Patents

Literature

33results about How to "Impact distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of E-TPU (expanded thermoplastic polyurethane) shoe material

InactiveCN107353428APromote environmental protectionReduce usage requirementsSolesDevices for pressing relfex pointsMaterials preparationThermoplastic polyurethane

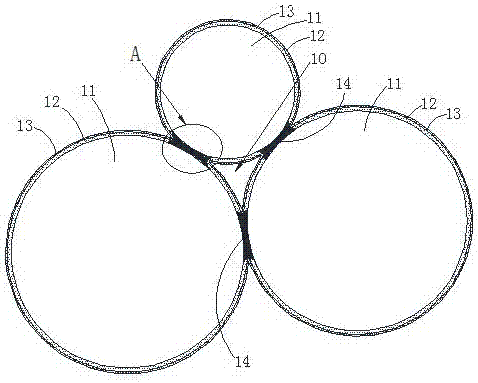

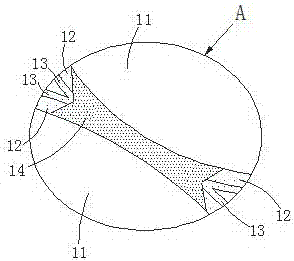

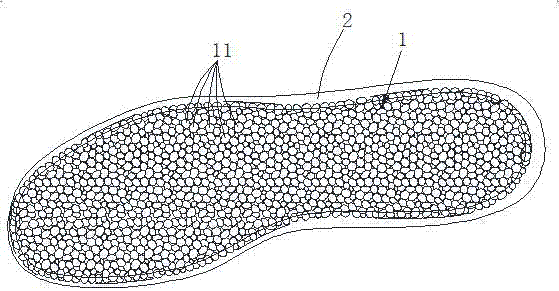

The invention relates to a production process of an E-TPU (expanded thermoplastic polyurethane) shoe material. The production process of the E-TPU shoe material comprises the steps implemented in sequence as follows: a, material preparation: 75-92 parts of TPU foamed particles, 5.9-19 parts of glue A, 0.9-4.8 parts of glue B and 0.38-1.5 parts of an accelerator are prepared by weight; b, addition of the glue A: the TPU foamed particles and the glue A are stirred uniformly; c, addition of the glue B: the glue B is added after the materials in the step b are mixed uniformly, and the materials are stirred uniformly; d, addition of the accelerator: the accelerator is added after the materials in the step c are mixed uniformly, the materials are mixed uniformly, and the mixture is injected into a die cavity; e, foaming: the die cavity is moved into an oven, foaming molding is performed at 50-70 DEG C for 2-3 min, and the molded shoe material can be obtained. The TPU particles can account for 90%-92% by weight of the shoe material, the weight reduction limit of the current shoe material is reached, and the E-TPU shoe material has the characteristics of being ultralight, ultrahigh in elasticity, more environment-friendly, low in cost and capable of performing massaging.

Owner:陈茂双

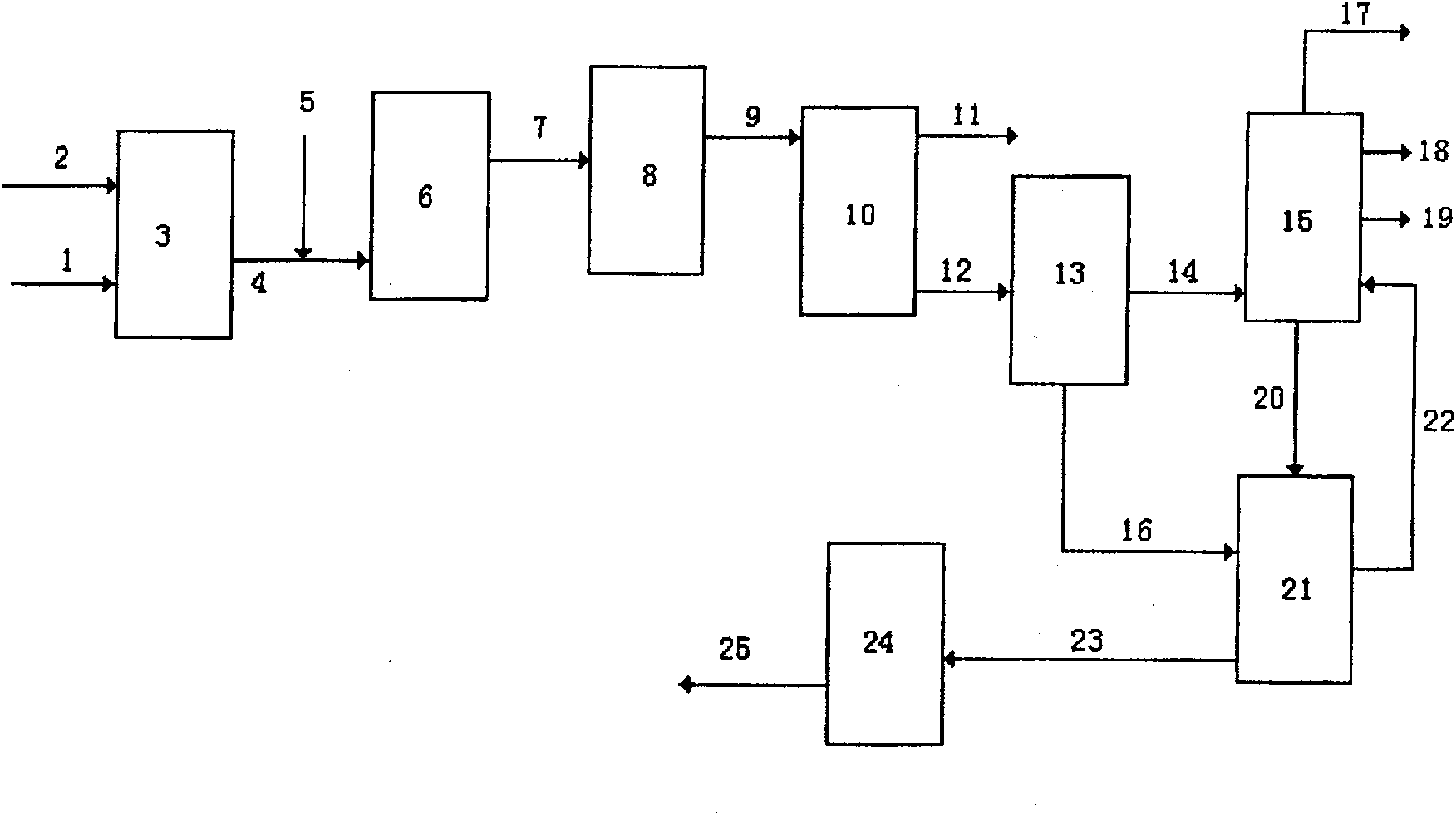

Heavy oil and residual oil combined treating process

ActiveCN101089144AExtended operating cycleGuaranteed normal feedingTreatment with hydrotreatment processesResidual oilSolvent

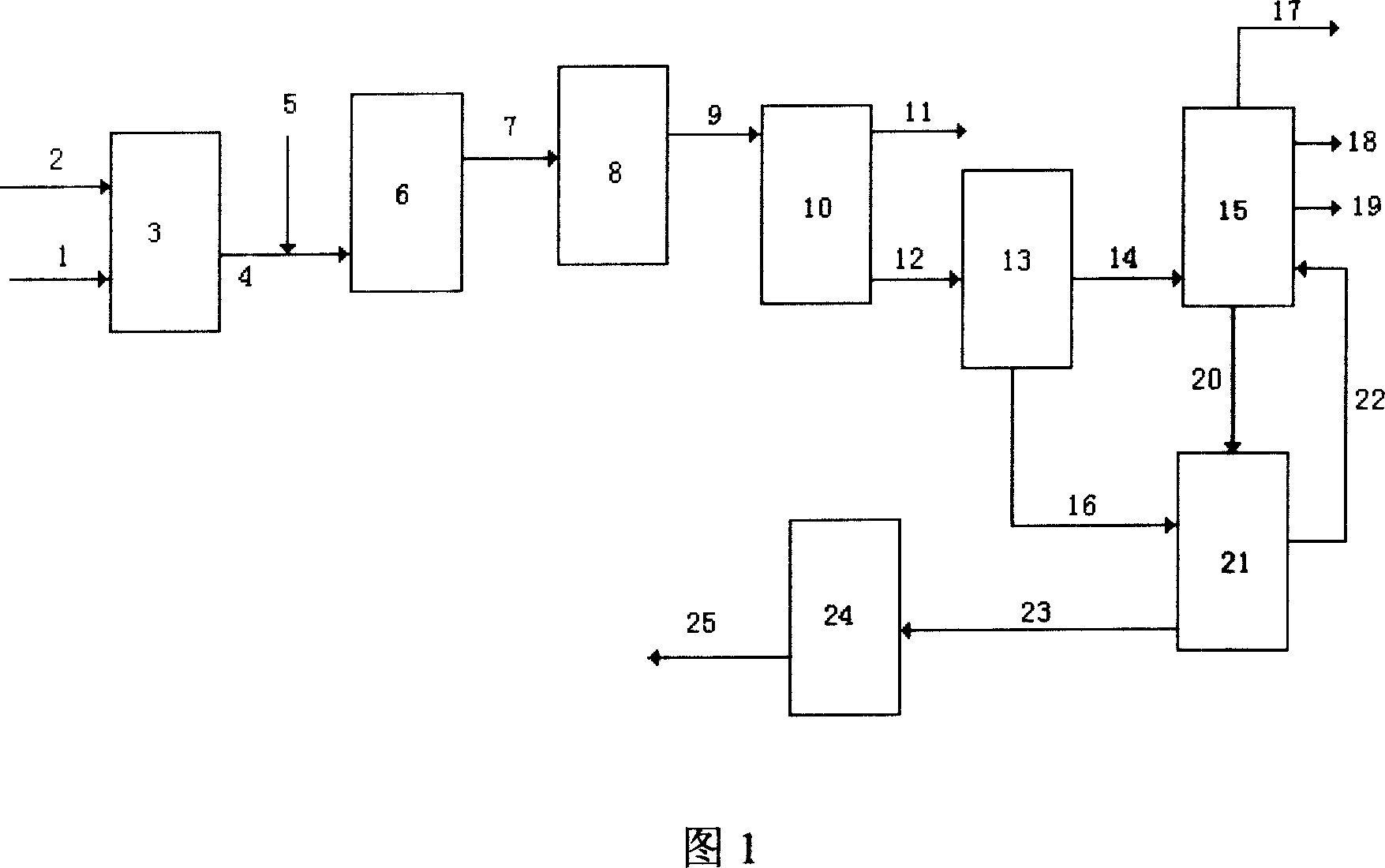

The heavy oil and residual oil combined treating process includes the following steps: hydrocracking heavy oil and residual oil material in a suspended bed in mild condition; fractionating the hydrocracked resultant into light fraction, heavy fraction and un-converted vacuum residue, which accounts for 20-45 wt% of the material; catalytically cracking the heavy fraction; and solvent deasphalting the un-converted vacuum residue to obtain deasphalted oil serving as the catalytically cracking material. The process of the present invention has stable hydrocracking operation in suspended bed, can utilize all the fractions in the material, and is suitable for treating various kinds of heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

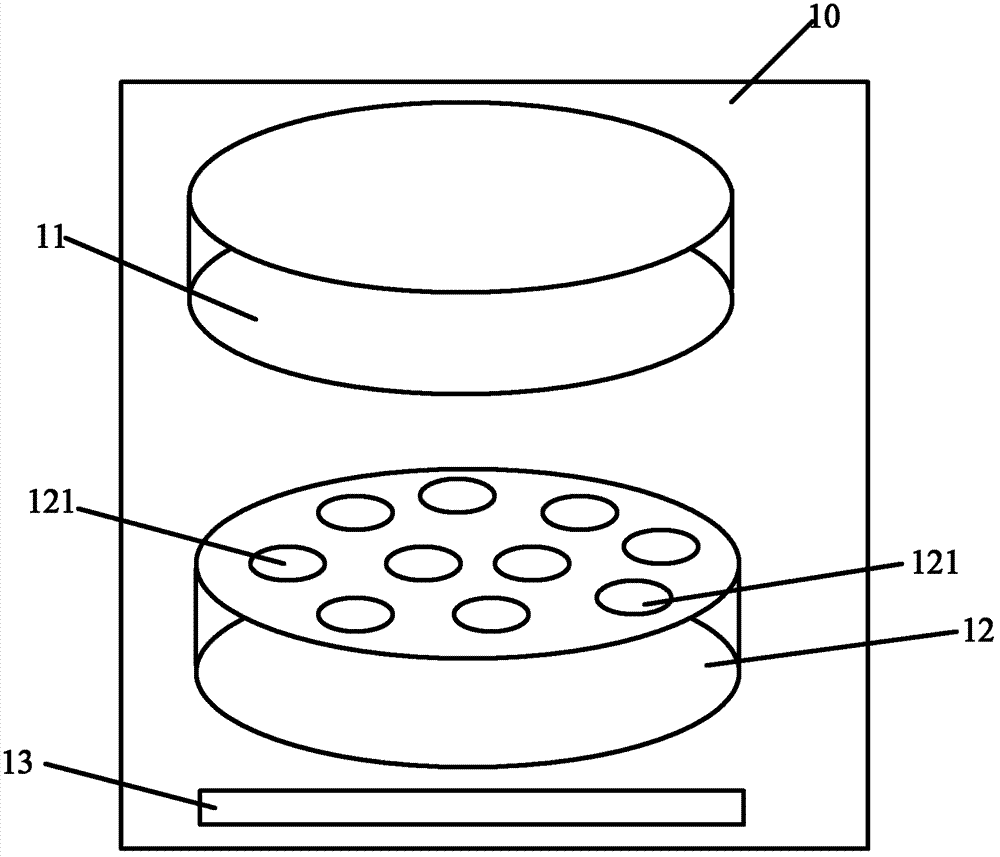

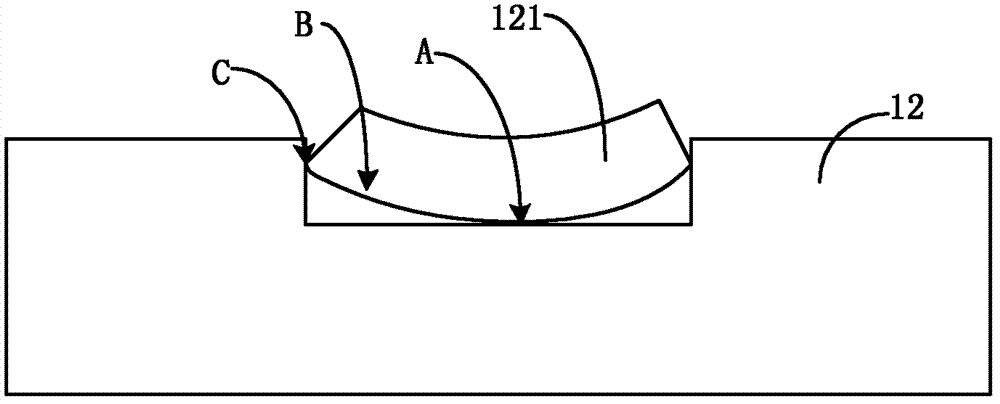

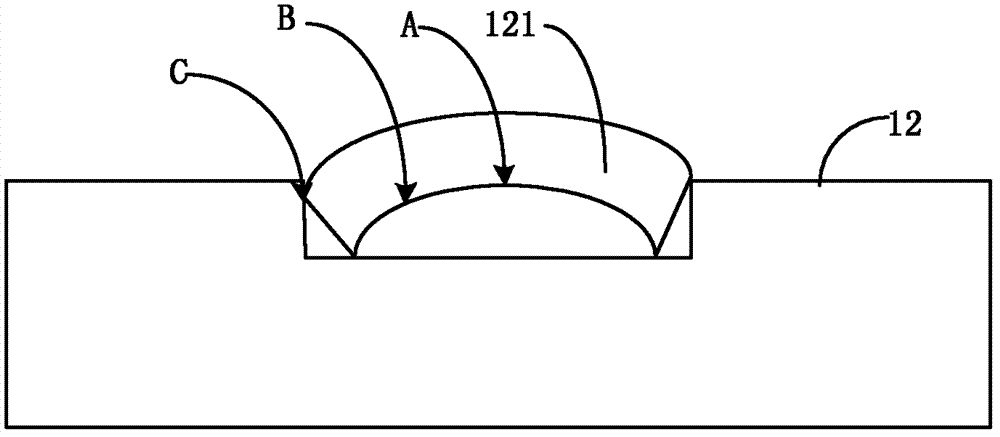

Graphite plate, reaction chamber with graphite plate, and substrate heating method

InactiveCN103074606AImprove uniformityEliminates the effects of uneven heatingChemical vapor deposition coatingGas phaseGraphite

The embodiment of the invention provides a graphite plate, a reaction chamber with the graphite plate, and a substrate heating method used in a chemical vapor deposition process. The graphite plate comprises a recess. A corresponding supporting frame is arranged at the position of the recess. The supporting frame is used for suspending a substrate, such that the substrate does not contact the graphite plate. According to the invention, the substrate is suspended, such that heat radiation is the main heating form of the heating of the graphite plate upon the substrate. Therefore, heating uniformity upon the substrate and especially a warped and deformed substrate is improved, and chemical vapor deposition process uniformity is improved.

