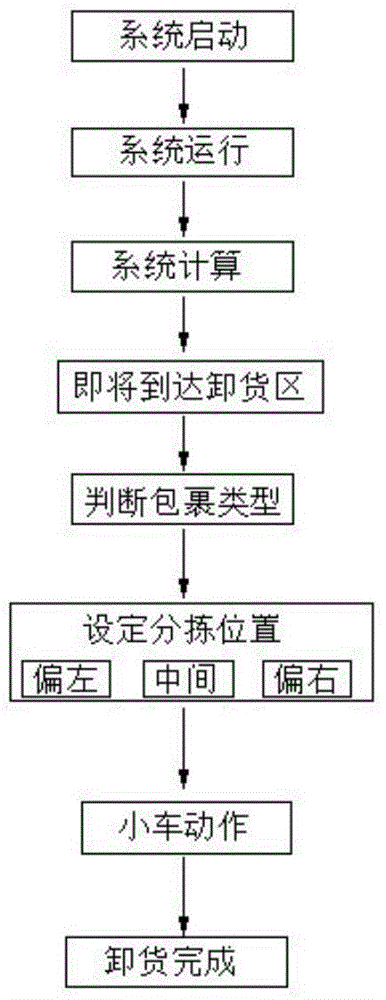

Unloading control method for crossed belt sorting machine

The invention discloses an unloading control method for a crossed belt sorting machine. A trolley with phototubes, a conveying main line, a control system, a supplied parcel conveying belt provided with gratings and phototubes and a parcel receiving area are included. The supplied parcel conveying belt is used for throwing parcels and transporting the parcels to the trolley. The trolley is used for receiving the parcels and transporting the parcels to the parcel receiving area. The conveying main line is used for driving the trolley to run. The gratings are used for detecting the center positions of the parcels and collecting size and weight information of the parcels. The phototubes are used for detecting the positions of the parcels. The control system is used for collecting and processing detection information of the gratings and the phototubes, adjusting the speed of the supplied parcel conveying belt, setting the parcel sorting position, setting the starting time point and the starting speed of the trolley during unloading and driving the trolley to act. The parcel receiving area is used for receiving the parcels unloaded from the trolley. By means of the unloading control method for the crossed belt sorting machine, mutual collisions and extrusion between the parcels which have the great disparity in weight and size during unloading are reduced, the damage rate of the parcels is reduced, and the sorting quality is improved.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

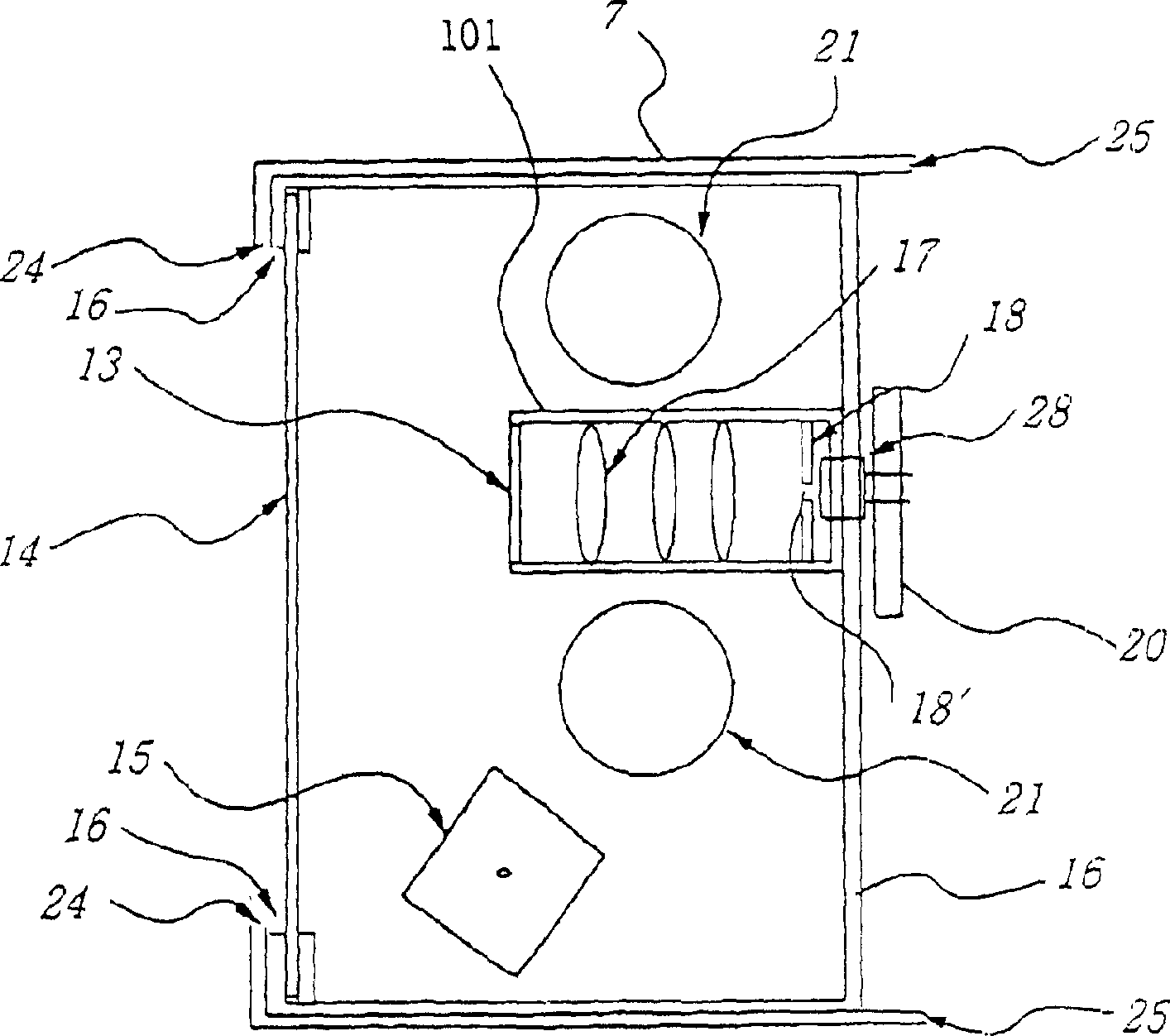

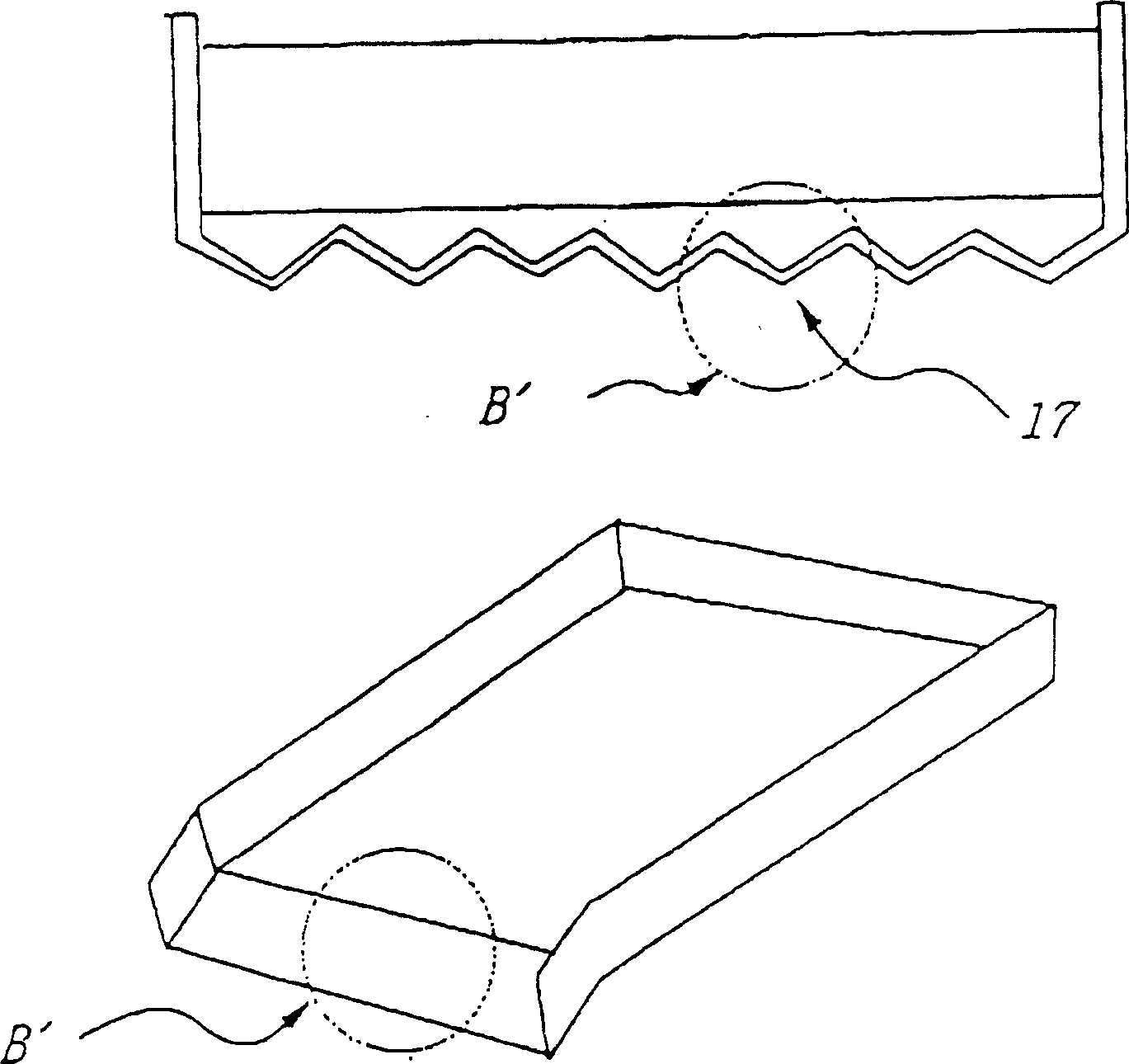

Color sorting machine

The present invention discloses a color sorting machine. Said machine includes a hopper which is positioned in upper most portion and through which the granular material can be charged; a feeder which is positioned under the hopper and is formed into a guide recessed groove; a downward slope connected with vibrator positioned in rear portion; an U-shaped slope which can make the detected material uniformly pass through the guide recessed groove and slide; an air spraying system for cleaning transparent plate of detection portion; and a slot-like sprayer nozzle, said nozzle can make the detected material be accurately and effectively blown out by means of air. Said color sorting machine has high selective accuracy, stable production efficiency and high quality.

Owner:AMECS

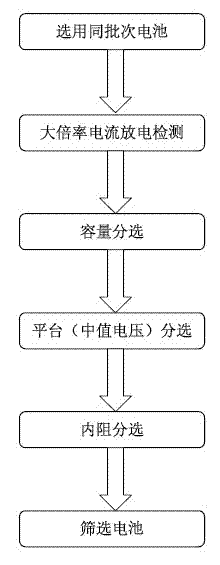

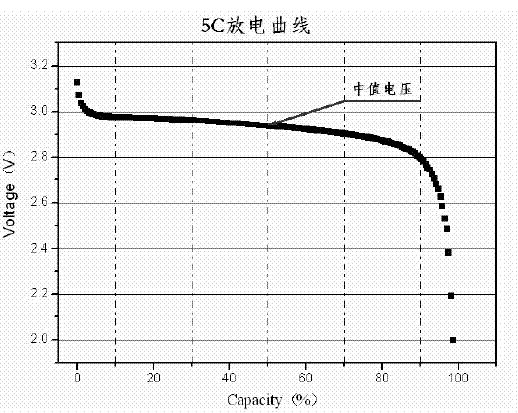

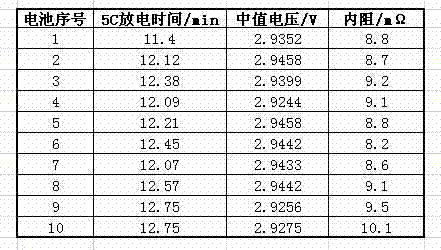

Method for separating secondary batteries

ActiveCN103084342ASimplify the sorting processSimplify sorting equipmentSortingElectrical batteryInternal resistance

The invention relates to a method for separating secondary batteries. The method comprises the following steps: (1) selecting a batch of secondary batteries in a full energy state, placing the batch of secondary batteries in a charge-discharge detection device for a lithium ion battery, discharging the secondary batteries in a 3C-10C rate, and recording discharge data by using a computer; (2) setting the low limit of discharge time according to the capacity range of the selected secondary batteries, and classifying the batteries with the discharge time longer than the low limit of discharge time according to a setting range; (3) setting a low limit discharge platform or a low limit mid-value voltage for the selected secondary batteries in the capacity range according to needs to obtain the batteries more than the low limit discharge platform or the low limit mid-value voltage; and (4) carrying out internal resistance separation on the batteries obtained in step (3), and selecting the batteries with satisfactory internal resistances. After the technical scheme is adopted, a separation process is simplified, separation equipment is reduced, the separation speed is increased and the separation quality is improved, the production cost is reduced, and the production efficiency is improved.

Owner:OPTIMUM BATTERY CO LTD

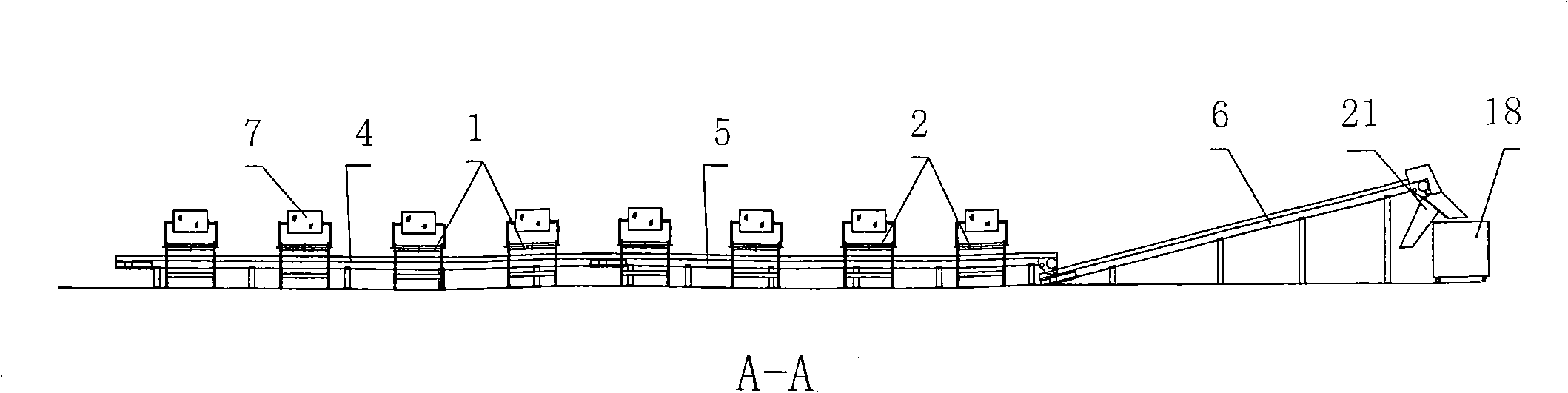

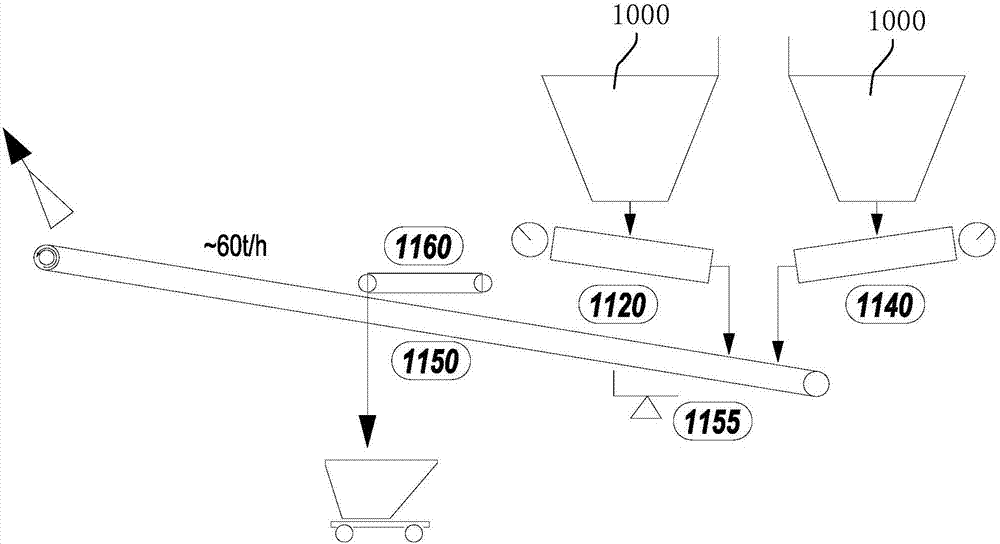

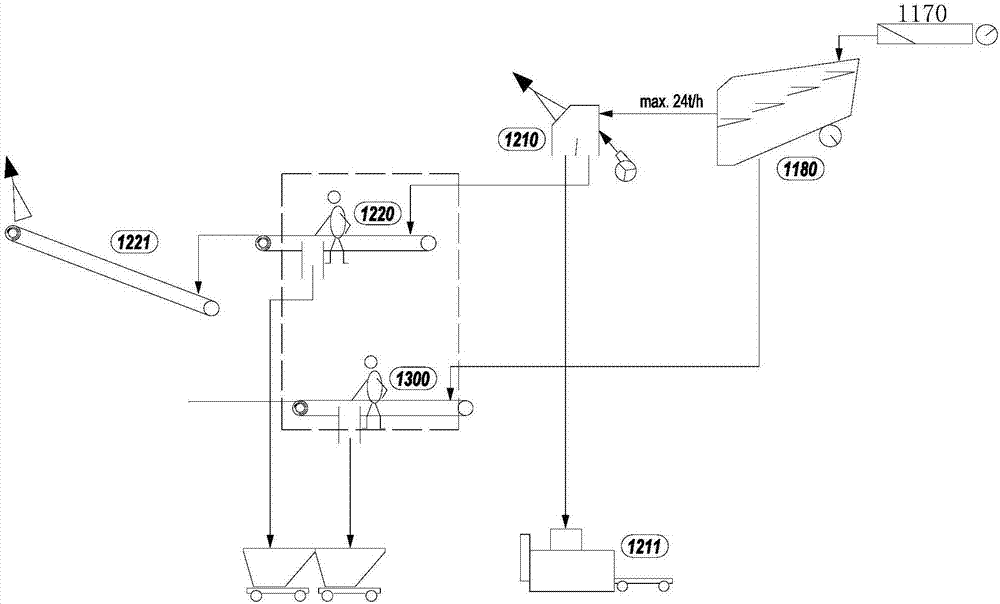

Grading technique for cutting cured leaf head and selecting slice on-line and device

InactiveCN101301109AEasy to replaceQuality improvementTobacco preparationSortingEngineeringControl switch

The present invention belongs to the tobacco leaf processing field for cigarette manufacture, in particular to an online chip selection grading technique for removing bundle head of raw tobacco, and the equipment thereof. Bundles of tobacco are put to a plurality of platform so as to be transferred to the machine for removing each bundle head, thereby, the bundle heads are separated from tobacco leaves, and then the bundle heads are tidied, disbanded, shaken, sieved and put into a bin; the tobacco leaves are shaken and put into selecting conveyer belt. The tobacco leaves are selected artificially comparing with a template in a template box. The selected tobacco leaves are conveyed into a bin through an output conveyer belt, while the remainder tobacco leaves are conveyed into a gathering bin through a gathering output conveyer belt. Person in a inspection bench can make corresponding treatments according to the condition of the tobacco leaves on the gathering output conveyer belt. The equipment comprises a platform for bearing bundles, a machine for removing bundle heads, conveyer belts, a bundle head processing unit, a platform for bearing leaves, a template box, bins, an inspection bench, and a control switch. The present invention has the advantages of good effect, reasonable technology, simple flow, compact equipment, reasonable arrangement, chip selection grading with high quality and high efficiency, and can be suitable for mass production.

