Patents

Literature

131results about How to "Reduce weight ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of operating a washing machine using steam

ActiveUS20070283508A1Decrease fabric load weightReduce load weightOther washing machinesControl devices for washing apparatusProcess engineering

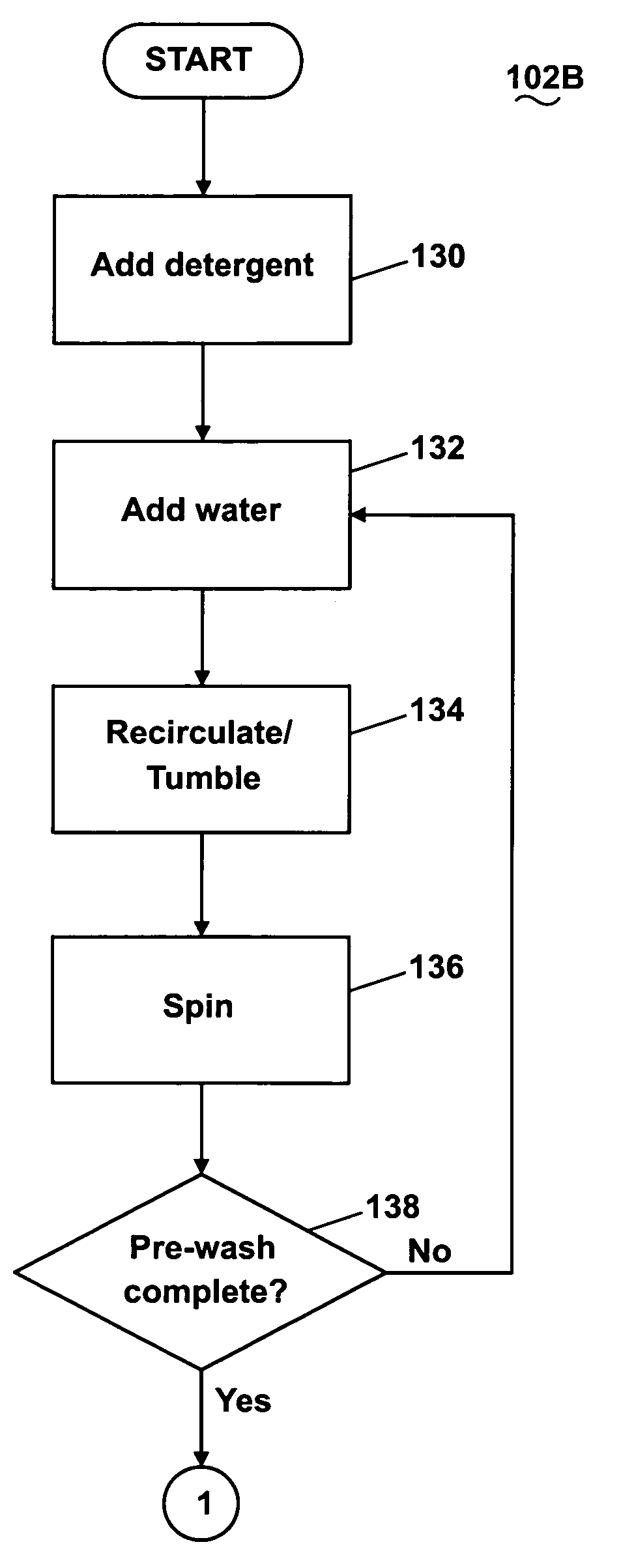

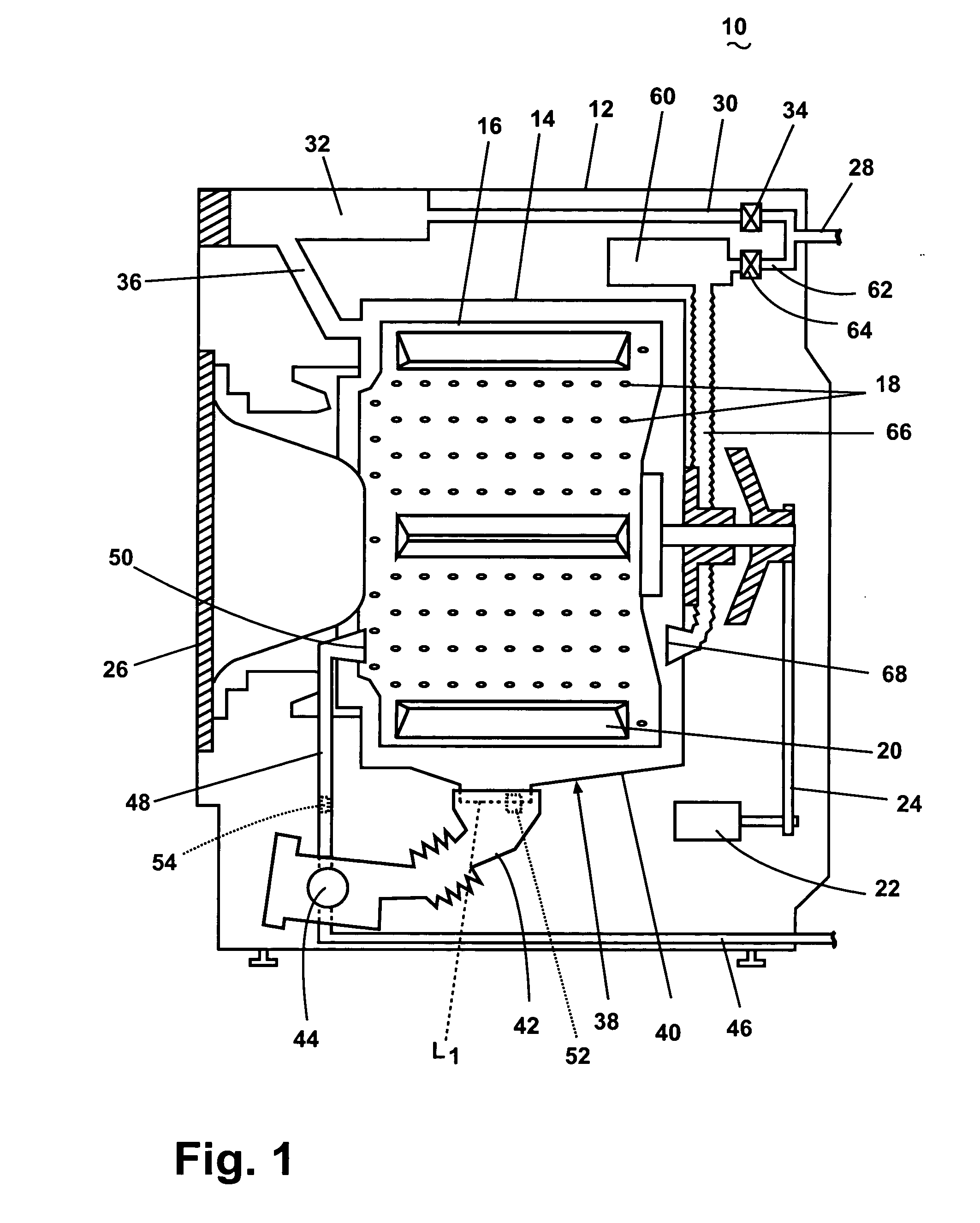

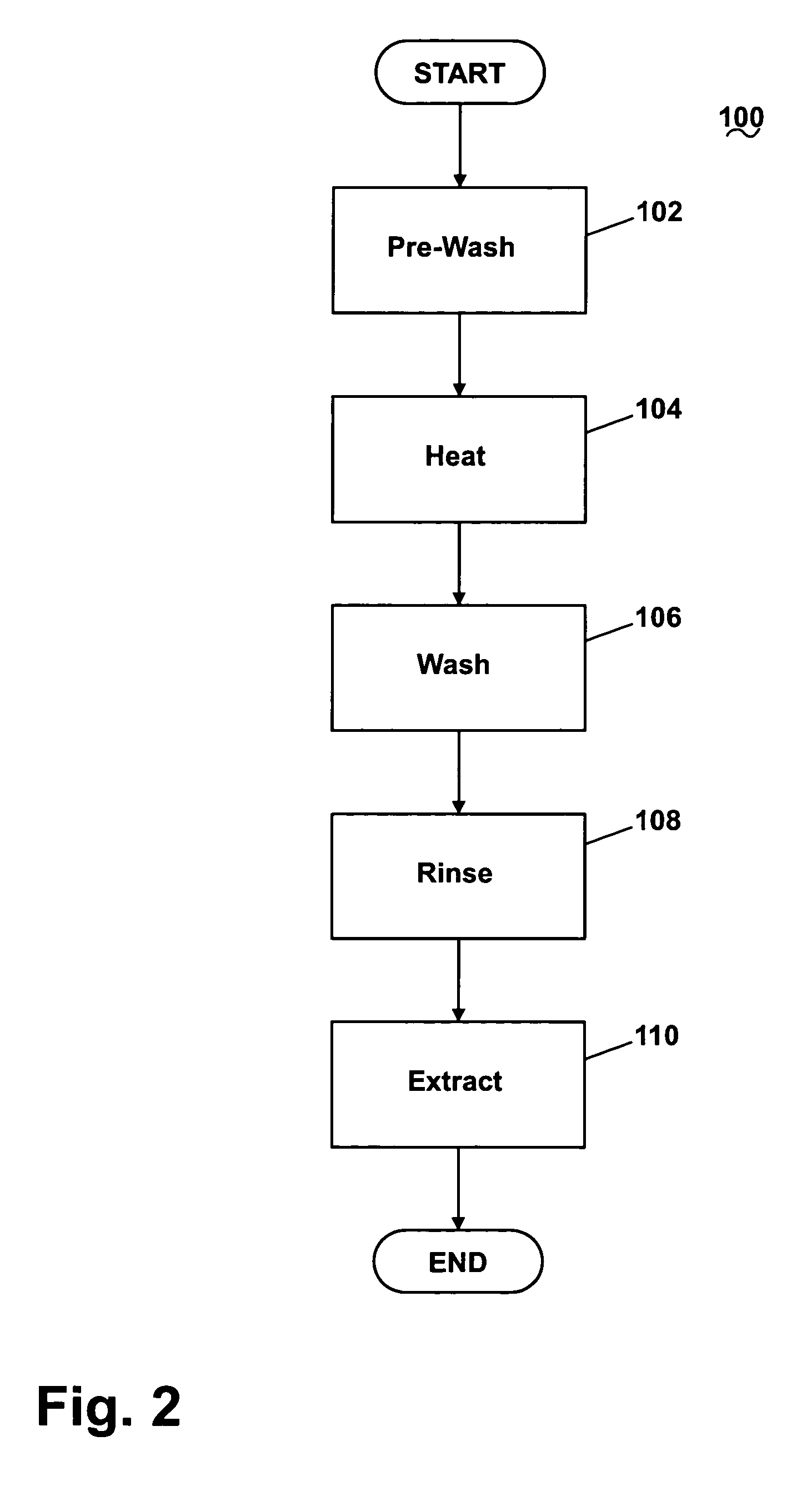

A method for operating a washing machine having a tub with a drum rotatably mounted in the tub and configured to hold a fabric load and a liquid recirculation system configured to recirculate liquid from the tub to the drum comprises a pre-wash step; a heating step comprising introducing steam into the tub and / or the drum; and a washing step comprising washing the fabric load with a second volume of liquid greater than the first volume of liquid. The pre-wash step can comprise recirculating a first volume of liquid between the tub and the drum without submerging a portion of the drum in the liquid and rotating the drum. In another embodiment, the pre-wash step can comprise recirculating a first volume of liquid between the tub and the drum to achieve a fabric load weight to liquid weight ratio of between about 1:0.5 and 1:2.7.

Owner:WHIRLPOOL CORP

Dosage form for administering prescribed dose

InactiveUS20010038855A1Reduce the amount requiredReduce startup timeBiocidePill deliveryMedical prescriptionSurgery

A dosage form, a therapeutic composition, and the use thereof is disclosed for administering a therapeutic agent accompanied by a pharmaceutically acceptable means administered for an indicated therapy.

Owner:DESJARDIN MICHAEL A +2

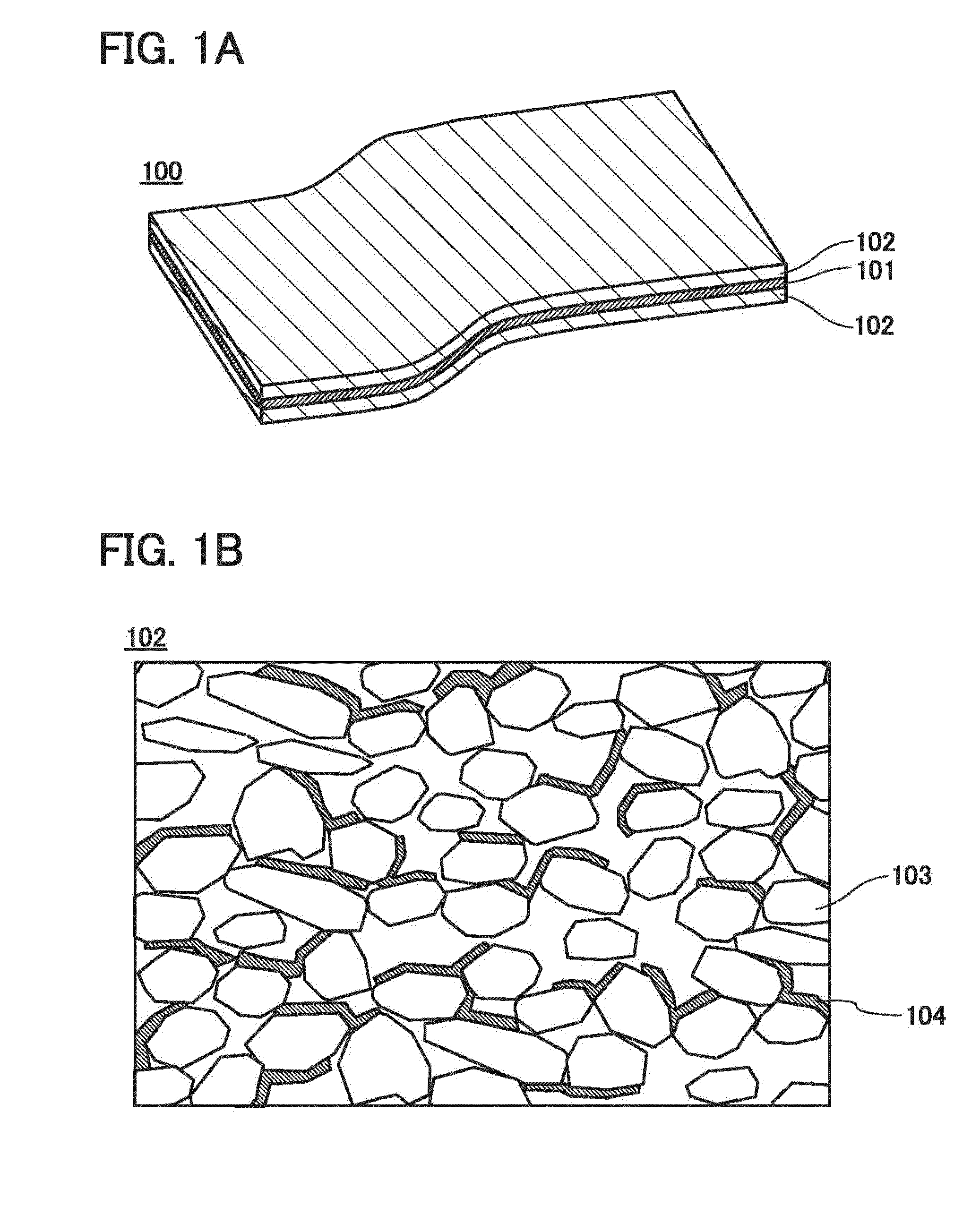

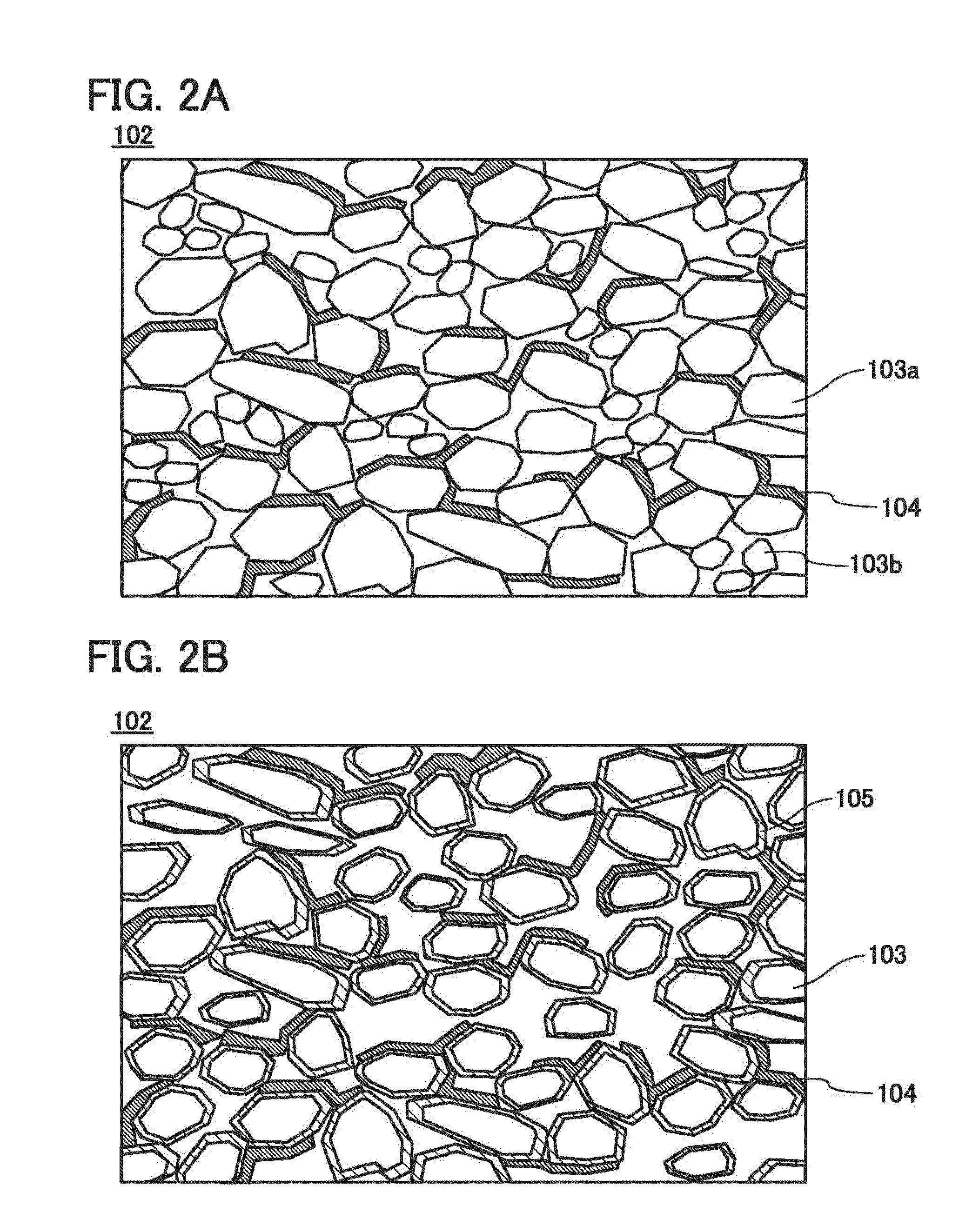

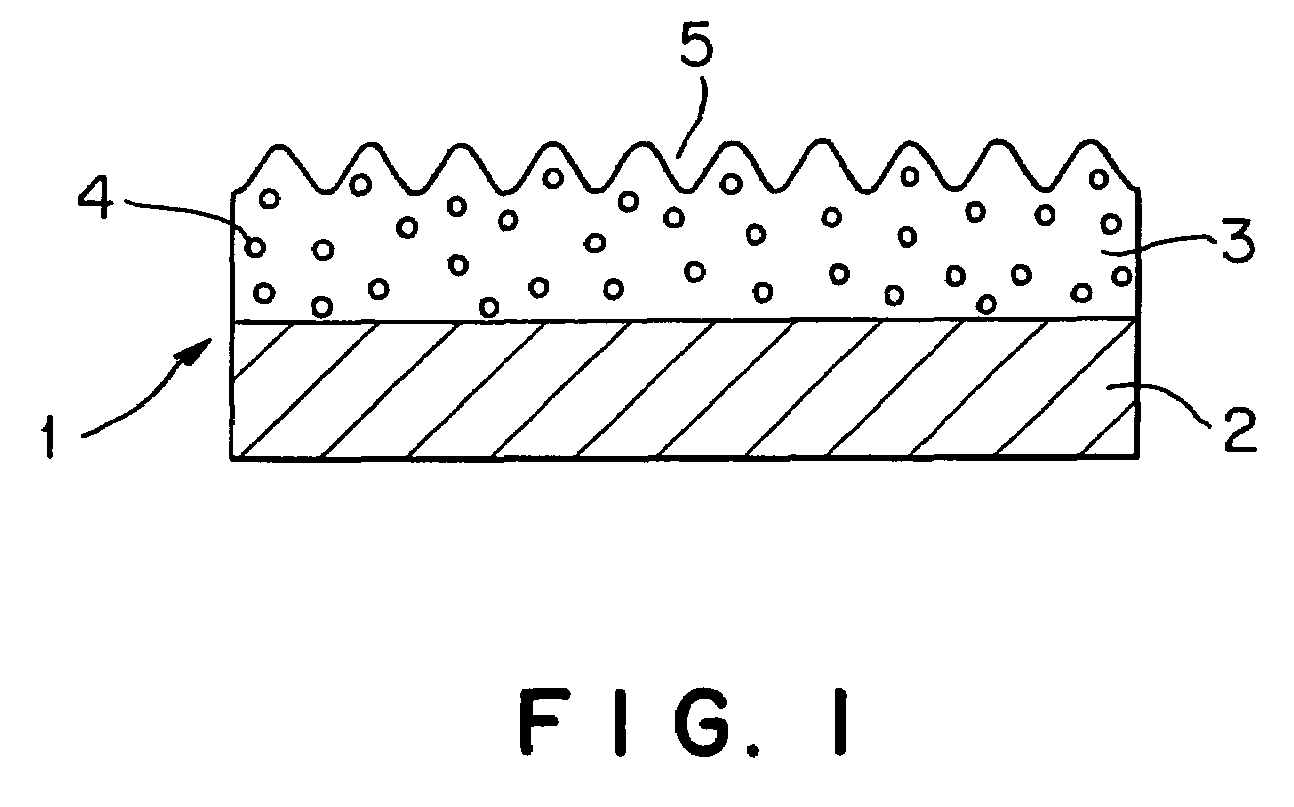

Positive electrode for nonaqueous secondary battery, method for forming the same, nonaqueous secondary battery, and electrical device

ActiveUS20140127568A1Lower discharge capacityHigh volumeConductive materialActive material electrodesEngineeringGraphene

A positive electrode for a nonaqueous secondary battery including an active material layer which has sufficient electron conductivity with a low ratio of a conductive additive is provided. A positive electrode for a nonaqueous secondary battery including an active material layer which is highly filled with an active material, id est, including the active material and a low ratio of a conductive additive. The active material layer includes a plurality of particles of an active material with a layered rock salt structure, graphene that is in surface contact with the plurality of particles of the active material, and a binder.

