Method of reclaiming fluorite from scheelite tailings

A technology of fluorite and tailings, which is applied in the field of environmental protection treatment of tailings, can solve the problems of high cost of chemicals, great environmental impact, and difficult industrial application, and achieve the effects of reducing production costs, reducing environmental impacts, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

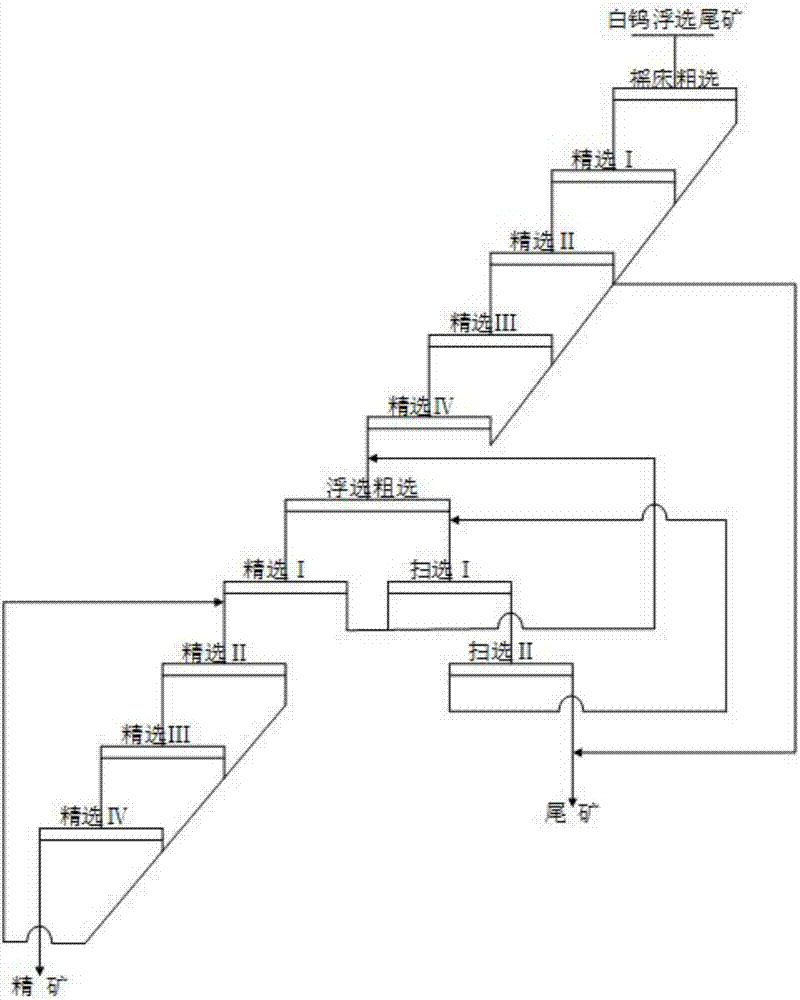

[0019] A scheelite flotation tailings containing CaF 2 18.16%, CaCO 3 2.07%, SiO 2 43.71%, after one rough and four fine shaker re-election, the recovery rate of fluorite reaches 71.26%, and then flotation is carried out on the re-eluted ore pulp.

[0020] The flotation process adopts a process of roughing once, four times of beneficiation and two times of sweeping. Among them, the middle ore of the first beneficiation and two times of sweeping are returned in sequence, and the middle ore of the second, third and fourth beneficiation are returned together. In a rough selection, first adjust the pH value of the pulp to 6-7, the amount of mixed inhibitor (the mass ratio of aluminum sulfate and water glass is 5:10) relative to the original ore is 2000g / t, and the addition of collector oleic acid relative to the original ore The amount is 100g / t. The amount of oleic acid added to the original ore in the two sweeps is 20g / t. In the first, second, third, and fourth beneficiat...

Embodiment 2

[0022] A scheelite flotation tailings containing CaF 2 20.45%, CaCO 3 10.79%, SiO 2 42.02%, after one coarse and four fine shaker re-elections, the recovery rate of fluorite reaches 80.25%, and then flotation is carried out on the re-eluted ore pulp.

[0023] The flotation process adopts a process of roughing once, four times of beneficiation and two times of sweeping. Among them, the middle ore of the first beneficiation and two times of sweeping are returned in sequence, and the middle ore of the second, third and fourth beneficiation are returned together. In a rough selection, first adjust the pH value of the pulp to 6-7, the amount of mixed inhibitor (the mass ratio of aluminum sulfate and water glass is 7:10) relative to the original ore is 5000g / t, and the addition of collector oleic acid relative to the original ore The amount is 80g / t. The amount of oleic acid added to the original ore in the two sweeps is 60g / t. In the first, second, third, and fourth benefici...

Embodiment 3

[0025] A scheelite flotation tailings containing CaF 2 20.45%, CaCO 3 10.79%, SiO 2 42.02%, after one coarse and four fine shaker re-elections, the recovery rate of fluorite reaches 80.25%, and then flotation is carried out on the re-eluted ore pulp.

[0026] The flotation process adopts a process of roughing once, four times of beneficiation and two times of sweeping. Among them, the middle ore of the first beneficiation and two times of sweeping are returned in sequence, and the middle ore of the second, third and fourth beneficiation are returned together. Firstly adjust the pH value of the pulp to between 6 and 7 in a rough selection, the addition amount of the mixed inhibitor (the mass ratio of aluminum sulfate and water glass is 6:10) relative to the original ore is 4000g / t, and the addition of the collector oleic acid relative to the original ore The amount is 50g / t. The amount of oleic acid added to the original ore in the two sweeps is 20g / t. In the first, seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com