Owner:云南新紫烟科技有限公司

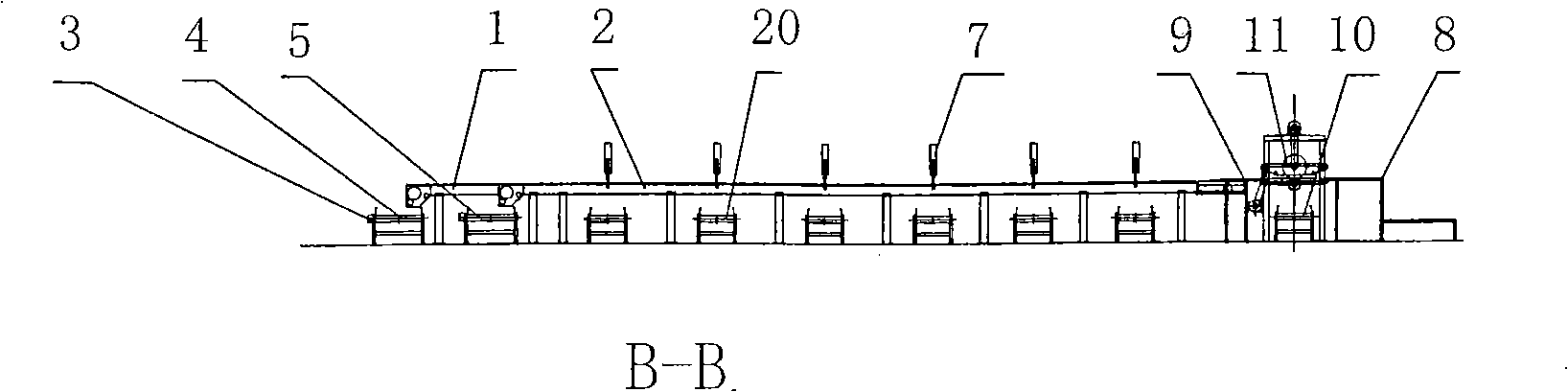

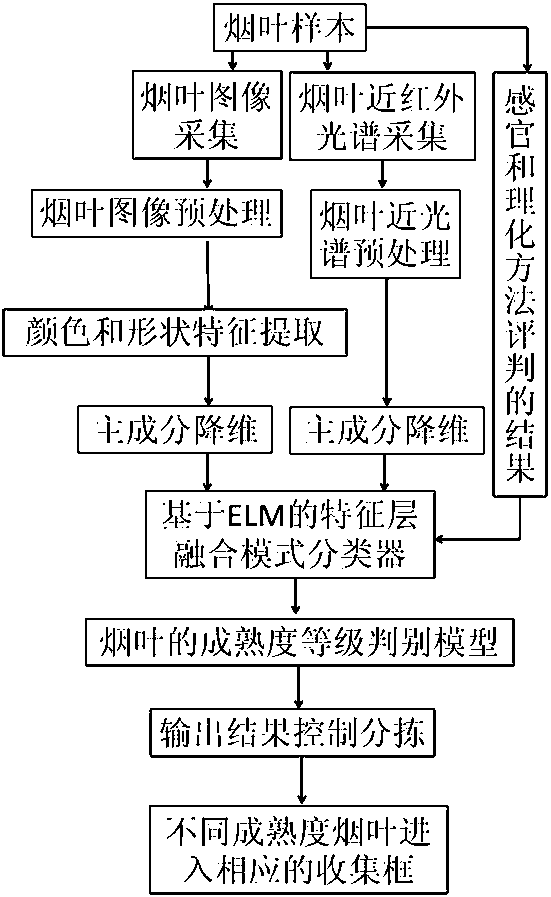

Tobacco leaf classification method based on spectrum and machine vision coupling

InactiveCN110705655AImprove accuracyImprove efficiencyMaterial analysis by optical meansCharacter and pattern recognitionPattern recognitionMachine vision

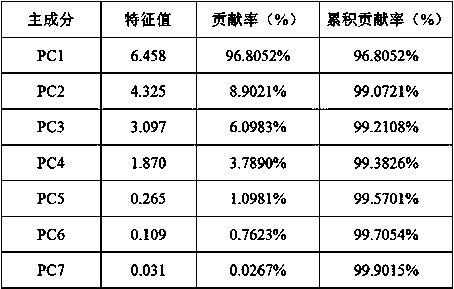

The invention discloses a tobacco leaf classification method based on spectrum and machine vision coupling. The tobacco leaf classification method comprises the steps of collecting near infrared spectrum values and images of tobacco leaves through a near infrared spectrometer and a camera; removing the background of the acquired image, reducing the noise, calculating the average value of the nearinfrared spectrum points of the tobacco leaves, and eliminating the influence of uneven distribution of tobacco leaf particles on the average value; extracting image features; performing dimension reduction processing on the image features and the near infrared spectrum to obtain main features; fusing the main features and processing the main features by adopting a normalization method; creating agrading model, dividing the samples into a training set and a verification set, and training and classifying the model to construct a model; importing the fused pre-classified tobacco leaf features into a classification model for discrimination so as to output a maturity judgment result; and a sorting device or a worker classifies the tobacco leaves according to the output maturity judgment result. The tobacco maturity can be automatically recognized and judged, classified collection can be guided or controlled, and the method has the advantages of being accurate in classification, high in automation degree and not prone to damage the tobacco.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Kitchen garbage component sorting machine

InactiveCN102151680AConducive to the protection of healthImprove protectionSolid waste disposalWet separationGratingSprocket

The invention discloses a kitchen garbage component sorting machine which belongs to auxiliary garbage treatment equipment. A vice speed reduction motor, a feeding hoper, a cleaning brush roll, a spiral conveyer, a support roller, a solid screened material collection box, a liquid screened material collection box, a main shaft and a main motor are arranged on a frame assembly; a revolving drum is arranged on the support roller; a cylindrical grating with a baffle is arranged on the revolving drum and integrally contains the cleaning brush roll and the spiral conveyer; the vice speed reduction motor is connected with the cleaning brush roll; the main motor is connected with the main shaft; a driving sprocket and a driving gear are fixedly arranged on the main shaft; a driven sprocket is fixedly arranged on the spiral conveyer; a ring-shaped gear is fixedly arranged on the revolving drum; the driving sprocket is connected with the driven sprocket; the driving gear is meshed with the ring-shaped gear; and a drawer type oil-water separator is inserted on the liquid screened material collection box. The machine is simple and reasonable in structure, high in operation efficiency, good in sorting quality, less in failure, clean in operation environment and free of pollution.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Automatic wet-process sorting control method for waste glass

InactiveCN107952781AImprove sorting qualityImprove sorting efficiencyGas current separationSolid waste disposalThree stageEngineering

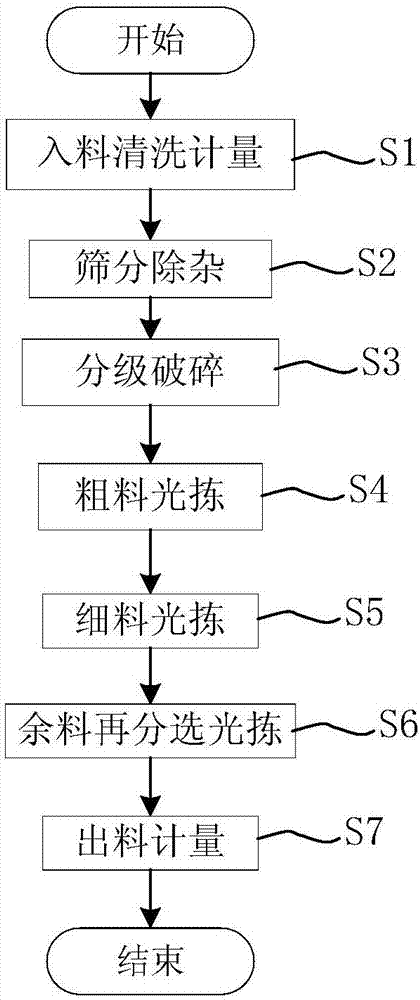

The invention discloses an automatic wet-process sorting control method for waste glass. The method comprises the following steps that S1, feeding, cleaning and metering are carried out, specifically,the waste glass is cleaned, water is removed, and then feeding is carried out by adopting a vibration feeding machine; S2, screening and impurity removal are carried out; S3, staged crushing is carried out, specifically, two-stage crushing is carried out on separated materials; S4, optical sorting is carried out on coarse materials, specifically, non-ferrous metals are removed by an eddy currentsorting machine, and three-stage screening is completed according to the granular size of 1-3mm, 3-8mm and 8-50mm; S5, optical sorting is carried out on fine materials; S6, optical sorting is carriedout on excess materials, specifically, screening is carried out continuously on materials with the granular size of 8-50 mm by adopting a three-stage broken glass optical sorting machine to carry outimpurity and mixed-color separation so as to obtain materials with the granular size of 8-16mm, 16-22mm and 22-50mm; and 7, discharging and metering are carried out, specifically, separated main-colorglass, colored glass pieces and stone ceramics are metered and discharged separately. The method has the advantages that various specifications can be subdivided, all the impurities can be removed, the sorting quality can be greatly improved, and the sorting efficiency and the productivity can be improved.

Owner:上海燕龙基再生资源利用有限公司

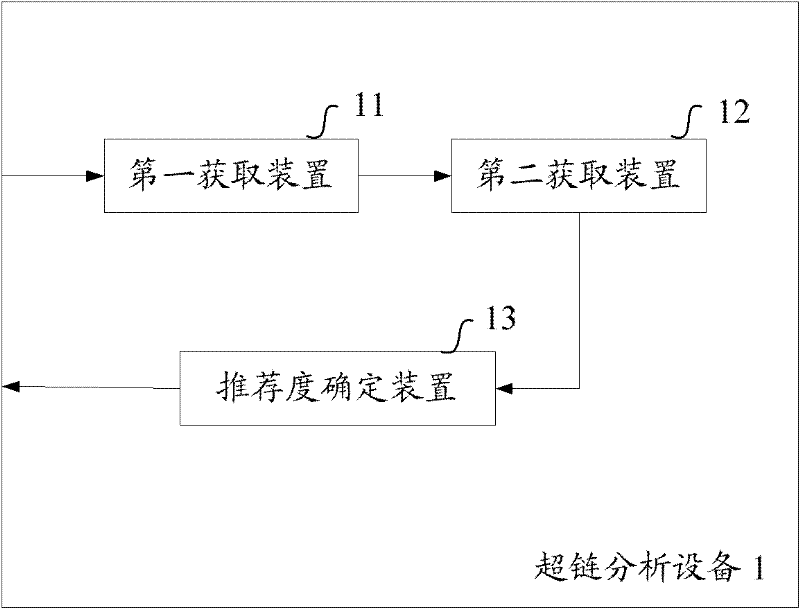

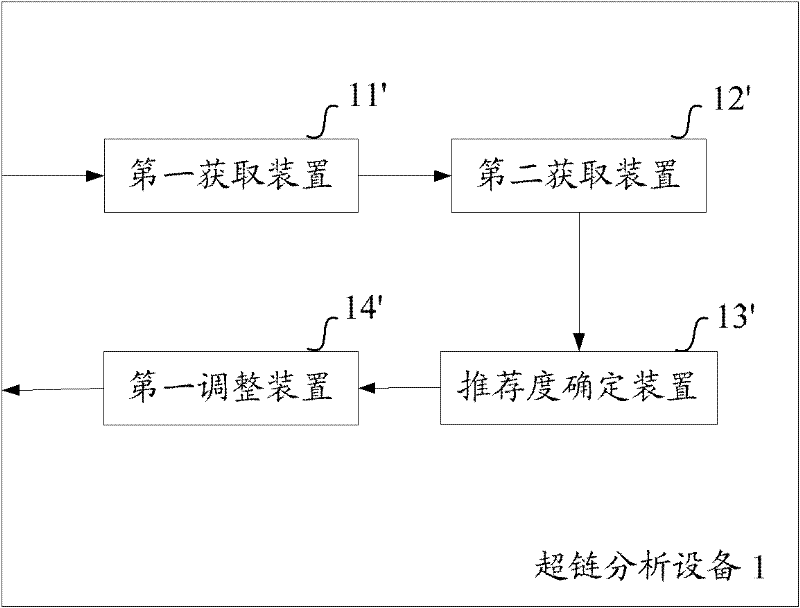

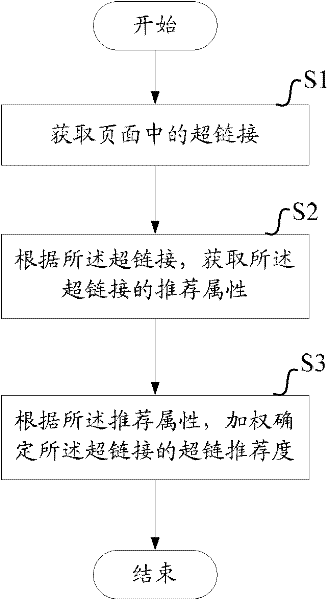

Method and equipment for determining recommendation degree of hyperlink based on recommendation attribute of hyperlink

ActiveCN102541946AImprove sorting qualityImprove user experienceSpecial data processing applicationsHyperlinkSorting algorithm

The invention aims to provide a method and equipment for determining the recommendation degree of a hyperlink based on the recommendation attribute of the hyperlink. The method comprises the following steps: acquiring a hyperlink in a page by using hyperlink analyzing equipment; acquiring the recommendation attribute of the hyperlink according to the hyperlink; determining the recommendation degree of the hyperlink through weighting according to the recommendation attribute. Compared with the prior art, the method has the advantages that the result accuracy and the search result ranking quality of page ranking algorithms such as PageRank can be improved and use experience of search users can be enhanced since the recommendation degree of the hyperlink is determined on the basis of the recommendation attribute of the hyperlink in the page.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

