Electro-galvanizing liquid automatic allocating and updating system

An automatic configuration and configuration system technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of not realizing the infinite cycle of electroplating production, large amount of waste water, complex system, etc., and achieve easy reuse, recovery of activity, and optimal configuration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The automatic configuration-renewal system of the electrogalvanizing solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

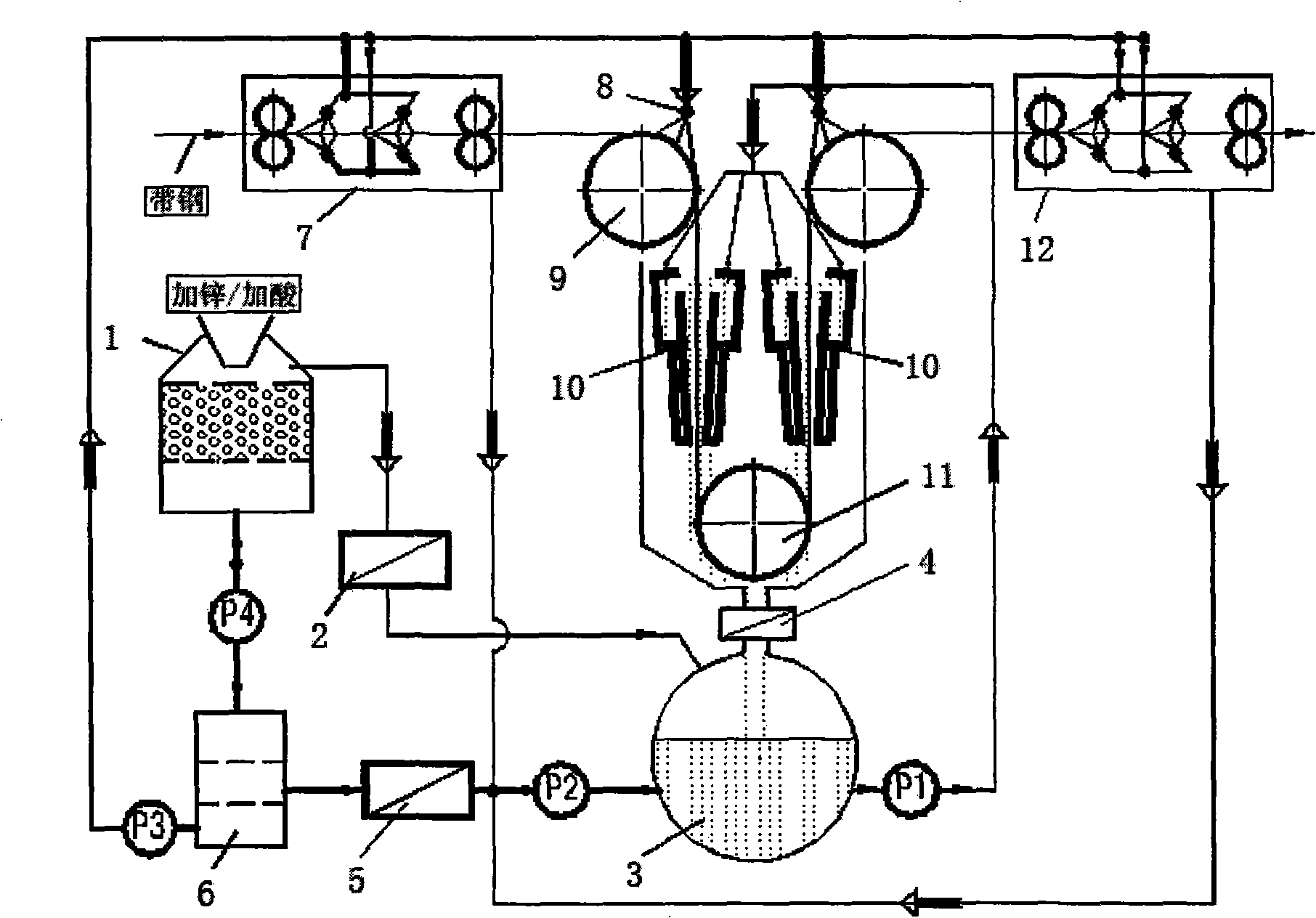

[0016] figure 2 Middle mark: 1-plating solution dissolving / configuration system, 2-primary filter, 3-plating solution collection tank, 4-secondary filter, 5-tertiary filter, 6-vacuum concentration separator, 7-plating Front rinsing device, 8-spray pipe for rinsing strip steel, 9-conductive roller, 10-anode device, 11-sinking roller, 12-post-plating rinsing device, P1-plating circulation supply pump, P2-plating solution renewal circulation pump , P3-strip spray water supply pump, P4-concentrate supply pump.

