Method and device for reducing flare discharge amount of ethylene machine of steam cracking device

A cracker and ethylene machine technology, applied in the chemical industry, can solve problems such as environmental impact and the danger of flare discharge devices, and achieve the effects of reducing emissions, reducing pollution, and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

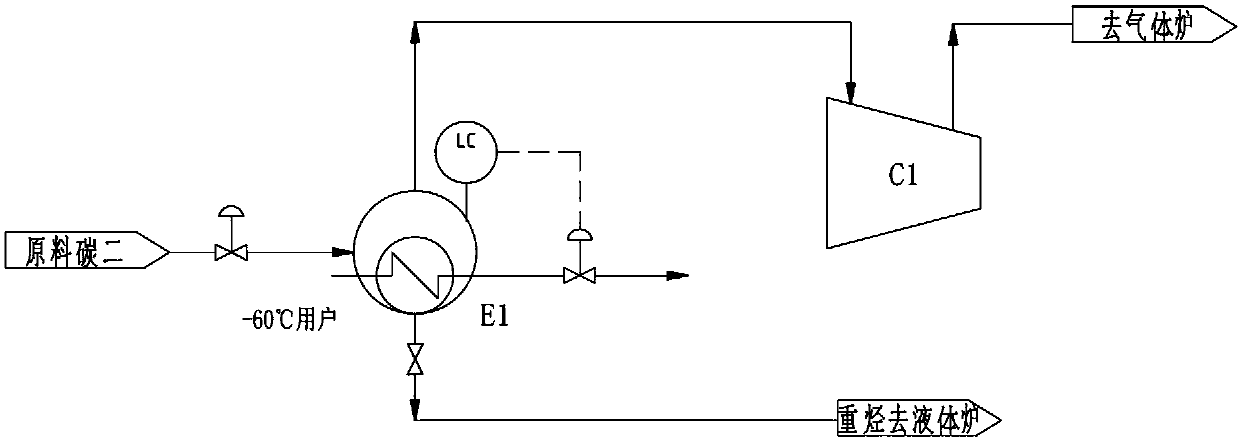

[0042] According to a specific embodiment of the present invention, comprising the following steps, such as figure 1 Shown:

[0043] (1) The liquid-phase ethane raw material is decompressed, such as the pressure drops to 48kPaA-700kPaG;

[0044] (2) The temperature of the liquid-phase ethane after decompression is reduced to -101°C to -40°C;

[0045] (3) The decompressed liquid-phase ethane enters the gasifier, and the heating medium is process medium or other public engineering medium;

[0046] (4) Liquid-phase ethane gasification can provide users with cooling capacity at the level of -101°C to -40°C.

[0047] (5) The vaporized liquid-phase ethane enters the compressor and is pressurized to the pressure required by the gas cracking furnace;

[0048] (6) The remaining liquid heavy components enter the inlet of the liquid cracking furnace after being pressurized by the pump.