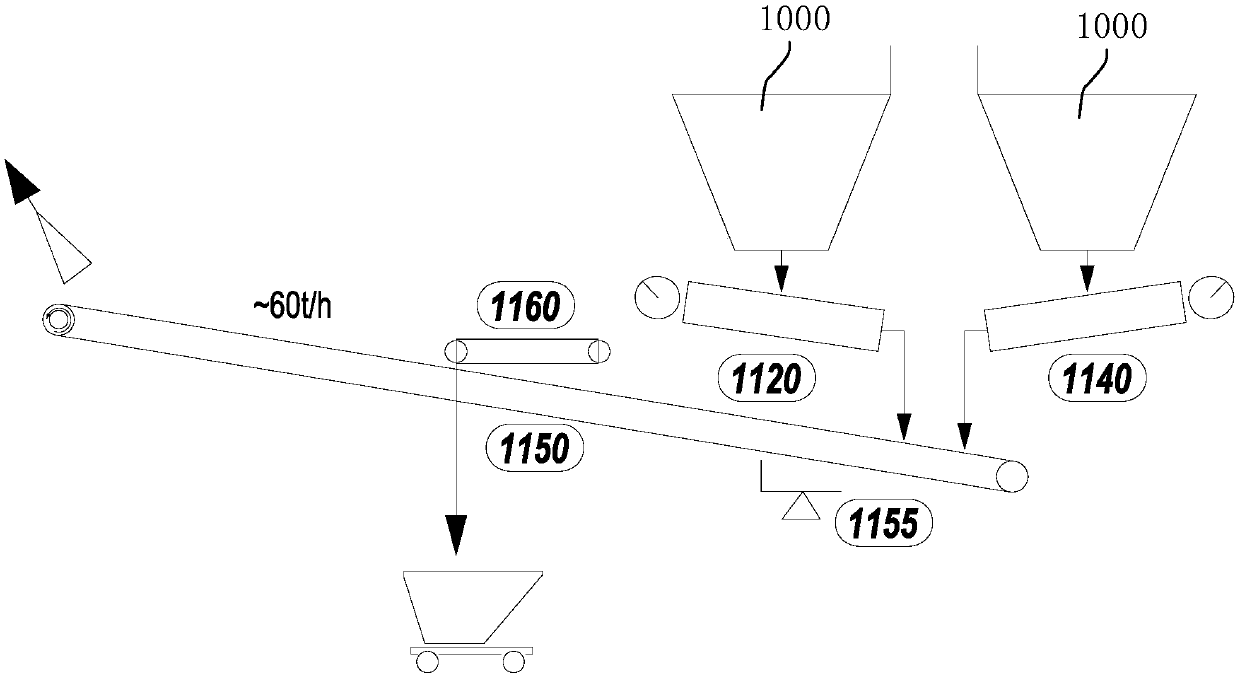

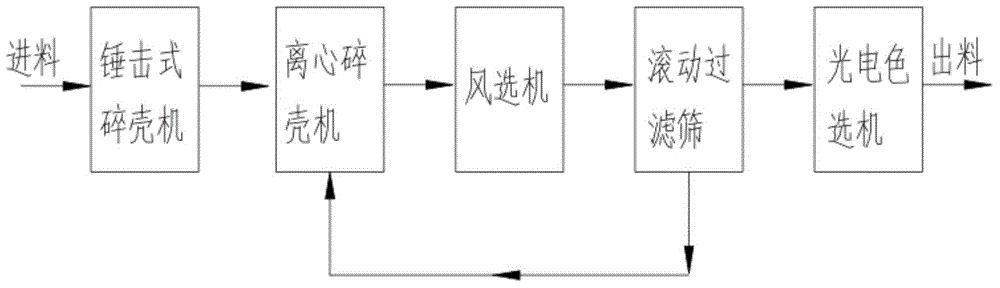

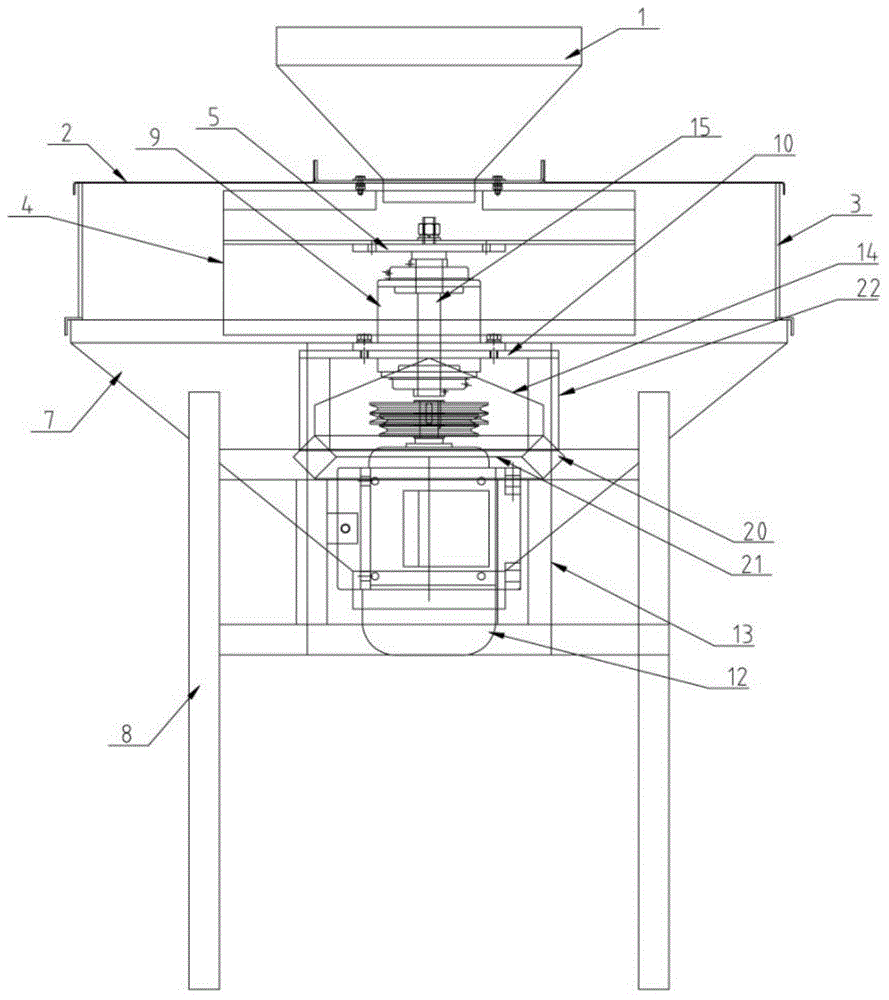

Husk crushing and sorting system for walnuts and sorting technology

The invention relates to a husk crushing and sorting system for walnuts and a sorting technology. The husk crushing and sorting system comprises a hammering type husk crushing machine, a centrifugal husk crushing machine, a winnowing machine, a rolling filtering screen and a photoelectric color selector, wherein the centrifugal husk crushing machine is arranged between the hammering type husk crushing machine and the winnowing machine; the hammering type husk crushing machine, the centrifugal husk crushing machine, the winnowing machine, the rolling filtering screen and the photoelectric color selector are connected through a conveying belt; the rolling filtering screen is connected with a material feeding hopper of the centrifugal husk crushing machine through a backflow conveying belt. The sorting technology for the walnuts comprises the specific steps: performing pretreatment, boiling and air-drying; performing husk crushing including hammering type husk crushing and centrifugal husk crushing; performing sorting including winnowing sorting and filtering screen sorting; performing photoelectric color selection. The husk crushing and sorting system for the walnuts can be continuously operated, is short in production period and high in feasibility, can be used for realizing complete husk crushing of the walnuts and complete separation between husks and kernels, and is high in quality, high in efficiency and low in labor cost.

Owner:陈建农 +1

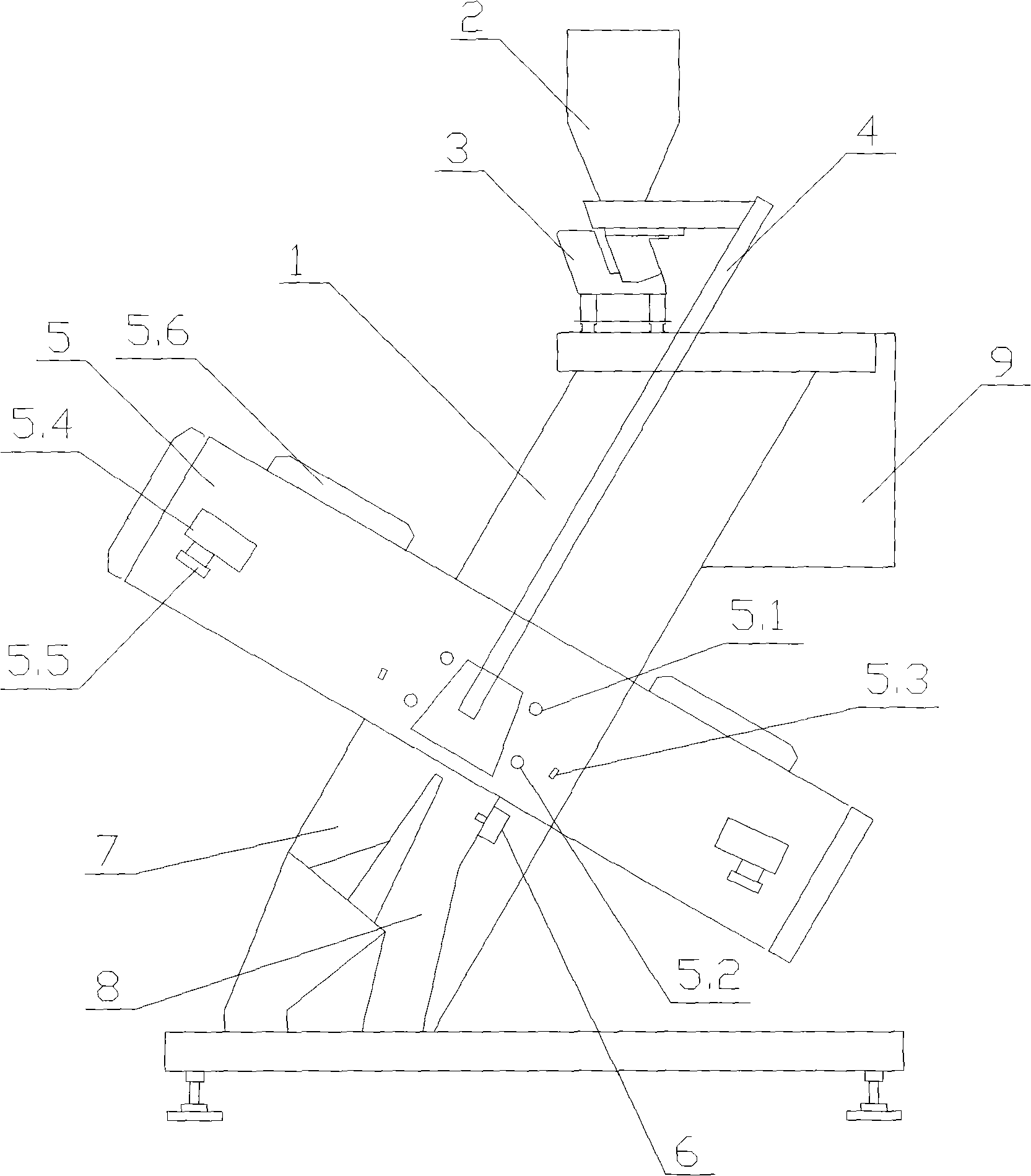

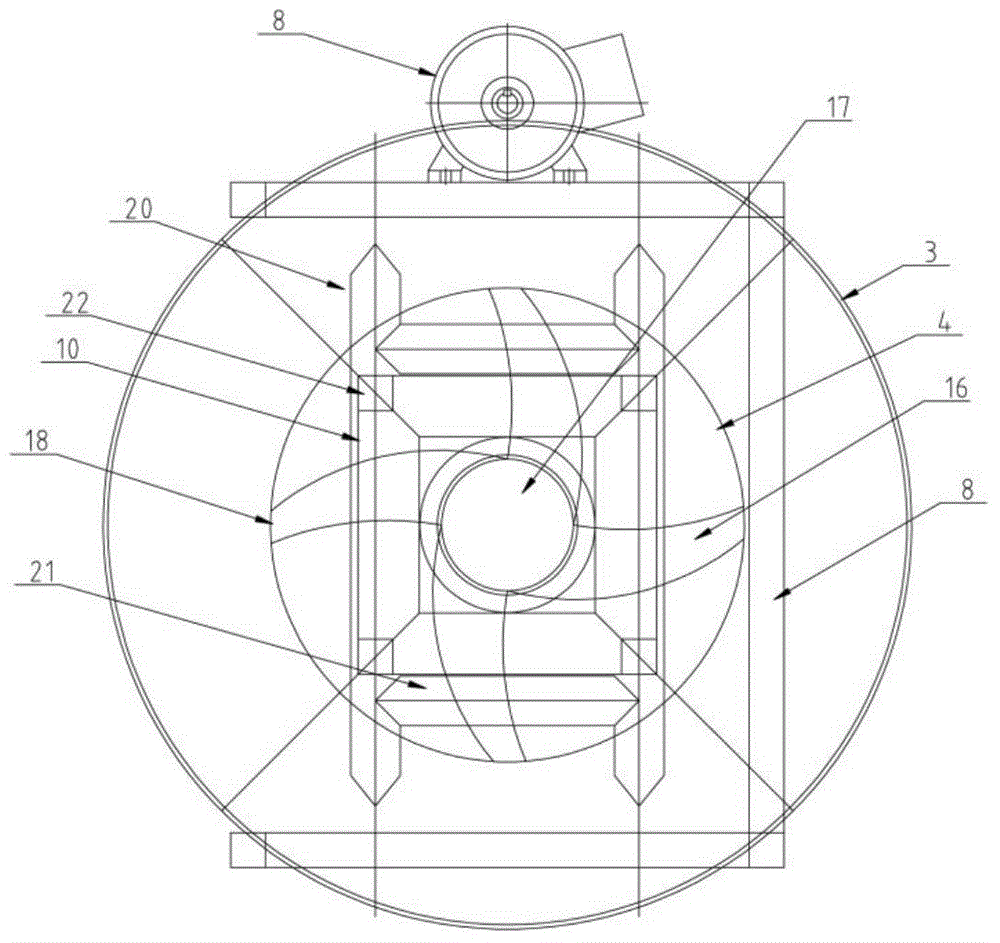

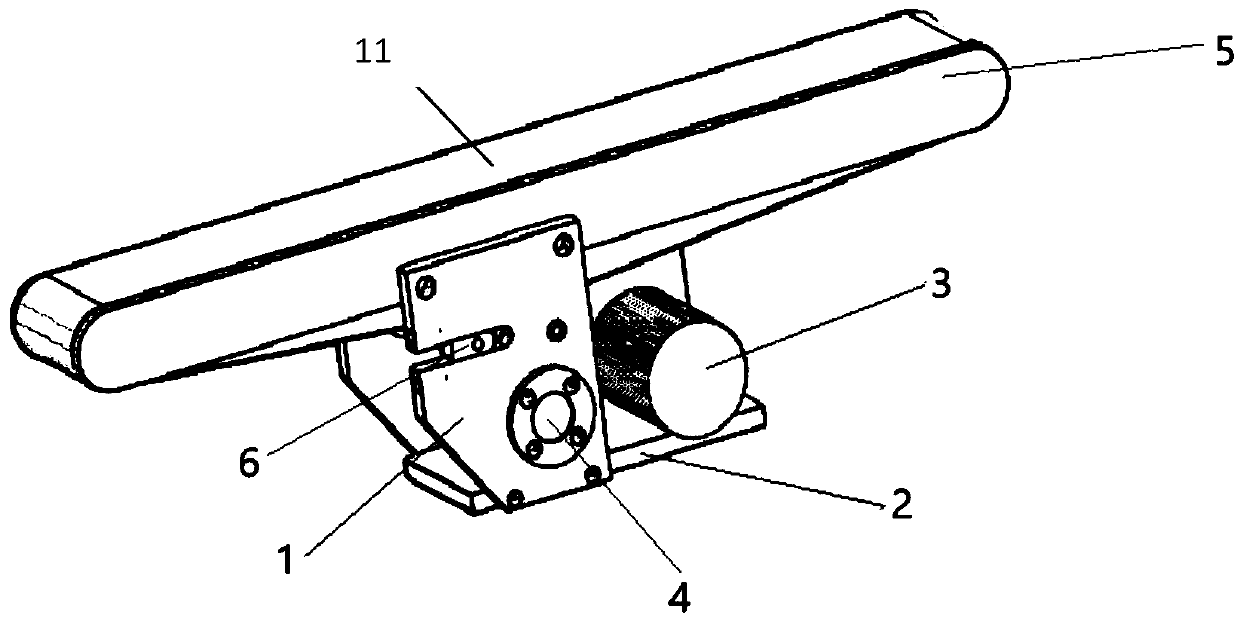

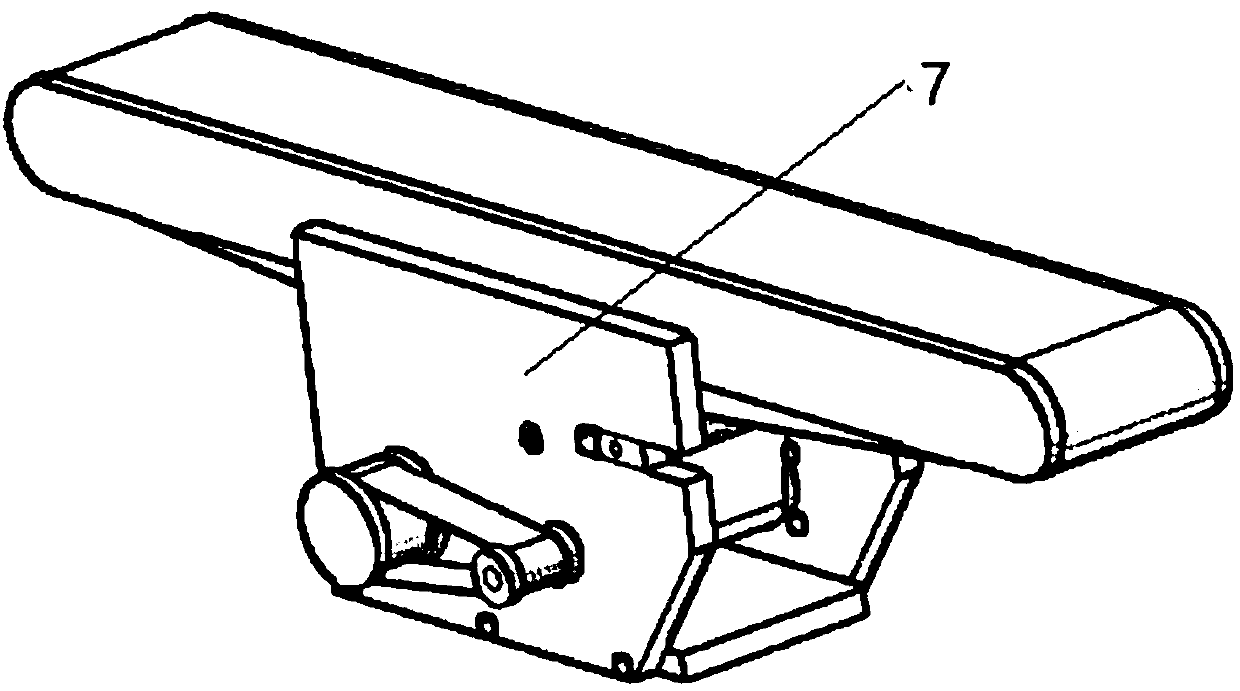

Adjustable seed gravity screening machine on-line

InactiveCN1745909ARealize adjustment decouplingImprove sorting qualitySievingScreeningElectric machineryDrive motor

A full-state in-line adjustable gravitational seed-screening machine with in-line regulation of vibration frequency and inclination is composed of three working planes, crank mechanism, 4 leaf springs, 2 connecting rods, 4 corner hinges, drive motor and frequency converter. The first working plane is elastically installed on the second one via 4 leaf springs. The second working plane is fixed to the third one via two corner hinges and the first connecting rod. The third working plane is fixed to the base of polishing machine via another two corner hinges and the second connecting rod.

