Patents

Literature

233 results about "Separate sample" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

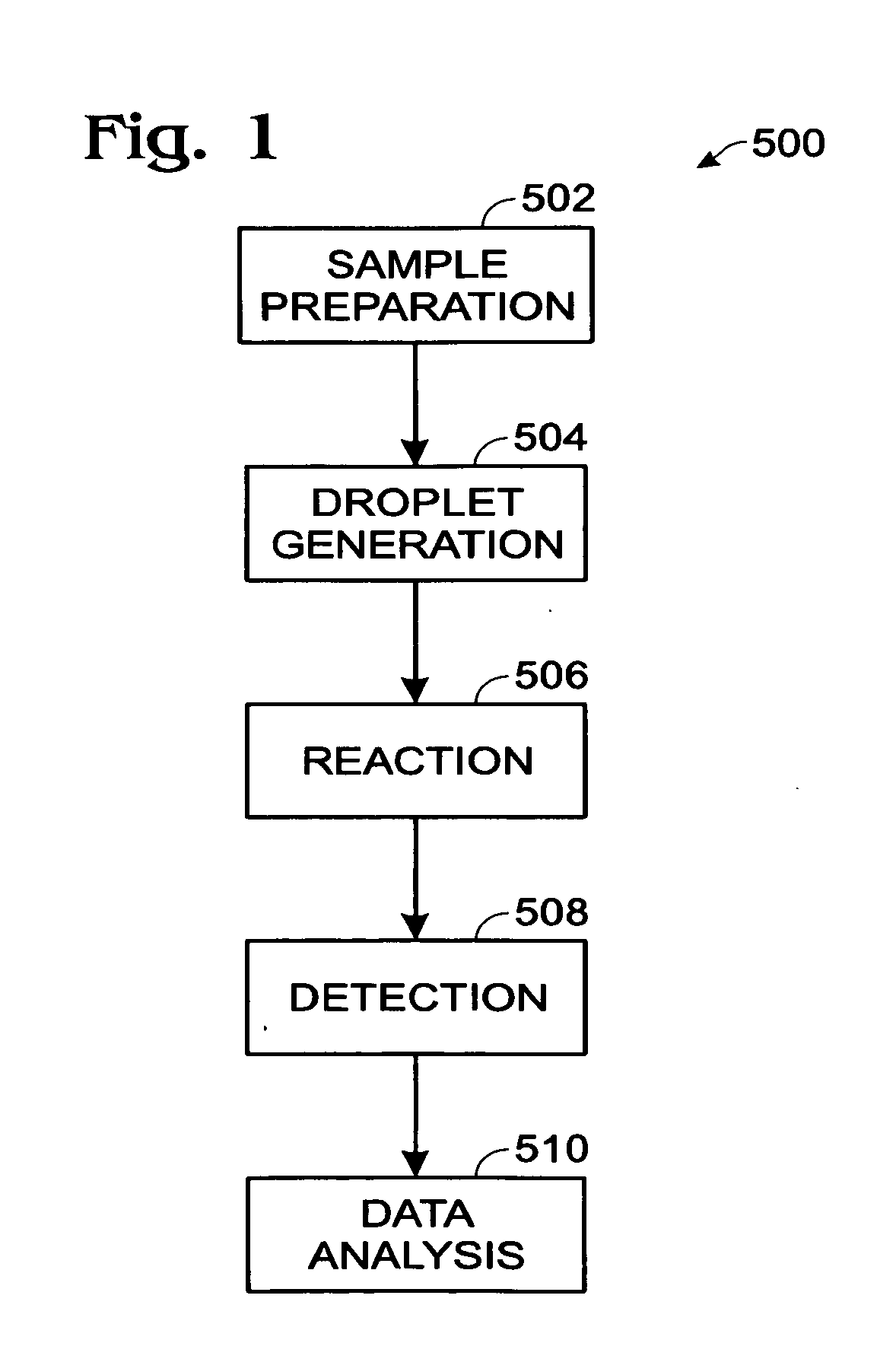

Droplet-based assay system

ActiveUS20100173394A1Easy CalibrationImprove accuracy and reliabilityBioreactor/fermenter combinationsBiological substance pretreatmentsAssayBiology

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

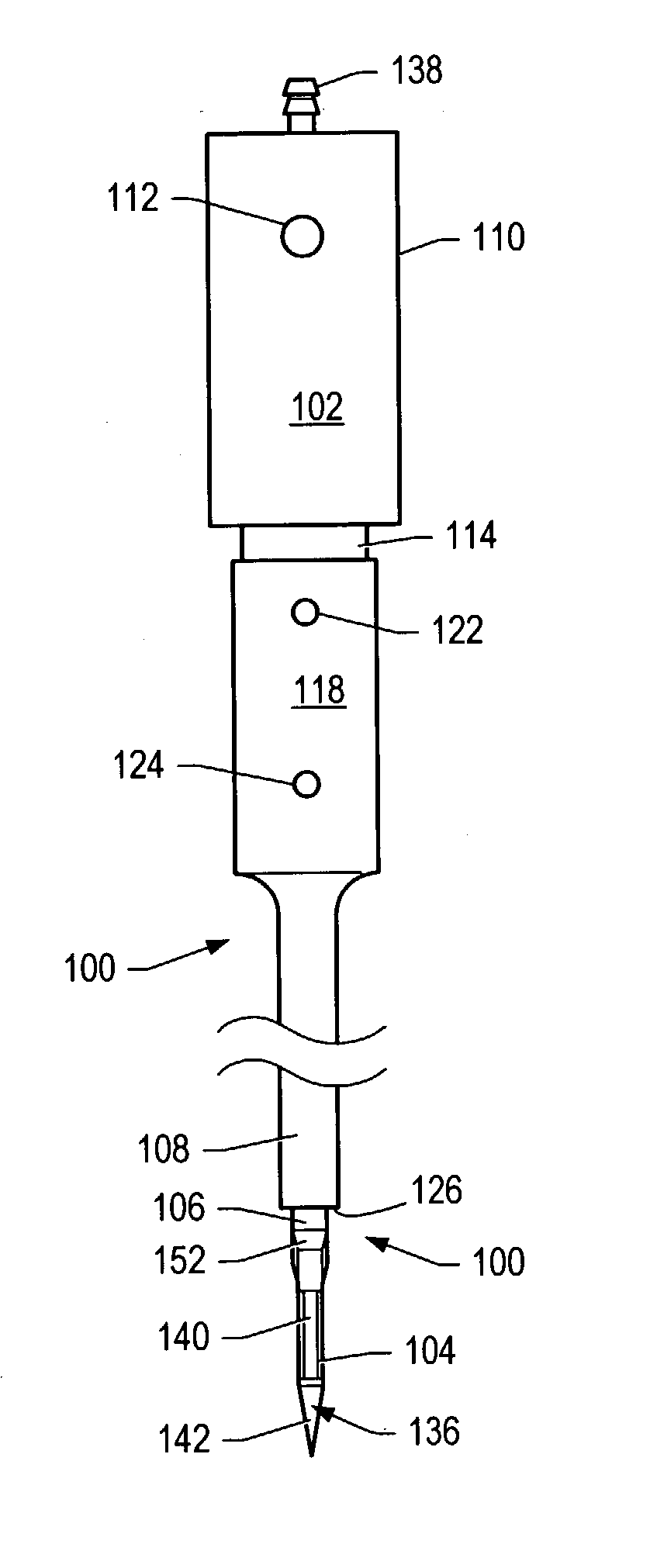

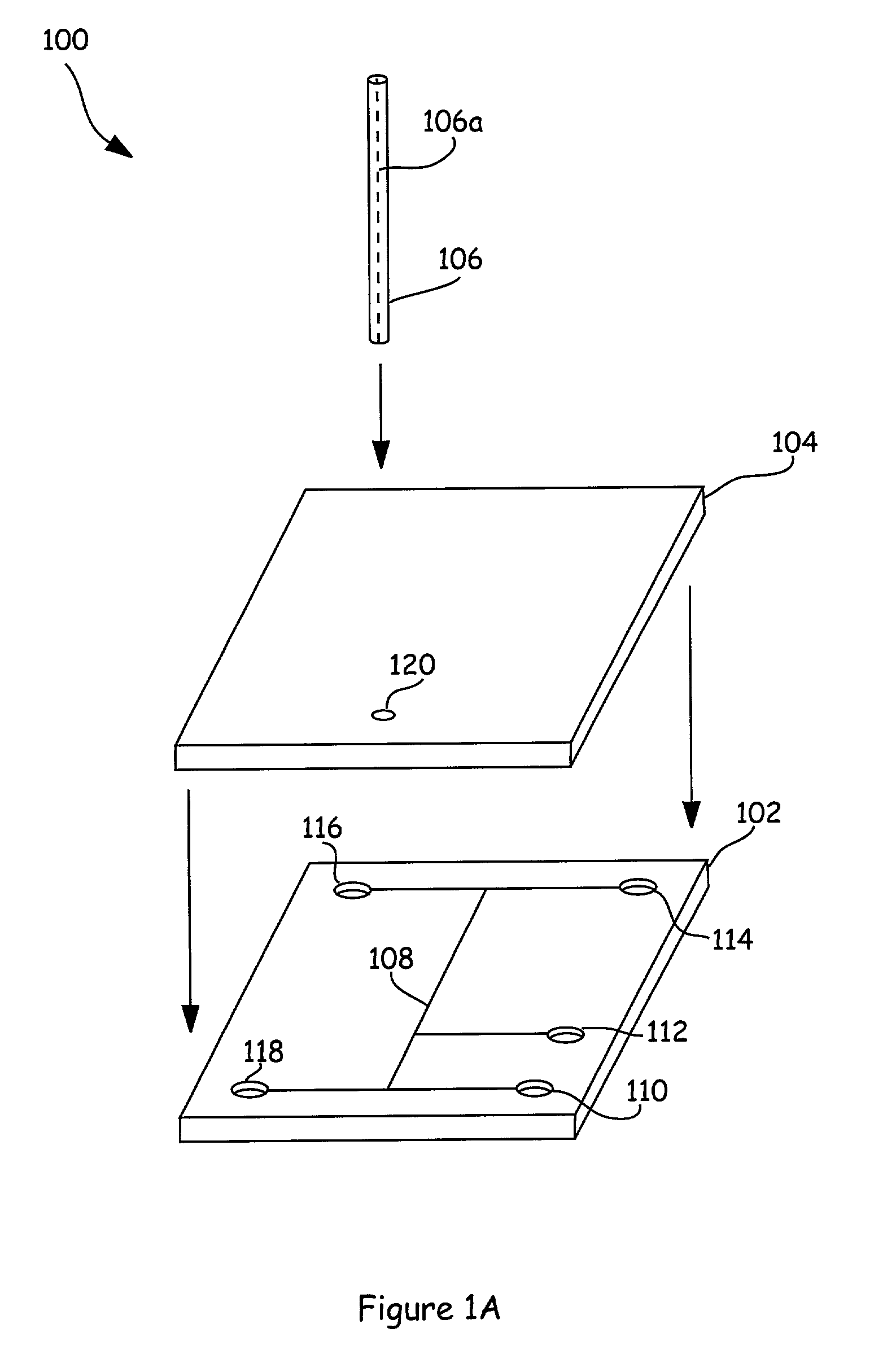

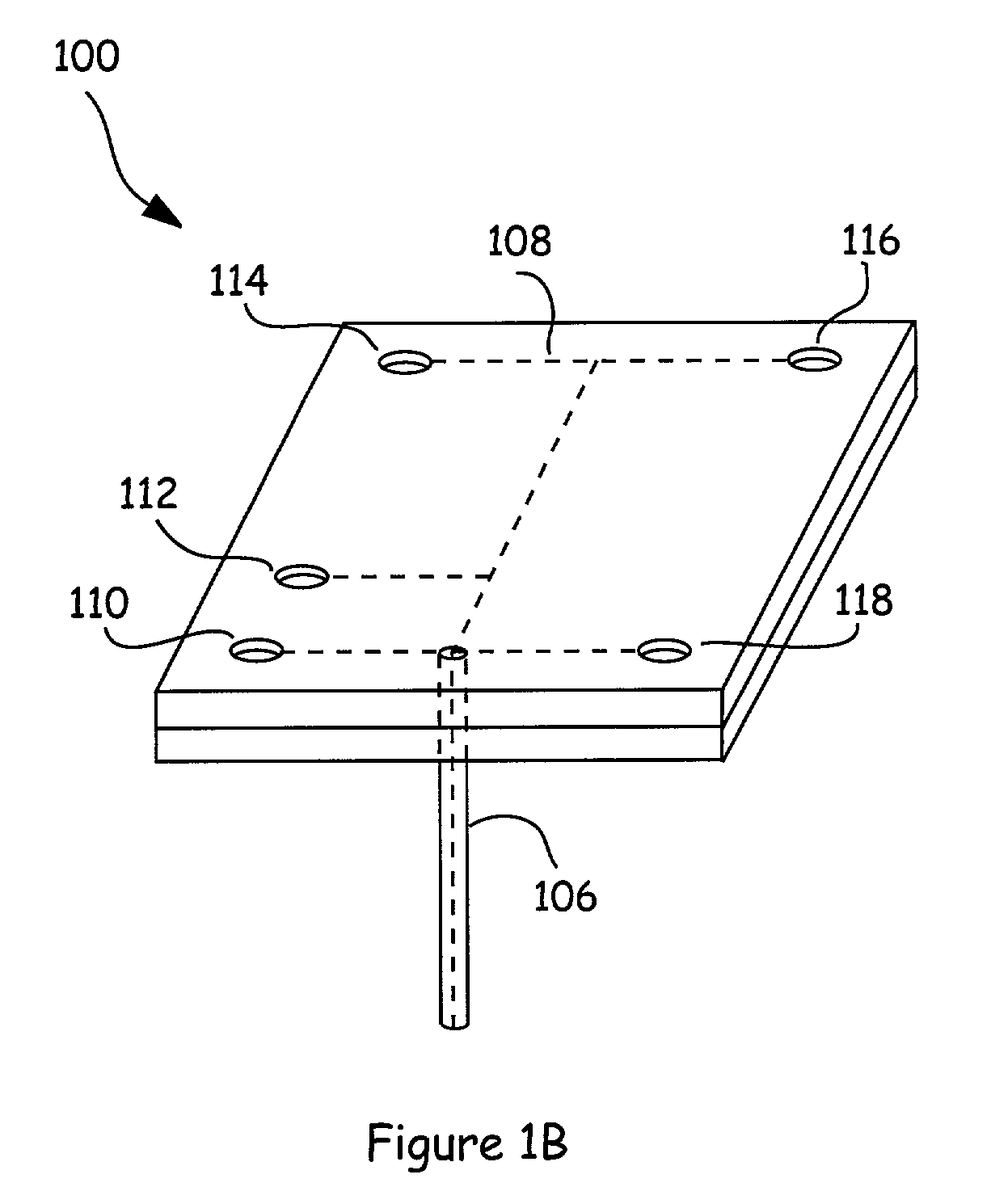

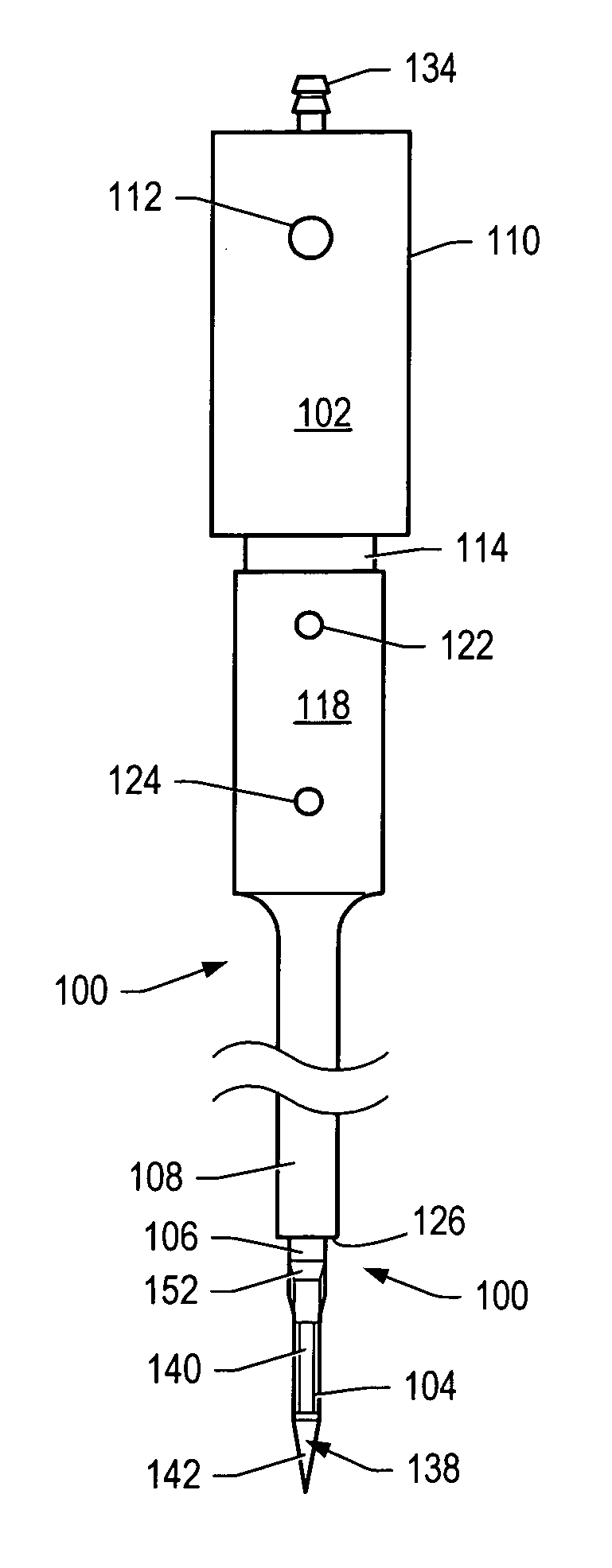

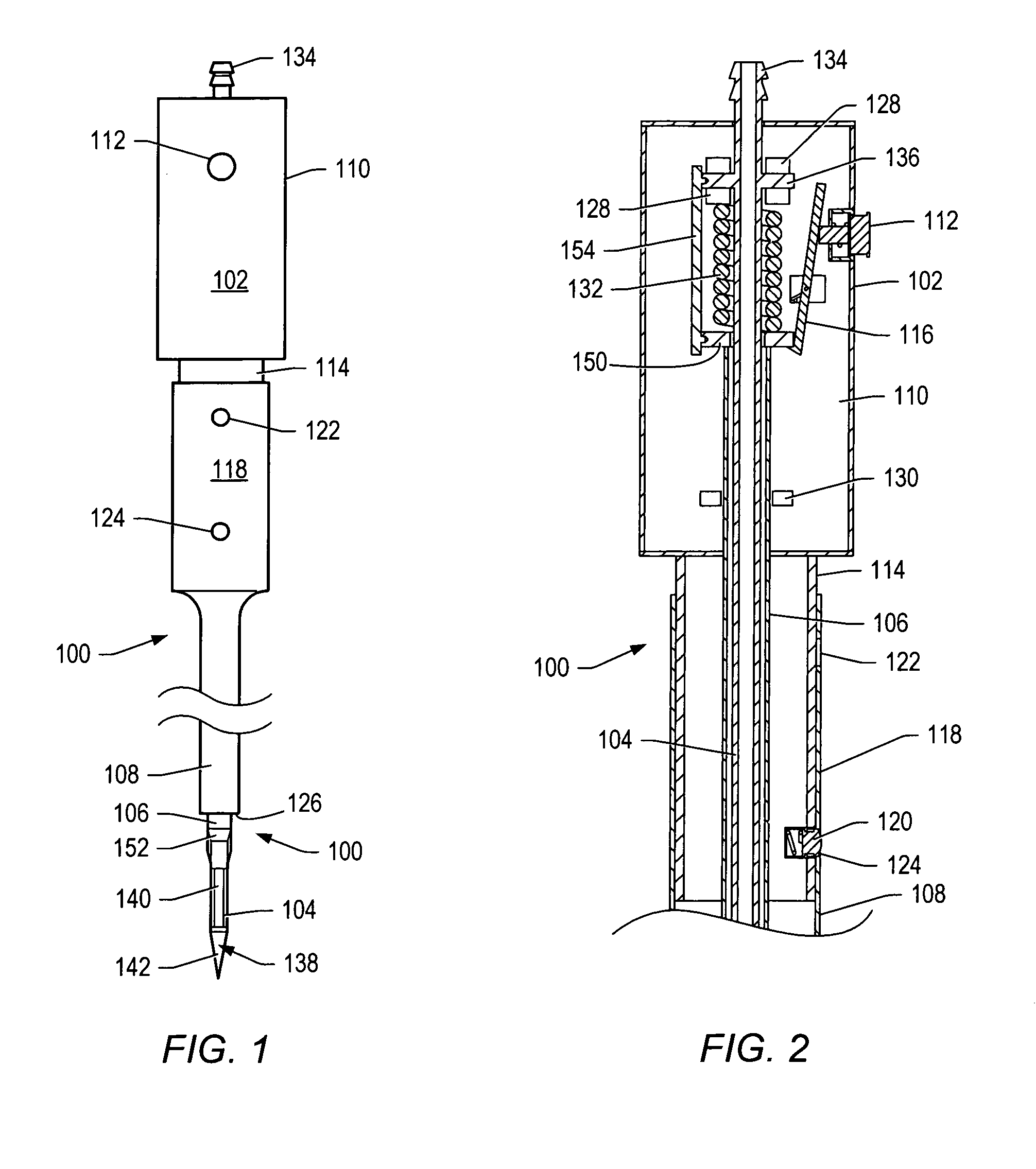

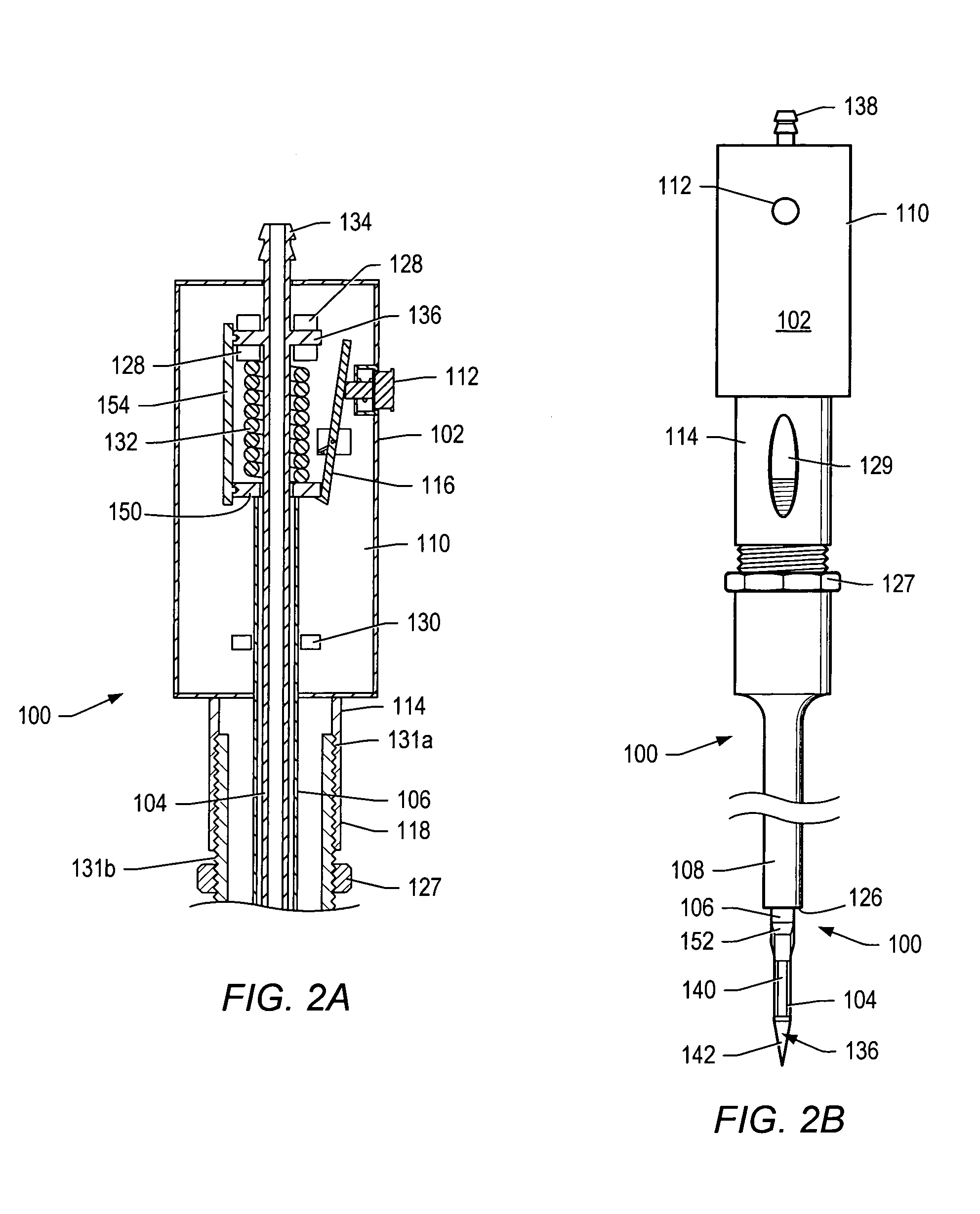

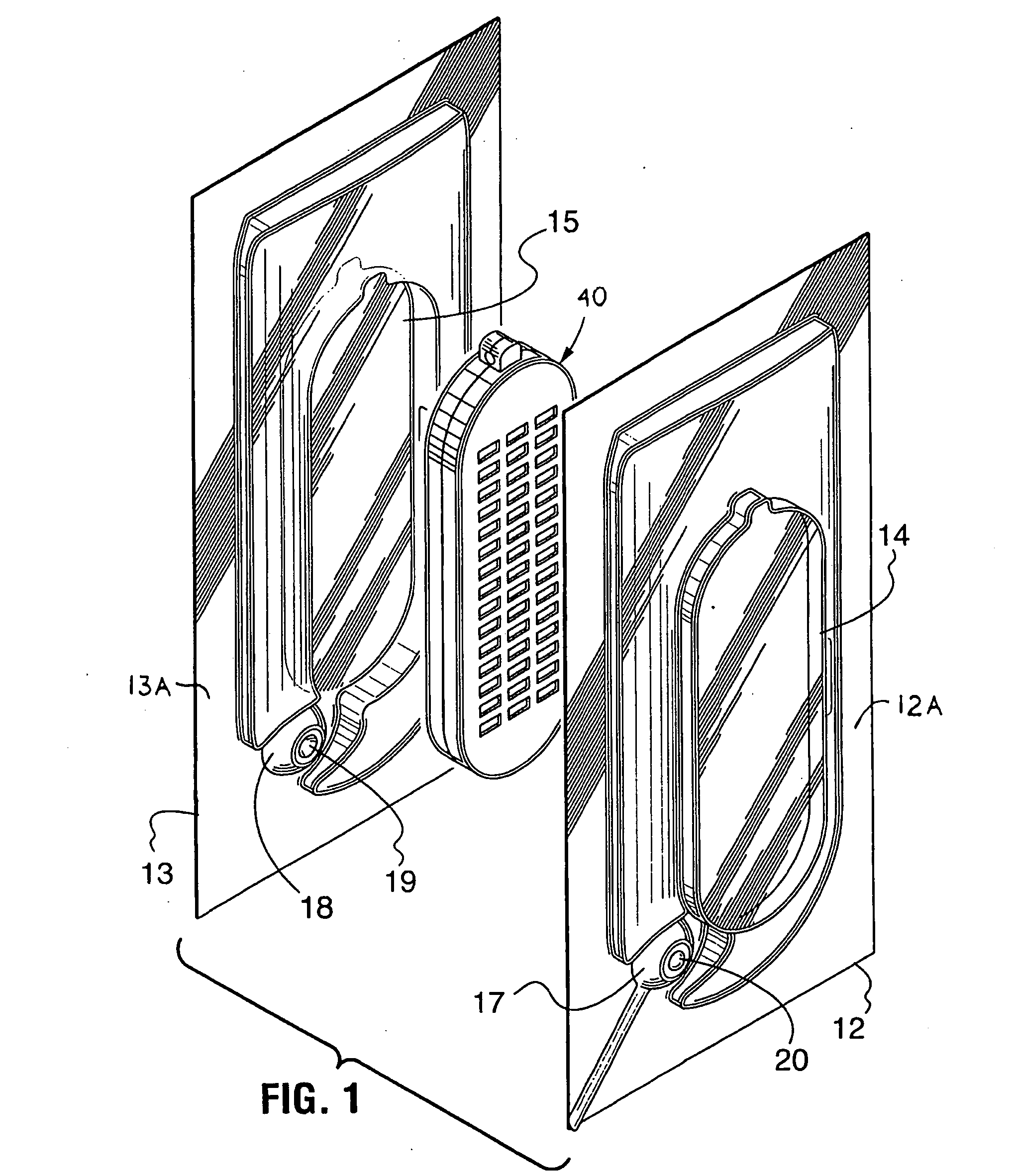

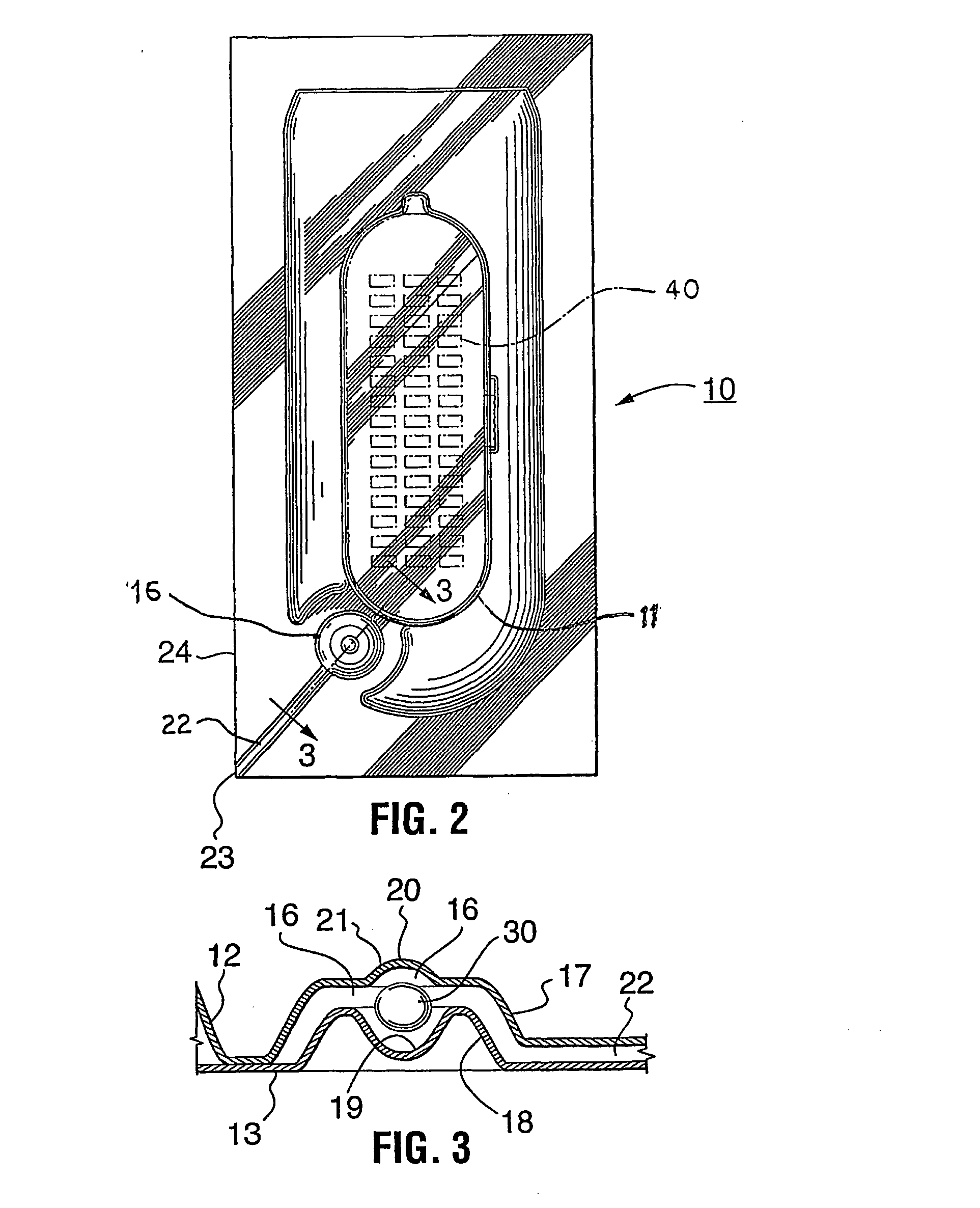

Biopsy needle

A biopsy needle assembly may include a sample needle, an actuator and a cutter. A sample needle may include a sample opening. A tissue sample may be positioned in the sample opening when the sample needle is inserted into tissue of a patient. The actuator may be activated to move the cutter relative to the sample needle and separate sample tissue in the sample opening from adjacent tissue. The biopsy needle assembly may be removed from the patient and the sample may be removed from the sample opening. In some embodiments, the sample needle may be inserted in tissue through an instrument (e.g., an endoscope). The biopsy needle assembly may include a sheath that inhibits a sample needle and a cutter from contacting the instrument when the biopsy needle is inserted in the instrument.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

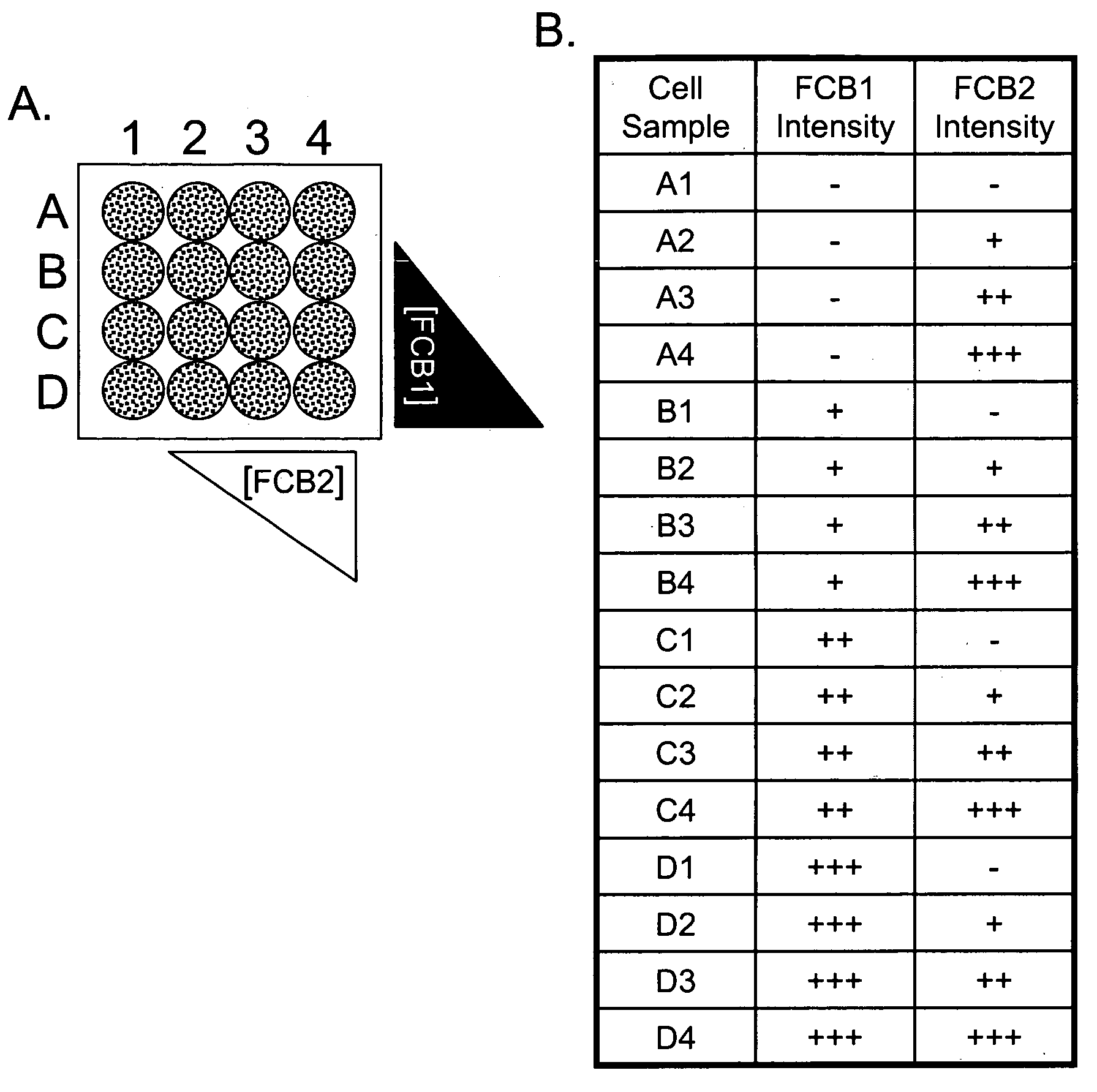

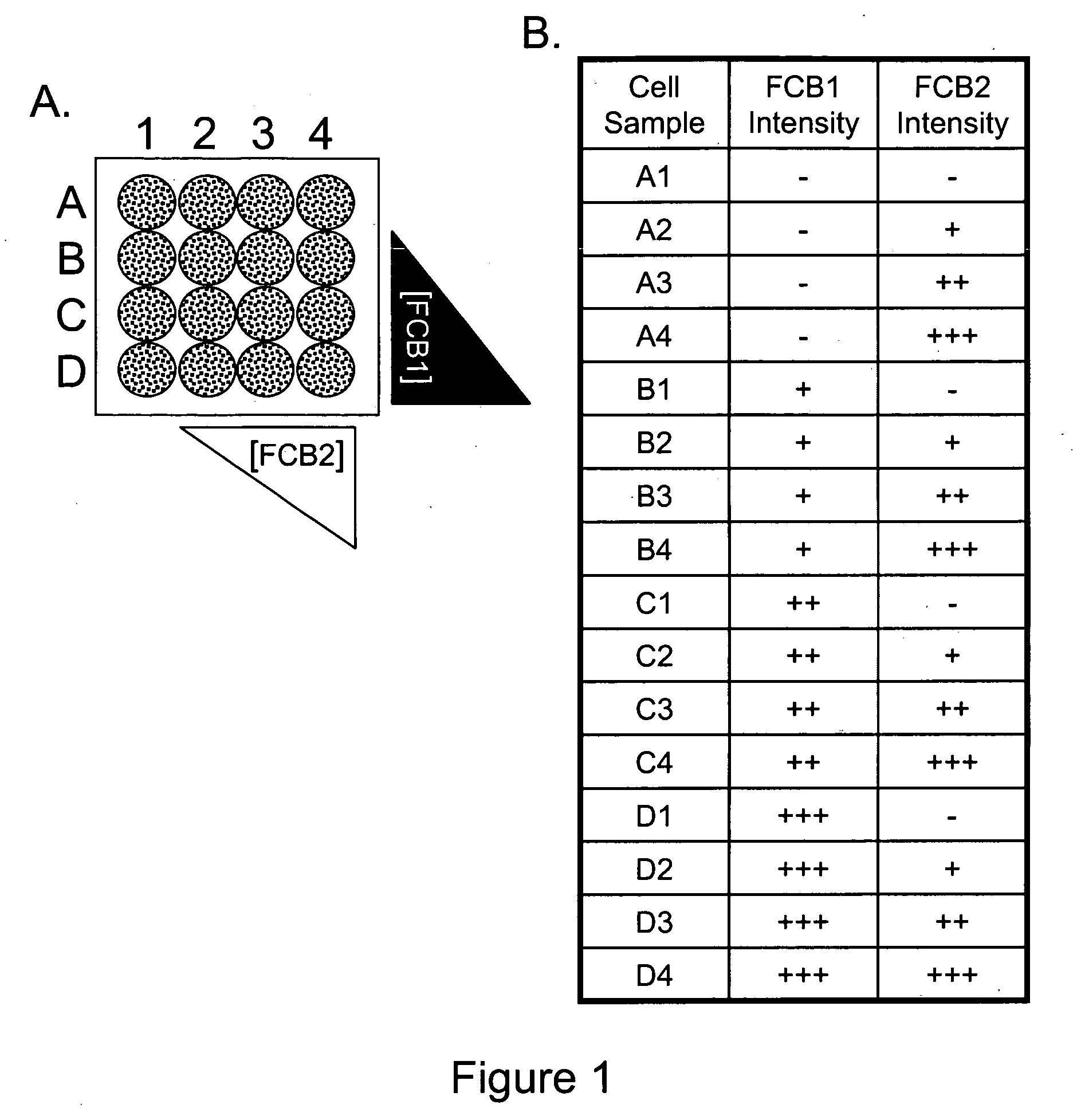

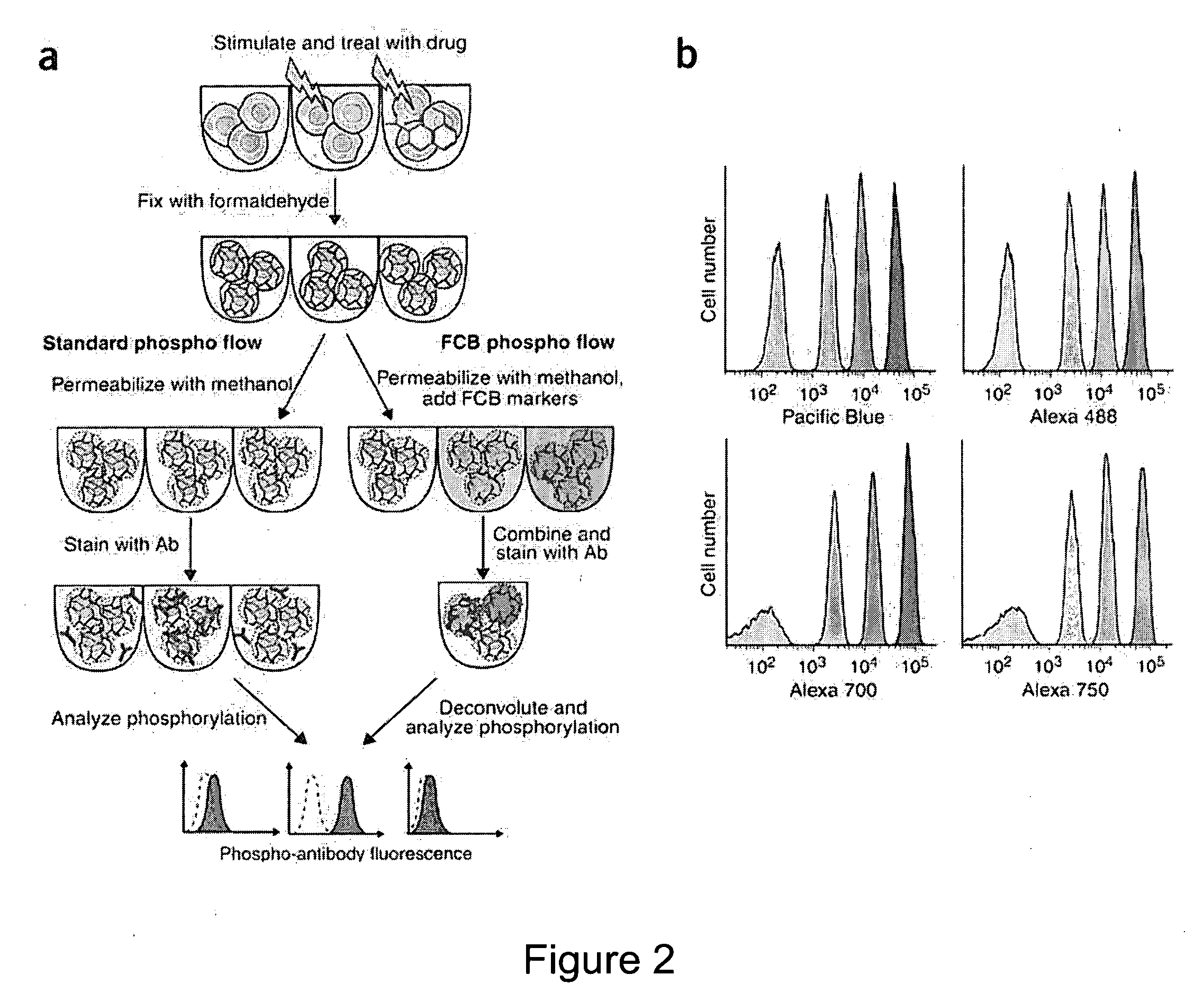

Multiplex cellular assays using detectable cell barcodes

ActiveUS20080241820A1Reduces regent consumptionImprove throughputMicrobiological testing/measurementBiological testingMultiplexingAnalyte

