Patents

Literature

86results about How to "Easy to solder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

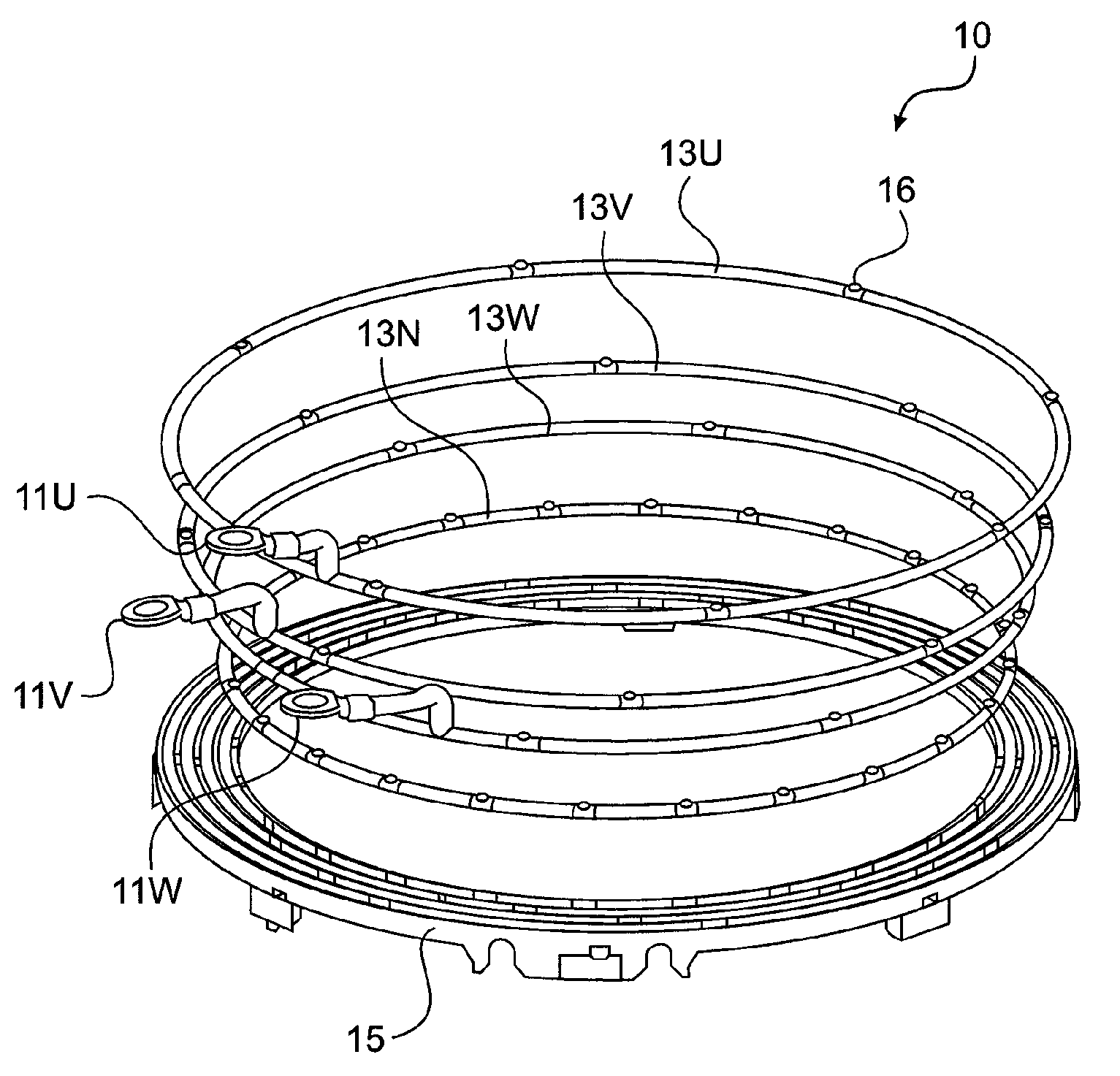

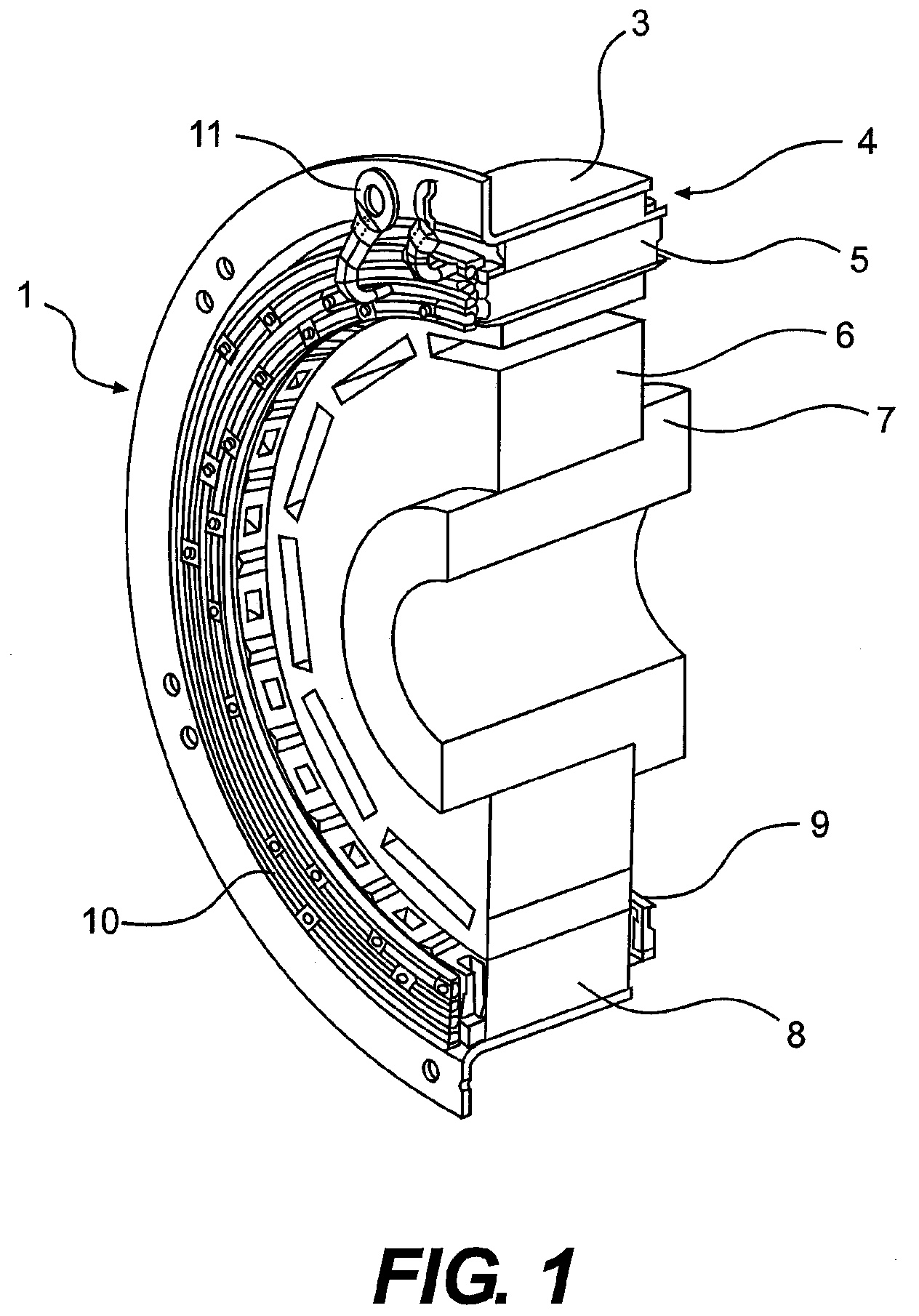

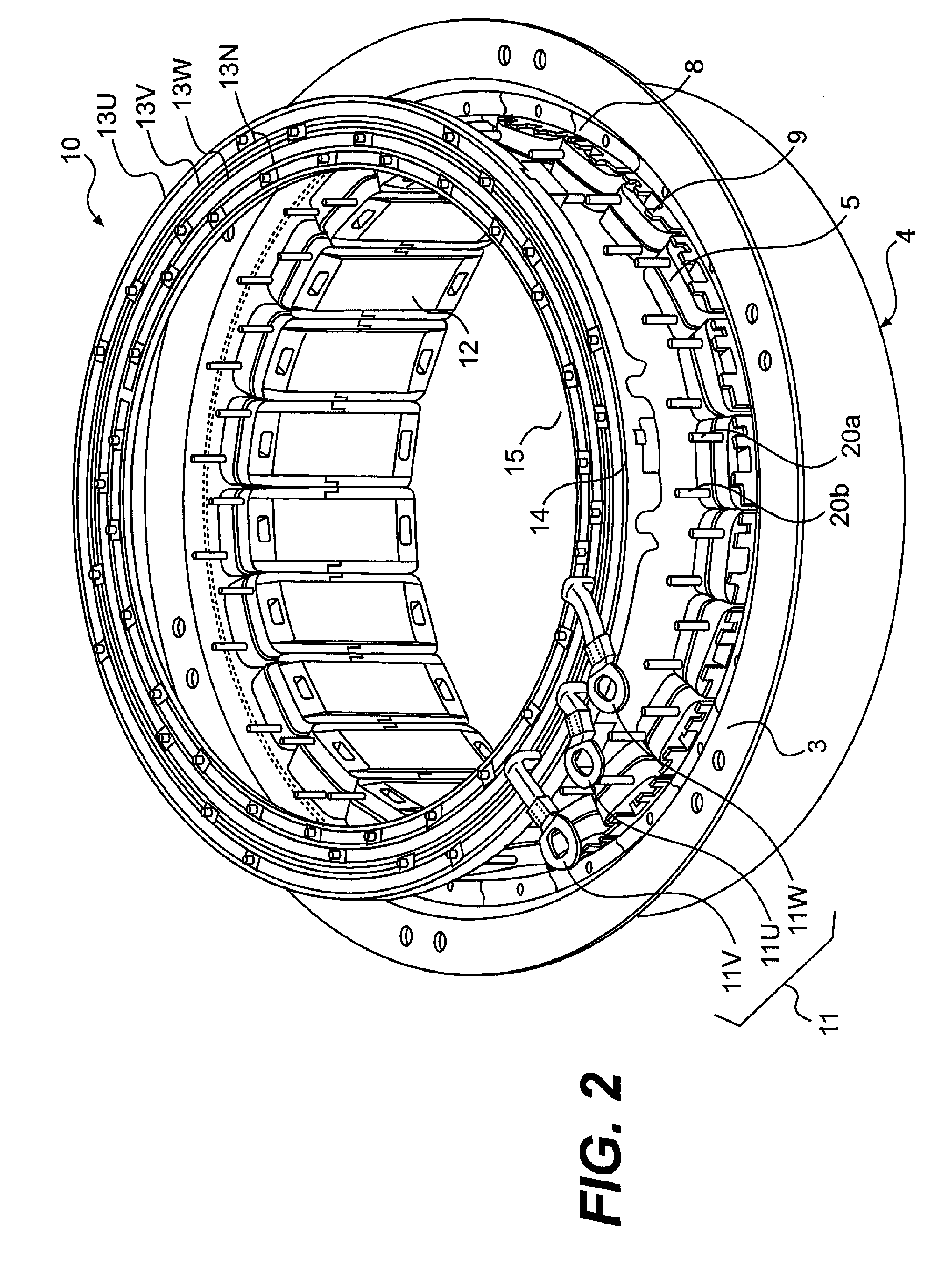

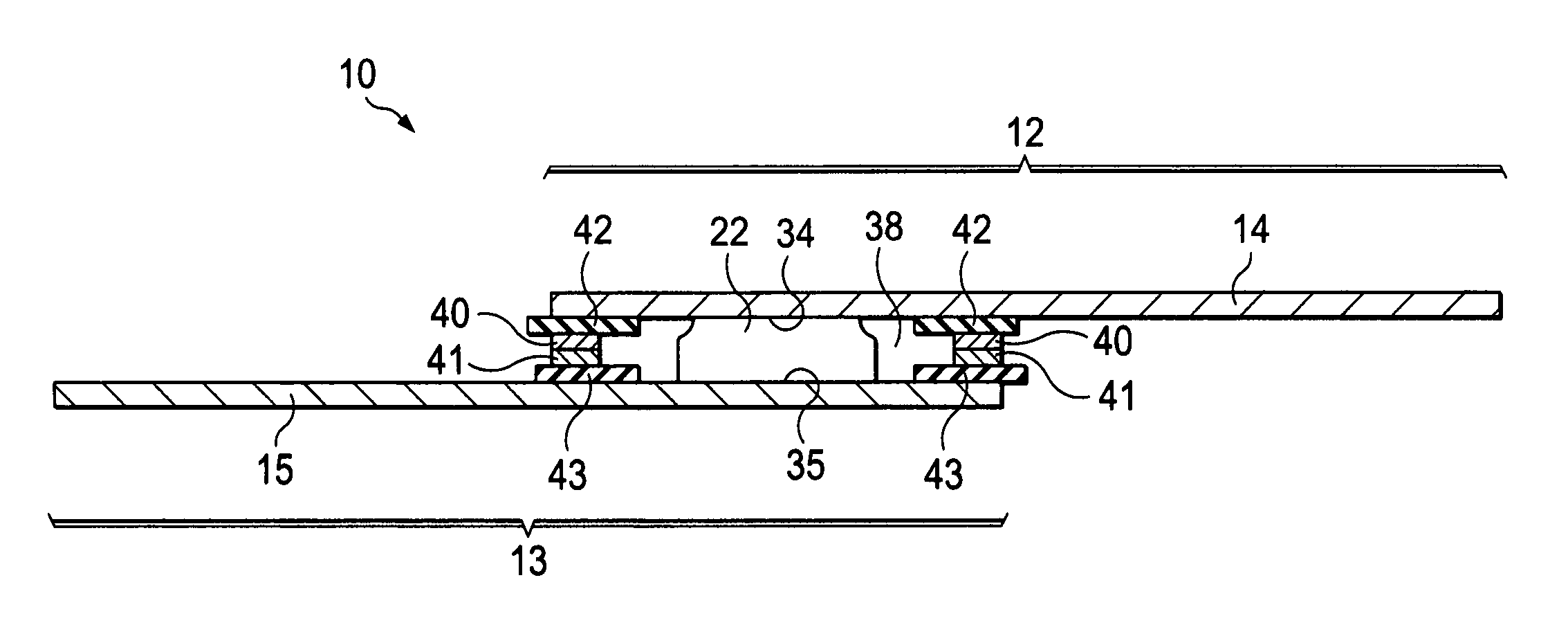

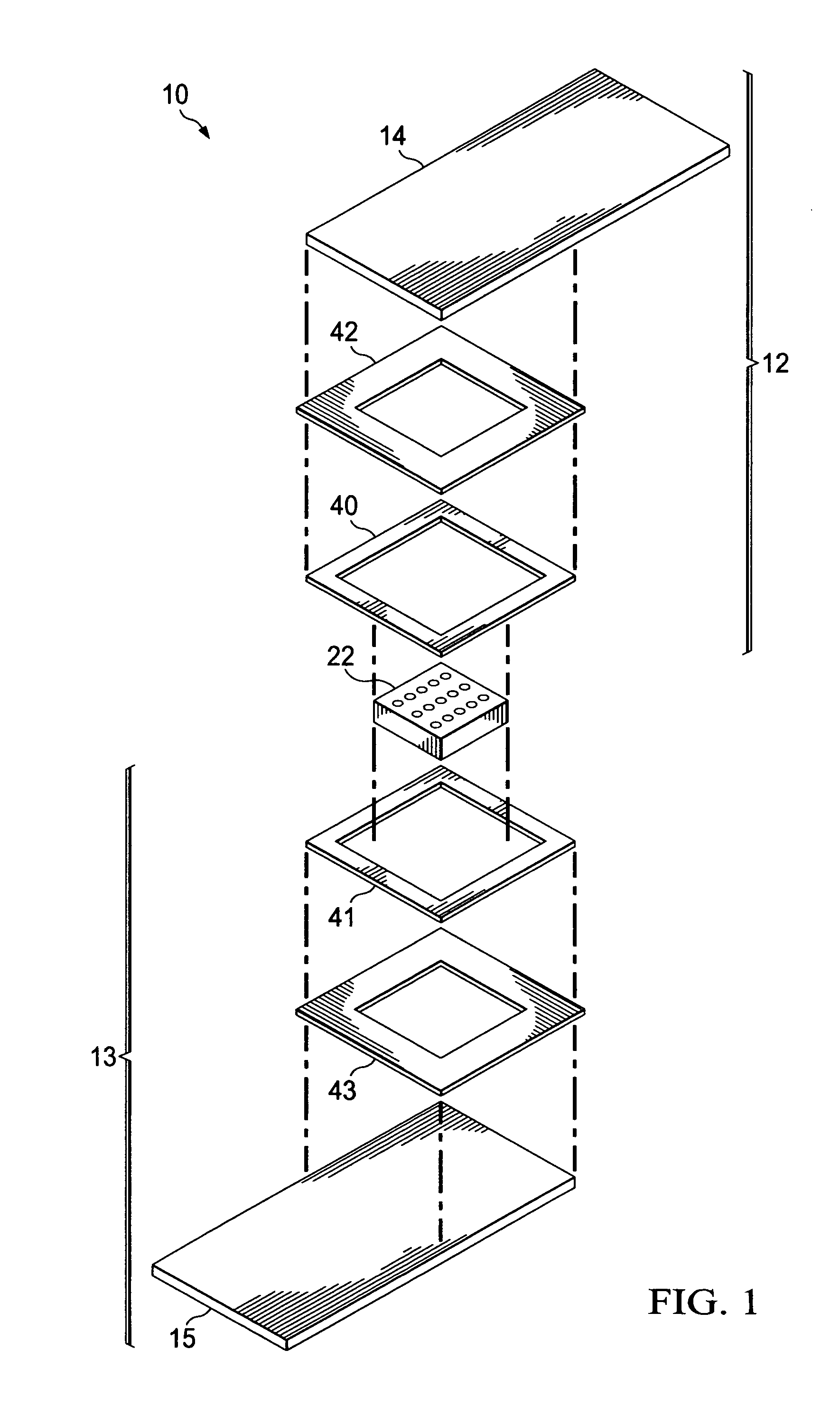

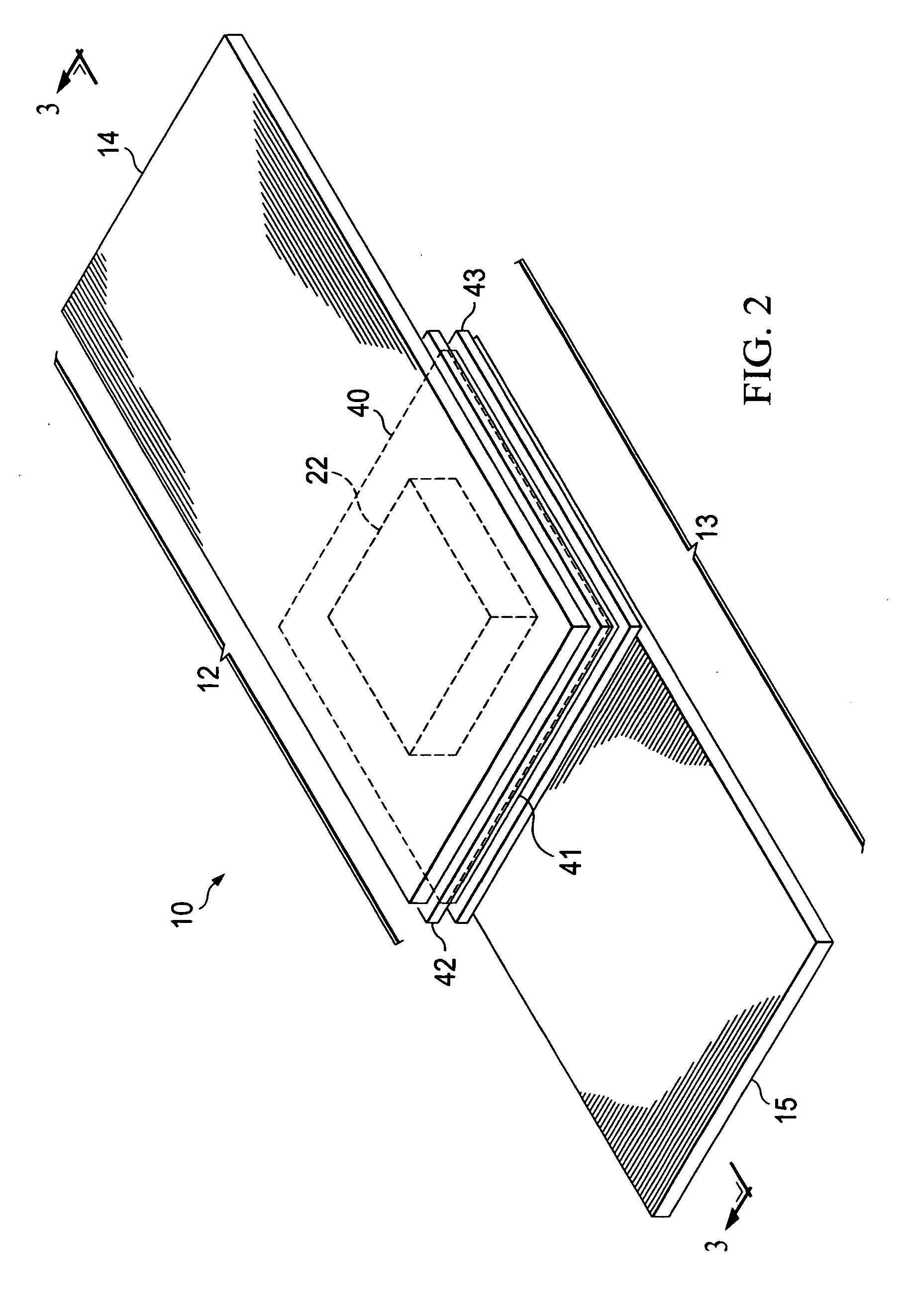

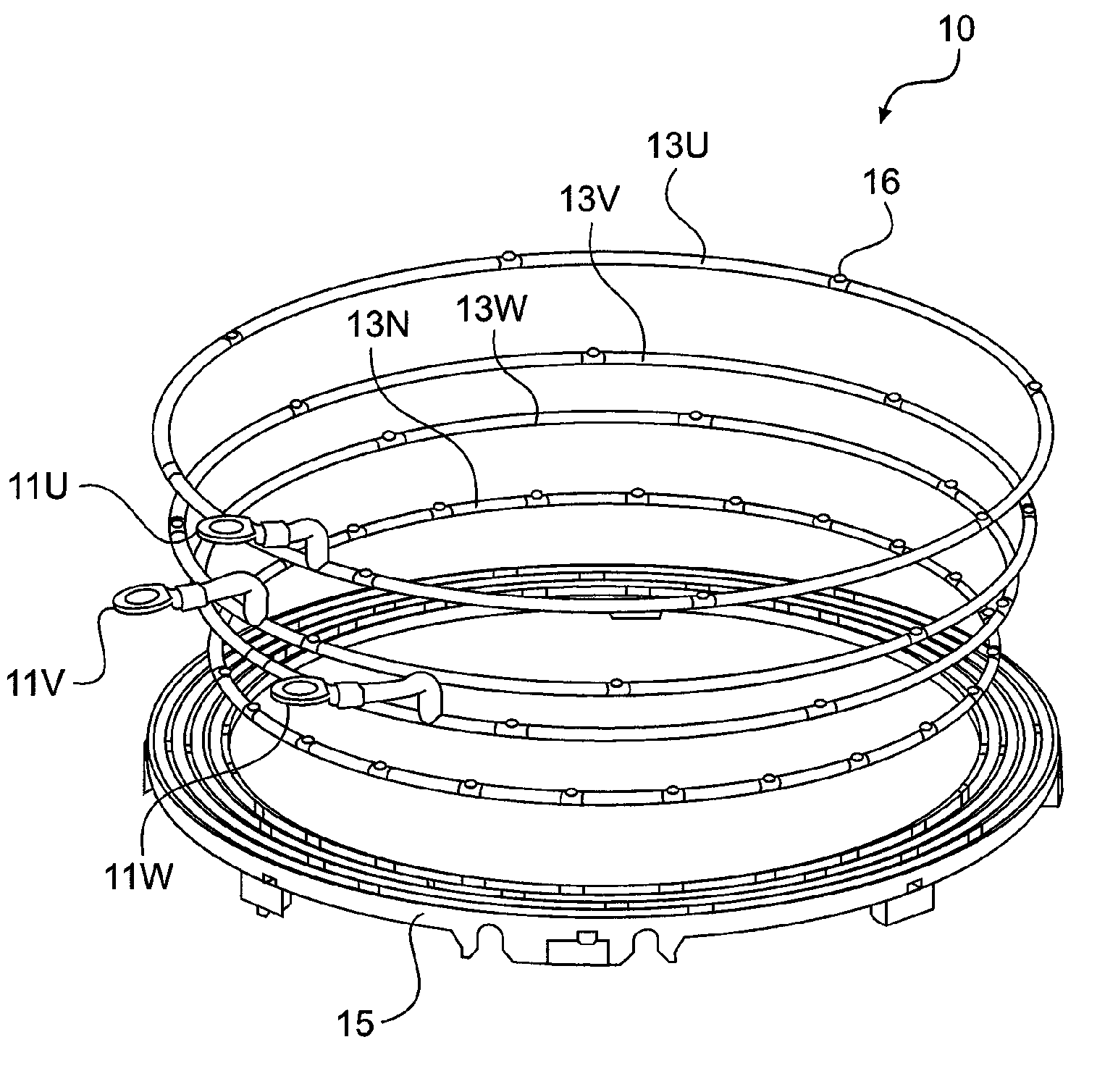

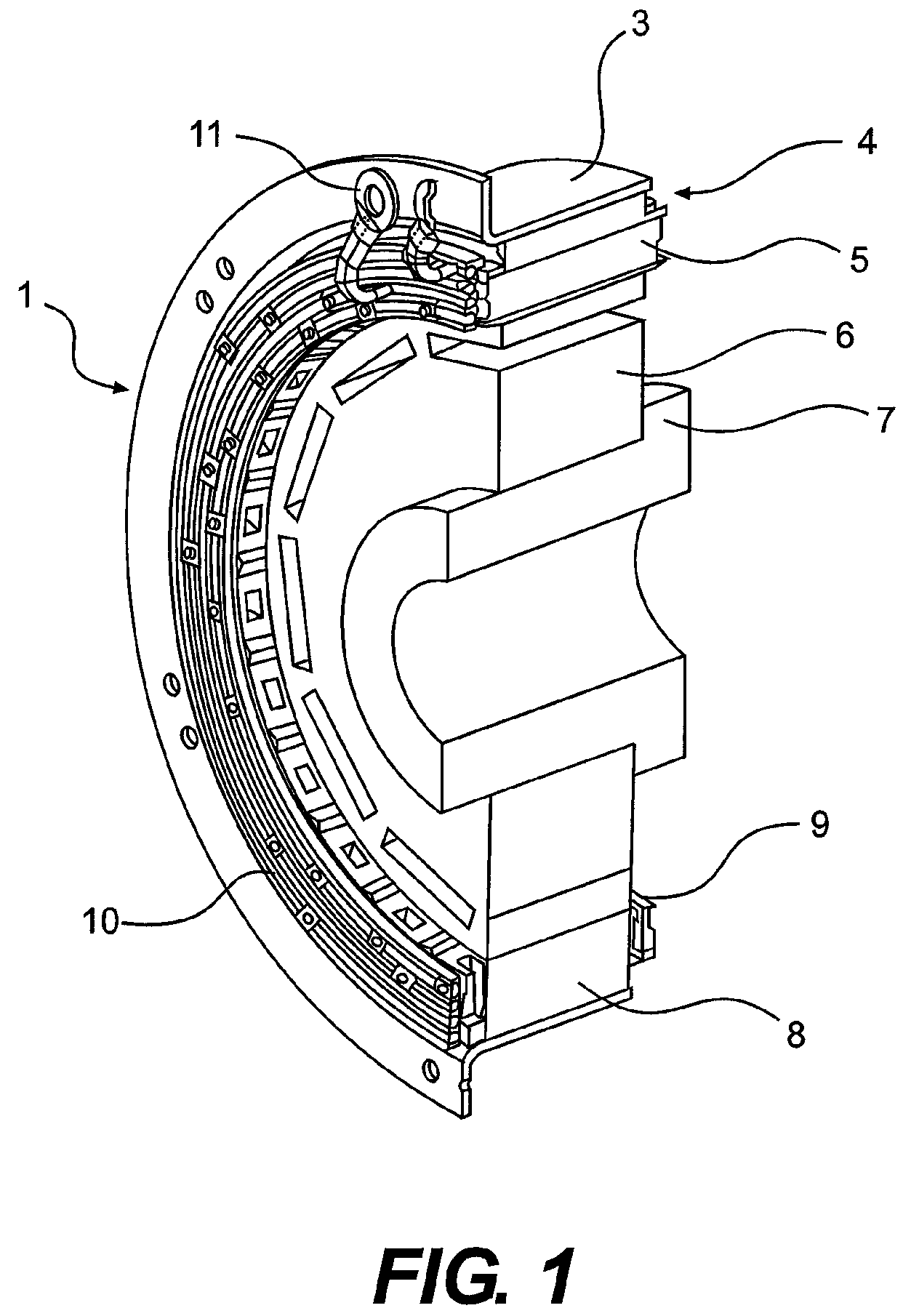

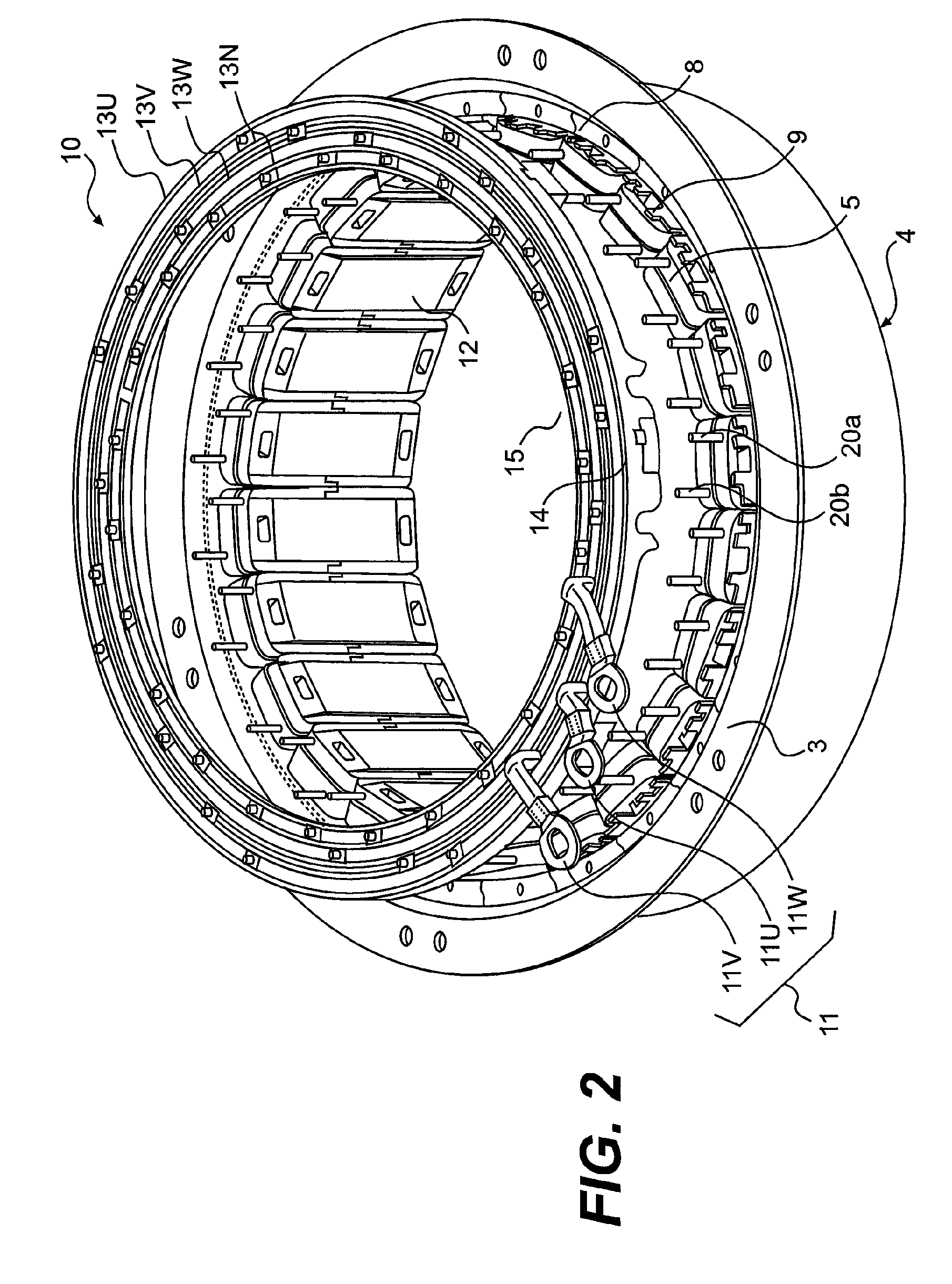

Rotary Electric Machine, Power Distribution Unit Therefor and Method for Assembling Rotary Electric Machine

ActiveUS20080265701A1Easily weldReduce in sizeWindingsManufacturing dynamo-electric machinesEngineeringElectrical conductor

The power distribution unit for a rotary electric machine includes a connecting ring unit that connects stator coils of the same phase. The connecting ring unit includes at least one linear conductor integrally formed in a ring-like shape, and the connecting ring unit includes a terminal section integrally formed in the linear conductor. The terminal section is constituted by a hole through which a wiring end of the stator coil is inserted and a protrusion formed in a direction of the hole to which the wiring end of the stator coil is connected. Also disclosed are a rotary electric machine includes the power distribution unit and a method for assembling a rotary electric machine.