Owner:SEMICON ENERGY LAB CO LTD

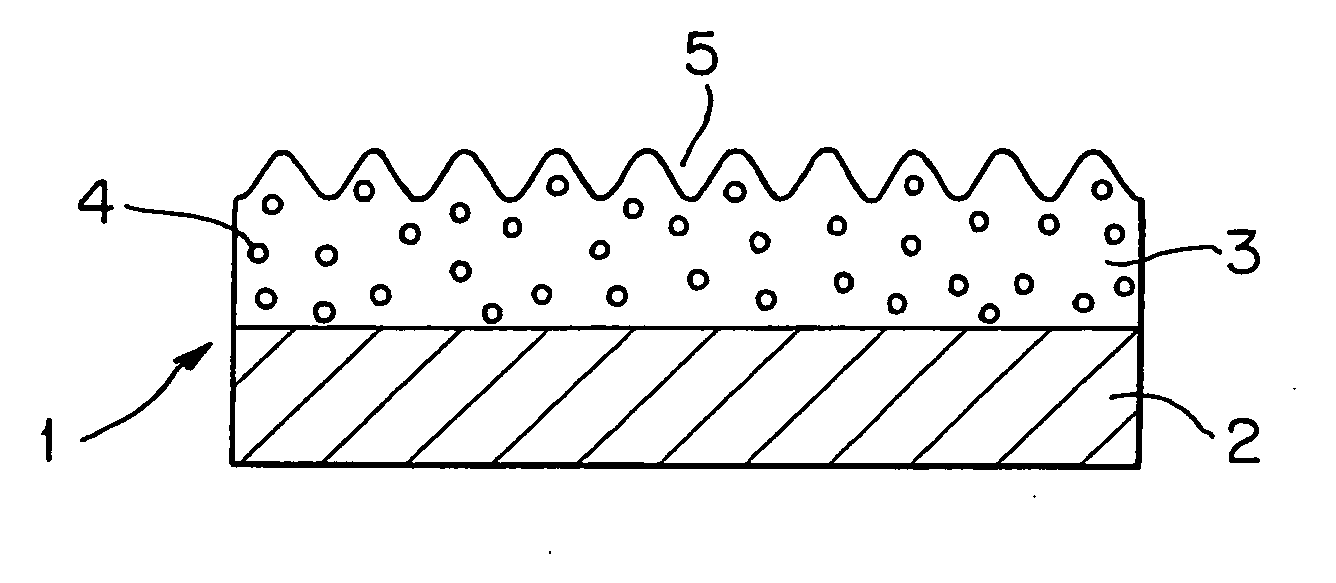

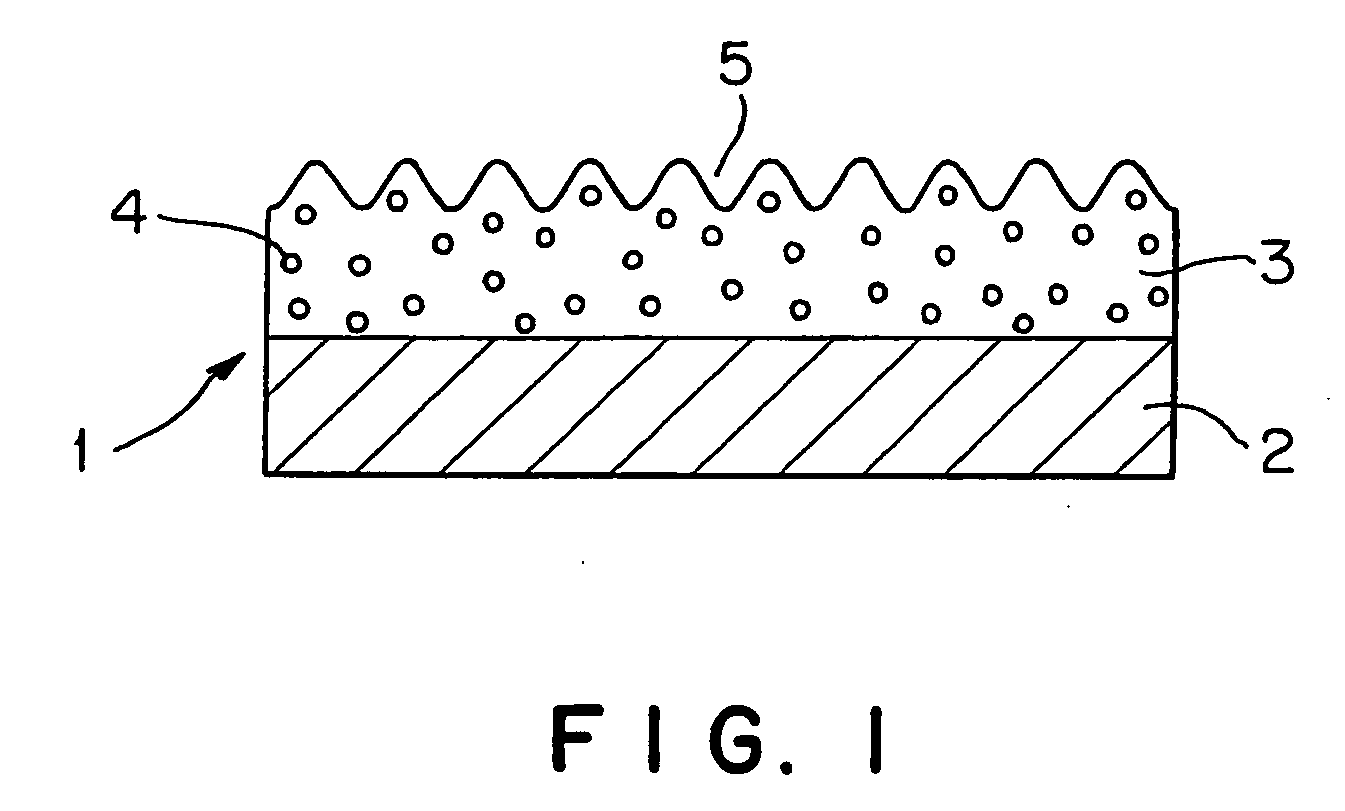

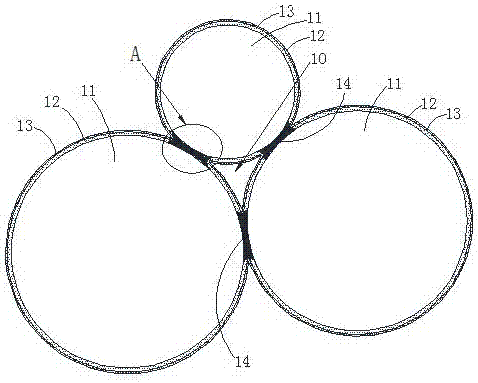

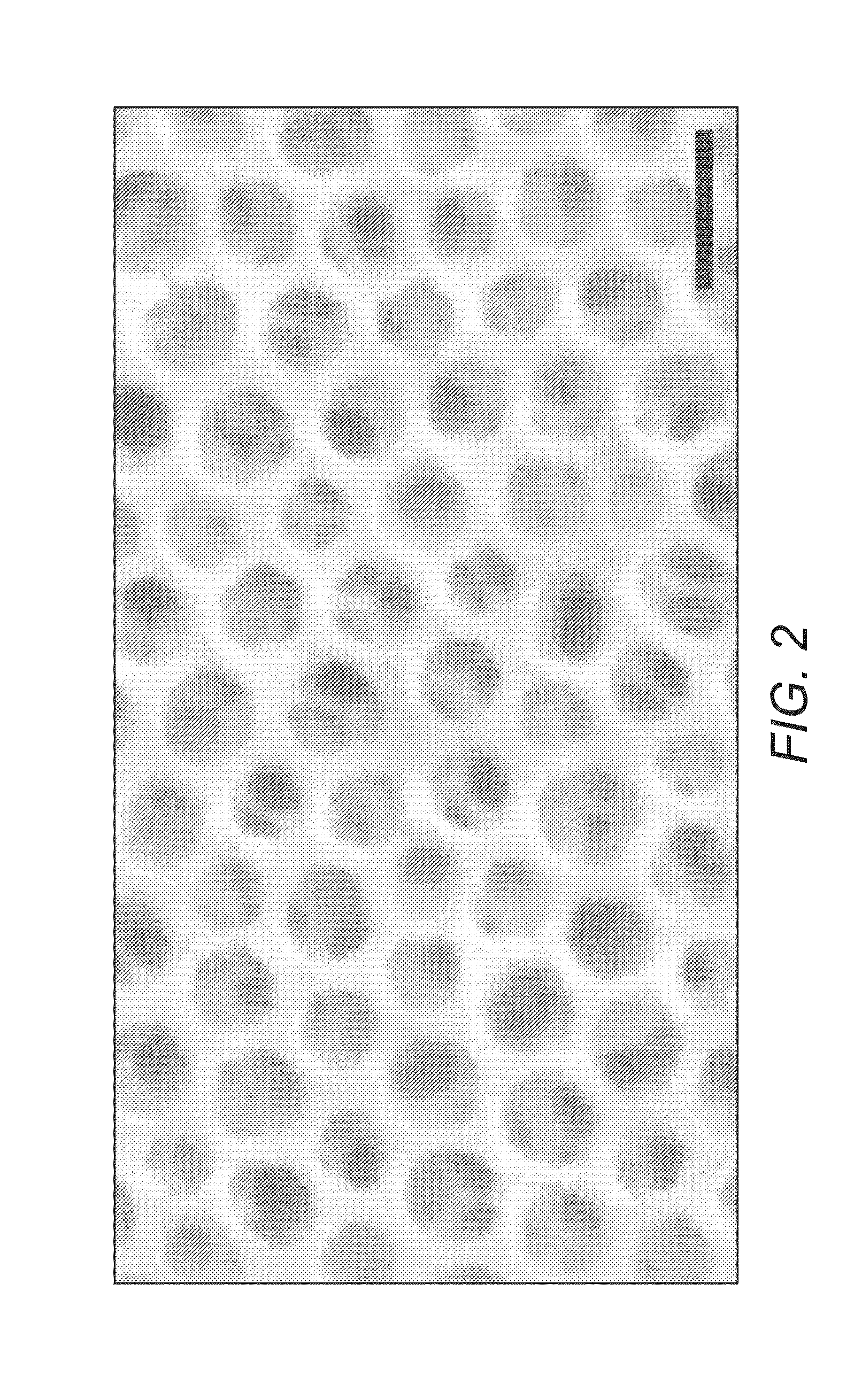

Antiglare film and process for producing the same

InactiveUS20060159902A1High propertyImprove clarityCathode ray tubes/electron beam tubesDiffusing elementsCoated surfaceTransmittance

Owner:DAI NIPPON PRINTING CO LTD

Antiglare film and process for producing the same

InactiveUS7033638B2High propertyImprove clarityCathode ray tubes/electron beam tubesDiffusing elementsLight reflectionSolvent

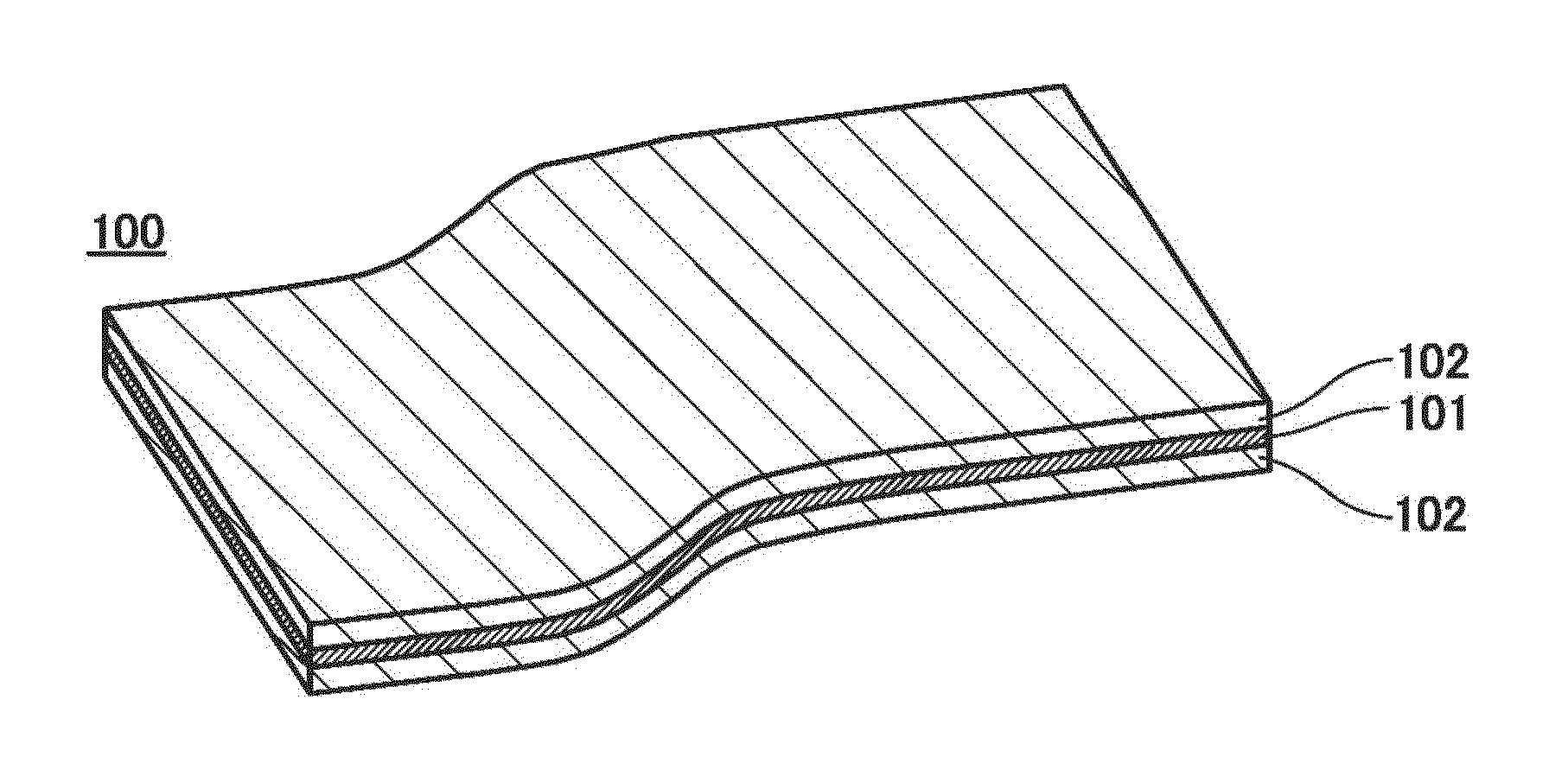

An antiglare film has a high level of anti-scintillation properties, high sharpness of transmitted images, high light transmittance (total light transmittance), and a high level of external light reflection preventive properties. A resin and non-agglomerative particles are incorporated in a coating composition using, as a solvent, a good solvent for the resin and a poor solvent for the resin. The coating composition is coated onto a substrate film to form a coating, which is then dried. As the amount of good solvent in the coating decreases, the poor solvent acts to cause gelation of the particles and the resin, allowing concaves and convexes to be advantageously formed on a surface of the resulting antiglare film.