We describe herein a cell-based multiplexing technique called detectable cell barcoding (DCB). In DCB, each individual sample is labeled with a different DCB signature that distinguishes each sample by one or both of detected intensity or type of detection characteristic. The samples are then combined and analyzed for a detectable characteristic of interest (e.g., presence of an analyte). By employing multiple distinct DCB labels at varying concentrations, one can perform multiplex analyses on up to hundreds or thousands (or more) of cell samples in a single reaction tube. DCB reduces reagent consumption by factors of 100-fold or more, significantly reduces data acquisition times and allows for stringent control sample analysis.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

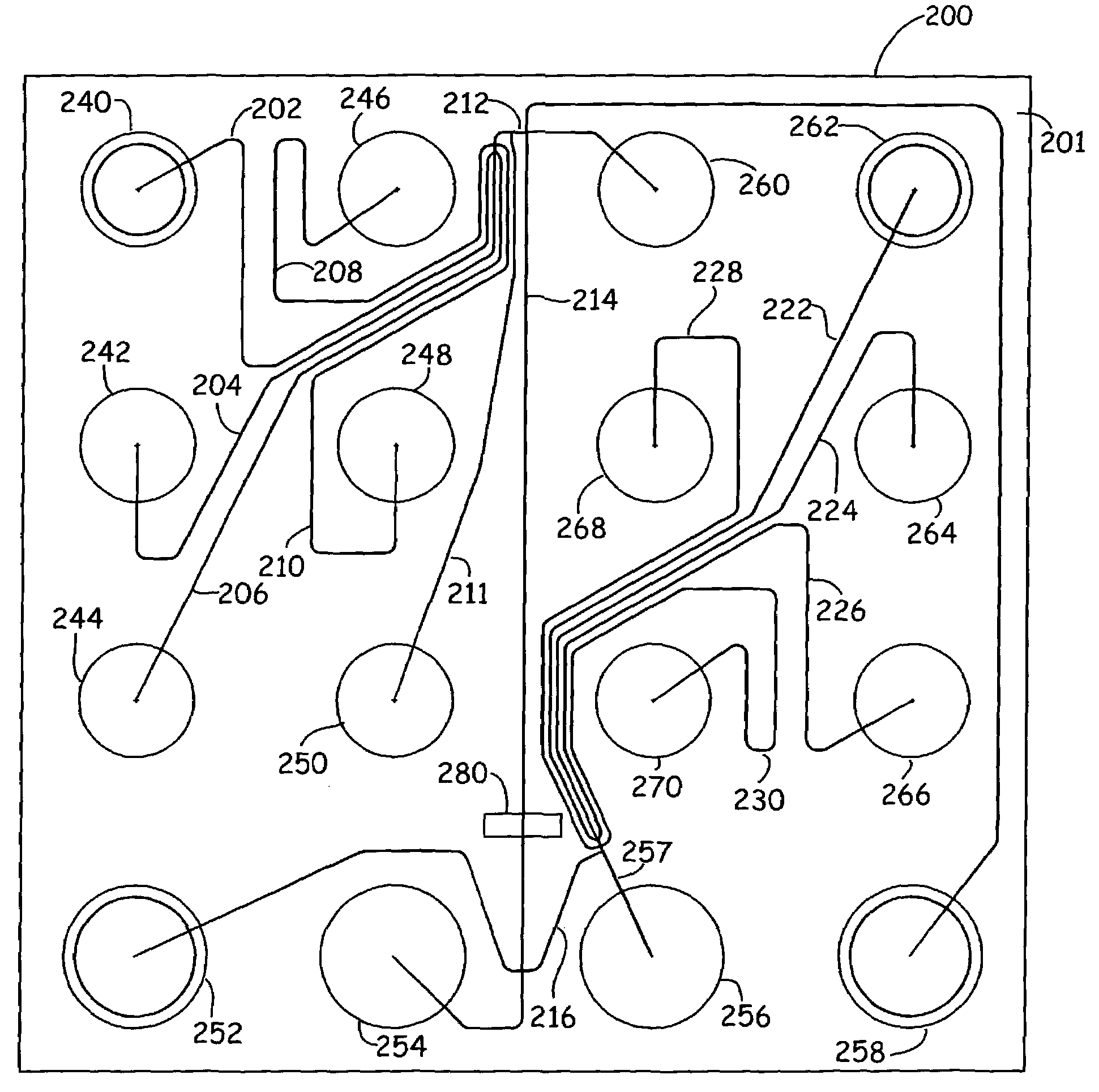

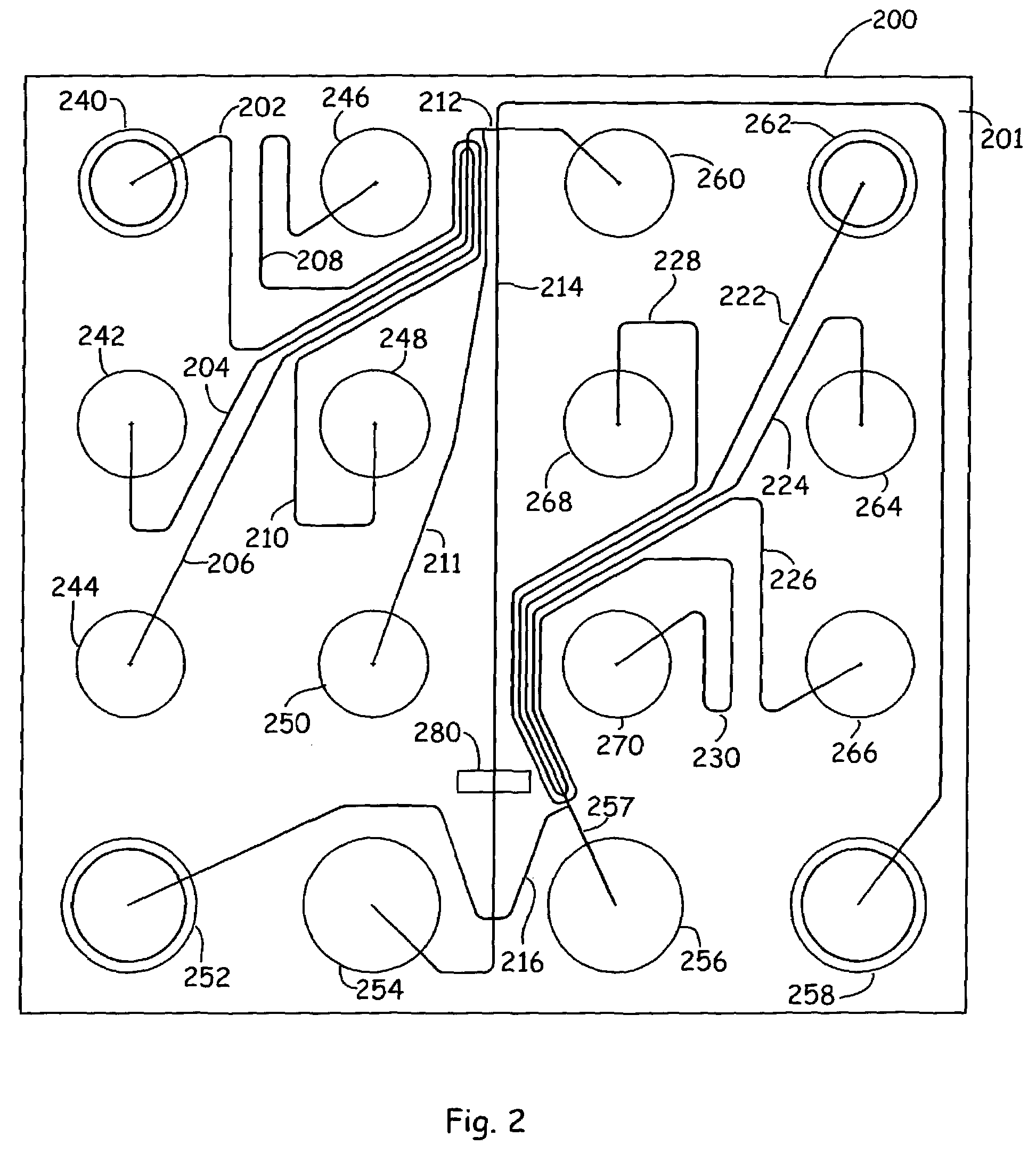

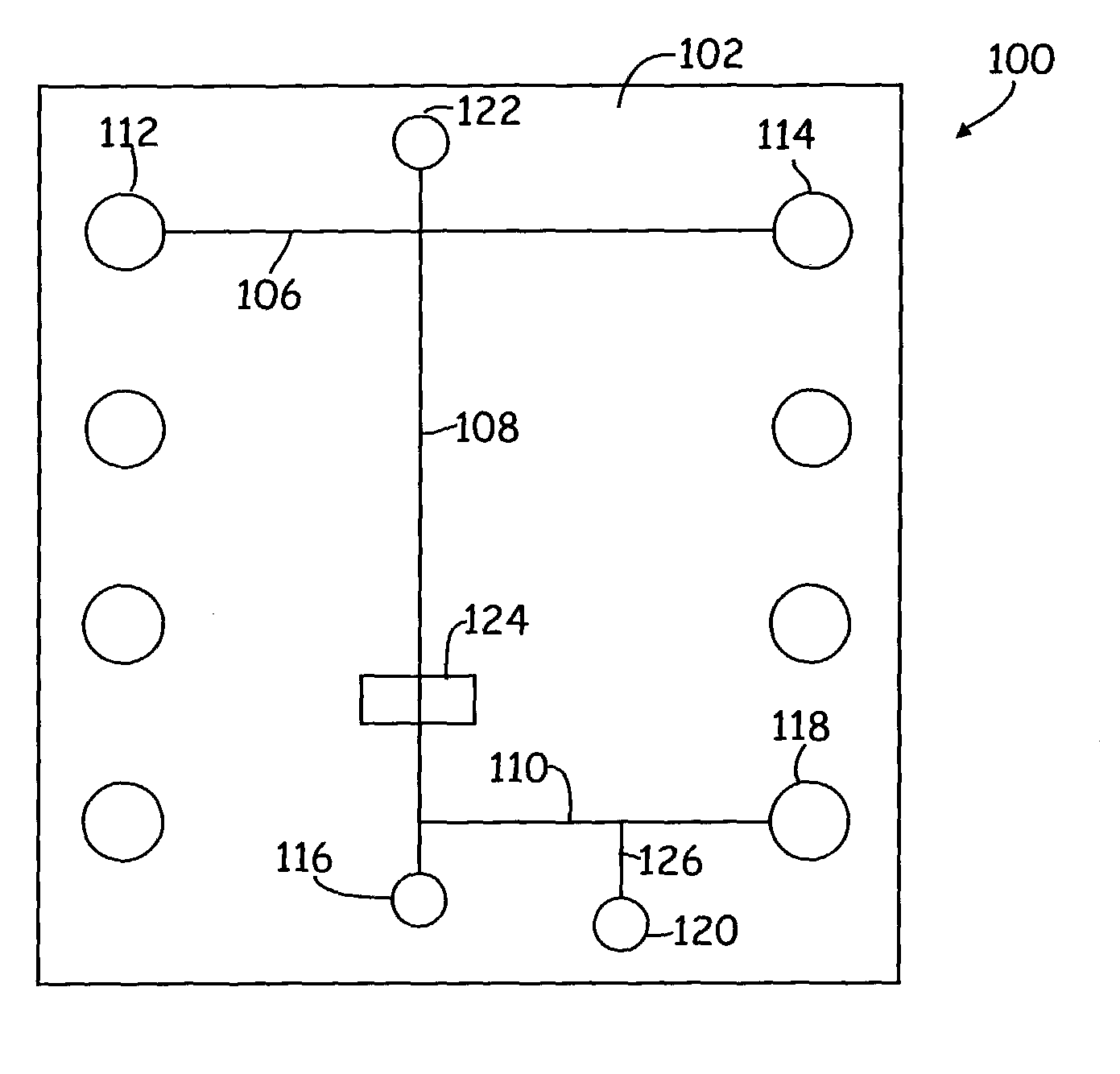

Methods, systems and apparatus for separation and isolation of one or more sample components of a sample biological material

ActiveUS7419784B2Bioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresisBiological materials

Devices, systems and methods for use in separating sample materials into different sample components and then isolating one or more of the sample components for further processing or analysis are disclosed. Devices employ configurations that optionally allow a sample material to be electrophoretically separated into sample components in a separation matrix within a separation conduit. The sample components may then be detected in a detection zone in the separation conduit, and then selected components shunted to a component collection conduit within the device downstream of the detection zone for further processing or analysis based on information received at the detection zone. Methods of using these devices, and systems that incorporate these devices are also envisioned.

Owner:CAPLIPER LIFE SCI INC

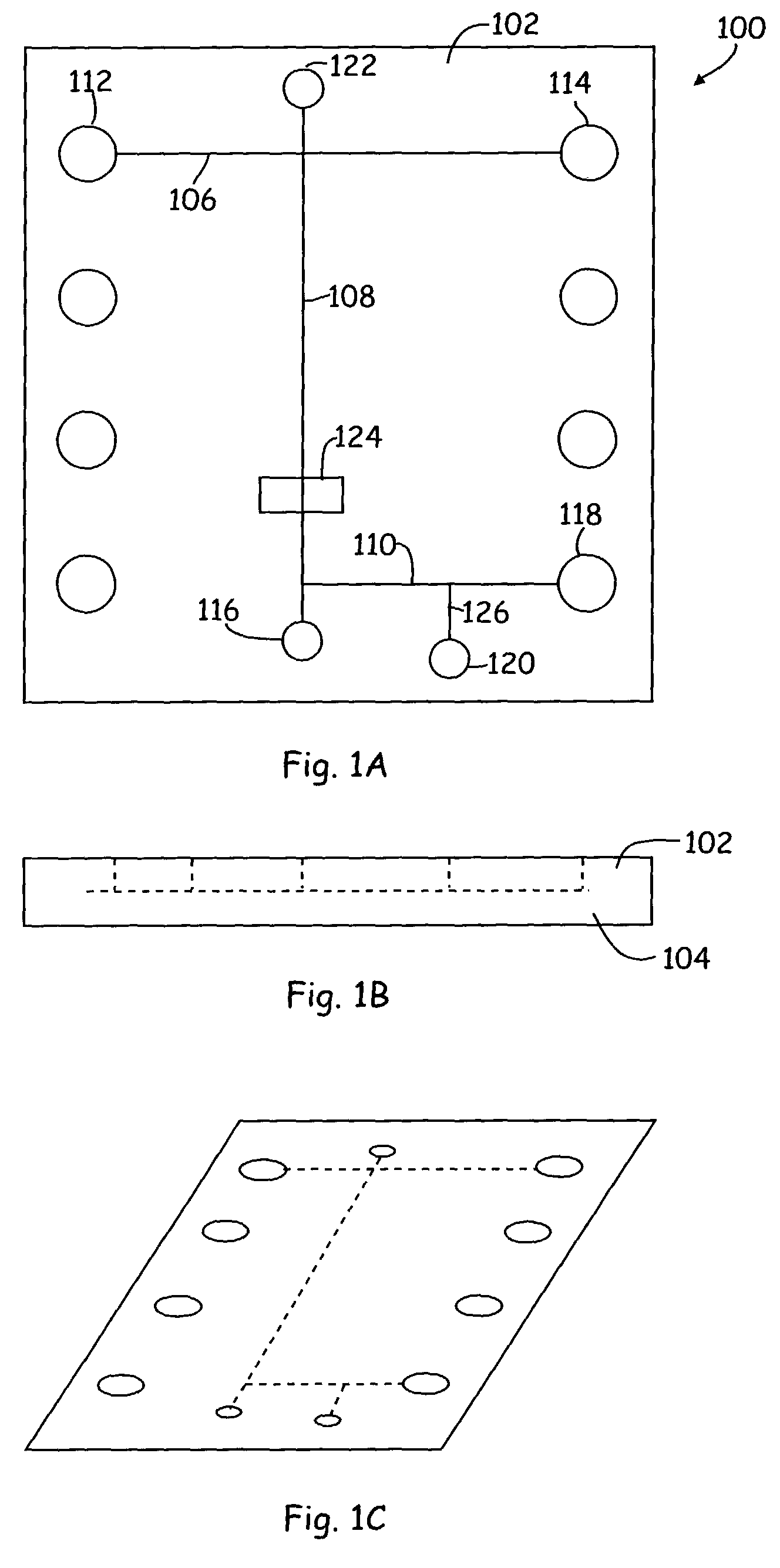

High throughput separations based analysis systems

InactiveUS7169277B2Increase flow resistanceSufficient flow resistanceSludge treatmentFixed microstructural devicesElectrophoresisBulk samples

Devices, systems and methods for use in separating sample materials into different fractions that employ bulk fluid flow for loading of samples followed by electrophoretic separation of the sample material. Devices employ configurations that optionally allow bulk sample loading with some or no displacement of a separation matrix within a separation conduit. Methods of using these devices, and systems that incorporate these devices are also envisioned.

Owner:CAPLIPER LIFE SCI INC

Methods, systems and apparatus for separation and isolation of one or more sample components of a sample biological material

ActiveUS20030215855A1AccuracyAccurate toleranceBioreactor/fermenter combinationsBiological substance pretreatmentsElectrophoresisBiological materials

Devices, systems and methods for use in separating sample materials into different sample components and then isolating one or more of the sample components for further processing or analysis are disclosed. Devices employ configurations that optionally allow a sample material to be electrophoretically separated into sample components in a separation matrix within a separation conduit. The sample components may then be detected in a detection zone in the separation conduit, and then selected components shunted to a component collection conduit within the device downstream of the detection zone for further processing or analysis based on information received at the detection zone. Methods of using these devices, and systems that incorporate these devices are also envisioned.

Owner:CAPLIPER LIFE SCI INC

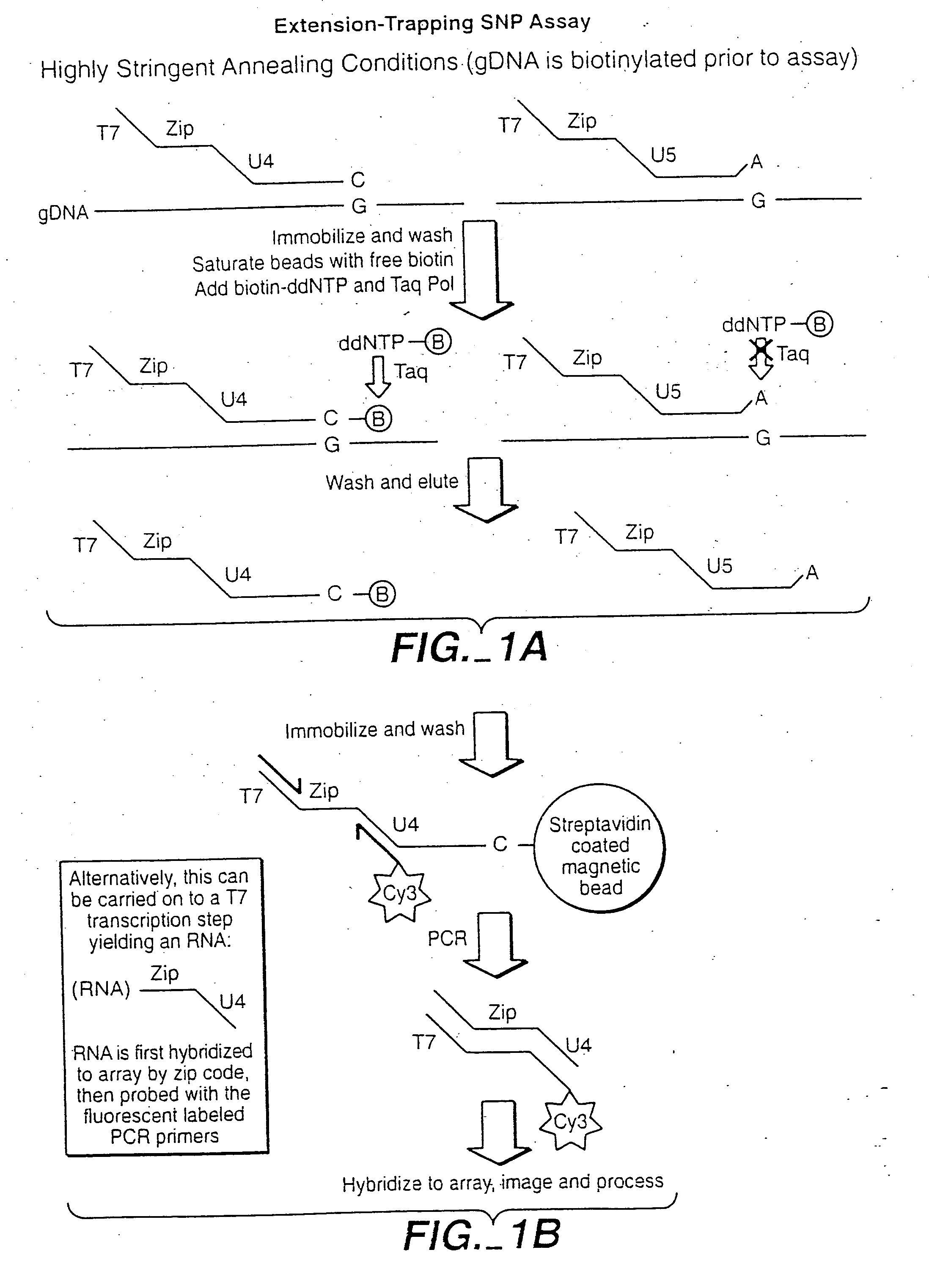

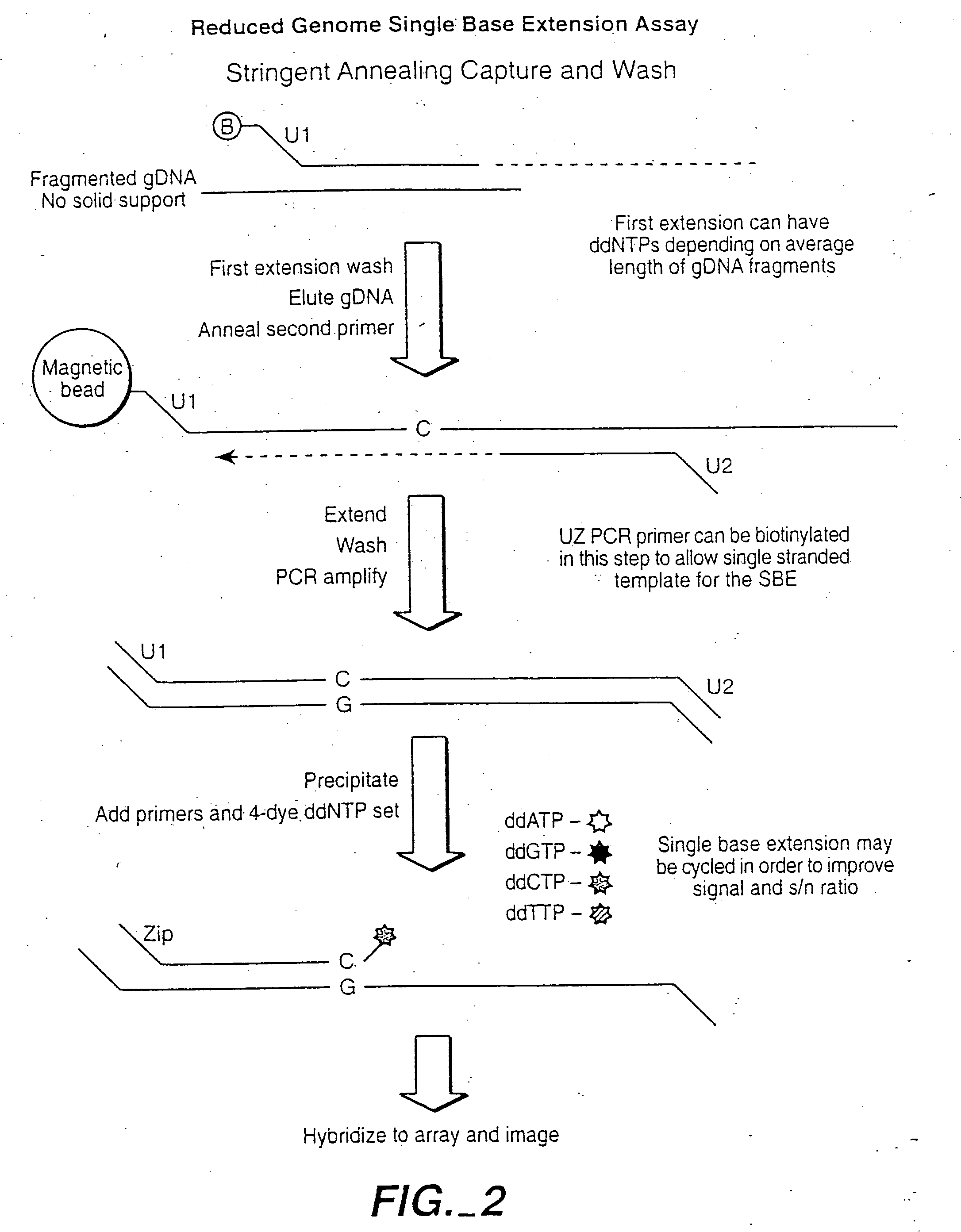

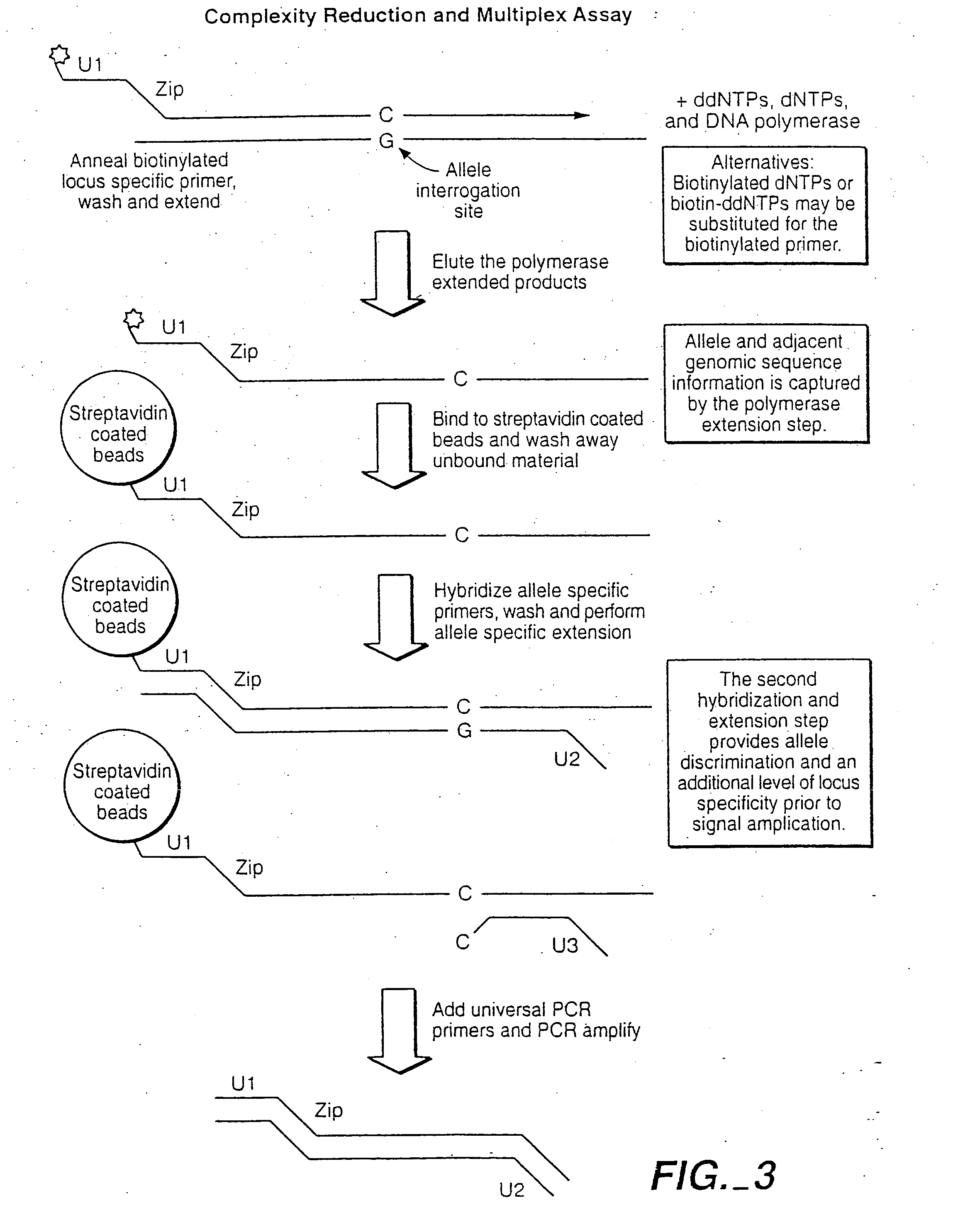

Multiplex sample analysis on universal arrays

The invention provides a method of identifying at least one target sequence in each sample of a plurality of samples. The method includes the steps of (a) contacting at least one target sequence within a plurality of separate samples each with a nucleic acid probe under conditions wherein the probes form hybridization complexes with the at least one target sequence, wherein each of the probes has the same target specific sequence and a different adapter sequence that is unique to a separate sample; (b) pooling the probes thereby forming a probe pool; and (c) detecting the presence of the adapter sequence in the probe pool, thereby identifying the at least one target sequences in each sample of the plurality of separate samples.

