Vacuum pouring method of ingot casting and heat-generating agent feeding barrel for ingot casting and vacuum chamber for pouring

A technology for vacuum pouring and feeding barrels, which is applied in the field of heating agent feeding barrels and vacuum chambers for pouring. It can solve the problems of low yield of ingots and unsatisfactory effects of heating agents, etc., so as to improve the yield and save the need for cutting risers. Process, the effect of reducing waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

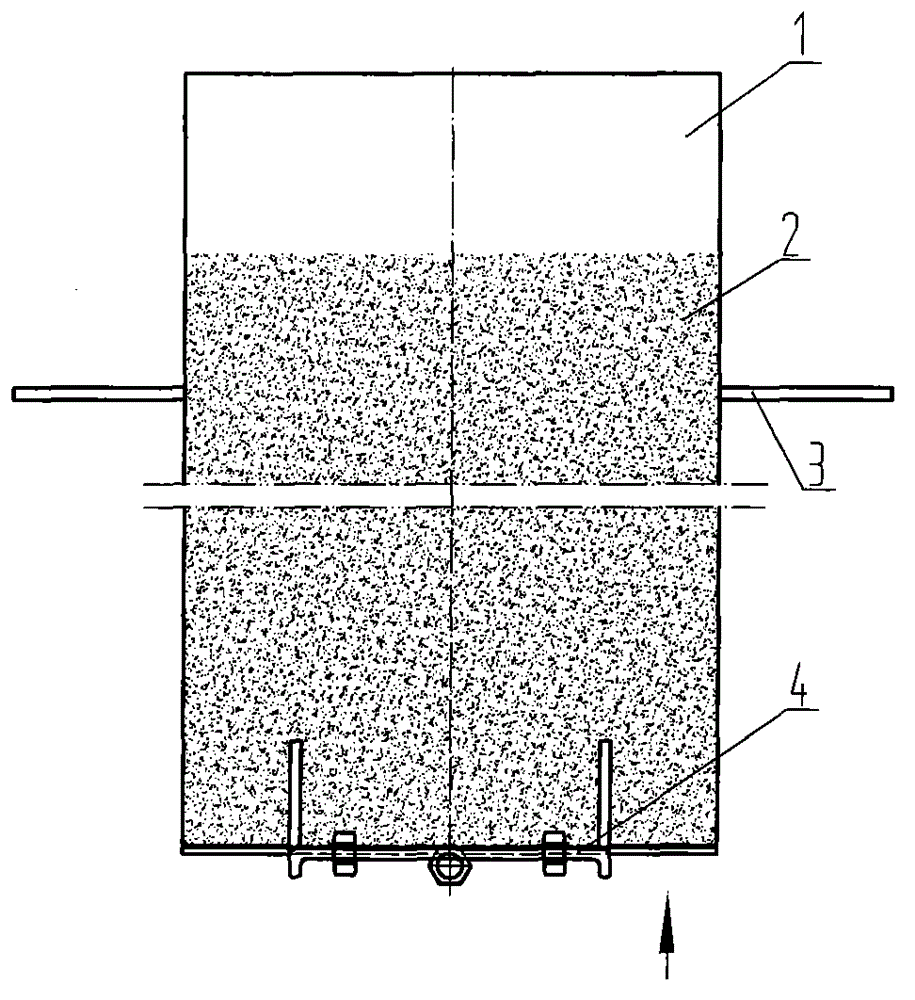

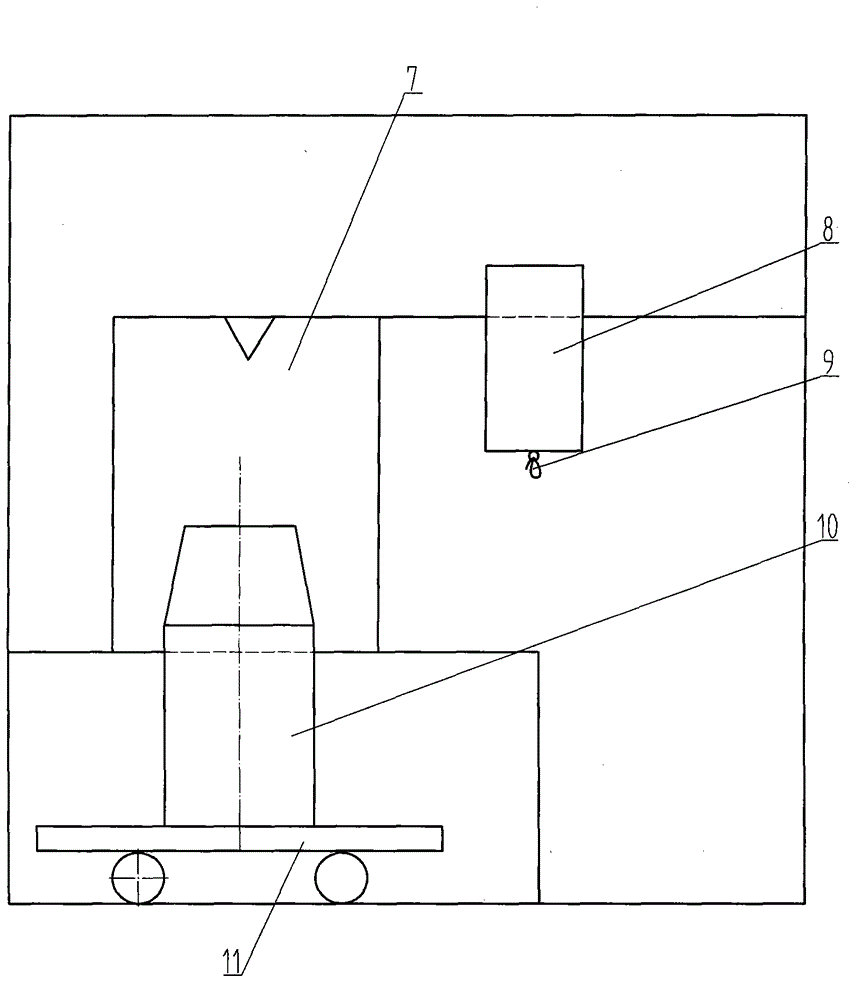

[0028] In Example 1, 2 tons of ingots were poured, the material was N04400, and the exothermic agent was a carbon-free exothermic agent.

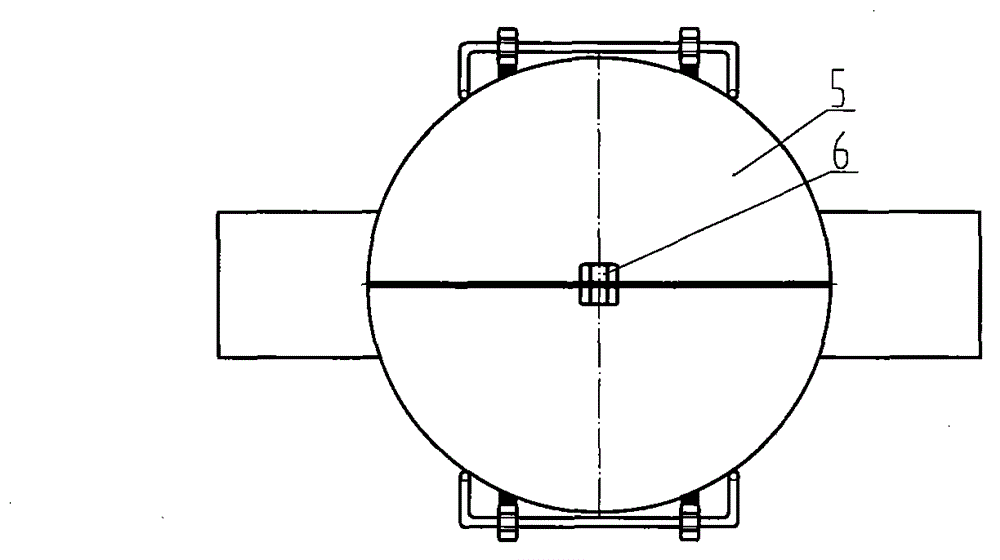

[0029] Vacuum pouring is carried out as follows: tie the bottom door 5 of the feeding barrel 8 with an asbestos rope, and close the bottom door 5; put the whole bag of heating agent into the feeding barrel 8, and put the feeding barrel into the chamber of the vacuum chamber. The cavity is fixed; the raw material is vacuum smelted in the crucible 7, and when the smelting of the raw material in the crucible is completed, it is poured into the ingot mold 10, and the vacuum chamber is broken for 20 seconds after the pouring is completed, so that the pressure of the vacuum chamber reaches about 10,000 Pa. Move the ingot mold 10 directly below the feeding barrel 8, the high temperature of the ingot mold itself will melt the asbestos rope tied to the floor door 5, the floor door 5 is opened, and the exothermic agent 2 enters the riser 12 of the ste...

Embodiment 2

[0030] Example 2 Ingot 0.2 tons, the material is N04400, the exothermic agent is carbon-free, and the exothermic agent breaks the vacuum chamber for 15 seconds, and the rest is the same as in Example 1. The obtained ingot riser ratio was 12%.

Embodiment 3

[0031] Example 3 Cast 10 tons of ingots, the material is N04400, the exothermic agent is carbon-free, and the exothermic agent breaks the vacuum chamber for 20 seconds, and the rest are the same as in Example 1. The resulting ingot riser ratio was 10%.

[0032] Table 1: Compared with the ordinary method for vacuum casting by adopting the method of the present invention to carry out vacuum casting, the ingot riser accounts for the weight ratio comparison table of the ingot:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com