Lithium ion battery electrode and preparation method thereof

A lithium ion battery and electrode technology, which is applied in the field of preparation of lithium ion battery electrodes to achieve the effects of improving specific capacity and rate performance, good dispersibility and small weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a lithium ion battery electrode, which uses arrayed carbon nanotubes to prepare a lithium iron phosphate positive electrode, which is prepared by the following steps:

[0028] Prepare array carbon nanotubes according to the method of Chem Phys Lett 1999; 303(5):467-474;

[0029] Weigh 2 g of carbon nanotube samples, add 1000 g of nitrogen methyl pyrrolidone (NMP), and ultrasonically disperse to obtain a stable carbon nanotube dispersion;

[0030] Weigh lithium iron phosphate, conductive carbon black and PVDF according to the mass ratio of 89:4:7, put the three into a container and stir, add carbon nanotube dispersion liquid dropwise, the mass ratio of dispersion liquid to lithium iron phosphate is 5:1 , after continuous stirring for 6 hours, the positive electrode slurry was obtained;

[0031] The positive electrode slurry is coated on the aluminum foil, dried, rolled and cut to obtain the positive electrode sheet.

[0032] Such as figure 1 A...

Embodiment 2

[0034] This embodiment provides a lithium-ion battery electrode, using an aqueous dispersion of sulfur-doped carbon nanotubes to prepare a positive electrode of lithium cobaltate, which is prepared by the following steps:

[0035] Preparation of sulfur-doped carbon nanotubes, prepared according to Carbon 2015; 92:245-253 method;

[0036] Weigh 1 g of the carbon nanotube sample, add it to 1000 g of water, and ultrasonically disperse to obtain a carbon nanotube aqueous dispersion;

[0037] Weigh lithium cobaltate, conductive graphite, and LA132 binder according to the mass ratio of 90:5:5, put the three into a container and stir, and add the carbon nanotube aqueous dispersion liquid dropwise until the slurry has a moderate viscosity and is suitable for coating , after continuous stirring for 6 hours, the positive electrode slurry was obtained;

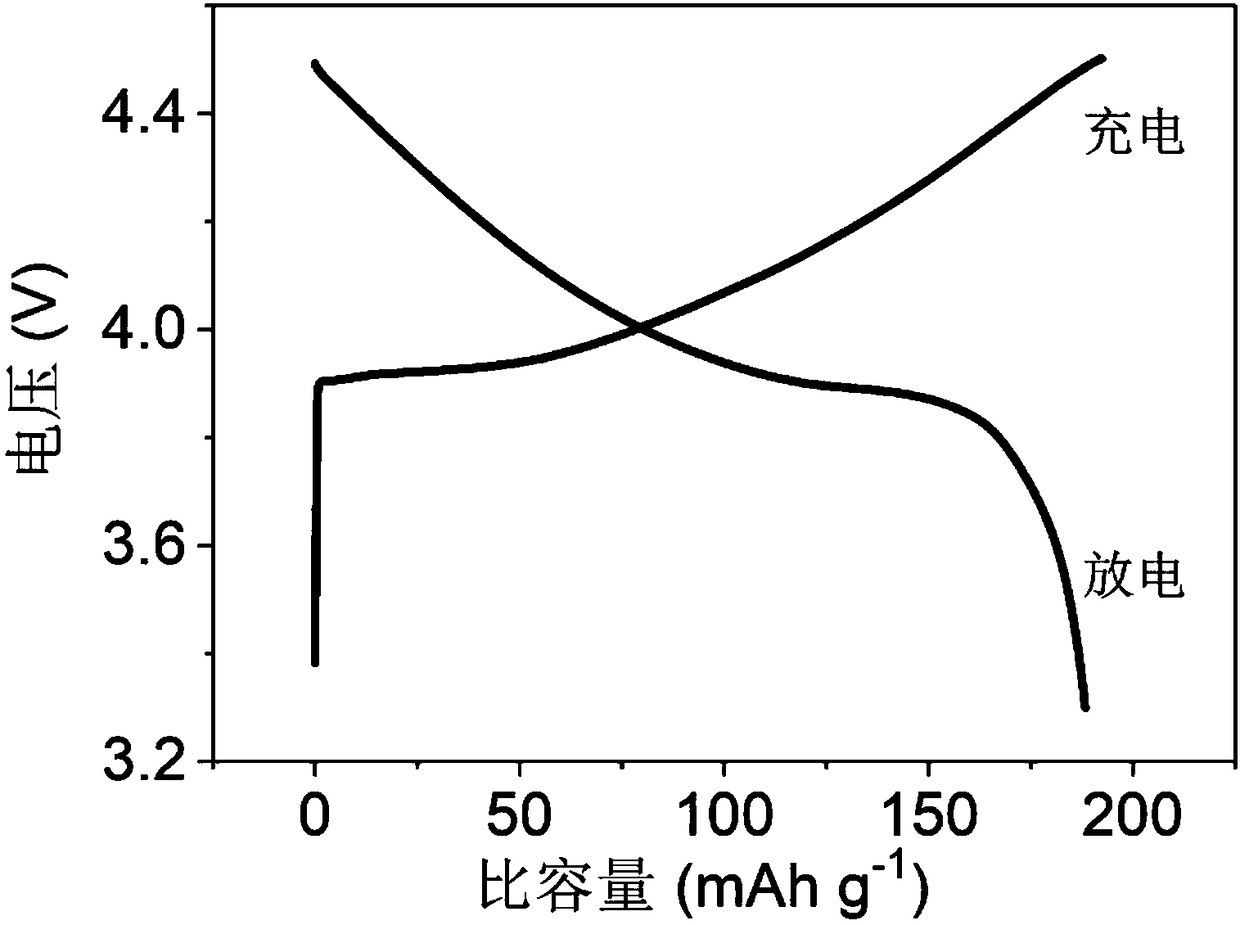

[0038] The positive electrode slurry is coated on the aluminum foil, dried, rolled and cut to obtain the lithium cobaltate positive el...

Embodiment 3

[0041] This embodiment provides a lithium-ion battery electrode, using an array carbon tube dispersion to prepare a graphite negative electrode, which is prepared by the following steps:

[0042] Prepare array carbon nanotubes according to the method of literature Chem Phys Lett 1999; 303(5):467-474;

[0043] Weigh 2 g of the carbon nanotube sample, add it into 1000 g of NMP, and disperse it ultrasonically to obtain a carbon nanotube dispersion;

[0044] Weigh graphite, conductive carbon black and PVDF according to the mass ratio of 85:5:10, put them into a container for stirring, and add the carbon nanotube dispersion liquid dropwise; after continuous stirring for 6 hours, the negative electrode slurry is obtained;

[0045] The negative electrode slurry is coated on the copper foil, dried, rolled and cut to obtain the negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com