Patents

Literature

41results about How to "Not easy to ablate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

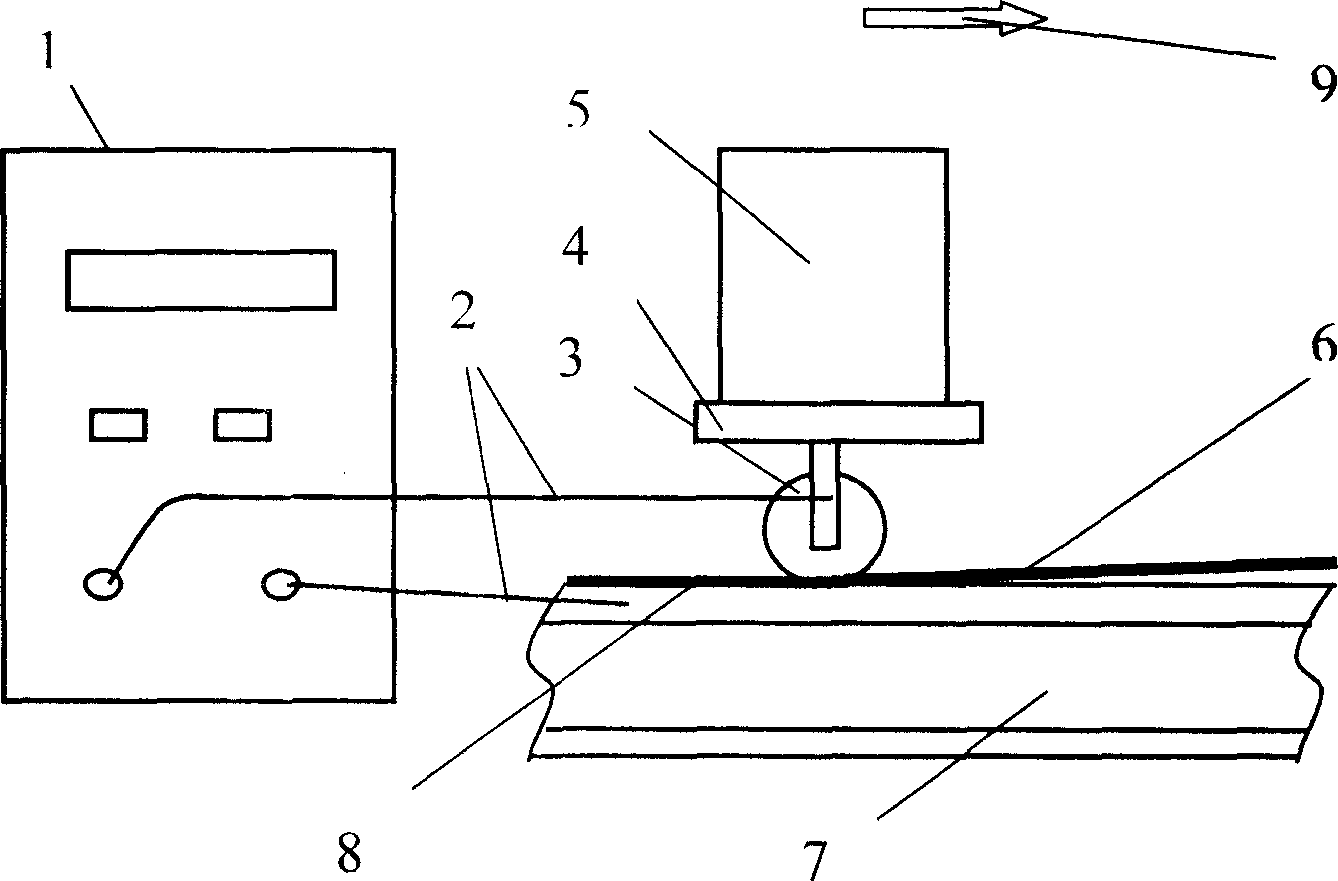

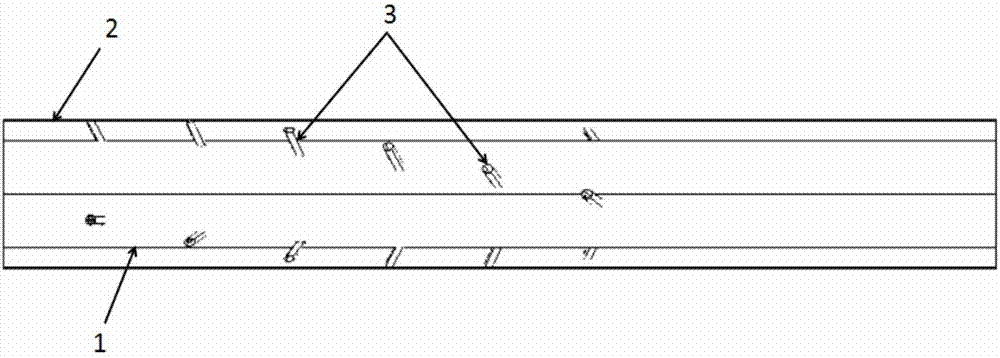

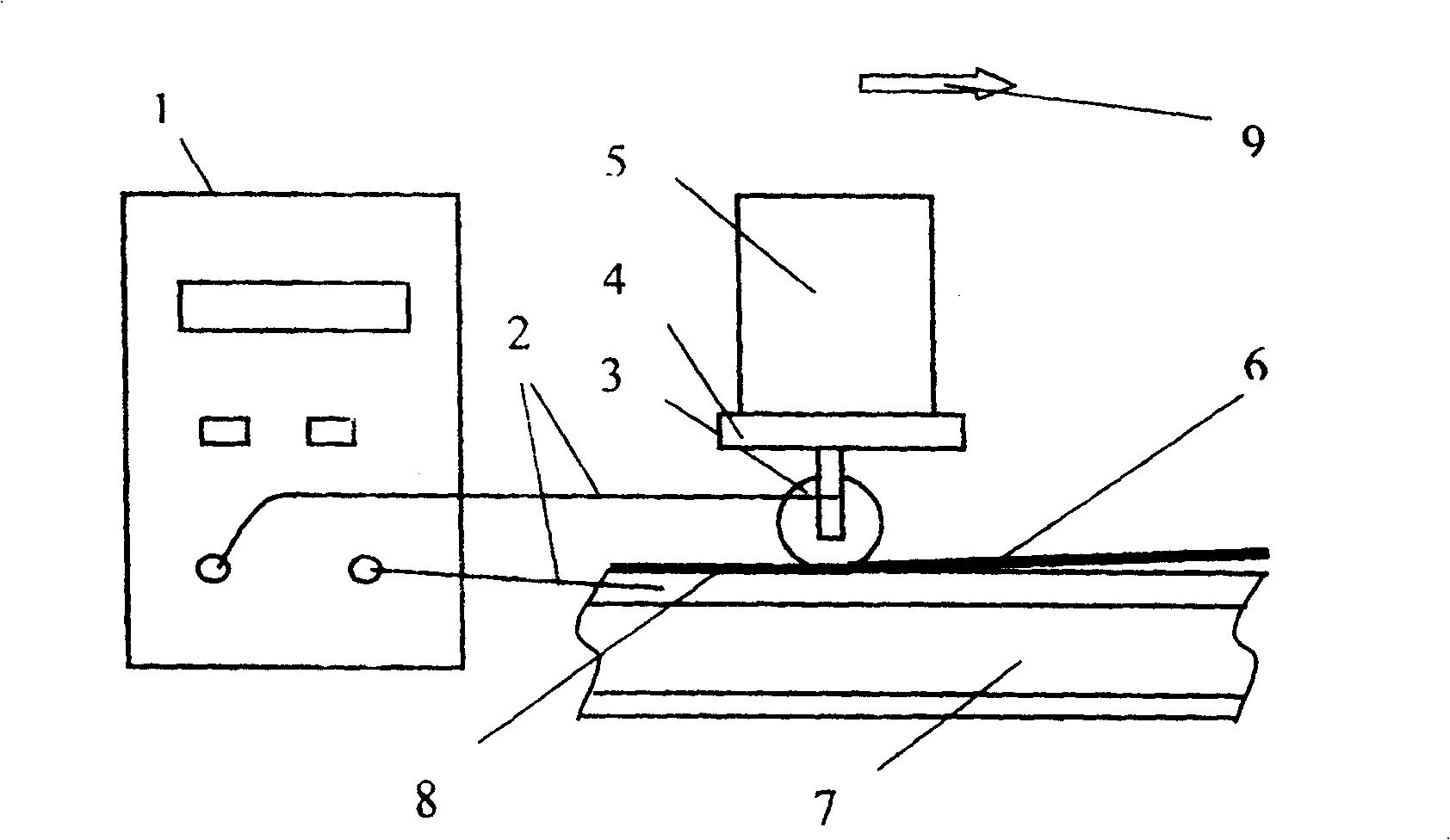

Steel rail surface alloy layer welding method and its material

InactiveCN1803370AGood welding performanceImprove corrosion resistanceWelding with roller electrodesWelding/cutting media/materialsMetallic materialsAlloy

The invention discloses a self-melting alloy powder material in the metal welding and railway signal control method, which comprises the following steps: polishing the railway surface to obtain fresh metal surface; proceeding resistance seam welding through resistance seam welding equipment; producing the needed alloy; coating alloy powder on the metal surface at 1000-1130 deg C fusing point. The powder displays NiCrBSi system self-melting alloy powder or NiCrBSiCu alloy system with HRC20-HRC45 welding layer hardness. The weight percentage of NiCrBSiCu alloy system is 0.2-0.5 percent C, 0.5-5.0 percent B, 1.0-5.0 percent Si, 3.0-15 percent Cr, 2-12 percent Fe, 3-20 percent Cu and Ni. The invention improves the bonding surface of metal and steel, which solves the problem of big rail damage and low production efficiency.

Owner:阴生毅

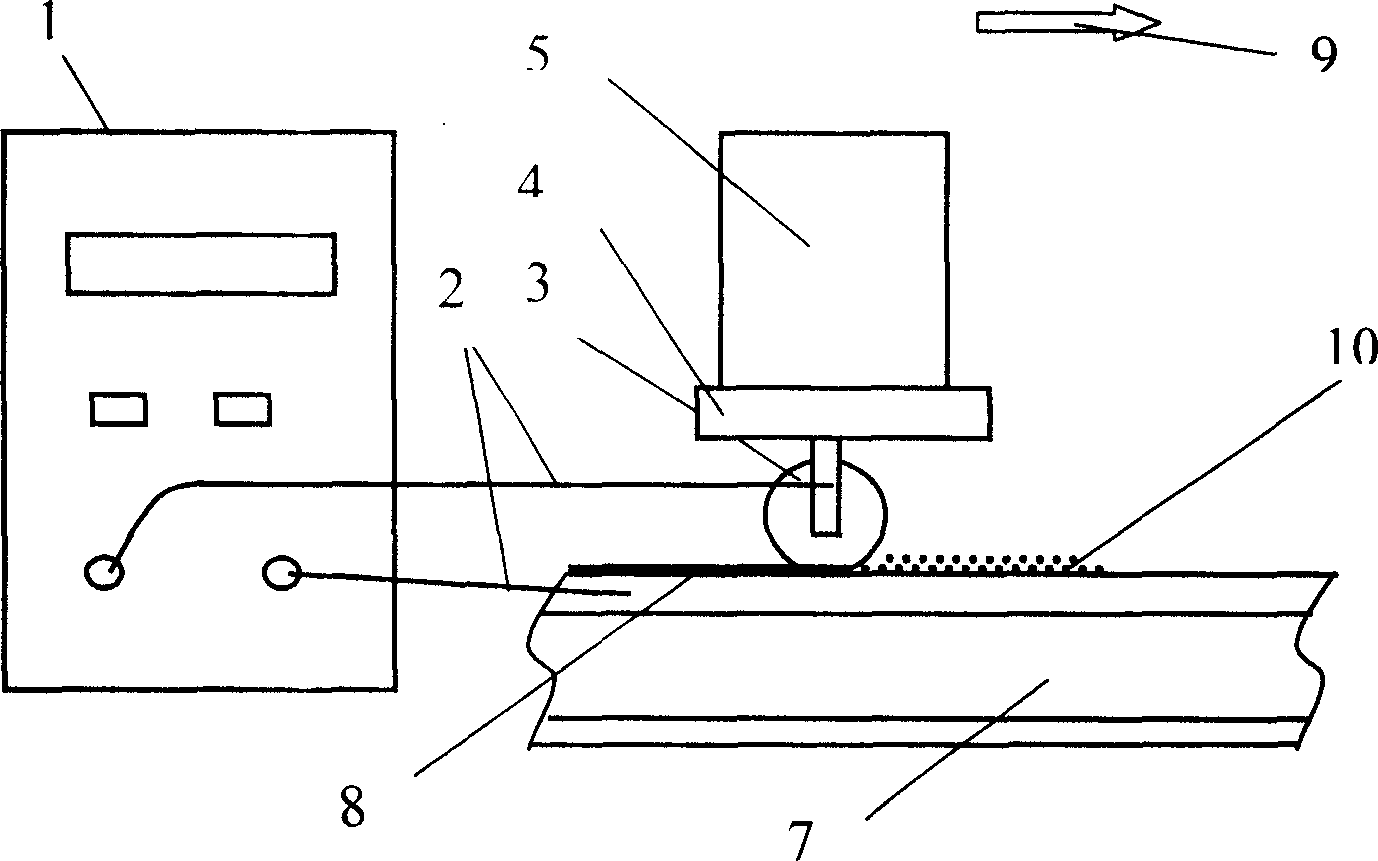

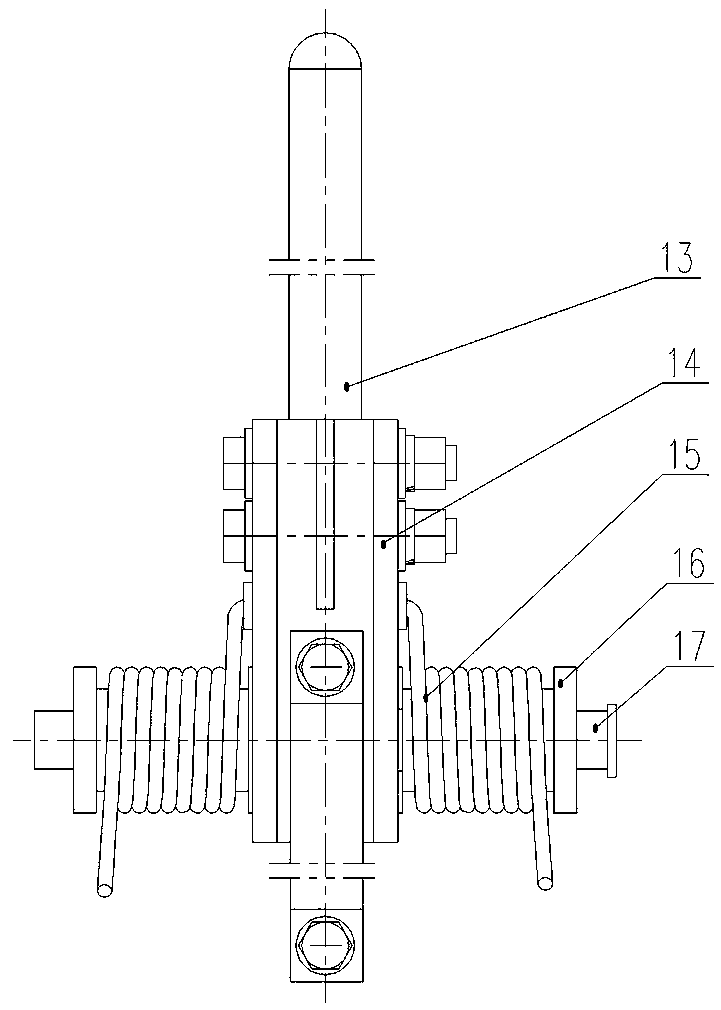

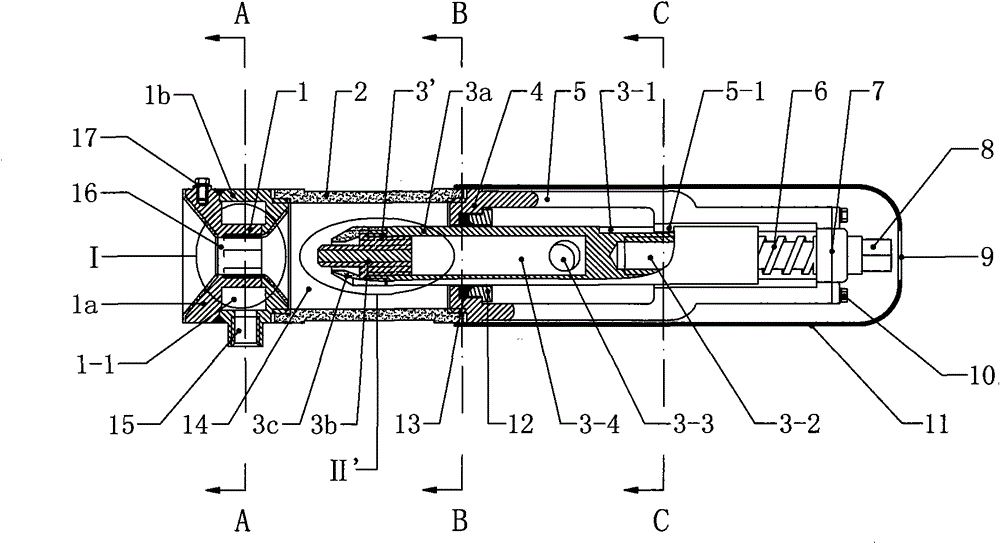

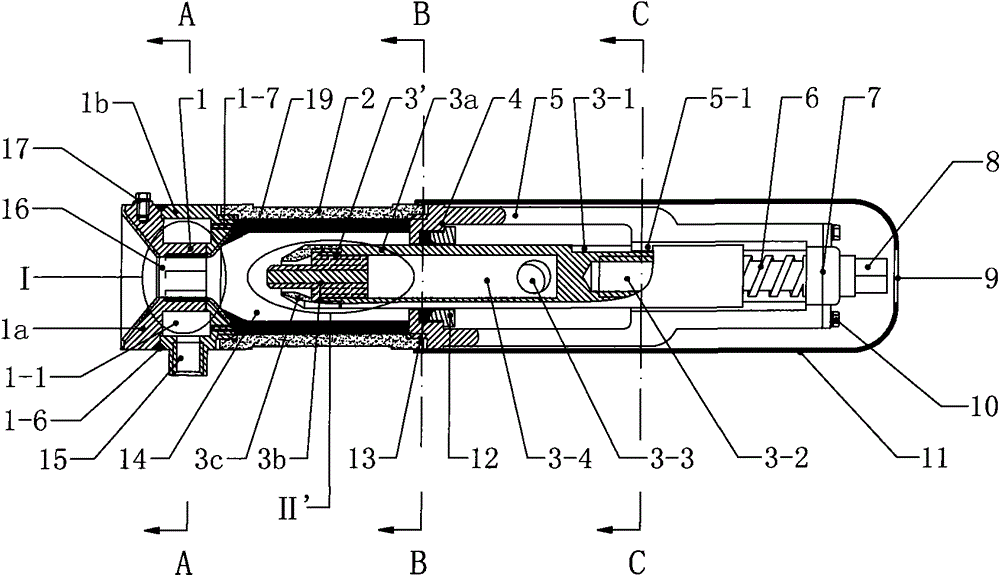

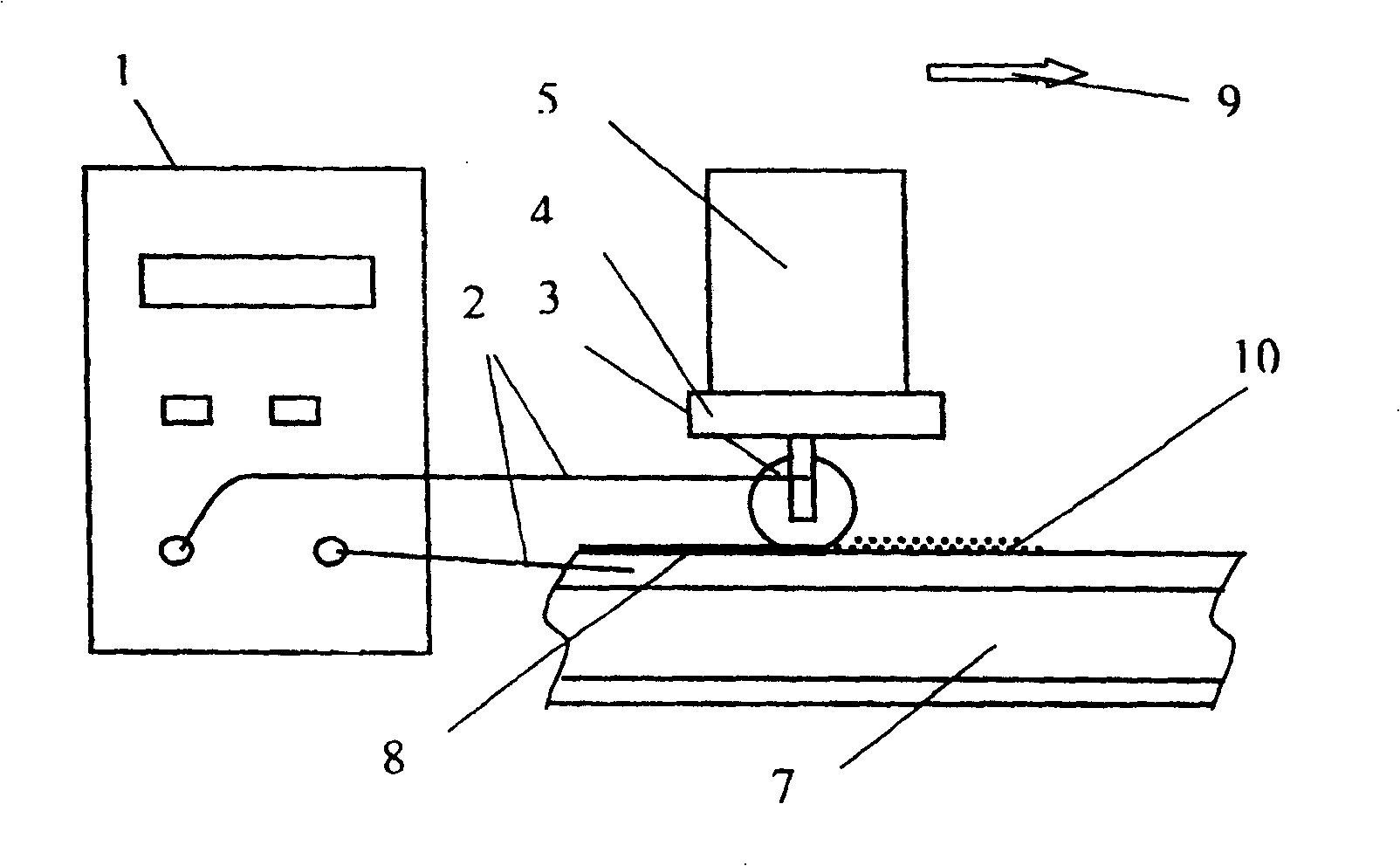

Multipole field breakdown type vacuum trigger switch

InactiveCN102130670AIncrease surface areaReduce ablationElectronic switchingBiomedical engineeringOperating life

The invention discloses a multipole field breakdown type vacuum trigger switch. In the invention, a top electrode and a bottom electrode of the trigger switch respectively comprise electrode bottom columns, electrode platforms and a plurality of columnar electrodes; the columnar electrodes of the top electrode and the bottom electrode extend in opposite directions and are staggered; gap widths between every two adjacent columnar electrodes are equal and are same as the gap widths between the tops of the columnar electrodes and the corresponding electrode platforms; the electrode platform of the bottom electrode is provided with a notch and a trigger electrode; the trigger electrode comprises a trigger needle and a trigger insulation sleeve ring; the axial section of the trigger needle is T-shaped; the trigger insulation sleeve ring is of a boss structure and embedded in the notch; the trigger needle comprises a trigger needle head and a trigger needle rod; one end of the trigger needle rod is connected with the trigger needle head, and the other end of the trigger needle rod passes through the trigger insulation sleeve ring and the electrode platform; the upper surface of the trigger needle head is lower than the upper surface of the electrode platform of the bottom electrode; and gaps exist between corners and the electrode platform of the bottom electrode. The trigger switchhas long service life and strong through-current capability under the condition of big current.

