Patents

Literature

101 results about "Hydroxylamine sulphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301952AImprove flotation recoveryAchieve high flotation separationFlotationReaction temperatureCarboxylic acid

A structural formula of a 6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent is represented by a formula (I), wherein R represents C2-C18 aliphatic hydrocarbon group. The preparation method comprises the steps as follows: caprolactam and hydroxylamine hydrochloride or hydroxylamine sulphate are taken as raw materials, methylbenzene is taken as a solvent, the reaction temperature ranges from 80 DEG C to 110 DEG C, the reaction lasts for 1-4 hours, and 6-amino hexyl hydroximic acid is generated; 6-amino hexyl hydroximic acid reacts with C2-C18 fat carboxylic acid at the reaction temperature ranging from 100 DEG C to 160 DEG C for 1-4 hours to generate 6-aliphatic hydrocarbon amido hexyl hydroximic acid, and the product yield can be higher than 91%; and 6-aliphatic hydrocarbon amido hexyl hydroximic acid used in flotation of scheelite, wolframite, tombarthite ore, tin ore, bauxite, titanic iron ore or fluorite ore is taken as the collecting agent, so that the flotation recovery rate can be increased by 3%-10%.

Owner:CENT SOUTH UNIV

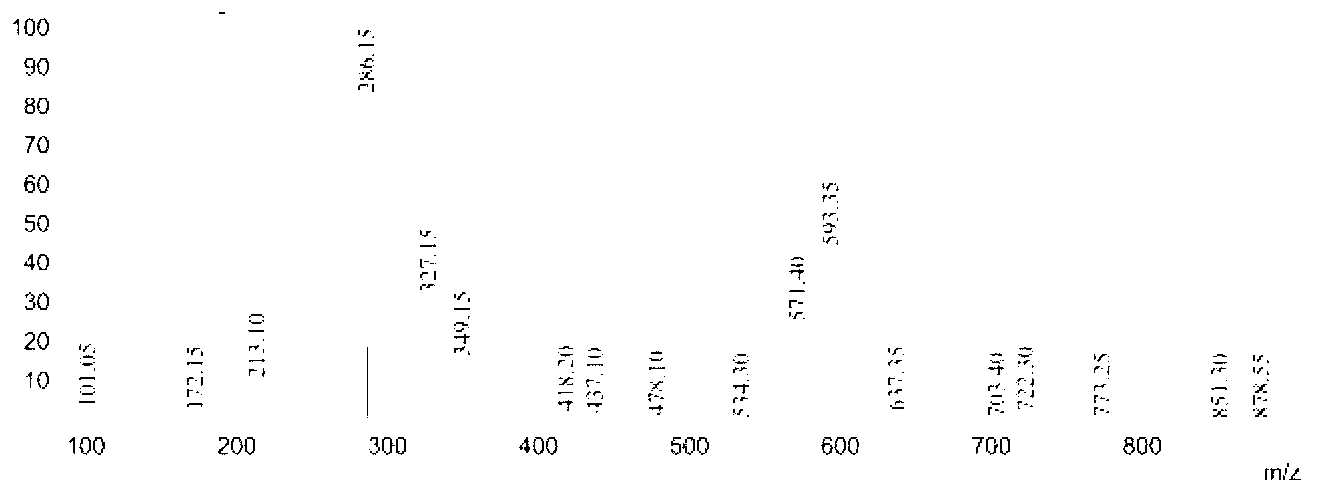

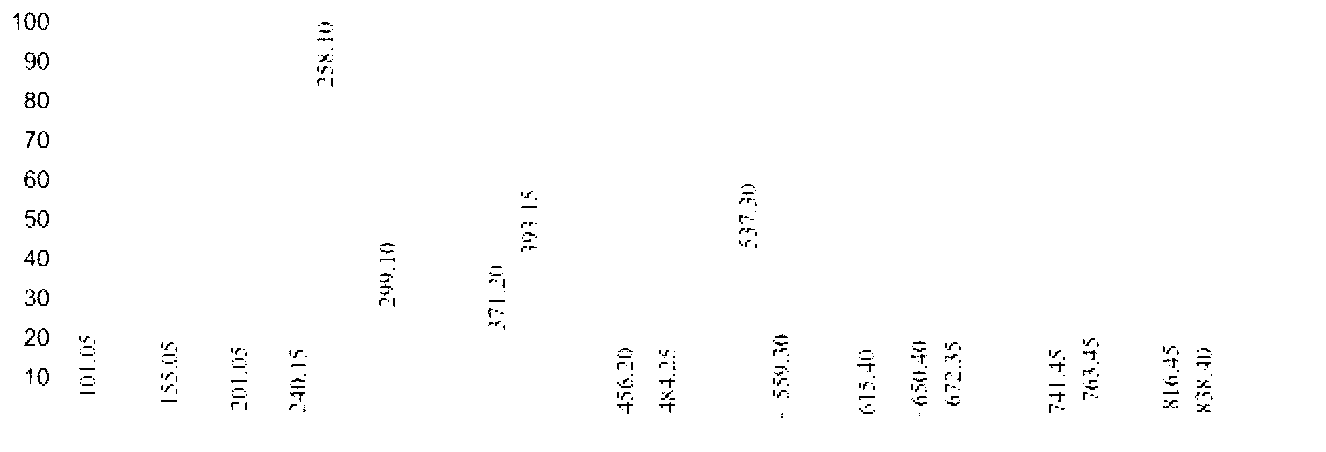

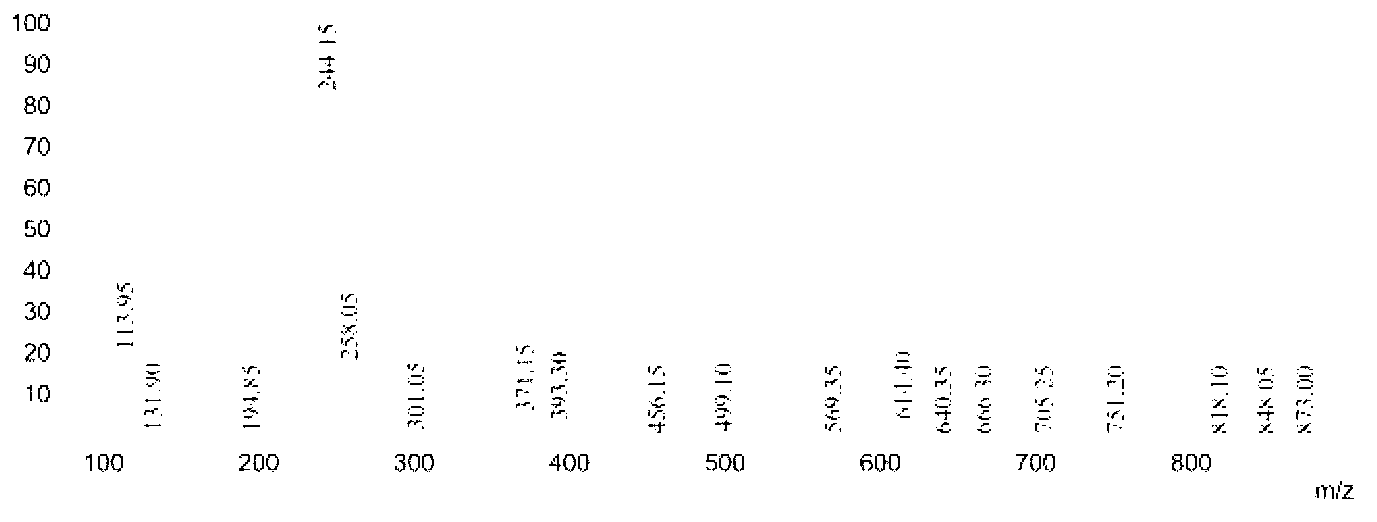

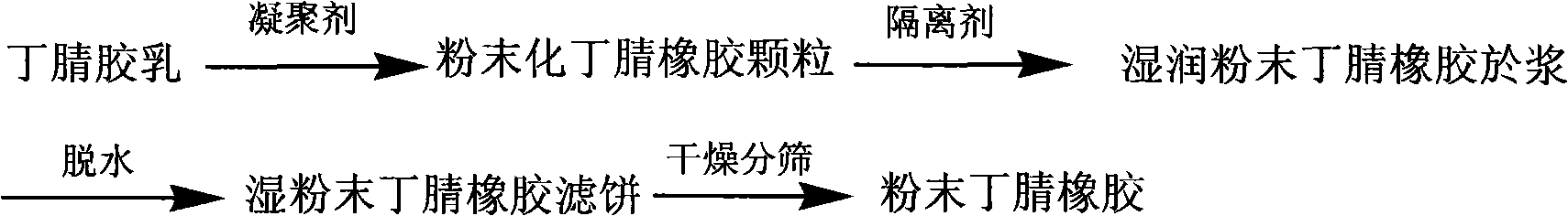

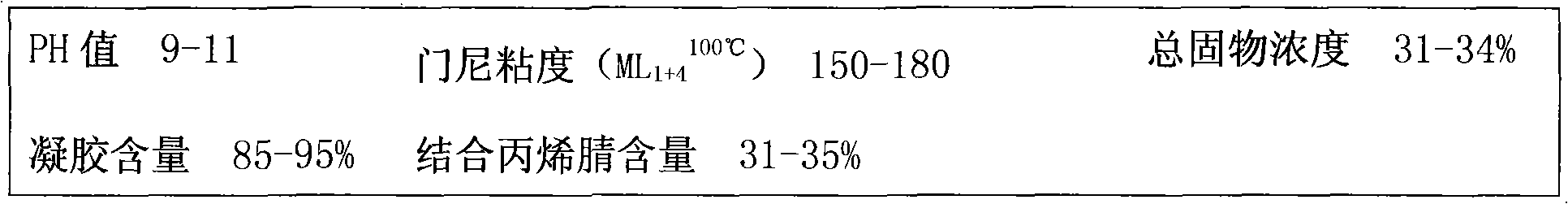

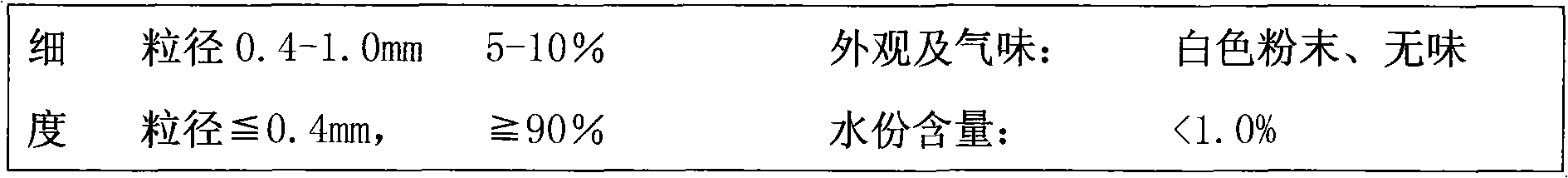

Method for producing cross-linking powder nitrile-butadiene rubber with medium and high nitrile content

The invention relates to a method for producing cross-linking powder nitrile-butadiene rubber with medium and high nitrile content; the method comprises the steps of synthesizing nitrile-butadiene rubber slurry, then flocculating the nitrile-butadiene rubber slurry followed by separating and powdering, and dehydrating and drying. In the stage of polymerization reaction, potassium carbonate is added to be a buffering agent of the reaction, and the mixed liquor of diethylhydroxylamine, hydroxylamine sulphate, potassium hydroxide and soft water is used as a composite terminator; in the stage of separating and powdering, WSL and DLTP are added to be an antiager, and univalent sodium salt and bivalent magnesium salt or univalent sodium salt or bivalent calcium salt are taken as a flocculant forcarrying out flocculating, separating and powdering on the nitrile-butadiene rubber slurry at 30-75 DEG C. The invention is simple in production technique, easy for operation, low in production cost,less in energy consumption and high in conversion rate which can be more than 95%; a novel composite terminator is adopted, so that mooney is stable and termination effect is good; the rubber powderis finer, and dispersity during processing is improved; and the heat-resistant quality of the product is very good, the wear resistance is good, and the invention can satisfy the requirement on application in high friction composite brake shoes of trains.

