Preparation method of iron-silicon-chromium-manganese-bismuth-zinc alloy soft magnetic powder

A technology of iron silicon chromium manganese bismuth and soft magnetic powder, which is applied in the field of soft magnetic alloy powder, can solve the problems of low tap density, low resistivity, poor electrical resistance, etc., and achieve improved tap density, resistivity, and The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

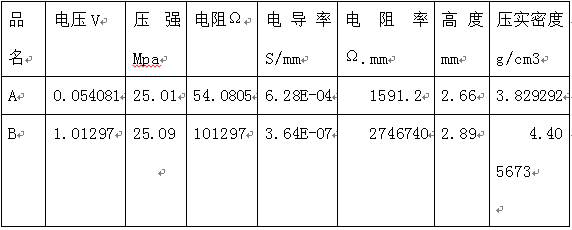

Examples

Embodiment Construction

[0018] The specific implementation manner of the embodiment of the present invention is described below.

[0019] A kind of preparation method of iron silicon chromium manganese bismuth zinc alloy soft magnetic powder, comprising

[0020] Follow the steps below:

[0021] 1) Add the soft magnetic alloy powder raw material containing iron, silicon, chromium, manganese, bismuth and zinc into the intermediate frequency induction furnace, and use argon blowing protection to smelt to obtain the alloy liquid. Preferably, the mass ratio of soft magnetic alloy powder raw materials is: chromium 2-10%, silicon 2-8%, manganese 0.1-2%, bismuth 0.1-2%, zinc 0.1-2%, iron balance.

[0022] Further, in the smelting process, gas bricks are pre-buried at the bottom of the prefabricated crucible, the furnace mouth of the intermediate frequency induction furnace is closed with a furnace cover, and argon is used as the furnace mouth protection gas. When smelting, first put iron, chromium and sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com