Owner:ILLUMINA INC

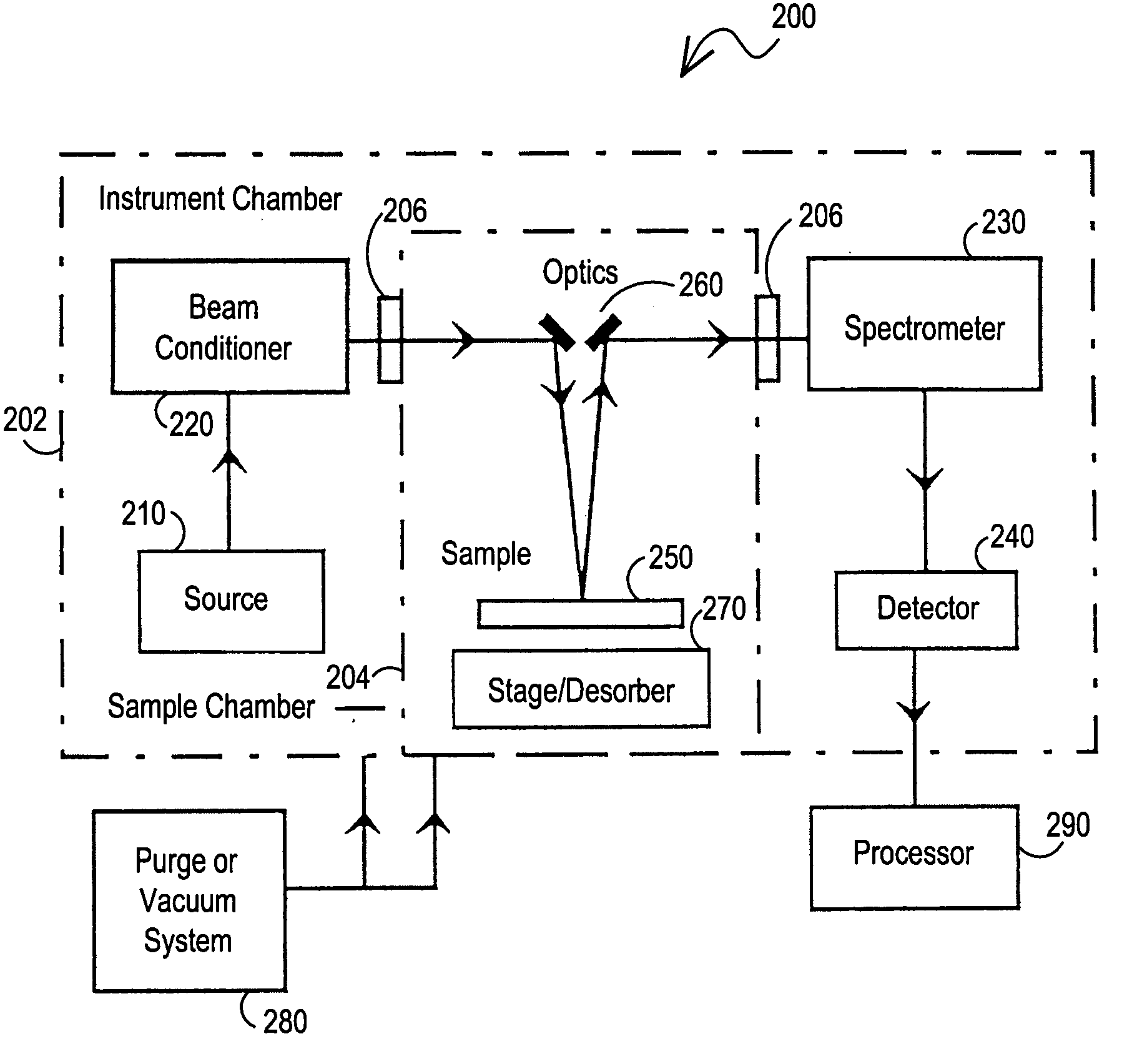

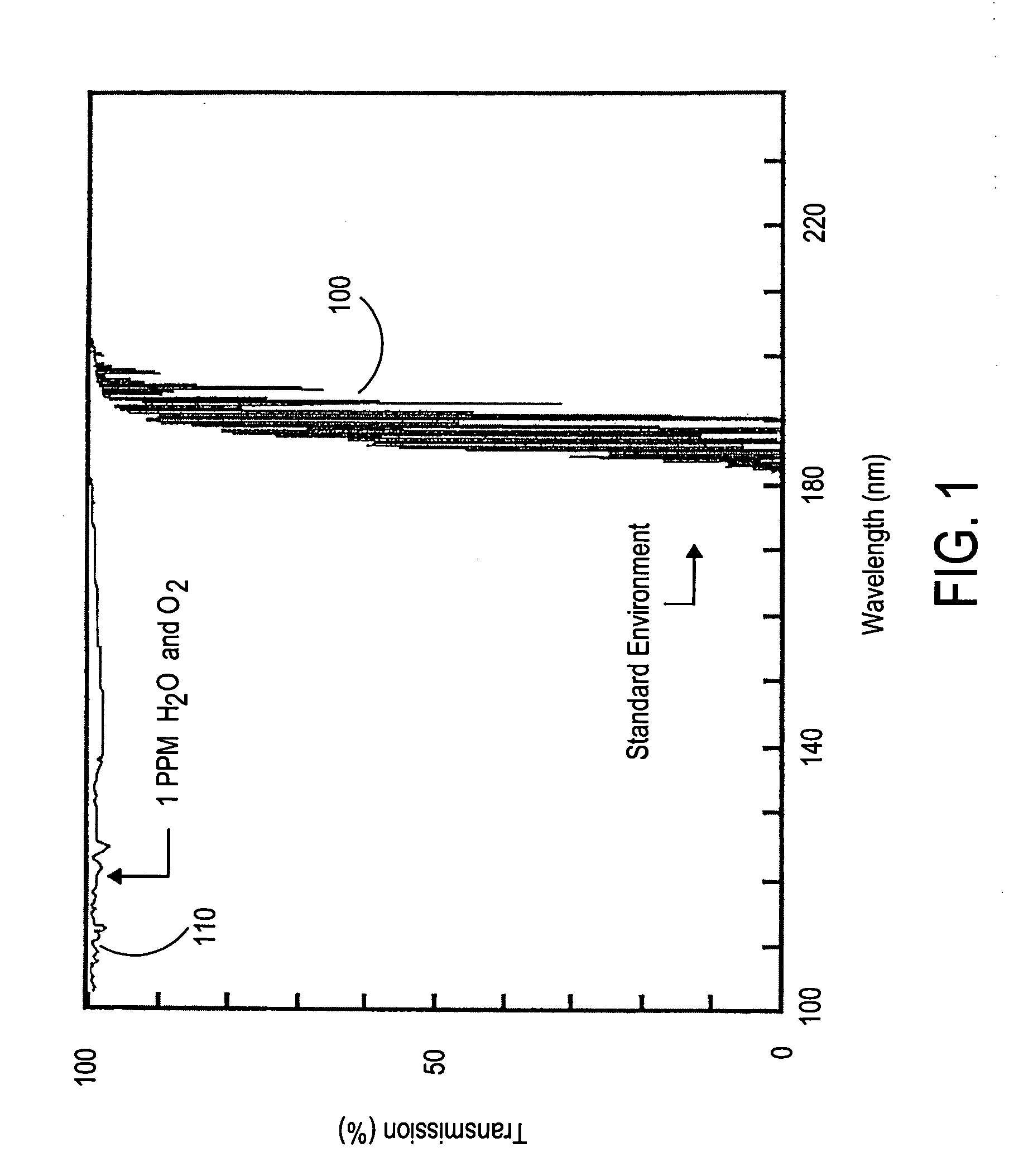

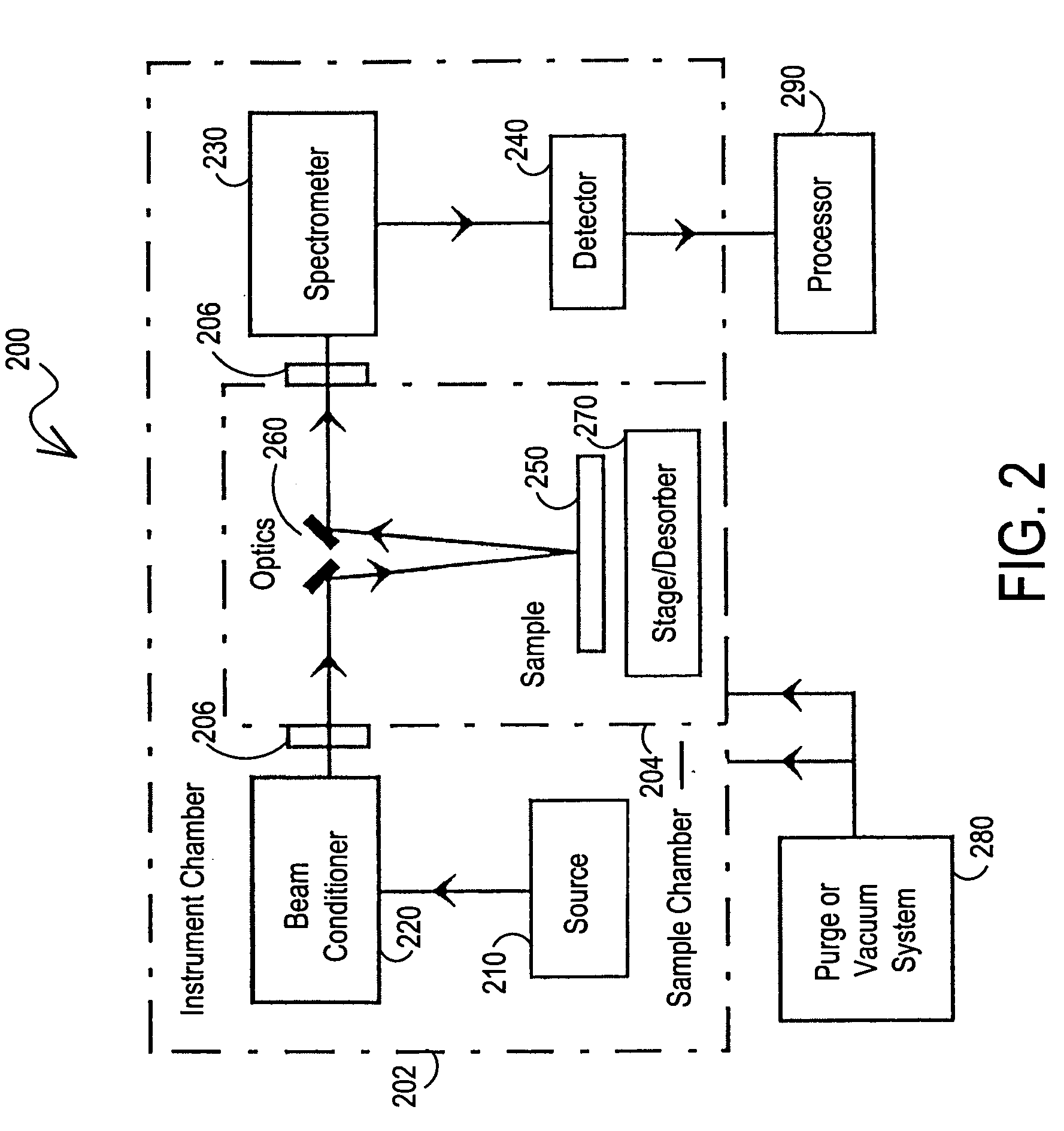

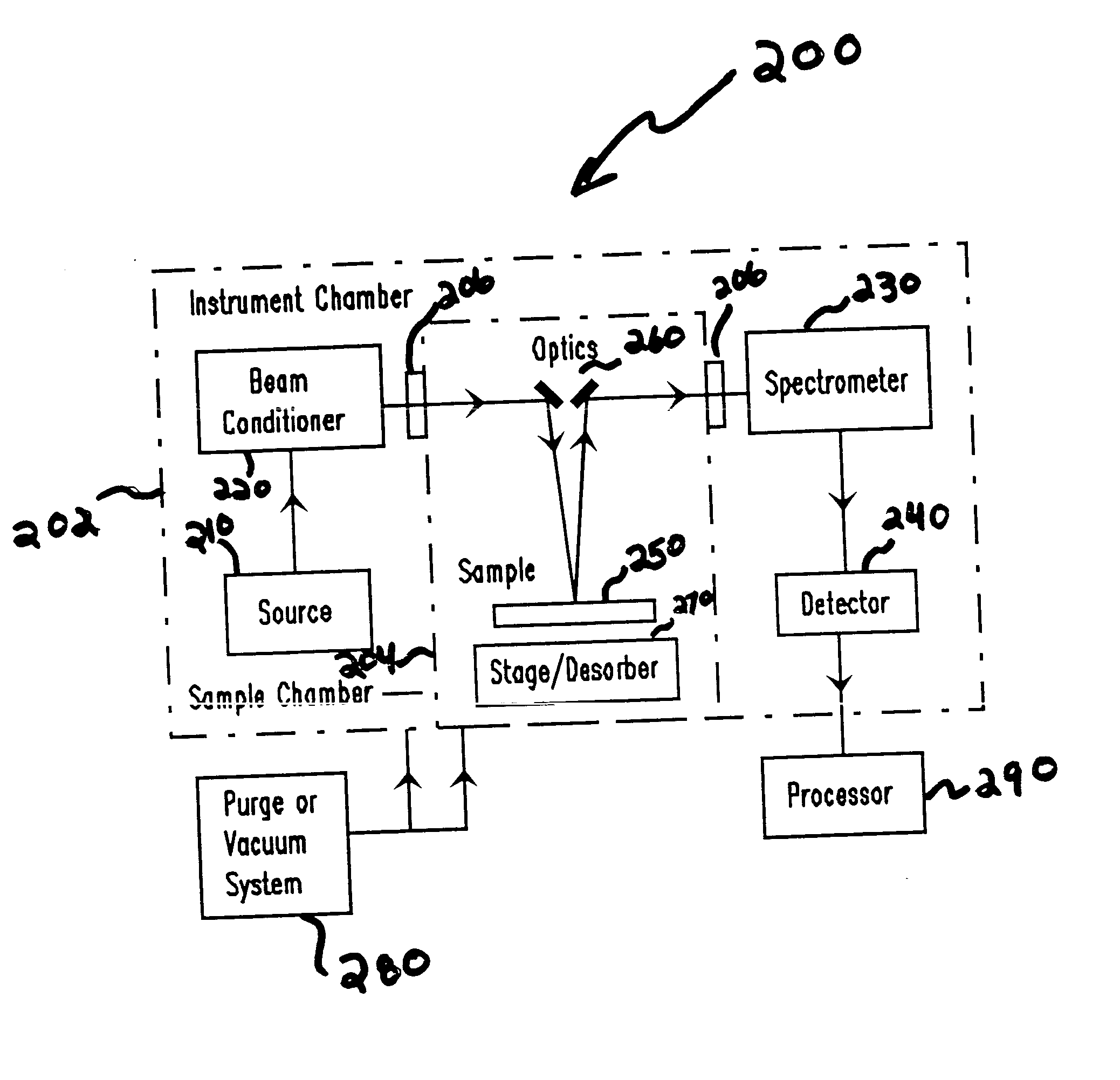

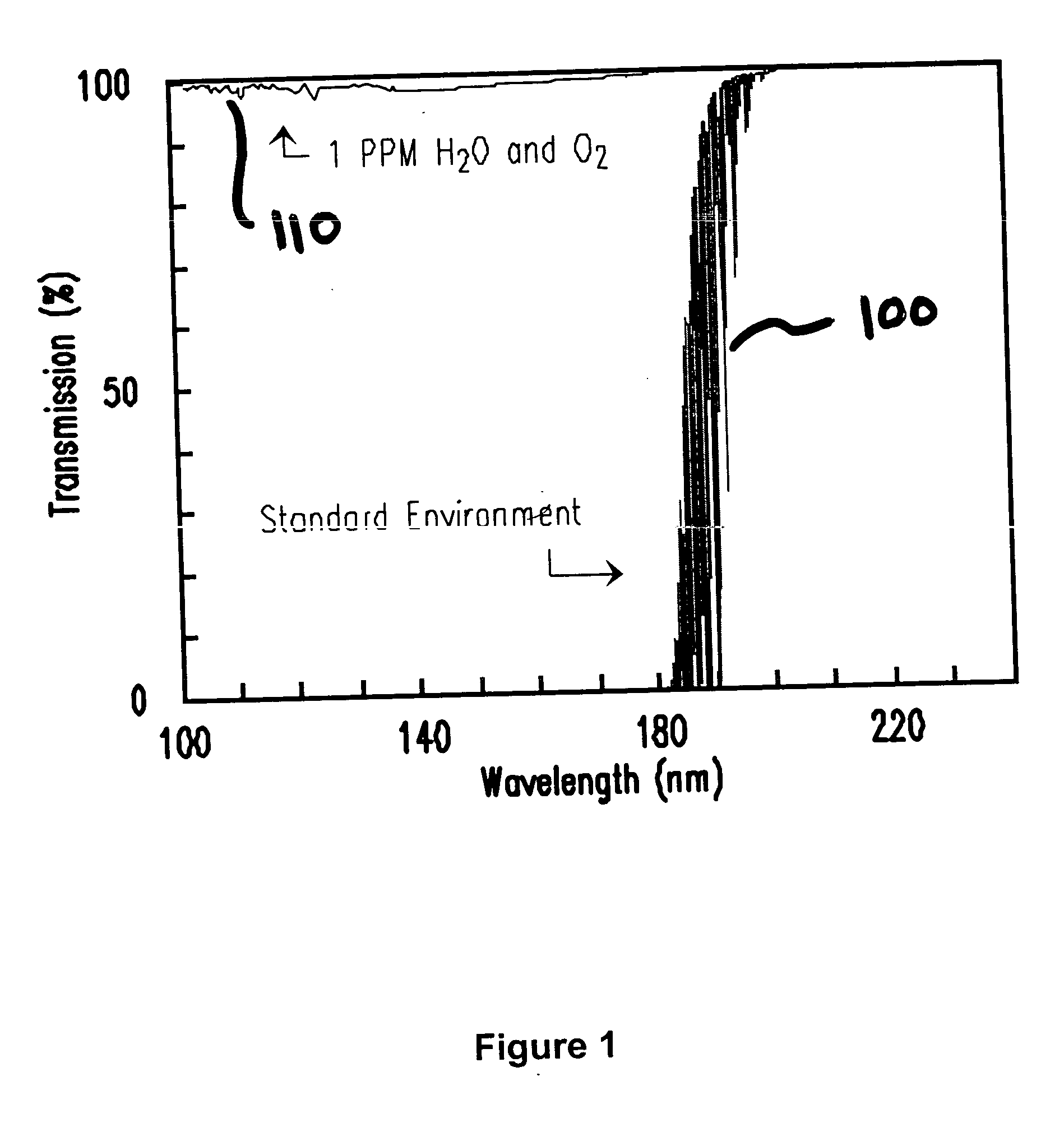

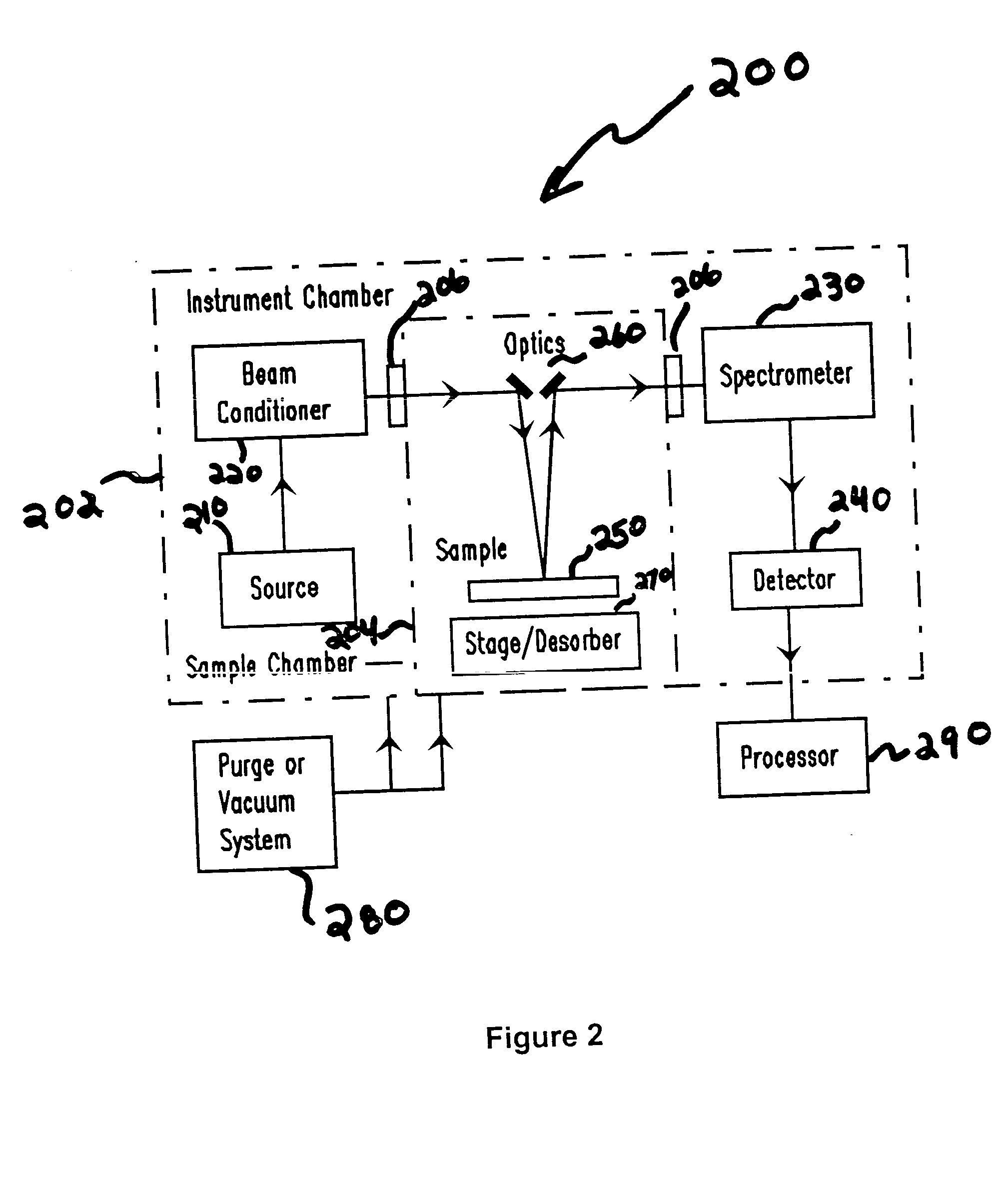

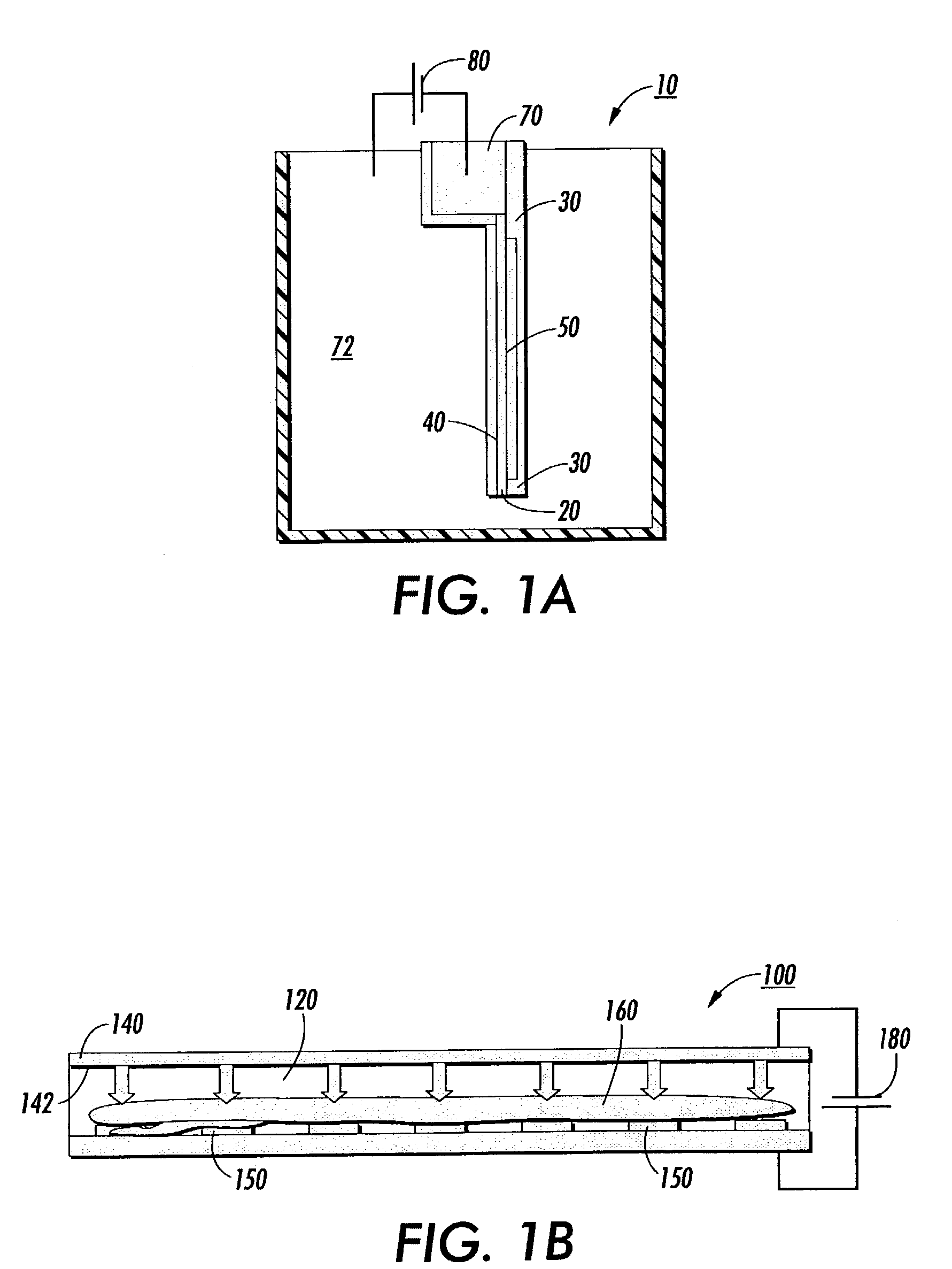

Vacuum ultraviolet reflectometer system and method

ActiveUS7067818B2Change levelThin layerSpectrum investigationPolarisation-affecting propertiesMetrologyUltraviolet

A spectroscopy system is provided which operates in the vacuum ultra-violet spectrum. More particularly, a system utilizing reflectometry techniques in the vacuum ultraviolet spectrum is provided for use in metrology applications. The system may further include the use of an array detector in combination with an imaging spectrometer. In this manner data for multiple wavelengths may be simultaneously collected. Moreover, the multiple wavelengths of data may be collected simultaneously for a two dimensional sample area. The system may further include the use of a fixed diffraction grating and does not require the use of polarizing elements. To ensure accurate and repeatable measurement, the environment of the optical path is controlled. The optical path may include a controlled environmental chamber in which non-absorbing purge gases are present or in which vacuum evacuation techniques are utilized. The controlled environment may further include a separate instrument chamber and a separate sample chamber. The controlled environment limits in a repeatable manner the absorption of VUV photons.

Owner:BRUKER TECH LTD

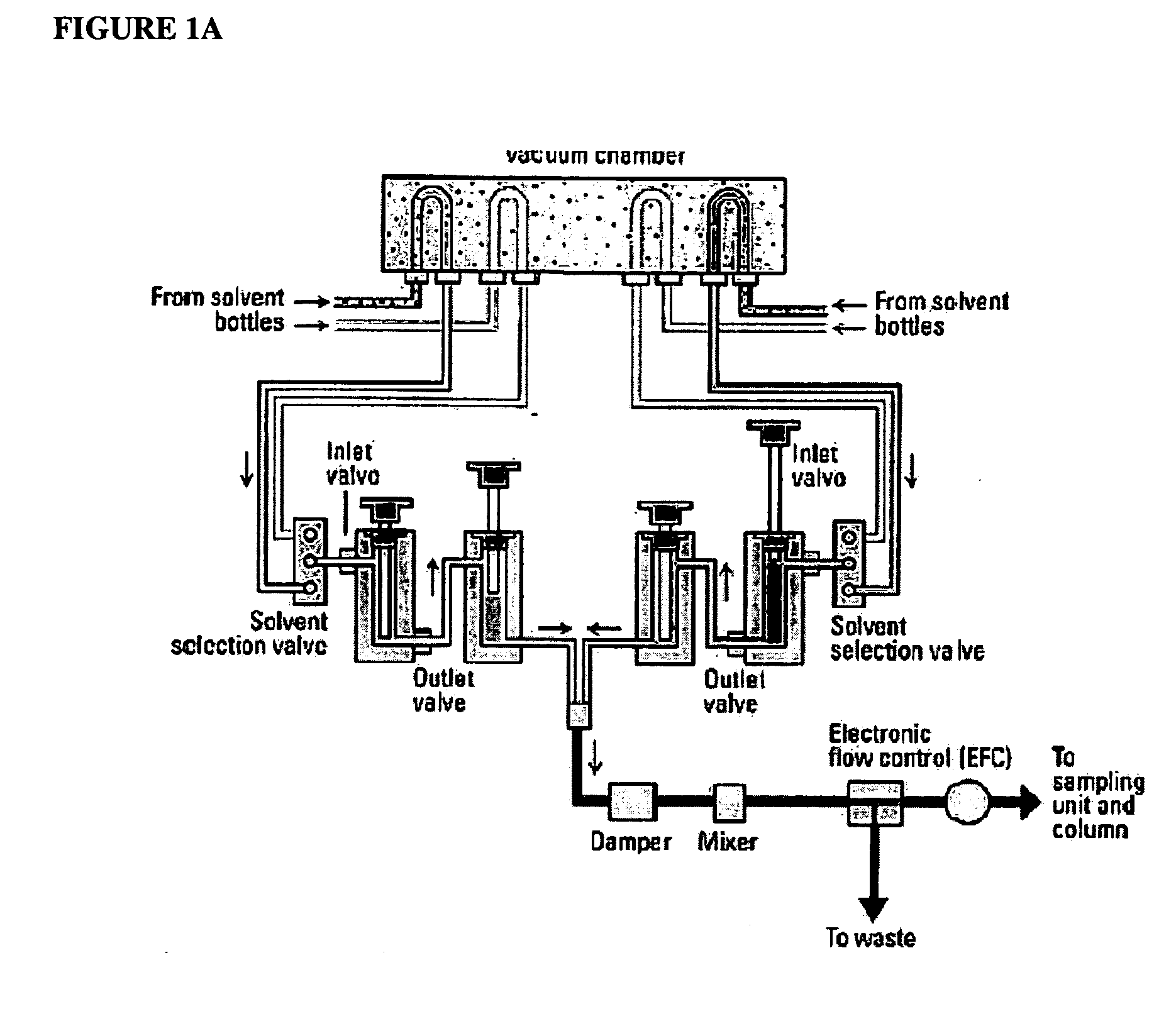

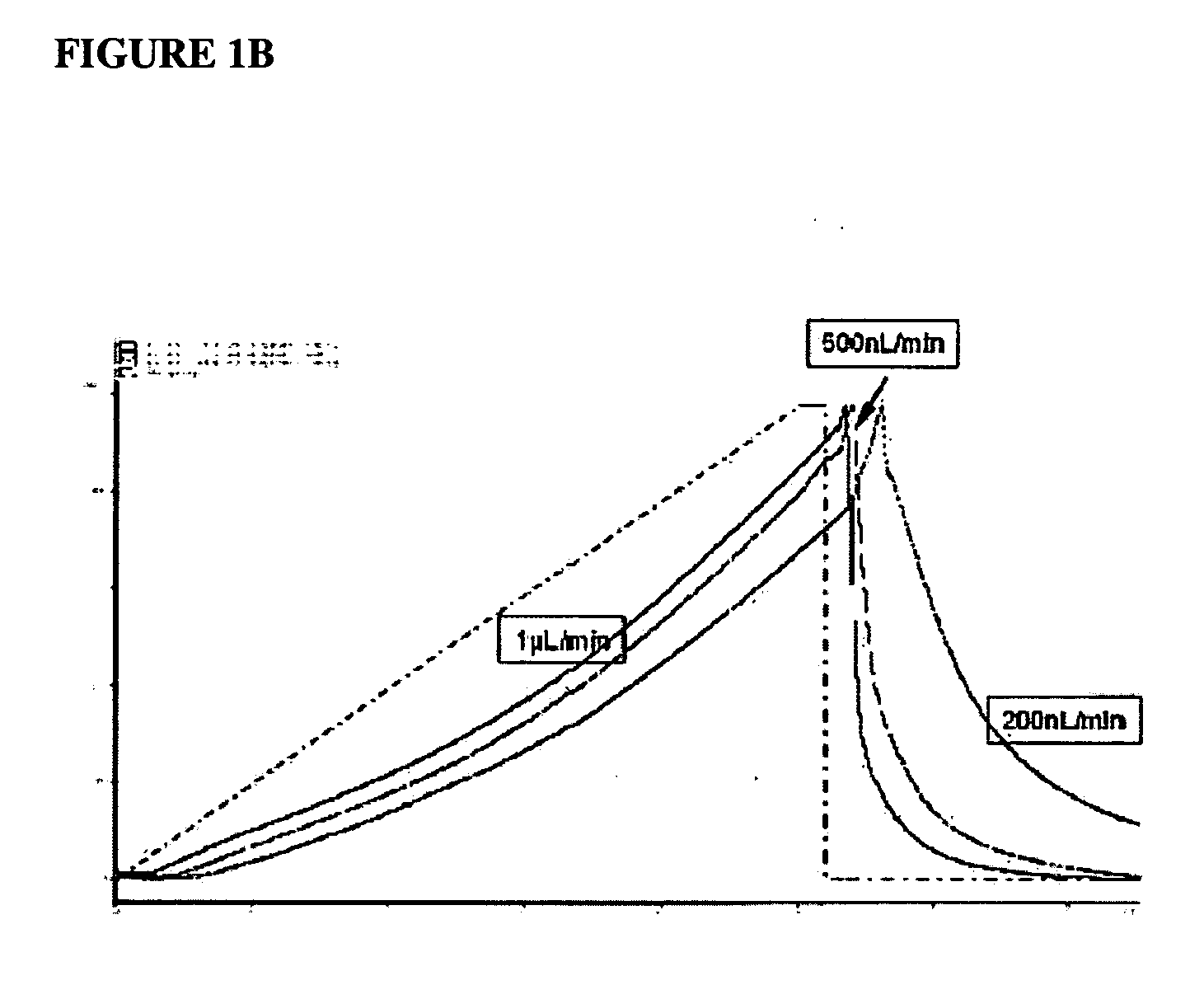

Devices, systems and methods for liquid chromatography

InactiveUS20060219637A1Increase flow rateIon-exchange process apparatusSamplingStationary phaseEngineering

Devices comprising a mechanism for selectively diverting a portion of a mobile phase flowing through a mobile-phase transporting conduit to a fluid-transporting conduit comprising a stationary phase for separating sample components are disclosed, as well as systems and methods for using the same.

Owner:AGILENT TECH INC

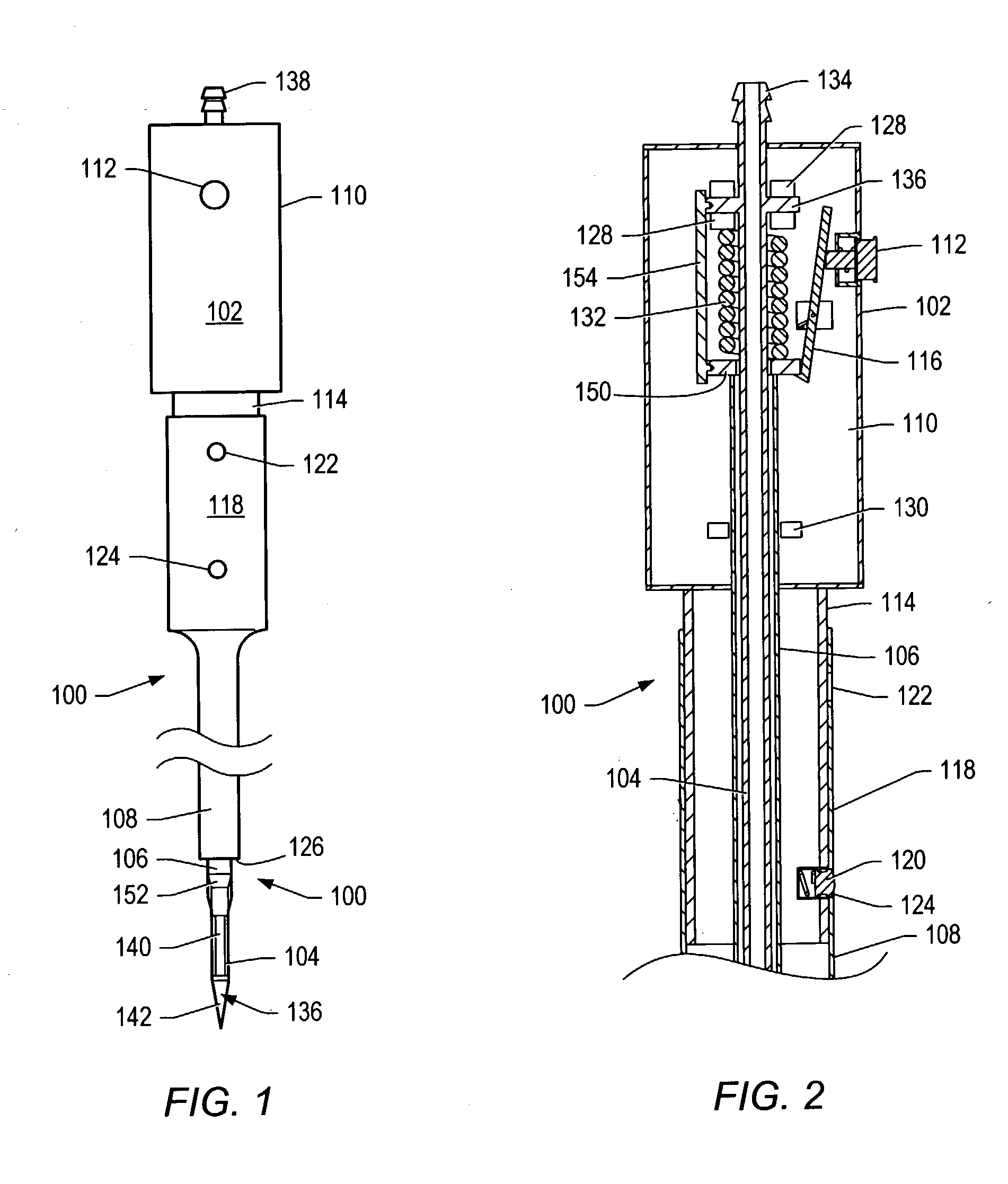

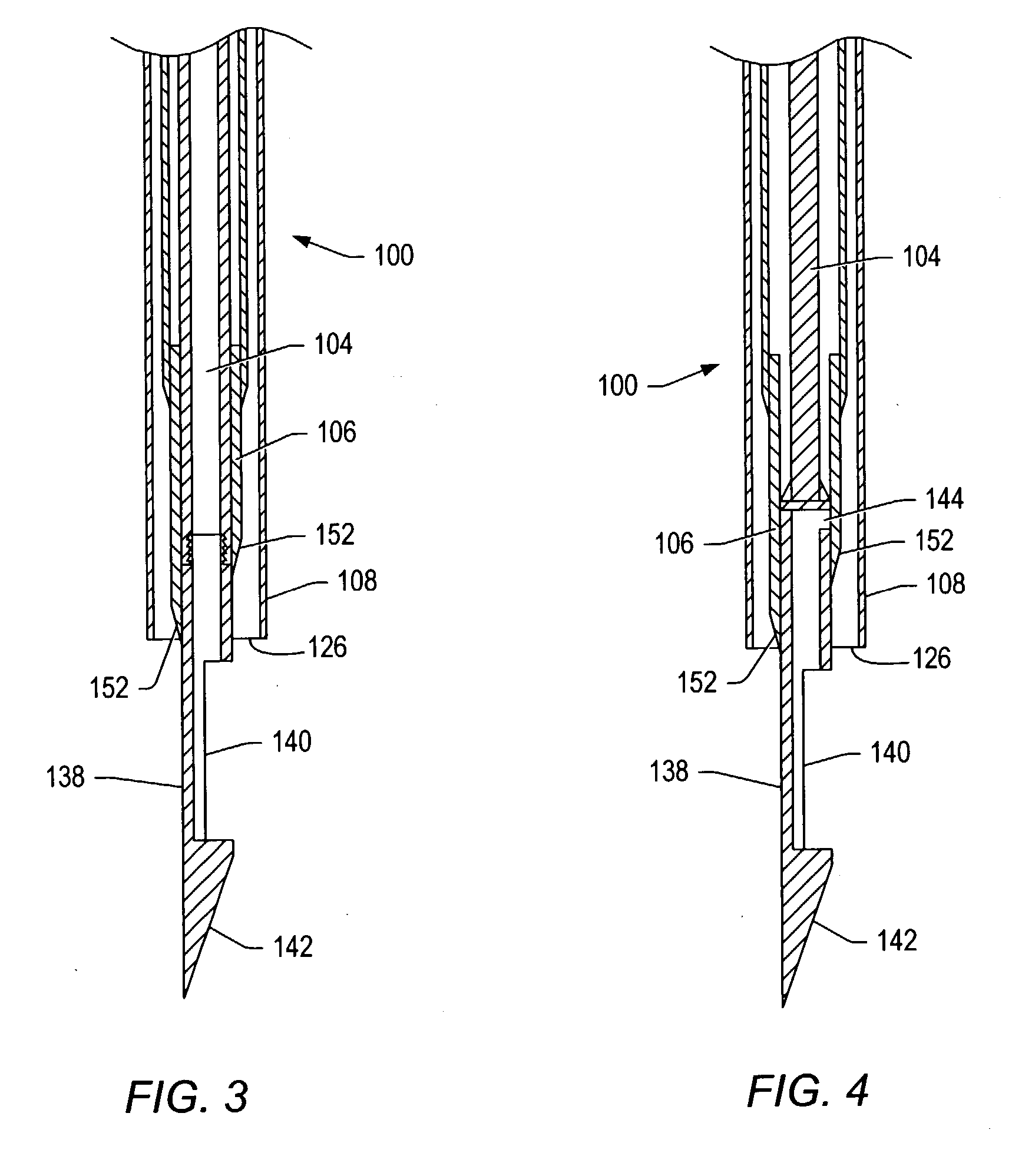

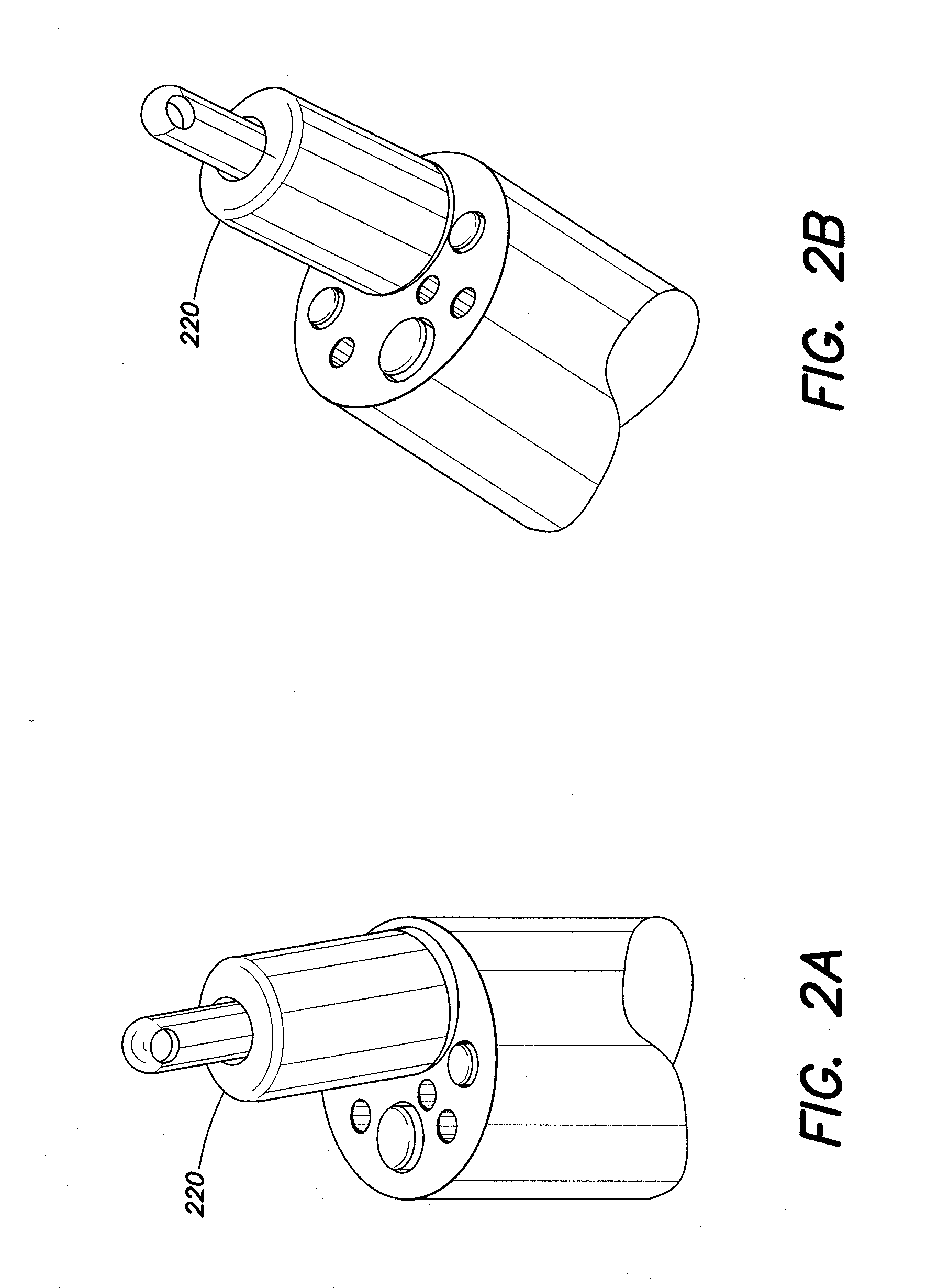

Biopsy needle

InactiveUS7131951B2High strengthEasy to insertSurgical needlesVaccination/ovulation diagnosticsTissue sampleActuator

A biopsy needle assembly may include a sample needle, an actuator and a cutter. A sample needle may include a sample opening. A tissue sample may be positioned in the sample opening when the sample needle is inserted into tissue of a patient. The actuator may be activated to move the cutter relative to the sample needle and separate sample tissue in the sample opening from adjacent tissue. The biopsy needle assembly may be removed from the patient and the sample may be removed from the sample opening. In some embodiments, the sample needle may be inserted in tissue through an instrument (e.g., an endoscope). The biopsy needle assembly may include a sheath that inhibits a sample needle and a cutter from contacting the instrument when the biopsy needle is inserted in the instrument.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

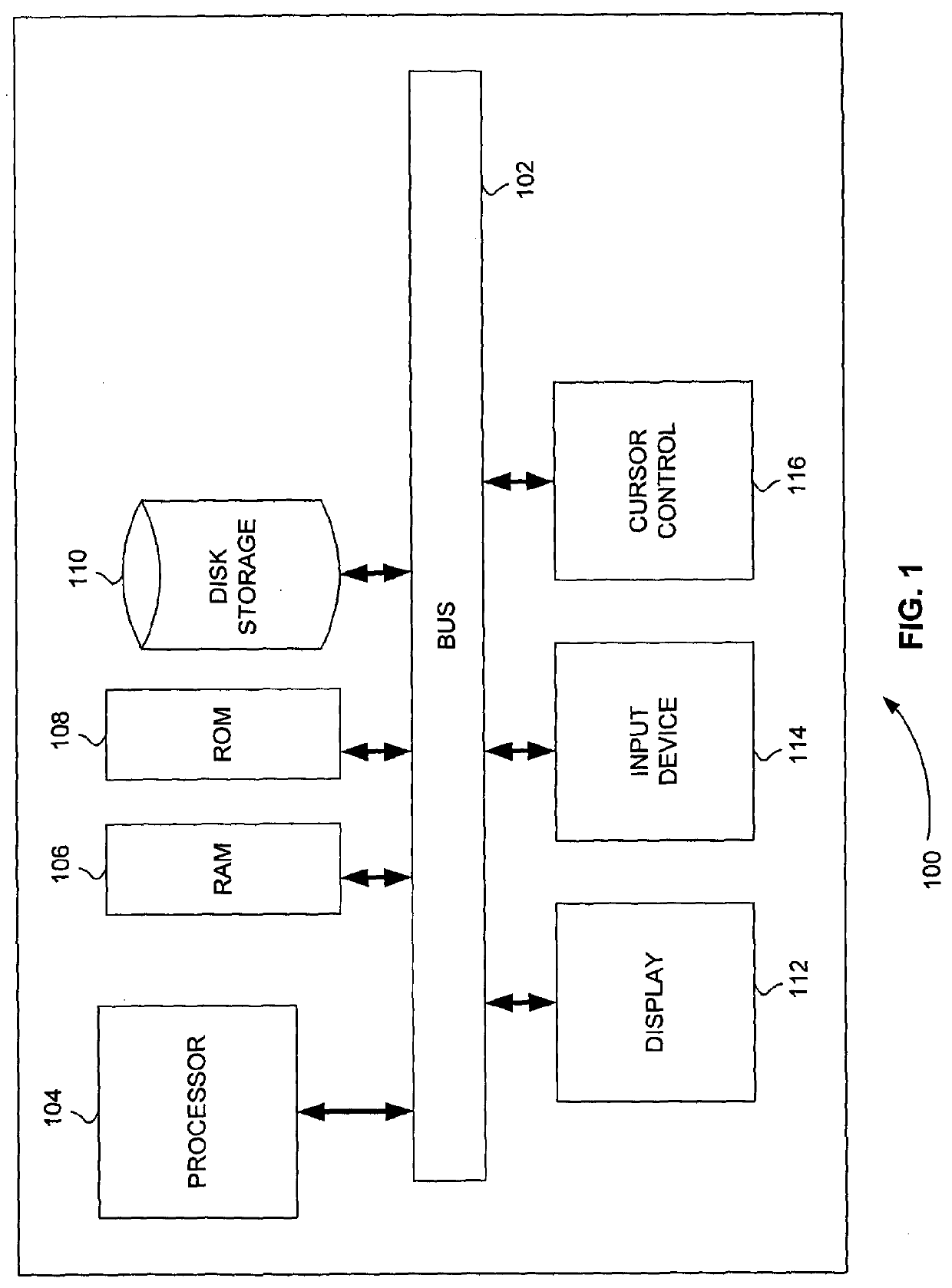

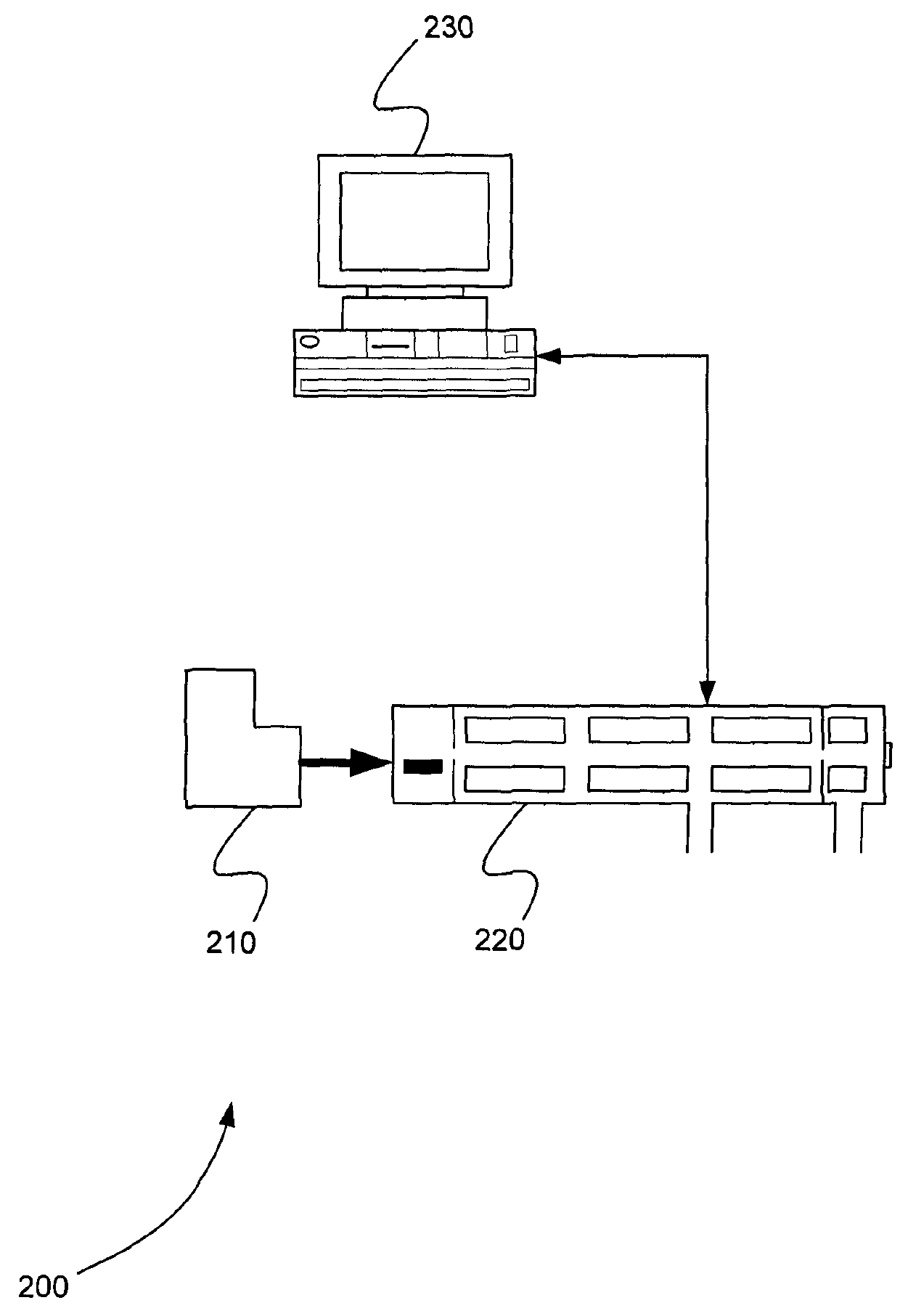

System, Method and computer program product for integrated analysis and visualization of genomic data

Described is a system for analysis and visualization of genomic data. The system allows a user to select at least one individual sample. The sample has chromosomal data representing a genome with a chromosome and also includes chromosomal measurements of at least one event at a particular location on the chromosome. A frequency of event is generated based on the selected sample. The frequency of event is a frequency of occurrence of the event in the selected sample. At least one annotation can be selected that includes chromosomal region specific information as related to the chromosome. Finally, the chromosomal data, the annotation, and the frequency of event on a display can all be simultaneously displayed, thereby allowing a user to view chromosomal region specific information with respect to a particular chromosomal event.