Owner:HITACHI ASTEMO LTD

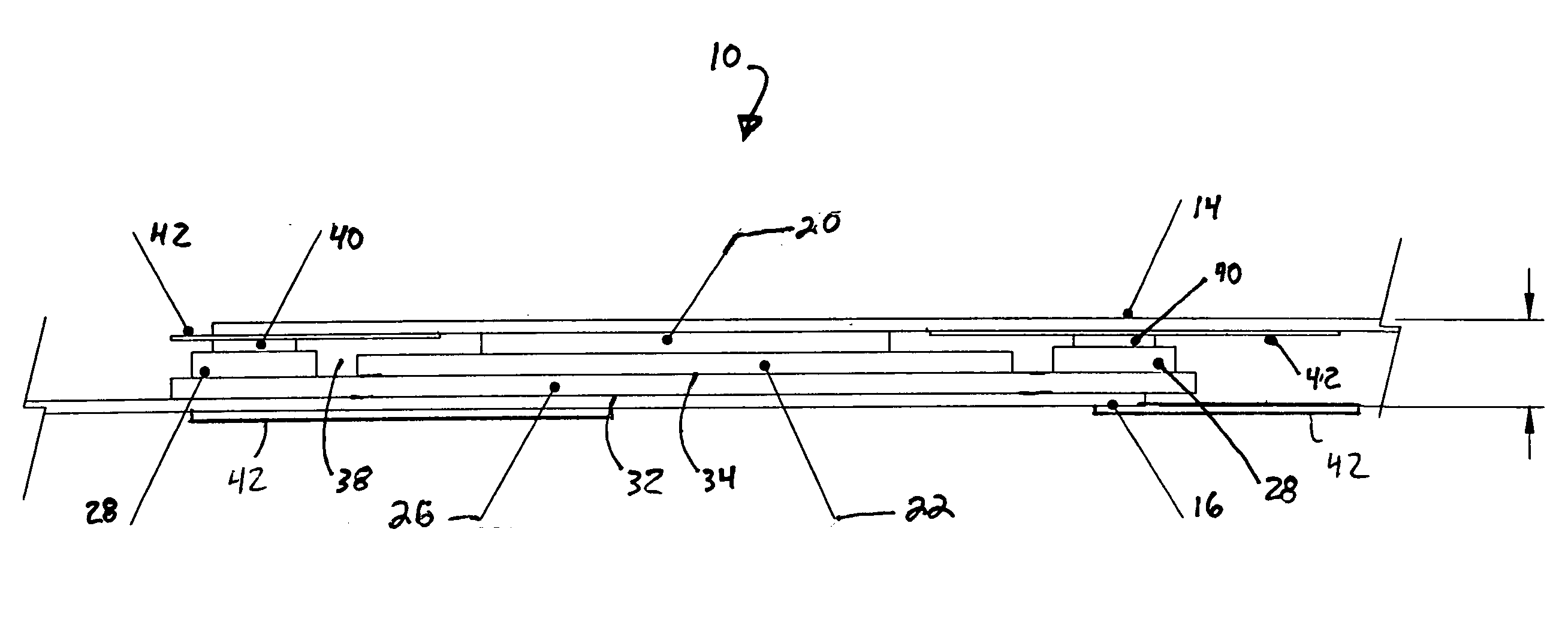

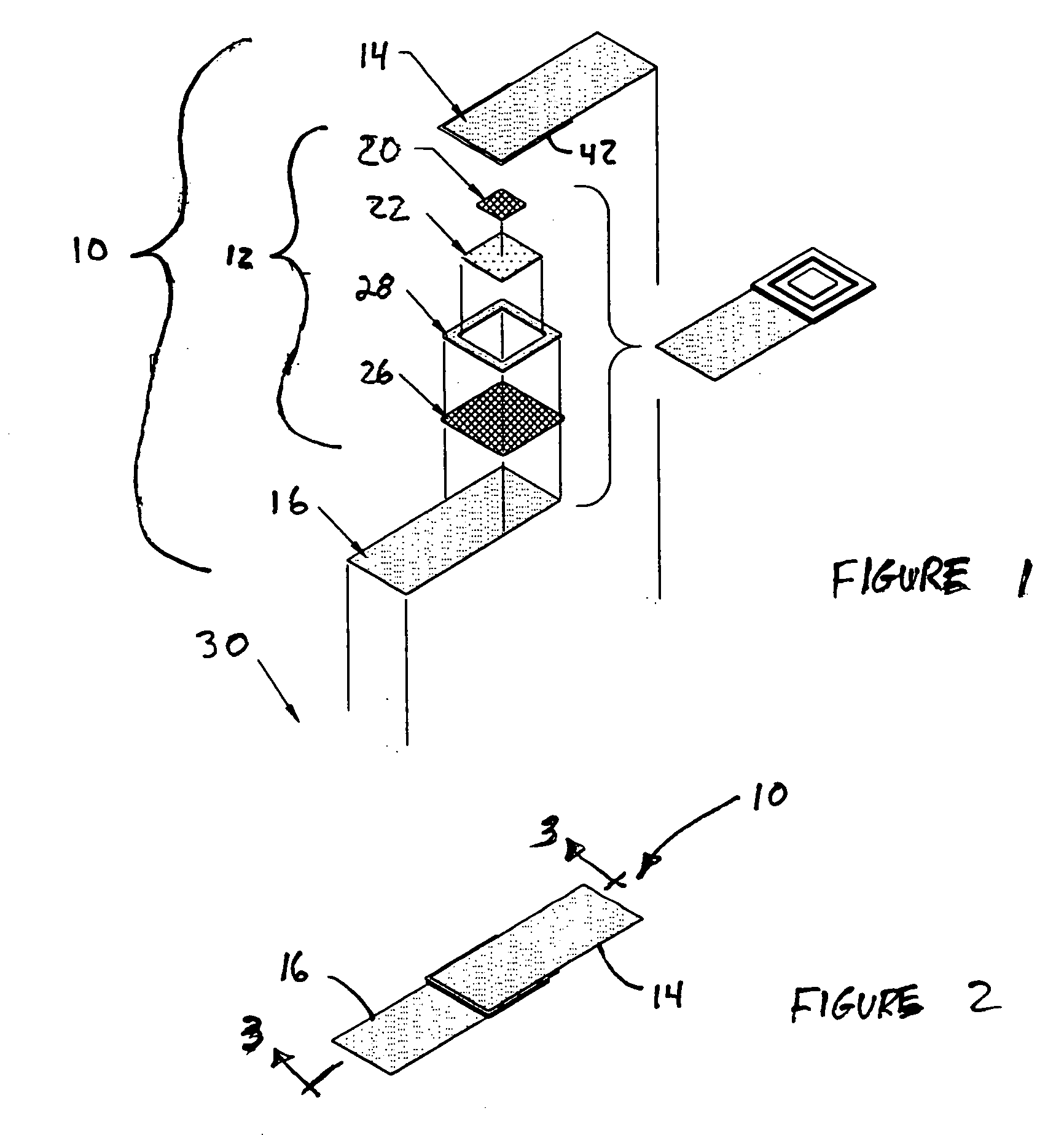

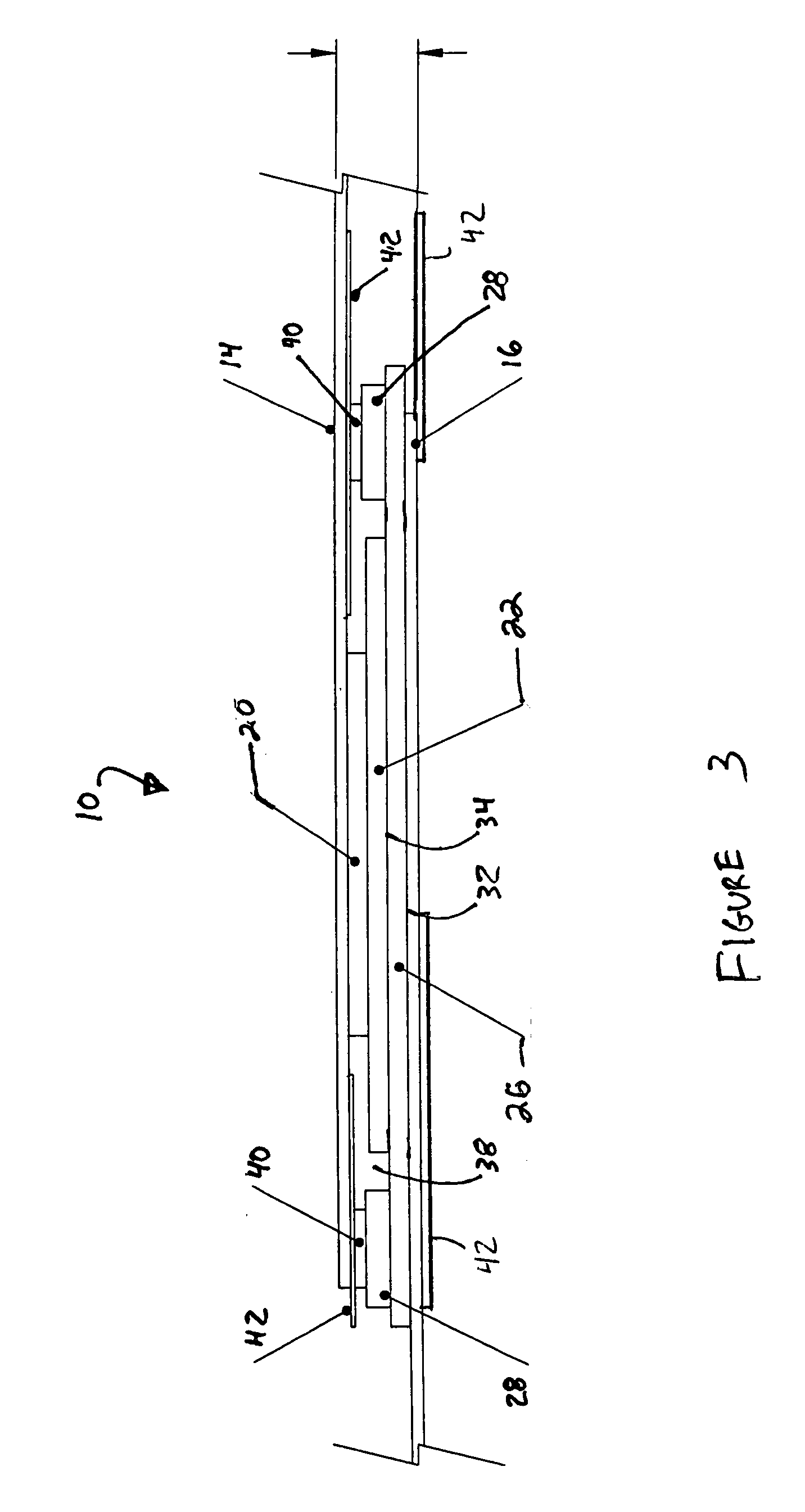

Flexible diode package and method of manufacturing

InactiveUS20100136748A1Simple packagingLow production costSemiconductor/solid-state device detailsSolid-state devicesAdhesiveExtreme temperature

A single step packaging process that both melts a solder and also cures an adhesive about a microelectronic circuit. The process finds technical advantages by simplifying packaging of a die that may be coupled to a planar flexible lead, which leads to a lower production cost and quicker manufacturing time. The planar flexible lead may be adapted to bend and flex during mechanical stress and during extreme temperature cycling, and allow direct mounting of the device to a member by easily welding or soldering. The invention may comprise a flexible solar cell diode that can be closely positioned on solar panels at an extremely low cost.

Owner:MICROSEMI

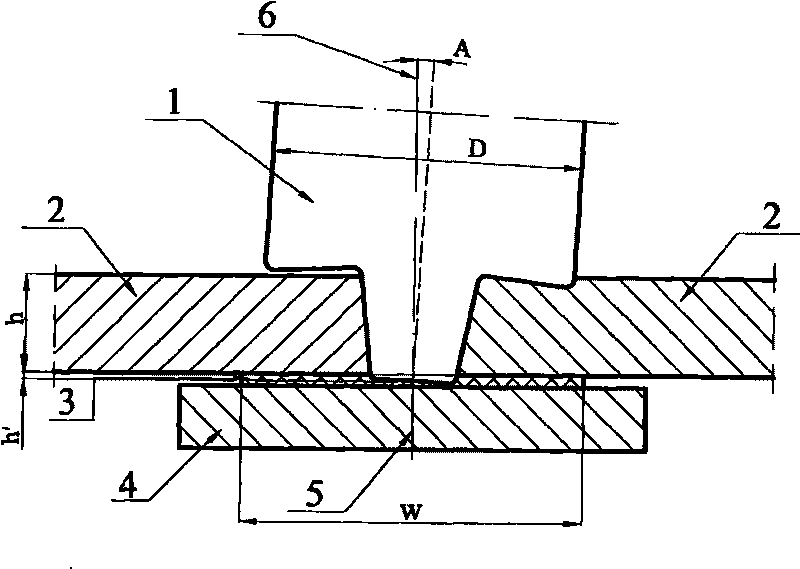

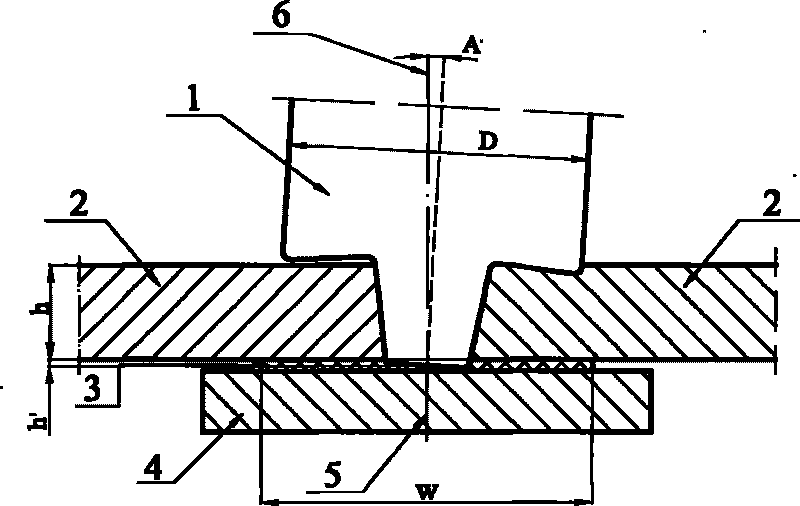

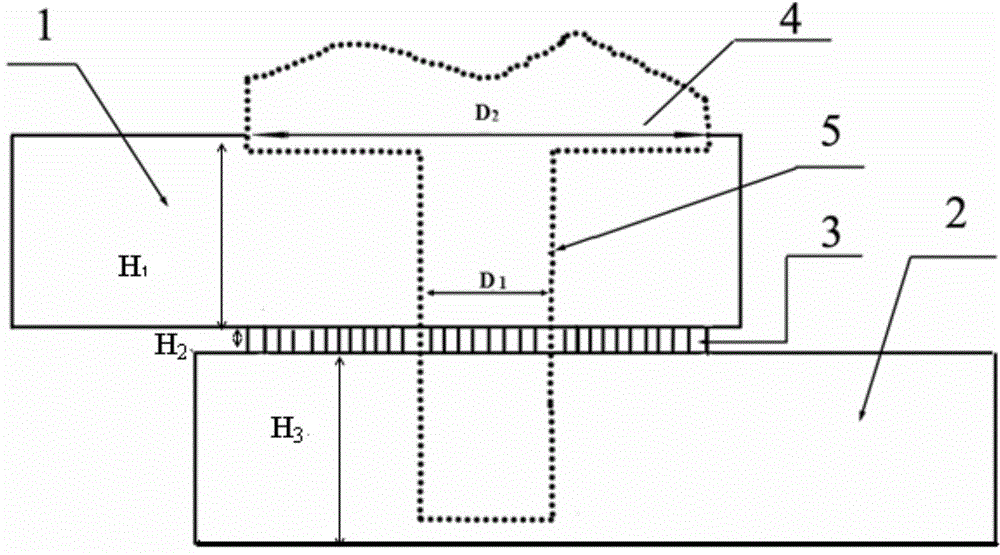

Method for eliminating incomplete penetration and weak root connection of friction stir welding joint

ActiveCN101733542AImprove stabilityAvoid volatilityNon-electric welding apparatusFriction weldingButt joint

The invention relates to friction stir welding, and discloses a method for eliminating incomplete penetration and weak root connection of a friction stir welding joint. The method comprises the following steps of: 1. producing a gasket, wherein materials and the heat treatment state of the gasket are the same as those of a to-be-welded workpiece; 2. assembling the gasket, namely arranging the gasket between the to-be-welded workpiece and a back rigid bottom plate; 3. preparing before welding, wherein an included angle between a stirring tool and the center of a main shaft is between 0 to 3 DEG; 4. formally welding; and 5. removing the gasket after finishing the welding, and polishing the back surface of a welding seam to ensure that the back surface of the welding seam is flush with a base body. The method for eliminating the incomplete penetration and the weak root connection of the friction stir welding joint can eliminate the defects of the incomplete penetration and the weak root connection which are often generated in stir welding, and has the advantages of improving welding quality, and enhancing stability of the welding process and the like. The method is suitable for butted joint type friction stir welding of all spacial shapes.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