Owner:HUANGSHAN HUALAN TECH

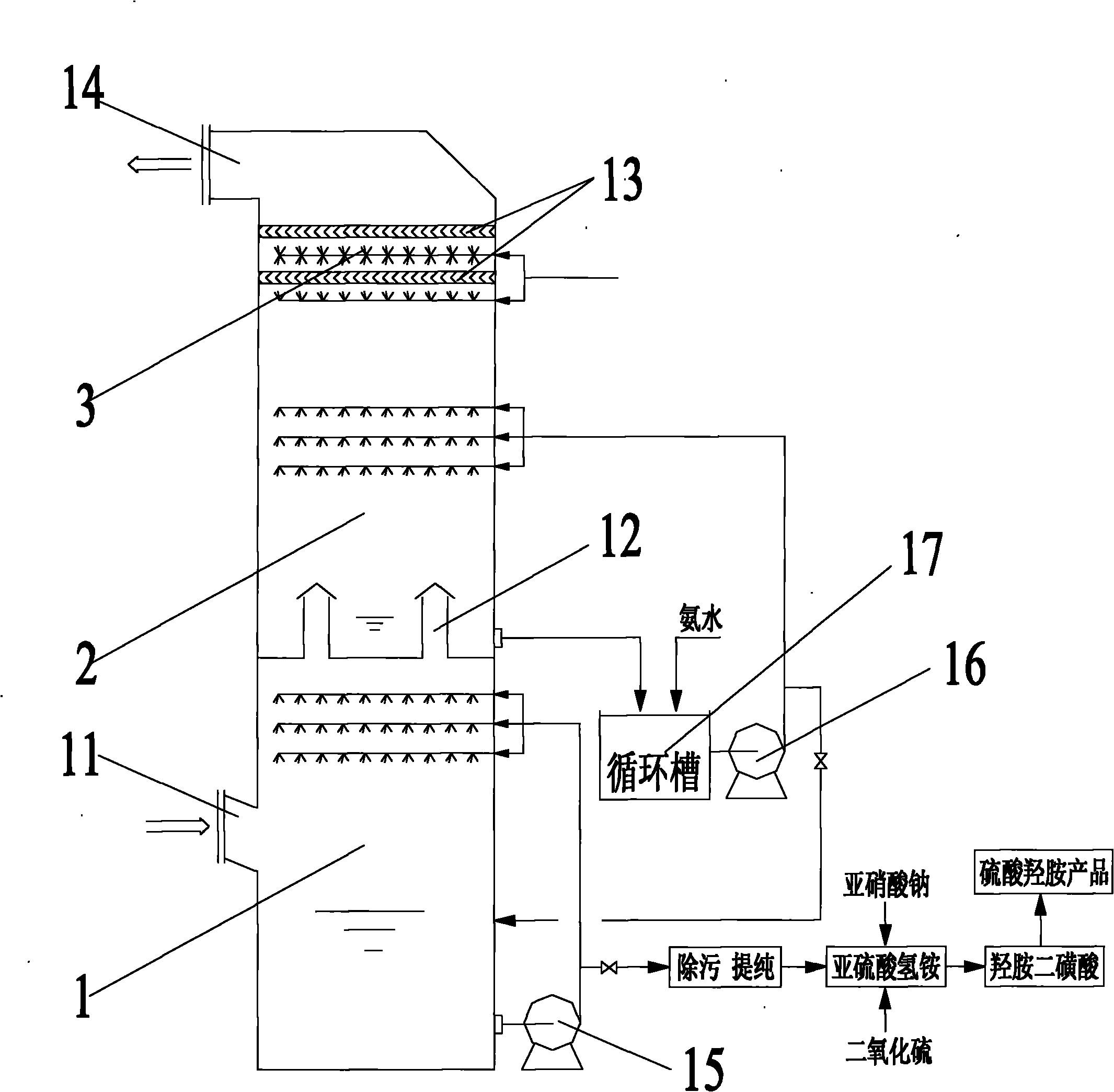

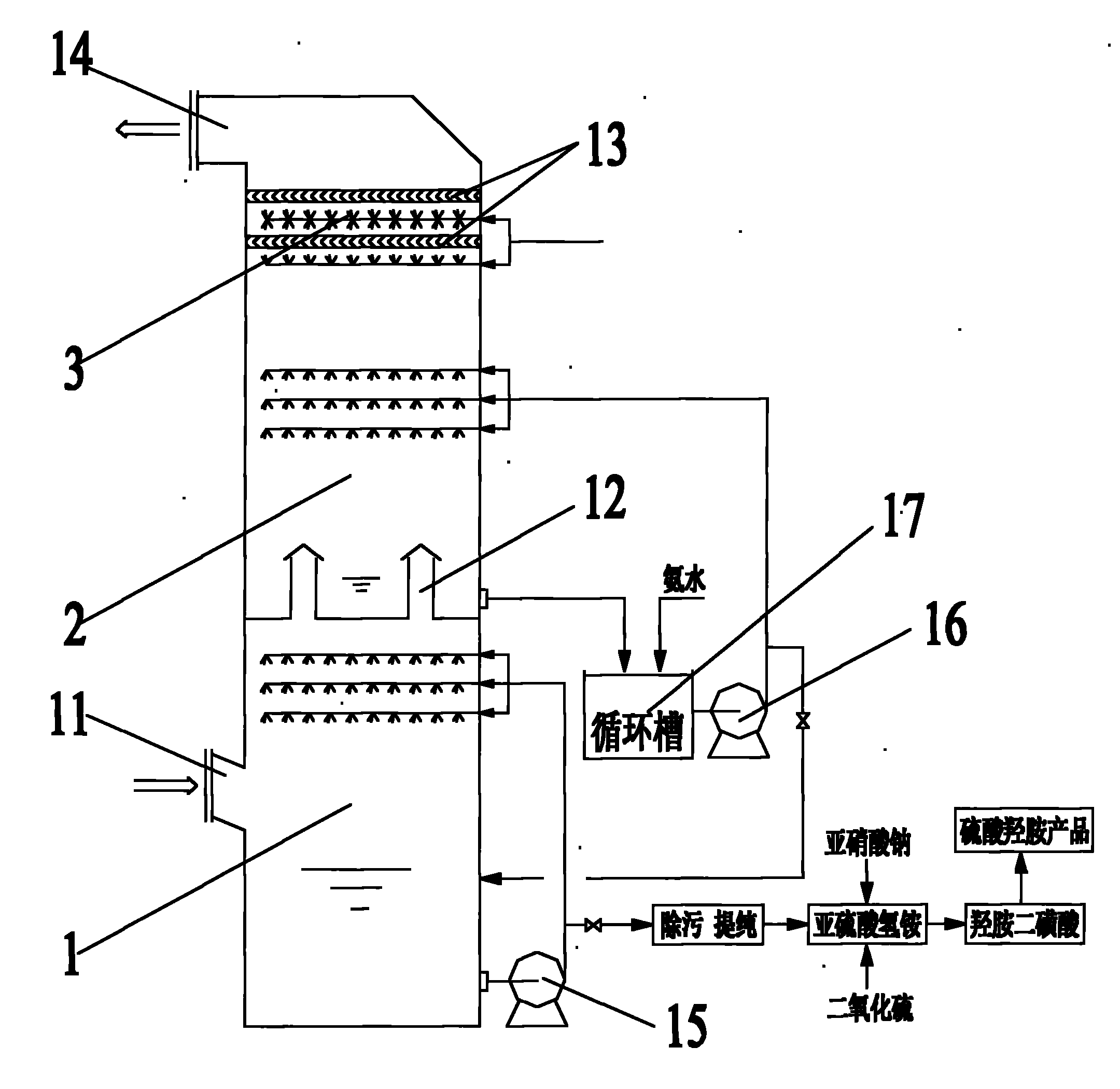

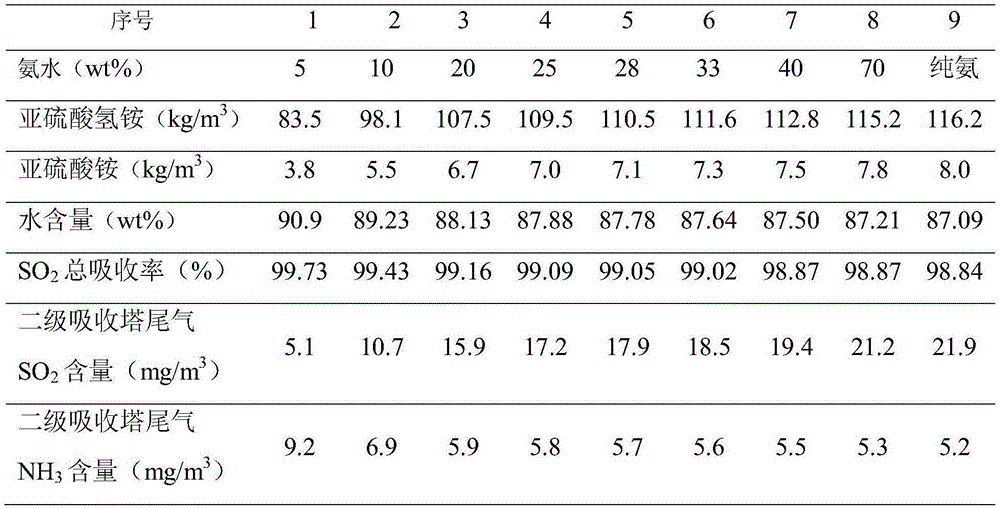

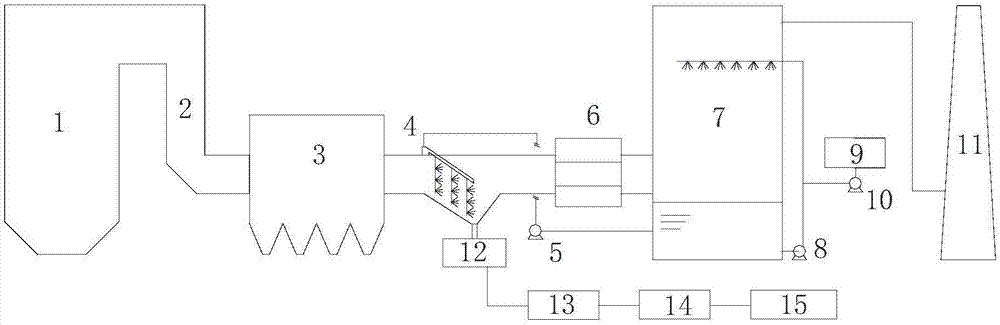

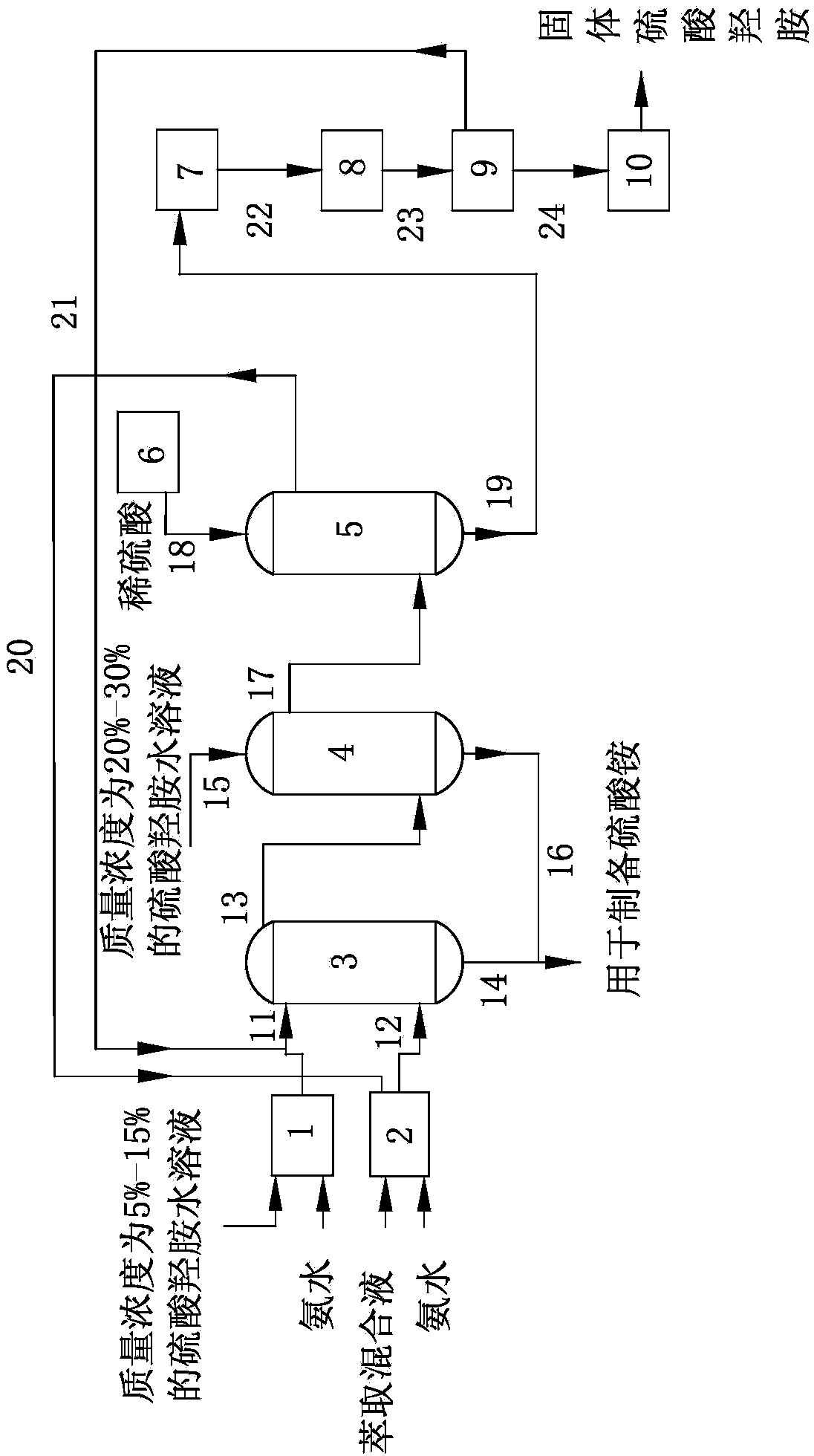

Method for recovering sulfur dioxide from flue gas and producing hydroxylamine sulphate and system thereof

ActiveCN101785964AAchieve enrichmentMaximizeDispersed particle separationAmmonium sulfatesFlue gasAmmonia

Owner:浙江菲达环保科技股份有限公司

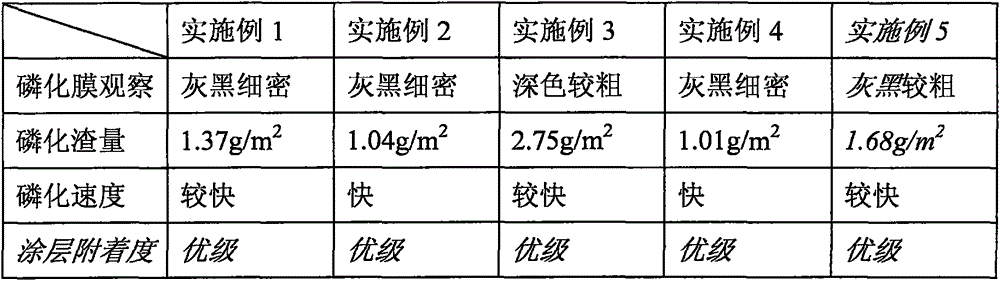

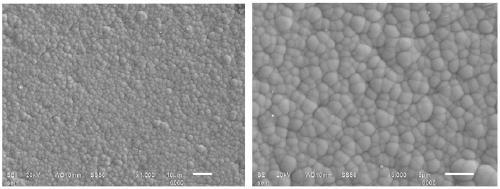

Normal-temperature phosphating solution forming phosphating film highly resistant to corrosion, preparing method and phosphating technology

InactiveCN105543826AImprove corrosion resistanceImprove protectionMetallic material coating processesOrganic acidNitrate