Owner:BIODISCOVERY

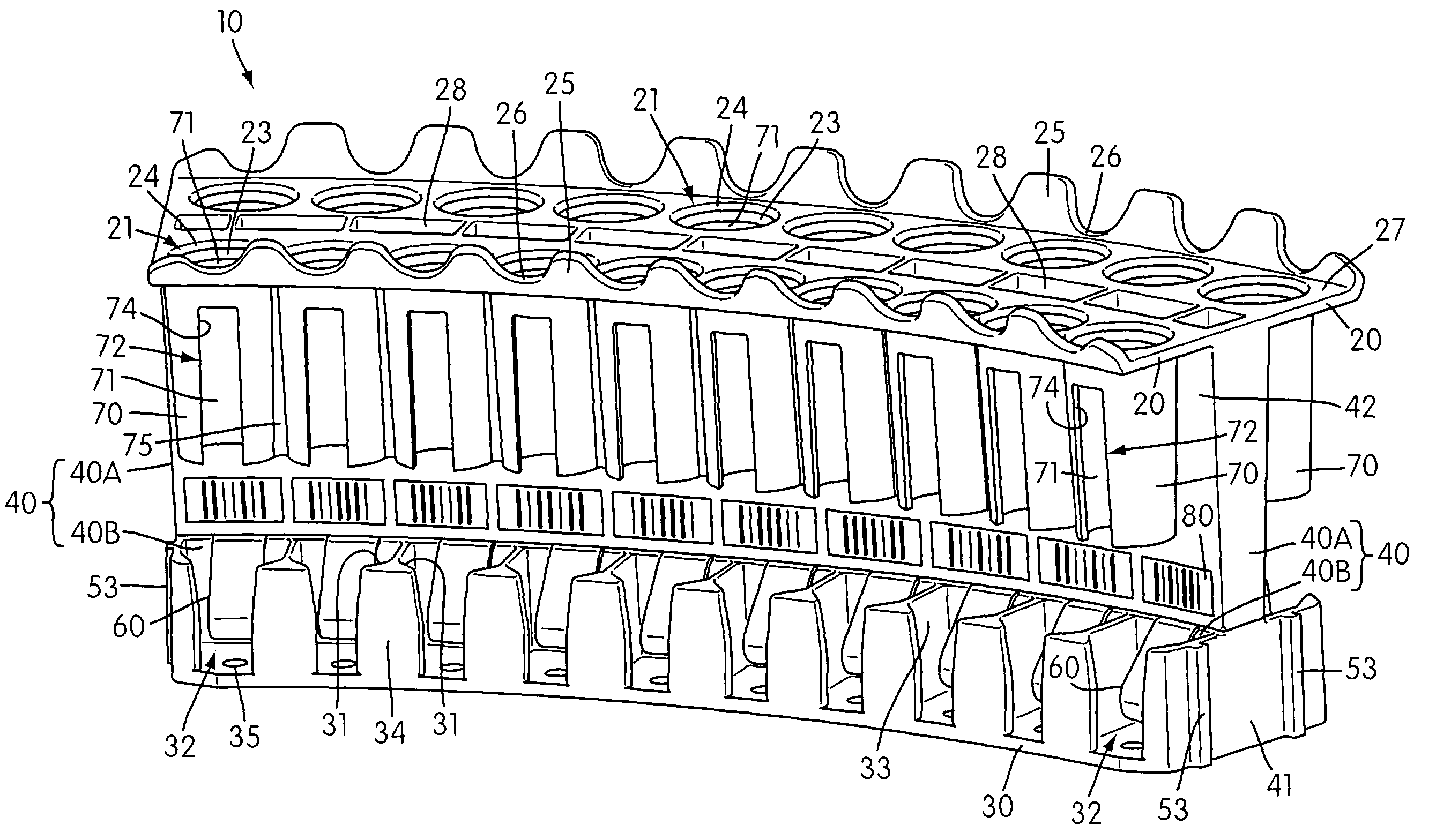

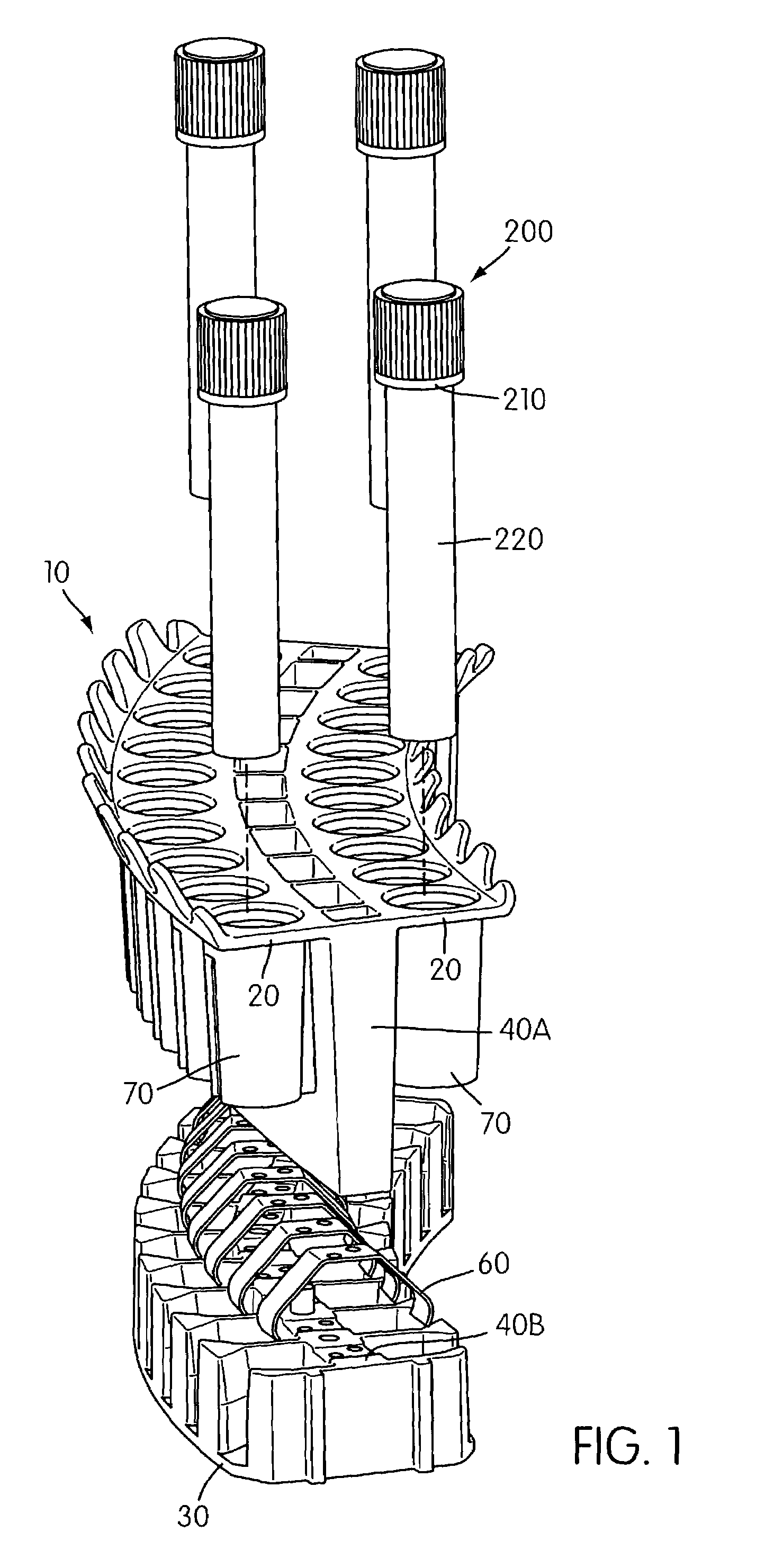

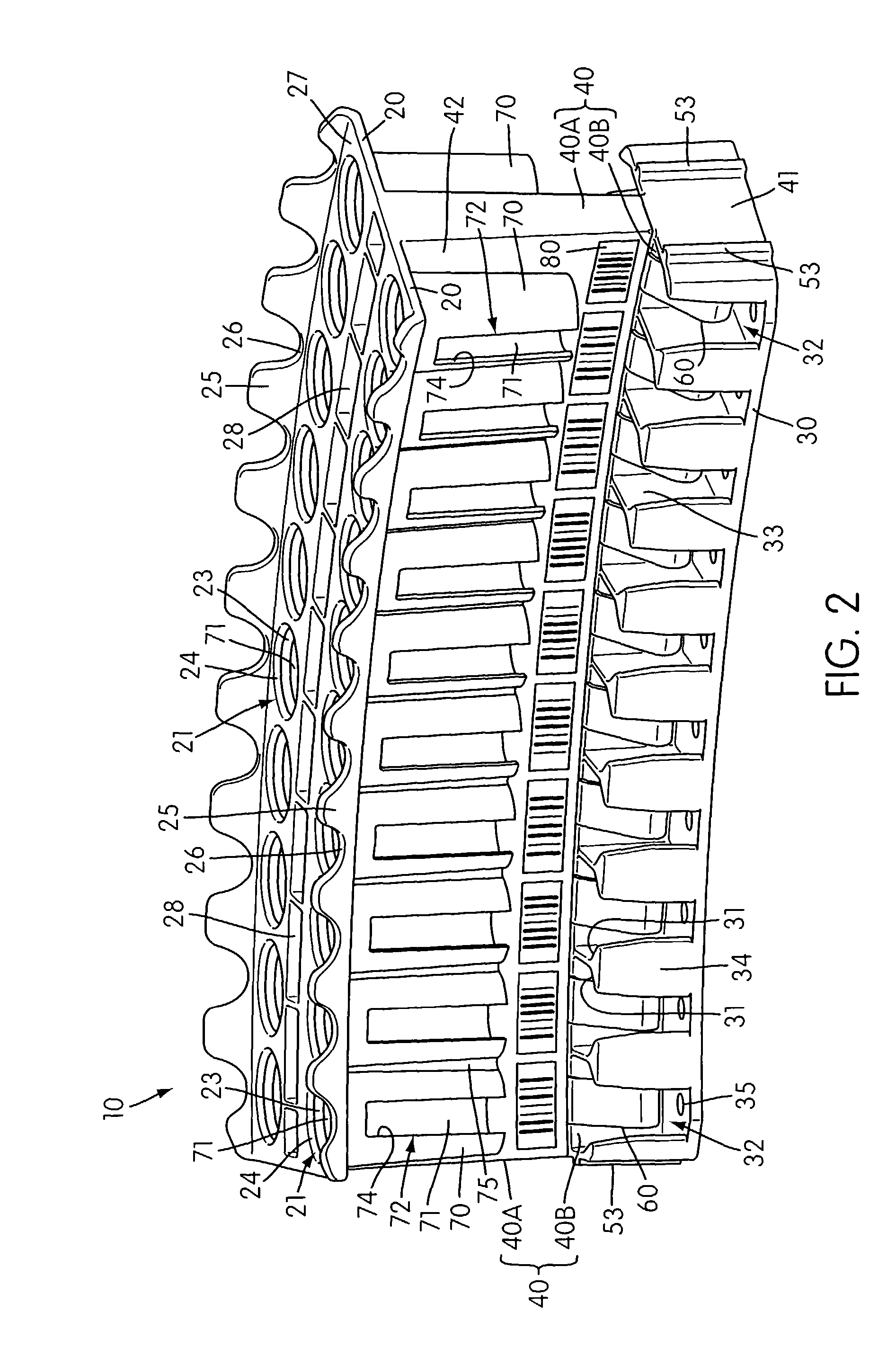

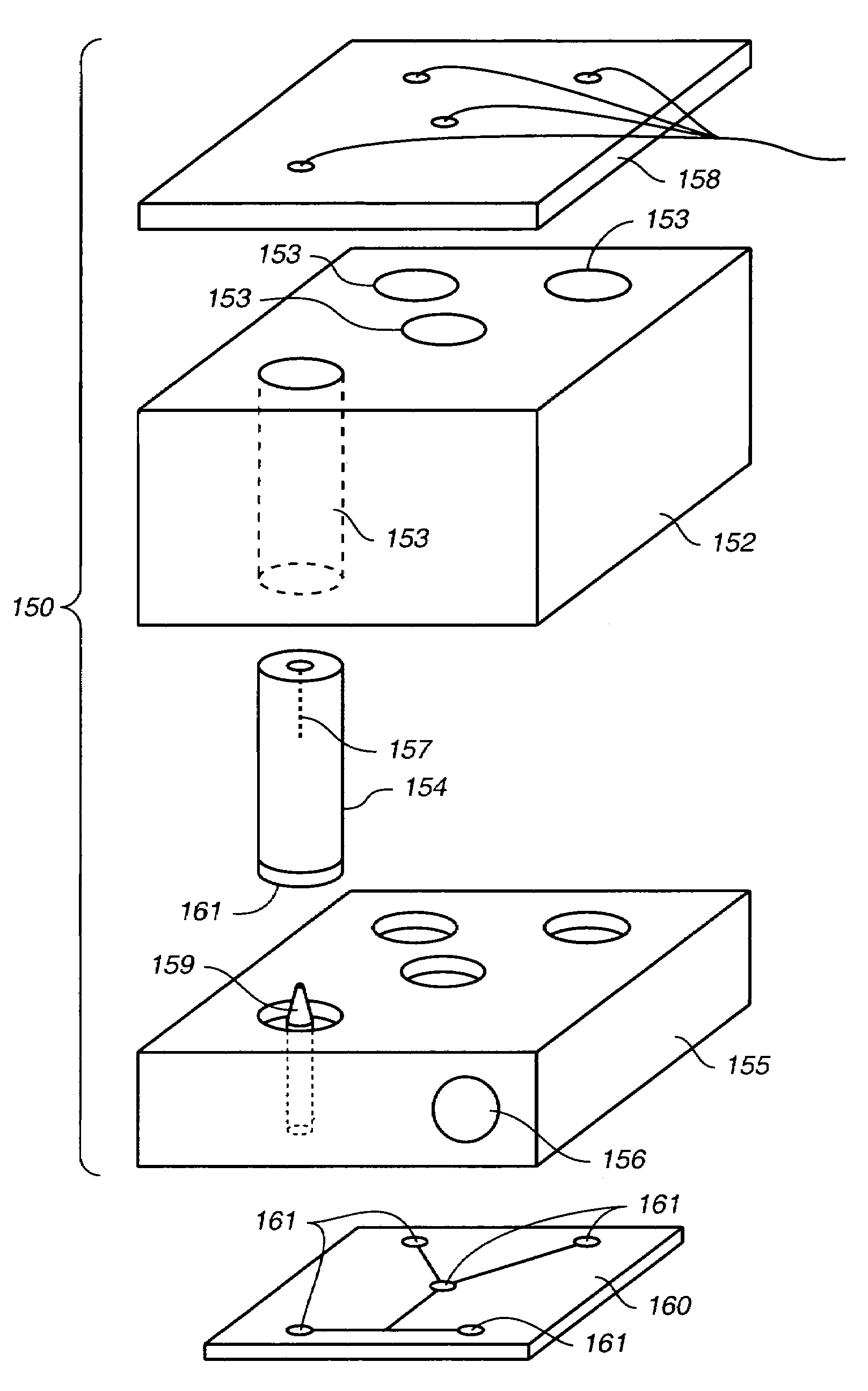

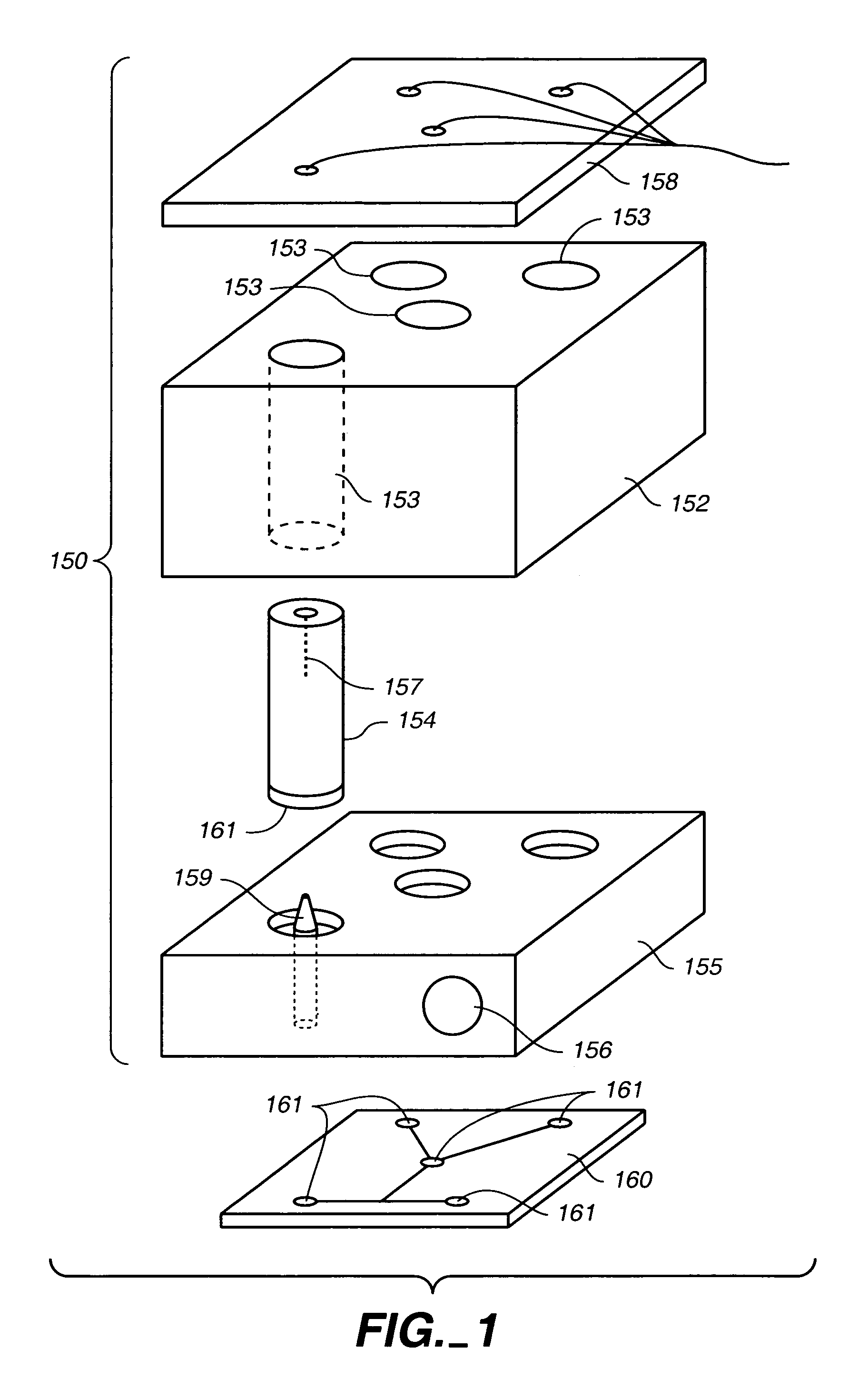

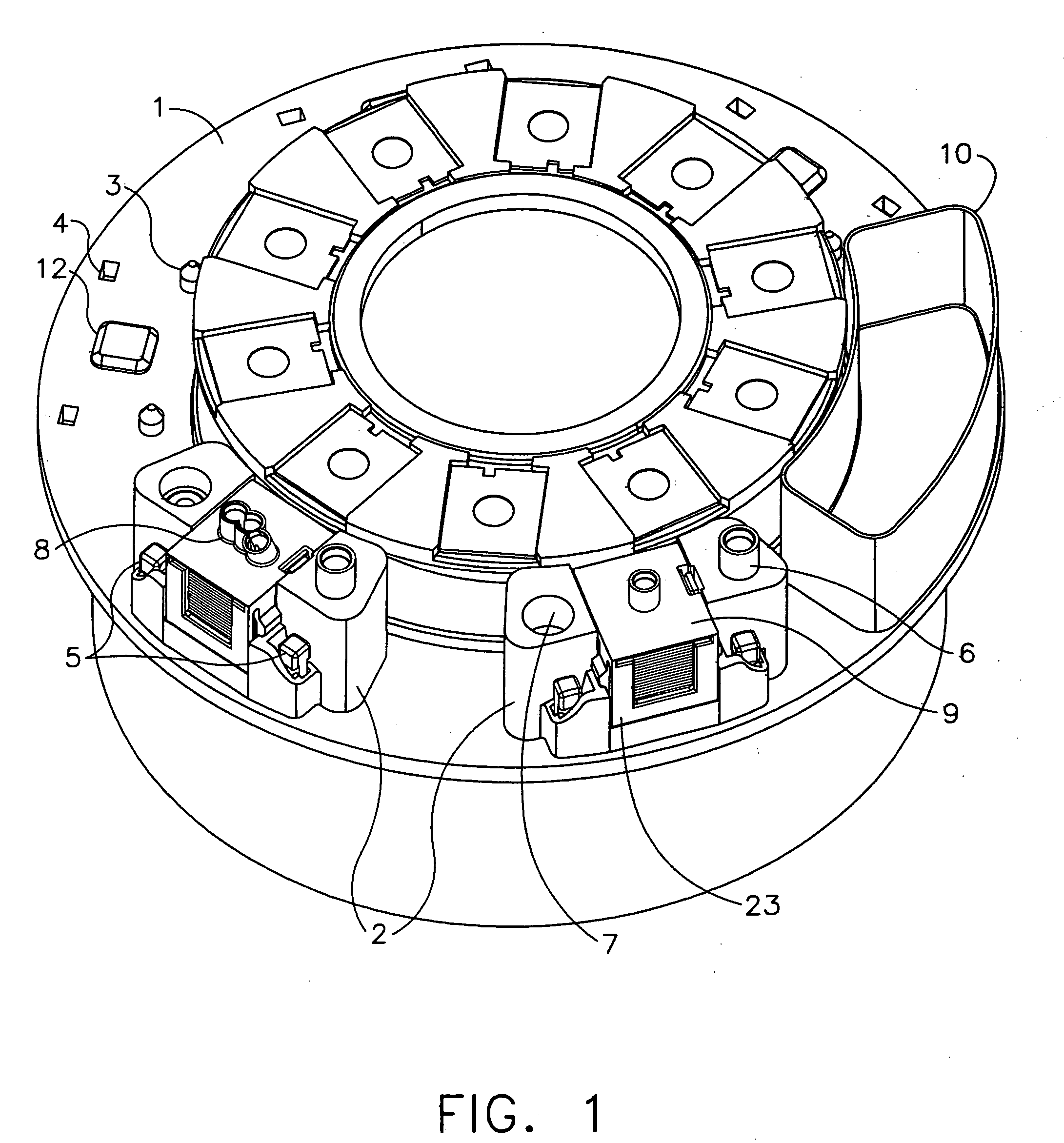

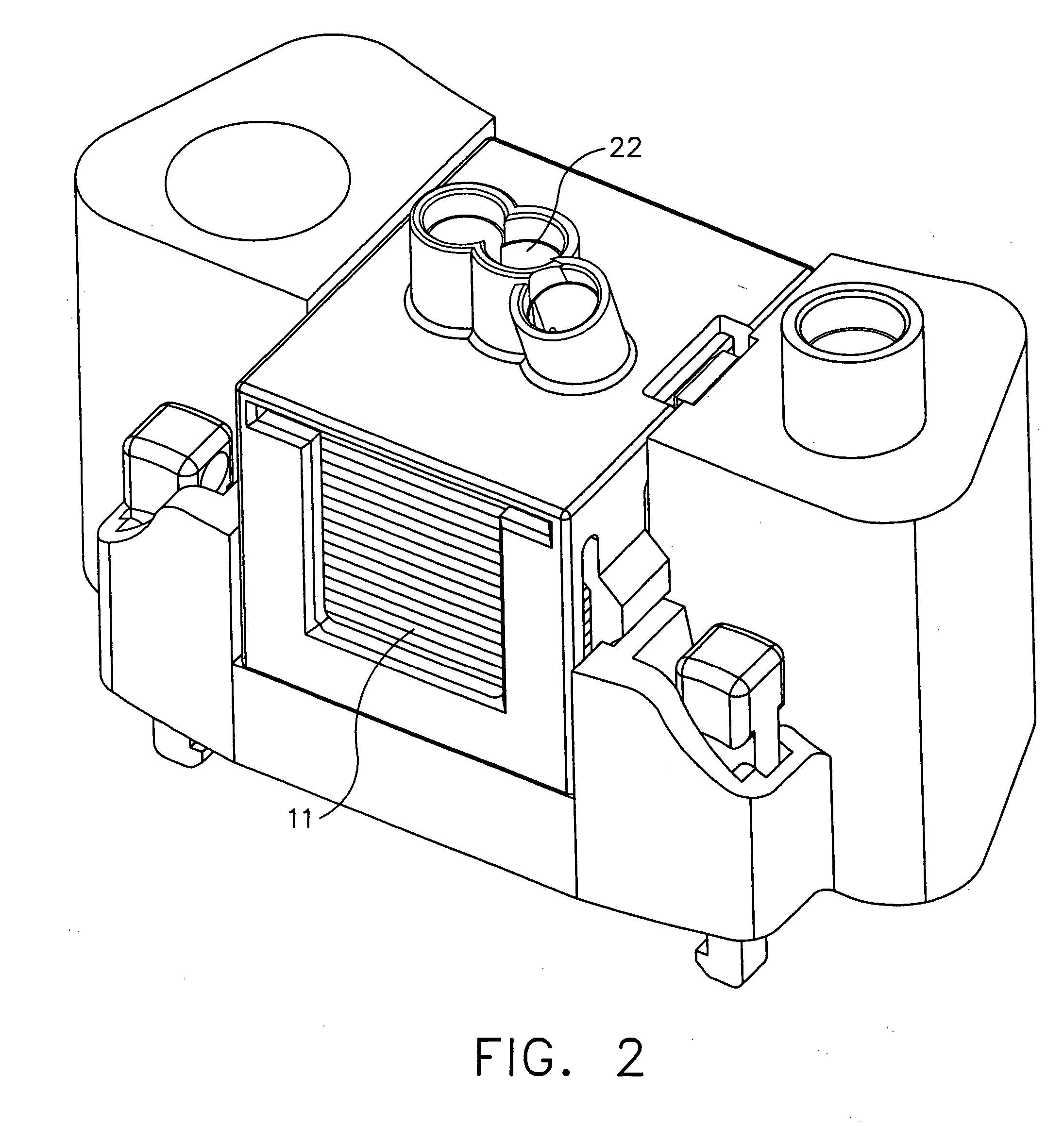

Sample carrier

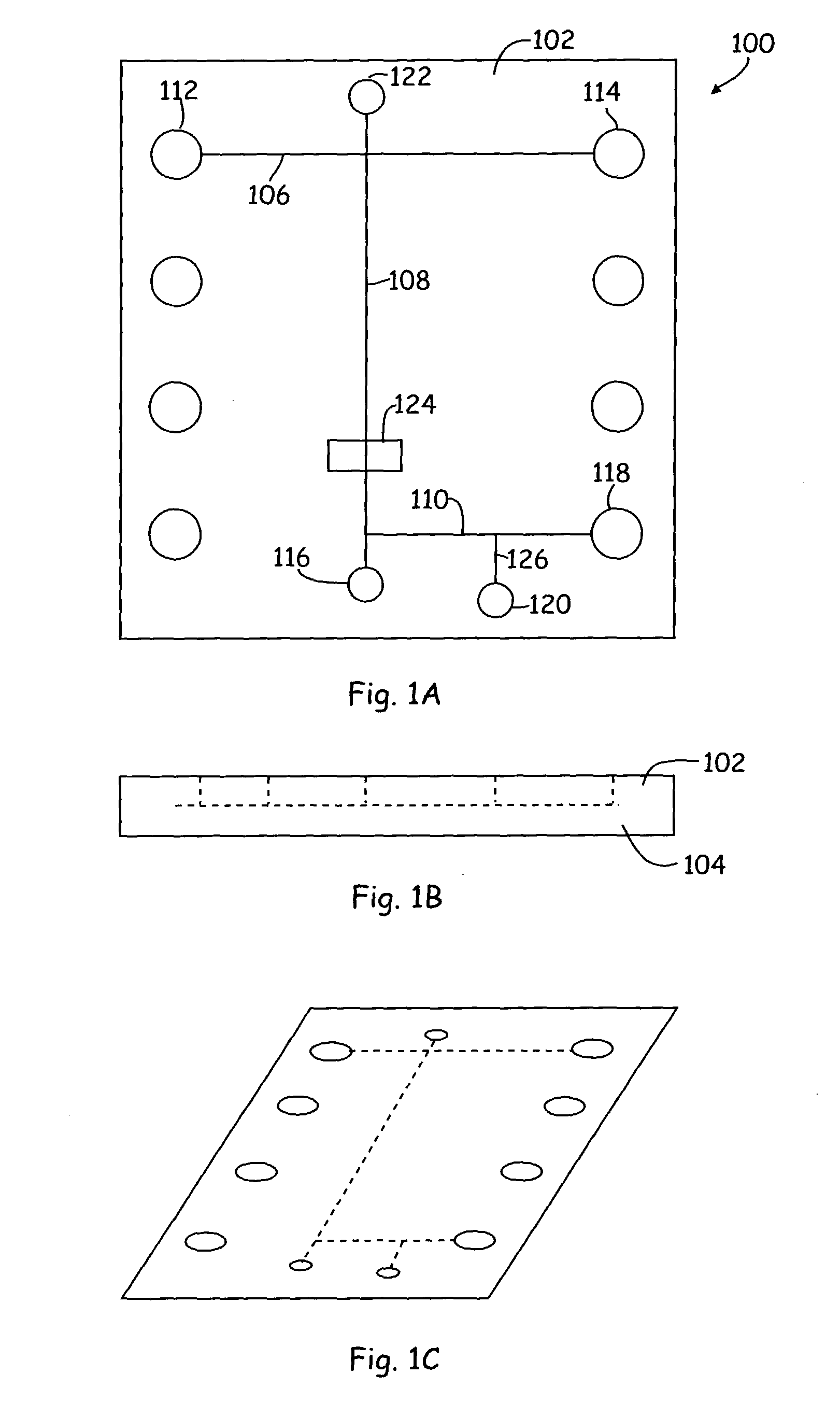

ActiveUS7282182B2Restricts vertical movementMinimizing chanceBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSeparate sample

A sample carrier comprising a top wall, a base, and a support wall joining the top wall and the base. The top wall includes aligned, spaced-apart openings on at least one side of the support wall which are sized to receive sample tubes. Sleeves depending from the top wall and circumscribing each opening direct sample tubes into sample tube holding areas. The sample tube holding areas each include one or more retaining walls extending upward from the base opposite the support wall. Springs extending outward from the support wall bias sample tubes against the retaining walls. A drip shield comprising a cover plate, a pair of through-holes for accessing sample tubes in the sample carrier, and a depending fin which separates sample tubes on opposite sides of the support wall protects against cross-contamination between sample tubes held by the sample carrier.

