Patents

Literature

62 results about "Mylar foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

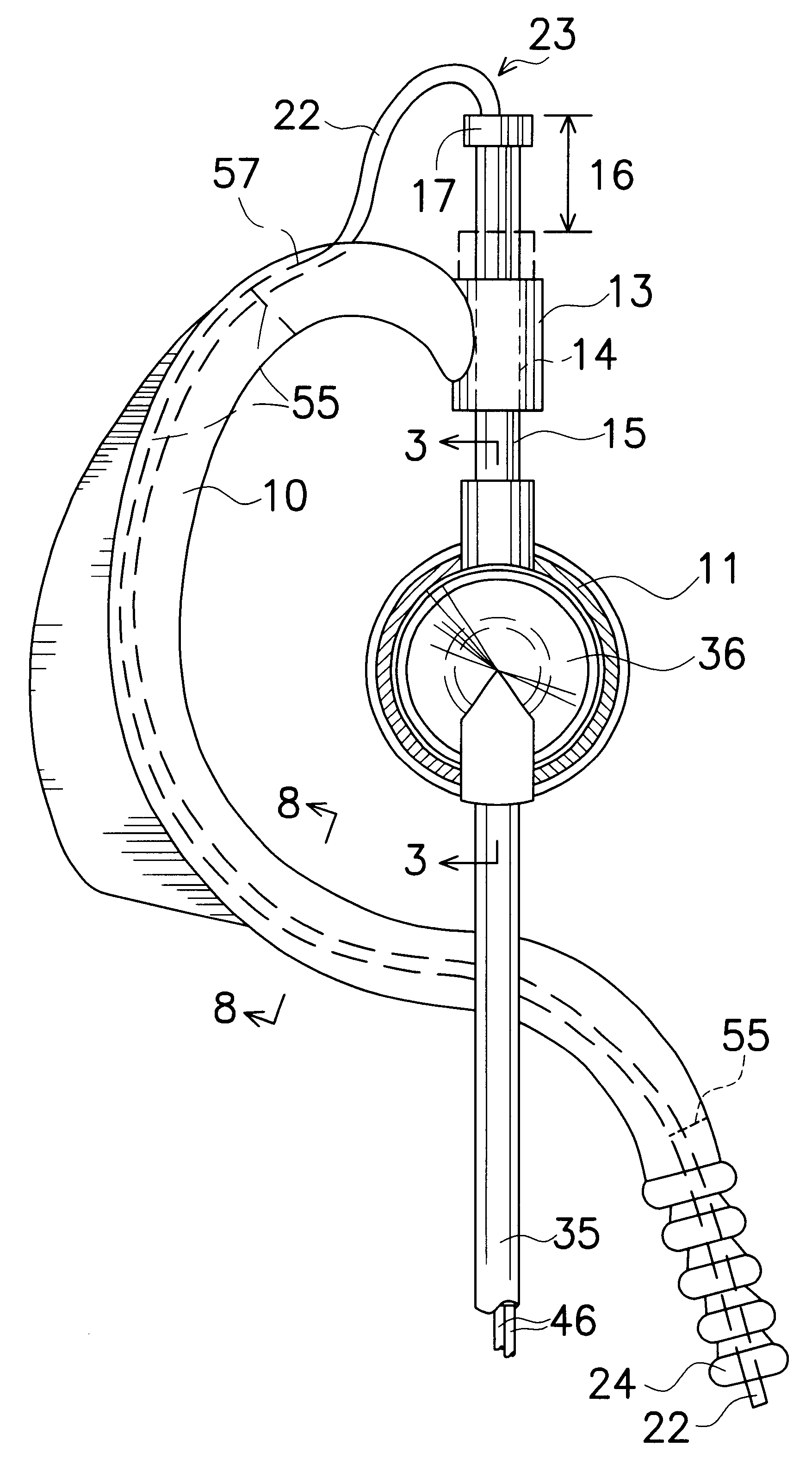

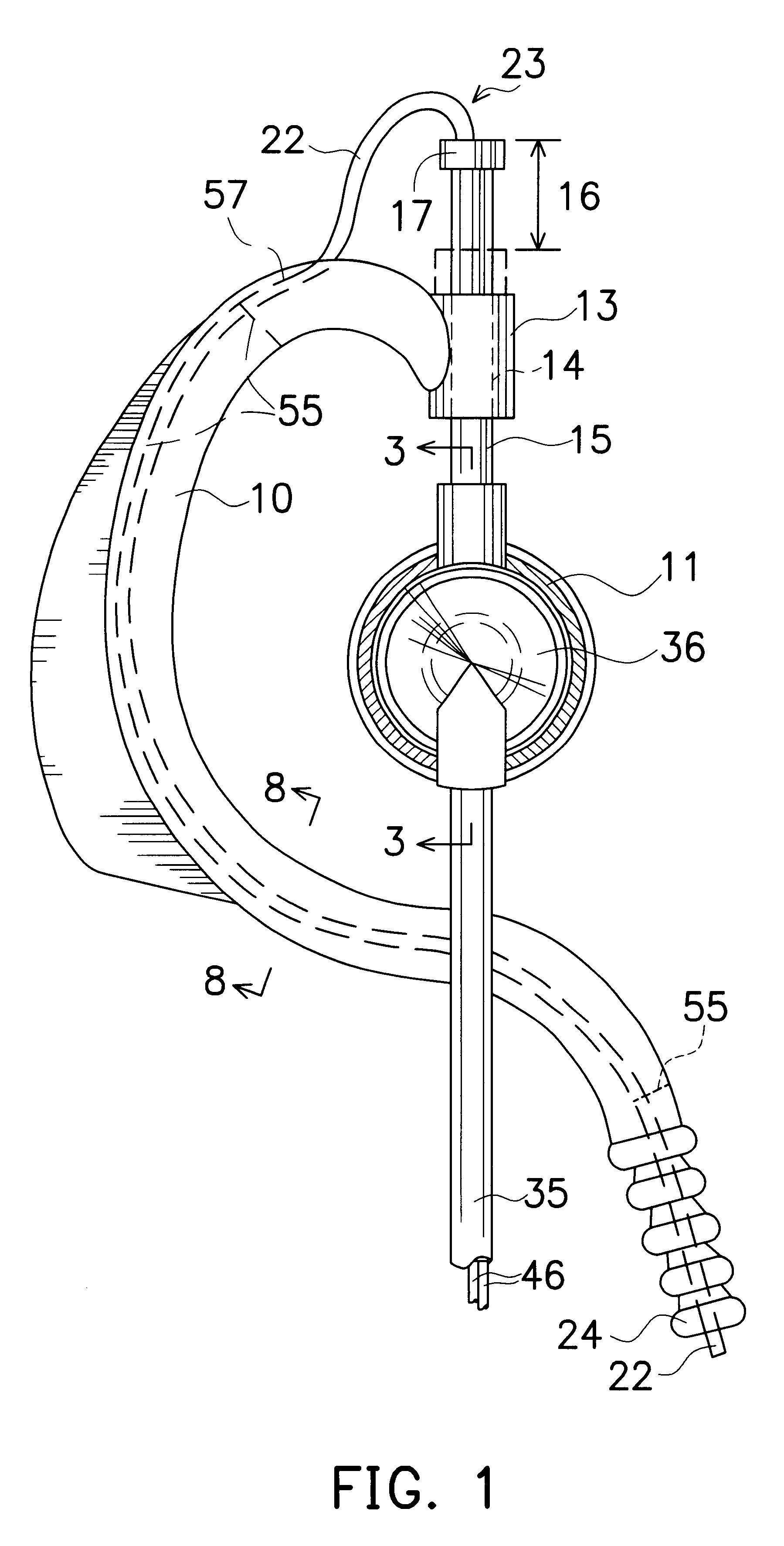

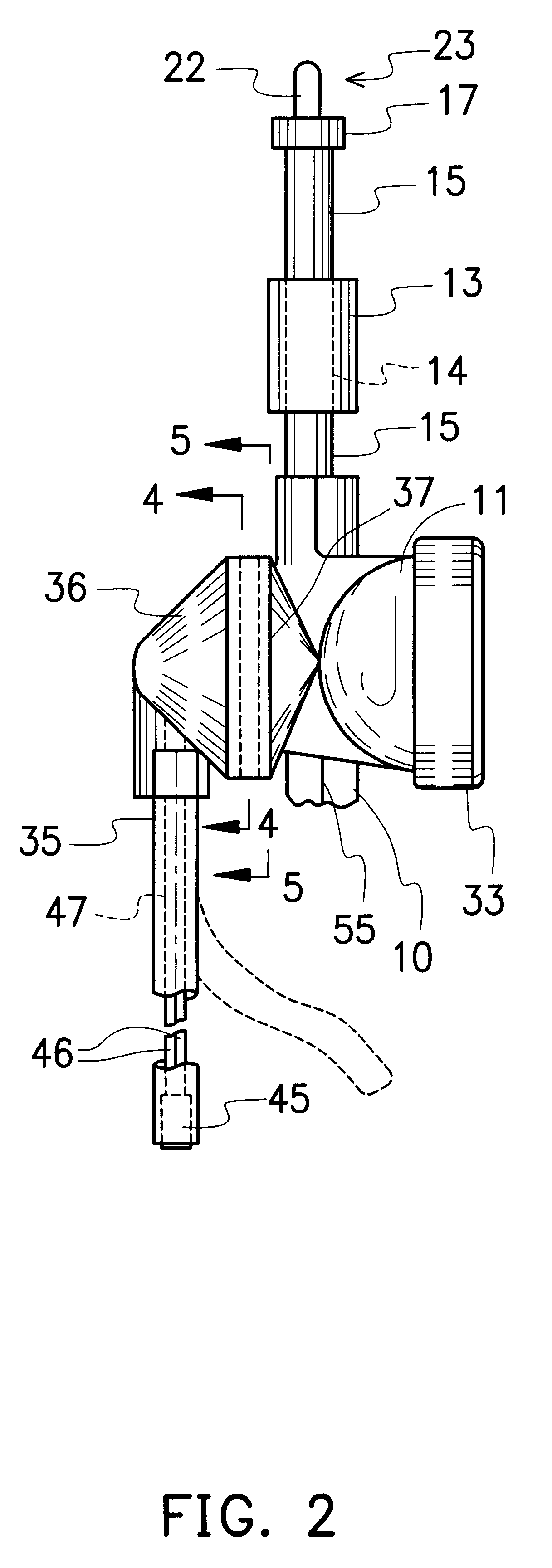

Adjustable earphones for personal audio and communication systems

InactiveUS6427018B1Prevent rusting and other corrosionAvoid partialMicrophonesLoudspeakersCommunications systemEngineering

An ear mounted earphone includes a speaker housing for positioning a speaker at the entrance to the auditory canal of an ear of a user. An elongate boom extends from the speaker housing and through a sleeve at one end of an earpiece so that the boom may be moved longitudinally and rotationally within the sleeve for adjustment purposes and will be frictionally held in adjusted position by the sleeve during use. A microphone arm with microphone may be rotatably mounted on the speaker housing to provide a microphone when the earphones are used with a communication system. The rotatability of the microphone arm allowing the same earphone and microphone arm to be adjusted for use with either the right or left ear of a user. An earpiece may be conveniently integrally molded as a single piece with a slit formed therein intermediate its length so the wire to the speaker and microphone can be positioned within the earpiece. The speaker may be waterproofed by a thin waterproof material such as mylar.

