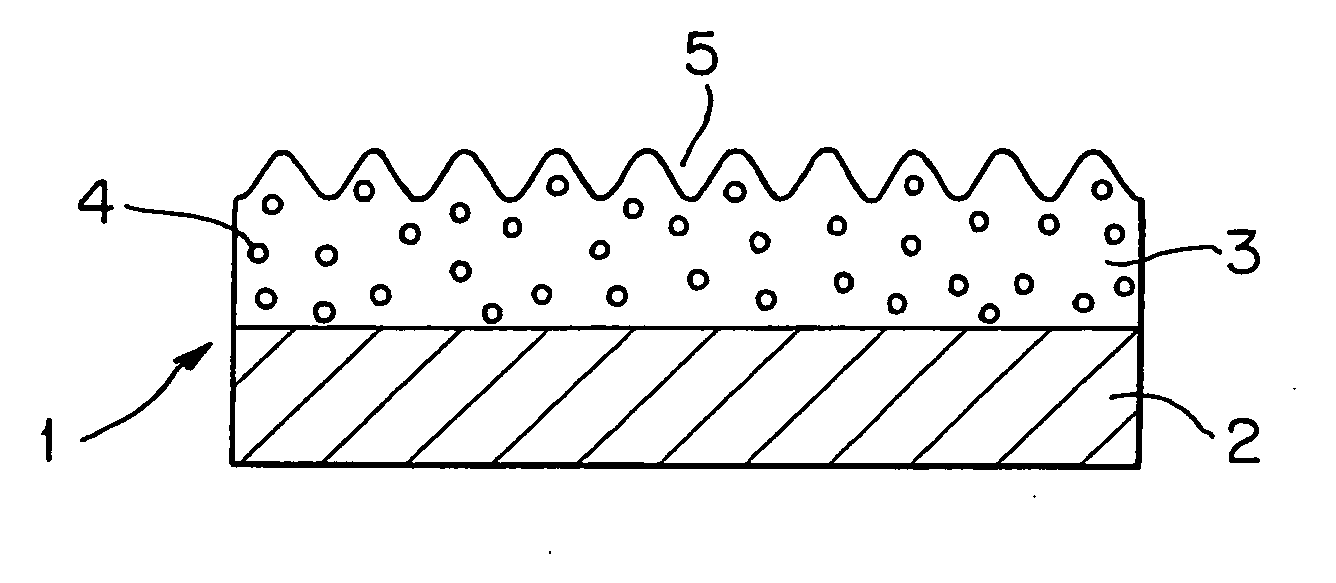

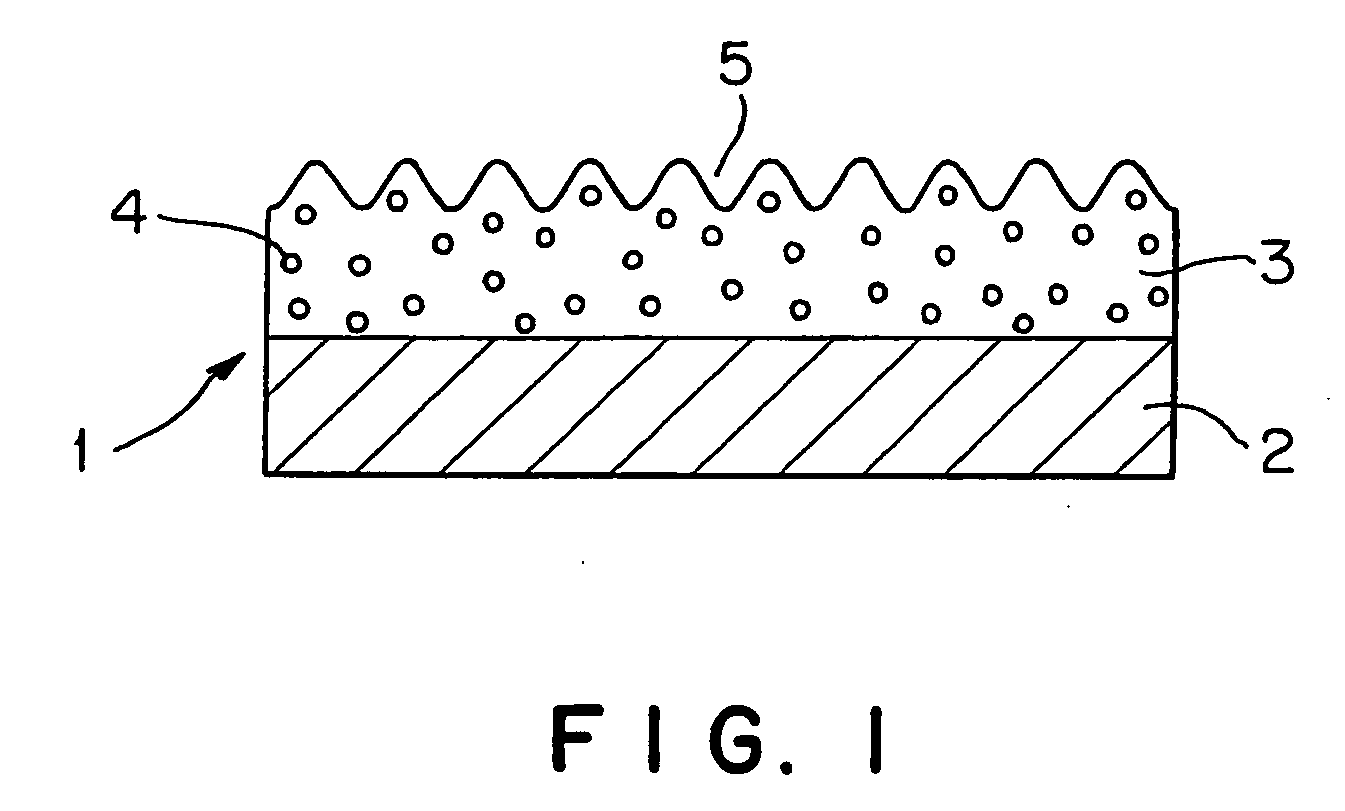

Antiglare film and process for producing the same

a technology of anti-glare film and process, applied in the field of anti-glare film, can solve the problems of deteriorating image visibility, difficult to perceive letters and the like displayed on the screen, and none of the conventional anti-glare films simultaneously satisfy all the above property requirements, and achieve high total light transmittance, high anti-scintillation properties, and high sharpness of transmitted images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0084] The following materials were thoroughly mixed together according to the following formulation to prepare a coating composition for a light diffusing resin layer.

Light-transparent resin100pts. wt.Pentaerythritol triacrylate(PET 30, manufactured by Nippon Kayaku Co., Ltd.)Photoinitiator5pts. wt.(Irgacure 184, manufactured by CIBA-GEIGY Ltd.)Light-transparent fine particles8pts. wt.Polystyrene resin filler(particle diameter 1.3 μm, refractive index 1.6)Good solvent60pts. wt.Methyl isobutyl ketone(relative evaporation rate R 1.6)Poor solvent15pts. wt.Isobutyl alcohol(relative evaporation rate R 0.64)

[0085] A cellulose triacetate film (TD-80U, thickness 80 μm, manufactured by Fuji Photo Film Co., Ltd.) was provided as a substrate. The coating composition prepared above was roll coated onto one side of the substrate. The coating was then dried at a temperature of 50° C. to form concaves and convexes on the surface of the coating, followed by application of ultraviolet light at 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com