Owner:GEN PROBE INC

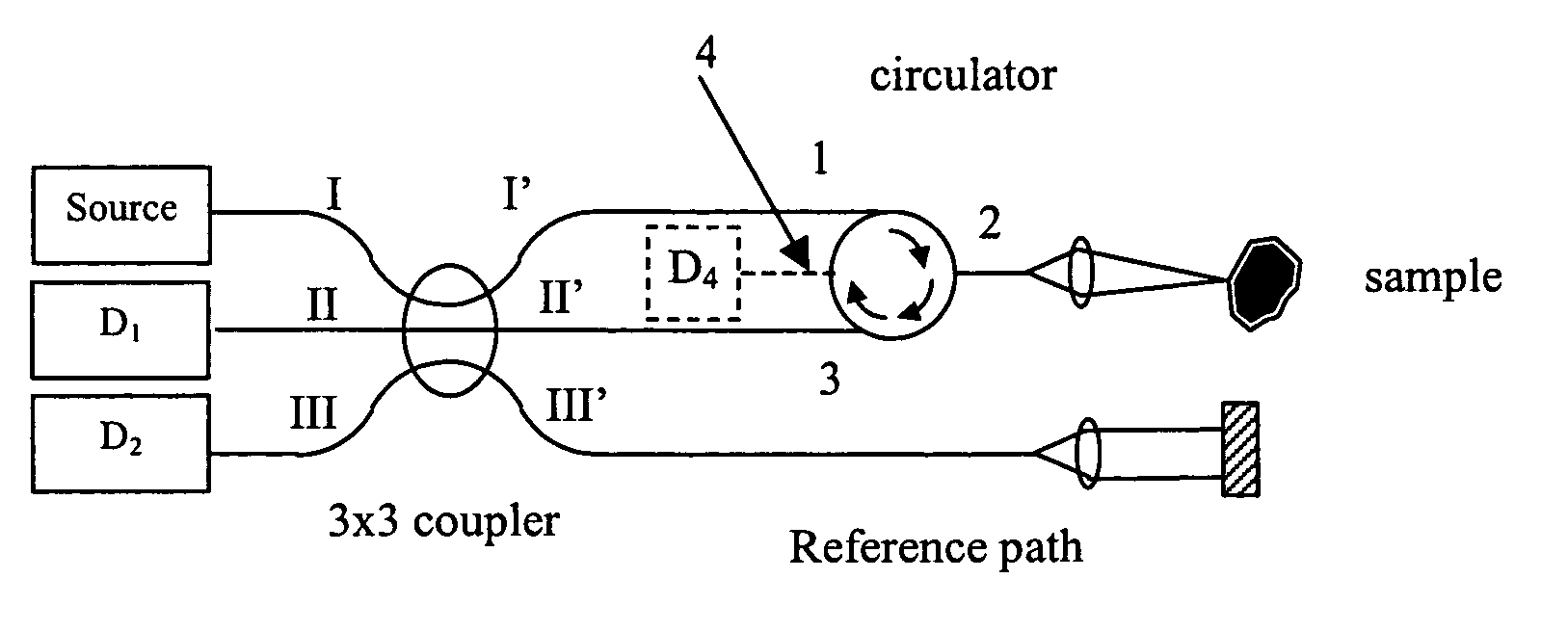

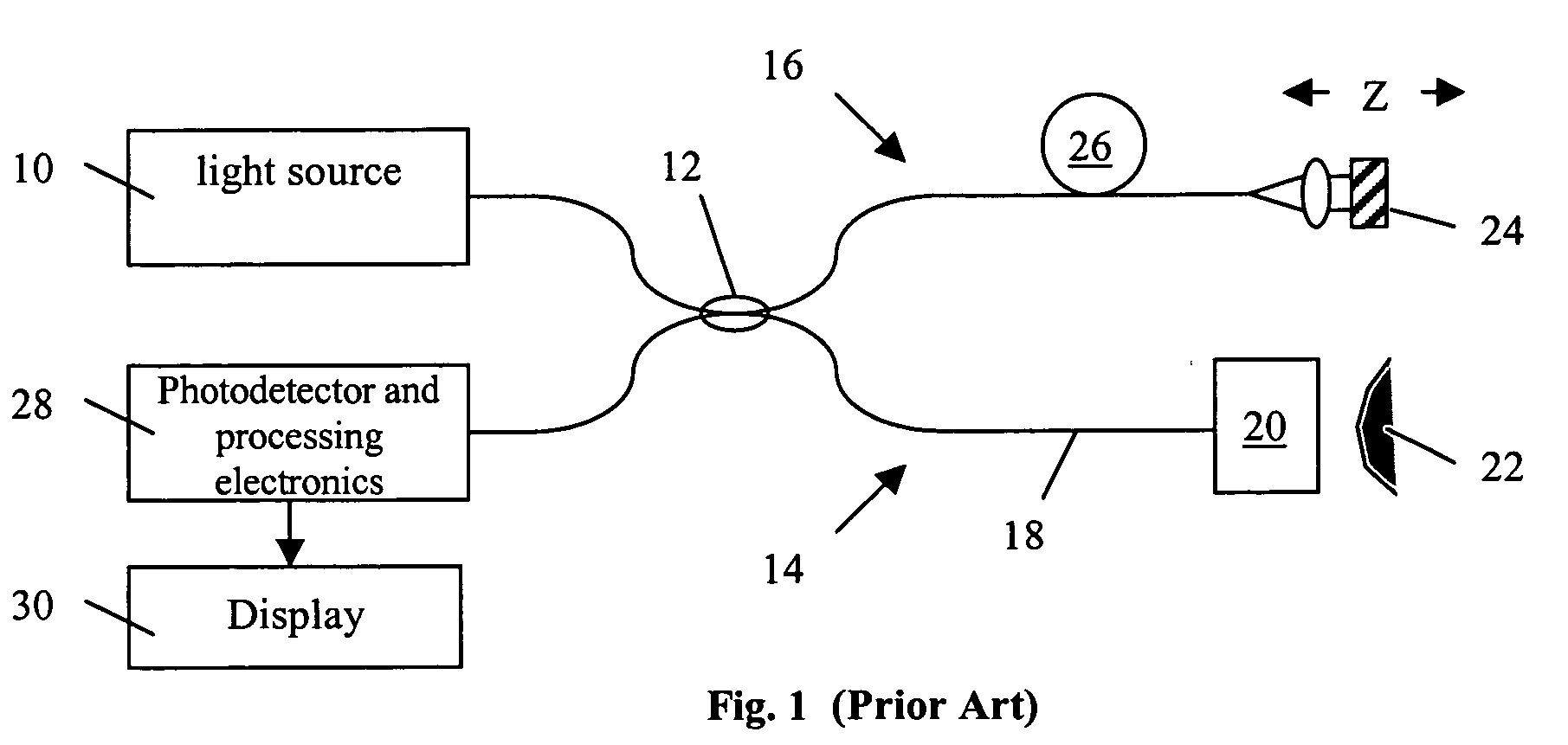

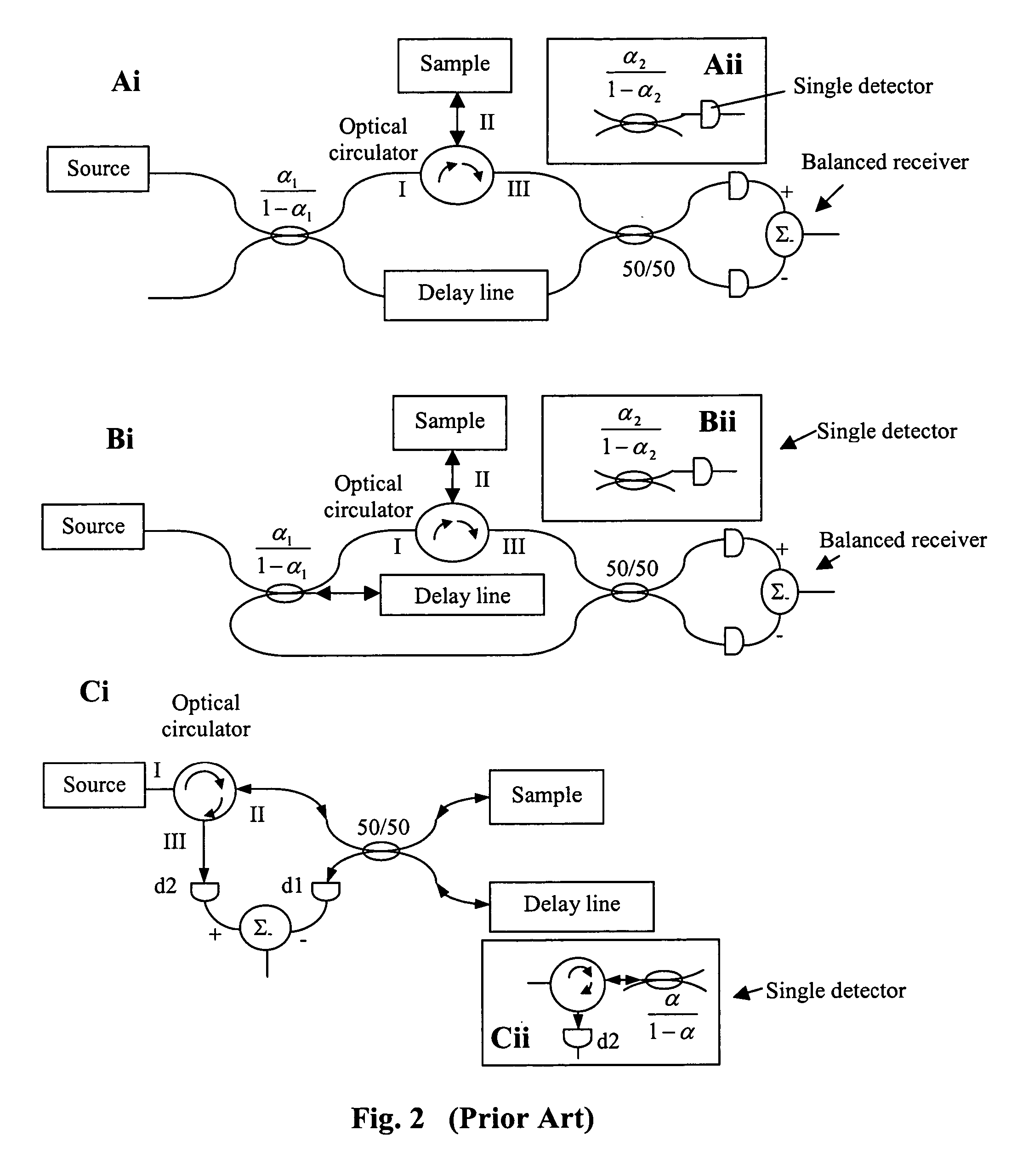

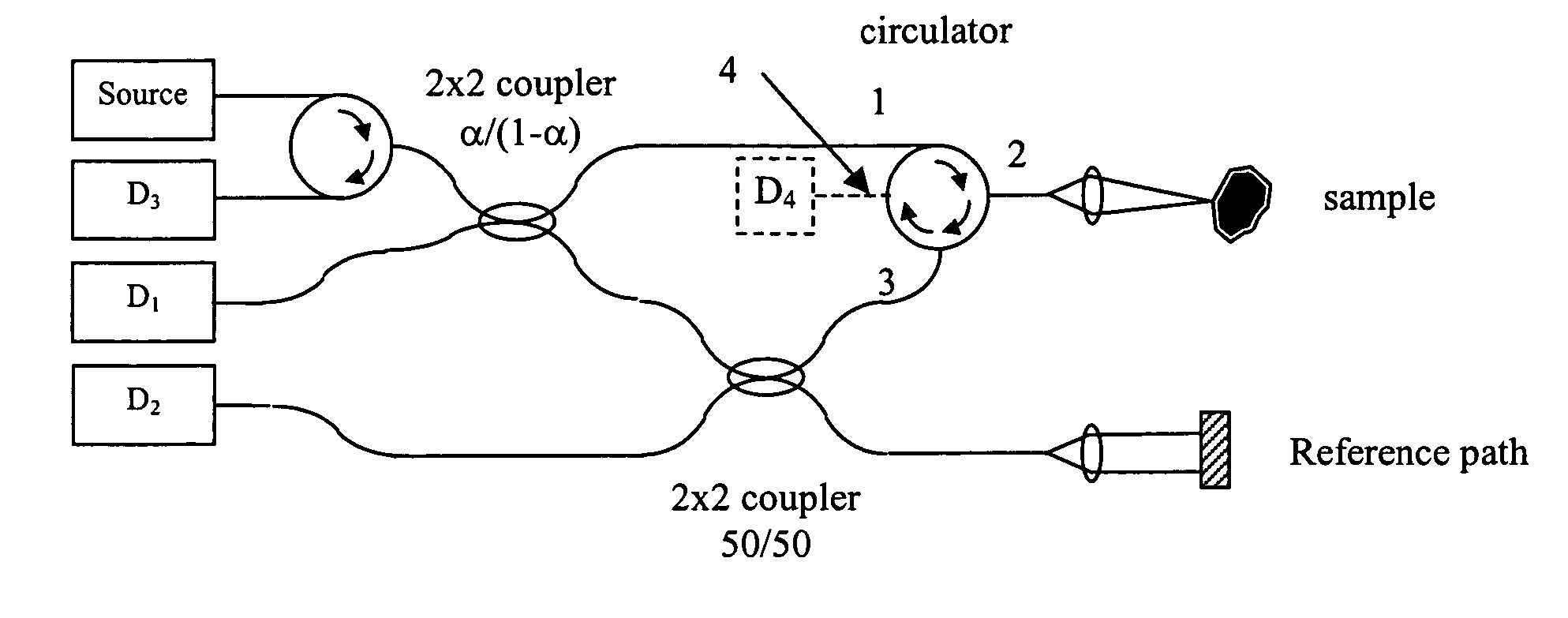

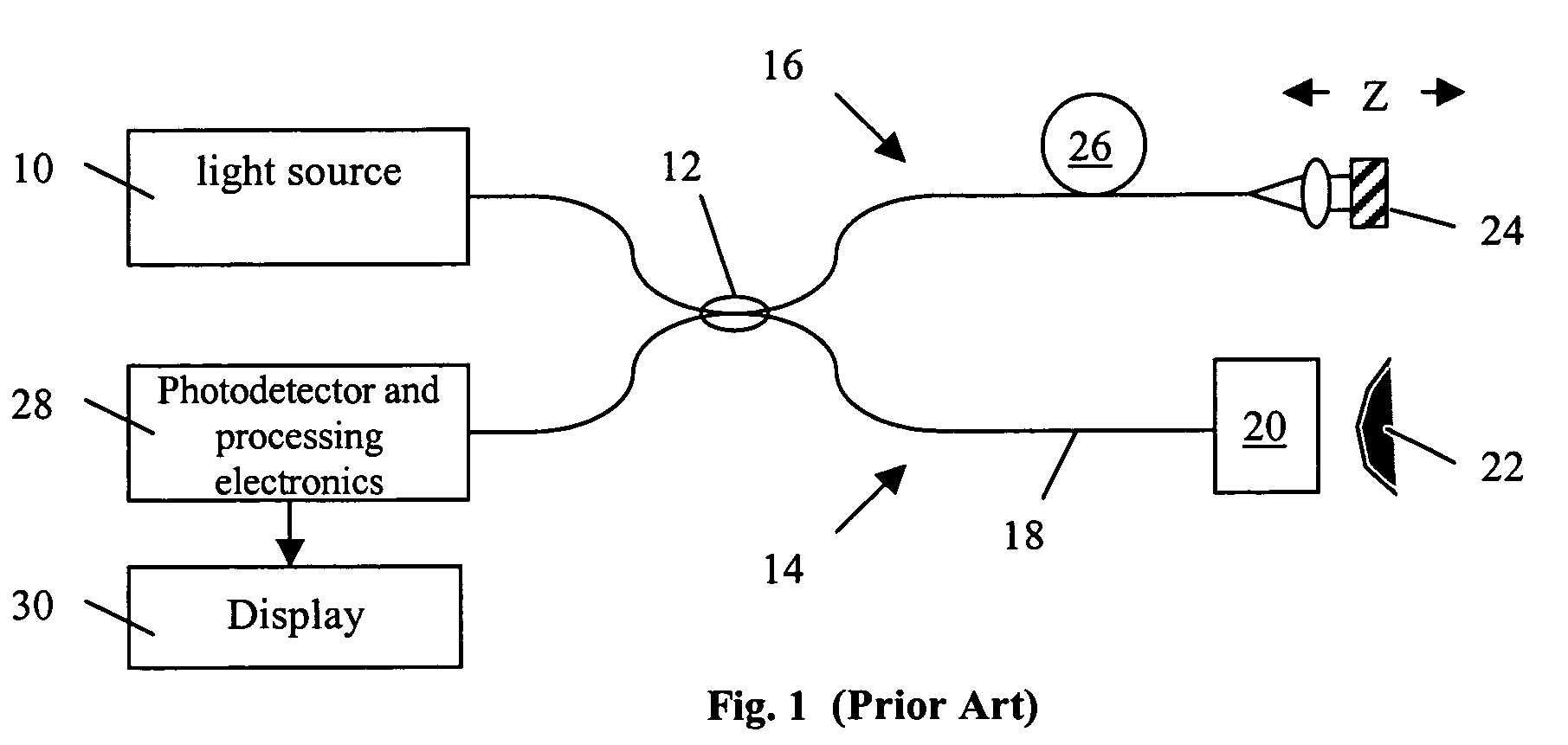

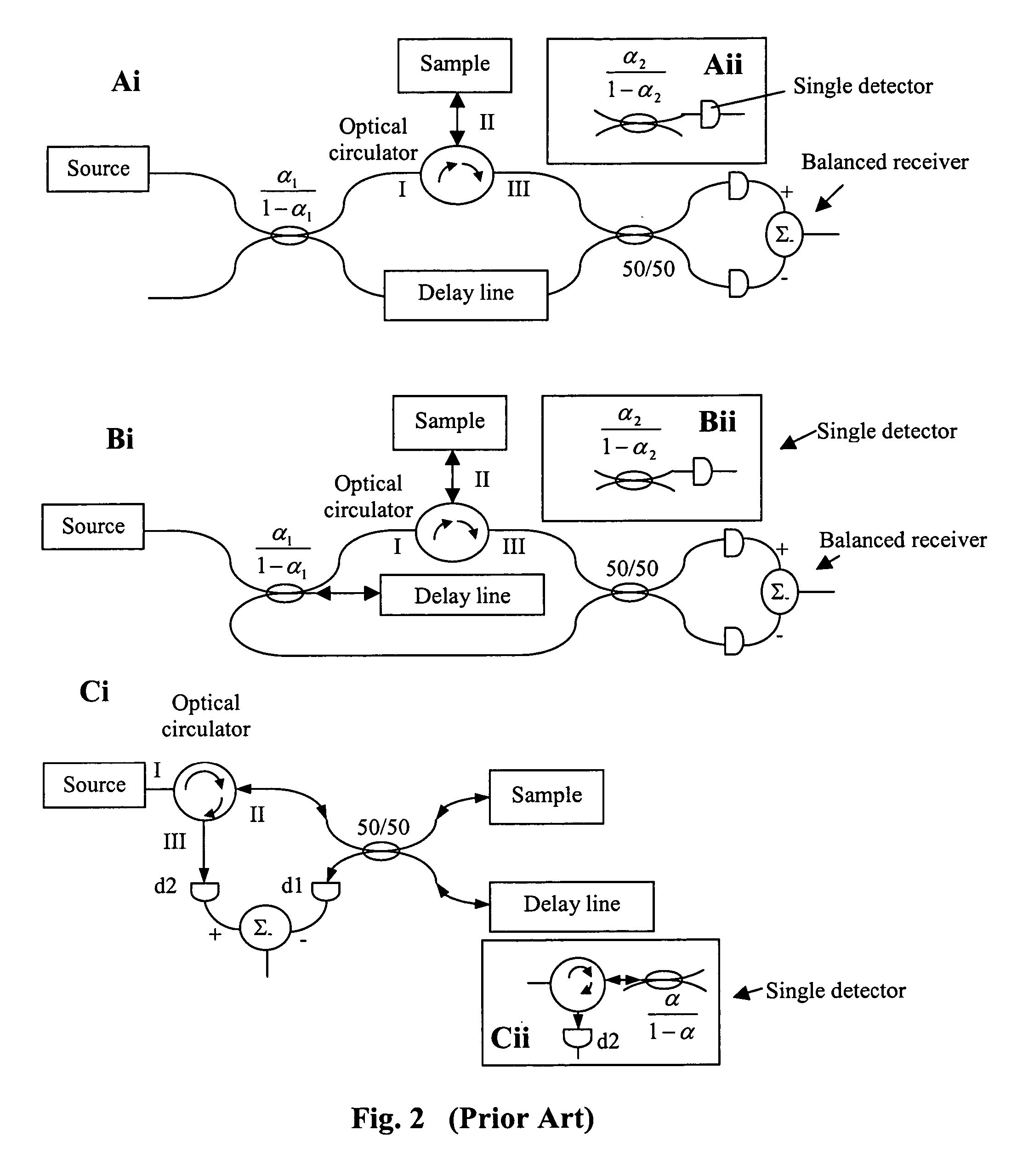

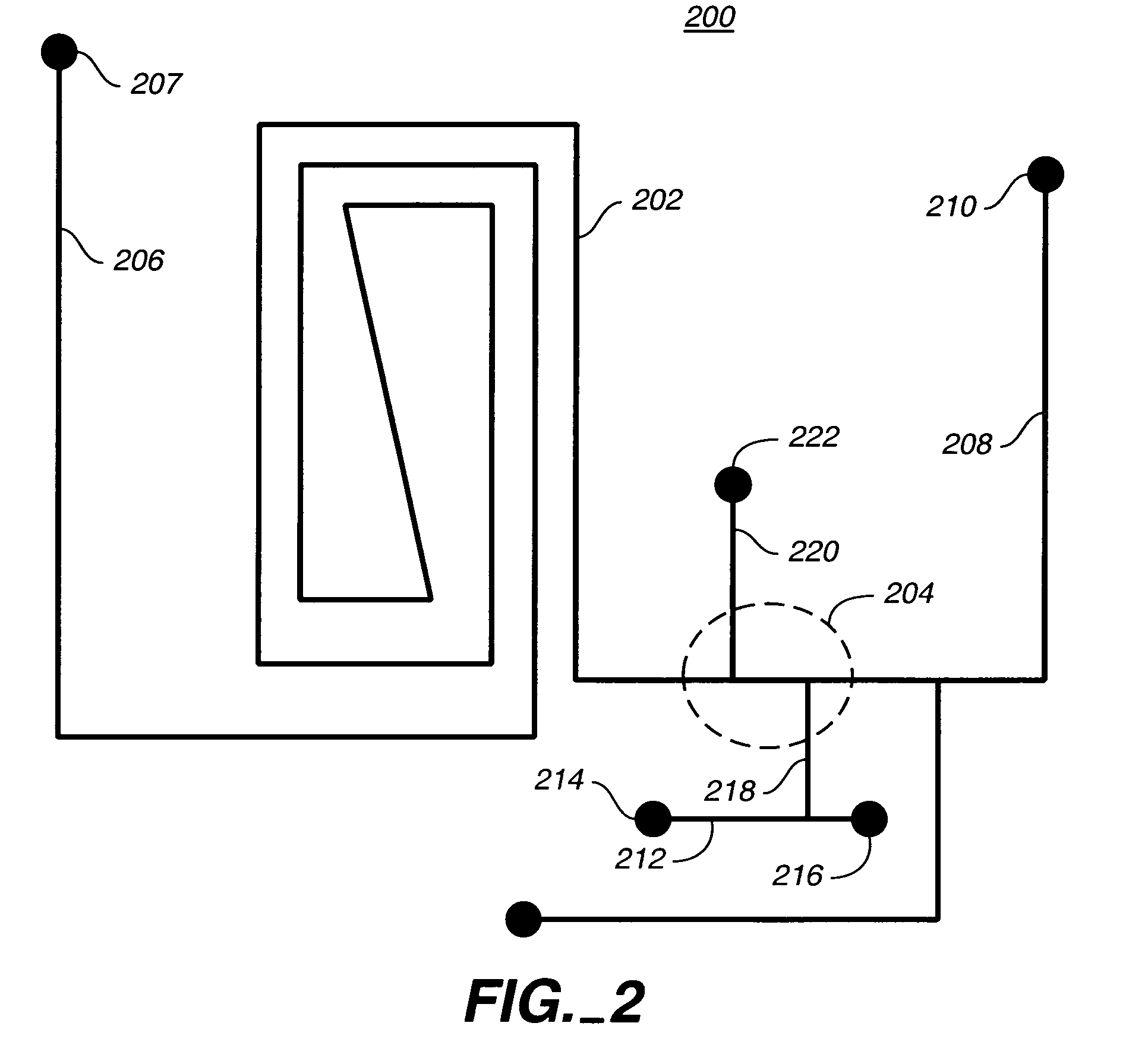

High efficiency balanced detection interferometer

InactiveUS20060109477A1Reduce system costLow costInterferometersUsing optical meansReflectometrySeparate sample

An interferometer configured for use in optical coherence domain (OCT) reflectometry systems is disclosed. In the preferred embodiments, efficient routing of light and a balanced detection arrangement provide a high signal to noise ratio. In a first set of embodiments, a 3×3 coupler is used to split light along separate sample and reference paths and also for combining light returning from those paths and supplying the interfered collected light to the detection system. In an alternate set of embodiments, a pair of cascaded 2×2 couplers provides a similar function. The interferometer can be used with various OCT modalities including time-domain and frequency domain approaches.

Owner:CARL ZEISS MEDITEC INC

High efficiency balanced detection interferometer

InactiveUS7388672B2Improve performanceEasily identifiableInterferometersUsing optical meansDiagnostic Radiology ModalitySignal-to-noise ratio (imaging)

An interferometer configured for use in optical coherence domain (OCT) reflectometry systems is disclosed. In the preferred embodiments, efficient routing of light and a balanced detection arrangement provide a high signal to noise ratio. In a first set of embodiments, a 3×3 coupler is used to split light along separate sample and reference paths and also for combining light returning from those paths and supplying the interfered collected light to the detection system. In an alternate set of embodiments, a pair of cascaded 2×2 couplers provides a similar function. The interferometer can be used with various OCT modalities including time-domain and frequency domain approaches.

Owner:CARL ZEISS MEDITEC INC

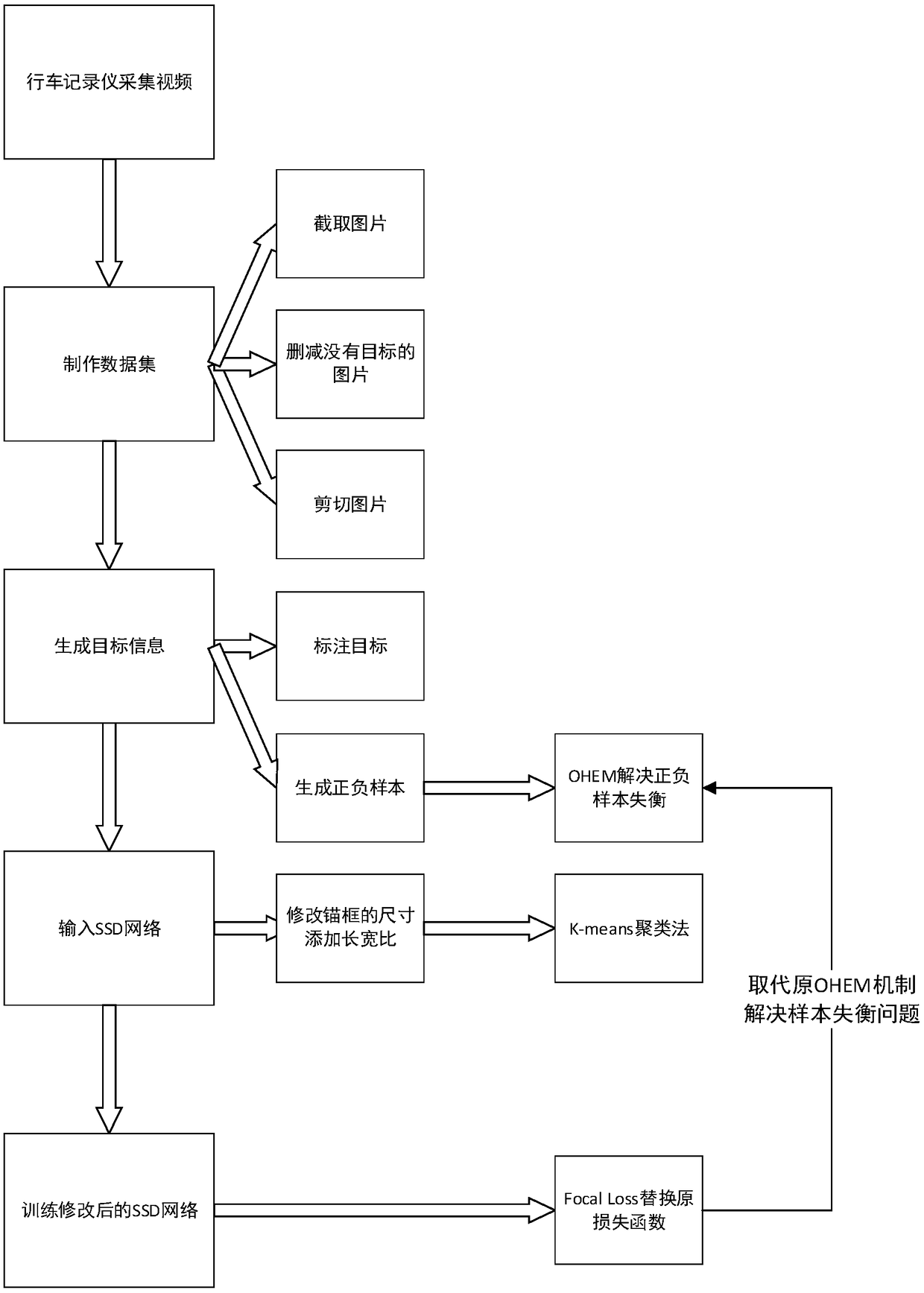

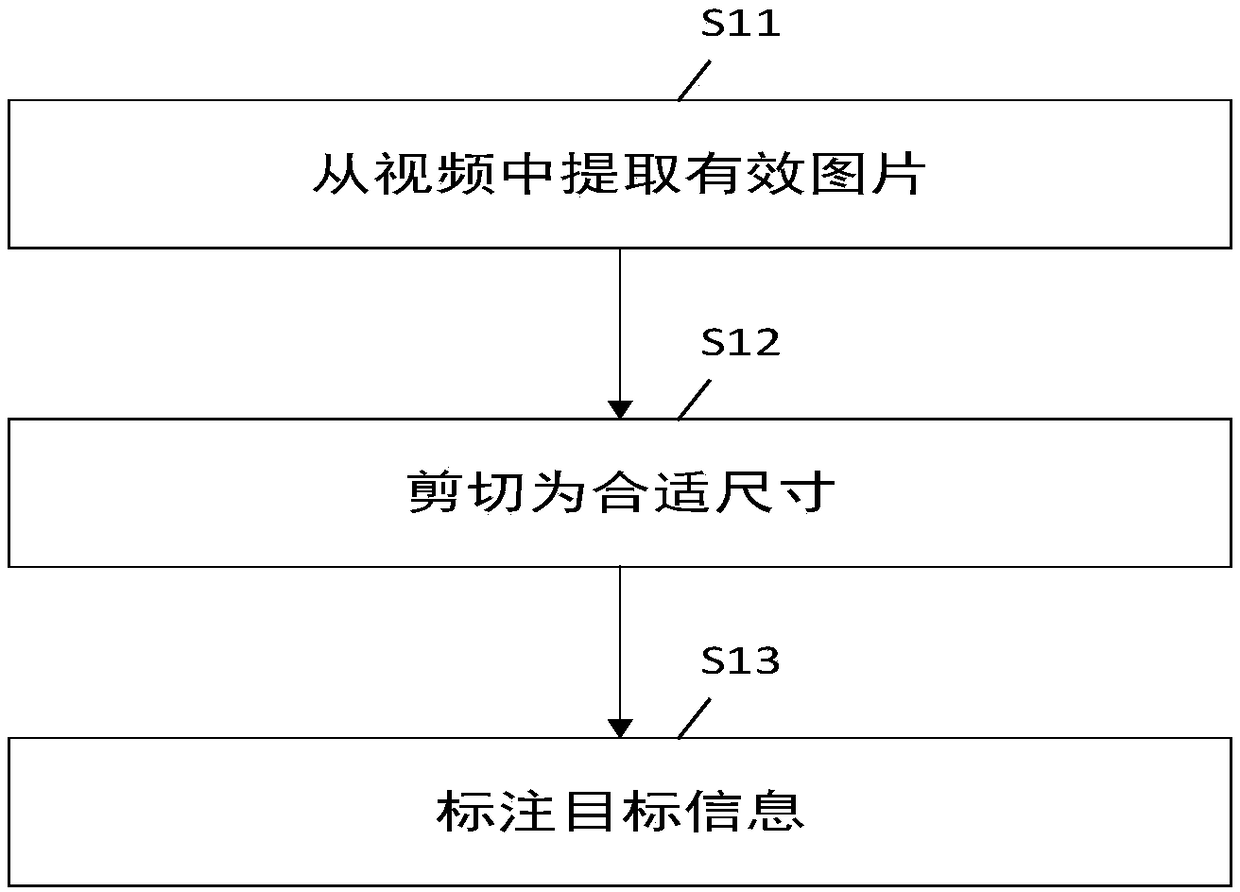

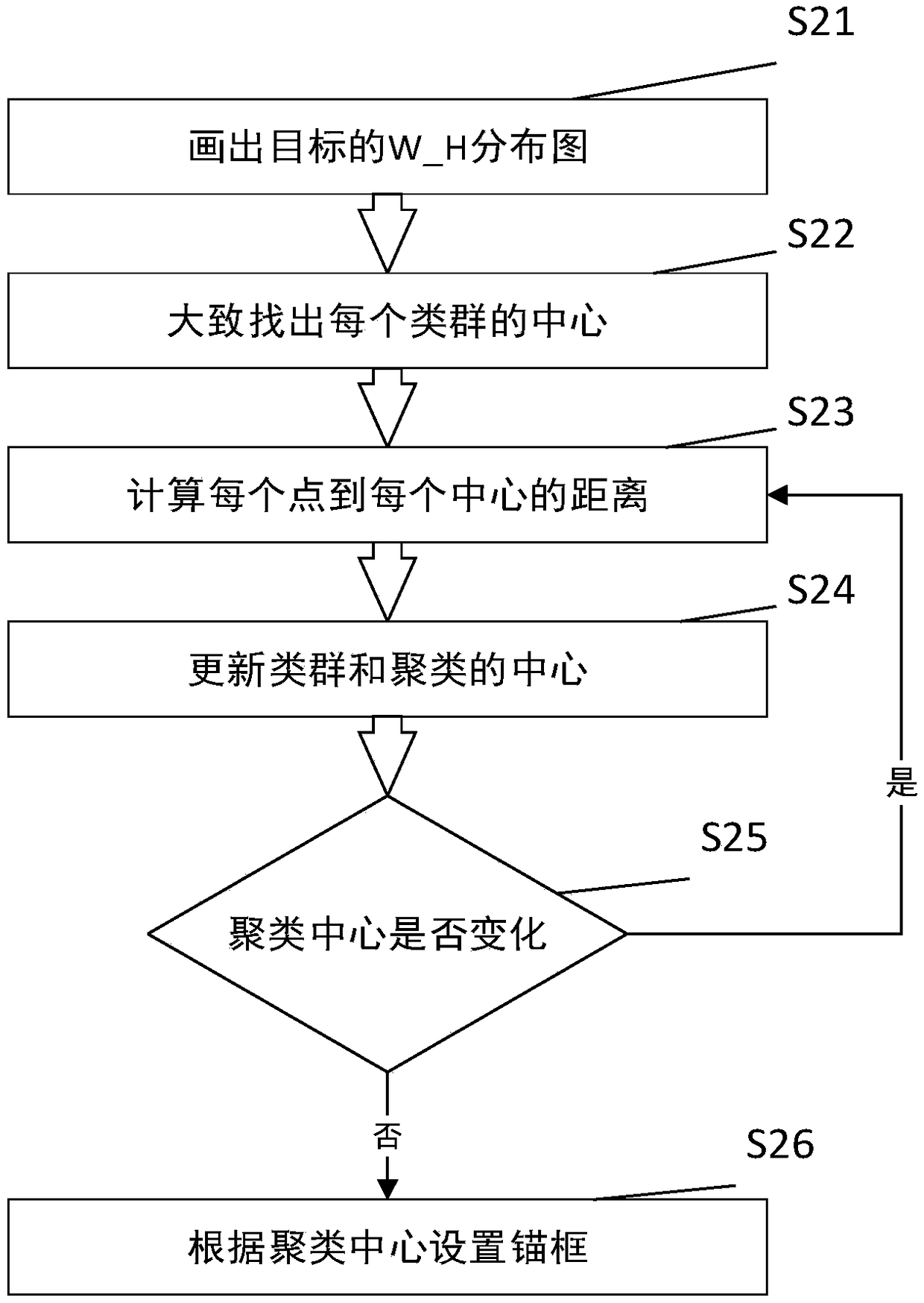

A multi-target detection method for vehicles and pedestrians based on improved SSD network

InactiveCN109409252AFast convergenceEfficient Classification and Regression ModelsCharacter and pattern recognitionData setSimulation

The invention discloses a vehicle and pedestrian multi-target detection method based on an improved SSD network. Step S1: a magnanimous driving video collected by a driving recorder is made into a picture input set with an appropriate size; Step S2: According to k-Means clustering method modifies the size and aspect ratio of the anchor frame in SSD network to fit the data set; Step S3, replacing the original loss function with the Focal Loss function, replacing the original Online Hard Example Mining (OHEM) mechanism, and solving the problem of positive and negative sample imbalance; Step S4,inputting a data set and training a new SSD network; Step S5: Using the trained SSD network to detect the object of the real-time input picture. According to the technical proposal of the invention, by means of clustering, Set the size and aspect ratio of the proposed anchor frame, By using Focal Loss function, the problem of the imbalance between positive and negative samples is solved, the importance of difficult-to-separate samples is increased, the occupation of memory is reduced, the training speed is improved, and the accuracy of the whole detection is also improved.

Owner:HANGZHOU DIANZI UNIV

Vacuum ultraviolet reflectometer system and method

ActiveUS20050001172A1Thin layerSmall featureSpectrum investigationPolarisation-affecting propertiesMetrologyUltraviolet

A spectroscopy system is provided which operates in the vacuum ultra-violet spectrum. More particularly, a system utilizing reflectometry techniques in the vacuum ultraviolet spectrum is provided for use in metrology applications. The system may further include the use of an array detector in combination with an imaging spectrometer. In this manner data for multiple wavelengths may be simultaneously collected. Moreover, the multiple wavelengths of data may be collected simultaneously for a two dimensional sample area. The system may further include the use of a fixed diffraction grating and does not require the use of polarizing elements. To ensure accurate and repeatable measurement, the environment of the optical path is controlled. The optical path may include a controlled environmental chamber in which non-absorbing purge gases are present or in which vacuum evacuation techniques are utilized. The controlled environment may further include a separate instrument chamber and a separate sample chamber. The controlled environment limits in a repeatable manner the absorption of VUV photons.

Owner:BRUKER TECH LTD

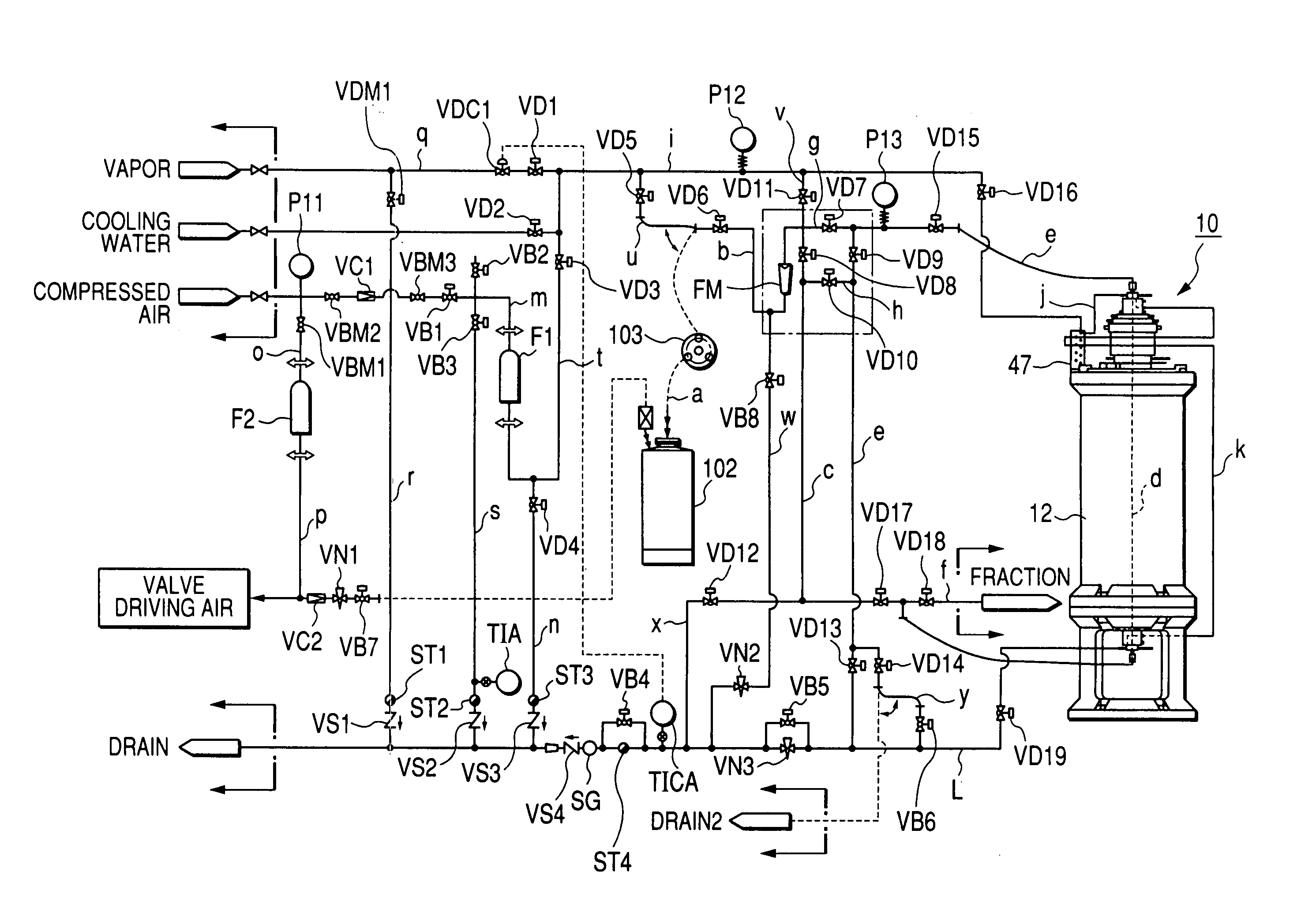

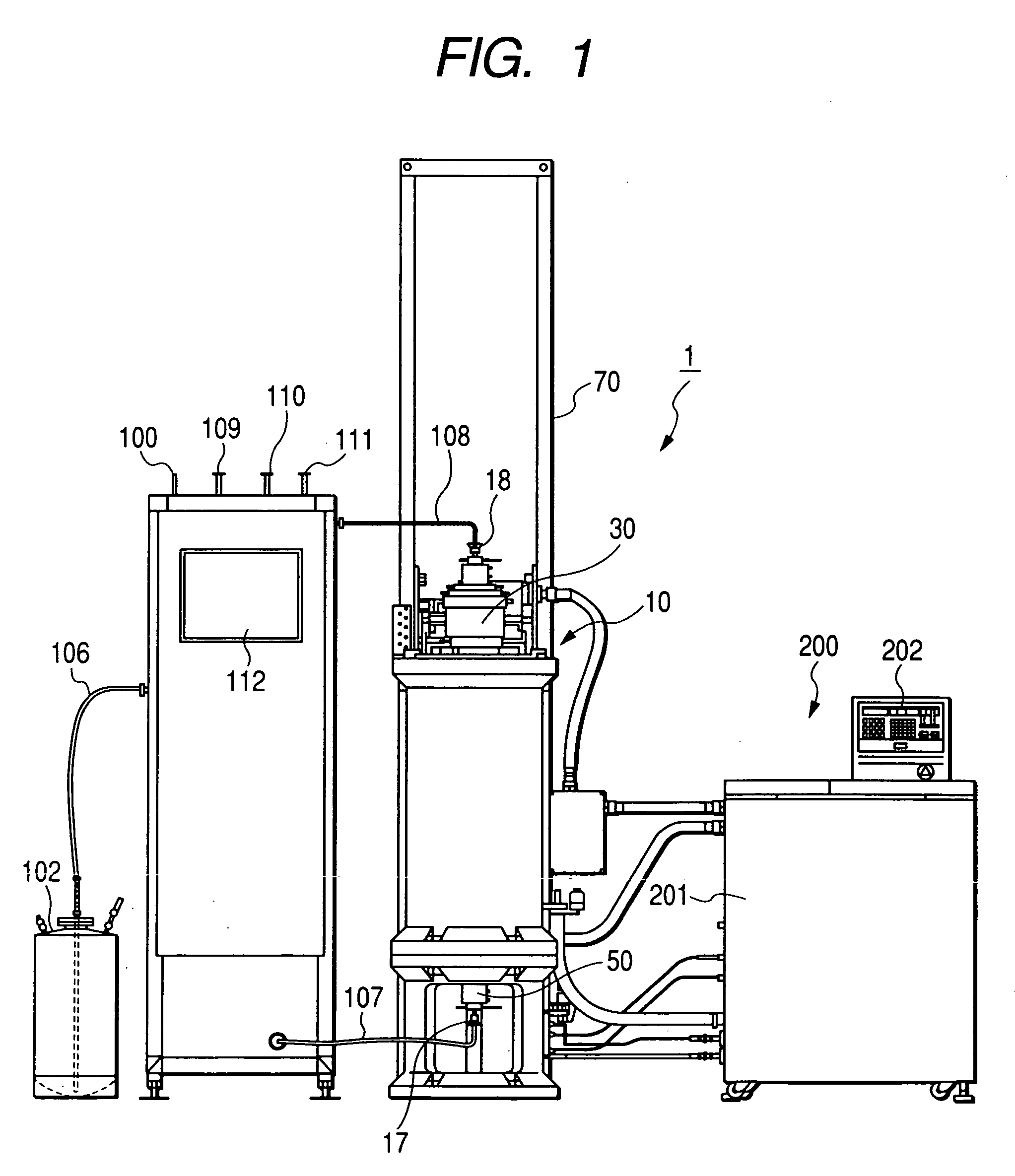

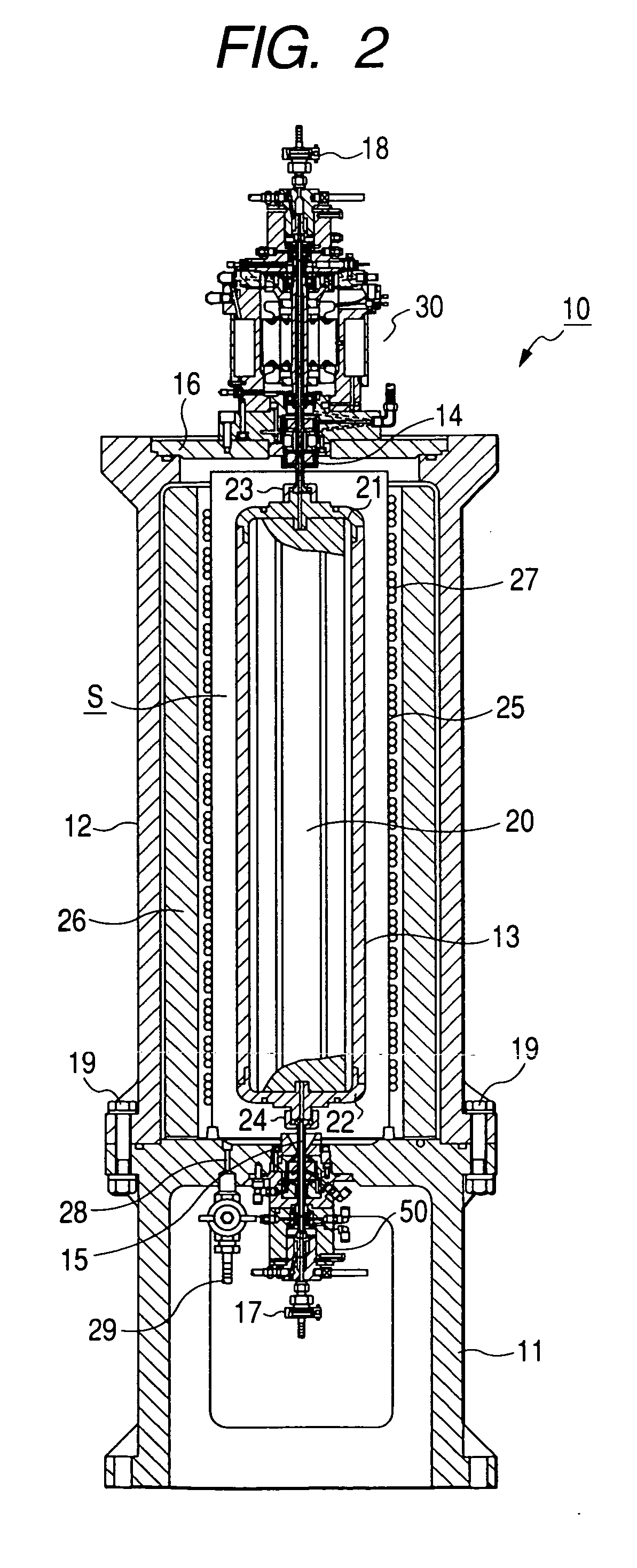

Centrifugal separator

A centrifugal separator includes: a sample line; and a rotating apparatus portion including a rotor that has a rotor chamber. The centrifugal separator centrifugally separates a sample by supplying the sample from the sample line into the rotor and driving to rotate the rotor in the rotor chamber and discharges the centrifugally separated sample from the rotor via the sample line. The centrifugal separator includes: a sterilizing apparatus for sterilizing at least a portion with which the sample is brought into contact by making a sterilizing fluid flow through the sample line.