Owner:COTRON

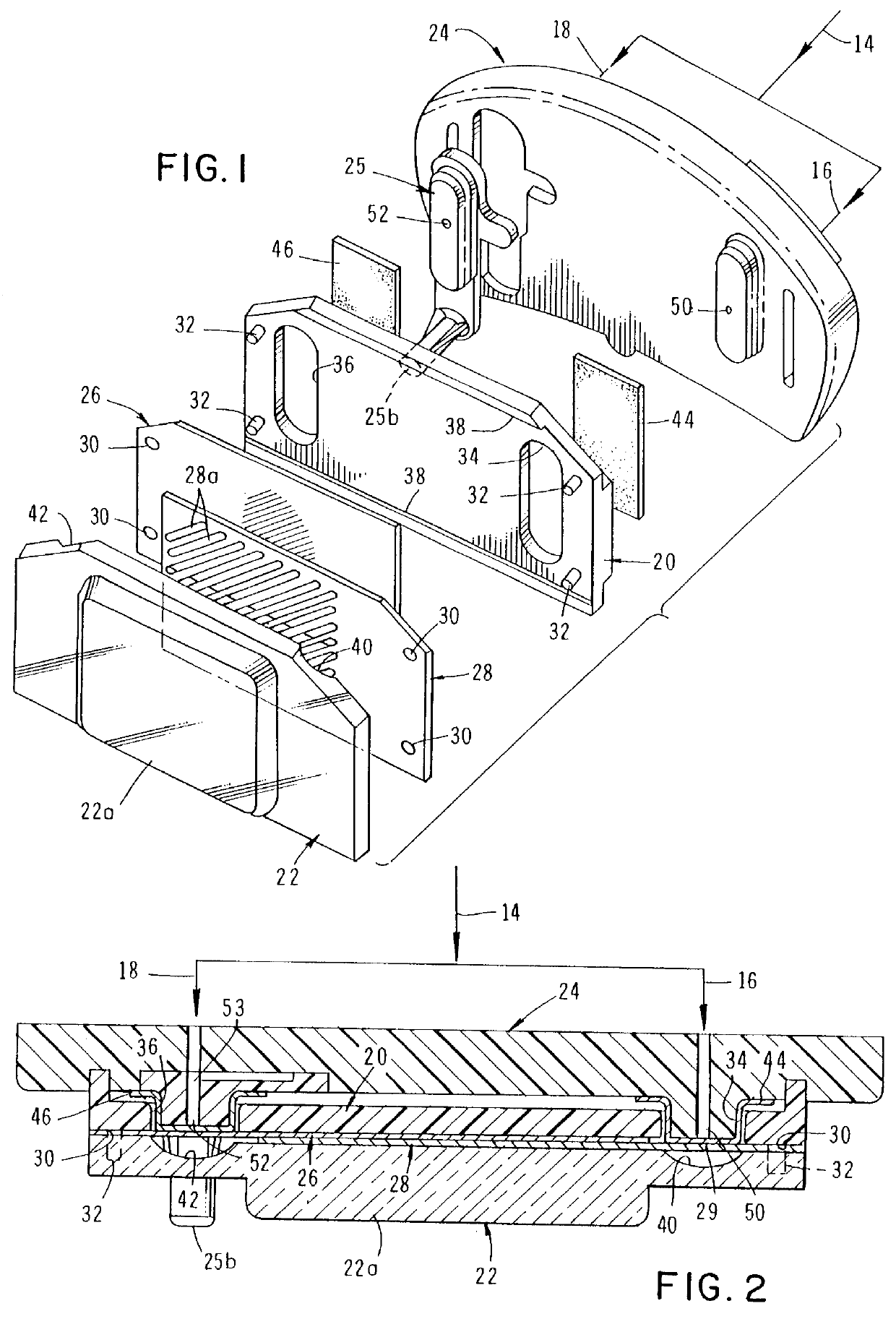

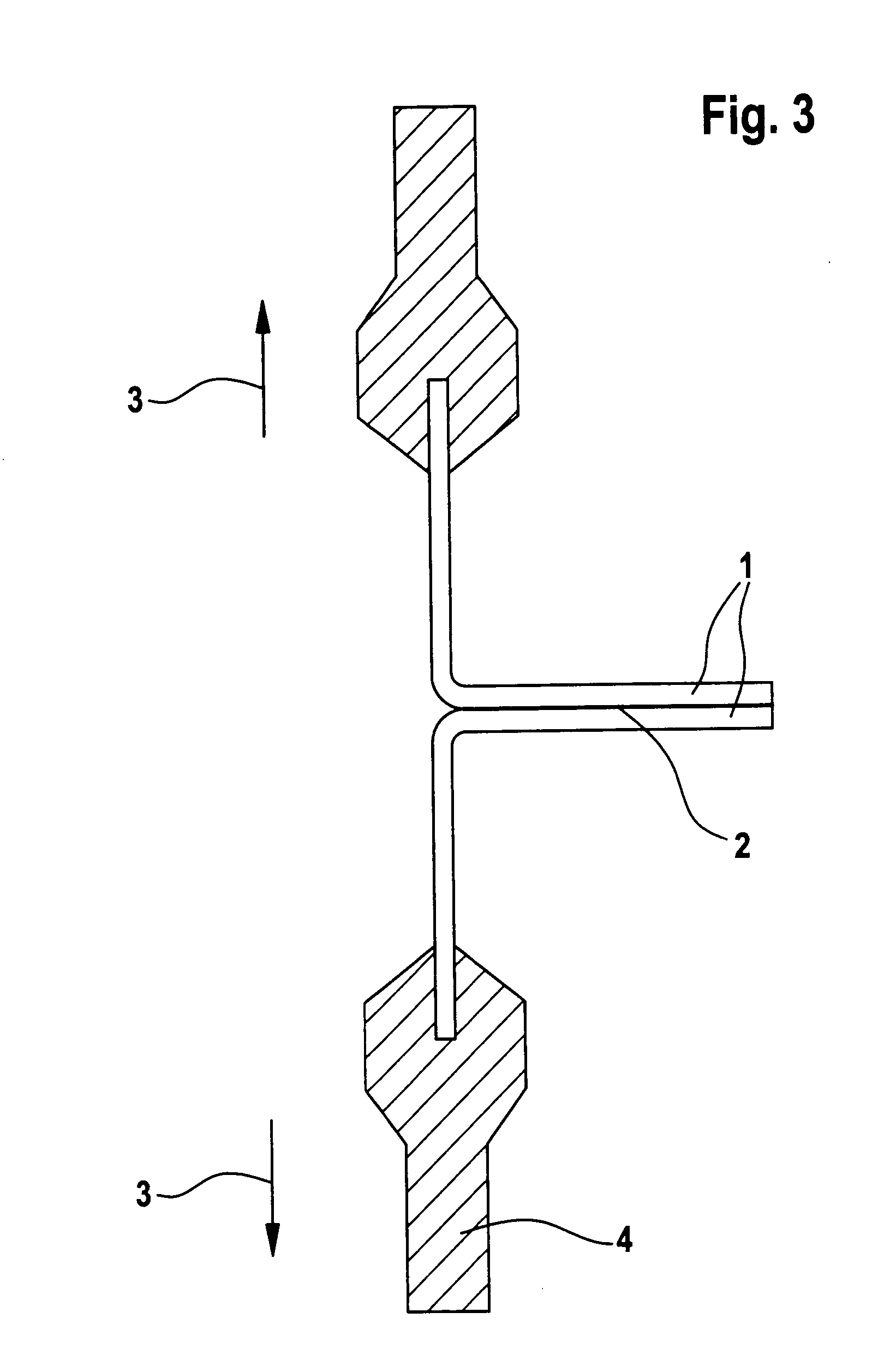

Apparatus for indicating fluid pressure in a conduit

InactiveUS6010482AEasy and inexpensive to manufactureFluid pressure measurement using elastically-deformable gaugesMedical devicesPolyesterCatheter

An apparatus for visually indicating fluid flow through a fluid system or apparatus such as a medical infusion device. The apparatus comprises a pair of thin, indicia bearing films disposed in an overlaying relationship. These films are shifted relative to each other by movement of mechanical actuators which are deflected solely by the pressure of the fluid within the fluid conduits of the system of the apparatus. The two films are stacked in closed proximity and are preferably constructed from a substantially transparent flexible material such as mylar. One surface of the inferior film is printed with a plurality of integrated symbols depicting various fluid flow conditions. The superior film functions as a mask over the inferior film and is printed with a pattern of diagonally extending, alternating clear and opaque stripes. The print ratio of the superior film permits viewing at any one time of only one of the symbols printed on the inferior film.

