Heavy oil supercritical extraction separation method and device

A supercritical and heavy oil technology, applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc., can solve problems such as equipment blockage, affecting device online rate and reliability, etc., and achieve reduced consumption, good fluidity and mass transfer performance , Reduce the effect of heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

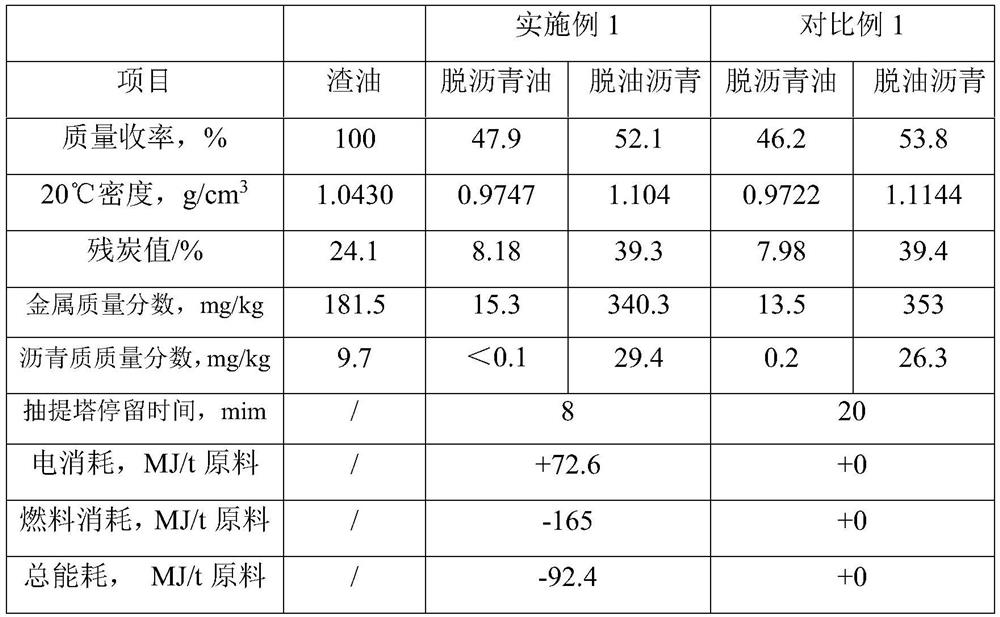

[0092] Embodiment 1 illustrates the effect of the heavy oil supercritical extraction separation method provided by the present invention.

[0093] The residual oil raw material is Middle East reduced residue (50wt% each of Saudi medium reduced residue and Saudi heavy reduced residue), and its properties are shown in Table 1.

[0094] The extraction solvent is commercially available n-butane (chemically pure, purity>99%).