Owner:DAI NIPPON PRINTING CO LTD

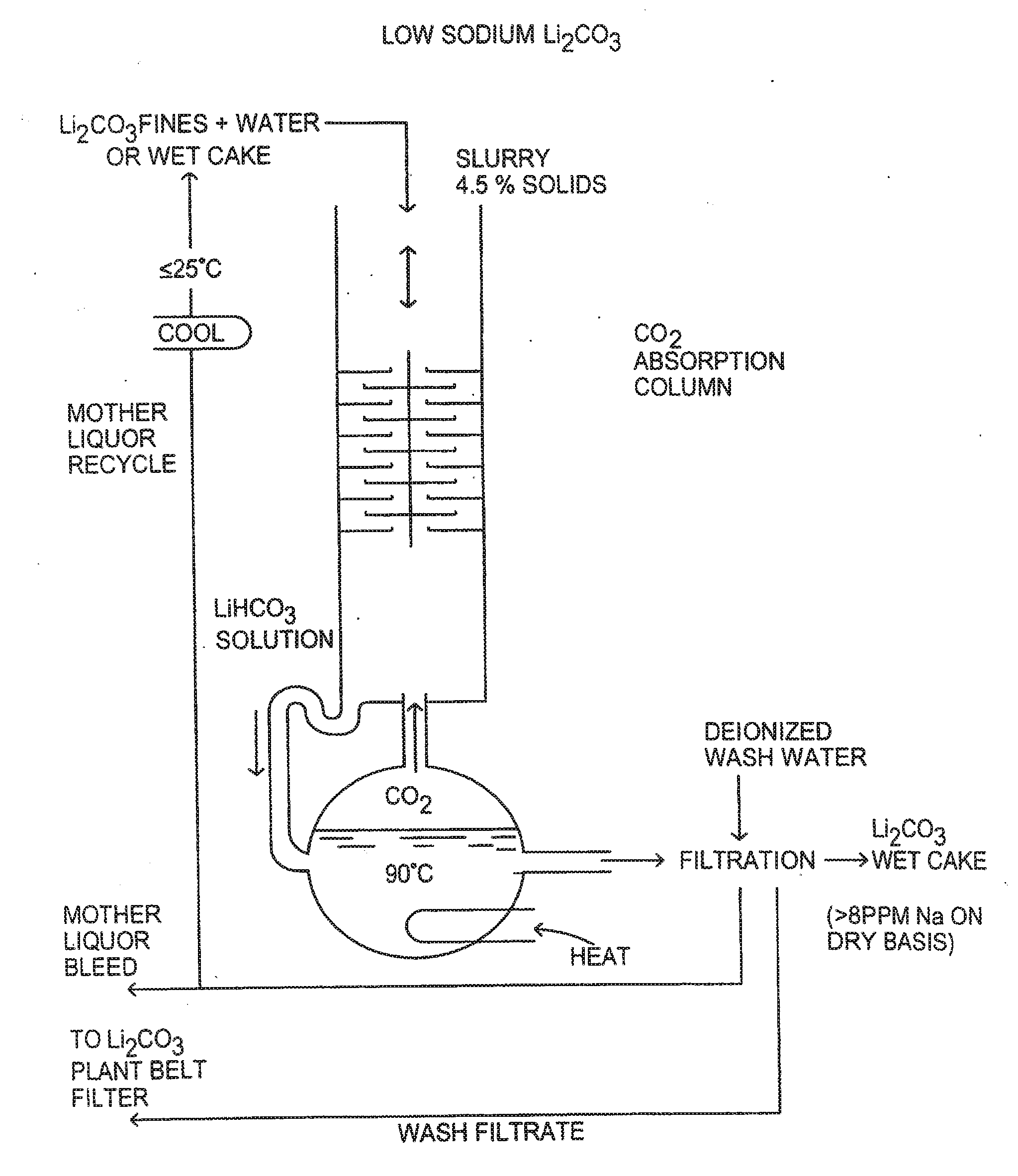

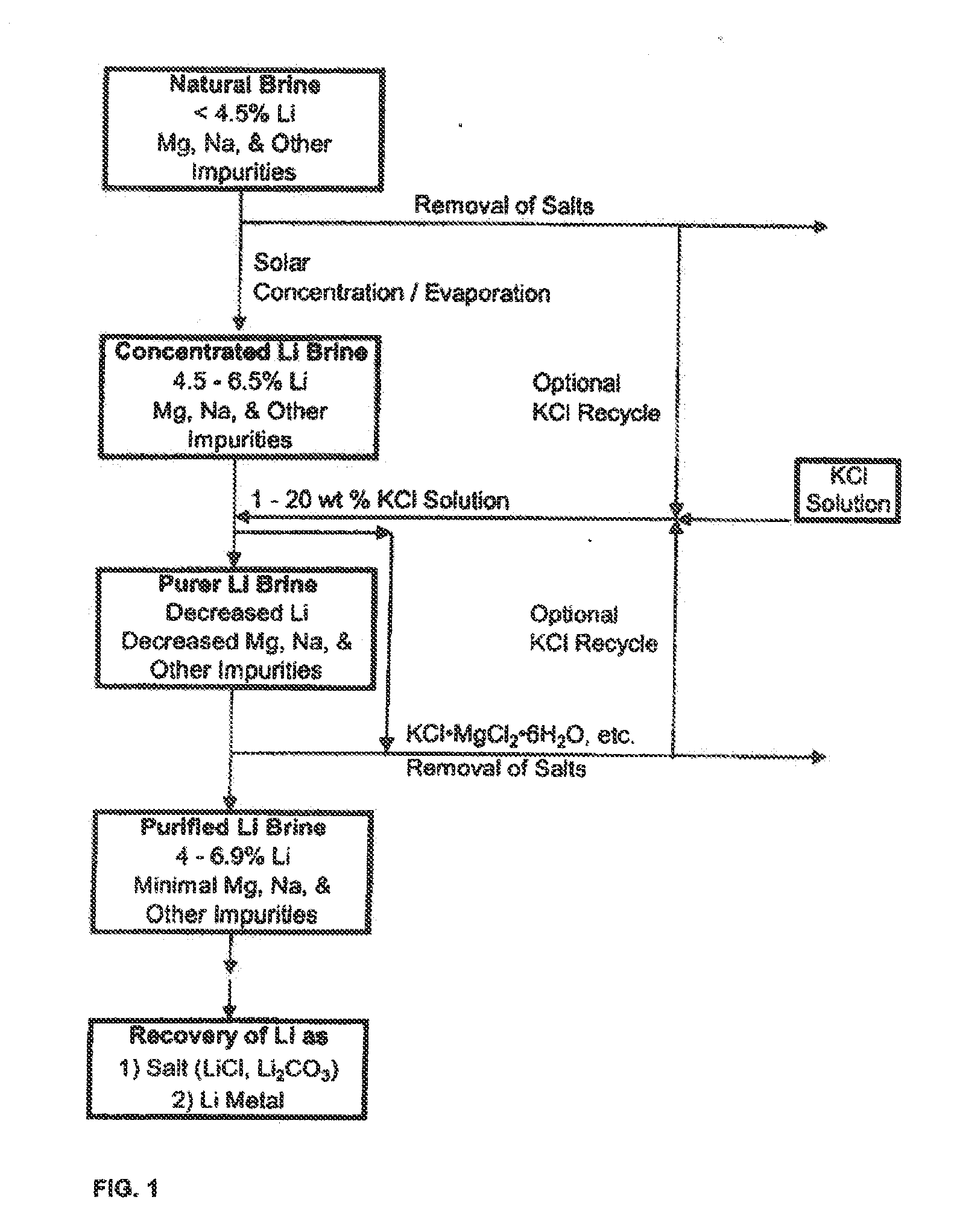

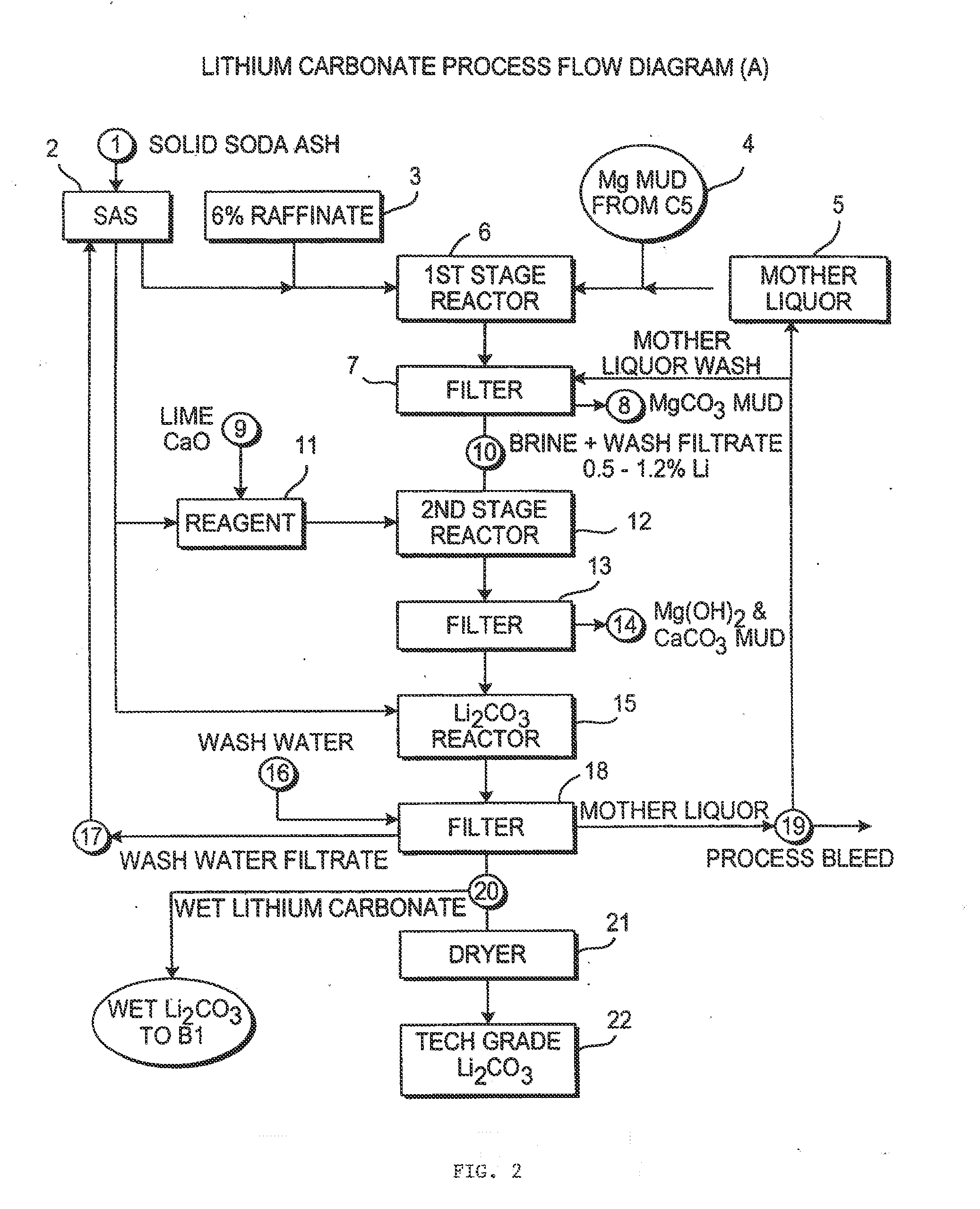

Production of high purity lithium compounds directly from lithium containing brines

ActiveUS20120189516A1Reduce in quantityReduce lossesMagnesium carbonatesSedimentation separationSalt waterLithium compound

A process for reducing the amount of magnesium in a lithium-containing brine by adding an aqueous solution of KCl to the brine to precipitate at least some of the magnesium as carnallite salt is disclosed. Lithium salts prepared using this magnesium removal process are also disclosed.

Owner:ROCKWOOD LITHIUM INC

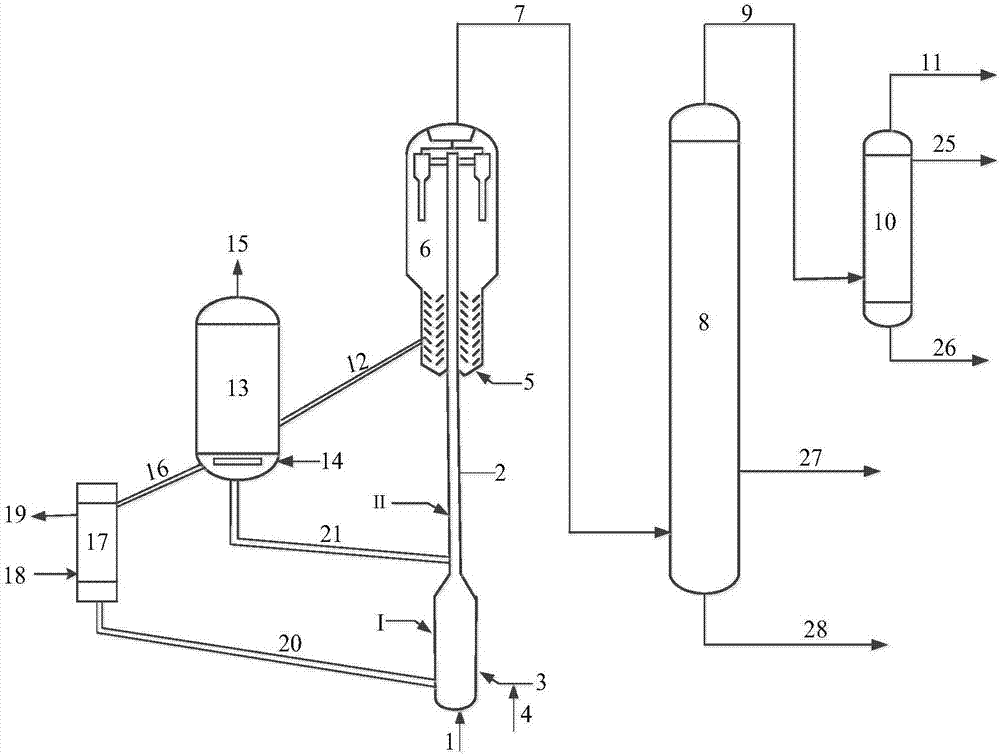

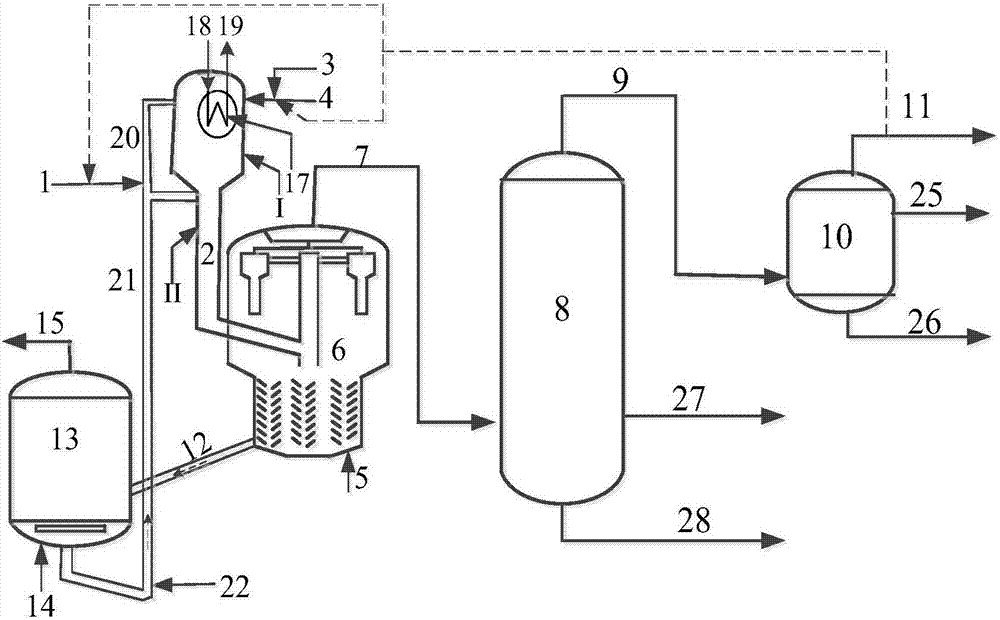

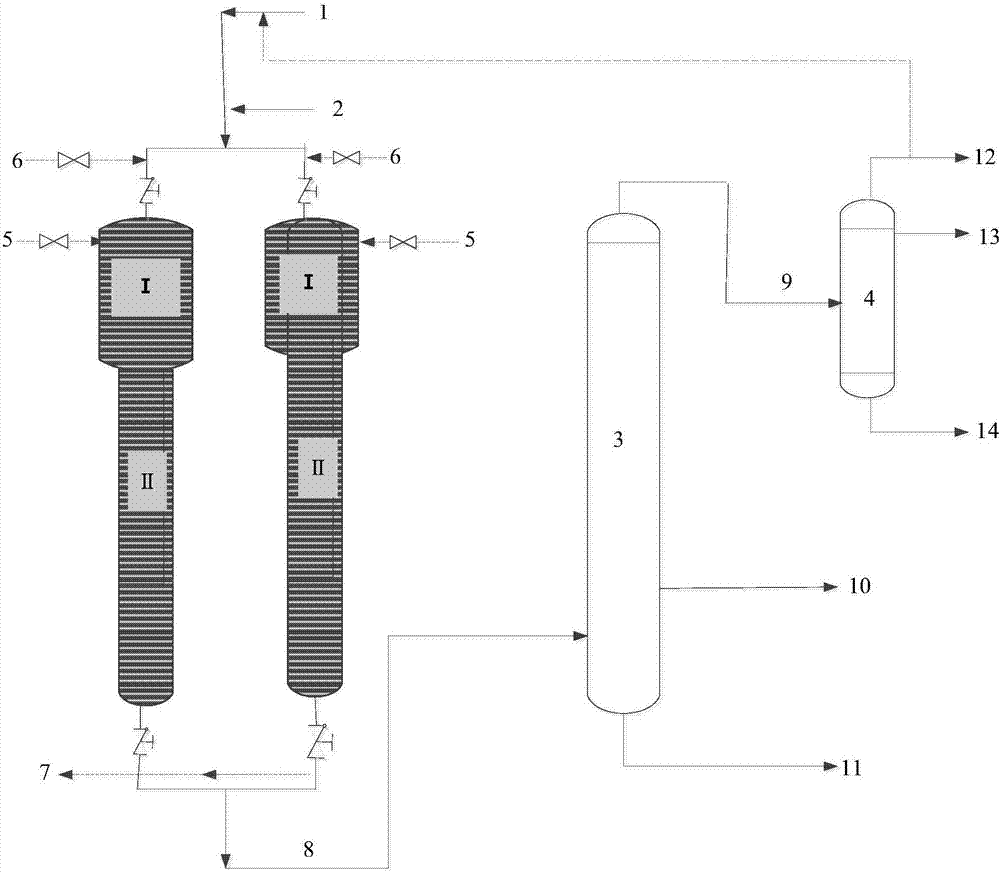

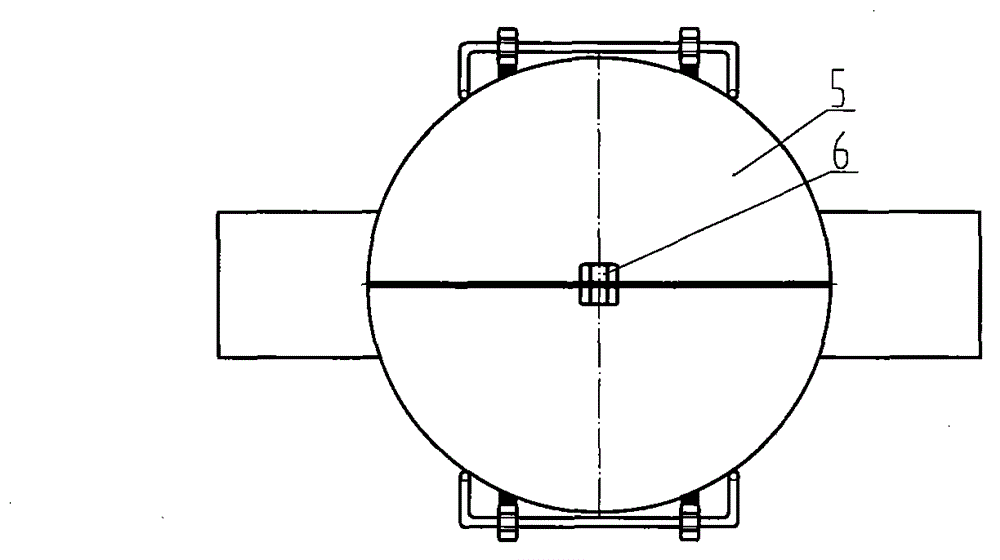

Processing method and system for inferior crude oil

ActiveCN107267211AEliminates rich gas compressorReduce device energy consumptionTreatment with hydrotreatment processesChemistryDry gas

The invention discloses a processing method and system for inferior crude oil. The method comprises the steps as follows: a, feeding hydrogen-containing gas and the inferior crude oil into a fluidized bed hydrogen absorption zone (I) of a fluidized bed riser reactor for contact with a first catalytic cracking catalyst and a hydrogen adsorption reaction to obtain a hydrogen absorption product; b, feeding the hydrogen absorption product obtained in the step a into a riser cracking zone (II) of the fluidized bed riser reactor for contact with a second catalytic cracking catalyst and a catalytic cracking reaction to obtain catalytic cracked oil-gas. The inferior crude oil processed by the system with the method has the advantages that the conversion rate of the inferior crude oil can be increased substantially, the yield of dry gas and coke is reduced, and accordingly, clean and efficient use of the inferior crude oil is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

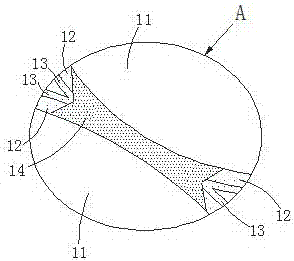

Production process of E-TPU (expanded thermoplastic polyurethane) shoe material

InactiveCN107353428APromote environmental protectionReduce usage requirementsSolesDevices for pressing relfex pointsMaterials preparationThermoplastic polyurethane

The invention relates to a production process of an E-TPU (expanded thermoplastic polyurethane) shoe material. The production process of the E-TPU shoe material comprises the steps implemented in sequence as follows: a, material preparation: 75-92 parts of TPU foamed particles, 5.9-19 parts of glue A, 0.9-4.8 parts of glue B and 0.38-1.5 parts of an accelerator are prepared by weight; b, addition of the glue A: the TPU foamed particles and the glue A are stirred uniformly; c, addition of the glue B: the glue B is added after the materials in the step b are mixed uniformly, and the materials are stirred uniformly; d, addition of the accelerator: the accelerator is added after the materials in the step c are mixed uniformly, the materials are mixed uniformly, and the mixture is injected into a die cavity; e, foaming: the die cavity is moved into an oven, foaming molding is performed at 50-70 DEG C for 2-3 min, and the molded shoe material can be obtained. The TPU particles can account for 90%-92% by weight of the shoe material, the weight reduction limit of the current shoe material is reached, and the E-TPU shoe material has the characteristics of being ultralight, ultrahigh in elasticity, more environment-friendly, low in cost and capable of performing massaging.

Owner:陈茂双

Chinese herbal medicine feed additive for improving production performance of piglets

InactiveCN102934757AIncrease the rate of weight gainIncrease feed intakeAnimal feeding stuffWeight gainingBaical Skullcap Root

The invention relates to a Chinese herbal medicine feed additive for improving the production performance of piglets. According to the theory of traditional Chinese medicine and the physiological features of piglets, the Chinese herbal medicine feed additive is prepared from astragalus root, baical skullcap root, coptis root, officinal magnolia bark, Chinese yam, dried orange peel, medicated leaven, hawthorn powder, white paeony root and liquorice in proportion by crushing and mixing and is added to the basic ration of the piglets according to the addition proportion being 0.6%. The Chinese herbal medicine feed additive is completely prepared from the Chinese herbal medicines, is free of antibiotic components and hardly causes drug resistance, and has the advantages of obviously improving the weight gain speed of the piglets, increasing the feed intake of the piglets, and reducing the feed to gain ratio and the diarrhea rate of the piglets.