Owner:PESCADERO BEACH HLDG

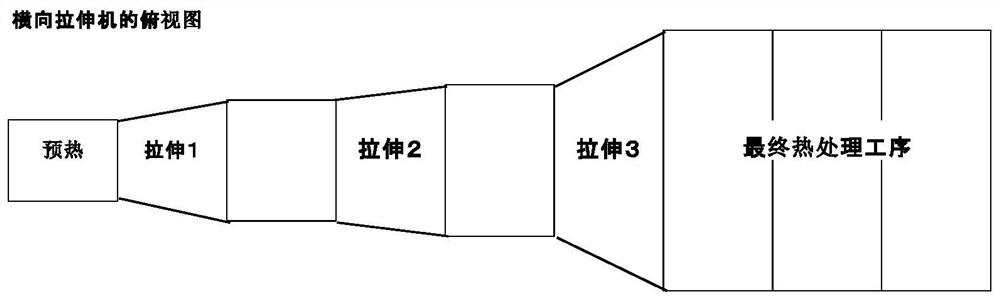

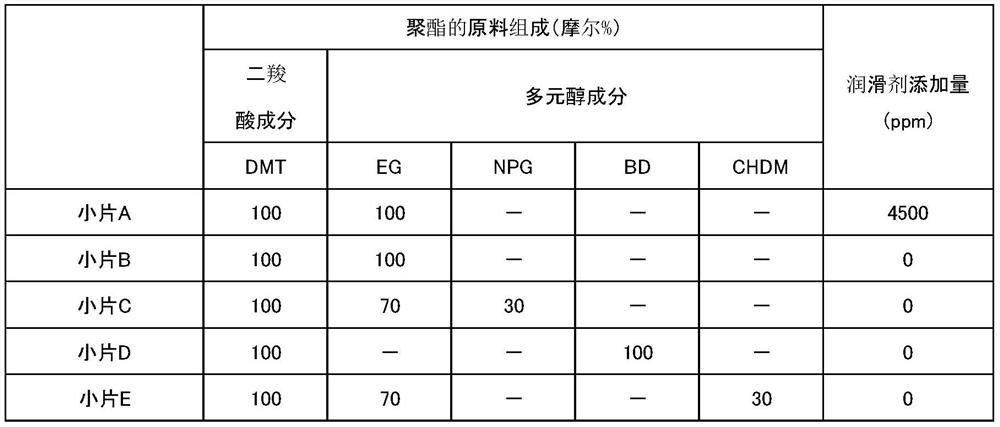

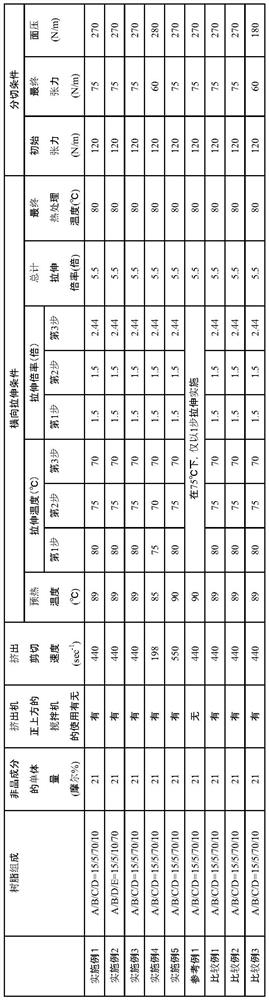

Polyester film with low percent thermal shrinkage and production method thereof

The invention discloses a mylar with low heat shrinkage rate containing at least one layer structured multilayer extrusion structure, it has low heat shrinkage rate especially low cross heat shrinkage rate, and high transparency, low fog, excellent friction performance, and excellent processing performance and dimension stability. The invention also discloses the mylar production method.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

Multilayer, metalized or ceramic-coated, sealable, biaxially oriented polyester film, its use, and process for its production

InactiveUS6797359B2Good metal adhesionImprove performanceMagnetic materials for record carriersSynthetic resin layered productsPolyesterPolymer science

The invention relates to a metalized or ceramic-coated, biaxially oriented, sealable polyester film with at least one base layer (B), with a sealable outer layer (A), and with a further non-sealable outer layer (C). The sealable outer layer (A) has a minimum sealing temperature (fin) of not more than 110° C. and a seal seam strength (fin) of at least 1.3 N / 15 mm of film width. The two outer layers (A) and (C) are characterized by particular features. The film of the invention is particularly suitable for use in flexible packaging, and particularly and specifically for use on systems which operate in a vacuum.

Owner:MITSUBISHI POLYESTER FILM

Multilayer, transparent, sealable, biaxially oriented polyester film, its use and process for its production

ActiveUS6855395B2Magnetic materials for record carriersSynthetic resin layered productsPolymer scienceBoPET

The invention relates to a biaxially oriented, sealable polyester film with at least one base layer (B), with a sealable outer layer (A) and with another, non-sealable outer layer (C). The sealable outer layer (A) has a minimum sealing temperature (fin) of not more than 110° C. and a seal seam strength (fin) of at least 1.3 N / 15 mm of film width. The two outer layers (A) and (C) are characterized by particular features. The film of the invention is particularly suitable for use in flexible packaging, and particularly and specifically for use on systems which operate in a vacuum.

Owner:MITSUBISHI POLYESTER FILM

Multilayer, metalized or ceramic-coated, sealable, biaxially oriented polyester film, its use, and process for its production

InactiveUS20040009355A1Magnetic materials for record carriersSynthetic resin layered productsPolyesterEngineering

The invention relates to a metalized or ceramic-coated, biaxially oriented, sealable polyester film with at least one base layer (B), with a sealable outer layer (A), and with a further non-sealable outer layer (C). The sealable outer layer (A) has a minimum sealing temperature (fin) of not more than 110° C. and a seal seam strength (fin) of at least 1.3 N / 15 mm of film width. The two outer layers (A) and (C) are characterized by particular features. The film of the invention is particularly suitable for use in flexible packaging, and particularly and specifically for use on systems which operate in a vacuum.