Owner:HUAZHONG UNIV OF SCI & TECH

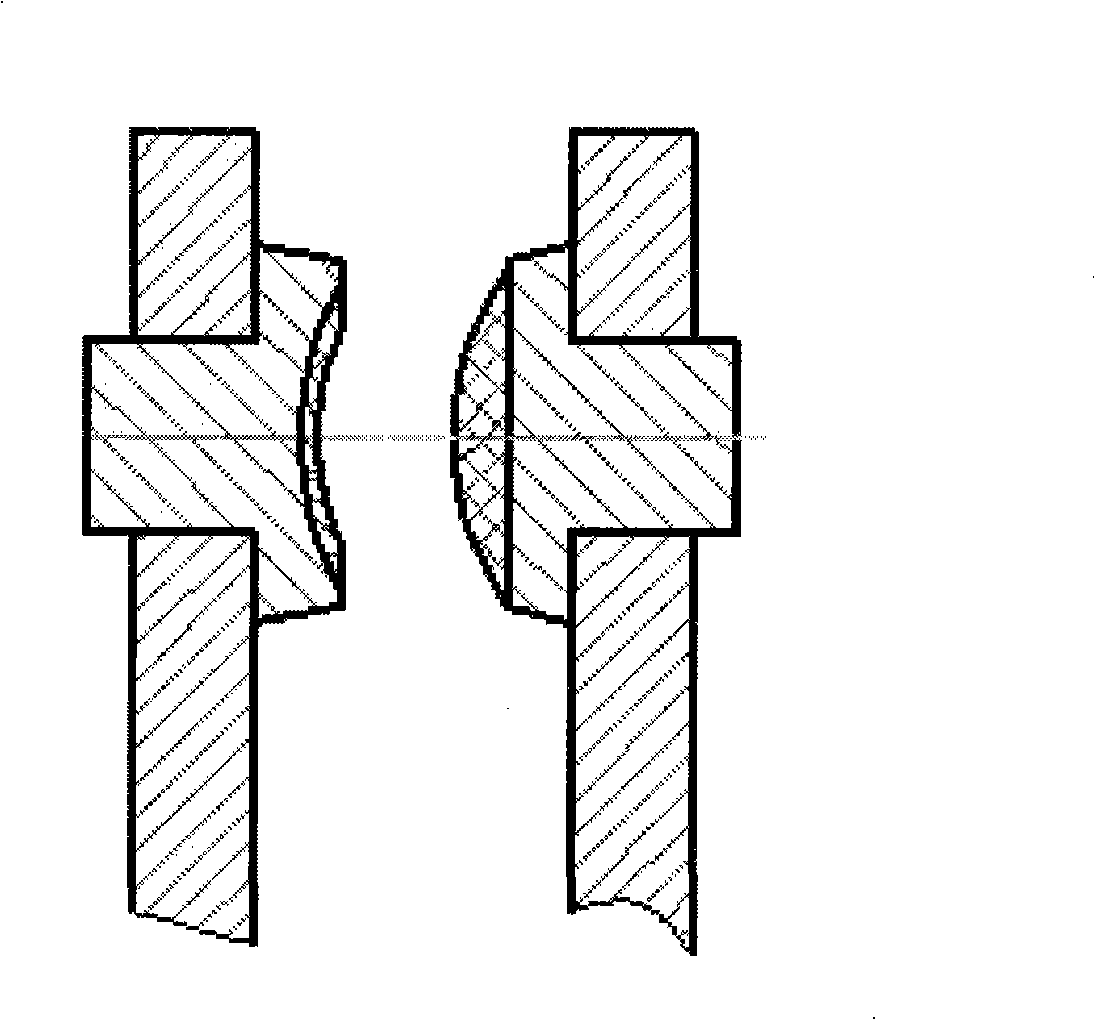

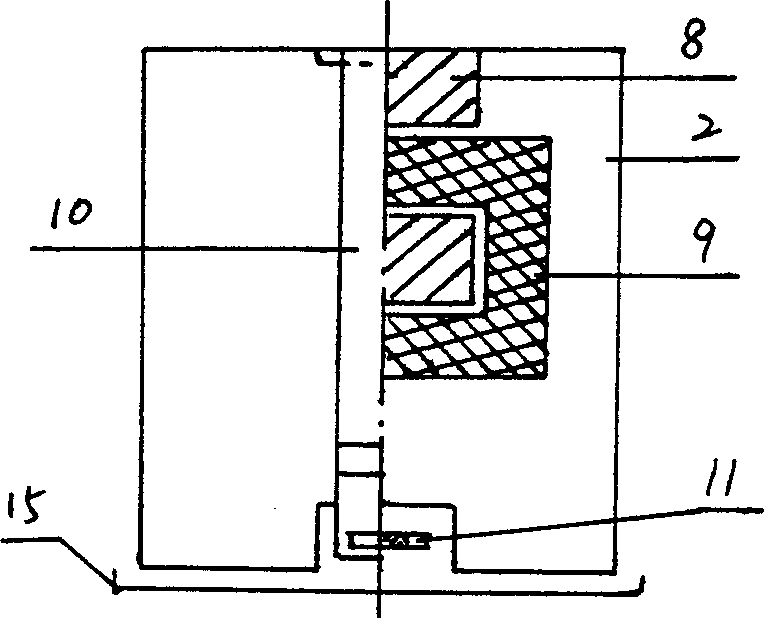

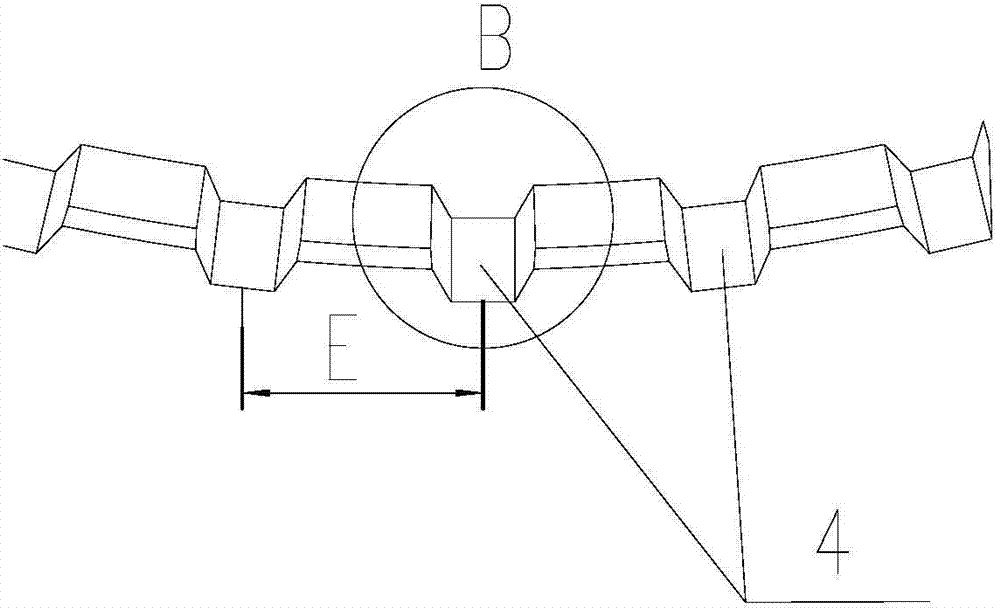

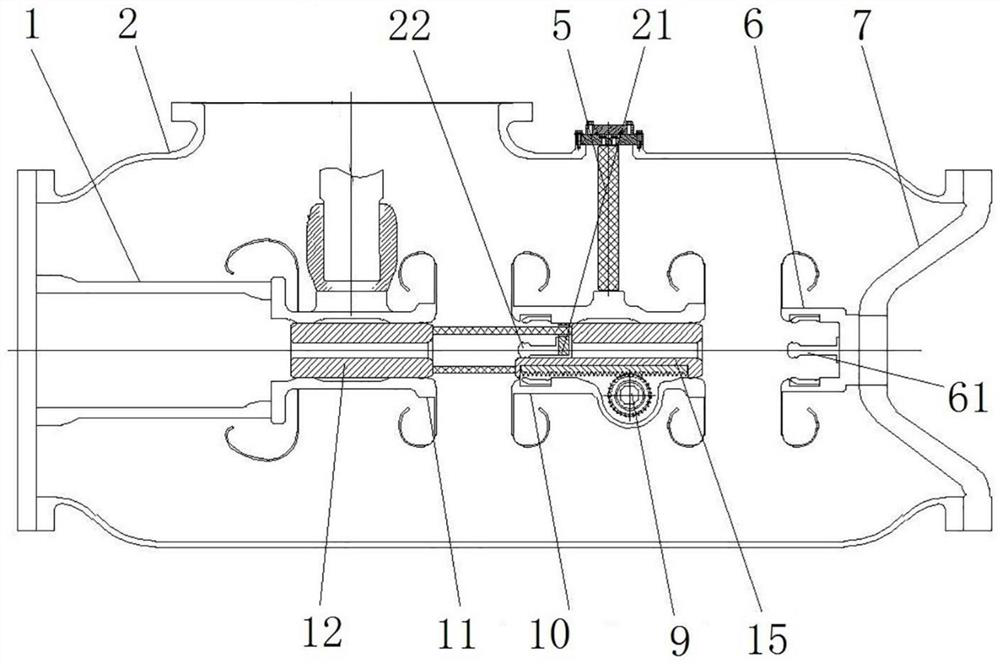

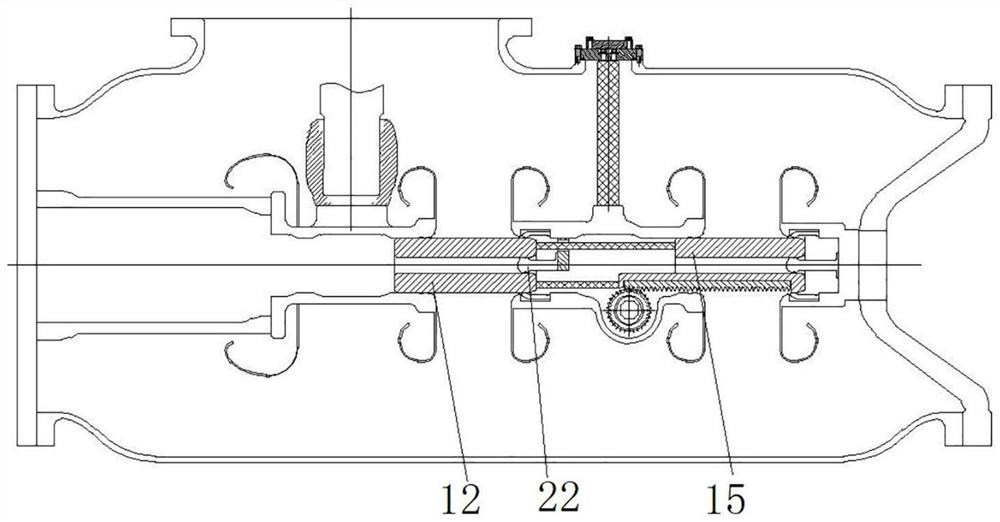

Conductive contact

InactiveCN101404217AMaximize contact areaContact state is stableContact surface shape/structureContact engagementsWeak currentEngineering

The invention relates to a conductive contact, in particular to a zigzag secondary camber conductive contact used for switches, relays and contactors, comprising a group of two contacts: a movable contact and a fixed contact; the movable contact and the fixed contact are respectively a concave camber and a convex camber which are coincident to each other; the invention uses the curve contact to replace a planar contact or point contact, solves the problems that the contact area of the conductive contact is extremely finite and the contact state is unstable, and overcomes the shortages that the existing conductive contact technique and product have weak current passing capability and the contacts are easy to be burned.