Owner:SHANGHAI JIAO TONG UNIV

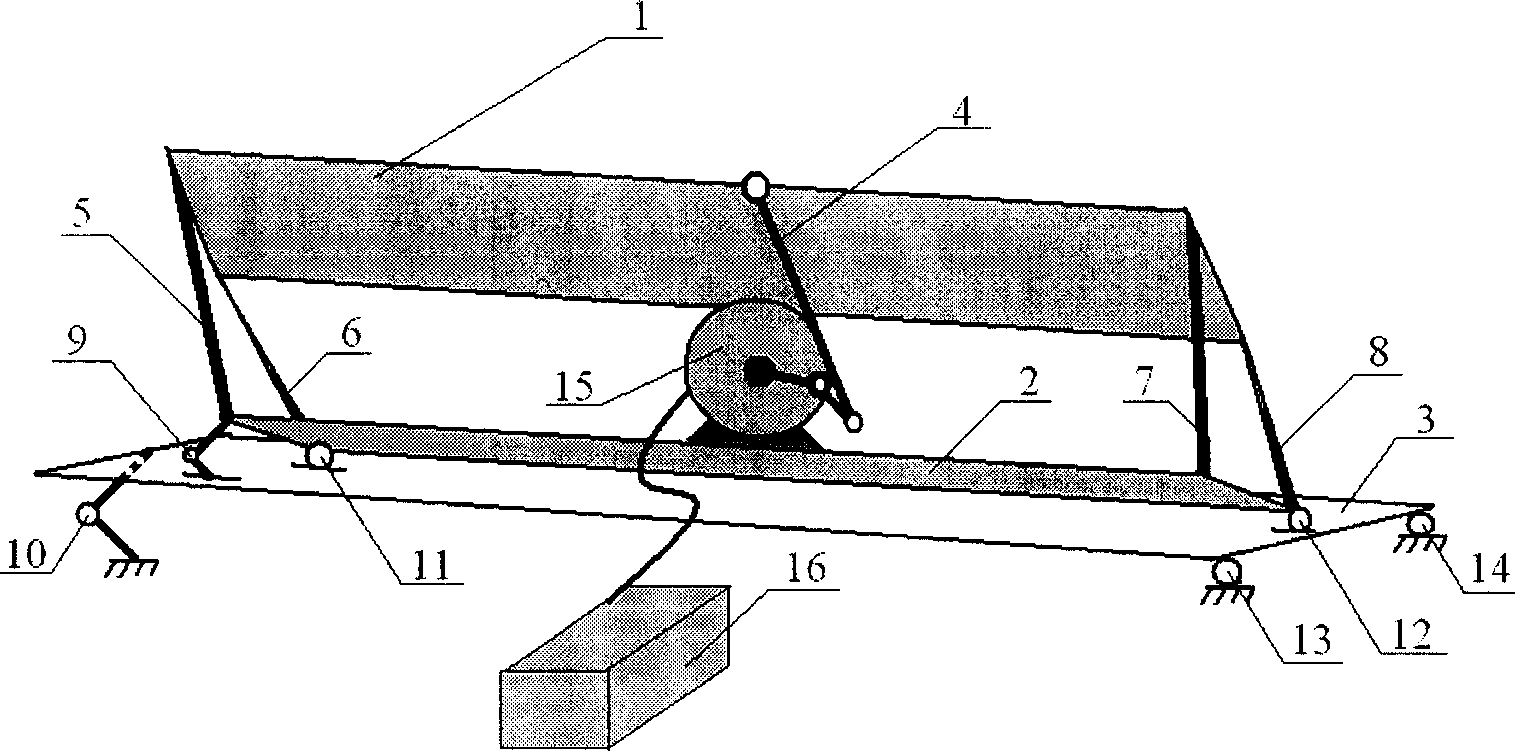

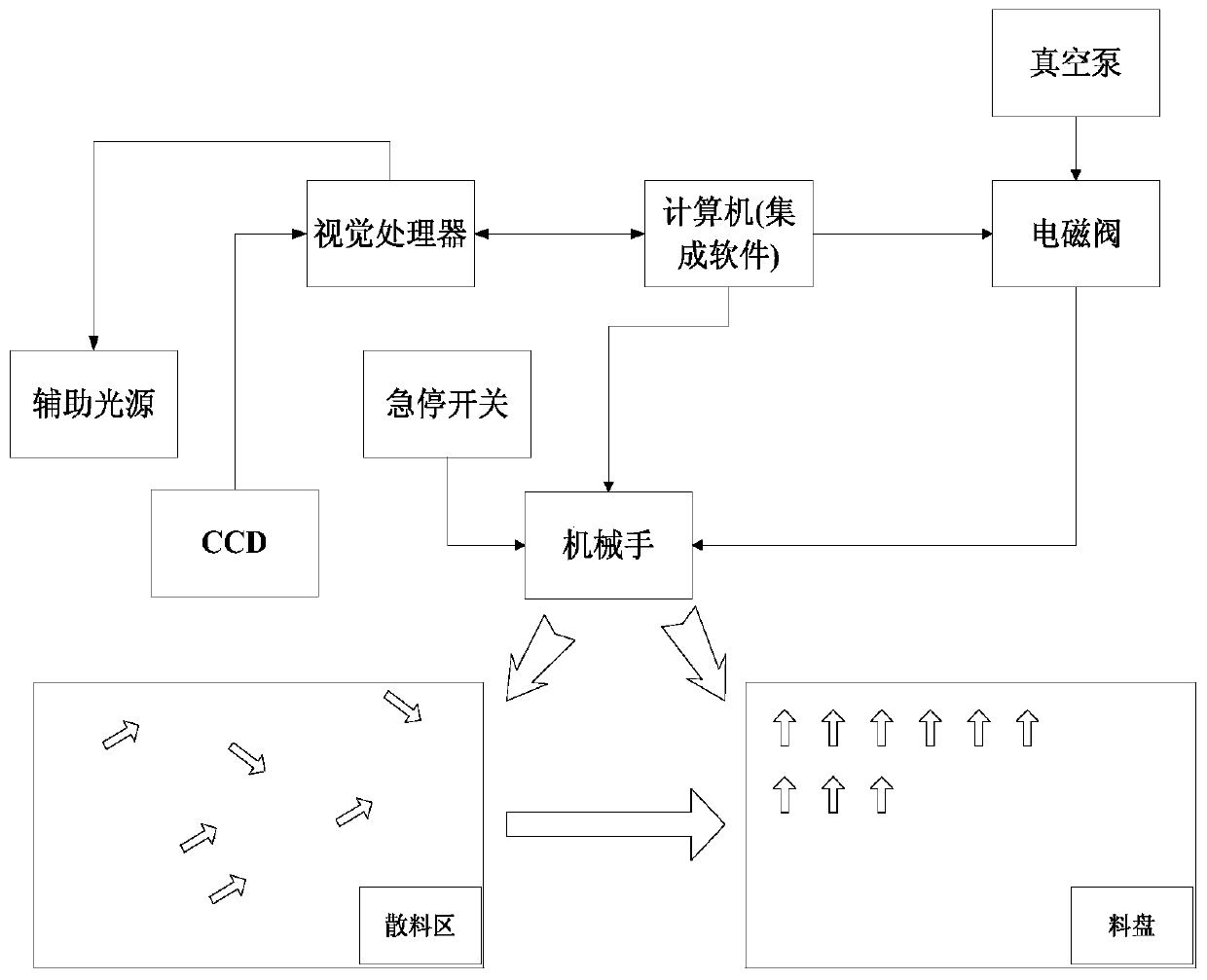

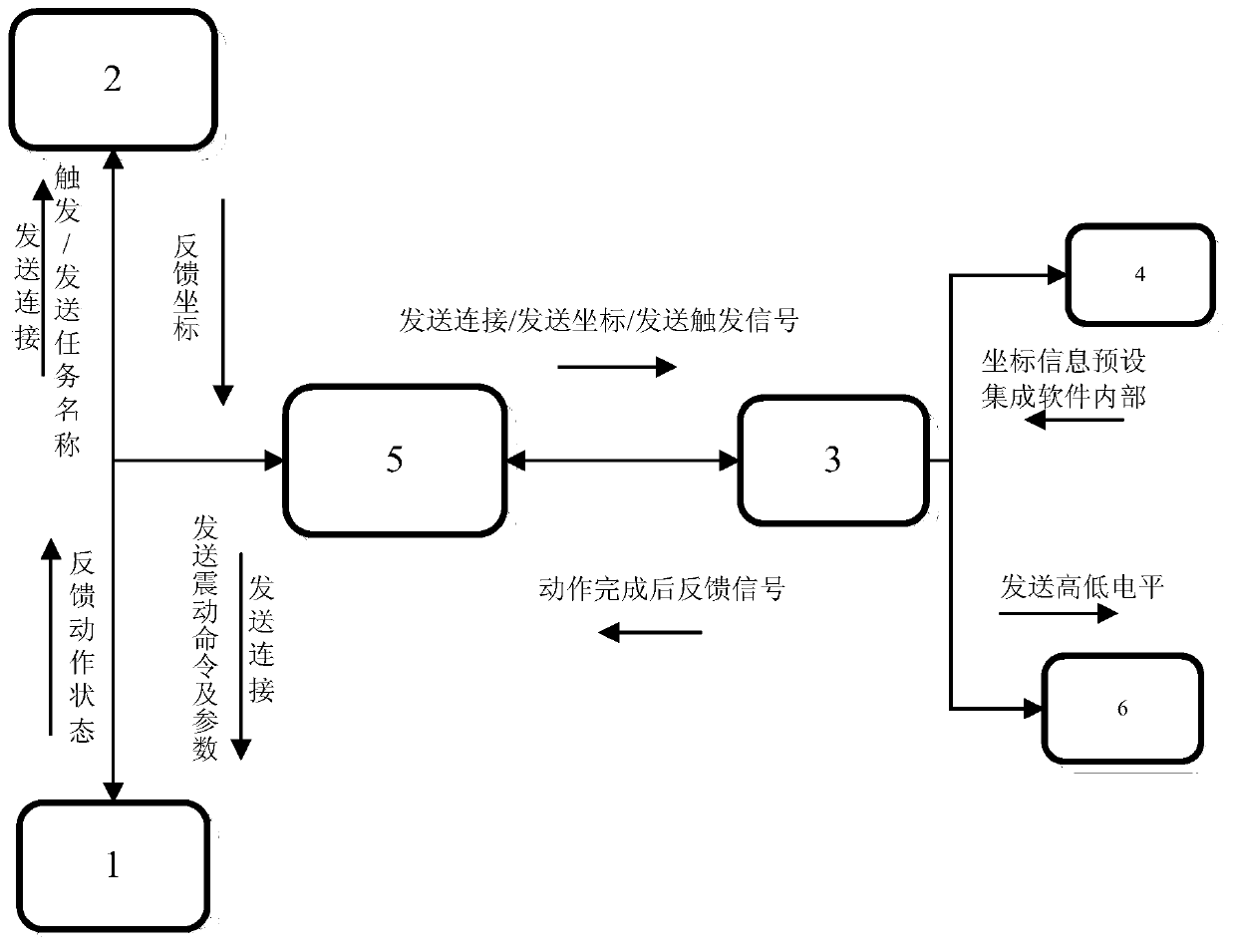

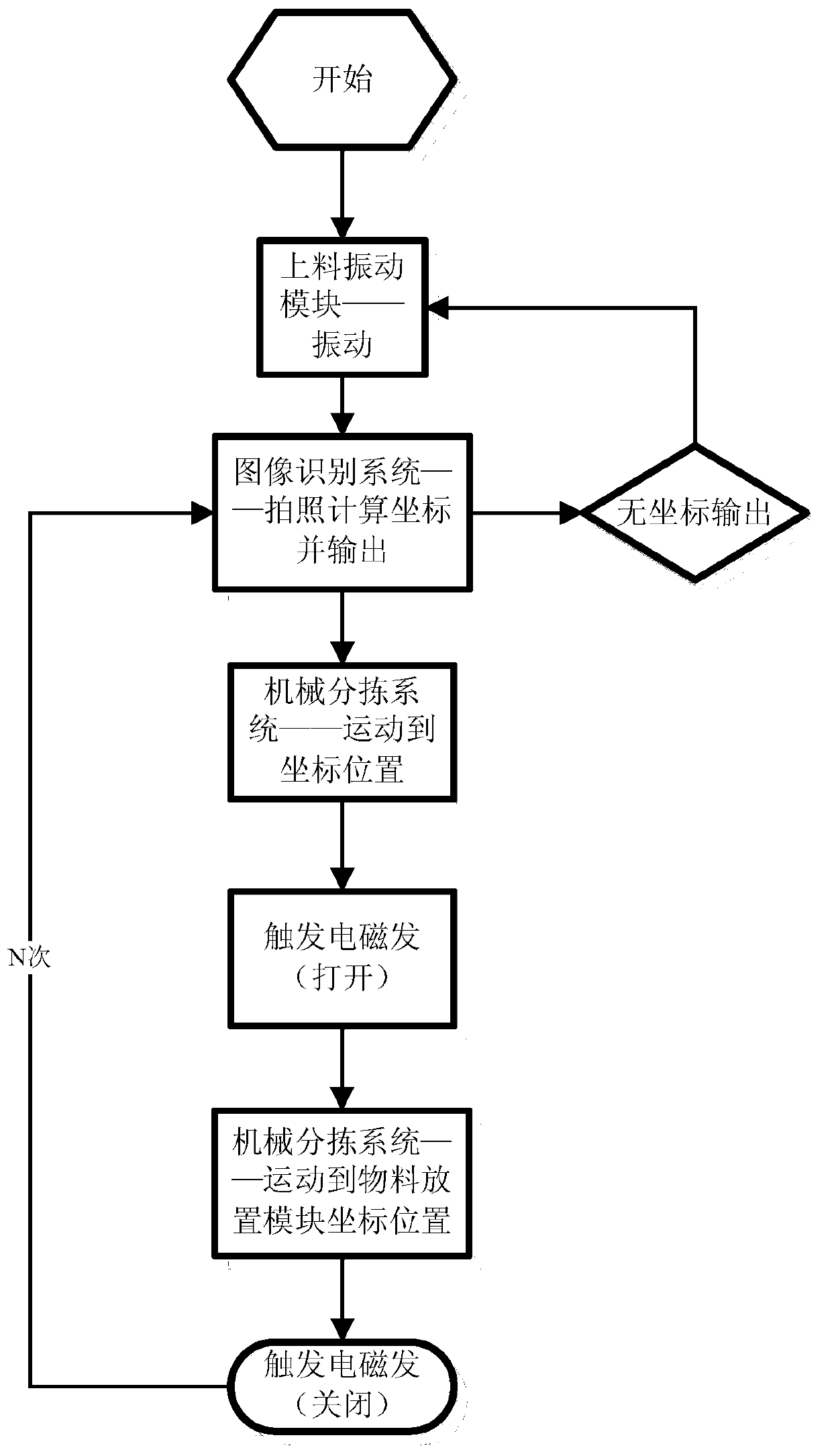

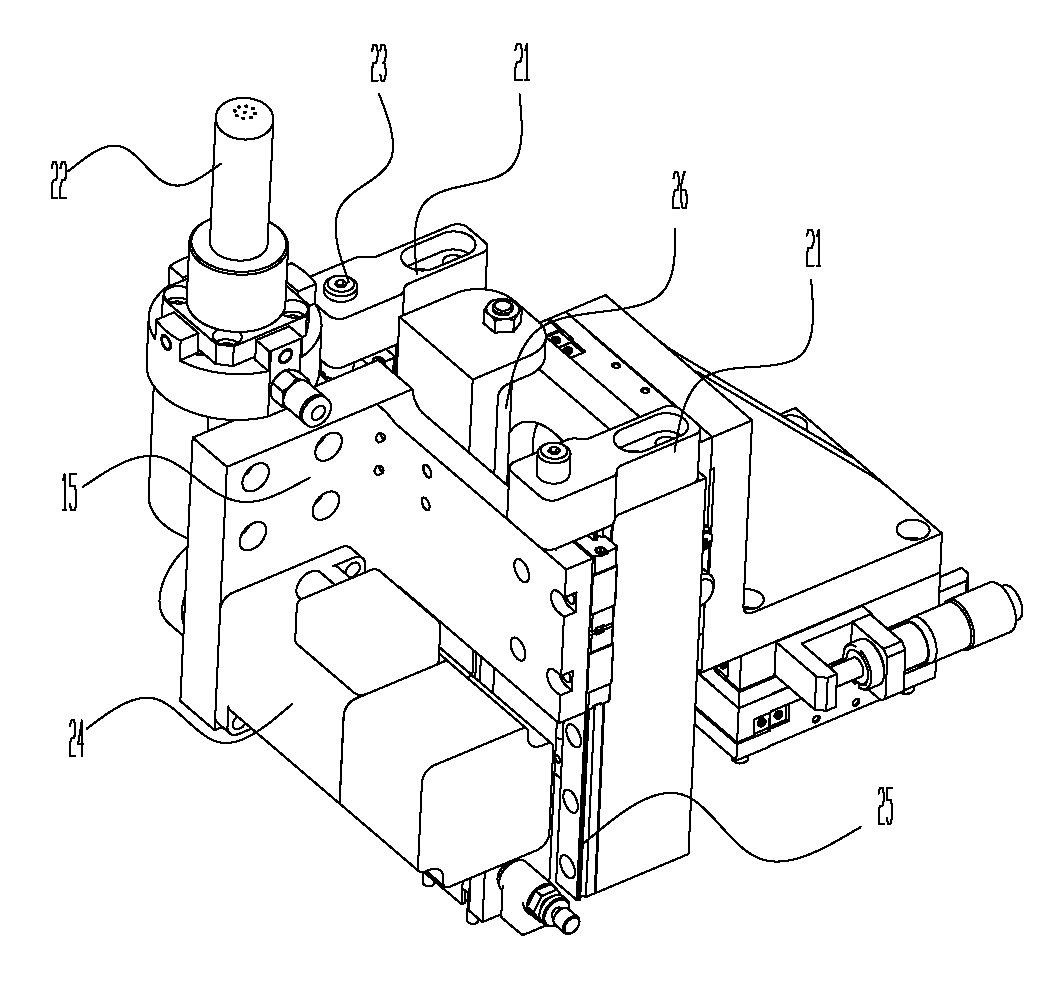

Intelligent sorting equipment for small-batch sheet type scattered devices

InactiveCN109731793ARealize automatic flippingEasy to operate and transferSortingNon destructiveOver treatment

The invention discloses intelligent sorting equipment for small-batch sheet type scattered devices. The equipment aims to solve the problem that small-batch bulk components after secondary screening of electronic components in the military industry cannot be produced by using automatic equipment. The accurate-positioning and non-destructive-picking intelligent sorting equipment for the small-batchsheet type scattered devices are designed through integrated research and development on a feeding vibration module, a mechanical sorting system, an image recognition system, a material placing module, software development and the like. According to the equipment, as a new breakthrough of intelligent manufacturing in the field of electronic assembly, under dragging by software, the feeding vibration module is driven to carry out turning-over treatment on the sheet type scattered devices, the software is switched to drive the image recognition system to realize automatic recognition and framejudgment of the sheet type components, the software commands and drives the mechanical sorting module to intelligently grab the sheet type scattered devices, accurate grabbing of 0402 packaging can beachieved, the software sets material placement to realize the high-precision array sorting and arranging of the sheet type scattered devices, and the sorting quantity and the operation period can further be clearly recorded.

