Patents

Literature

45results about How to "Simplify the flotation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

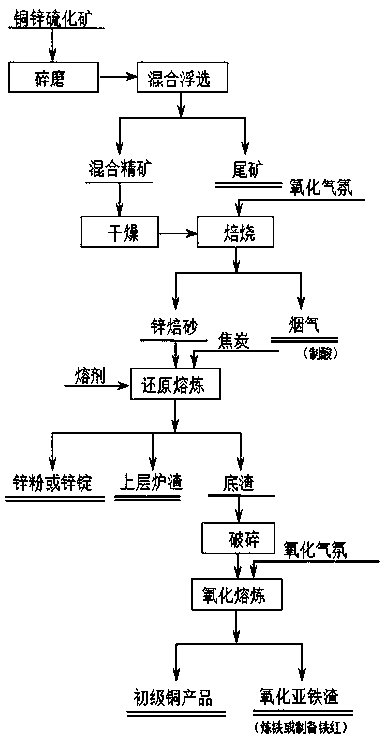

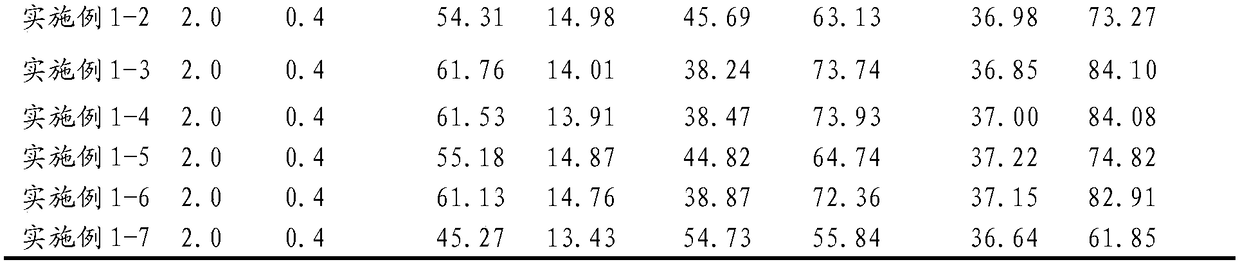

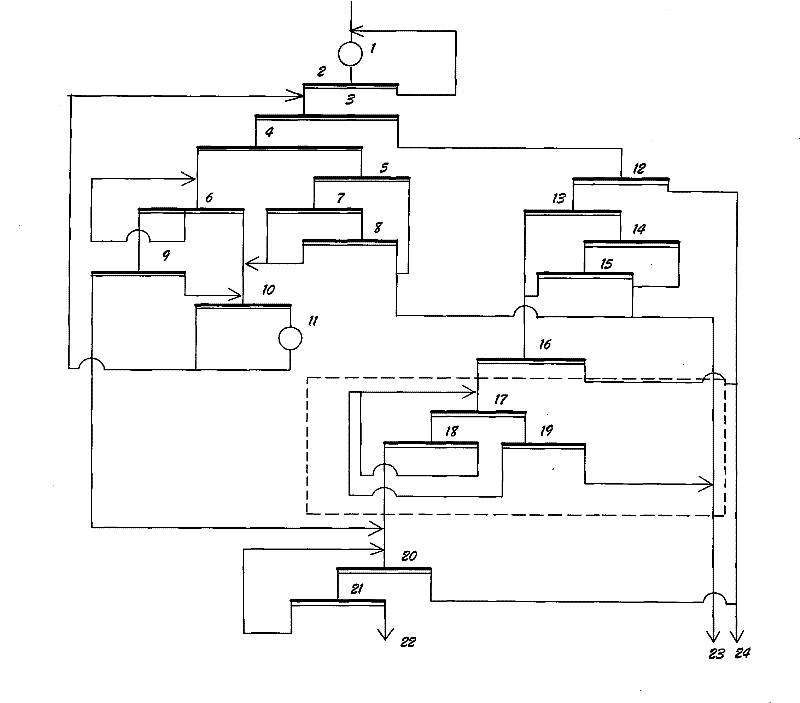

Process for processing low grade hematite ore

ActiveCN101773869ASimplify the flotation processSimple processWet separationSmall footprintFerromagnetism

The invention belongs to the technical field of preparing low grade hematite ore, in particular to a process for processing a low grade hematite ore. The process comprises the following steps: the ore is ground until monomer separation and then coarse and fine classification is carried out on pulp; coarse grain pulp is subject to reselecting, ferromagnetism and sieving to obtain a part of the concentrate; the fine grain pulp is conveyed to a mixing tank for separating sample, and then is conveyed to a second mixing tank to be mixed with medicine for size mixing; the mixture is pumped to a rough flotation column; the under flows of the rough flotation column is fed to a cleaning flotation column, the under flow of the cleaning flotation column is the ultimate iron ore concentrate; foam of the rough flotation column is conveyed to an one-stage scavenging flotation column by a pump; the under flow of the one-stage scavenging flotation column and the foam of the cleaning flotation column are mixed and return to the rough flotation column, and products of the one-stage scavenging flotation column are final tailings. The process has the beneficial effects of smaller occupation area by replacing a flotation machine with the flotation column, can recycle fine-grade valuable mineral effectively, improve the ultimate concentrate grade, provides reference significance for the mineral separation of the ore of the same type in China, and has obvious economic benefits and social benefits.

Owner:ANSTEEL GRP MINING CO LTD

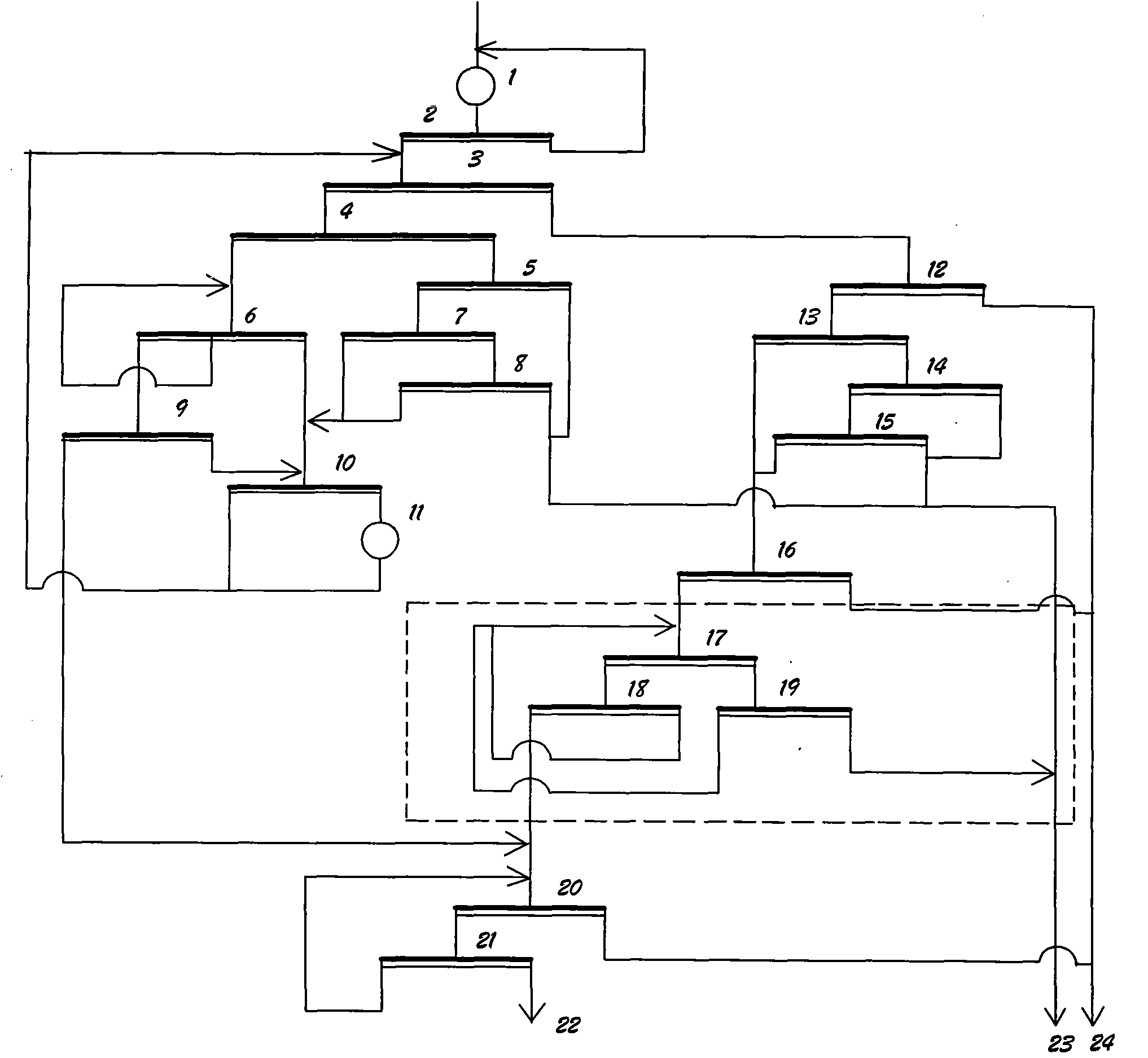

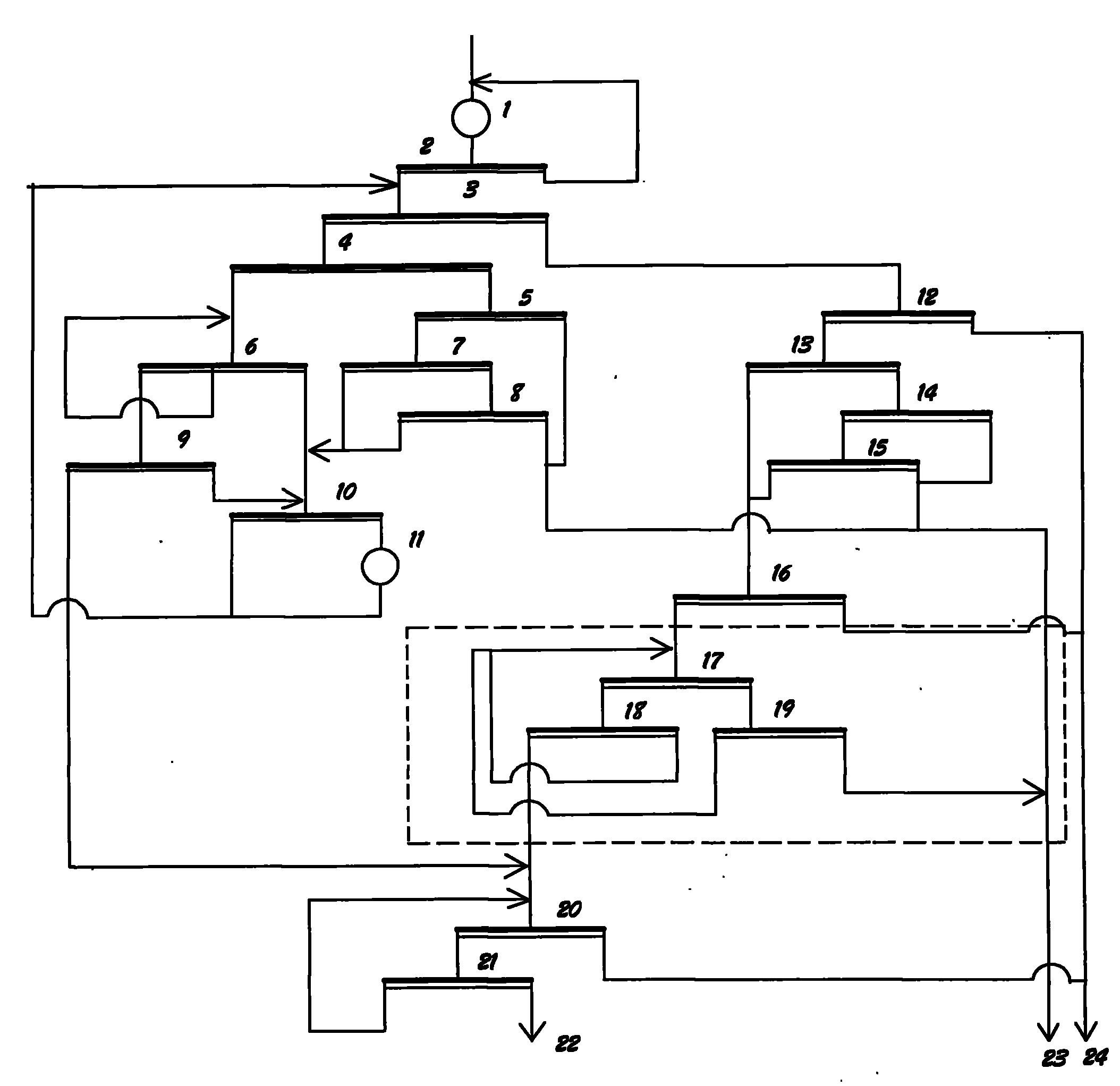

Beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore

InactiveCN106076590AEliminate the need for deslimingThe beneficiation process is simpleFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Beneficiation method of sulphide ore

ActiveCN103736569AIncrease productivityIncrease production costFlotationGrain treatmentsMining engineeringSulfidation

A beneficiation method of sulphide ore relates to improvement of a beneficiation method of sulphide ore, and especially adopts a combined flotation method with a cylindrical grinder. The beneficiation process comprises the steps of performing first-stage screening of sulphide ore to obtain a first-stage coarse particle concentrate A1 and a first-stage tailing product A2; and the beneficiation process is characterized in that the first-stage tailing product A2 is subjected to a combined screening process by a cylindrical grinder. The method of the invention can effectively overcome the problem that sulphide ore with a small disseminated grain size and complex material composition cannot be recovered effectively with routine flotation methods in a flotation process, adopts a combined screening process of first-stage tailings by using a cylindrical grinder, and achieves satisfied metal recovery effect on ultrafine particle fractions in the ore by beneficiation with a cylindrical grinder.