Owner:李健全 +2

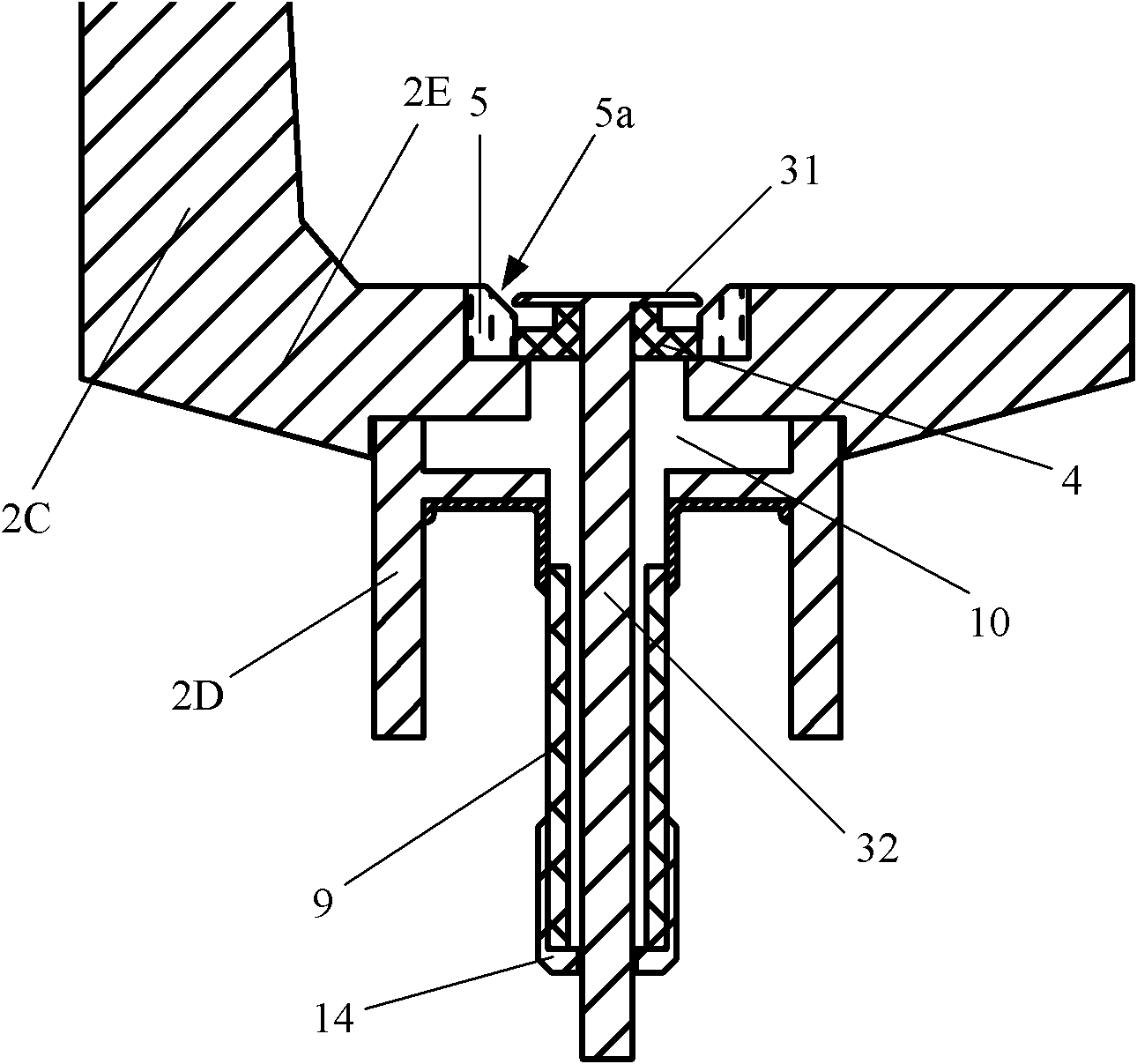

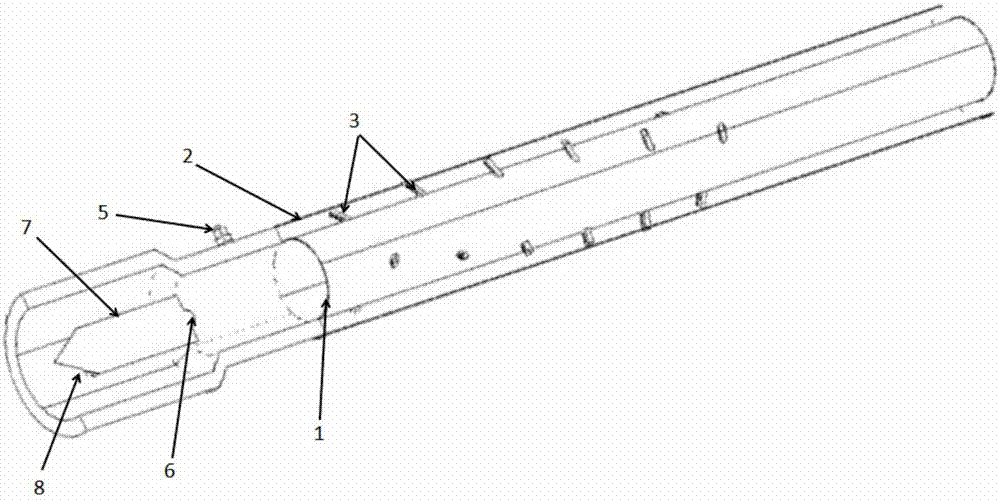

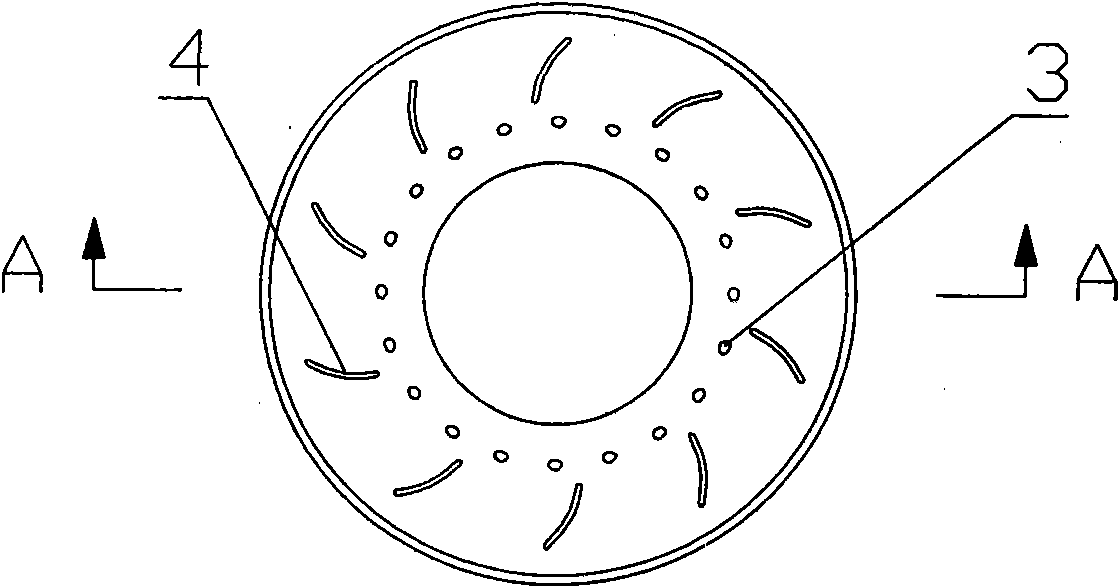

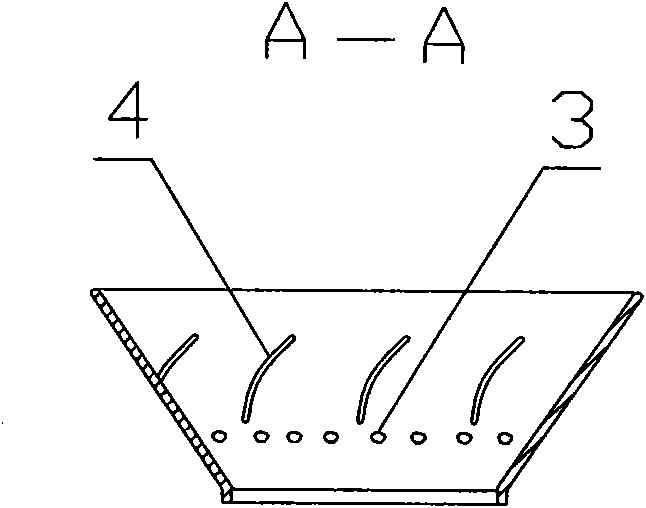

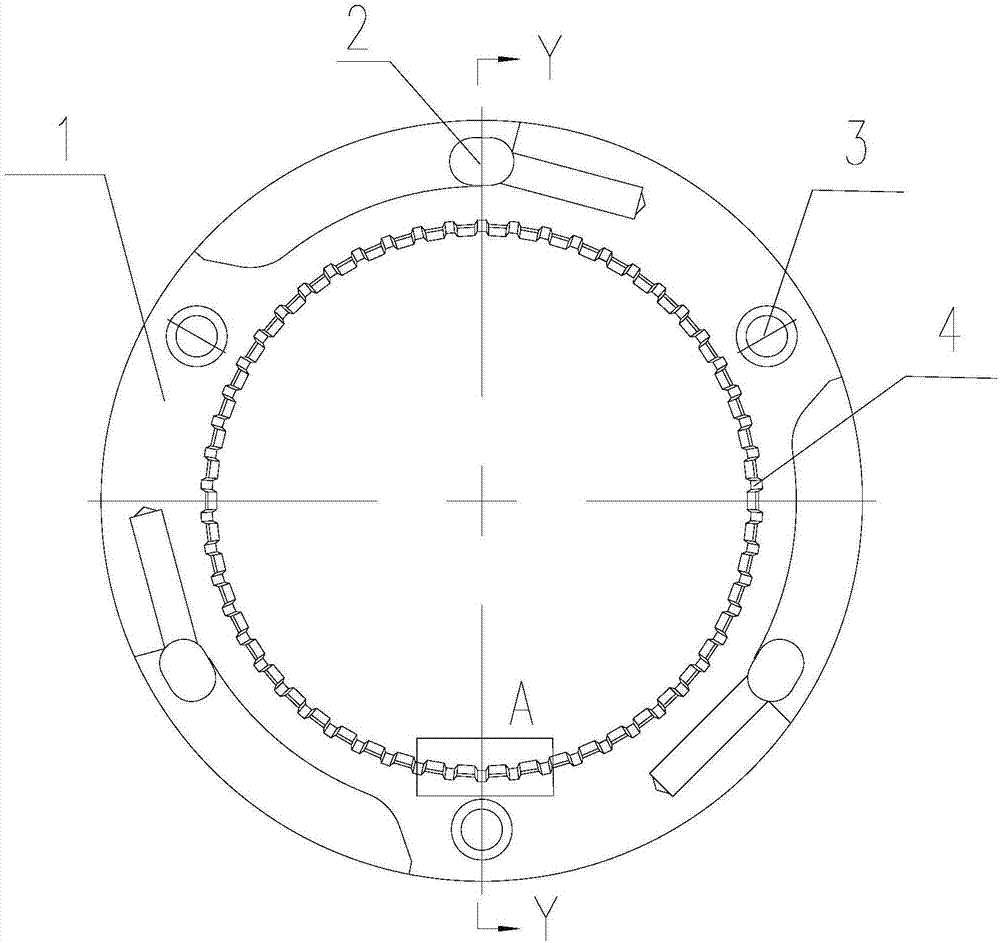

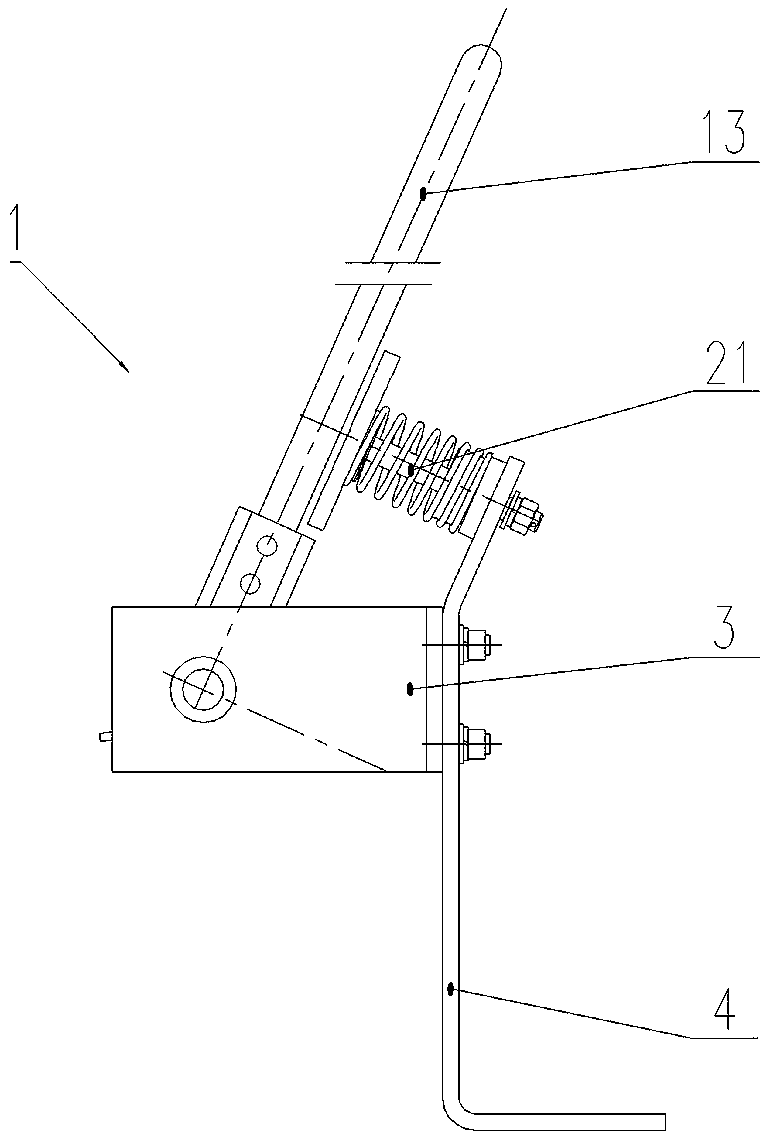

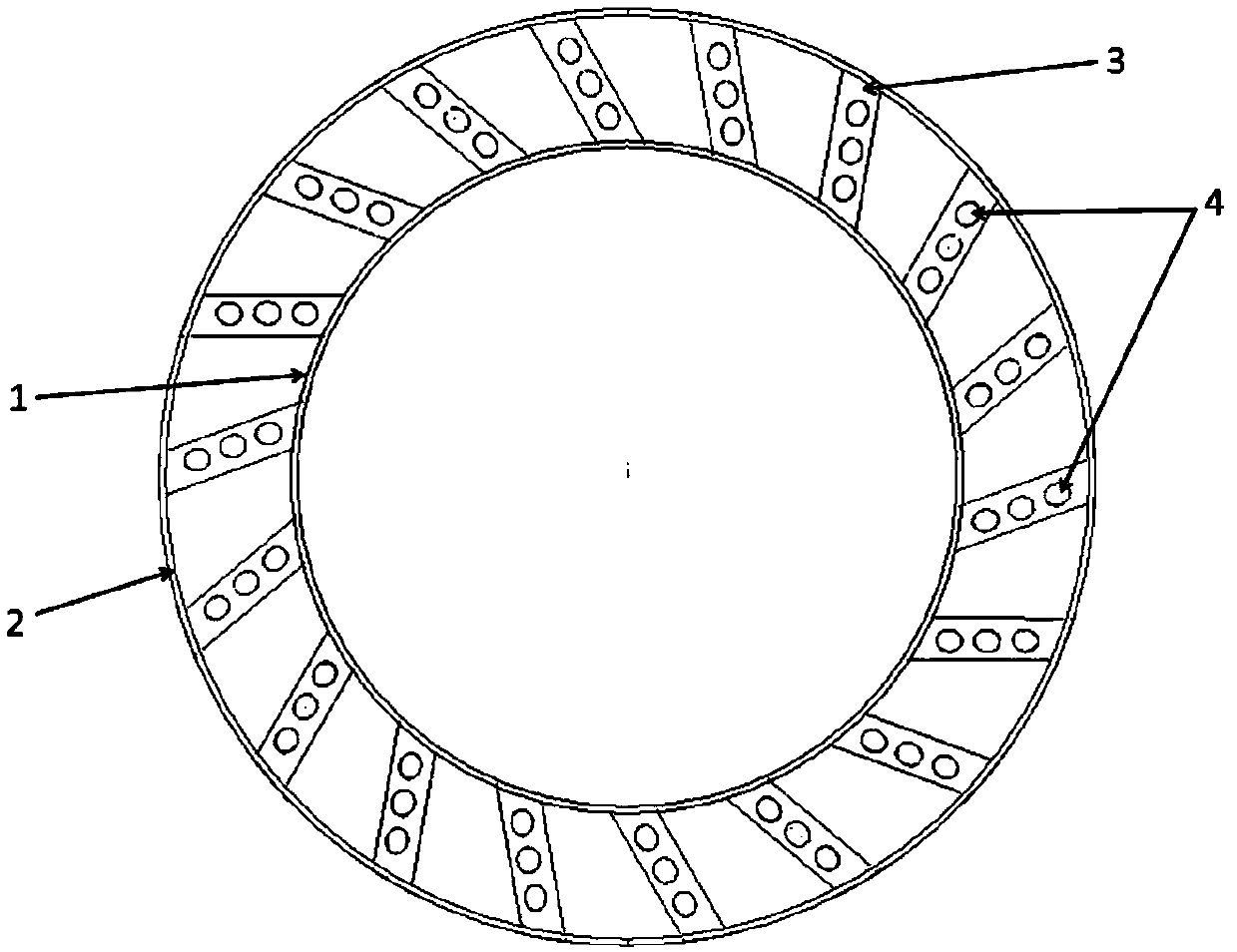

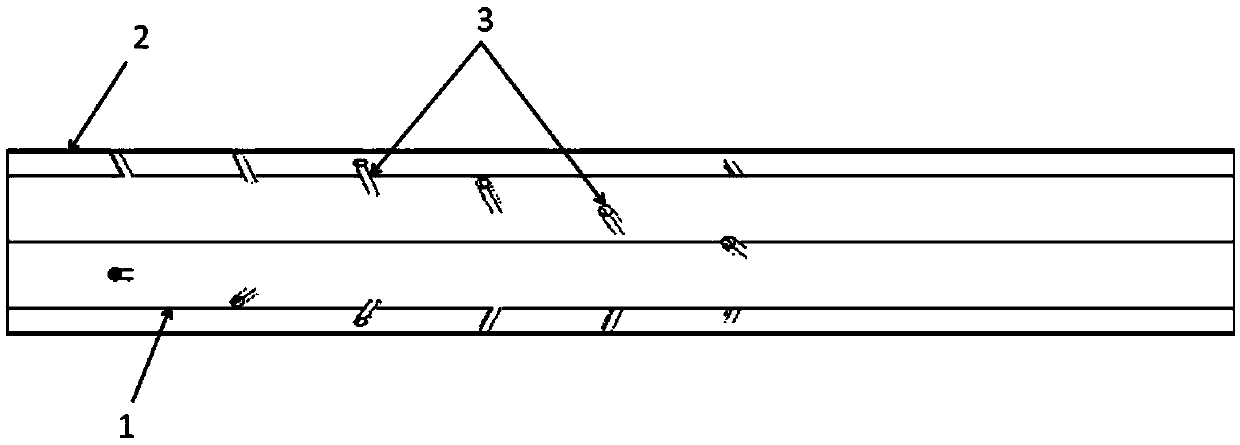

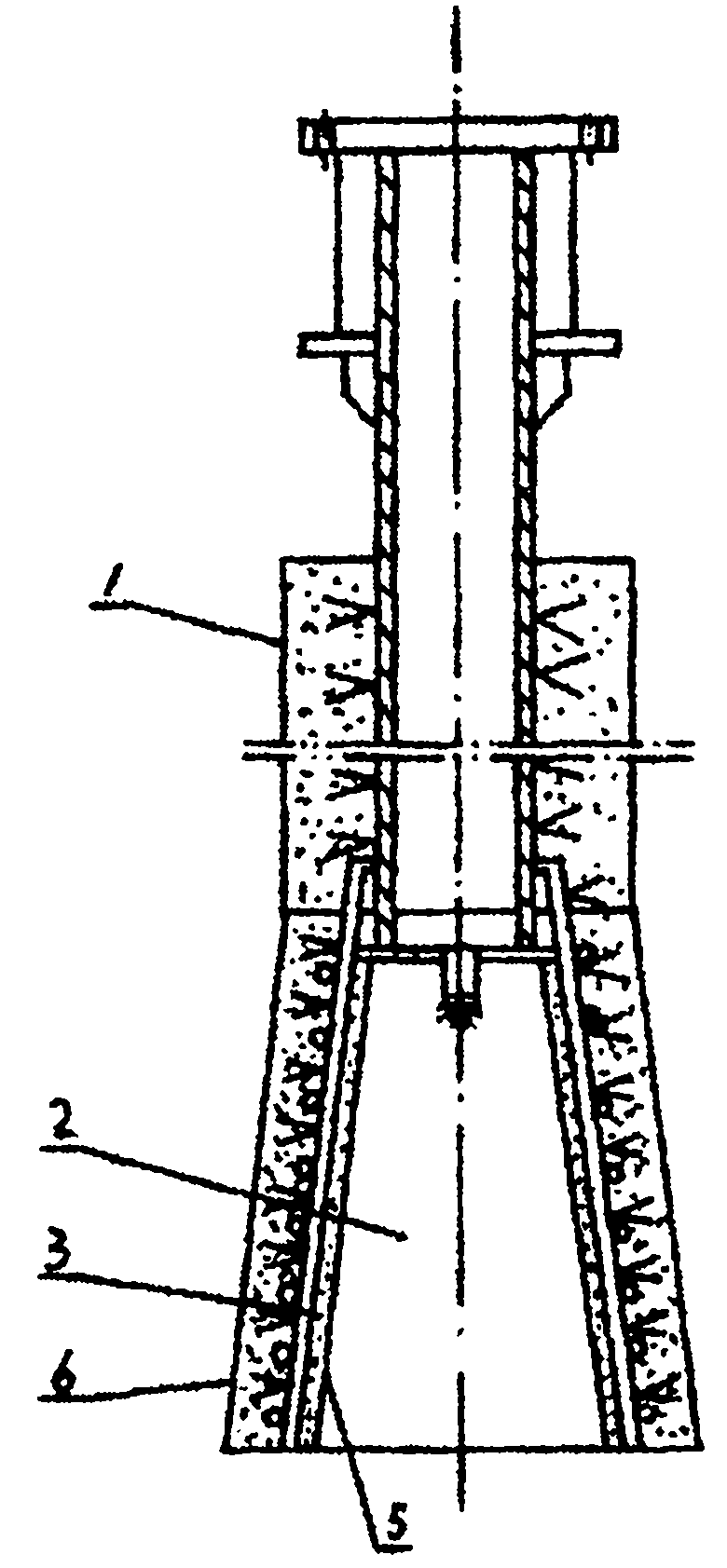

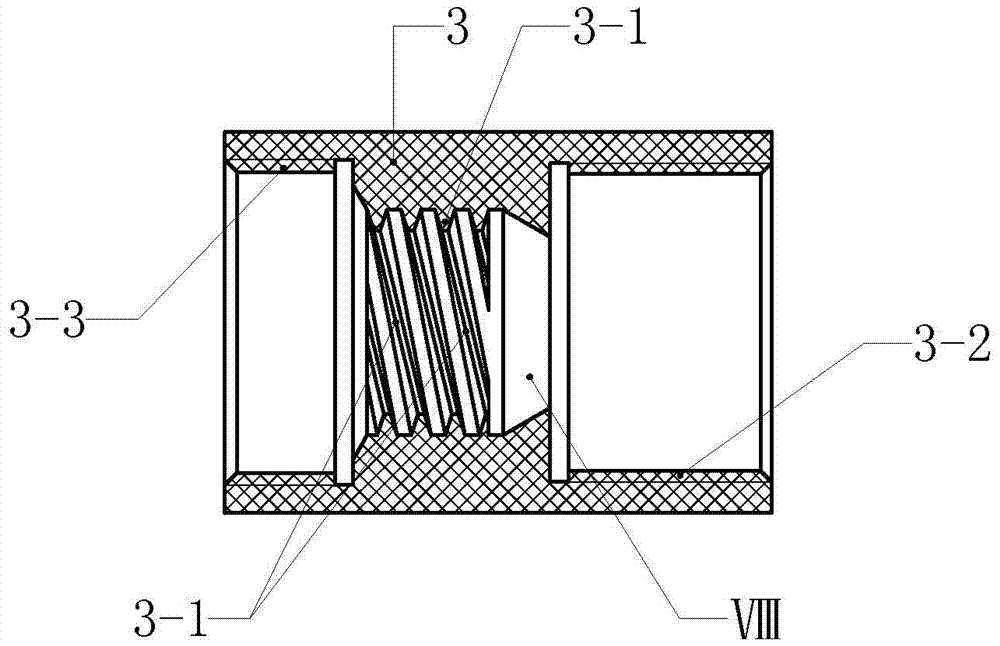

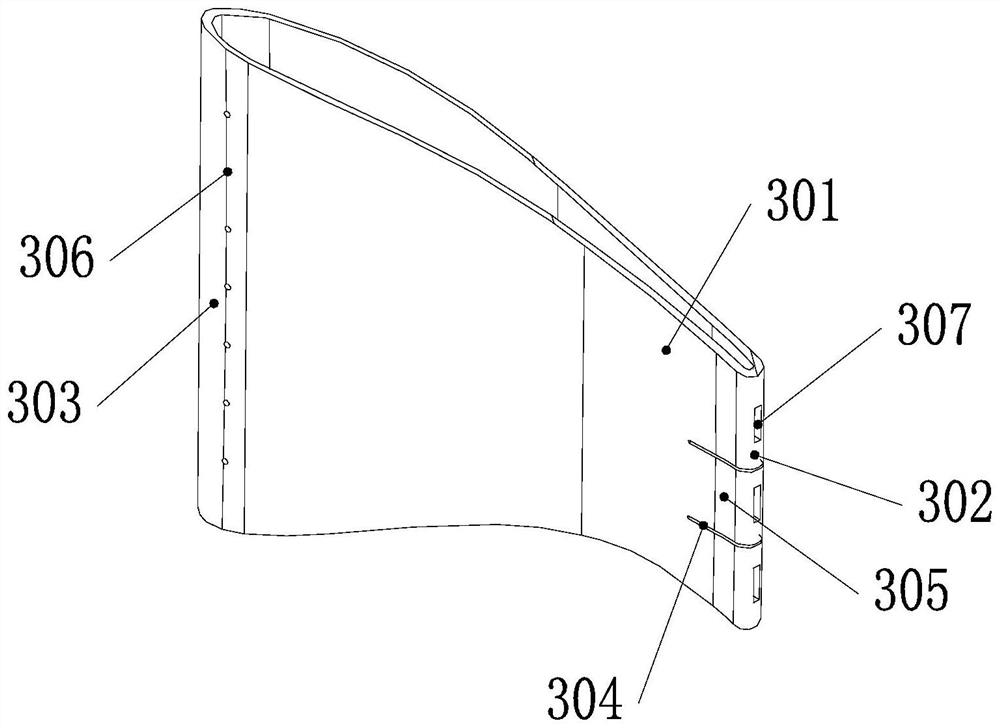

Detonation chamber of pulse detonation engine

InactiveCN102606343AImprove convenienceNot easy to ablateIntermittent jet plantsShortest distanceShort distance

The invention relates to a detonation chamber of a pulse detonation engine, which is characterized in that a plurality of detonation enhancing devices are arranged on the inner wall of an engine, and a distance between every two detonation enhancing devices is 0.5-1 time of the inner diameter of the inner wall of the engine. Each detonation enhancing device comprises a contraction section, a fixing rib and a flow guiding section. The contraction section forming a gradually contracted flow channel is arranged along the air inlet direction and then in linkage with the flow guiding section. Compared with a common Schelkin spirally-mutational flow channel, the forward direction flow losses are small, the forward direction flow losses in the detonation chamber is reduced, and the detonation waves can be formed in a short distance. The detonation enhancing devices are not easily ablated, and the service life of the detonation chamber can be effectively improved. Traditional Schelkin spirals are connected with the engine in a welding mode. When the engine works at high frequency, the temperature in the detonation chamber is high, and welding spots are easily ablated to enable the Schelkin spiral to be invalid.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

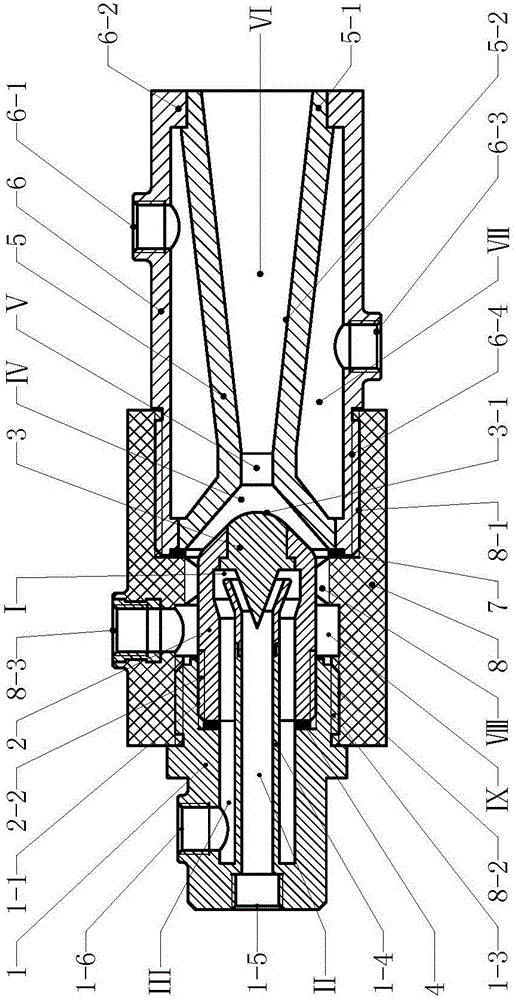

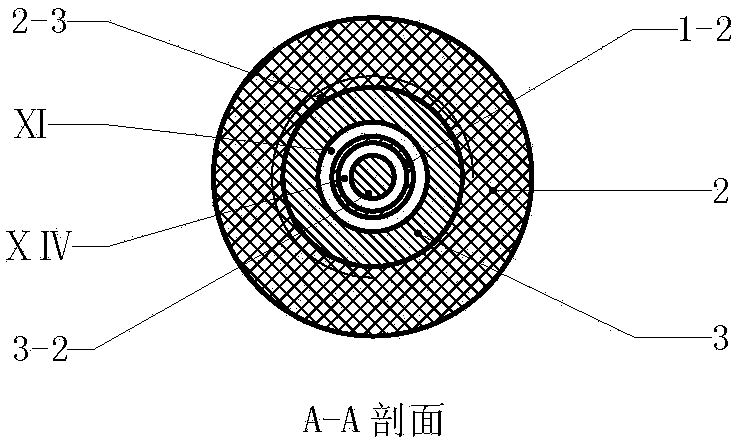

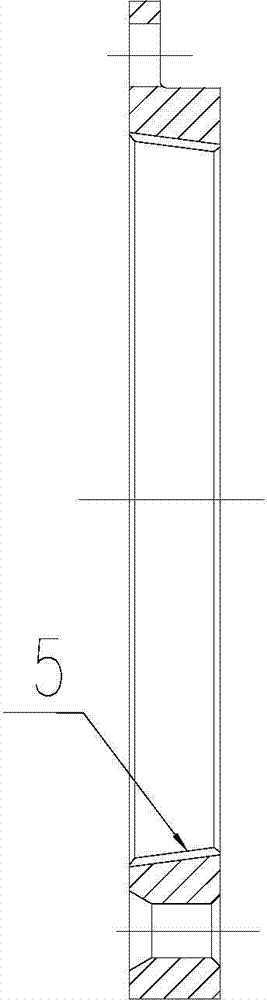

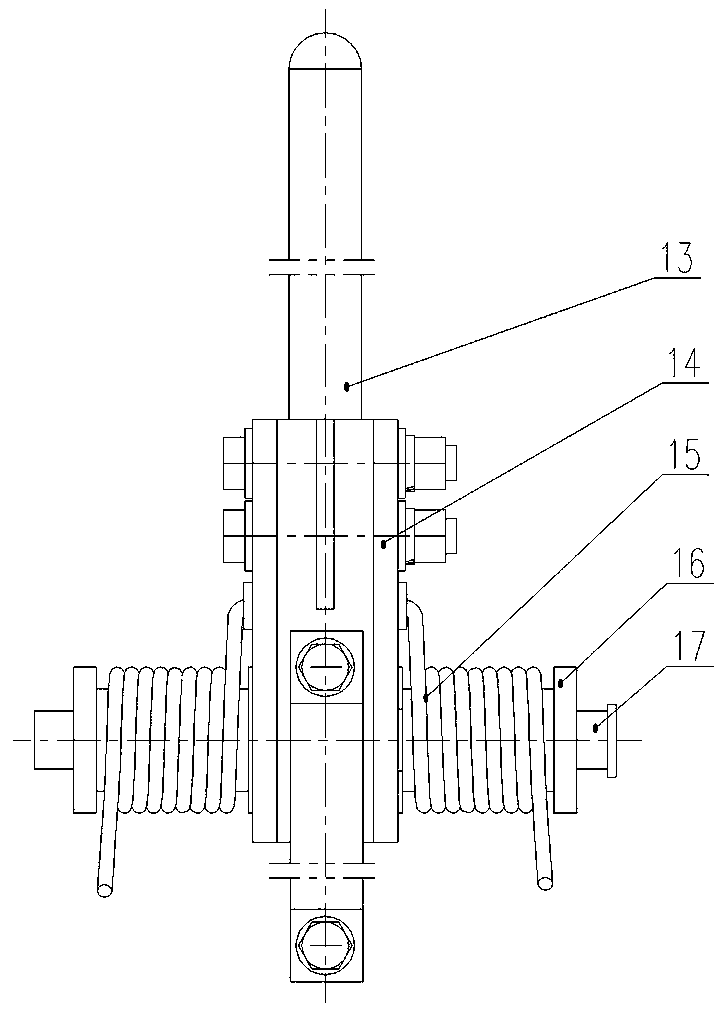

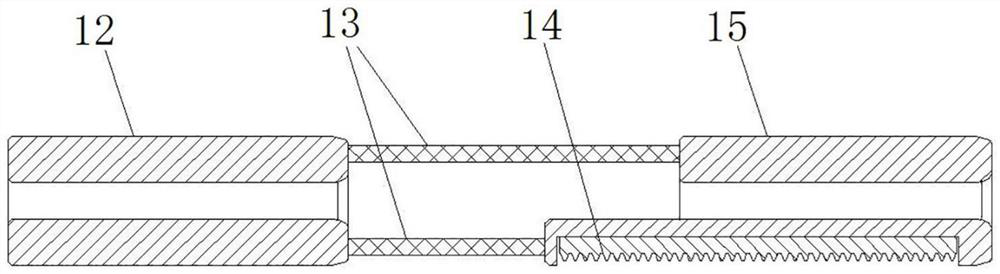

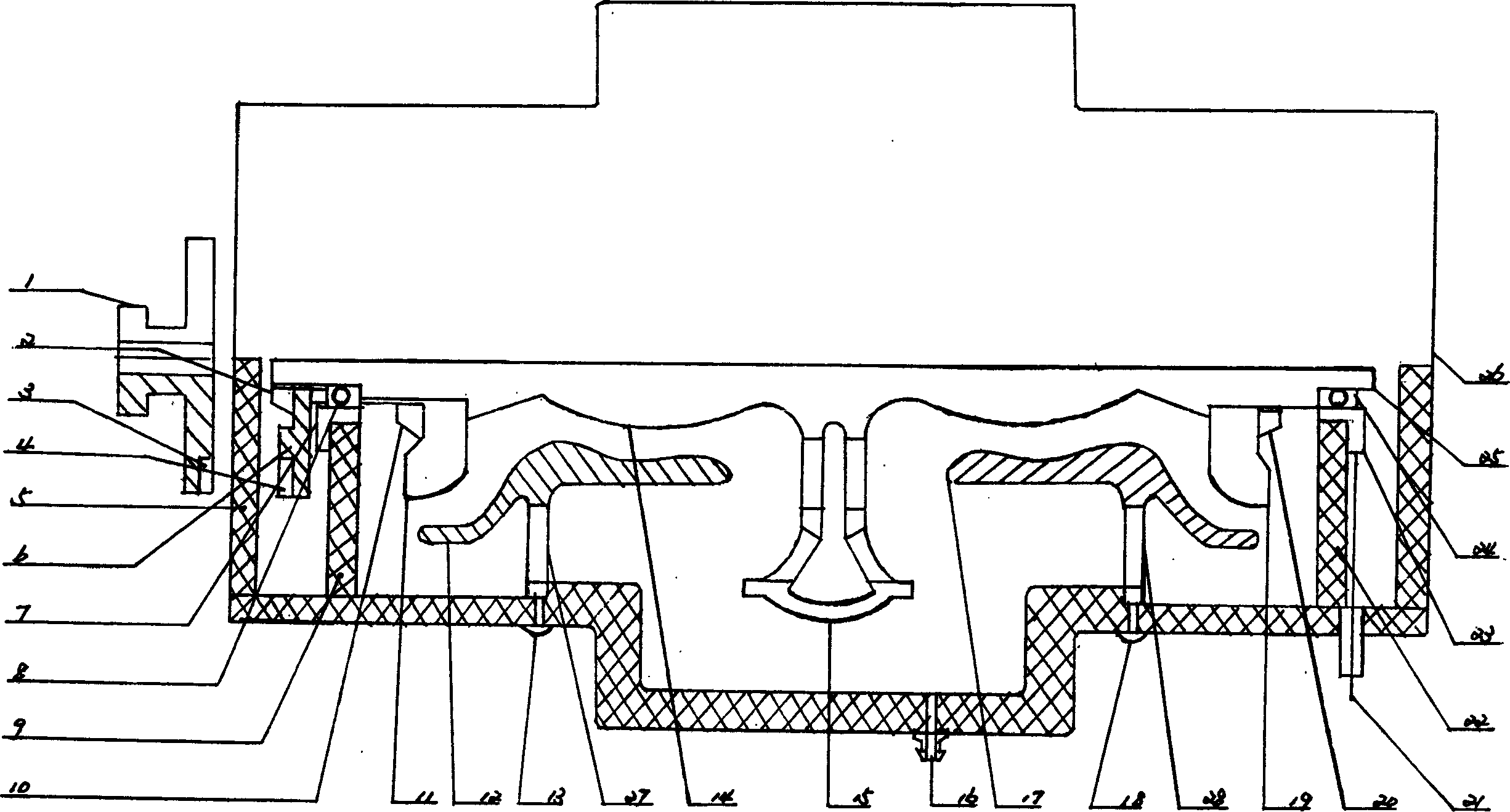

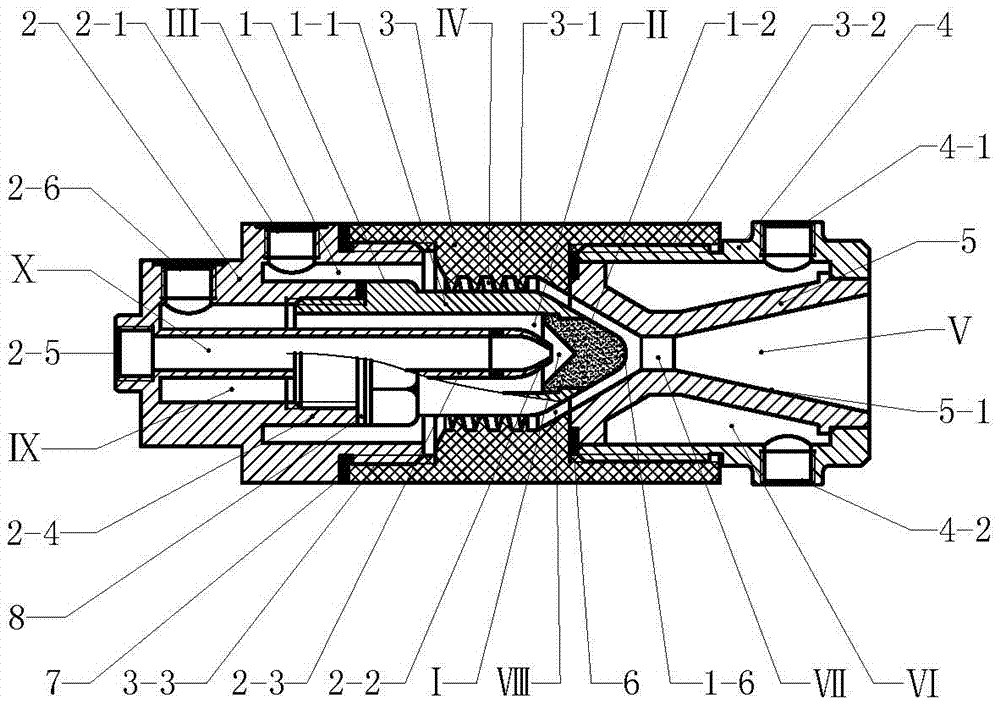

Cathode cooling structure of plasma spraying gun

The invention relates to a cathode cooling structure of a plasma spraying gun. The cathode cooling structure is composed of a rear seat, a cathode sleeve and a cathode head, wherein a guide tube is arranged in a rotation body structure of the rear seat, the cathode sleeve is of a hollow rotation body structure, the internal space of the cathode sleeve forms a cooling cavity, the cathode head is embedded into the front end of the cathode sleeve, the front end of the cathode head extends out of the cathode sleeve, the rear end of the cathode head is a conical cooling tail protrusion, the cooling tail protrusion extends into the cooling cavity, the guide tube on the rear seat extends into the cooling cavity of the cathode sleeve, and a water outlet of the guide tube surrounds the cooling tail protrusion at the rear end of the cathode head. The space between the outer wall of the guide tube and a rear seat wall body serves as a water return channel, the internal space of the guide tube serves as a guiding channel, a cooling water input interface is communicated with the guiding channel, the guiding channel is communicated with the water return channel through the surrounding space of the cooling tail protrusion at the rear end of the cathode head. The cathode cooling structure cools the cathode head in a close flushing mode and can quickly carry away heat of the cathode head and enable a cathode not to be easily ablated.