Owner:张鑫

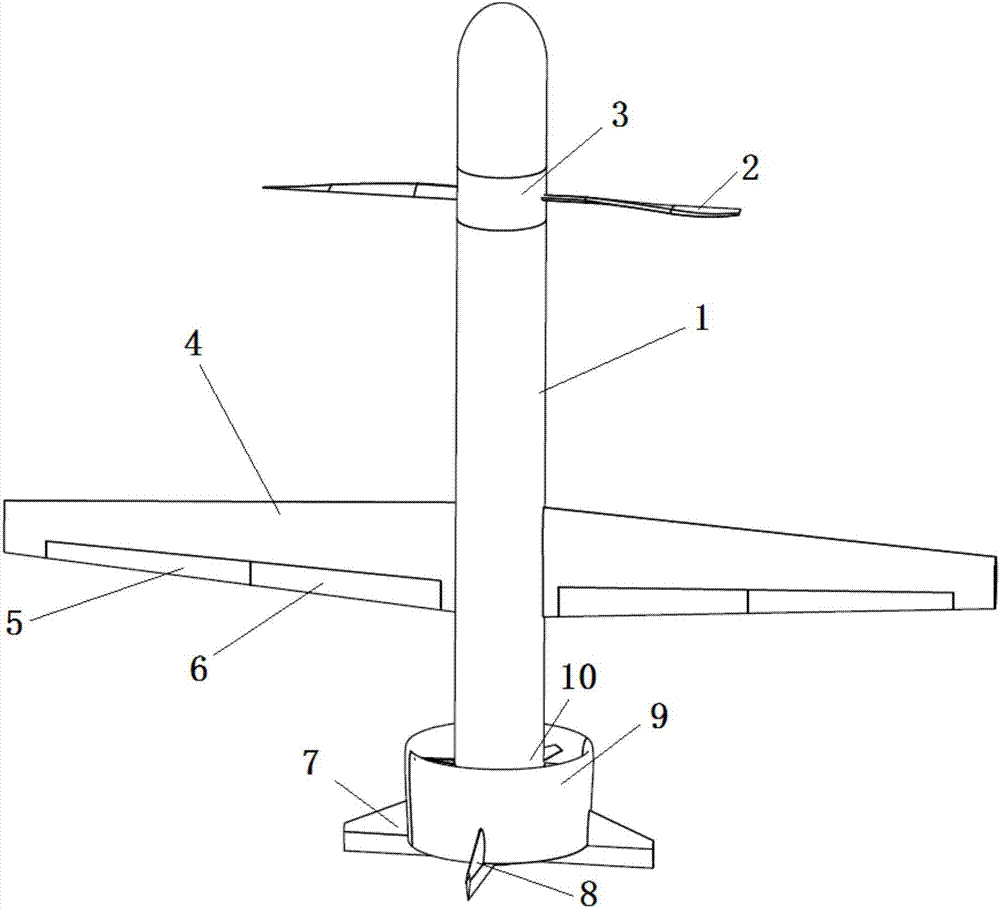

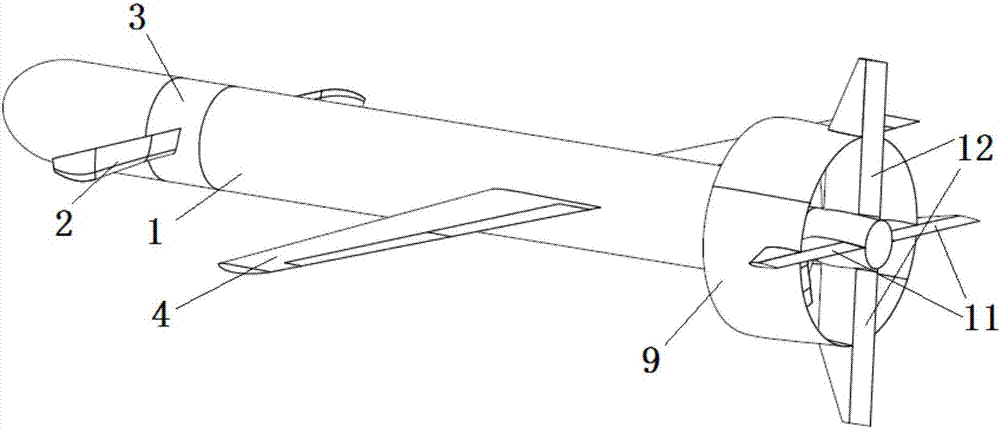

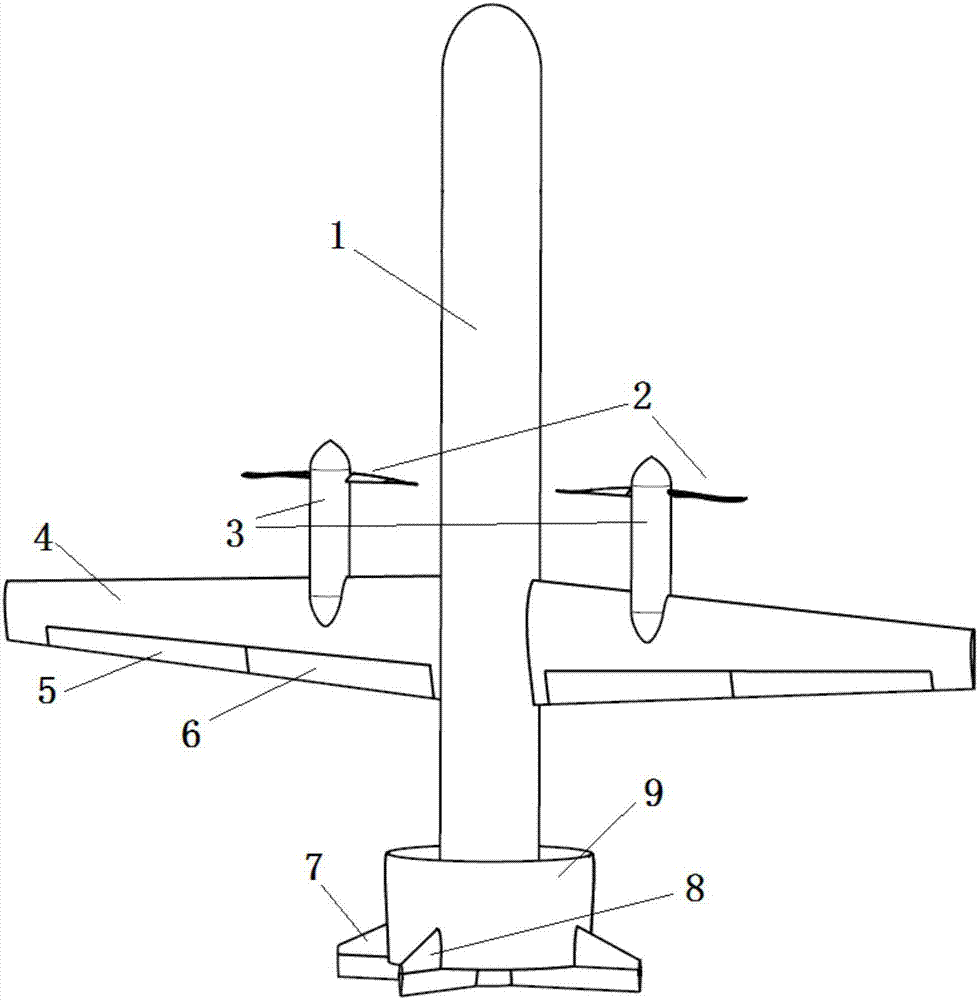

Hybrid power tail sitting type vertical takeoff and landing long-endurance unmanned aerial vehicle and flight control method thereof

ActiveCN107089328ALower fuel consumptionReduce powertrain weightVertical landing/take-off aircraftsElectric machineryTailplane

The invention provides a hybrid power tail sitting type vertical takeoff and landing long-endurance unmanned aerial vehicle and a flight control method thereof. The unmanned aerial vehicle comprises a fuselage, wings, a main driving motor, propellers, a piston power ducted propeller and tail wings mounted on a duct. According to the invention, two sets of power systems, namely a motor and a piston engine, are adopted; in a vertical takeoff and landing stage which is short in time and requires large power, the motor serves as driving power, the advantage of high power-weight ratio of the motor can be fully exerted, and thus the weight of the power systems is reduced; in a cruising flight stage, the tail piston engine and the ducted propeller system driven by the tail piston engine drive the unmanned aerial vehicle to fly forward, and the piston power and the ducted propeller system can be selected and designed according to the optimal cruising state without considering the vertical takeoff and landing state, so that the fuel consumption rate of the cruising state can be effectively reduced; in combination with high-aspect-ratio wings, long-time flight of the unmanned aerial vehicle can be ensured; and meanwhile, because the weight of the power systems is reduced, the empty weight ratio of the unmanned aerial vehicle can be reduced, and the loading capacity of the unmanned aerial vehicle can be effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

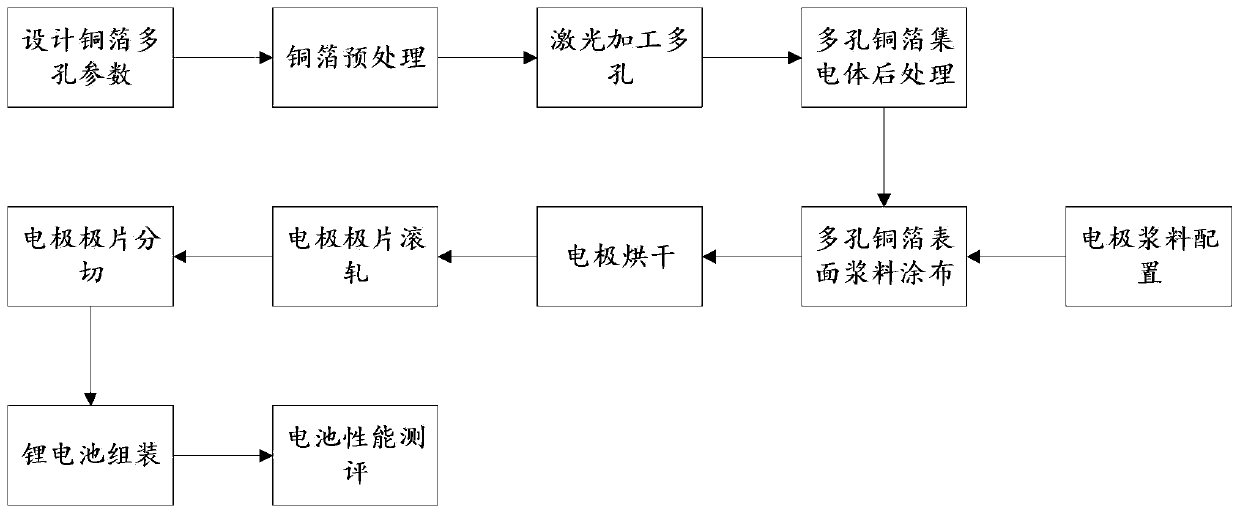

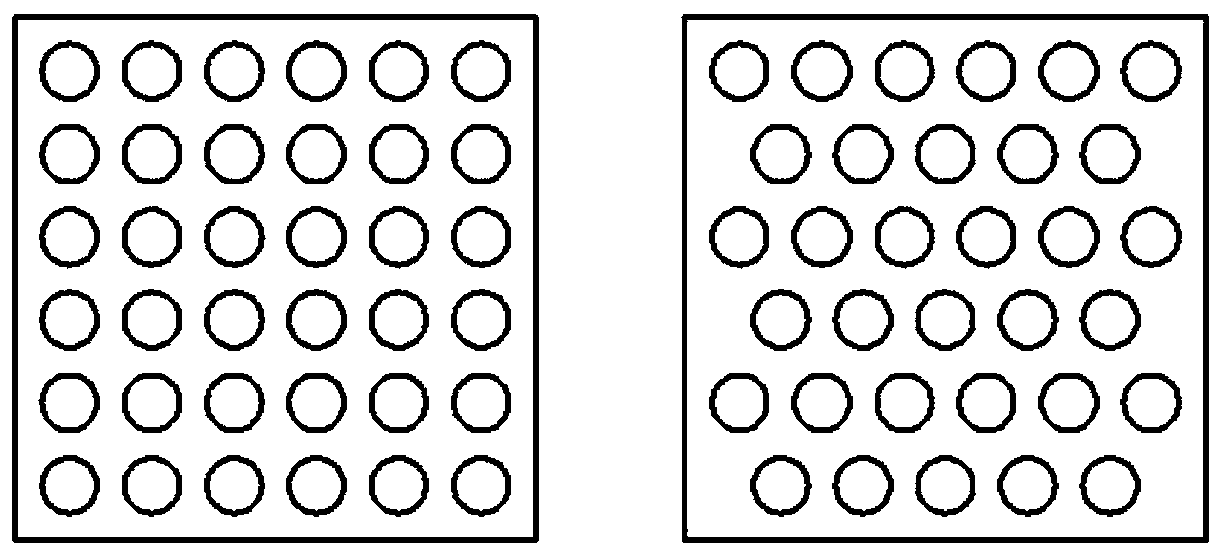

Method for preparing porous copper foil current collector of lithium battery

InactiveCN110492107ARealize multi-hole processingQuality improvementElectrode carriers/collectorsLaser beam welding apparatusComposite filmCopper foil

The embodiment of the invention discloses a method for preparing a porous copper foil current collector of a lithium battery, and relates to the technical field of lithium battery preparation. The method comprises the following steps: S1, pretreating a copper foil; S2, machining multiple holes in the copper foil in a laser machining mode; S3, carrying out post-treatment on the copper foil; S4, coating two sides of the copper foil with the electrode slurry; S5, drying the copper foil coated with the electrode slurry in a drying oven; and S6, performing rolling and slitting treatment on the dried copper foil to obtain a lithium battery electrode plate. According to the method, on the premise that the mechanical strength of the foil is guaranteed, the invalid quality of the copper foil current collector is reduced, the conductivity is improved, the adhesive force between the copper foil current collector and a negative active material composite film is enhanced, and the technical effectsof effectively improving the mechanical stability, the overall specific capacity, the rapid charging and discharging capacity and the long-term cycle life of the lithium battery electrode are achieved.

Owner:INNO LASER TECH CORP LTD +1

Preparation process for copper foil for lithium ion battery current collector

InactiveCN102931414AIncrease the unit weight gram capacityReduce weight ratioElectrode carriers/collectorsVacuum evaporation coatingElectricityElectrical battery

The invention relates to an electrochemical coating film and particularly relates to a preparation process for a copper foil for a lithium ion battery current collector. The preparation method comprises the steps of: firstly, carrying out local insulating treatment on the surface of an electro-deposition roller of an electrolytic copper foil to form a lattice point shaped pattern; then, carrying out an electro-deposition process for the electrolytic copper foil, wherein the copper foil obtained by deposition is a mesh-shaped foil sheet with the lattice point pattern consistent with that of the electrical insulating region. According to the preparation process for the copper foil for the lithium ion battery current collector, the mesh-hole-shaped copper foil for the cathode current collector of the lithium ion battery is prepared, the weight ratio of the copper foil in the cathode piece in the lithium ion battery can be reduced, the unit weight capacity of the cell is improved, and the preparation process can be compatible with the copper foil production device used in the existing lithium ion battery production; and the preparation process can be achieved only by improving the existing copper foil production device part, namely the electro-deposition roller.

Owner:IRICO

Modified silica sol, fireproof liquid, composite fireproof glass as well as preparation method and application thereof

ActiveCN112320807AStrong adhesionHigh bonding strengthFireproof paintsSilicon compoundsOrageneOrganic polymer

The invention belongs to the technical field of inorganic nano materials, and particularly relates to modified silica sol, fireproof liquid, composite fireproof glass and a preparation method and application thereof. The preparation method of the modified silica sol comprises the following steps: 1) mixing silica sol to be modified with a silane coupling agent and reacting; and 2) mixing an organic polymer containing a reaction group with the material obtained in the step 1) and reacting to obtain the modified silica sol. The modified silica sol is prepared by the preparation method and is used for preparing the fireproof liquid, and the obtained fireproof liquid is high in crosslinking density and good in adhesive force.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +2

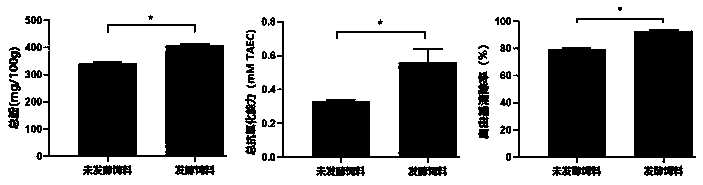

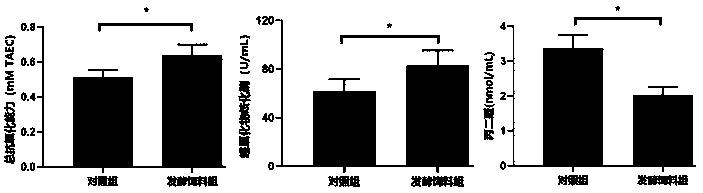

Preparation method and application of bacteria-enzyme synergistic fermented rice bran meal for improving growth performance of growing and fattening pigs

PendingCN111436526AIncrease feed intakeImprove digestibilityBacteriaFood processingBiotechnologyPhytase

The invention discloses a preparation method and application of bacteria-enzyme synergistic fermented rice bran meal for improving growth performance of growing and fattening pigs. The method comprises: (1) preparing a strain activation culture medium; (2) strain activation and fermentation seed liquid preparation: inoculating bacillus subtilis, saccharomyces cerevisiae and lactobacillus plantaruminto the activation culture medium for activating, performing mixing, adding acid protease and phytase, and performing uniform mixing to obtain a fermentation seed liquid; and (3) a two-step fermentation process: premixing rice bran meal and a soybean hull raw material in a ratio of 4:1, adding the fermentation seed liquid obtained in the step (2) according to 5-10% of the premixed raw materials,introducing warm water to make the total moisture account for 35-40% of the total mass of the fermentation system, performing uniform stirring, transferring obtained mixture into a fermentation tank,performing fermentation for 24 hours, filling an anaerobic breathing bag, and performing fermentation for 48 hours to obtain a fermented feed. The fermented feed replaces protein raw materials in daily ration of the fattening pigs with 10% of equal nitrogen, the feed intake and daily gain of the fattening pigs can be remarkably improved, the feed conversion ratio is reduced, the nutrient digestibility of the fattening pigs is improved, and the serum oxidation resistance of the fattening pigs is enhanced.

Owner:ZHEJIANG UNIV

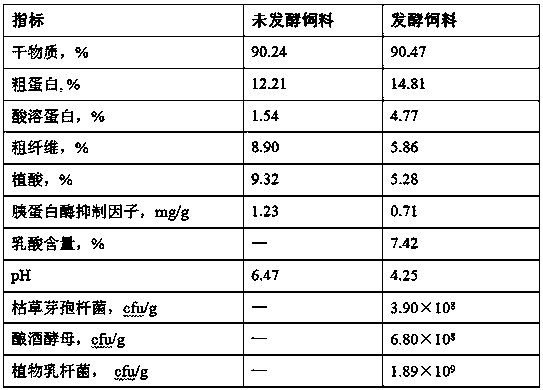

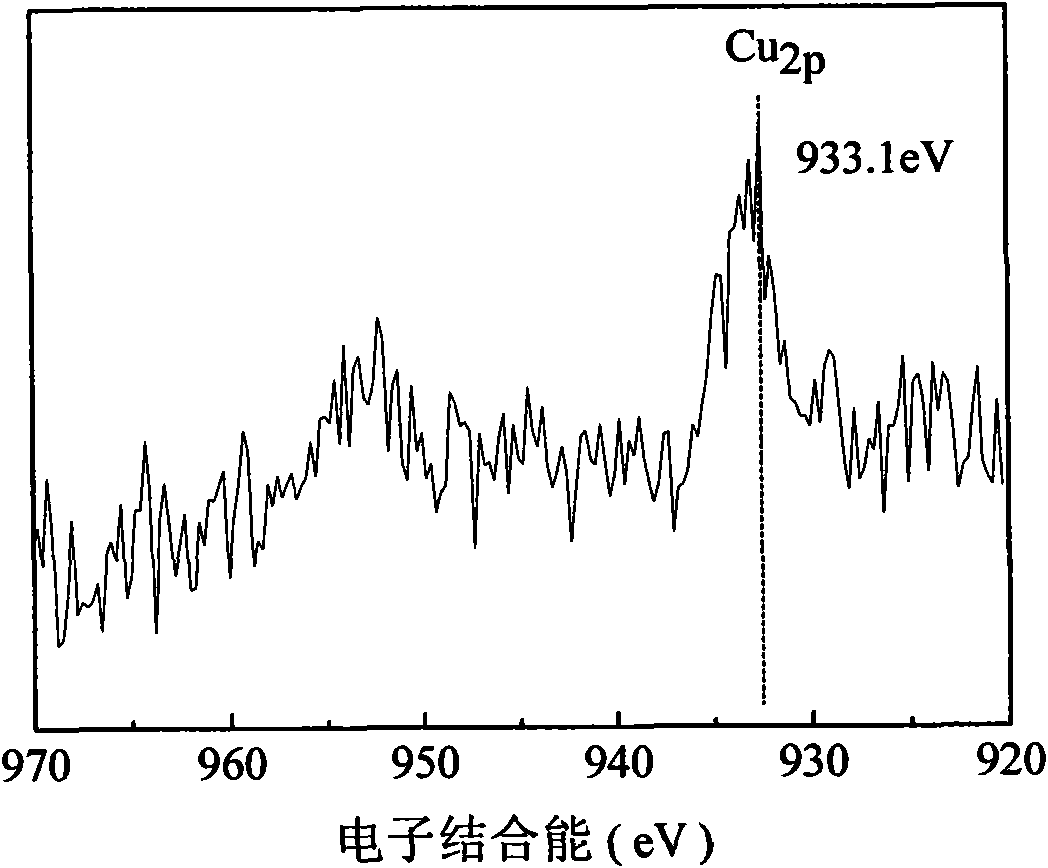

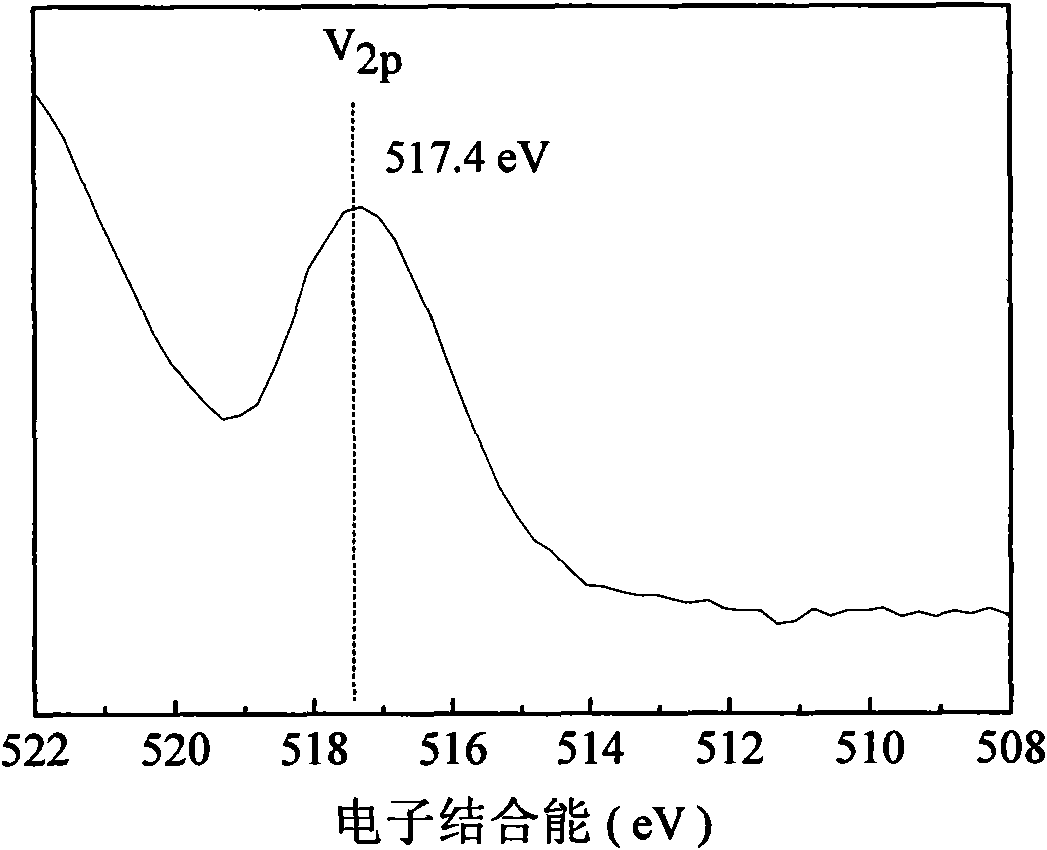

Catalyst for synthesizing methylaniline from methylbenzene by one step and preparation method thereof

InactiveCN101837293AReduce usageReduce weight ratioMolecular sieve catalystsAmino preparation by hydrogen substitutionMolecular sieveMethylaniline

The invention belongs to the technical field of catalysis, in particular to a catalyst for synthesizing methylaniline from methylbenzene by one step. The catalyst consists of active ingredients and a carrier, wherein the active ingredients are CuO and V2O5; the molar ratio of the CuO to the V2O5 is 0.1-2:1; the carrier is silicon oxide, titanium oxide, alumina or a molecular sieve; and the load of the active ingredients CuO and V2O5 is 5 to 32 percent, wherein the load refers to the weight percentage of the active ingredients CuO and V2O5 in the integral supported catalyst. Compared with the conventional catalyst for amination of methylbenzene, the catalyst prepared by the method has low consumption; in the implementation, the weight ratio of the catalyst to a raw material hydroxylamine sulphate is reduced to be 1:8.2, the catalyst has good activity, and the conversion rate of the methylbenzene and the yield of the methylaniline are respectively 66.23 percent and 61.22 percent; and the preparation process for the catalyst is simple and the raw materials are readily available.

