Production process of E-TPU (expanded thermoplastic polyurethane) shoe material

A production process and popcorn technology, which is applied to shoe soles, footwear, instruments for pressing reflection points, etc., can solve the problems of large surface damage of TPU foam particles, large amount of PU, and high density, and reduce production costs and market. The effect of improving competitiveness and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

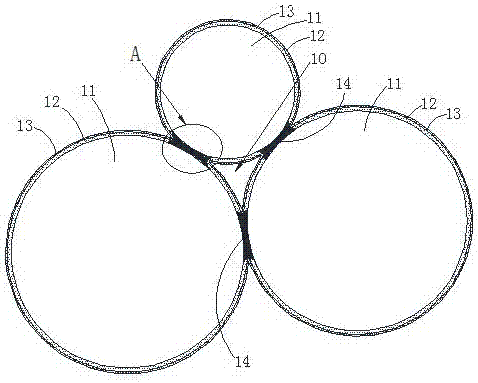

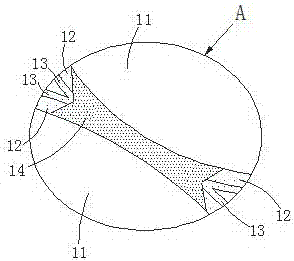

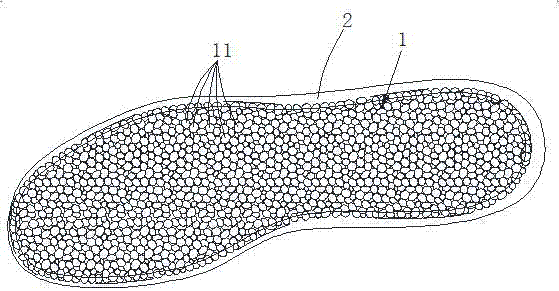

[0019] The manufacturing process of TPU popcorn shoe material, the making of the TPU popcorn shoe material of the present embodiment comprises the following steps of carrying out successively: a. material preparation: prepare 90 parts of TPU foamed particles, A glue 7.6 parts, B glue by weight 1.9 parts, 0.5 parts of accelerator; b. Add glue A: Stir TPU foam particles and glue A in the mixing chamber of the pouring machine evenly. Only glue A can ensure the fluidity of glue A. The distribution on the surface of the foamed particles is more uniform, the thickness of the glue layer is smaller, and the distribution of the glue is lower; c. Add B glue: after step b is mixed evenly, add B glue and stir evenly. When adding B glue, when there is no promotion In the case of the agent, the reaction between glue A and glue B is relatively slow. At this time, glue B can be evenly distributed on the surface of glue A before substantially reacting with glue A; d. Add accelerator: step c is ...

Embodiment approach 2

[0022] The making of the TPU popcorn shoe material of the present embodiment comprises the following steps of carrying out successively: a. material preparation: prepare 92 parts of TPU expanded particles, A glue 5.91 parts, B glue 1.69 parts, accelerator 0.4 part by weight; b .Add glue A: Stir TPU foam particles and glue A in the mixing chamber of the pouring machine; c. Add glue B: mix well in step b, then add glue B and stir well; d. Add accelerator: mix in step c After the accelerator is uniform, add the accelerator. Before the accelerator is mixed, atomize it, then mix it with the material evenly, and then quickly inject it into the mold cavity; the accelerator is an amino compound, such as a dithiocarbamate accelerator, an amino-terminated polyether accelerator , N, N-dimethylaniline, etc., adjust the curing time by selecting the type of accelerator; e. Foaming: the mold cavity is moved into the oven, and the molded shoe material can be obtained by foaming at 50-70°C. The...

Embodiment approach 3

[0024] The making of the TPU popcorn shoe material of the present embodiment comprises the following steps of carrying out successively: a. material preparation: prepare 75 parts of TPU expanded particles, A glue 18.8 parts, B glue 4.7 parts, accelerator 1.5 parts by weight; .Add glue A: Stir TPU foam particles and glue A in the mixing chamber of the pouring machine; c. Add glue B: mix well in step b, then add glue B and stir well; d. Add accelerator: mix in step c After the accelerator is uniform, add the accelerator. Before the accelerator is mixed, atomize it, then mix it with the material evenly, and then quickly inject it into the mold cavity; the accelerator is an amino compound, such as a dithiocarbamate accelerator, an amino-terminated polyether accelerator , N, N-dimethylaniline, etc., adjust the curing time by selecting the type of accelerator; e. Foaming: the mold cavity is moved into the oven, and the molded shoe material can be obtained by foaming at 50-70°C. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com