Owner:JINCHUAN GROUP LIMITED

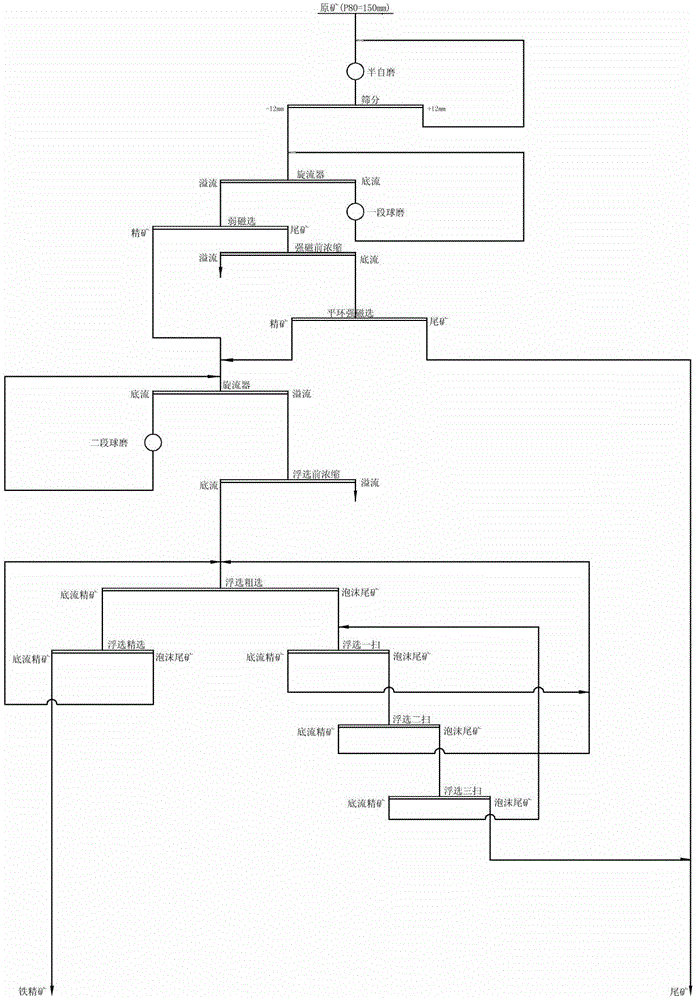

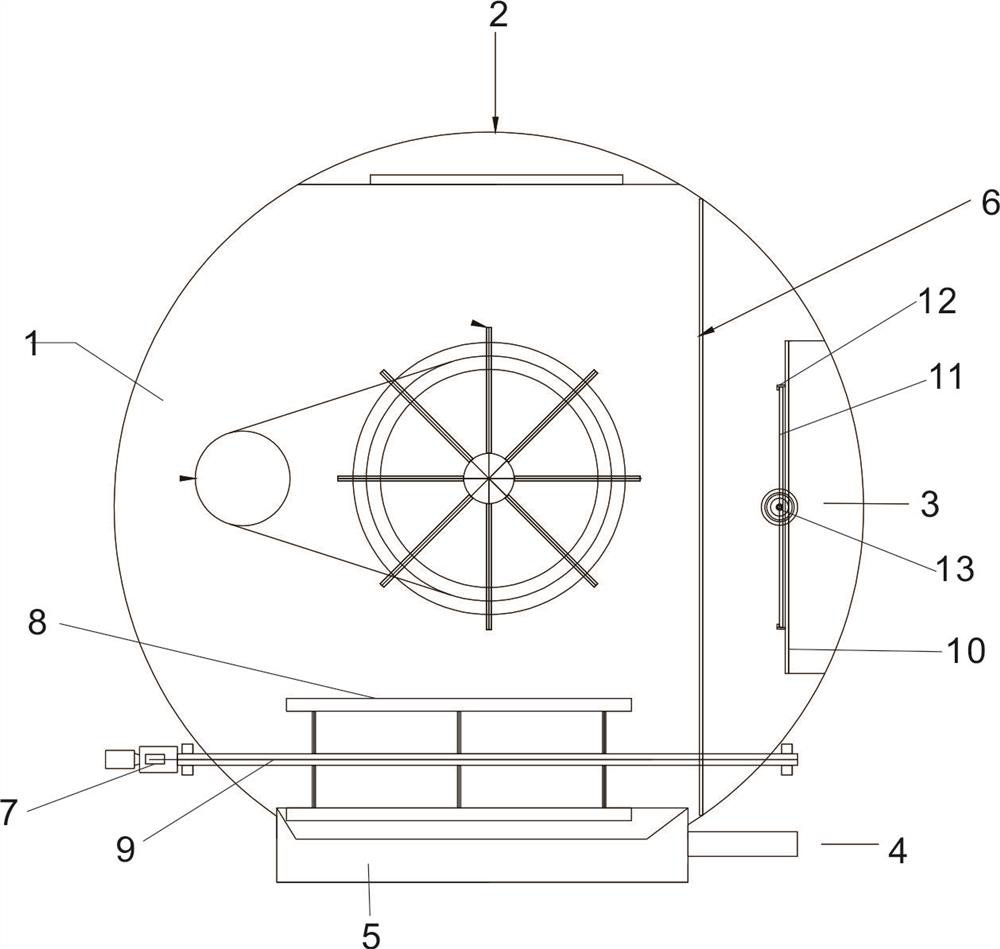

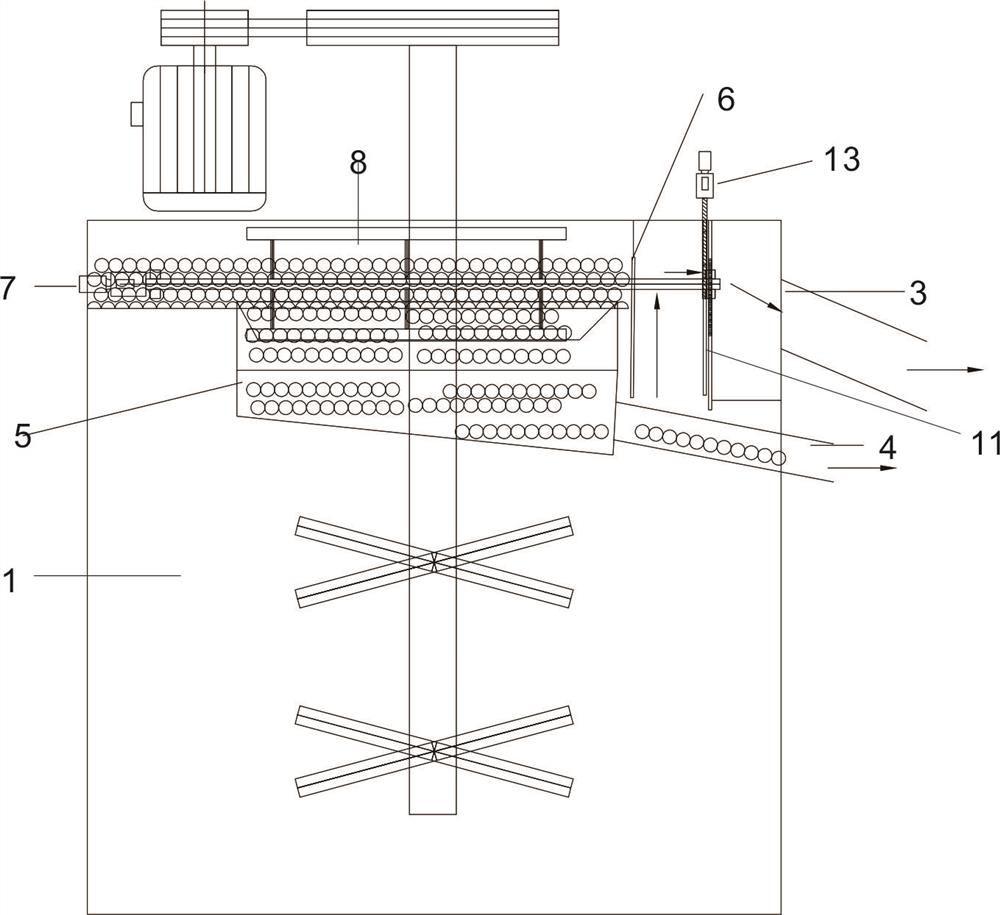

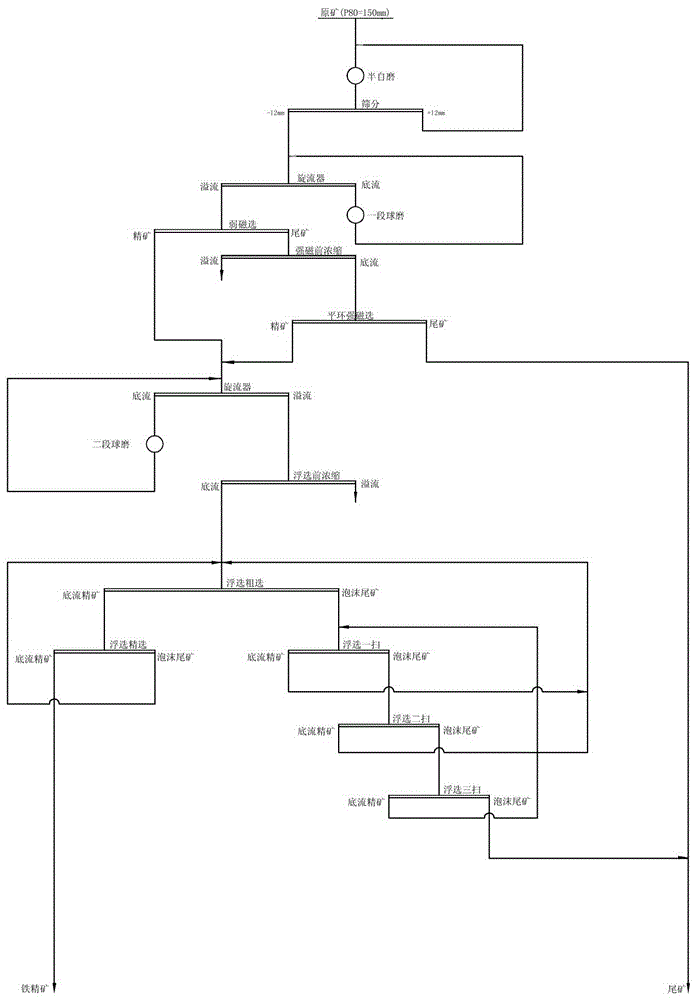

Micro-fine particle red magnetic mixed iron ore sorting process

The invention relates to a micro-fine particle red magnetic mixed iron ore sorting process characterized by including stage grinding-classification-weak magnetic operation-strong magnetic operation-anionic reverse flotation operation, the anionic reverse flotation is performed by use of a one-coarse, one-fine and large circulation mine returning three-scavenging system. According to the micro-fine particle red magnetic mixed iron ore sorting process, first stage ball-milling is performed, then weak magnetic-strong magnetic separation is performed, excess-grinding is effectively prevented, the effect of the magnetic separation can be ensured; after secondary stage ball-milling, anionic reverse flotation operation is directly performed, the advantage of good micro-fine particle iron ore sorting effect of reverse flotation is full used, by use of the technological process, iron concentrate with the iron grade of 65% and the iron recovery rate of more than 73% can be obtained, the final sorting indicators can be further optimized, and the high recovery rate of the iron concentrate can be ensured.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