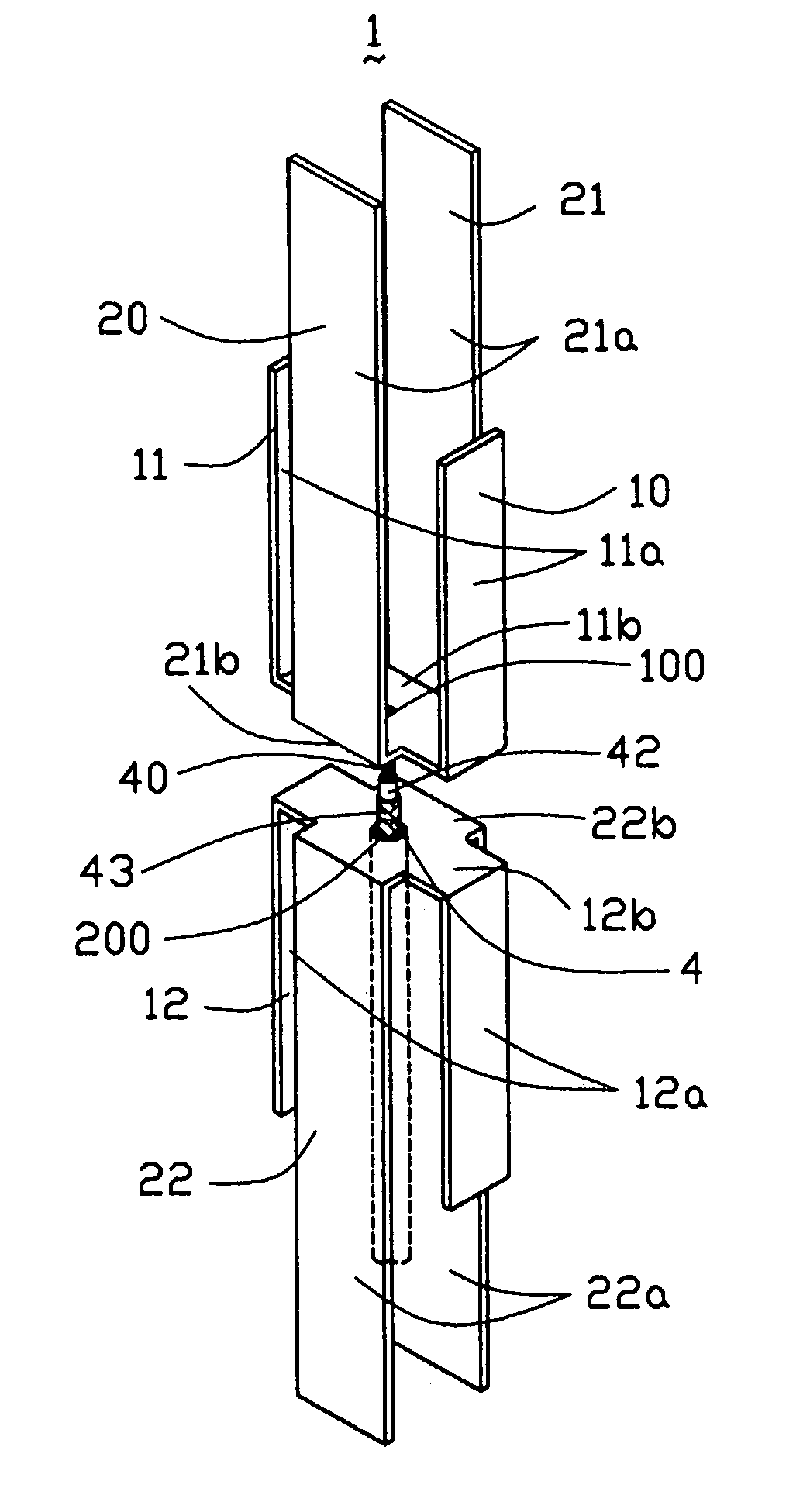

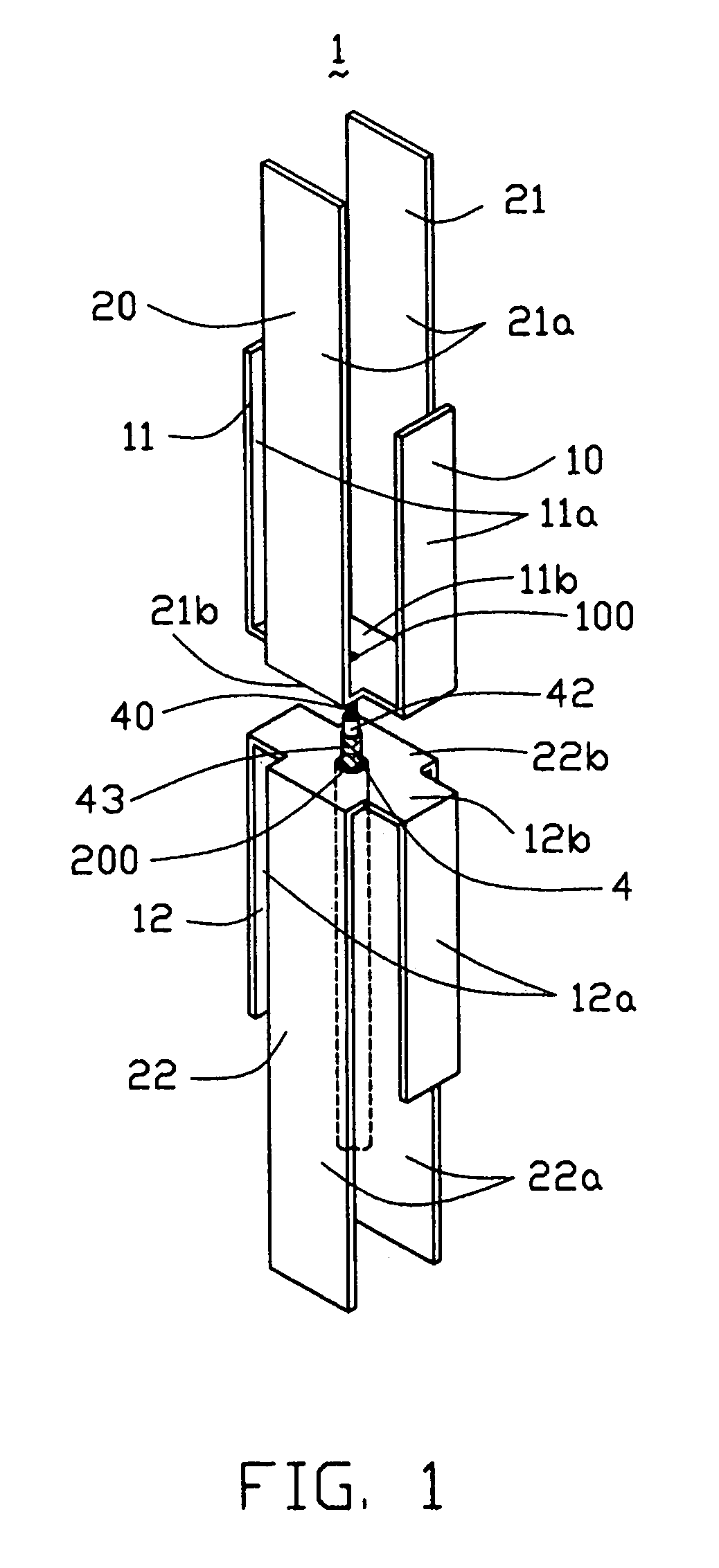

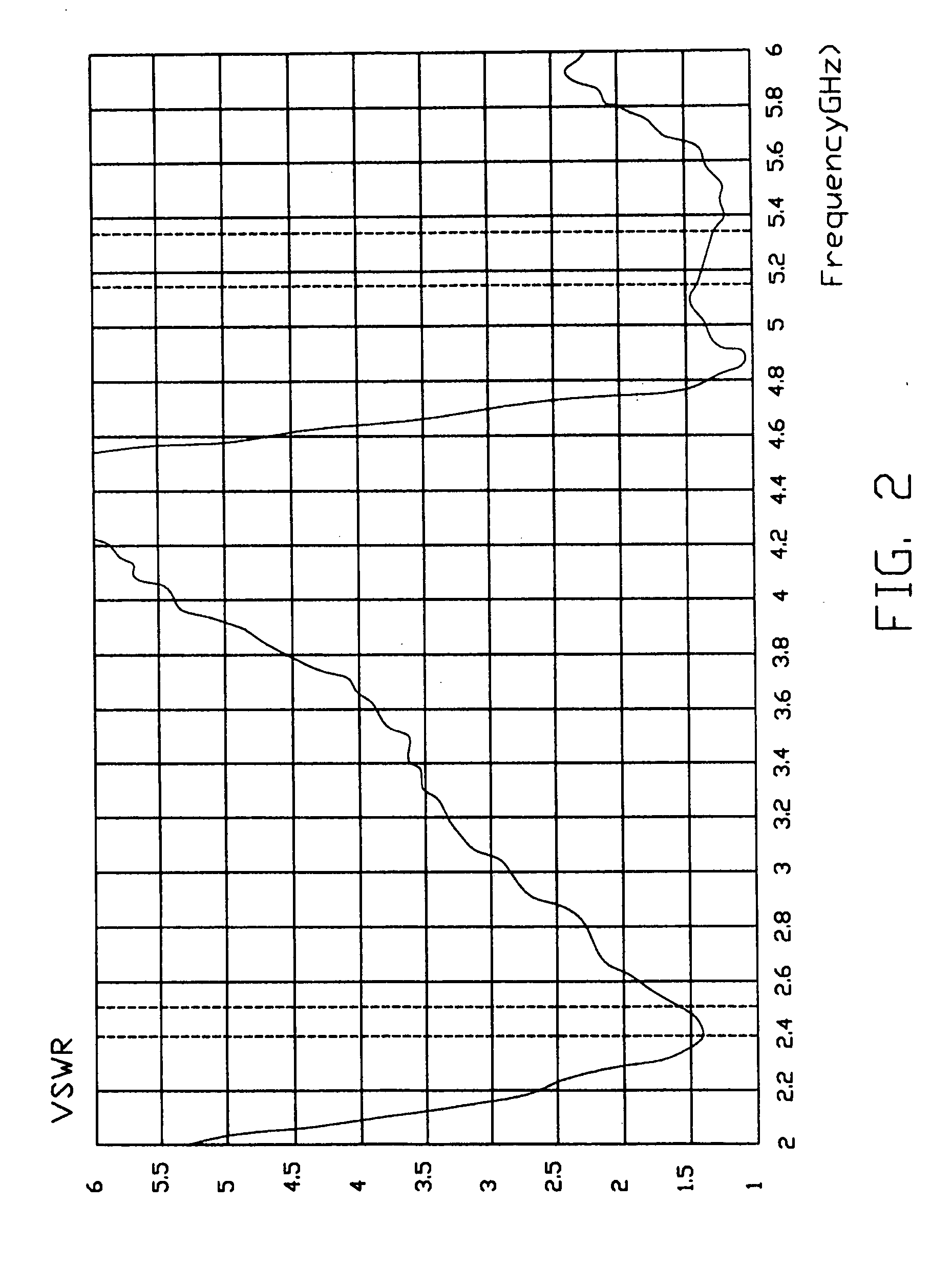

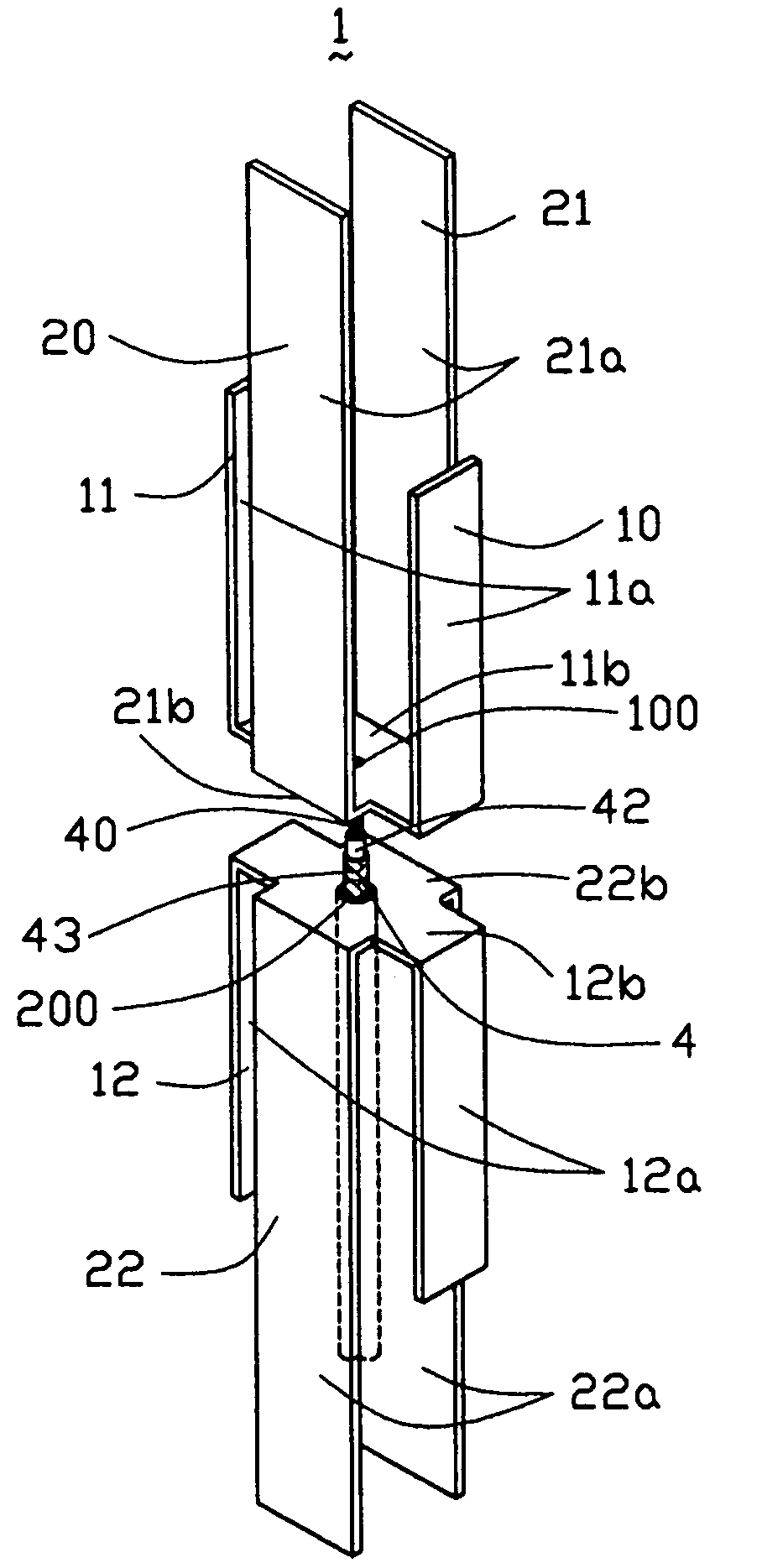

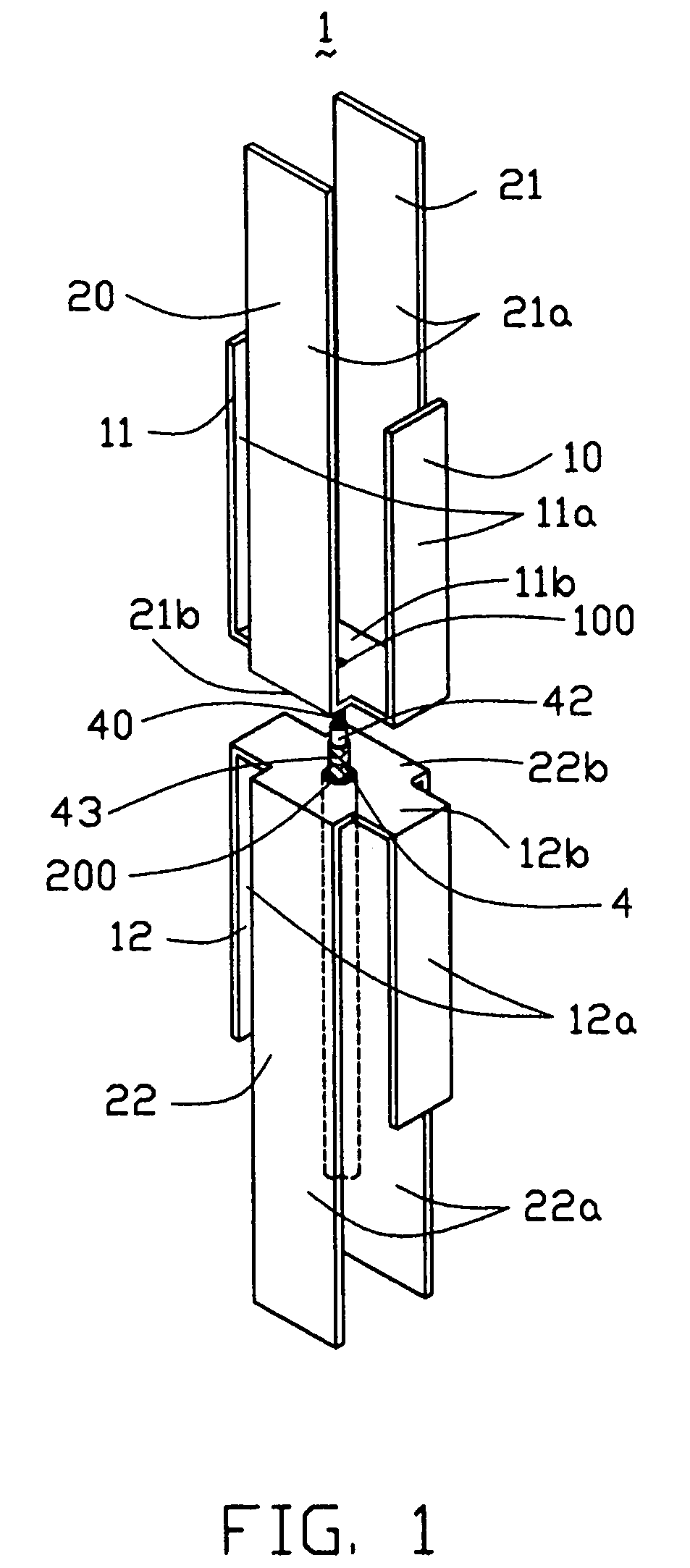

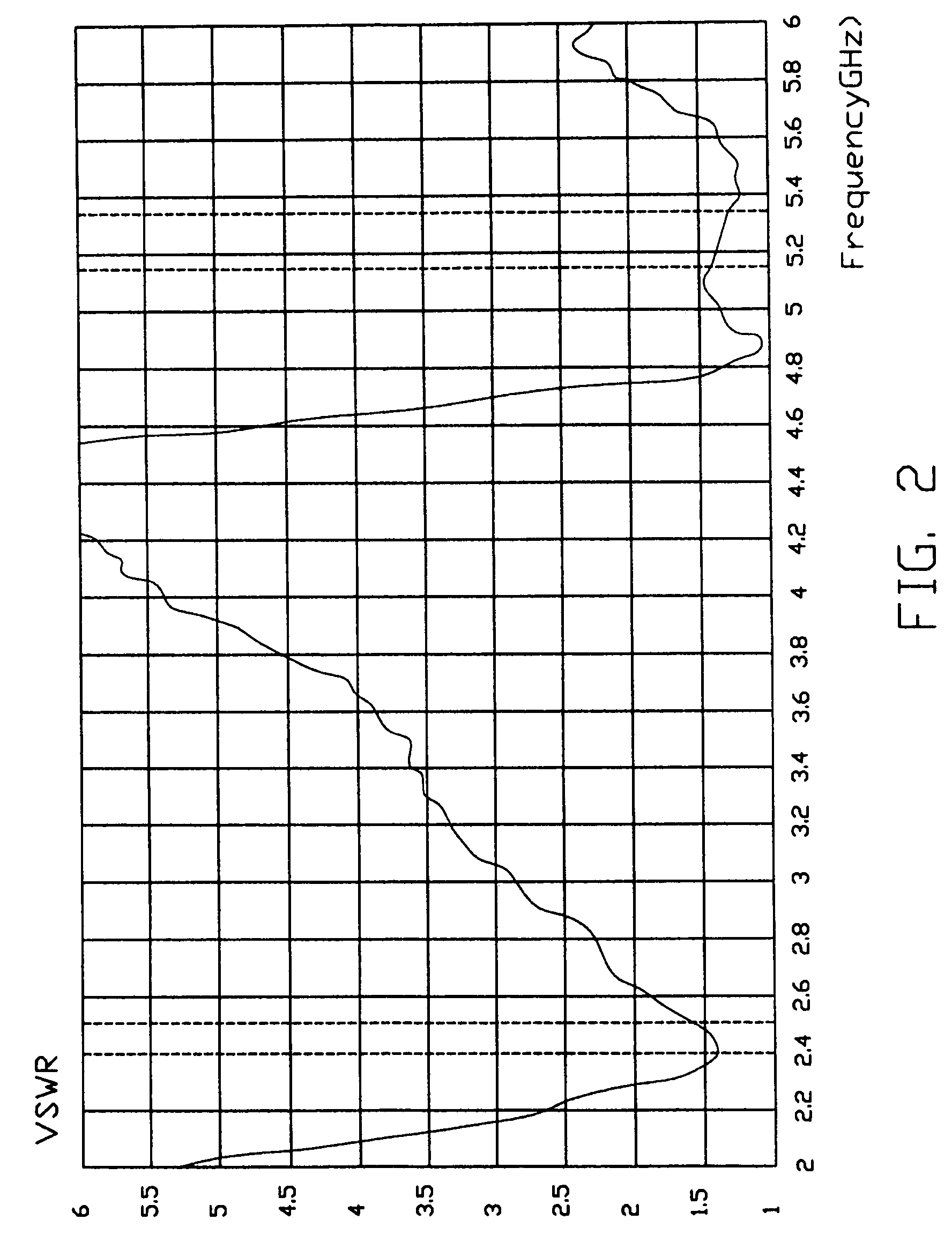

Dual-band dipole antenna

InactiveUS20050243007A1Simple structureLow costSimultaneous aerial operationsAntenna feed intermediatesDual band antennaDipole antenna

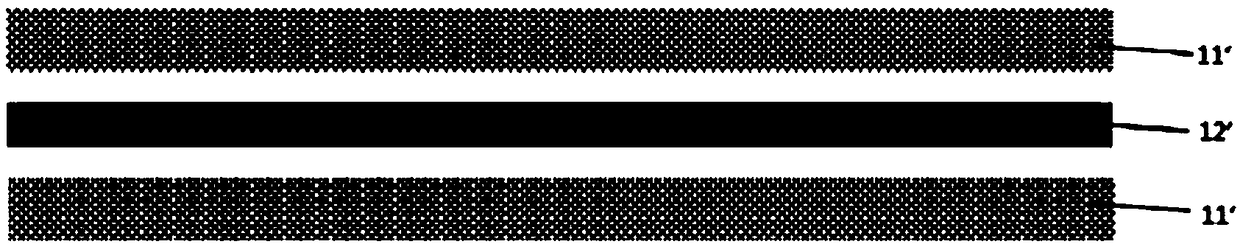

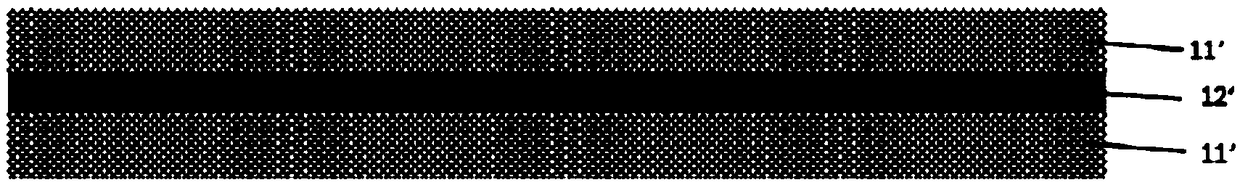

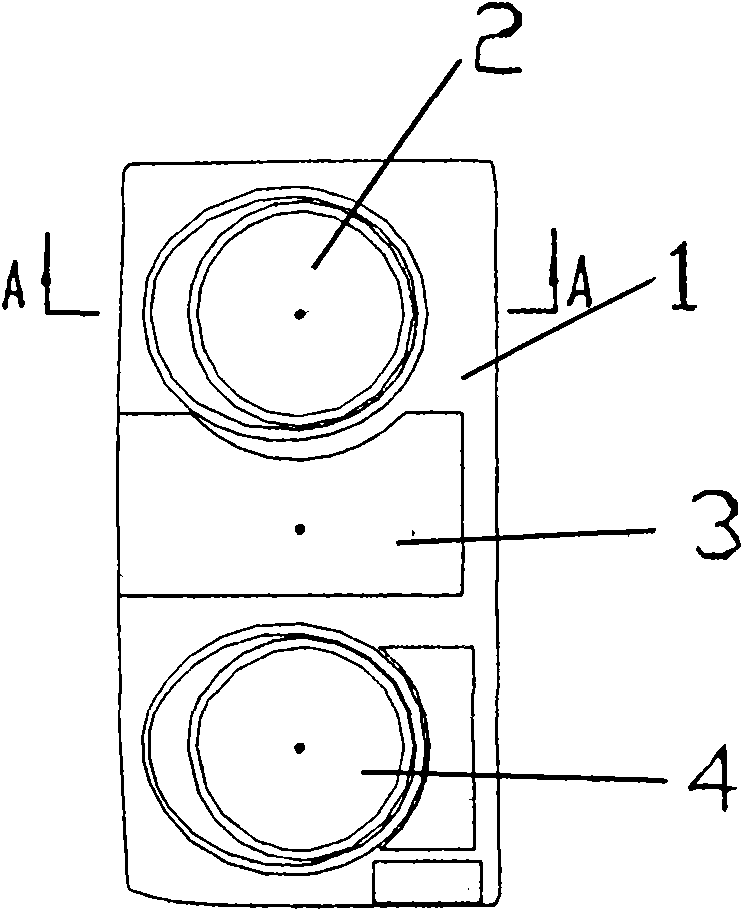

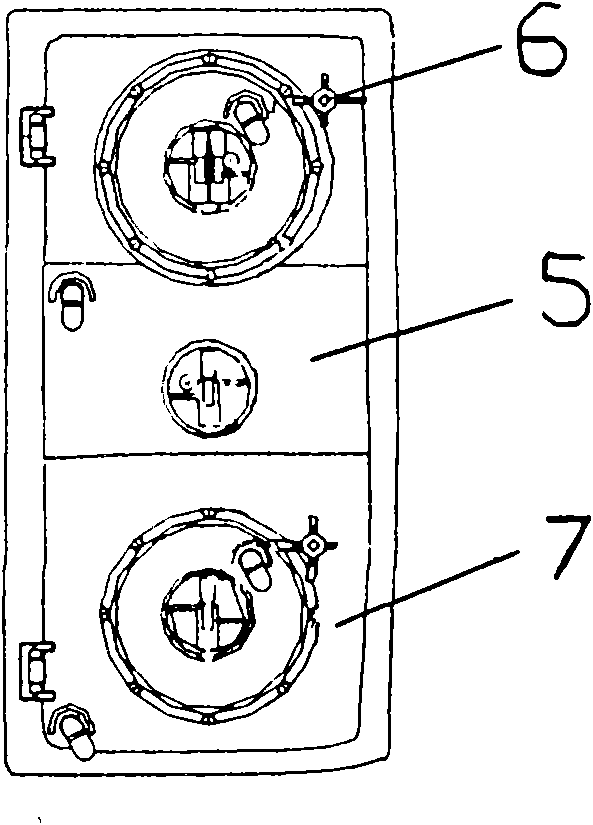

A dual-band antenna (1) includes a first antenna (2) and a second antenna (3). The first antenna includes a u-shaped first dipole half (11) and an n-shaped second dipole half (12). The first dipole half is disposed above the second dipole half with a space therebetween and the two dipole halves are mirror imaged. The second antenna includes a u-shaped third dipole half (21) and an n-shaped fourth dipole half (22). The first and the third dipole halves are crossly connected with each other at bottom. The second and the fourth dipole halves are crossly connected with each other at top.