Owner:BRILLIANT LIGHT TECH

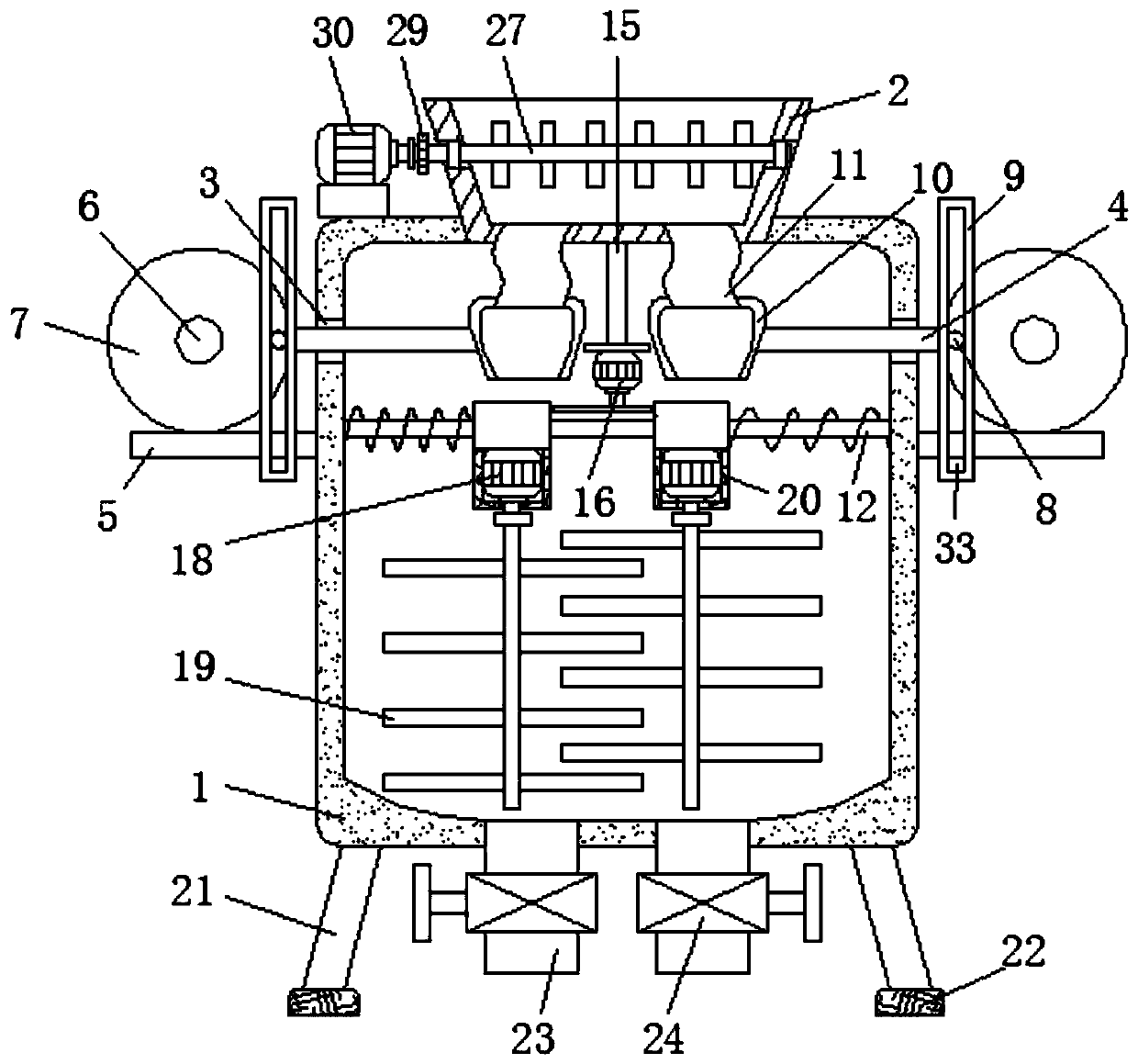

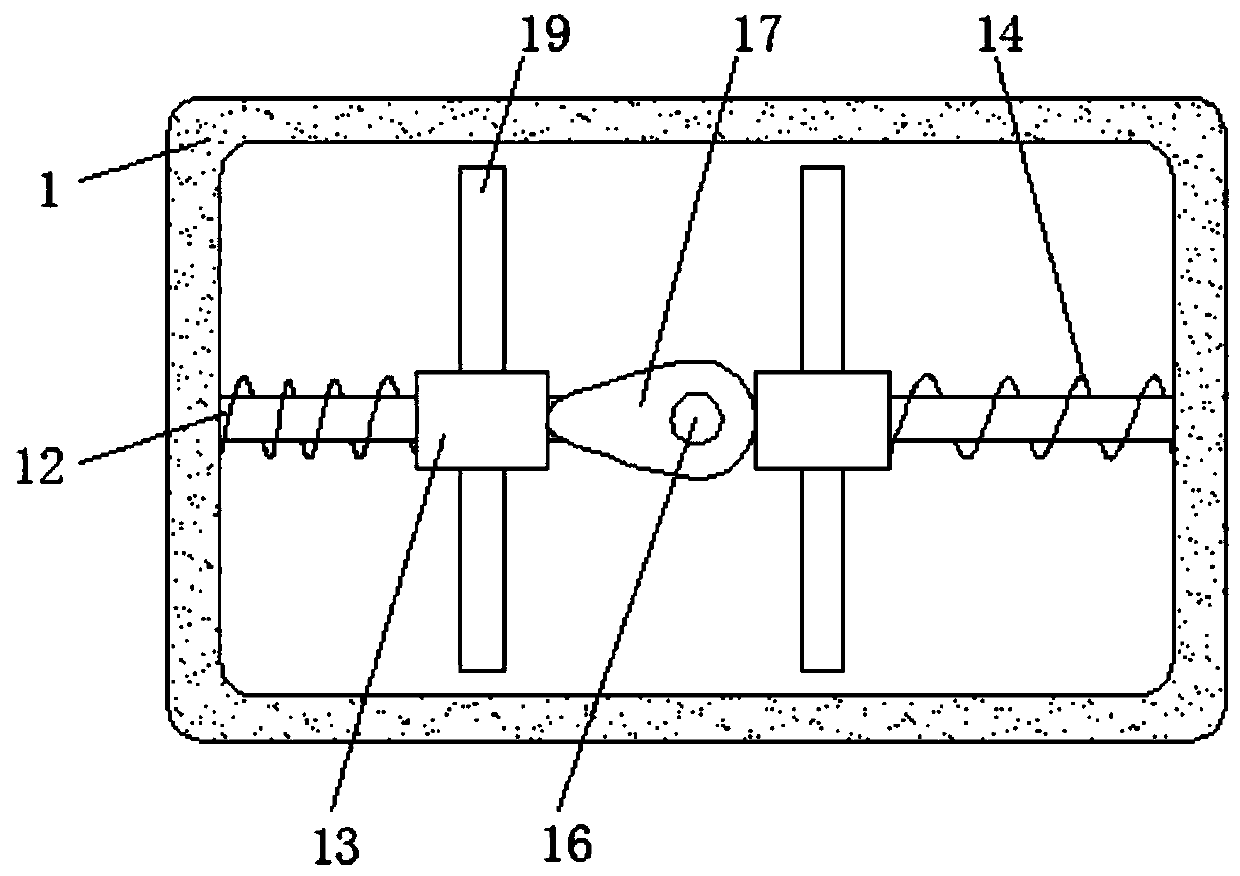

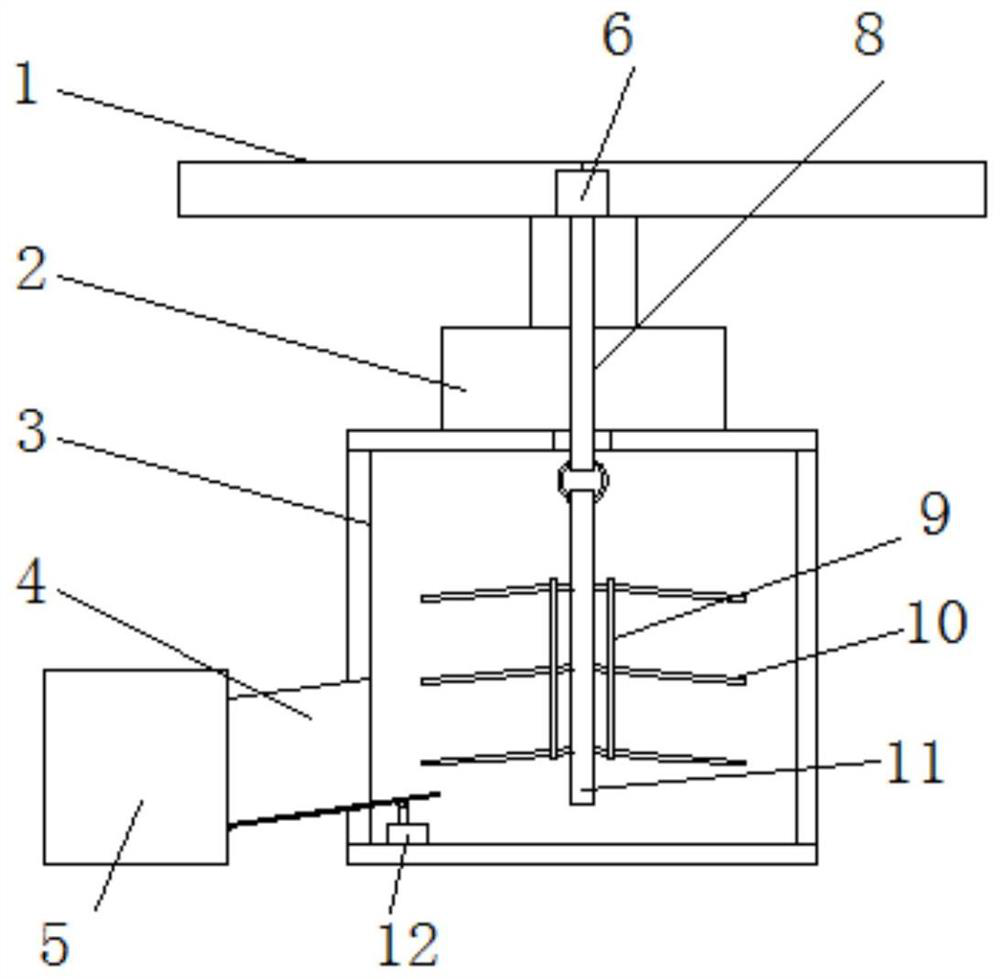

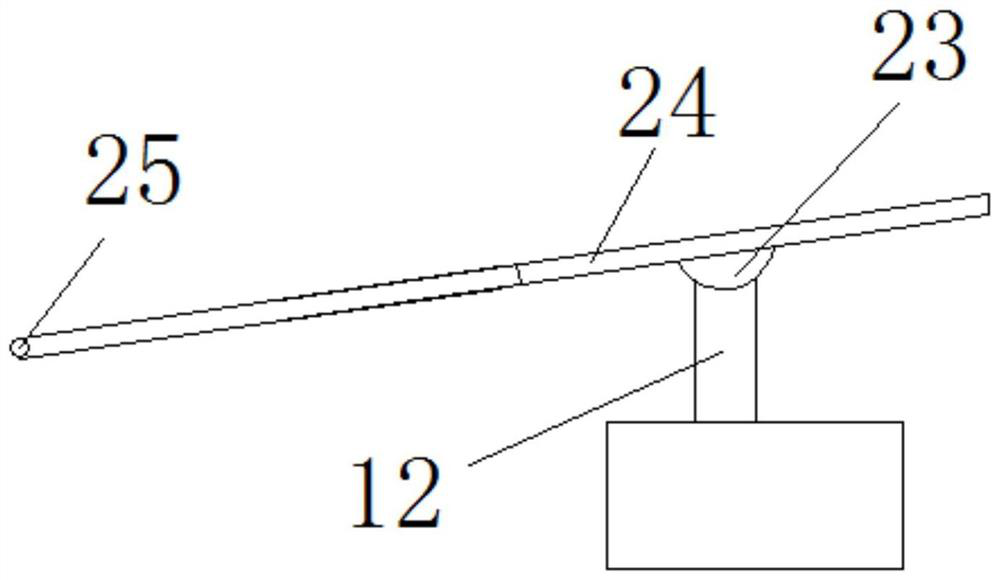

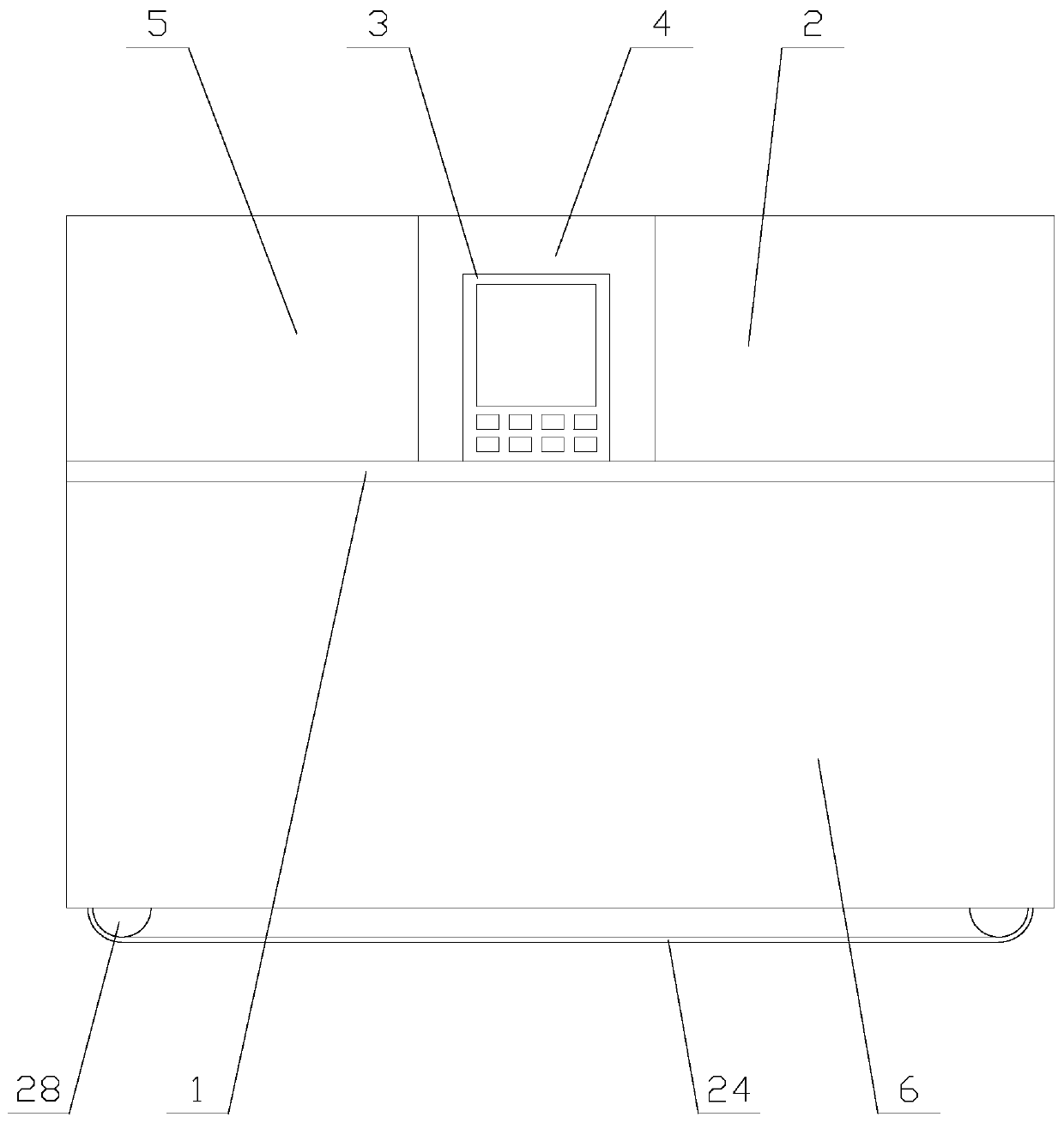

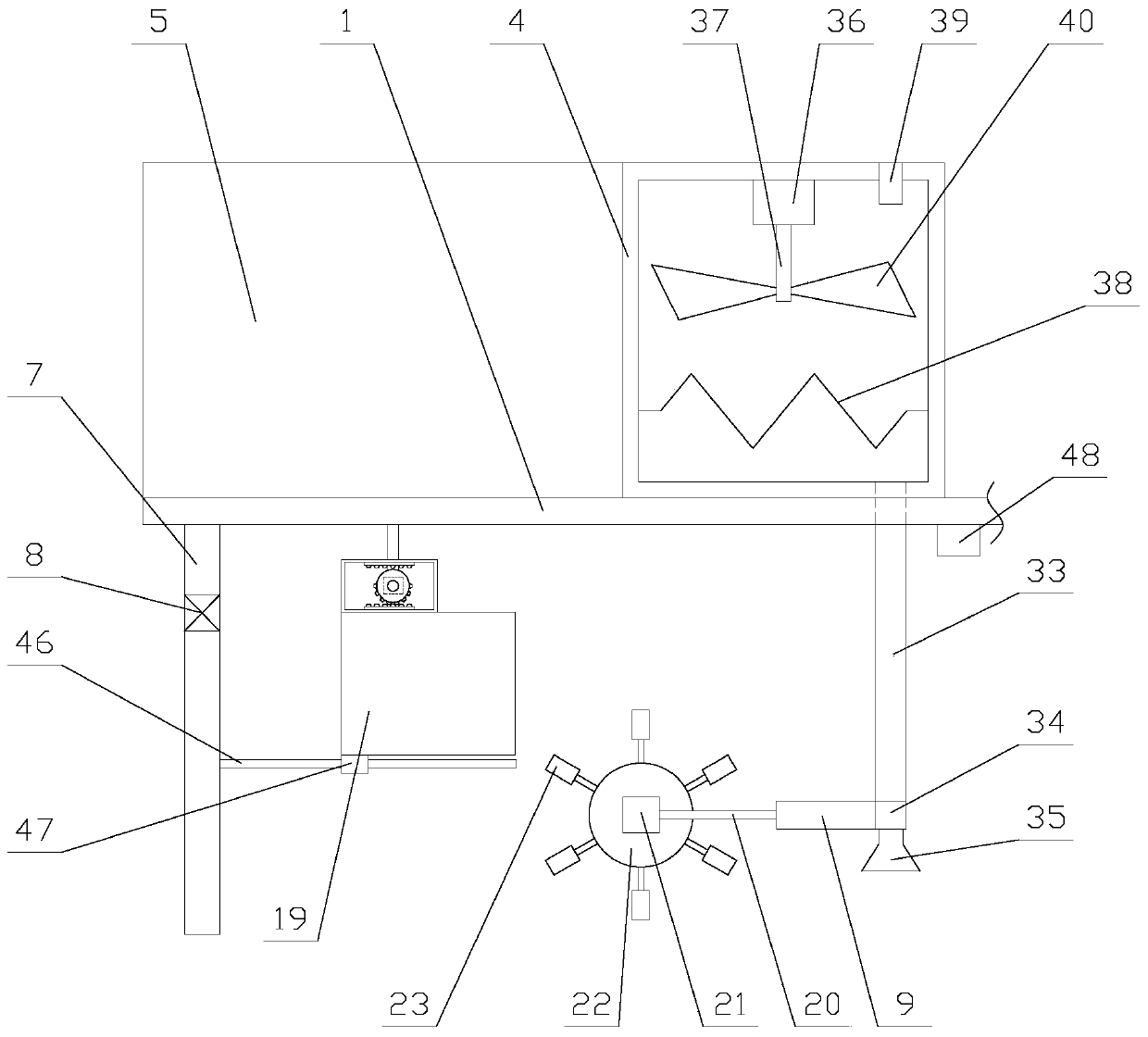

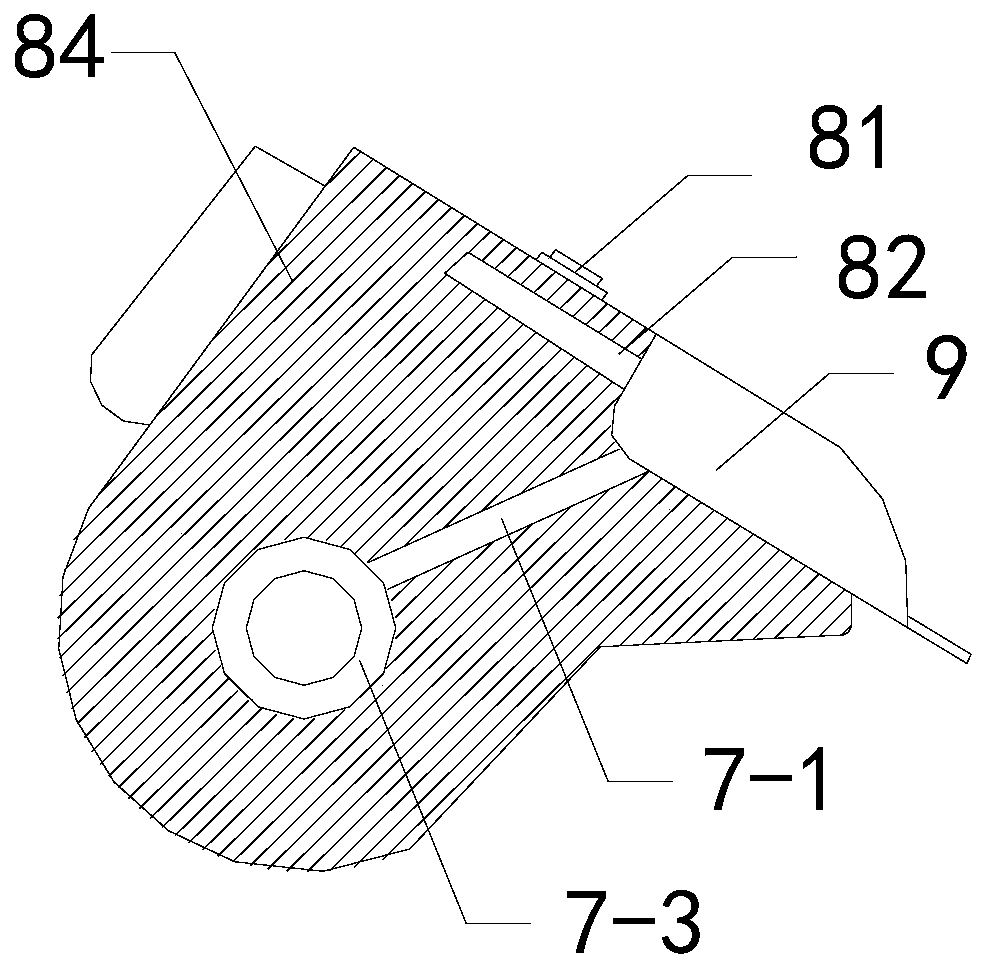

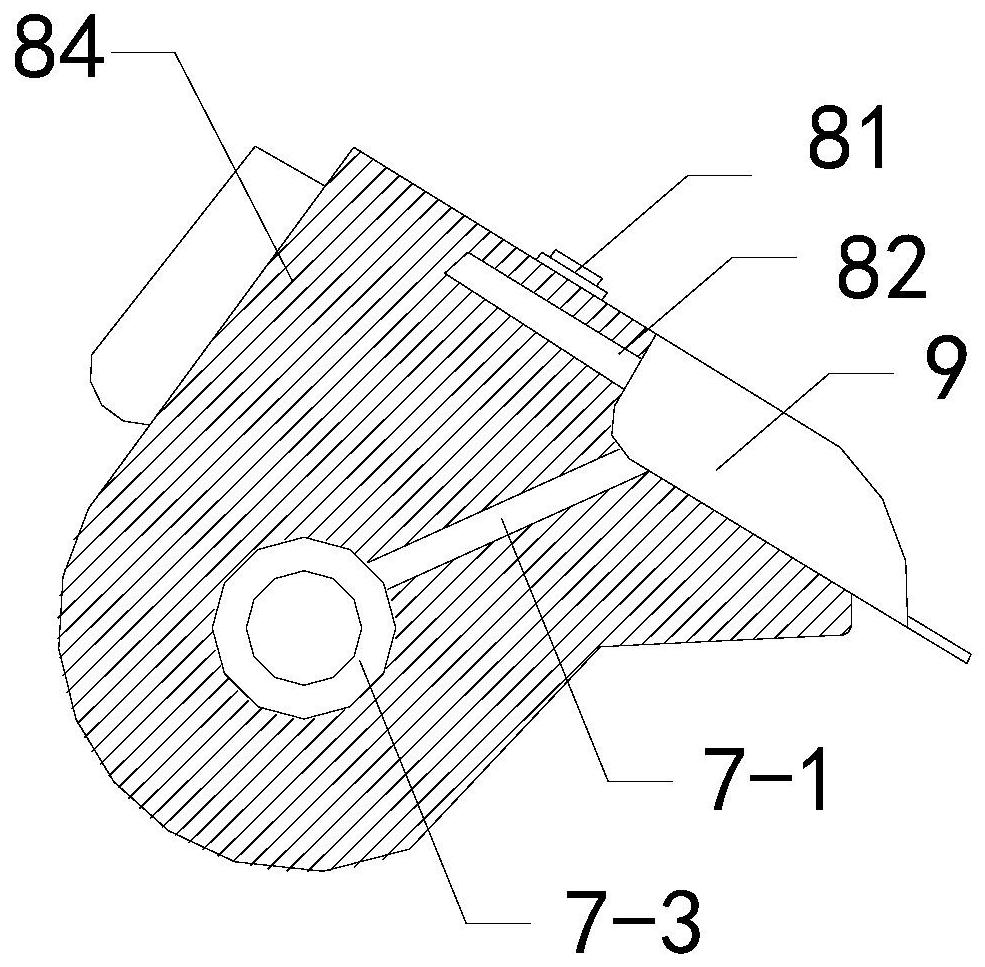

Pug mixing device for making preserved eggs

InactiveCN110898738AAvoid accumulationImpact distributionTransportation and packagingMixer accessoriesCircular discElectric machinery

The invention relates to the technical field of preserved eggs, particularly to a pug mixing device for making preserved eggs. The device includes a shell, the upper end of the shell is connected to afeeding apparatus, through grooves are respectively disposed at the upper parts of the left side and right side on the outer wall of the shell, push rods are movably connected in the through grooves,opposite ends of the two push rods are respectively connected to discharging hoppers, output shafts of first speed reduction motors are connected to discs, the outer walls of the discs are connectedto push heads, push plates are equipped with movable grooves used in cooperation with the push heads, sliding blocks are movably sleeved outside a guide rod, third speed reduction motors are mounted at the lower ends of the sliding blocks, and output shafts of the third speed reduction motors are connected to stirring shafts. The pug mixing device provided by the invention have stronger functionality and practicability, not only can guarantee the uniform mixing effect of yellow mud slurry, but also can accelerate the uniform mixing speed of the yellow mud slurry, improves the working efficiency, and is more convenient to use.

Owner:FUQUAN BAOLI FOOD

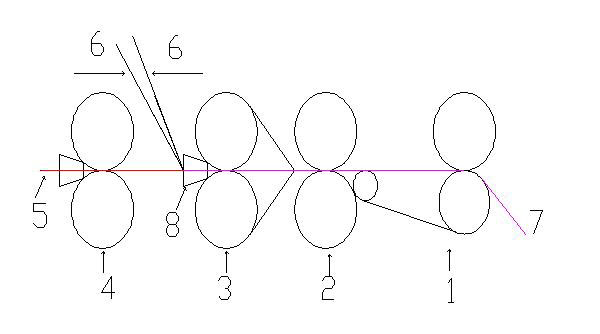

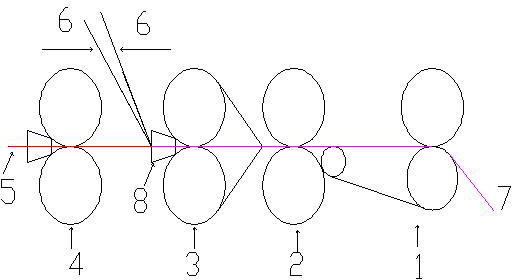

Improved ring spinning frame and spinning process thereof

InactiveCN102071500AClosely arrangedReduce widthDrafting machinesContinuous wound-up machinesYarnEngineering

The invention belongs to the field of spinning, specifically to an improved ring spinning frame and a spinning process thereof. The improved ring spinning frame comprises a back roller, a middle roller, a second roller and a front roller in turn. The improved ring spinning frame is characterized in that the back roller and the middle roller are provided with a feeder which consists of a suspended spindle and a flare opening; a servo motor for controlling the back roller is provided with a variable speed intelligent controller which is connected with an encoder arranged on the front roller; the output opening of the front roller is provided with a suction groove and a deformed pipe with negative pressure; a grid ring is sleeved on the deformed pipe, and is drawn through a leather roller. The invention is capable of shortening the process flow, increasing the production efficiency and lowering the production cost; and moreover, the spun yarn is excellent, little in hairiness, high in strength and variety in colors.

