Processing method and system for inferior crude oil

A low-quality raw material oil and processing method technology, which is applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment, etc., can solve the problems of difficult acid slag treatment, high energy consumption, environmental pollution, etc., and save gas-rich compressors, Reduced device energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

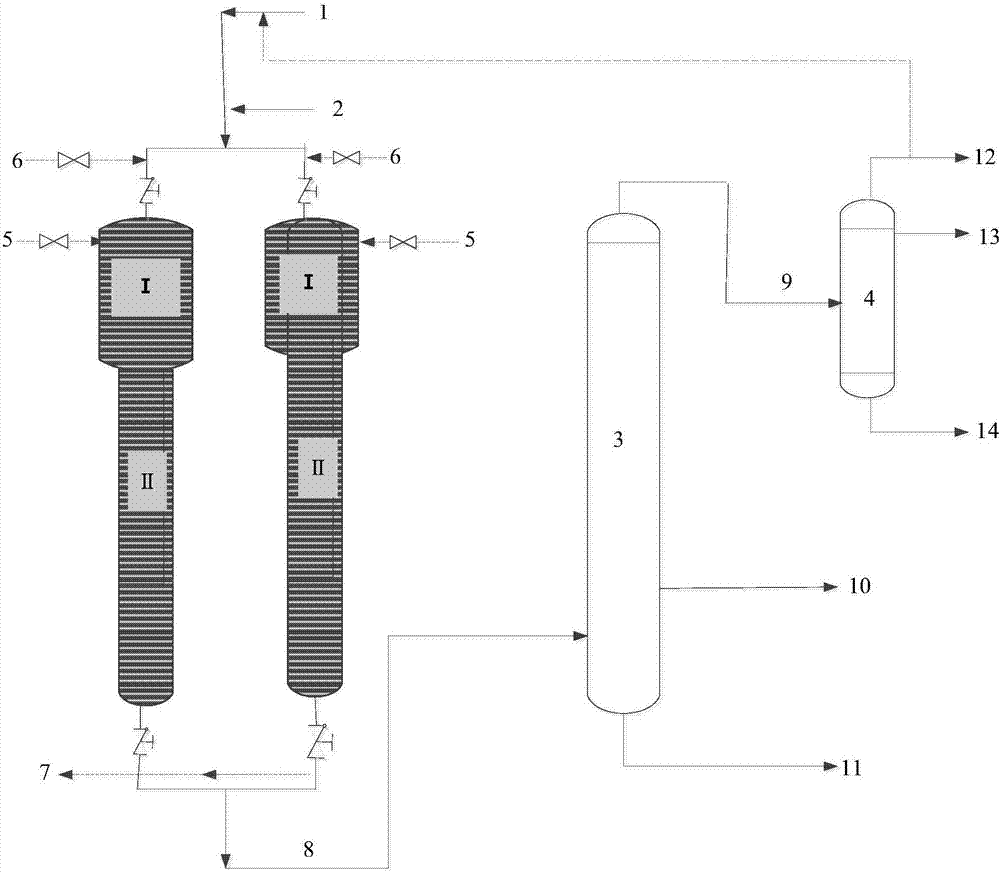

[0066] This example follows figure 1 The flow process of shale oil A is used as the raw material for catalytic cracking, and the test is carried out on a small-scale continuous regenerative fixed-bed reactor. meters, length is 0.15 meters, cracking zone II has a diameter of 0.02 meters and a length of 2.30 meters) and set the heat taking coil to use molten salt as cooling medium to cool the adsorbent; use CAT-1 catalyst as both adsorbent and catalytic cracking catalyst , The microreactivity (MAT) of the CAT-1 balancer is 62. After being preheated at 300°C, the shale oil A enters the top of the hydrogen adsorption zone I where the diameter of the fixed bed reactor expands. Ethylene, etc.) flows from top to bottom as a hydrogen-containing gas, H 2 The volume ratio of raw material oil is 400, and the hydrogen adsorption reaction is carried out under the conditions of adsorption temperature of 400°C, weight ratio of catalyst and inferior raw material oil of 4.0, and adsorption t...

