Cathode of microporous membrane structure and plasma pyrolysis water spraying gun

A technology of microporous membrane and cathode, applied in the direction of plasma and electrical components, can solve the problem of easy ablation of the cathode, and achieve the effect of enhanced cooling effect and excellent thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

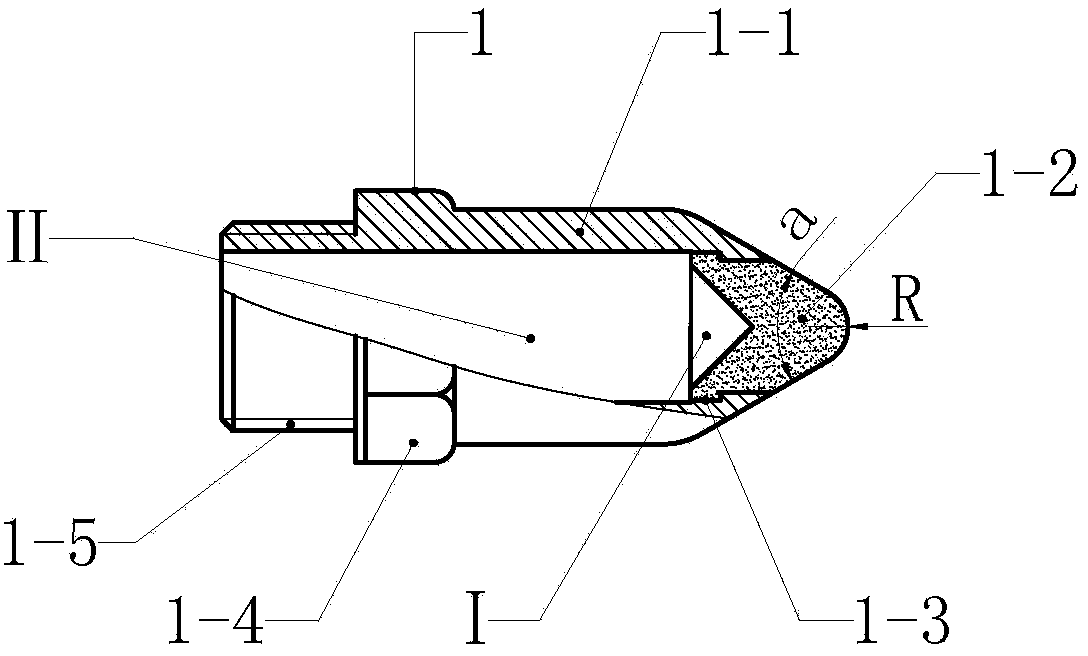

[0016] Example 1 figure 1 In the illustrated embodiment, a cathode of a microporous membrane structure is composed of a microporous membrane cathode head (1-2) and a cathode sleeve (1-1), wherein the microporous membrane cathode head (1-2) is metal Powder sintered microporous membrane structure, the micropores between the metal powder constitute the filtration channel of water molecules, the rear end center of the microporous membrane cathode head (1-2) has a conical groove (Ⅰ), the groove (Ⅰ) ) constitutes the water source inlet, and there is a flange (1-3) outside the rear end of the microporous membrane cathode head (1-2), and the flange (1-3) constitutes the axial limit of the microporous membrane cathode head (1-2). Bit structure, the head of the microporous membrane cathode head (1-2) is a conical structure that shrinks from the back to the front, and its cone angle (a) is 60°, the head end of the microporous membrane cathode head (1-2) It is an arc-shaped structure, ...