Owner:SHANDONG HUALE NEW MATERIAL TECH

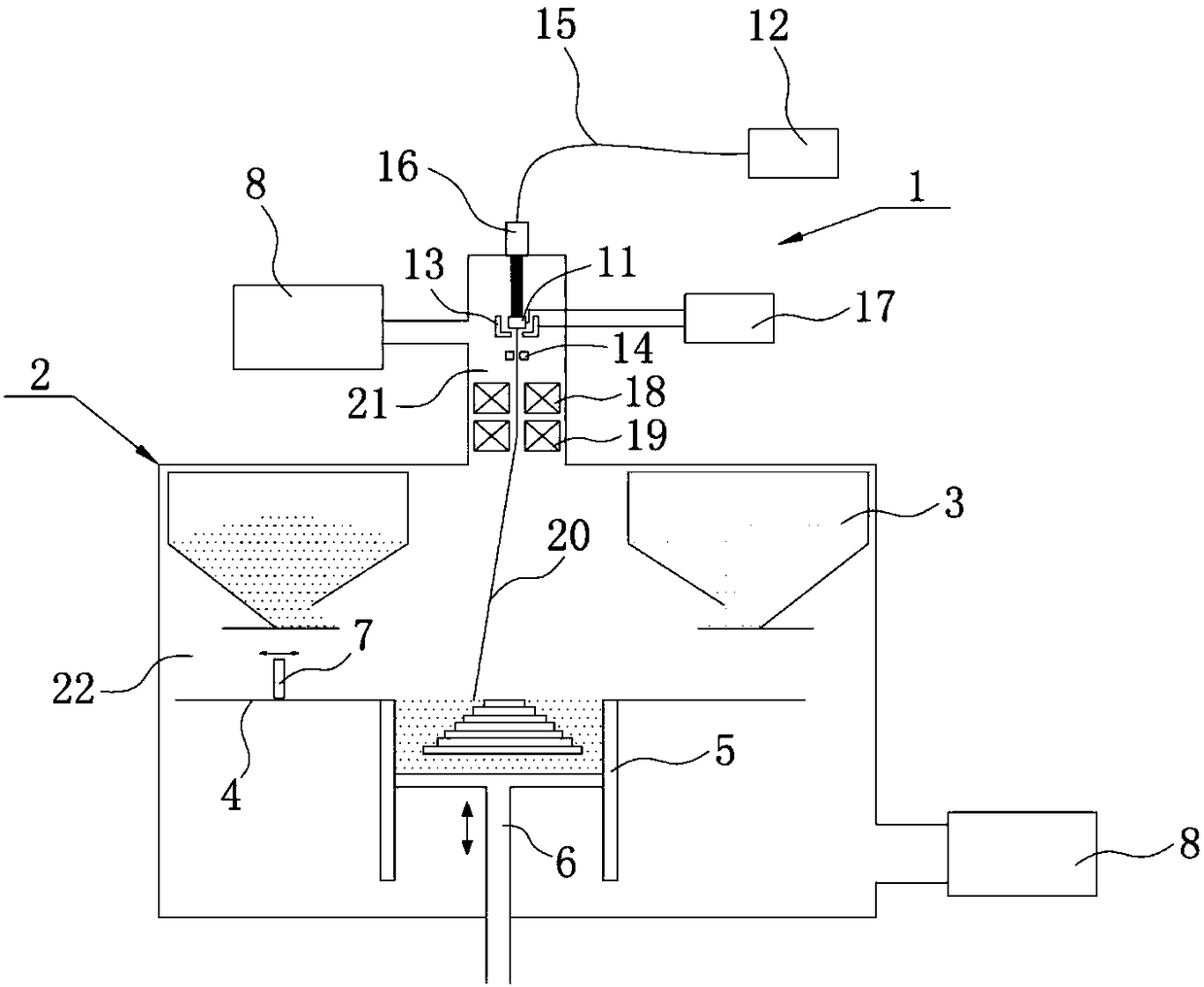

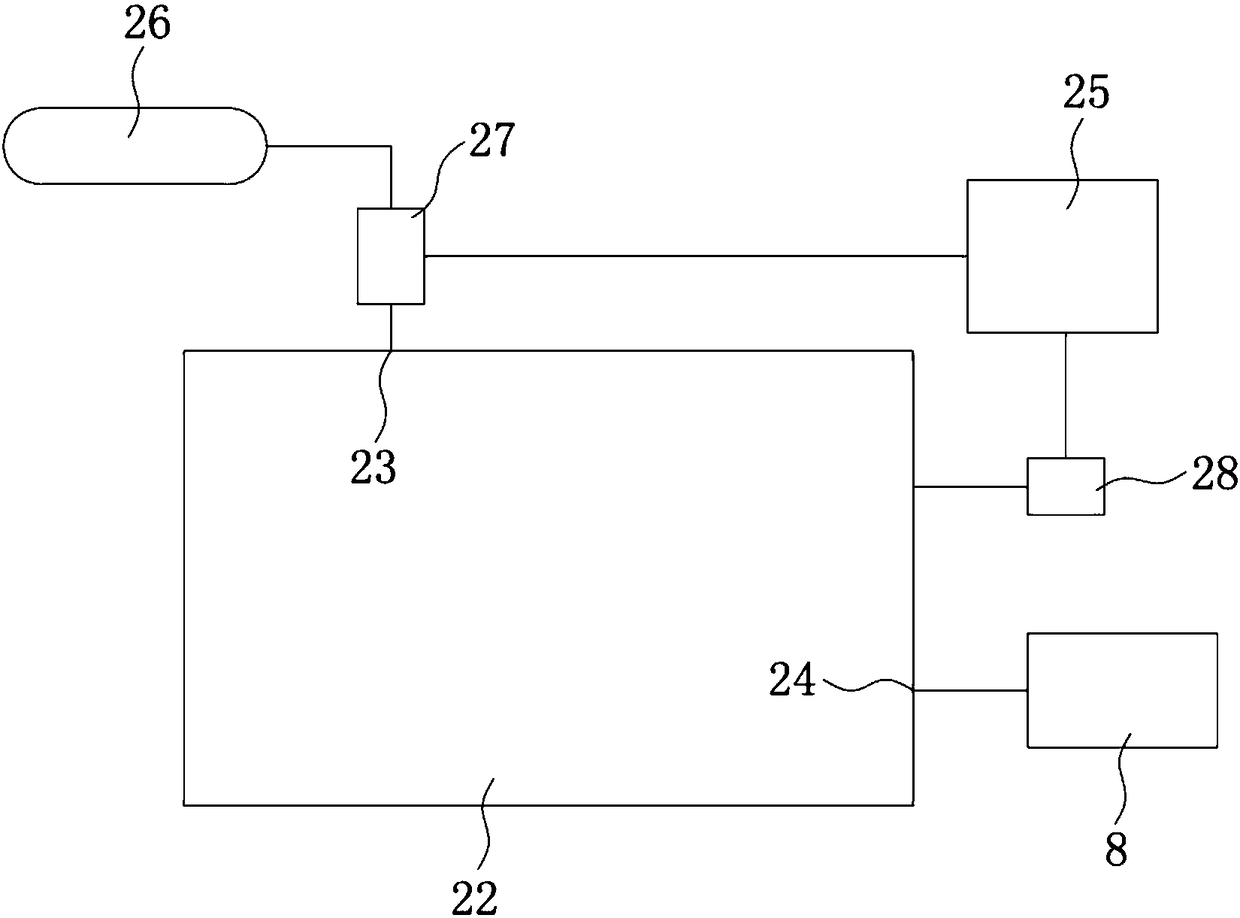

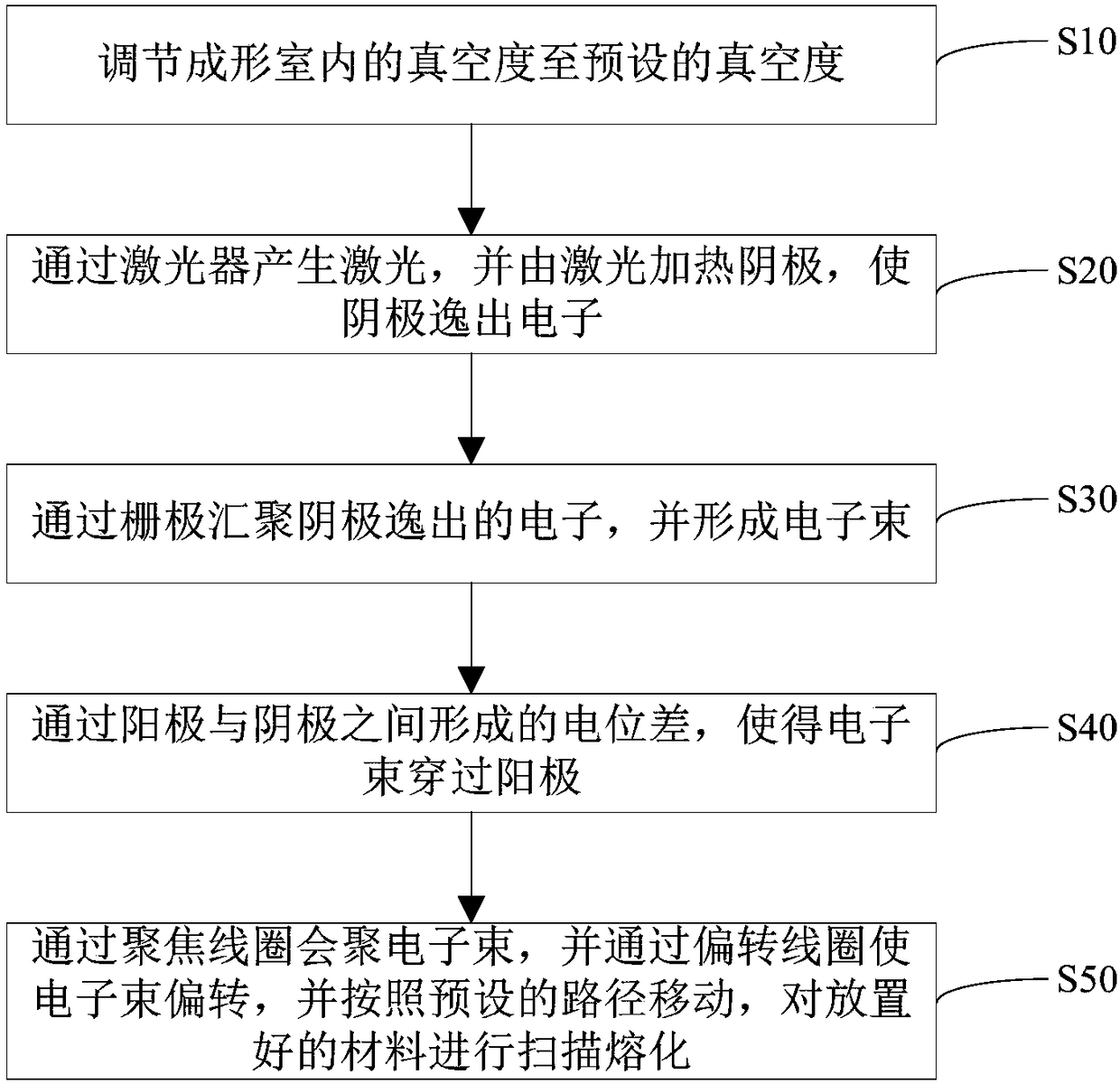

Additive manufacturing device and method

PendingCN108437472AExtend your lifeImpact distributionAdditive manufacturing apparatusIncreasing energy efficiencyElectric heatingPower flow

The invention belongs to the technical field of additive manufacturing, and discloses an additive manufacturing device and method. The additive manufacturing device comprises a ray generating device.The ray generating device comprises a cathode, a laser, a grid electrode and an anode. Electrons can escape after the cathode is heated. The laser is used for generating lasers, and the lasers are used for heating the cathode. The grid electrode is used for collecting the electrons to form an electron beam. The anode is located below the cathode and arranged in a ground connection mode, a hole isformed in the middle of the anode, and a potential difference which is used for enabling the electron beam to pass through the hole is formed between the anode and the cathode. According to the additive manufacturing device and method, the lasers are generated by the laser, the cathode is heated by the lasers, the cathode can generate the electrons, the electron beam can be formed, and therefore compared with the mode of electric heating of a cathode in the prior art, the additive manufacturing device and method have the advantages that high-current heating is not required, the phenomenon thatdue to the fact that a magnetic field is generated by current, distribution of the electrons can be affected is avoided, the life of the cathode is prolonged, the quality of beam spots in the additive manufacturing process is improved, and the quality and the efficiency of additive manufacturing are also improved.

Owner:QUICKBEAM CO LTD

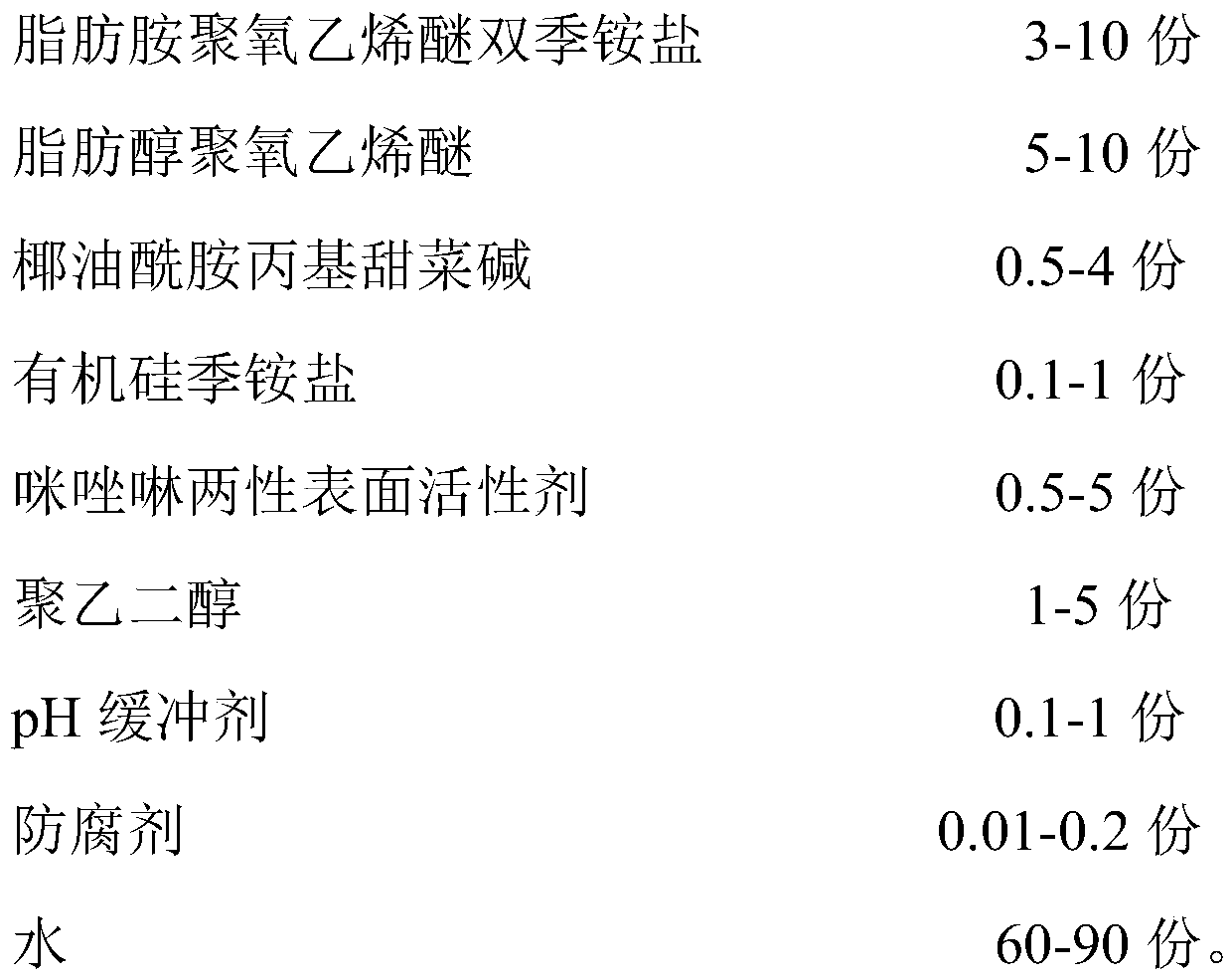

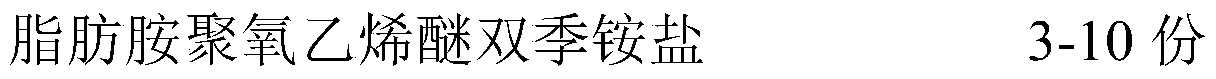

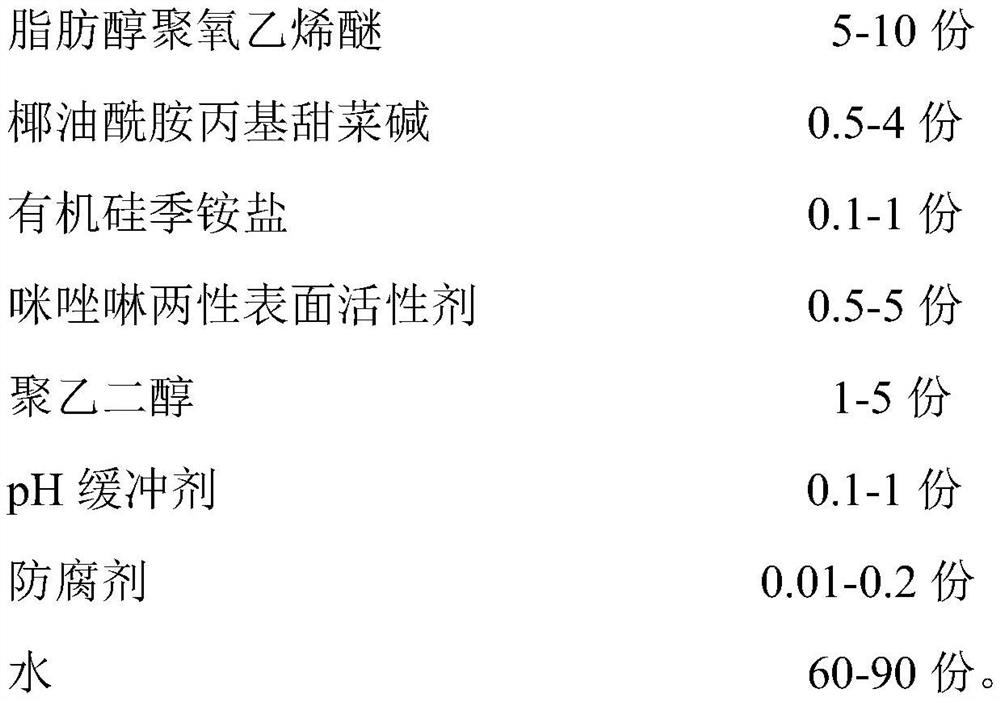

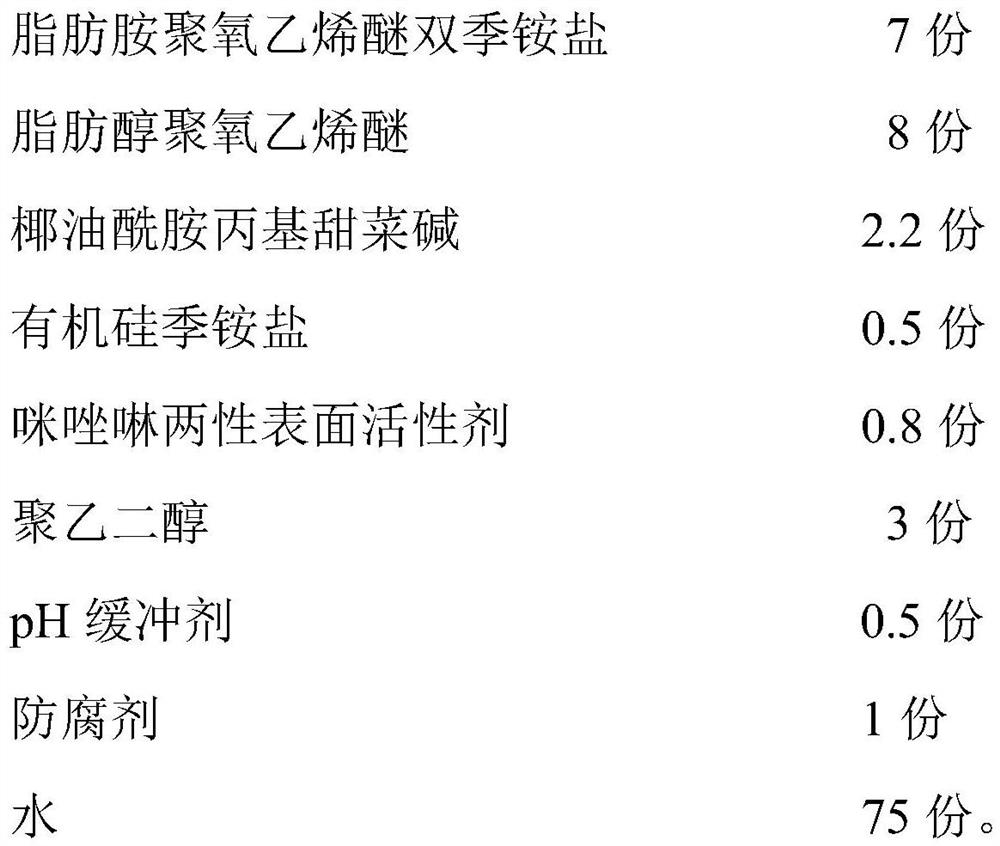

Anti-staining silk and wool washing liquid detergent and preparation method thereof

ActiveCN109810802AGood dispersionImprove stabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsStainingPh buffering

The invention relates to the technical field of toiletries, in particular to anti-staining silk and wool washing liquid detergent and a preparation method thereof. The anti-staining silk and wool washing liquid detergent is prepared from the following components: fatty amine polyoxyethylene ether biquaternary ammonium salt, fatty alcohol polyoxyethylene ether, cocamidopropyl betaine, organosiliconquaternary ammonium salt, an imidazoline ampholytic active agent, polyethylene glycol, a pH buffering agent, a preservative and water. The anti-staining silk and wool washing liquid detergent is usedfor washing clothes made of real silk, wool and cashmere and the like, has no corrosion on the clothes, can keep the clothes soft, and is high in detergency and good in anti-staining, antibacterial property and anti-static effect.

Owner:东莞市嘉宏有机硅科技有限公司

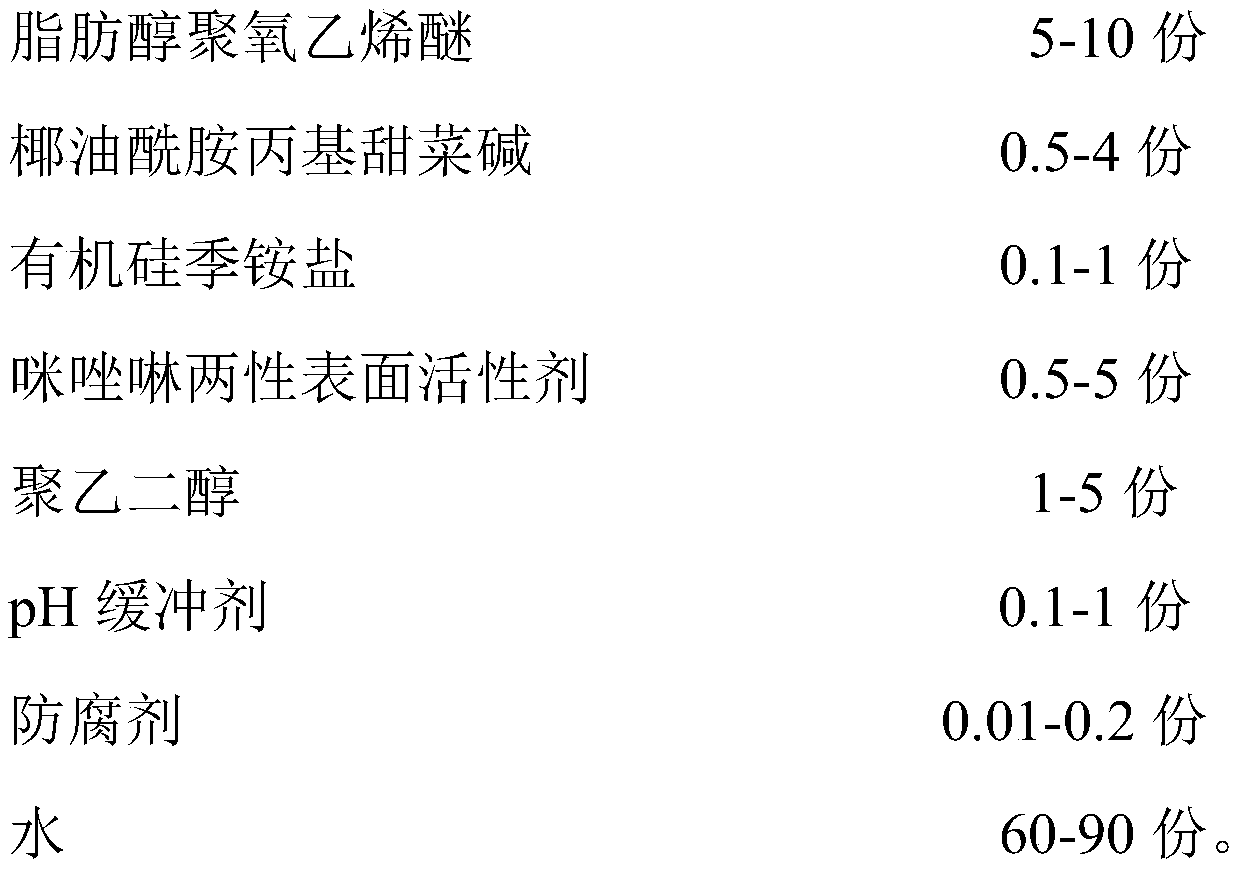

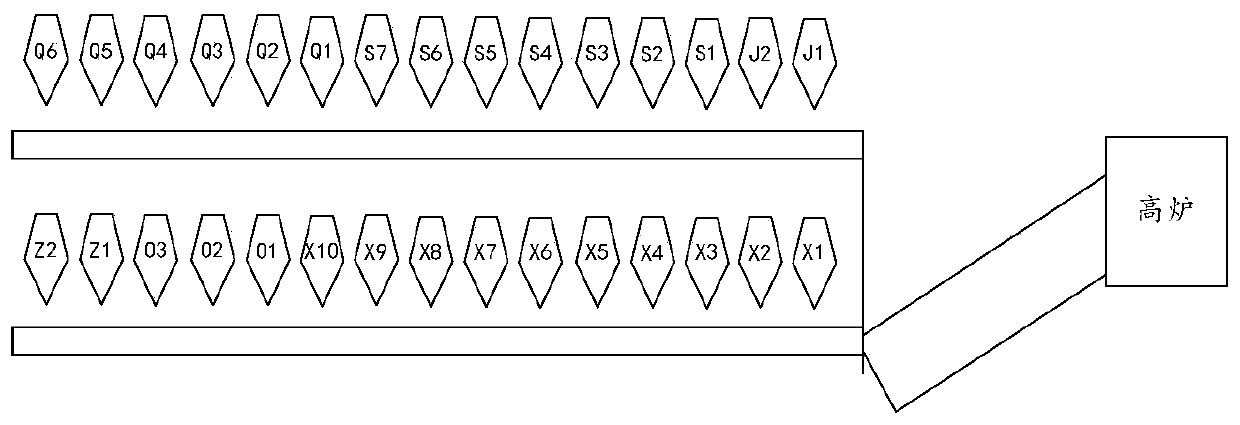

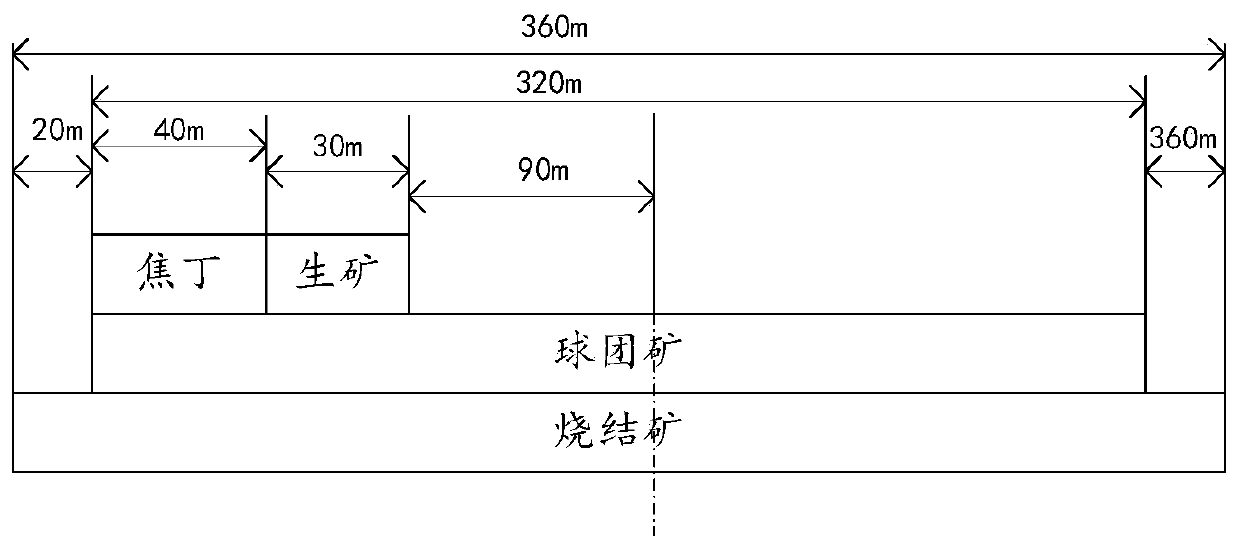

Material sequence control method applied to high-proportion pellet smelting

InactiveCN111286568AWell mixedImpact distributionSteel manufacturing process aspectsBlast furnace detailsIndustrial engineeringCoal gas

The invention discloses a material sequence control method applied to high-proportion pellet smelting. The material sequence control method comprises the following steps that the feeding starting time, the feeding total time length and the first second flow of each furnace charge in N furnace charges are set according to the N furnace charges required by the smelting and the addition amount of each furnace charge, so that material strips of pellets on a feeding belt completely fall into the material strips of a sintered ore, and the coverage rate is 85% or above; the feeding sequence of the Ntypes of furnace charges is controlled in that timing is carried out by taking the moment when feeding is started in the smelting as a starting point, and when the timing reaches the feeding startingmoment of the ith type of furnace charge in the N types of furnace charges, the ith type of furnace charge is fed to a feeding belt at the first second flow aiming at the ith type of furnace charge; and when the total feeding duration corresponding to the ith furnace burden is reached, feeding is stopped. According to the method, the stable distribution of the gas in the furnace can be prevented from being influenced by the difference between the pellet ore and the sintered ore in physical, chemical and metallurgical properties and the like, so that the distribution of the gas in the furnace is more stable.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