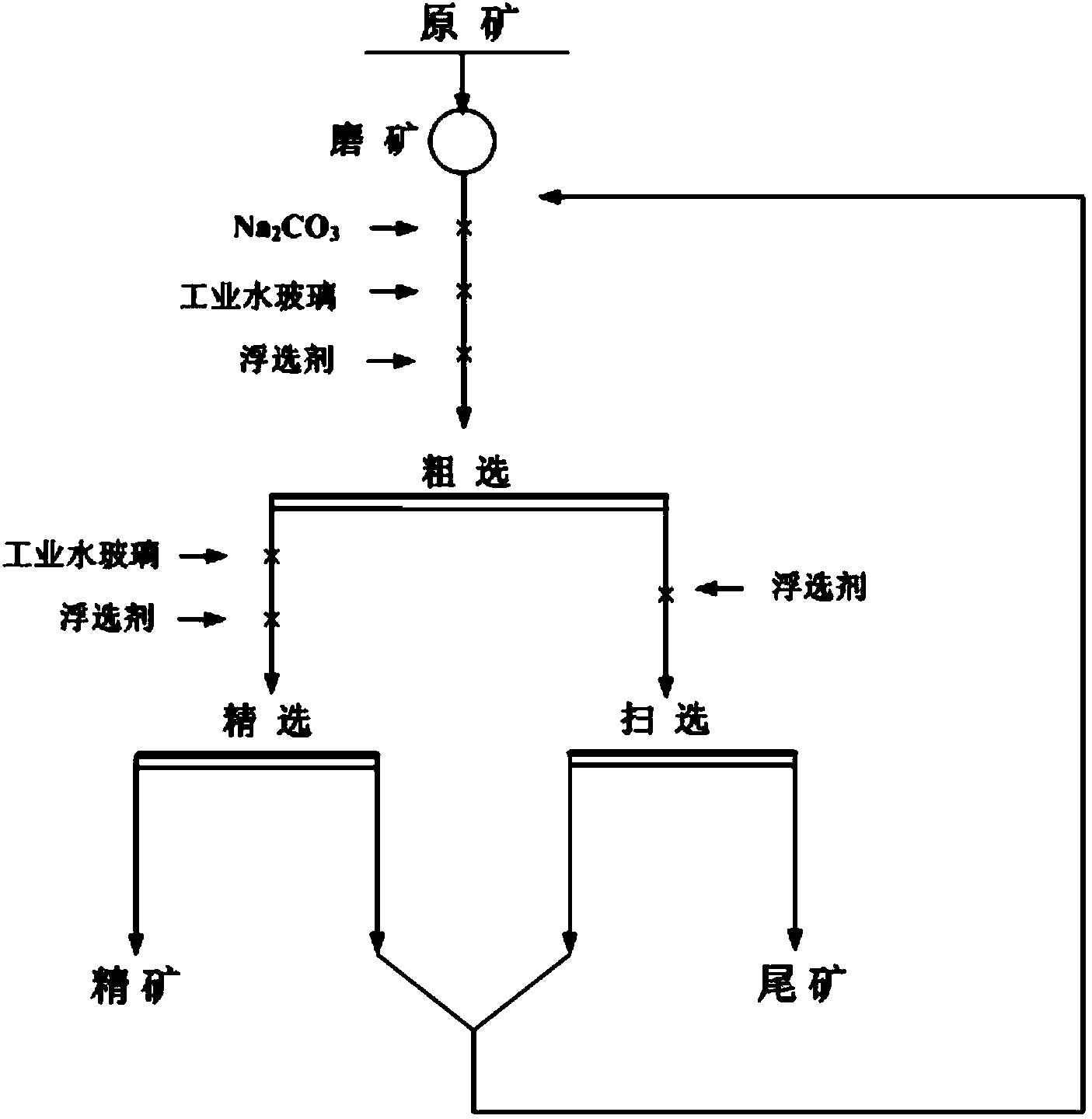

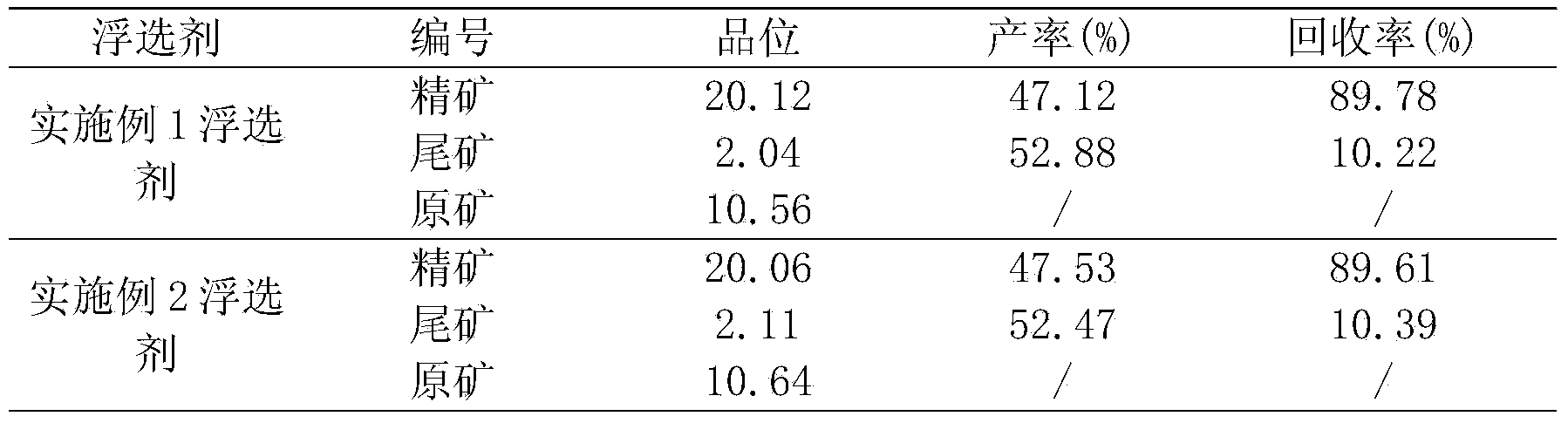

Manganese carbonate ore floatation agent and floatation method

The invention provides a manganese carbonate ore floatation agent and a flotation method. The floatation agent is prepared by taking soybean oil and hydroxylamine hydrochloride or hydroxylamine sulphate as raw materials and enabling the product obtained after the soybean oil is emulsified to react with the product obtained after the hydroxylamine hydrochloride or the hydroxylamine sulphate is neutralized through the alkali. The floatation method for recycling the manganese carbonate through the floatation agent comprises the step of raw ore processing and the step of closed loop floatation. The floatation agent has good electivity for the manganese carbonate, the grade of the flotation concentrate produced by processing the low-grade manganese carbonate ore with the raw ore grade ranging from 8% to 12% through the closed loop circulation floatation technology including the steps of coarse processing, rough processing and sweeping can be improved to be more than 20%, the manganese recycling rate is larger than 85%, no inhibitors need to be added during the floatation process, and the whole production cost is obviously reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

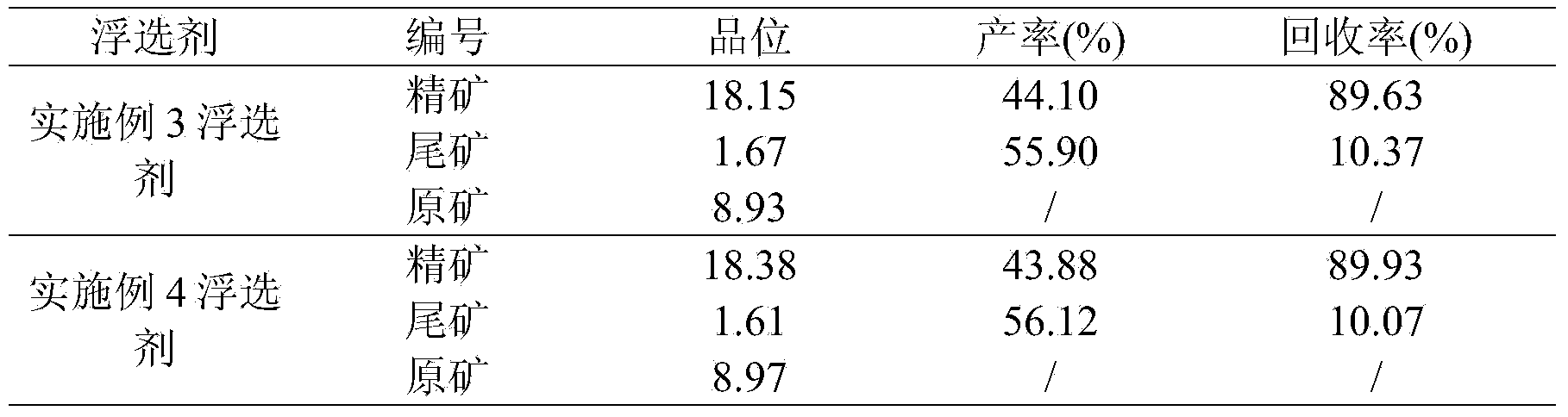

Production process for ultrapure iron concentrate powder

InactiveCN106984424ASimplify the flotation processShorten the flotation processMagnetic separationGrain treatmentsPollutionMaterials science

The invention discloses a production process for ultrapure iron concentrate powder. The production process comprises the following process steps of: (1) performing (-)200-mesh screening on ore pulp to obtain undersized products; (2) magnetically separating the undersized products to obtain magnetically separated concentrate and tailings; (3) washing the magnetically separated concentrate to obtain ultrafine ores and tailings; and (4) dehydrating and drying the ultrafine ores to obtain ultrapure iron concentrate powder. According to the production process disclosed by the invention, production of ultrapure iron concentrate powder is realized through simple magnetic separation, so that a common flotation process is reduced; magnetic separation requires grinding fineness which is lower than that of flotation, a floatation process requires heating ore pulp and adding a plurality of reagents, and a magnetic separation process is relatively simple, so that ore grinding cost and grading cost are lower; and the flotation process is not easily controlled, used reagents have great influences on environment, and the magnetic separation process is simple and is free of influences on environment. The production process is simple in implementation process, is lower in investment, is simple in process, and is free of pollution; and the produced ultrapure iron concentrate powder is high in grade and is low in cost.

Owner:HEBEI IRON & STEEL GRP MINING

Direct flotation method of zinc sulfide ore

The invention relates to a direct flotation method of zinc sulfide ore. The method includes the steps of grinding the zinc sulfide ore to form ore pulp, adjusting the PH value of the ore pulp to reach 6-11, adding N-alkyl dithiocarbamic acid sodium as a collecting agent and terpenic oil as a foaming agent into the ore pulp, adding zero or little copper sulfate as an activating agent and carrying out flotation. According to the method, copper activation-free direct flotation of the zinc sulfide ore can be realized, the use amount of copper sulfate can be remarkably lowered, and subsequent flotation separation of zinc sulfide and other metal sulfide ore can be promoted.