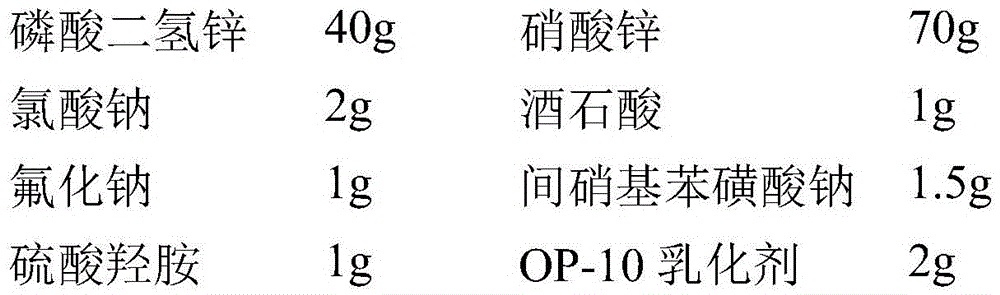

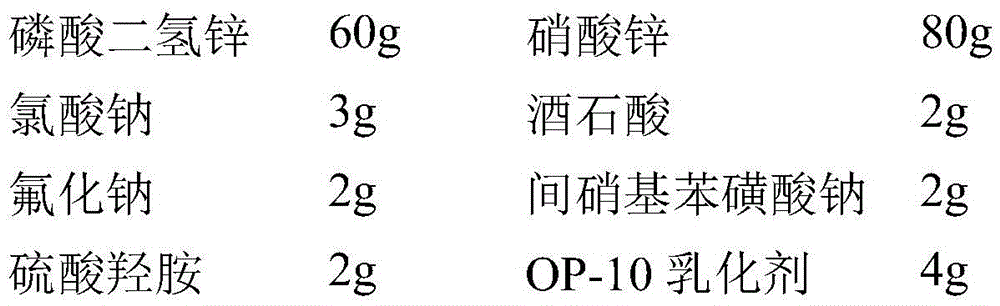

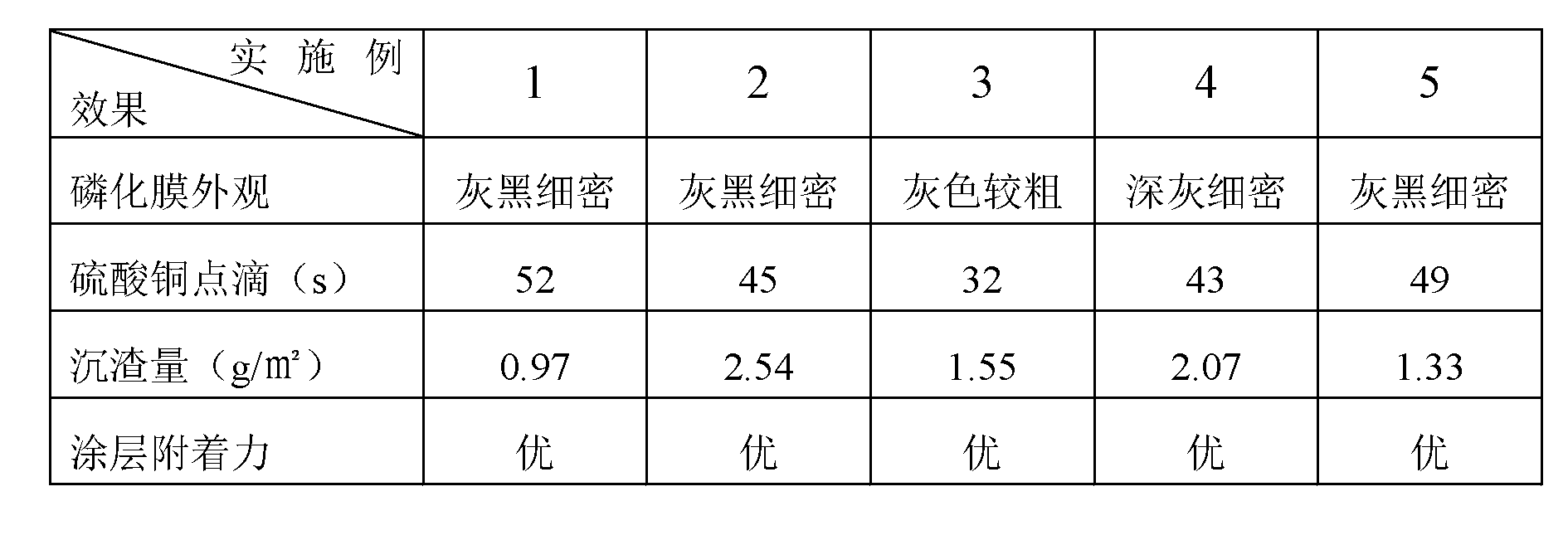

The invention relates to a normal-temperature phosphating solution forming a phosphating film highly resistant to corrosion, a preparing method and a phosphating technology. The phosphating solution comprises 40-60 g / L of dihydric phosphate, 60-80 g / L of nitrate, 2-4 g / L of chlorate, 1-2 g / L of nitrophenol compound, 1-3 g / L of hydroxylamine sulphate, 1-3 g / L of organic acid complexing agent, 1-2 g / L of sodium fluoride, 2-4 g / L of surfactant and the balance water. By means of the phosphating solution, a workpiece is soaked and subjected to spraying for 5-20 min or brushed 2-3 times at the normal temperature of 5-40 DEG C, and then the workpiece is naturally aired to obtain the phosphating film. According to the normal-temperature phosphating solution forming the phosphating film highly resistant to corrosion and the phosphating technology, the phosphating film highly resistant to corrosion can be rapidly formed at the normal temperature, and meanwhile no oil removing, rust removing and post-phosphating closing treatment is needed. The phosphating technology is simplified, the phosphating efficiency is improved, the cost is reduced, the formed phosphating film is even and dense, and higher corrosion resistance is achieved.

Owner:CENT IRON & STEEL RES INST +1

Low-temperature single-component zinc series phosphating solution and preparation method thereof

InactiveCN102703889AFast film formationImprove corrosion resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a low-temperature single-component zinc series phosphating solution and a preparation method thereof. The low-temperature single-component zinc series phosphating solution comprises the components of 5-9 g / L of zinc oxide, 12.5-30 g / L of phosphoric acid, 3-6.2 g / L of nitric acid, 0.3-1 g / L of nickel nitrate, 0.5-1.5 g / L of sodium m-nitrobenzenesulfonate, 1.5-2.5 g / L of sodium chlorate, 1-2.5 g / L of hydroxylamine sulphate, 1-2 g / L of citric acid, and the balance of water. According to the invention, sodium chlorate, hydroxylamine sulphate and sodium m-nitrobenzenesulfonate are used together as a compound accelerator, and the characteristics of the three accelerators are brought into full play, so that the prepared phosphating solution is stable, the sediment weight is light, and the performance of the phosphate film is good. The low-temperature single-component zinc series phosphating solution has the advantages of convenience in use, less difficulty in control technique, high speed of film formation, wide applications and simple preparation method.

Owner:武汉永正科技发展有限公司

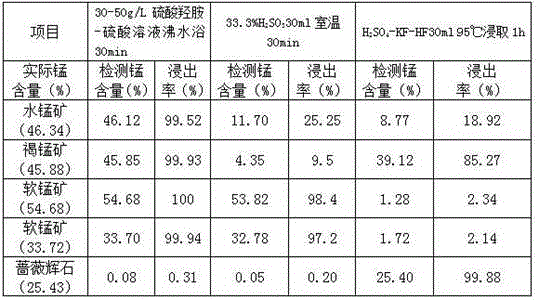

Manganese ore phase analyzing method

InactiveCN105866387AImprove accuracySolve the problems of large error, serious series phase and low efficiencyPreparing sample for investigationEarth material testingHydrofluoric acidPerchloric acid

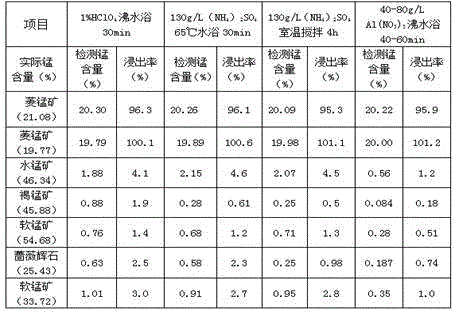

The invention relates to an analysis determination method for specific compounds in ore, in particular to a manganese ore phase analyzing method. The manganese ore phase analyzing method is characterized in by comprising the following steps that firstly, manganese ore is weighed and smashed; secondly, an aluminum nitrate aqueous solution is added into the smashed manganese ore, extracting and filtering are carried out, filter residues are collected, and the manganese carbonate ore phase of filter liquor is determined; thirdly, a hydroxylamine sulphate and sulfuric acid solution is added into the filter residues collected in the second step, extracting and filtering are carried out, filter residues are collected, and the manganese oxide ore phase of filter liquor is determined; fourthly, the filter residues obtained the third step are ashed, mixed acid including nitric acid, hydrofluoric acid and perchloric acid is added for dissolving the ashed filter residues, and the manganese ore phase is determined. The manganese ore phase analyzing method is accurate and simple, the influence of phase shifting in the extraction processes is greatly relieved, the accuracy of an analyzing result is improved, and the problems that in a traditional manganese ore phase analyzing method, errors are large, phase shifting is serious, and efficiency is low are solved.

Owner:SHANDONG INST OF GEOLOGICAL SCI

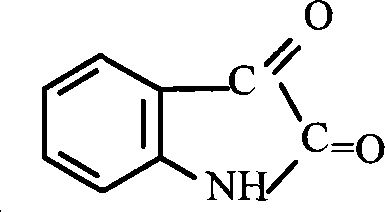

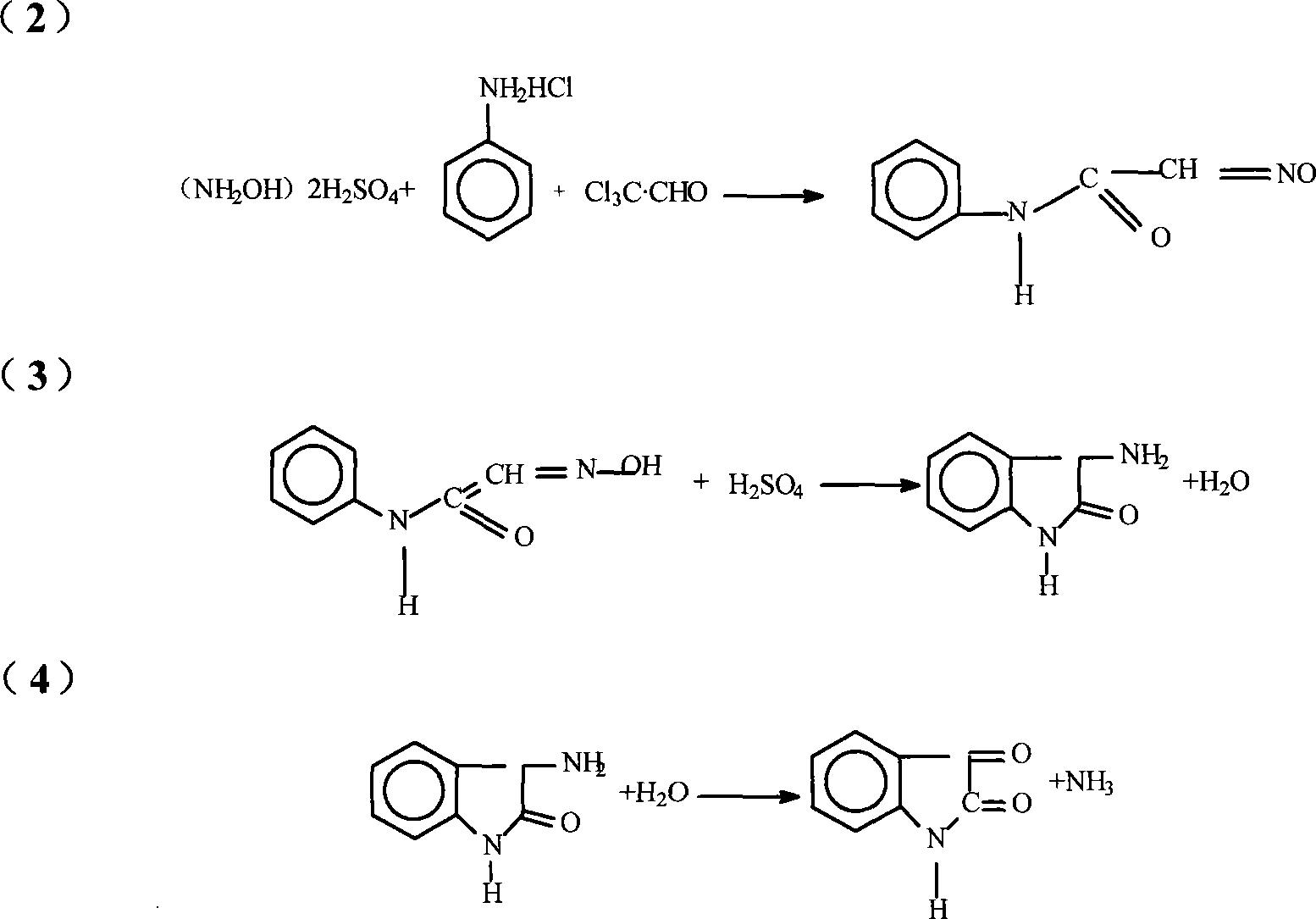

Method for preparing isatin

The invention relates to a preparative method for isatin, including the procedures as follows: compounding hydroxylamine sulphate; utilizing the hydroxylamine sulphate to synthesize oximido antifebrin; carrying out cyclization reaction and deamination reaction for the oximido antifebrin to product the coarse product of the isatin; and refining the coarse product of the isatin to obtain the isatin product, wherein, sodium nitrite, carbonate and supercarbonate of alkali metal and sulfur dioxide are adopted as the raw materials to synthesize the ydroxylamine sulphate. Te alkali metal is kalium or natrium. The isatin product produced by the method disclosed in the present invention has the advantages of high purity and good quality.

