Manganese carbonate ore floatation agent and floatation method

A technology of manganese carbonate ore and flotation agent, which is applied in flotation, solid separation and other directions, can solve the problems of complex flotation process, high cost and complicated process, and achieves simplified flotation process flow, improved flotation efficiency and production cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

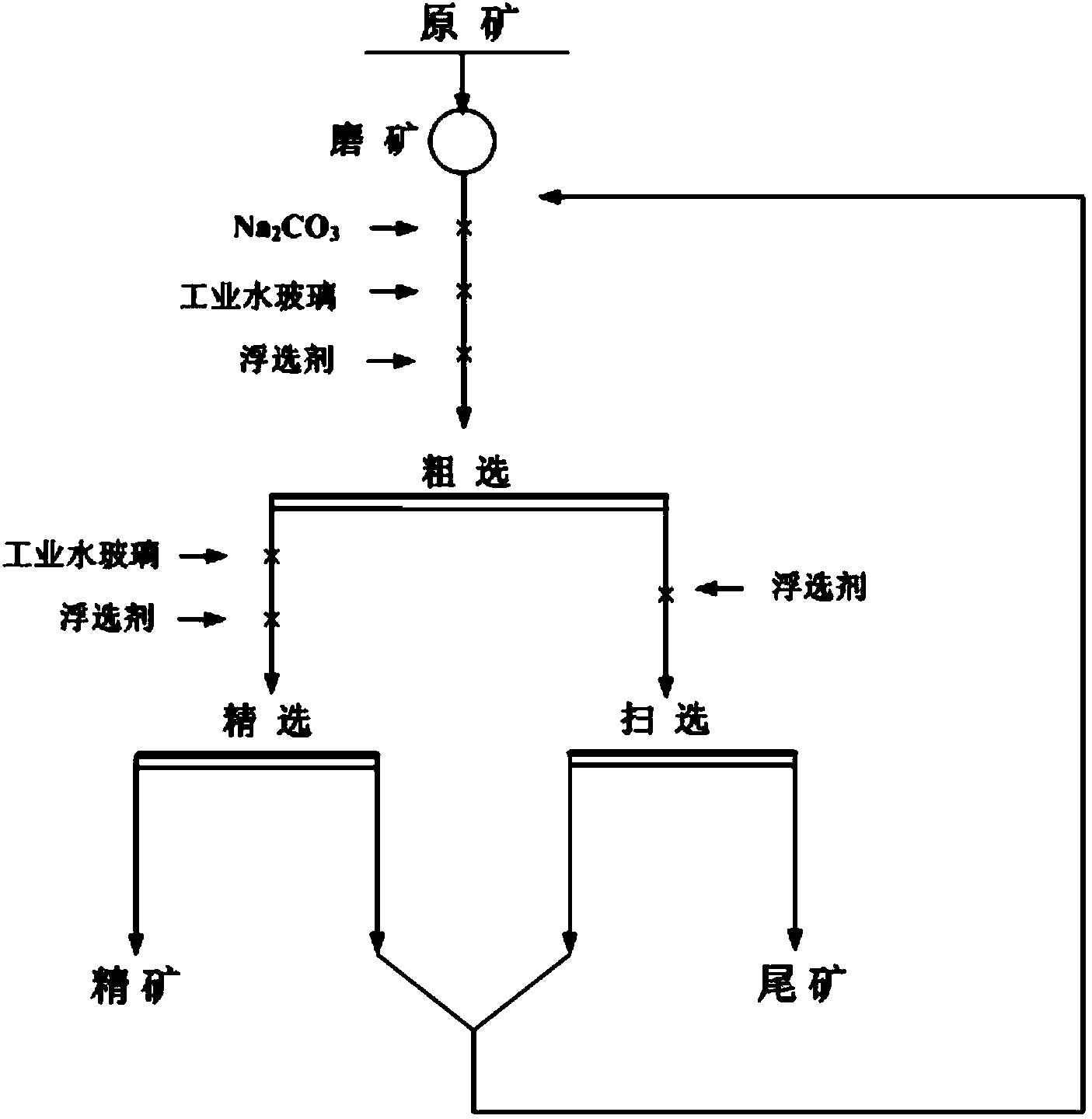

Method used

Image

Examples

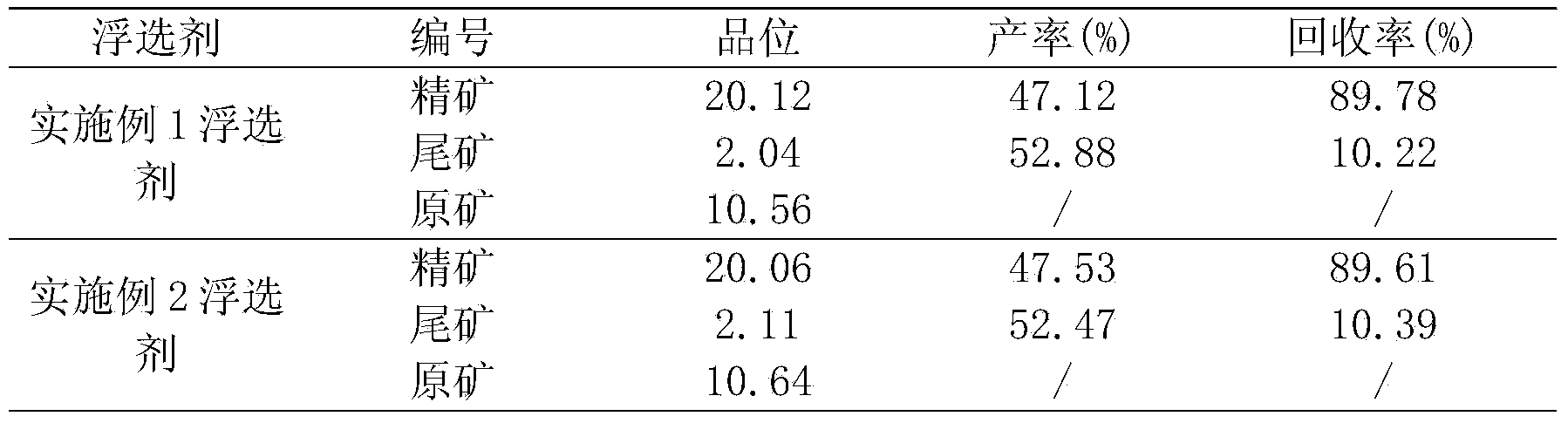

Embodiment 1

[0019] The flotation agent is prepared as follows:

[0020] (1) Take 15 grams of soybean oil and 30ml of distilled water in a three-necked flask, add 0.3 grams of sodium dodecylbenzenesulfonate, stir and dissolve, dropwise add 1.5g mass percent concentration to be catalyzed by 98% concentrated sulfuric acid, and heat up to 95%. Condensed and refluxed at °C for 15 hours, cooled and separated, added enough absolute ethanol to dissolve the upper oil phase, and then separated the upper layer of ethanol again to retain the upper ethanol liquid, and rotary evaporation to remove the ethanol to obtain A.

[0021] (2) Weigh 2.8 g of hydroxylamine hydrochloride into a round-bottomed flask, add 10 ml of ethanol, cool down to about 0 °C in an ice-water bath, add 1.61 g of NaOH, stir for 0.5 hours, filter, and wash the filtered product with an appropriate amount of methanol to obtain Filtrate B.

[0022] (3) Transfer the filtrate B to a round-bottomed flask, heat it to 30°C, slowly add A,...

Embodiment 2

[0024] The flotation agent is prepared as follows:

[0025] (1) Take 15g of soybean oil and 45ml of distilled water in a three-necked flask, add 0.3g of Tween 80 and stir to dissolve, dropwise add 1.5g of concentrated sulfuric acid with a mass percentage concentration of 78%, and heat up to 95°C for condensation and reflux for 15 hours. Cool and separate the liquid, add an appropriate amount of anhydrous ethanol to dissolve the supernatant, and then separate the supernatant again to retain the supernatant, and remove the solvent by rotary evaporation to obtain A.