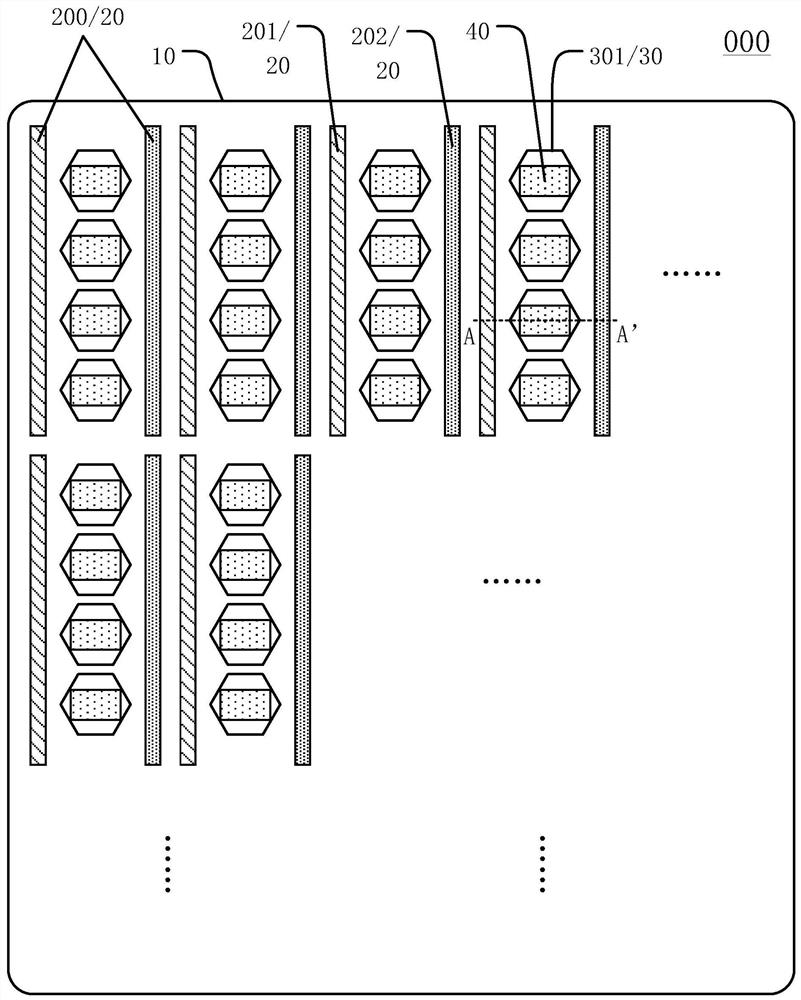

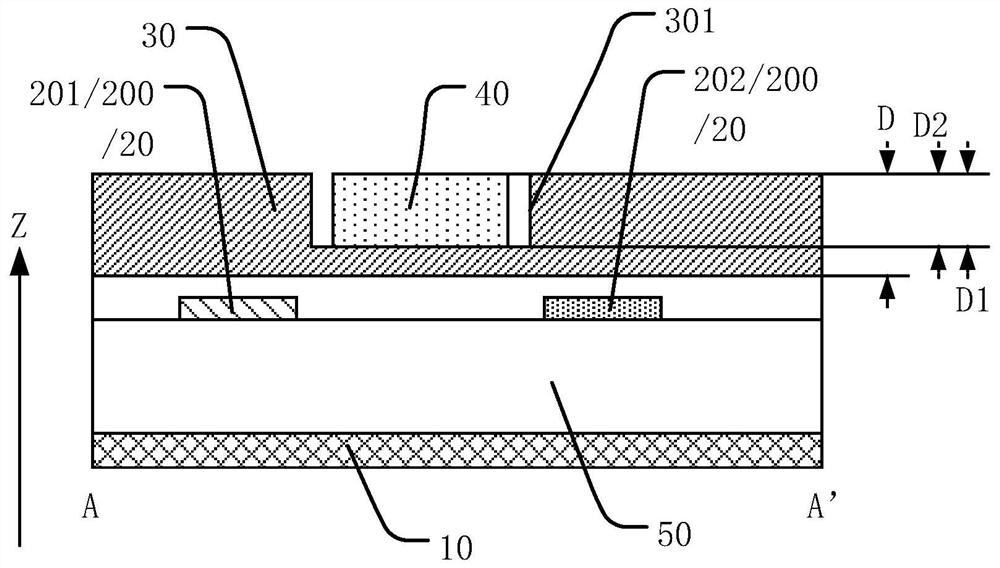

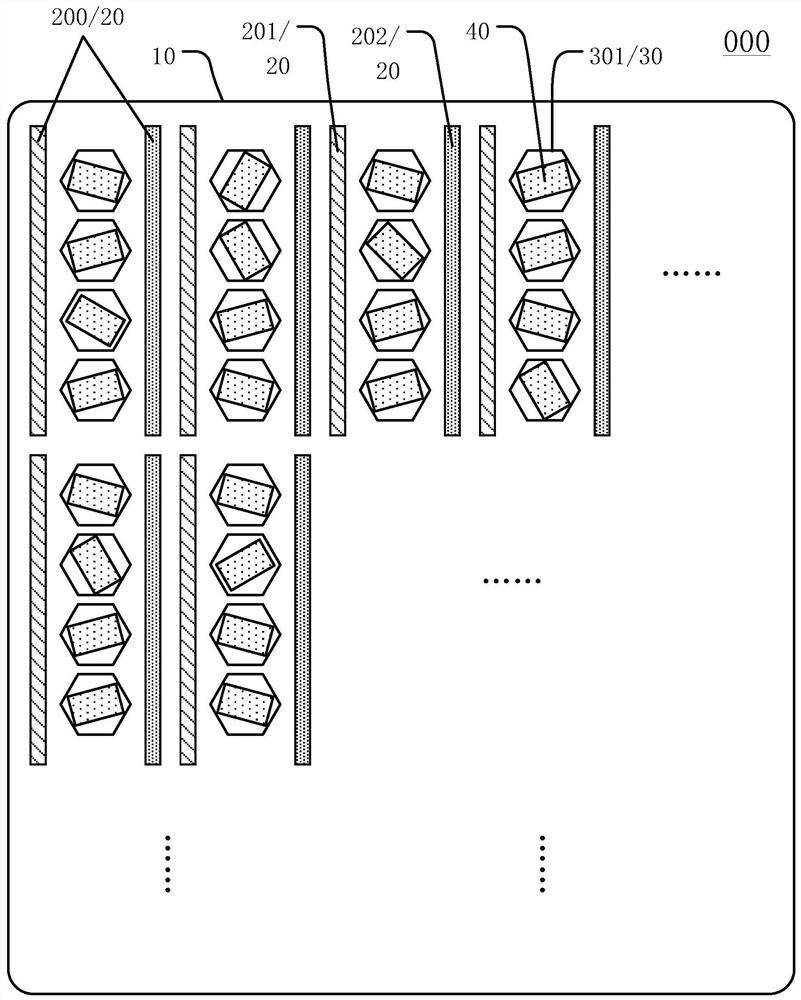

Display panel and display device

ActiveCN113380937AImpact distributionEvenly distributedSolid-state devicesIdentification meansDisplay deviceEngineering

The invention discloses a display panel and a display device, and belongs to the technical field of display. The display panel comprises a substrate, a counterpoint electrode layer and a first planarization layer, wherein the counterpoint electrode layer comprises a plurality of counterpoint electrode groups, each counterpoint electrode group at least comprises a first counterpoint electrode and a second counterpoint electrode, a plurality of grooves are formed in the side, away from the substrate, of the first planarization layer, one light-emitting element is arranged in one groove, and the light-emitting elements can rotate in the grooves in the direction parallel to the plane where the substrate is located. The display device comprises the display panel. According to the invention, the situation that the positions of light-emitting elements are changed after alignment is completed to affect the subsequent process and the display effect can be avoided, the redundant light-emitting elements can be recovered after alignment is completed, the light-emitting elements are uniformly distributed on a substrate as much as possible, and the display effect is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

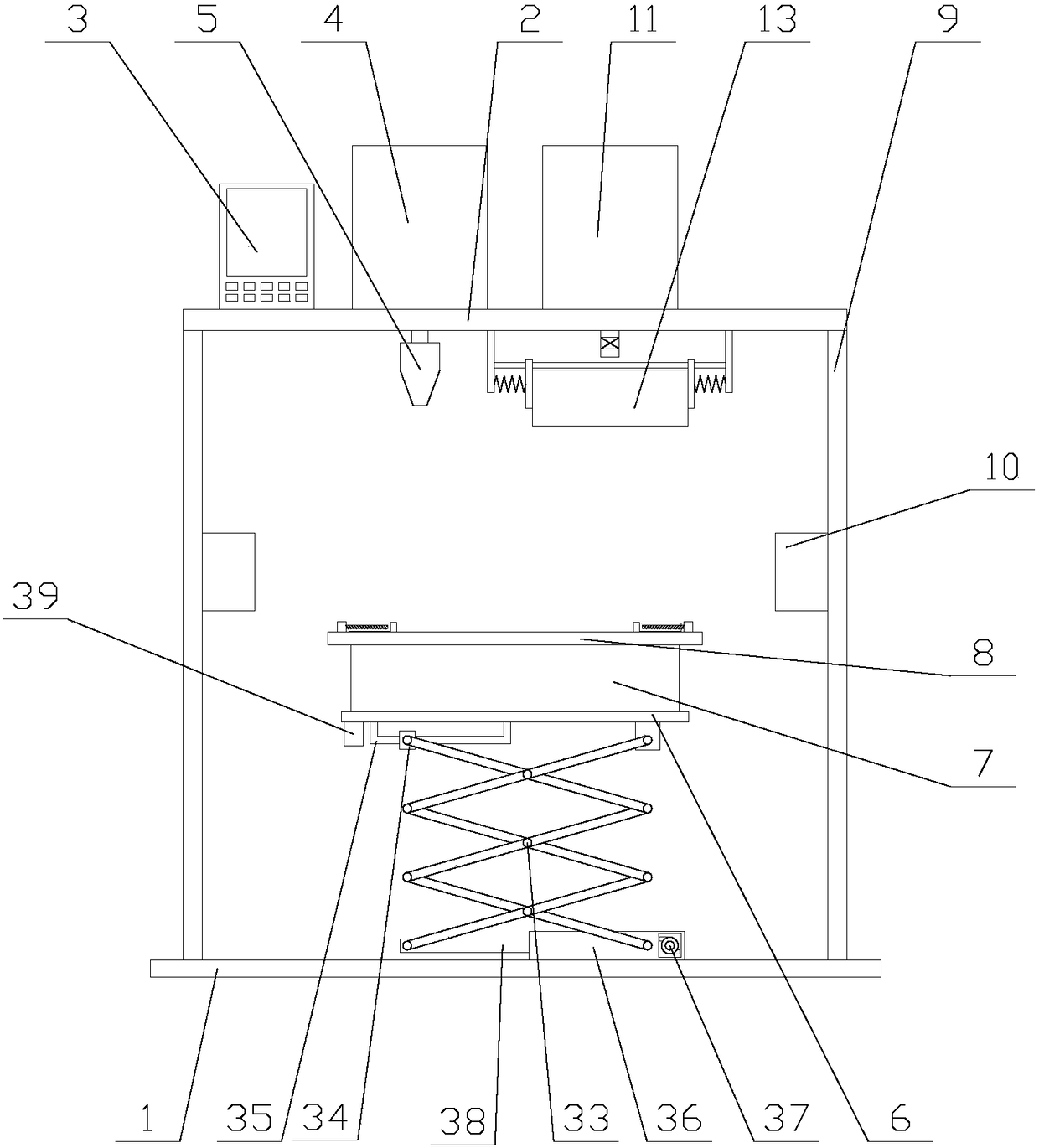

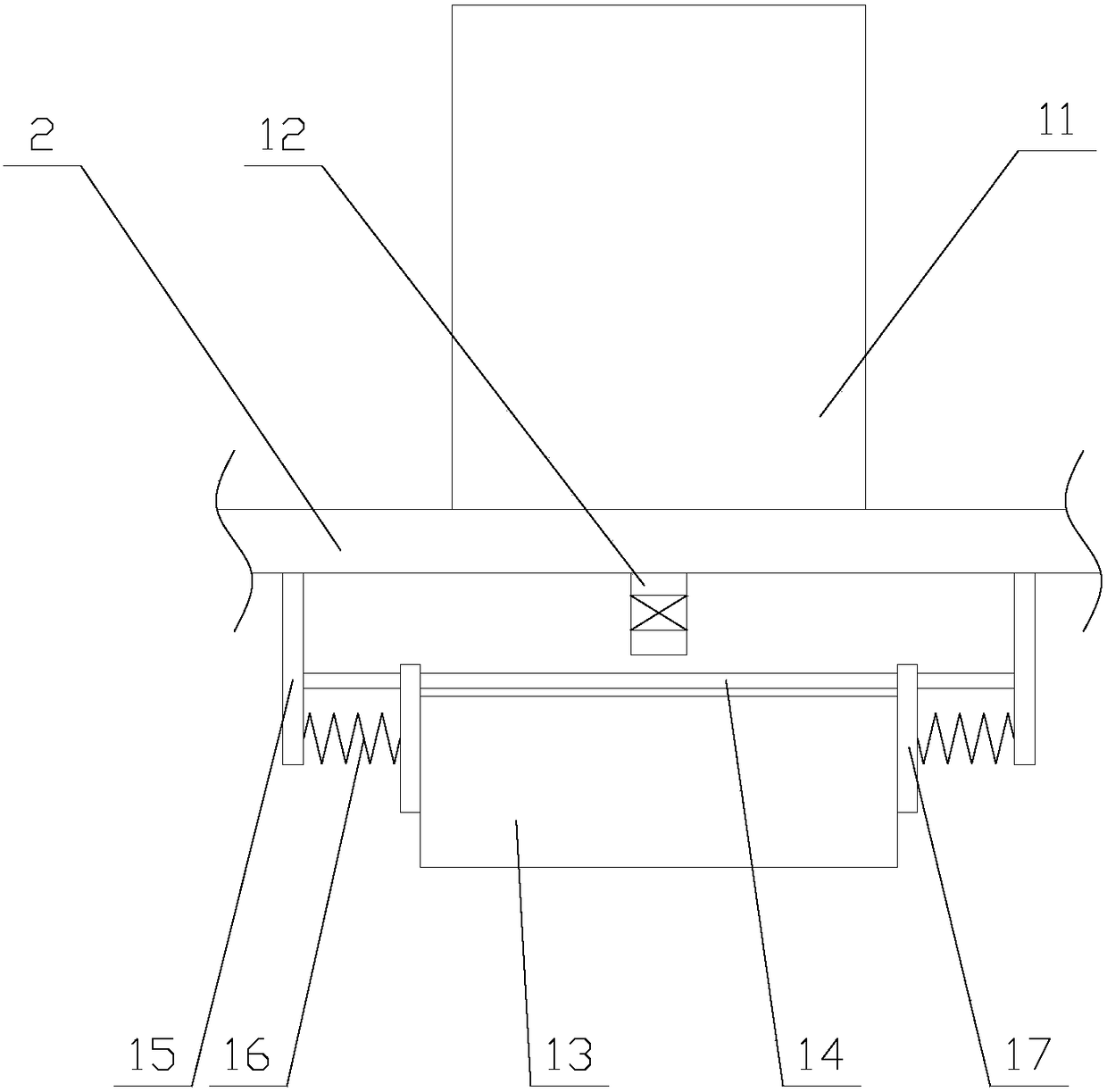

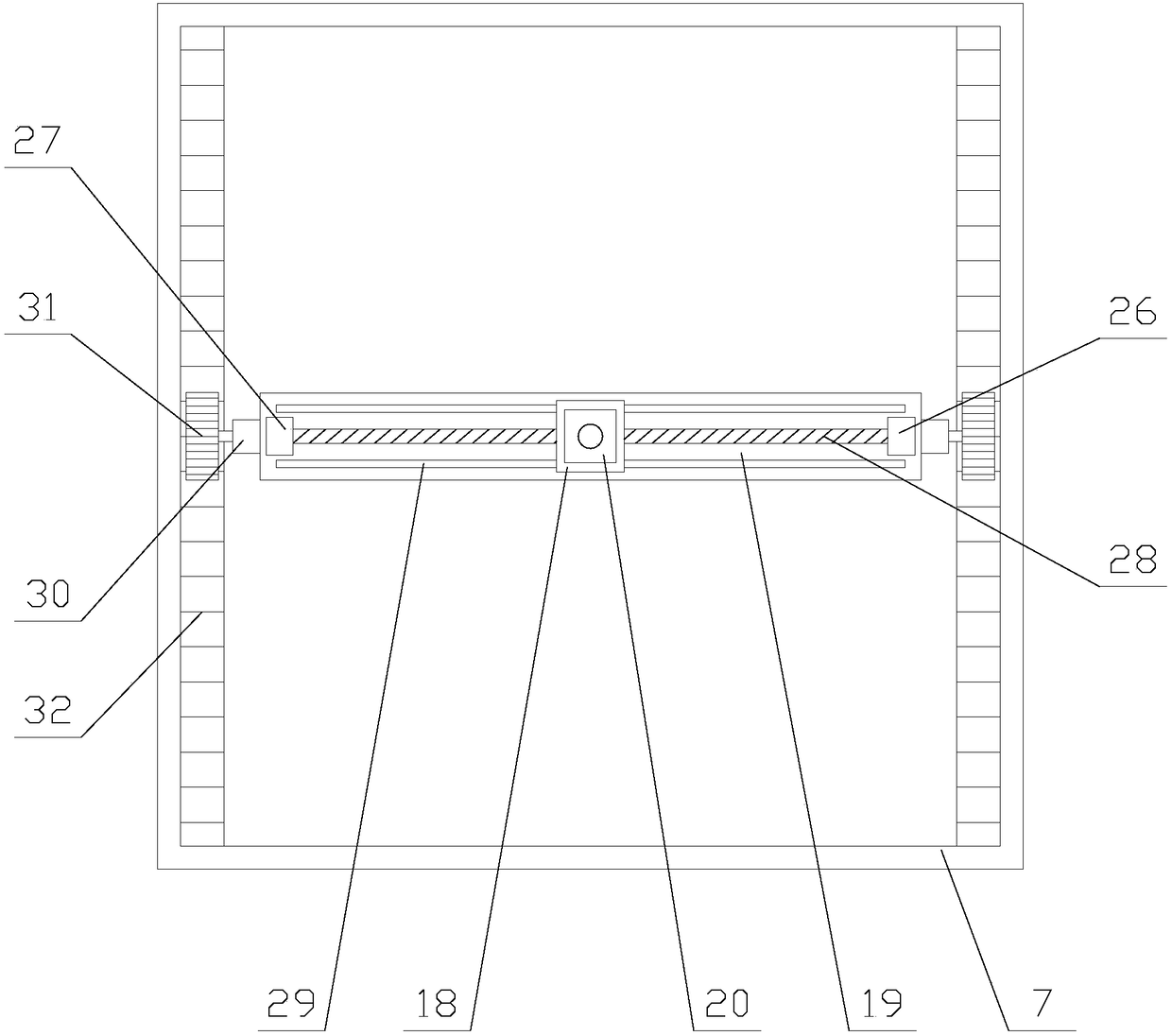

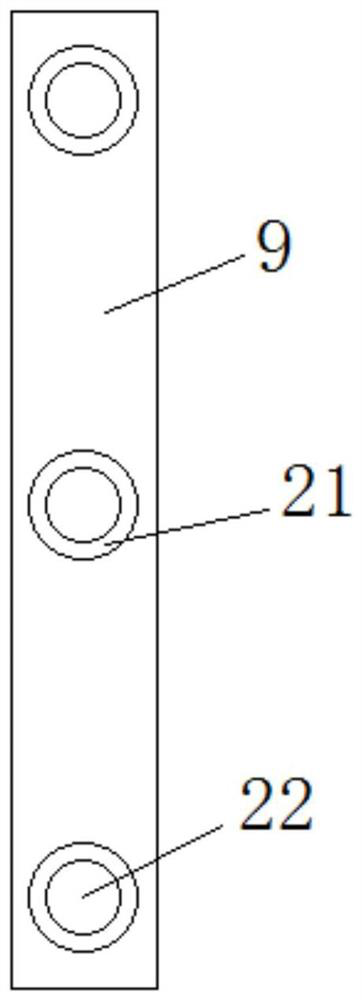

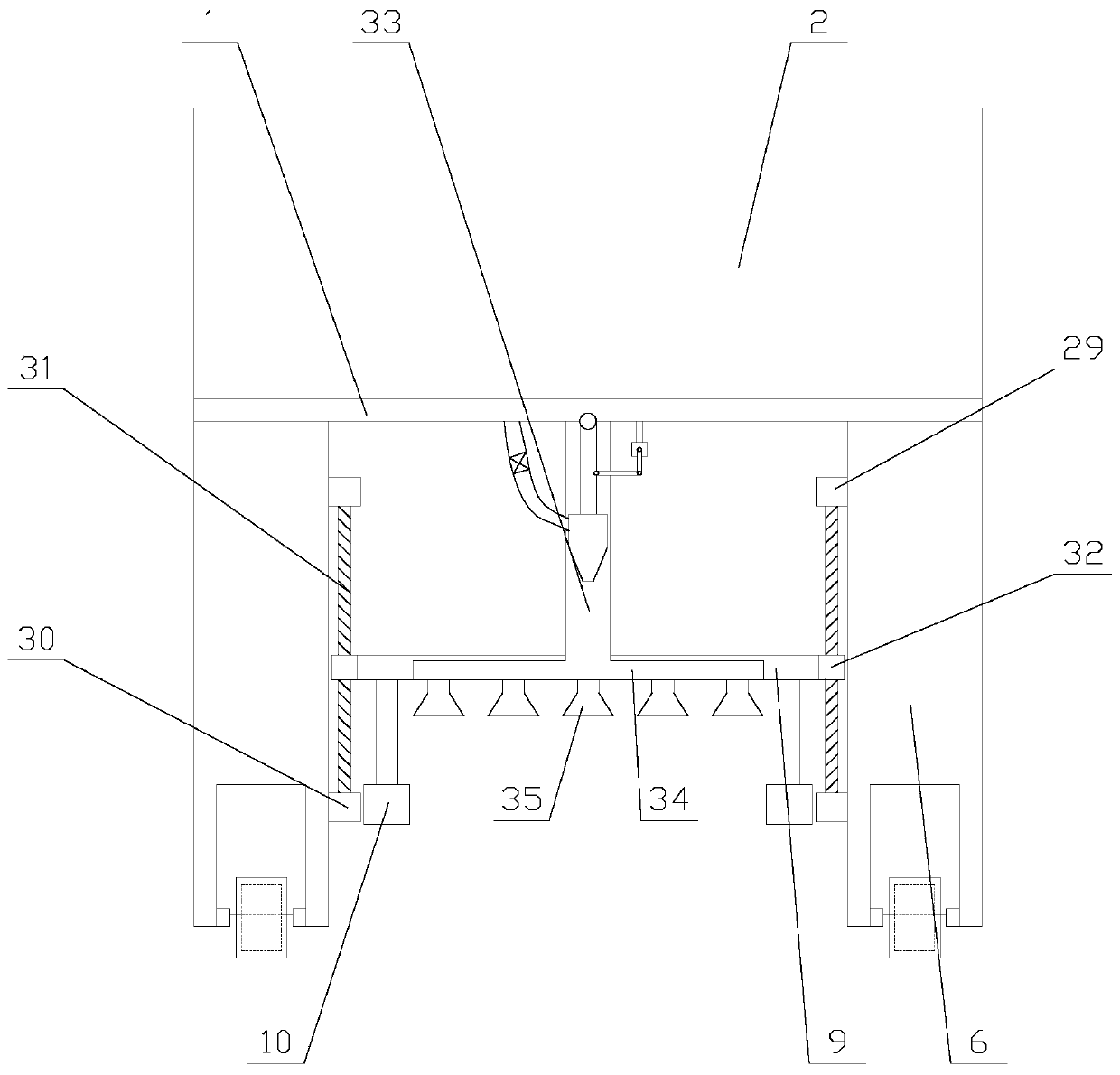

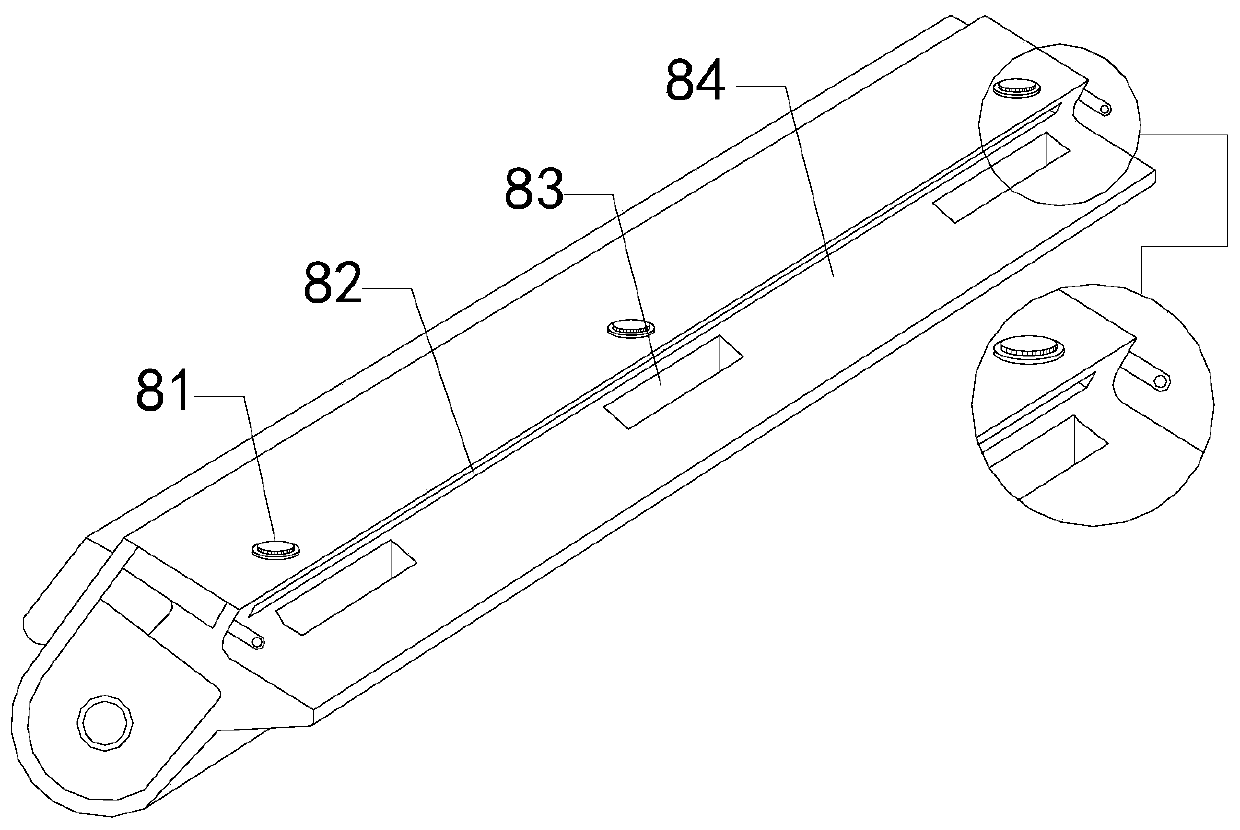

Magnetic powder inspection equipment with high detection accuracy

InactiveCN108614031AEasy to fall onImpact distributionMaterial magnetic variablesEngineeringElectrical and Electronics engineering

The invention relates to magnetic powder inspection equipment with high detection accuracy. The equipment comprises a base, a top plate, a controller, a magnetic powder box, a spray head, a lifting mechanism, a support plate, a translation box, a rotary plate, a fastening mechanism, a cleaning mechanism, two support plates and two magnetizing devices, wherein the cleaning mechanism comprises an alcohol box, a dropper, a sponge block and a mounting assembly, the mounting assembly comprises a guide rod and two mounting units, and each mounting unit comprises a lifting plate, a spring and a pressing plate; a translation mechanism comprises a translation block, a translation plate, a first motor, an offset assembly and two translation assemblies. According to the magnetic powder inspection equipment with high detection accuracy, oil stains on the surface of a workpiece are removed through the cleaning mechanism, and the condition that oil stains adsorb magnetic powder and affect distribution of magnetic marks is prevented; in addition, the rotary plate is driven to rotate and offset through the translation assemblies, surplus magnetic powder is thrown conveniently through rotation of the workpiece after the magnetic powder falls onto the surface of the workpiece, magnetic mark display is correct, and the detection accuracy and the practicability of the equipment are conveniently improved.

