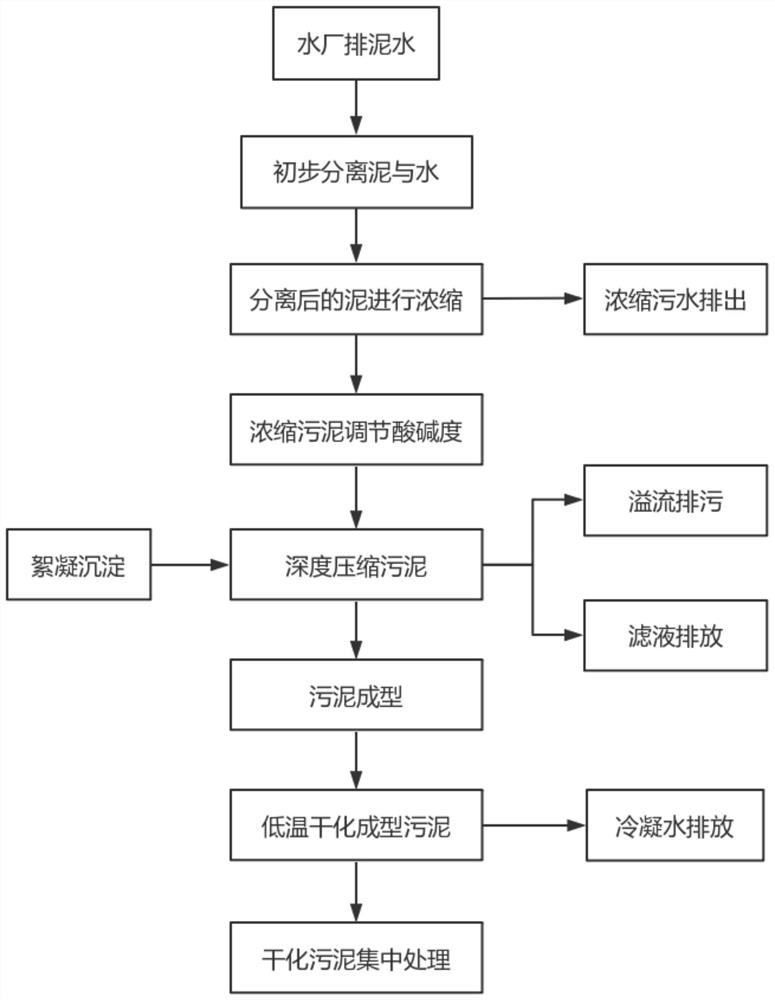

Heat energy and solar energy linkage sludge drying treatment equipment and process

A technology for drying sludge and treatment equipment, which is applied in the directions of sludge treatment, dehydration/drying/thickened sludge treatment, water/sludge/sewage treatment, etc. It can solve the problems of technology that needs to be perfected, short service life of equipment, and pressing time. Long and other problems, to achieve the effect of easy management and orderly consumption, low degree of secondary pollution, and large volume of water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

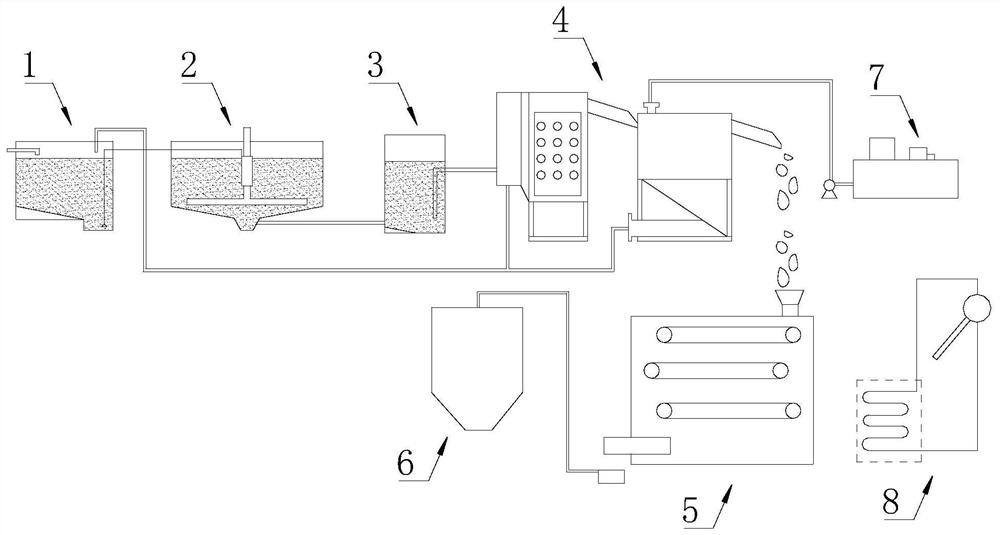

[0049] see figure 1 The thermal energy and solar energy linkage drying sludge treatment equipment, including the sludge discharge tank 1, the sludge concentration tank 2, the homogenization tank 3, the dehydrator 4, the low temperature drying machine 5, the drying sludge silo 6, the flocculation Agent machine 7 and solar auxiliary heat machine 8.

[0050] The sludge discharge tank 1 preliminarily precipitates and separates the sludge in the tap water. The upper tap water can be used for water supply, and the bottom sludge is separated from the upper tap water for dehydration treatment. The water content of the bottom sludge is between 99.6% and 99.2%. The supernatant from sludge discharge tank 1 is collected and pumped to the municipal sewage pipe network outside the plant.

[0051] The sludge concentration tank 2 concentrates the sludge that has been preliminarily precipitated and separated. Sediment or centrifuge the bottom sludge separated from tap water to reduce the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com