Owner:HON HAI PRECISION IND CO LTD

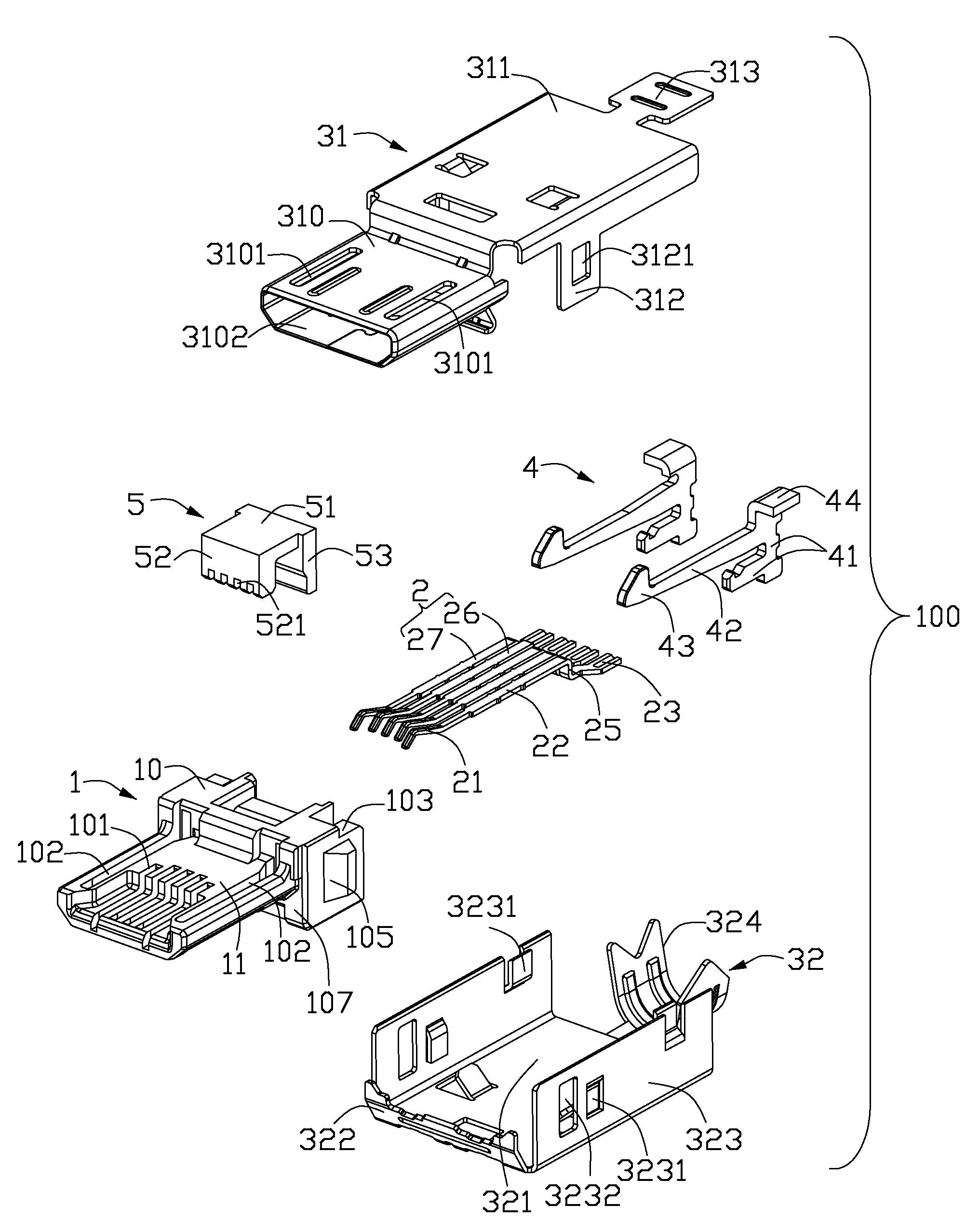

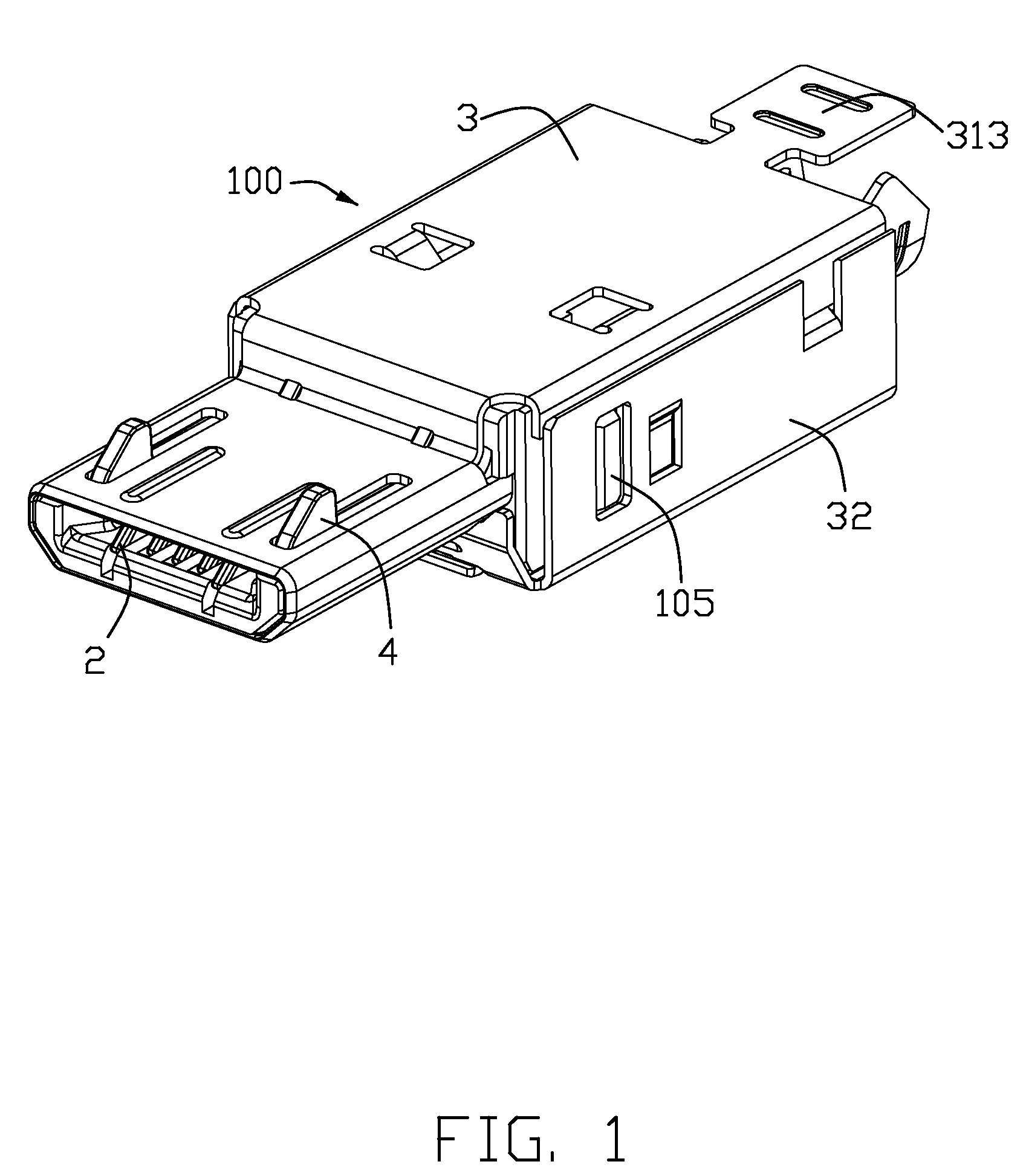

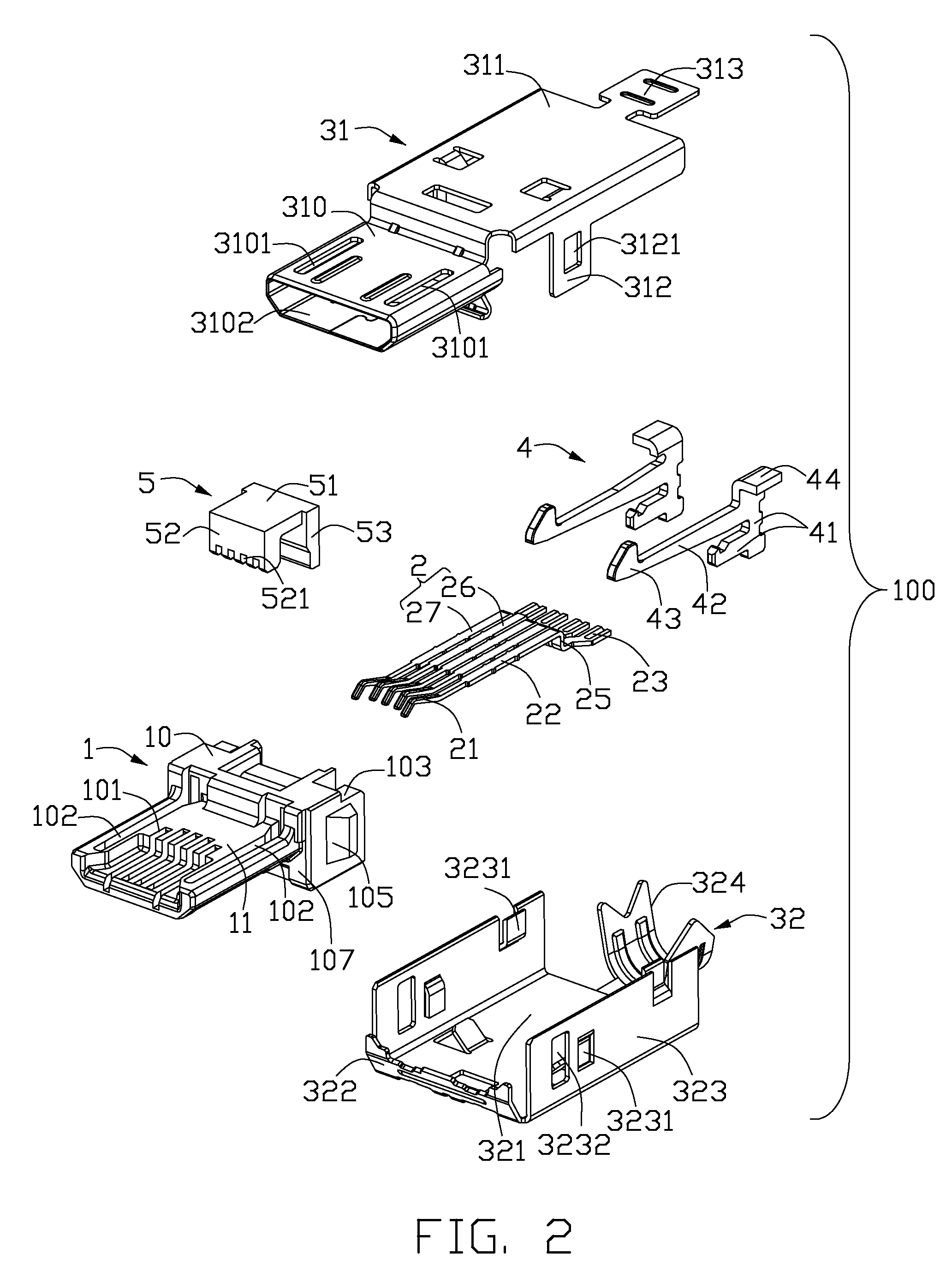

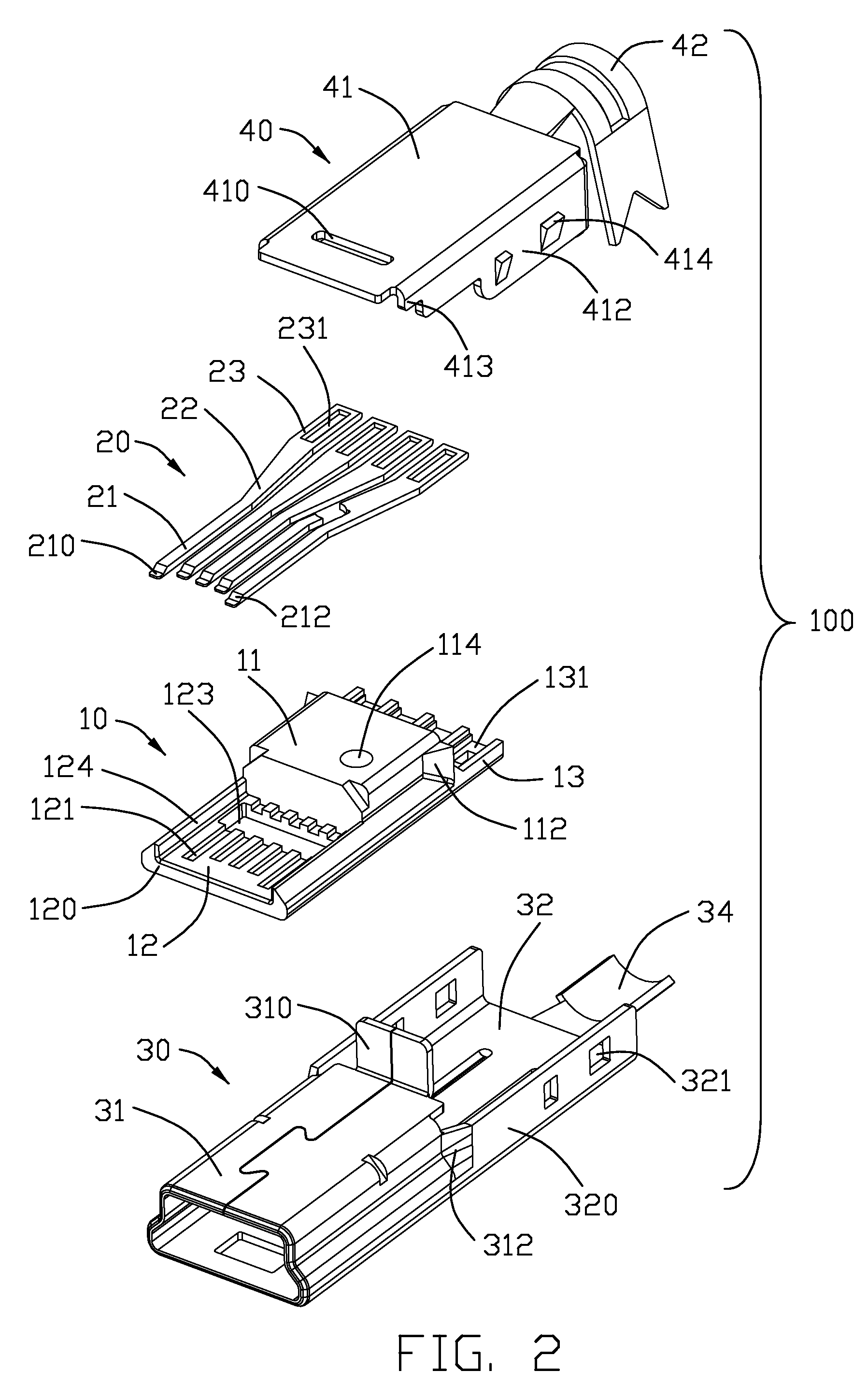

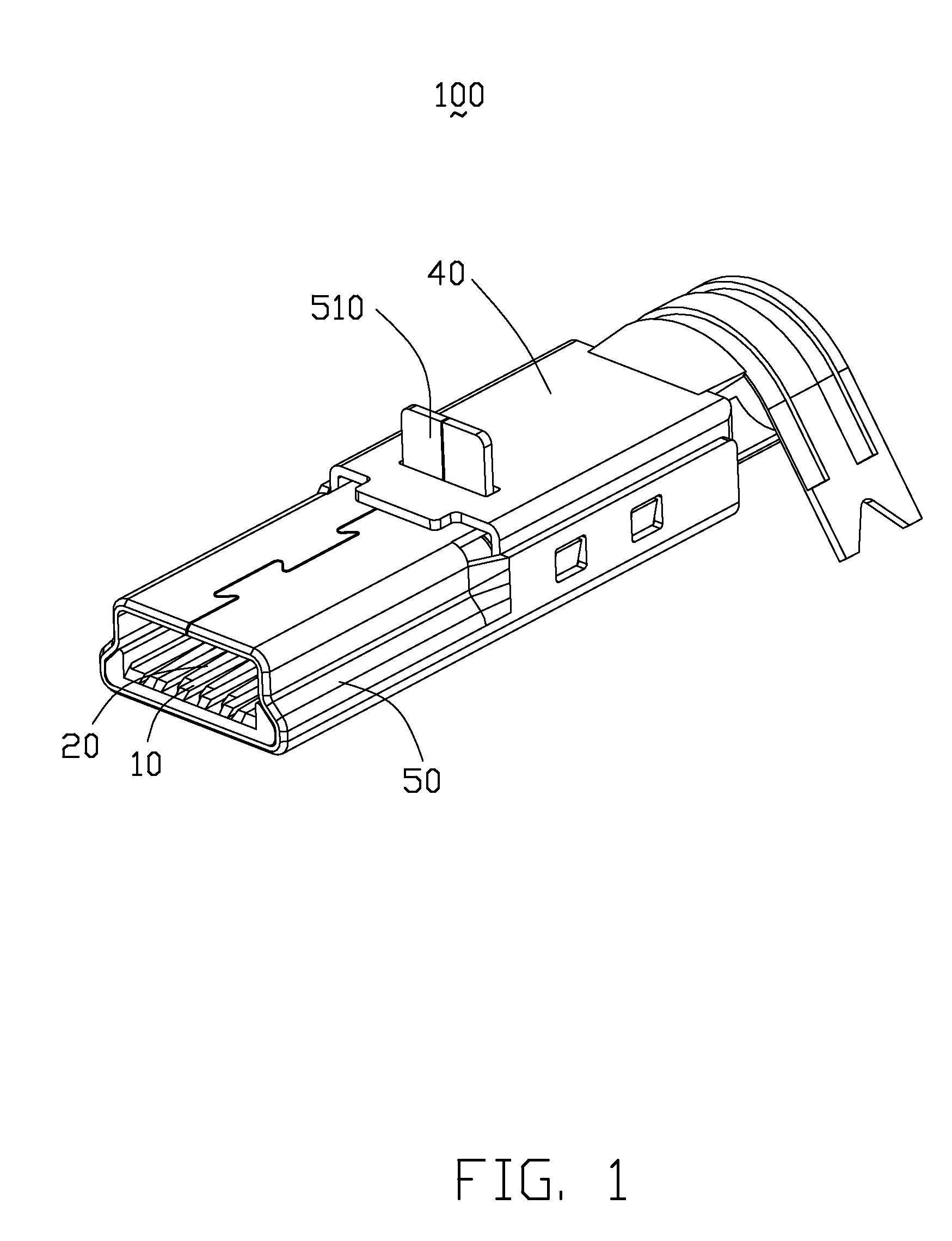

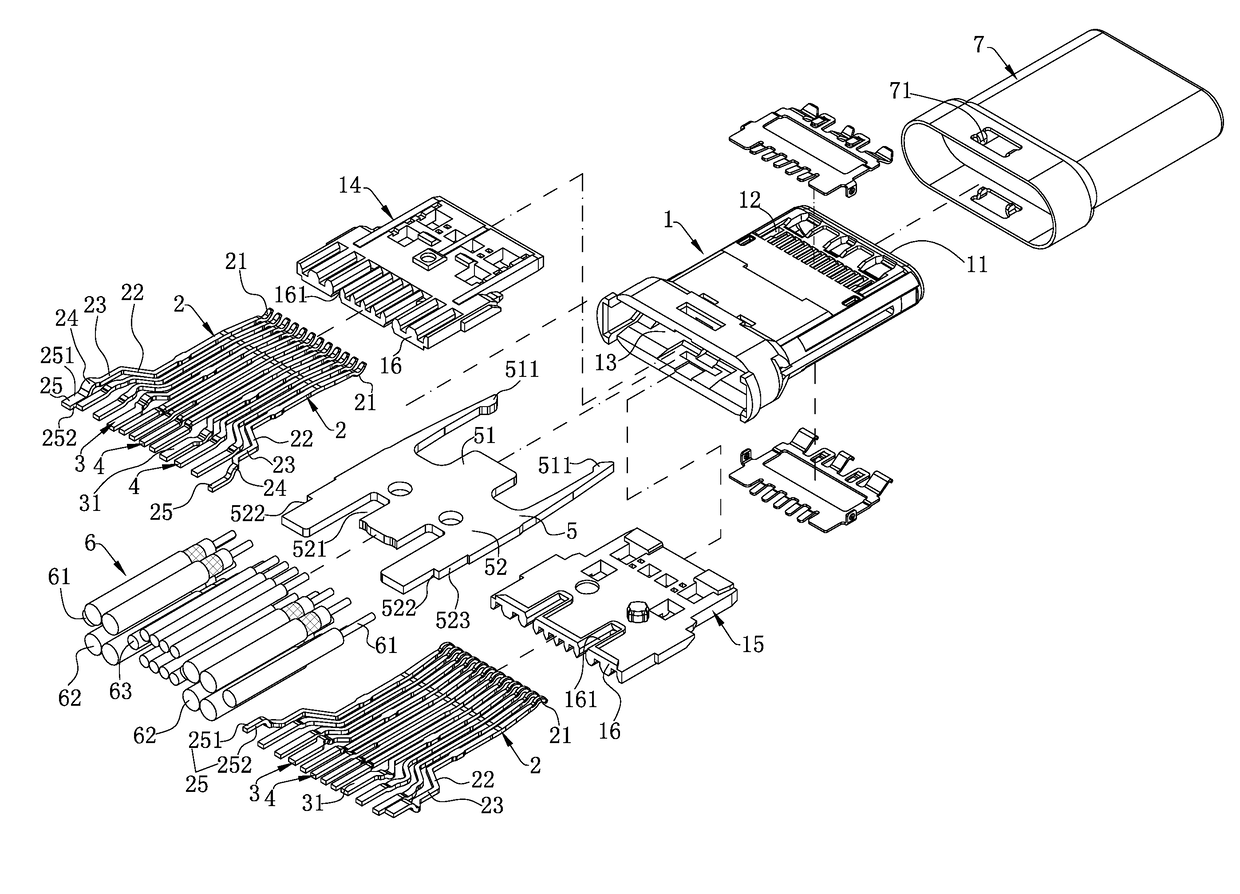

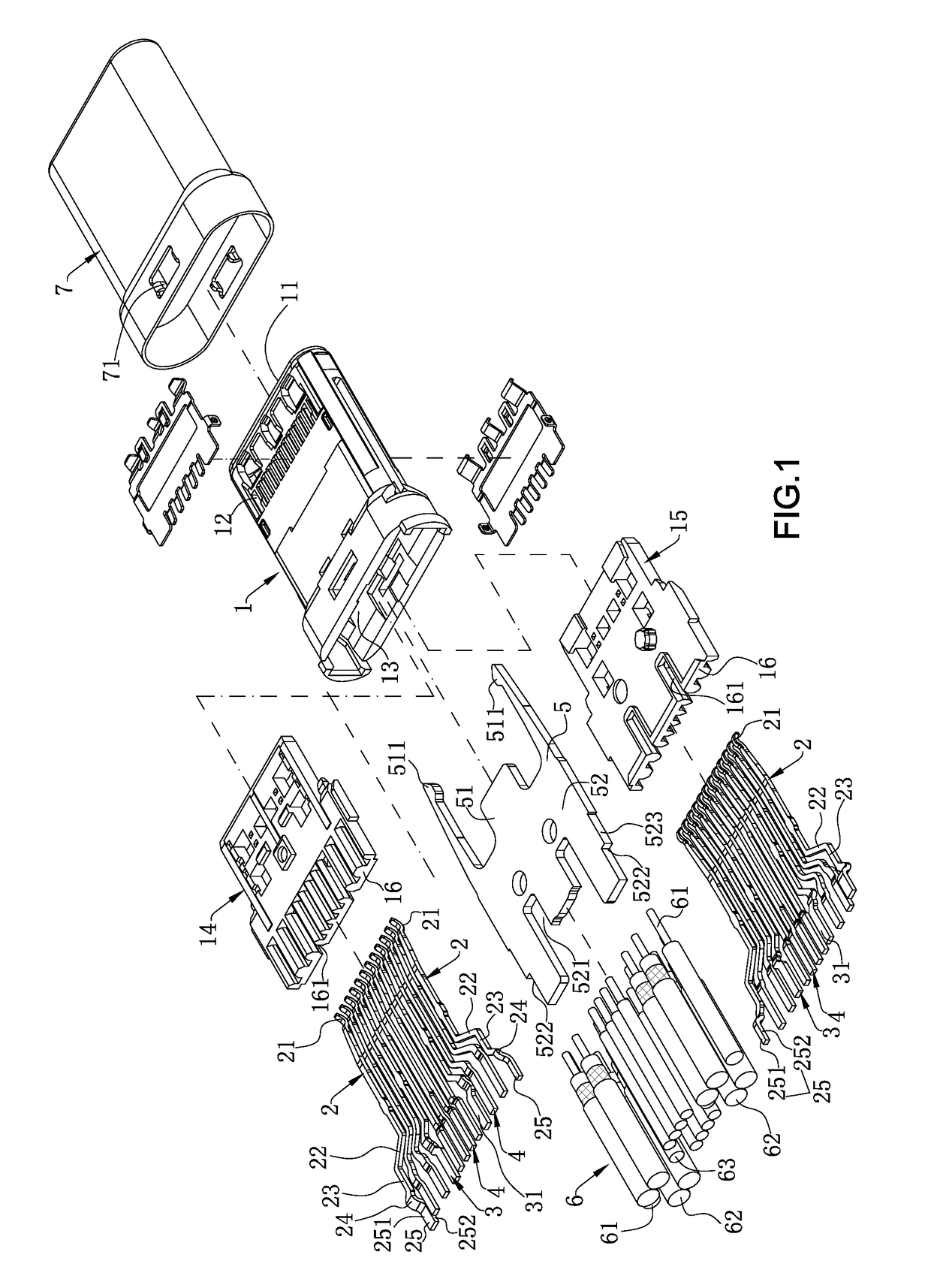

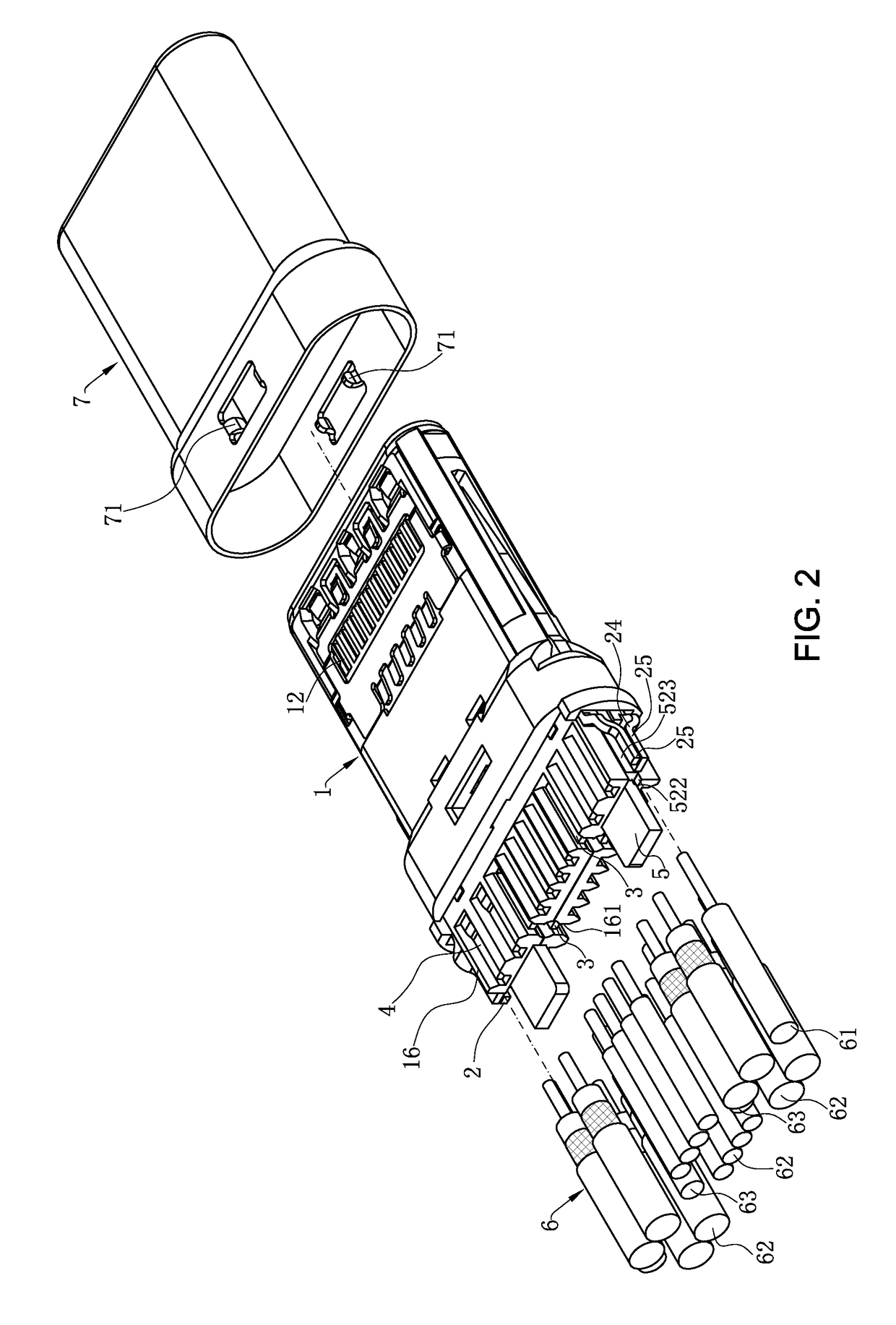

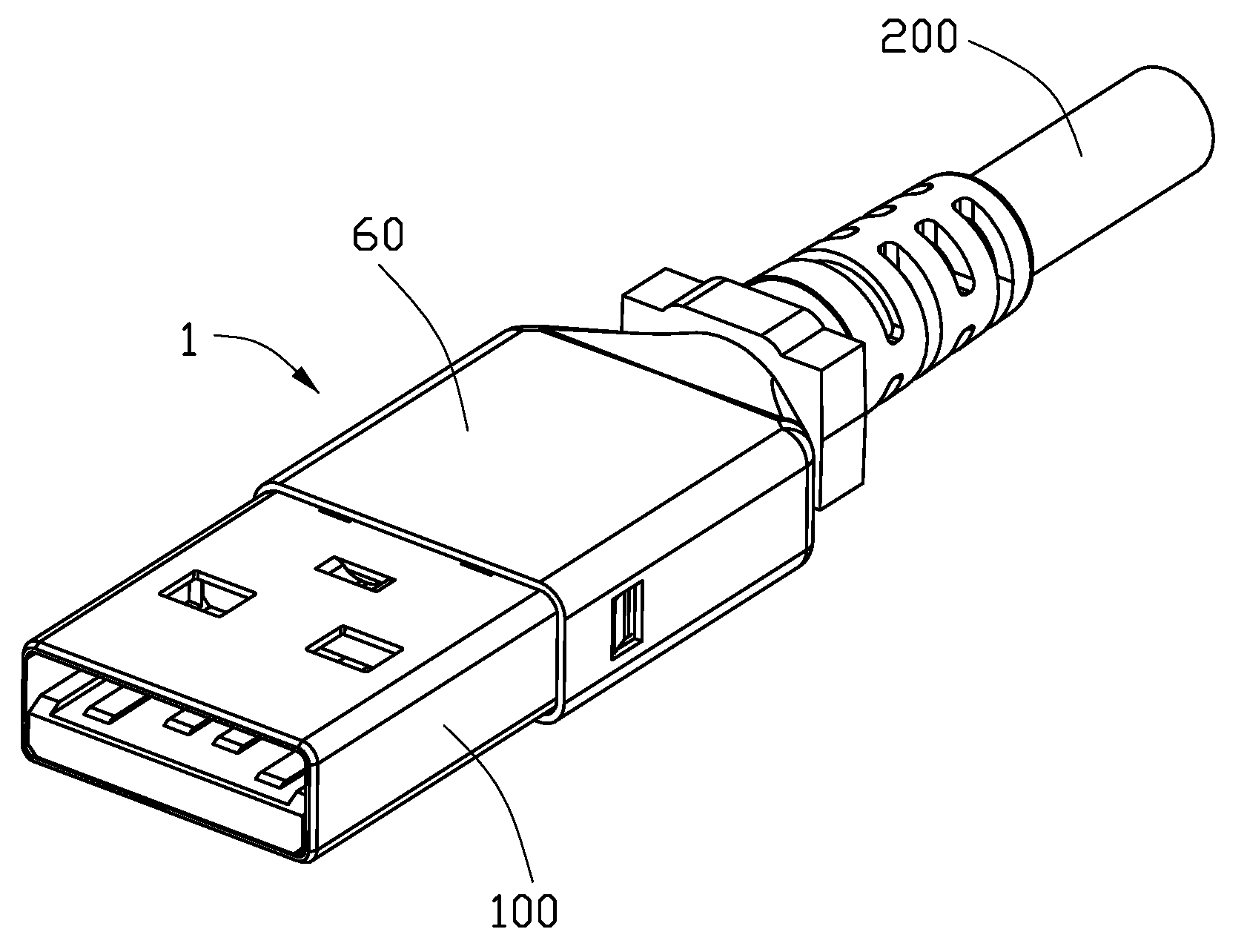

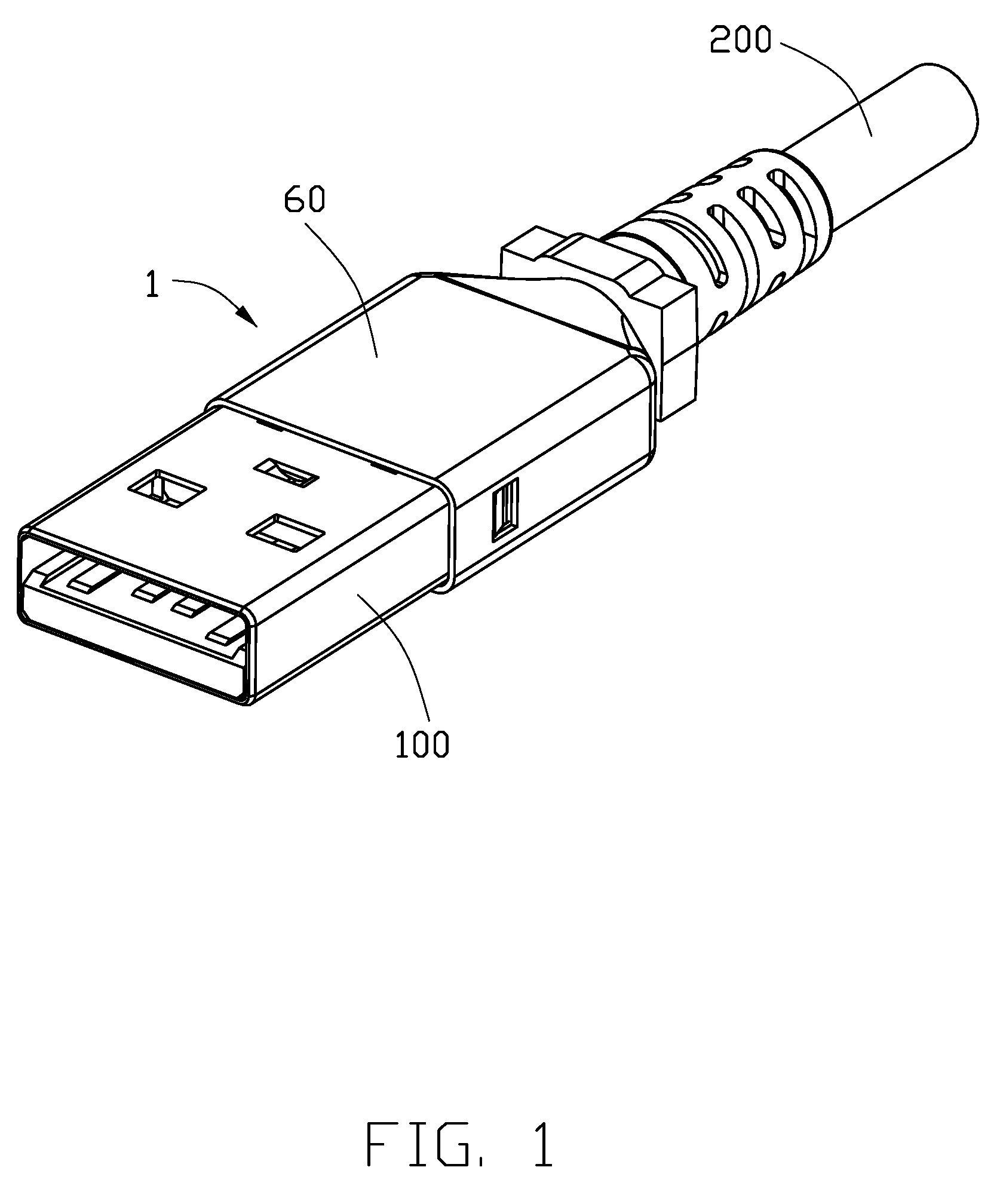

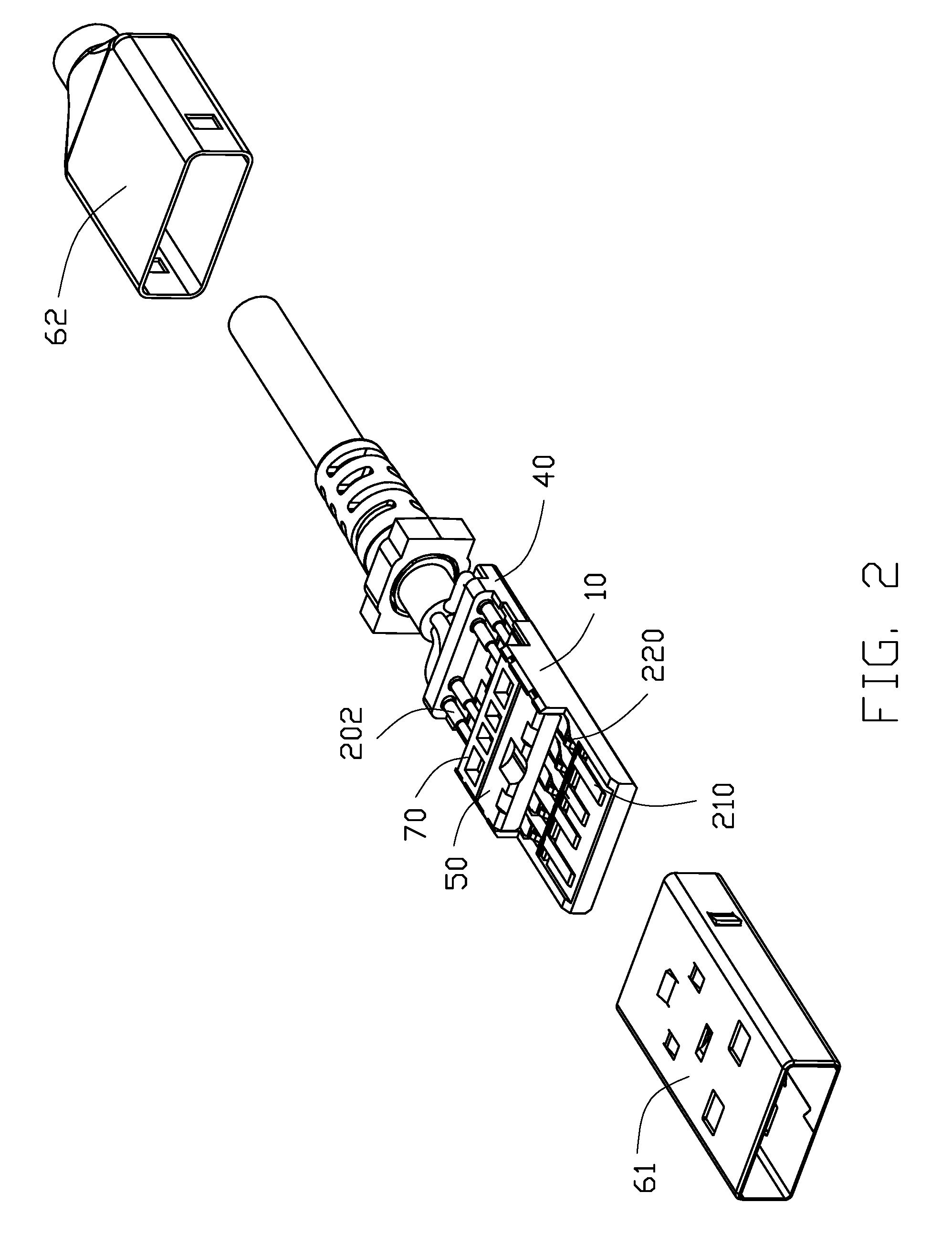

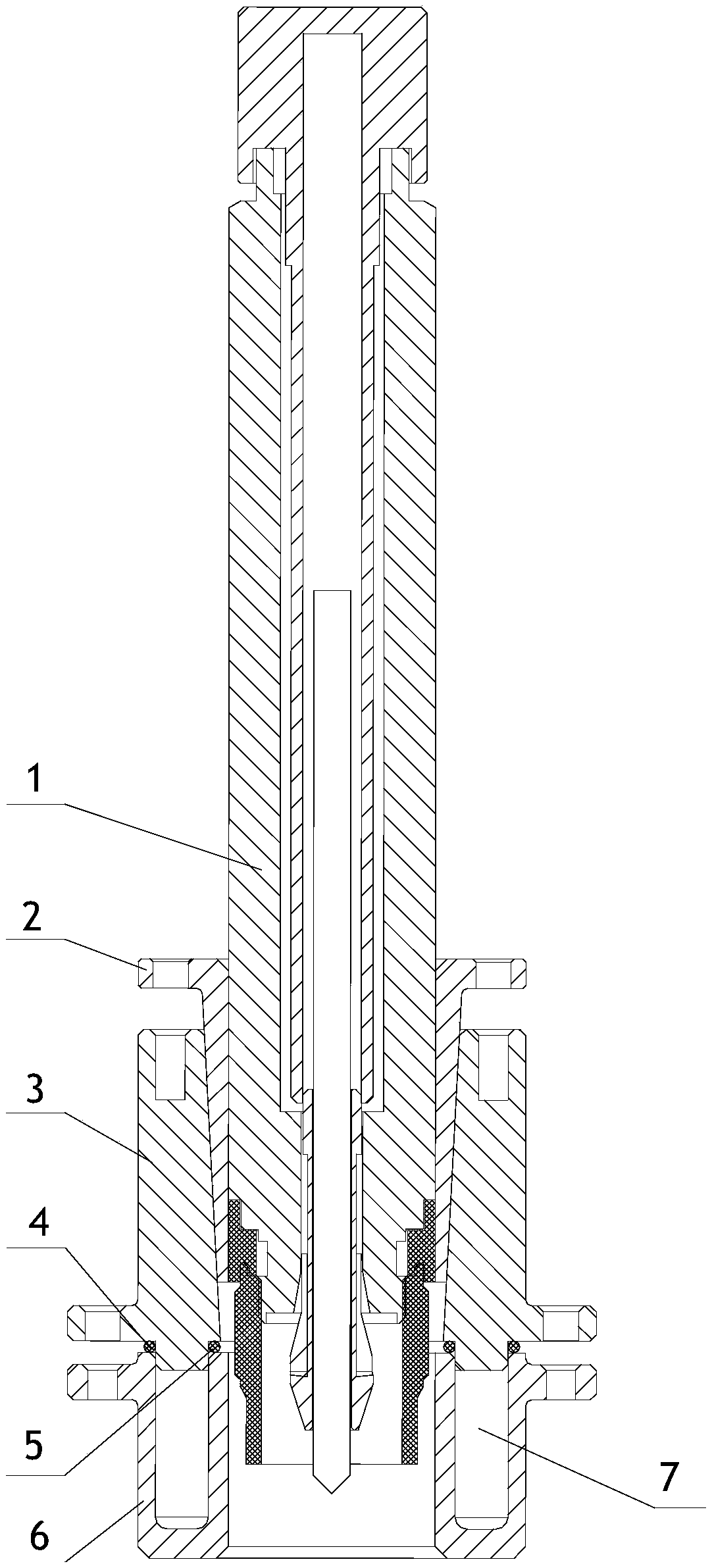

Cable connector assembly with an improved spacer

InactiveUS7845965B2Easy to solderImproved contact arrangementElectrically conductive connectionsElectric discharge tubesEngineeringSoldering

A cable connector assembly includes an insulative housing (1) with a number of passages (101), a shell (3) covering the insulative housing, a number of contacts (2) received in the passages of the insulative housing, and a spacer (5) assembled to the insulative housing. The contact includes a retaining portion (22), an extending portion (25) extending form the retaining portion and a soldering portion (23) bending from the end of the extending portion, and the all soldering portions are coplanar. The spacer includes a pressing portion (52) and a vertical wall (53). The pressing portion presses on the retaining portion of the contact, and the vertical wall engages with the soldering portion of the contact.

