Processing method and system for inferior crude oil

A technology of inferior raw material oil and processing method, which is applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems that the non-hydrotreating method is difficult to meet the requirements, the acid residue is difficult to deal with, and the energy consumption is high. It is suitable for continuous operation of large-scale production, saves the rich gas compressor, and reduces the energy consumption of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

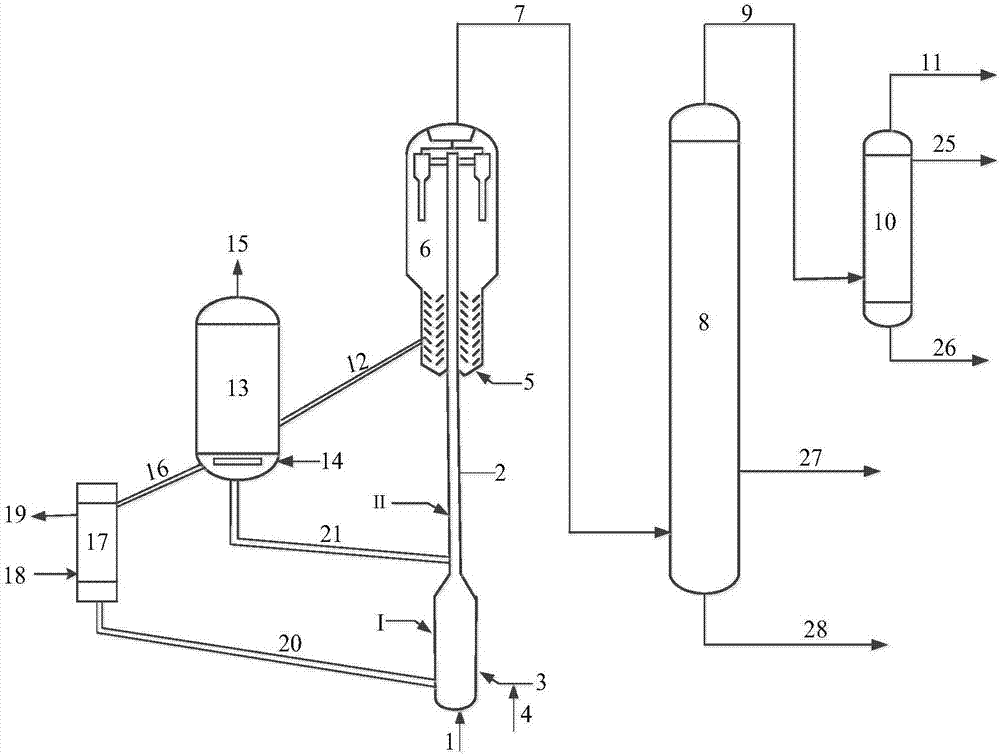

[0083] This example follows figure 1 The process of shale oil A is used as the raw material for catalytic cracking, and the test is carried out on a small-scale continuous regeneration fluidized bed riser reactor. The shale oil A is fed from the bottom, and the diameter of the bottom of the reactor is expanded into the cracking zone of the riser 5 times of the inner diameter of II becomes fluidized bed hydrogen adsorption zone I, and the length of hydrogen adsorption zone I is 14% of the length of riser cracking zone II. Adsorption zone I introduces the cold regenerated catalytic cracking agent from outside as the first catalytic cracking catalyst, and the dry gas with a hydrogen gas fraction of 85% (the rest is methane, ethane and ethylene, etc.) flows from bottom to top as hydrogen-containing gas, and the The pipe cracking zone is transported into the high-temperature heat regenerated catalytic cracking agent as the second catalytic cracking catalyst; the CAT-3 catalyst is u...