Owner:HEBEI UNIV OF TECH

Dispersion of taste masked crystals or granules of active substances, chewable soft capsules filled with said dispersion, and process for preparing same

The present invention concerns a dispersion of crystals or granules of active substance in a lipophilic vehicle, said crystals or granules being coated by a coating for taste masking purposes. The invention also it concerns unit dosage forms and preferentially chewable or fast dissolving soft gelatin capsules filled with said dispersion as well as process for manufacturing same.

Owner:R P SCHERER TECH INC

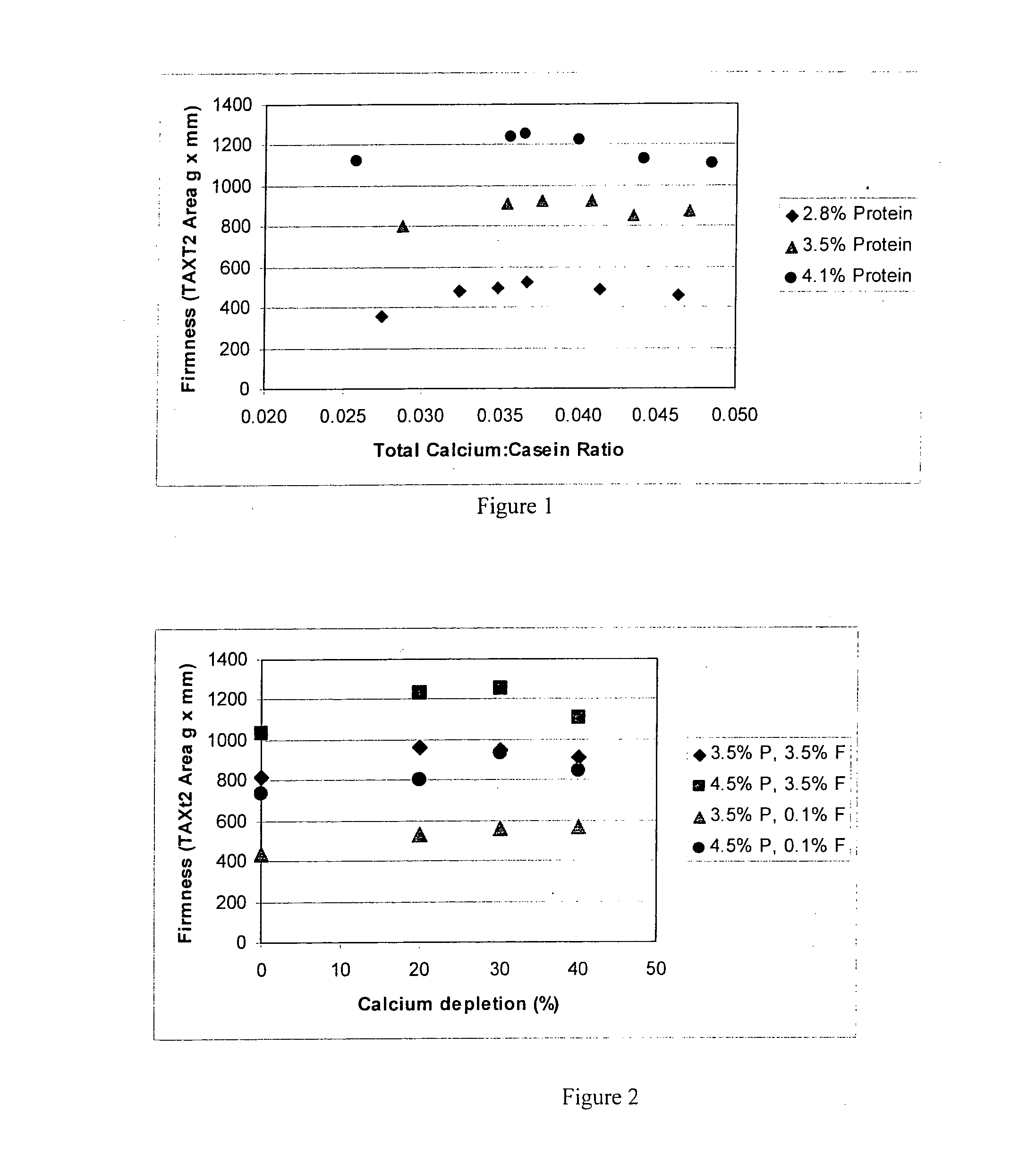

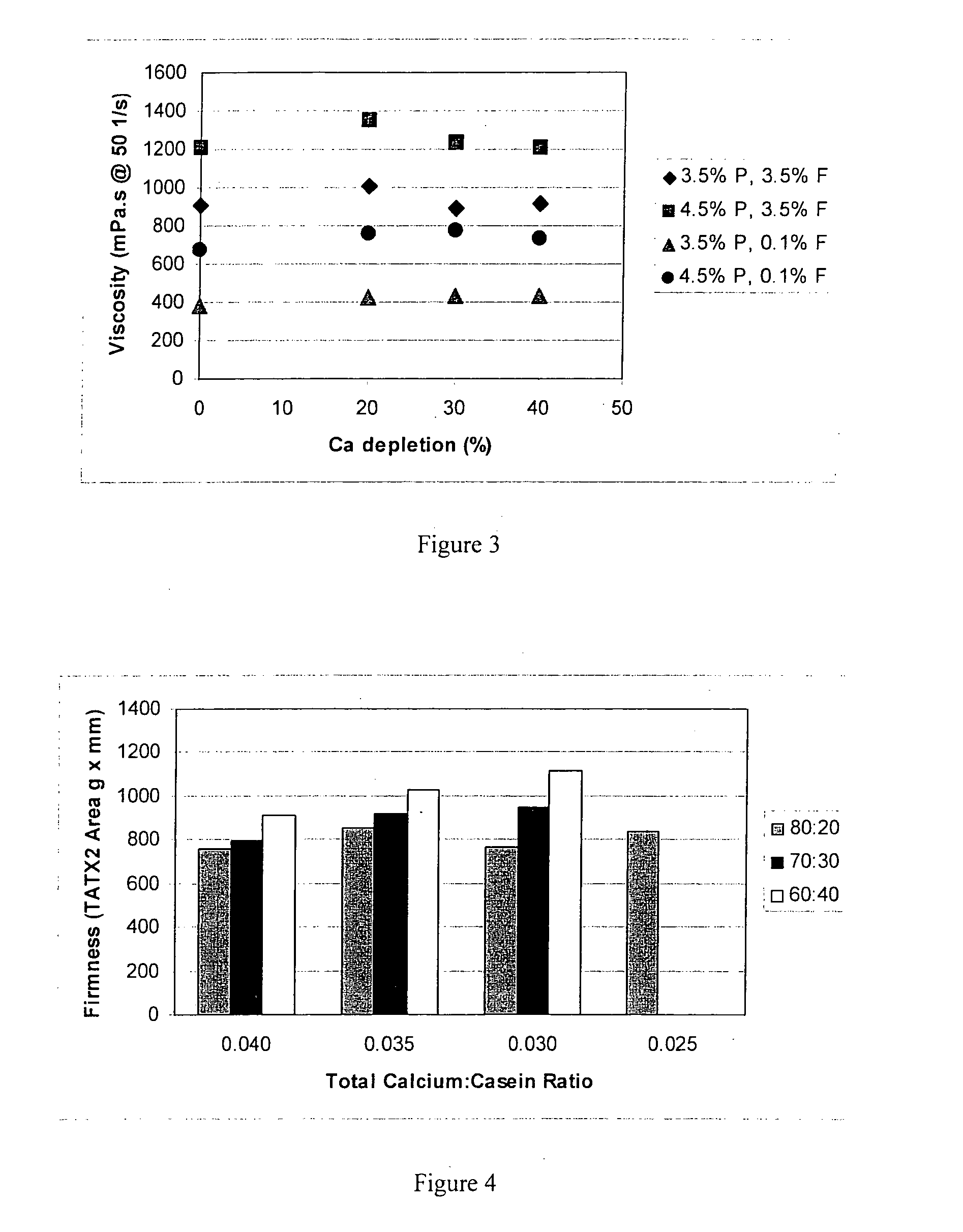

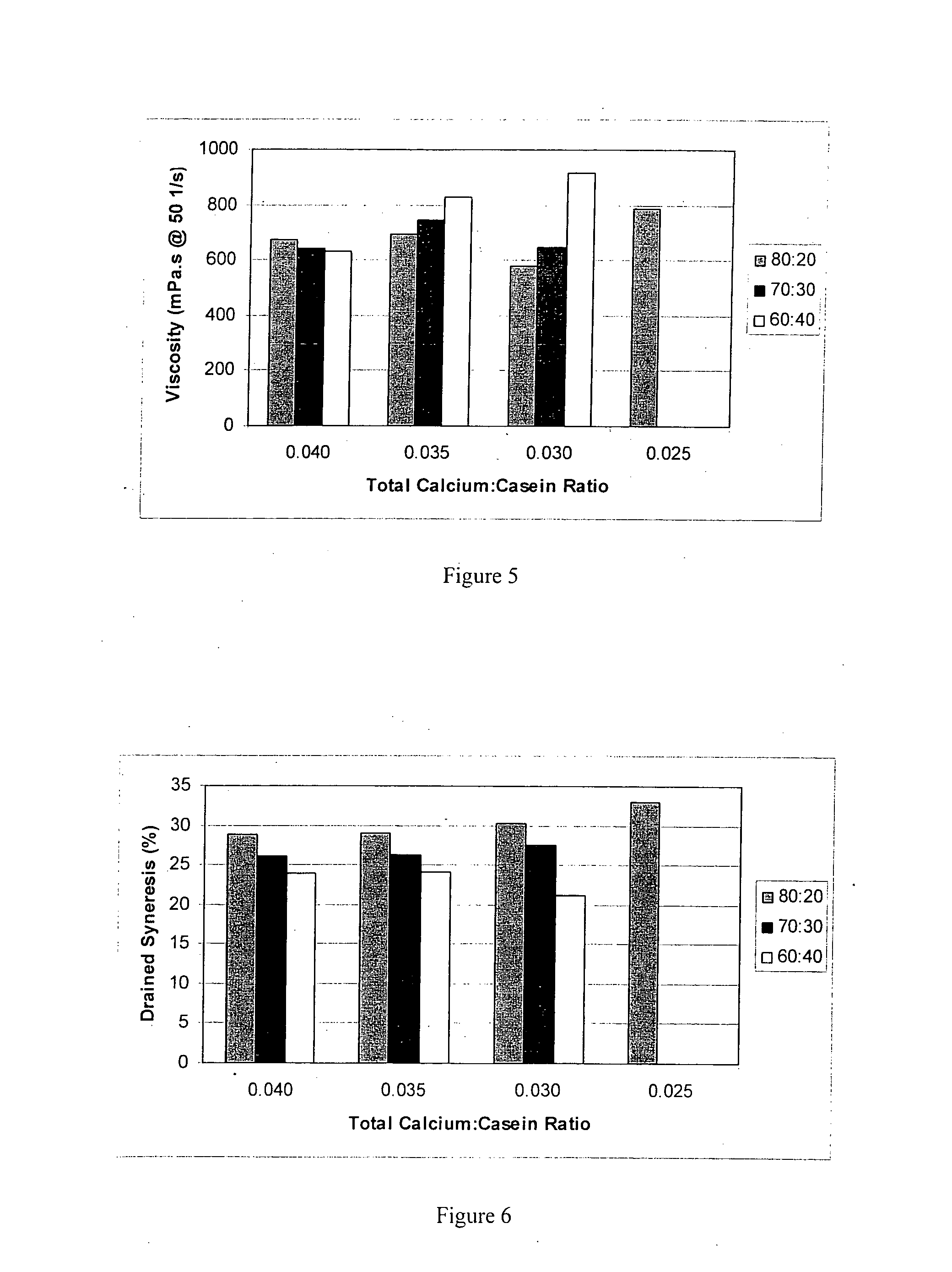

Dairy Product and Process

InactiveUS20100143538A1Reduce syneresis)Increase textural firmnessMilk preparationCheese manufactureAdditive ingredientPotassium

A method for preparing a yoghurt is provided. The method comprises (a) preparing a calcium-depleted milk composition comprising either (i) calcium-depleting a starting milk composition, or (ii) including within a starting milk composition a calcium-depleted milk ingredient selected from milk, fat standardised milk, skim milk, or milk concentrate; and (b) acidifying the calcium-depleted milk composition with chemical acidification or lactic acid producing bacteria, to prepare a yoghurt, wherein the calcium depletion is by contacting the milk composition or ingredient with a cation exchanger to replace calcium in the composition or ingredient with sodium or potassium.

Owner:FONTERRA COOP GRP LTD

Formula and making method for non-burnt brick

InactiveCN103922688AFacilitate cross-linkingExcellent adhesionSolid waste managementCalcium silicateBrick

The invention relates to a formula and a making method for a non-burnt brick, and solves the problems of high treatment cost and no benefit to environmental protection of power plant sintered ash. A small amount of iron powder, calcium oxide and other useful brickmaking substances contained in the power plant sintered ash are utilized to improve the brick strength, so that the made non-burnt brick has the advantages of high strength, high heat resistance temperature, and good durability. The making method includes: taking 30-35 parts by weight of lump power plant sintered ash with a particle size of 5-10mm, 20-25 parts by weight of coal slag powder, 20-25 parts by weight of common sand, 6-8 parts by weight of cement, 3-7 parts by weight of calcium oxide with a particle size of 5-15mm, 3-5 parts by weight of calcium silicate, 1-1.5 parts by weight of sodium sulfate, 0.5-1 part by weight of sodium silicate, 3-5 parts by weight of water-soluble unsaturated resin and 1.5-2 parts by weight of turtle powder, adding 8-15 parts by weight of water to conduct mixing stirring so as to obtain a moist material, and subjecting the moist material to compression moulding by a non-burnt brick molding machine under a pressure of 25MPa.

Owner:JINJIANG MINYI RENEWABLE RESOURCES

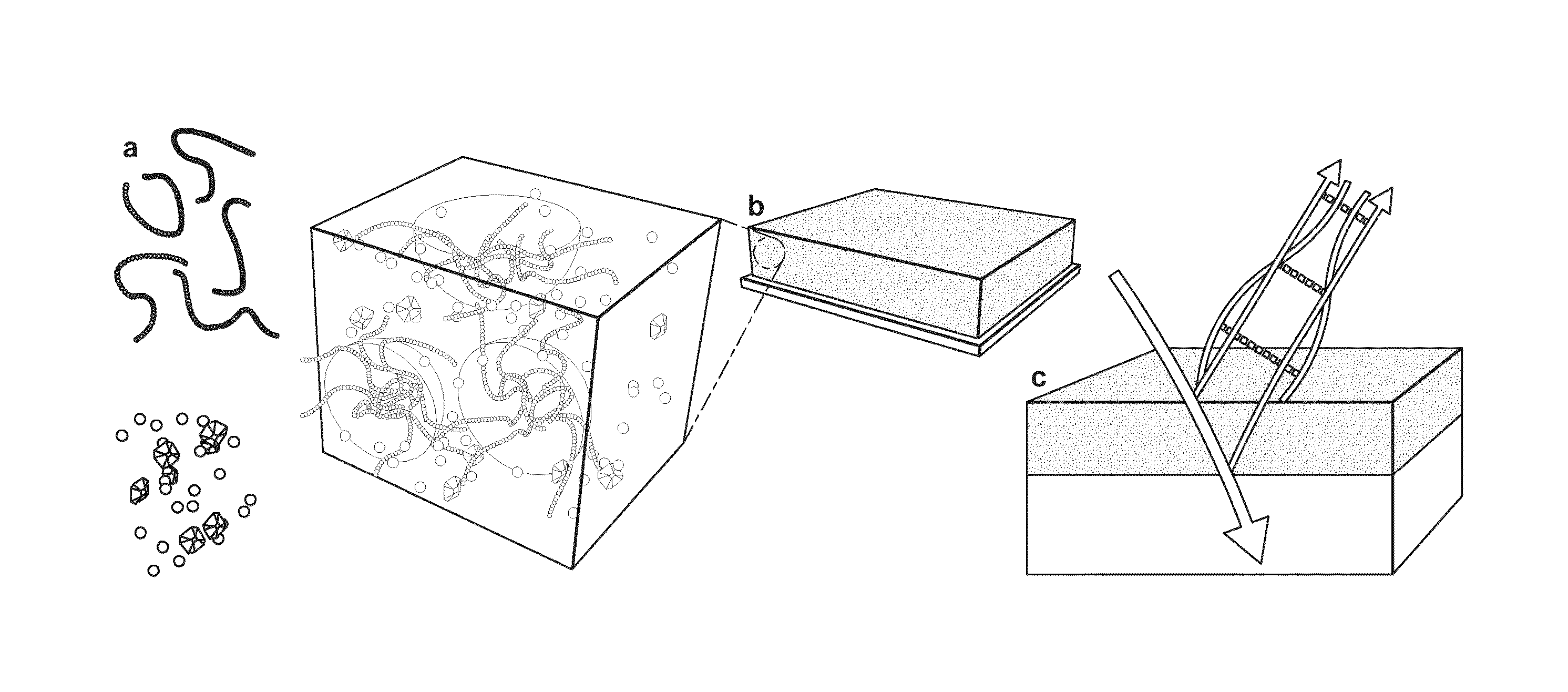

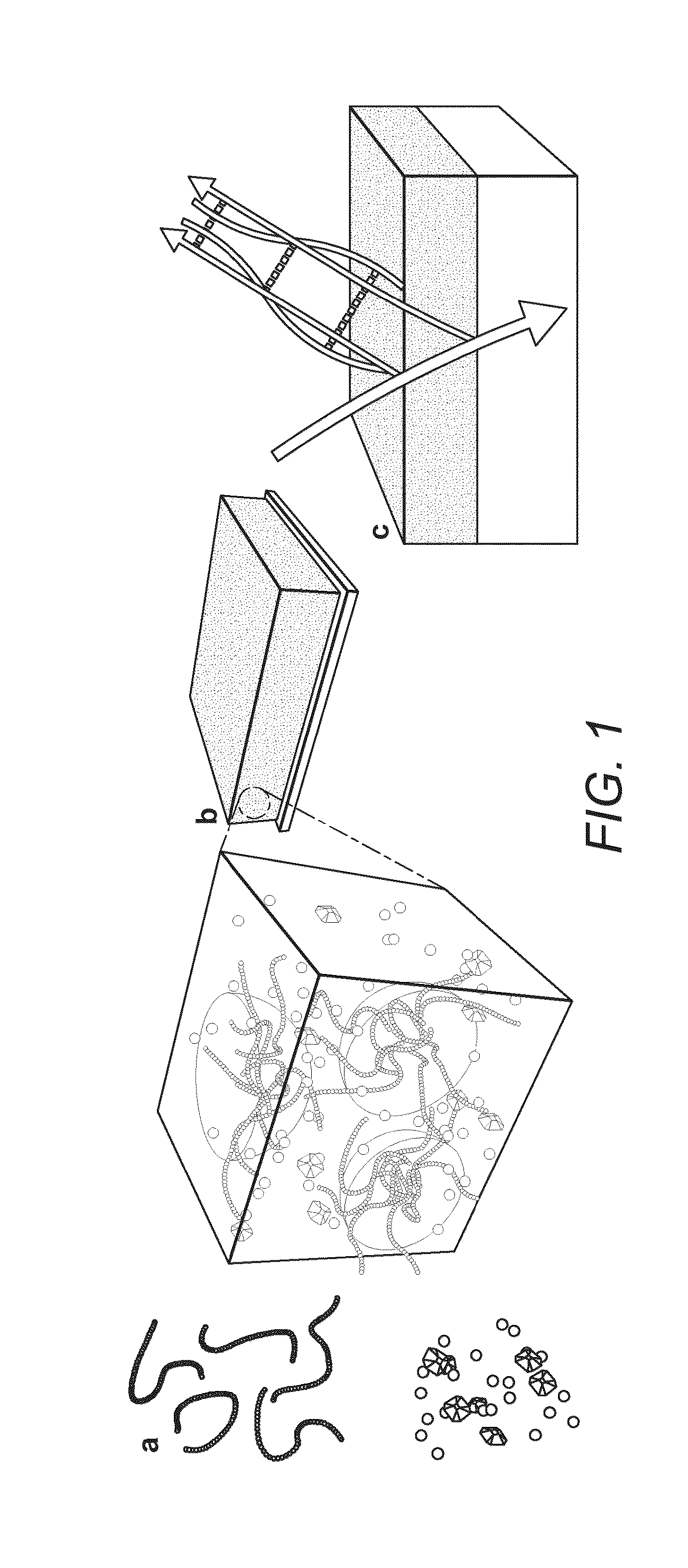

Mesoporous inorganic coatings with photocatalytic particles in its pores

InactiveUS20150376441A1Effective antireflective properties for patterningEffective self-cleaning propertySynthetic resin layered productsCatalyst activation/preparationPorosityMetallurgy

This invention relates to coatings for substrates, in particular antireflective coatings (ARCs) and self-cleaning coatings (SCCs). A coating for a substrate comprises a mesoporous inorganic skeleton having photocatalytic particles provided therein and / or thereon, the coating having a porosity in excess of 50 v / v %, for example, greater than 55%, 60%, 65%, 70 v / v %.