Owner:XIANGSHUI HENRYDA TECH CHEM

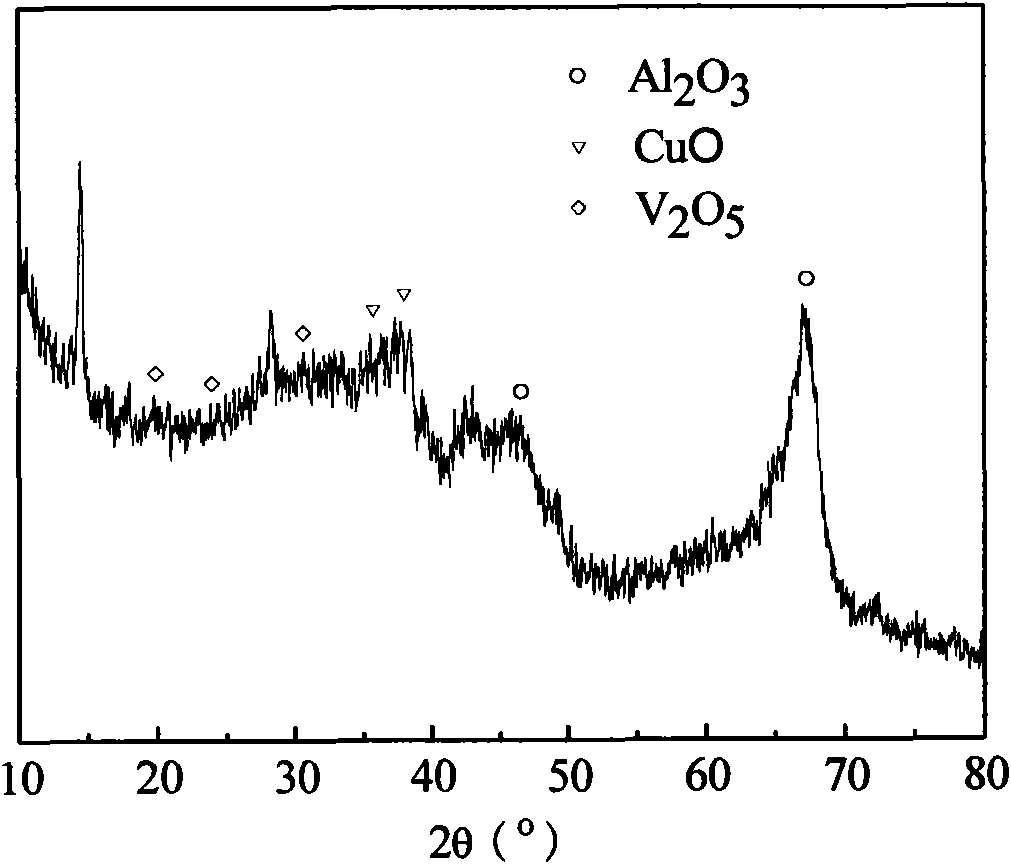

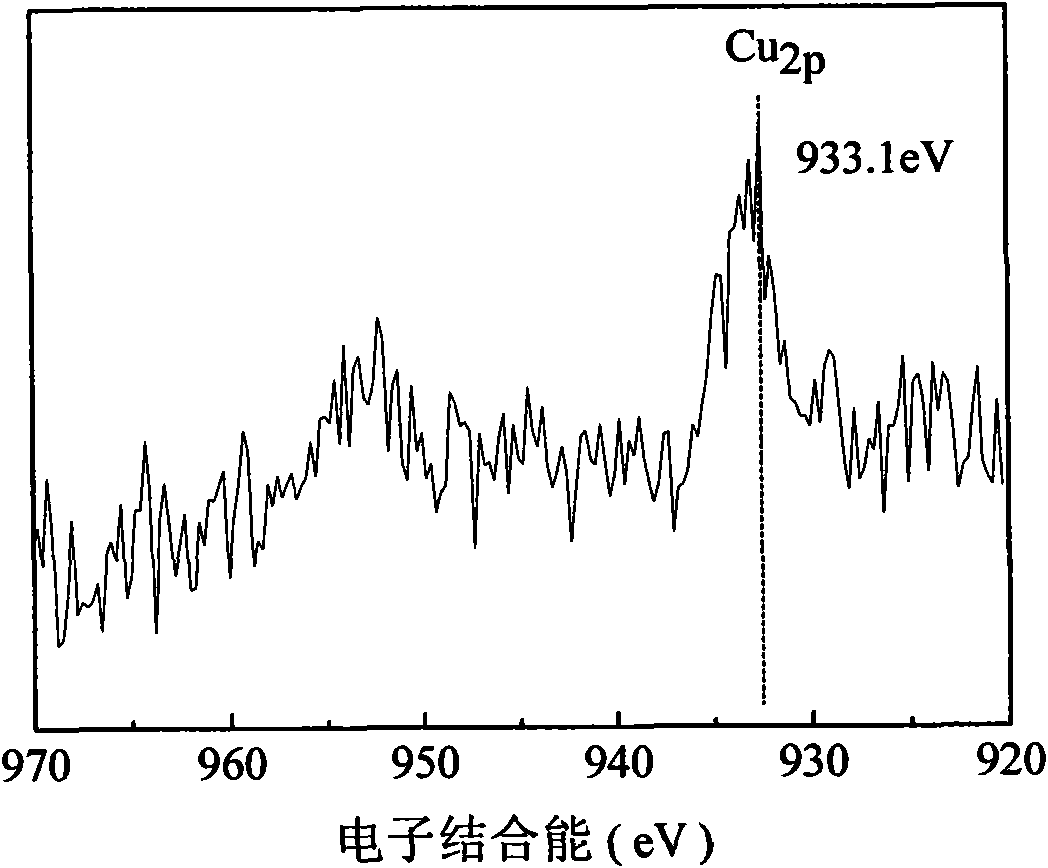

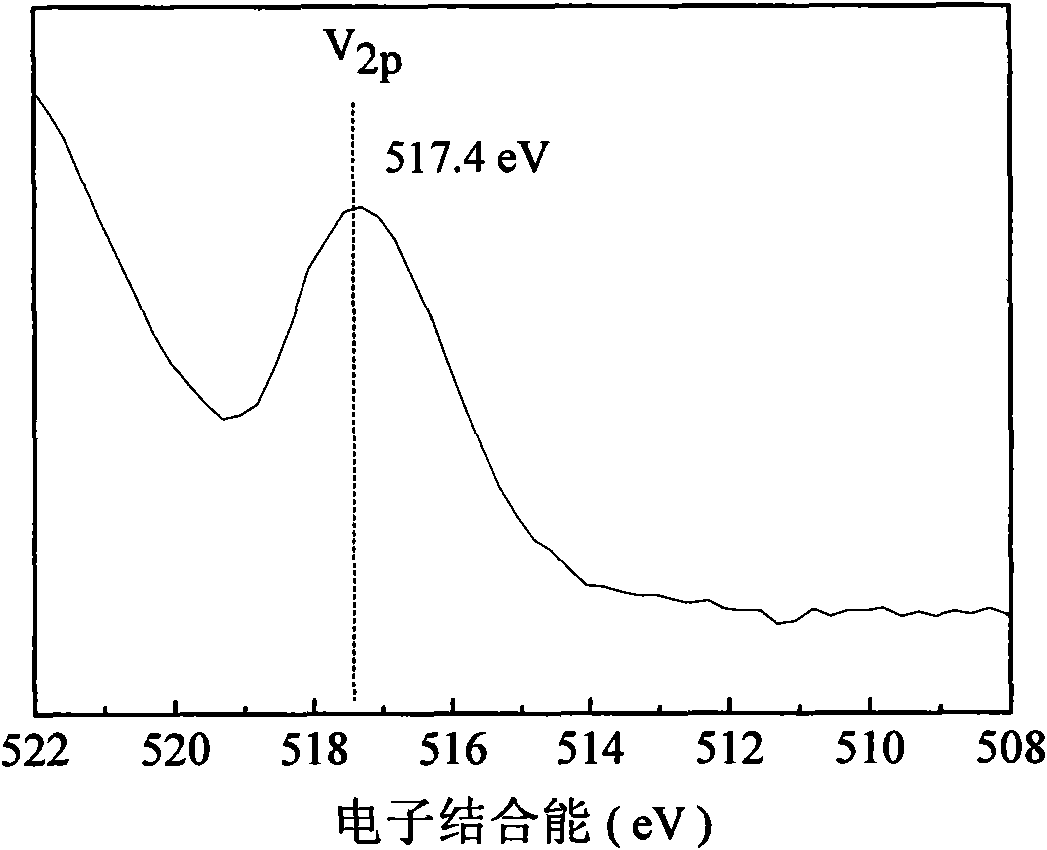

Catalyst for synthesizing methylaniline from methylbenzene by one step and preparation method thereof

InactiveCN101837293AReduce usageReduce weight ratioMolecular sieve catalystsAmino preparation by hydrogen substitutionMolecular sieveMethylaniline

The invention belongs to the technical field of catalysis, in particular to a catalyst for synthesizing methylaniline from methylbenzene by one step. The catalyst consists of active ingredients and a carrier, wherein the active ingredients are CuO and V2O5; the molar ratio of the CuO to the V2O5 is 0.1-2:1; the carrier is silicon oxide, titanium oxide, alumina or a molecular sieve; and the load of the active ingredients CuO and V2O5 is 5 to 32 percent, wherein the load refers to the weight percentage of the active ingredients CuO and V2O5 in the integral supported catalyst. Compared with the conventional catalyst for amination of methylbenzene, the catalyst prepared by the method has low consumption; in the implementation, the weight ratio of the catalyst to a raw material hydroxylamine sulphate is reduced to be 1:8.2, the catalyst has good activity, and the conversion rate of the methylbenzene and the yield of the methylaniline are respectively 66.23 percent and 61.22 percent; and the preparation process for the catalyst is simple and the raw materials are readily available.

Owner:HEBEI UNIV OF TECH

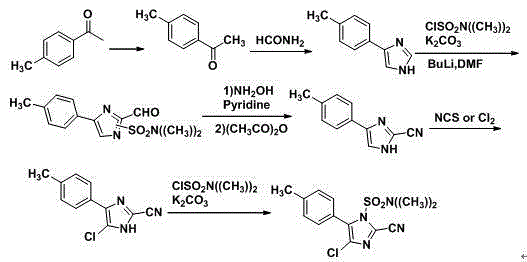

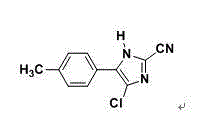

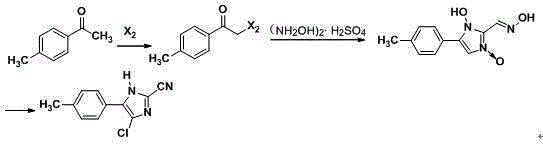

Synthetic method for 2-cyano-4-chloro-5-(4-methylphenyl)imidazole

The invention relates to a synthetic method for 2-cyano-4-chloro-5-(4-methylphenyl)imidazole. The synthetic method comprises the following steps: (1) by taking p-methylacetophenone as a raw material, carrying out a halogenating reaction under a light condition to obtain a compound I; (2) dissolving the obtained compound I in a solvent, stirring the mixture to react at a certain temperature, and performing cooling and suction-filtering to obtain a compound II; (3) dissolving the obtained compound II in a solvent and carrying out a reaction with glyoxal and hydroxylamine sulphate at a certain temperature to obtain a compound III; and (4) dissolving the obtained compound III in a solvent, carrying out a reaction with sulfoxide chloride in an ice bath in a manner of raising the temperature to room temperature and keeping the temperature for the reaction, dropwise adding sulfur chloride, and after reaction, washing the product to obtain a compound IV which is 2-cyano-4-chloro-5-(4-methylphenyl)imidazole. The synthetic method is good in atom economy, simple and convenient in process operation and high in product yield and industrial application value.

Owner:RUDONG ZHONGYI CHEM

Normal-temperature non-slag phosphating solution used before electrophoresis of galvanized steel sheet for automobile and preparation method of normal-temperature non-slag phosphating solution

ActiveCN105369238AObserve the sheddingReduce pollutionElectrophoretic coatingsMetallic material coating processesSulfonateElectrophoresis

The invention discloses a normal-temperature non-slag phosphating solution used before electrophoresis of a galvanized steel sheet for an automobile and a preparation method of the normal-temperature non-slag phosphating solution and belongs to the technical field of metal surface treatment. The phosphating solution comprises 1.6%-1.8 g / L of ZnO, 3.5%-4.5 g / L of Ni(No3)2.6H2O, 1.0-1.4 g / L of hydroxylamine sulphate, 0.1-0.2 g / L of Na2MoO4.2H2O, 1.1-1.3 g / L of C6H8O7, 4-6 g / L of NaNO3, 0.8-1.6 g / L of a 40 wt% H2ZrF6 solution, 9-11 g / L of a 50 wt% Mn(NO3) 2.4H2O solution, 19-22 g / L of a 85 wt% H3PO4 solution, 0.01-0.02 g / L of a Cu(NO3)2.3H2O solution, 0.3-0.5 g / L of polyvinyl alcohol, 0.7-0.9 g / L of sodium 3-nitrobenzene sulfonate, 2.5-4.0 g / L of a 60% H2TiF6 solution, and the balance water. The non-slag phosphating solution can be used at the normal temperature and is long in service life and low in use cost.