Owner:周开根

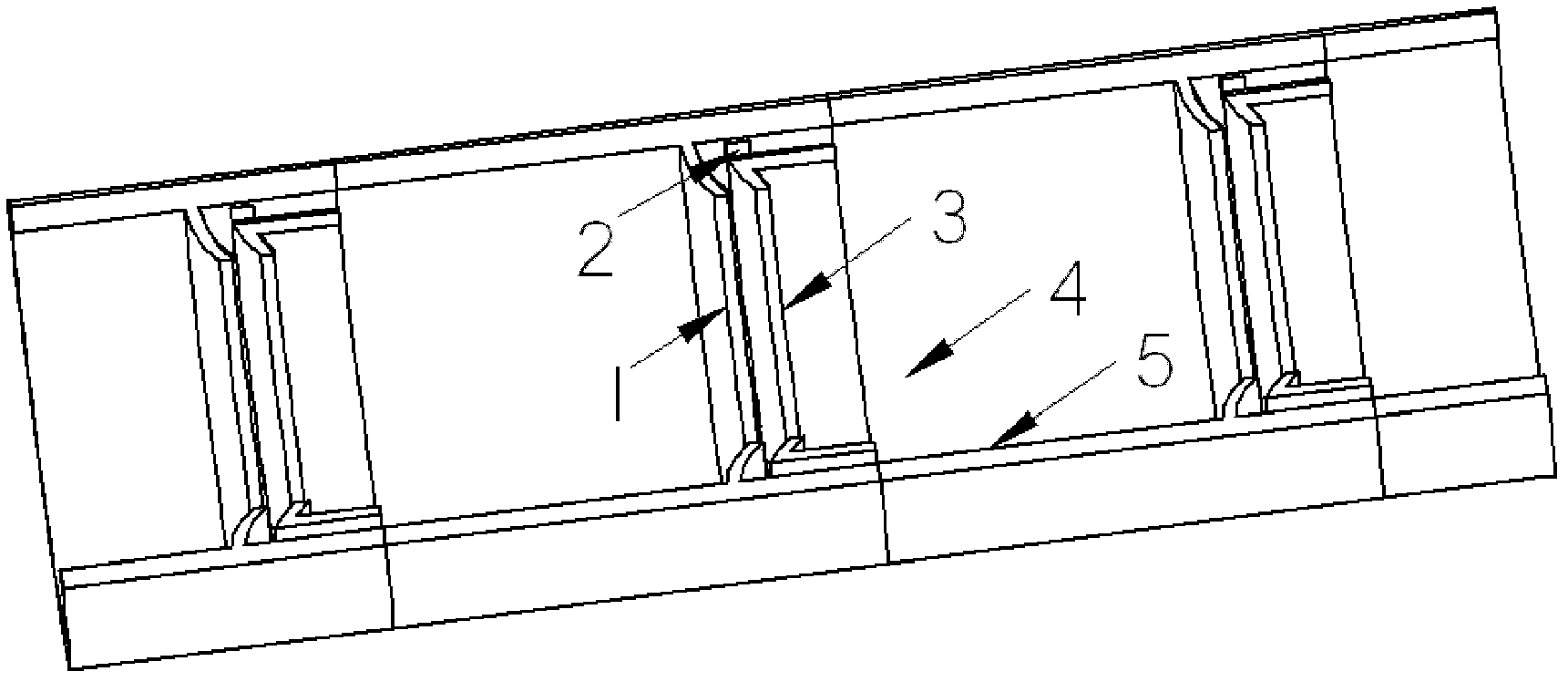

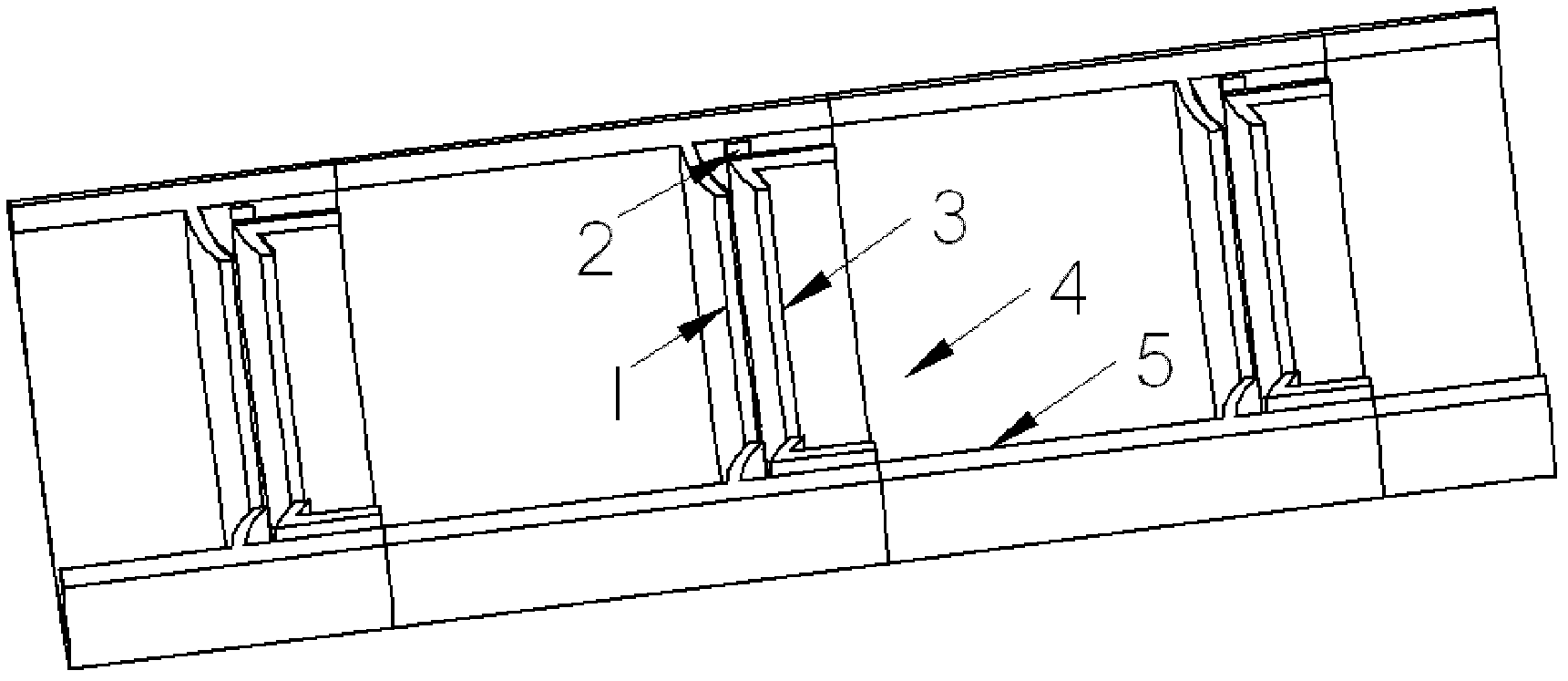

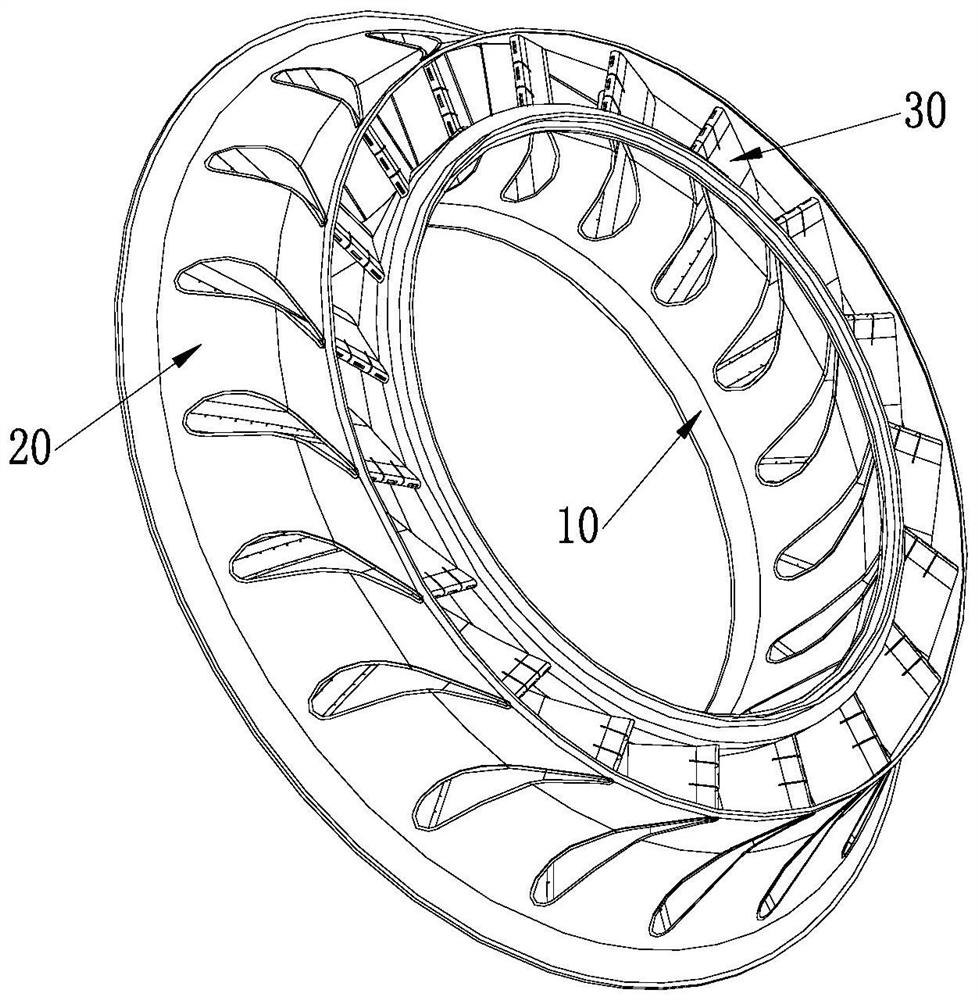

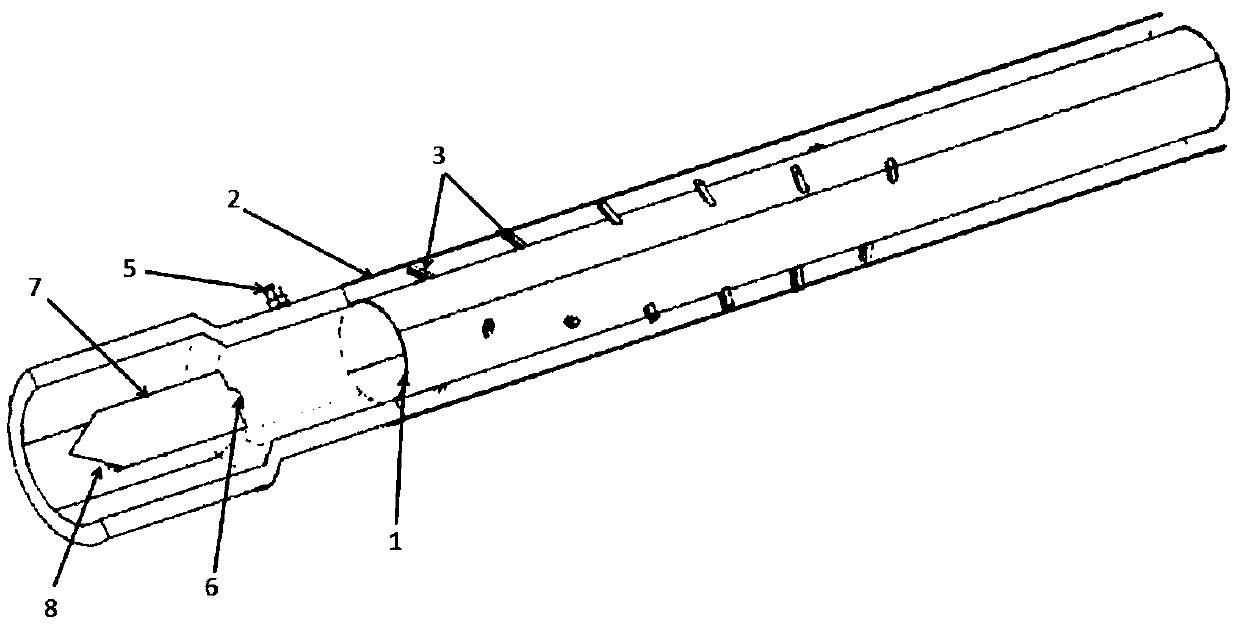

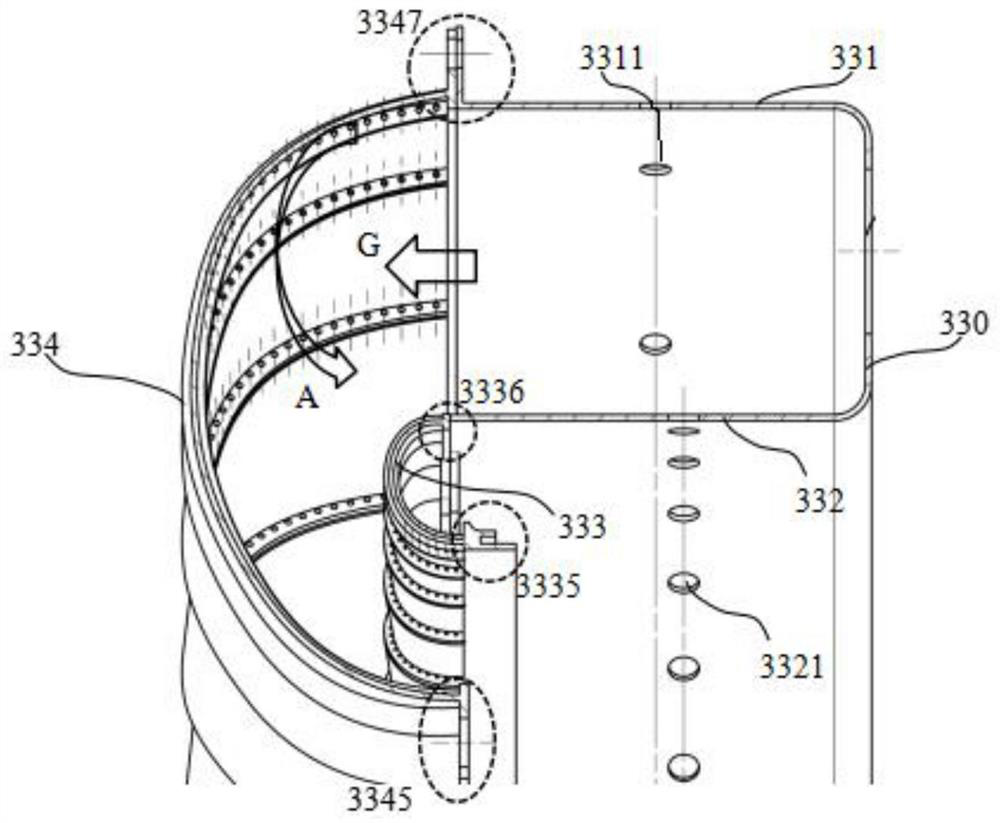

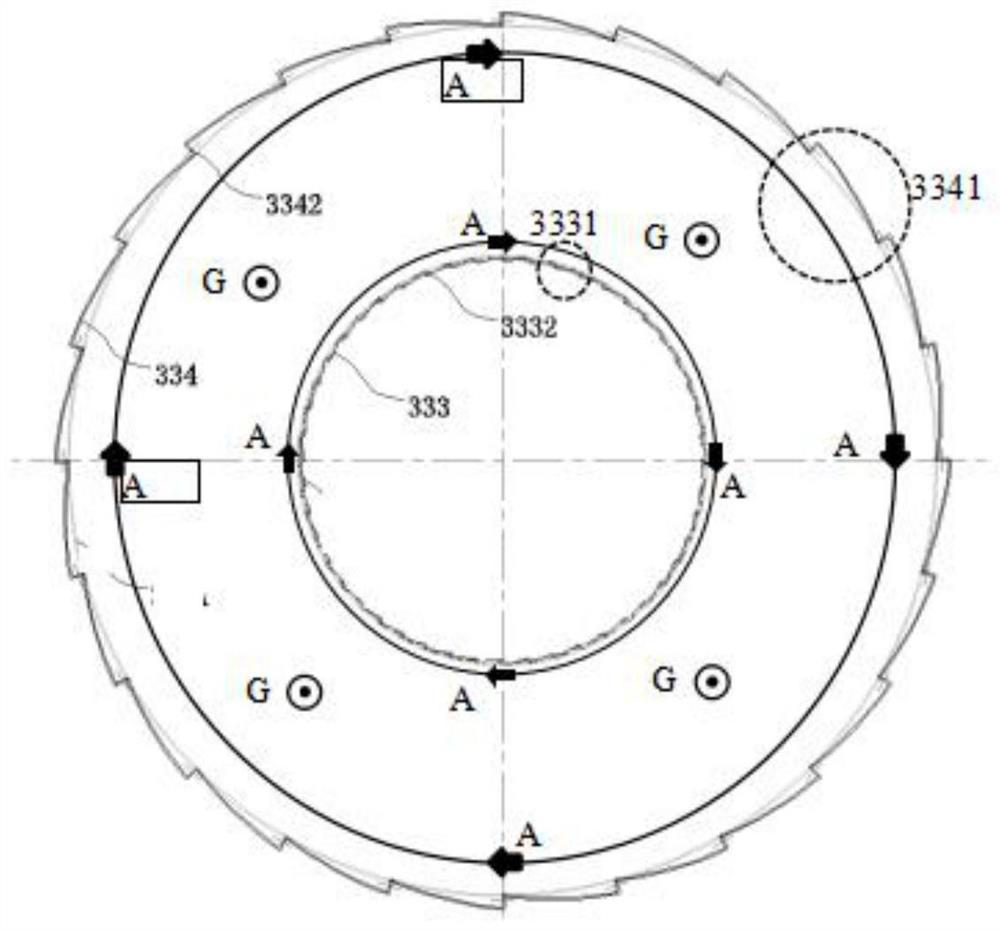

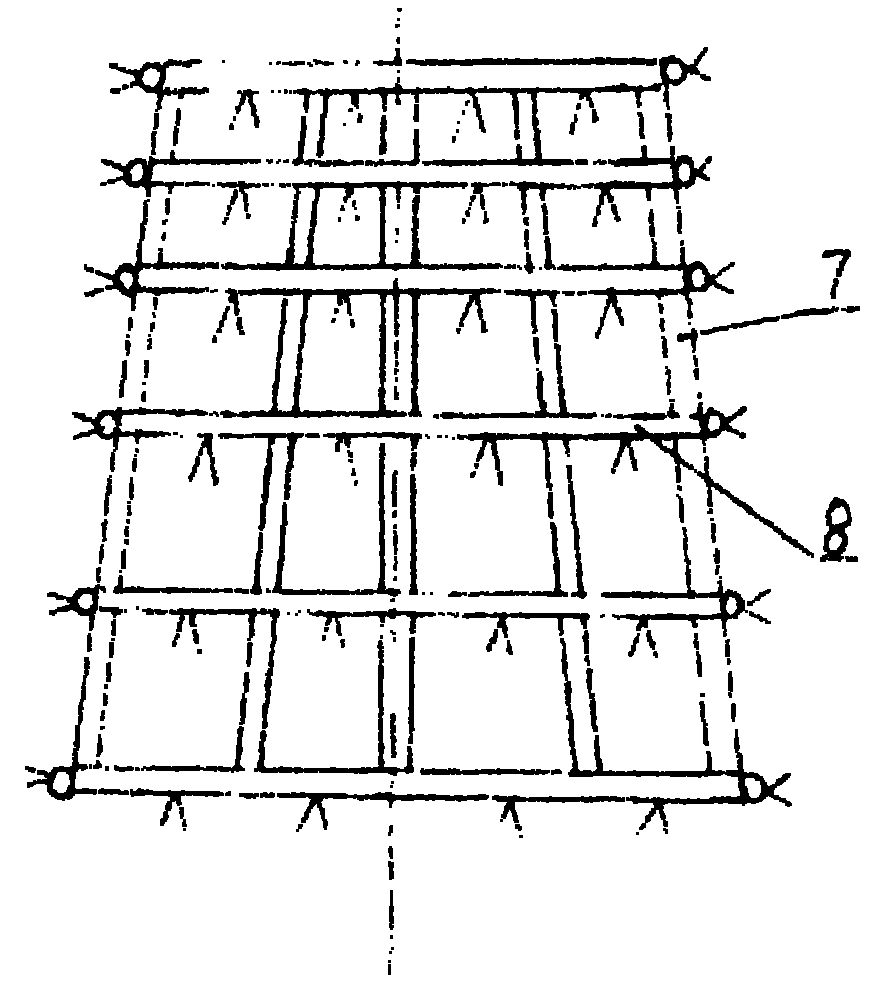

Pulse-detonation engine combustion chamber

InactiveCN107339166ASmall flow resistanceReduce ablative effectIntermittent jet plantsRocket engine plantsCombustion chamberClockwise

The invention discloses a pulse-detonation engine combustion chamber, and belongs to the technical field of detonation engines. A plurality of rows of gas inlet devices are arranged on a gas inlet path housing and the combustion chamber wall surface; and every two rows of pneumatic gas inlet devices are spaced by a distance which is 0.5-1 time the diameter of the combustion chamber. Each gas inlet device is composed of a drainage section and a gas inlet, wherein the gas inlet path housing defines a circular ring shaped secondary gas inlet path, the drainage section is in the form of a hollow cylinder connecting the gas inlet path housing to the engine wall surface, the cylinder has the same angles of inclination in the axial direction and the peripheral direction of an engine, and a plurality of gas inlets are formed in the front wall surface of the cylinder. The plurality of rows of gas inlet devices are uniformly distributed in a staggered mode in the peripheral direction of the combustion chamber, and positions of the rear row of gas inlet devices are determined by rotating positions of the front row of gas inlet devices clockwise. Other parts are not arranged inside the combustion chamber, so that the service life of the combustion chamber is long; and the drainage sections are arranged outside the combustion chamber, so that internal flow resistance of the detonation chamber is effectively reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

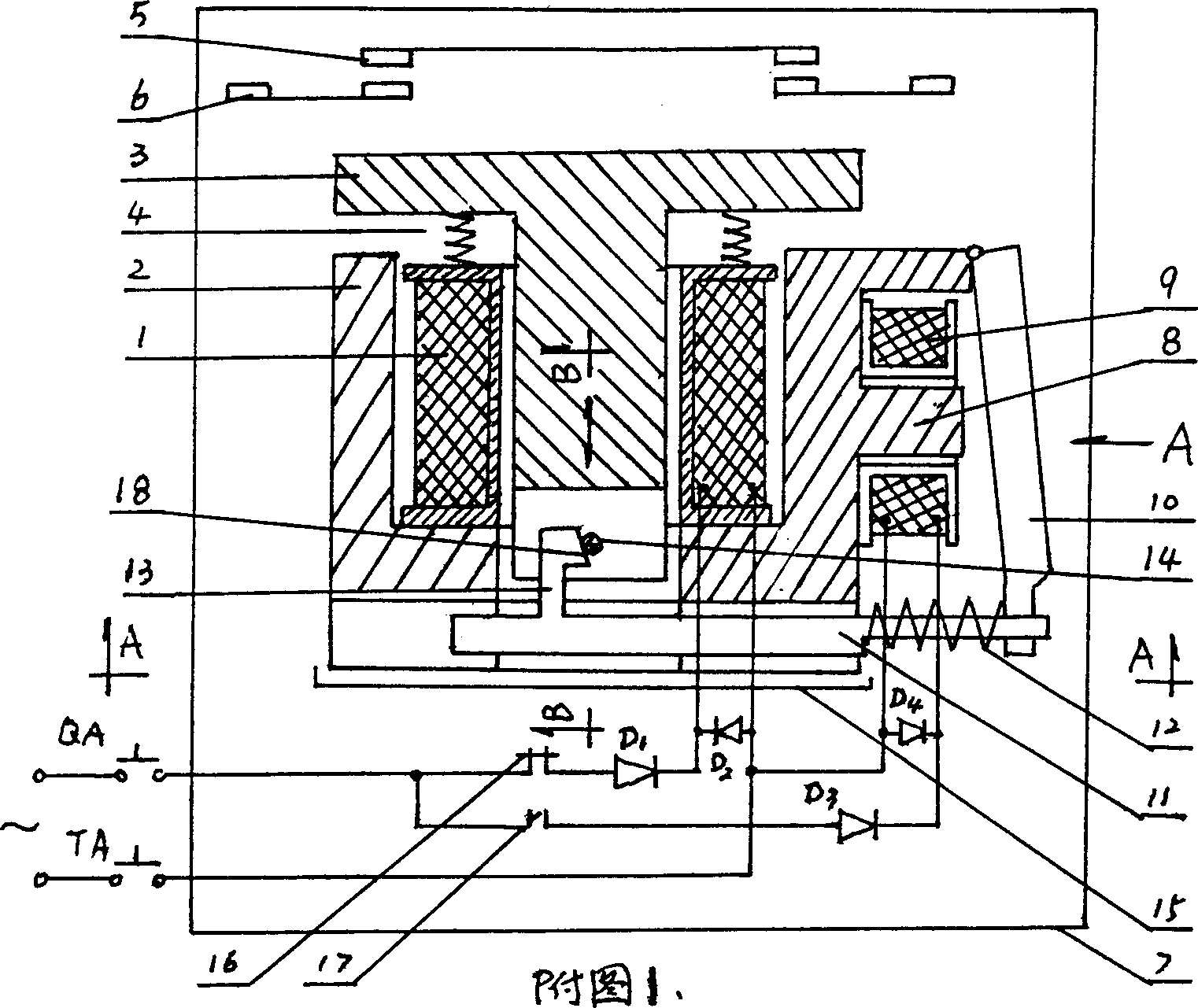

Mechanical self-latching type ac contact means

InactiveCN1107963CNo power consumptionNo electromagnetic noiseNon-polarised relaysEngineeringControl circuit

It has not only major structure of general contactor but also has secondary static iron-core, as well as corollary secondary coil and locker armature which can drive locking bolt to lock or release lockpin by locking core and controll locking or releasing of dynamic iron core thus to control on or off in controlled circuit. The advantages are: the two coils are only energized in the moment that controlled circuit is actuated to on or released to off, the contactor has no power dissipation, electromagnetic noise and vibration when the controlled circuit is working, safe and reliable operate and release, long service life, rational structure, simple mfg. process and low cost.