Owner:KUNMING UNIV OF SCI & TECH

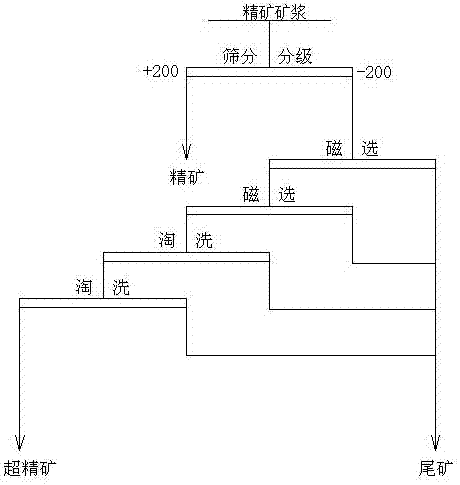

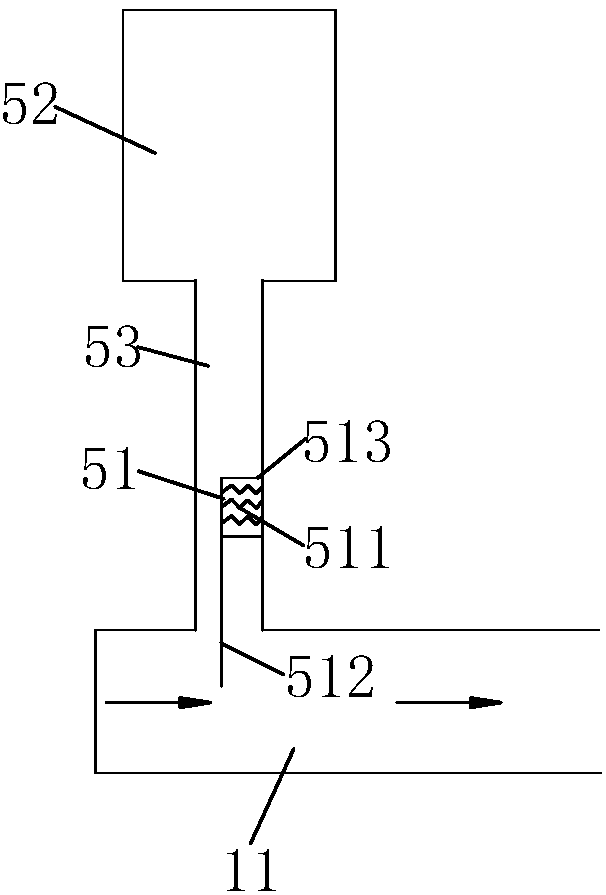

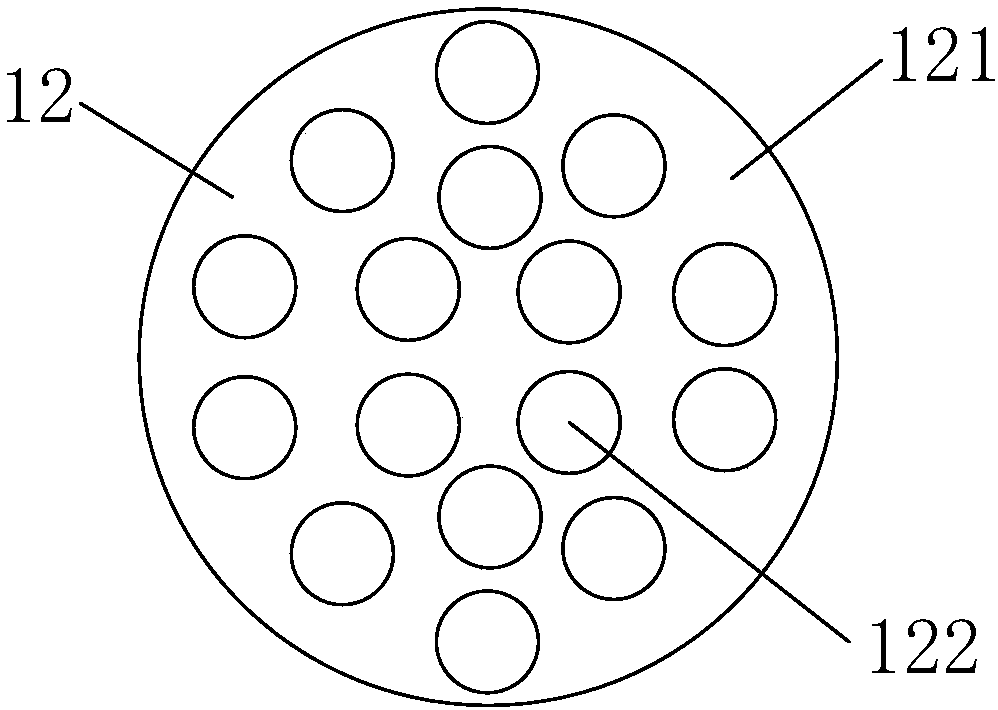

Flotation system and process for refractory minerals

The invention belongs to the technical field of flotation of refractory minerals, in particular to a flotation system and process for refractory minerals. The flotation system comprises a feeding mechanism, a flotation mechanism, a tailing collection mechanism and a concentrate collecting mechanism; the feeding mechanism comprises a feeding transport pipe and a slurry mixing module for fully mixing a collecting agent and ore pulp; the system further comprises a collecting agent adding mechanism communicating with the feeding transport pipe, the collecting agent adding mechanism is located between a feed inlet of the feeding mechanism and the slurry mixing module, a collecting agent adding adjuster for changing the adding amount is arranged in the collecting agent adding mechanism, and theadjusting amount of the collecting agent adding adjuster is determined by ore pulp flow; and the system further comprises a bubble generating device arranged between the flotation mechanism and the slurry mixing module. The system is simple in structure, the flow of the floatation process is simplified, the adding amount of a collecting agent can be synchronous with the ore pulp flow, and accordingly the flotation effect is ensured advantageously.

Owner:额尔古纳诚诚矿业有限公司

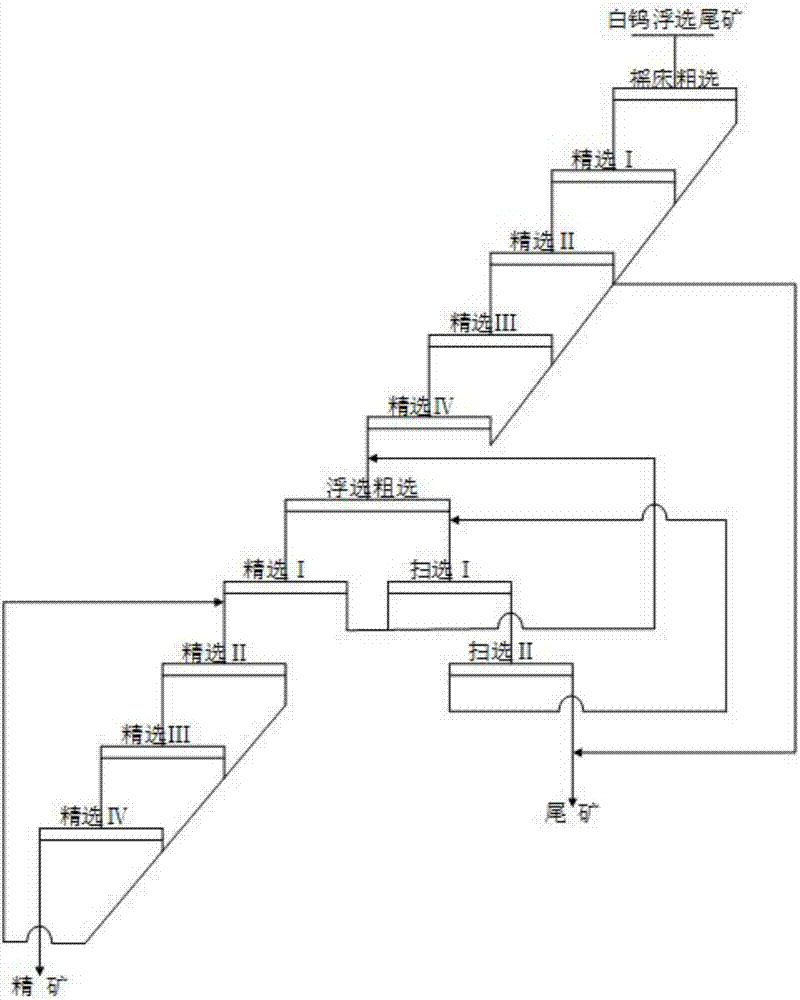

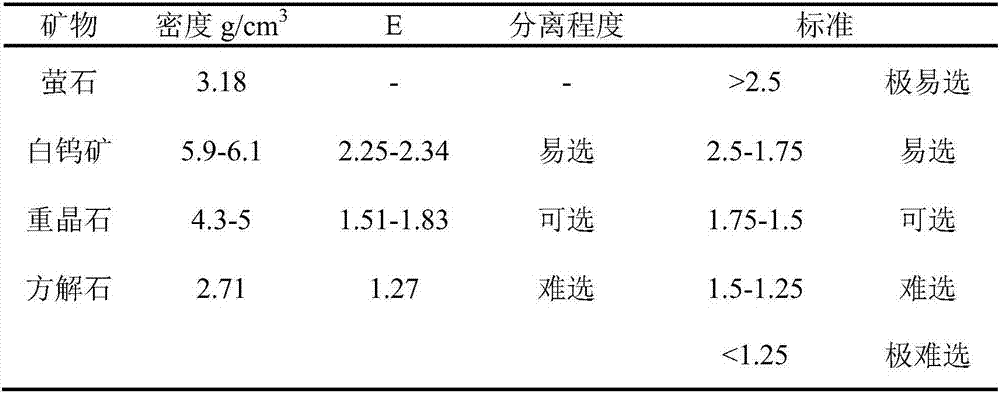

Method of reclaiming fluorite from scheelite tailings

The invention discloses a method for recovering fluorite from scheelite tailings. The method mainly adopts a gravity separation-flotation combined process. Firstly, the scheelite tailings are removed through a shaker gravity separation process of one coarse and four fines The scheelite and barite minerals in the process are enriched with fluorite minerals; and then the fluorite is recovered through a flotation process of one rough, four fine and two sweeps. Under the condition of fully recovering fluorite, the present invention greatly reduces the cost, improves the recovery rate of fluorite, reduces the amount of chemicals used in the flotation process, reduces the separation burden of the flotation process, and reduces the impact on the environment. pollution and promote the comprehensive utilization of resources.

Owner:湖南临武嘉宇矿业有限责任公司

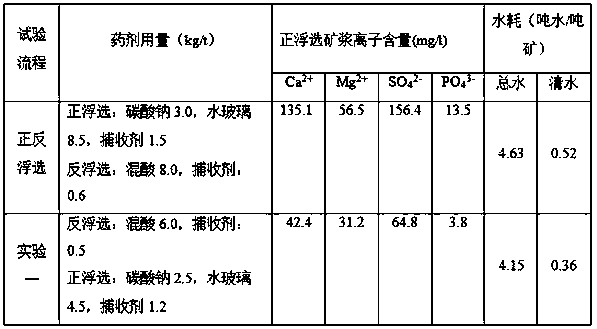

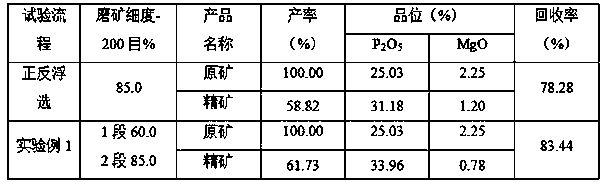

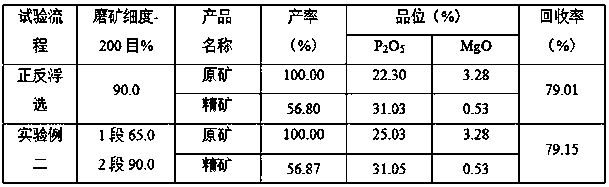

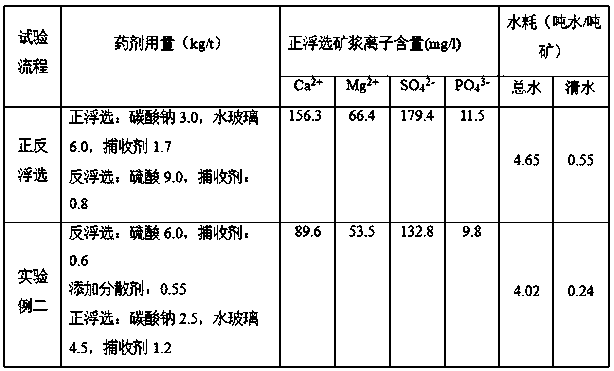

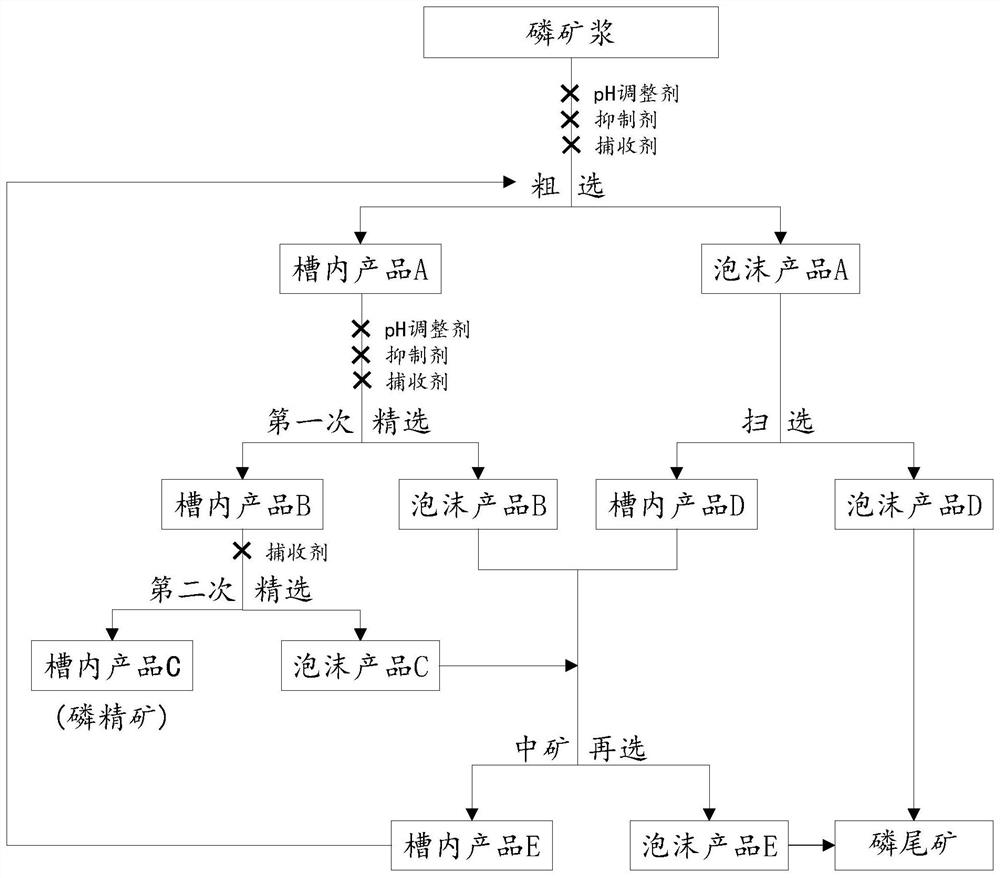

Reverse-direct flotation method for siliceous-calcareous collophanite

The invention relates to a reverse-direct flotation method for siliceous-calcareous collophanite. According to the method, after raw ore is ground, a flotation process sequentially comprising reverseflotation magnesium removal and direct flotation desilicication operation is adopted, reverse flotation return water enters a reverse flotation water return pool and then returns to reverse flotationmagnesium removal so as to be used, direct flotation return water enters a direct flotation water return pool and then returns to direct flotation desilicication operation, and surplus direct flotation return water is fed into the reverse flotation water return pool so as to be used for reverse flotation. According to the invention, with the method, water can be saved, all wastewater can be recycled, and the treatment cost is low; by using a flotation process sequentially comprising reverse flotation and direct flotation, less water is needed, and reverse flotation return water enters the reverse flotation return water pool and then is reused for reverse flotation; and on the premise that the indexes of the concentrate yield, the grade and the recovery rate are similar to those in the prior art, the dosage of chemicals is small, the ion content of ore pulp in direct flotation operation is low, and water consumption is small.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