Embodiment 2

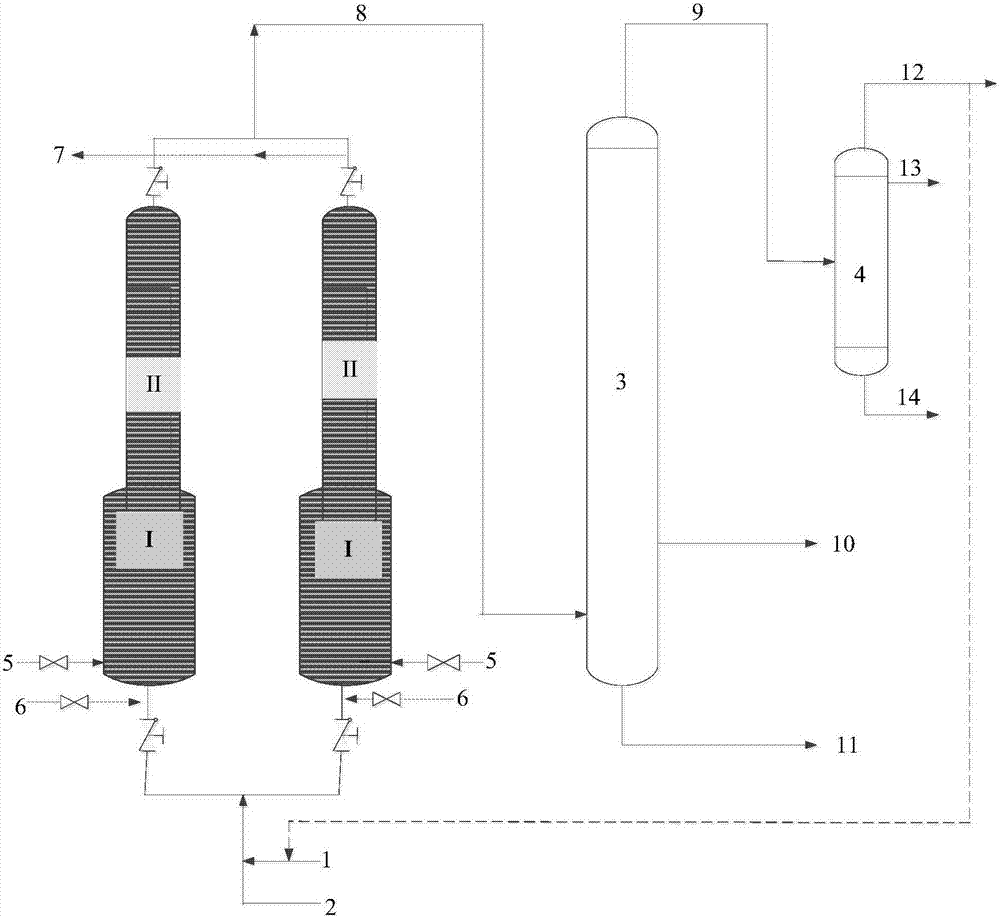

[0073] This example follows figure 2 The flow process of the test is carried out, and the residual oil B is used as the raw material for catalytic cracking, and the test is carried out on a small-scale continuous regenerative fixed-bed reactor. , the length is 0.30 meters, the diameter of the cracking zone II is 0.02 meters, and the length is 1.15 meters), and the heating coil is set to use molten salt as the cooling medium to cool the catalyst; the CAT-1 catalyst is used as the adsorbent and catalytic cracking catalyst at the same time, The microreactivity (MAT) of the CAT-1 balancer was 64. After being preheated at 260°C, the residual oil B enters the bottom of the hydrogen adsorption zone I where the diameter of the fixed bed reactor expands. Hydrogen-containing gas flows from bottom to top, H 2 The volume ratio of the raw material oil is 200, and the hydrogen adsorption reaction is carried out under the conditions of the adsorption temperature of 300 ° C, the weight ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com