Owner:EPPENDORF HIMAC TECH CO LTD

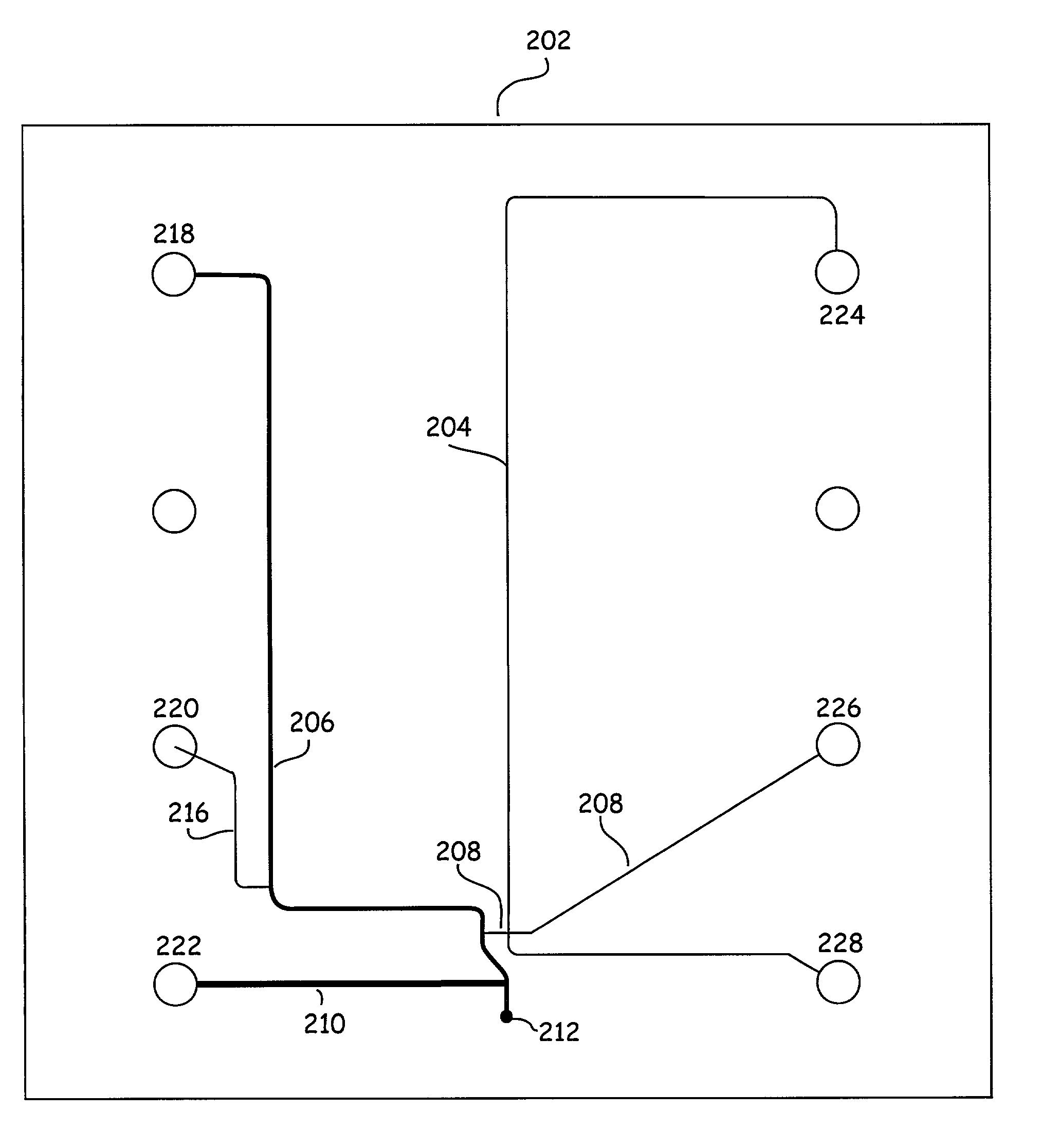

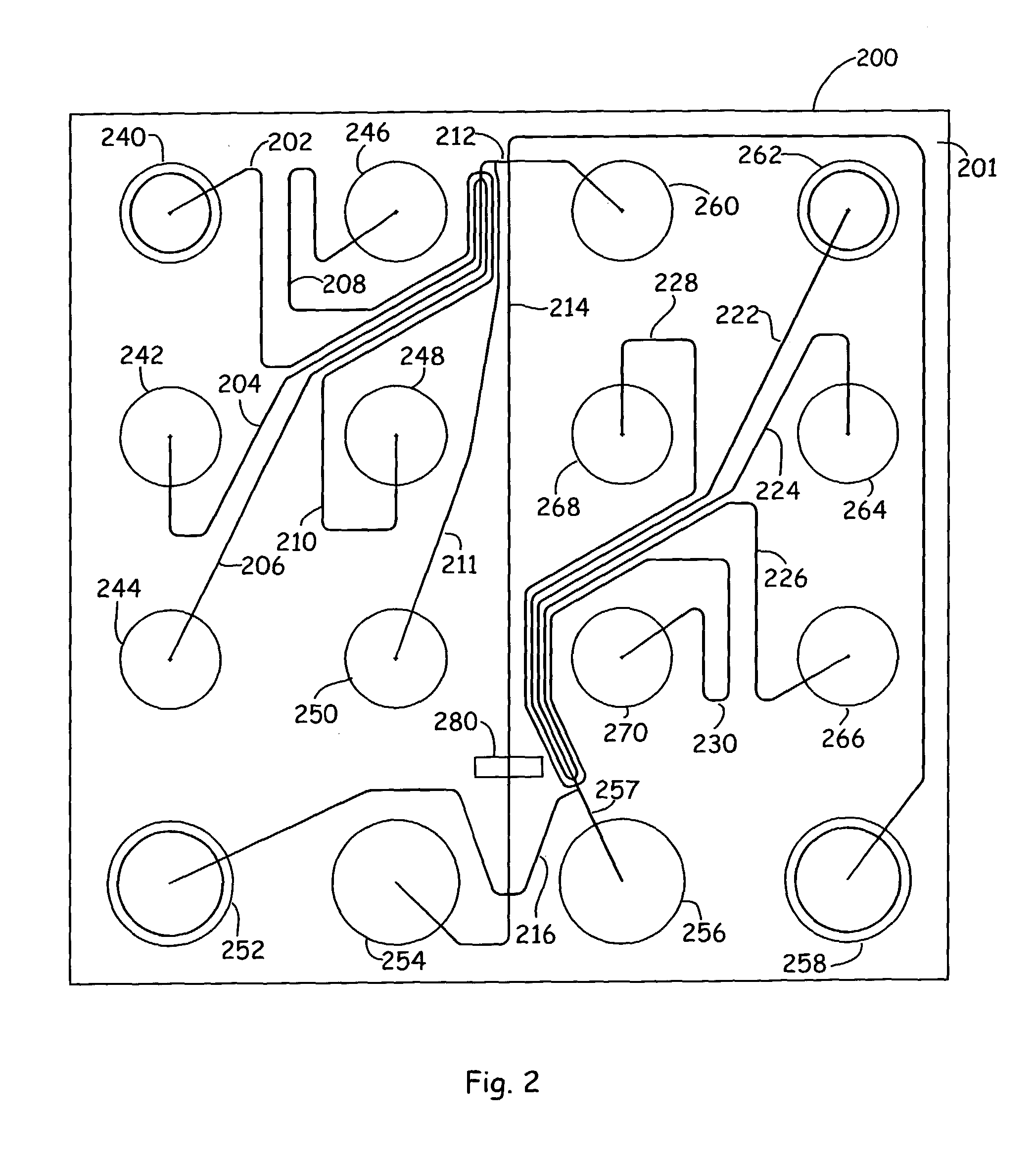

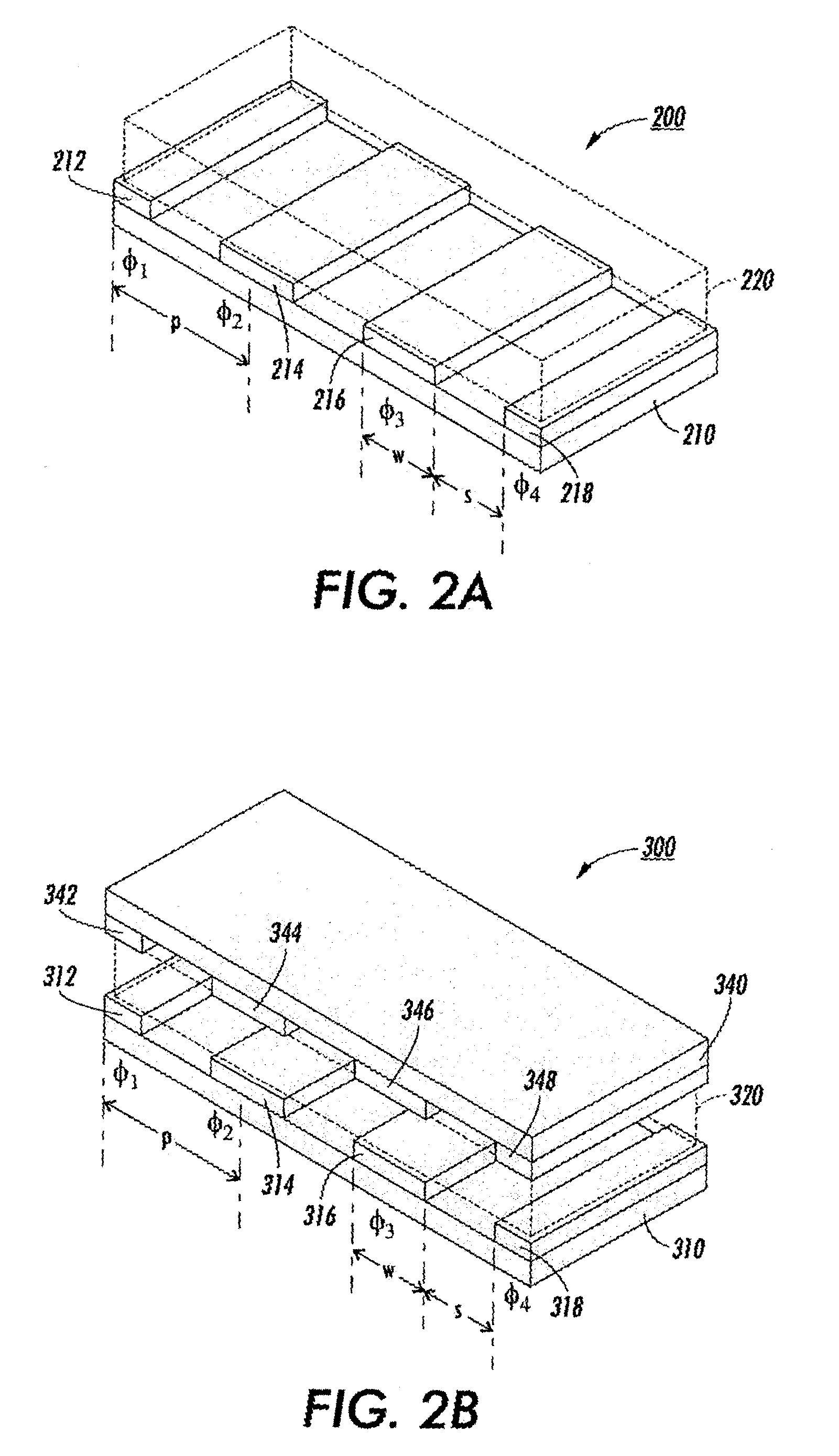

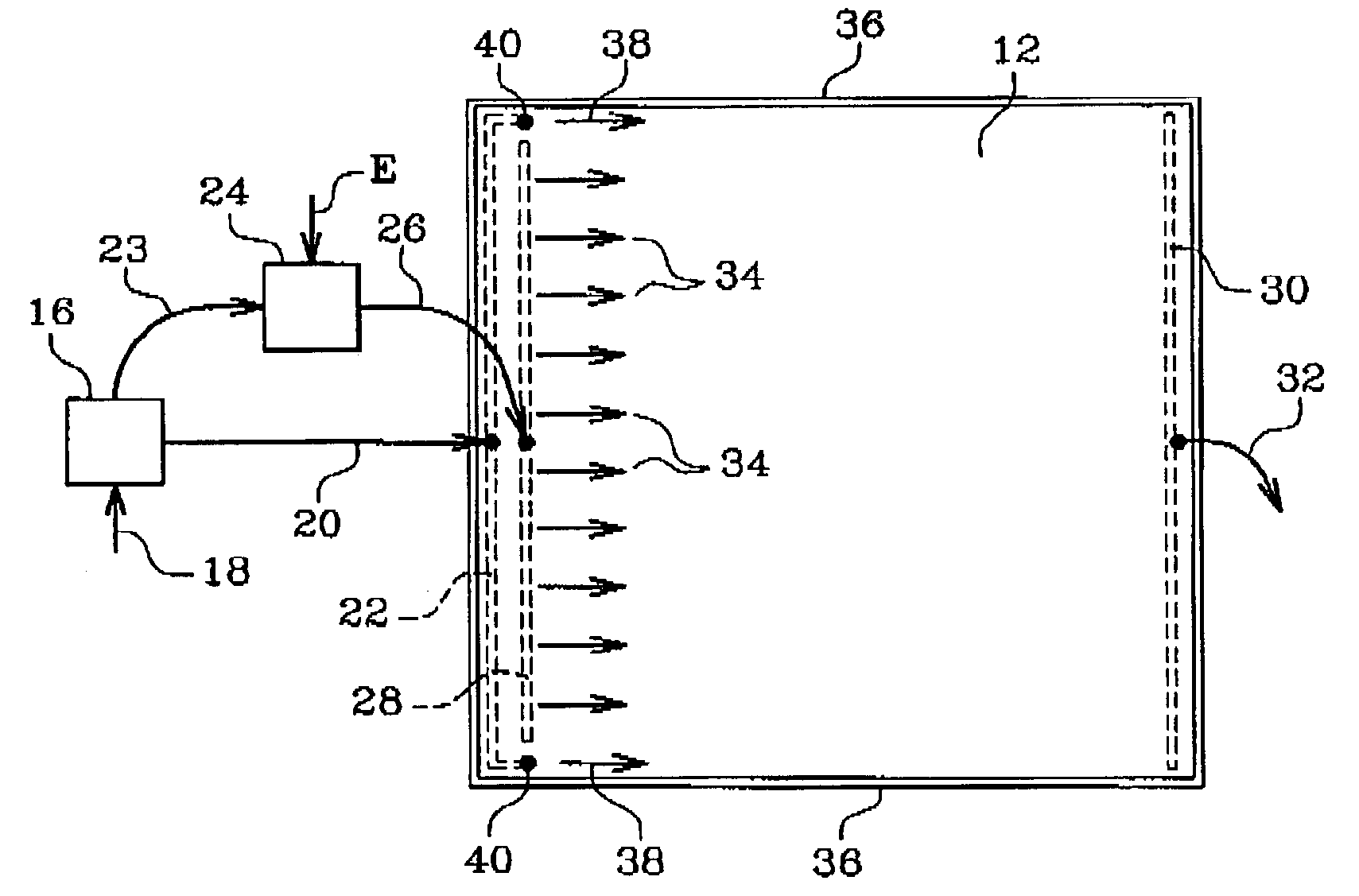

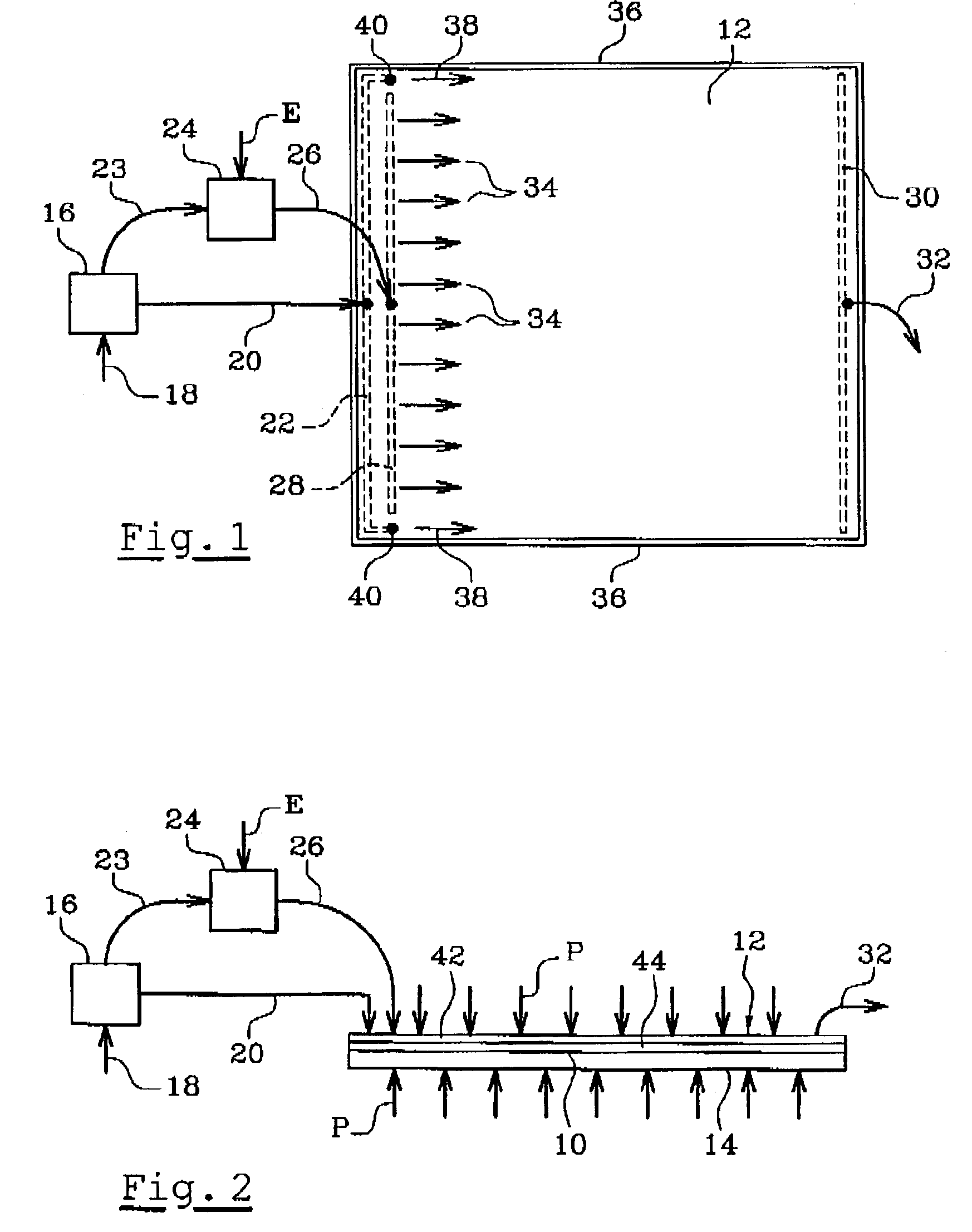

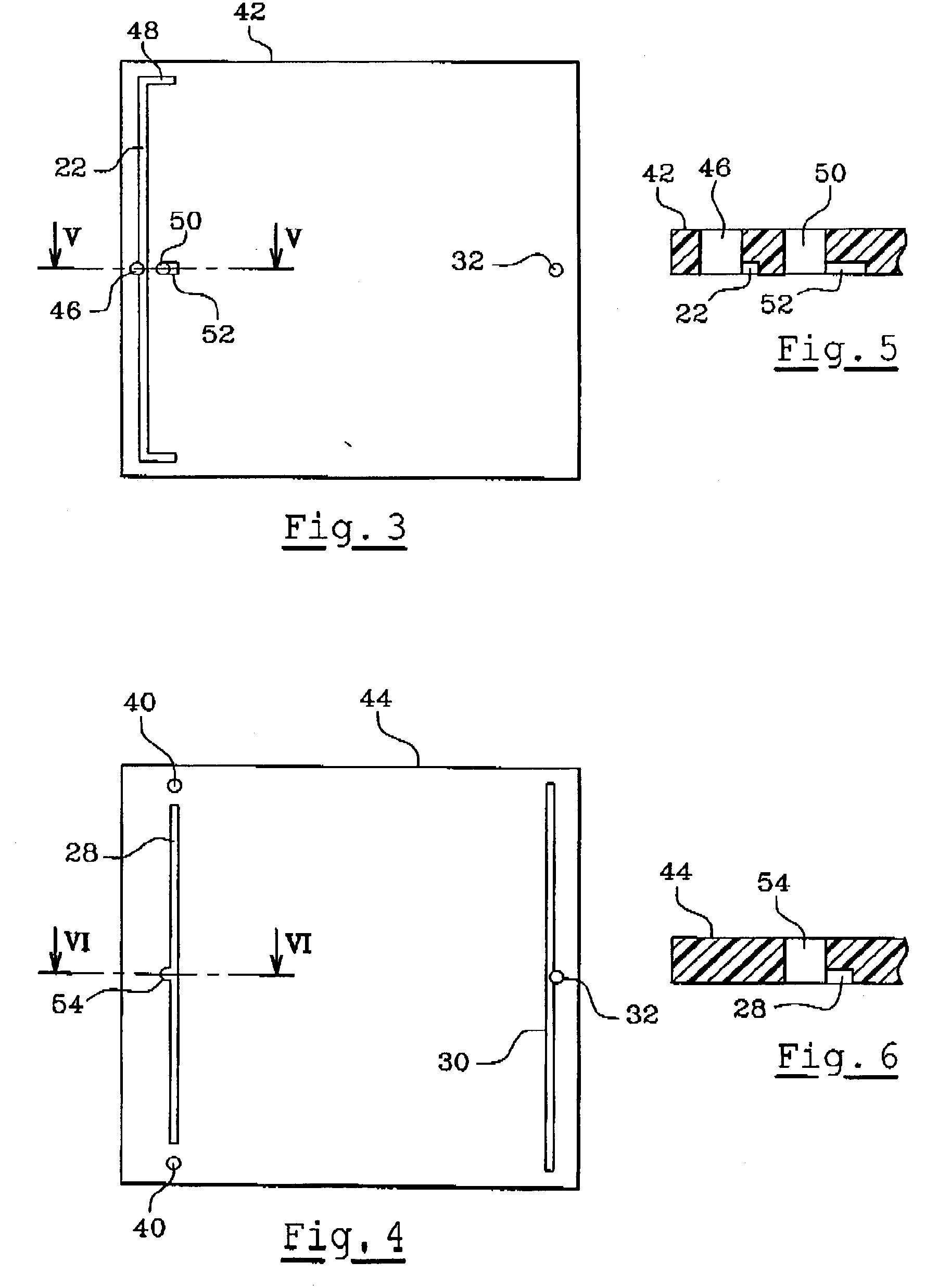

Distributed multi-segmented reconfigurable traveling wave grids for separation of proteins in gel electrophoresis

ActiveUS7156970B2Reduce processing timeIncrease field strengthElectrostatic separatorsSludge treatmentElectrophoresisEngineering

Various traveling wave grids and electrophoretic systems, and electrode assemblies using such grids, are disclosed. A configuration in which a voltage potential is used to load a biomolecule sample against a grid is disclosed. A unique strategy of using multiple, reconfigurable grids in such systems is also described. The strategy involves initially conducting a broad protein separation and then selectively tailoring one or more grids, and conducting one or more secondary processing operations. Related strategies and specific methods are additionally disclosed for separating samples of biomolecules and components thereof using the noted systems, assemblies, and grids.

Owner:PALO ALTO RES CENT INC

Portable apparatus for separating sample and detecting target analytes

Owner:SANDIA NAT LAB

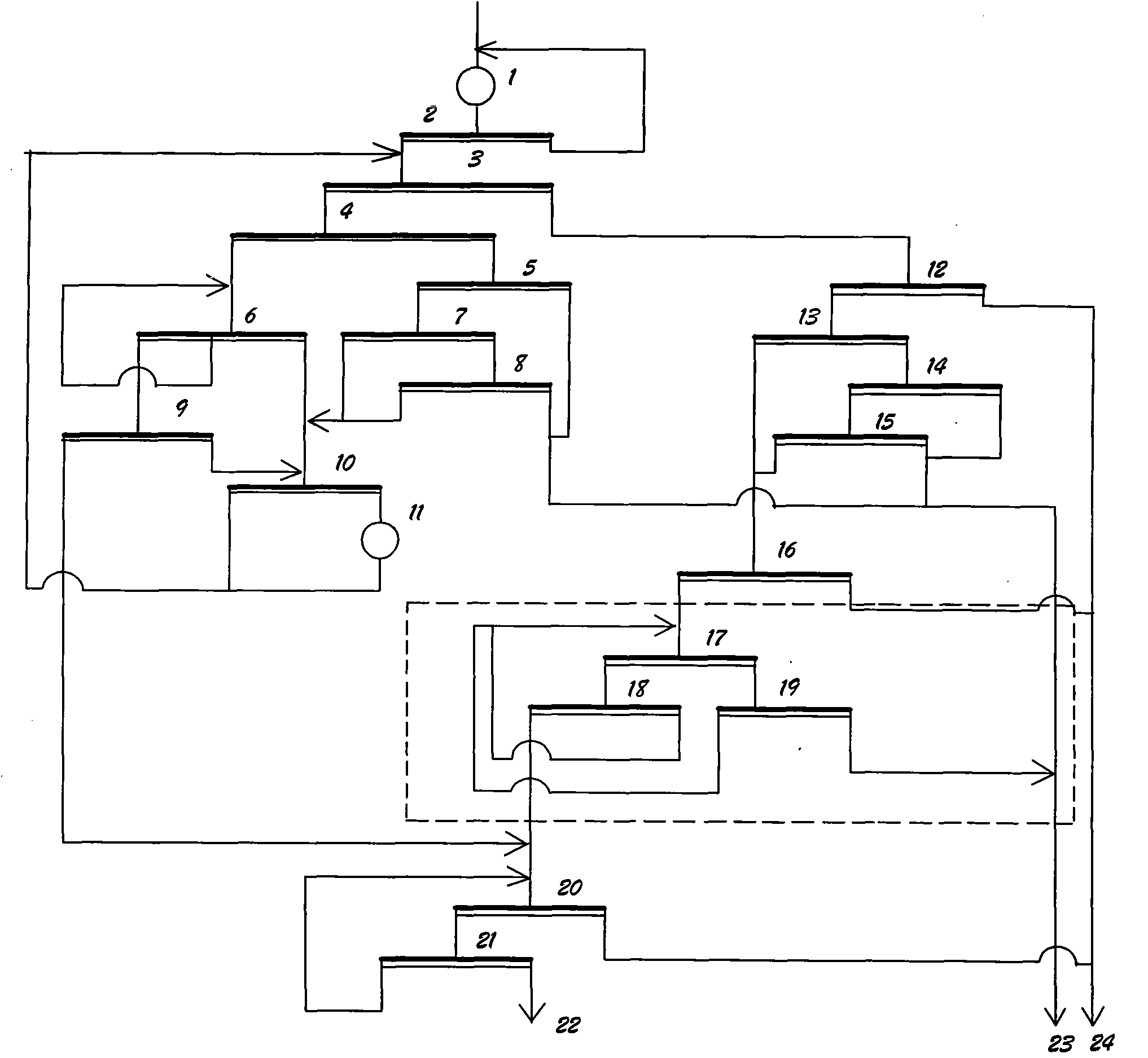

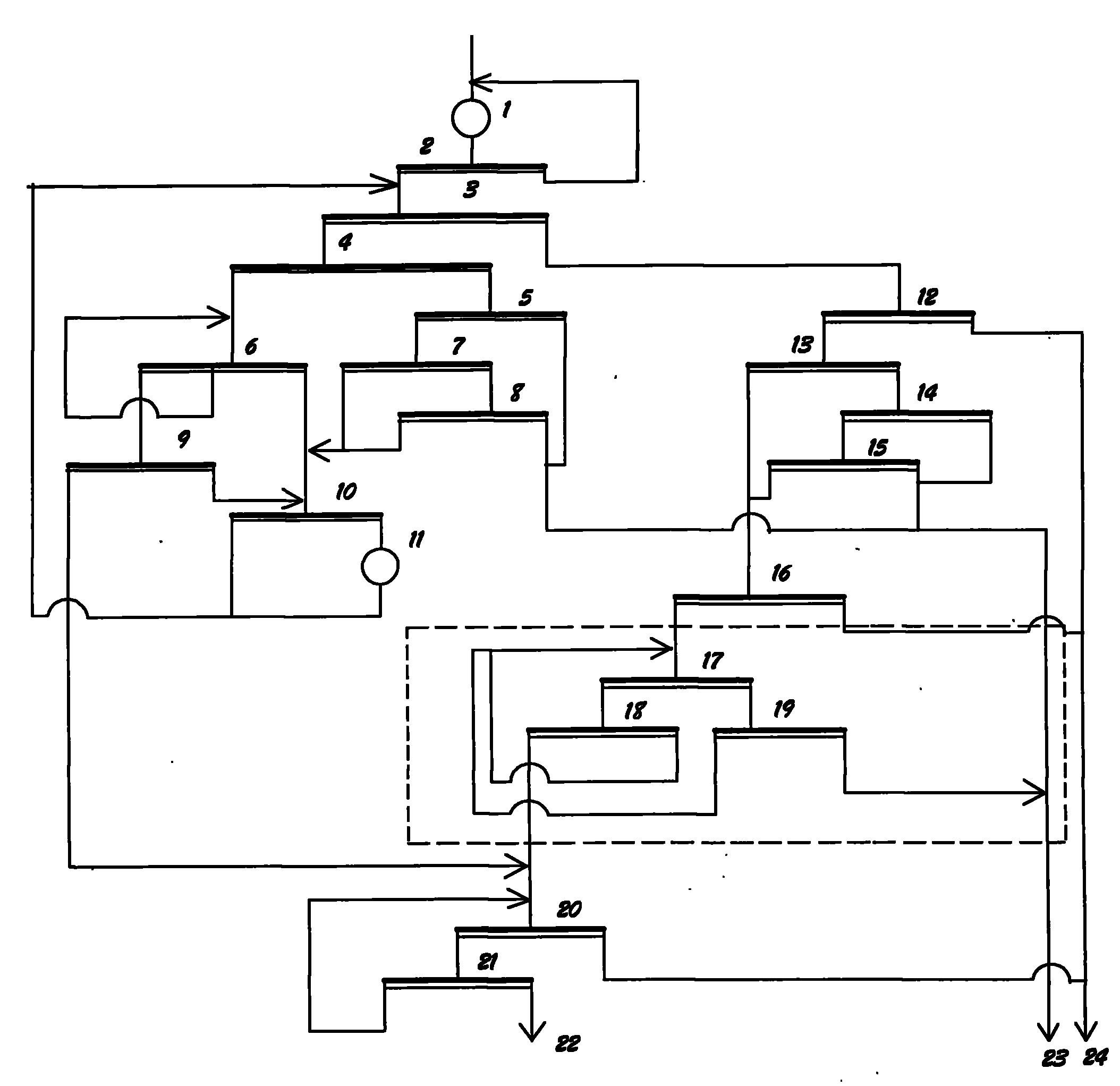

Process for processing low grade hematite ore

ActiveCN101773869ASimplify the flotation processSimple processWet separationSmall footprintFerromagnetism

The invention belongs to the technical field of preparing low grade hematite ore, in particular to a process for processing a low grade hematite ore. The process comprises the following steps: the ore is ground until monomer separation and then coarse and fine classification is carried out on pulp; coarse grain pulp is subject to reselecting, ferromagnetism and sieving to obtain a part of the concentrate; the fine grain pulp is conveyed to a mixing tank for separating sample, and then is conveyed to a second mixing tank to be mixed with medicine for size mixing; the mixture is pumped to a rough flotation column; the under flows of the rough flotation column is fed to a cleaning flotation column, the under flow of the cleaning flotation column is the ultimate iron ore concentrate; foam of the rough flotation column is conveyed to an one-stage scavenging flotation column by a pump; the under flow of the one-stage scavenging flotation column and the foam of the cleaning flotation column are mixed and return to the rough flotation column, and products of the one-stage scavenging flotation column are final tailings. The process has the beneficial effects of smaller occupation area by replacing a flotation machine with the flotation column, can recycle fine-grade valuable mineral effectively, improve the ultimate concentrate grade, provides reference significance for the mineral separation of the ore of the same type in China, and has obvious economic benefits and social benefits.