Owner:孙凤广

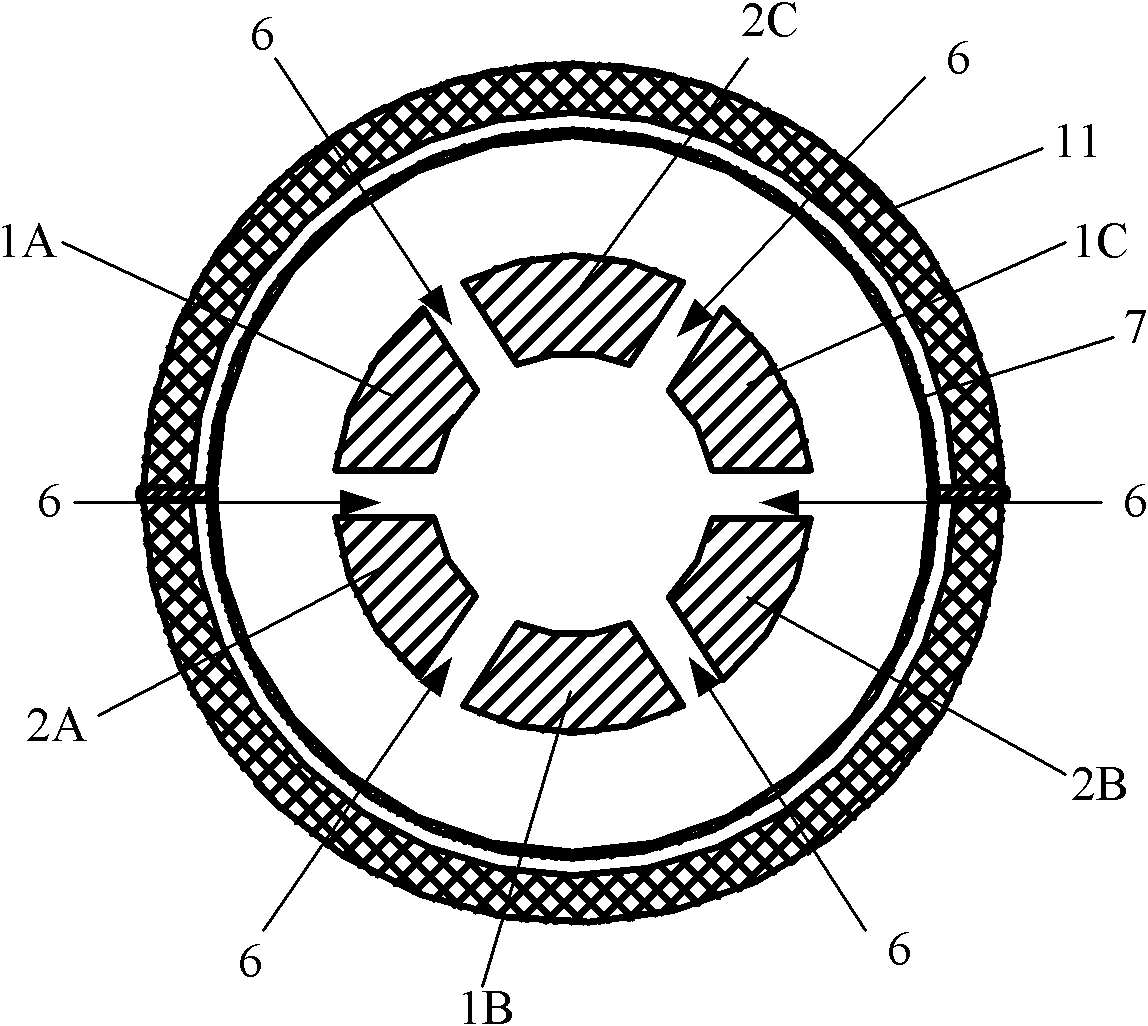

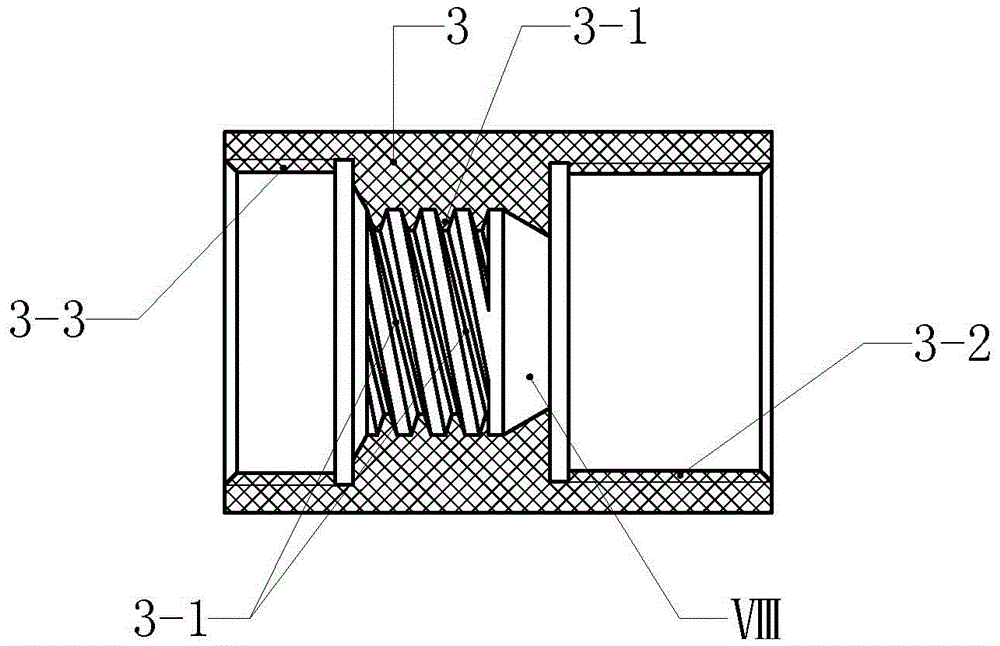

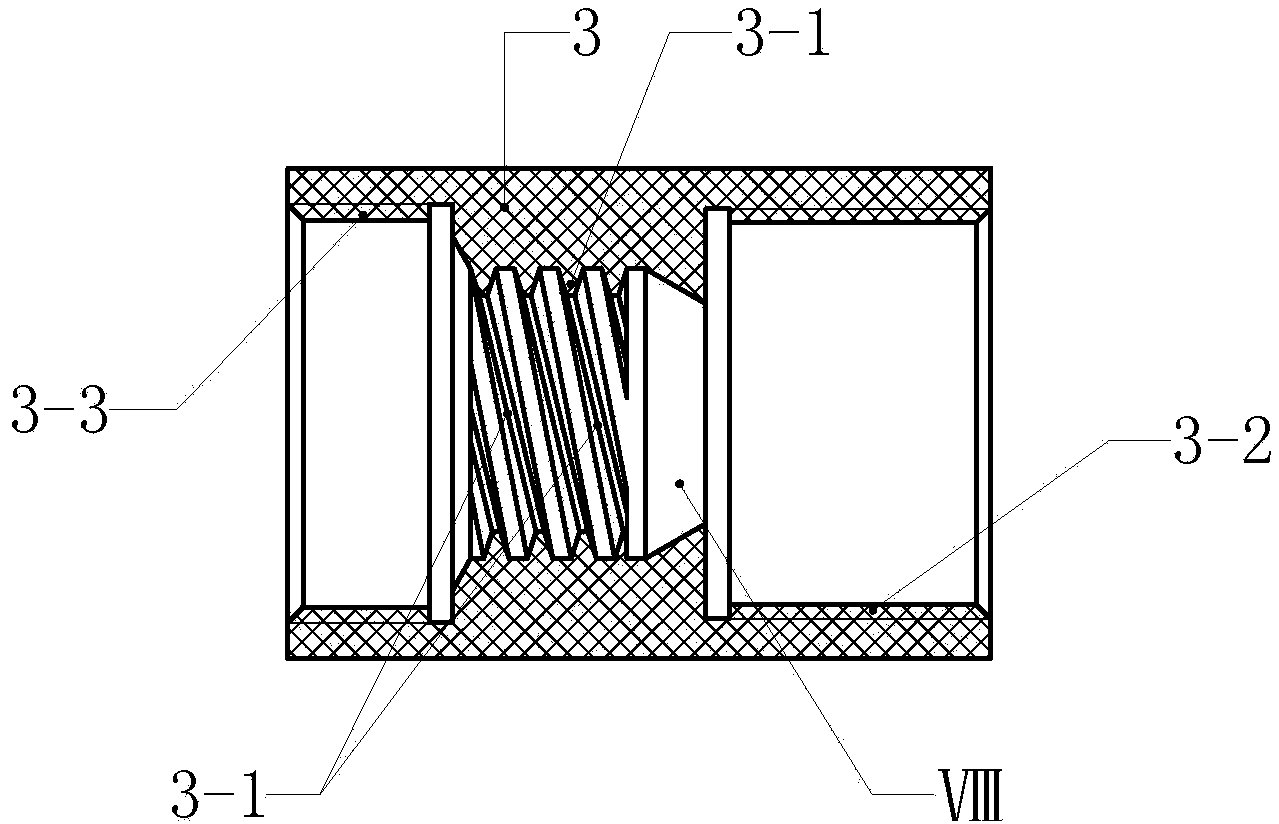

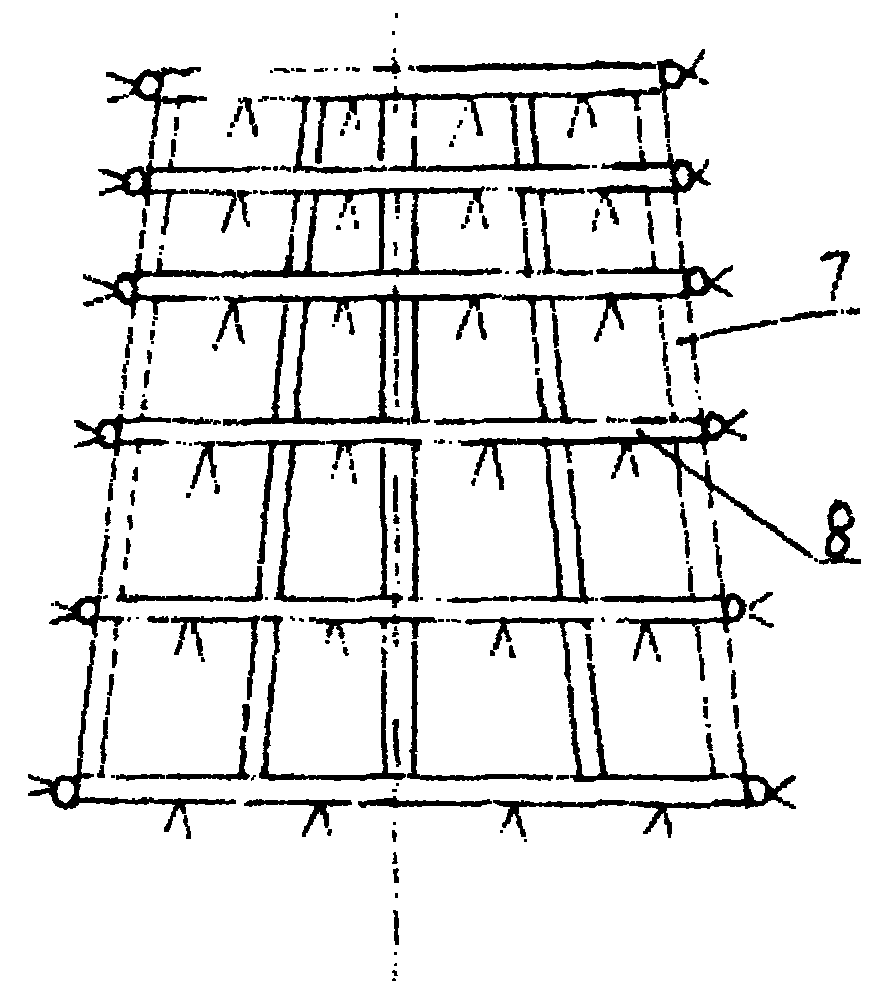

Composite cathode for plasma spray gun

InactiveCN104333969AImprove cooling effectExtended service lifePlasma techniqueComposite cathodeEngineering

A composite cathode for a plasma spray gun relates to a cathode structure of the plasma spray gun and is formed by a cathode sleeve and a cathode head. The cathode sleeve is in a hollow rotation body structure; the cathode head is embedded to the inner space at the front portion of the cathode sleeve; the front end of the cathode head extends out of the cathode sleeve; the embedded section of the cathode head is in a cylinder structure; the inner space of the cathode sleeve at the back end of the cylinder structure forms a cooling cavity; the back end of the cylinder structure of the cathode head is a flow guidance cone which is reduced gradually backwards; the axis of the flow guidance cone is overlapped with the axis of the embedded section; the circumference of the flow guidance cone is provided with a plurality of cooling rib plates; the cooling rib plates and the cathode head are integrated in a radial arrangement manner; the flow guidance cone and the cooling rib plates are arranged in the cooling cavity; and spaces between the plurality of cooling rib plates form cooling branch grooves. According to the composite cathode, the cathode is divided into two components to carry out processing, thereby making production simple, improving processing efficiency of the components, and saving material cost; and the composite cathode is suitable for a washing cooling mode, and heat at the head portion of the cathode can be removed quickly.

Owner:周开根

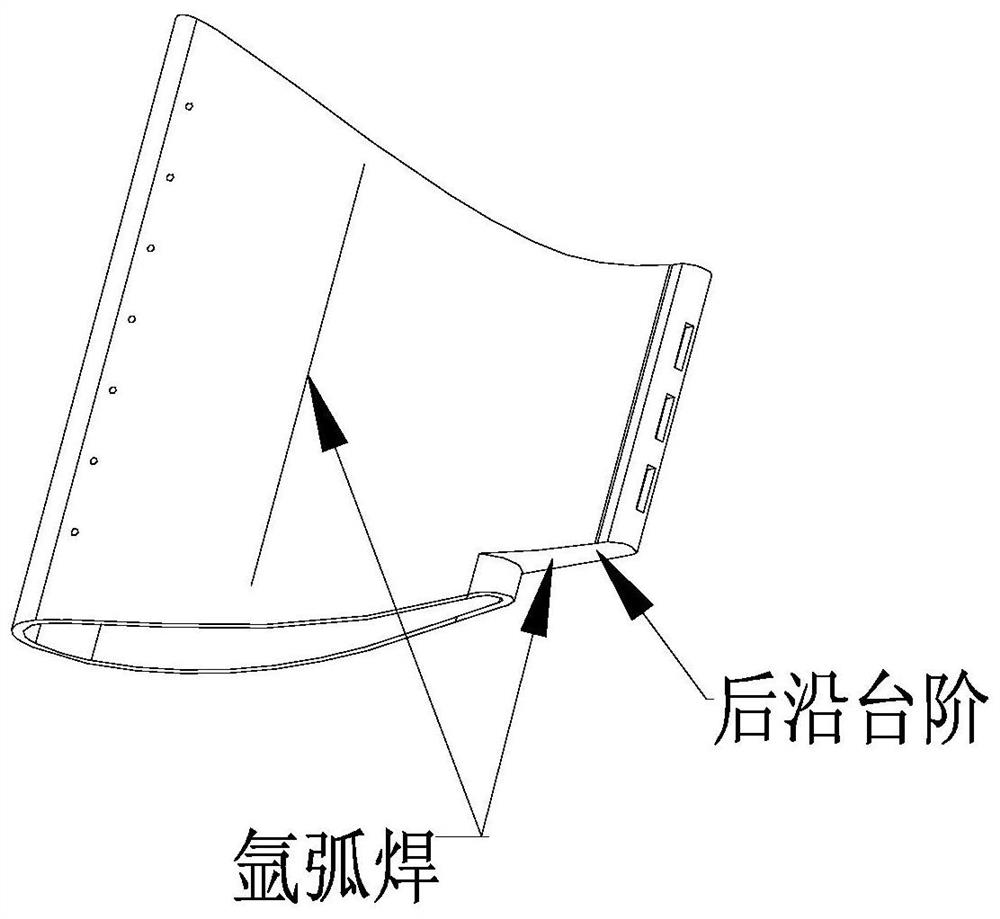

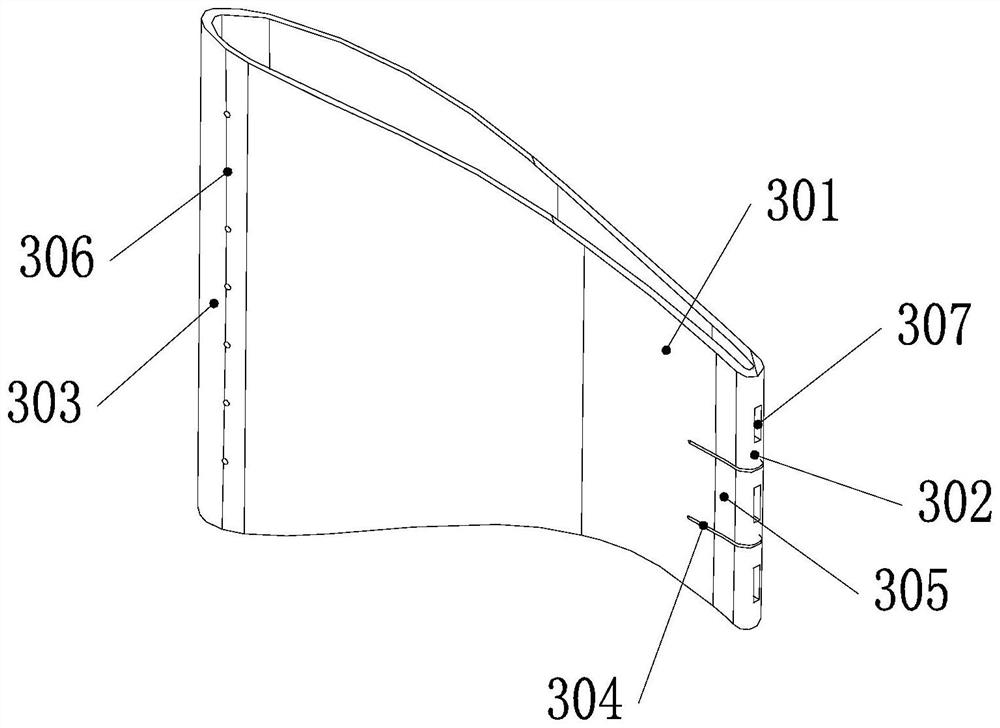

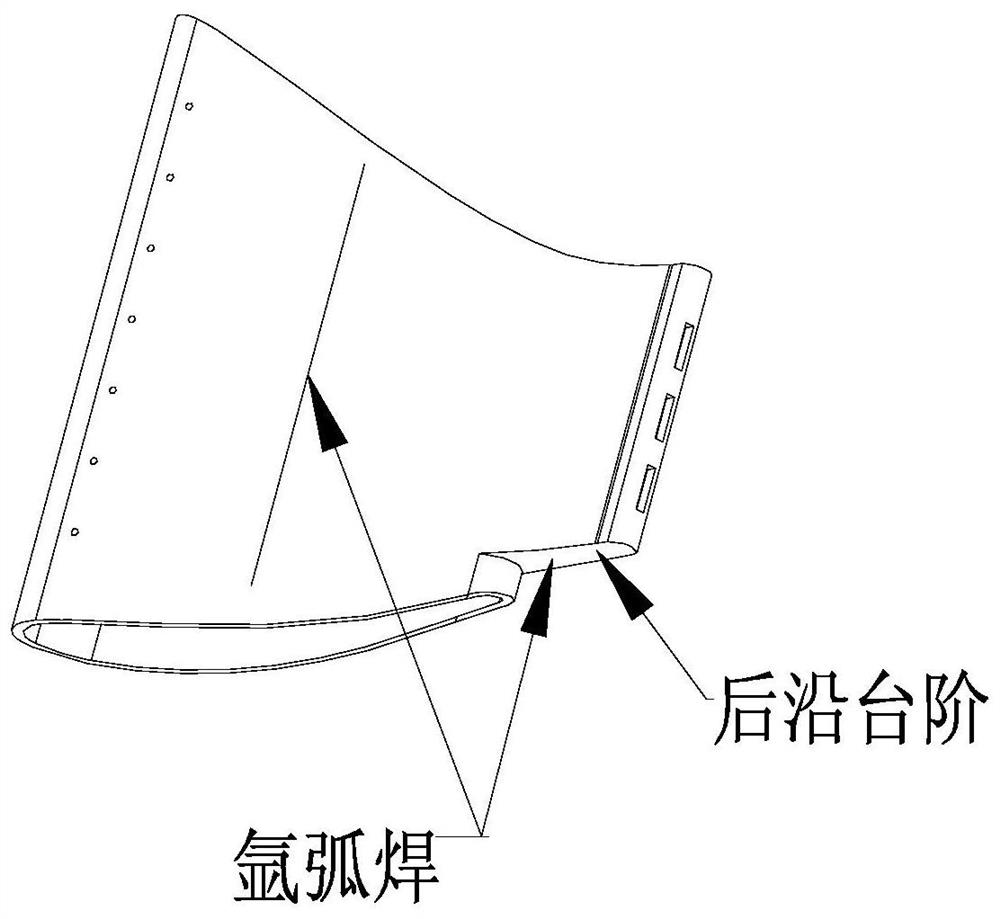

Adjustable turbine guiding device and forming method

ActiveCN111828099AIncrease flexibilityImprove cooling effectEfficient propulsion technologiesStatorsClassical mechanicsFront edge

The invention discloses an adjustable turbine guiding device and a forming method. The device comprises an annular inner ring assembly, an annular outer ring assembly and guiding blades, wherein the inner ring assembly is coaxially sleeved with the outer ring assembly, and the guiding blades are connected between the inner ring assembly and the outer ring assembly. The tail edge end faces of the guiding blades are provided with deformation adjusting seams extending towards the front edges of the guiding blades, the deformation adjusting seams communicate with blade basins and blade backs of the guiding blades, and the deformation adjusting seams are used for enabling the tail edges of one sides of the guiding blades to form angle-adjustable auxiliary wings for adjusting the direction of airflow flowing through the blade basins of the guiding blades and the flow area between every two adjacent guiding blades.

Owner:CHINA HANGFA SOUTH IND CO LTD

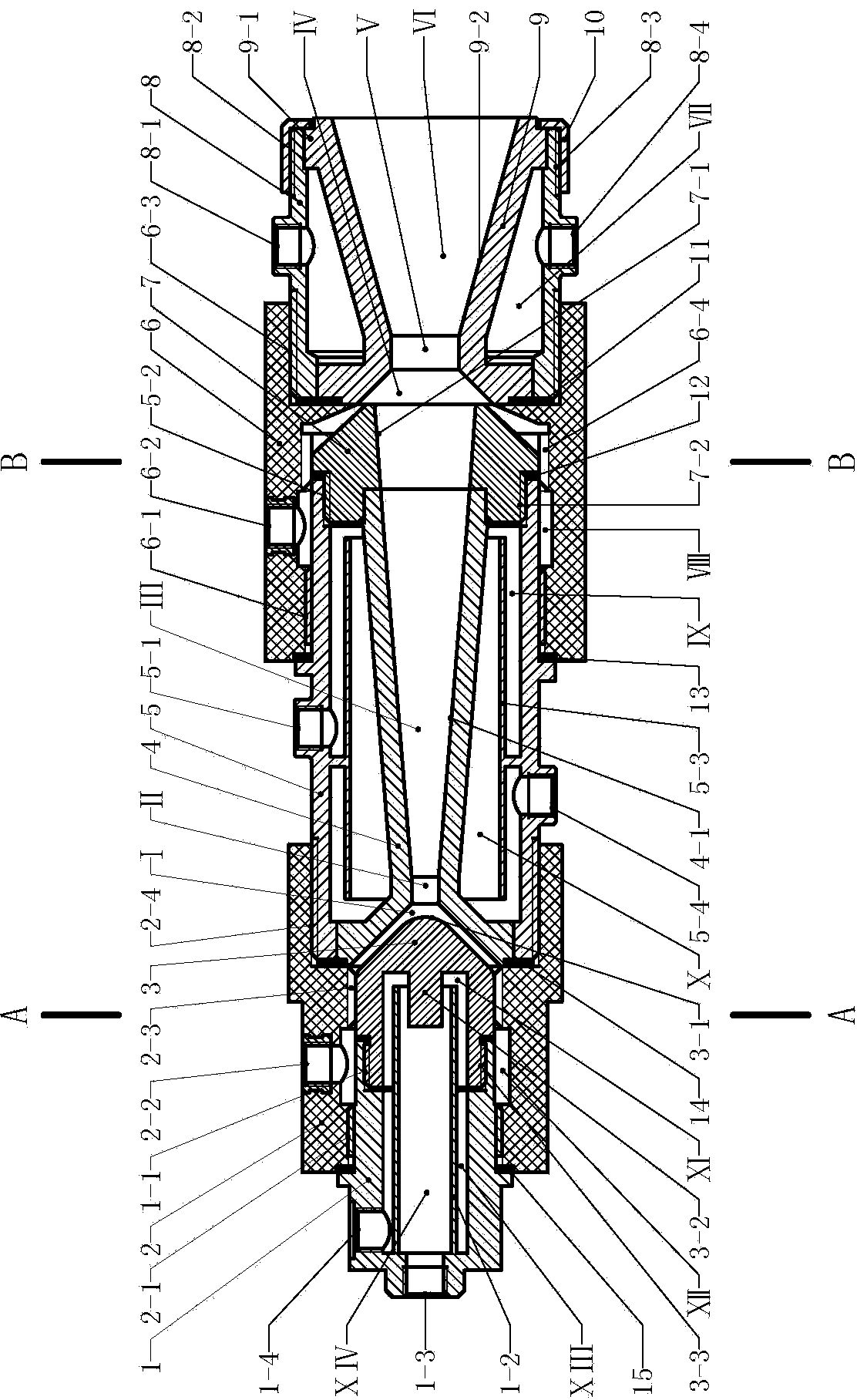

Two-stage arc plasma torch

The invention discloses a two-stage arc plasma torch, and relates to a plasma device. The two-stage arc plasma torch is composed of a back base, a first cathode, a first insulating torch frame, a first anode, a second cathode, a first pipe sleeve, a second insulating torch frame, a second anode and a second pipe sleeve, wherein the first cathode is installed in an installing spiral opening in the front end of the center of a rotating body of the back base, the second cathode is connected to the front end of the first anode, the first anode and the second cathode are embedded in the first pipe sleeve, the second anode is embedded in the second pipe sleeve, the back base and the first cathode are installed in a rear installing groove of the first insulating torch frame, the first pipe sleeve, the first anode and the second cathode are installed in a front installing groove of the first insulating torch frame and a rear connecting groove opening of the second insulating torch frame, and the second pipe sleeve and the second anode are installed in a front connecting groove opening of the second insulating torch frame (6). Two-stage high-temperature plasma arcs are generated in the plasma torch, the plasma torch can reach a higher processing temperature, and the heating efficiency and the decomposition capacity of the plasma torch are improved.

