Adjustable turbine guide and its forming method

A technology of turbine guide and forming method, which is applied in the field of forming adjustable turbine guide and adjustable turbine guide, which can solve the problems of low cycle life, turbine guide ablation, and difficulty in angle adjustment, and achieve cycle life Long, increase the temperature before the turbine, good work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

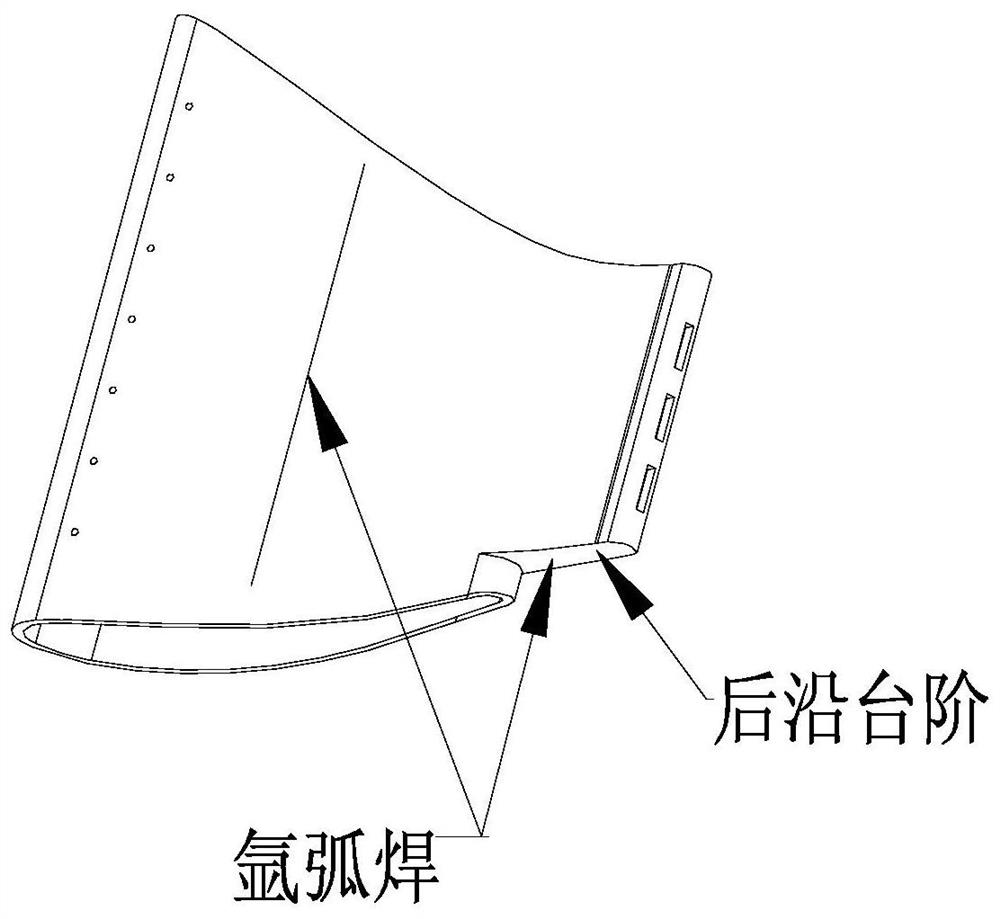

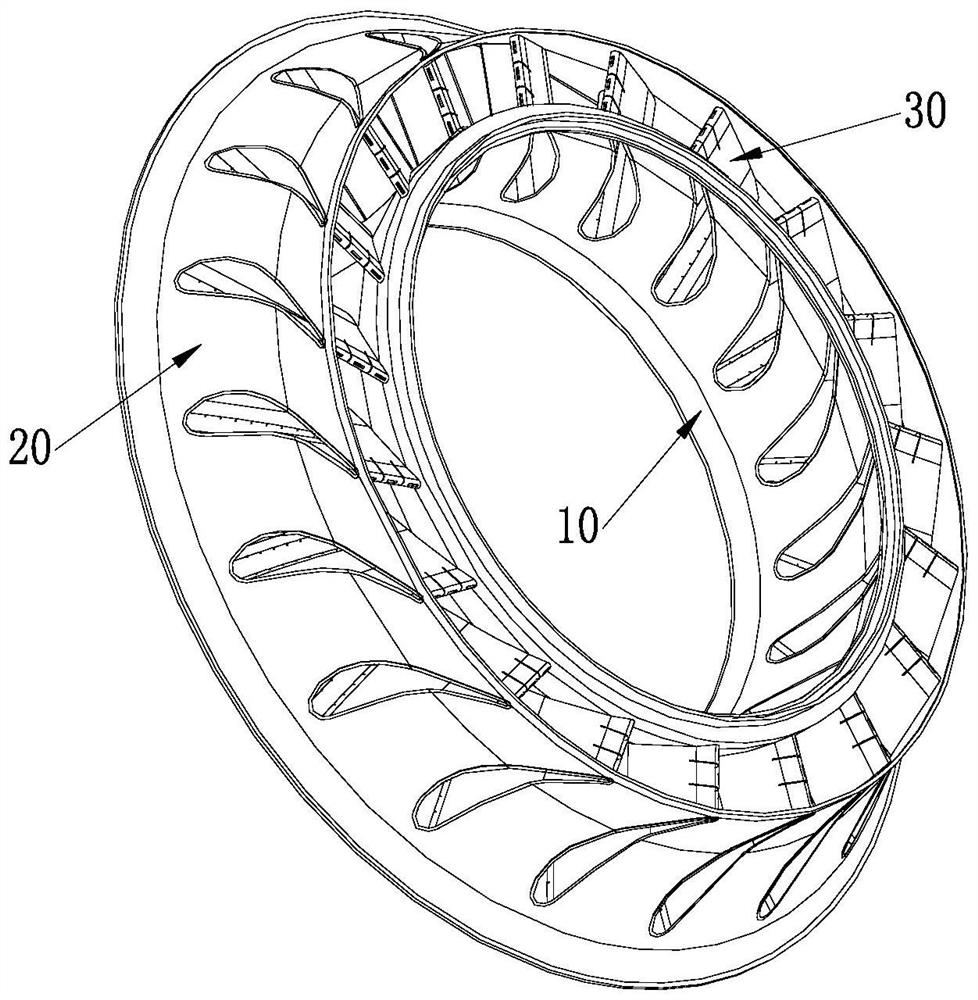

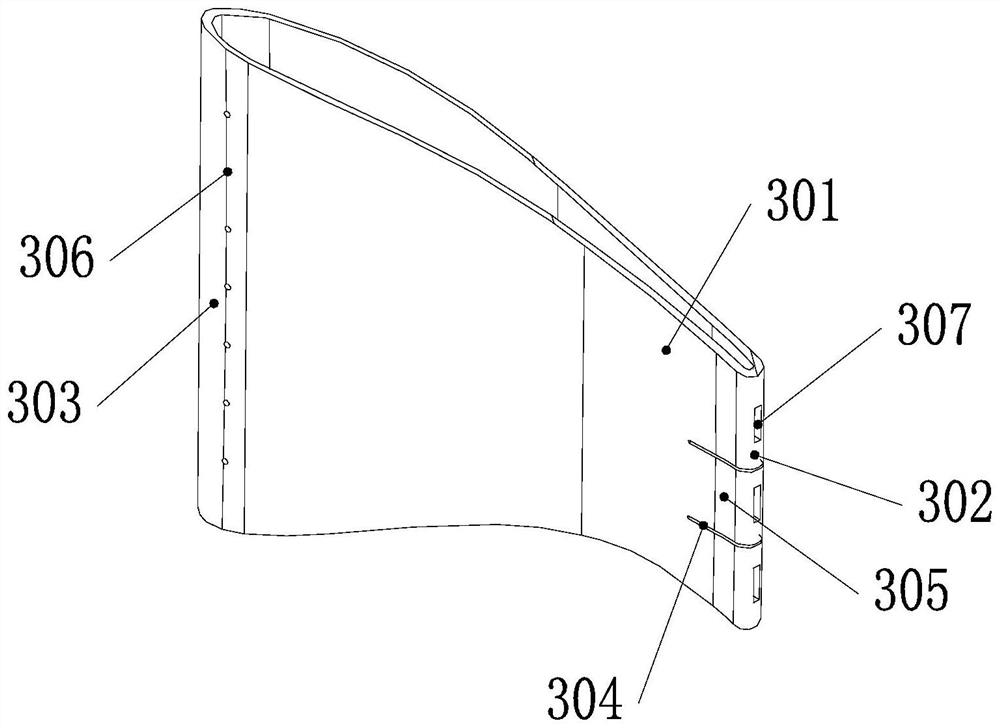

[0031] refer to figure 2 and image 3 , the preferred embodiment of the present invention provides an adjustable turbine guide, comprising: an annular inner ring assembly 10, an annular outer ring assembly 20 coaxially sleeved outside the inner ring assembly 10, and a ring connected to the inner ring assembly 10. The guide vane 30 between the ring assembly 10 and the outer ring assembly 20, the trailing edge end surface 302 of the guide vane 30 is provided with a deformation adjustment slit 304 extending toward its leading edge 303, and the deformation adjustment slit 304 communicates with the vane of the guide vane 30. Back, the deformation adjustment slit 304 is used to make the trailing edge 301 on one side form an adjustable aileron 305 with an adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com