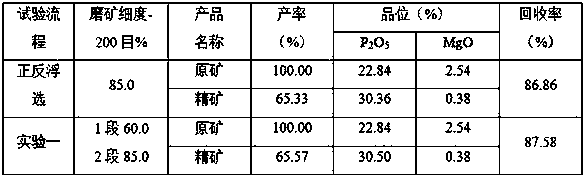

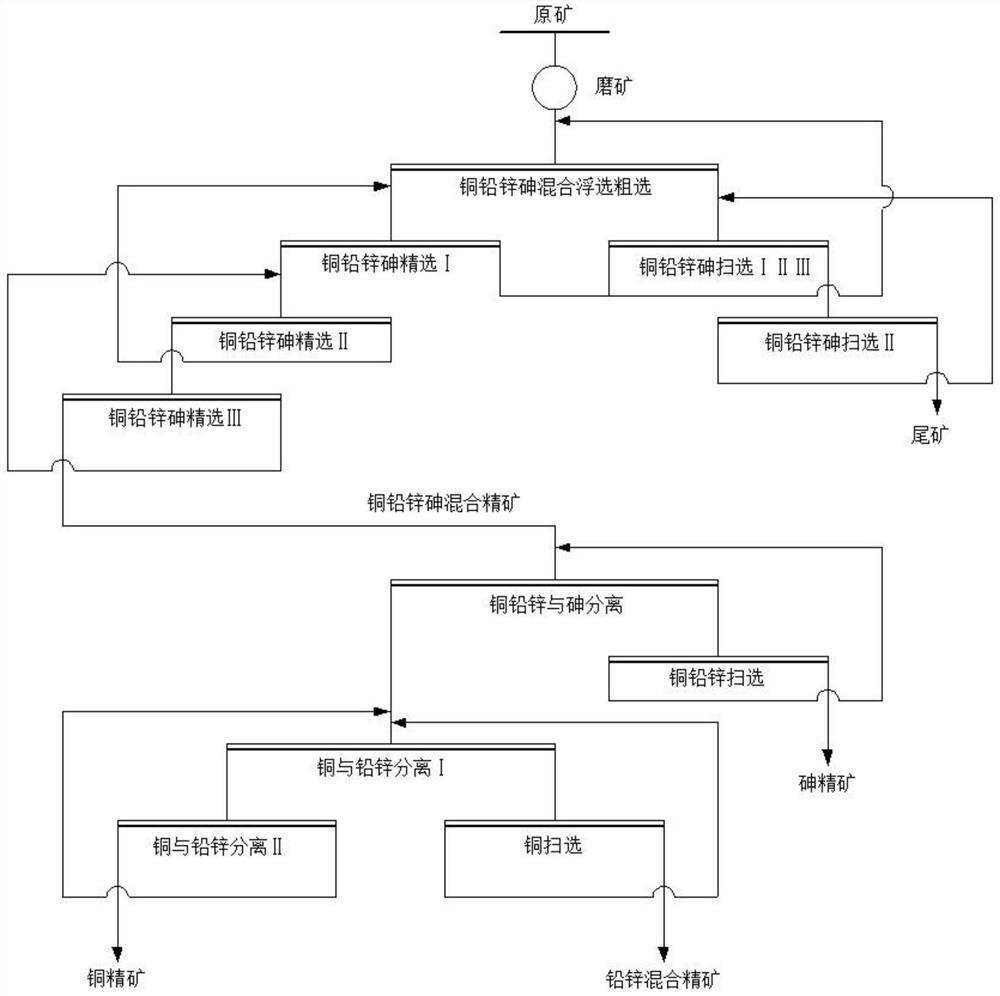

Complex multi-metal sulfide ore copper-lead-zinc-arsenic flotation separation method

ActiveCN111617884ALarge amount of limeReduce the amount and type of medicineFlotationGrain treatmentsXanthateLead zinc

The invention relates to the technical field of metallurgy, and discloses a complex multi-metal sulfide ore copper-lead-zinc-arsenic flotation separation method which comprises the following steps: S1, ore grinding operation, specifically, crushing raw ore, adding the crushed raw ore and water into a ball mill, and grinding the crushed raw ore, wherein the discharge condition of the ball mill is that the ore grinding fineness reaches the standard that 0.074 mm fineness accounts for 65-70%; and S2, copper-lead-zinc-arsenic bulk flotation operation, specifically, adding dilute sulfuric acid intoa flotation machine to adjust the pH value of ore pulp to be weakly alkaline, using butyl xanthate as a collecting agent and terpenic oil as a foaming agent, and performing primary roughing, tertiaryconcentration and secondary scavenging after stirring is conducted in the adding process to obtain copper-lead-zinc-arsenic bulk concentrates and tailings. Reagents used in the method are conventional beneficiation reagents and are free of pollution to the environment, low in price, and easy to purchase in the market, control cost is convenient, good copper-lead-zinc-arsenic valuable element separation effect can be achieved, and the obtained concentrate products are high in quality and low in mutual metal content.

Owner:河北省地质实验测试中心

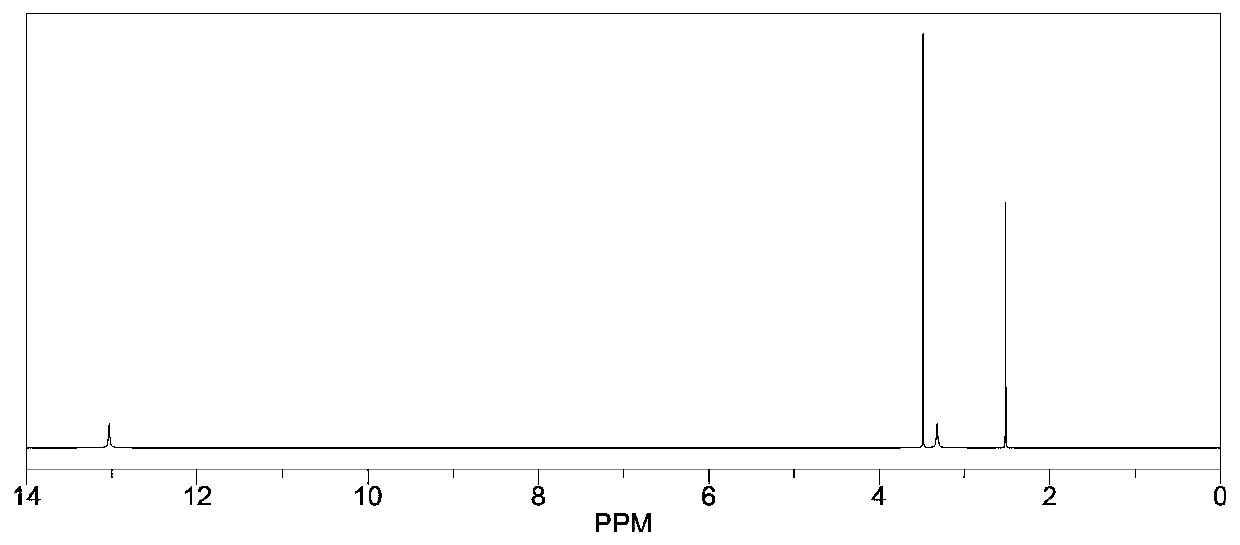

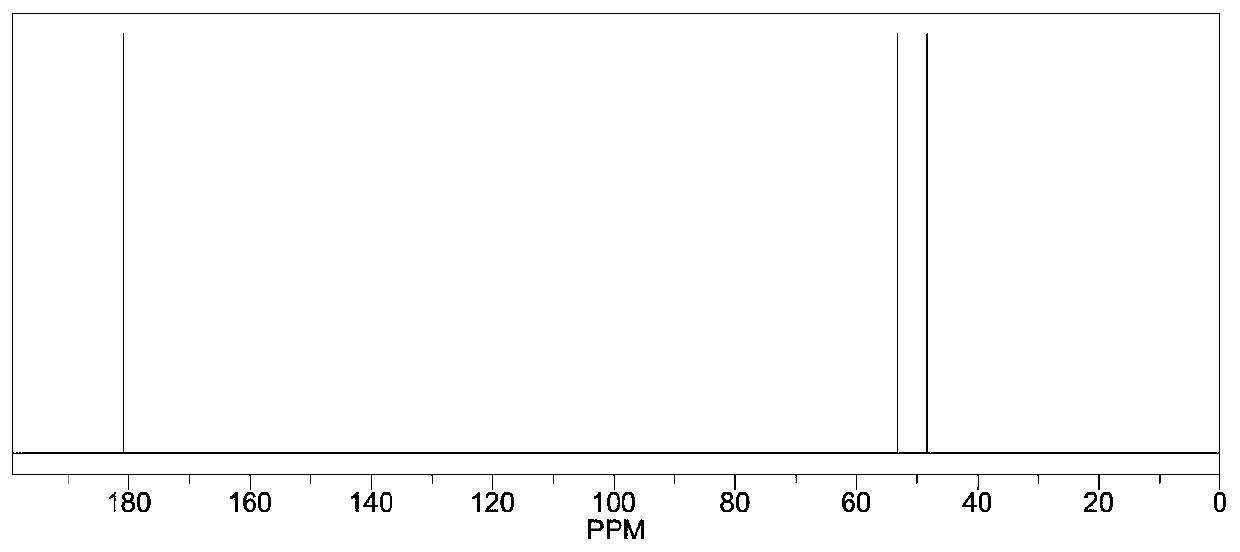

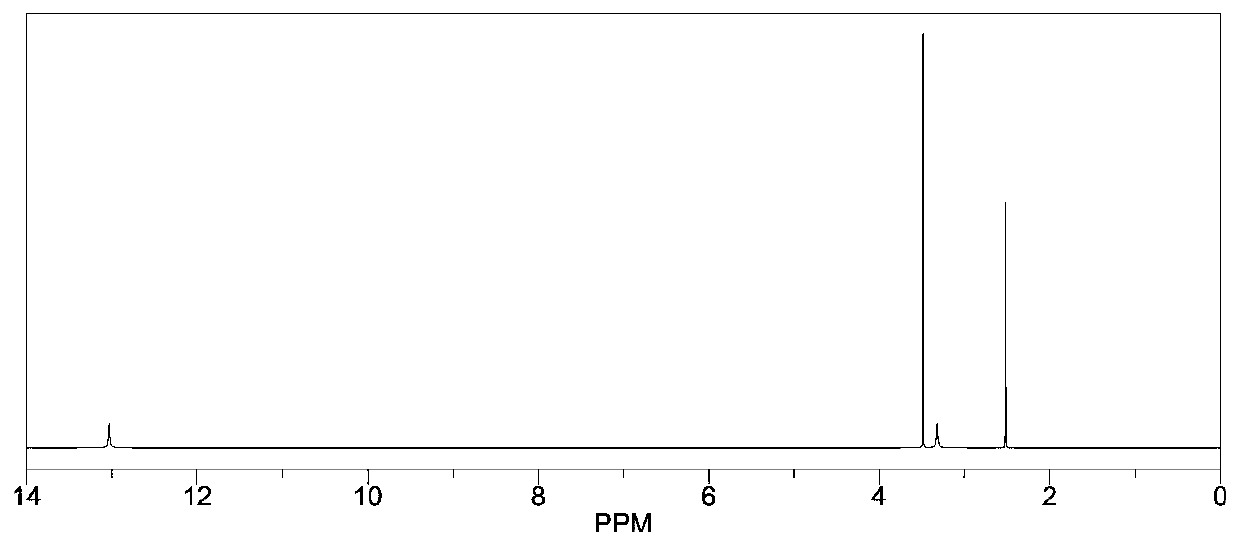

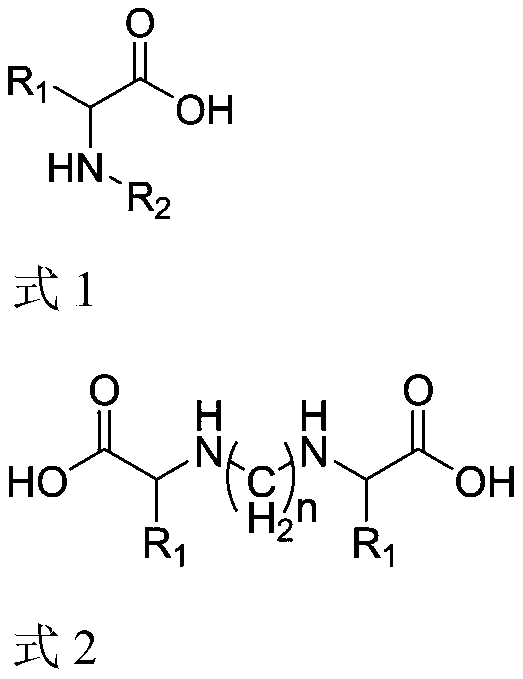

Inhibitor of iron-containing sulphide ore, flotation reagent and application

The invention belongs to the field of sulphide ore flotation, and particularly discloses application of a 2-alkyl amino substituted carboxylic acid compound as an inhibitor of iron-containing sulphideore. The invention further provides a sulphide ore floating agent containing the 2-alkyl amino substituted carboxylic acid compound. It is found that the 2-alkyl amino substituted carboxylic acid compound can selectively inhibit the iron-containing sulphide ore in flotation of the sulphide ore such as ferromolybdenum, galvanized iron, leaded iron, copper containing iron and bismuth containing iron, the flotation technological process can be simplified, the agent dosage is reduced, environmental pollution is reduced, and the production cost is reduced.