Owner:ANSTEEL GRP MINING CO LTD

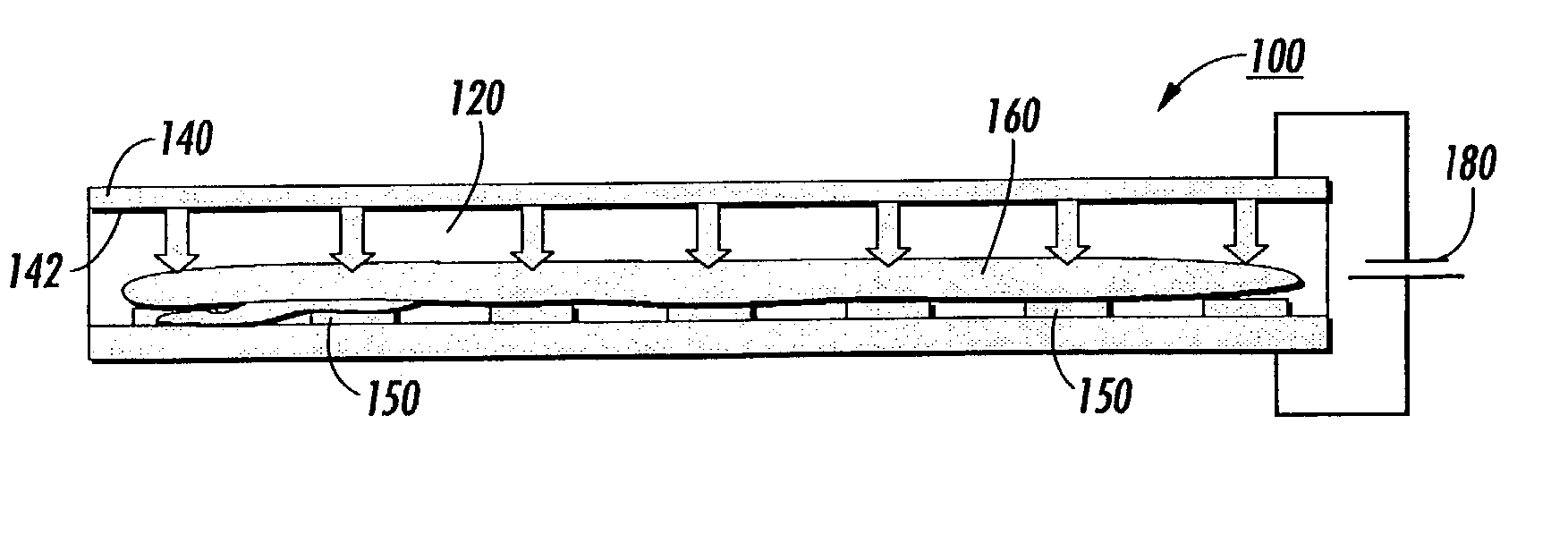

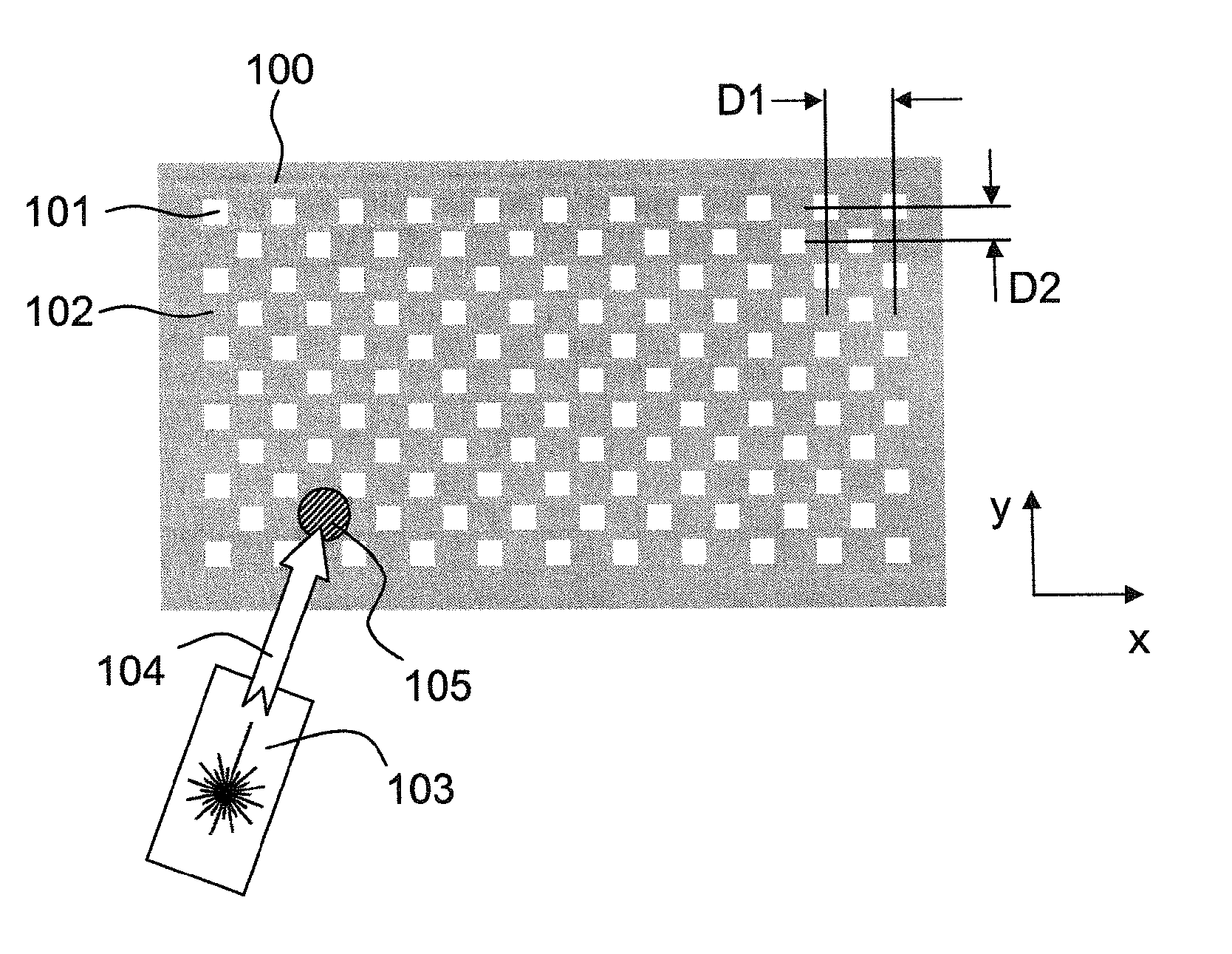

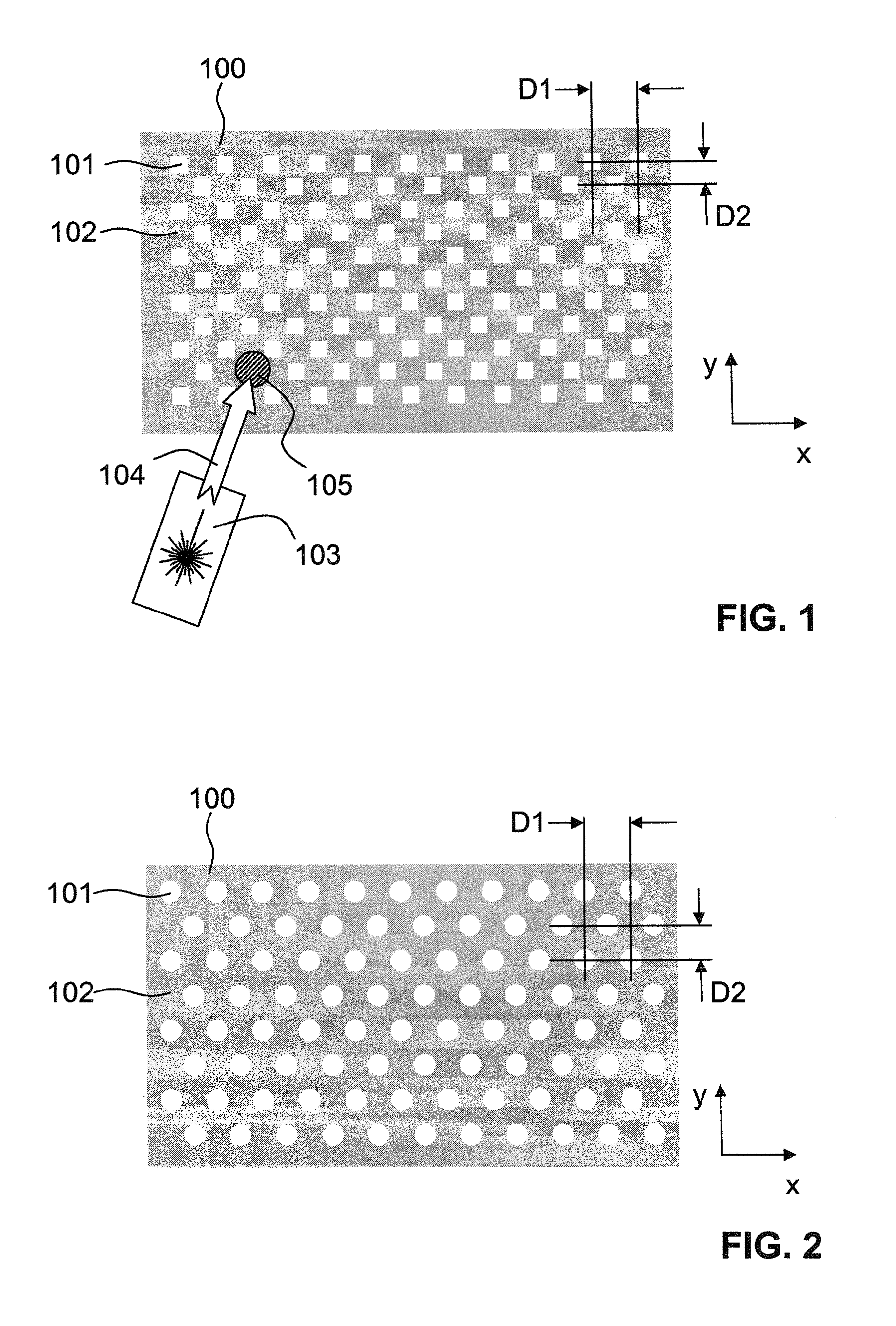

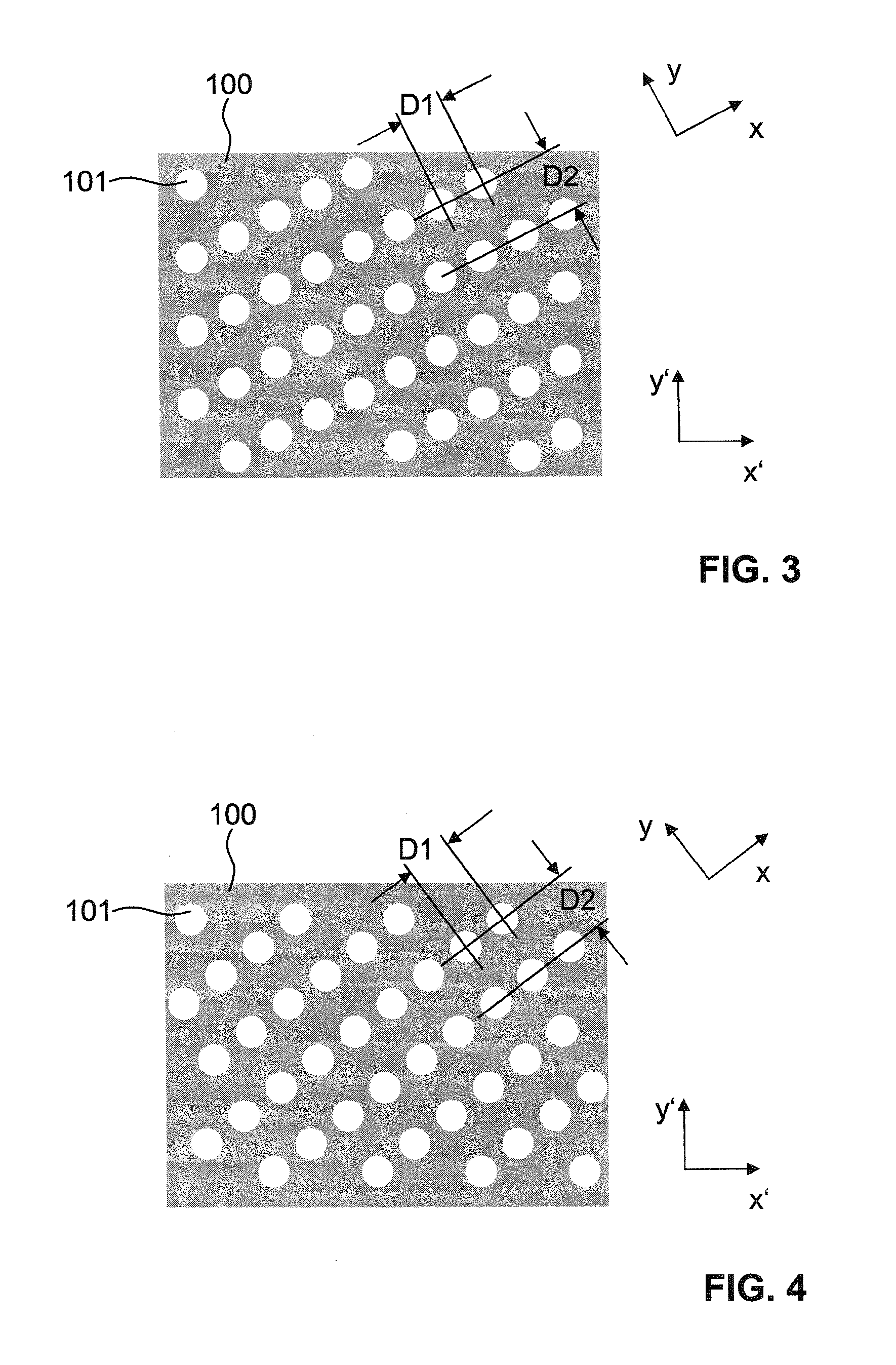

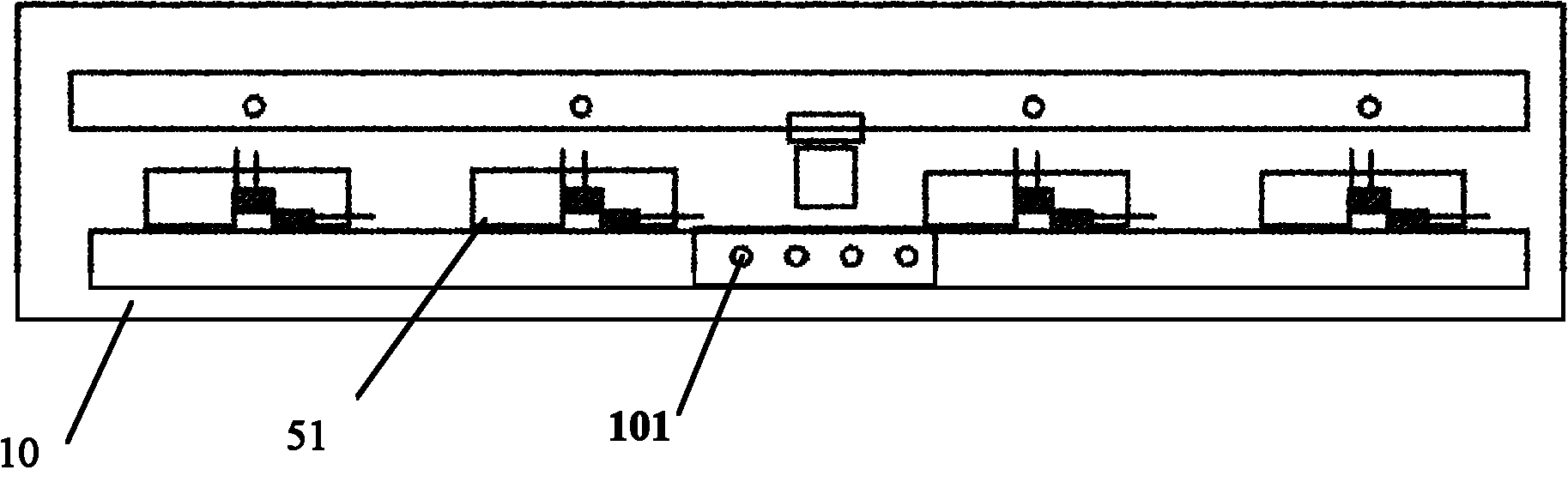

High-density sample support plate for automated sample aliquoting

A sample support plate (100) for a variety of possible applications, including MALDI mass spectrometry, is disclosed. A plurality of spatially separated sample recipient sites (101) are arranged on the surface of a substrate. The recipient sites are mutually separated by areas having a different wettability than the recipient sites. They are arranged in a plurality of rows consisting of a plurality of recipient sites whose centers are regularly spaced along a first direction with a predetermined periodicity (D1), the rows being regularly spaced along a second direction perpendicular to the first direction with a predetermined centerline distance (D2). Each recipient site has a maximum lateral dimension that is preferably smaller than the diameter of a beam spot (104) of a desorption laser beam (103). In order to enable unsupervised splitting of bulk liquid samples into droplets at the sample recipient sites, the periodicity along the first direction and the centerline distance along the second direction are chosen such that each recipient sites has a next neighbor at a distance that is less than or equal to three times the minimum lateral dimension of each recipient site. In preferred embodiments, the sample recipient sites are arranged in a checkerboard-type pattern or in rows that are inclined relative to the edges of the sample support plate.

Owner:ETH ZZURICH +1

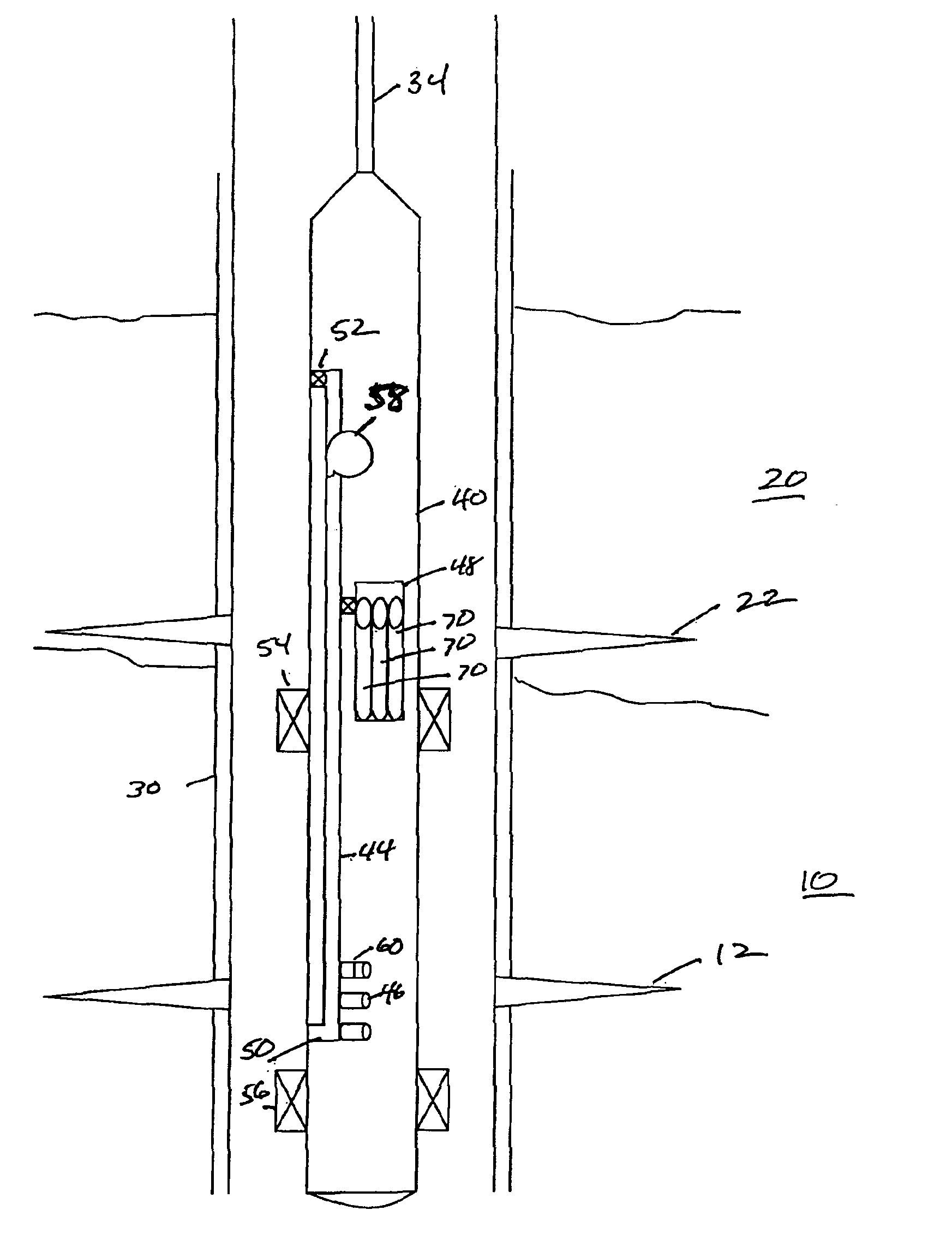

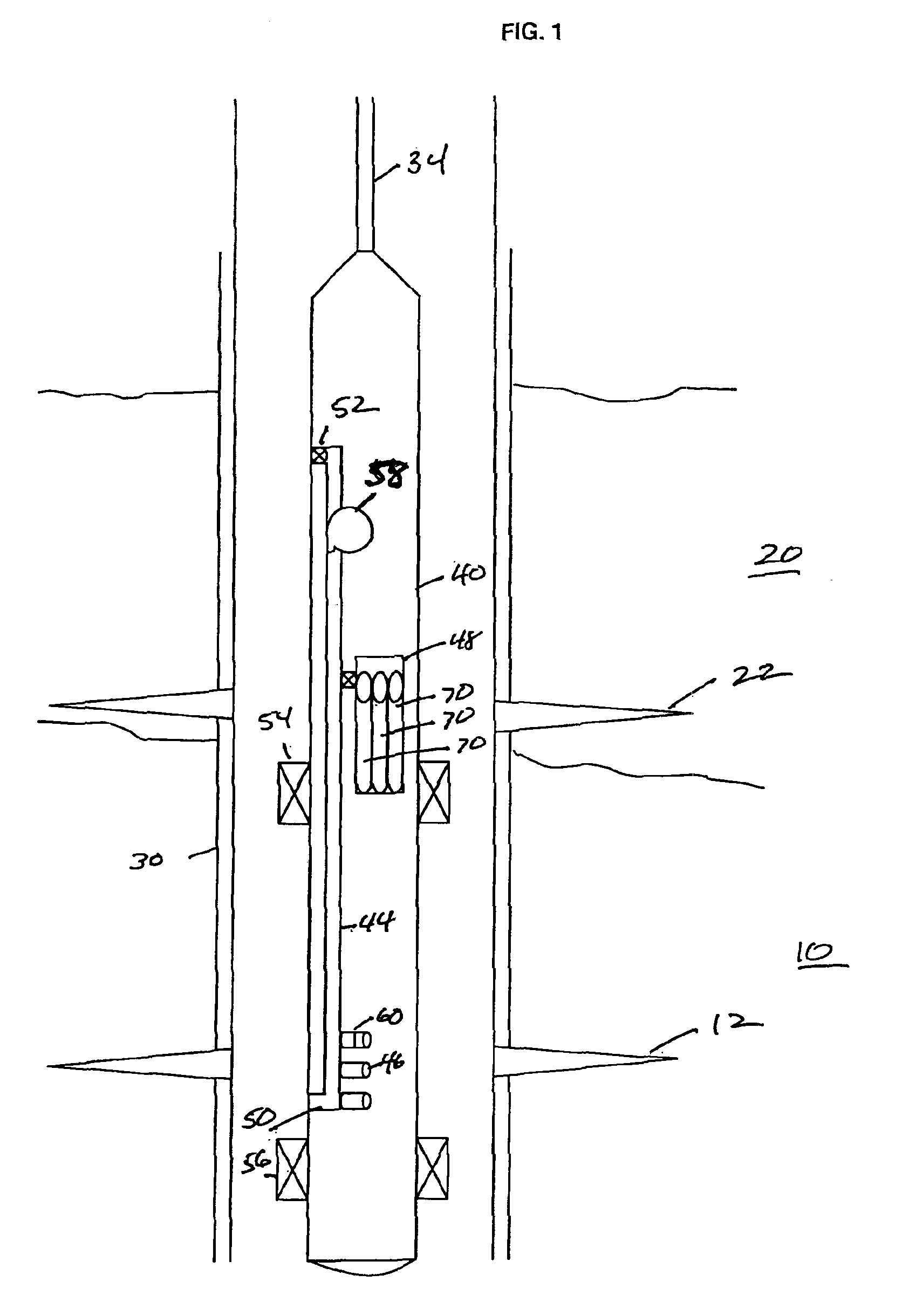

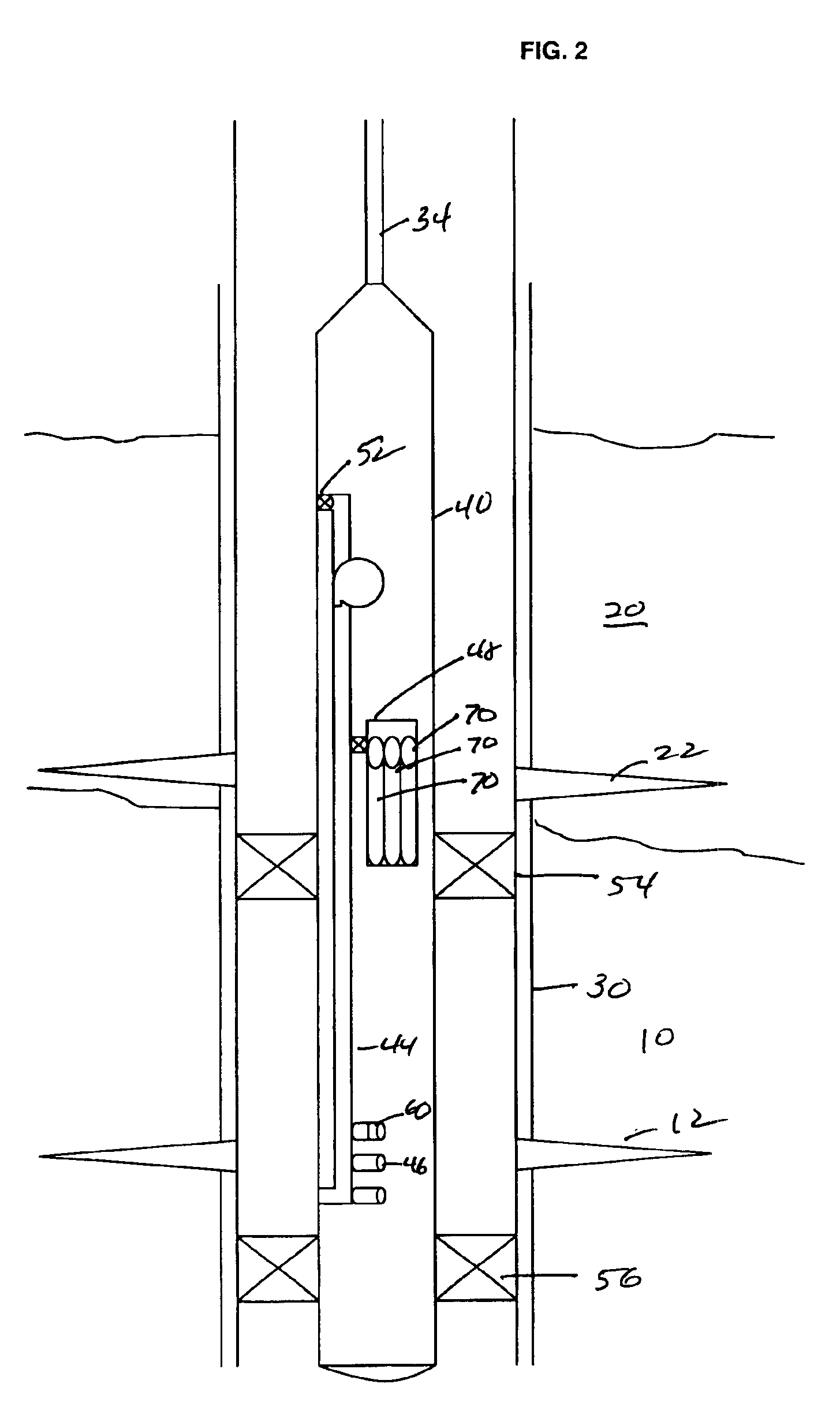

Retrieving a sample of formation fluid in as cased hole

A method for retrieving a formation fluid sample through a cased borehole utilizing a sampling tool. Sampling tool straddle packers are set about a first set of perforations and annular fluid is drained from the isolated zone, through a central conduit in the tool and discharged above or below the packers. Formation fluid is induced to flow into the central conduit and into sample chambers. The packers are unset, the tool moved to the next set of perforations that are azimuthally offset from the first set of perforations and the sampling process repeated, with subsequent samples being placed in separate sample chambers.

Owner:SHELL OIL CO

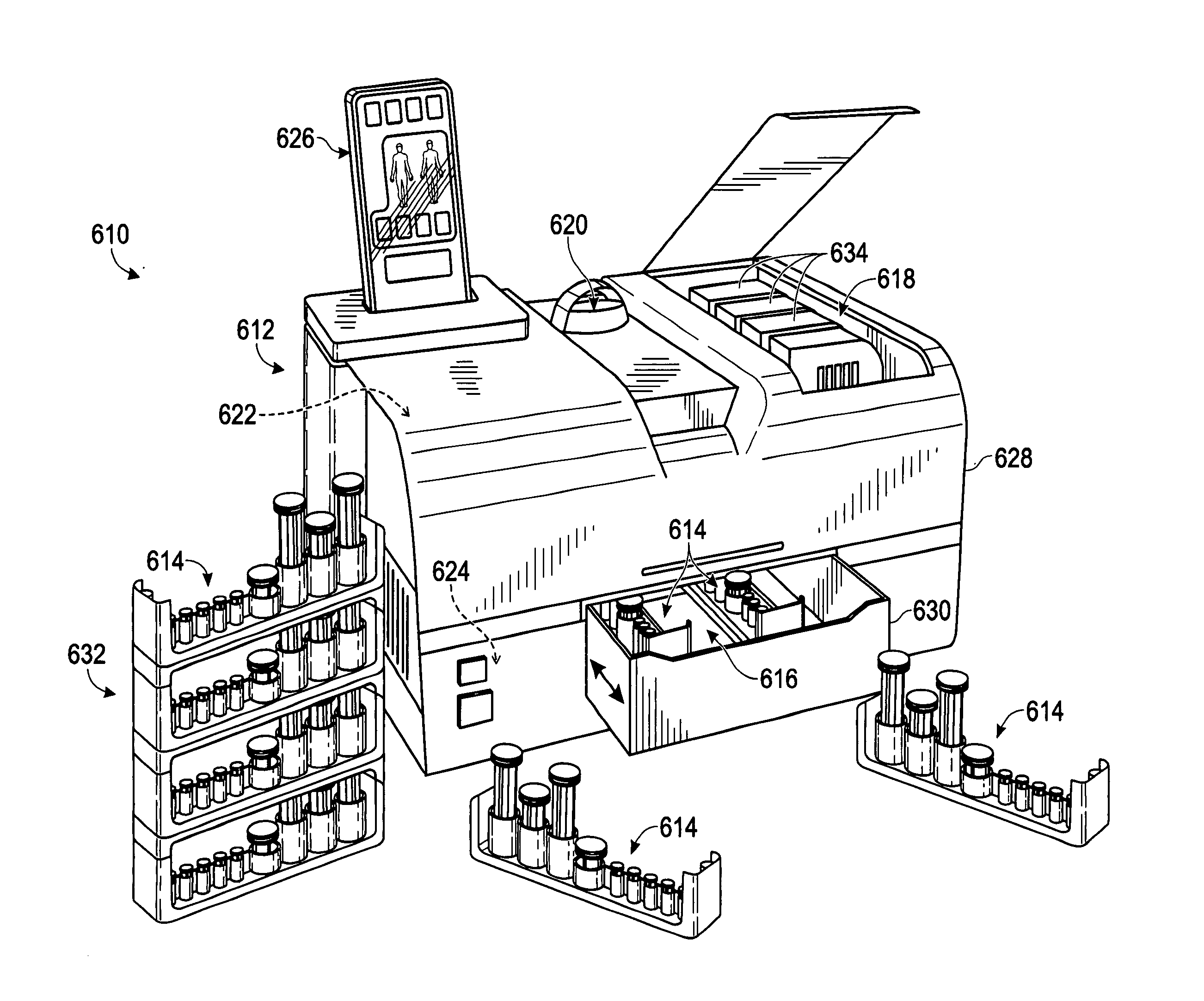

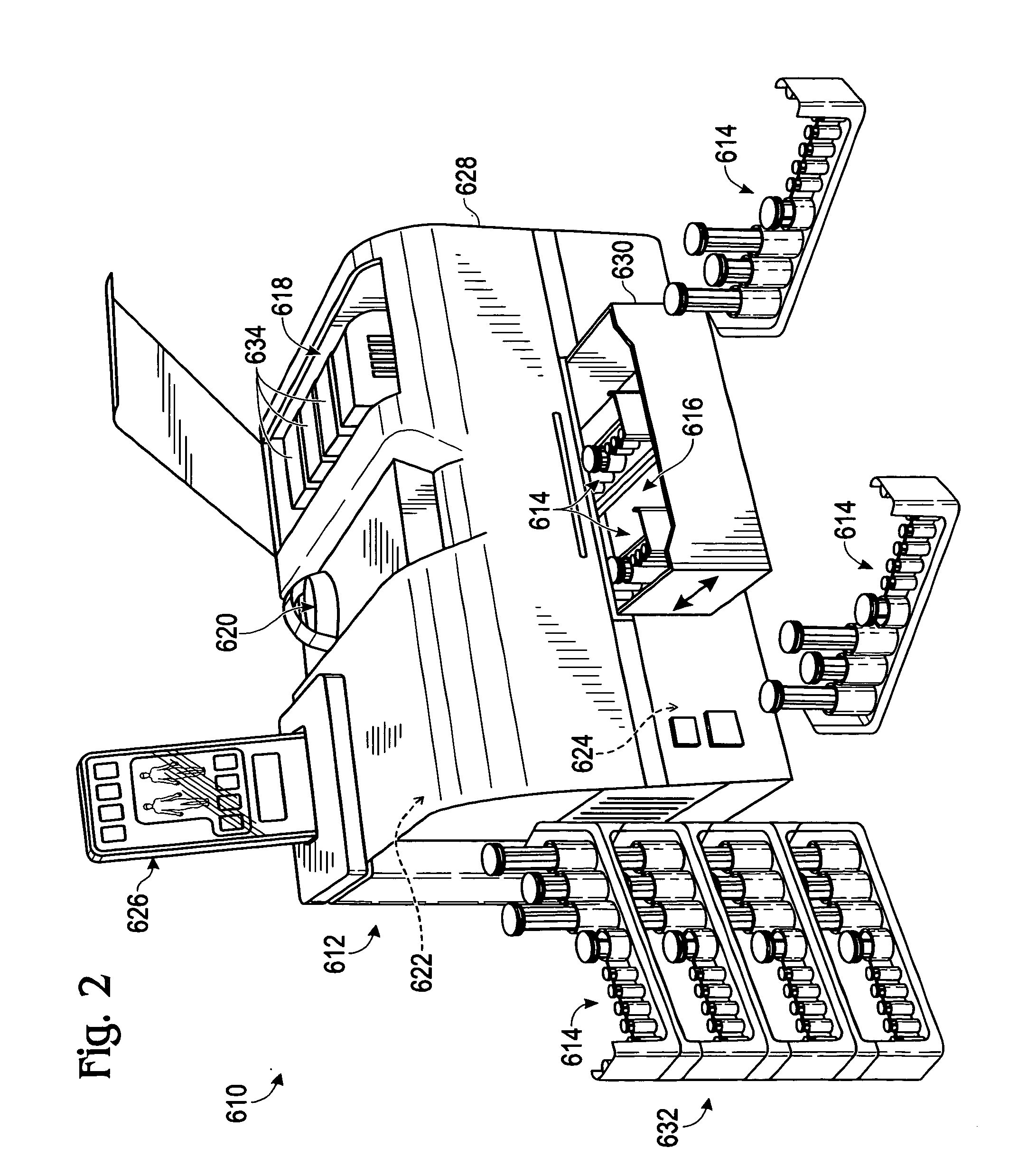

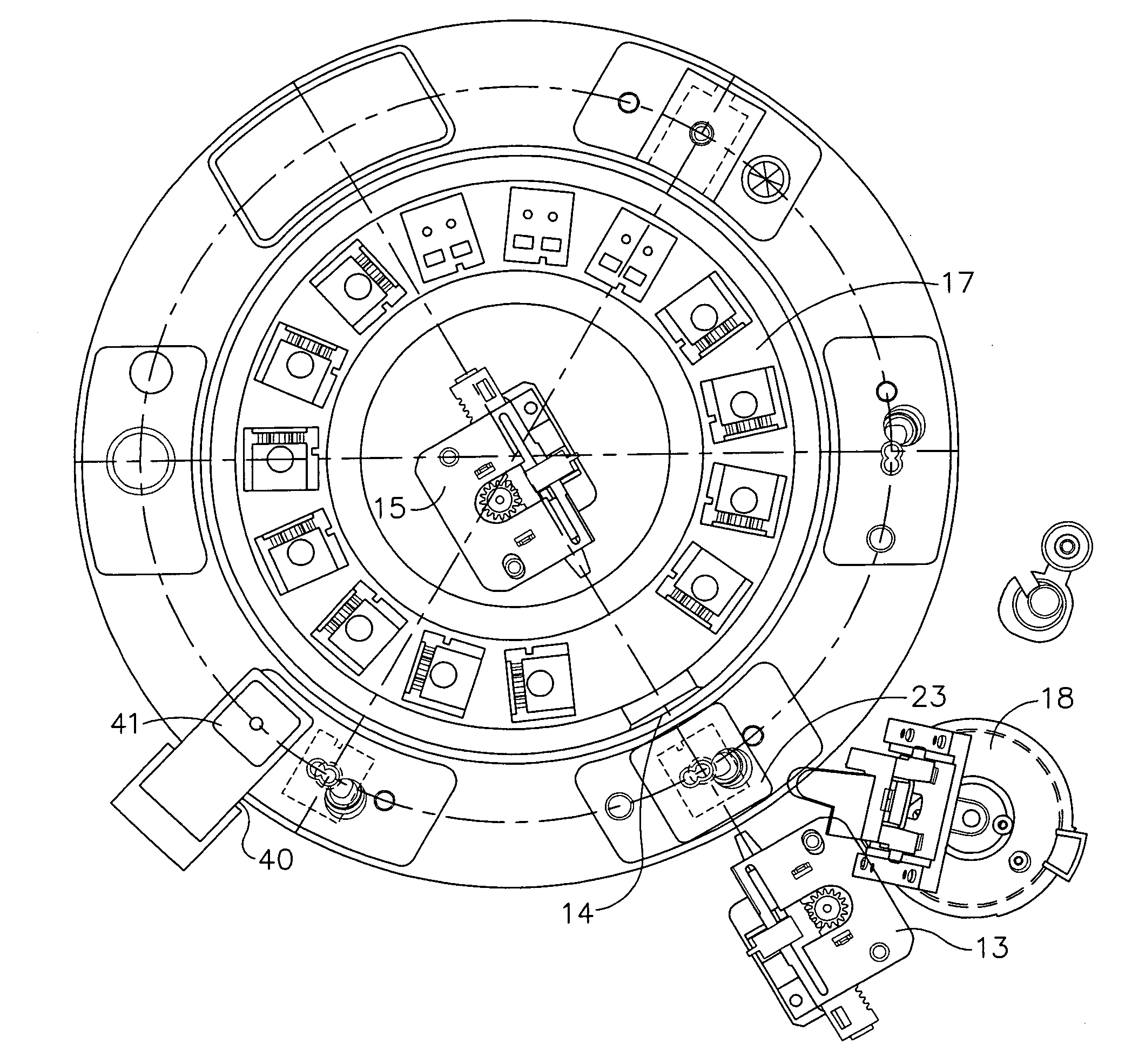

Analyzer having removable holders or a centrifuge

ActiveUS20050123444A1Minimizing number of degree of motionEasy to insertSpecific gravity using centrifugal effectsMaterial analysis by optical meansTransport systemMeasurement device

An analyzer, preferably a desktop analyzer, includes: a component transport system; a liquid dispense or aspirating station; a member removably located on the transport system. The removable holder includes: a probe tip dispenser; a fluid supply section for holding a sample; a test element recess for holding one or more test elements or test element holders, wherein the removable holder is configured to contain the test element recess such that a test element can be acted upon by the liquid dispense or aspirating station, while the test element is in the recess; and a measurement device to analyze a sample. Another aspect provides a removable centrifuge model on the transport system, which separates samples, such as whole blood before analysis.

Owner:ORTHO-CLINICAL DIAGNOSTICS

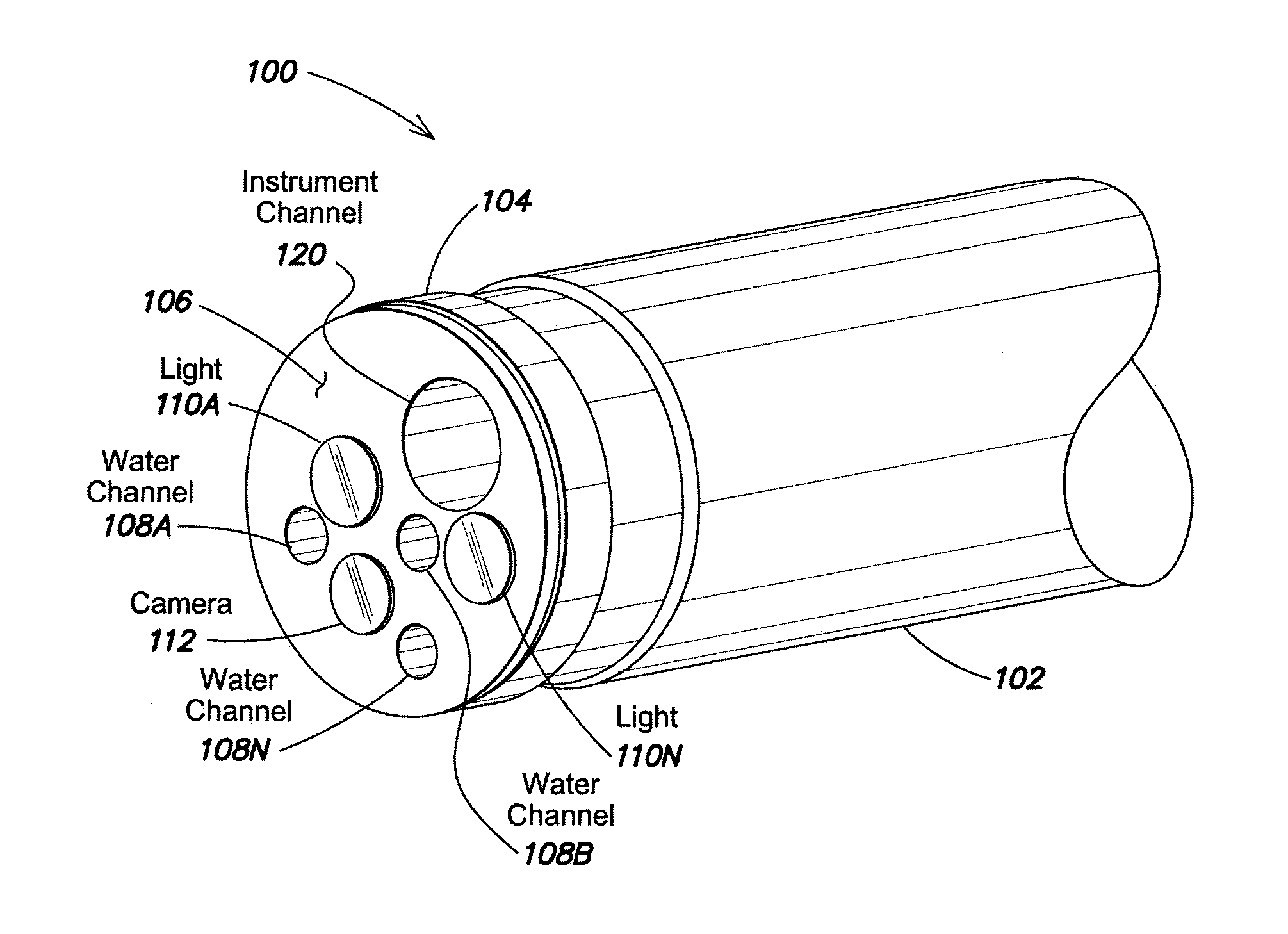

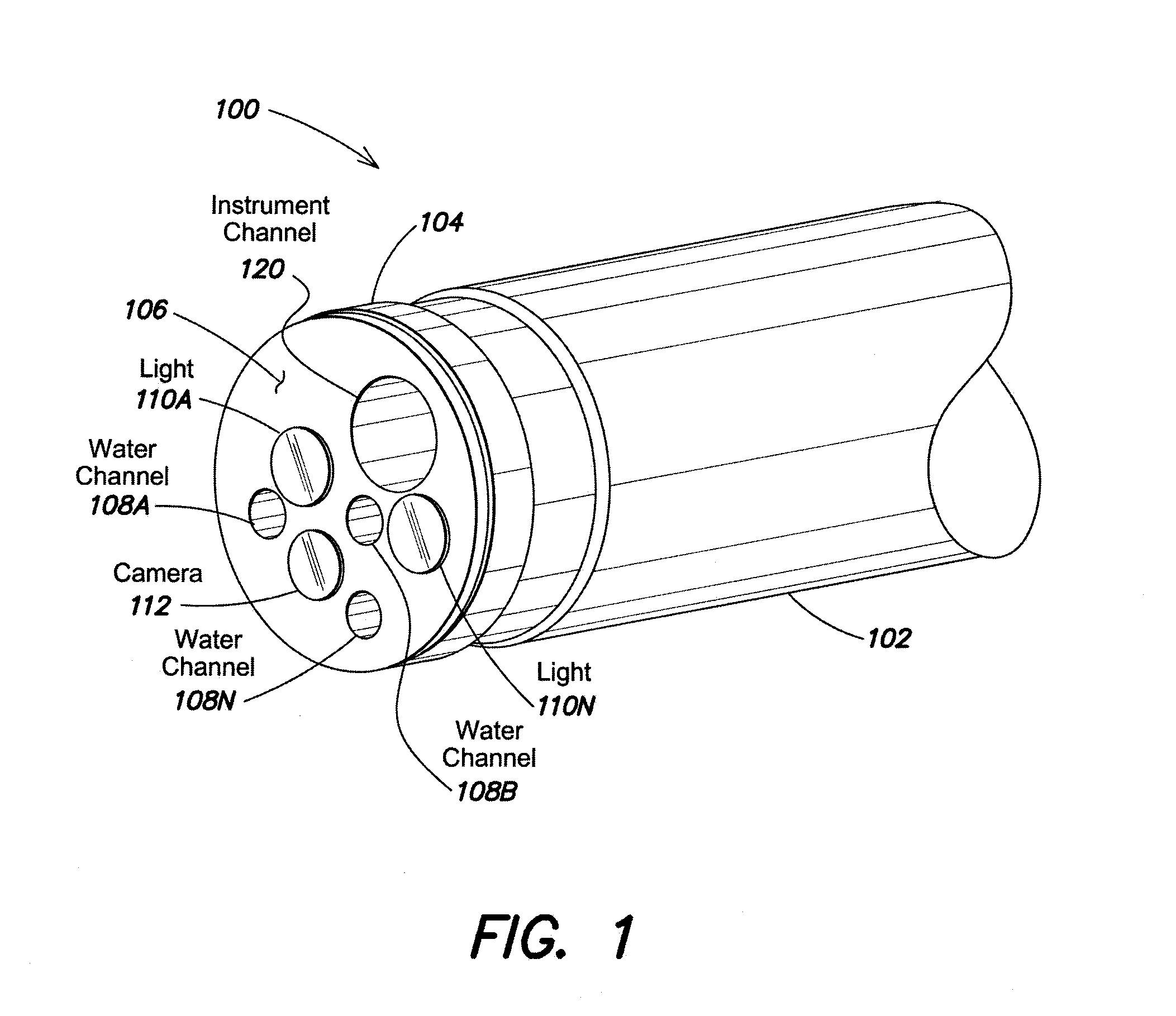

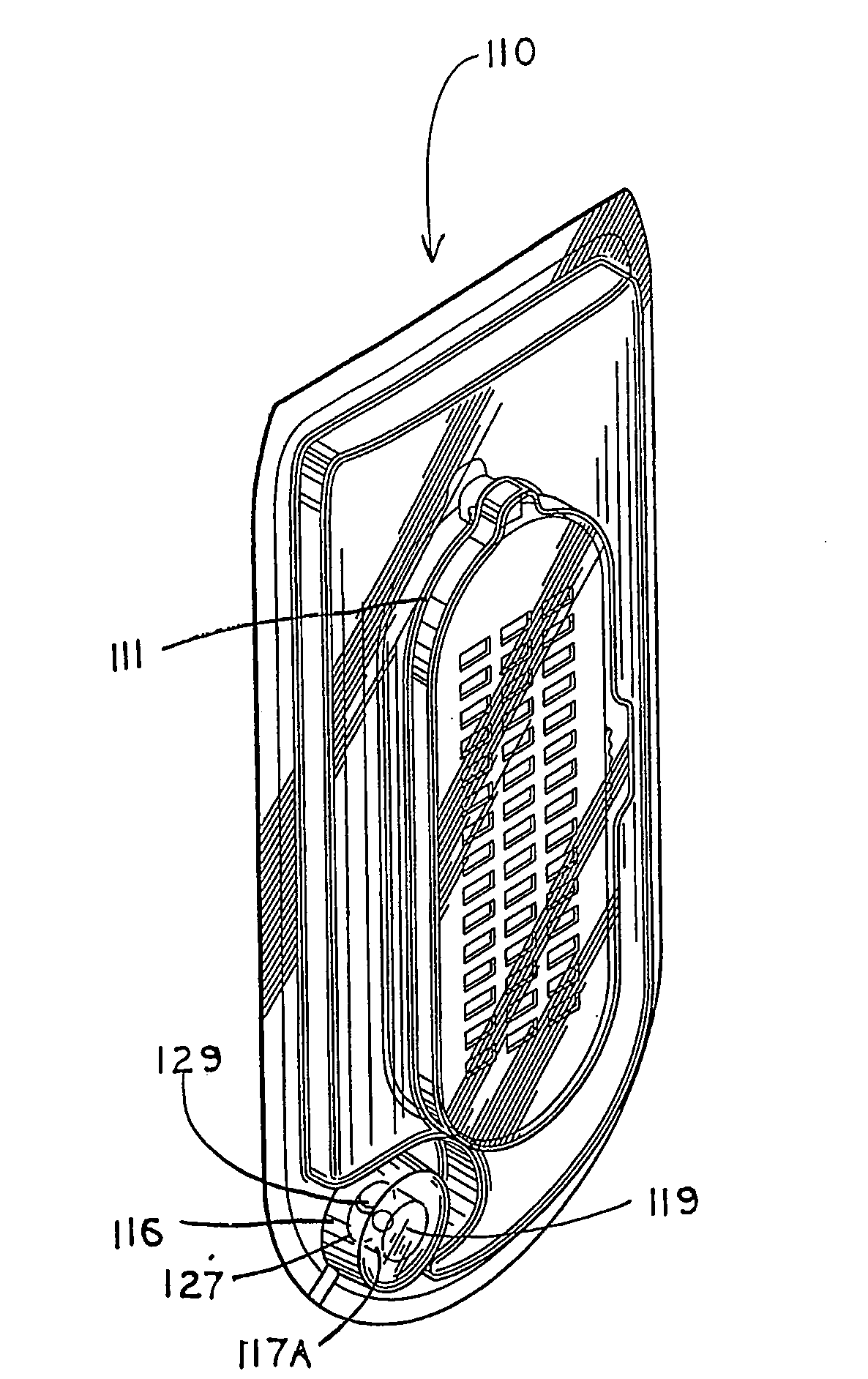

Endoscopic tool for debriding and removing polyps

ActiveUS20130144186A1Easily and efficiently obtainedEasily and efficiently obtain sampleSurgical needlesVaccination/ovulation diagnosticsComputer scienceSeparate sample

An improved endoscopic tool easily and efficiently obtains samples of multiple polyps from a patient by debriding one or more polyps and retrieving the debrided polyps without having to alternate between using a separate cutting tool and a separate sample retrieving tool and may be used with an endoscope.