Owner:SHANGHAI AEROSPACE ELECTRONICS CO LTD +1

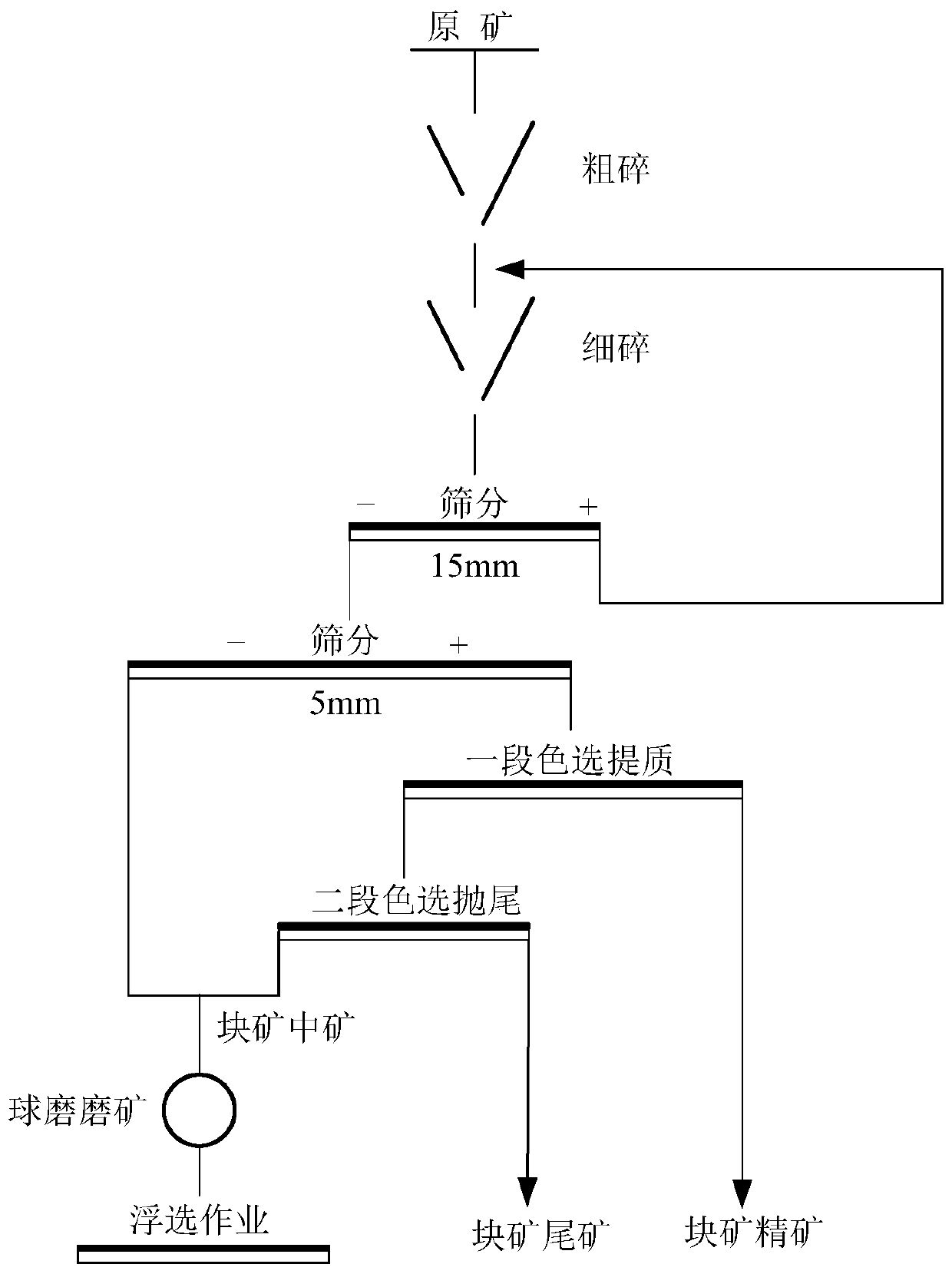

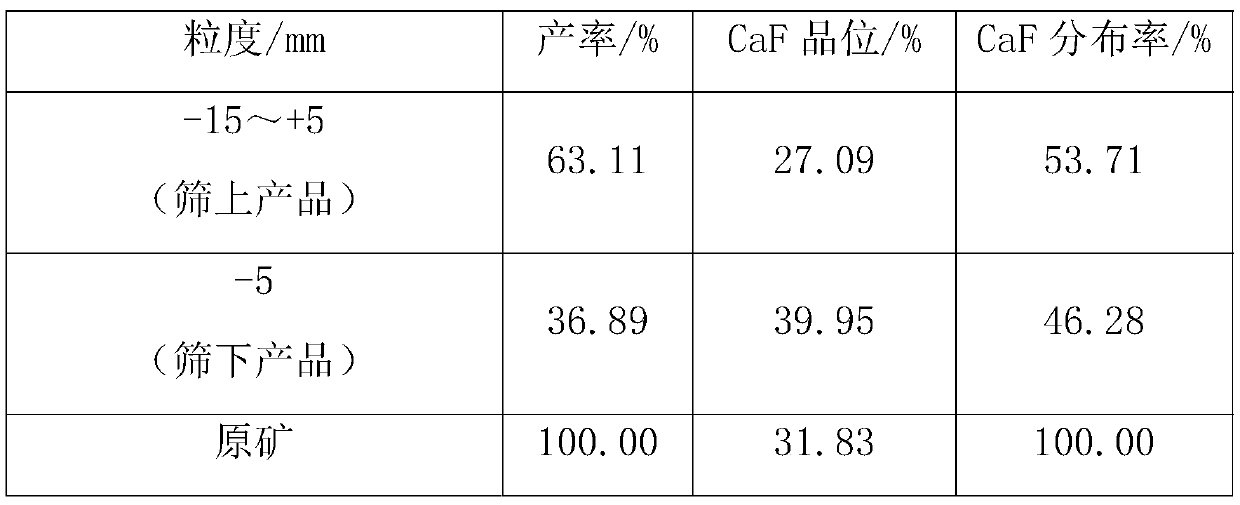

Fluorite lean ore color sorting upgrading-tailing pre-sorting method

The invention provides a fluorite lean ore color sorting upgrading-tailing pre-sorting method. The method comprises the following steps that (1) fluorite lean ore is crushed through two sections of closed circuits, and crushed products are -15 mm; (2) the crushed products are screened to obtain oversize products and undersize products, wherein the size of sieve pores is 5 mm, and the oversize products enter a first section color sorter for fluorite upgrading and sorting to obtain lump ore concentrates; (3) tailings sorted through the first section of color sorter enter into a second-section color sorter for tailing discarding sorting to obtain lump ore tailings and lump ore middlings; and (4) the undersize products in the step (2) and the lump ore middlings in the step (3) are mixed and ground, and then flotation is conducted. According to the method, the raw ore amount entering a ball mill is greatly reduced by pre-upgrading and sorting and pre-tailings-discarding of a large quantityof hard minerals, so that the beneficiation feed grade is improved, over-crushing of the hard minerals to the fluorite in the ore grinding process is reduced, so that the production cost is reduced, and the sorting quality is improved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

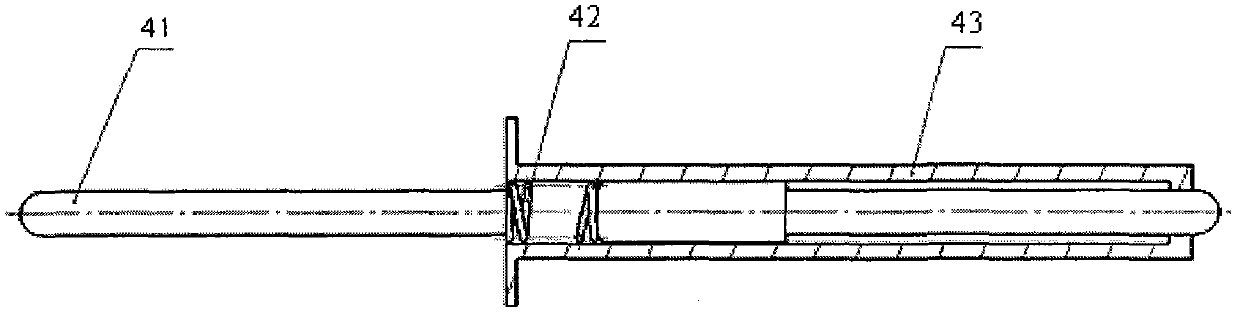

Ejector pin device of die grading equipment

InactiveCN103077918AImprove alignment accuracyEasy to replaceSemiconductor/solid-state device manufacturingEngineering

Owner:广东志成华科光电设备有限公司

Intelligent winter jujube sorting device

ActiveCN110270512AAvoid missing detectionImprove efficiency and accuracySortingGradingZiziphus jujubaEngineering

The invention discloses an intelligent winter jujube sorting device which comprises a feeding and piling mechanism, a feeding inlet, a color selecting mechanism, a first size sorting mechanism and a second size sorting mechanism. Through the feeding and piling mechanism, it can be effectively guaranteed that winter jujubes fall into the feeding inlet one by one, the winter jujubes enter the color selecting mechanism from the feeding inlet and are subjected to color selection through the color selecting mechanism, the winter jujubes subjected to color selection enter the first size sorting mechanism and the second size sorting mechanism, and then the first size sorting mechanism and the second size sorting mechanism perform size sorting on the winter jujubes subjected to color selection. An image processing technology instead of human eyes is adopted for performing color selection on the winter jujubes, pickup skipping and wrong pickup can be effectively prevented, and the sorting accuracy and efficiency are improved; and the winter jujube sizes are fast graded through the size sorting mechanisms, the structure is simple, operation and maintenance are easy, and the sorting efficiency and quality are greatly improved.

Owner:TIANJIN AGRICULTURE COLLEGE

Small automatic garbage sorting device

InactiveCN108672326AImprove sorting efficiency and qualitySpeed up reuseSortingElectromagnetic inductionGravitation

The invention discloses a small automatic garbage sorting device which is a box structure formed by connecting a plurality of garbage sorting and recycling units. The garbage sorting and recycling units comprise conveying mechanisms, screening mechanisms, sliding mechanisms, recycling mechanisms, and post-processing mechanisms. Wherein the screening mechanisms are sequentially an electromagnetic induction screening mechanism, a photosensitive induction screening mechanism and a gravity sensing screening mechanism; the screening mechanisms and the recycling mechanisms respectively correspond tobe matched through sliding mechanisms. The box-type structure of the ''upper, middle and lower'' are used for separating different kinds of garbage accurately through three circular sorting in a garbage classification device for the first time, and the defect that the garbage classification device can only sort garbage one-time can be filled. In addition, the sorting efficiency and the quality are improved on the basis of guaranteeing the separation precision, and therefore the resource reuse speed is accelerated.