Owner:羊芳

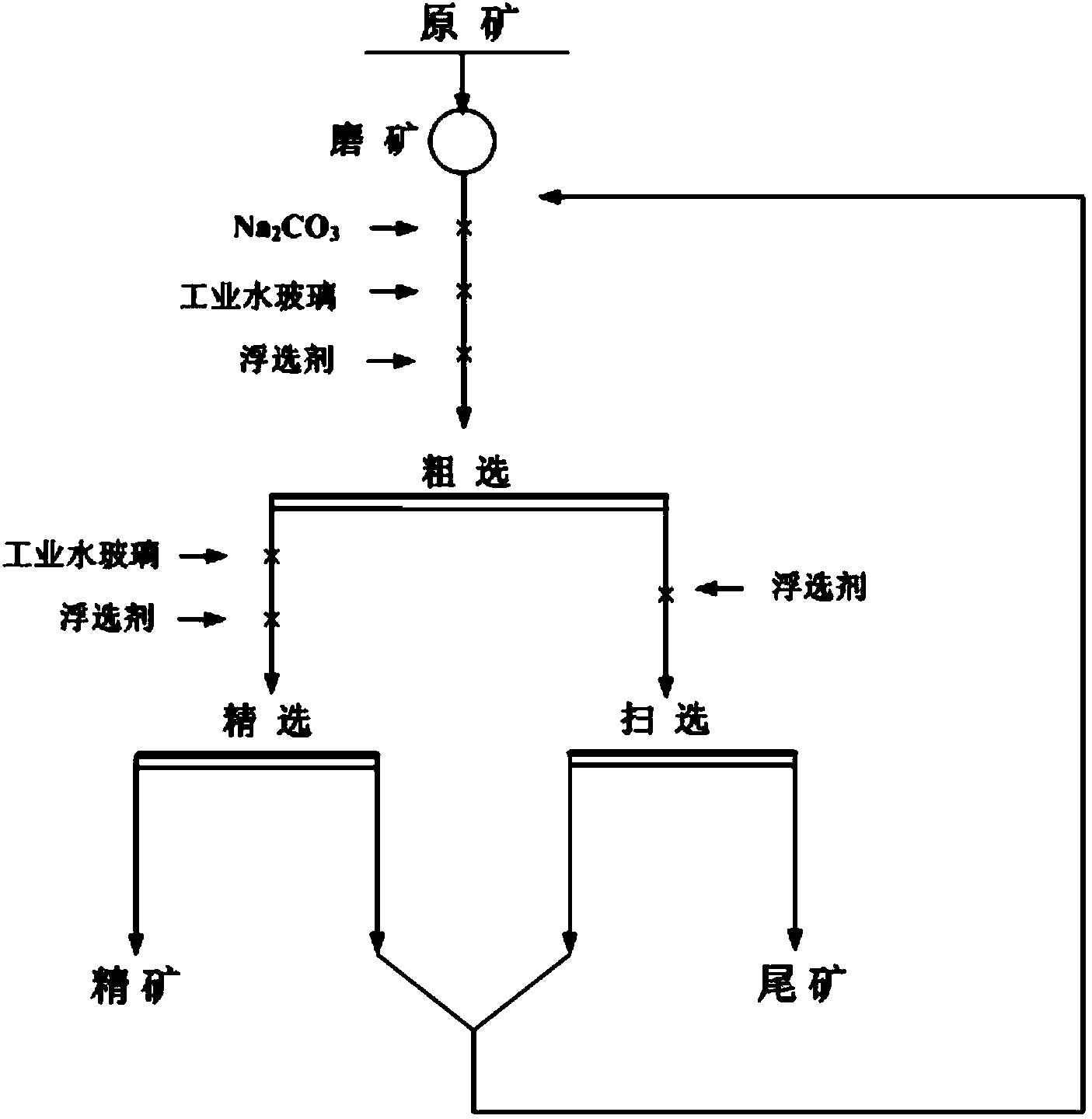

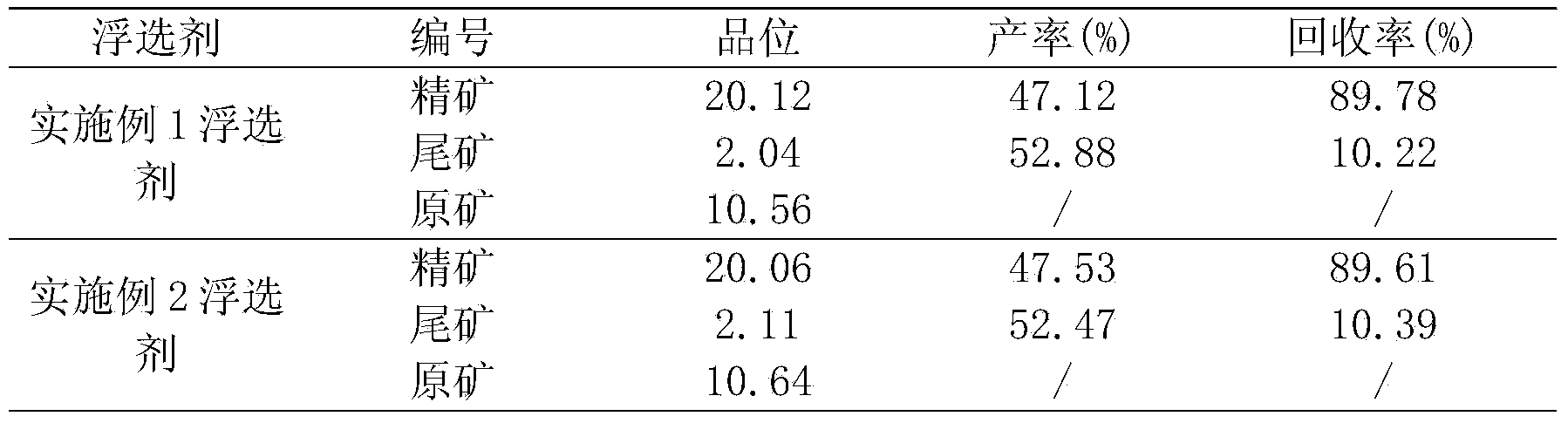

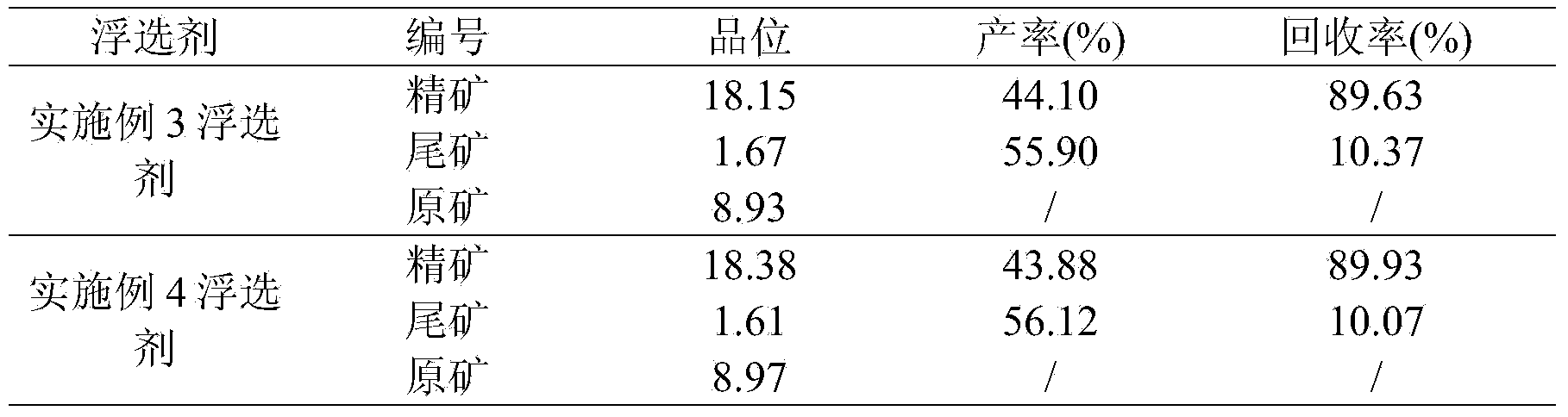

Manganese carbonate ore floatation agent and floatation method

The invention provides a manganese carbonate ore floatation agent and a flotation method. The floatation agent is prepared by taking soybean oil and hydroxylamine hydrochloride or hydroxylamine sulphate as raw materials and enabling the product obtained after the soybean oil is emulsified to react with the product obtained after the hydroxylamine hydrochloride or the hydroxylamine sulphate is neutralized through the alkali. The floatation method for recycling the manganese carbonate through the floatation agent comprises the step of raw ore processing and the step of closed loop floatation. The floatation agent has good electivity for the manganese carbonate, the grade of the flotation concentrate produced by processing the low-grade manganese carbonate ore with the raw ore grade ranging from 8% to 12% through the closed loop circulation floatation technology including the steps of coarse processing, rough processing and sweeping can be improved to be more than 20%, the manganese recycling rate is larger than 85%, no inhibitors need to be added during the floatation process, and the whole production cost is obviously reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Normal-temperature phosphating solution and method for preparing same

InactiveCN102864446AGood removal effectAccelerated corrosionMetallic material coating processesCrazingPhosphoric acid

The invention provides a normal-temperature phosphating solution and a method for preparing the same. The normal-temperature phosphating solution is mainly made from materials of hydroxylamine sulphate, phosphoric acid, sodium dihydrogen phosphate, fatty alcohol polyoxyethylene ether, cerous nitrate, zinc oxide, manganese phosphate and water. The preparation technology is simple and practicable, and the operation is convenient. The normal-temperature phosphating solution has competences of rust and oil fouling removing, and economizes the whole phosphating process by being combined with a sand blasting process; phosphating film after phosphating process has good anti-crazing, deformation resistant and shock resistant competences and a good combining capacity with an organic coating, and the phosphating film is a good base layer for the coating; and the normal temperature during a phosphating process is operable, the phosphating time is short, and the effect is good.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

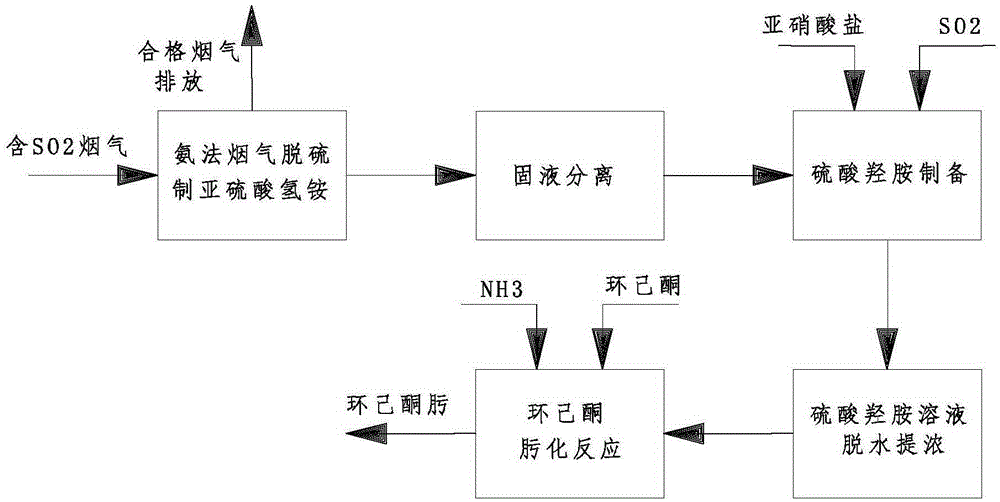

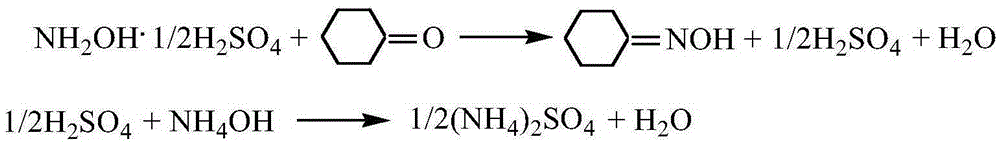

Method for producing by-product cyclohexanone-oxime through flue gas desulphurization by ammonia method

ActiveCN105348145ASolve the problem of desulfurizationIncrease added valueDispersed particle separationOximes preparationResource utilizationHydroxylamine sulphate

The invention discloses a method for producing by-product cyclohexanone-oxime through flue gas desulphurization by an ammonia method. The method comprises the following steps: ammonia or ammoniacal liquor is taken as an absorbent, sulfur dioxide in flue gas is absorbed in a flue gas absorbing tower, then ammonium bisulfite is prepared; the ammonium bisulfite is subjected to a reaction with nitrite and sulfur dioxide to prepare hydroxylamine sulphate; and the hydroxylamine sulphate and cyclohexanone are subjected to a reaction by employing a counter current oximation mode to produce cyclohexanone-oxime. The method has the advantages that SO2-containig flue gas is discharged with a standard, a sulfur resource in the flue gas and an ammonia resource in a desulfurizer can be recovered, a cyclohexanone-oxime product which has the advantages of high additional value and large product market space can be produced, high grade resource utilization of the by-product can be enhanced, waste can be changed into valuables, and economic benefit of flue gas desulphurization by the ammonia method can be increased.

Owner:SINOPEC NANJING ENG & CONSTR +1

Preparation method of zinc-series metal treatment fluid

ActiveCN105483681AImprove bindingFast film formationMetallic material coating processesHexamethylenetetraminePhosphate

The invention discloses a preparation method of a zinc-series metal treatment fluid, and also discloses a using method of the zinc-series metal treatment fluid. The zinc-series metal treatment fluid comprises the following raw materials in parts by weight: 80-150 parts of zinc dihydrogen phosphate, 20-40 parts of zinc oxide, 15-40 parts of a phosphoric acid and nitric acid mixed solution, 10-30 parts of calcium nitrate, 2-5 parts of manganese carbonate, 2-4 parts of sodium fluorosilicate, 1-4 parts of hydroxylamine sulphate, 3-6 parts of a triazole compound, 2-3 parts of sodium citrate, 5-15 parts of a polyphosphate, 1-3 parts of sodium fluoride, 1-2 parts of ammonium peroxydisulfate, 5-10 parts of sodium molybdate, 1-3 parts of hexamethylenetetramine, 3-5 parts of sodium trimetaphosphate, and 2-4 parts of nickel sulfate.

Owner:广东志远环保设备有限公司

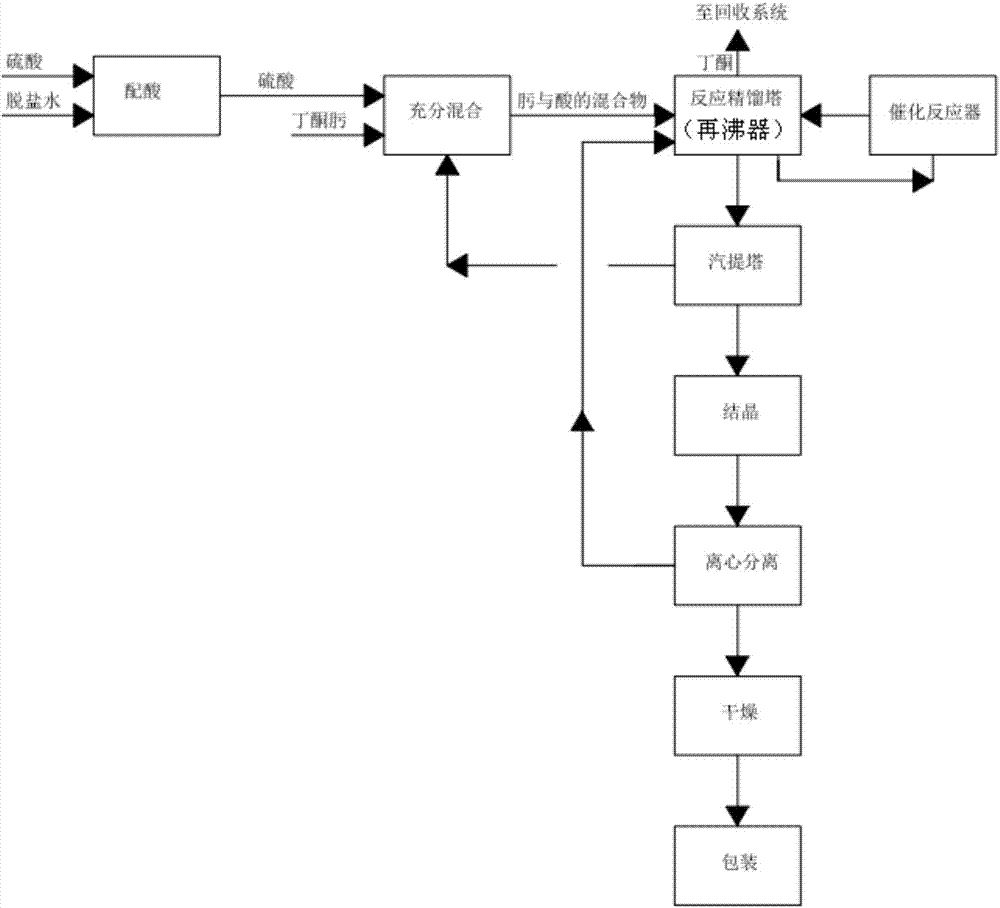

Preparation method of hydroxylamine sulphate

ActiveCN107539966AEasy to handleImprove qualityPhysical/chemical process catalystsHydroxylamineOrganic matterSolution flow

The invention discloses a preparation method of hydroxylamine sulphate. The preparation method comprises the following steps: 1), evenly mixing the raw materials of an acid solution and oxime, rectifying in a reaction rectifying column, obtaining a mixed solution of hydroxylamine sulphate and unreacted oxime and acid in a column reactor; 2), conveying part of the mixed solution obtained in the column reactor to a stripping tower through a pump, stripping to remove an organic matter and part of water, conveying part of the mixed solution to a reactor filled with a catalyst to have a further reaction; enabling a liquid material obtained in the reaction to return to the column reactor of the rectifying column, and enabling a gaseous phase to return to the upper middle part of the rectifying column; 3), crystalizing a concentrated hydroxylamine sulphate solution flowing out from a tower kettle of the stripping tower, separating the liquid and the solid, and drying to obtain hydroxylamine sulphate.