Owner:CAMBRIDGE ENTERPRISE LTD

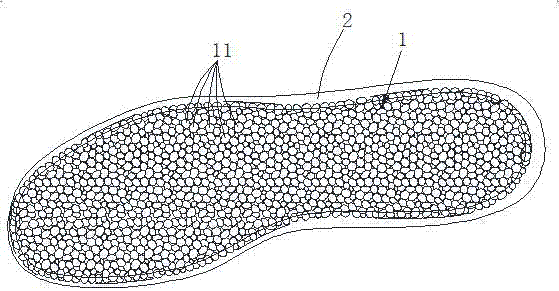

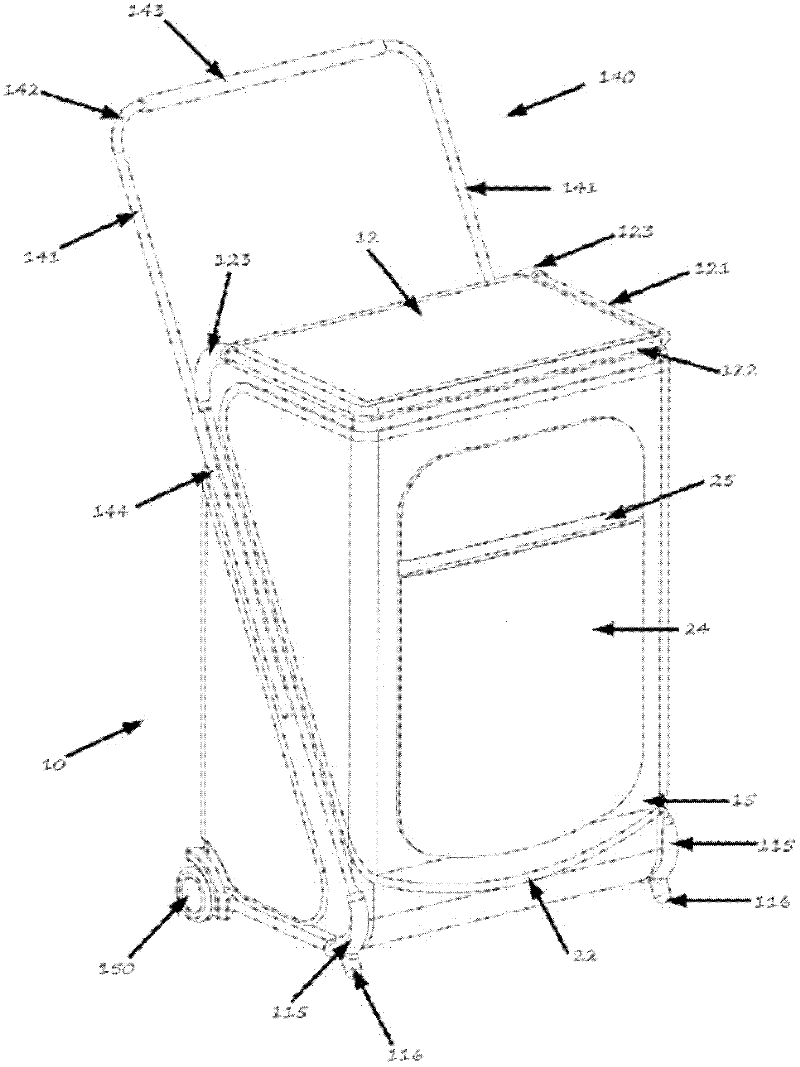

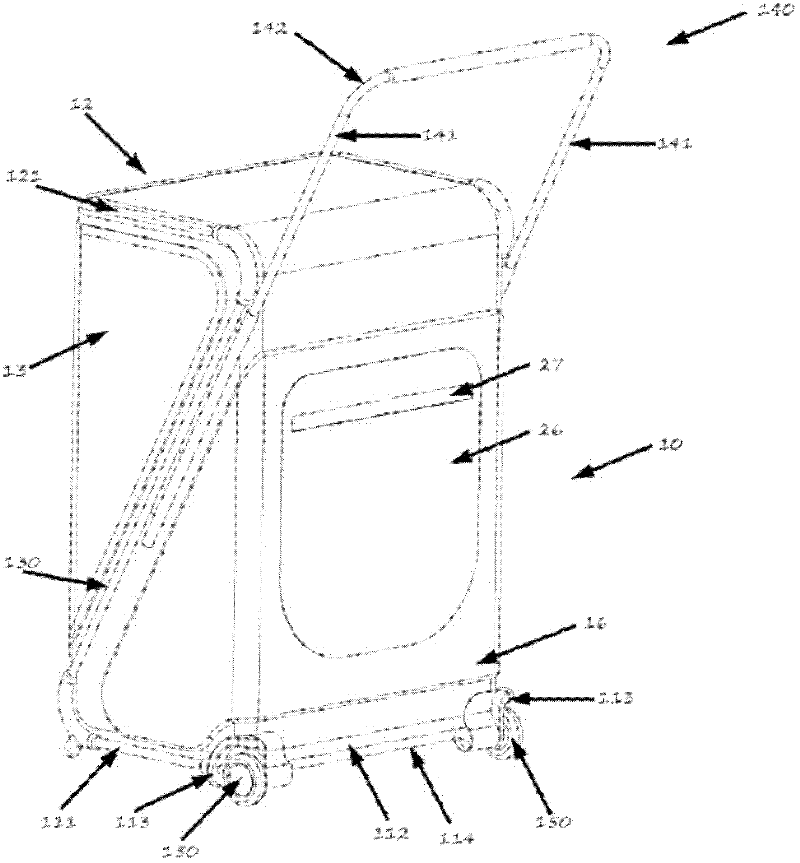

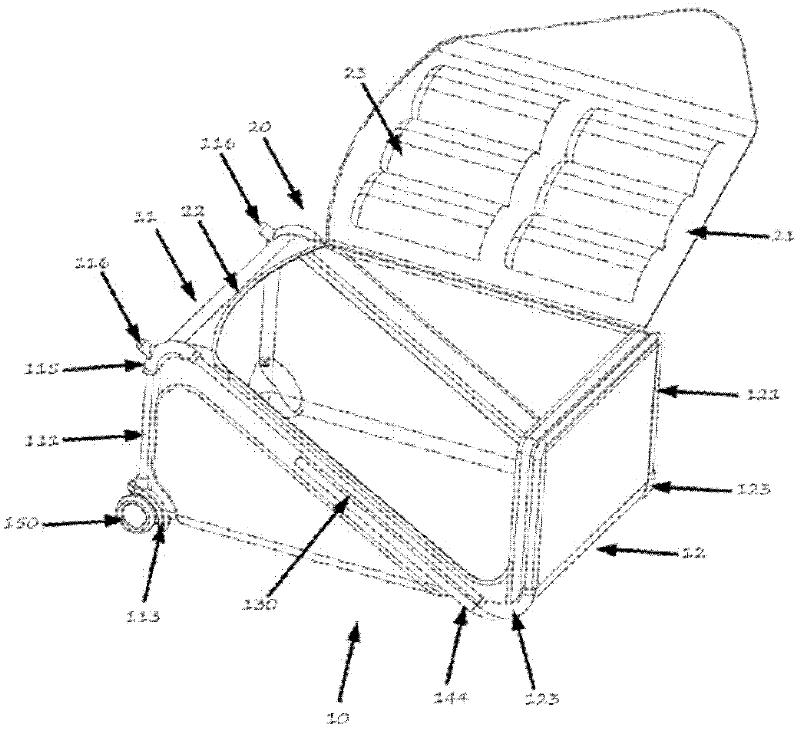

Luggage

InactiveCN102450801AReduce weight ratioReduce the chance of tipping overLuggageOther accessoriesFabric structureSupport plane

Owner:英国优品国际采购公司

Lithium ion battery electrode and preparation method thereof

InactiveCN108511692AWidely distributedReduce weight ratioMaterial nanotechnologyCell electrodesCarbon nanotubeSlurry

The invention provides a lithium ion battery electrode and a preparation method thereof. The preparation method comprises the following steps: dispersing carbon nanotubes in a solvent to obtain a dispersion, wherein a mass ratio of the carbon nanotubes to the solvent is 0.0002 to 0.02:1; mixing an active material, an additive and a binder, adding the dispersion liquid dropwise during the mixing toobtain an electrode slurry; coating the current collector with the electrode slurry, drying and rolling to obtain the lithium ion battery electrode. The present invention also provides the lithium ion battery electrode prepared by the above method. The carbon nanotubes in the electrode obtained by the method have good dispersibility.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

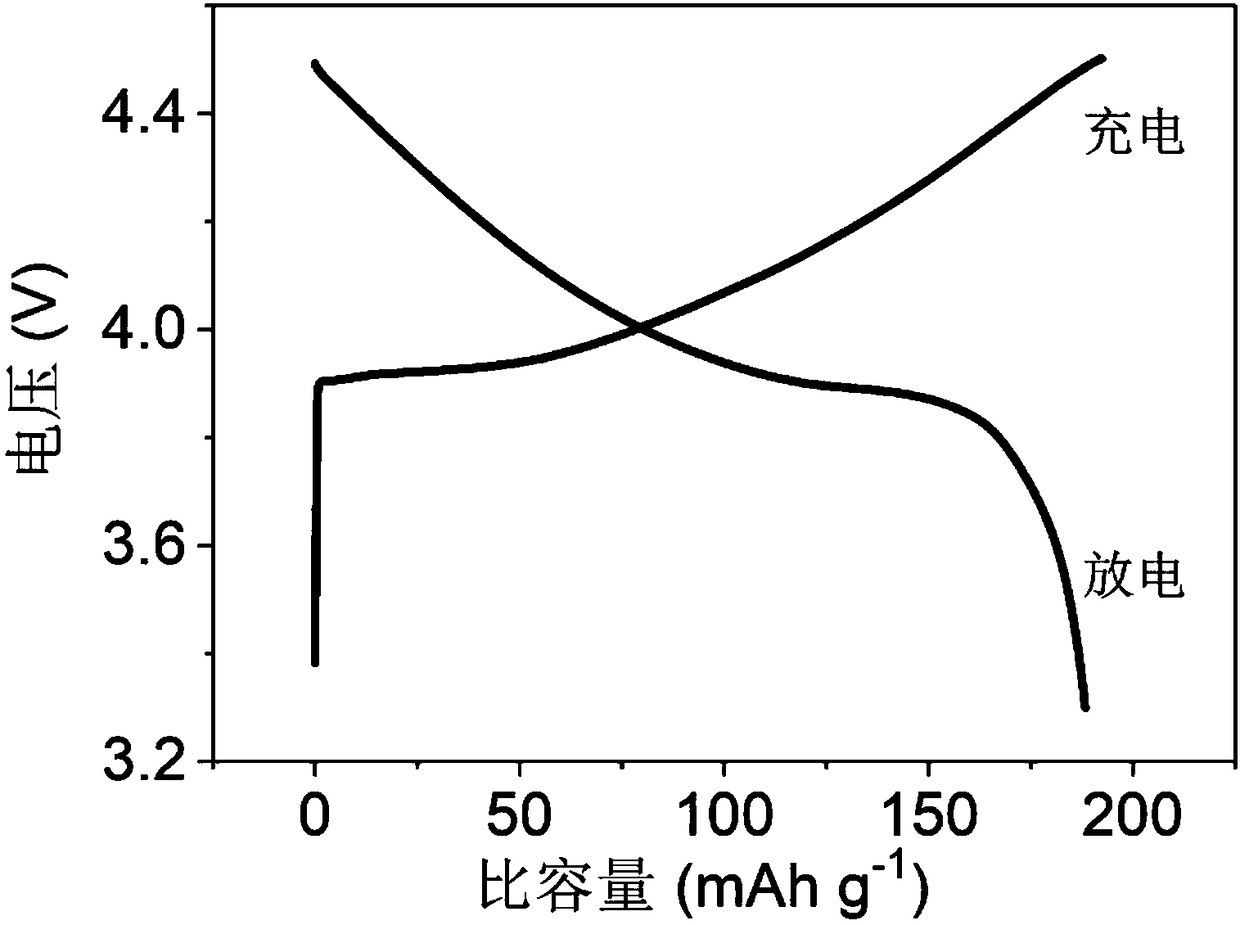

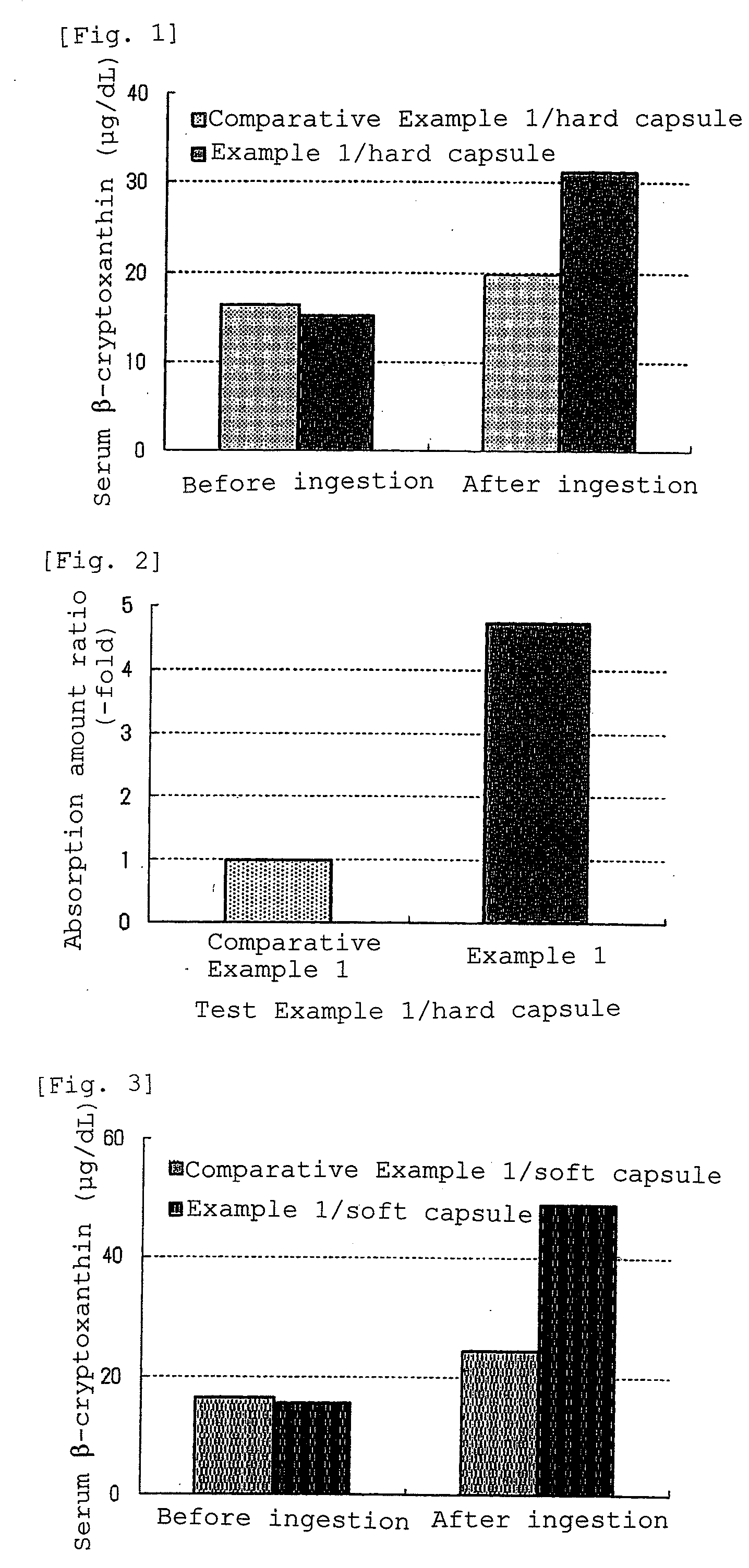

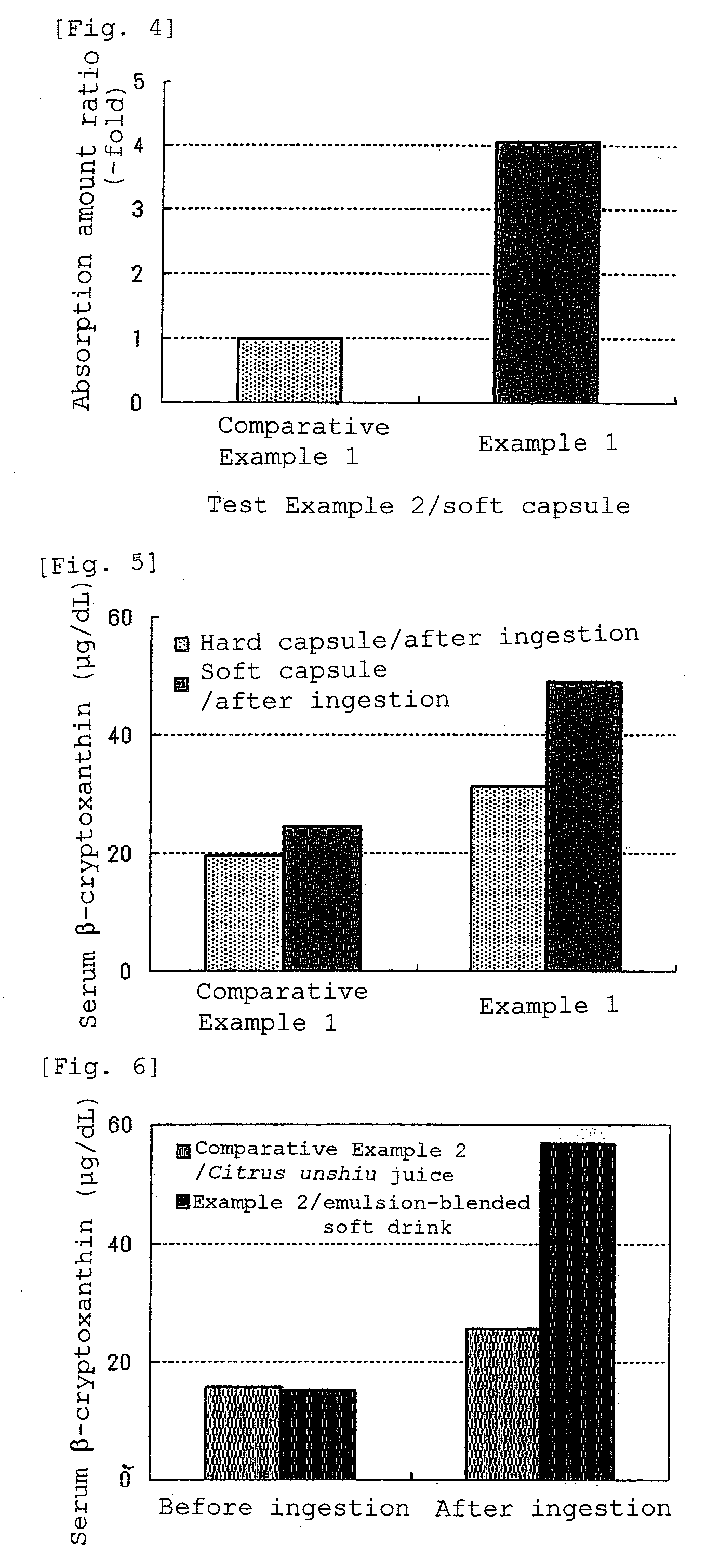

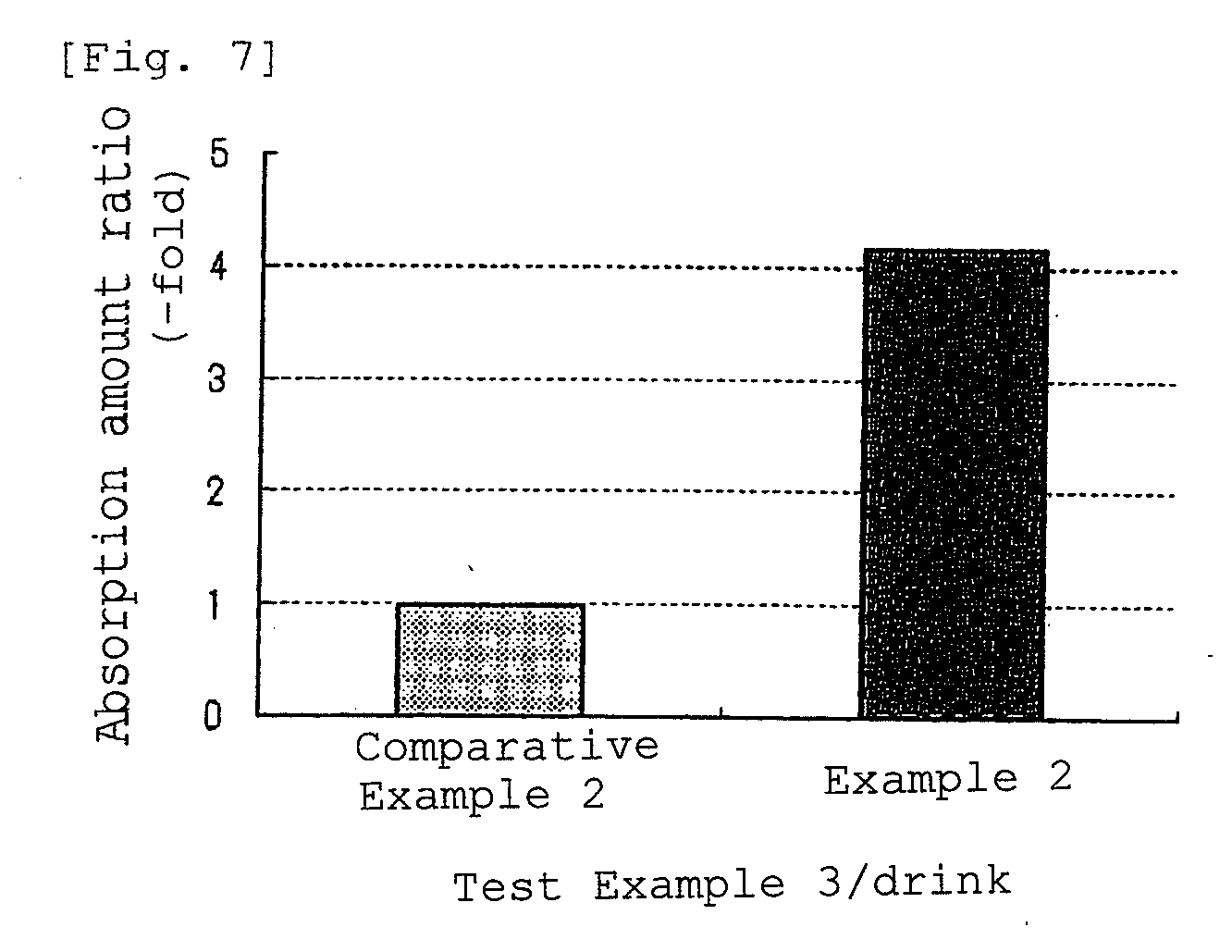

Highly bioavailable oral administration composition of cryptoxanthin

InactiveUS20090258111A1Safely ingestedImprove antioxidant capacityHydroxy compound active ingredientsTea extractionNatural productOral medication

A composition having improved bioavailability, of cryptoxanthin derived from a natural product, particularly that derived from Citrus unshiu Marc known to be rich in cryptoxanthin, and a method for economically and conveniently producing the same are provided. As a cryptoxanthin highly bioavailable oral administration composition, which is a composition comprising natural product-derived cryptoxanthin, wherein the amount of dietary fibers contained in said composition is 400 times by weight or less based on cryptoxanthin, this composition is a composition wherein the bioavailability of cryptoxanthin is improved 2 times or more in comparison with the case of directly ingesting a natural product containing said cryptoxanthin.