Owner:HON HAI PRECISION IND CO LTD

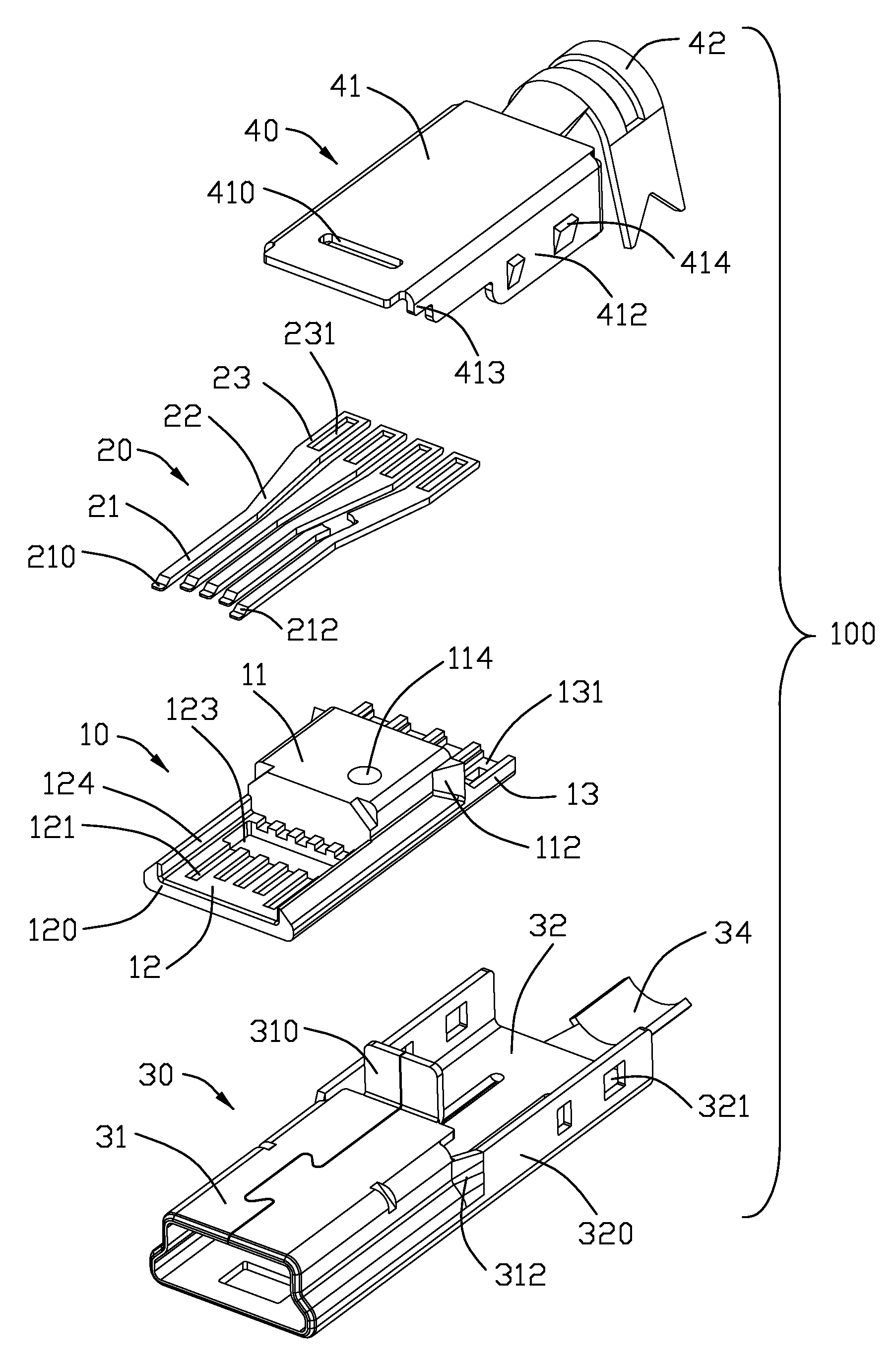

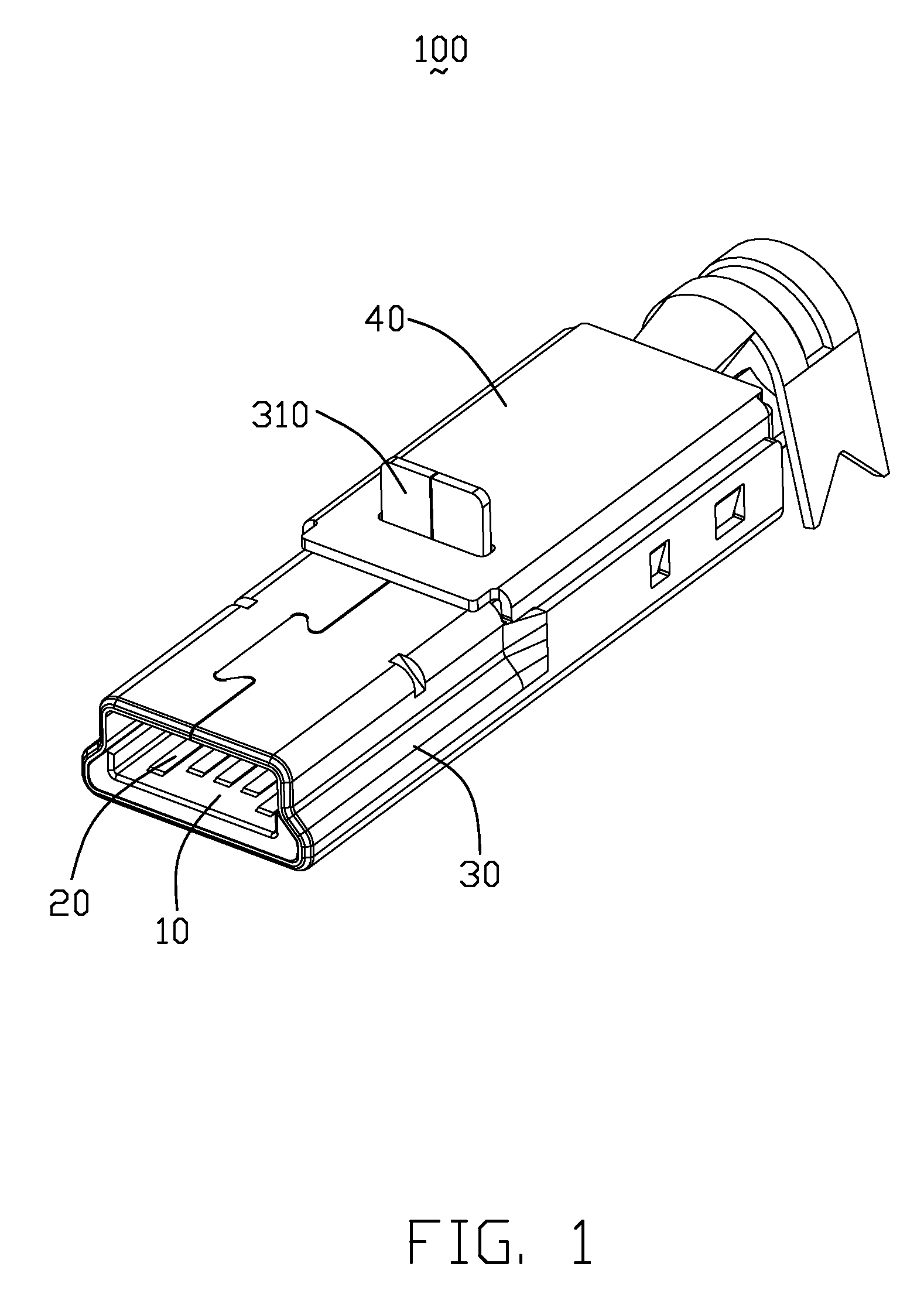

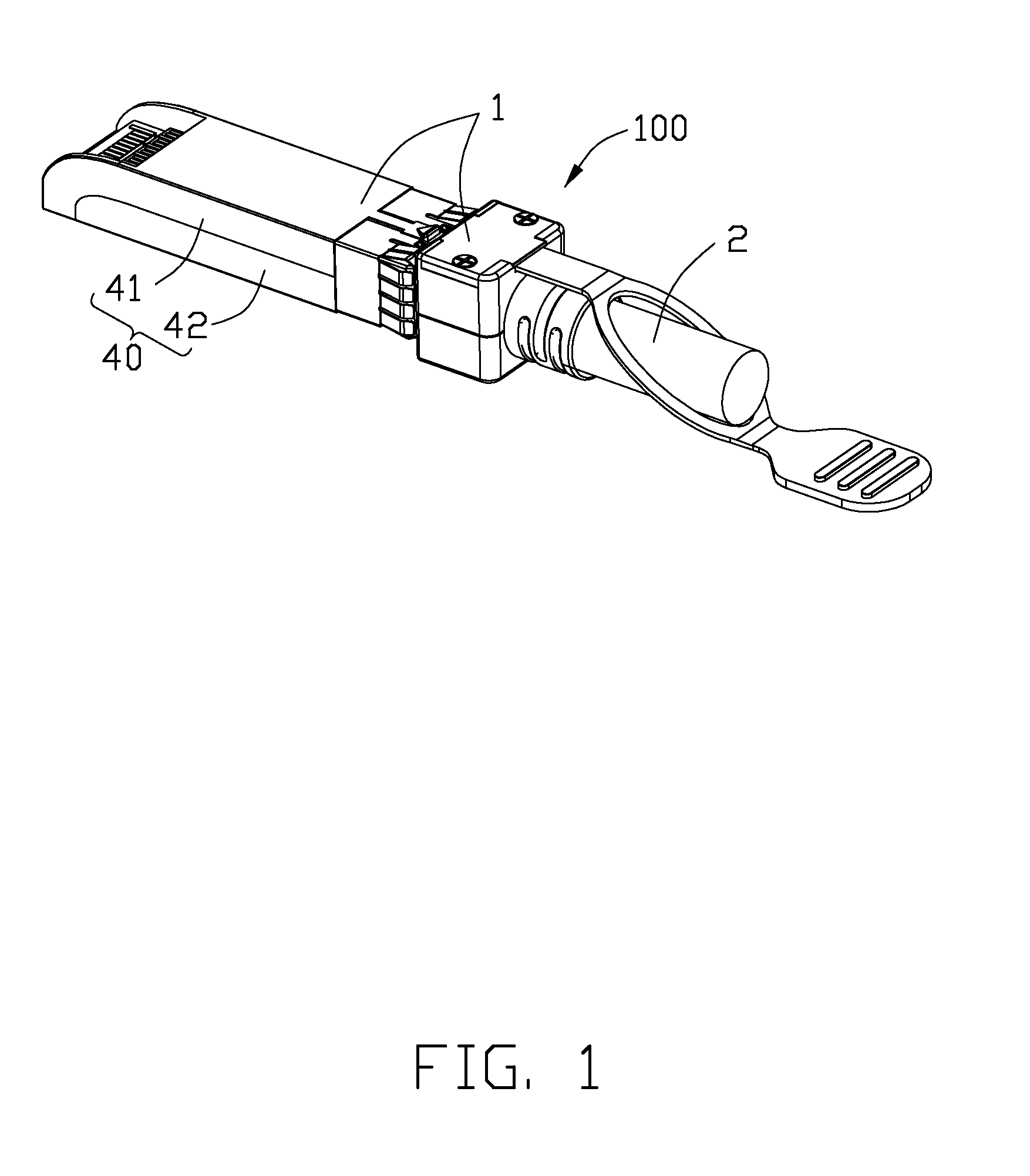

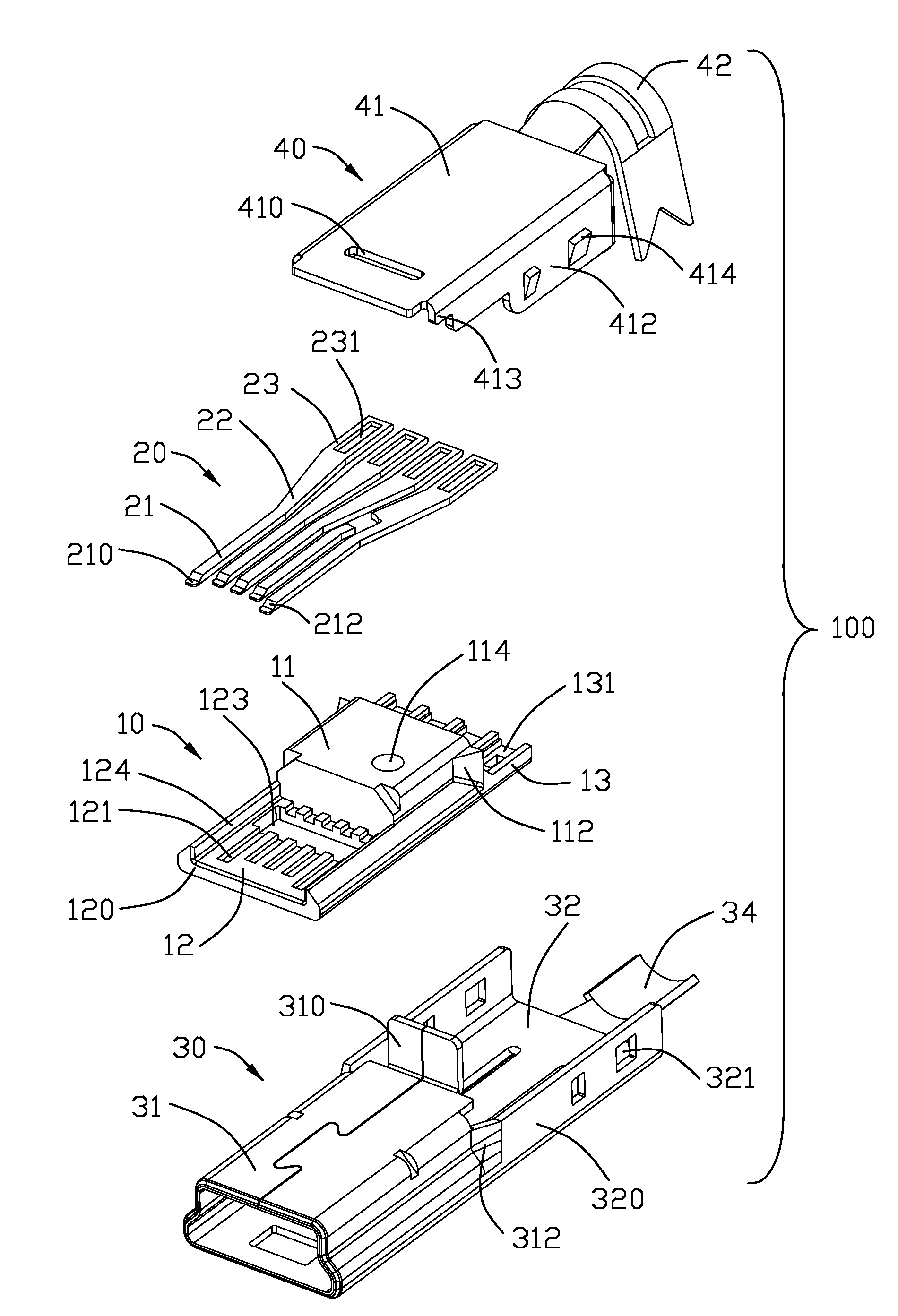

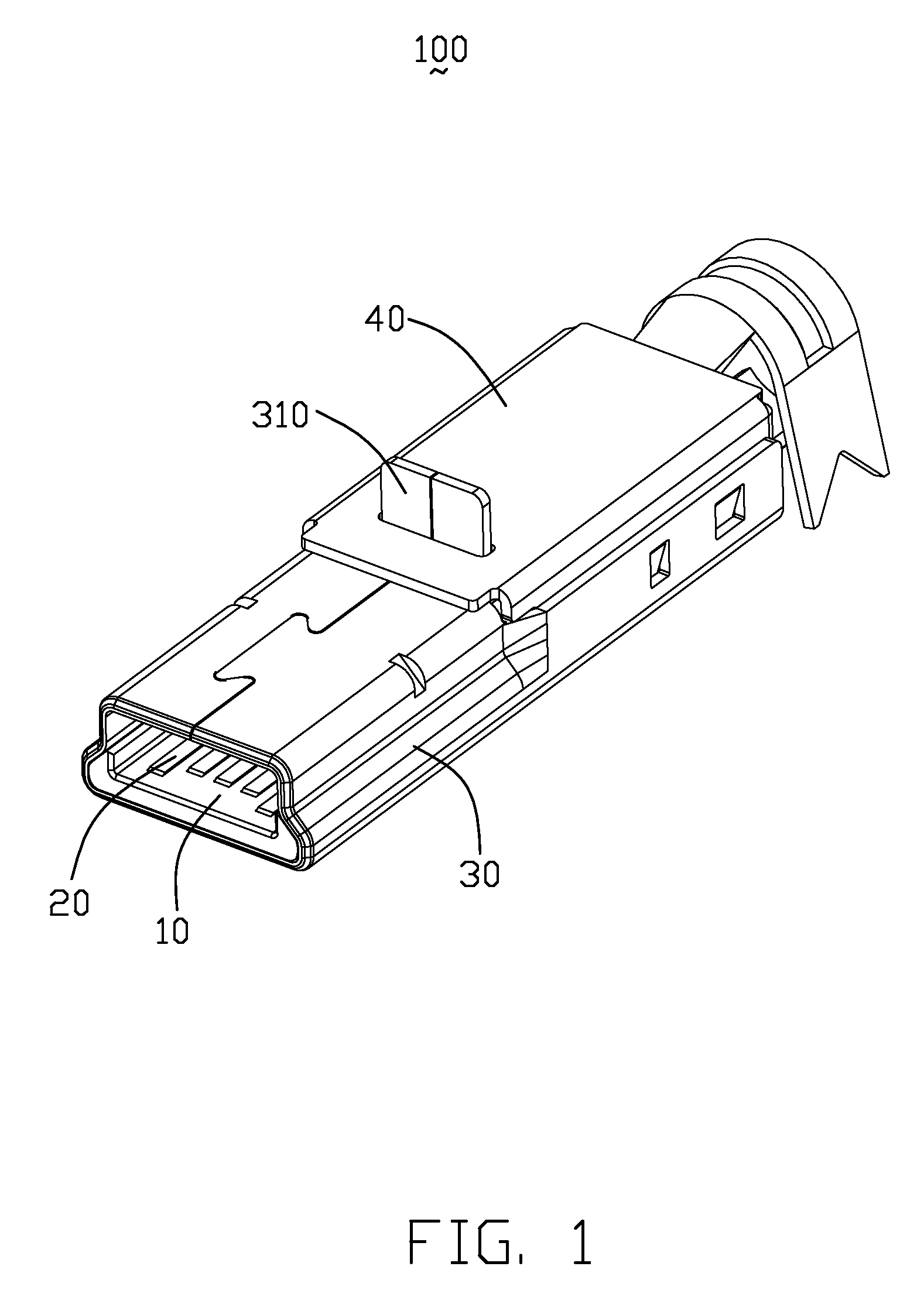

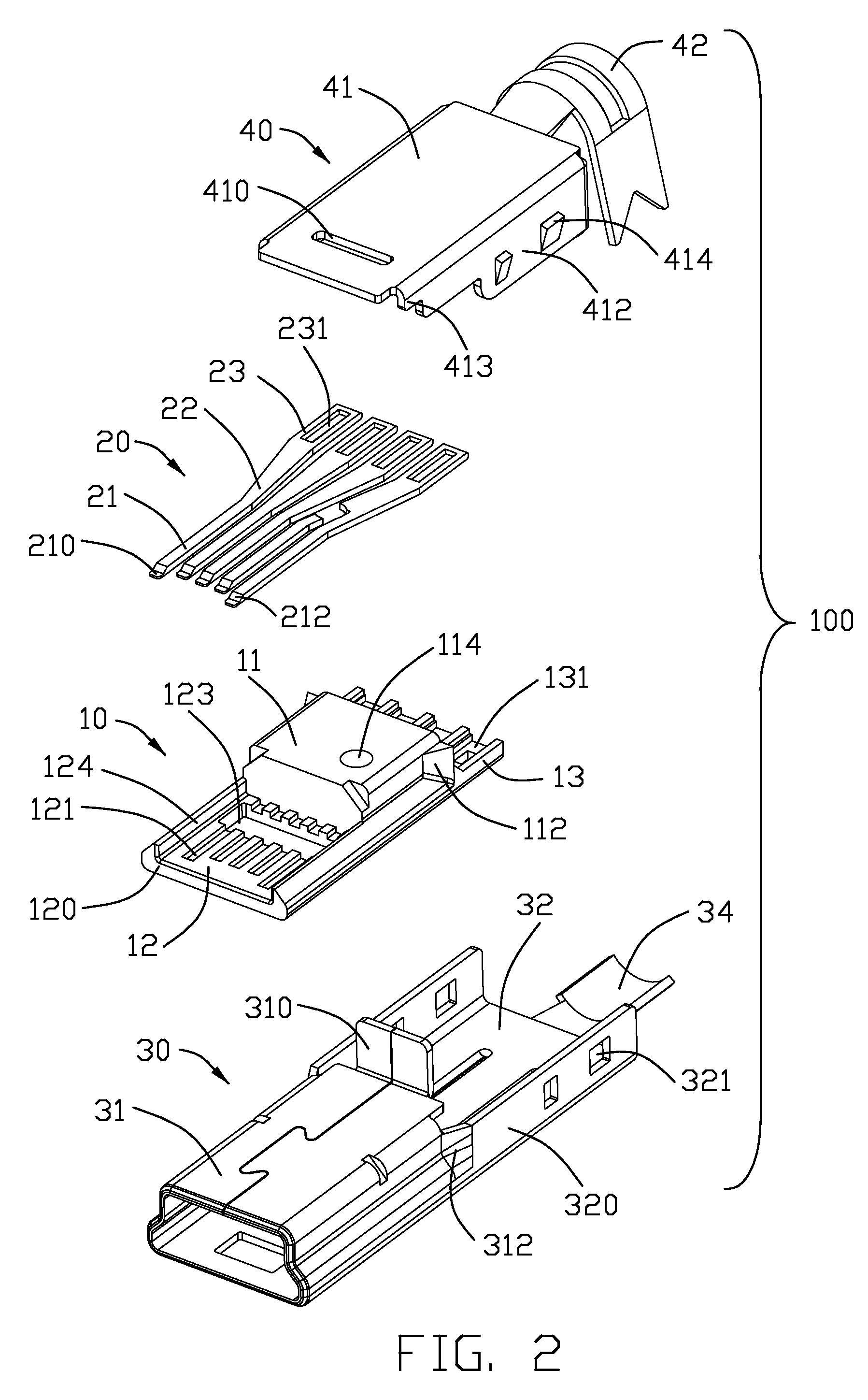

Electrical connector with improved contacts

InactiveUS7736190B2Prevent jumpingSmooth connectionElectric discharge tubesSoldered/welded conductive connectionsElectrical connectorMechanical engineering

An electrical connector (100) comprises an insulative housing (10), a shell encapsulating the insulative housing and a plurality of contacts (20) received in the housing abreast. The insulative housing defines a tongue (12), a plurality of passageways (121) and receiving grooves (131), the passageways extending to the tongue, the tongue has a stopping portion (126) in the front of each passageway. A cavity is defined below each stopping portion and communicated with the passageway. Each contact has a contacting portion (21) and a tail portion (23) wider than the contacting portion, the contacting portions are received in a corresponding passageways with the tail portions received in a corresponding receiving grooves. Each contacting portion defines a tab (210) protruding forwardly from a bottom surface thereof, the tab is received in the cavity and protected by the stopping portion (126); each tail portion is stamped downwards to form a notch (231) receiving wires and soldering with the wires.