Owner:NANAN YONGTENG TECH CONSULTATION CO LTD

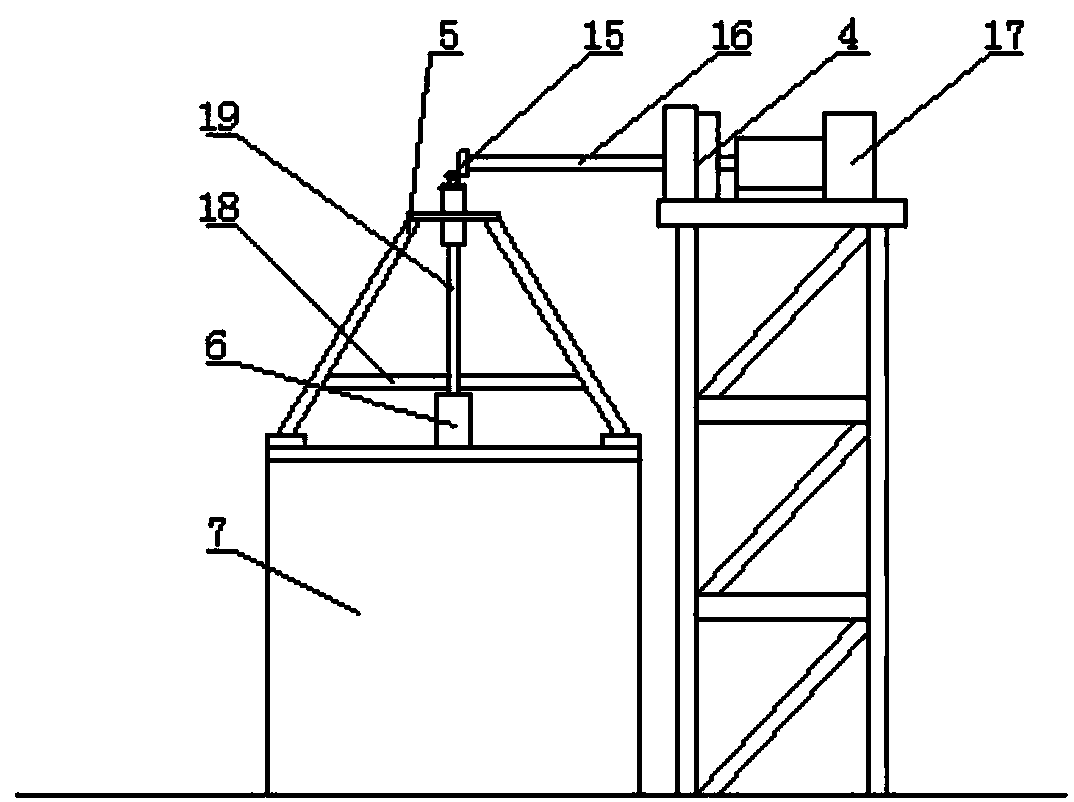

Adjustable suspension type surface cleaning device for household appliance castings

ActiveCN109623671AIncrease contact areaEasy to cleanAbrasive machine appurtenancesAbrasive blasting machinesSurface cleaningEngineering

The invention discloses an adjustable suspension type surface cleaning device for household appliance castings. The adjustable suspension type surface cleaning device comprises a shot blasting chamber, a conveying rail, a supporting block, a lifting hook and a shot blasting machine, wherein the supporting block is arranged at the upper end of the shot blasting chamber, sliding rails which are symmetrically distributed are arranged at the upper end of the supporting block, sliding blocks are arranged in the sliding rails, the lifting hook is arranged at the bottom of the sliding blocks, the shot blasting machine is arranged on one side of the shot blasting chamber, the shot blasting machine communicates with the shot blasting chamber through a connecting pipe, a fixed column clamped with the bottom of the lifting hook is arranged at the bottom of the lifting hook, a plurality of connecting shafts which are uniformly and movably connected are arranged on the fixed column, fixed rods which are fixedly connected are arranged on the connecting shafts, first connecting rods are movably connected with the vertically-distributed fixing rods through the fixing holes, an adjusting shaft movably connected with the bottom of the connecting pipe is arranged at the bottom of the connecting pipe, an adjusting plate which is parallel to the bottom of the connecting pipe is arranged on the adjusting shaft, an electric hydraulic push rod which is fixedly connected with the bottom of the shot blasting chamber is arranged at the bottom of the shot blasting chamber, and the upper end of the electric hydraulic push rod is movably connected with an adjusting plate right above the electric hydraulic push rod.

Owner:CHUZHOU JINNUO INDAL

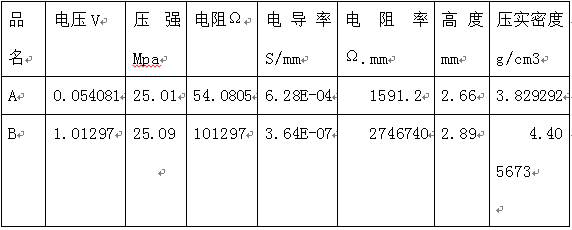

Water-gas combined atomization preparation method for iron-silicon-chromium-gallium-indium-nitrogen alloy soft magnetic powder

ActiveCN113878124AImprovement featuresImprove rust resistanceMagnetic materialsIncreasing energy efficiencyIndiumGallium

The invention relates to a water-gas combined atomization preparation method for iron-silicon-chromium-gallium-indium-nitrogen alloy soft magnetic powder. The preparation method comprises the following steps that (1) a soft magnetic alloy powder raw material containing iron, silicon, chromium, gallium and indium is added into a medium-frequency induction furnace, and smelting is conducted by adopting argon blowing protection to obtain alloy liquid; and (2) under the nitrogen protection condition, the alloy liquid is poured into an atomizing tower in a negative pressure environment, two media including negative pressure overspeed gas and a high-pressure ammonia water solution act on an alloy liquid column flow in sequence, the alloy liquid column flow is dispersed and torn into metal liquid drops under the action of negative pressure supersonic speed gas, then the metal liquid drops are impacted and cooled through the high-pressure ammonia water solution, the metal liquid drops are further crushed and cooled into nearly-spherical alloy soft magnetic powder, and meanwhile, a compact oxidation film and a compact nitride film are formed on the surface of the alloy soft magnetic powder. The method can be used for preparing the alloy soft magnetic powder with high tap density, high surface resistivity and high loss characteristics, and the alloy soft magnetic powder can be widely applied as a powder raw material of inductor devices.

Owner:泉州市鑫航新材料科技有限公司

An adjustable suspension surface cleaning device for castings of household appliances

ActiveCN109623671BIncrease contact areaEasy to cleanAbrasive machine appurtenancesAbrasive blasting machinesSurface cleaningStructural engineering

The invention discloses an adjustable suspension type surface cleaning device for castings of household electrical appliances, which comprises a shot blasting chamber, a conveying rail, a support block, a hook and a shot blasting machine. The upper end of the shot blasting chamber is provided with a support block. The upper end of the support block is provided with a symmetrically distributed slide rail, the slide rail is provided with a slider, the bottom of the slider is provided with a hook, and a shot blasting machine is provided on one side of the shot blasting chamber, and the shot blasting machine passes through The connecting pipe communicates with the shot blasting chamber, and the bottom of the hook is provided with a clamping fixed column, and the fixed column is provided with a number of evenly movable connecting shafts, and the connecting shafts are all provided with fixedly connected fixing rods, so The first connecting rod movably connects the vertically distributed fixing rods through the fixing holes, the bottom of the connecting pipe is provided with a movably connected adjusting shaft, and the adjusting shaft is provided with an adjusting plate parallel to the bottom of the connecting pipe. The bottom of the shot blasting chamber is provided with a fixedly connected electro-hydraulic push rod, and the upper end of the electro-hydraulic push rod is movably connected with the adjustment plate directly above.

Owner:CHUZHOU JINNUO INDAL

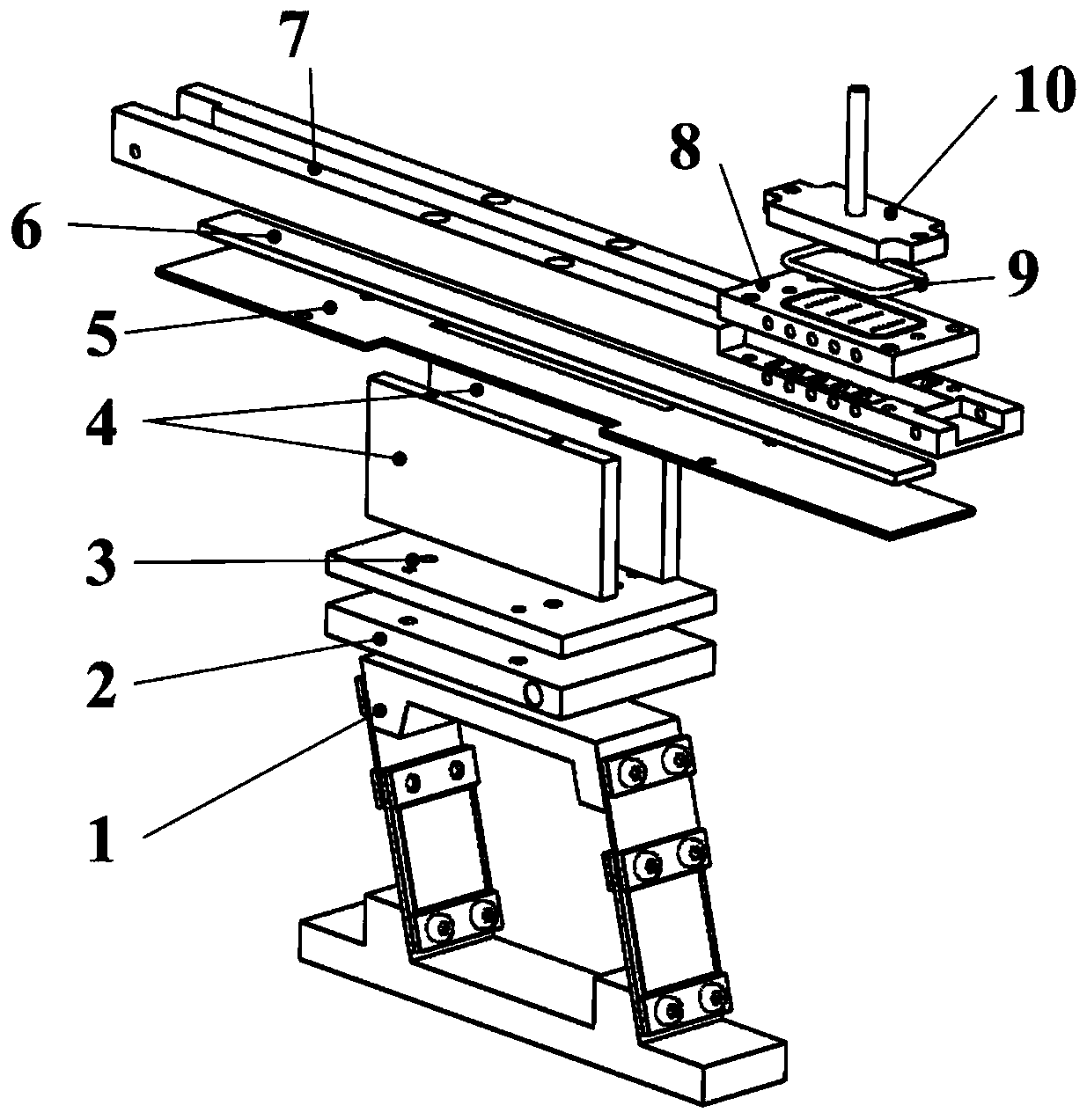

An intelligent automatic magnetic particle flaw detection device for track switch detection

ActiveCN108301376BImpact distributionEasy to reuseRailway cleaningRailway auxillary equipmentWater storage tankWater flow

The invention relates to an intelligent automated magnetic powder flaw detection device for track turnout detection. The intelligent automated magnetic powder flaw detection device comprises a water storage tank, a drying box, a magnetic powder box, a scouring mechanism, a lifting mechanism, a drying mechanism, a recovery mechanism and two support blocks; the lifting mechanism comprises a liftingplate and two lifting assemblies, and the scouring mechanism comprises a water pipe, a rotating rod, a spraying head, a hanging rod, a first motor, a first connecting rod and a second connecting rod;and the recovery mechanism comprises a recovery assembly, a recovery box and a horizontal-moving assembly, and the recovery assembly comprises a side rod, a second motor, a rotating disc and a plurality of second electromagnets. The intelligent automated magnetic powder flaw detection device for track turnout detection makes the spraying head swing back and forth and spray out high speed water flow through the scouring mechanism, impurities, such as oil dirt and dust, adhering to a turnout are scoured, the turnout restores to be clean, the situation that distribution of magnetic powder is affected by the impurities, and consequently, the equipment detection accuracy is reduced is prevented, not only that, the magnetic powder for testing is recovered through the recovery mechanism, reutilization of the magnetic powder is facilitated, and the practicability of equipment is improved.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

Preparation method of iron-silicon-chromium-manganese-bismuth-zinc alloy soft magnetic powder

ActiveCN114147230APromote spheroidizationLow melting pointTransportation and packagingMetal-working apparatusManganeseZinc alloys

The invention relates to a preparation method of iron-silicon-chromium-manganese-bismuth-zinc alloy soft magnetic powder, which comprises the following steps of: 1) adding soft magnetic alloy powder raw materials containing iron, silicon, chromium, manganese, bismuth and zinc into a medium-frequency induction furnace, and smelting by adopting argon blowing protection to obtain alloy liquid; (2) under the nitrogen protection condition, the alloy liquid is poured into an atomizing tower in a negative pressure environment, in the pouring process, two media of negative pressure overspeed gas and high pressure atomized water act on an alloy liquid column flow in sequence, the alloy liquid column flow is dispersed and torn into metal liquid drops under the action of negative pressure supersonic speed gas, and then the metal liquid drops are separated from the metal liquid drops; and then through impact and cooling of high-pressure atomized water, the metal liquid drops are further crushed and cooled into nearly-spherical metal powder particles, and meanwhile a compact composite oxidation film is formed on the surfaces of the metal powder particles. The method can be used for preparing the iron-silicon-chromium-manganese-bismuth-zinc alloy soft magnetic powder with high tap density and high surface resistivity, and the iron-silicon-chromium-manganese-bismuth-zinc alloy soft magnetic powder is widely applied as a powder raw material of an inductor device.

Owner:泉州市鑫航新材料科技有限公司

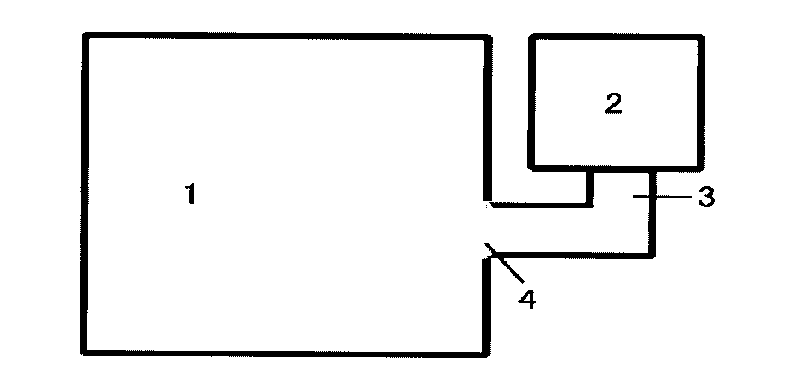

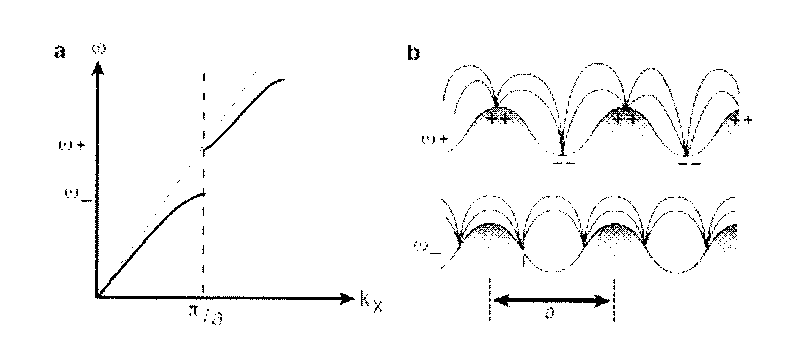

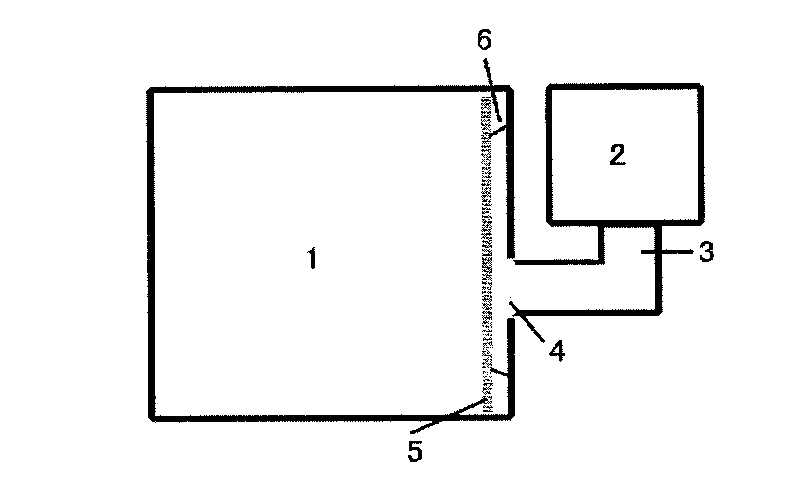

Microwave oven having metal sub-wavelength structure

InactiveCN101586819BPerformance is not affectedReduce lossDomestic stoves or rangesLighting and heating apparatusMicrowave ovenDielectric plate

A microwave oven having metal sub-wavelength structure belongs to the technical field of microwave heating and relates to the electromagnetics of metal sub-wavelength structure, comprising a microwaveoven cavity, a magnetron, a wave guide, and a microwave output window; and further comprising a dielectric plate having a metal sub-wavelength structure and fixed on the wall of the microwave oven cavity in front of the microwave output window through a support. The microwave energy from the magnetron passes through the metal sub-wavelength structure on the dielectric plate and radiates in the microwave oven cavity via the microwave output window; metal surface electronics and the microwave energy can be coupled by the metal sub-wavelength structure to effectively improve the uniformity of microwave energy distribution. The invention not only can effectively improve the uniformity of microwave field distribution in the microwave oven cavity, but can effectively improve the energy transmission efficiency and reduce the cost of the microwave oven by increasing the space utilization of the microwave oven cavity on the basis of safety.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

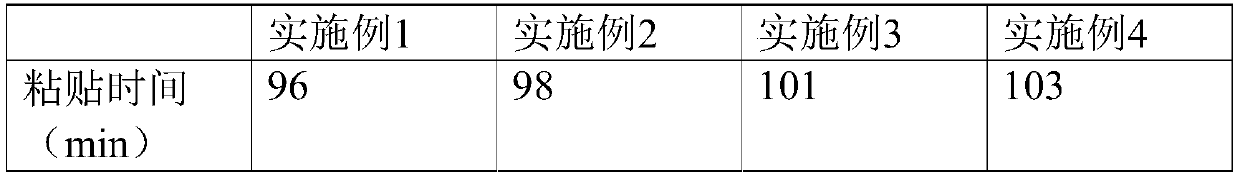

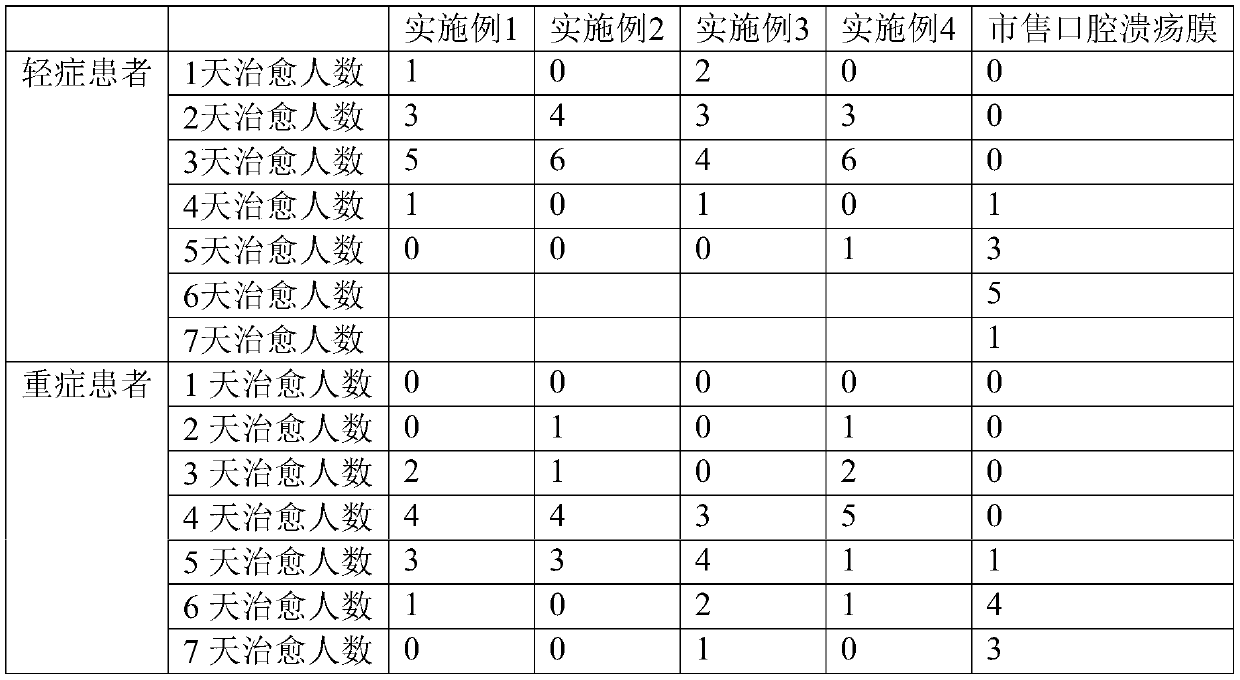

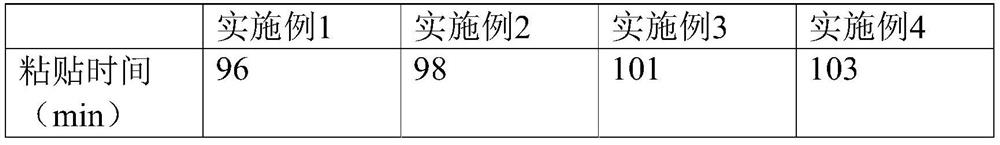

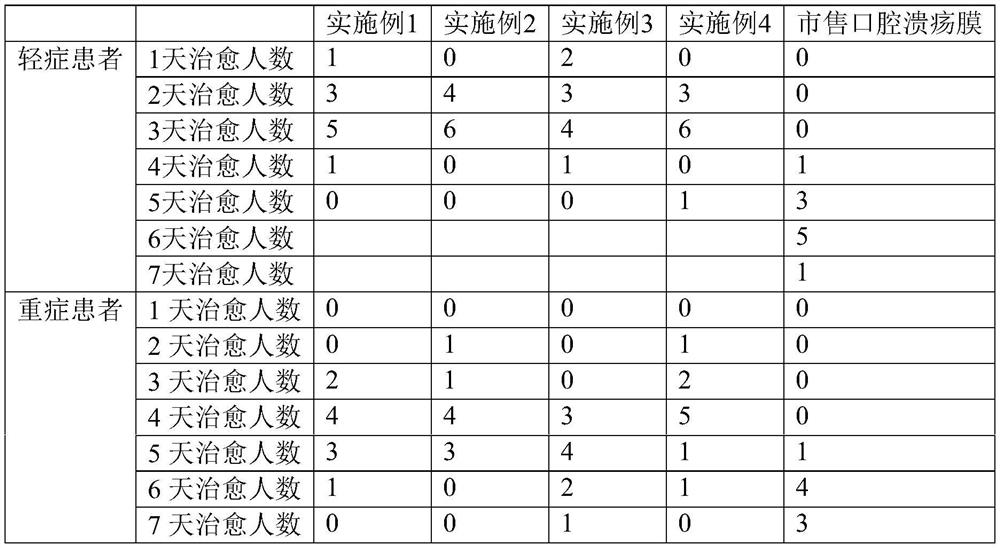

Compound oral ulcer patch and preparation method thereof

ActiveCN111249328AInhibition of dissolutionMuscle strengtheningHydroxy compound active ingredientsDigestive systemAntimicrobial drugPharmaceutical Substances

The invention relates to a compound oral ulcer patch and a preparation method thereof. The compound oral ulcer patch includes a myogenic layer, a slow-release layer and a heat-clearing antibacterial layer; and the myogenic layer includes a film-forming material, a plasticizer, a solvent softener and a myogenic drug, the slow-release layer includes a film-forming material, a plasticizer and a softener, and the heat-clearing antibacterial layer includes a film-forming material, a slow-release component and a heat-clearing antibacterial drug component. The compound oral ulcer patch adopts a three-layer composite structure, and the myogenic layer is in contact with an ulcer part and mainly uses the myogenic drug to promote rapid muscle generation and repair of the ulcer part; the heat-clearingantibacterial layer mainly uses the heat-clearing antibacterial drug for clearing heat and killing bacteria in an oral cavity to mainly provide a good environment for recovery of the ulcer part, andthe slow-release layer uses bletilla striata polysaccharide or chitosan and has the main effects of preventing the myogenic layer from being dissolved by saliva after the heat-clearing antibacterial layer is completely dissolved. The compound oral ulcer patch can make the ulcer part quickly recover muscle generation while effectively improving the oral environment by using the three-layer structure.