Owner:CENT SOUTH UNIV

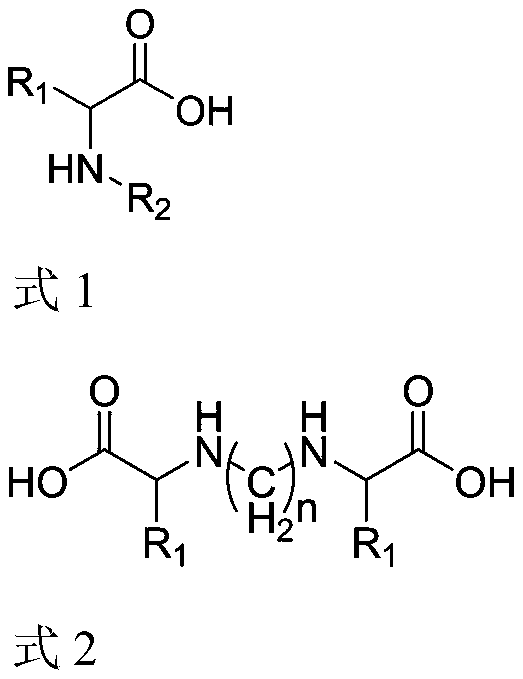

Dressing and smelting combination method for copper-zinc sulfide ores difficult to treat

InactiveCN107805721AHigh recovery rateLess fixed investmentRotary drum furnacesCrucible furnacesSmelting processFerrous

The invention discloses a dressing and smelting combination method for copper-zinc sulfide ores difficult to treat and belongs to the field of dressing and smelting. The dressing and smelting combination method for the copper-zinc sulfide ores is used for solving the problems that flotation separation of the copper-zinc sulfide ores is difficult, the traditional dressing and smelting process is long, and the treatment cost is high. Firstly, the copper-zinc sulfide ores are treated through the processes of ore crushing, ore grinding and mixing flotation, and thus mixed flotation concentrates are obtained; then, roasted zinc is obtained after drying and oxidation roasting, coke and slag forming constituents are added for reduction smelting, thus a zinc product, smelted upper-layer slag and smelted bottom slag are obtained, the upper-layer slag is directly used for being sold or used as paving stone, and copper in the bottom slag is enriched preliminarily; and finally, the bottom slag issubjected to selective oxidation smelting at the temperature of 1350-1550 DEG C, thus a primary copper product and ferrous oxide slag are obtained, and the ferrous oxide slag is directly used for ironsmelting or dye manufacturing. The dressing and smelting combination method provides a new method for clean utilization of the copper-zinc sulfide ores difficult to treat, the total recycling rate ofcopper is 80%-90%, and the total recycling rate of zinc is 82%-92%, and the method is short in process, environmentally friendly, and good in industrializing application prospect.

Owner:KUNMING UNIV OF SCI & TECH

Method for recovering indium-enriched marmatite from copper, zinc and indium coexisting polymetallic ore under low-alkaline condition

ActiveCN106622641AReduce over-crushingIncrease dissociationFlotationMechanical material recoveryIndiumSulfur

The invention discloses a method for recovering indium-enriched marmatite from copper, zinc and indium coexisting polymetallic ore under a low-alkaline condition. By adoption of the method, the technical problems that under the high-alkaline condition, indium-enriched marmatite is poor in floatability, difficult in excitation and low in indium recovery rate, and concentrate metals are high in content are solved. The method comprises the steps that a chemical agent is added into crushed and ground raw ore, slurry is formed through blending, and then copper, zinc and sulfur iso-flotation is conducted; and coarse grains are reground after iso-flotation rough concentrate is graded, an inhibitor is added for adjusting the mineral slurry and the pH value of the slurry, then copper selection is conducted, and copper concentrate and copper cleaner tailings are obtained; the copper cleaner tailings and copper, zinc and sulfur iso-flotation tailings are blended, then an activator is added and blended with the slurry, zinc and sulfur bulk flotation is conducted, and coarse grains are reground after zinc and sulfur bulk flotation rough concentrate is graded; and lime is added for adjusting the pH value of the mineral slurry, then zinc selection is conducted, and zinc concentrate and zinc cleaner tailings are obtained. By adoption of the method, the use amount of the inhibitor in the copper and zinc grading operation, the flotation mineral flurry pH value and the concentrate metal contents are lowered, and the indium and zinc recovery rates are increased; and meanwhile, the flotation process is simplified, and the flotation efficiency is improved.

Owner:KUNMING UNIV OF SCI & TECH

Method for flotation separation of potassium feldspar and quartz

InactiveCN108126825ARealize flotation separationNo pollution in the processFlotationHydrofluoric acidMalonic acid

The invention belongs to the technical field of flotation separation methods, and particularly relates to a method for flotation separation of potassium feldspar and quartz. A regulator malonic acid capable of replacing HF in a traditional hydrofluoric acid method can be found, the using effect of malonic acid is equivalent to that of HF, the requirement for the pH value in the flotation separation process is lowered, no pollution is caused to the environment, and the flotation separation process is simplified.

Owner:CHANGCHUN GOLD RES INST

Continuous ore grinding reverse-direct flotation method for siliceous-calcareous collophanite

The invention relates to a siliceous-calcareous collophanite continuous ore grinding reverse-direct flotation method, which comprises that after crushed raw ore is subjected to two-stage continuous ore grinding classification operation, a flotation process sequentially comprising reverse flotation magnesium removal and direct flotation desilication operation; reverse flotation return water entersa reverse flotation return water pool and then returns to be used for reverse flotation magnesium removal; and direct flotation return water enters a direct flotation return water pool and then returns to the direct flotation desilicication operation, and surplus direct flotation return water is fed into the reverse flotation return water pool to be used for reverse flotation. According to the invention, the method has the advantages of being simple in process, low in investment cost, low in operation effect and cost and the like, effectively avoid the influence of excessive Ca<2+>, PO4<3-> and SO4<2-> carried in reverse flotation return water on phosphorite direct flotation, easily achieves the stable operation of the reverse-direct flotation process in actual production, and achieves lowchemicals consumption, low ion content of ore pulp in direct flotation operation and low water consumotion on the premise that the indexes of the concentrate yield, the grade and the recovery rate are not reduced.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

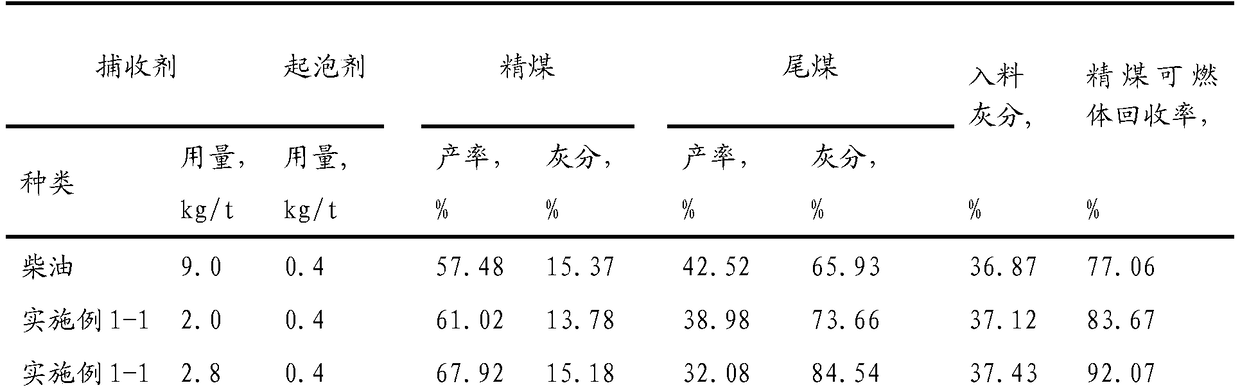

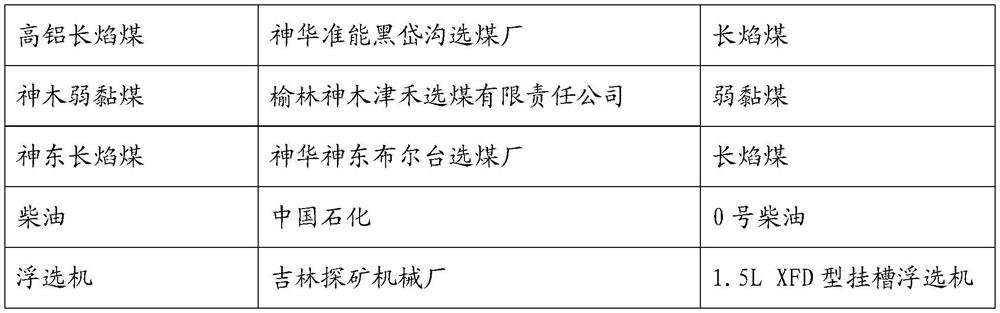

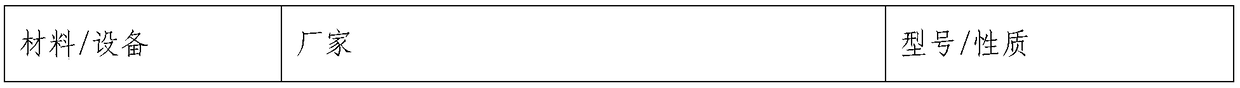

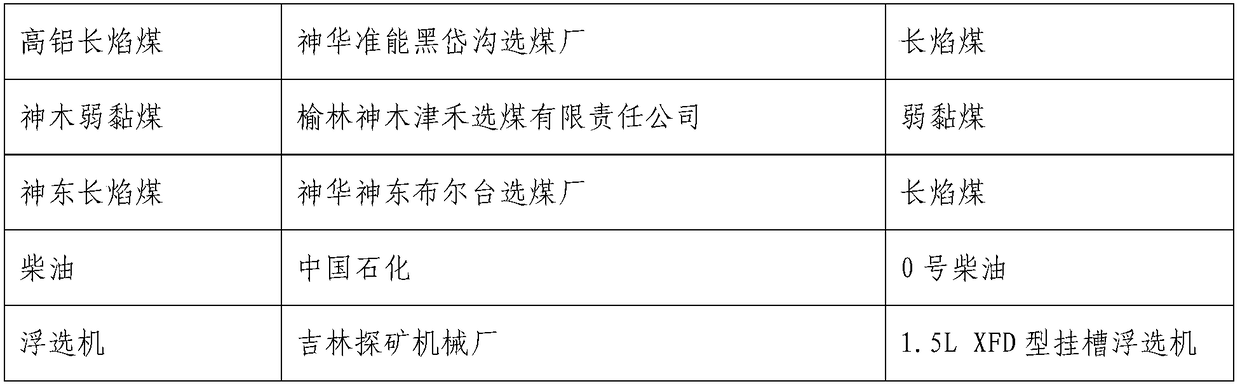

Low-order coal slurry flotation collecting agent compounded with acid aldehyde ether and preparing method and application of low-order coal slurry flotation collecting agent

ActiveCN109201341AEnhanced flotation mineralization processEffective coverageFlotationEtherEngineering

The invention provides a low-order coal slurry flotation collecting agent compounded with acid aldehyde ether and a preparing method and application of the low-order coal slurry flotation collecting agent. The collecting agent comprises following components including, by mass percent, 60%-85% of C10-C16 hydrocarbon oil, 5%-15% of C6-C8 acid, 5%-15% of C5-C9 aldehyde and 5%-15% of C4-C10 ether. According to the provided low-order coal slurry flotation collecting agent compounded with the acid aldehyde ether, the collecting agent has the characteristics that components are simple, the collectingagent can serve as the low-order coal slurry flotation collecting agent to finish economical and efficient sorting of conventional flotation, reagent consumption is low, the flotation cost is low, and the sorting efficiency is high.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Process for processing low grade hematite ore

ActiveCN101773869BSimplify the flotation processSimple processWet separationSmall footprintFerromagnetism

The invention belongs to the technical field of preparing low grade hematite ore, in particular to a process for processing a low grade hematite ore. The process comprises the following steps: the ore is ground until monomer separation and then coarse and fine classification is carried out on pulp; coarse grain pulp is subject to reselecting, ferromagnetism and sieving to obtain a part of the concentrate; the fine grain pulp is conveyed to a mixing tank for separating sample, and then is conveyed to a second mixing tank to be mixed with medicine for size mixing; the mixture is pumped to a rough flotation column; the under flows of the rough flotation column is fed to a cleaning flotation column, the under flow of the cleaning flotation column is the ultimate iron ore concentrate; foam of the rough flotation column is conveyed to an one-stage scavenging flotation column by a pump; the under flow of the one-stage scavenging flotation column and the foam of the cleaning flotation column are mixed and return to the rough flotation column, and products of the one-stage scavenging flotation column are final tailings. The process has the beneficial effects of smaller occupation area by replacing a flotation machine with the flotation column, can recycle fine-grade valuable mineral effectively, improve the ultimate concentrate grade, provides reference significance for the mineral separation of the ore of the same type in China, and has obvious economic benefits and social benefits.