Owner:重庆顺雅电子科技有限公司

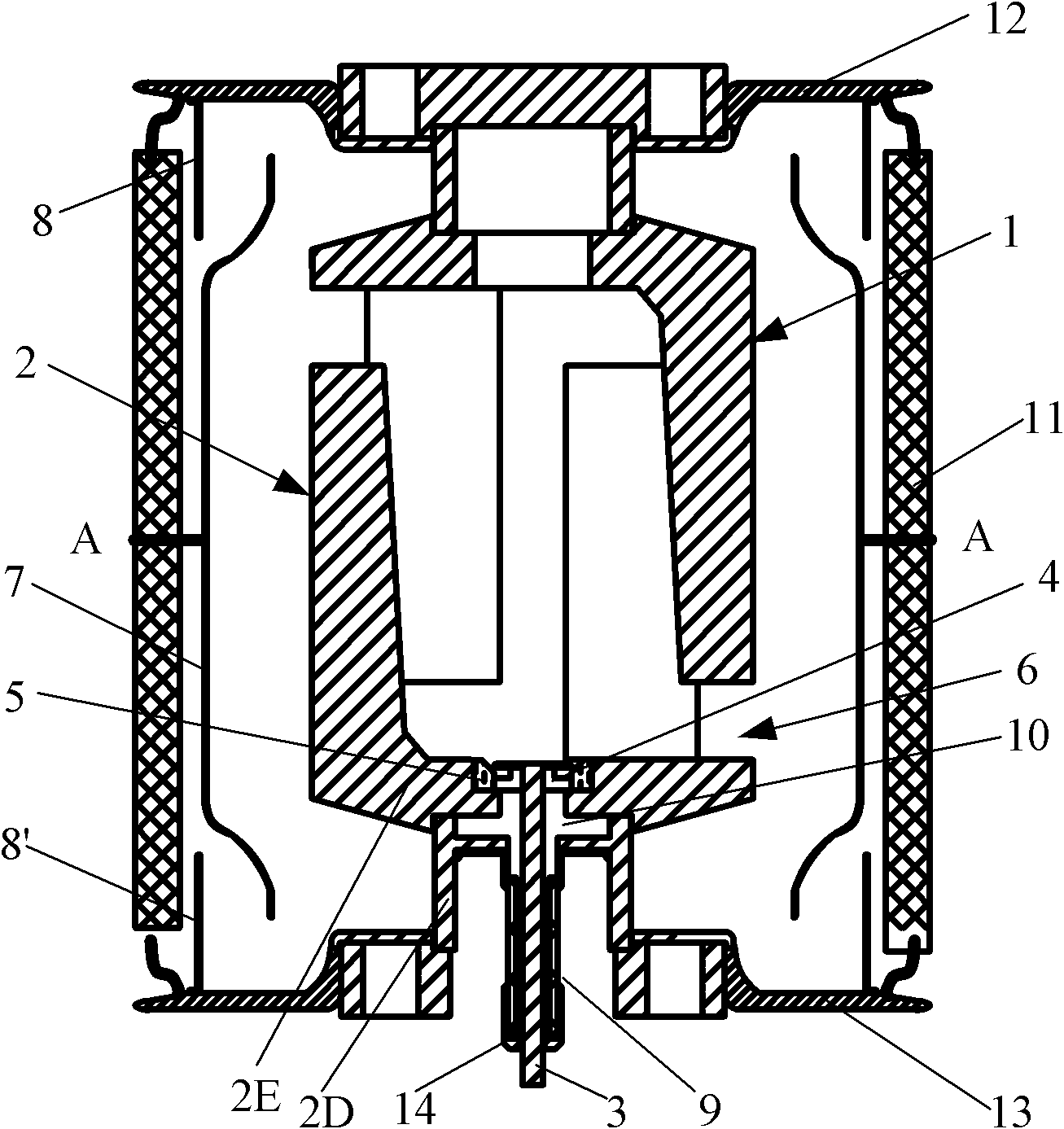

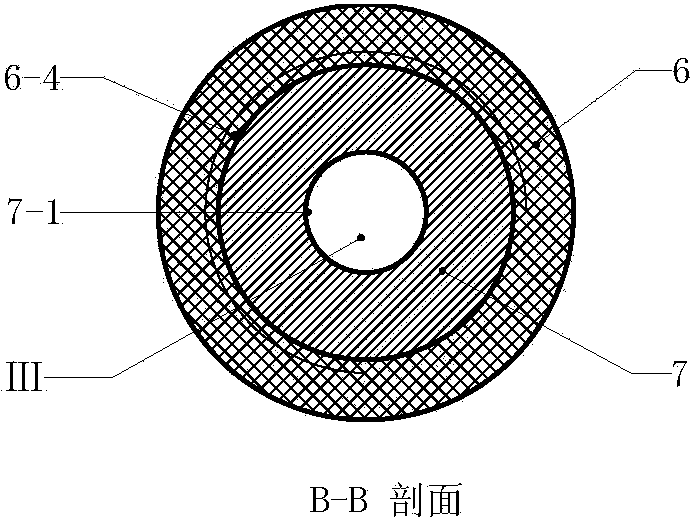

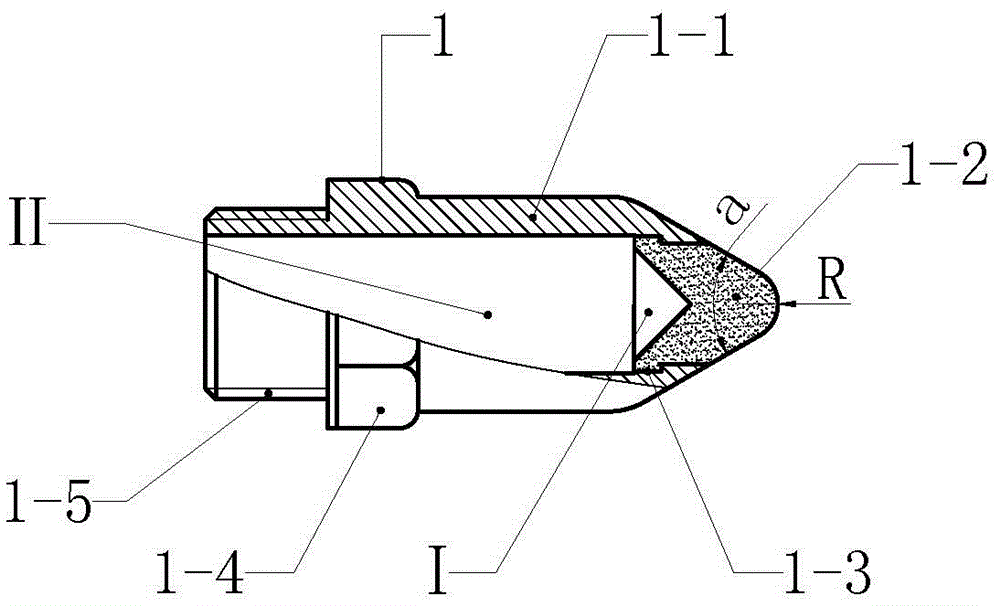

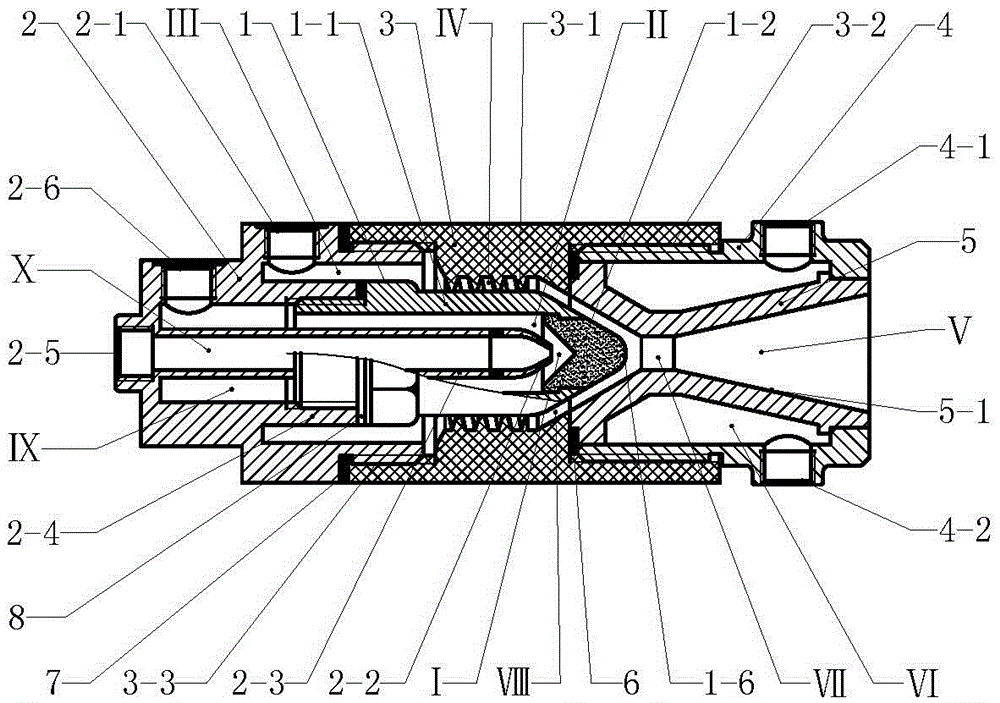

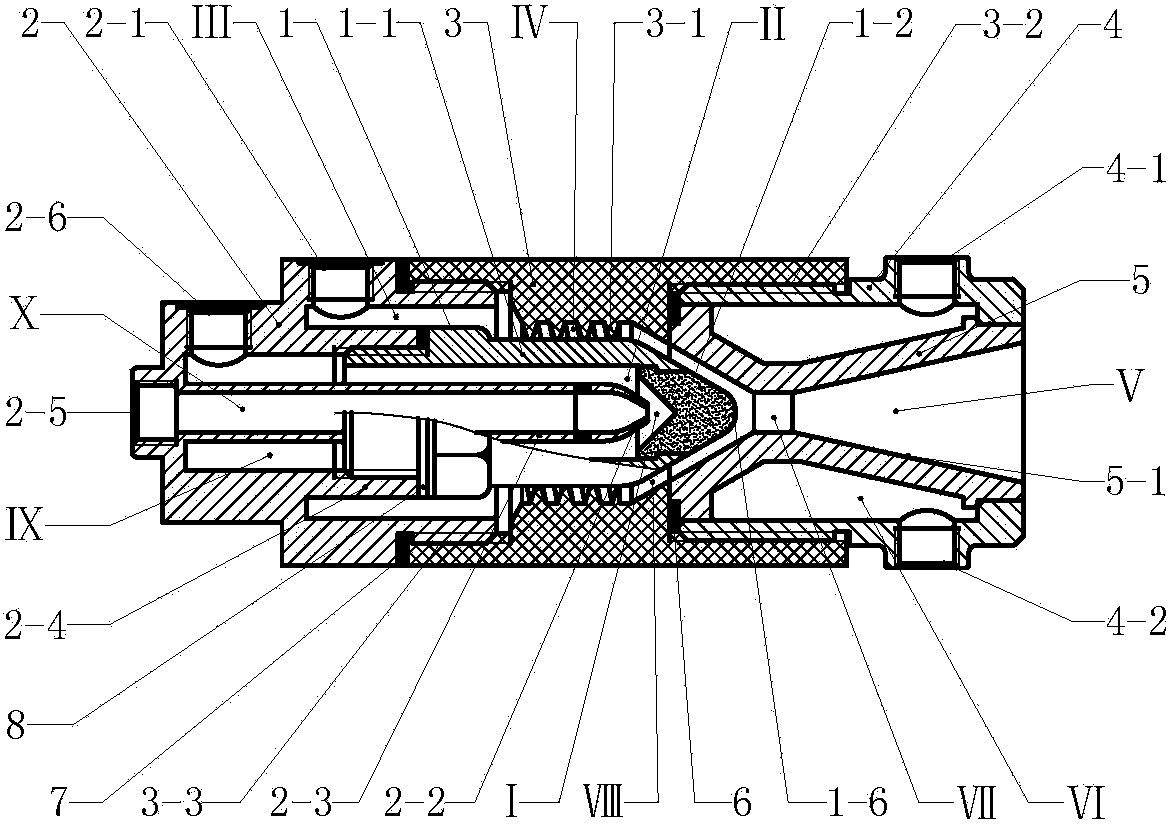

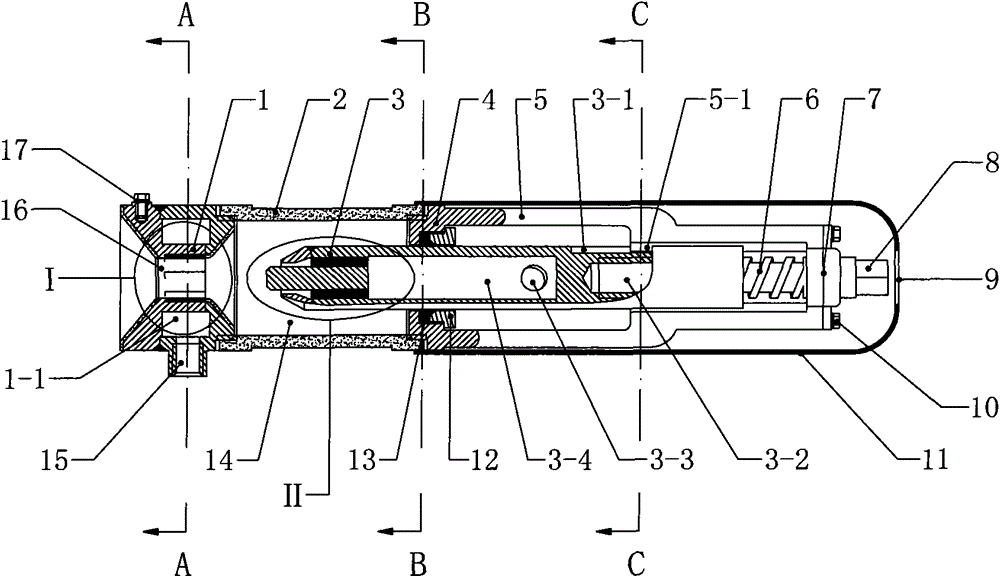

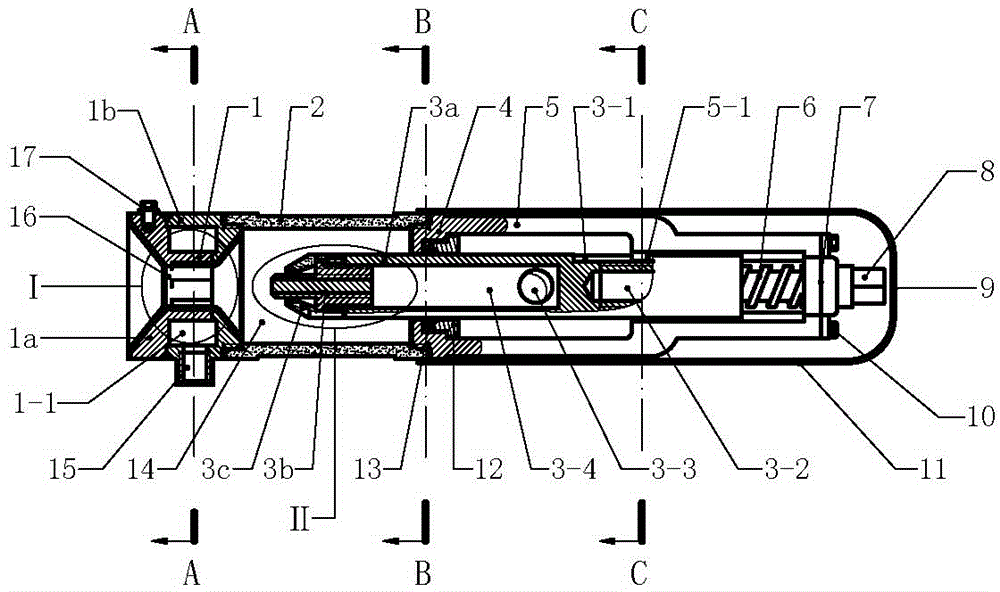

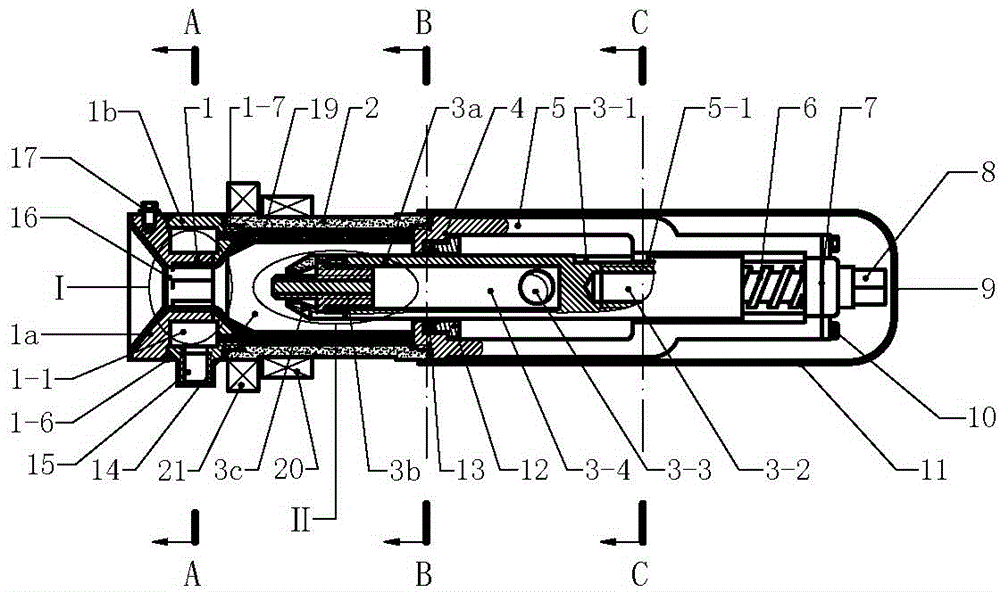

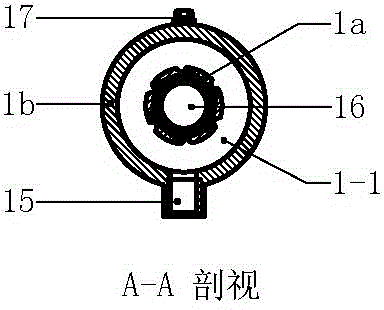

Plasma pyrolysis water spray gun for millipore membrane cathode

ActiveCN106604516ANot easy to ablateOvercome the disadvantage of being easily ablatedPlasma techniqueElectric dischargeFiltration membrane

A plasma pyrolysis water spray gun for a millipore membrane cathode is disclosed and the invention relates to a plasma spray gun. The spray gun consists of a rear seat, the cathode, a spiral fluid director, an anode sheath and an anode. A water supply liquid guide tube and a cathode connecting rod are arranged in a revolving body of the rear seat, the cathode consists of a millipore membrane cathode head and a cathode sleeve, the millipore membrane cathode head has a millipore filtration membrane structure which is formed via metal powder sintering operation, the millipore membrane cathode head is inserted into a wall body of a front part of the cathode sleeve, a spiral liquid guide rib is arranged in the revolving body of the spiral fluid director, a screw pitch space of the spiral liquid guide rib forms a spiral liquid guide passageway, the cathode is connected on a front end of the cathode connecting rod, a rear end of the spiral fluid director is mounted on the rear seat, the anode sheath carrying the anode is mounted on a front end of the spiral fluid director, a head part of the cathode enters an inlet space of a Venturi jet pipe of a rear end of the anode, the inlet space of a Venturi jet pipe forms an electric discharge zone, and an inner space of an expansion segment of the Venturi jet pipe of the anode forms an injection chamber. According to the plasma pyrolysis water spray gun, heat of the cathode head can be rapidly absorbed via latent heat of water vaporization, and therefore the cathode cannot be easily ablated.

Owner:JIANGSU YAFENG ALLOY MATERIAL

Composite alterant for nickel aluminum molybdenum-silicon iron alloy loaded nano-aluminum-silicon oxide ball milling cast iron and preparation method thereof

The invention relates to an alterant for ball milling cast iron, in particular to the composite alterant for the nickel aluminum molybdenum-silicon iron alloy loaded nano-aluminum-silicon oxide ball milling cast iron and a preparation method thereof. The alterant is prepared from the following raw materials, by weight, of 2-3 parts of nano-alumina, 1-2 parts of potassium fluoborate, 2-3 parts of nickel powder, 1-2 parts of aluminum powder, 1-2 parts of molybdenum powder, 0.2-0.4 part of oxidized graphene, 1-2 parts of nano silica, 3-5 parts of expanded graphite powder, 1-2 parts of monazite micro powder, 4-5 parts of ferrosilicon powder with the silicon content being 45%, 0.3-0.4 part of magnesium aluminosilicate, 20-25 parts of ethanol aqueous solutions with the concentration being 5%-10% and 0.4-0.5 part of an addition agent. Nano composite powder bodies and a nickel aluminum molybdenum-silicon iron alloy which are loaded by expanded graphite powder are bonded and loaded mutually to prepare the composite alterant with stable performance. The alterant is stable in high temperature, the nucleating effect is good, and graphite spheroidization is stable and durable. According to the alterant, the graphitizing process is facilitated, the structural organization is improved, strength and abrasion resisting are further improved, and compared with a traditional alterant, using is more convenient and faster, and the additional production cost is reduced.

Owner:徐世云

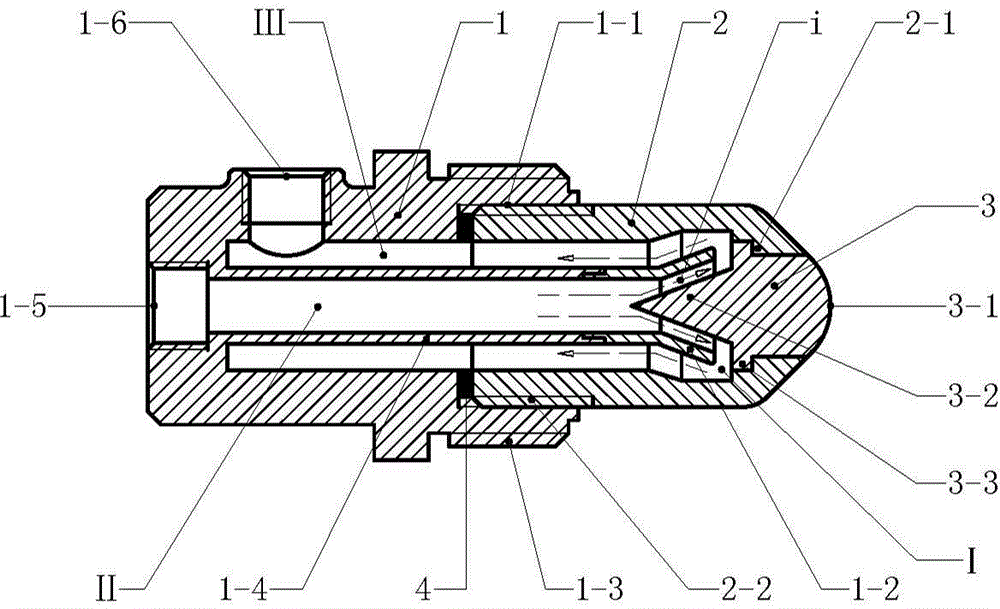

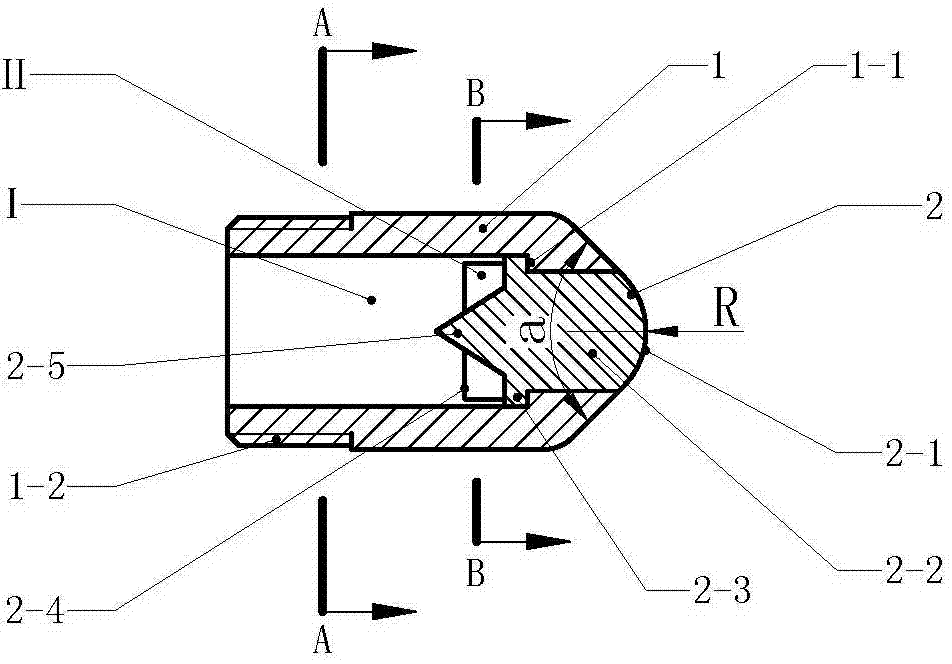

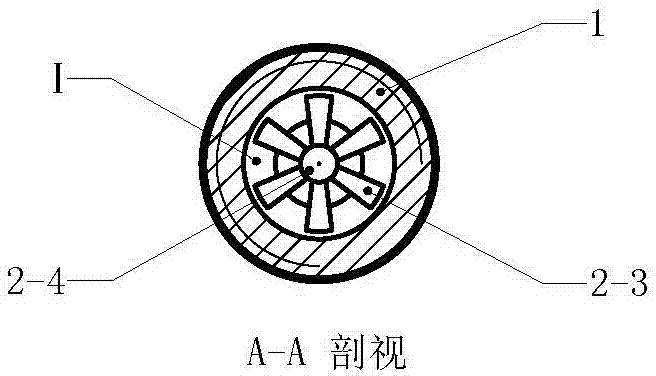

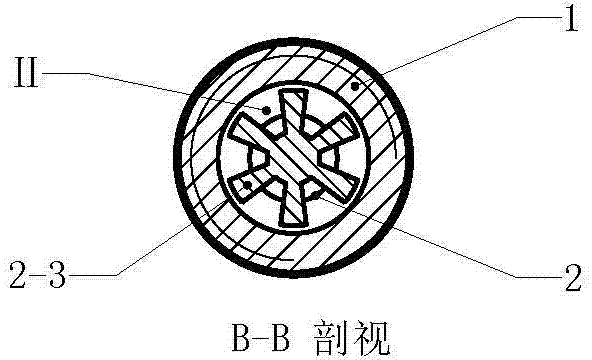

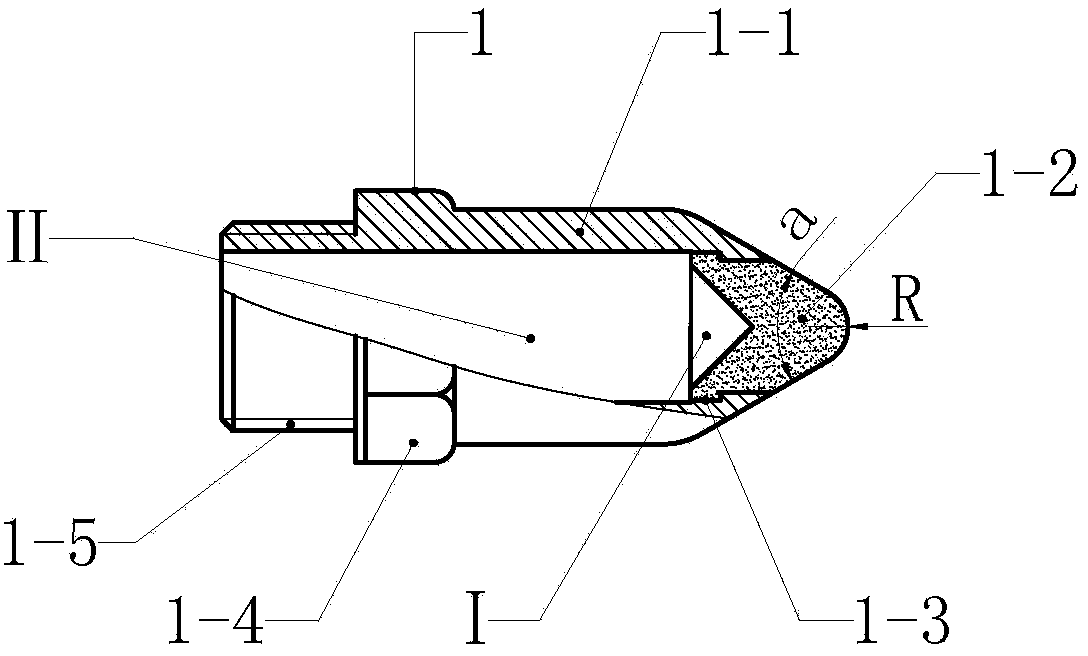

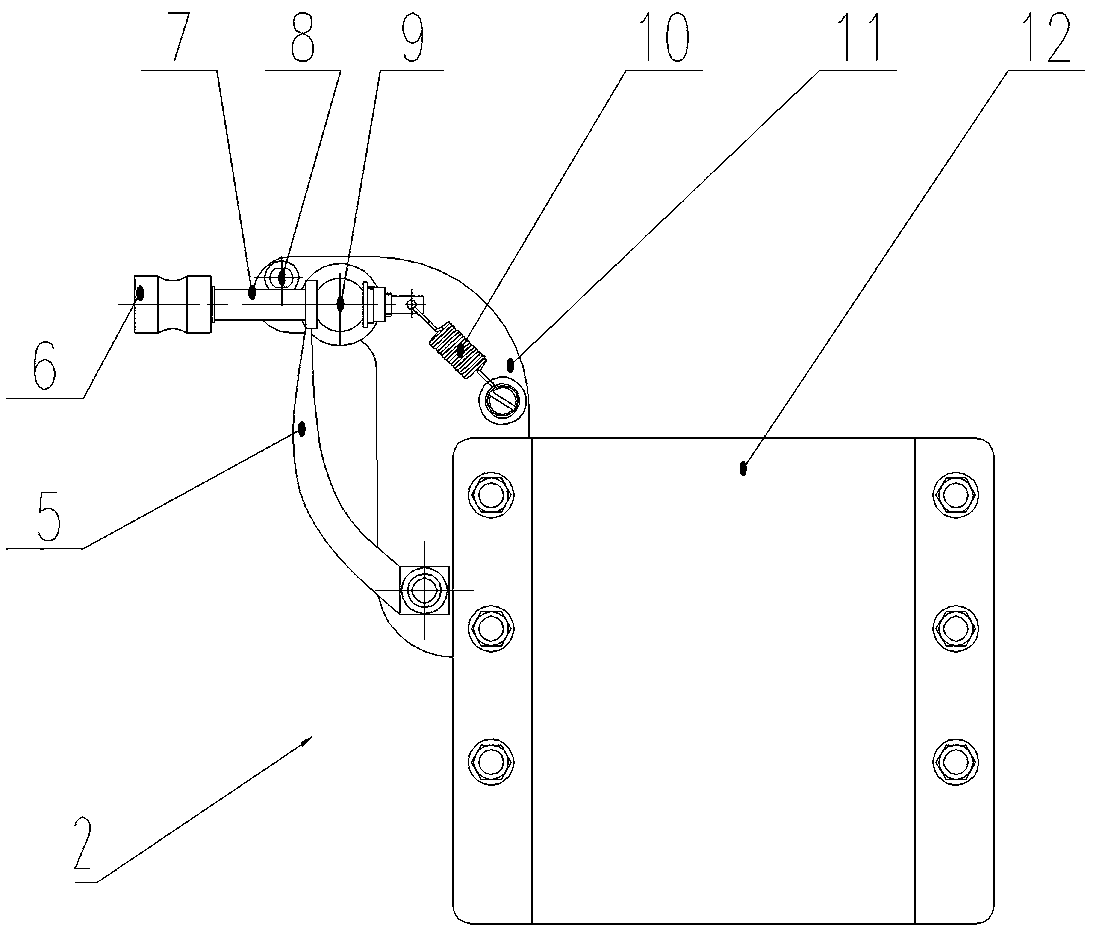

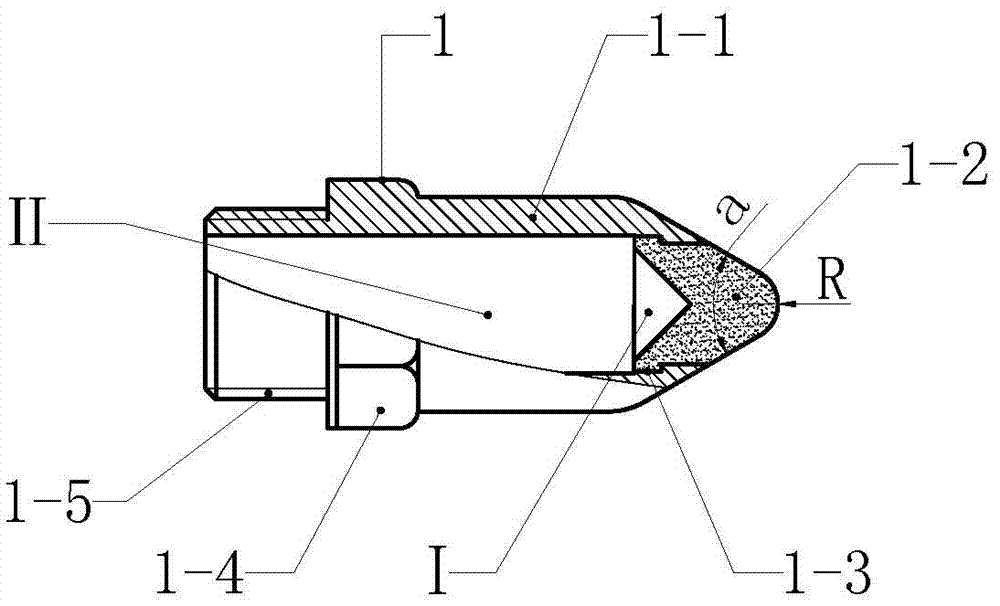

Cathode of microporous membrane structure and plasma pyrolysis water spraying gun

ActiveCN104378903ANot easy to ablateOvercome the disadvantage of being easily ablatedPlasma techniqueLatent heatHeat energy

The invention relates to a plasma spraying gun and discloses a cathode of a microporous membrane structure and a plasma pyrolysis water spraying gun. The cathode is composed of a microporous membrane cathode head and a cathode sleeve, a hydrone filter channel is formed by micropores of the microporous membrane cathode head, the microporous membrane cathode head is embedded in the wall of the front portion of the cathode sleeve, and the head portion of the microporous membrane cathode head stretches out of the front end of the cathode sleeve. The plasma pyrolysis water spraying gun is composed of a rear base, the cathode, a spiral flow diverter, an anode sleeve and an anode, wherein a rotation body of the rear base is internally provided with a water supply guide pipe and a cathode connection rod, a rotation body of the spiral flow diverter is internally provided with a spiral guide rib, the anode is of a Venturi spraying pipe structure and is embedded in the anode sleeve, the space between the outer wall of the anode and the inner wall of the anode sleeve forms a cooling water sleeve, the cathode is connected with the front end of the cathode connection rod of the rear base, the rear end of the spiral flow diverter is installed on the rear base, and the anode sleeve and the anode are installed at the front end of the spiral flow diverter. Heat energy of the cathode head is rapidly absorbed through latent heat of vaporization of water, so that the cathode is not prone to ablation.