Owner:河南护理职业学院

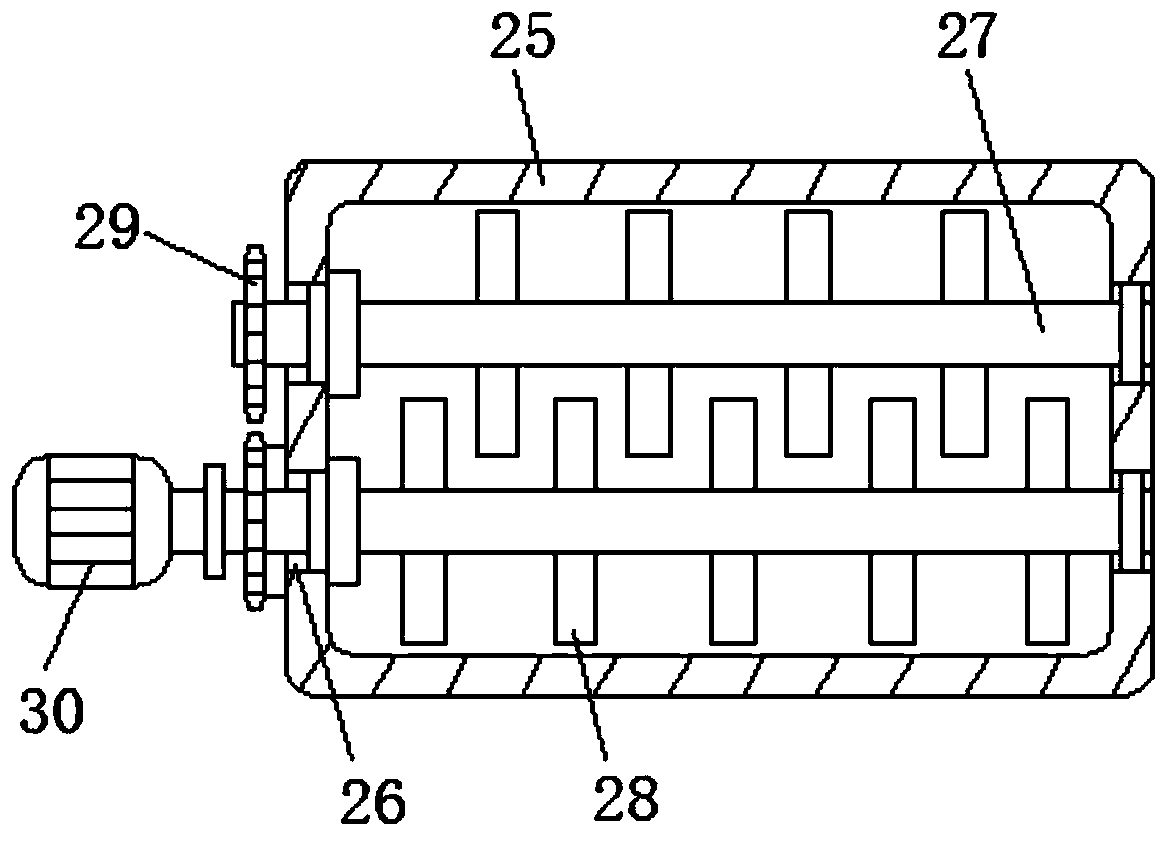

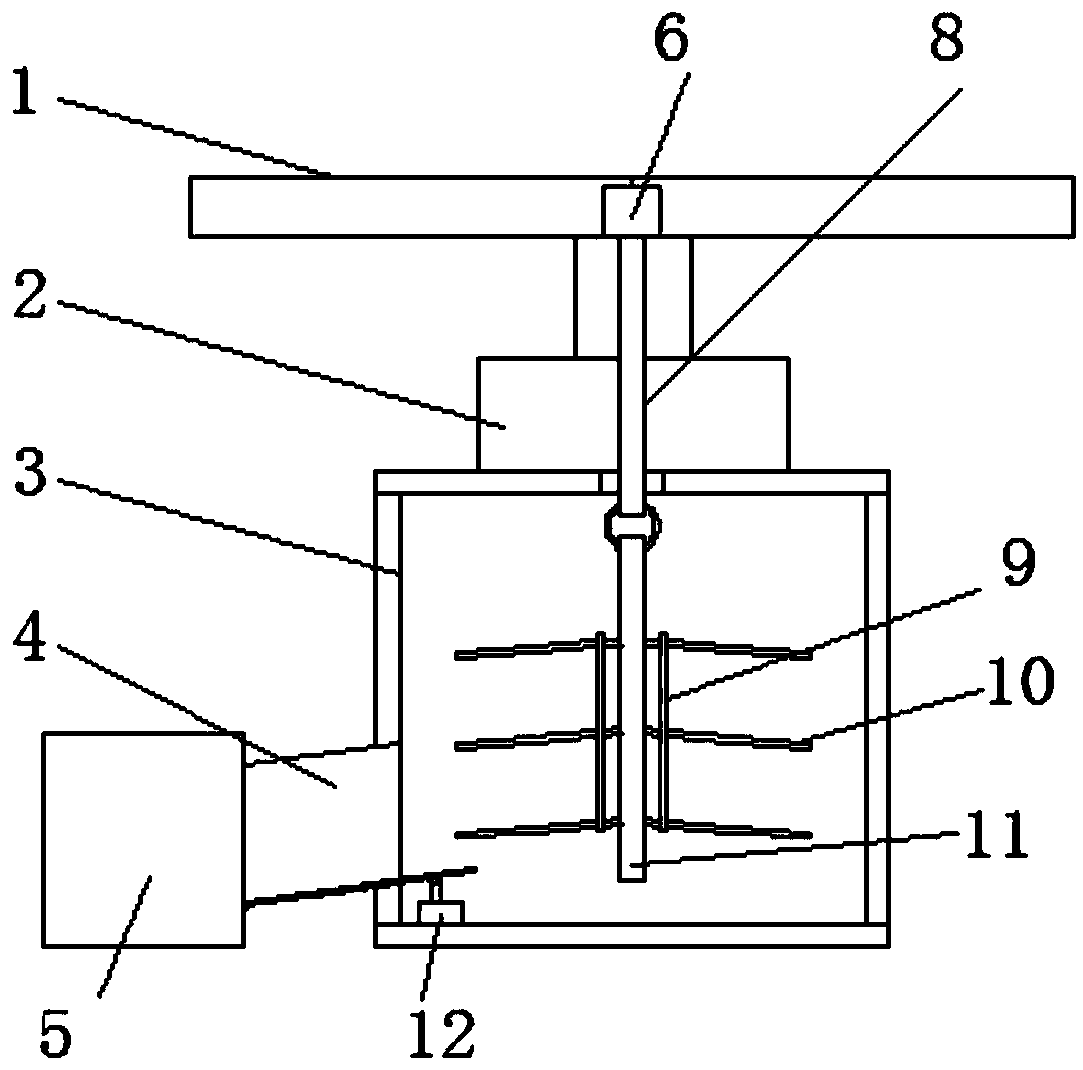

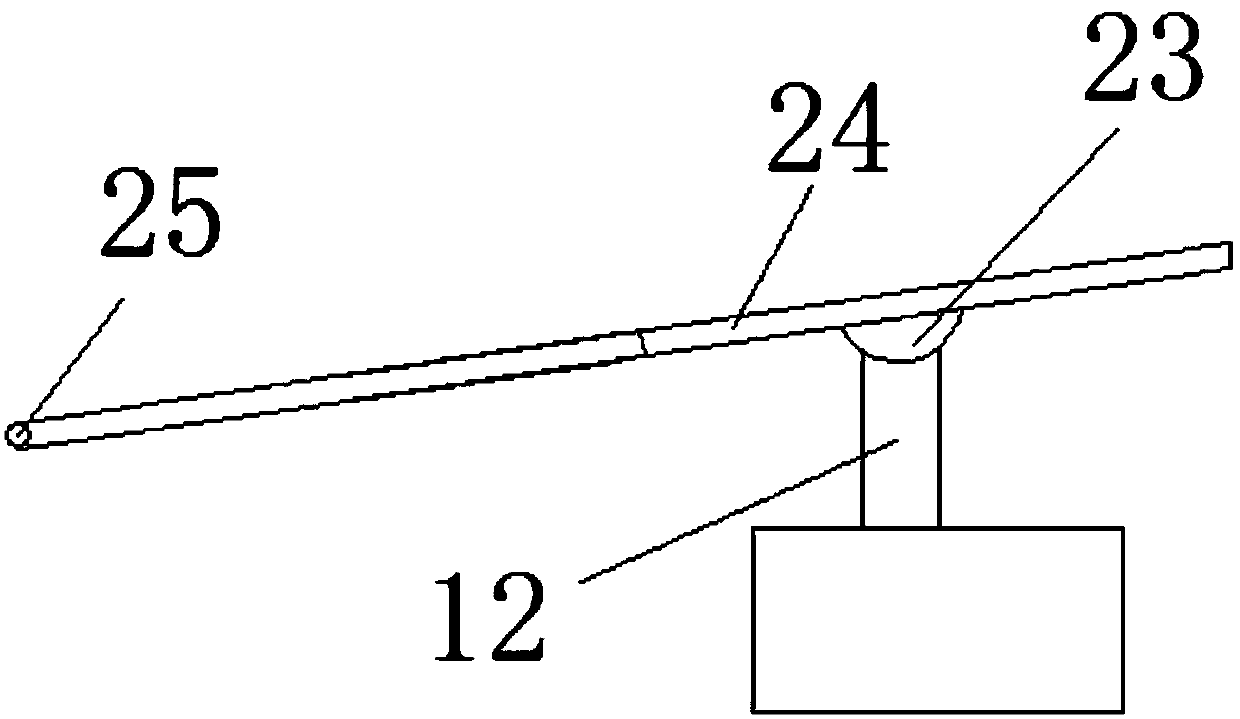

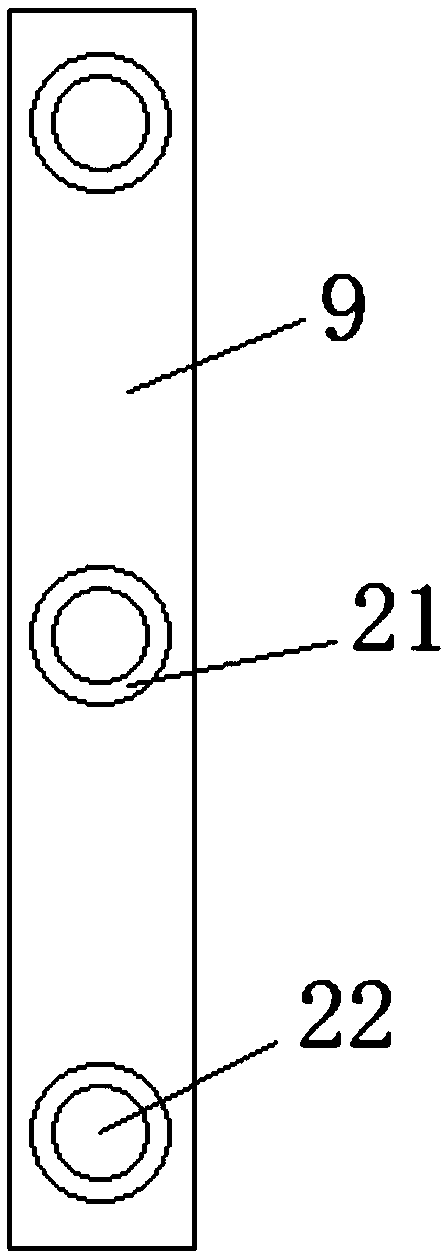

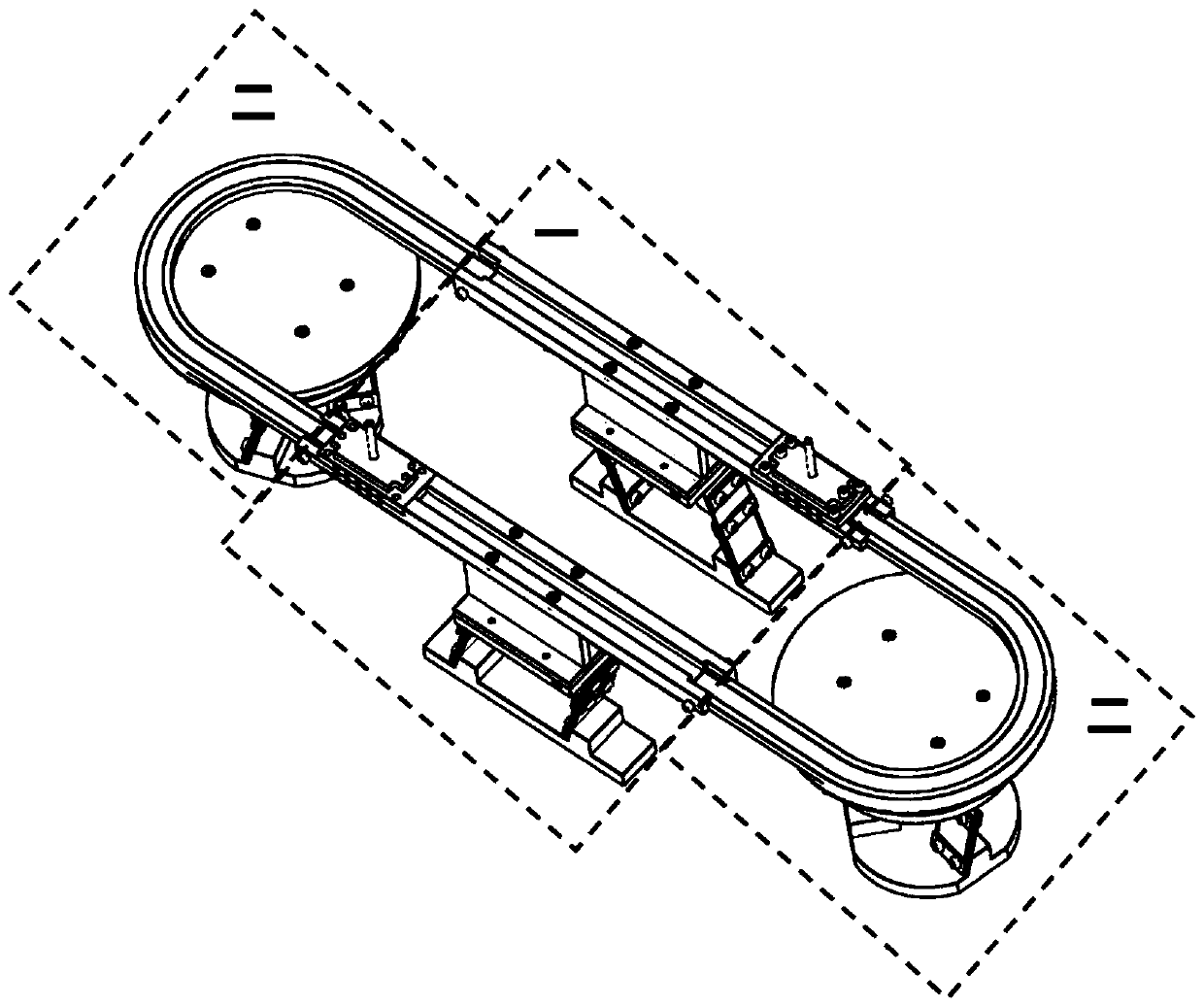

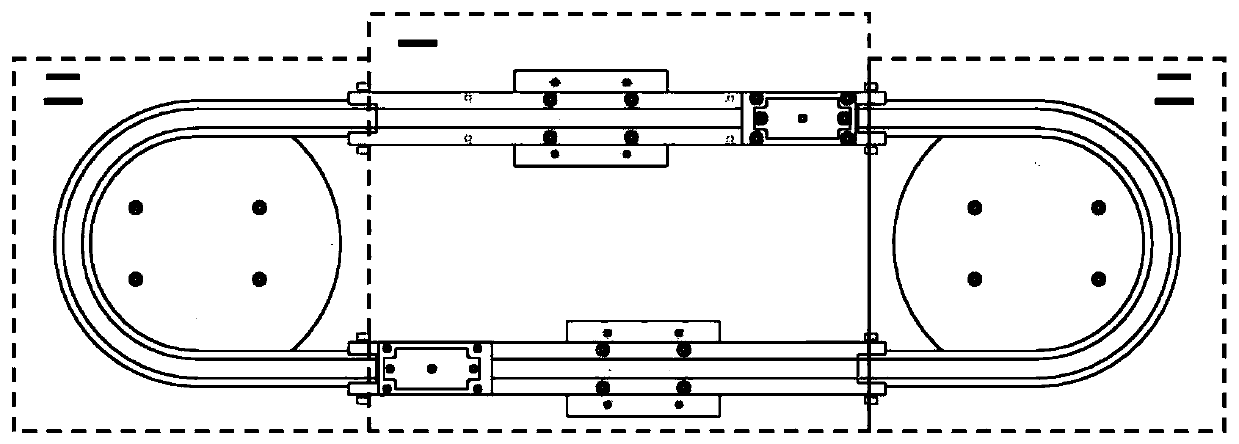

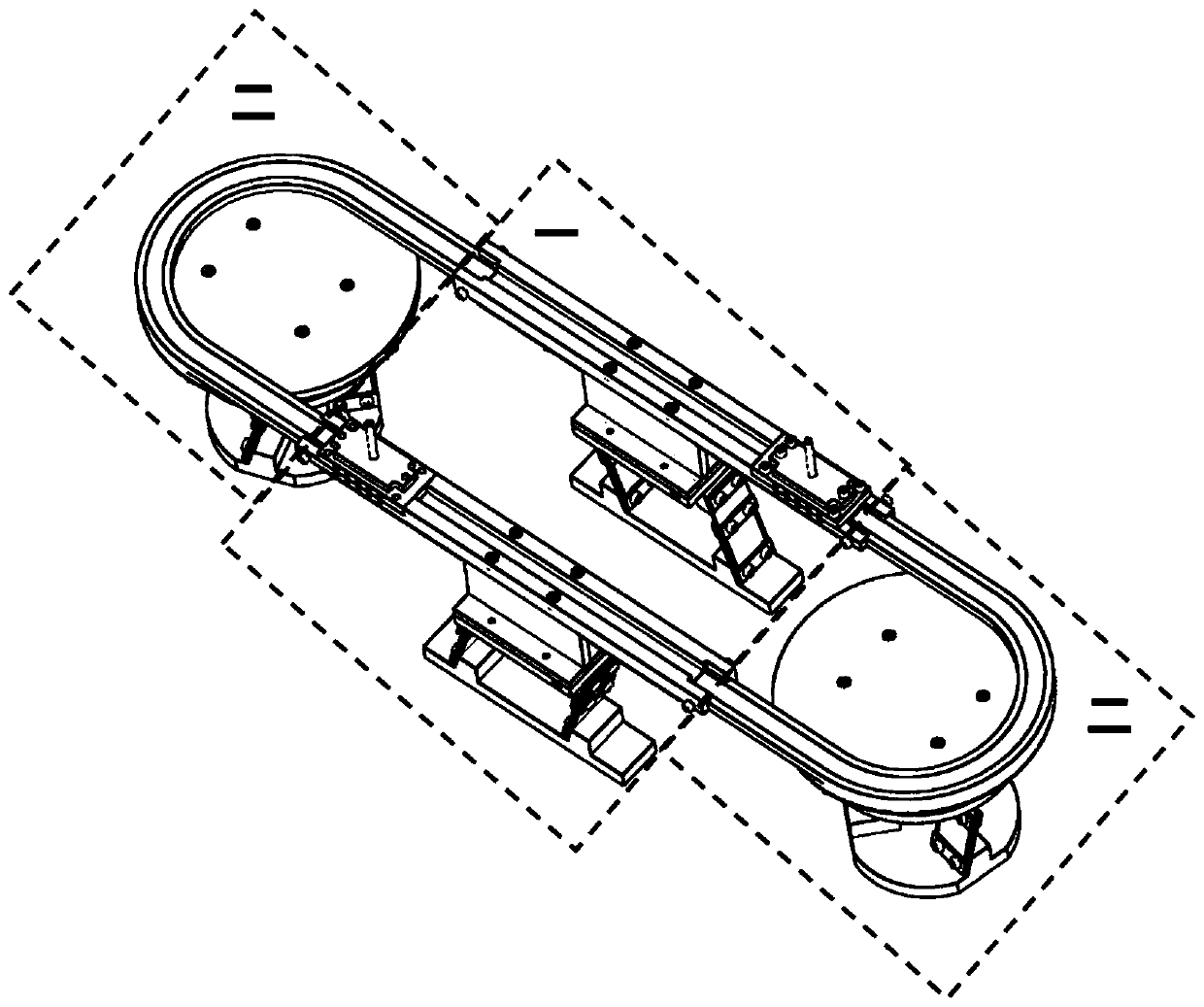

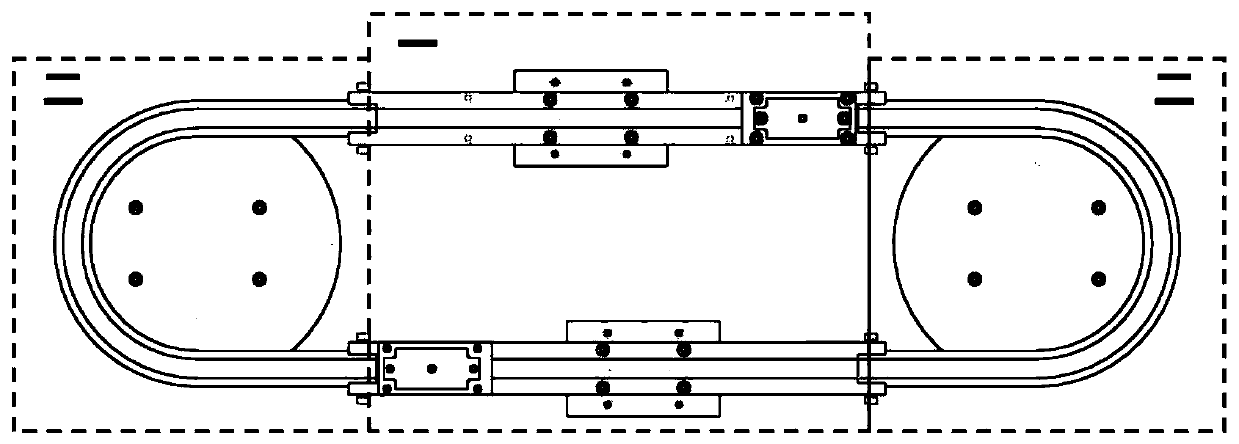

A fast-cycle atomic layer deposition device for micro-nanoparticles

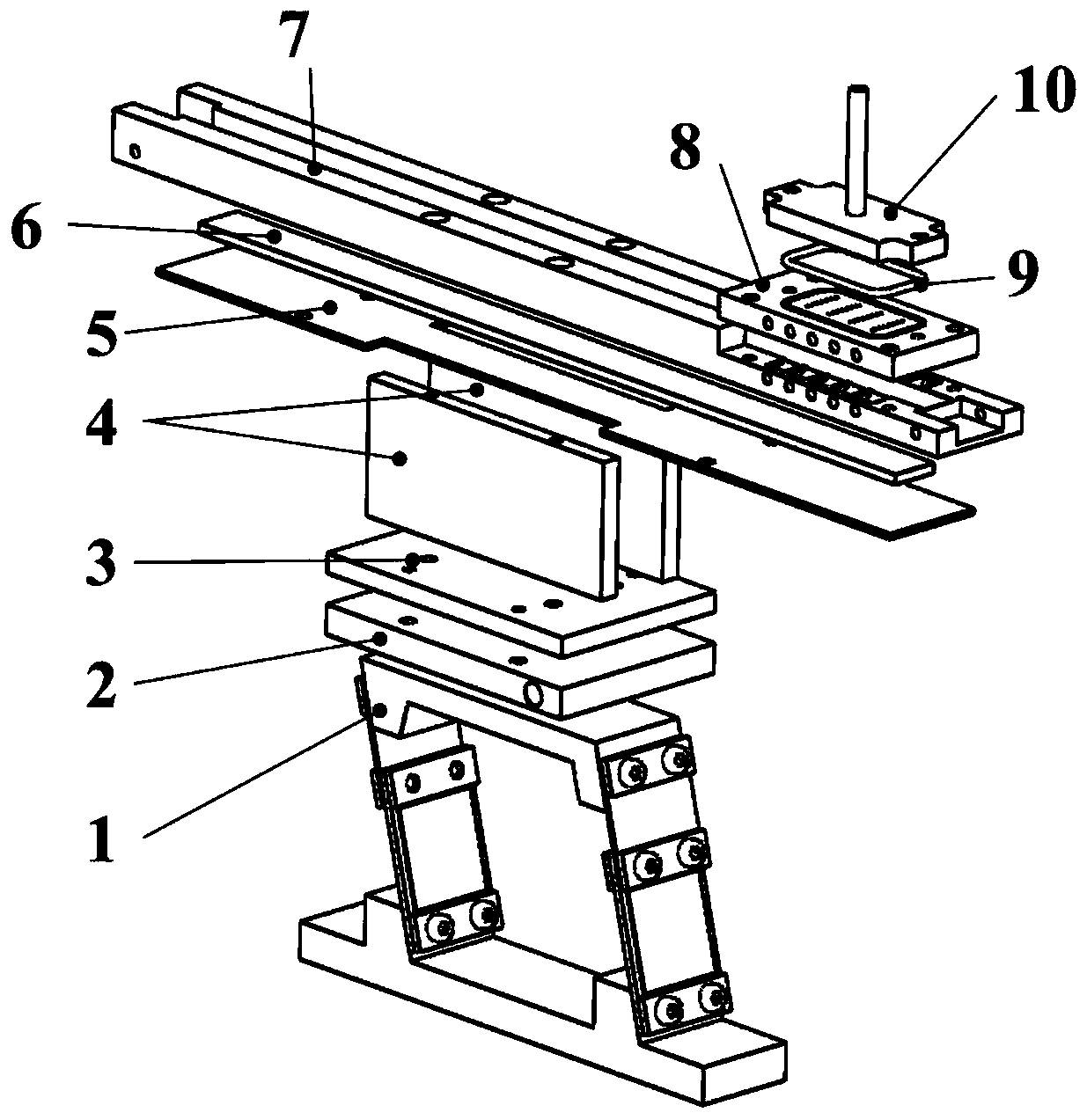

ActiveCN109881180BImpact distributionSmooth transmissionChemical vapor deposition coatingLinear motionElectric machine

The invention belongs to the field of coating equipment manufacturing, and discloses rapidly circulating atomic layer deposition equipment for micro-nano particles. The rapidly circulating atomic layer deposition equipment for the micro-nano particles is formed by connecting two linear motion devices and two rotational motion devices end to end, and a sealed oval is formed. The linear motion devices comprise linear vibration motors, first cooling plates, first supporting plates, first heating pieces and material grooves which are sequentially connected from bottom to top in the vertical direction, atomic layer deposition reaction areas are arranged at one ends of the material grooves, and precursor spraying heads are mounted above the atomic layer deposition reaction areas. The rotationalmotion devices comprise rotational vibration motors, second cooling plates, second supporting plates, second heating pieces and rotational motion material grooves which are sequentially connected frombottom to top in the vertical direction. According to the rapidly circulating atomic layer deposition equipment for the micro-nano particles, the particles can circularly move in the material groovesat a stable motion speed, and the thicknesses of surface films of the micro-nano particle are controlled by controlling the times of the micro-nano particle passing through the atomic layer deposition reaction areas.