Owner:ANSTEEL GRP MINING CO LTD

Low-rank coal slime flotation collector compounded with ester aldehyde ether and its preparation method and application

ActiveCN109201345BEnhanced flotation mineralization processImprove hydrophobicityFlotationEtherEngineering

Owner:CHINA SHENHUA ENERGY CO LTD +1

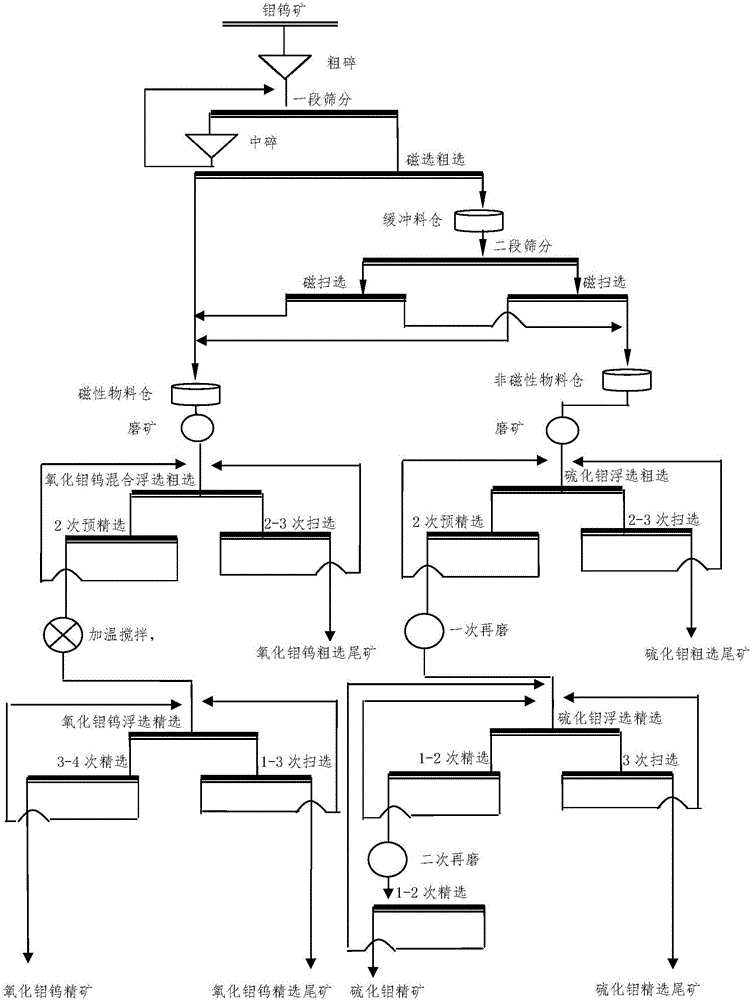

Low-grade tungsten-molybdenum polymetallic ore beneficiation method

The invention discloses a low-grade tungsten-molybdenum polymetallic ore beneficiation method. The low-grade tungsten-molybdenum polymetallic ore beneficiation method comprises the following steps that (1) raw ore is multi-metal associated ore of iron, molybdenum, bismuth, sulfur and tungsten, after the raw ore is crushed, ground and graded, iron ore concentrate is obtained by adopting a magnetic separation process of one-time roughing and two-time concentration, and iron tailings enter a thickener to be concentrated; (2) the concentrated iron tailings are subjected to molybdenum-bismuth mixed flotation through the technological process of one-roughing, three-sweeping and three-concentrating, molybdenum-bismuth mixed rough concentrate and molybdenum-bismuth tailings are obtained, wherein molybdenum-bismuth separation is conducted on the molybdenum-bismuth mixed rough concentrate, and the molybdenum-bismuth tailings enter a tungsten flotation stage; (3) the molybdenum-bismuth mixed rough concentrate is subjected to molybdenum-bismuth separation through the technological process of one-time roughing, two-time sweeping and four-time concentration, and molybdenum concentrate and bismuth middlings are obtained; and (4) the molybdenum-bismuth tailings are subjected to tungsten normal-temperature flotation through the technological process of one-roughing, three-sweeping and five-refining, and tungsten concentrate is obtained. According to the method, a low-grade tungsten-molybdenum polymetallic ore can be efficiently recycled.

Owner:湖南有色黄沙坪矿业有限公司 +1

A low-rank coal slime flotation collector compounded with acid ketone ether and its preparation method

The invention provides a low-rank coal slime flotation collector compounded with acid ketone ether and a preparation method thereof. In terms of mass percentage, the collector includes: C 10 -C 16 Hydrocarbon oil 60‑85%; C 6 -C 8 Acid 5‑15%; C 5 -C 10 Ketone 5‑15%; C 4 -C 10 Ether 5‑15%. The collector provided by the invention has simple components, can be obtained by compounding a small amount of reagents, and can be used in conventional low-rank coal slime flotation technology, with small reagent consumption, low flotation cost, and high separation efficiency. Significant economic benefits.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Compound ester-aldehyde-ether low-rank coal slime flotation collector and preparation method and application thereof

ActiveCN109201345AEnhanced flotation mineralization processImprove hydrophobicityFlotationEtherEngineering

The invention provides a compound ester-aldehyde-ether low-rank coal slime flotation collector and a preparation method and application thereof. The collector is simple in component, can serve as thelow-rank coal slime flotation collector to complete economical efficient sorting of conventional flotation, and has the advantages of being small in chemical consumption, low in flotation cost, high in sorting efficiency and the like. The compound ester-aldehyde-ether low-rank coal slime flotation collector comprises, by mass, 60-85% of C10-C16 hydrocarbon oil, 5-15% of C10-C18 ester, 5-15% of C5-C9 aldehyde and 5-15% of C4-C10 ether.