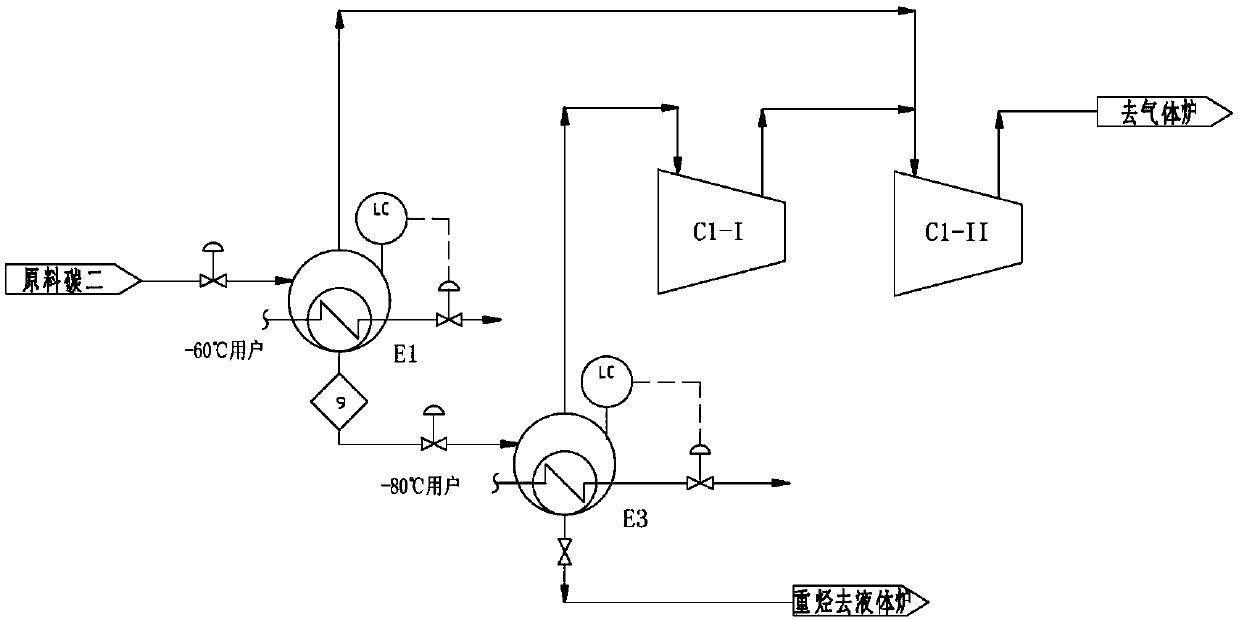

[0049] The method of the present invention can be used in more complex demand situations, for exa...

Embodiment 1

[0076] Such as figure 1 As shown, the raw material carbon-two liquid-phase ethane is decompressed by the regulating valve, and then gasified in the gasifier 1E1 of the user, and the remaining liquid phase is sent to the liquid furnace for cracking; the gas phase is compressed to about 700kPaG by the compressor C1, and then subsequently heated Enter the gas furnace for cracking at 72°C. The specific parameters are as follows: (1) When the ethane raw material is decompressed to 278kPaG, the saturation temperature of the ethane raw material is -60°C, which can provide users with cooling capacity at the level of -60°C. (2) If the ethane raw material is decompressed to 55kPaG, the saturation temperature of the ethane raw material is -80°C, which can provide users with cooling capacity at the -80°C level. (3) If the ethane raw material is decompressed to 48kPaA, the saturation temperature of the ethane raw material is -101°C, which can provide users with cooling capacity at the lev...

Embodiment 2

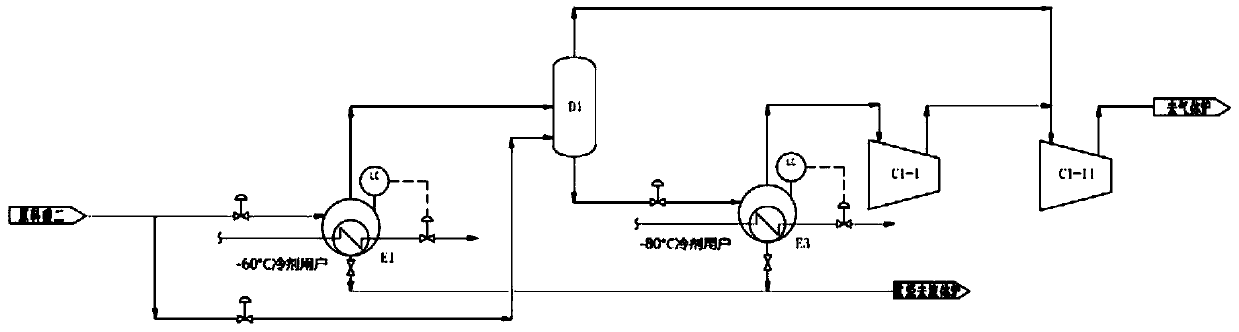

[0078] When downstream users require different refrigerant grades, the ethane raw material can be flashed to two different pressure grades to provide users with cooling capacity of different grades, such as figure 2 shown.

[0079] The specific implementation plan is as follows. The raw carbon is divided into two streams. The first stream is decompressed to 278kPaG and then goes to the user's gasifier 1E1 to provide the user with a cooling capacity of -60°C. The gas phase of the user's gasifier 1E1 goes to the gas Liquid separation tank D1; the second stream goes to gas-liquid separation tank D1. The pressure of the gas-liquid separation tank D1 is controlled at about 278kPaG, the gas phase of the gas-liquid separation tank D1 goes to the second stage C1-II of the compressor, and the liquid phase of the gas-liquid separation tank D1 is decompressed to 55kPaG again. Provide -80 ℃ grade cooling capacity. The gas phase of the gasifier 2E3 of the user goes to the first stage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com