Owner:MITSUBISHI POLYESTER FILM

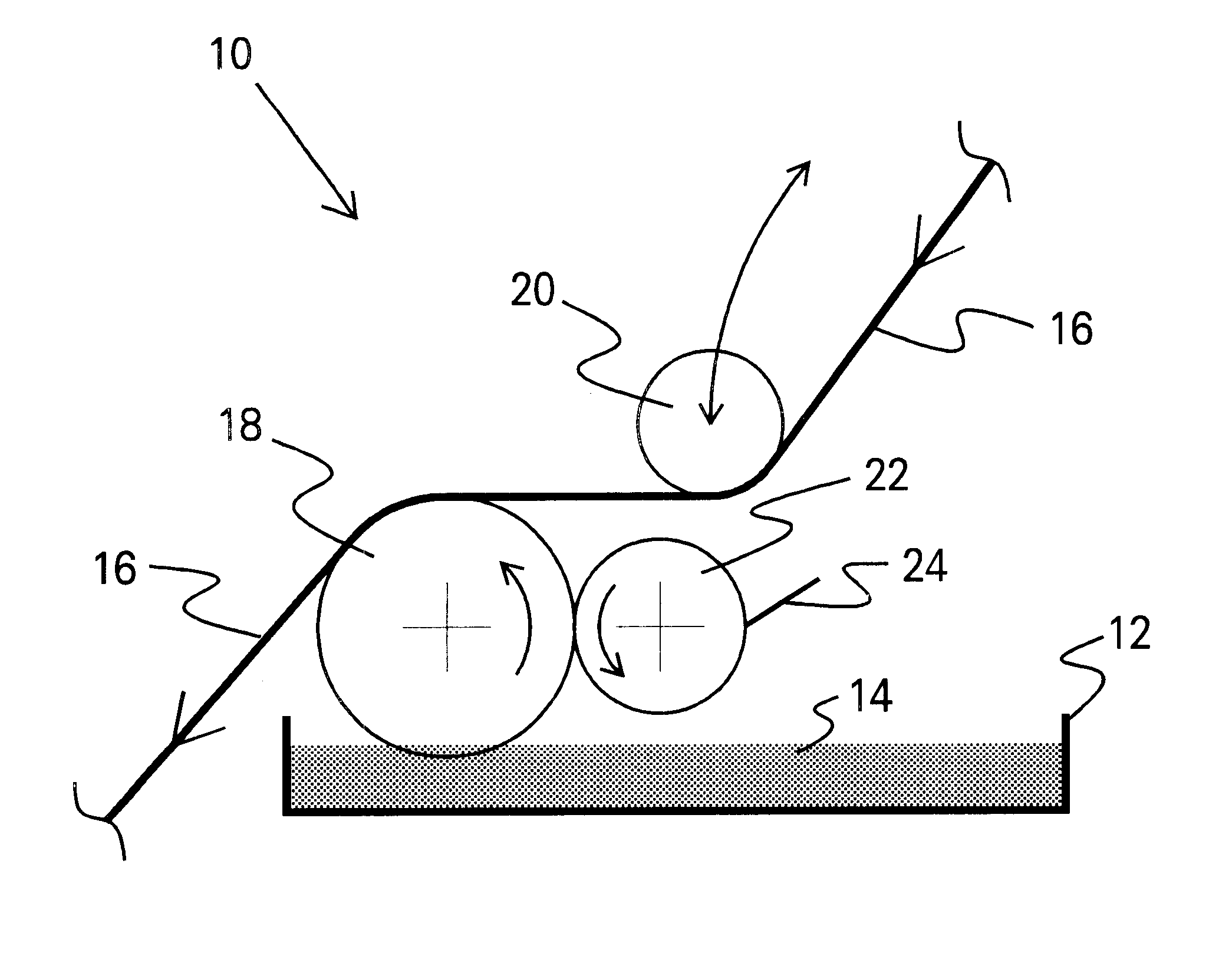

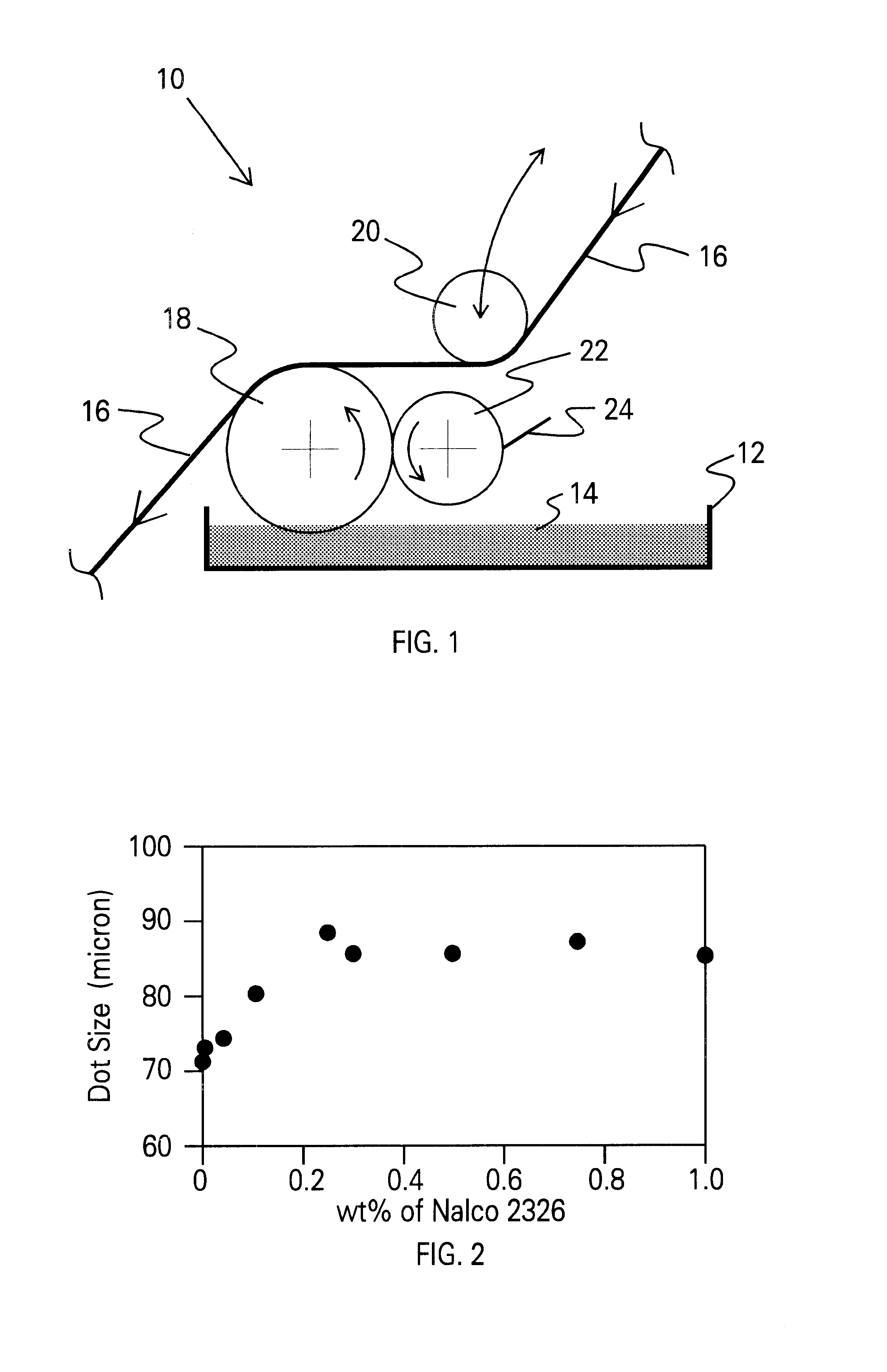

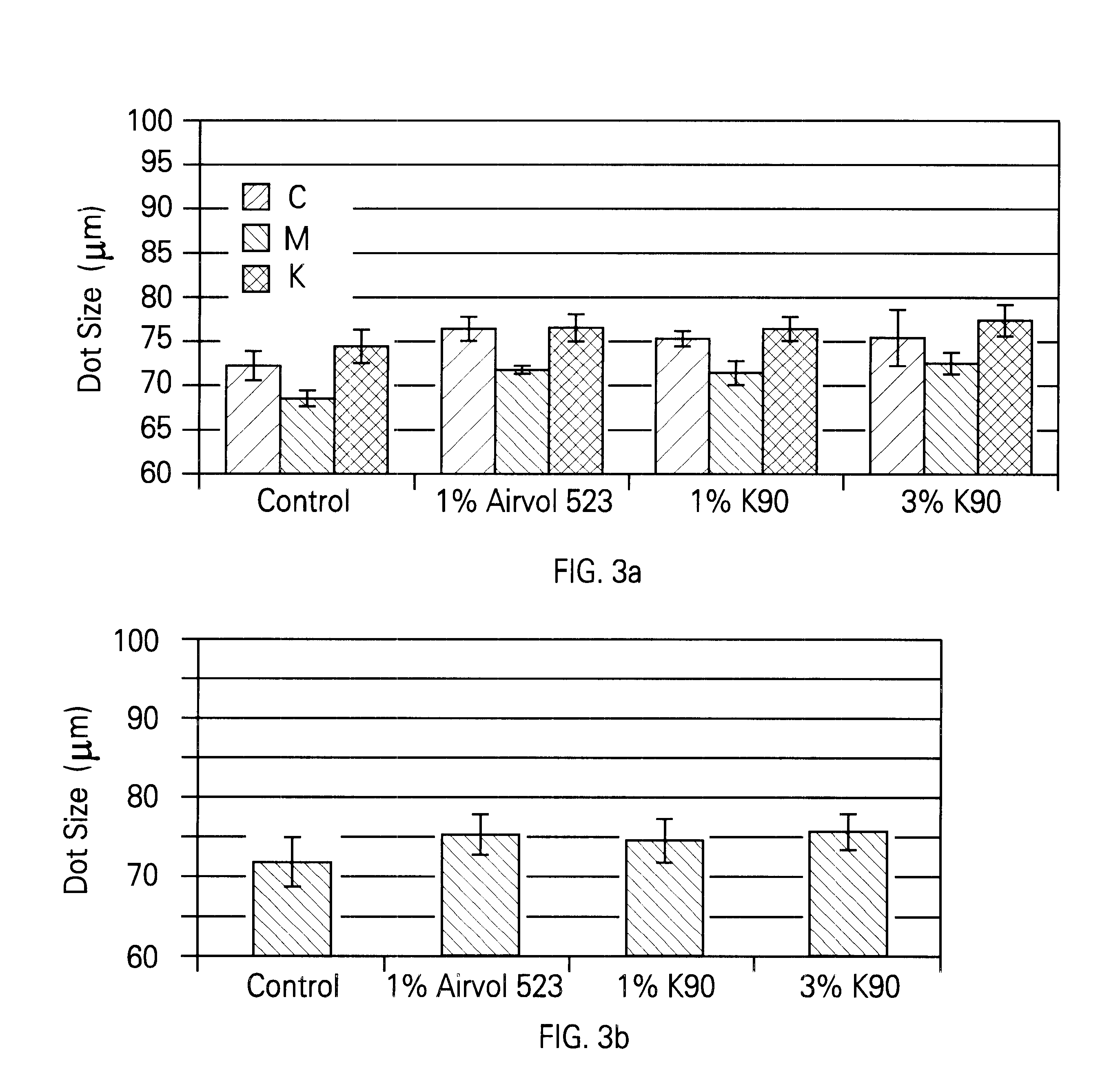

Increasing dot size on porous media printed with pigmented inks

It is found that by wetting coated media, such as film-based media (e.g., Mylar film) and resin-coated papers (e.g., photobase paper), with a dilute polymer solution or colloidal silica or colloidal alumina dispersion with small particle size, the dot size increases compared to the current default dot size when printed with pigment-based inks in a Hewlett-Packard CP-2500 or CP-3500 printer. No previous efforts are known to increase the dot size on coated porous media printed with pigment inks.