Owner:HUAZHONG UNIV OF SCI & TECH

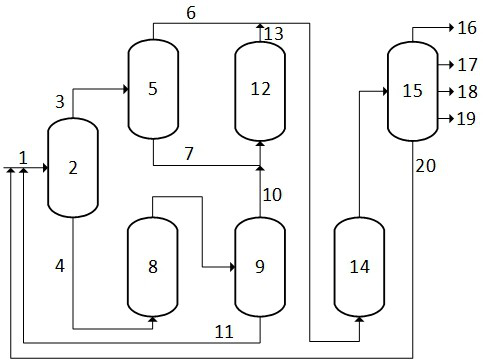

Inferior raw oil lightening treatment process and system

ActiveCN113122328AFlexible handlingAchieve separationTreatment with hydrotreatment processesBulk chemical productionFuel oilHydrogen treatment

The invention provides an inferior raw oil lightening treatment process and system. The treatment process comprises the following steps: firstly, treating inferior raw oil in a solvent deasphalting unit to obtain deasphalted oil and deoiled asphalt; feeding the deasphalted oil into a degumming unit to be treated to obtain a first light fraction and a first heavy fraction; mixing and feeding the deoiled asphalt, optional catalytic diesel oil and hydrogen into a fluidized bed hydrogenation reaction zone for reaction, and separating a reaction effluent to obtain a second light fraction and unconverted tail oil; mixng the first heavy fraction and the second light fraction with hydrogen, and then feeding an obtained mixture into a hydrotreating reaction zone for reaction; mixing and feeding the first light fraction and the hydrogenation reaction effluent into a catalytic cracking reaction zone for reaction, and separating the reaction effluent to obtain dry gas, liquefied gas, catalytic gasoline, catalytic diesel oil and catalytic heavy oil. According to the process, organic combination of a decarburization process and a hydrogenation process in lightening of the inferior raw oil is realized, lightening of the inferior raw oil is realized to the greatest extent, and meanwhile, the running period of a device is greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

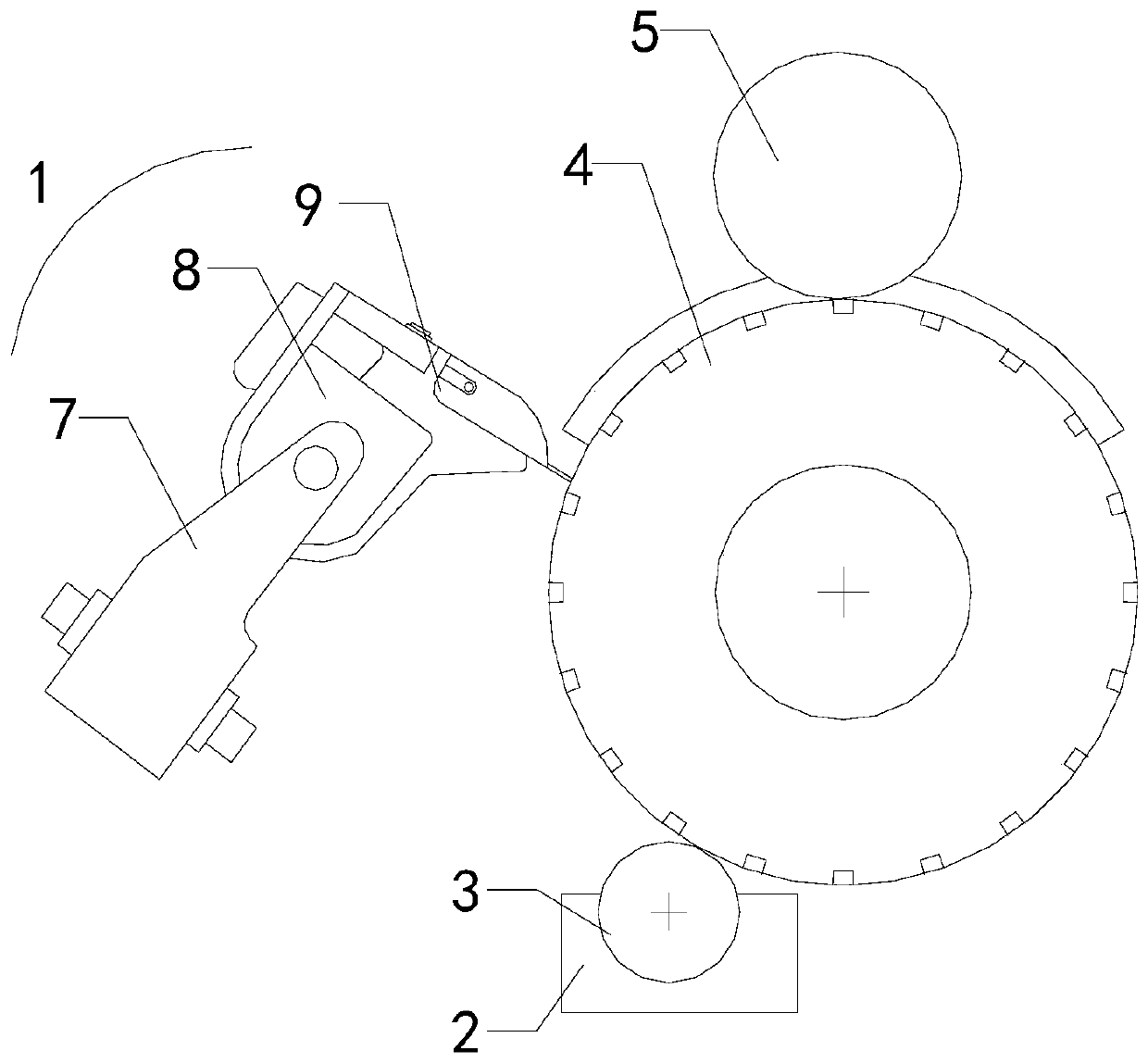

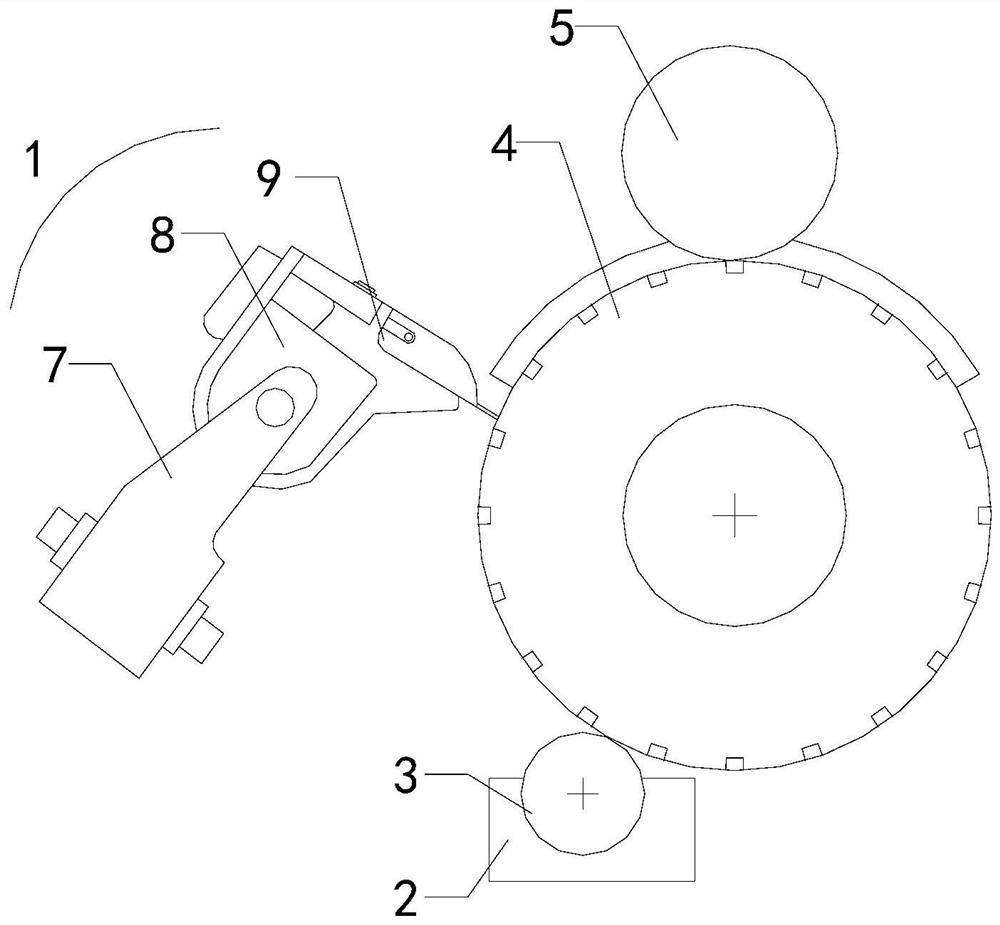

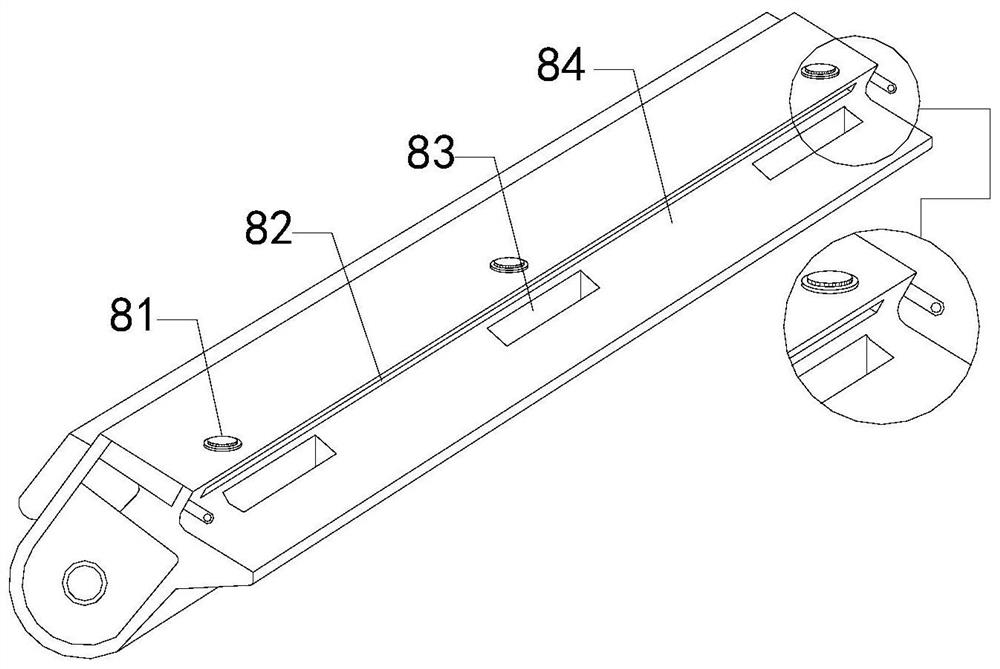

Printing machine doctor blade system with leveling function

The invention discloses a printing machine doctor blade system with a leveling function. The structure of the doctor blade system comprises a doctor blade structure, an ink tank, an ink transfer roller, a printing plate cylinder and an impression cylinder, wherein the ink tank is provided with the ink transfer roller, the ink transfer roller is positioned obliquely below the printing plate cylinder, the printing plate cylinder and the ink transfer roller are movably attached to each other, one side of the ink transfer roller is provided with the doctor blade structure, the impression cylinderis arranged in the middle of the top end, opposite to the ink tank, of the printing plate cylinder, and the impression cylinder and the printing plate cylinder are closely attached to each other. According to the doctor blade system, whether a doctor blade is placed horizontally or not is calibrated through a blade placing platform, so that the blade body, tangent to the printing plate cylinder, of the doctor blade is further ensured to be in the same horizontal line without deflection, and the doctor blade can scrape the printing plate cylinder uniformly; and according to the doctor blade, three thread knobs are fixed on the blade placing platform uniformly and equidistantly, when the doctor blade is installed, three points are stressed uniformly, so that the adhesion degree between the doctor blade placing platform and the doctor blade is further guaranteed, and the influence on the distribution of the doctor blade caused by local lifting or the gap of the doctor blade is avoided.

Owner:GUANGDONG NEW GRAND LONG PACKING CO LTD

Heavy oil and residual oil combined treating process

ActiveCN100569925CExtended operating cycleGuaranteed normal feedingTreatment with hydrotreatment processesResidual oilSolvent

The invention discloses a method for combined processing of heavy and residual oil, which comprises the following content: the low-quality heavy and residual oil raw material is subjected to suspension bed hydrocracking under moderate conditions, and the yield of unconverted vacuum residual oil accounts for 20% by weight of the raw material. 45wt%, and then fractionate the suspended bed hydrocracking product into light fraction, heavy fraction (VGO) and unconverted vacuum residue, VGO undergoes catalytic cracking treatment, unconverted vacuum residue undergoes solvent deasphalting treatment, solvent The deasphalted oil obtained from the deasphalting process is used as the raw material for catalytic cracking. Compared with the prior art, the method of the invention effectively solves the problem that the suspended bed hydrocracking is not easy to operate stably, and at the same time can make full use of all the fractions in the raw material, and no unusable materials are generated. The method of the invention is suitable for processing various inferior heavy and residual oils.

