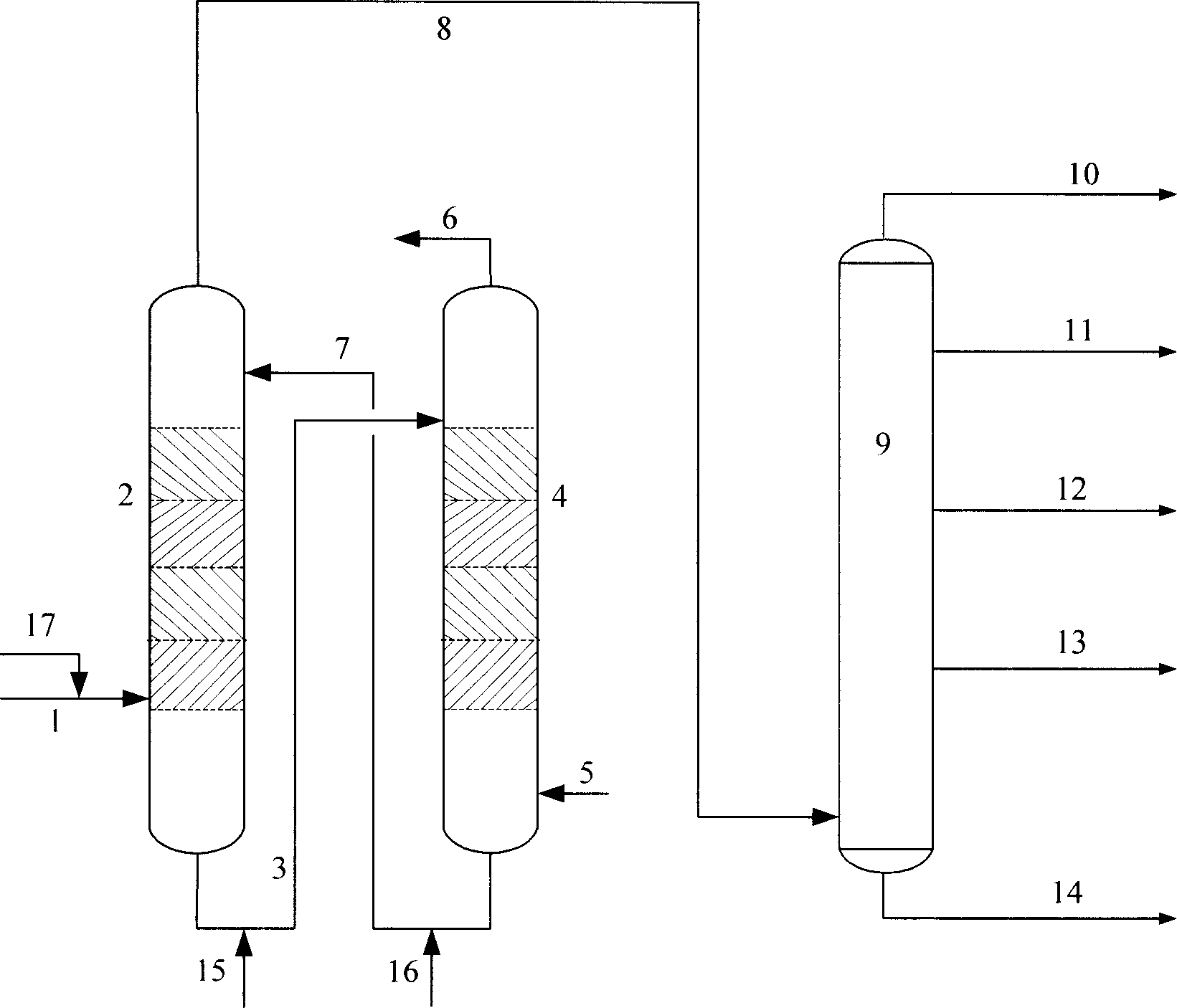

Catalytic no-hydroprocessing adsorbing desulfurization for hydrocarbon oil in moving bed reactor

A moving bed reactor, adsorption desulfurization technology, applied in the refining of hydrocarbon oil, petroleum industry, etc., can solve the problem of insufficient deep desulfurization, and achieve the effect of low olefin content, good desulfurization effect, and cetane number improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The gasoline raw material numbered A is alternately contacted with CAT-5 and ADT-5 (the total weight ratio of the front and back is 0.05:1) in a small continuous moving bed reactor for catalytic conversion and adsorption. The main operating conditions are: the reaction temperature is 400°C, the reactor pressure is 0.2 MPa, and the volumetric space velocity of the gasoline feedstock is 10 hours -1 , with water vapor as the dilution medium, the volumetric space velocity of water vapor is 0.5 hours -1 . The desulfurized product obtained from the top of the reactor is cooled and separated to obtain gaseous products and liquid products. The regeneration temperature of CAT-5 and ADT-5 is 550°C and the pressure is 0.2 MPa. The test conditions, product distribution and main properties of gasoline are listed in Table 2.

Embodiment 2

[0055] The gasoline raw material numbered B is alternately contacted with CAT-5 and ADT-5 (the total weight ratio of the front and rear is 1:1) in a small continuous moving bed reactor for catalytic conversion and adsorption. The main operating conditions are: the reaction temperature is 250°C, the reactor pressure is 0.2 MPa, and the volumetric space velocity of the gasoline raw material is 0.5 hours -1 , with water vapor as the dilution medium, the volumetric space velocity of water vapor is 0.05 hours -1 . The desulfurized product obtained from the top of the reactor is cooled and separated to obtain gaseous products and liquid products. The regeneration temperature of CAT-5 and ADT-5 is 450°C and the pressure is 0.2 MPa. The test conditions, product distribution and main properties of gasoline are listed in Table 3. It can be seen from Table 3 that the desulfurization rate of gasoline is as high as 93.69% by weight.

Embodiment 3

[0057] The gasoline raw material numbered C is alternately contacted with CAT-5 and ADT-5 (the total weight ratio of the front and back is 50:1) in a small continuous moving bed reactor for catalytic conversion and adsorption. The main operating conditions are: the reaction temperature is 450°C, the reactor pressure is 0.4 MPa, and the volume space velocity of the gasoline raw material is 80 hours -1 , with nitrogen as the dilution medium, the volumetric space velocity of nitrogen is 5.0 hours -1 . The desulfurized product obtained from the top of the reactor is cooled and separated to obtain gaseous products and liquid products. The regeneration temperature of CAT-5 and ADT-5 is 650°C and the pressure is 0.4 MPa. The test conditions, product distribution and main properties of gasoline are listed in Table 3. It can be seen from Table 3 that the desulfurization rate of gasoline is as high as 94.74% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com