Embodiment 2

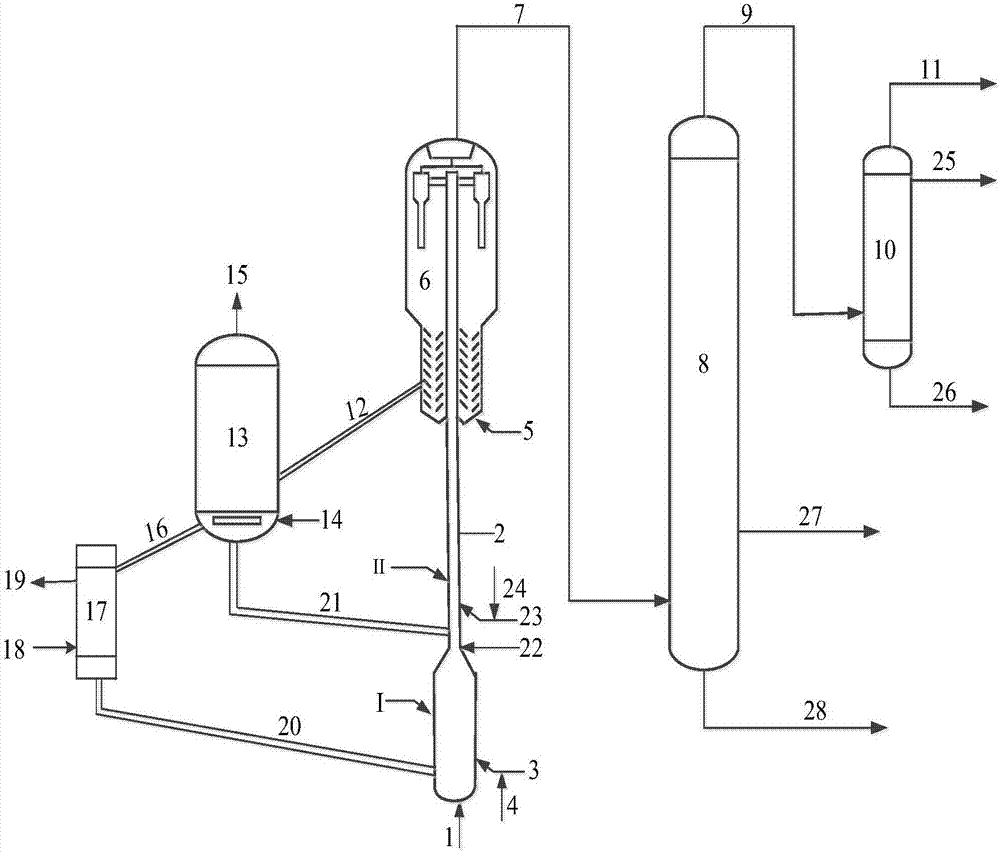

[0090] Example 2 according to figure 2The equipment and process of the experiment were carried out, and the residual oil B and the vacuum wax oil C in Table 1 were used as raw materials for catalytic cracking, and the residual oil B and the vacuum wax oil C were fed in partitions, that is, the residual oil B was subjected to hydrogen adsorption in a fluidized bed. Zone I feeds and vacuum wax oil C feeds in riser cracking zone II; the diameter of the fluidized bed at the bottom of the reactor expands into a turbulent fluidized bed hydrogen adsorption zone (the inner diameter of the fluidized bed hydrogen adsorption zone is the 3 times of the inner diameter of the cracking zone of the riser, the length of the hydrogen adsorption zone of the fluidized bed is 10% of the cracking zone of the riser), and the first catalytic cracking catalyst of the cooling of the external heating is introduced, and the volume fraction is 80% % dry gas (the rest is methane, ethane and ethylene, etc....

Embodiment 3

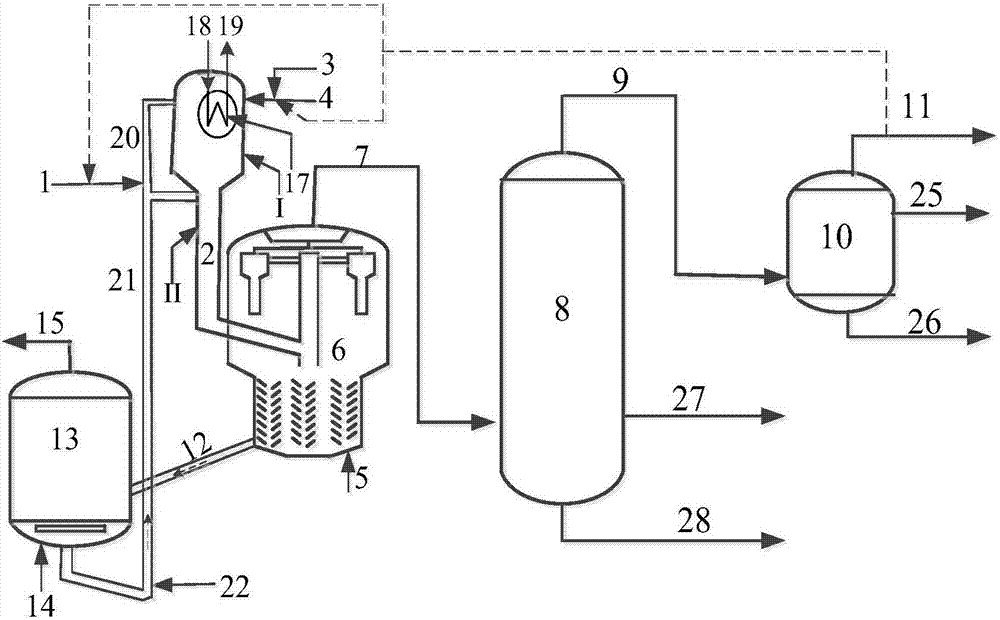

[0097] This example follows image 3 The process of residual oil B is used as the raw material for catalytic cracking, and the test is carried out on a small continuous regeneration downflow fluidized bed riser reactor. The residual oil B is fed on top, and the diameter of the top of the reactor is expanded to be a fluidized bed hydrogen adsorption zone. , the diameter of the fluidized bed hydrogen adsorption zone I is 4.2 times the diameter of the riser cracking zone II, the length of the fluidized bed hydrogen adsorption zone I is 30% of the length of the riser cracking zone II and built in The heat coil cools the first catalytic cracking catalyst, and the riser section is transported into the high-temperature second catalytic cracking catalyst; CAT-3 catalyst is used, and the balancer MAT=63. After being preheated at 350°C, the residual oil enters the top of the enlarged fluidized bed adsorption reaction zone I of the reactor. With the hydrogen-containing gas flowing from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com