Owner:CHINA PETROLEUM & CHEM CORP +1

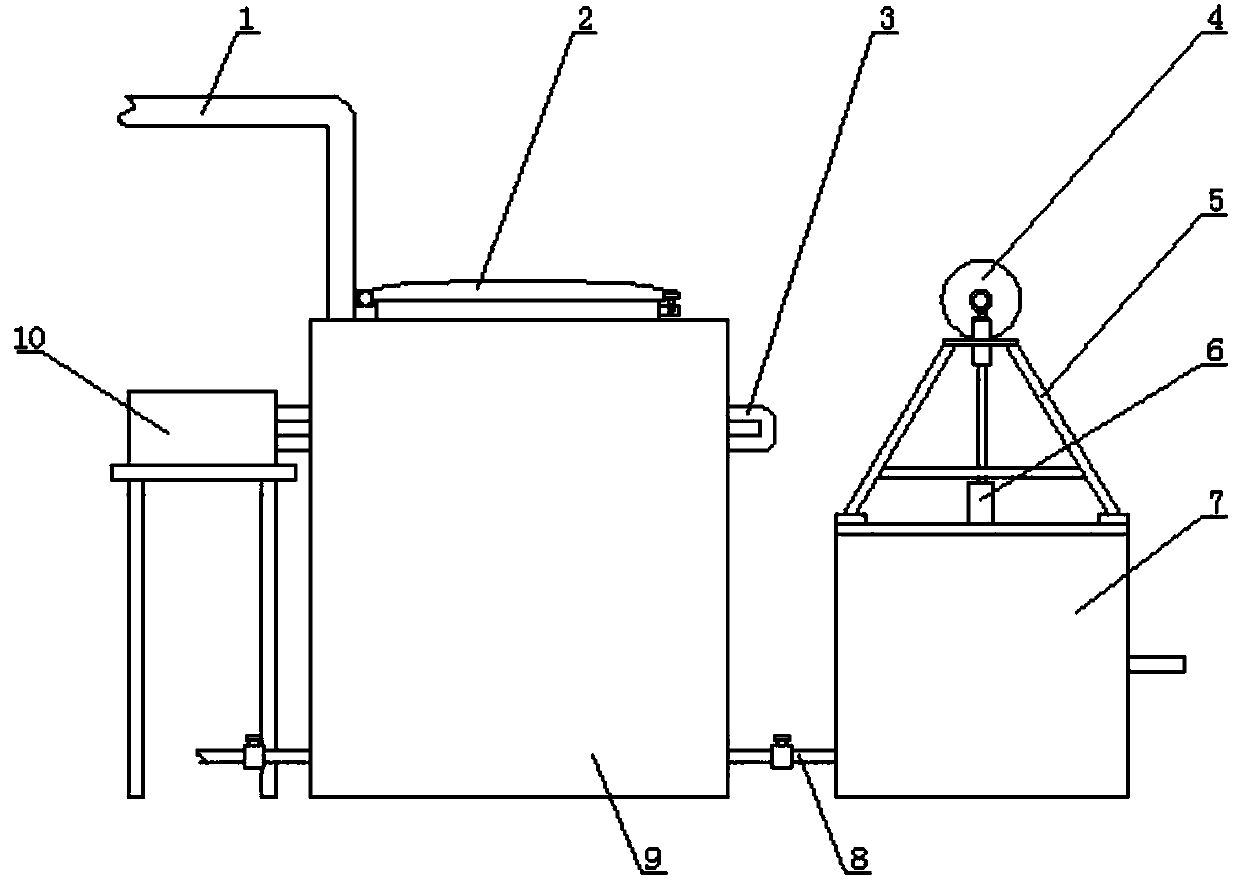

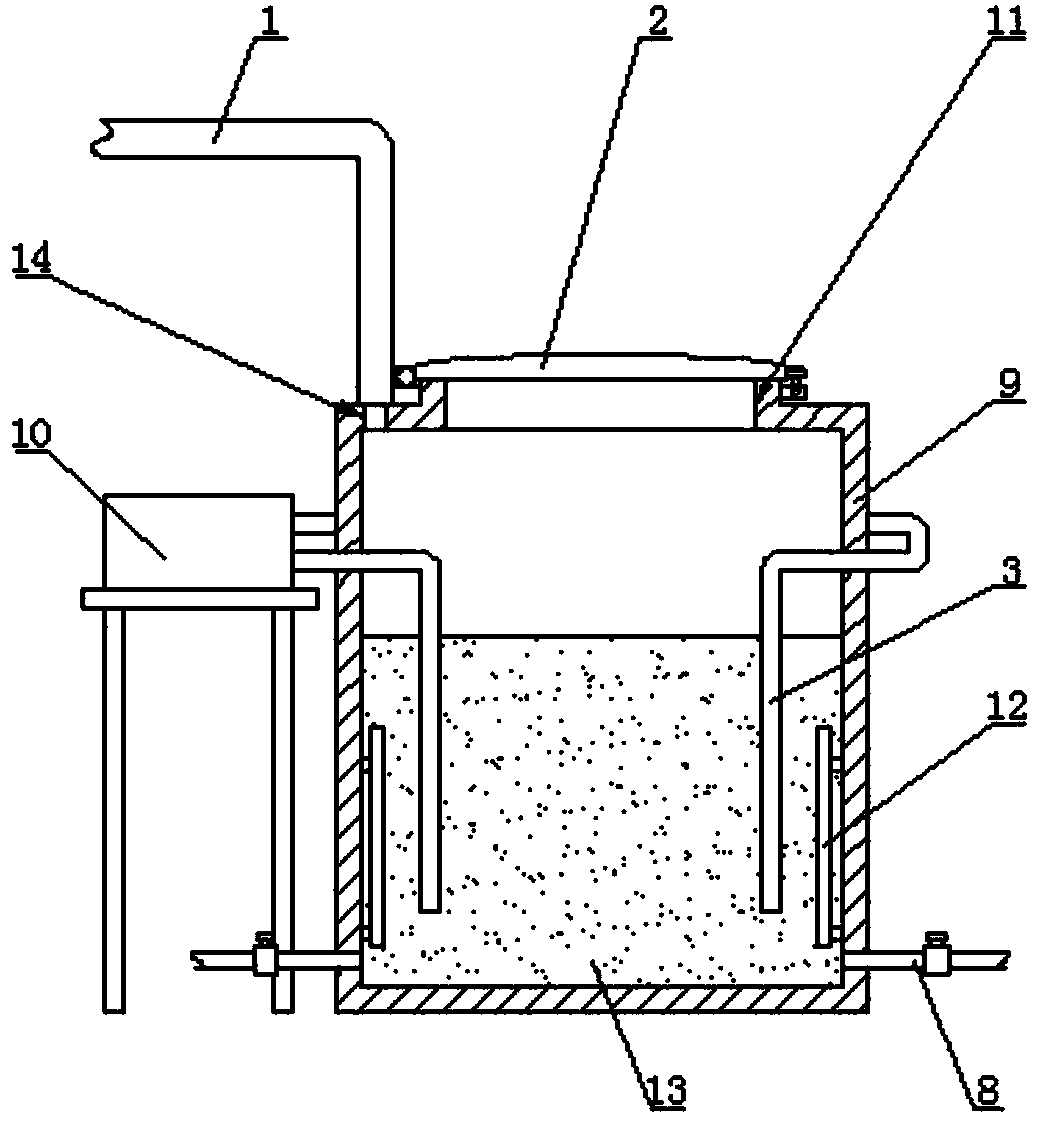

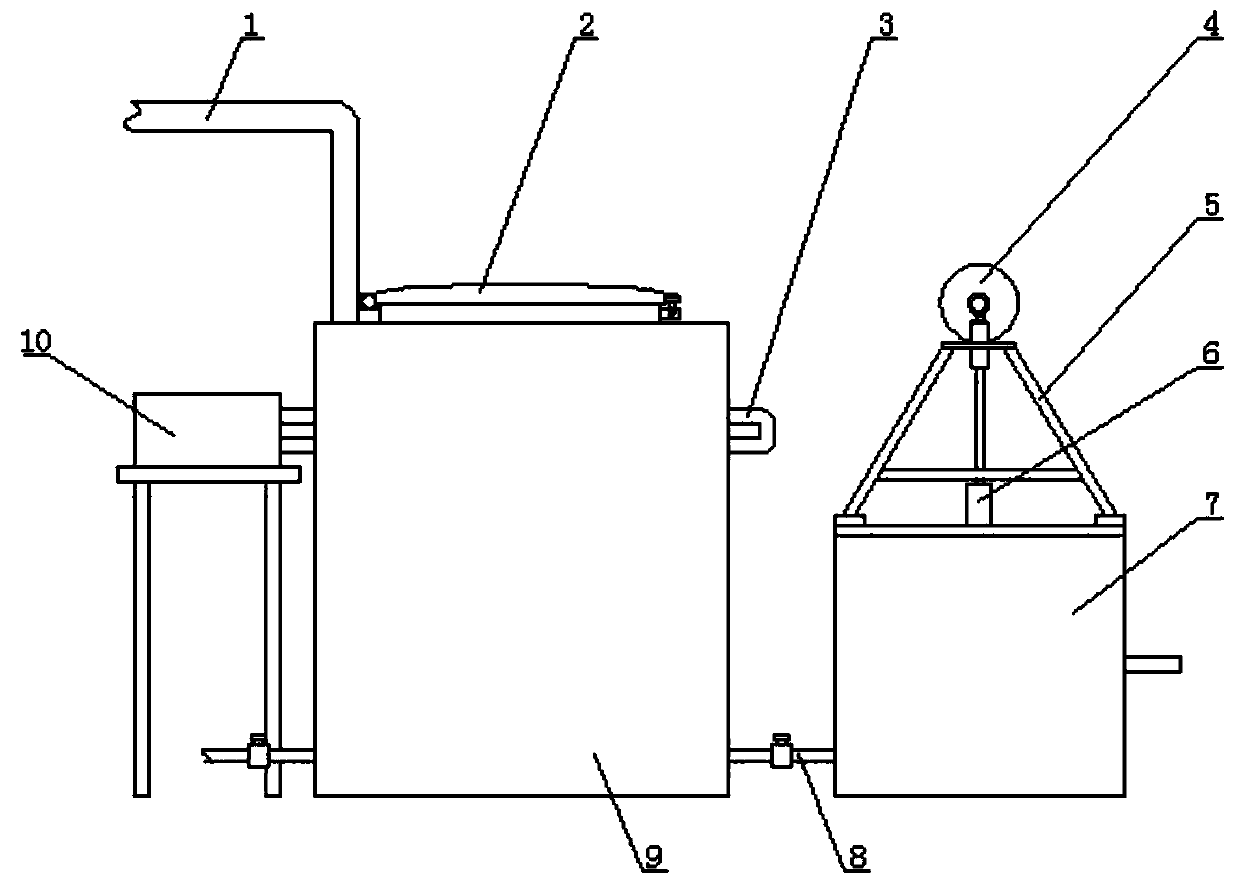

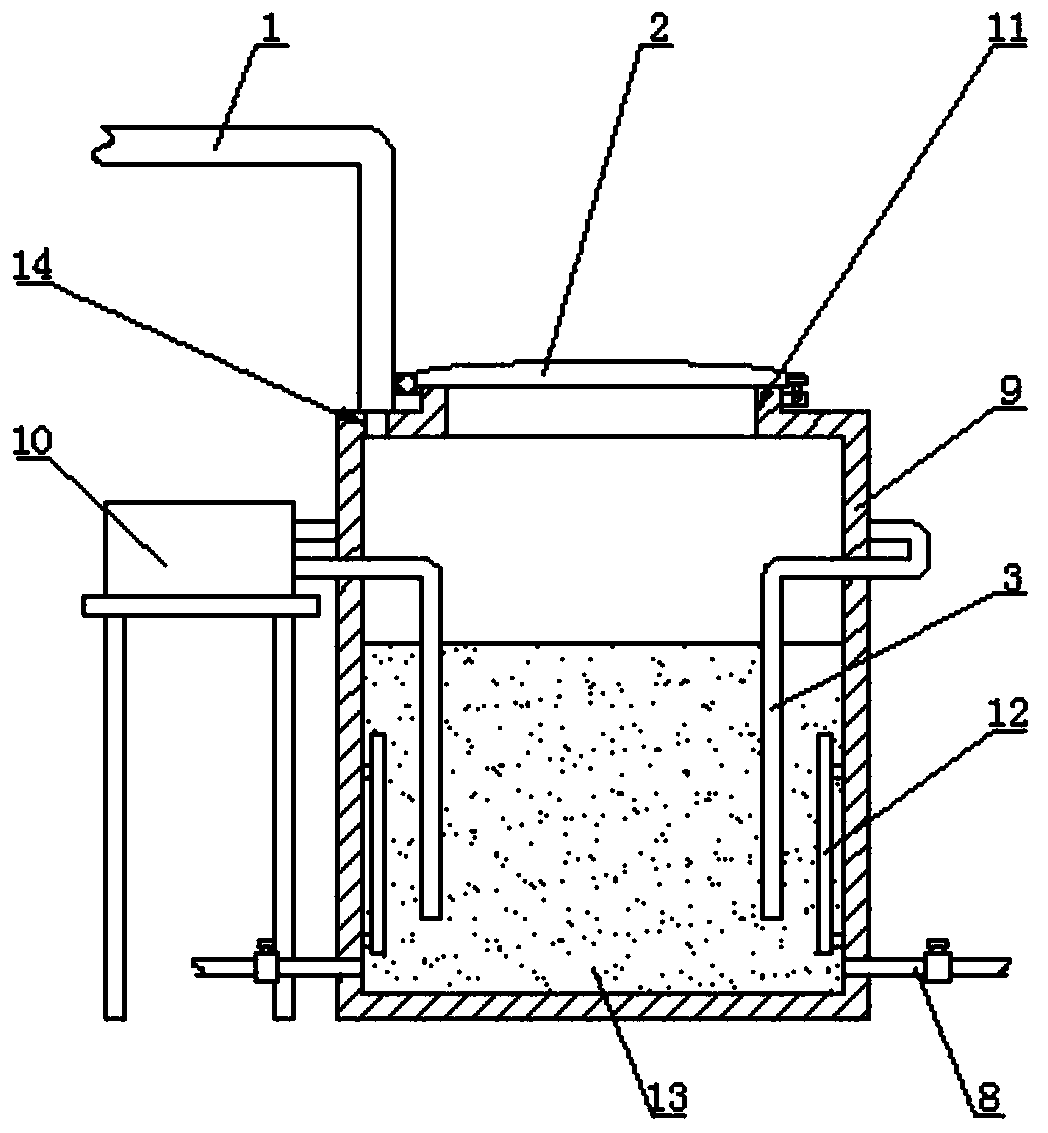

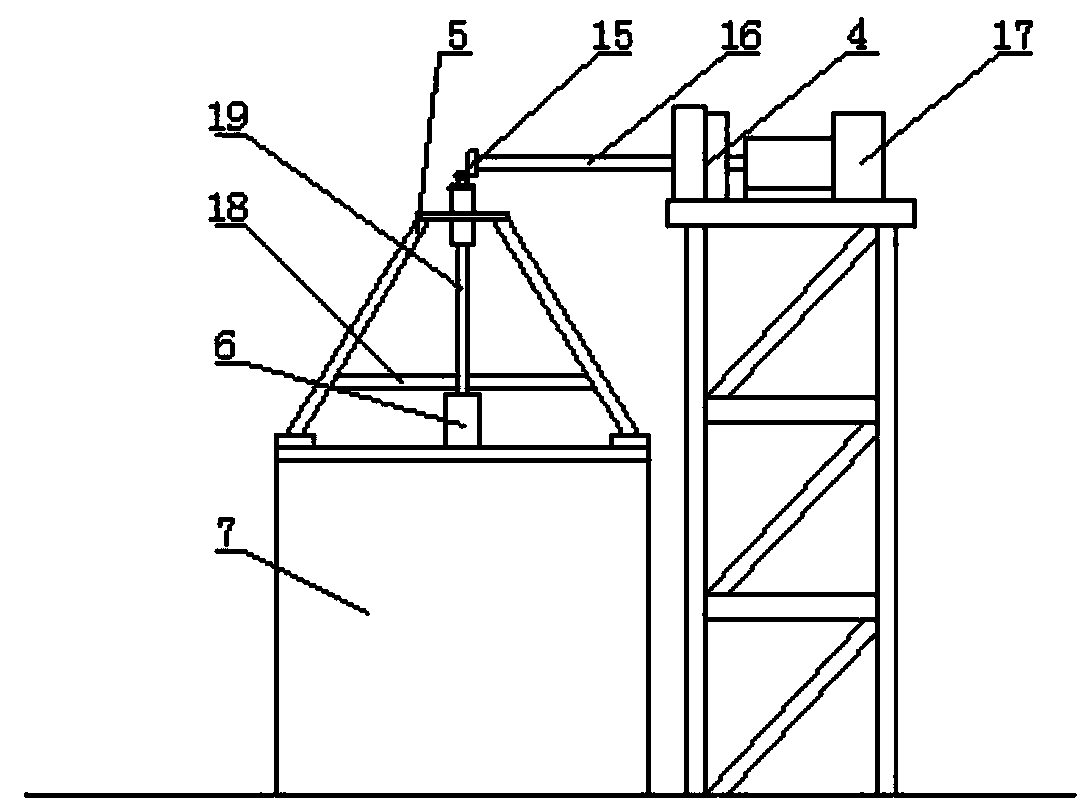

Mould surface TD (Thermal Diffusion) treatment pre-mixing production device

ActiveCN107779811AImprove quality and yieldSimple structureSolid state diffusion coatingMaterials scienceWide mouth

The invention relates to the field of mould manufacturing, in particular to a mould surface TD (Thermal Diffusion) treatment pre-mixing production device. The mould surface TD treatment pre-mixing production device comprises a premixing device and a surface TD treatment device; the premixing device comprises a wide mouth premixing tank; a premixing sealing cover is movably embedded into the inneredge of a wide mouth which is formed in the wide mouth premixing tank; a machine frame is mounted on the upper end surface of the premixing sealing cover; the upper end of a rotating shaft is rotatably mounted in a flat end surface which is formed on the machine frame; the lower end of the rotating shaft penetrates through the premixing sealing cover and extends into the wide mouth premixing tank;the upper end part of the rotating shaft is connected with an output end of a power output device; the mould surface TD treatment pre-mixing production device comprises a hollow tank body which is provided with an opening; at least two air inlets are uniformly formed in the side wall of the hollow tank body at an interval; an air inlet is mounted in each of the air inlets; an exhaust end of eachair inlet pipe is positioned at the bottom of the inner side of the hollow tank body; an air inlet end of each air inlet pipe communicates with an exhaust end of an air compressing pump.

Owner:天津开山金属模具科技有限公司

Rapidly circulating atomic layer deposition equipment for micro-nano particles

ActiveCN109881180AImpact distributionSmooth transmissionChemical vapor deposition coatingLinear motionMicro nano

The invention belongs to the field of coating equipment manufacturing, and discloses rapidly circulating atomic layer deposition equipment for micro-nano particles. The rapidly circulating atomic layer deposition equipment for the micro-nano particles is formed by connecting two linear motion devices and two rotational motion devices end to end, and a sealed oval is formed. The linear motion devices comprise linear vibration motors, first cooling plates, first supporting plates, first heating pieces and material grooves which are sequentially connected from bottom to top in the vertical direction, atomic layer deposition reaction areas are arranged at one ends of the material grooves, and precursor spraying heads are mounted above the atomic layer deposition reaction areas. The rotationalmotion devices comprise rotational vibration motors, second cooling plates, second supporting plates, second heating pieces and rotational motion material grooves which are sequentially connected frombottom to top in the vertical direction. According to the rapidly circulating atomic layer deposition equipment for the micro-nano particles, the particles can circularly move in the material groovesat a stable motion speed, and the thicknesses of surface films of the micro-nano particle are controlled by controlling the times of the micro-nano particle passing through the atomic layer deposition reaction areas.

Owner:HUAZHONG UNIV OF SCI & TECH

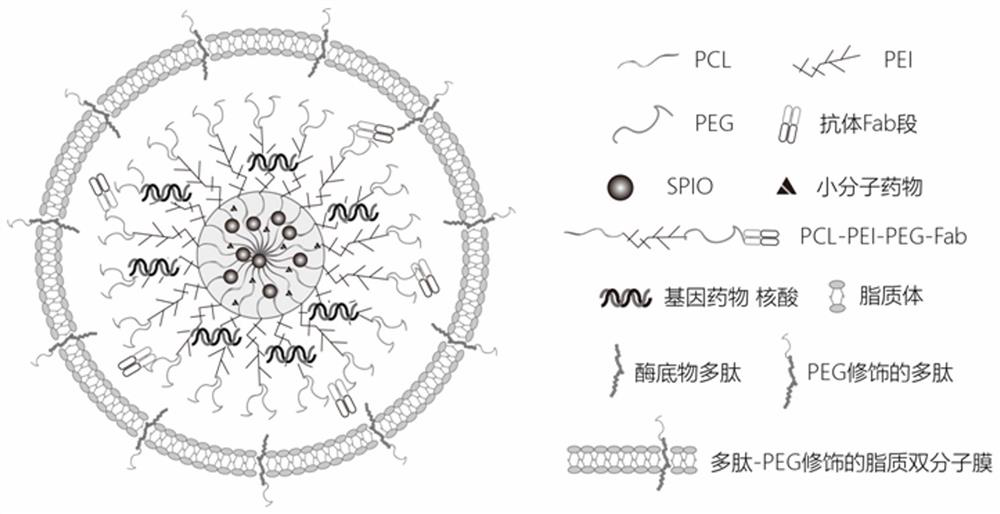

MMP enzyme sensitive placenta microenvironment and tumor microenvironment targeting vector as well as preparation method and application thereof

PendingCN114377150AImpact distributionImpact releaseOrganic active ingredientsPowder deliveryBiophysicsFetus fetus

The invention discloses an MMP enzyme sensitive placenta microenvironment and tumor microenvironment targeting vector and a preparation method and application thereof.The targeting vector is of a core-shell double-layer structure, and an enzyme substrate polypeptide-PEG modified lipid bimolecular membrane which is disintegrated in a targeted mode under the action of high-expression enzyme in contact with placenta tissue interstitial fluid serves as a shell; a placental trophoblast surface specificity high expression marker antibody modified drug carrier is used as an inner core, and the drug carrier is a copolymer formed by a polyethylene glycol modified polycation carrier and hydrophobic degradable polyester. The MMP enzyme sensitive placenta microenvironment and tumor microenvironment targeting carrier can effectively avoid non-specific drug absorption of other organs outside a maternal placenta and a fetus, so that delivery and function regulation of specific drugs of lesion trophoblast cells in the placenta are realized.

Owner:中山大学南昌研究院

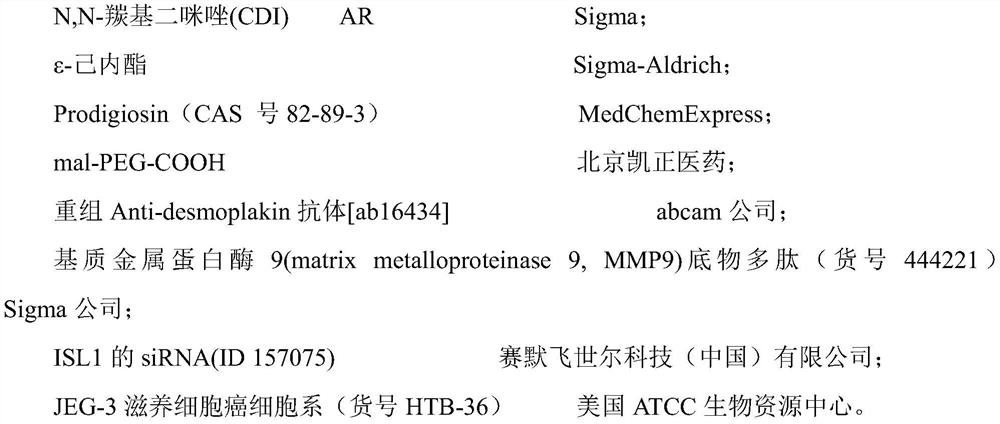

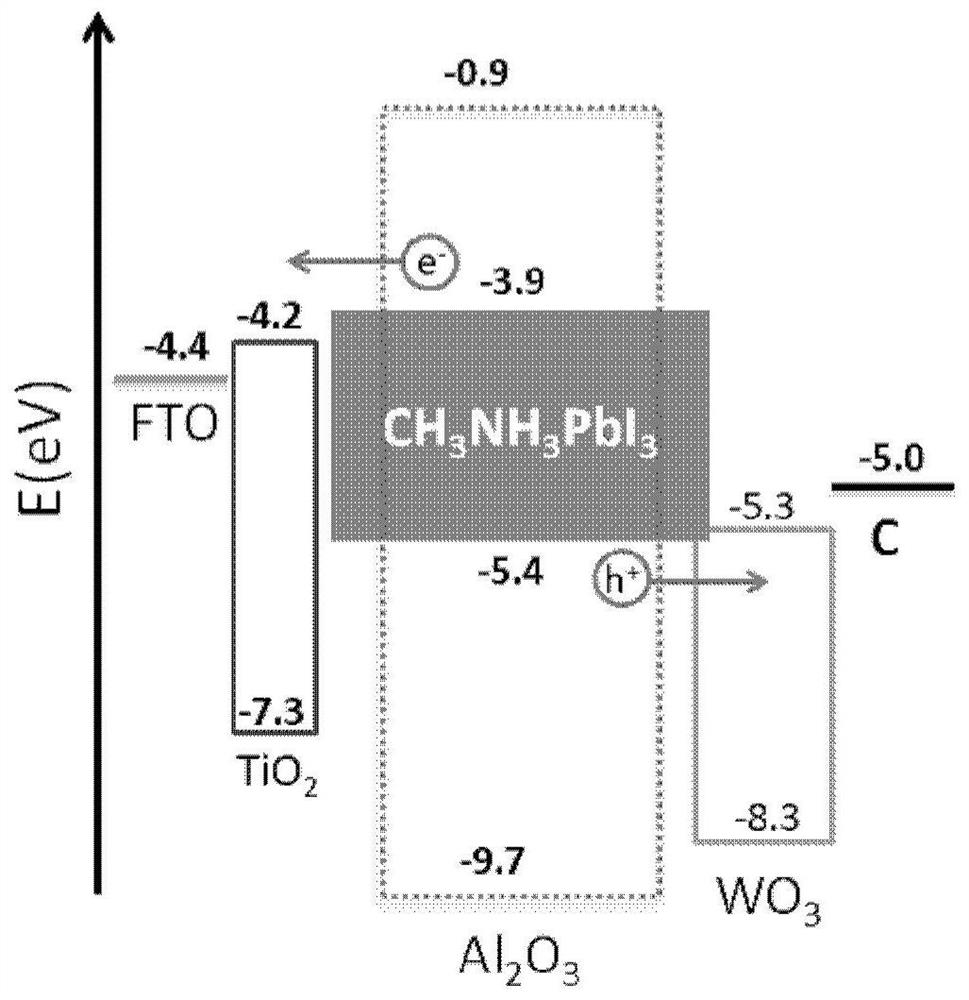

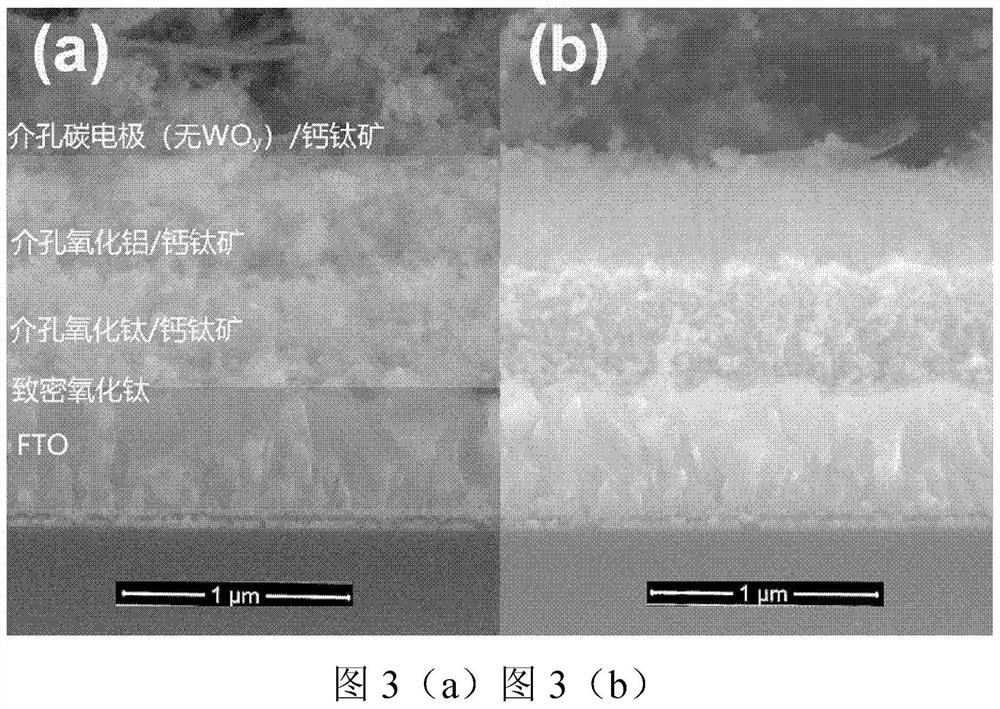

Mesoporous carbon electrode for carbon-based perovskite solar cells and preparation method thereof

ActiveCN109671849BImprove hole transport abilityImprove performanceMaterial nanotechnologySolid-state devicesPerovskite solar cellBattery cell

A mesoporous carbon electrode for carbon-based perovskite solar cells and a preparation method thereof, the preparation method comprising the following steps: (1) preparing an electrode containing cellulose and optional NiO X or WO y The carbon electrode slurry of nanomaterials, wherein, x is 1~1.5; ℃ sintering to obtain mesoporous carbon electrodes. The preparation process of the mesoporous carbon electrode of the present invention is simple, low in cost and good in repeatability, and the assembled carbon-based perovskite solar cell has good photoelectric conversion efficiency.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A printing machine doctor blade system with leveling function

The invention discloses a printing machine doctor blade system with a leveling function. The structure of the doctor blade system comprises a doctor blade structure, an ink tank, an ink transfer roller, a printing plate cylinder and an impression cylinder, wherein the ink tank is provided with the ink transfer roller, the ink transfer roller is positioned obliquely below the printing plate cylinder, the printing plate cylinder and the ink transfer roller are movably attached to each other, one side of the ink transfer roller is provided with the doctor blade structure, the impression cylinderis arranged in the middle of the top end, opposite to the ink tank, of the printing plate cylinder, and the impression cylinder and the printing plate cylinder are closely attached to each other. According to the doctor blade system, whether a doctor blade is placed horizontally or not is calibrated through a blade placing platform, so that the blade body, tangent to the printing plate cylinder, of the doctor blade is further ensured to be in the same horizontal line without deflection, and the doctor blade can scrape the printing plate cylinder uniformly; and according to the doctor blade, three thread knobs are fixed on the blade placing platform uniformly and equidistantly, when the doctor blade is installed, three points are stressed uniformly, so that the adhesion degree between the doctor blade placing platform and the doctor blade is further guaranteed, and the influence on the distribution of the doctor blade caused by local lifting or the gap of the doctor blade is avoided.

Owner:GUANGDONG NEW GRAND LONG PACKING CO LTD

A kind of anti-staining silk wool cleaning detergent and preparation method thereof

ActiveCN109810802BEasy to operateEasy to controlInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOLEAMIDOPROPYL BETAINEPolymer science

The invention relates to the technical field of toiletries, in particular to an anti-staining silk and wool detergent and a preparation method thereof. The anti-staining silk hair cleaning detergent comprises the following components: fatty amine polyoxyethylene ether diquaternary ammonium salt, fatty alcohol polyoxyethylene ether, cocamidopropyl betaine, organosilicon quaternary ammonium salt, imidazoline amphoteric surface Active agent, polyethylene glycol, pH buffer, preservative and water. The anti-staining silk and wool detergent is used for washing clothes made of silk, wool and cashmere, etc. It has no corrosion to clothes, can keep clothes soft, has strong detergency, and has good anti-staining, antibacterial and antistatic effects.

Owner:东莞市嘉宏有机硅科技有限公司

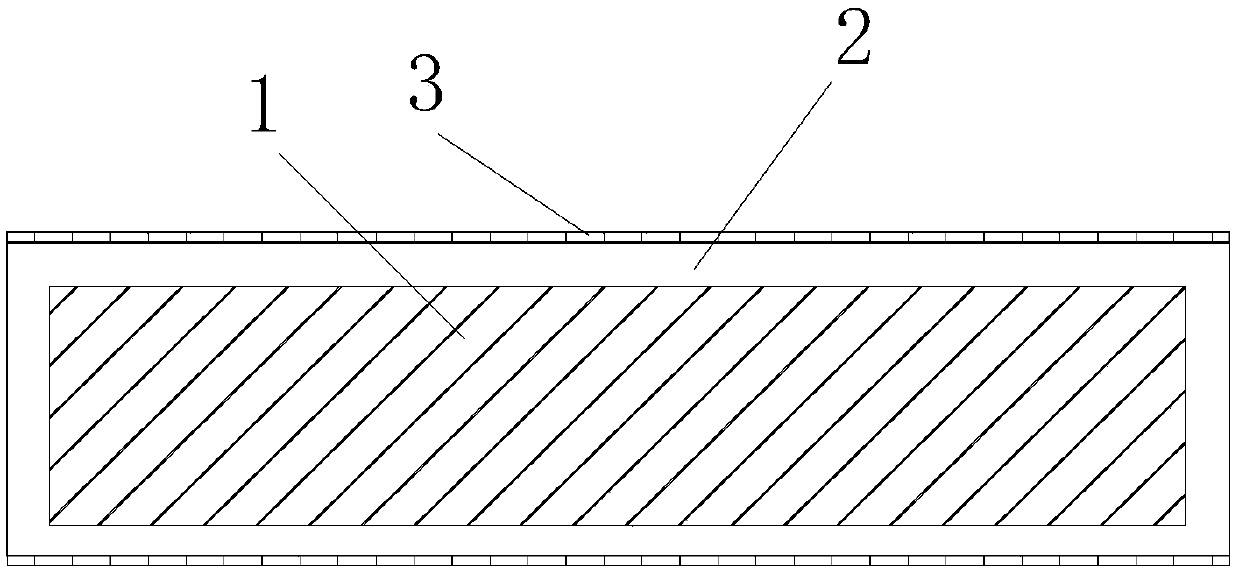

Novel E0 grade plate and preparation method thereof

InactiveCN110315830AImprove surface strengthImprove surface propertiesNon-fibrous pulp additionCoatings with pigmentsPolymer scienceMelamine formaldehyde

The invention relates to a novel E0 grade plate and a preparation method thereof. The novel E0 grade plate comprises a base plate, and the outside of the base plate is wrapped by decorative paper, which is processed by melamine-formaldehyde-organic particle mixed solution; the surface of the decorative paper is wrapped by an electron beam cured coating. According to the novel E0 grade plate, the decorative paper on the surface is impregnated by the melamine-formaldehyde-organic particle mixed solution, of which the organic particles are mesoporous double-layer organic silicon spheres in a double-layer porous structure, so that formaldehyde in the novel E0 grade plate can be absorbed by the organic particles and further avoid being released.

Owner:孙学民

A mold surface td treatment premix production device

ActiveCN107779811BEasy to handleImpact distributionSolid state diffusion coatingWide mouthPulp and paper industry

The invention relates to the field of mould manufacturing, in particular to a mould surface TD (Thermal Diffusion) treatment pre-mixing production device. The mould surface TD treatment pre-mixing production device comprises a premixing device and a surface TD treatment device; the premixing device comprises a wide mouth premixing tank; a premixing sealing cover is movably embedded into the inneredge of a wide mouth which is formed in the wide mouth premixing tank; a machine frame is mounted on the upper end surface of the premixing sealing cover; the upper end of a rotating shaft is rotatably mounted in a flat end surface which is formed on the machine frame; the lower end of the rotating shaft penetrates through the premixing sealing cover and extends into the wide mouth premixing tank;the upper end part of the rotating shaft is connected with an output end of a power output device; the mould surface TD treatment pre-mixing production device comprises a hollow tank body which is provided with an opening; at least two air inlets are uniformly formed in the side wall of the hollow tank body at an interval; an air inlet is mounted in each of the air inlets; an exhaust end of eachair inlet pipe is positioned at the bottom of the inner side of the hollow tank body; an air inlet end of each air inlet pipe communicates with an exhaust end of an air compressing pump.

Owner:天津开山金属模具科技有限公司

A kind of compound oral ulcer patch and preparation method thereof

ActiveCN111249328BInhibition of dissolutionMuscle strengtheningHydroxy compound active ingredientsDigestive systemOral ulcersAntimicrobial drug

The invention relates to a compound oral ulcer patch and a preparation method thereof, comprising a muscle-generating layer, a slow-release layer and a heat-clearing and antibacterial layer, and the muscle-generating layer includes a film-forming material, a plasticizer, a solvent softener, and a muscle-generating drug , the slow-release layer includes a film-forming material, a plasticizer and a softener, and the heat-clearing and antibacterial layer includes a film-forming material, a sustained-release component, and a heat-clearing and antibacterial drug component. The invention adopts a three-layer composite structure, the myogenic layer is in contact with the ulcer site, and mainly adopts muscle-inducing drugs to promote rapid muscle growth and repair of the ulcer; the heat-clearing and antibacterial layer mainly uses heat-clearing and antibacterial drugs for clearing away heat and killing Bacteria mainly provide a good environment for the recovery of ulcers. The slow-release layer uses bletilla striata polysaccharide or chitosan, which mainly prevents the saliva from dissolving the myogenic layer after the heat-clearing and antibacterial layer is dissolved. The three-layer structure can effectively improve the oral environment and at the same time make the ulcer site recover quickly.

Owner:河南护理职业学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com