Owner:CHINA SHENHUA ENERGY CO LTD +1

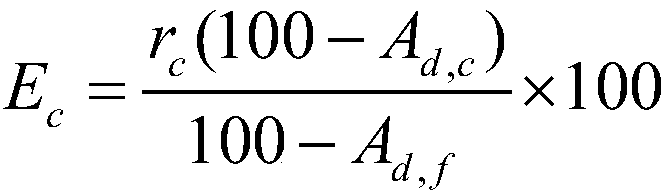

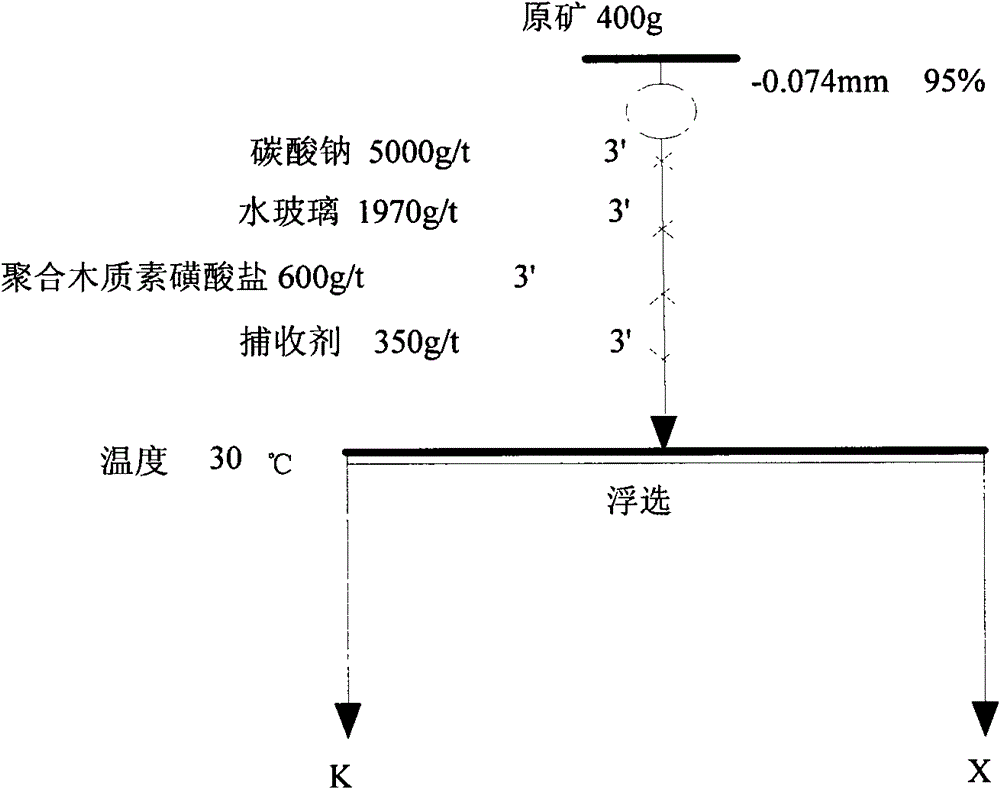

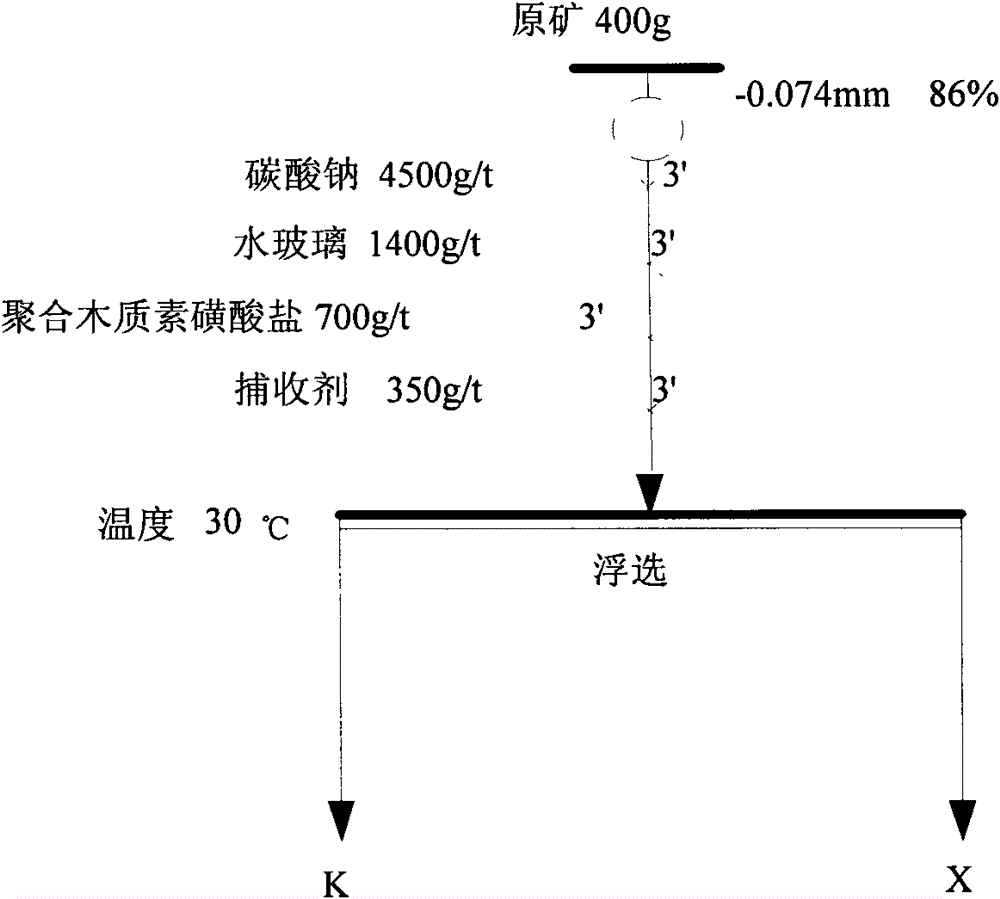

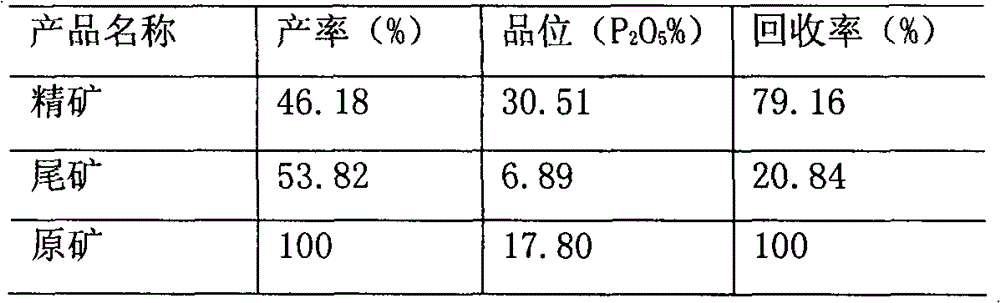

Collophanite flotation collector and application thereof

The invention discloses a collophanite flotation collector and application thereof. The collector consists of the following materials in percentage by mass: 55 to 75 percent of mixed hydroxamic acid. 24 to 44 percent of unsaturated fatty acid of C18 and 1 to 3 percent of OP-10 and is prepared by the method comprising the following steps of: mixing coconut oil and palm oil in a mass ratio of 2:1-2 to obtain mixed oil; heating the mixed oil until the mixed oil is melted; maintaining the temperature; adding hydroxylamine, NaOH or KOH into the mixed oil to react; and after the reaction, acidizing and separating the reactant to obtain mixed hydroxamic acid, wherein sodium carbonate serves as a modifier and sodium silicate and polymerized lignosulfonate serve as an inhibitor. The collector provided by the invention can realize positive floatation for low-grade collophanite at the normal temperature of between 25 and 35 DEG C.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A kind of inhibitor, flotation agent and application of iron-bearing sulfide ore

ActiveCN110064523BFlotation has no effectEnhanced inhibitory effectFlotationMining engineeringSulfidation

The invention belongs to the field of sulphide ore flotation, and particularly discloses application of a 2-alkyl amino substituted carboxylic acid compound as an inhibitor of iron-containing sulphideore. The invention further provides a sulphide ore floating agent containing the 2-alkyl amino substituted carboxylic acid compound. It is found that the 2-alkyl amino substituted carboxylic acid compound can selectively inhibit the iron-containing sulphide ore in flotation of the sulphide ore such as ferromolybdenum, galvanized iron, leaded iron, copper containing iron and bismuth containing iron, the flotation technological process can be simplified, the agent dosage is reduced, environmental pollution is reduced, and the production cost is reduced.

Owner:CENT SOUTH UNIV

A Flotation Separation Method of Copper, Lead, Zinc and Arsenic in Complex Polymetallic Sulfide Ore

ActiveCN111617884BReduce dosageSimplify the flotation processFlotationGrain treatmentsEngineeringXanthate

The present invention relates to the field of metallurgy technology, and discloses a complex polymetallic sulfide ore copper-lead-zinc-arsenic flotation separation method, including the following steps: Step S1: ore grinding operation: crushing the raw ore and putting it into a ball mill with water Grinding and discharging conditions of the ball mill are that the grinding fineness reaches ‑0.074mm, accounting for 65-70%; Step S2: Copper, lead, zinc and arsenic mixed flotation operation: add dilute sulfuric acid to the flotation machine to adjust the pH value of the pulp to the weakest Alkaline, with butyl xanthate as collector and terpineol oil as foaming agent, and after stirring separately during the addition process, one roughing, three times of refining and two sweeping are carried out to obtain copper, lead, zinc and arsenic mixed concentrate mines and tailings. The medicament used in the design of the present invention is a conventional mineral dressing medicament, which has no pollution to the environment, is cheap, is easy to buy in the market, and is convenient for cost control. The intermetallic content in the product is low.

Owner:河北省地质实验测试中心

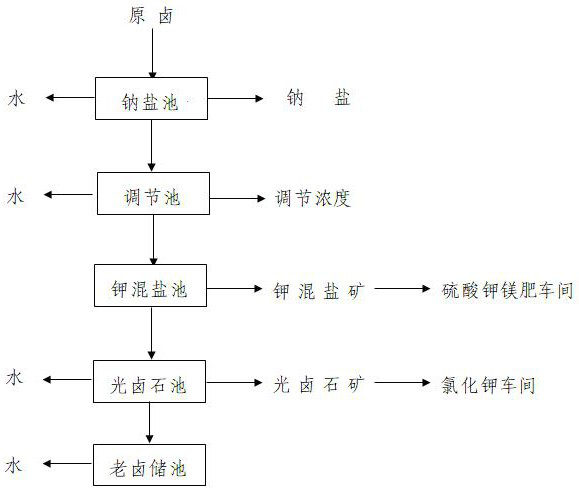

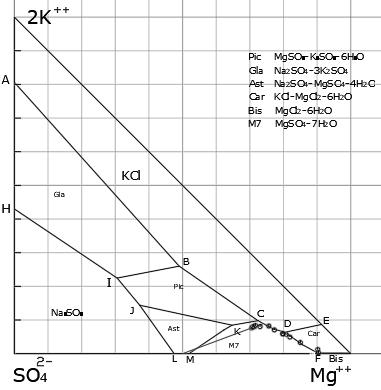

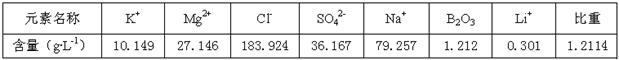

A kind of magnesium sulfate subtype salt lake brine salt field natural evaporation staged mineralization technology

ActiveCN110283001BReduce lossesReduce salt pan processAlkali metal sulfite/sulfate purificationAlkali metal chloridesCarnalliteSodium salt

The present invention relates to a sub-type magnesium sulfate subtype salt lake brine natural evaporation staged ore-forming process, comprising the following steps: (1) pumping brine from a magnesium sulfate subtype salt lake well into a sodium salt pool, naturally evaporating to precipitate sodium chloride, and then When the sharp salt is close to saturation, it is introduced into the adjustment pool, and when the brine point reaches the epsom salt and is about to be precipitated, it is imported into the potassium mixed salt pool; (2) in the potassium mixed salt pool, the brine obtained in step (1) continues to be evaporated naturally, and when the brine is close to light brine The stone is saturated and will be imported into the carnallite pool when it is about to be separated out, and the potassium mixed salt ore is separated out, and the potassium mixed salt ore is separated out, and the potassium mixed salt ore enters the potassium magnesium sulfate fertilizer workshop to produce langbeinite products; (3) in the carnallite In the pool, the brine obtained in step (2) continues to be evaporated naturally, and when the brine reaches the old brine point, it is introduced into the old brine storage tank, and carnallite ore is precipitated, and the carnallite ore enters the potassium chloride workshop to produce potassium chloride products . The invention has the advantages of simple process, low production cost and high sulfur-potassium ratio of potassium mixed salt ore.

Owner:青海中信国安锂业发展有限公司

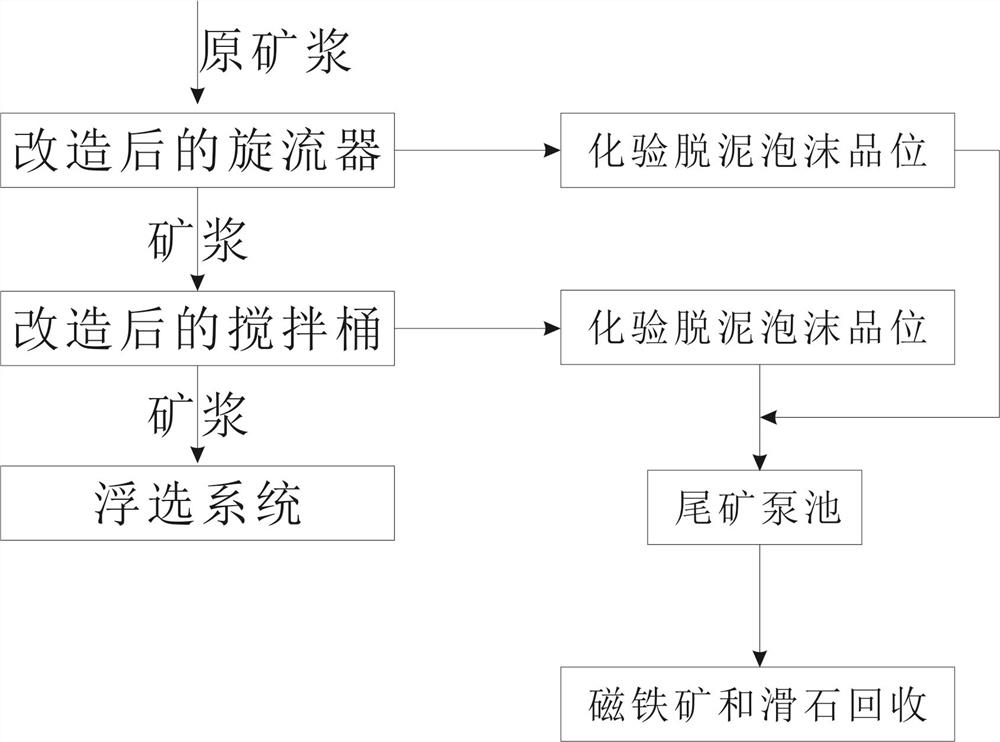

Desliming method for high-argillization high-talc ore

PendingCN113492062ASimplify the flotation processIncrease productivityFlotationMining engineeringTalc

The invention relates to a desliming method for high-argillization high-talc ore. According to the desliming method, desliming structures are arranged in a hydrocyclone and a stirring barrel, flotation operation can be directly conducted on raw ore pulp, the desliming process is completed in the flotation process, that is, the desliming process is synchronously completed in the modified stirring barrel and the hydrocyclone, pre-desliming does not need to be conducted, the whole flotation process is simplified, production efficiency can be improved, the desliming product can be subjected to magnet recovery, and talc of the desliming product can also be used for manufacturing of building materials or the paint industry.

Owner:CHINA MOLYBDENUM

A sorting process of fine-grained red magnetic mixed iron ore

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Reverse flotation process for synchronously removing silicon and magnesium impurities from collophanite and collecting agent of reverse flotation process

PendingCN114653480ASimplify the flotation processReduce dosageFlotationPhosphoric Acid EstersFoaming agent

The invention relates to a reverse flotation process for synchronously removing silicon and magnesium impurities from collophanite and a collecting agent thereof. The collecting agent comprises the following raw materials: an amine medicament, alpha sulfonated saturated fatty acid sodium, alkyl phosphate salt, non-polar oil and a foaming agent in a mass ratio of (30-42): (13-25): (5-13): (19-33): (10-21). The reverse flotation technology comprises the following steps that after raw collophanite is ground, water is added to obtain phosphoric ore pulp, a pH adjusting agent, an inhibitor and a collecting agent are sequentially added into the phosphoric ore pulp, reverse flotation roughing is conducted, the pH adjusting agent, the inhibitor and the collecting agent are sequentially added into a product in a tank, first reverse flotation concentration is conducted, the collecting agent is added into the product in the tank, and second reverse flotation concentration is conducted. And secondary reverse flotation concentration is conducted, and phosphate concentrate is obtained. According to the method, the phosphorite flotation technological process is simplified, and the purpose of synchronous reverse flotation by adding a reagent once in phosphorite beneficiation is achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Low-rank coal slime flotation collector compounded with ketone aldehyde ether and its preparation method and application

ActiveCN109201344BEnhanced flotation mineralization processImprove hydrophobicityFlotationEtherProcess engineering

The invention provides a low-order coal slime flotation collector compounded with ketone aldehyde ether and its preparation method and application. The collector has simple composition and can be used as a low-rank coal slime flotation collector to complete conventional The economical and efficient sorting of flotation has the characteristics of small chemical consumption, low flotation cost and high sorting efficiency. The low-rank coal slime flotation collector of compound ketone aldehyde ether provided by the invention comprises each component of following mass percentage: C 10 -C 16 Hydrocarbon oil 60‑85%; C 5 -C 10 Ketone 5‑15%; C 5 -C 9 Aldehyde 5‑15%; C 4 -C 10 Ether 5‑15%.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com