Owner:INTERSCOPE

Air Freshener Package

Owner:ASHLAND LICENSING & INTPROP LLC

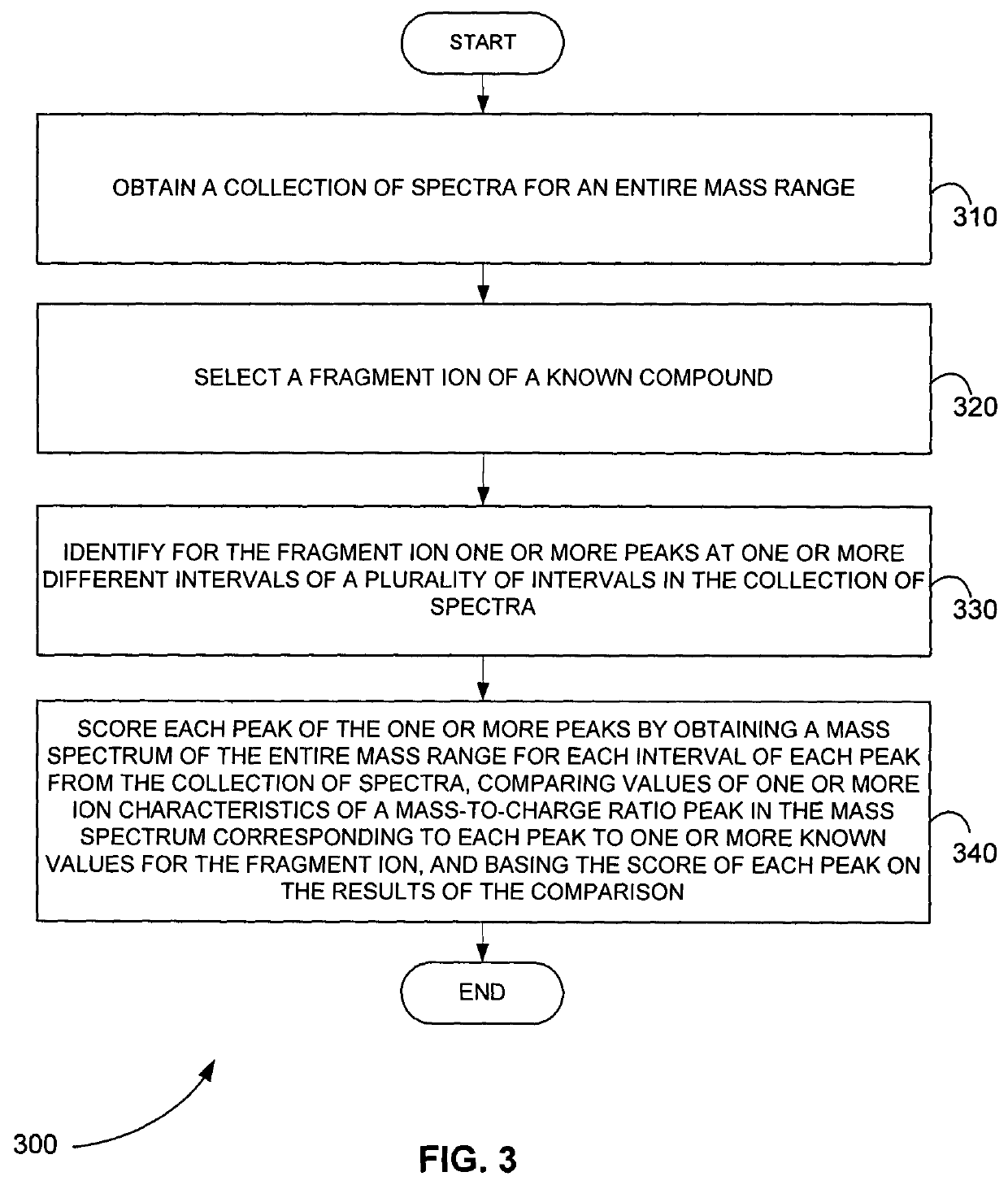

Use of windowed mass spectrometry data for retention time determination or confirmation

ActiveUS9343276B2Molecular entity identificationComponent separationRetention timeMass Spectrometry-Mass Spectrometry

A scan of a separating sample is received by a mass spectrometer at each interval of a plurality of intervals. The spectrometer performs at each interval one or more mass spectrometry scans. The scans have one or more sequential mass window widths in order to span an entire mass range at each interval and produce a collection of spectra for the entire mass range for the plurality of intervals. One or more peaks at one or more different intervals in the collection of spectra are identified for a fragment ion. A mass spectrum of the entire mass range is retrieved for each interval of each peak. Values for one or more ion characteristics of a mass-to-charge ratio peak in the mass spectrum corresponding to each peak are compared to one or more known values for the fragment ion. Each peak is scored based on the comparison.

Owner:DH TECH DEVMENT PTE

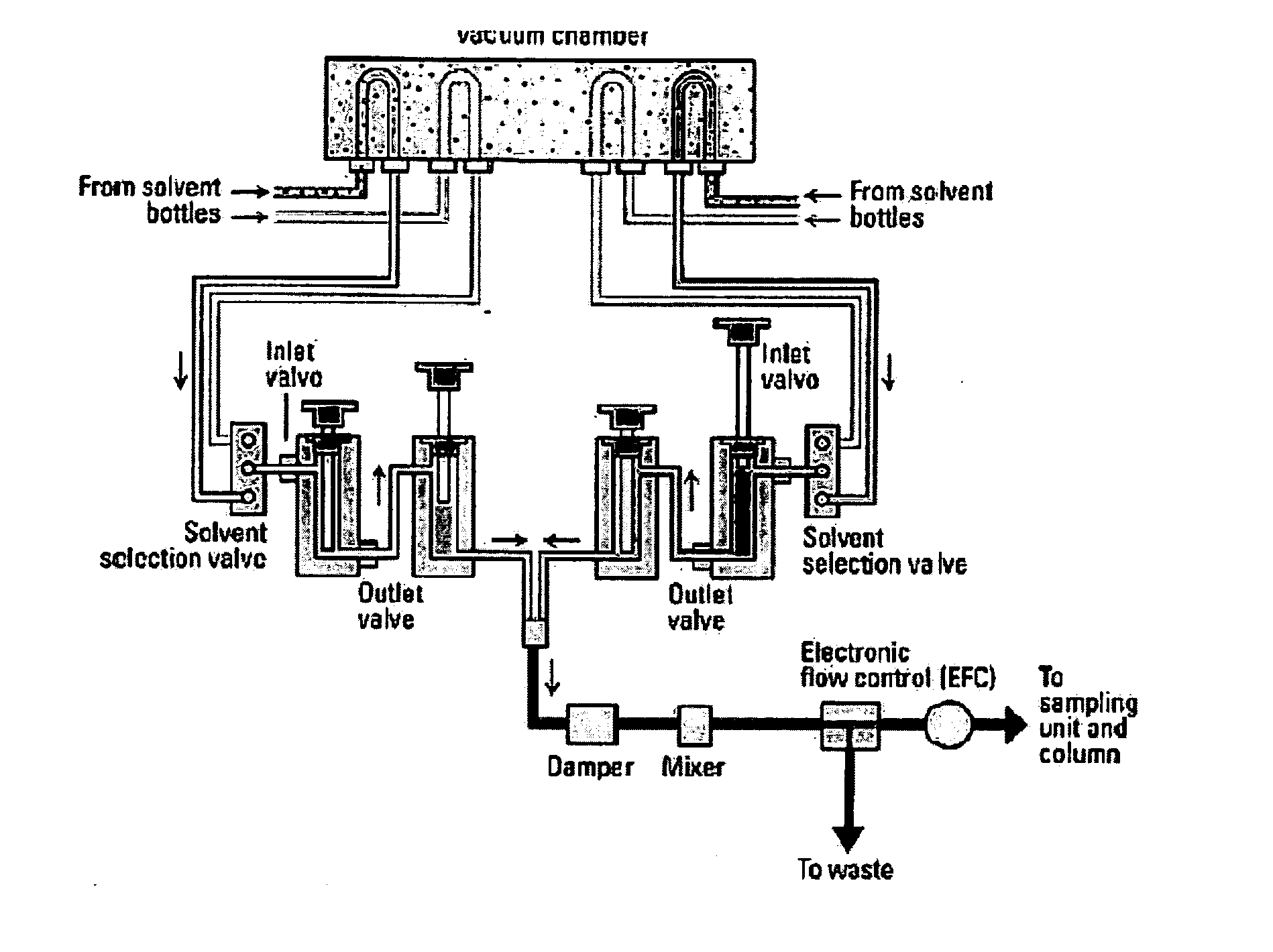

Apparatus for separating sample components by liquid chromatography under pressure

InactiveUS20040020834A1The process is simple and effectiveReduce edge effectsIon-exchange process apparatusComponent separationStationary phaseEngineering

Apparatus for separating the components of a sample by OPLC type chromatography using liquid under pressure, the apparatus comprises a stationary phase forming one or more sample treatment paths and means for feeding moving phase to one end of the stationary phase, with means at the opposite end of the stationary phase for collecting moving phase, means for injecting moving phase also being provided at the sides of the stationary phase in order to eliminate edge effects in the fronts of sample components and in order to separate treatment paths from one another.

Owner:BIONISIS SA

Efficient screw-in soil sampling device

InactiveCN107132072AAvoid mutual contaminationPrevent fallingWithdrawing sample devicesInsertion stentPrecession

The invention discloses an efficient screw-in soil sampling device. The efficient rotary soil sampling device comprises a bracket and a sampling barrel, wherein a moving rod is arranged in the sampling barrel; the left side of the moving rod is fixedly connected with a pulling tray; the tail end of the right side of the moving rod is fixedly connected with a moving block; the moving block is pressed against a fixed block; the left side of the fixed block is fixedly connected with a sampling pipe; a sliding plate is arranged below the sampling pipe; a sample box is arranged below the sliding plate; the sample box is provided with a plurality of independent sample grids. A screw-in driving device is provided, so that a sampling depth can be reached accurately, and the sampling accuracy is increased; the sampling barrel is provided to obtain soil samples at different depths by one-time perforation, and the sampling efficiency is increased; the rotary sample box which is provided with the independent sample grids is provided for separating and storing soil samples, so that mutual pollution among the soil samples is avoided, the samples are prevented from falling off at the same time, the sample quantity is ensured, and sampling demands are satisfied.

Owner:ANHUI YIQI SOFTWARE TECH

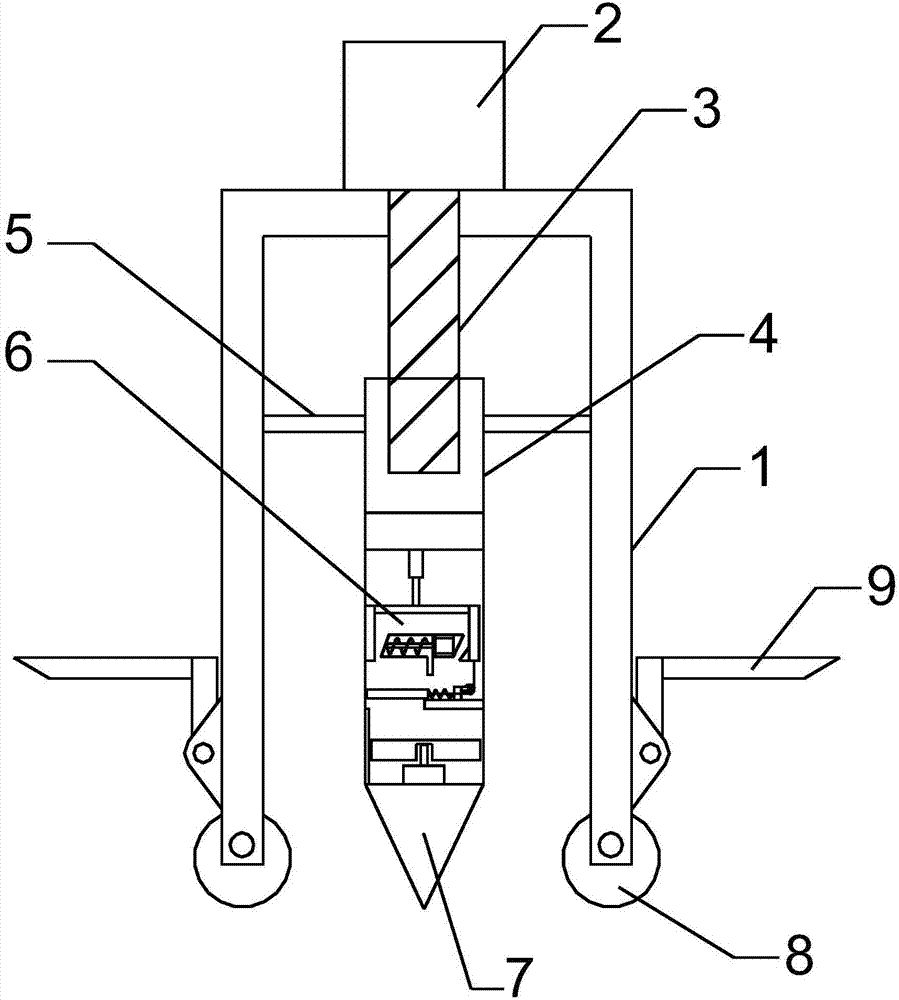

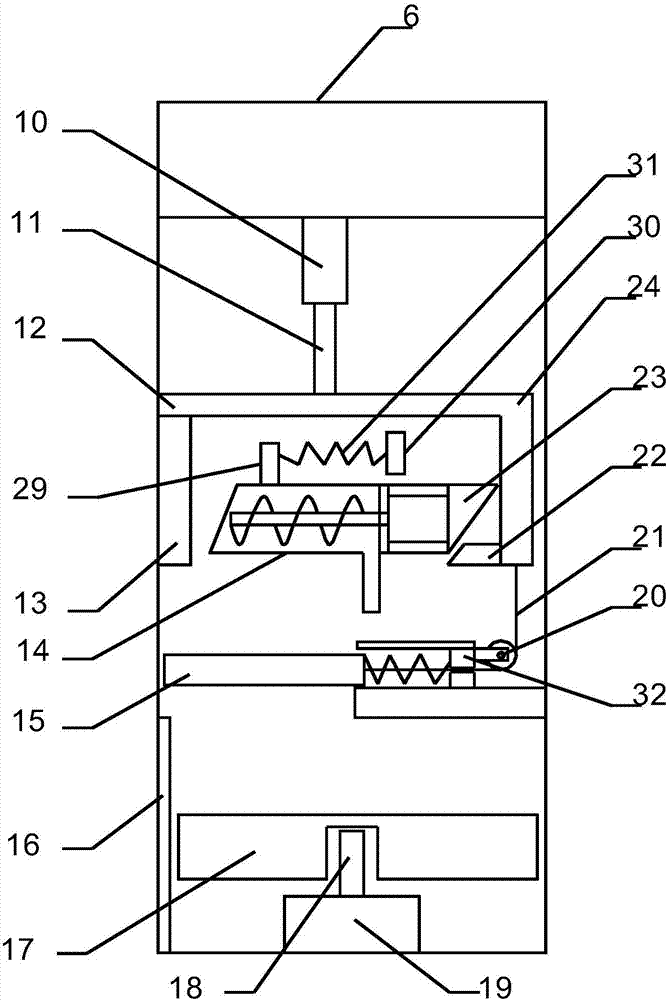

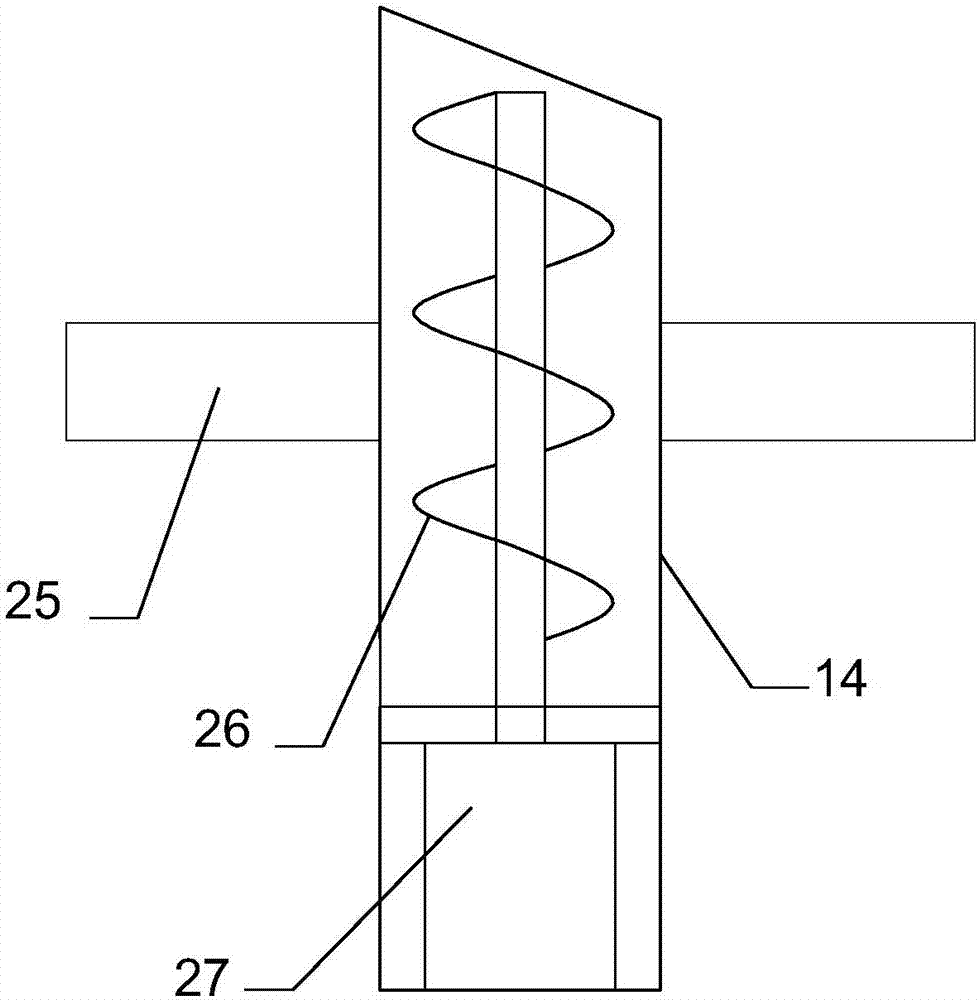

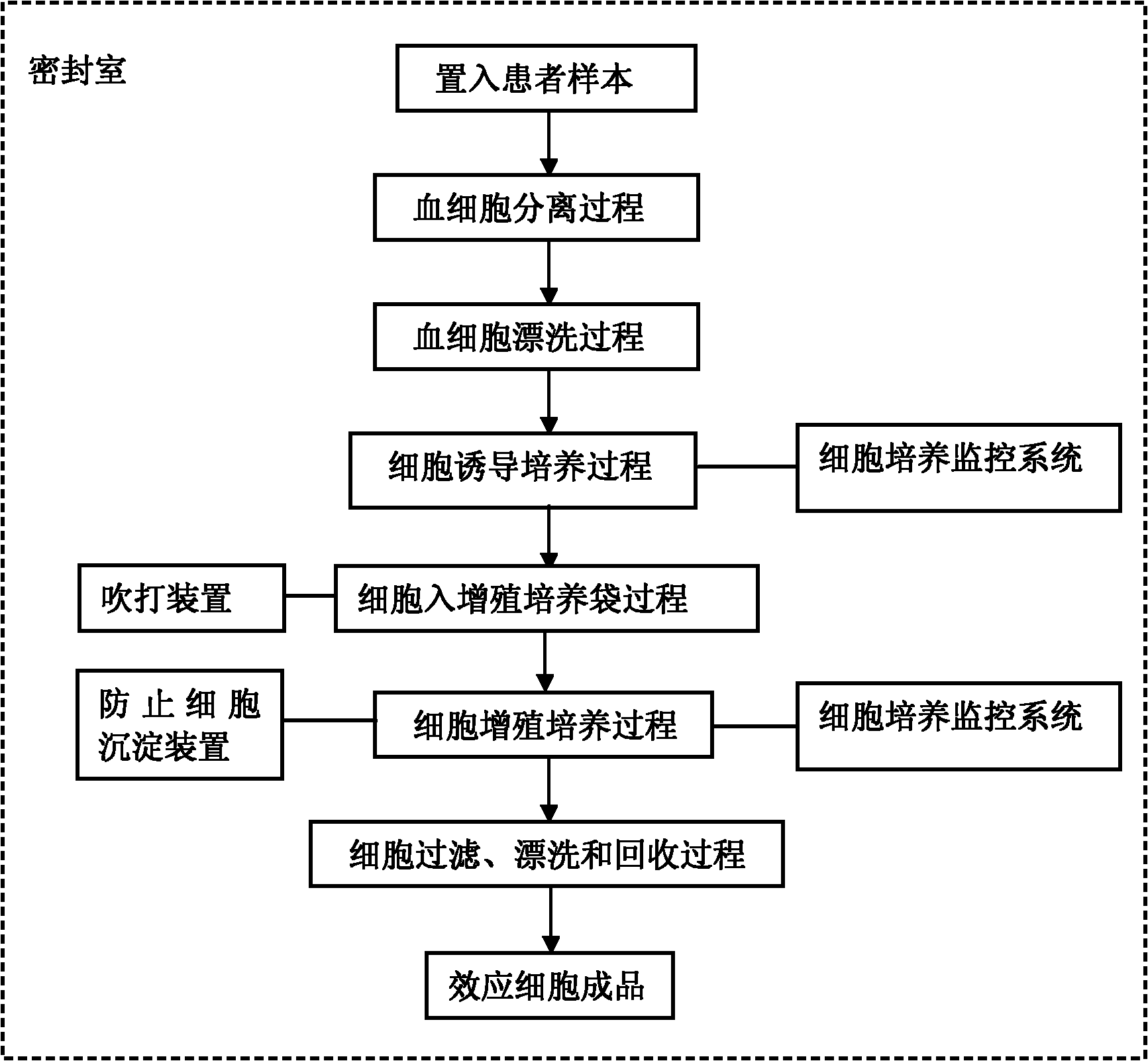

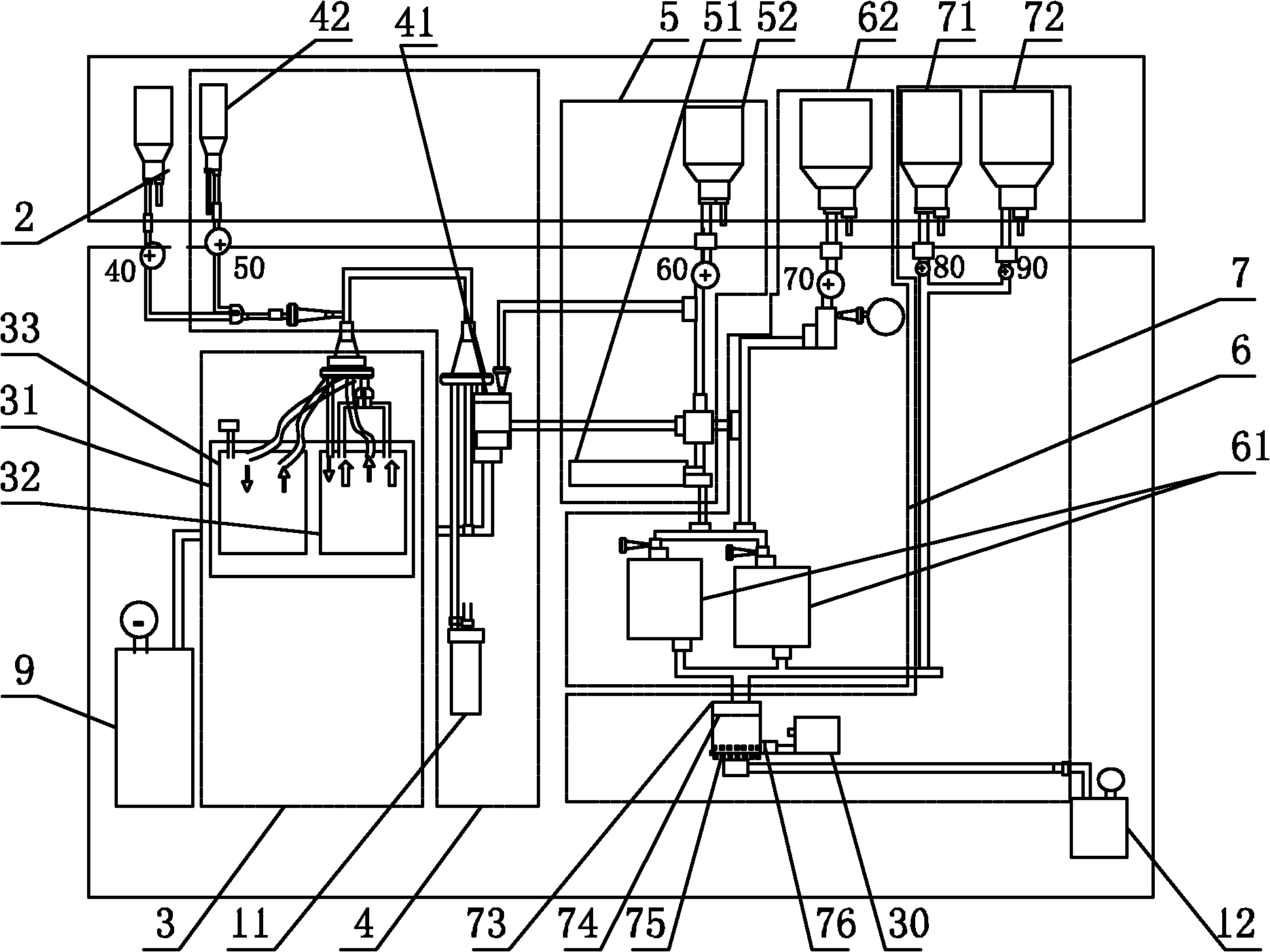

Medical automatic cell production device and production method thereof

ActiveCN102061260ARaise the ratioAvoid pollutionApparatus sterilizationTissue/virus culture apparatus3D cell cultureWorking environment

The invention belongs to the technical field of cell culture and particularly discloses a medical automatic cell production device and a production method thereof. The medical automatic cell production device comprises a laminar-flow sterile sealed chamber, in which a sample bottle (such as a blood bottle) is arranged; and a cell separation device for separating samples, a cell rinsing device, a cell induction culture device, a cell proliferation culture device and cell filtering, rinsing and recycling devices for filtering, rinsing and recycling cultured cells are connected through connecting pipes in sequence behind the sample bottle in the sealed chamber. By the invention, the cell separation, the induction culture, the large-scale proliferation culture, cell filtering, rinsing and recycling processes and the like of each patient can be completed in an independent system which is completely sealed and sterile, and therefore the constant conditions of a cell culture environment are ensured, the effector cell proportion is greatly improved, a GMP standard is reached and treatment requirement of patients can be satisfied. In addition, the medical cell production method has high automation degree, simple and convenient operation process, small operation error and high repeatability and can be widely applied to different working environments and occasions, such as medical treatment, biopharming and the like.

Owner:GUANGZHOU YIDAI PHARMA

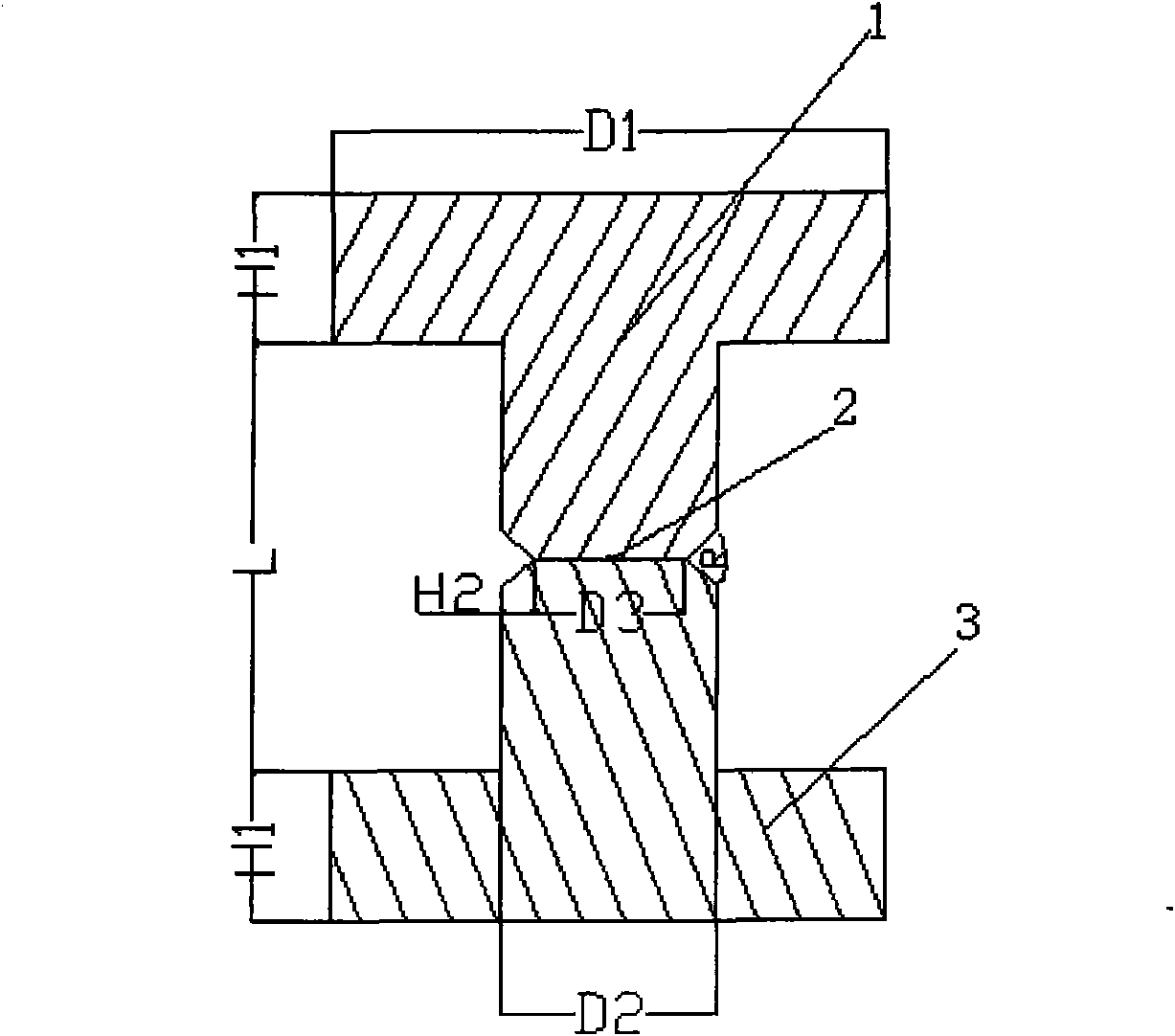

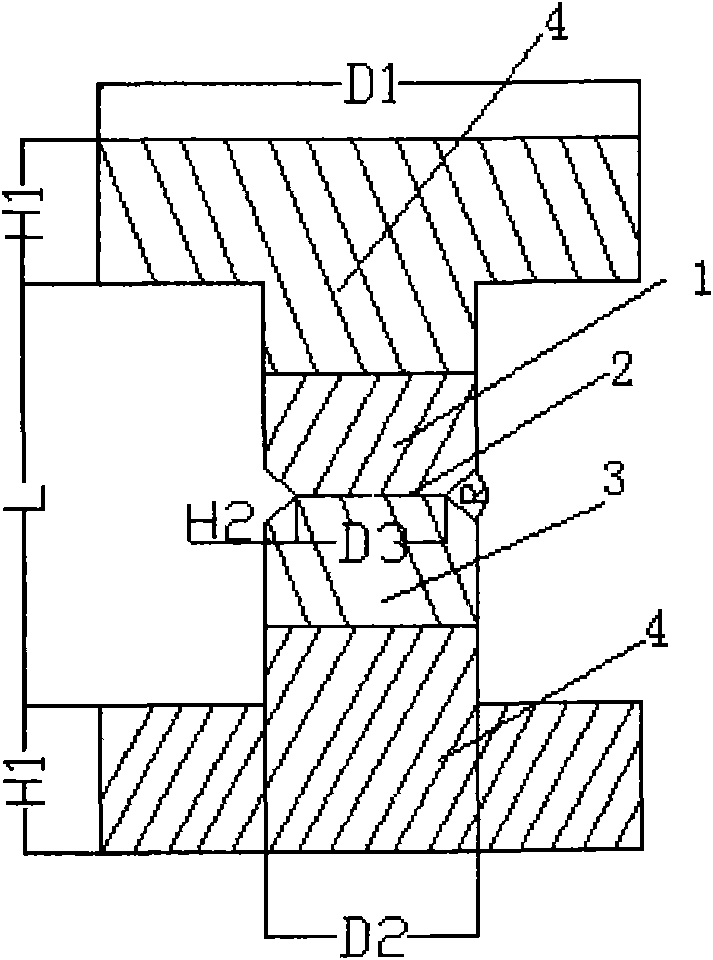

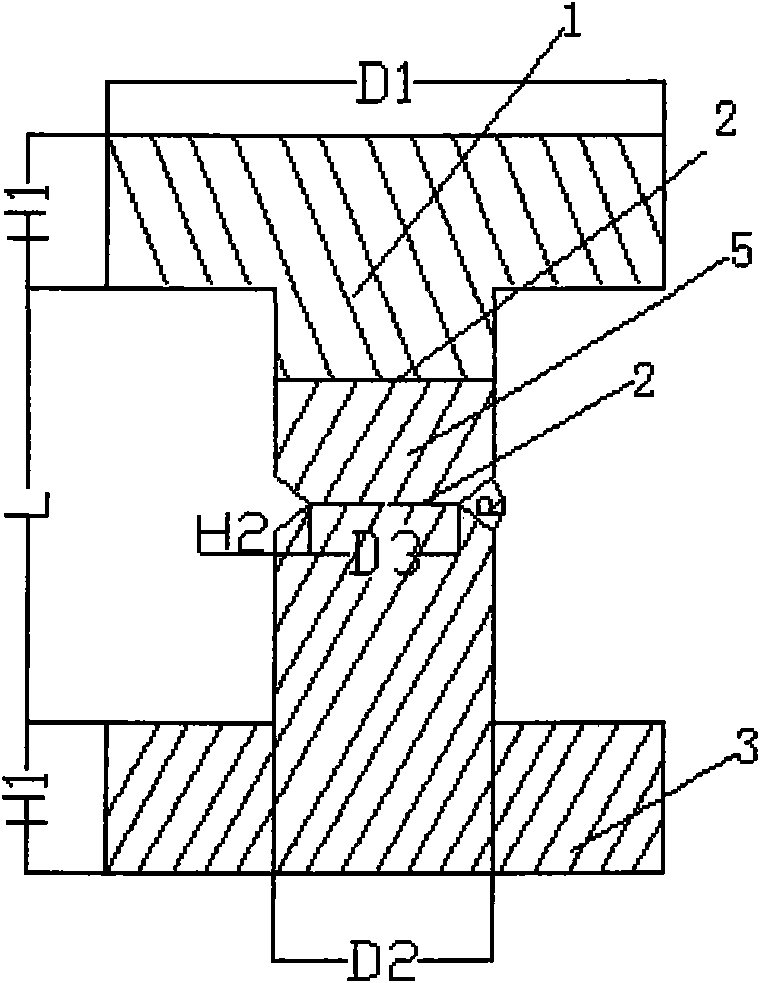

Method for preparing metal composite material bonding interface separated sample

ActiveCN101957281AEasy to separatePreparing sample for investigationUsing mechanical meansBond interfaceUniversal testing machine

The invention introduces a method for preparing a metal composite material bonding interface separated sample. The method comprises the following steps of: sampling from an entire metal composite material plate; machining the sample to be dumbbell-shaped along thickness direction, wherein the thickness directions of base layer metal and composite layer metal are both the length direction of the dumbbell-shaped sample; placing the bonding interface of the metal composite material at a middle position of the dumbbell-shaped sample; forming a V-shaped groove on the dumbbell-shaped sample; overlapping a bottom cross line of the V-shaped groove with a metal composite material bonding interface line; snapping the bonding interface with a 50-ton universal testing machine to completely separate the bonding interface of the metal composite material; and cutting the sample according to testing requirements. By the method, the bonding interface of the metal composite material with small thickness can be completely separated or a certain bonding interface of a multi-layer metal composite material can be completely separated, so that the problem of difficult complete separation of the metal composite material bonding interface is solved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com