Owner:UNITIKA LTD

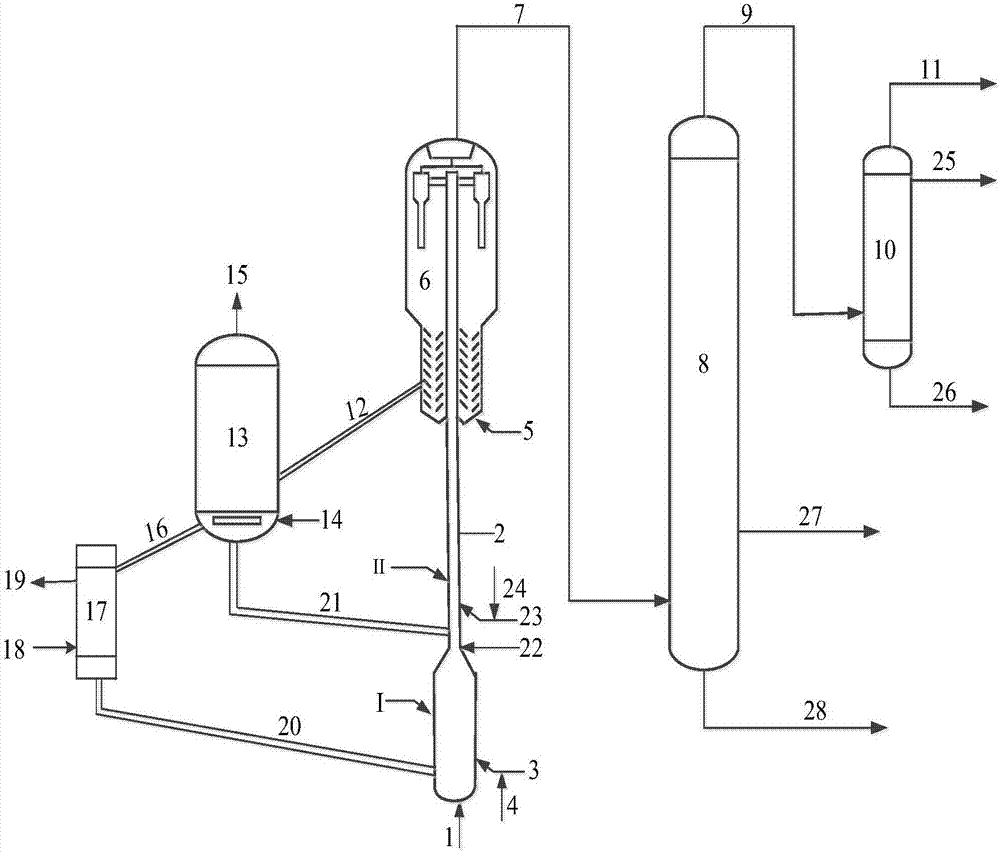

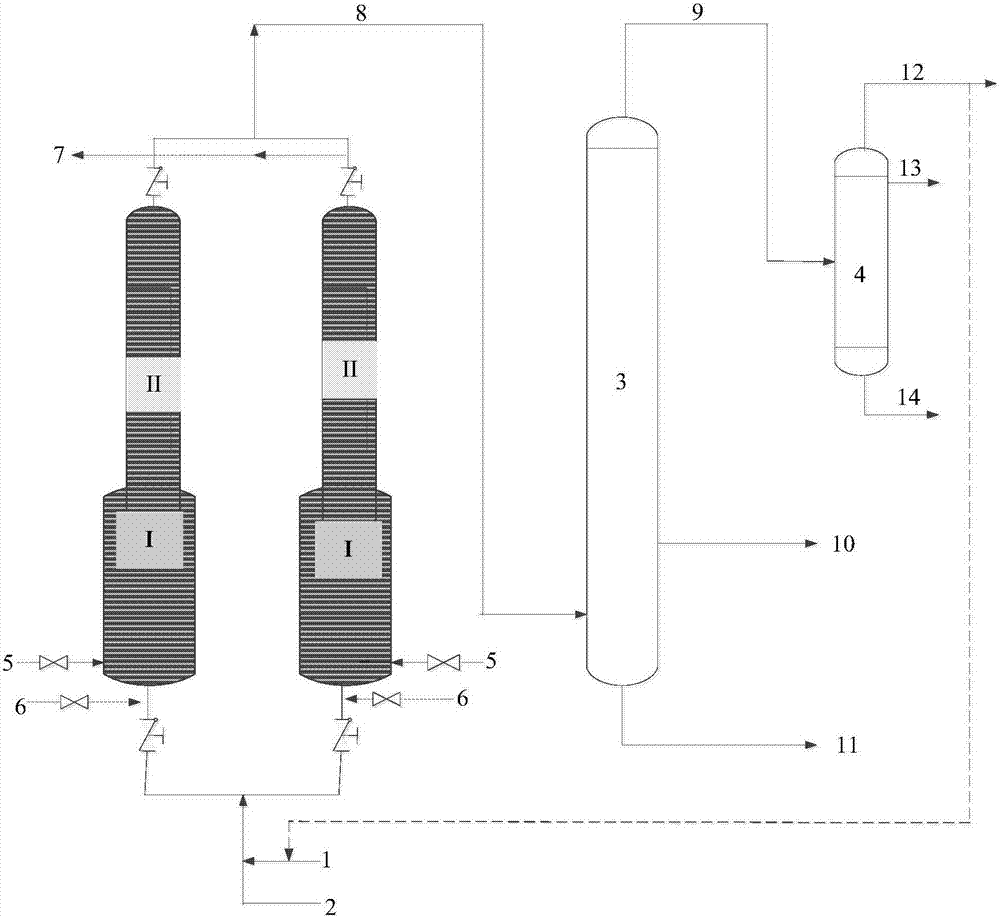

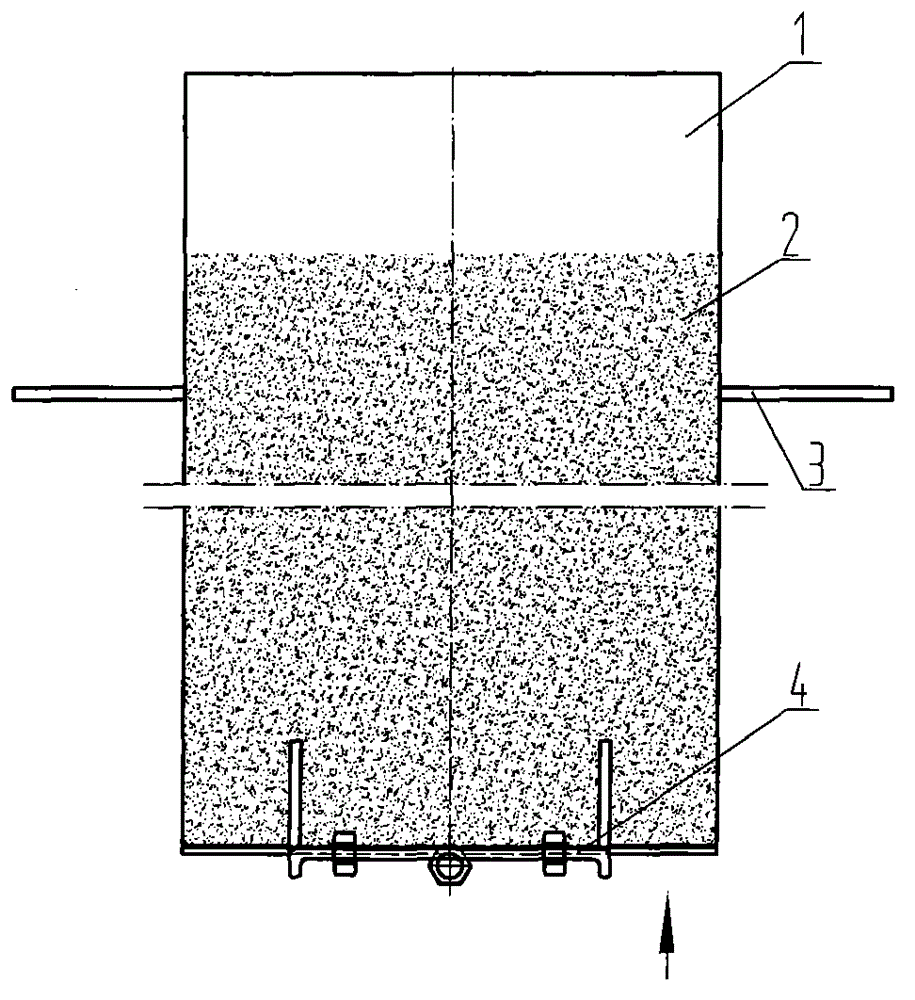

Processing method and system for inferior crude oil

ActiveCN107267207ARestore activityIncrease pressureTreatment with hydrotreatment processesHydrogenSorbent

The invention discloses a processing method and system for inferior crude oil. The method comprises the steps as follows: a, feeding hydrogen-containing gas and the inferior crude oil into a hydrogen absorption zone (I) of a fixed bed reactor for contact with an adsorbent and a hydrogen adsorption reaction to obtain a hydrogen absorption product; b, feeding the hydrogen absorption product obtained in the step a into a cracking zone (II) of the fixed bed reactor for contact with a catalytic cracking catalyst and a catalytic cracking reaction to obtain catalytic cracked oil-gas. The inferior crude oil processed by the system with the method has the advantages that the conversion rate of the inferior crude oil can be increased substantially, the yield of dry gas and coke is reduced, and accordingly, clean and efficient use of the inferior crude oil is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

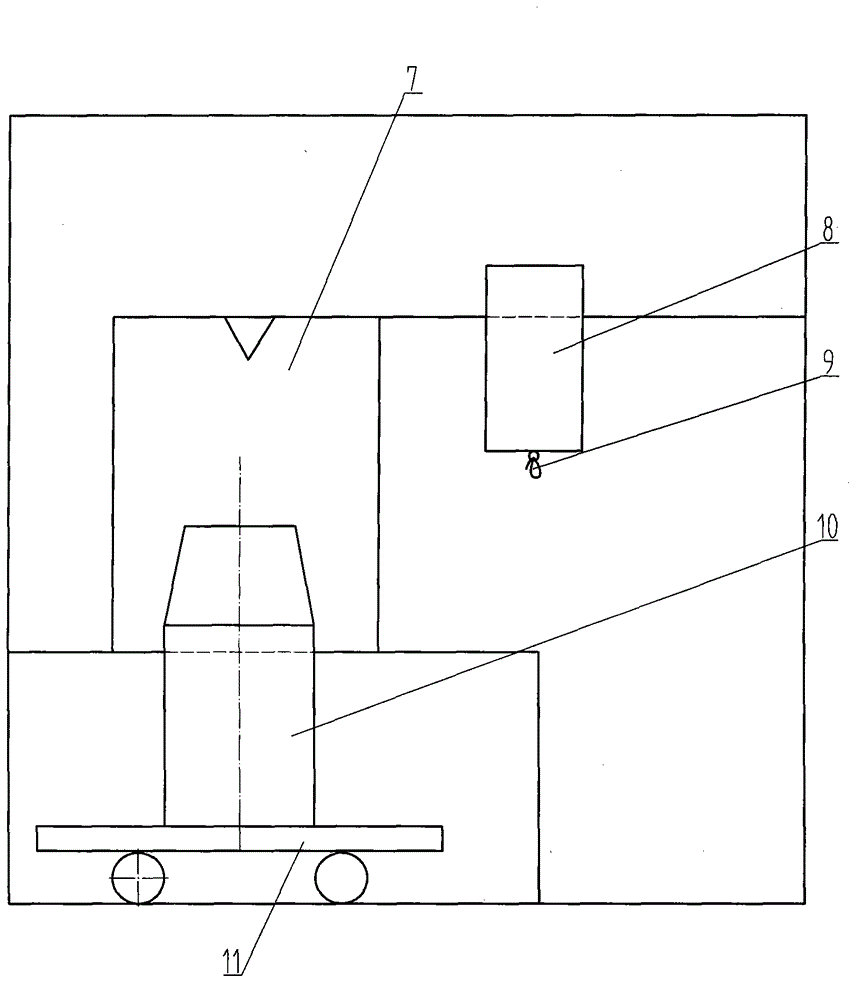

Vacuum pouring method of ingot casting and heat-generating agent feeding barrel for ingot casting and vacuum chamber for pouring

The invention provides a vacuum pouring method of ingot casting and a heat-generating agent feeding barrel for ingot casting and a vacuum chamber for pouring. The shortcoming that during vacuum poring in the prior art, a heat-generating agent adding method enables ingot casting yields to be low, the effect of the added heat-generating agent is not ideal is overcome. The method comprises at least two steps, namely pouring liquid steel into an ingot mould in a vacuum mode and adding the heat-generating agent into a riser. After the liquid steel is poured into the ingot mould, the vacuum chamber is broken immediately. When the pressure of the vacuum chamber reaches 8000-12000 Pa, the heat-generating agent is immediately added into the riser in the vacuum chamber. The feeding barrel is arranged inside the vacuum chamber. The feeding barrel comprises a barrel body. A bottom plate door which turns downwards is arranged on the bottom of the barrel body. The bottom plate door is closed through a hot melting component. According to the method, the feeding barrel and the vacuum chamber, the ingot casting yields are high, and the effect of the heat-generating agent can be achieved greatly.

Owner:秦皇岛核诚镍业有限公司

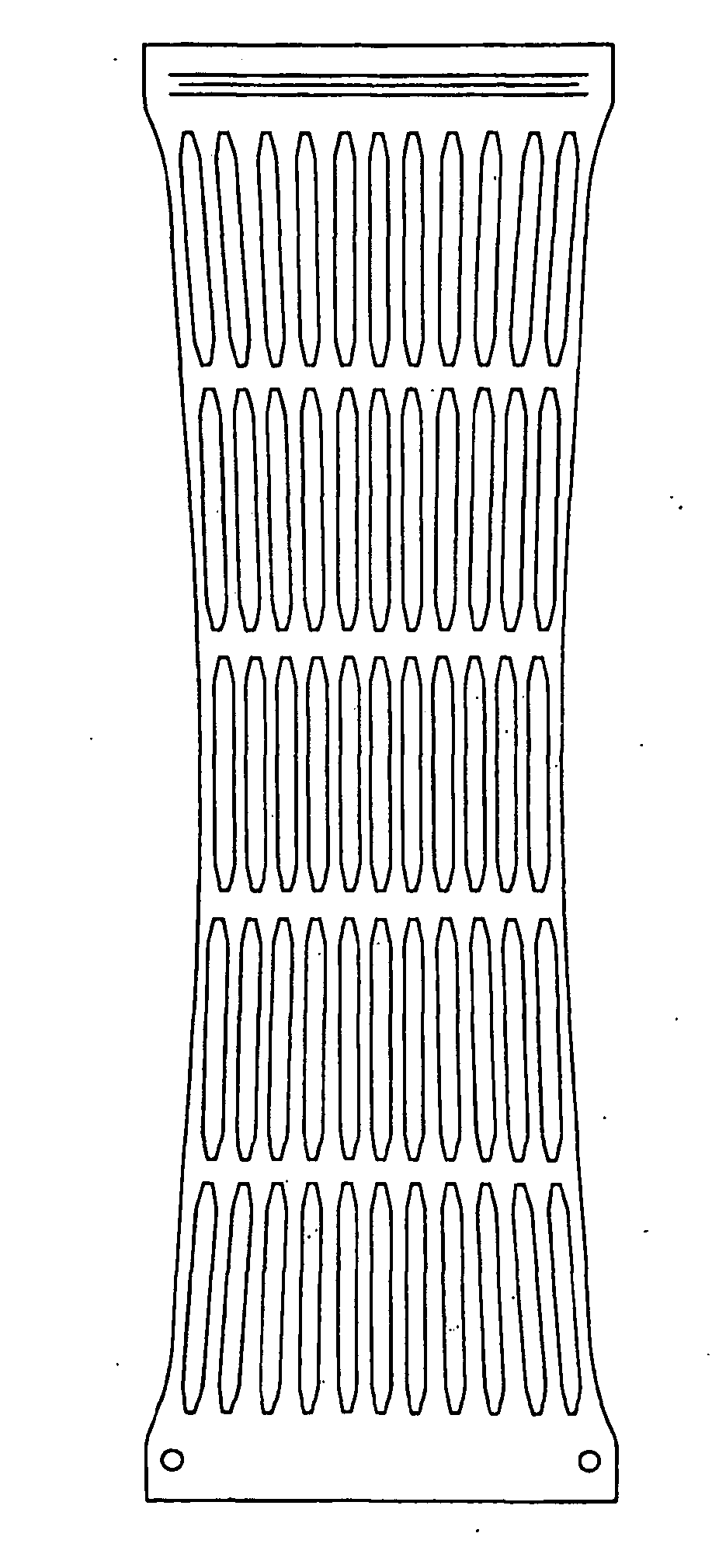

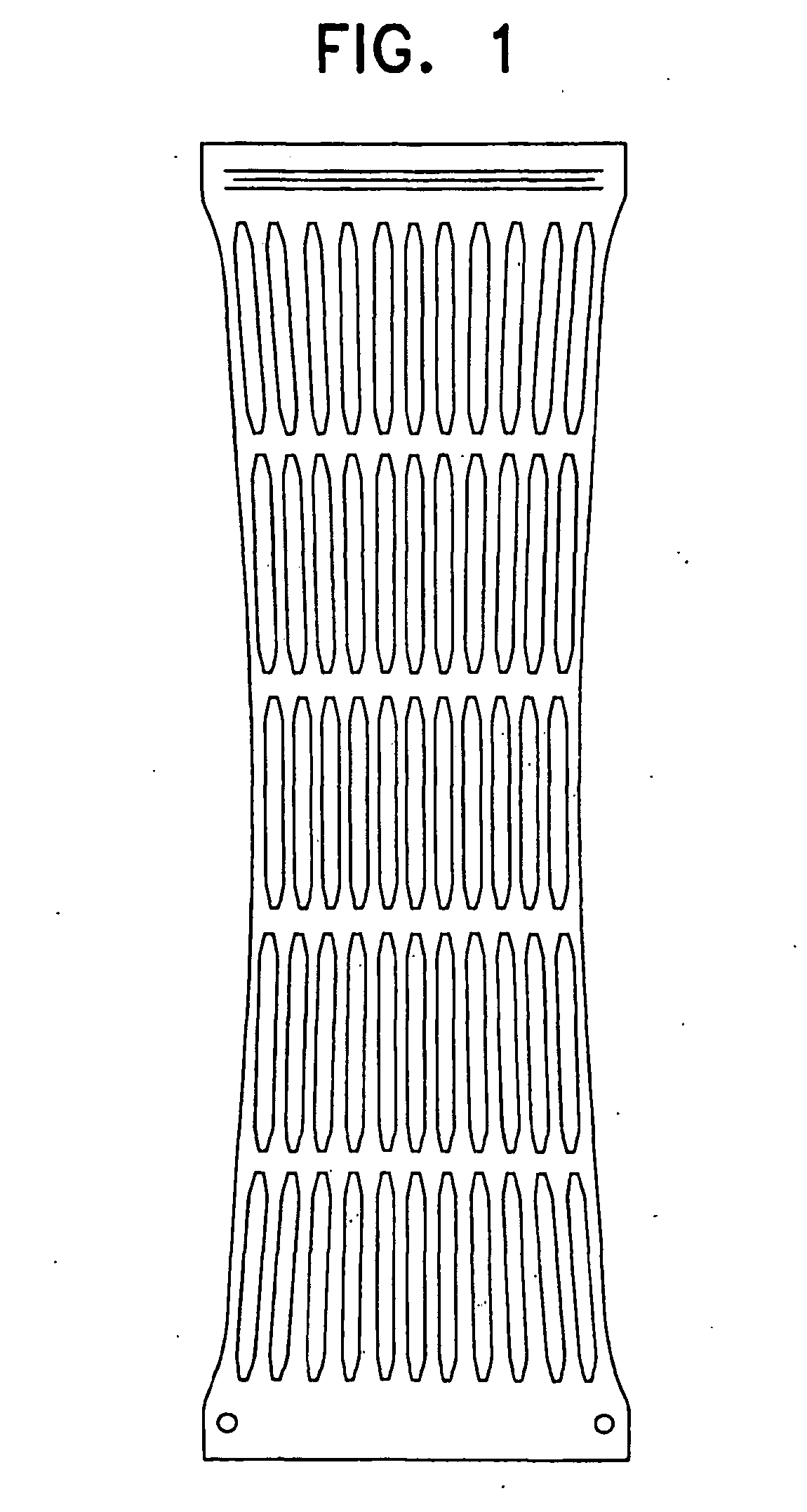

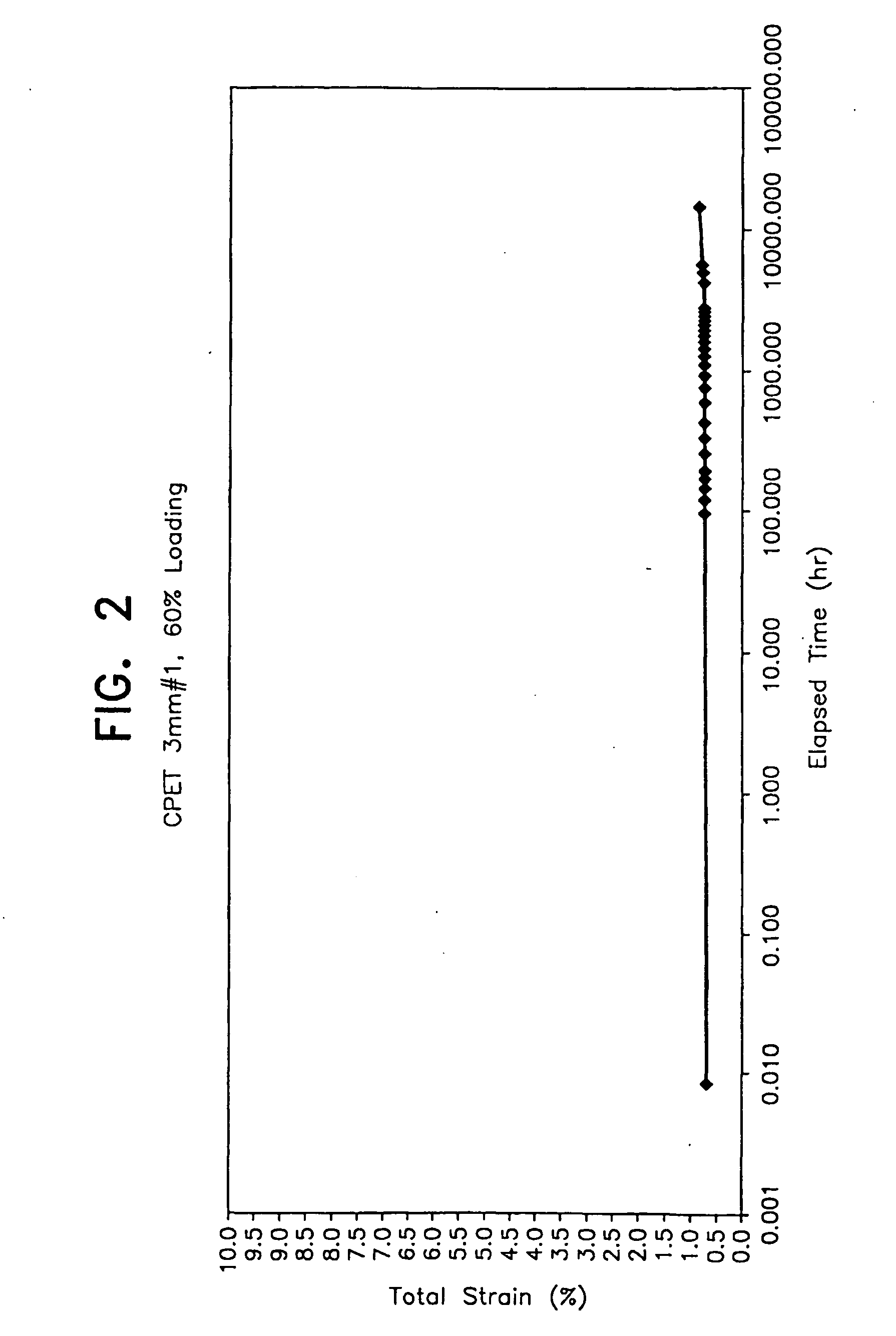

Integral polyethlene terephthalate grids, the method of manufacture, and uses thereof