Owner:HON HAI PRECISION IND CO LTD

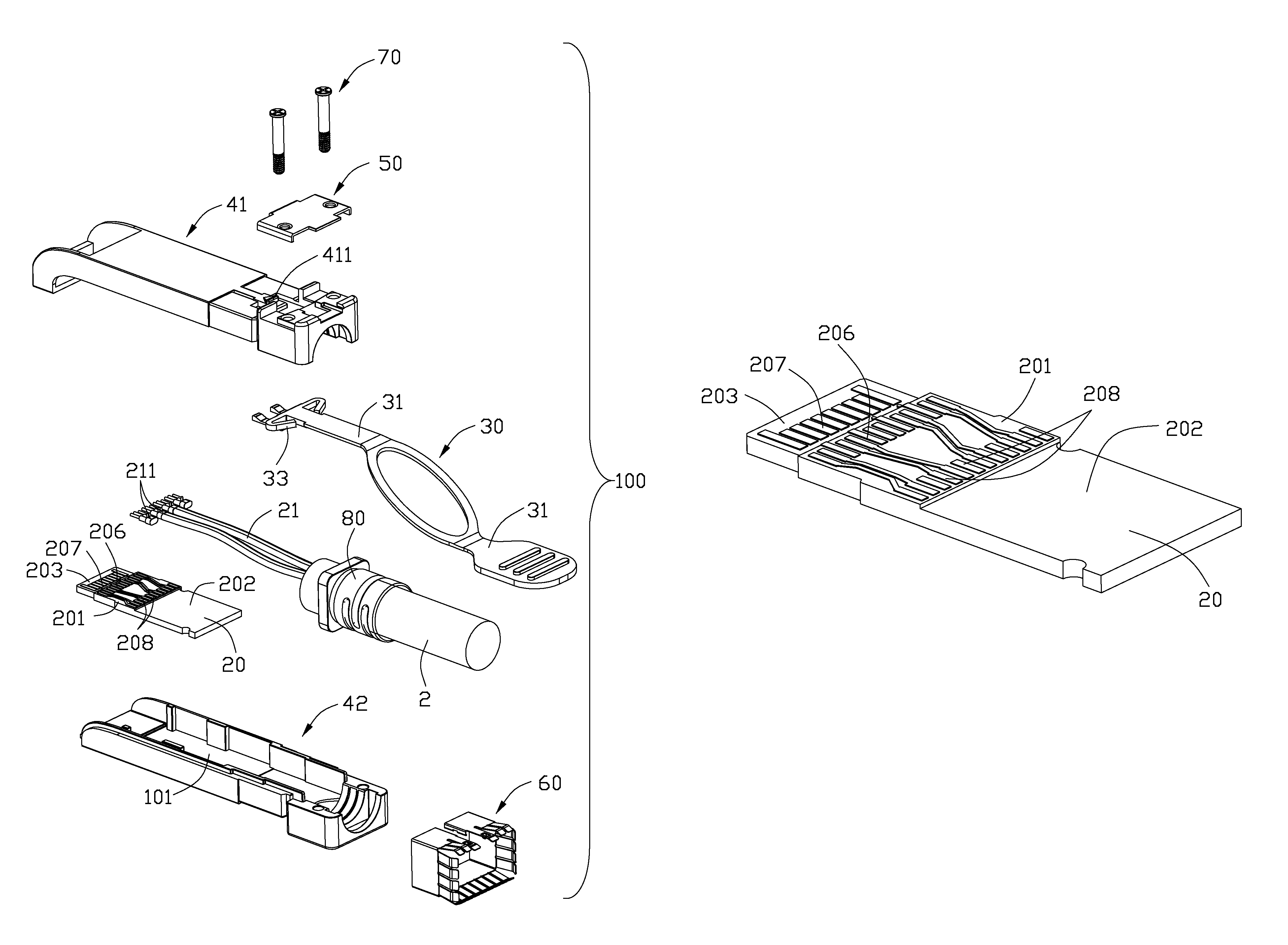

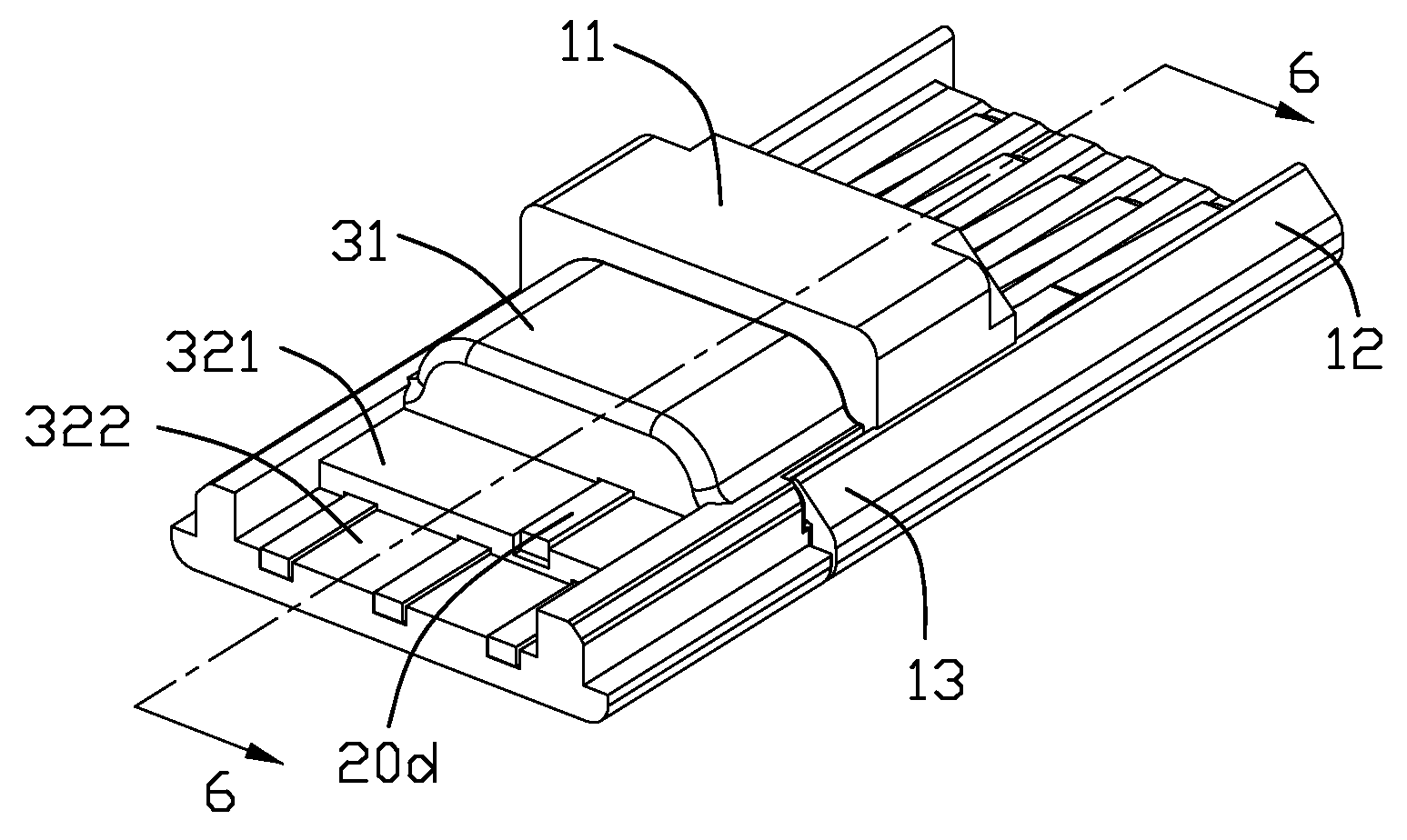

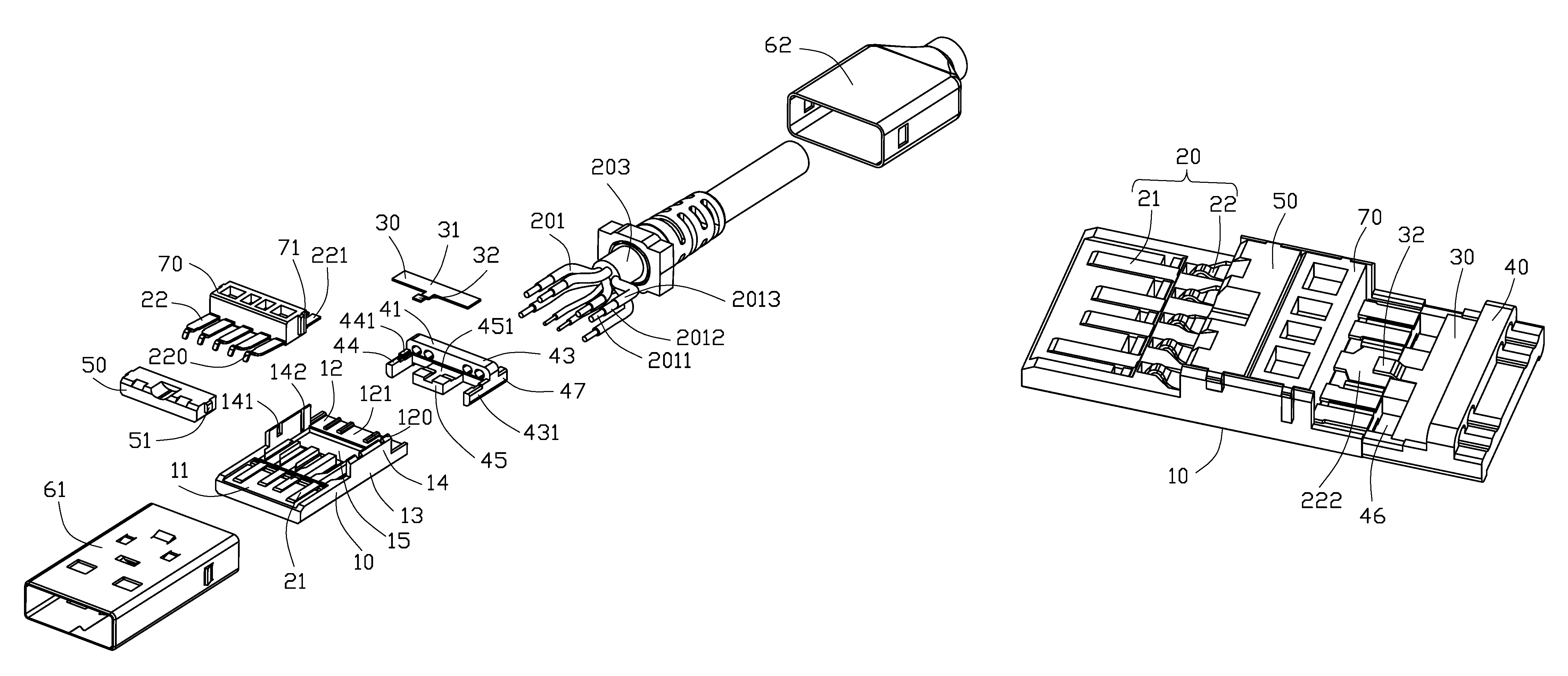

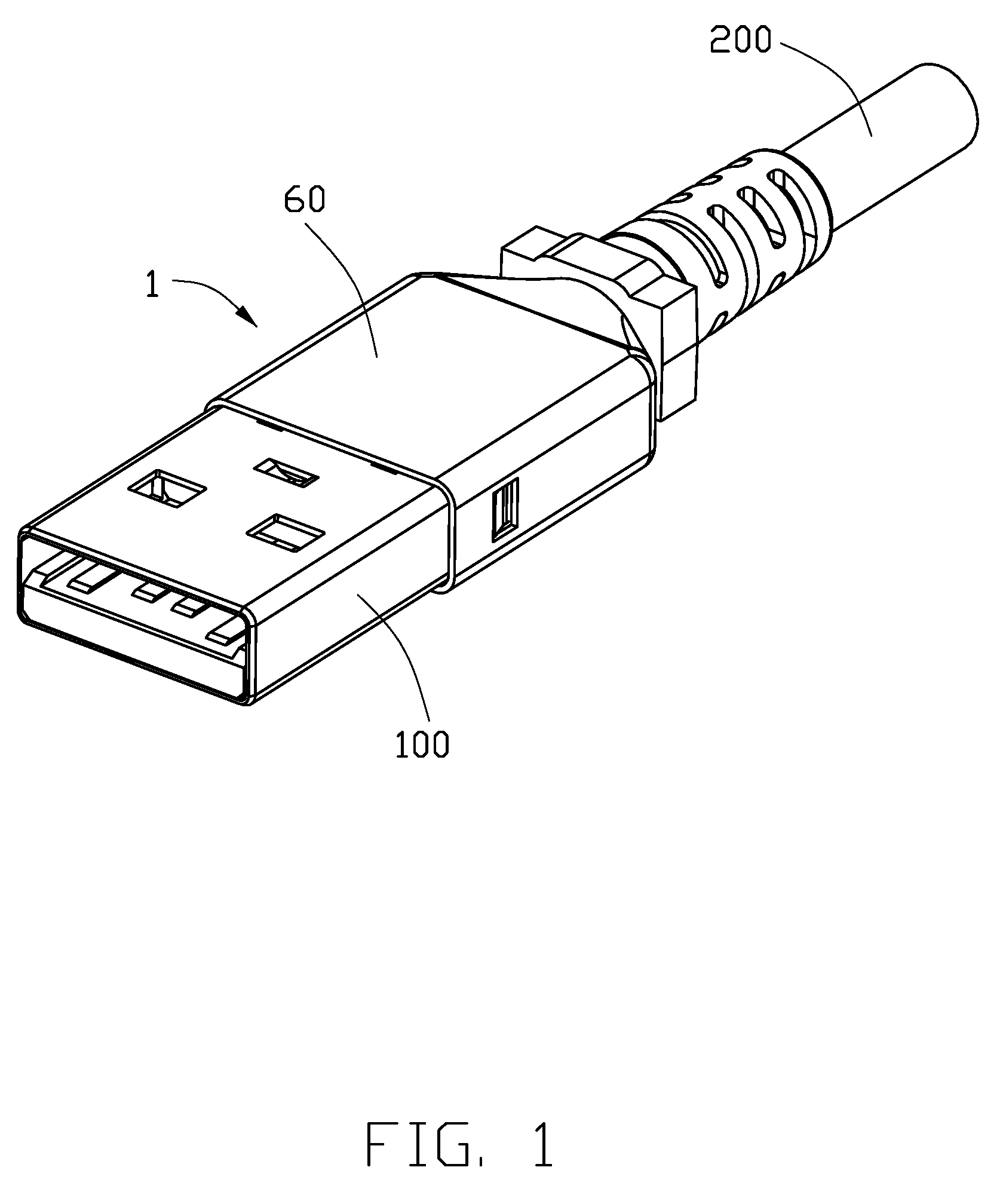

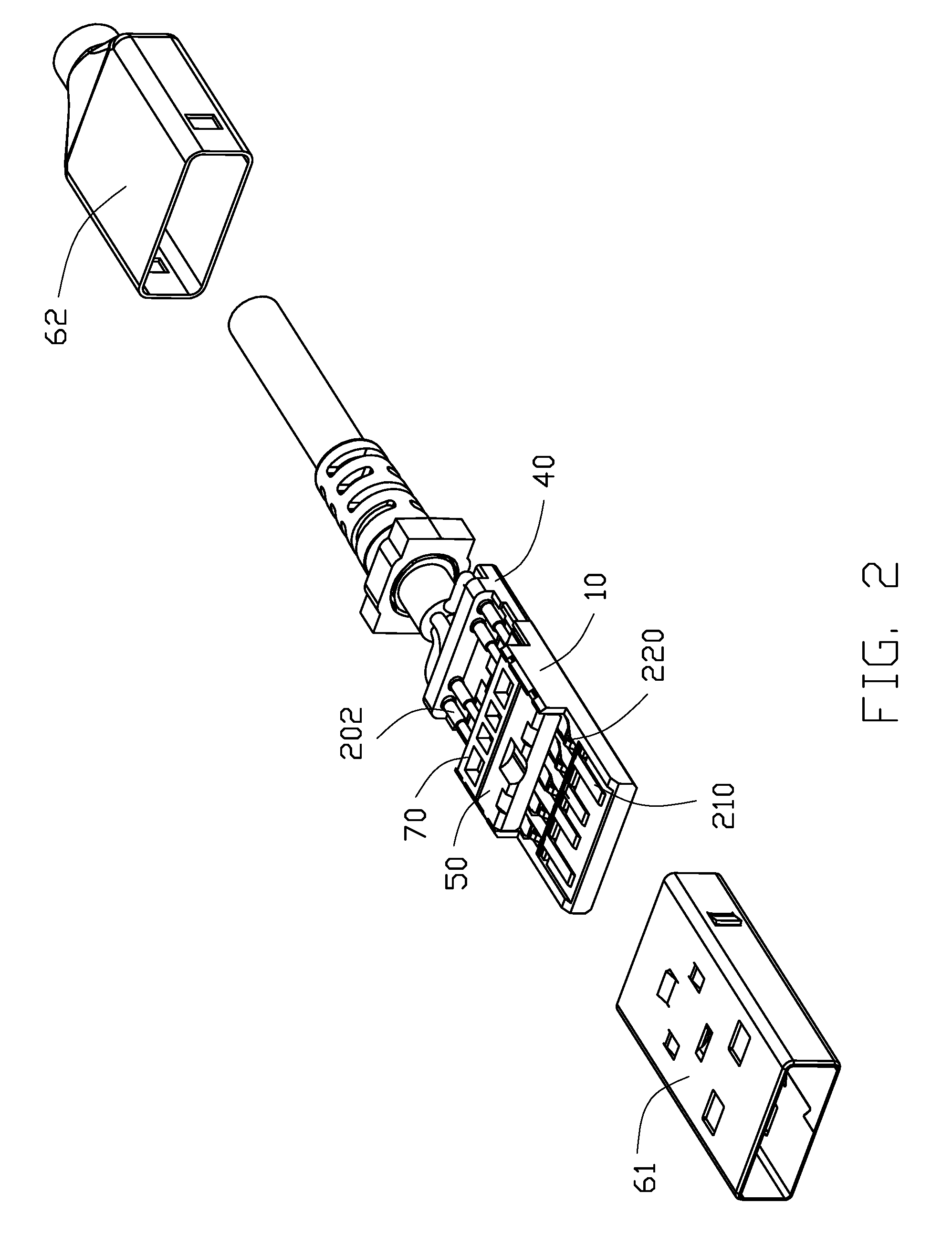

Cable assembly having an improved circuit board

ActiveUS8662917B2Easy to solderImproved internal circuit boardCoupling device detailsElectrical apparatus contructional details

A cable assembly (100) includes a cover (40) defining a cavity (101), a circuit board (20) assembled in the cavity and including a first surface (201) and a second surface (202) lower than the first surface, and a cable (2) having a jacket (22) and a number of wires (21) shrouded by the jacket. Each wire includes an inner coat (210) and a conductor having a free end (211) exposed outwardly from the inner coat for being soldered to the first surface, with the inner coat disposed on the second surface.

Owner:HON HAI PRECISION IND CO LTD

Dual-band dipole antenna

InactiveUS7230578B2Simple structureLow costSimultaneous aerial operationsAntenna feed intermediatesCross connectionDual band antenna

Owner:HON HAI PRECISION IND CO LTD

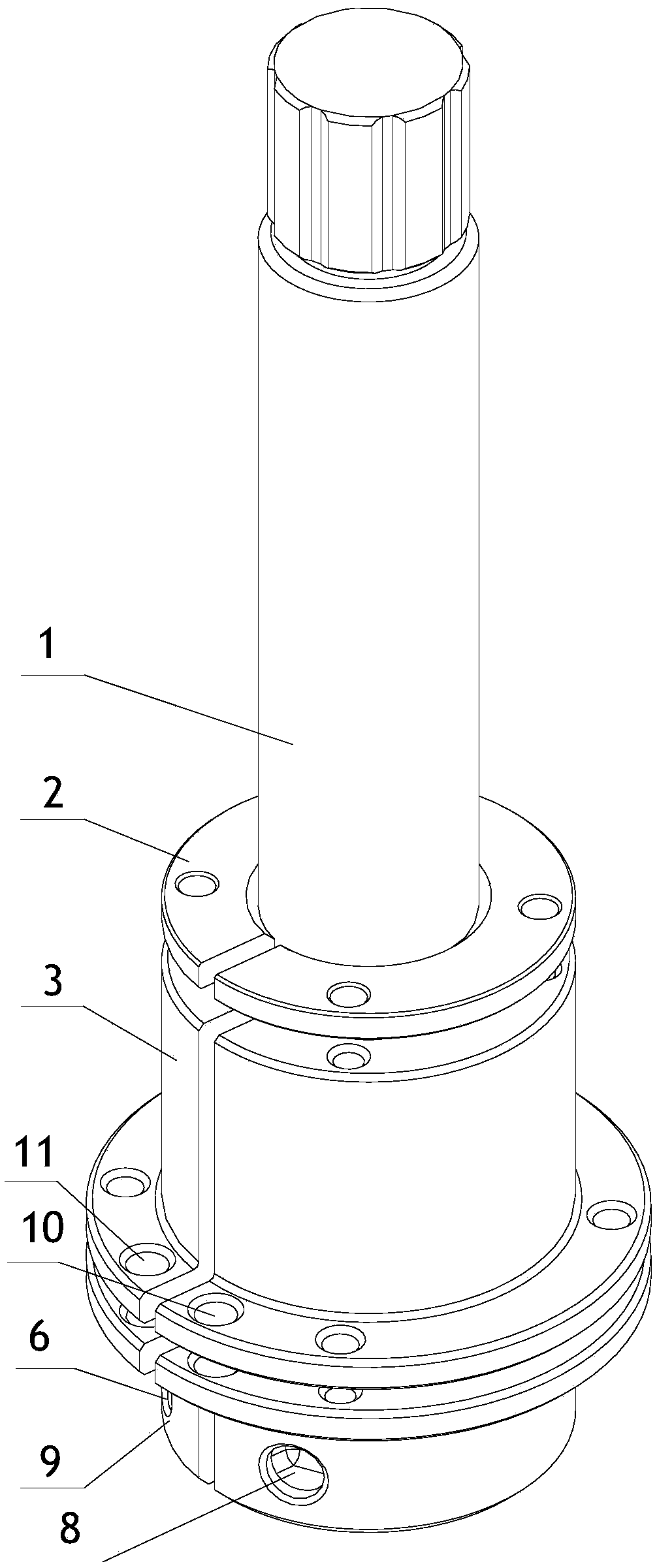

Power distribution unit for rotary electric machine with linear conductor connecting ring having terminal section with axially extending hole for connecting stator coil, and method for assembling rotary electric machine

ActiveUS7952245B2Reduce the numberEasy to solderWindings insulation shape/form/constructionMechanical energy handlingElectrical conductorElectric machine

The power distribution unit for a rotary electric machine includes a connecting ring unit that connects stator coils of the same phase. The connecting ring unit includes at least one linear conductor integrally formed in a ring-like shape, and the connecting ring unit includes a terminal section integrally formed in the linear conductor. The terminal section is constituted by a hole through which a wiring end of the stator coil is inserted and a protrusion formed in a direction of the hole to which the wiring end of the stator coil is connected. Also disclosed are a rotary electric machine includes the power distribution unit and a method for assembling a rotary electric machine.

Owner:HITACHI ASTEMO LTD

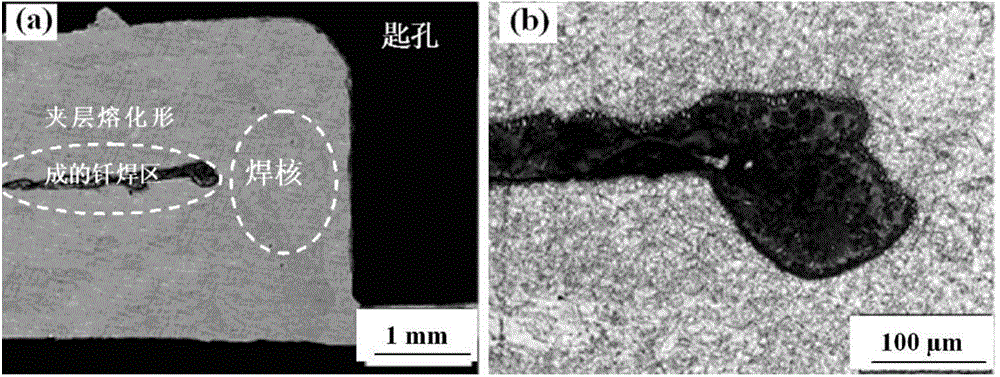

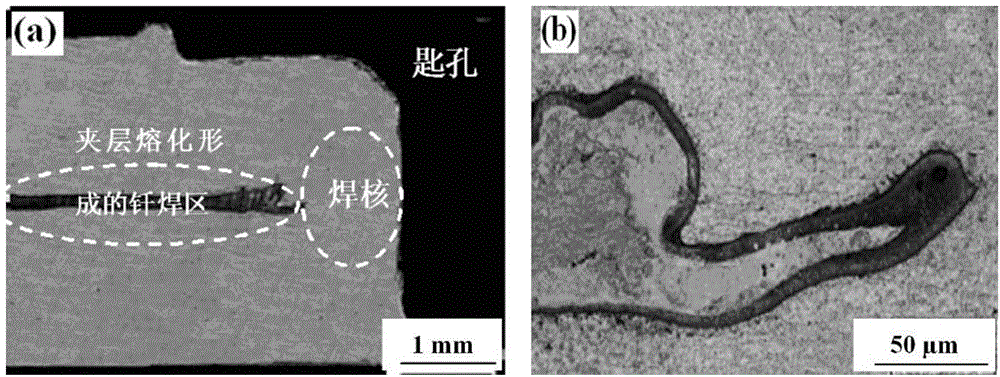

Welding method capable of eliminating hook defects of magnesium alloy friction stirring overlap joint

ActiveCN104668765AEliminates hook defectsImprove performanceNon-electric welding apparatusJoint heatSpot welding

The invention provides a welding method capable of eliminating hook defects of a magnesium alloy friction stirring overlap joint (including spot welding and wire welding) and belongs to the technical field of magnesium alloy welding. The welding method has the advantages that a low-melting-point metal or alloy interlayer is prearranged between an upper magnesium alloy plate and a lower magnesium alloy plate which are to be welded, pressure and heat generated from shaft shoulder friction are adopted to enable the interlayer and magnesium alloy to react, and a novel combination area is generated in a joint heat affected zone and a thermo-mechanically affected zone, so that formation of the hook defects is avoided, and mechanical properties of the welded joint is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Welding flux used in filigree golden blank cloisonn product and manufacturing method for cloisonn product

ActiveCN103624863AGood liquidityEasy to solderDecorative surface effectsSpecial ornamental structuresSolderingPolishing

The invention relates to a welding flux used in a filigree golden blank cloisonn product and a manufacturing method for the cloisonn product. The method comprises the following steps of making a blank, inlaying a wire, installing the wire, soldering, pickling, painting blue, polishing blue, painting bright white glaze, polishing blue again, polishing, plating gold and the like. The soldering medicine powder comprises the following ingredients of 55-60% of gold, 6-8% of sliver, 27-32% of red metal, 4-7% of cadmium and arsenic trioxide which accounts 22-26wt% of above ingredients. During pickling, the soldered gold blank is pickled for three times and pickled for 10-12 minutes each time; and after blue painting, the sintering temperature is 790-820DEG C. The welding flux used for soldering has the advantages of good liquidity, firmness in welding and easiness in welding. The obtained cloisonn filigree has the advantages of preciseness in positioning, abrasion resistance, high hardness and no colour fading. The white glaze varnishing technology and two-time blue polishing are adopted, so that the obtained artware has the advantages of better color and high collection value, is always new and is free from rusting, and the high-level artistic enjoyment of people can be satisfied.

Owner:赵爱民

Electrical connector with two-piece configured housing

InactiveUS7798861B2Preventing short circuitEasy to solderElectric discharge tubesCoupling device detailsElectrical connectorElectrical bonding

Owner:HON HAI PRECISION IND CO LTD

Integrated circuit with flexible planer leads

ActiveUS20080237827A1Easily welding and solderingEasy to solderSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

A microelectronic device including a microelectronic circuit and at least one planar flexible lead. These planar flexible leads are adapted to bend and flex during mechanical stress allow direct mounting of the device to a member, and withstand extreme thermal cycling, such as −197° C. to +150° C. such as encountered in space.

Owner:MICROSEMI

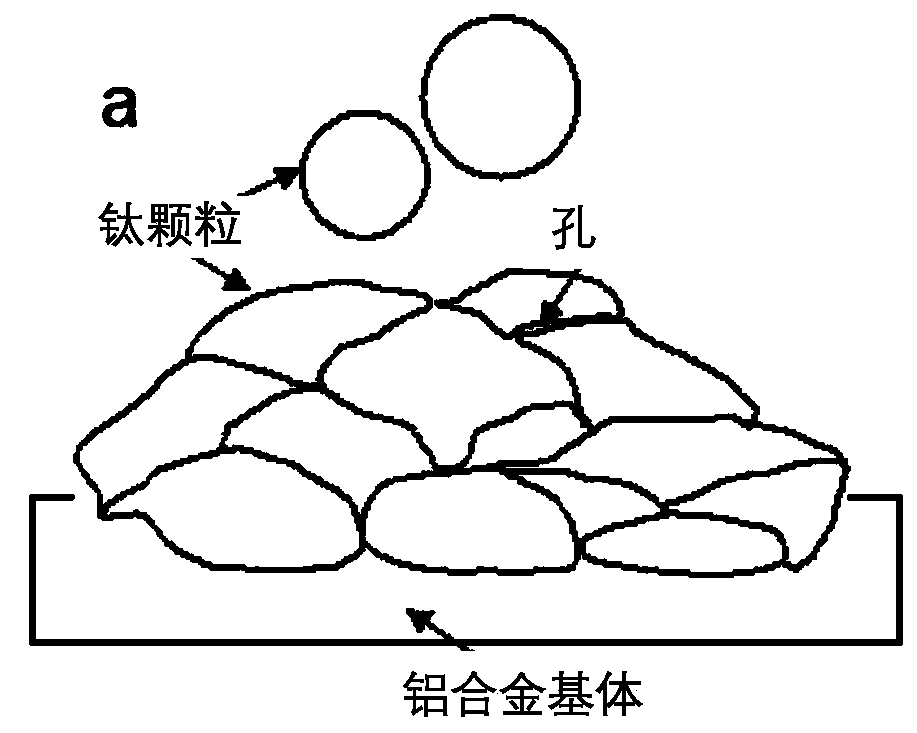

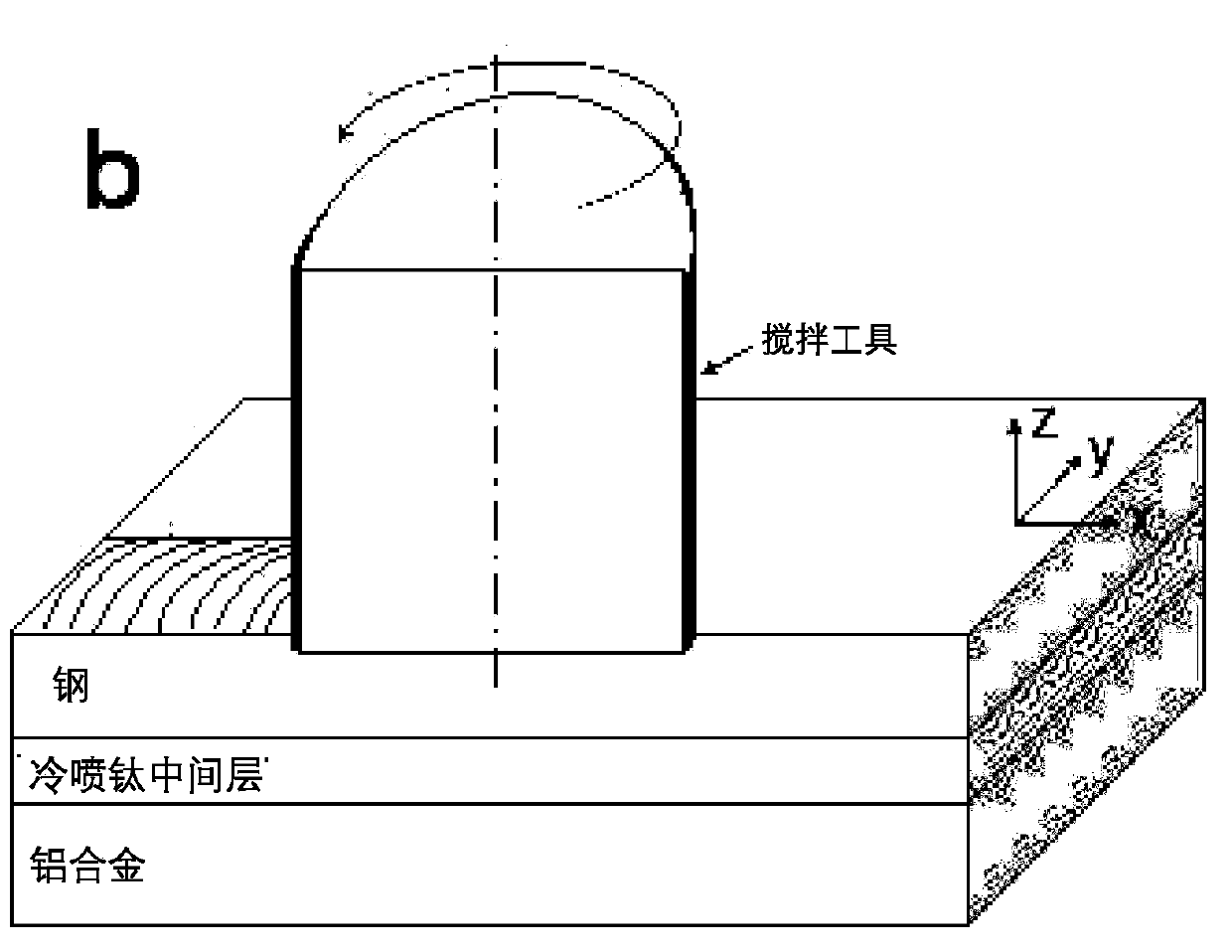

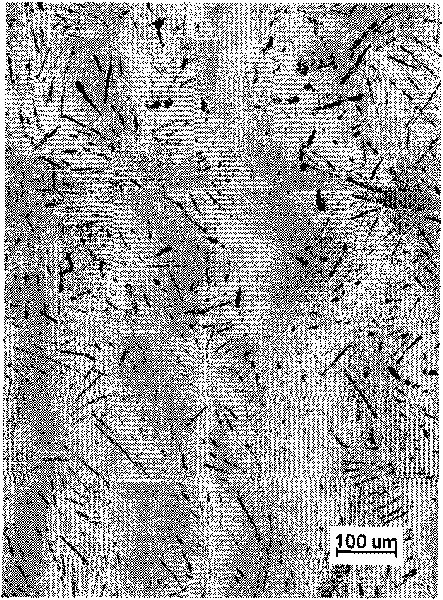

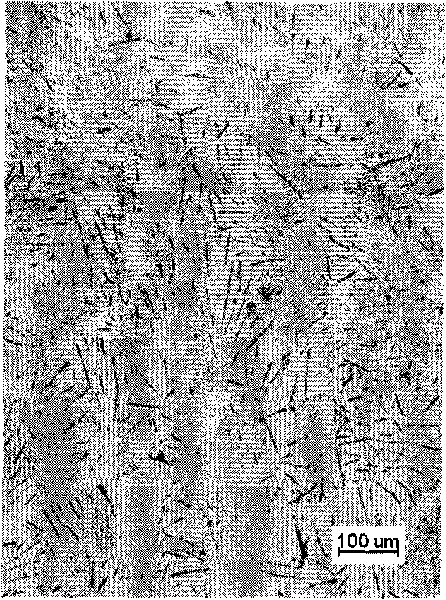

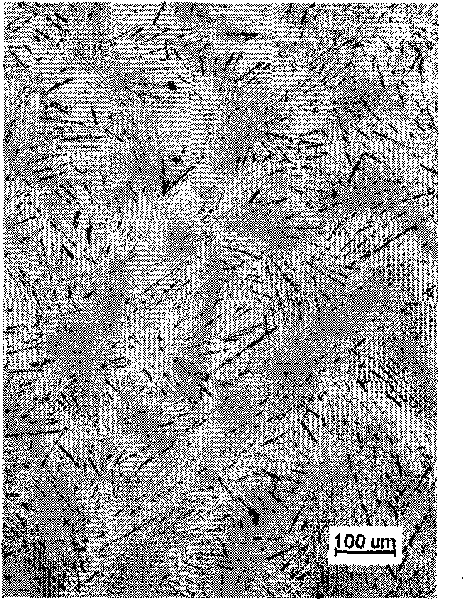

Friction stir welding method of cold-sprayed Ti coating assisted aluminium-steel dissimilar metal lap joint

InactiveCN109940260APrevent direct contact reactionsSuppress generationWelding/soldering/cutting articlesNon-electric welding apparatusNeedle freeCrazing

The invention relates to the technical field of friction stir welding, in particular to a friction stir welding method of cold-sprayed Ti coating assisted aluminium-steel dissimilar metal lap joint. The friction stir welding method comprises the following steps of removing oil stain and impurities on the surface of an Al2O24 substrate to be sprayed and the surface of a low-carbon steel to be welded; cleaning and coarsening oxides on the surface of the Al2O24 substrate; depositing a Ti coating on the Al2O24 substrate; milling the Ti coating to obtain a Ti coating which has a certain thickness and a smooth surface; forming a lap joint connector that a steel substrate is at the upper part, the Ti coating is in the middle, and an aluminium substrate is at the lower part; and performing friction stir welding lap joint. The Ti middle layer is cold-sprayed on the surface of the aluminium substrate, solid-phase connection is generated in the friction stir process of a needle-free stirring headon the surface of steel so as to prevent direct contact and reaction of aluminium and steel and completely inhibit generation of IMCs and hot cracks, the spraying and welding process is simple, the wire welding or spot welding of aluminium-steel plates of different sizes is realized, and the automation is easily realized.

Owner:SICHUAN UNIV

Tin-zinc-bismuth-copper leadless solder with low cost and welding spot thereof

InactiveCN101733575ALow costEasy to solderWelding/cutting media/materialsSoldering mediaWeld seamTin

The invention relates to a leadless solder with low cost, in particular to a tin-zinc-bismuth-copper leadless solder with low cost and a welding spot (or a welding seam) formed by the same, and belongs to the fields of the technique and the application of brazing materials. The solder comprises the following components by mass percent: 6.0-10.0% of Zn, 1.0-3.0% of Bi, 0.5-1.0% of Cu and the balance of Sn. Compared with an Sn-Pb solder and a traditional Sn-Zn solder, the invention provides leadless solder alloy which has no pollution and is easy to weld. The solder has the following advantages: (1) the melting point is lower than 200 DEG C, the temperature is lower than the heat resistance temperature of the packaging of an IC and approaches to the eutectic melting point of Sn-Pb, the properties of wetting and spreading are excellent, and the solder is easy to weld; and (2) the solder completely adopts alloying elements with low cost of raw materials. The welding spot (seam) formed by the solder has better bonding strength and use reliability.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Environment-friendly high-phosphorus chemical nickel plating solution for airtight glass-sealed binding terminal, and applications thereof

InactiveCN103938193ARefined grain sizeFast platingLiquid/solution decomposition chemical coatingChemical platingBULK ACTIVE INGREDIENT

The invention discloses an environment-friendly high-phosphorus chemical nickel plating solution for an airtight glass-sealed binding terminal. The environment-friendly high-phosphorus chemical nickel plating solution comprises the following active ingredients according to concentration: 25-27g / L nickel sulfate, 19-22g / L sodium hypophosphite, 20-23g / L sodium hydroxide, 41-44g / L lactic acid, 1.5-2.3g / L trisodium citrate, 13-15g / L malic acid, 8-12g / L glycine, 0.2-0.4ml / L OP-10, 0.26-0.3g / L stannous chloride, 0.26-0.34g / L maleic anhydride and 3-5mg / L N,N-diethylaminopropyne. The invention discloses a method for performing chemical plating by adopting the chemical nickel plating solution. A stainless steel needle and an iron cover can be simultaneously subjected to chemical nickel plating and be evenly plated, no nickel nuclear generated on sintered glass can be guaranteed, and the difficulty in keeping the smoothness and cleanness of the surface of glass can be solved.

Owner:深圳市迪凯鑫科技有限公司

Electrical connector assembly

ActiveUS20180212366A1Poor electrical contactGood shielding effectCoupling device detailsEngineeringElectrical and Electronics engineering

An electrical connector assembly includes an insulating body, multiple signal terminals received in the insulating body, a metal ground member fixed on the insulating body, and at least one ground core wires. The metal ground member has a plate surface and a cutting surface connected with the plate surface. The ground core wire is soldered to the cutting surface. The cutting surface is rough, the frictional force between the cutting surface and the ground core wires is great.