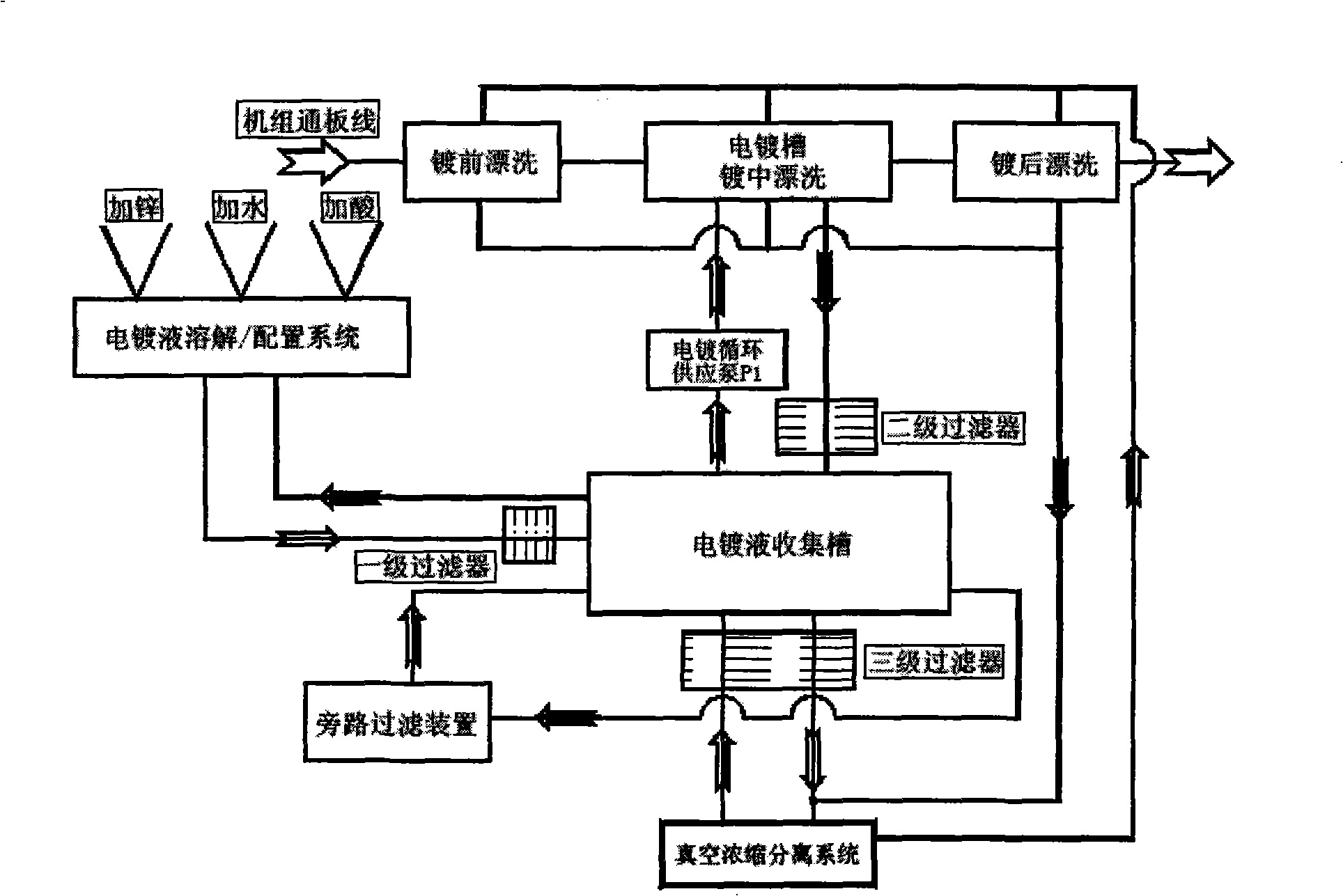

[0017] combine figure 1 and figure 2 As shown, the automatic configuration-renewal system of electrogalvanizing solution provides electroplating solution to the electroplating tank, which includes electroplating solution dissolving / configuration system 1, filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com