Embodiment 2

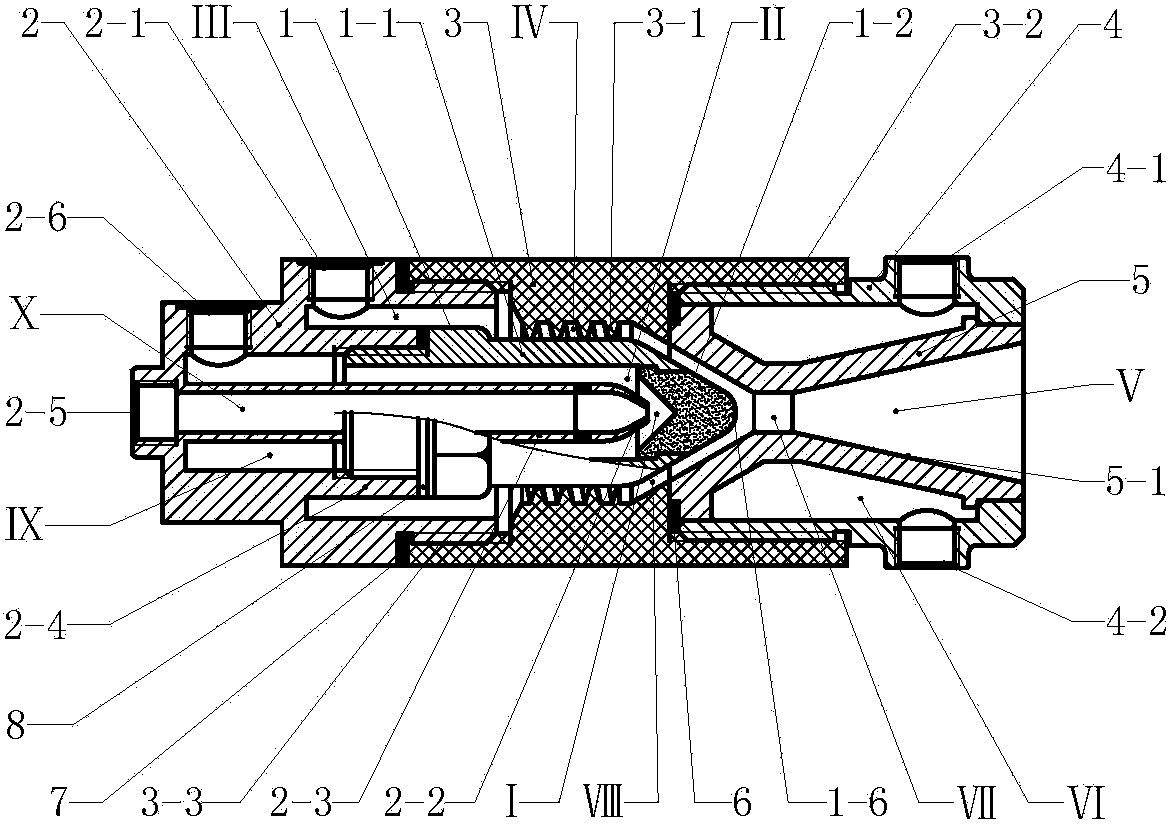

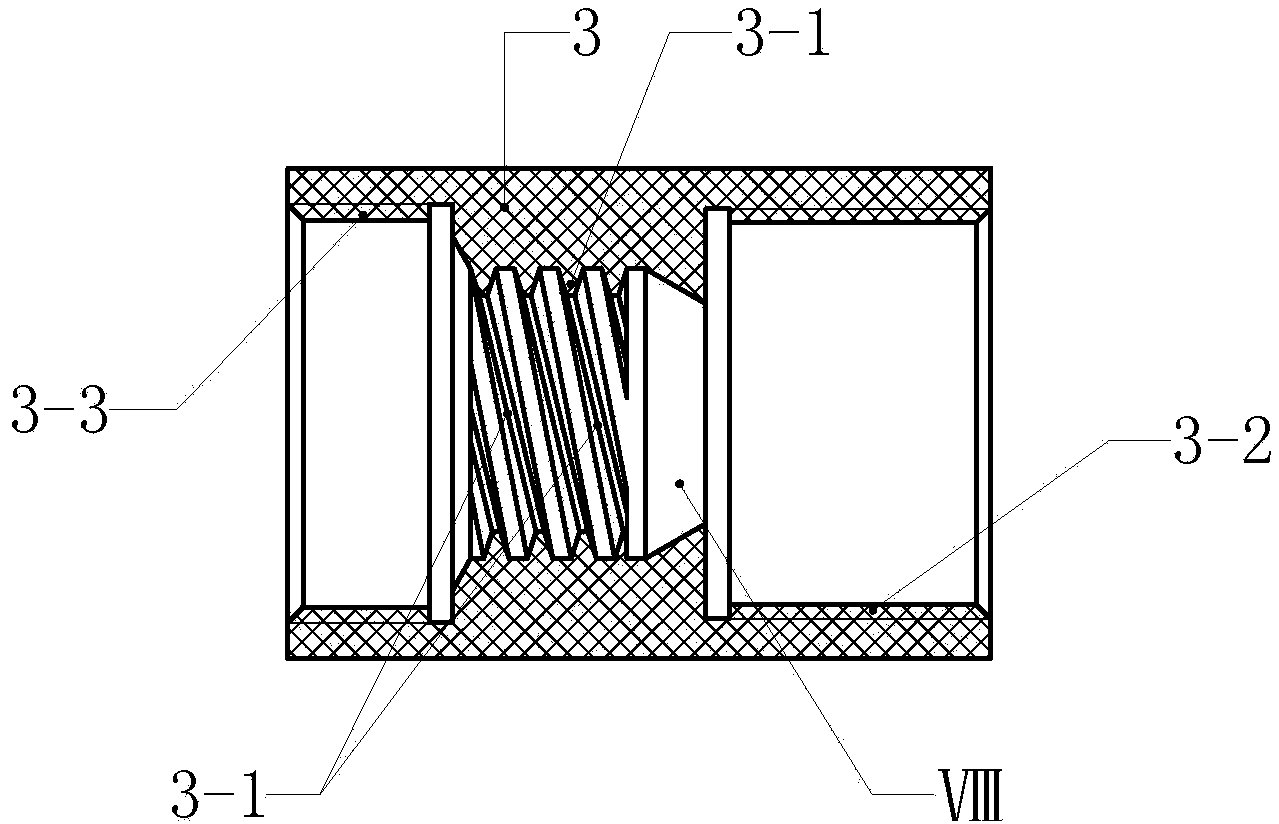

[0017] Example 2 figure 2 In the illustrated embodiment, the plasma pyrolysis water spray gun is composed of a back seat (2), a cathode (1), a spiral deflector (3), an anode sleeve (4) and an anode (5), wherein the back seat ( 2) It is a revolving body structure. There are water supply guide pipes (2-3) and cathode connecting rods (2-4) in the revolving body of the rear seat (2), and the cathode connecting rods (2-4) are circular tube structures. The water supply diversion pipe (2-3) and the cathode connecting rod (2-4) are arranged coaxially, the water supply diversion pipe (2-3) is inside the tube of the cathode connecting rod (2-4), and the water supply diversion pipe (2- 3) The space inside the tube constitutes the cooling water supply channel (Ⅸ), the space between the outer wall of the water supply diversion pipe (2-3) and the inner wall of the cathode connecting rod (2-4) constitutes the cooling return water channel (IX), and the water supply diversion The water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com