Owner:LOTES

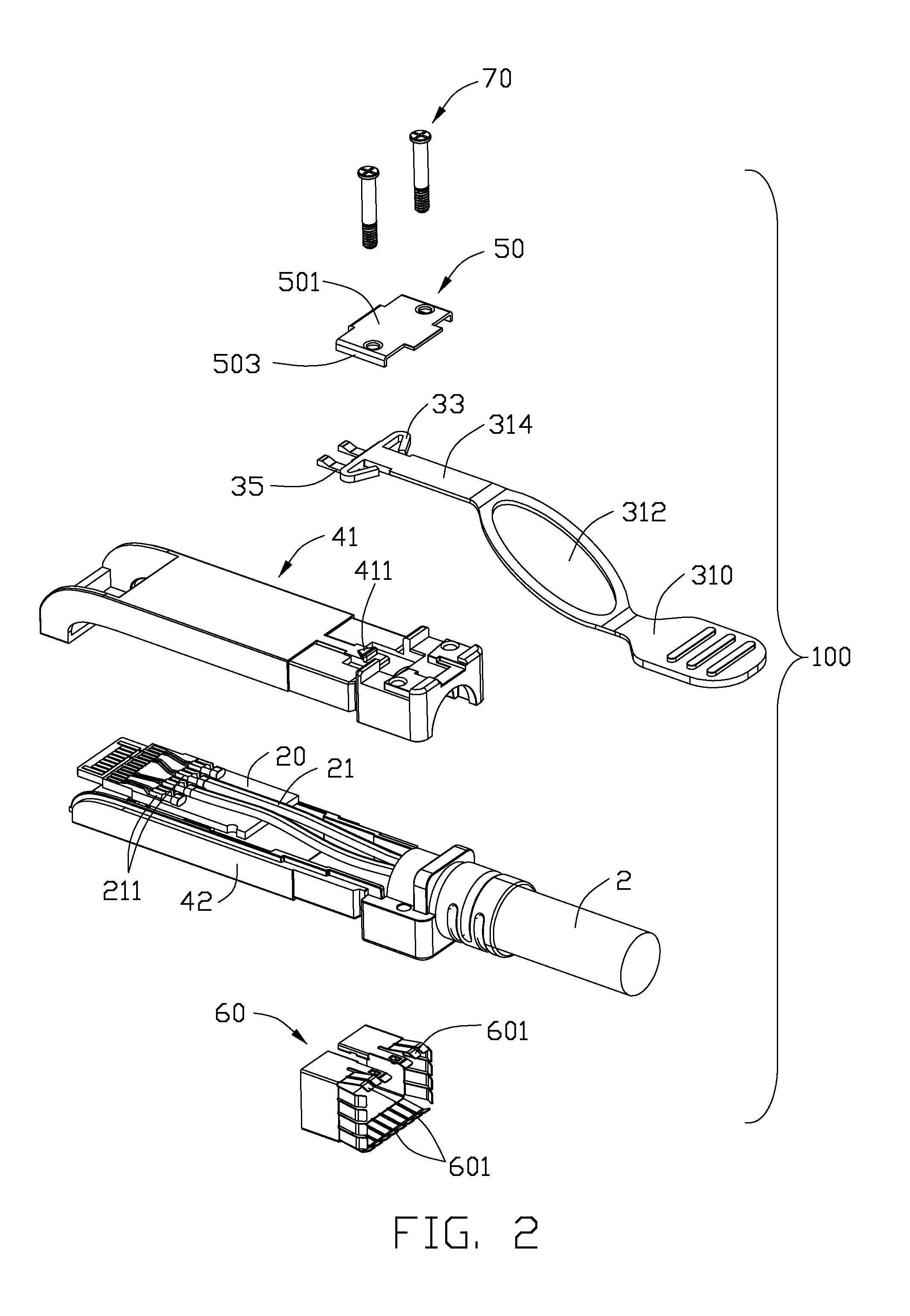

Cable connector assembly with spacer

InactiveUS9583887B2Easy to solderEasy to cutElectrically conductive connectionsContact member assembly/disassemblyEngineeringElectric wire

A cable connector assembly has a connector and a cable with a number of coaxial wires and a number of unshielded wires. The connector includes an insulative housing with a front tongue and a rear end, a number of contacts with mating portions exposed on the front tongue and connecting portions exposed on the rear end, and a spacer assembled to the rear end. The spacer forms a plurality of positioning holes extending therethrough along a front-to-back direction, and a passageway extending therethrough along a vertical direction perpendicular to the front-to-back direction. The coaxial wires are inserted through the corresponding positioning holes and across the passageway to reach the corresponding contacts along the front-to-back direction so as to cut the coaxial wires in the passageway along the vertical direction.

Owner:FOXCONN INTERCONNECT TECH LTD

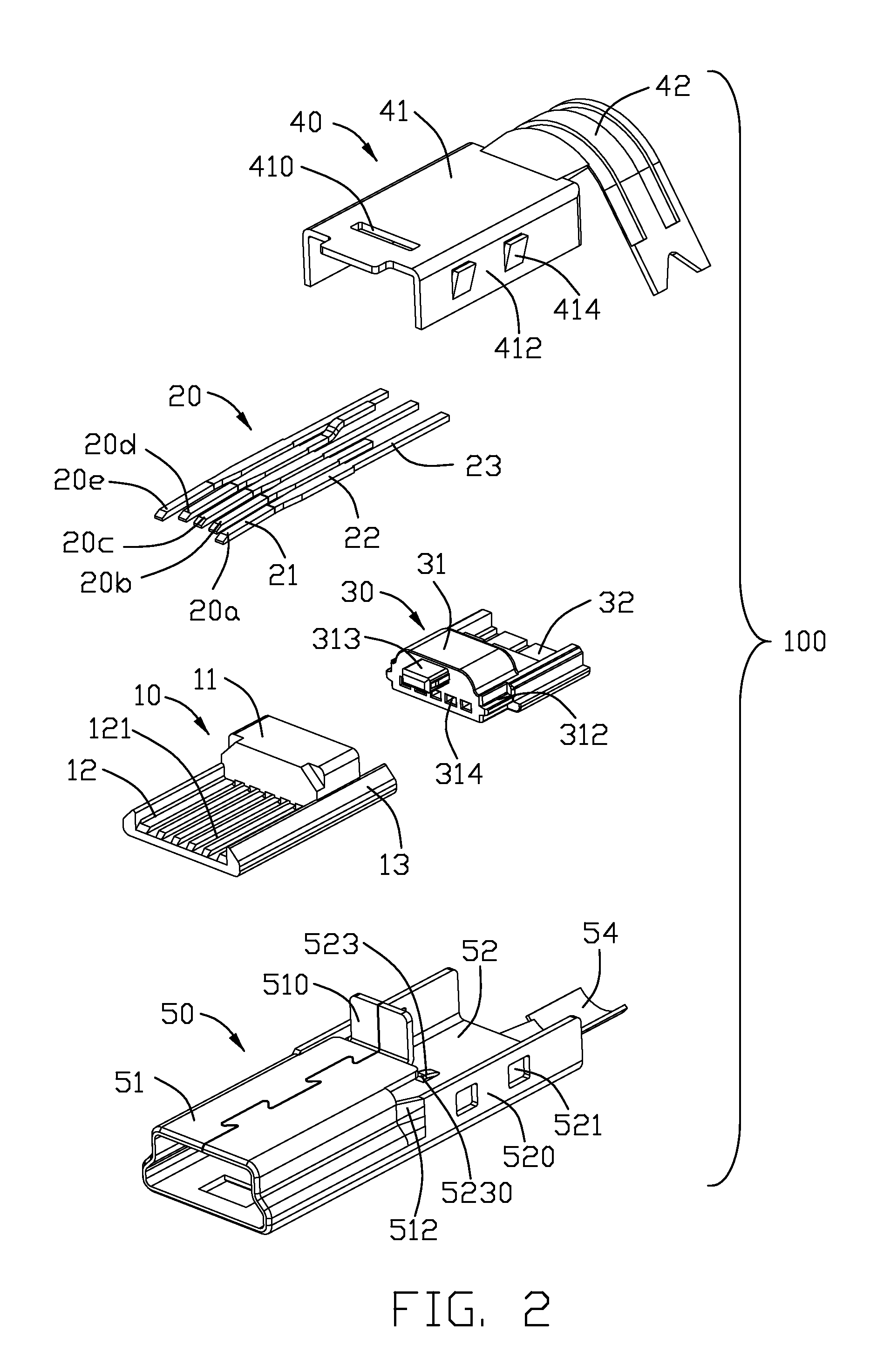

Electrical connector with improved contacts

InactiveUS20090280663A1Smooth connectionEasy to solderElectric discharge tubesSoldered/welded conductive connectionsElectrical connectorMechanical engineering

An electrical connector (100) comprises an insulative housing (10), a shell encapsulating the insulative housing and a plurality of contacts (20) received in the housing abreast. The insulative housing defines a tongue (12), a plurality of passageways (121) and receiving grooves (131), the passageways extending to the tongue, the tongue has a stopping portion (126) in the front of each passageway. A cavity is defined below each stopping portion and communicated with the passageway. Each contact has a contacting portion (21) and a tail portion (23) wider than the contacting portion, the contacting portions are received in a corresponding passageways with the tail portions received in a corresponding receiving grooves. Each contacting portion defines a tab (210) protruding forwardly from a bottom surface thereof, the tab is received in the cavity and protected by the stopping portion (126); each tail portion is stamped downwards to form a notch (231) receiving wires and soldering with the wires.

Owner:HON HAI PRECISION IND CO LTD

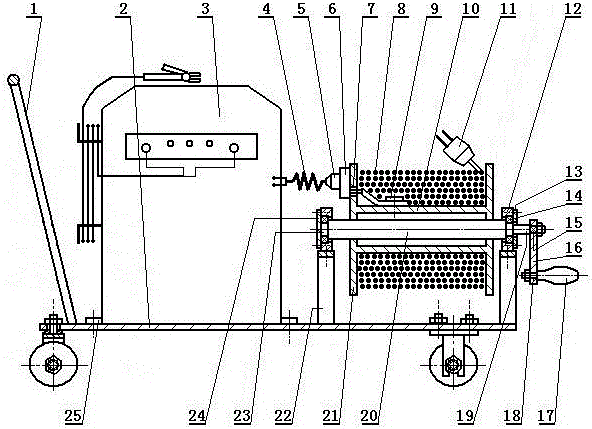

Electric welding machine capable of remotely welding

InactiveCN106425190AEasily weld objectsEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an electric welding machine capable of remotely welding. The electric welding machine is characterized in that a reel is arranged at the right end of the electric welding machine; a flexible conductor which is remotely connected with a power supply is wound on the reel; a first circular through hole, which penetrates through the upper end of a left baffle of the reel and is located in the left end of the flexible conductor, is connected with a socket; the socket is tightly plugged with a first plug of a power input line of the electric welding machine; the interior of the left end of the flexible conductor is compressed on a barrel of the reel through a screw and a pressing plate; the exterior of the right end of the flexible conductor is connected with a second plug; shaft necks on bearing positions at left and right ends of a reel shaft of the reel are respectively matched with the inner holes of the bearings at left and right ends; the outer diameters of the bearings at left and right ends are respectively matched with the bearing holes of the bearing bases at left and right ends; the bearing bases at left and right ends are respectively locked on the upper end face of a left / right bracket through bolts. According to the invention, the functions of the present electric welding machine are maintained while the convenience is supplied for conveniently, quickly and easily welding the articles in the place away from the fixed power socket.

Owner:罗炳寅

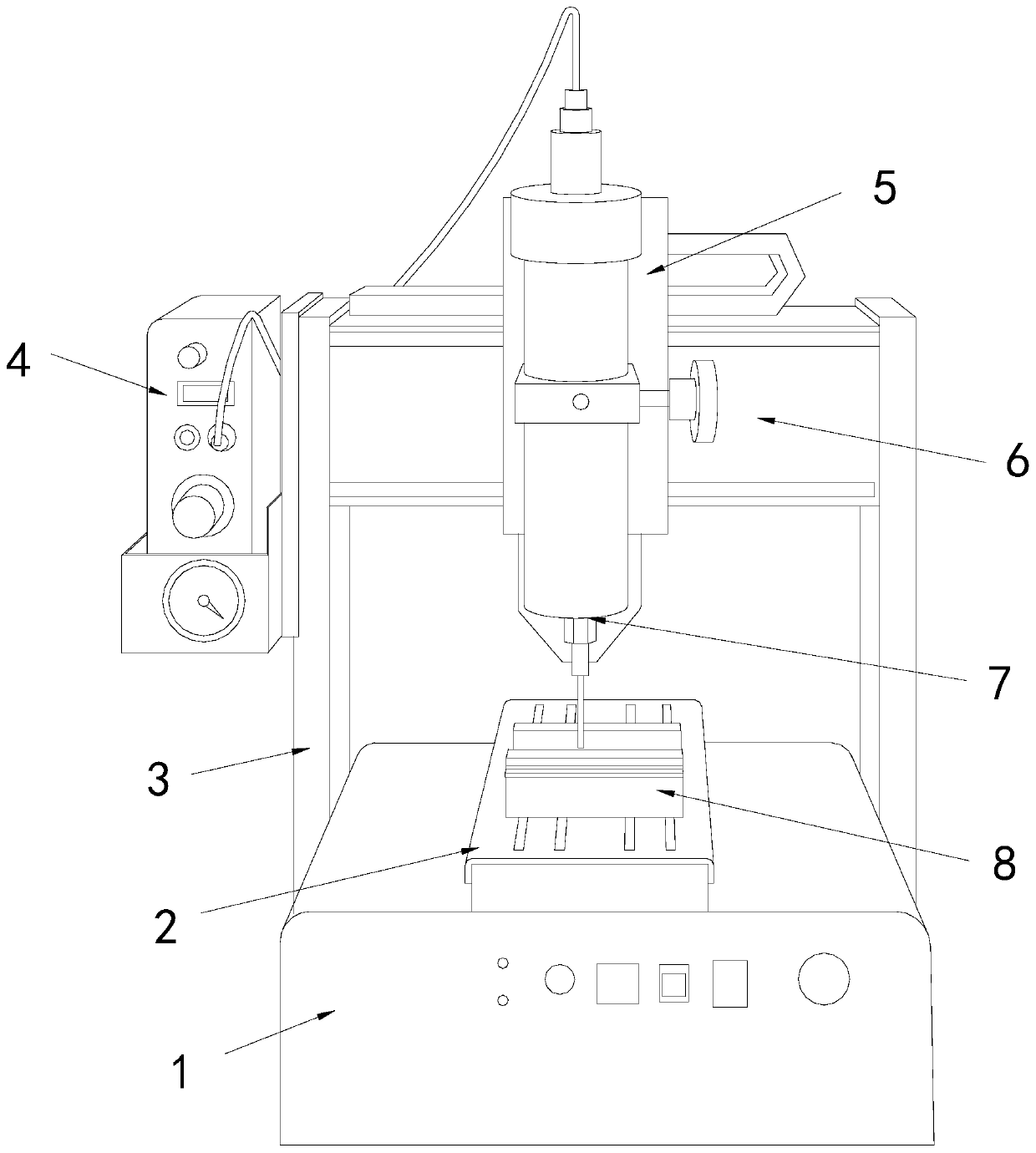

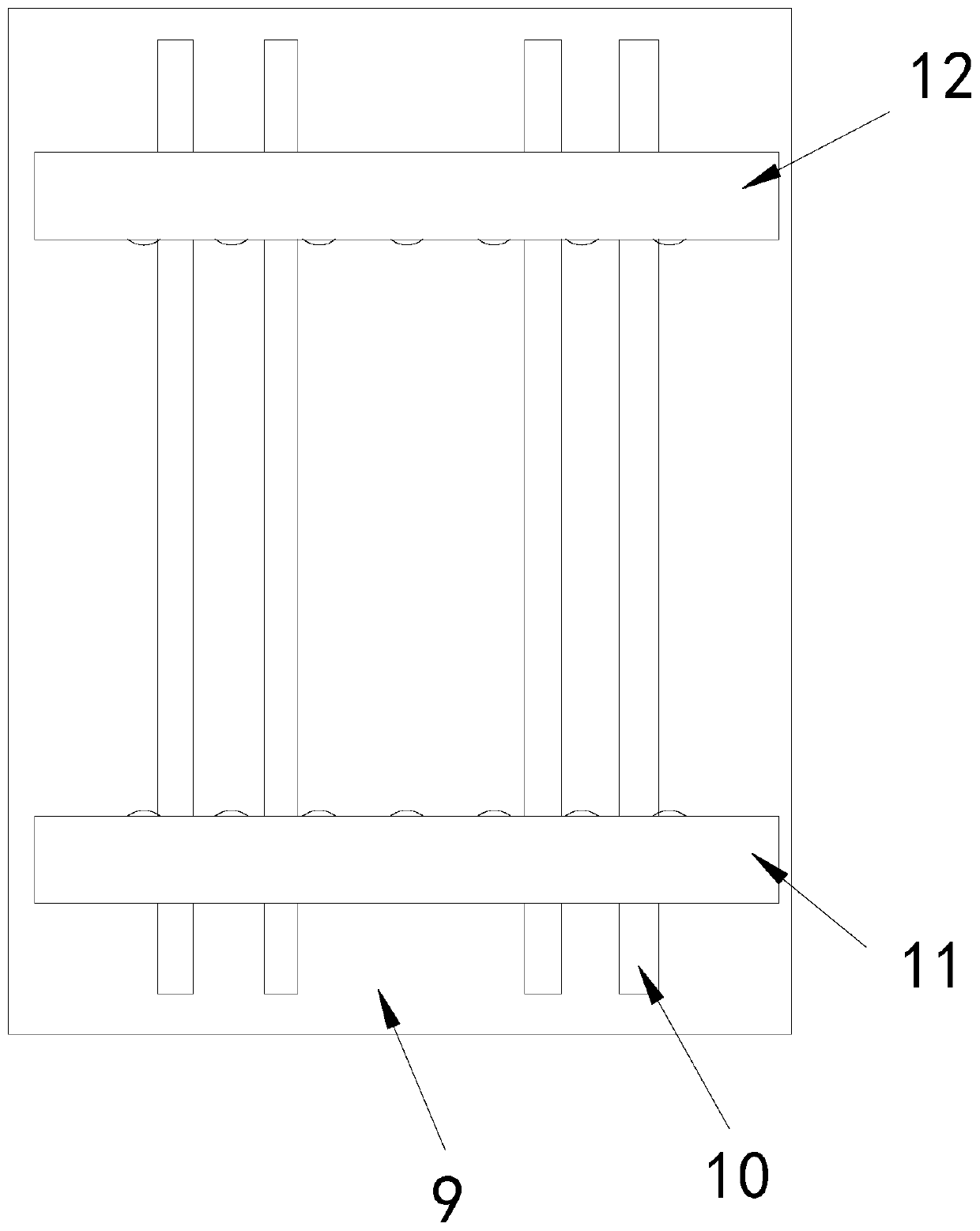

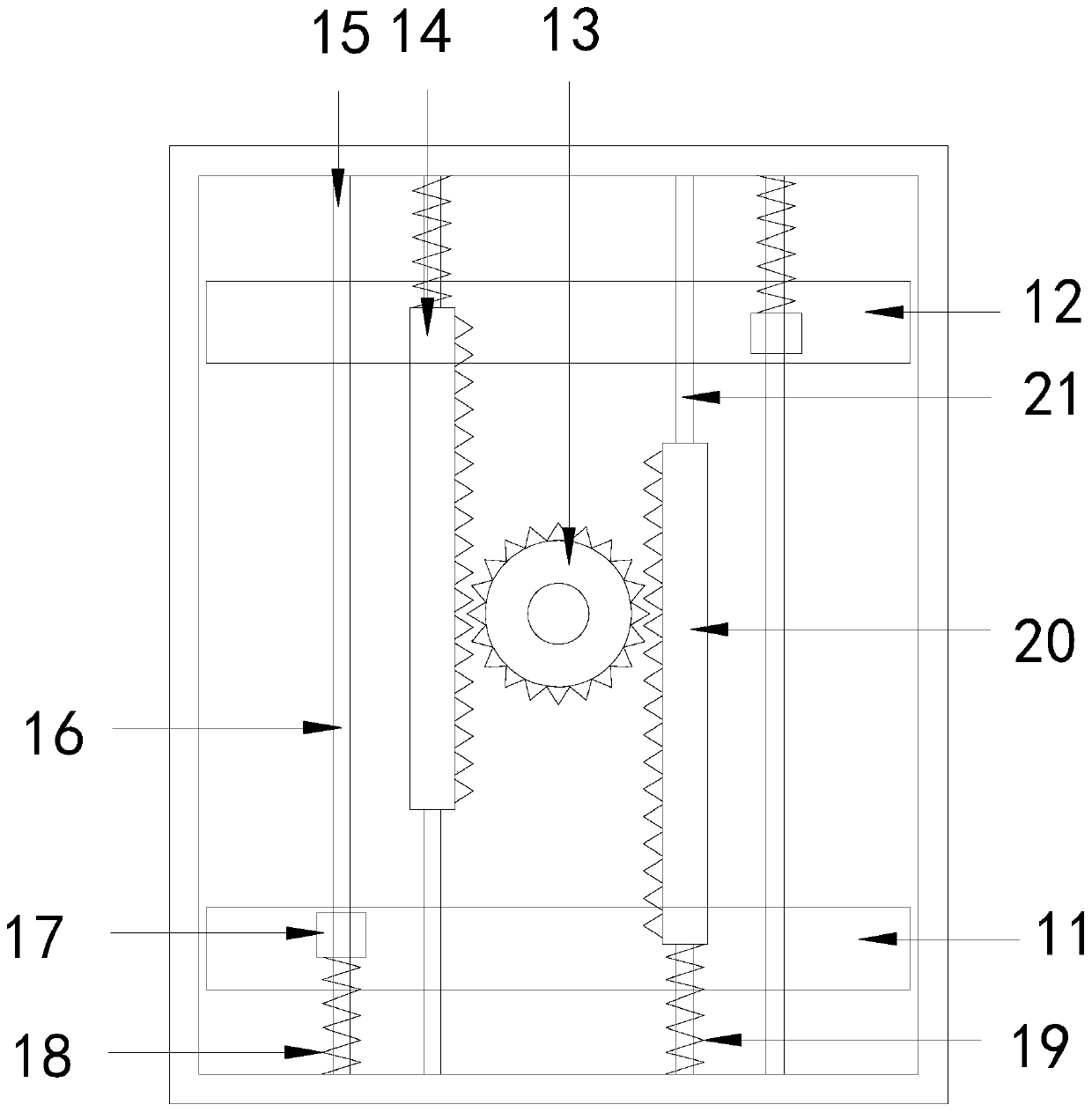

Tin device for processing printed circuit boards

InactiveCN110722236AGood solderAvoid leaningWelding/cutting auxillary devicesAuxillary welding devicesPrinted circuit boardStructural engineering

The invention discloses a tin device for processing printed circuit boards. The structure of the tin device comprises a base, a sliding workbench, stand columns, a tin supply system, a slider, a sliderail, a tin spraying head and a clamp, the sliding workbench is mounted on the base, a clamp is arranged on the sliding workbench, the two sides of the base are respectively connected with the standcolumns, the top of the stand columns are connected with the slide rail, the slide rail is in sliding connection with the slider, the slider is connected with the tin spraying head, the tin spraying head is connected with the tin supply system, the tin supply system is arranged on the side surface of the stand column, the clamp comprises a protective base, a moving device, a first clamping plate and a second clamping plate, a moving device is arranged in the protective base, the first clamping plate and the second clamping plate are parallel to each other and are arranged on the protective base, the moving device is connected with the first clamping plate and the second clamping plate respectively. The tin device has the benefit effect that the double-panel type printed circuit board is clamped and fixed through the hourglass-shaped pulley, the circuit board can be kept in a horizontal state, soldering is facilitated better, and tilting is prevented.

Owner:陈强

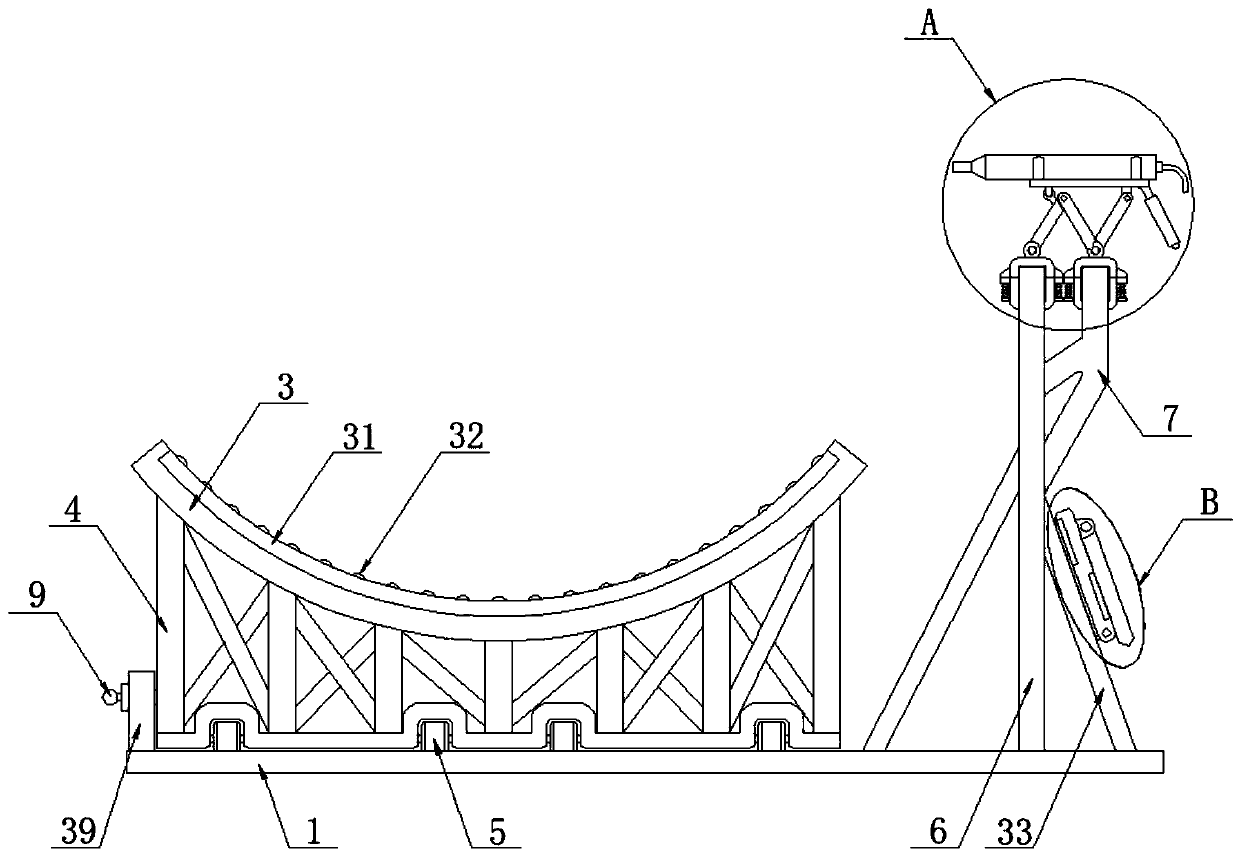

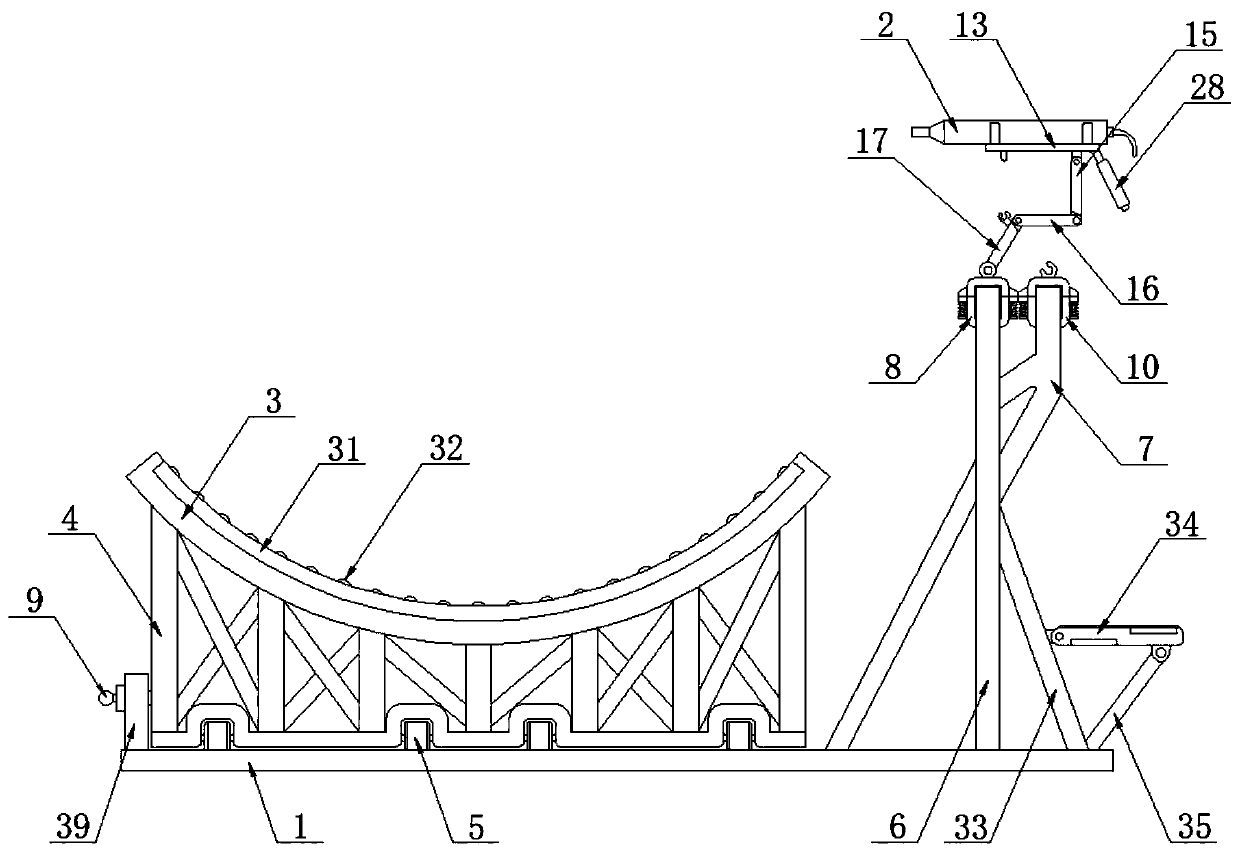

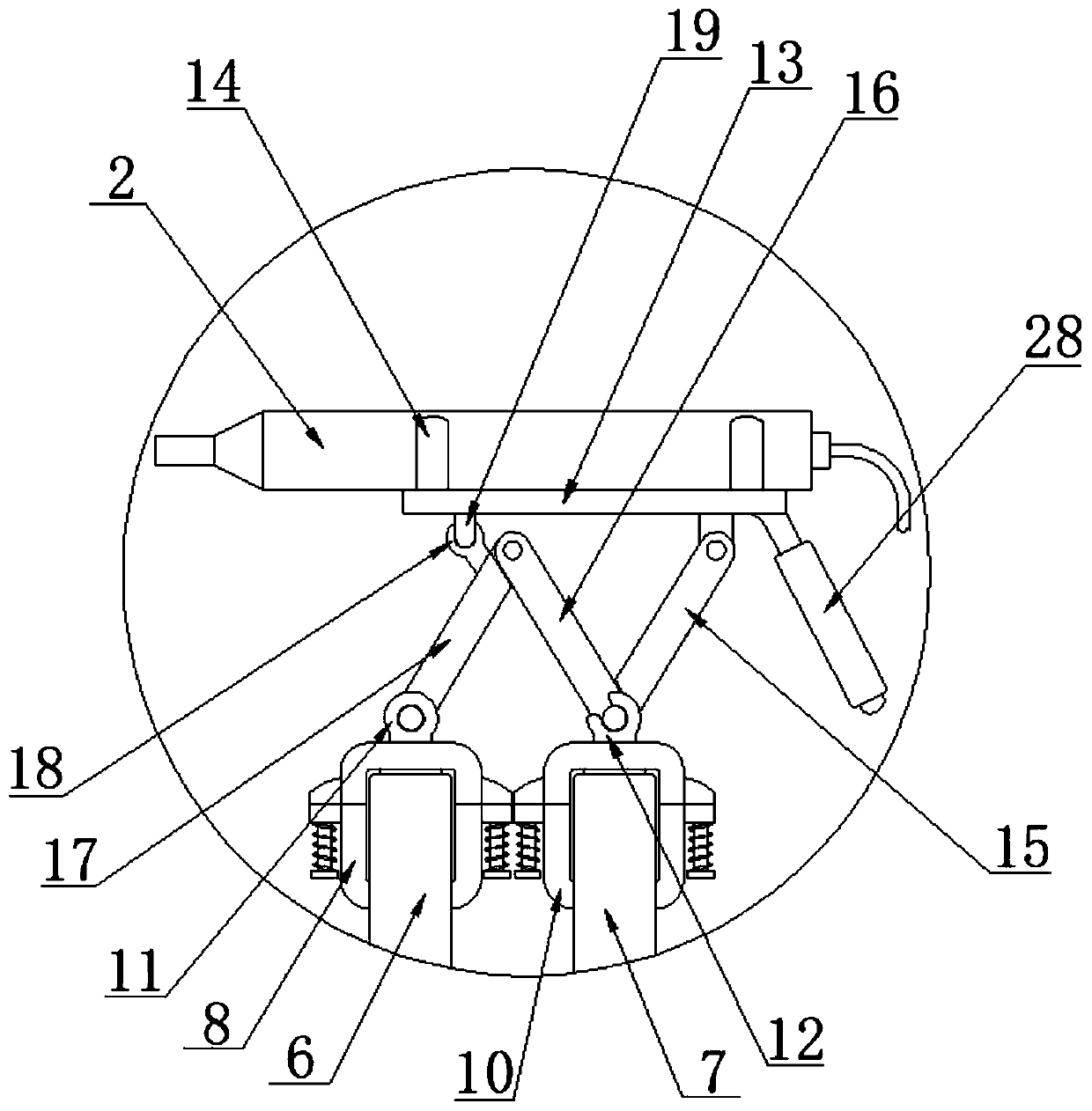

Welding assembly and method for machining pressure vessel for aerospace experiment

InactiveCN110757039AEliminate frictionEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesSteel framePressure vessel

The invention discloses a welding assembly and method for machining a pressure vessel for an aerospace experiment, and relates to the technical field of welding assemblies. The welding assembly comprises a base frame, a welding gun and a bracket. The bottom of the bracket is fixedly connected with a steel frame, and the bottom of the steel frame is slidably connected with the top of the base platethrough wheels. A U-shaped main supporting frame is fixedly connected between the front side and the rear side of the right side of the top of the base plate. A U-shaped auxiliary supporting frame isfixedly connected between the front side and the rear side of the right side of the U-shaped main supporting frame. According to the welding assembly and method for machining the pressure vessel forthe aerospace experiment, a first connecting rod, a second connecting rod and a third connecting rod are folded, the joint of the first connecting rod and the second connecting rod is clamped in a first buckle, then the welding gun and a tray can be horizontally placed stably, and the exterior of the vessel can be stably welded; and if the angle and distance of the welding gun needs to be adjusted, the first connecting rod, the second connecting rod and the third connecting rod can be stretched to realize welding and adjustment within a wide range.