Owner:江苏艾科维科技股份有限公司

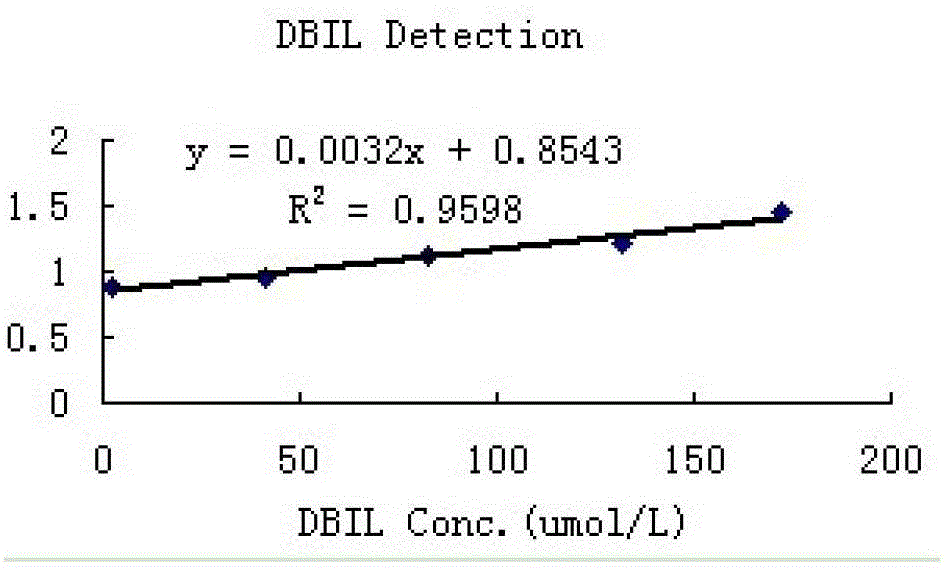

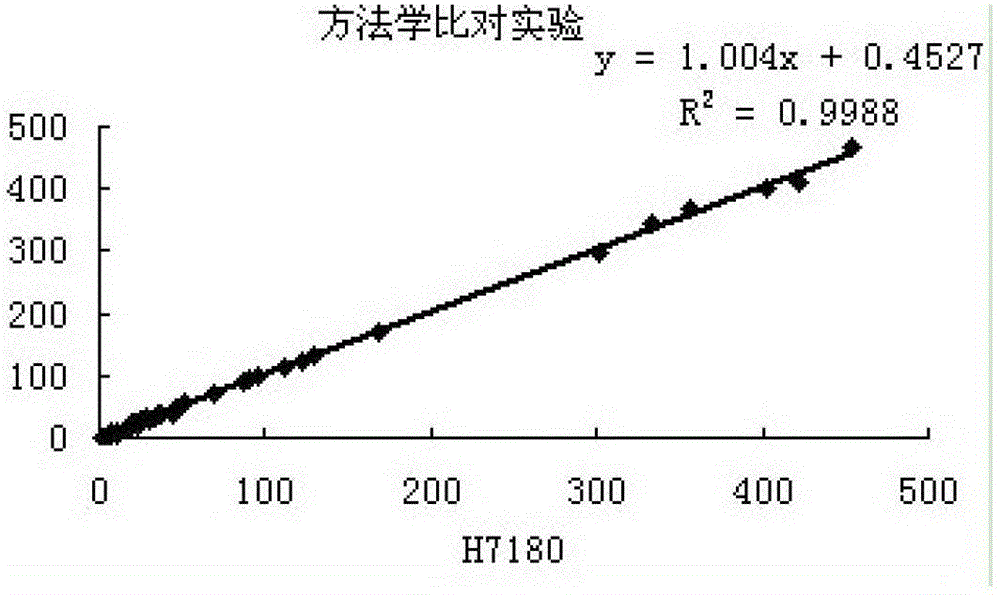

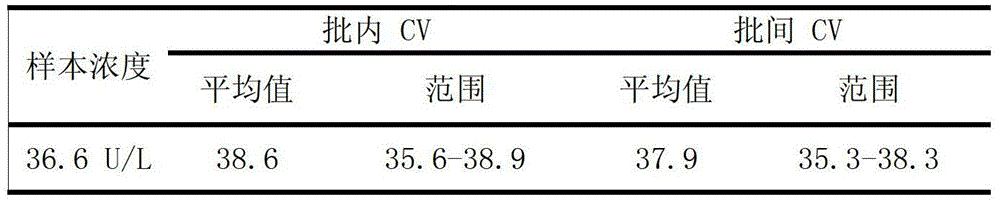

Direct bilirubin detection reagent

ActiveCN103333945AHigh sensitivityImprove accuracyMicrobiological testing/measurementColor/spectral properties measurementsVitamin CFreeze-drying

The invention discloses a direct bilirubin detection reagent. The direct bilirubin detection reagent comprises diluents and reaction reagents. The diluents comprise a buffer 1, a surfactant, an antiseptic and ascorbate oxidase. The reaction reagents comprise a buffer 2, common salt, disodium ethylene diamine tetraacetate, hydroxylamine sulphate, etidronic acid, sodium persulfate, sulfuric acid, an antiseptic and a freeze-drying protective agent. The direct bilirubin detection reagent has good sensitivity, accuracy, precision and linearity and can satisfy clinical examination requirements.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

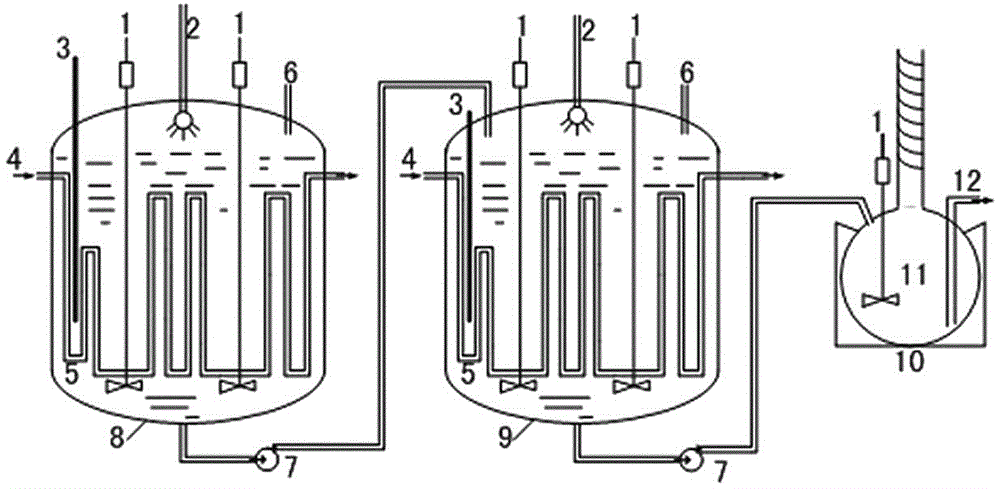

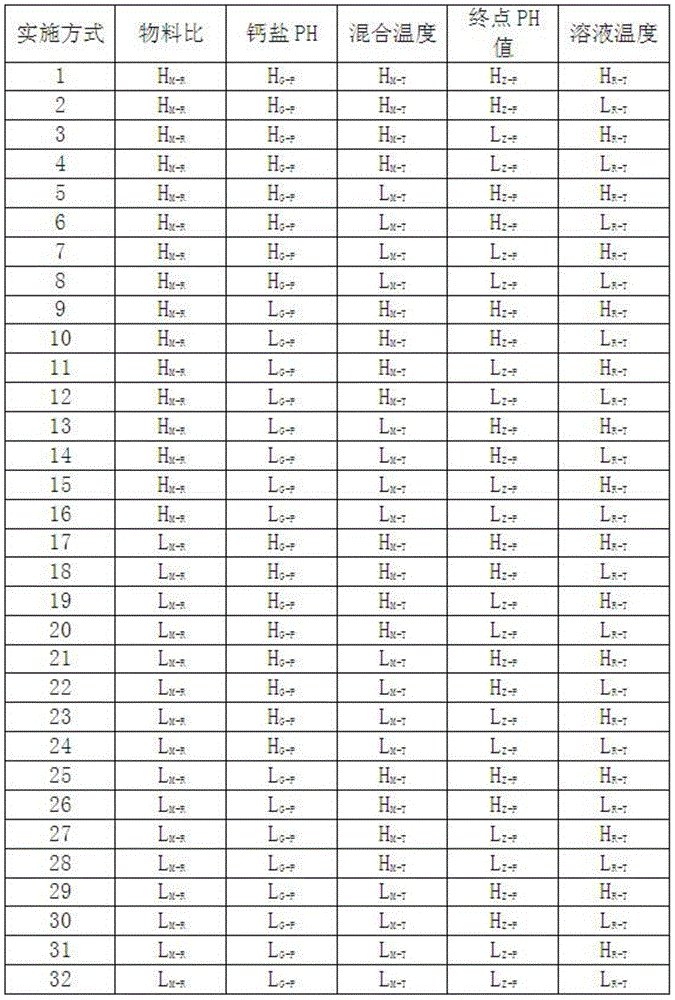

Preparation method of hydroxylamine sulphate and devices used in preparation method

ActiveCN105731400AAchieve recyclingRaw materials are cheap and easy to getHydroxylamineChemical/physical/physico-chemical stationary reactorsNitriteFlue gas

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

Method used for recycling sulfur and nitrogen resources from flue gas and producing hydroxylamine sulphate

InactiveCN107349771AReduce manufacturing costTurn waste into treasureGas treatmentUsing liquid separation agentLiquid wasteHydroxylamine

The invention discloses a method used for recycling sulfur and nitrogen resources from flue gas and producing hydroxylamine sulphate. The method comprises following steps: 1, boiler fuel gas is subjected to pre-dedusting and then spray cooling dedusting, after spray cooling dedusting, the flue gas is mixed with an oxidizing agent for oxidation, after oxidation, the flue gas is delivered into an absorbing tower for circulating spray and synchronous desulphurization and denitration, so that flue gas purifying is realized, and an absorption liquid containing SO4<2-> and NO2<-> is obtained; 2, the absorption liquid is discharged, and is used for spray cooling dedusting of flue gas, wherein NO2<-> in the absorption liquid is reacted with SO2 in flue gas, and a sulfur nitrogen compound absorption waste liquid is obtained; and 3, the sulfur nitrogen compound absorption waste liquid is subjected to defouling and purifying so as to obtain a hydroxylamine disulfonate solution, and the hydroxylamine disulfonate solution is subjected to hydrolysis at 95 to 110 DEG C so as to obtain a hydroxylamine sulphate solution, and separation and purification are carried out so as to obtain hydroxylamine sulphate solid. The method is capable of solving nitrite waste water problems in wet synchronous desulphurization and denitration, realizing recycling of sulfur and nitrogen resources in flue gas, and producing hydroxylamine sulphate which is relatively high in economical value.

Owner:ZHEJIANG UNIV

Preprocessing method of magnesium alloy electro-coating technology

InactiveCN103469282AImprove organizational structureImprove anti-corrosion performanceElectrophoretic coatingsMetallic material coating processesPretreatment methodNickel salt

The invention discloses a preprocessing method of the magnesium alloy electro-coating technology. The preprocessing method comprises the step of carrying out phosphating processing on a magnesium alloy workpiece in a phosphating solution. The formula of the phosphating solution comprises the components of 15-20g / L of zinc oxide, 10-15ml / L of phosphoric acid, 3-5g / L of sodium fluoride, 10-12g / L of sodium nitrate, 2-3g / L of ammonium molybdate, 4-8g / L of hydroxylamine sulphate, and 4-5g / L of lauryl sodium sulfate. The PH value of the phosphating solution is 3-5, the temperature of the phosphating solution is 40-50DEG C, the phosphating time is 15-20 minutes, and 2-3g / L of nickel nitrate and 4-8g / L of manganous nitrate are further added into the phosphating solution. According to the preprocessing method, when phosphating processing is carried out on the magnesium alloy workpiece, the nickel salt and the manganese salt are added in the phosphating solution, therefore, the tissue structure of a phosphating film is effectively improved, the follow-up electro-coating technology is optimized, and the film obtained through the electro-coating technology has the excellent corrosion resistance.

Owner:昆山纯柏精密五金有限公司

Fast chemical reduction gold plating solution and application method thereof

InactiveCN109207971AFast depositionMaintain stabilityLiquid/solution decomposition chemical coatingTin platingPolyethylene glycol

The invention belongs to the technical field of chemical gold plating and particularly relates to a fast chemical reduction gold plating solution and an application method thereof. The fast chemical reduction gold plating solution comprises the following density components: 0.5-1.5 g / L of a water-soluble gold compound ( in Au), 5-20 g / L of sodium hypophosphite, 1-5 g / L of hydroxylamine sulphate, 25-55 g / L of ammonium citrate tribasic, 5-15 g / L of ethylene diamine tetraacetic acid disodium, 0.1-3.0 g / L of amino acid, 0.001-0.02 g / L of thiol-polyethylene glycol, 0.001-0.02 g / L of alkyl pyridinebromide, 0.001-0.005 g / L of ligninsulfonate, 0.01-0.1 g / L of borane dimethylamine and 0.01-0.3 g / L of tartaric germanium. The gold plating solution is excellent in stability and high in deposition rate. An obtained gold plating layer is smooth, uniform, bright and compact in surface and has better corrosion resistance and tin plating backflow and gold line forming performance.

Owner:南雄市溢诚化工有限公司

Pulpy dye composite for dyeing island superfine nylon/ polyurethane synthetic leather

InactiveCN101985809AHigh color fastnessSolve the color flower problem of vat dye leucosome dyeingDyeing processDisperse dyePhosphate

The invention relates to a pulpy dye composite for dyeing island superfine nylon / polyurethane synthetic leather. The pulpy dye composite comprises three parts, namely a penetrating agent, a plastic swelling agent and a dye solubilizing agent, wherein the penetrating agent comprises N-decyl azone, N-isooctyl pyrrolidone, triamyl phosphate, sulphobetaine, triethylene glycol methyl ether (TGME), dipropylene glycol diethyl ether, dimethyl valnoctamide and water; the plastic swelling agent comprises N-isopropyl phthalimide, N-(n-butyl)phthalimide and alkyl naphthalene polyoxyethylene ether phosphate; and the dye solubilizing agent comprises thiourea oxide, hydroxylamine sulphate and N-ethoxyl sulfinic salt. The preparation of the dye composite comprises dyeing, adjusting a dye bath, converting, reducing the temperature and draining liquid. The dye composite has the beneficial effects that the color fastness is better than the color fastness of the dyeing with disperse dye and acidic dye; and the staining fastness on multiple groups of fiber is especially enhanced by one level or more than one level.

Owner:SHANGHAI QUALITY TEXTILE CHEM CO LTD +1

Preparation method of high-purity solid hydroxylamine sulphate

The invention discloses a preparation method of high-purity solid hydroxylamine sulphate. The preparation method of the high-purity solid hydroxylamine sulphate comprises the following steps: adding a 5-15% hydroxylamine sulphate aqueous solution into a first reactor, mixing the hydroxylamine sulphate aqueous solution with 18-23% ammonia water, controlling the temperature of the first reactor to 20-30 DEG C, and regulating the pH value of the solution to 5.8-6.5, so that a first reaction product is obtained; fully mixing an extracting agent, a diluter and a stabilizer in a volume ratio of 1:(3-3.5):(0.001-0.002), putting the obtained mixture into a second reactor, regulating the pH value to 7.0-7.8 by adopting 18-23% ammonia water, and controlling the temperature of the second reactor to 20-30 DEG C, so that a second reaction product is obtained; carrying out extraction, concentration, cold crystallization, centrifugation and vacuum drying on the first reaction product and the second reaction product, so that the target product high-purity solid hydroxylamine sulphate is obtained. The preparation method of the high-purity solid hydroxylamine sulphate has the advantages of simple temperature, mild reaction conditions, high yield and low cost.