Owner:SHANGHAI DIANJI UNIV

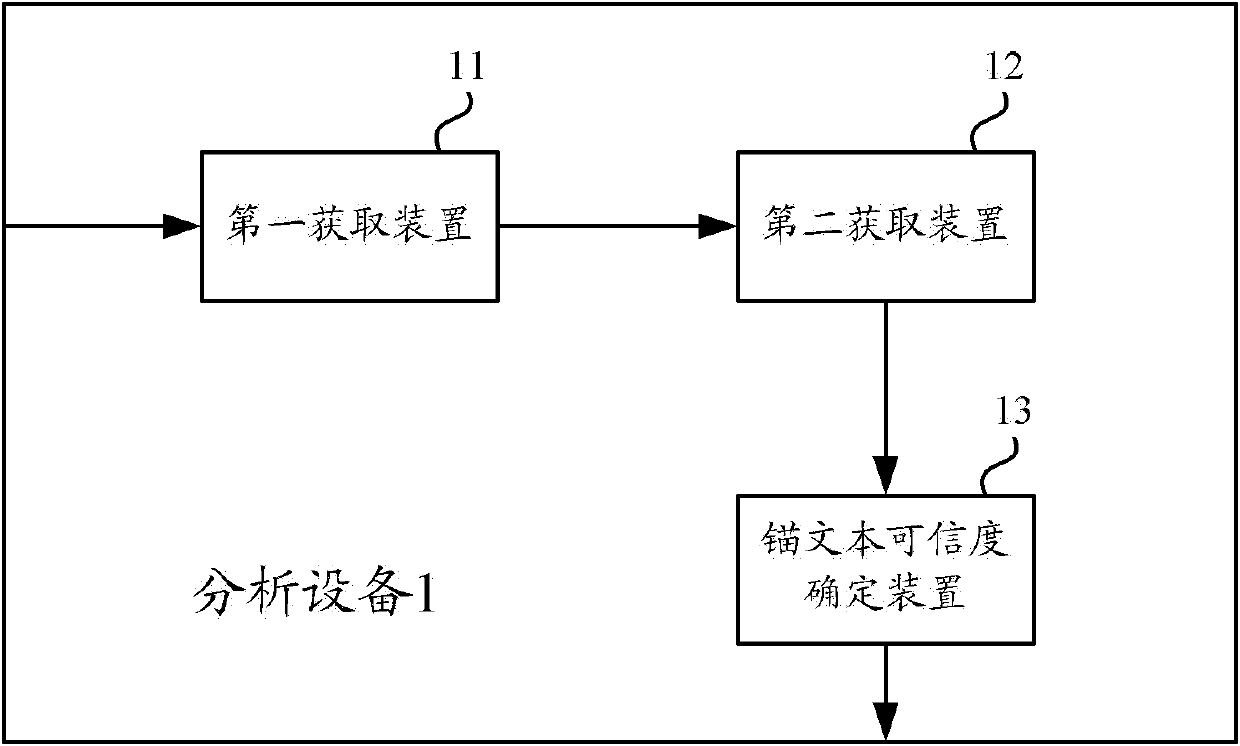

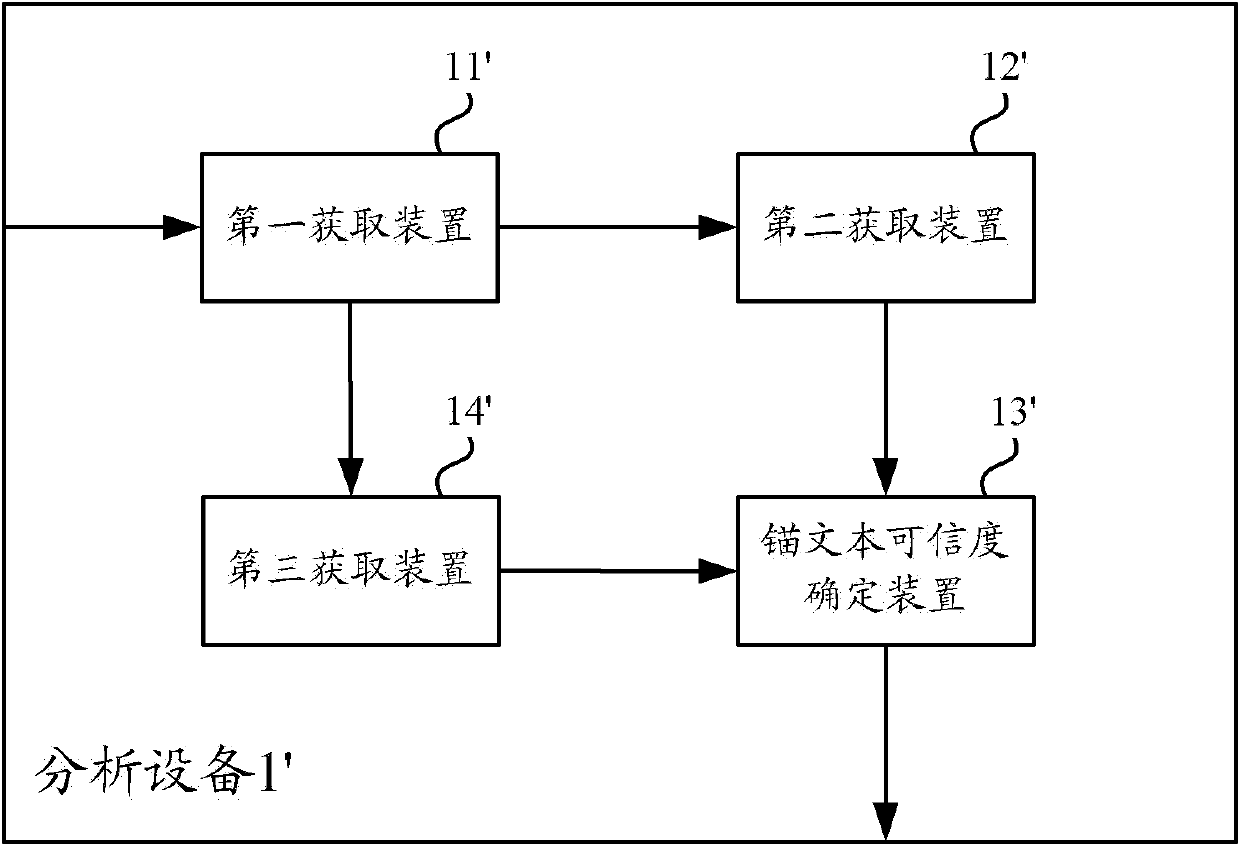

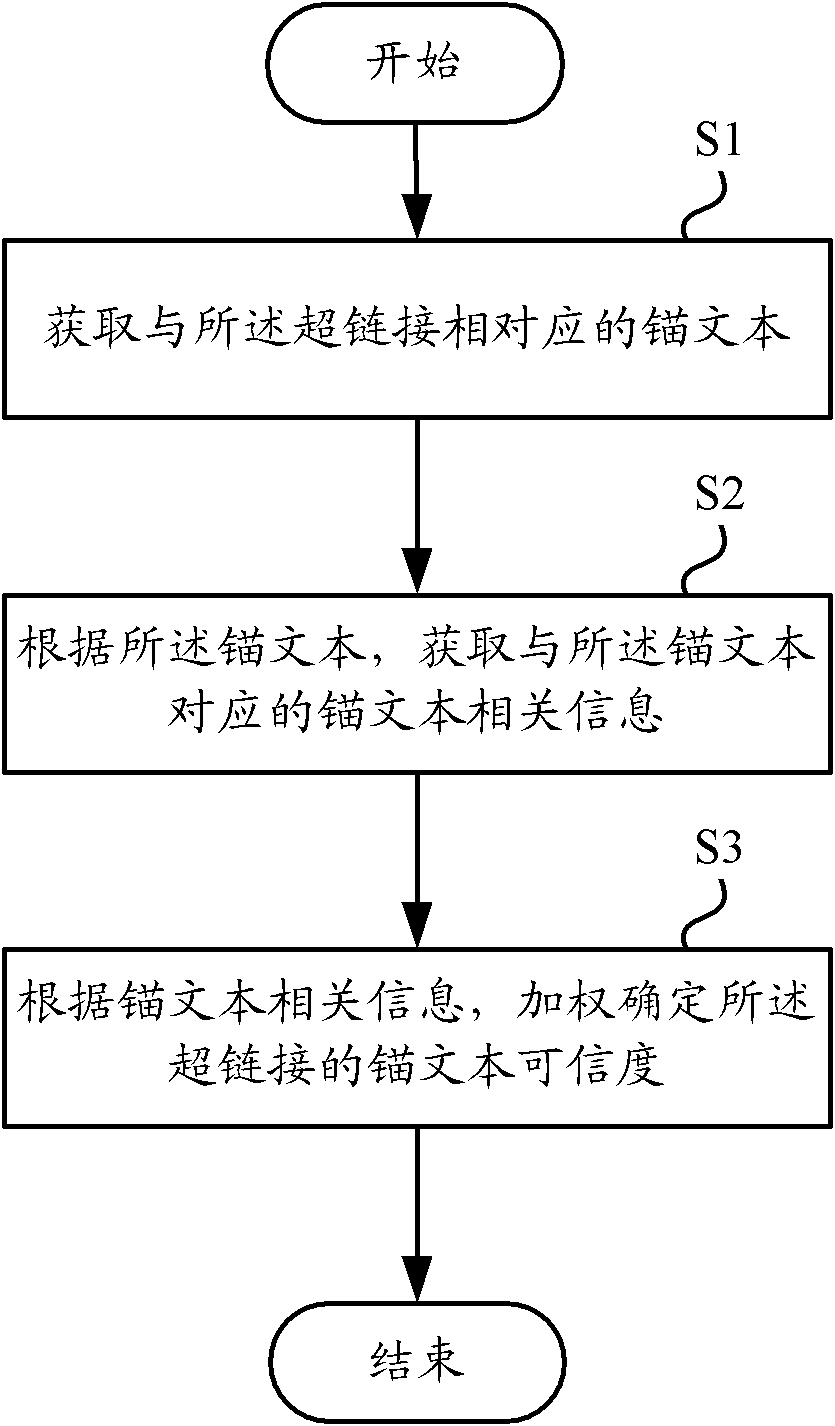

Analysis equipment and method for determining reliability of anchor text of hyperlink

InactiveCN102567417AReasonable content relevanceAccurate detectionSpecial data processing applicationsHyperlinkRelevant information

The invention provides analysis equipment and method for determining the reliability of an anchor text of a hyperlink. The method comprises the following steps of: obtaining an anchor text corresponding to the hyperlink; obtaining anchor text relevant information corresponding to the anchor text according to the anchor text; and weighting and determining the reliability of the anchor text of the hyperlink according to the anchor text relevant information. Compared with the prior art, the method is used for determining the reliability of the anchor text of the hyperlink through weighting based on the anchor text relevant information, so that the content relativity between the anchor text of the hyperlink and a hyperlink pointed page is more reasonable. Furthermore, the analysis equipment and method for determining the reliability of the anchor text of the hyperlink can be applied to a search engine field, and also can be used for accurately detecting a false anchor text of a cheating hyperlink and an invalid anchor text of an overdue hyperlink, and adjusting a page authority score and a ranking based on the false anchor text and the invalid anchor text, so that the sequencing quality of search results of a search engine is further improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

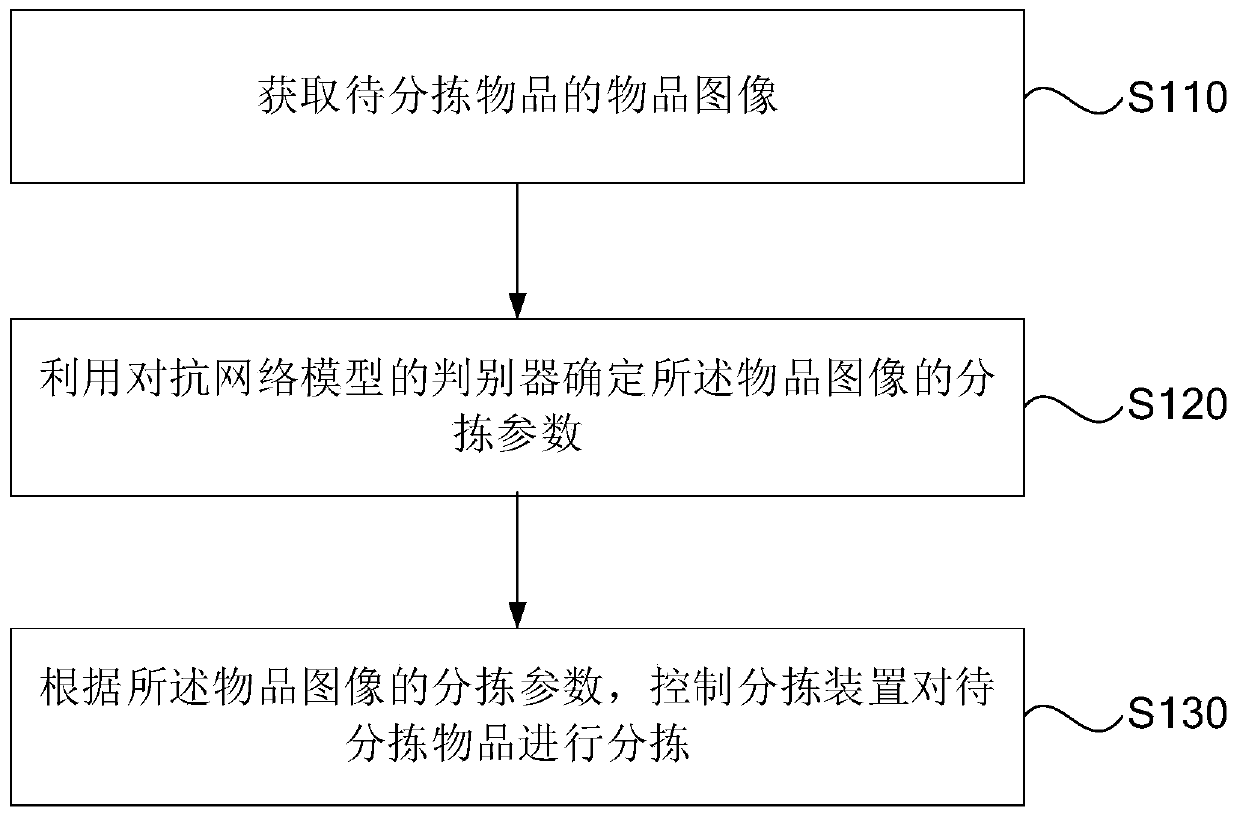

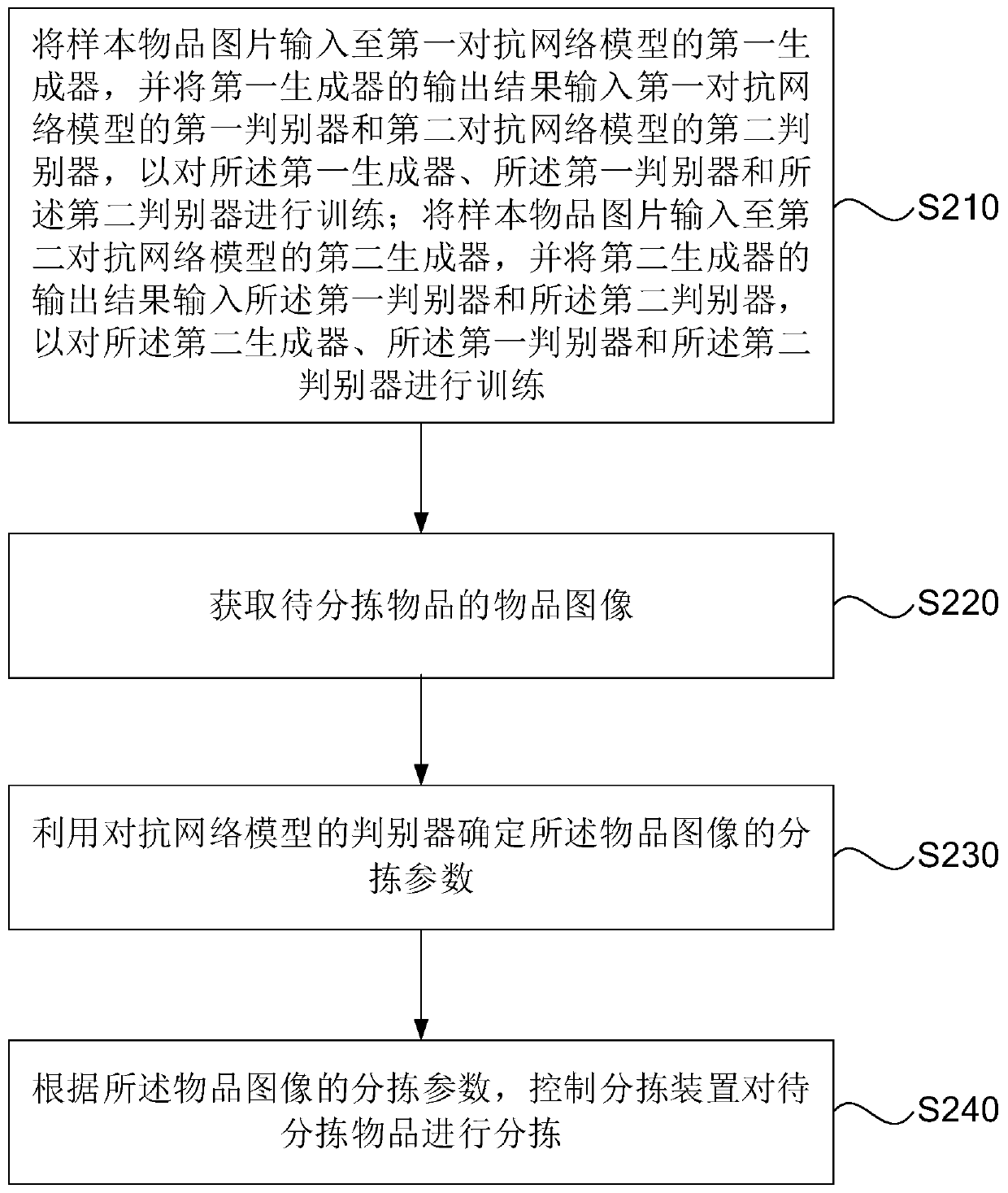

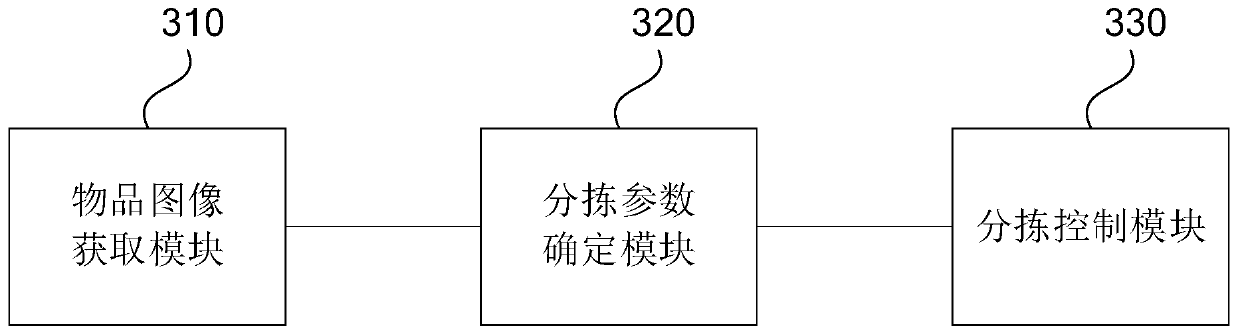

Article sorting method, device, storage medium and electronic equipment

ActiveCN109894383AQuick sortingAccurate sortingCharacter and pattern recognitionSortingDiscriminatorNetwork model

The embodiment of the invention discloses an article sorting method, device, storage medium and electronic equipment. The article sorting method comprises the following steps of acquiring an article image of an article to be sorted; determining a sorting parameter of the article image by using a discriminator against a network model; and according to the sorting parameter of the article image, controlling a sorting apparatus to sort the article to be sorted. By executing the article sorting method, device, storage medium and electronic equipment, an image based on articles can be realized, sothat the sorting efficiency and the sorting quality can be improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

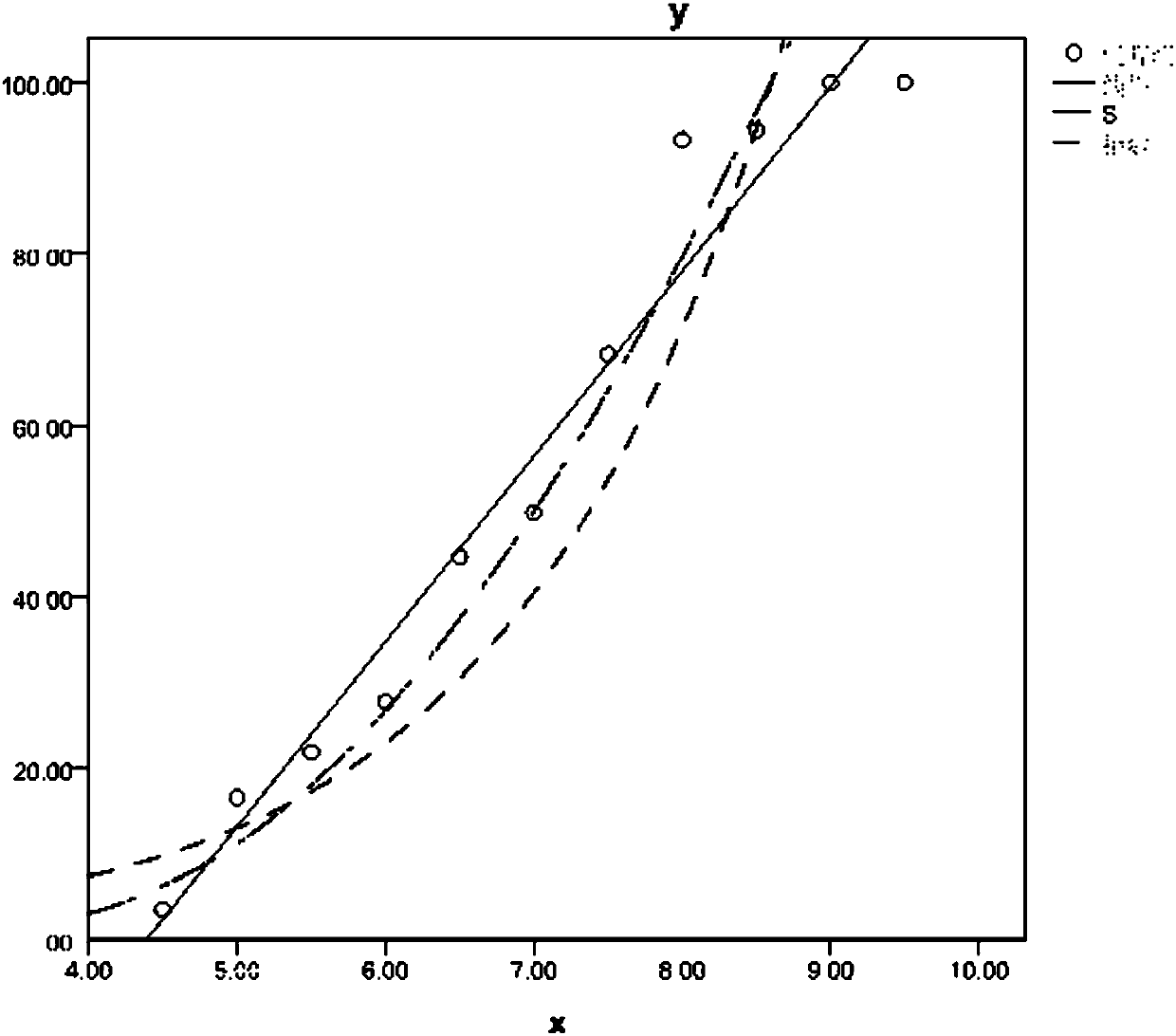

Method for predicting industrial applicability of separated tobacco leaves through appearance characteristic indexes of tobacco leaves

ActiveCN107589228AImprove sorting qualityImprove sorting efficiencyMaterial analysisBiologySeparate sample

The invention discloses a method for predicting industrial applicability of separated tobacco leaves through appearance characteristic indexes of tobacco leaves. The method comprises the following steps: sampling; preparing an industrial separation sample; measuring and calculating a classified sample ratio and quantizing appearance quality indexes; performing sensory evaluation on industrially separated samples, quantizing the indexes and determining the industrial applicability; establishing tobacco leaf industrial applicability classification and prediction model based on appearance indexes, and determining the appearance characteristic indexes and index values; establishing a fitted curve between the appearance characteristic indexes and corresponding weight ratios thereof; and calculating an industrial applicability quantized predicted value of batches of raw materials according to the appearance characteristic indexes and the fitted curve. The method disclosed by the invention has important significances for guiding industrial separation of tobacco leaf raw material quantization and improving the industrial applicability of the tobacco leaf raw materials.