Owner:合肥化机装备制造有限公司

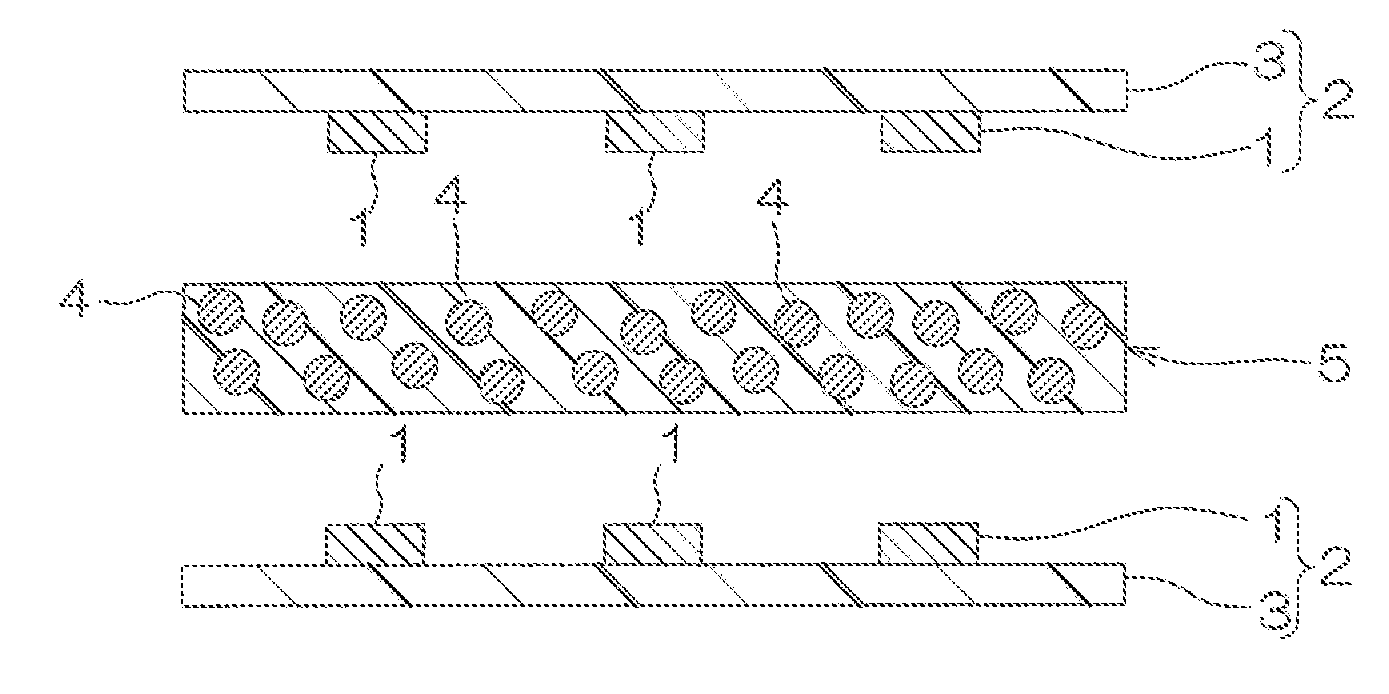

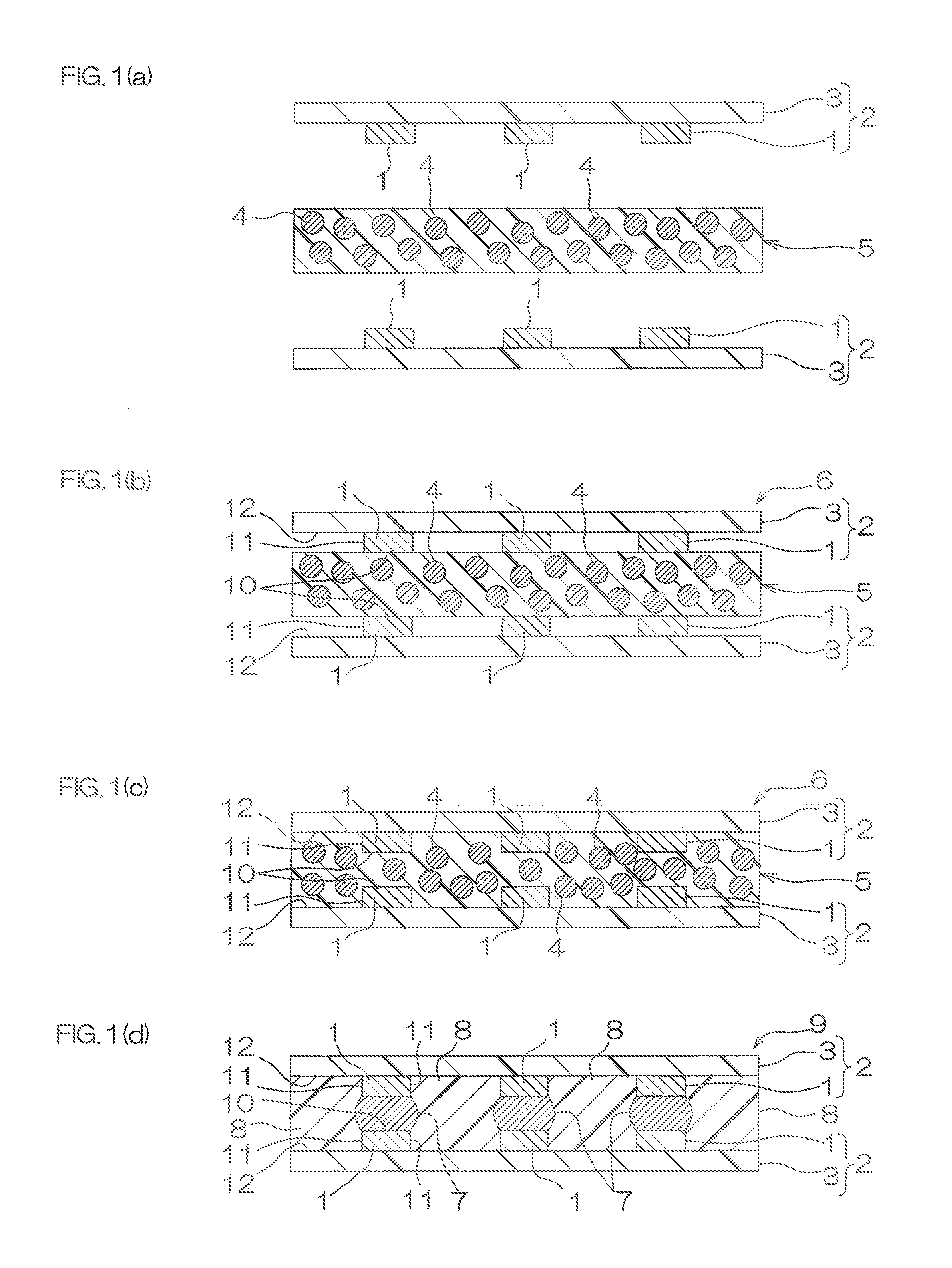

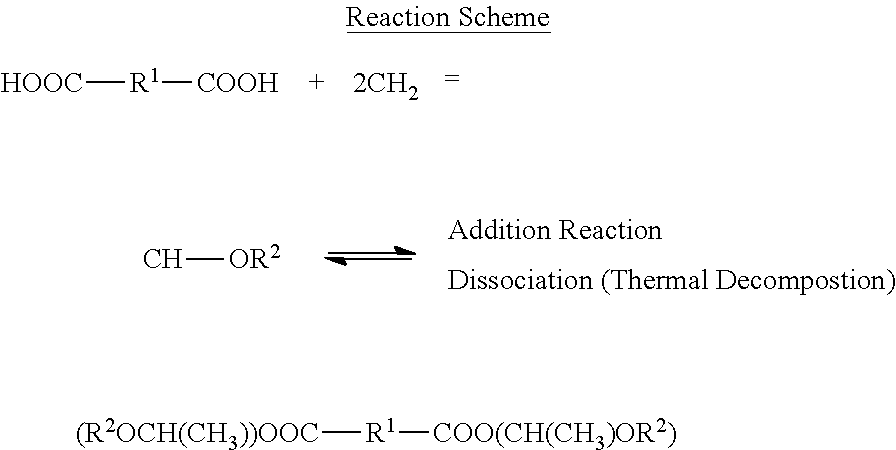

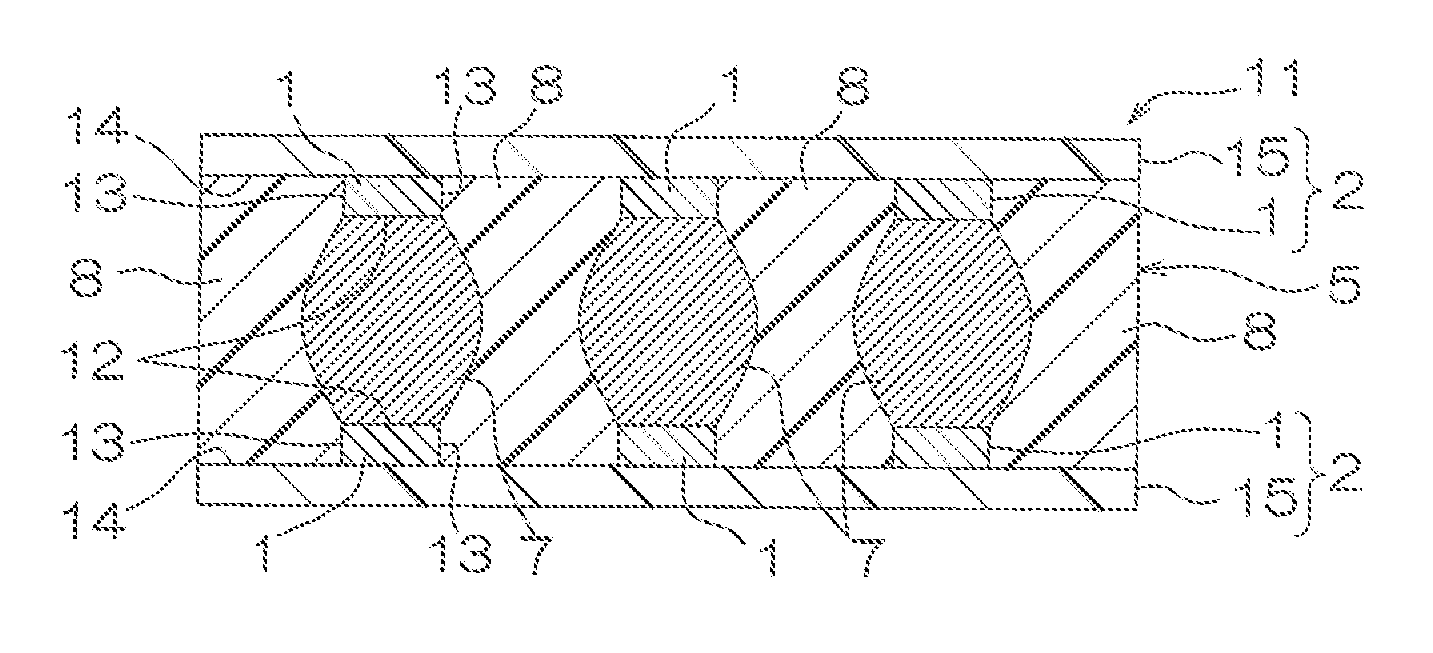

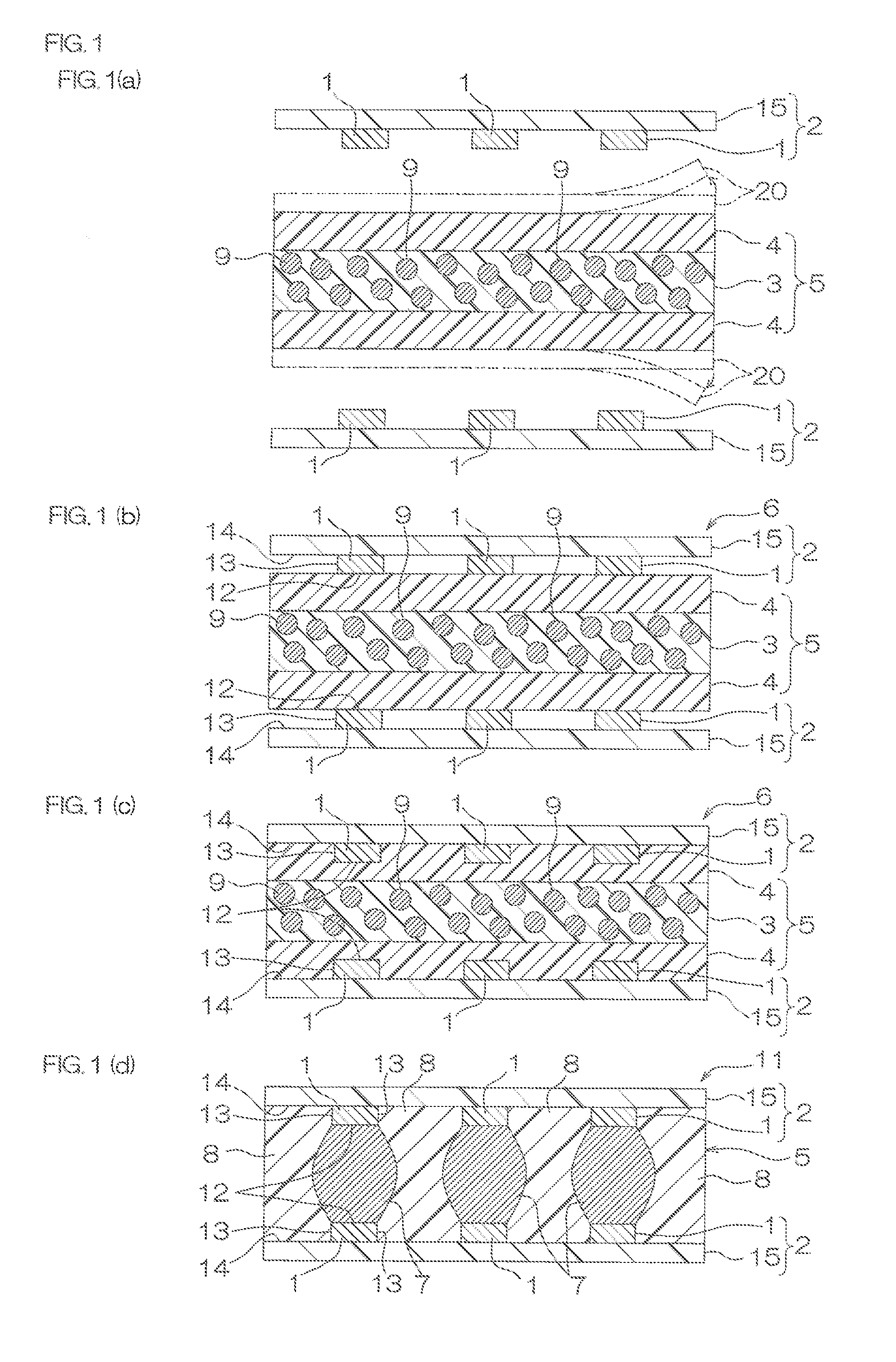

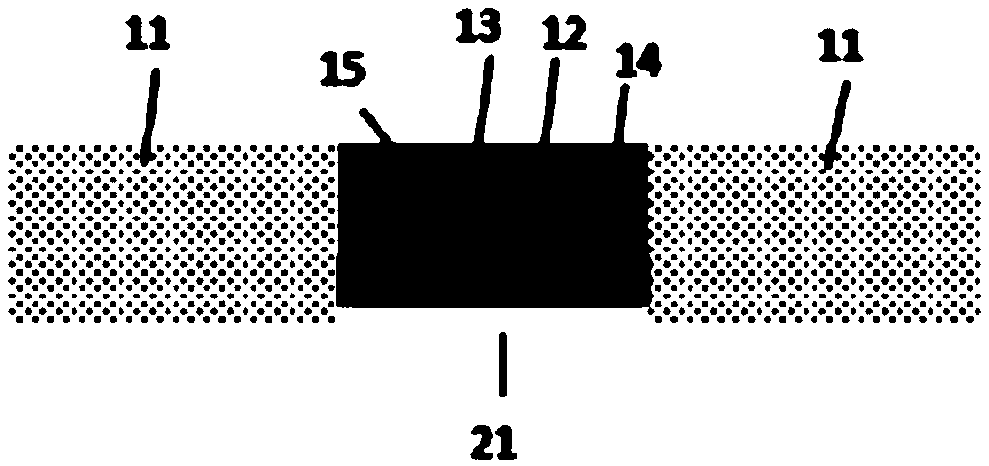

Joining sheet, electronic component, and producing method thereof

InactiveUS20130277092A1Excellent solder meltingEasy to joinSolid-state devicesEpoxy resin adhesivesCarboxylic acidElectronic component

A joining sheet contains solder particles, a thermosetting resin, a thermoplastic resin, and a blocked carboxylic acid.

Owner:NITTO DENKO CORP

Cable connector assembly with spacer

InactiveUS20160329660A1Easy cutting processEasy to cutElectrically conductive connectionsContact member assembly/disassemblyEngineeringElectric wire

A cable connector assembly has a connector and a cable with a number of coaxial wires and a number of unshielded wires. The connector includes an insulative housing with a front tongue and a rear end, a number of contacts with mating portions exposed on the front tongue and connecting portions exposed on the rear end, and a spacer assembled to the rear end. The spacer forms a plurality of positioning holes extending therethrough along a front-to-back direction, and a passageway extending therethrough along a vertical direction perpendicular to the front-to-back direction. The coaxial wires are inserted through the corresponding positioning holes and across the passageway to reach the corresponding contacts along the front-to-back direction so as to cut the coaxial wires in the passageway along the vertical direction.

Owner:FOXCONN INTERCONNECT TECHNOLOGY LIMITED

Joining sheet, electronic component, and producing method thereof

ActiveUS20130258632A1Deactivation can be suppressedPromote meltingPrinted circuit assemblingSynthetic resin layered productsActive agentElectronic component

A joining sheet includes a solder layer which contains solder particles, a thermoplastic resin, and an active agent capable of activating the solder particles and a thermosetting resin-containing layer which is laminated on at least one surface in a thickness direction of the solder layer and contains a thermosetting resin.

Owner:NITTO DENKO CORP

A resistor and a method for manufacturing the resistor

InactiveCN109102973AStrong cooling capacityGood thermal stabilityResistor manufactureResistor detailsAlloy elementSurface oxidation

The invention discloses a resistor and a method for manufacturing the resistor. The resistor comprises a resistor unit and electrodes connected at both ends of the resistor unit; and the resistor unitis an alloy material, which has strong heat dissipation ability, good thermal stability and high bearing power. A method for manufacturing a resistor comprises: connecting a sheet-like pure metal electrode material to both ends of a sheet-like resistive alloy element; using laser or mechanical cutting or grinding cutting or grinding the resistive alloy element so as to trim the resistance of theresistor; applying a layer of insulating heat conductive adhesive on the lower surface of the resistance element by using the spraying technology; carrying out surface oxidation protection treatment on the resistor to form a resistor product.

Owner:NANJING SART SCI & TECH DEV

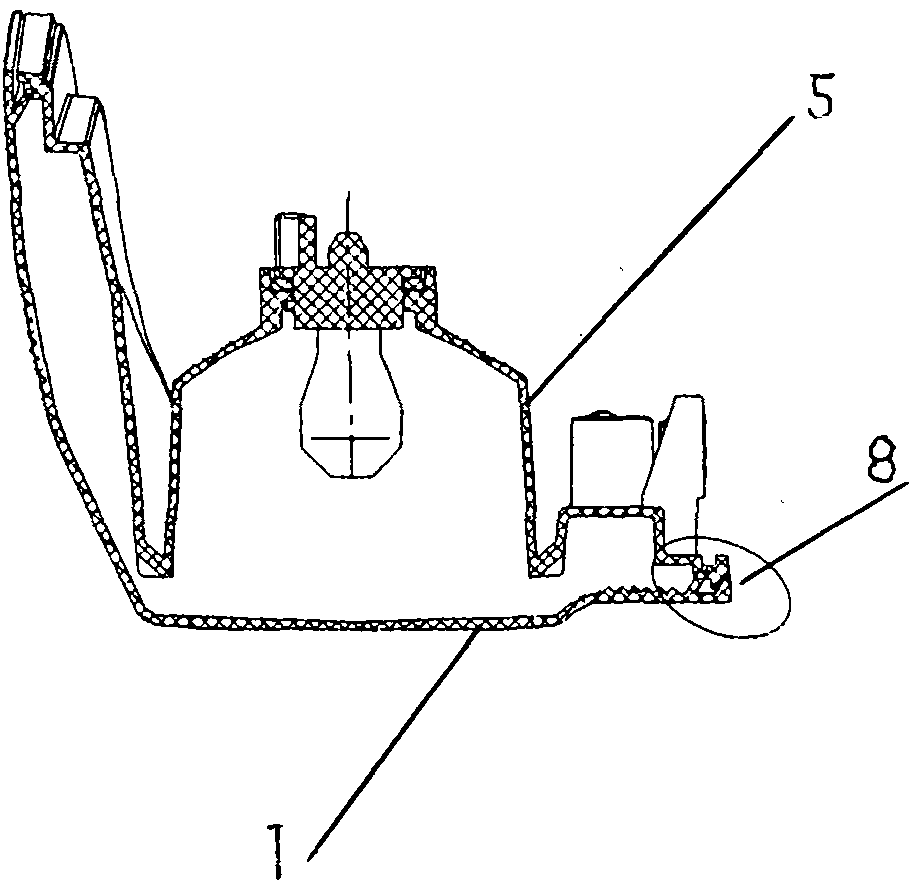

Automobile combined rear lamp structure

ActiveCN101776239AEasy to solderReduce processing difficultyOptical signallingLight fasteningsEngineeringSignal lamp

The invention discloses an automobile combined rear lamp structure, which comprises a lamp housing, a brake lamp / rear position lamp, a rear steering signal lamp and a rear fog lamp / backup lamp, wherein the brake lamp / rear position lamp, the rear steering signal lamp and the rear fog lamp / backup lamp are arranged on the lamp housing. The invention is characterized in that a welded limiting rib is arranged on the right side of a lens, the welded limiting rib protrudes upward, the vertical section of the welded limiting rib is approximately trapezoidal, and the welded limiting rib is fixedly connected with a small limiting boss arranged on the right side of the lamp housing; a primary positioning pin is arranged at the upper part on the right side behind the lamp housing and a secondary positioning pin is arranged at the lower part on the right side behind the lamp housing; a primary positioning hole and a second positioning hole are arranged on a rail lamp reinforcement, and the primary positioning pin and the secondary positioning pin arranged behind the lamp housing are respectively matched with the primary positioning hole and the secondary positioning hole. The invention has the advantages that the welding is firm, water is not apt to enter and the service life is long; and the positioning is accurate and the installation is stable.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

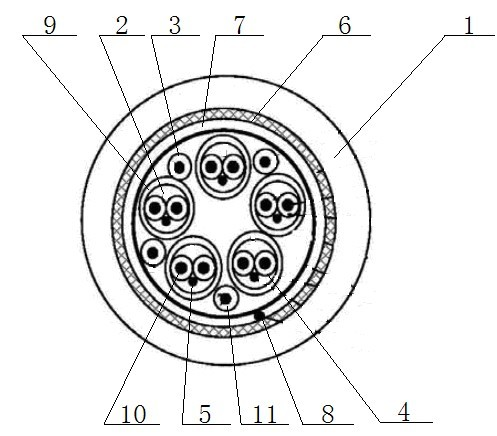

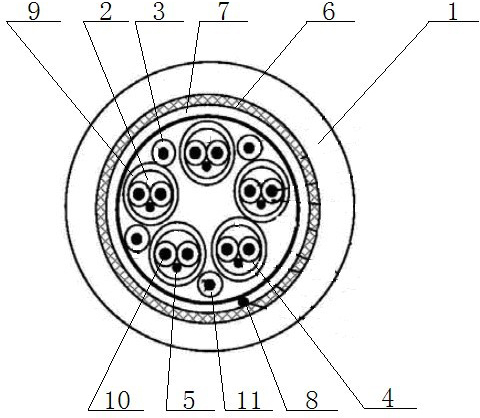

High definition multimedia interface (HDMI) linear material

InactiveCN102024513ASmall outer diameterMeeting the needs of the miniaturization trendInsulated cablesMetal/alloy conductorsElectrical conductorElectromagnetic interference

The invention discloses a high definition multimedia interface (HDMI) linear material, comprising a core wire, at least one external paired core wire and a core wire jacket, wherein, the inner part of the core wire is provided with inlayer aluminum mylar foil, an internal paired core wire, inner cascading water earth wires and anti-electromagnetic interference earth wires, and the outer part of the core wire is coated with outer-layer aluminum mylar foil, anti-electromagnetic interference braided-layer core wires and the core wire jacket; the inner paired core wire and the external paired core wire are in a round layered structure which comprises a conductor layer and an insulating layer arranged outside the conductor layer; the specification of the manufacturing material of the conductor layer is 36AWG (American wire gauge) of tinned cooper wires; the core wire jacket is made of Teflon; and the external diameter of the core wire jacket is 3.6+ / -0.15 millimeters. The linear material provided by the invention not only has smaller wire material outer diameter, but also has better welding performance.

Owner:SUZHOU YIHUA COMMUNICATED CONNECTOR

Magnetically-controlled plasma welding method and welding device

InactiveCN109590590AIncrease the electric field strengthImprove welding effectPlasma welding apparatusMetallic materialsEngineering

The invention discloses a magnetically-controlled plasma welding method and a welding device. According to the magnetically-controlled plasma welding method, adding of a longitudinal magnetic field along the direction of a welding gun between the welding gun and a workpiece welded is adopted. Under restraint of a longitudinal magnetic field, the drastic contracting effect is produced by electric arcs. The electric field intensity of the electric arcs is strengthened conspicuously, and thus the electric arcs have strong longitudinal penetrating power. Therefore, by adding the longitudinal magnetic field between the welding gun and the workpiece welded, a high-thickness plate or other special metal materials which are difficult to weld can be welded easily; and moreover, under the action ofelectrified coil current, the workpiece welded also has function of preheating before welding and heat treatment after welding, and the welding joint molding quality is improved obviously.

Owner:邢台子中电子科技有限公司

Special welding electrode for surfacing and repairing broken teeth of medium-load and medium-speed gear

InactiveCN102489900AEasy to useEasy to solderWelding/cutting media/materialsSoldering mediaFerrosiliconLanthanum

Disclosed is a special welding electrode for surfacing and repairing broken teeth of a medium-load and medium-speed gear. Chemical components of the coating of the special welding electrode in weight percent (wt %) include 25-35% of marble, 14-20% of fluorite, 3-5% of quartz, 2-4% of chalk, 4-6% of high carbon ferrochromium, 2-4% of high carbon ferromanganese, 3-5% of graphite, 2-4% of ferrosilicon, 2-4% of ferrotitanium, 3-5% of ferromolybdenum, 4-6% of lanthanum trioxide, 7-9% of metallic nickel, 6-8% of medium carbon ferrochromium and 3-5% of ferrovanadium, and a core wire is an H08A steel welding wire. When the special welding electrode is used, preheating at the temperature of 200-300 DEG C is performed before welding, and tempering at the temperature of 100-200 DEG C is performed after welding. The special welding electrode is convenient to use on site, easy in welding and non-cracking after welding. The surface hardness of the gear after welding ranges from HRC (Rockwell hardness) 50 to HRC 55, and the service life of the repaired gear is three to four times that of an original gear.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com