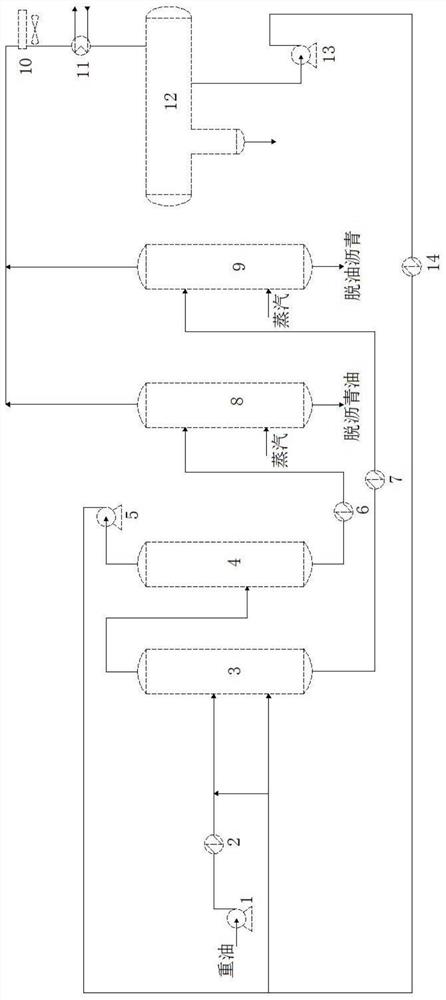

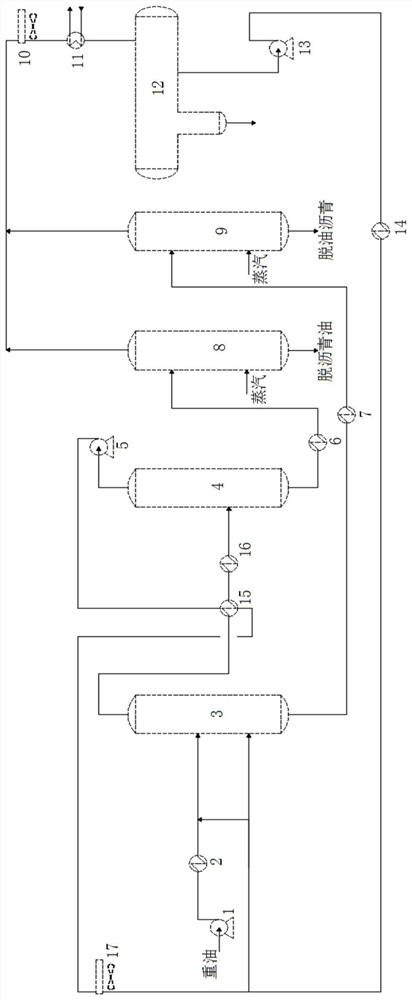

[0095] use as figure 1 The heavy oil supercritical extraction and separation process shown is used for extraction and separation.

[0096] Wherein, the packing filled between the upper distributor in the extraction tower and the top of the tower is a plate corrugated packing without openings. There is no filler installed between the upper distributor and the lower distributor.

[0097] The temperature of the residual oil raw material is 150°C, and the temperature of the residual oil raw material after passing through the raw material heater is 170°C. The...

Embodiment 2

[0109] Embodiment 2 illustrates the effect of the heavy oil supercritical extraction separation method provided by the present invention.

[0110] Residuum raw material, heavy oil supercritical extraction separation device and process are the same as in Example 1. The extraction solvent is n-pentane. The critical temperature of n-pentane is 196.6°C and the critical pressure is 3.37MPa.

[0111] The temperature of the residual oil raw material is 150°C, and the temperature of the residual oil raw material after passing through the raw material heater is 230°C.

[0112] The operating conditions of the extraction tower are 11-14MPa, 210-230°C; the operating conditions of the solvent recovery tower are 4-4.5MPa, 210°C.

[0113] The weight ratio of the total extraction solvent entering the extraction tower and the residual oil raw material is 1.6:1;

[0114] After being treated by the above method, the obtained deasphalted oil and deoiled asphalt products are shown in Table 2. ...

Embodiment 3

[0116] Embodiment 3 illustrates the effect of the heavy oil supercritical extraction separation method provided by the present invention.

[0117] Residuum raw material, heavy oil supercritical extraction separation device and process are the same as in Example 1. The extraction solvent is a mixed solvent of n-butane and n-pentane (50% by mole fraction). The pseudocritical temperature of the mixed solvent is 174.3°C, and the pseudocritical pressure is 3.58MPa ( T C is the pseudocritical temperature, P C is the false critical pressure, x i is the mole fraction of each component, T c,i ,P c,i are the critical temperature and critical pressure of the i solvent, respectively).

[0118] The temperature of the residual oil raw material is 150°C, and the temperature of the residual oil raw material after passing through the raw material heater is 230°C.

[0119] The operating conditions of the extraction tower are 9-11MPa, 190-200°C; the operating conditions of the solvent re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical temperature | aaaaa | aaaaa |

| Critical pressure | aaaaa | aaaaa |

| Critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com