Low-ally CADI wear-resisting material and preparing method thereof

A technology for austempering ductile iron and wear-resistant materials, applied in the field of metal materials, can solve the problems of inability to meet the CADI performance requirements of austenitic ductile iron, poor carbide morphology, and many trace elements, and achieve moderate hardness and impact toughness. , the effect of improving mechanical properties and reducing casting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the low-alloy ausferrite ductile iron CADI wear-resistant material wear-resistant parts with carbides, the specific steps are as follows:

[0045] 1. Ingredients and smelting;

[0046] a. The types and weight ratios of ingredients are as follows: carburizer 2.6-3.0%, the carbon content of the carburizer is not less than 95%; scrap steel 60-65%, the scrap steel is scrap carbon steel and its edges and corners, Carbon in scrap steel is 0.2-0.5%; pig iron (Q10 or Q12) 10-15%; ausferitic ductile iron CADI return charge with carbides 20-26.6%, ferromanganese and ferrochrome are determined according to other charge components; adding method The method is as follows: first add steel scrap, recarburizer, ausferrite ductile iron CADI return material with carbides, pig iron Q10 and ferrochrome alloy to the electric furnace first, add recarburizer to the bottom of the furnace first, and press it with scrap steel. Ferromanganese and ferrosilicon are added ...

Embodiment 1

[0069] Chemical composition of wear parts (by weight): carbon (C) 3.40%, silicon (Si) 2.40%, manganese (Mn) 0.40%, sulfur (S) 0.012%, phosphorus (P) 0.035%, chromium (Cr) 0.30%, the balance is iron (Fe).

[0070] Castings with the above components are melted using the following raw materials and proportions: 10.0% pig iron (Q10), 26.6% ausferitic ductile iron CADI with carbides, 60.0% scrap carbon steel (Q235), and ferrosilicon (FeSi75) 0.5%, ferrochrome (FeCr55) 0.3%, recarburizer (C) 2.6%, ferromanganese (FeMn65) 0.0%. According to the above ratio, the raw materials are put into the electric furnace, and the castings are prepared according to the following melting process.

[0071] Casting isothermal quenching process: solution temperature: 900°C, solution time: 90 minutes (min), isothermal quenching temperature: 270°C, quenching time: 60 minutes;

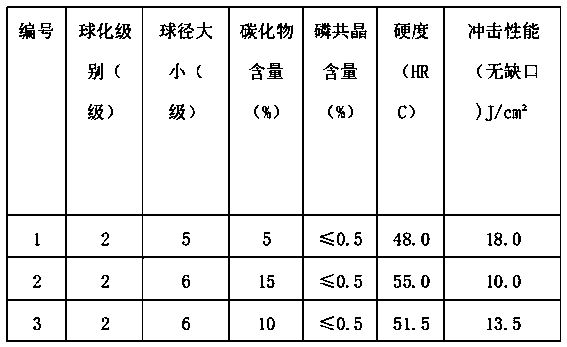

[0072] The rest of the preparation process is the same as the aforementioned process steps. The finished product number is 1...

Embodiment 2

[0074] Chemical composition of wear parts (by weight): carbon (C) 3.70%, silicon (Si) 2.40%, manganese (Mn) 0.60%, sulfur (S) 0.012%, phosphorus (P) 0.04%, chromium (Cr) 0.60%, the balance is iron (Fe).

[0075] The castings with the above components are melted, and the following raw materials and proportions are used: pig iron (Q10) 15.0%, ausferitic ductile iron CADI return material with carbides 20.0%, carbon scrap steel (Q235) 60%, and recarburizer 3.0% , ferrosilicon (FeSi75) 0.8%, ferrochromium (FeCr55) 0.8%, ferromanganese (FeMn65) 0.4%. According to the above ratio, the raw materials are put into the electric furnace, and the castings are prepared according to the following melting process.

[0076] Casting isothermal quenching process: solution temperature: 910°C, solution time: 90 minutes (min); isothermal quenching temperature: 270°C, quenching time: 90 minutes (min);

[0077] The rest of the preparation process is the same as the aforementioned process steps, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com