Owner:QUZHOU JUHUA POLYAMIDE FIBER

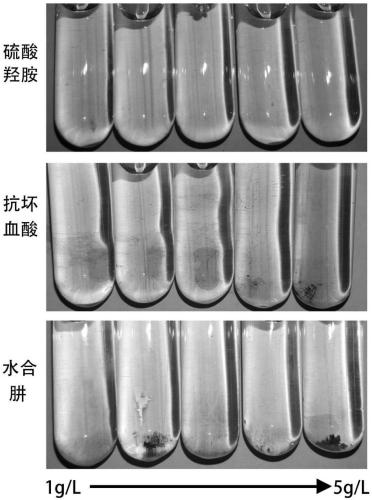

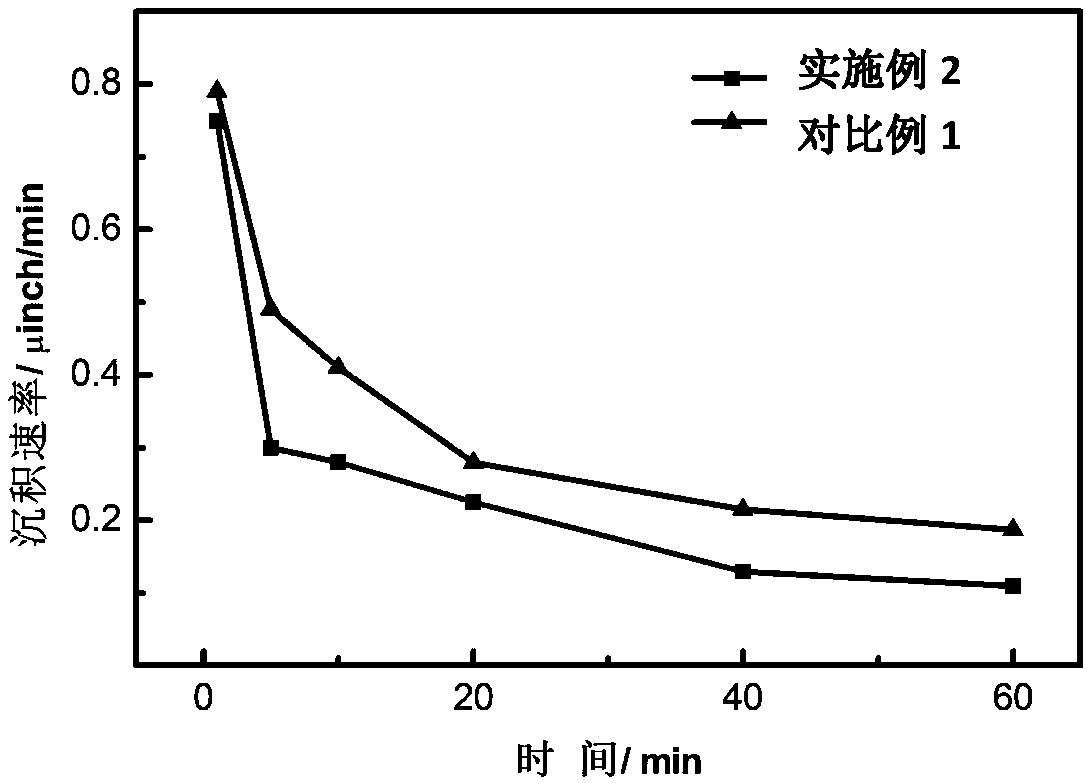

Foam sorting activator and application thereof

ActiveCN112246445AImprove hydrophobicityPlay a role in reduction modificationFlotationActive agentHydroxylamine sulfate

The invention discloses a foam separation activating agent, which comprises the following components in parts by weight: 0-10 parts of a soluble copper salt, 5-200 parts of an ammonium / amine salt and1-100 parts of a reducing active agent, wherein the soluble copper salt is selected from at least one of copper sulfate, copper nitrate, copper chloride or copper carbonate, the ammonium / amine salt isselected from at least one of ammonia water, ammonium carbonate, ammonium sulfate, ammonium chloride, diamine hydrogen phosphate, ammonium humate or ethylenediamine phosphate, and the reducing activeagent is selected from at least one of ascorbic acid, hydrazine hydrate, hydroxylamine hydrochloride or hydroxylamine sulfate. The foam separation activating agent is high in activating efficiency, stable and firm in activating effect, good in hydrophobicity of activated materials and high in flotation rate, can effectively improve the foam sorting capacity of the to-be-activated materials, and achieves the efficient foam separation and recycling of target components in the materials.

Owner:CHINA ENFI ENGINEERING CORPORATION

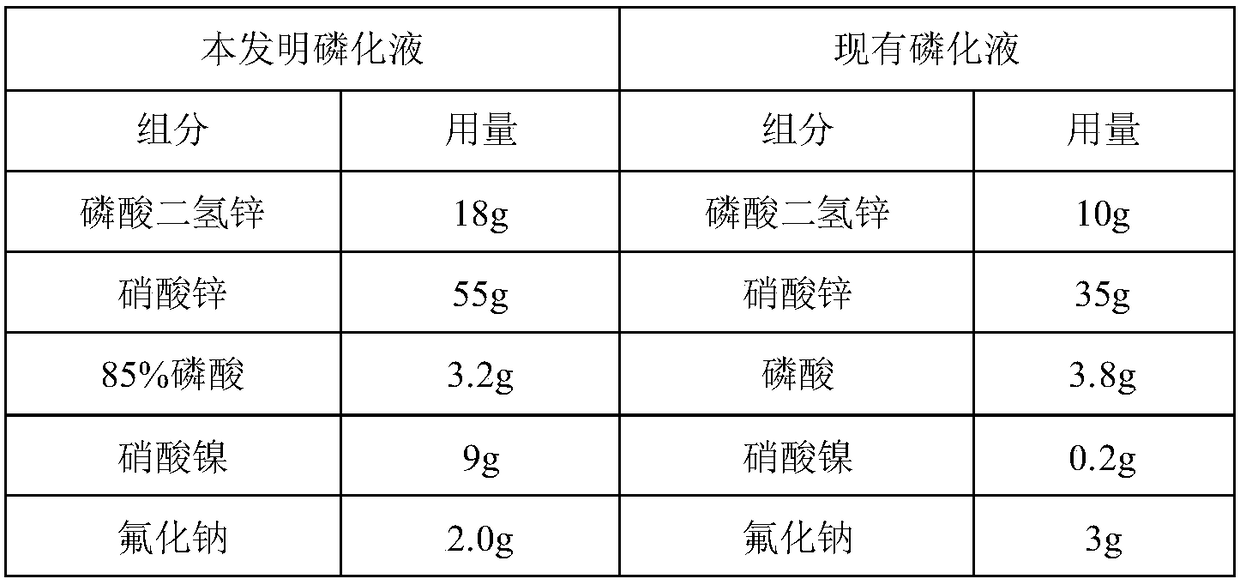

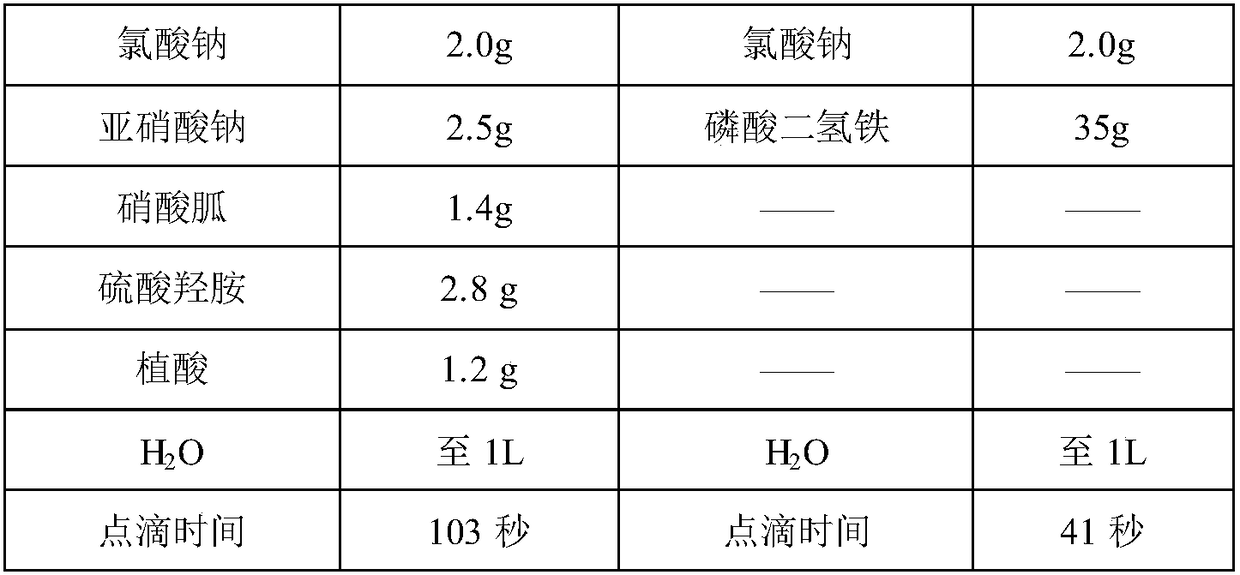

Phosphating solution and phosphating method for aluminum alloy surface treatment

InactiveCN109280912ASimple processEasy to operateMetallic material coating processesPhosphatePhosphoric acid

The invention relates to the technical field of aluminum alloy surface treatment, and relates to a phosphating solution and a phosphating method for aluminum alloy surface treatment. The phosphating solution comprises the following components with the following concentrations: 17-23g / L of zinc dihydrogen phosphate, 45-60g / L of zinc nitrate, 2.5-3.5g / L of 85% phosphoric acid, 6-10g / L of nickel nitrate, 2.0-2.5g / L of sodium fluoride, 1.5-2.1g / L of sodium chlorate, 2.0-4.0g / L of sodium nitrite, 1.0-1.5g / L of guanidine nitrate, 2.5-3.5g / L of hydroxylamine sulphate, 1.0-1.5g / L of phytic acid and the balance deionized water. The phosphating method comprises the following steps: (1) carrying out pretreatment on aluminum alloy sheets; (2) placing the pretreated aluminum alloy sheets in the phosphating solution and phosphating for 10-20min at 40-50 DEG C; and (3) washing the phosphated aluminum alloy sheets by virtue of the deionized water and blow-drying the aluminum alloy sheets by virtue ofhot air. The phosphating solution and the phosphating method for aluminum alloy surface treatment are simple in process, convenient to operate, and low in treatment cost; phosphating is carried out ata low temperature, so that energy is saved; chromium is not used in the phosphating solution, so that the problem of poison of chromium to environment and human body is avoided; few sediments duringworking are achieved; and a film formed through phosphating is uniform and compact, and a film layer is high in adhesion with an aluminum alloy matrix, and high in corrosion resistance.

Owner:JIANGSU UNIV OF TECH

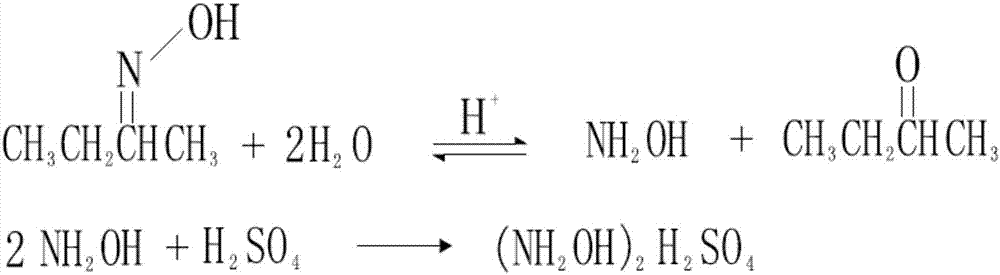

Preparation method of solid hydroxylamine sulfate

ActiveCN111285338AStrong complexing effectImprove adsorption capacityOther chemical processesOrganic compound preparationDoped grapheneHydroxylamine sulfate

The invention relates to the field of chemical engineering, and in particular, relates to a preparation method of solid hydroxylamine sulfate. According to the preparation method of the solid hydroxylamine sulfate through the reaction of sulfuric acid and diacetylmonoxime, conventional reagents are used in the method, no toxic raw material is used, the reaction process conditions are mild, the technological process is short, the production cost is low, a byproduct butanone can be generated, and the method is economical and environmentally friendly; the recyclable metal-doped graphene adsorbingmaterial is adopted, organic residues in a hydroxylamine sulfate solution can be efficiently adsorbed by utilizing a strong complexing effect between metal ions and diacetylmonoxime, and the method has the advantages of energy conservation, environmental protection and high utilization rate.

Owner:ZHEJIANG JINHUA NEW MATERIALS

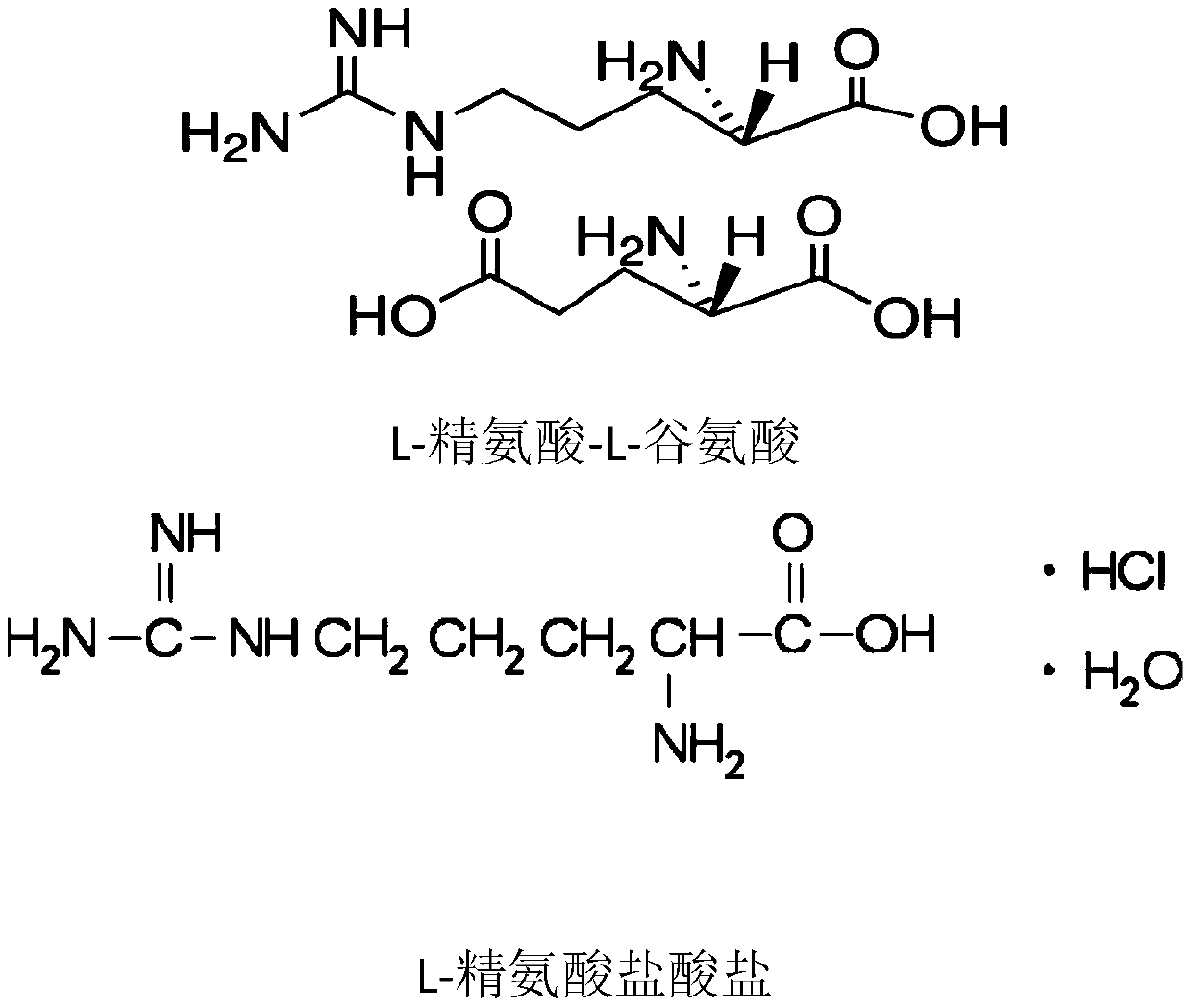

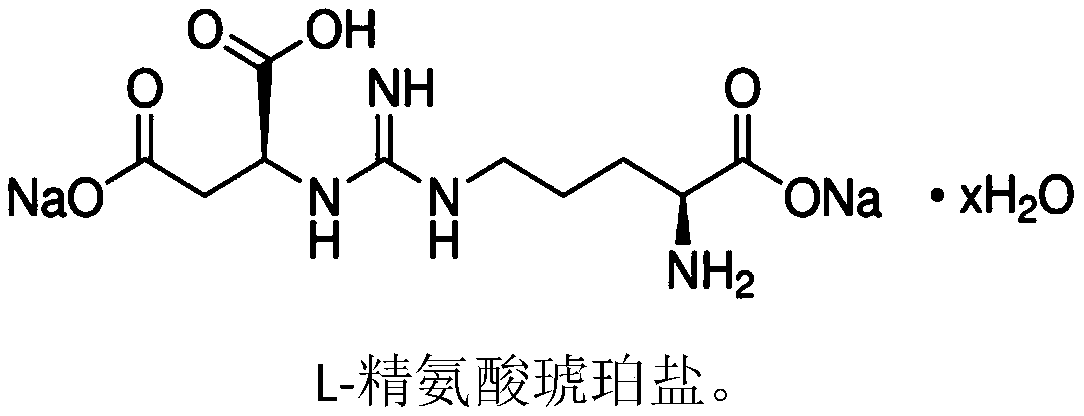

Applications of L-arginine and derivative of L-arginine in preparation of cyclododecanoneoxime, and method used for preparing cyclododecanoneoxime