Owner:兴化金孔雀实业发展有限公司

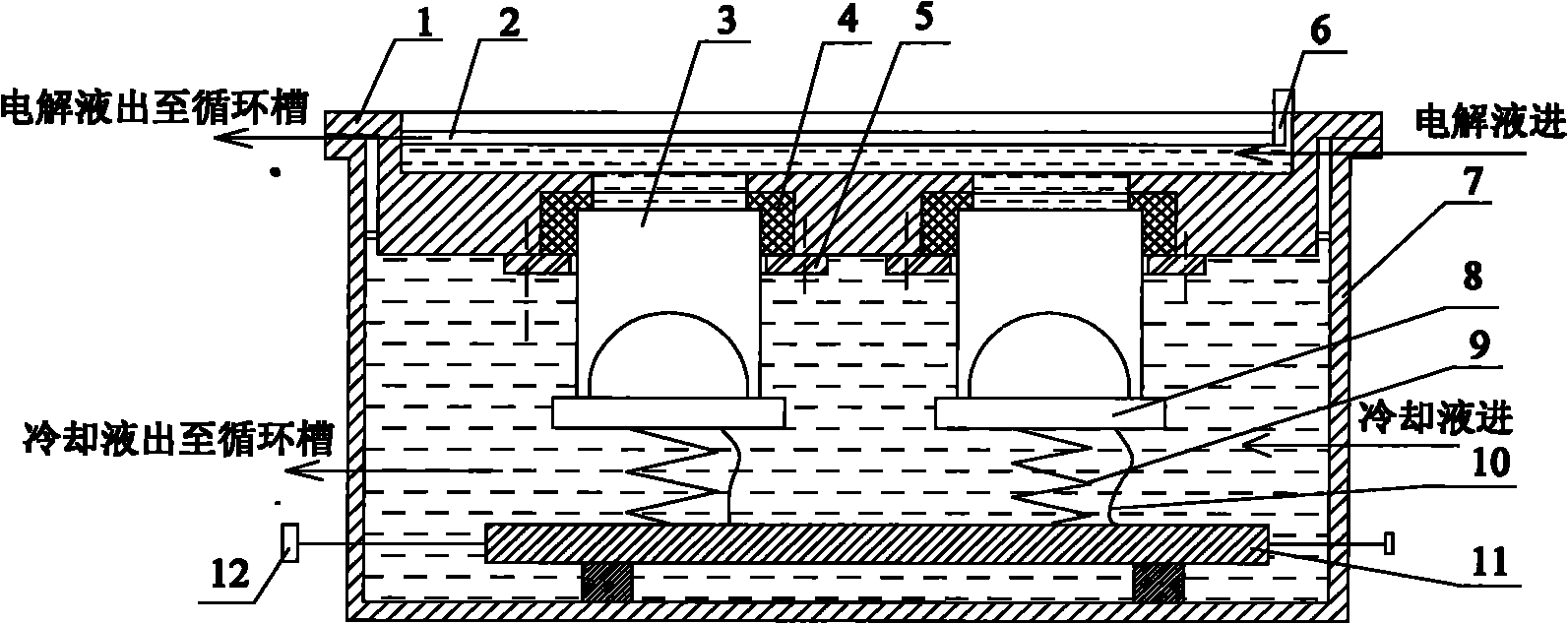

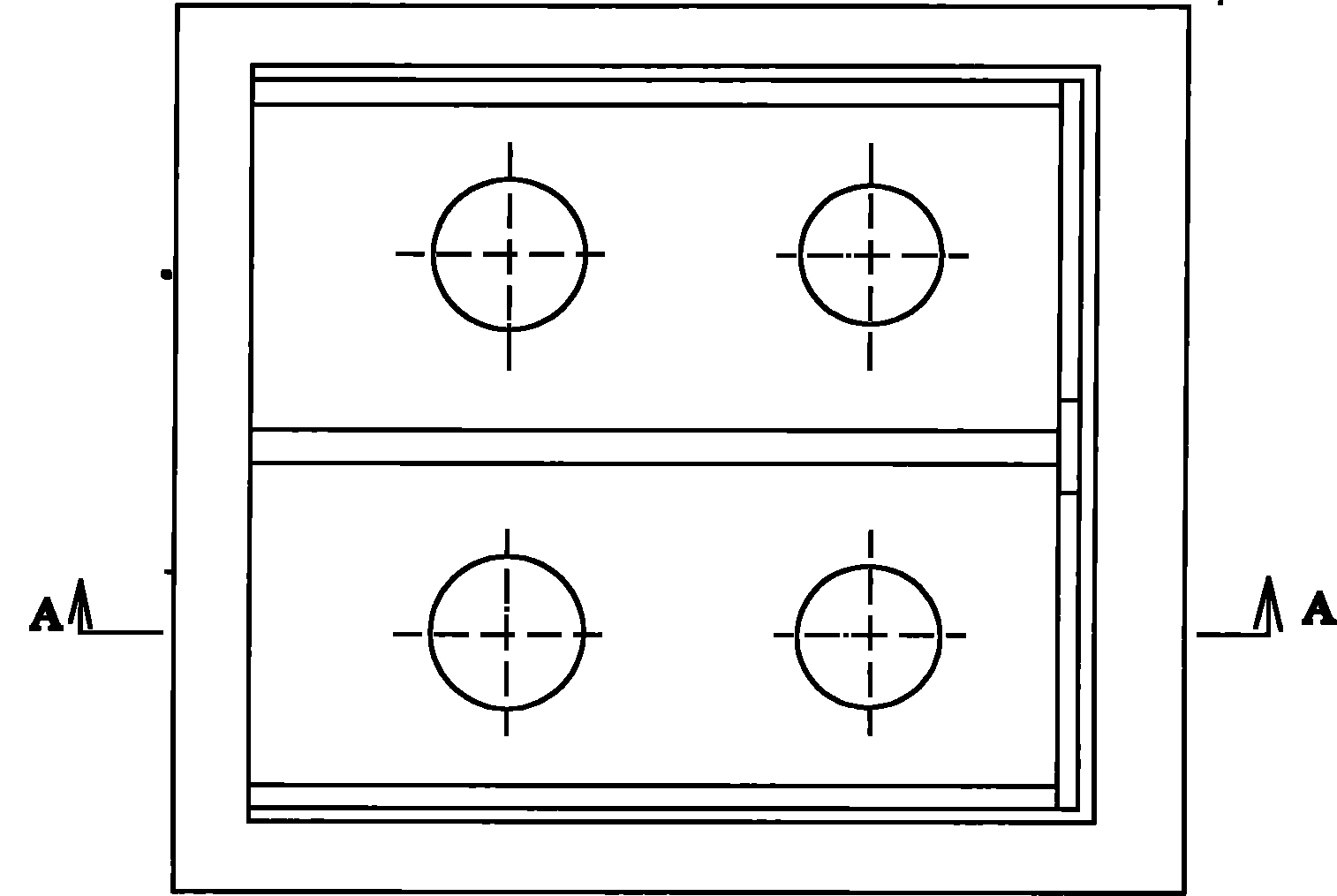

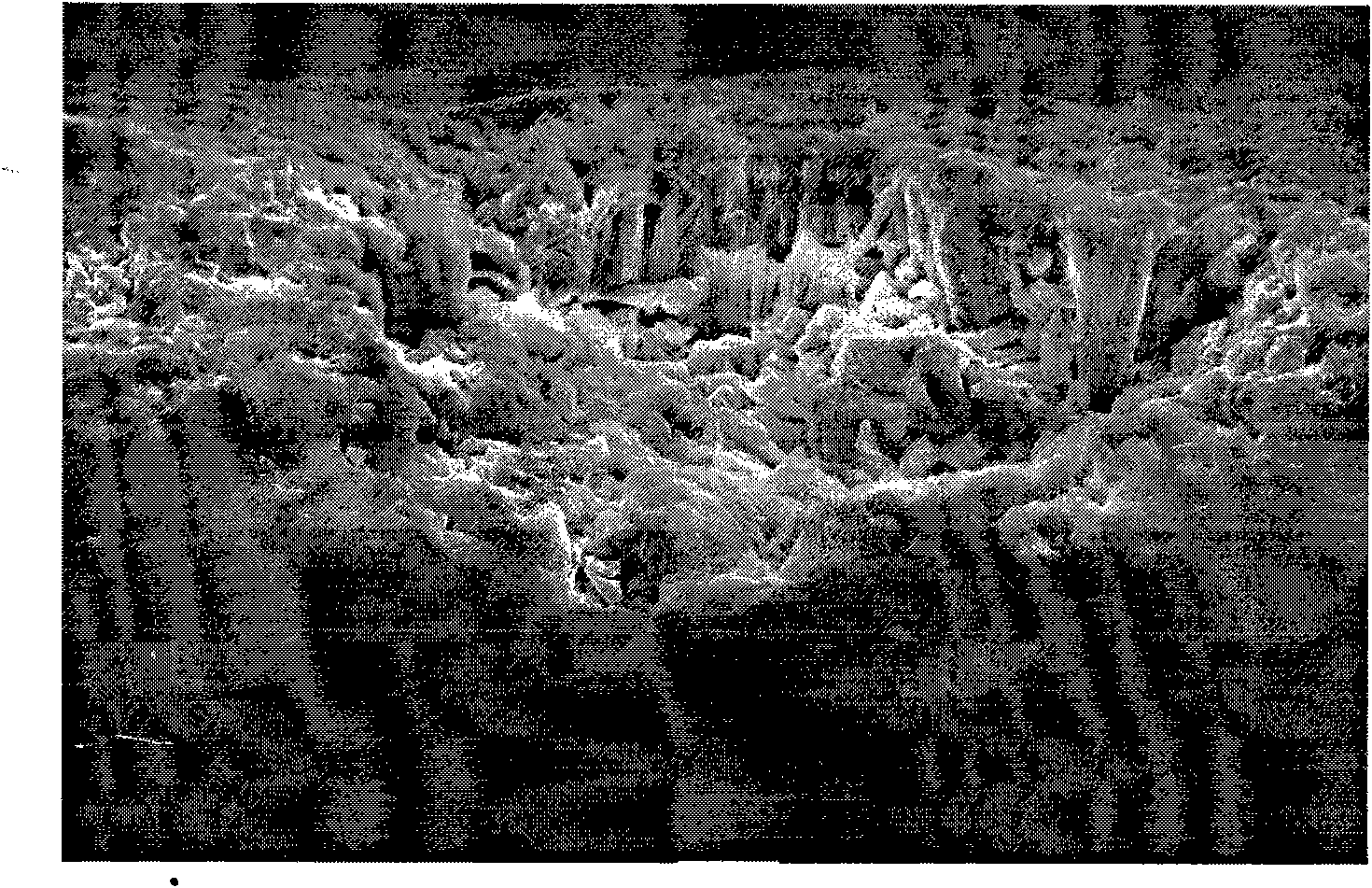

Hard anodizing method of top surface of piston

InactiveCN101942687AReduce solubilityHigh film forming efficiencyAnodisationPlungersAnodizingHeat flow

The invention provides a hard anodizing method of the top surface of a piston, which comprises the steps of generating a dense oxidation film on the top surface of the piston by adopting a hard anodizing surface processing technology; carrying out the surface processing on the top surface of the piston by utilizing a hard anodizing surface processing power supply device and a composite cooling oxidation device in the course of hard anodic oxidation processing to ensure that heat flow generated in the course of generating the oxidation film on the top of the piston is transmitted to an aluminum piston matrix part without the need of oxidation; and exchanging the heat with circulating cooling liquid. The invention is beneficial to the generation of the oxidation film; the thickness of the processed oxidation film on the top surface of the piston can reach 120 to 150 micrometers, and the hardness can reach 450 to 560HV; and the method has the advantages of dense film tissue, high production efficiency, less electrolyte amount, low energy consumption, stable and reliable performance and almost no waste.

Owner:XIHUA UNIV

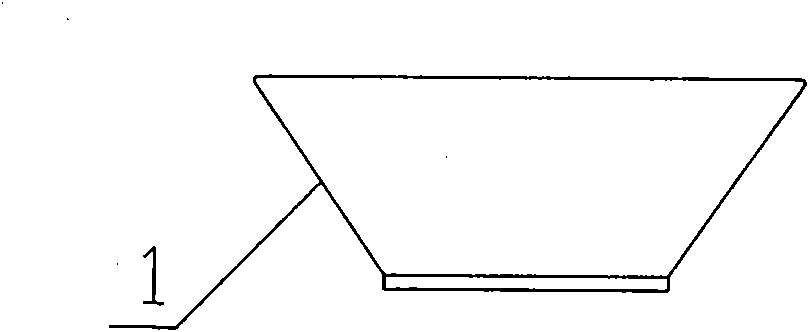

Fire accumulation cover of burner

The invention discloses a fire accumulation cover of a burner. The fire accumulation cover comprises a fire accumulation cover main body (1), wherein air intake holes (3) are arranged at the circumference of the fire accumulation cover main body (1) near the bottom; the top edge of the fire accumulation cover (1) is outwards and is downwards provided with an integral hemming bracket (8); guide ribs (4) are arranged at the circumference of the inner side of the fire accumulation cover main body (1); the guide ribs (4) are in an arc rotary shape or loop line shape or spiral shape; and the fire accumulation main body (1) is maded of a cast iron material or an iron plate or a non-metal refractory material, wherein enamel is sintered at the two sides of the iron plate, an iron plate skeleton is lined inside the non-metal refractory material. The fire accumulation cover disclosed by the invention enables the flame heat to be concentrated at the bottom of a pan bottom; the heat loss caused by the gap between the fire accumulation cover and the pan bottom is less, and the heat is fully utilized, thereby saving energy sources; the fire accumulation cover is not easy to burn, thereby enhancing the service life of the fire accumulation cover; and the guide ribs in the arc rotary shape or loop line shape or spiral shape have better reflection and flame guide functions.

Owner:张文征

Direct current disconnector and harmonic current break device thereof

ActiveCN108766827AAchieve conversionEffective breakingHigh-tension/heavy-dress switchesAir-break switchesHarmonicEngineering

The invention relates to a direct current disconnector and a harmonic current break device thereof. The direct current disconnector includes a fixed contact and a conductive knife switch, the conductive knife switch includes an upper contact tube, a static side arc strike assembly is arranged on the side, close to the conductive knife switch, of the fixed contact, and a dynamic side arc strike assembly is arranged on the upper contact tube. The static side arc strike assembly comprises a static side arc strike seat and a self-resetting arc strike rod, and a static side blocking piece is arranged on the side, back to the conductive knife switch, of the self-resetting arc strike rod. The dynamic side arc strike assembly comprises a dynamic side arc strike seat and a self-resetting arc strikearm, the swinging plane of the self-resetting arc strike arm is perpendicular to the swinging plane of the self-resetting arc strike rod, and a dynamic side blocking piece is arranged on the side, close to the fixed contact, of the self-resetting arc strike arm. The self-resetting arc strike arm is provided with a conductive end for being in conducting contact with the self-resetting arc strike rod and intersecting with the swinging plane of the self-resetting arc strike rod, and the hinged part of the self-resetting arc strike arm is located on the outer side of the swinging plane of the self-resetting arc strike rod. Compared with the prior art, a main contact of the disconnector is not prone to being ablated by harmonic current.

Owner:HENAN PINGGAO ELECTRIC +3

Lock pin type synchronous ring

InactiveCN104500611AImprove shift performanceLarge synchronization capacityMechanical actuated clutchesGroove widthAngular degrees

The invention provides a lock pin type synchronous ring for a heavy truck transmission synchronizer. Axial oil grooves are formed in the synchronous ring taper surface, and molybdenum is sprayed on the taper surface. The width of each axial oil groove in the synchronous ring taper surface is in a range of 2.5mm to 4.5mm, and the groove depth is in a range of 0.7mm to 1.1mm. The ratio of the groove width to the groove depth is between 2 and 7, the ratio of the groove width to the groove distance is in a range of 0.35 to 0.45, and the angles on the two sides of the oil grooves are in a range of 20 degrees to 45 degrees. The synchronous ring has the advantages of being abrasion resistant and high-temperature resistant, good in oil discharge radiation performance, capable of increasing the synchronous ring service life and particularly applicable to heavy truck transmission synchronizers.

Owner:LUZHOU CHANGJIANG MACHINERY

DC isolating switch and its harmonic current breaking device

ActiveCN108766827BAchieve conversionEffective breakingHigh-tension/heavy-dress switchesAir-break switchesStructural engineeringDirect current

The invention relates to a direct current disconnector and a harmonic current break device thereof. The direct current disconnector includes a fixed contact and a conductive knife switch, the conductive knife switch includes an upper contact tube, a static side arc strike assembly is arranged on the side, close to the conductive knife switch, of the fixed contact, and a dynamic side arc strike assembly is arranged on the upper contact tube. The static side arc strike assembly comprises a static side arc strike seat and a self-resetting arc strike rod, and a static side blocking piece is arranged on the side, back to the conductive knife switch, of the self-resetting arc strike rod. The dynamic side arc strike assembly comprises a dynamic side arc strike seat and a self-resetting arc strikearm, the swinging plane of the self-resetting arc strike arm is perpendicular to the swinging plane of the self-resetting arc strike rod, and a dynamic side blocking piece is arranged on the side, close to the fixed contact, of the self-resetting arc strike arm. The self-resetting arc strike arm is provided with a conductive end for being in conducting contact with the self-resetting arc strike rod and intersecting with the swinging plane of the self-resetting arc strike rod, and the hinged part of the self-resetting arc strike arm is located on the outer side of the swinging plane of the self-resetting arc strike rod. Compared with the prior art, a main contact of the disconnector is not prone to being ablated by harmonic current.

Owner:HENAN PINGGAO ELECTRIC +3

Arc plasma gun

The invention discloses an arc plasma gun and relates to plasma heating equipment. The gun is characterized by consisting of an anode, a cathode, a gun barrel and a back seat, wherein the anode has a hollow annular body structure; a cooling groove is formed in an annular body and provided with a cooling water interface; the cathode has a hollow stick body structure; a cooling cavity is formed in a stick body and provided with a working water interface; the back seat has a disc body structure; the center of a disc body is provided with a passage hole; the anode, the gun barrel and the back seat are arranged coaxially; the back end of the gun barrel is connected to the back seat so as to form a gun body; the anode is connected to the front end of the gun barrel; the annular space of the anode forms a jet orifice; the internal space of the gun barrel forms an air chamber; the front end of the cathode extends into the gun barrel through the passage hole on the back seat; a discharge spaceis formed in the space between the front end of the cathode and the anode; a back stick body of the cathode is outside the gun body; and the working water interface is connected to the cooling cavityof the cathode from the outside of the gun body. The efficiency of the gun is almost 100 percent and the anode and the cathode are protected from being ablated more effectively.

Owner:周开根

Double-break isolating switch and GIS equipment

PendingCN114743824ANot easy to damageExtend your lifeSwitchgear arrangementsAir-break switch detailsDisconnectorEngineering

Owner:PINGGAO GRP +3

Combustion chamber of a pulse detonation engine

InactiveCN107339166BSmall flow resistanceReduce ablative effectIntermittent jet plantsRocket engine plantsCombustion chamberEngineering

The invention discloses a pulse-detonation engine combustion chamber, and belongs to the technical field of detonation engines. A plurality of rows of gas inlet devices are arranged on a gas inlet path housing and the combustion chamber wall surface; and every two rows of pneumatic gas inlet devices are spaced by a distance which is 0.5-1 time the diameter of the combustion chamber. Each gas inlet device is composed of a drainage section and a gas inlet, wherein the gas inlet path housing defines a circular ring shaped secondary gas inlet path, the drainage section is in the form of a hollow cylinder connecting the gas inlet path housing to the engine wall surface, the cylinder has the same angles of inclination in the axial direction and the peripheral direction of an engine, and a plurality of gas inlets are formed in the front wall surface of the cylinder. The plurality of rows of gas inlet devices are uniformly distributed in a staggered mode in the peripheral direction of the combustion chamber, and positions of the rear row of gas inlet devices are determined by rotating positions of the front row of gas inlet devices clockwise. Other parts are not arranged inside the combustion chamber, so that the service life of the combustion chamber is long; and the drainage sections are arranged outside the combustion chamber, so that internal flow resistance of the detonation chamber is effectively reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

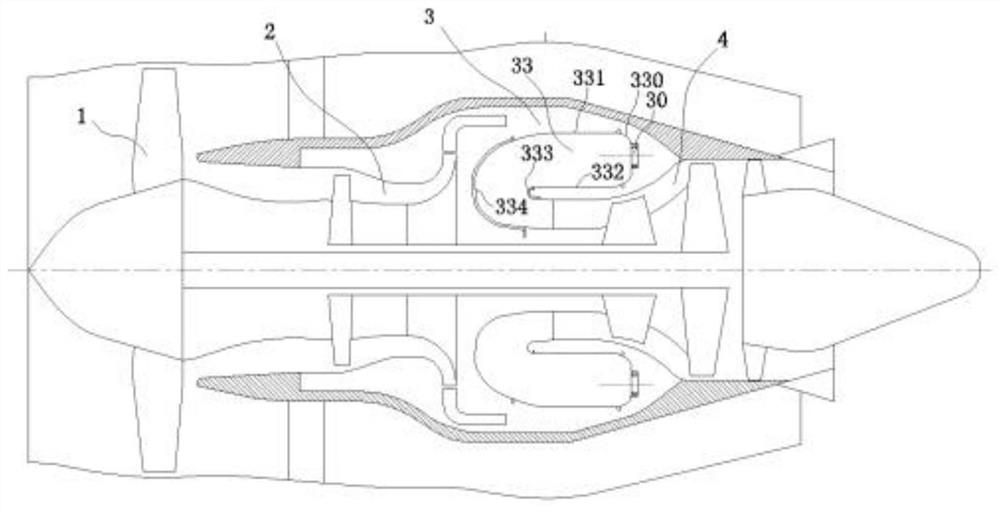

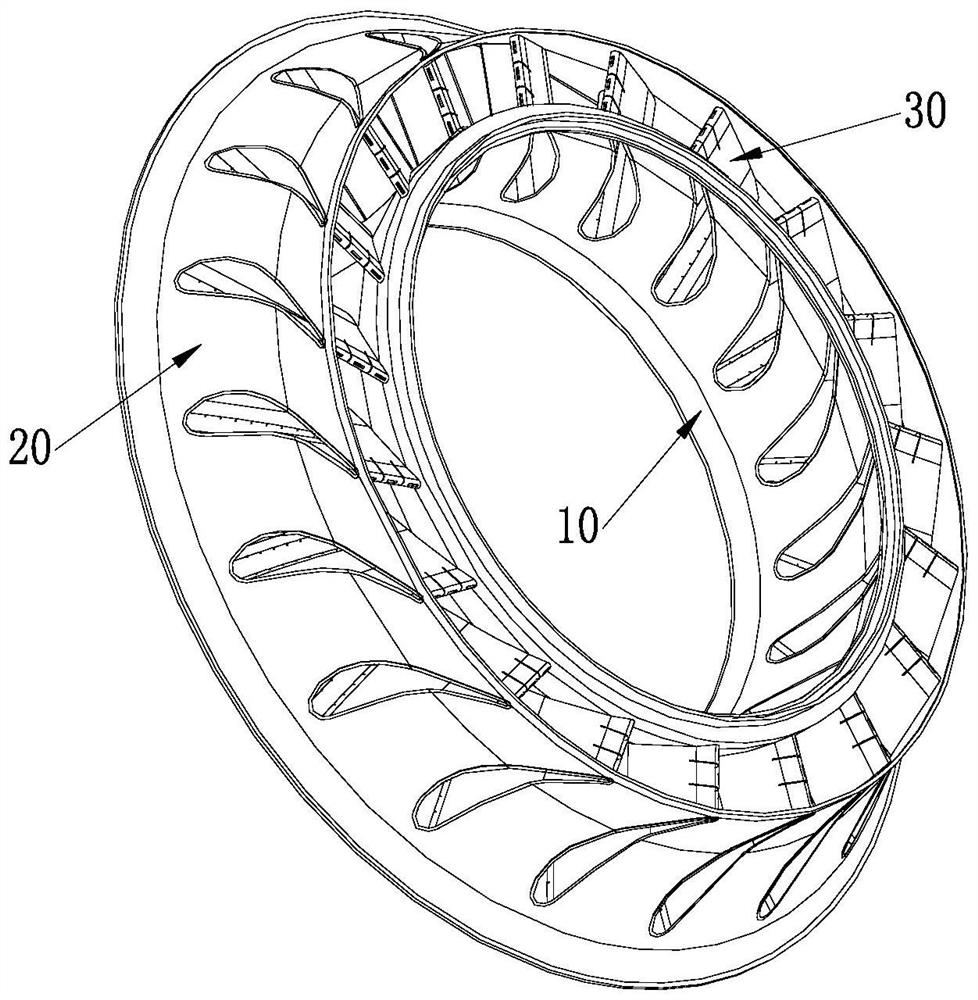

A cooling structure for the flame cylinder and the elbow of the backflow combustor

ActiveCN113154457BReduce heating effectWith gas collection effectContinuous combustion chamberCombustion chamberEngineering

The invention discloses a cooling structure for a recirculation combustion chamber, which comprises a flame tube outer ring, a flame tube inner ring, a large bend, a small bend and a flame tube head. One end of the flame tube outer ring is provided with a large bend, a large bend It is a ring structure, the other end of the flame tube outer ring is provided with a flame tube head, the inside of the flame tube outer ring is provided with a flame tube inner ring, and the end of the flame tube inner ring close to the large bend tube is provided with a small bend; the flame tube outer ring , which is provided with a plurality of outer ring mixing holes, and is divided into a plurality of first L-shaped unit bodies along the circumferential direction; the small elbow is in a ring structure, and is divided into a plurality of second L-shaped unit bodies along the circumferential direction . The invention belongs to the technical field of cooling, and the cooling efficiency of an L-shaped cooling elbow is higher than that of a conventional cooling elbow; the L-shaped cooling elbow is not easy to be ablated; the L-shaped cooling elbow can reduce the cost of sheet metal processing; The assembly of the segmental lap welded structure of the pipe is simple and easy to realize.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