Owner:CHINA TOBACCO JIANGSU INDAL

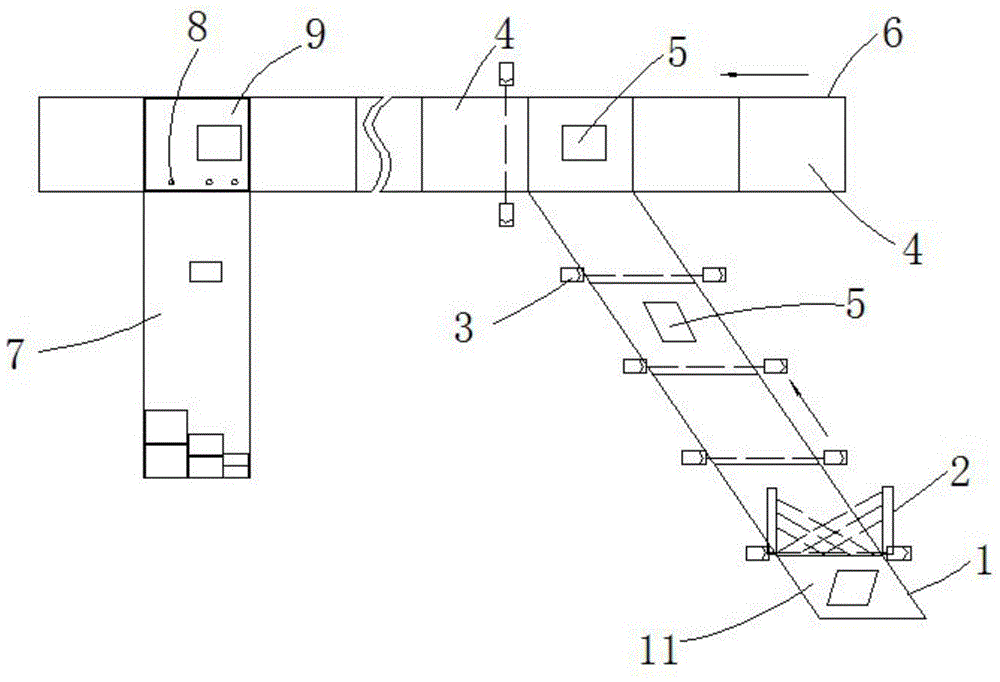

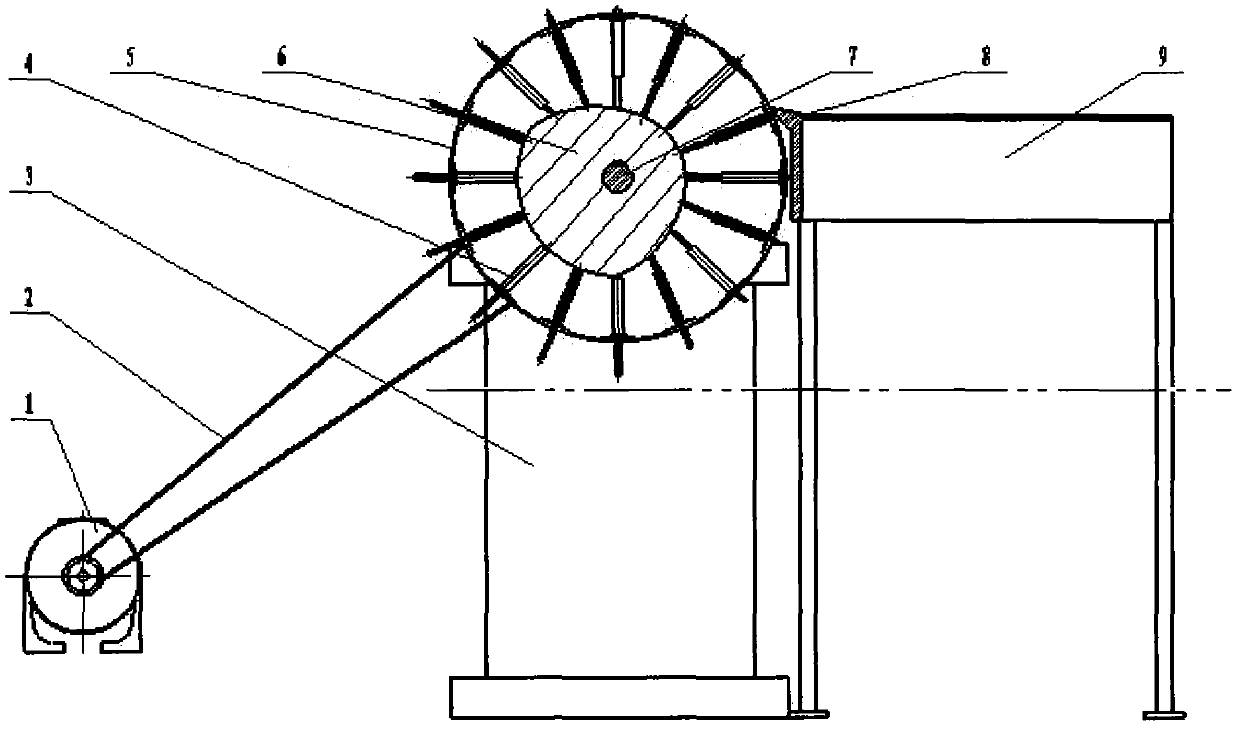

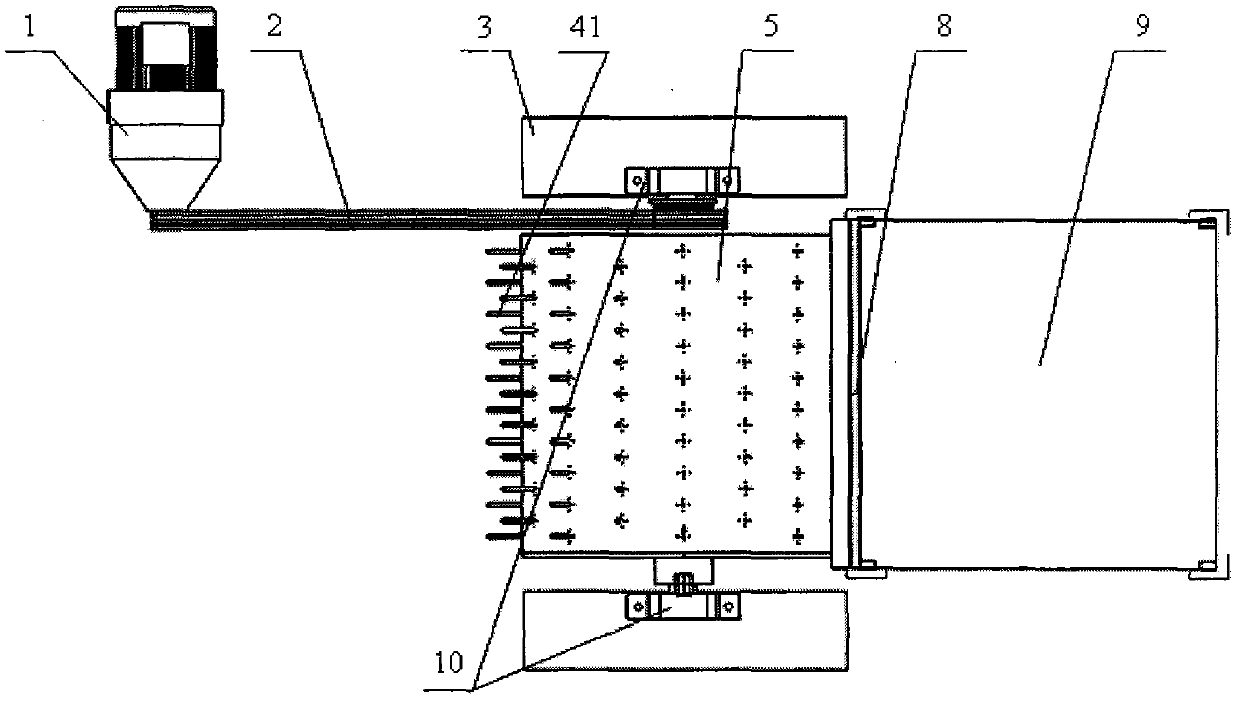

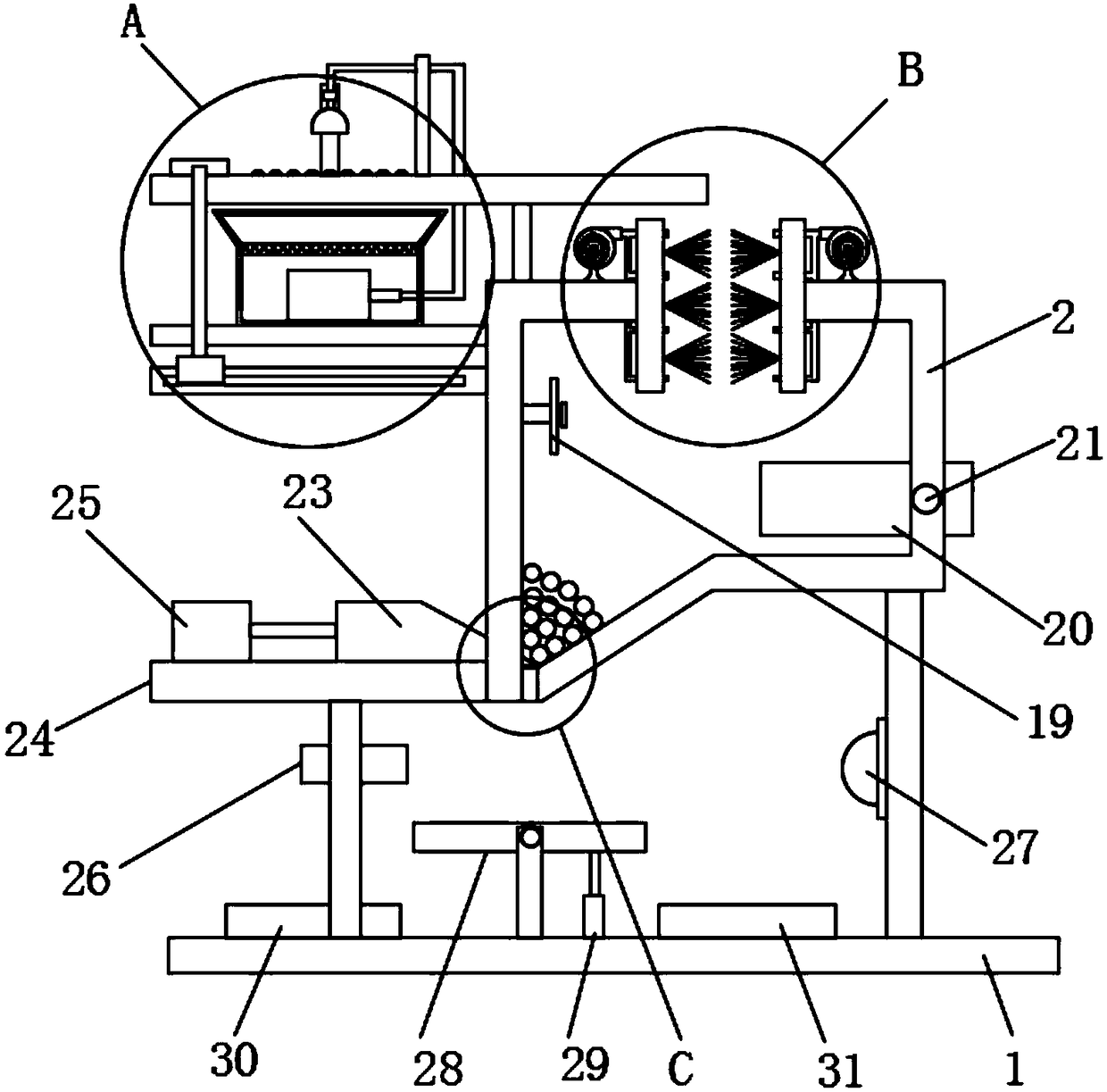

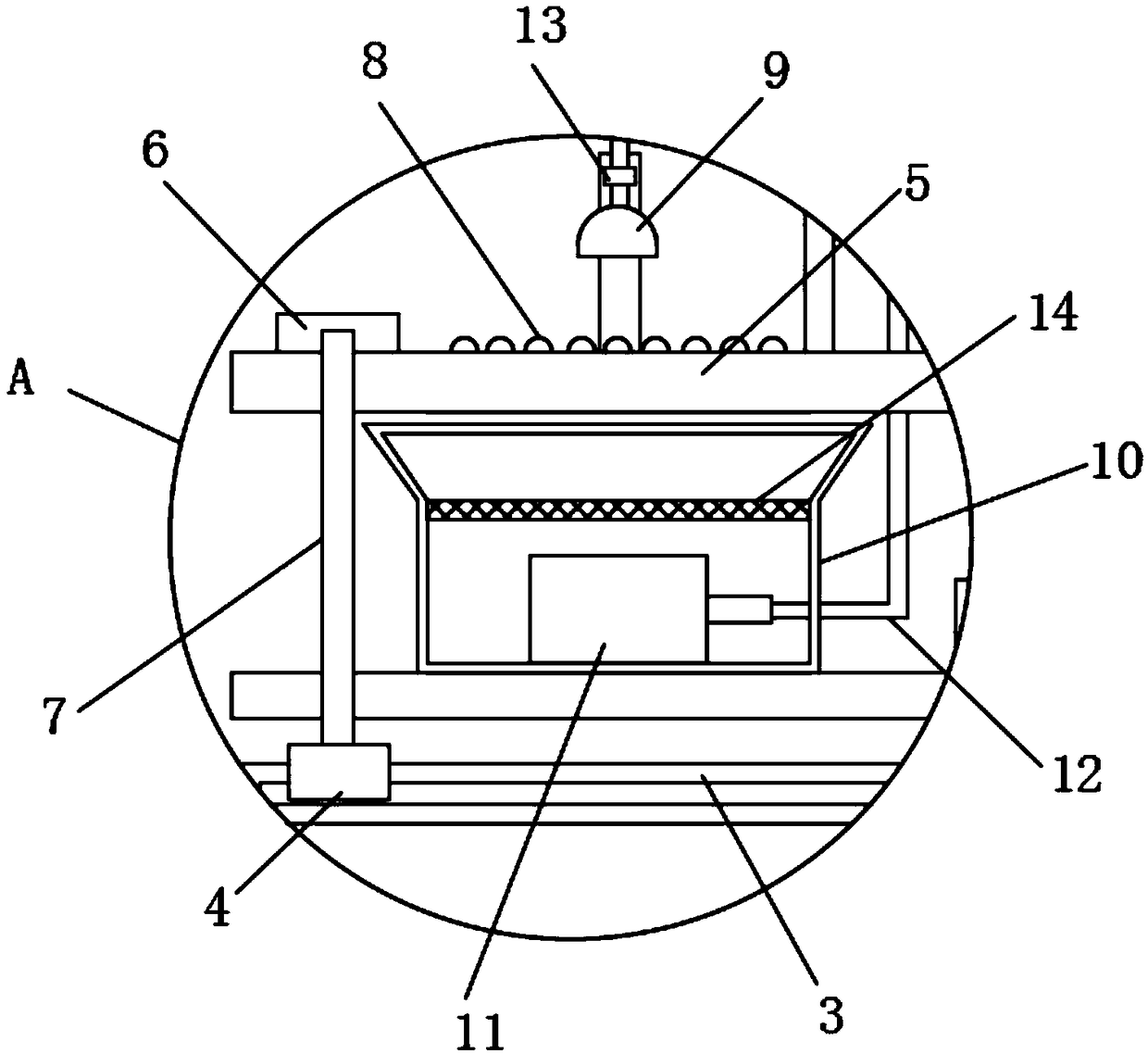

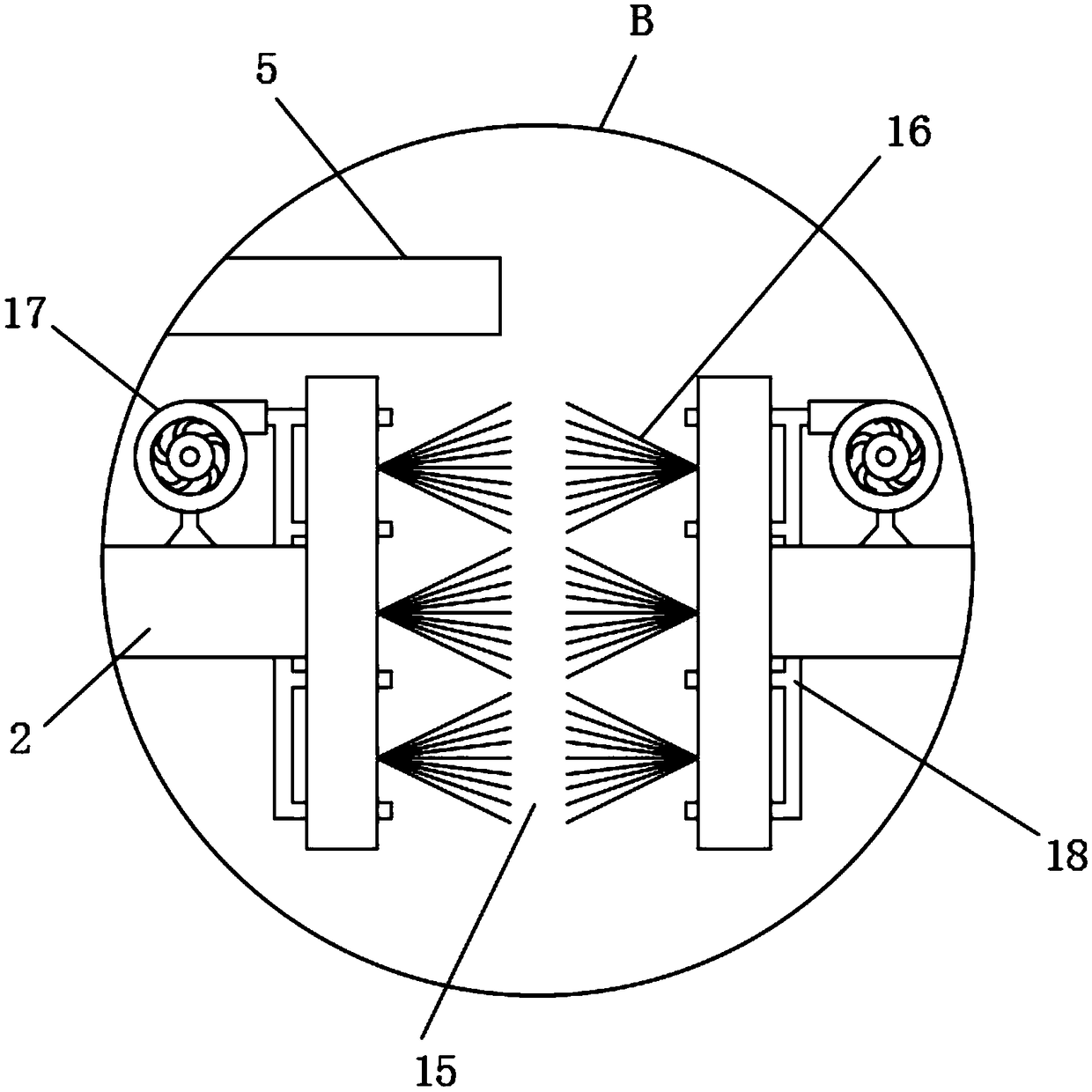

Drum-type garbage sorting machine

InactiveCN102601036AEfficient sortingImprove sorting efficiencySievingScreeningWaste collectionEngineering

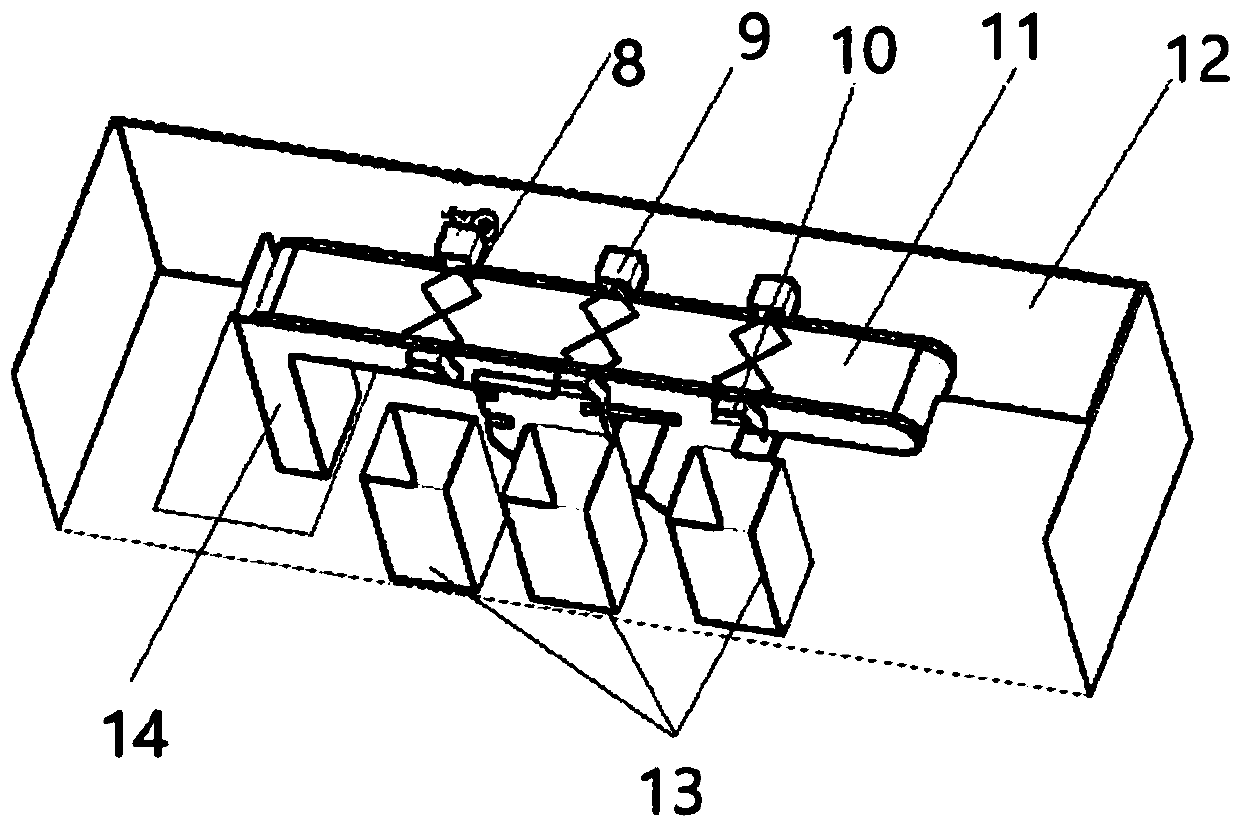

The invention relates to a drum-type garbage sorting machine, which comprises a motor 1, a V belt transmission mechanism 2, a frame 3, a sorting needle device 4, a drum 5, a constant cam 6, a main shaft 7, a scraper 8, a garbage collecting plate 9 and a connecting shaft base 10. When the drum-type garbage sorting machine is used, the motor 1 inputs power, and the rotary speed and the torque are transferred to the drum 5 through the V belt transmission mechanism 2. The constant cam 6 is fixed on the frame 3 through the main shaft 7 and the connecting shaft base 10. A sorting needle 41 can stretch in different work areas through the relative movement of the drum 5 and the constant cam 6 so as to hook and separate garbage that is easy to wind. Then, sorted garbage is collected to an appointed storage container through the scraper 8 and the garbage collecting plate 9. The drum-type garbage sorting machine is simple in structure, is simple and convenient to operate and easy to popularize.

Owner:INNER MONGOLIA UNIV OF TECH

Pearl detection device with automatic sorting function

ActiveCN108714571AAffect the color test resultsAvoid Manual SortingGas current separationDrying gas arrangementsMicrocontrollerPEAR

The invention discloses a pearl detection device with an automatic sorting function. The pear detection device comprises a base, wherein four supporting plates are arranged on the upper side wall of the base, the upper ends of two of the four supporting plates are jointly connected with a placement box, the upper side wall of the placement box is fixedly connected with a connecting plate, the upper end of the connecting plate is fixedly connected with a cleaning plate, a plurality of through holes are formed in the upper side wall of the cleaning plate, a plurality of pearls are arranged on the upper side wall of the cleaning plate, and the upper side