[0026] (2) Weigh 3.5g of hydroxylamine hydrochloride into a round-bottomed flask, add 10ml of ethanol, cool down to about 0°C in an ice-water bath, add 2.4g of NaOH, stir for 1 hour, filter, and wash with an appropriate amount of methanol to obtain filtrate B.

[0027] (3) Transfer the filtrate B to a round-bottomed flask, heat it to 45°C, slowly add A dropwise, stir for 2 hours, add an appropriate amount of NaOH so...

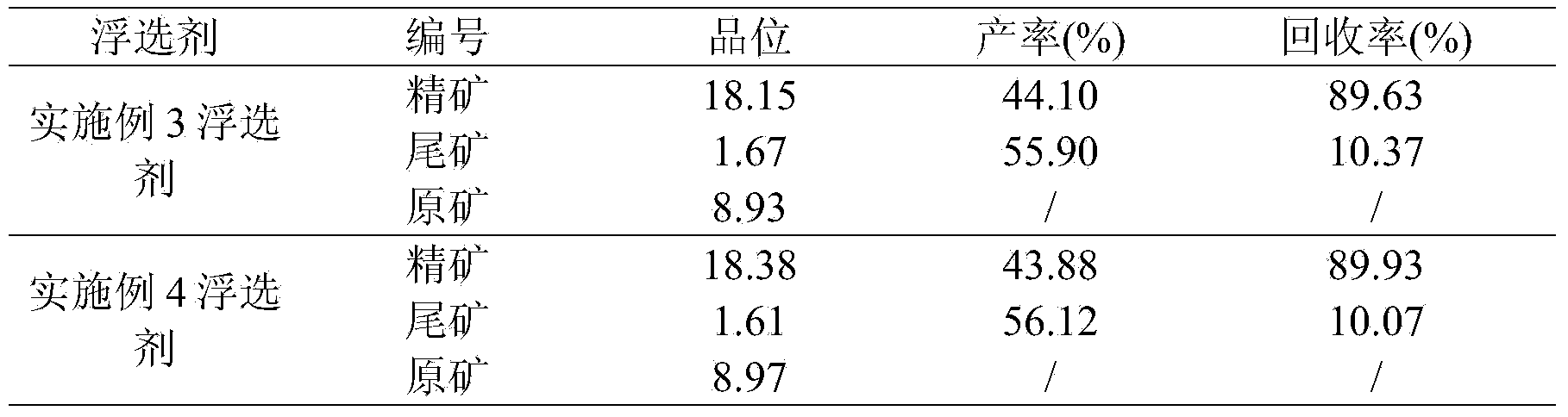

Embodiment 3

[0029] The flotation agent is prepared as follows:

[0030] (1) Take 15g soybean oil and 60ml distilled water in a three-necked bottle, add 0.6g sodium dodecylbenzenesulfonate, stir and dissolve, dropwise add 2.25g concentrated sulfuric acid with a mass percentage concentration of 98%, and heat up to 95°C Condensing and refluxing for 10 hours, cooling and separating, adding an appropriate amount of anhydrous ethanol to dissolve the upper layer liquid, separating the upper layer liquid again to retain the upper layer liquid, and removing the solvent by rotary evaporation to obtain A.

[0031](2) Weigh 5.6g of hydroxylamine sulfate into a round-bottomed flask, add 10ml of ethanol, cool down to about 0°C in an ice-water bath, add 4.8g of NaOH, stir for free for 0.5 hours, filter, and wash with an appropriate amount of methanol to obtain filtrate B.

[0032] (3) Transfer the filtrate B to a round-bottomed flask, heat it to 50°C, slowly add A dropwise, stir and react for 2 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com