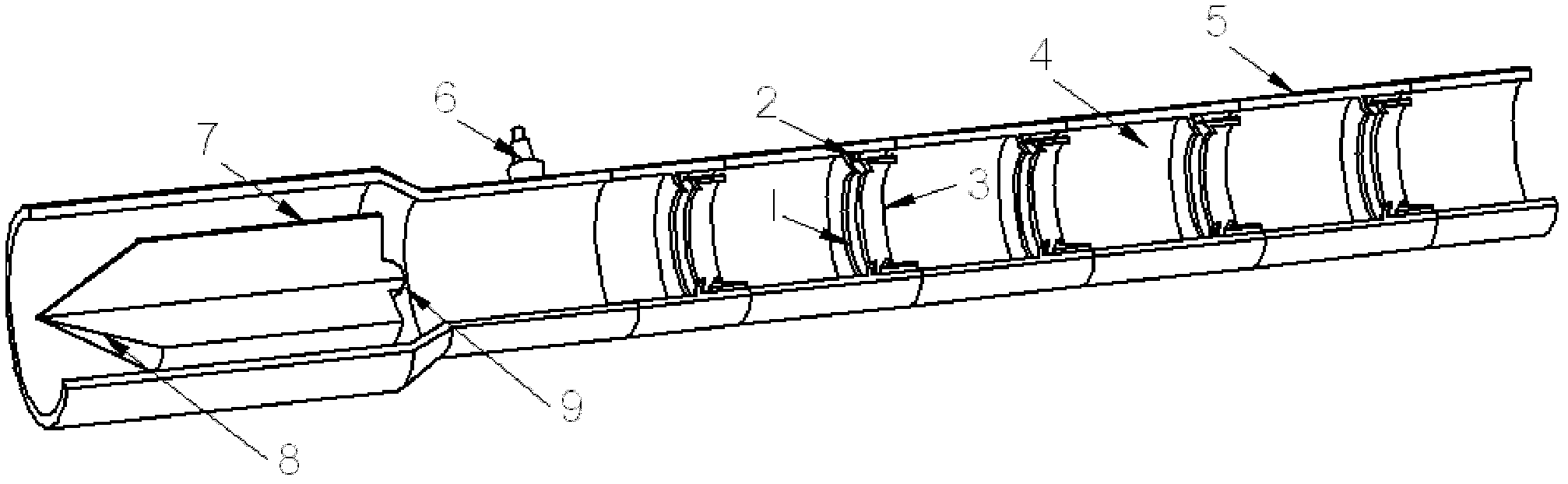

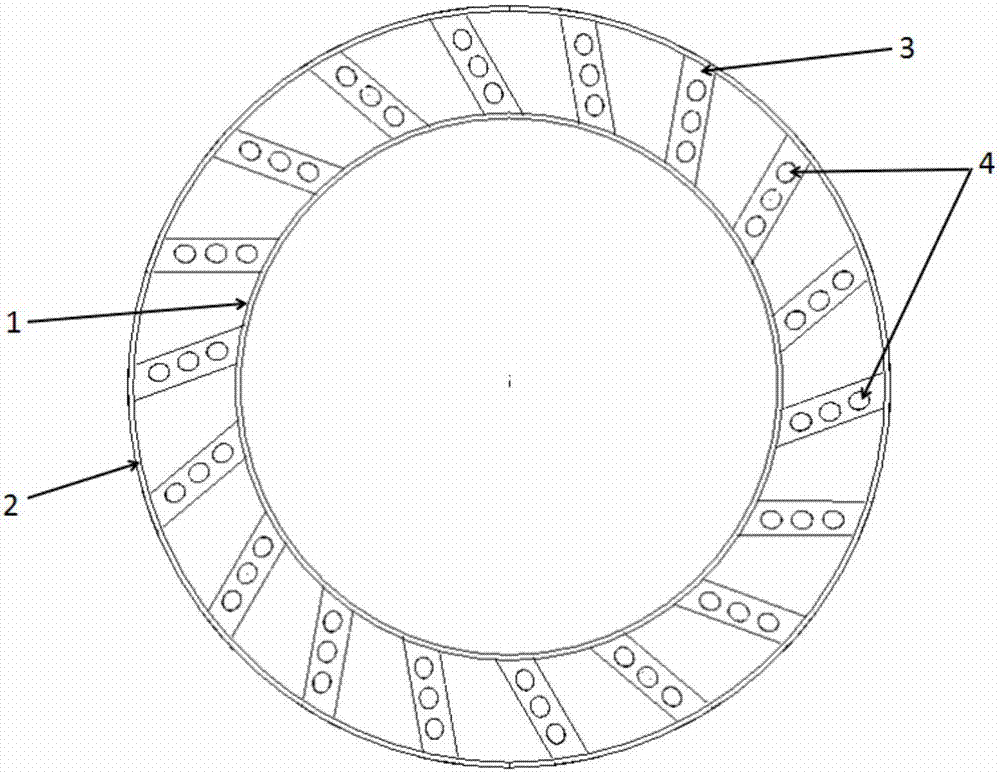

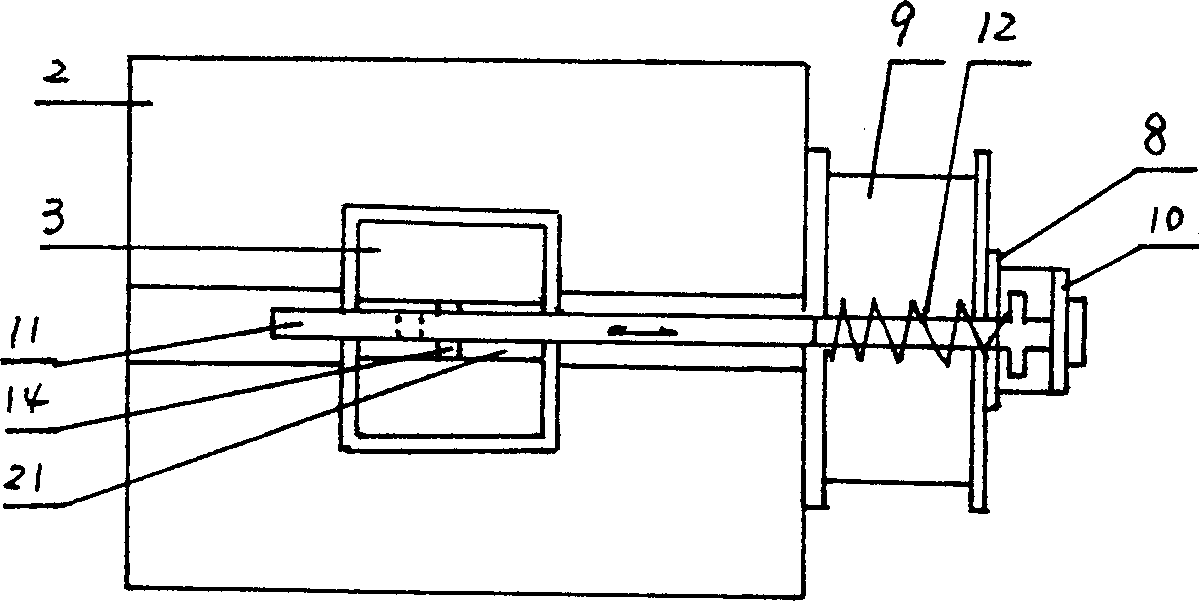

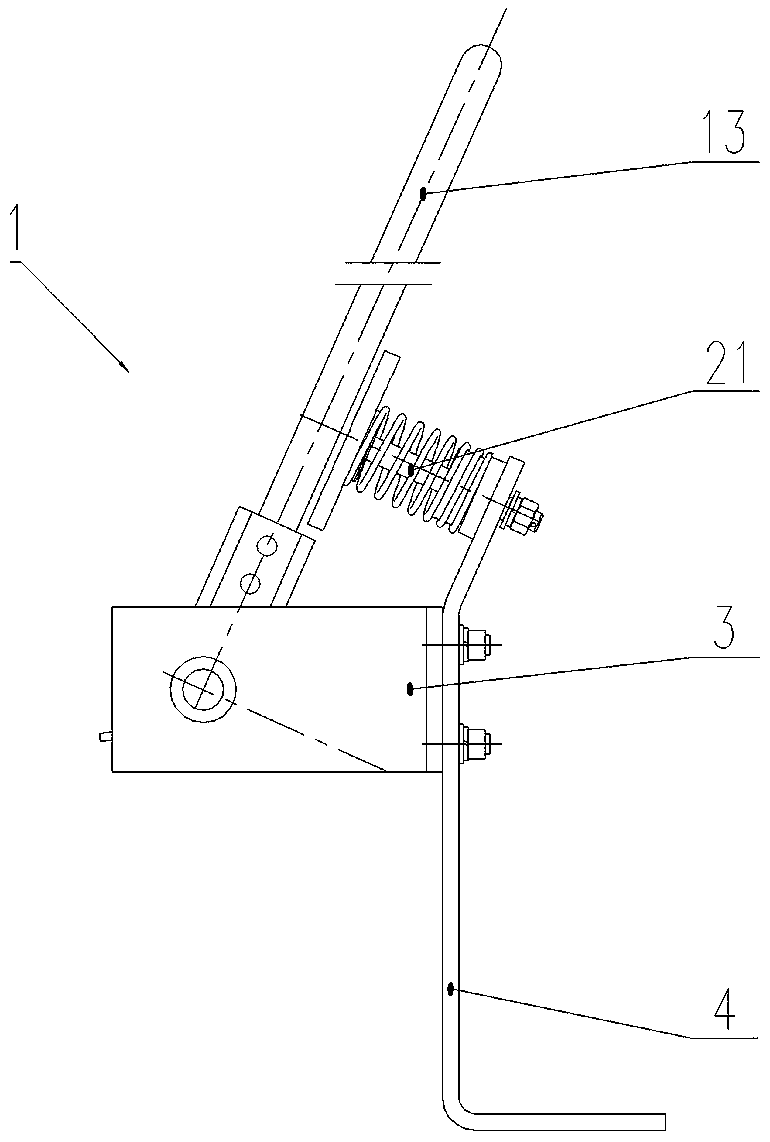

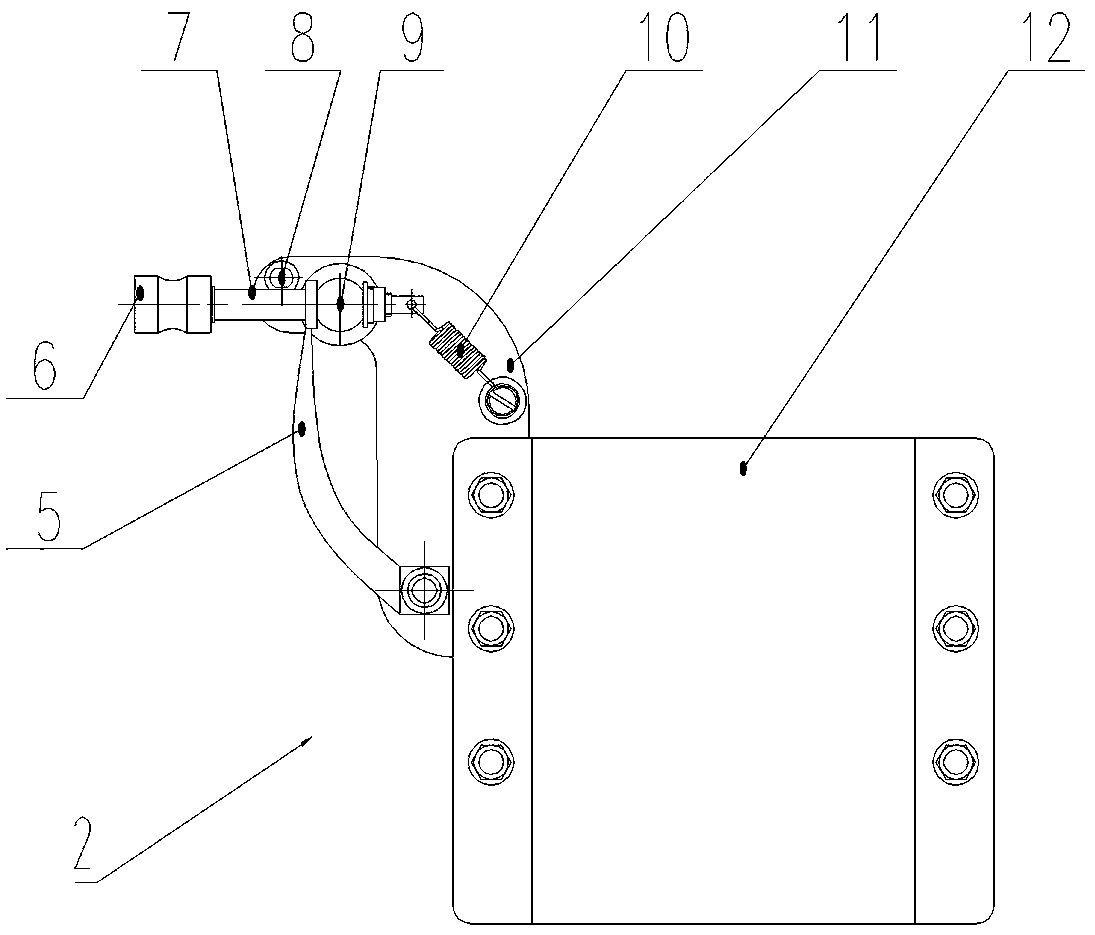

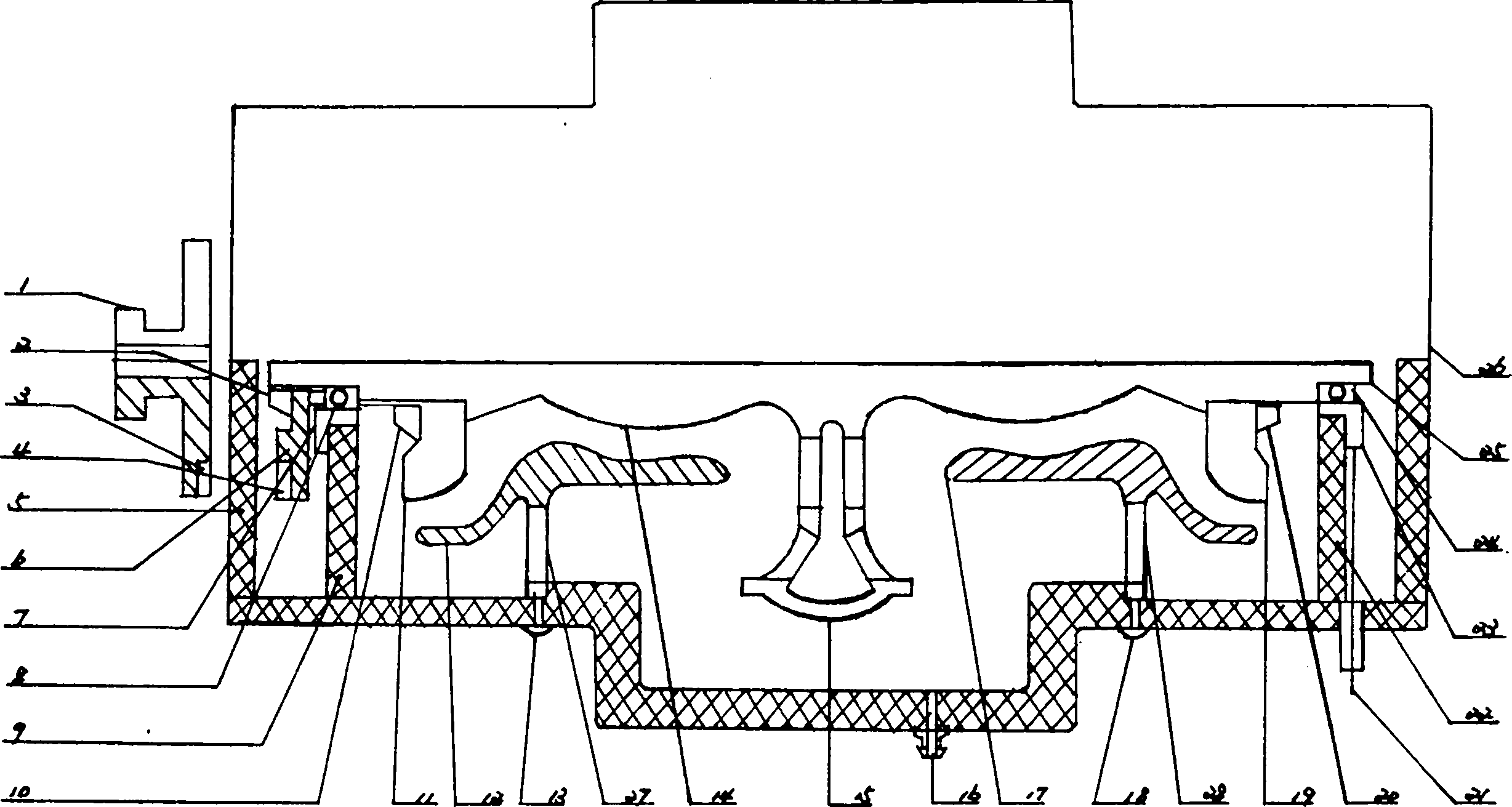

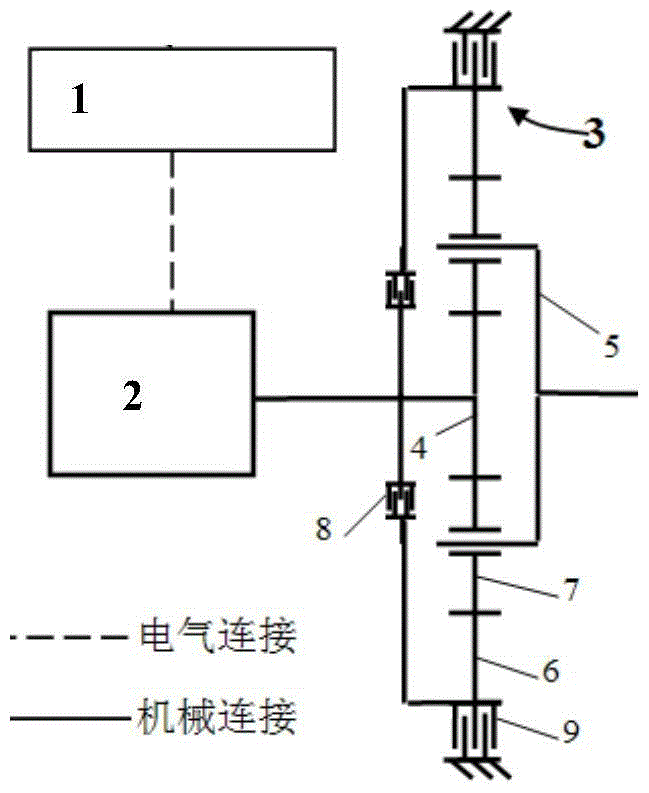

Swirl high energy magnetic coupling switch

ActiveCN101055974BNot easy to ablateExtended service lifeRotary spark gapsDynamo-electric gearsCouplingHigh energy

A vortex high-energy magnetic coupling switch, wherein the rotation of coupling discs (1) (6), drive the rotation of leaves (11) (19) on a circular trigger electrode axis (25) to produce a high-speed vortex field. The high-speed rotary vortex field takes away the ionized gas sputtering substance generated by the discharge of an electrode (14) and electrodes (12) (17), through a collection purifier (15), cycling from area B to area A through airflow windows (27) (28), thus improving the electrode cooling conditions to prevent electrode ablation from polluting the electrode cavity, and extending the service life. The invention applies to all kinds of high voltage, high current, and anti-impact pulse discharging devices.

Owner:牡丹江旋宇激光有限公司

Hot metal pretreatment long-service-life spray gun

The invention relates to a steel mill blast furnace hot metal pretreatment tool, in particular to a hot metal pretreatment long-service-life spray gun. The hot metal pretreatment long-service-life spray gun comprises a gun body and a vaporizing chamber positioned at the lower part of the gun body, wherein the vaporizing chamber comprises an inner side and an outer side which are formed by a heat resistant steel skeleton and a poured refractory material. The whole alloy steel structure of the vaporizing chamber is changed; heat resistant stainless steel reinforcement is welded into the skeleton and poured into the vaporizing chamber formed by the refractory material; and because the steel reinforcement is arranged in the refractory material, not in direct contact with hot metal and difficult to be ablated, the hot metal pretreatment long-service life spray gun has longer service life which commonly can reach more than 200 times and low cost, improves the service life by more than 3 times compared with the common spray gun and completely can meet the requirement of production.

Owner:通化耐博耐火材料有限责任公司

Arc plasma torch

The invention provides an arc plasma torch and relates to a plasma heating device. The arc plasma torch is characterized in that the torch is composed of a positive pole, a combined negative pole, a torch barrel and a back seat, wherein the positive pole, the torch barrel and the back seat are arranged in a coaxial mode, the back end of the torch barrel is connected on the back seat to form a torch body, the positive pole is connected at the front end of the torch barrel, a loop core space of the positive pole forms a nozzle, an inner space of the torch barrel forms an air chamber, and the back seat forms a back closed end of the torch barrel; the positive pole is of a hollow ring form structure, a ring-form cooling groove is arranged in the ring form, and the ring-form cooling groove is connected with a cooling water port; and the combined negative pole is composed of a negative pole rod, a negative pole head and a negative pole cap, the portion from the middle to the front end of the negative pole rod is of a tubular structure, a cooling cavity is formed in the space in a tube, the front end of the negative pole head is a reduced circular conical surface, and a back portion solid of the negative pole head is provided with a driving water gasification hole or a vaporization fin. The arc plasma torch is used in a gasification device, the efficiency of the torch reaches nearly 100%, and the arc plasma torch can effectively protect the negative pole and the negative pole from being ablated.

Owner:南通东湖国际商务服务有限公司

A cathode with a microporous membrane structure

ActiveCN104378903BNot easy to ablateOvercome the disadvantage of being easily ablatedPlasma techniqueFiltrationVaporization

A cathode with a microporous membrane structure and a plasma pyrolysis water spray gun, relating to a plasma spray gun, the cathode is composed of a microporous membrane cathode head and a cathode sleeve, and the micropores of the microporous membrane cathode head form a filtration channel for water molecules , the microporous membrane cathode head is embedded in the wall body at the front of the cathode sleeve, and the head of the microporous membrane cathode head protrudes from the front end of the cathode sleeve; the plasma pyrolysis water spray gun consists of a rear seat, a cathode, a spiral deflector, The anode sleeve and the anode are composed of a water supply guide pipe and a cathode connecting rod in the rotator of the rear seat, and a spiral guide rib is provided in the rotator of the spiral deflector. The anode is a venturi nozzle structure, and the anode is installed in an embedded manner. In the anode sleeve, the space between the outer wall of the anode and the inner wall of the anode sleeve constitutes a cooling water jacket, the cathode is connected to the front end of the cathode connecting rod of the rear seat, the rear end of the spiral deflector is installed on the rear seat, and the anode sleeve and the anode are installed on the spiral front end of deflector. The invention utilizes the latent heat of vaporization of water to quickly absorb the heat of the cathode head, so that the cathode is not easy to be ablated.

Owner:XINGHUA GOLDEN PEACOCK IND DEV CO LTD

Adjustable turbine guide and its forming method

ActiveCN111828099BIncrease flexibilityImprove cooling effectEfficient propulsion technologiesStatorsEngineeringFront edge

The invention discloses an adjustable turbine guider and a forming method, comprising: an annular inner ring assembly, an annular outer ring assembly coaxially sleeved outside the inner ring assembly, and an inner ring assembly and an outer ring assembly. For the guide vane between the components, the trailing edge end surface of the guide vane is provided with a deformation adjustment seam extending toward its leading edge. The deformation adjustment seam connects the vane pot and the blade back of the guide vane. The deformation adjustment seam is used to make the trailing edge on one side An adjustable aileron with an adjustable angle is formed to adjust the airflow direction flowing through the vane basin of the guide vane and the flow area between two adjacent guide vanes.

Owner:CHINA HANGFA SOUTH IND CO LTD

Strontium titanate annular piezoresistor copper-tin electrode manufacturing method

InactiveCN113161092AConvenient welding ring pressure workEasy to solderResistors adapted for applying terminalsStrontium titanateTin plating

The invention discloses a strontium titanate annular piezoresistor copper-tin electrode manufacturing method which comprises the steps of 1) printing an annular piezoelectric electrode on an annular piezoelectric magnet through copper paste, and sintering the annular piezoelectric electrode into a copper electrode; and 2) carrying out tin plating processing on the copper electrode in the step 1), wherein tin plating is carried out in two modes, one mode is tin immersion, the copper electrode is immersed in a solution containing tin ions, and tin is replaced with copper, and the other mode is tin electroplating, a barrel plating method is adopted, the piezoresistor with a copper electrode is placed in a cathode barrel plating tank, tin metal is connected to an anode, and tin can be electroplated on the copper electrode after the electroplating solution passes through current. Compared with the prior art, the method has the advantages that the electrode is sintered through copper paste, the harshness of the process for sintering the copper electrode is greatly reduced, the copper-tin electrode is formed through tin plating, tin soldering is facilitated, ablation is not prone to occurring during tin soldering, the tin layer protects inner layer copper from being easily oxidized, the production technology is mature and reliable, and the cost is low.

Owner:肇庆市正科集志电子科技有限公司

Steel rail surface alloy layer welding method and its material

InactiveCN100431766CGood welding performanceImprove corrosion resistanceWelding with roller electrodesWelding/cutting media/materialsMetallic materialsAlloy

The invention discloses a self-melting alloy powder material in the metal welding and railway signal control method, which comprises the following steps: polishing the railway surface to obtain fresh metal surface; proceeding resistance seam welding through resistance seam welding equipment; producing the needed alloy; coating alloy powder on the metal surface at 1000-1130 deg C fusing point. The powder displays NiCrBSi system self-melting alloy powder or NiCrBSiCu alloy system with HRC20-HRC45 welding layer hardness. The weight percentage of NiCrBSiCu alloy system is 0.2-0.5 percent C, 0.5-5.0 percent B, 1.0-5.0 percent Si, 3.0-15 percent Cr, 2-12 percent Fe, 3-20 percent Cu and Ni. The invention improves the bonding surface of metal and steel, which solves the problem of big rail damage and low production efficiency.

Owner:阴生毅

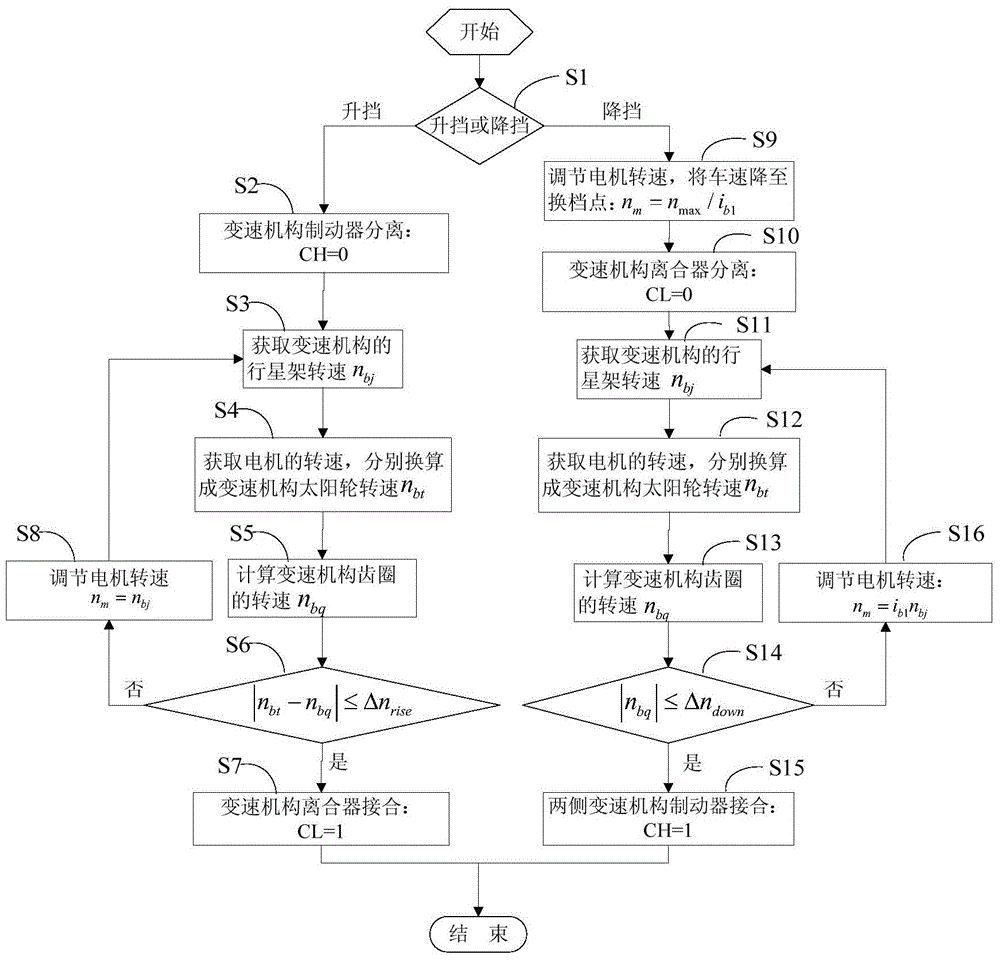

A large transmission ratio interval shift control method for series electric transmission vehicles

ActiveCN104315131BMeet the requirements of maximum output torqueImprove temperature riseGearing controlTransmission elementsElectricityActive edge

Owner:CHINA NORTH VEHICLE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com