wall of the cleaning plate is connected with a push plate in a sliding mode. According to the pearl detection device, the pearls are washedand then detected, so that the color detection results of the pearls are prevented from being influenced by impurities, intermittent falling of the to-be-detected pearls is realized through intermittent clamping of a wedge-shaped block and a wedge-shaped groove, then sequential detection of the color of the pearls is completed, and sorting between the high-quality pears and the pears with the poorquality is achieved through the connection between an S9702-RGB color sensor and an STM32 microcontroller, so that manual sorting is avoided, the working efficiency of the pearl sorting is improved,the sorting quality is high, convenience and practicability are achieved, and the popularization is high.

Owner:深圳润福金技术开发有限公司

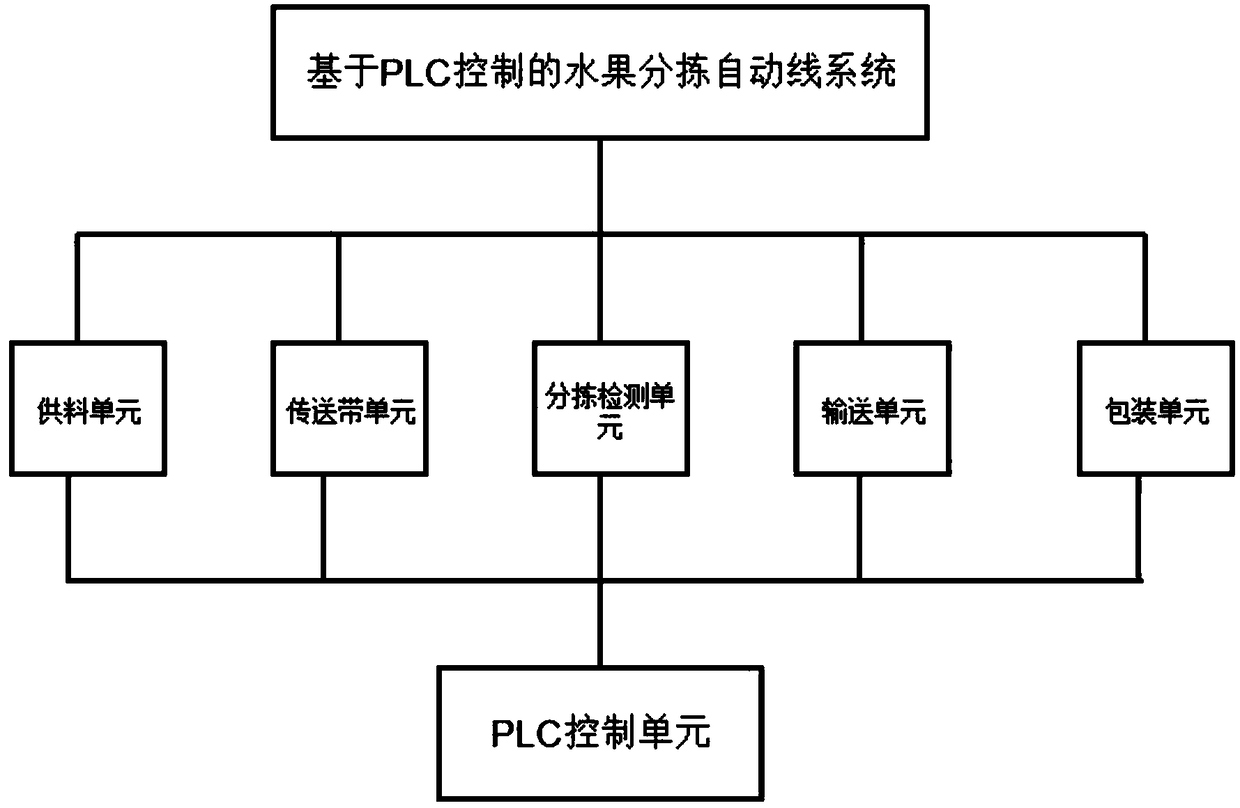

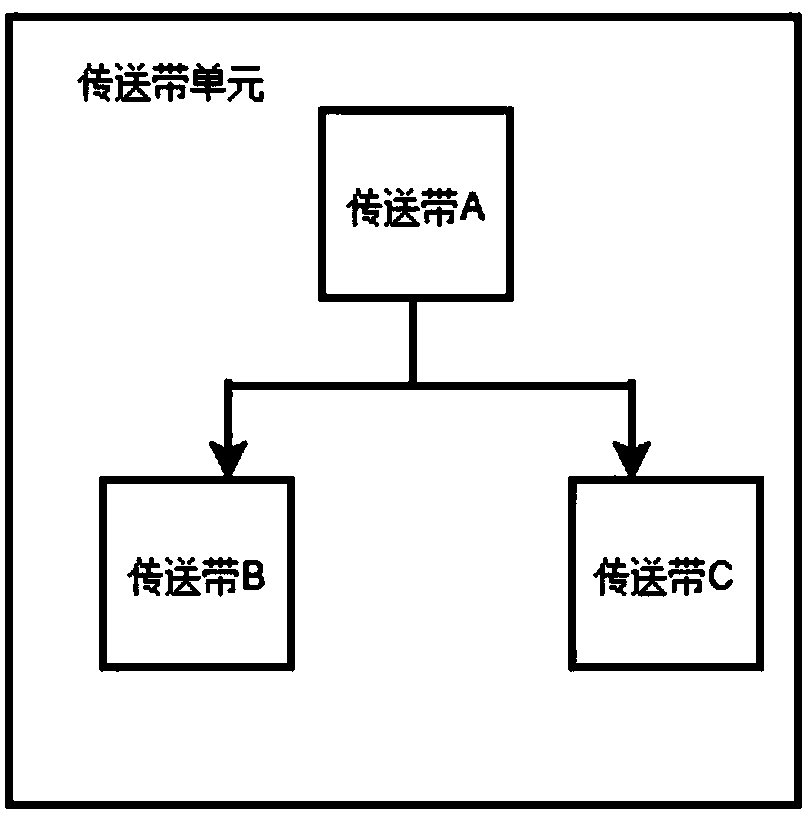

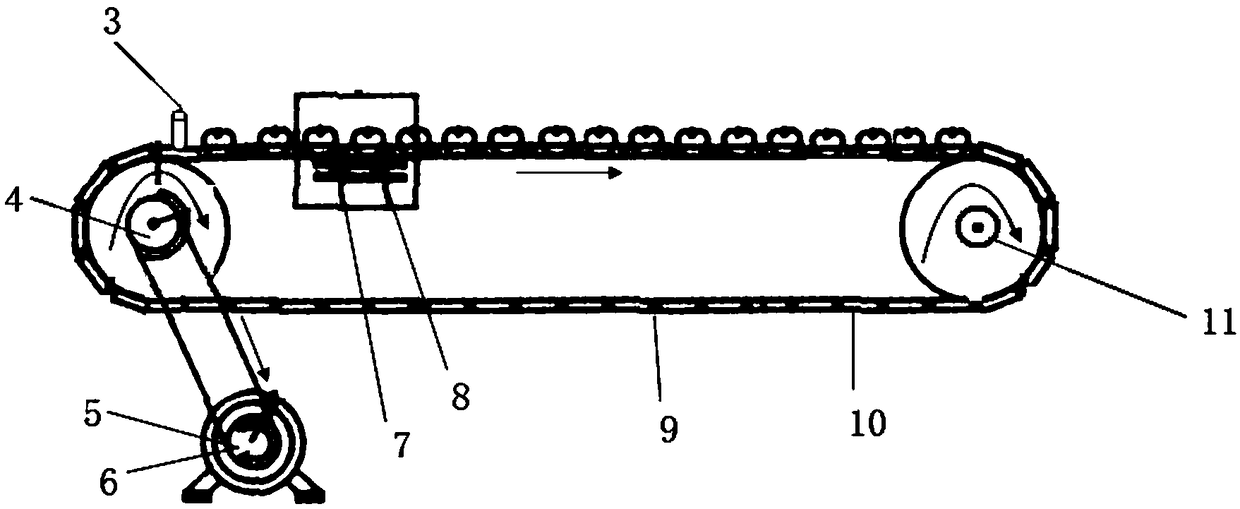

Fruit sorting automatic line system based on PLC control

PendingCN108855974AImprove fine sortingMeet different sorting requirementsSortingComputer moduleConveyor belt

The invention relates to the technical field of fruit and vegetable sorting, in particular to a fruit sorting automatic line system based on PLC control. The fruit sorting automatic line system comprises a conveyor belt unit, a sorting detection unit, a conveying unit and a PLC control unit, wherein the conveyor belt unit comprises multiple groups of conveying belts and is used for transporting fruits; the sorting detection unit comprises various types of detection modules; each group of conveyor belt is at least provided with one detection module according to the types of fruits needed to besorted; each detection module is used for detecting sorting level of the fruits on the conveyor belts; the conveying unit comprises a plurality of manipulators; each group of conveyor belt is at leastprovided with one manipulator; the conveying unit is used for grabbing and conveying the fruits on the conveyor belts under the control of the PLC control unit. According to the scheme, by automatically sorting and detecting multiple qualities and types of the fruits, fine sorting and sorting quality of the fruits are improved.

Owner:阜阳职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com