ActiveCN110498748AReduce interfacial tensionReduce decomposition rateOximes preparationCyclododecanoneDecomposition

The invention discloses applications of L-arginine and a derivative of L-arginine in preparation of cyclododecanoneoxime, and a method used for preparing cyclododecanoneoxime. The derivative of L-arginine comprises one or a plurality of components selected from L-arginine-L-glutamic acid, an L-arginine hydrochloride, and an L-arginine succinate. According to the preparation method, one or more than one components selected from L-arginine and the derivative of L-arginine are taken as auxiliary agents, cyclododecanone is reacted with hydroxylamine sulphate to prepare cyclododecanoneoxime. The auxiliary agents are capable of controlling iron ion content in the reaction system, inhibiting hydroxylamine sulphate decomposition, inhibiting cyclododecylamine generation, and increasing reaction selectivity, and are convenient to separate and recycle.

Owner:WANHUA CHEM GRP CO LTD +1

Ultrasonic phosphating solution for carbon steel, preparation method thereof and method for phosphating carbon steel by adopting phosphating solution

InactiveCN104651820AImprove corrosion resistanceHas anti-fouling propertiesMetallic material coating processesPorosityCarbon steel

Owner:TIANJIN UNIV

Normal-temperature corrosion-resistant phosphating solution and preparation method thereof

InactiveCN106498380APrevent rustSimplify the phosphating processMetallic material coating processesPhosphateNitrobenzene

The invention discloses a normal-temperature corrosion-resistant phosphating solution and a preparation method thereof. The normal-temperature corrosion-resistant phosphating solution is prepared from the following raw materials in parts by weight: 35-56 parts of deionized water, 6-8 parts of sodium molybdate dehydrate, 2-7 parts of chromic acid, 5-8 parts of hydroxylamine sulphate, 4-8 parts of methyl methacrylate, 4-5 parts of sodium fluoroborate, 4-9 parts of tartaric acid, 22-24 parts of citric acid, 2-6 parts of cyclohexanehexol hexaphosphate ester, 1-8 parts of ammonium cuprate, 2-6 parts of m-nitrobenzene, 3-6 parts of sodium silicate and 6-10 parts of manganese dihydrogen phosphate. Compared with a conventional phosphating solution and a conventional phosphating process, the normal-temperature corrosion-resistant phosphating solution disclosed by the invention has the advantages that when a workpiece is subjected to phosphating by adopting the normal-temperature corrosion-resistant phosphating solution, the phosphating process is simplified, the phosphating efficiency is improved, and the phosphating cost is reduced; meanwhile, a phosphating film formed by adopting the normal-temperature corrosion-resistant phosphating solution not only is denser and more uniform, but also can be used for effectively protecting the workpiece from corrosion; and the preparation method is simple and low in cost.

Owner:JIANGSU JINGWEI TECH INNOVATION CONSULTING CO LTD

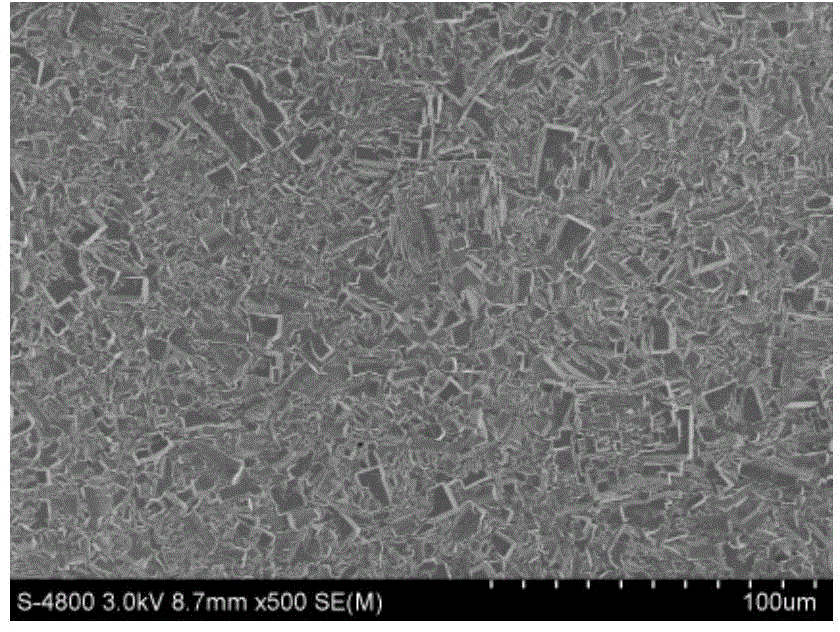

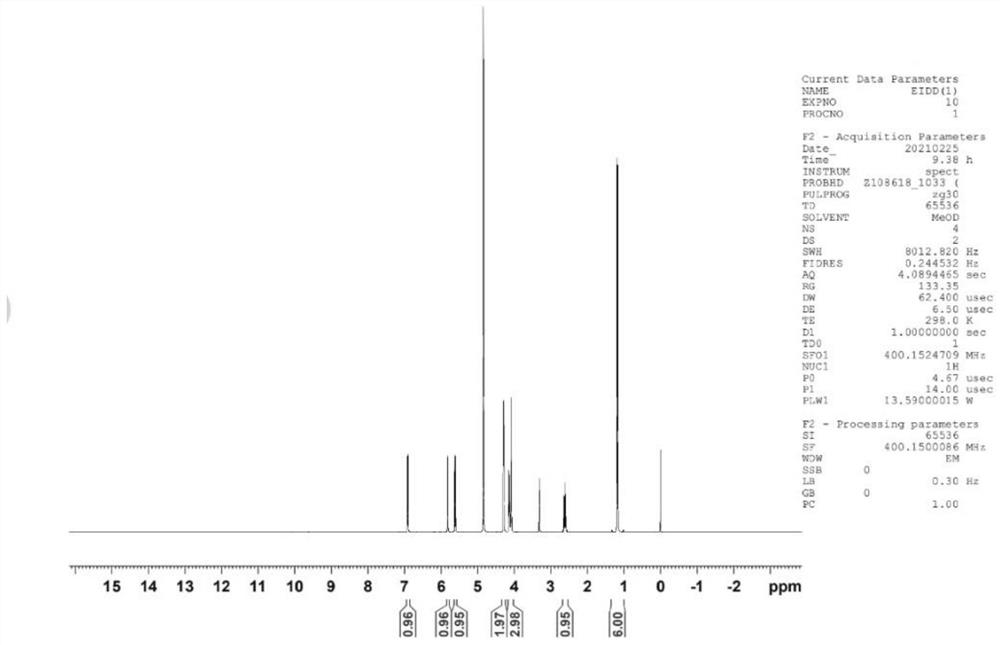

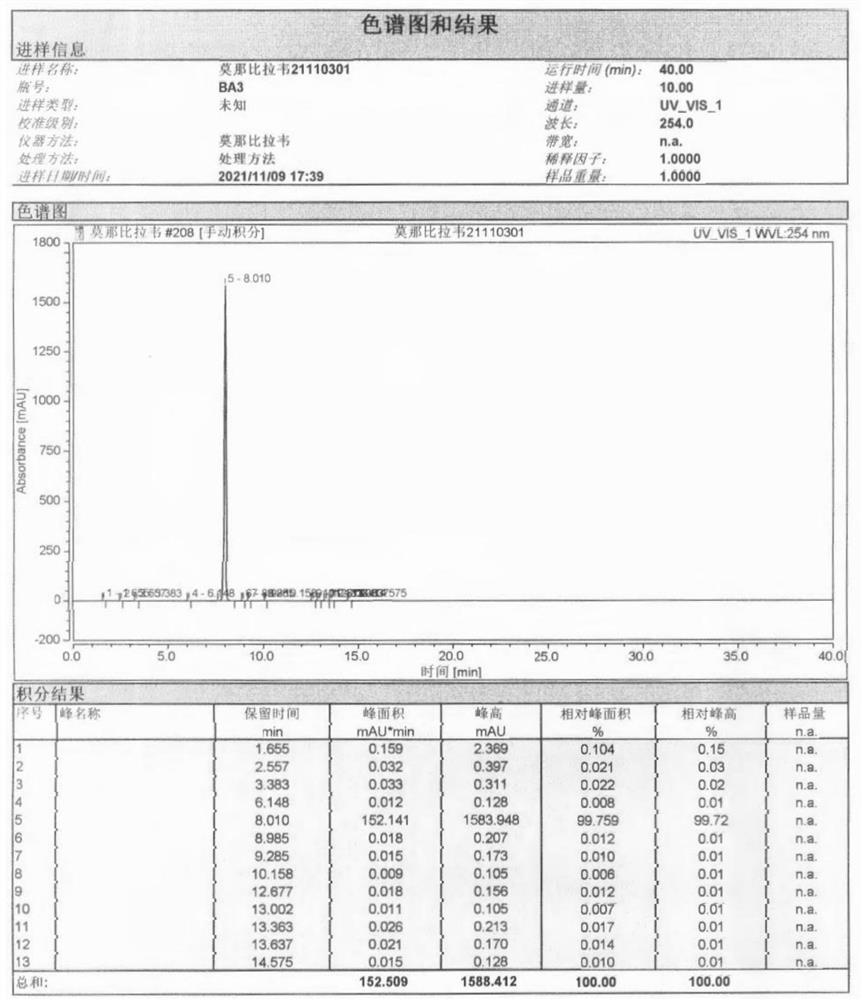

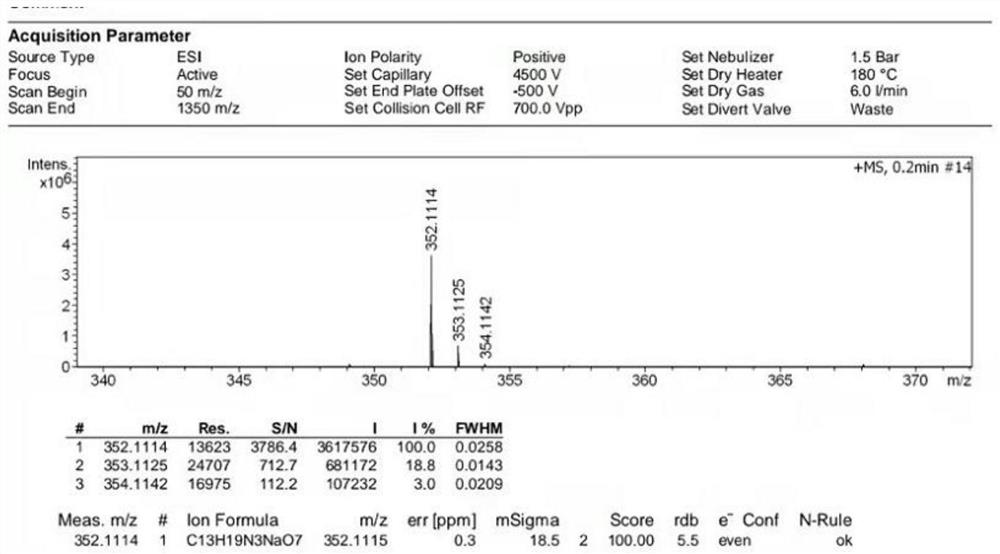

Preparation method of antiviral drug mupiravir

PendingCN114292303AReduce generationImprove route efficiencySugar derivativesAntiviralsAntiviral drugChemical compound

A preparation method of an antiviral drug mupiravir comprises the following steps: S1, synthesizing a compound 2: putting a compound 1 cytidine into a reaction container, and taking the compound 1 cytidine as a raw material; adding the solution 1 into the reaction container for replacement, and adding a protecting group DMF-DMA after three times of replacement; s2, synthesizing a compound 3; S3, synthesizing a compound 4; S4, synthesizing Molnupiravir: adding a solution 4 into a reaction system of the compound 4; the solution 4 comprises a reaction solvent and hydroxylamine sulfate; adding a pulping solvent into the intermediate 4, heating to 50 DEG C, and pulping for 30 minutes to obtain a product Molnupiravir; according to the preparation method, cytidine is taken as a starting raw material, DMF-DMA protecting groups are added, then esterification reaction, protecting group removal and hydroxyamination reaction are sequentially performed, a five-step one-pot method is realized, the route efficiency is effectively improved, the yield is increased, generation of three wastes is also effectively reduced, and the Molnupiravir with relatively high purity is obtained by finally purifying the system.

Owner:ANHUI HAIKANG PHARMA

High-efficiency preparation method of novel phosphating solution

InactiveCN103572275ASolution to short lifeLess sedimentMetallic material coating processesO-Phosphoric AcidHydroxylamine

The invention discloses normal-temperature phosphating solution free from nitrite and heavy metal; the film forming speed of the phosphating solution is rapid; phosphating film grains are rapidly refined; and the corrosion resisting property of the phosphating solution is greatly increased. The technical scheme provided by the invention is as follows: the phosphating solution is composed of six main components including phosphoric acid, zinc oxide, calcium nitrate, barium nitrate, hydroxylamine sulphate and nitric acid. The novel phosphating solution disclosed by the invention has the advantages that: the phosphating solution is free from nitrite and heavy metal; about 2 g of French grey, uniform and compact phosphating films per square metre can be generated by immersing at 5-40 DEG C and phosphating for 5-10 min; the dropping time of CuSO4-resistant solution is up to 90-140 s; the immersion time of 3% sodium chloride resistant solution is 240 min; first-stage clean phosphating production is realized; furthermore, the service life of the phosphating solution is longer; little sediment is generated; the generated phosphating film has good quality; and the novel phosphating solution disclosed by the invention can be used for coating the surface of steel.

Owner:TIANJIN JIANFA PRECISION MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com