ActiveUS20100254771A1Low costImprove toughnessLayered productsProtective foundationPolyethylene terephthalatePolyethylene terephthalate glycol

An integral polymer grid with a plurality of interconnected, oriented polyethylene terephthalate strands and an array of openings therein is made from a polyethylene terephthalate sheet-like starting material having holes or depressions therein that form the openings when the sheet-like material is uniaxially or biaxially stretched. The grid has a higher tensile strength to weight ratio and a higher creep reduced strength to weight ratio than corresponding ratios associated with a grid made from a non-polyethylene terephthalate starting material.

Owner:TENSAR CORPORATION LLC +1

Anti-tear high-toughness conducting rubber and preparation method thereof

ActiveCN108530898AImprove electrical performanceImprove mechanical propertiesBreaking strengthVulcanization

The invention relates to the technical field of preparation and rubber, in particular to anti-tear high-toughness conducting rubber and a preparation method thereof. The preparation method comprises the following steps: adding an appropriate amount of conventional conducting powder into a rubber matrix, further adding 0.1 to 0.5 percent of ultrafine powder, performing the banburying and open smelting step by step by adopting a rubber mixing machine according to the technological requirement, mixing silicone rubber and hydroxyl oil by virtue of a mixing machine, adding the conducting powder, ametal passivation agent and a vulcanization catalyst into an open smelting machine, uniformly mixing, extruding, and vulcanizing. The electric performance and mechanical performance of the conductingrubber are improved, the volume density of the conducting rubber is reduced, the tear strength and breaking strength are improved, and the toughness is improved. By adding the ultrafine powder, the weight ratio of the conventional conducting powder is reduced, a lubricating effect is realized, the extruding forming speed is increased, and the production efficiency is improved.

Owner:NO 33 RES INST OF CHINA ELECTRONICS TECHNOOGY GRP

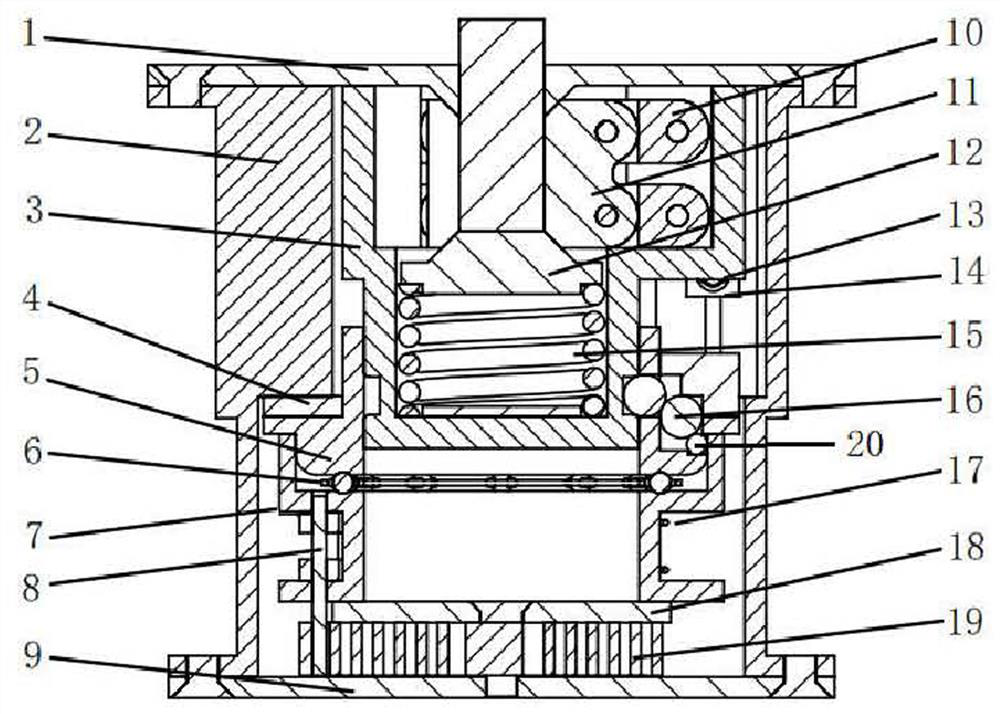

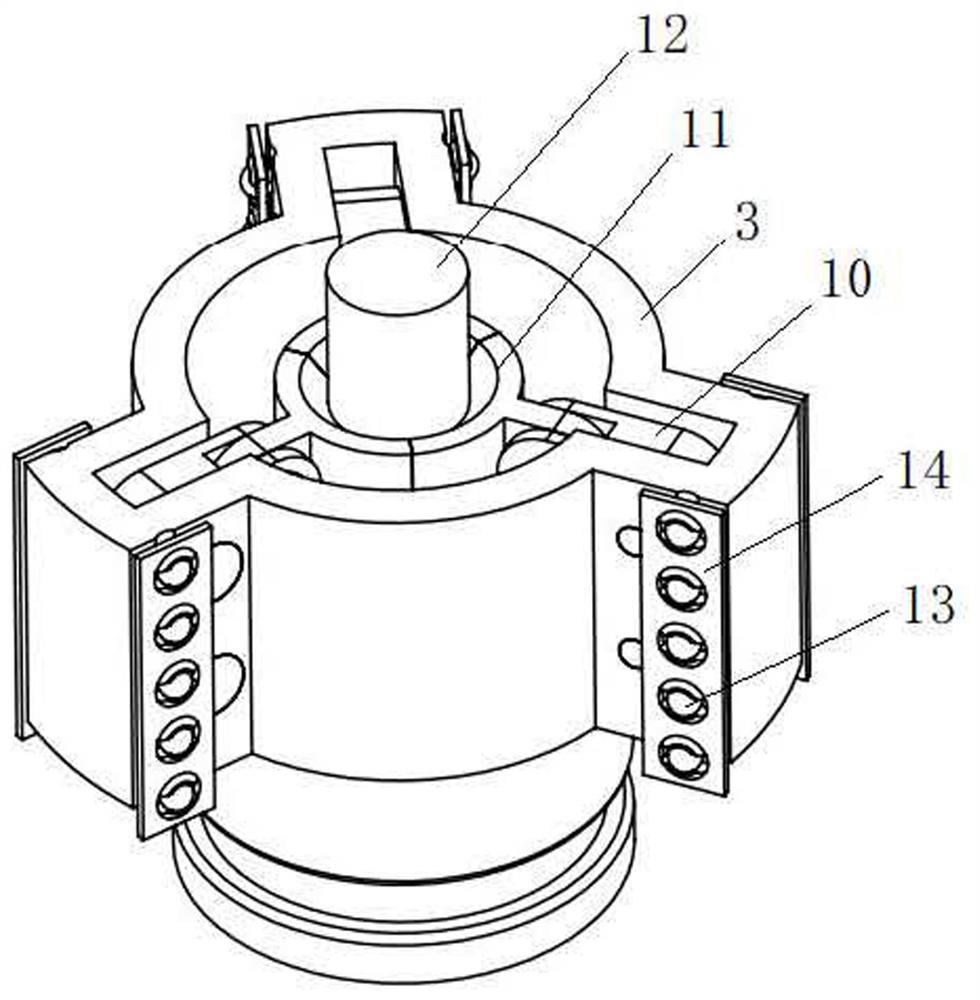

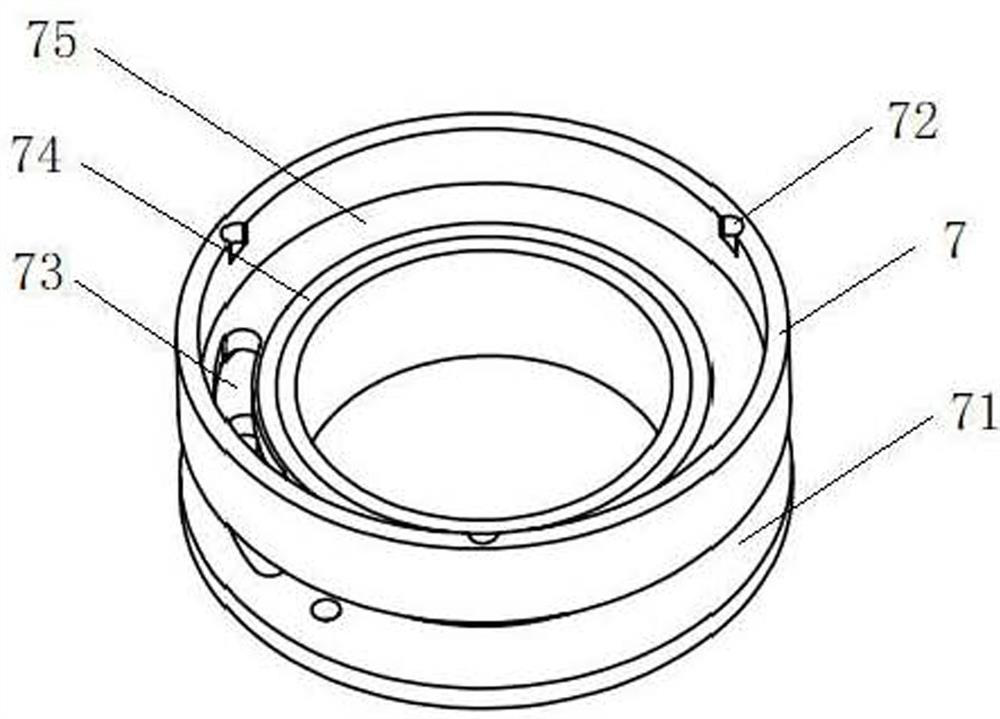

Compression and release device based on memory alloy

ActiveCN113830329AExpand smoothlyHigh strengthCosmonautic vehiclesAntenna adaptation in movable bodiesSatellite antennasSatellite technology

The invention relates to the technical field of spaceflight launching satellites, and concretely relates to a compression and release device based on memory alloy. The device comprises a shell, a sliding block, a driving block, a split nut, a driving spring cover, a driving spring, a connecting rod mechanism, a small ball control mechanism and a driving mechanism, wherein the sliding block is arranged in the shell, the driving spring and the driving spring cover are arranged in the containing cavity of the sliding block from bottom to top, the split nut is in threaded connection with the driving spring cover, the split nut is connected with the sliding block through the connecting rod mechanism, and the connecting rod mechanism pulls the split nut when the sliding block moves downwards, so that locking of the driving spring cover is relieved; the driving mechanism, the driving block and the small ball control mechanism are arranged at the bottom of the shell from bottom to top, and the small ball control mechanism is arranged on the outer side of the lower end of the sliding block and used for limiting axial movement of the sliding block; and the driving mechanism is used for driving the driving block to rotate to a preset position. According to the invention, the task requirement of unfolding the satellite antenna is met, and the reliability and safety of compressing and releasing the satellite antenna are improved.

Owner:沈阳中科新宇空间智能装备有限公司 +1

Medium-chromium wear-resistant lining board

InactiveCN104087842AGood wear resistanceThere are few types of alloysFoundry mouldsFoundry coresChromiumWear resistant

The invention discloses a medium-chromium wear-resistant lining board, belonging to the technical field of wear-resistant lining boards. The medium-chromium wear-resistant lining board is composed of the following components in percentage by weight: 0.65-0.8% of C, 0.6-0.8% of Mn, 0.6-0.8% of Si, 5.6-6.2% of Cr, 0.6-0.7% of Mo, 0.03-0.05% of B, at most 0.2% of Cu, at most 0.01% of P, 0.02-0.1% of Re and the balance of Fe. By reasonably improving the formula of the wear-resistant lining board and using the reasonable processing technique, the wear-resistant lining board has the advantages of favorable wear resistance, favorable corrosion resistance and favorable toughness, and can be used as a ball mill lining board or composite self-fixing lining board; the surface HRC is greater than or equal to 60 Mpa, the shock absorption energy is greater than or equal to 20J, and the service life is 10000-12000 hours; and the wear-resistant lining board has fewer alloy types, lower weight ratio and lower cost.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

Hypromellose acetate succinate for use as hot-melt extrusion carrier, hot-melt extrusion composition, and method for producing hot-melt extrudate

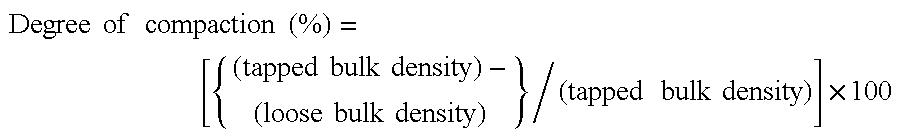

Provided are hypromellose acetate succinates (HPMCAS) for use as a hot-melt extrusion carrier having a volume average particle size (D50) of from 70 to 300 as measured by dry laser diffraction and a loose bulk density of from 0.25 to 0.40 g / cm3; and a hot-melt extrusion composition comprising the HPMCAS and a drug. Also provided is a method for producing a hot-melt extrudate including the steps of: hot-melting the hot-melt extrusion composition at a hot-melt temperature equal to or higher than a melting temperature of the HPMCAS, or at a hot-melt temperature equal to or higher than a temperature at which both of the HPMCAS and the drug become melt; and extruding the hot-melted composition.

Owner:SHIN ETSU CHEM IND CO LTD

Bacillus amyloliquefaciens probiotics capable of producing phytase and preparation as well as preparation method of probiotics

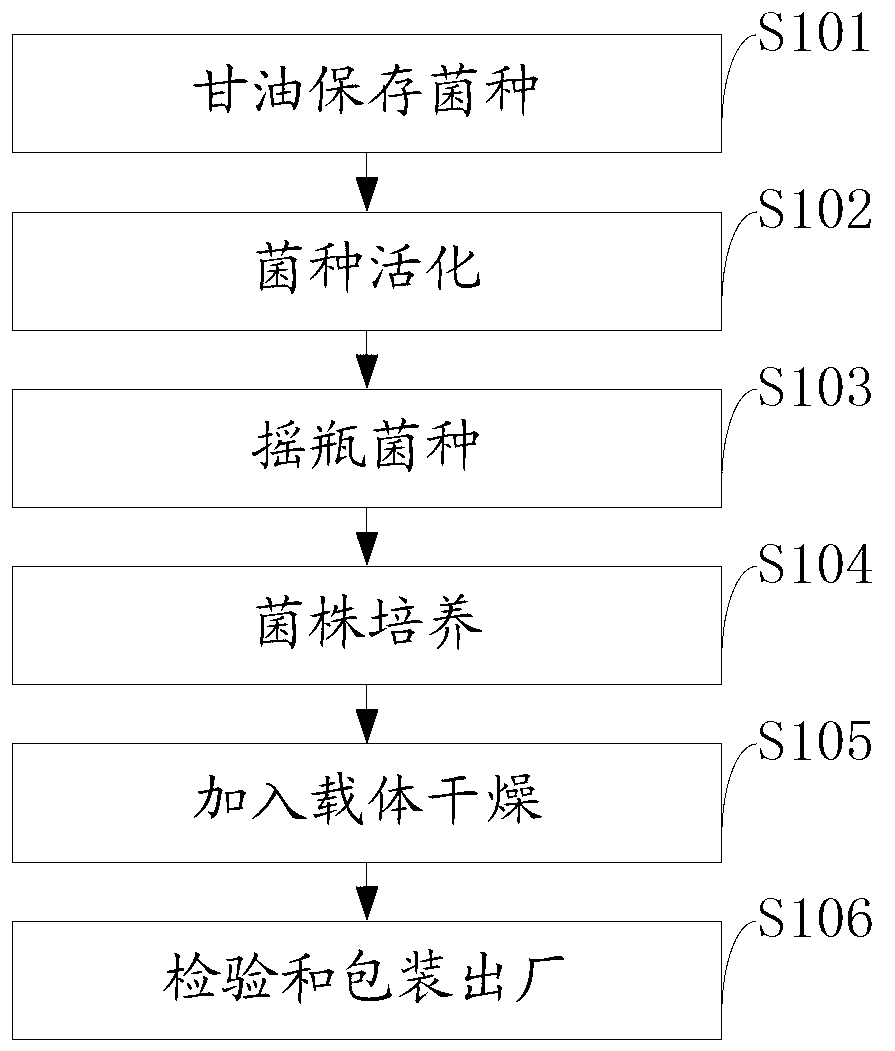

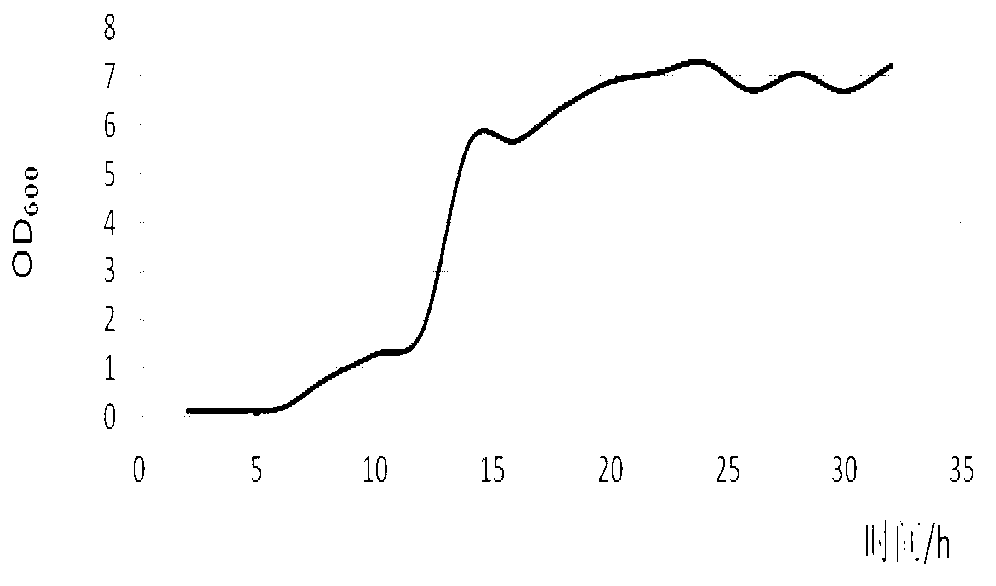

InactiveCN103289934AMaintain micro-ecological balancePromote growthBacteriaHydrolasesBiotechnologyPhytase

The invention discloses bacillus amyloliquefaciens probiotics capable of producing phytase, and a preparation as well as a preparation method of the bacillus amyloliquefaciens probiotics. The gene GenBank accession number of the rRNA (Ribosomal Ribonucleic Acid) gene sequence of the bacillus amyloliquefaciens T6, 16S is JX081245. According to the method, a shallow tray fermentation culture method and a submerged fermentation culture method are applied to strain culture, and the specific steps include strain storage by glycerinum, strain activation, strain treatment in a shake flask, strain culture, load of the strain to a carrier, drying, inspection, and packaging to obtain a finished product. The novel probiotics preparation is prepared by using the bacillus amyloliquefaciens strain capable of producing the phytase, which is heat resistant, dryness resistant, acid resistant, alkali resistant and long in storage period, is stable in quality, and can be used for keeping intestinal microecological balance of livestock and poultry, ensuring that the growth and development of an animal in an ideal state reaches the maximum capacity of the animal, improving the feed digestion rate of the animal, improving the disease resistant capacity of the animal, promoting animal health, reducing the calcium phosphate addition amount in daily ration, reducing the excretion amount of the calcium phosphate in excrements of livestock and poultry, protecting environment and achieving the proposes of energy conservation and emission reduction.

Owner:四川伯乐福生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com