Owner:HEWLETT PACKARD DEV CO LP

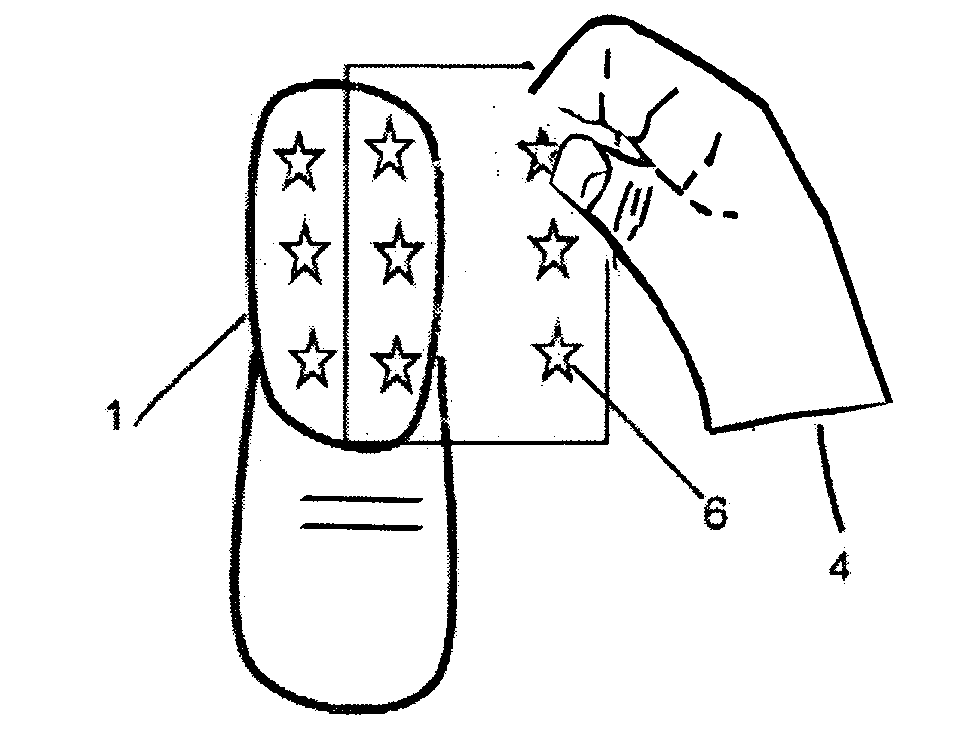

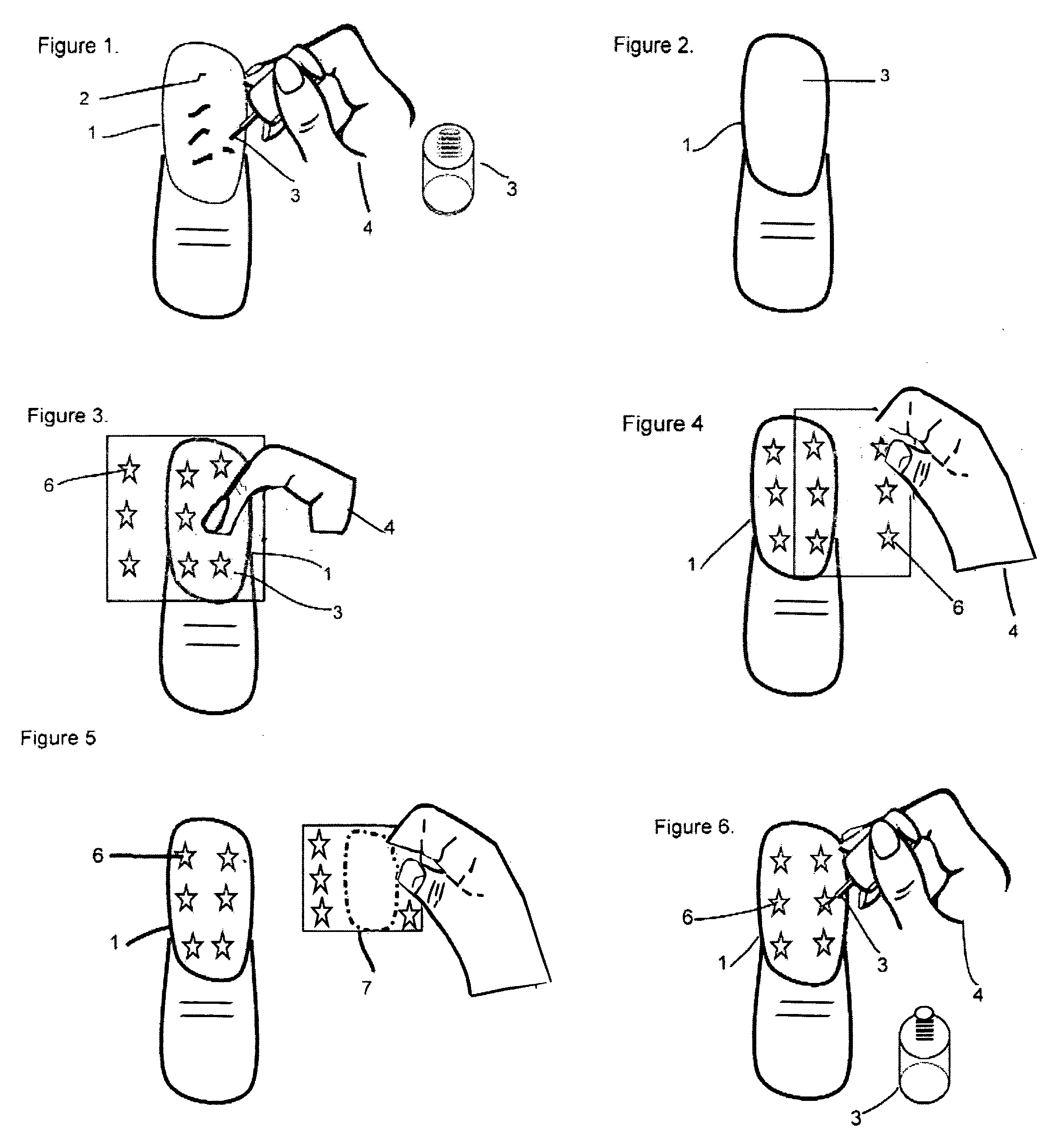

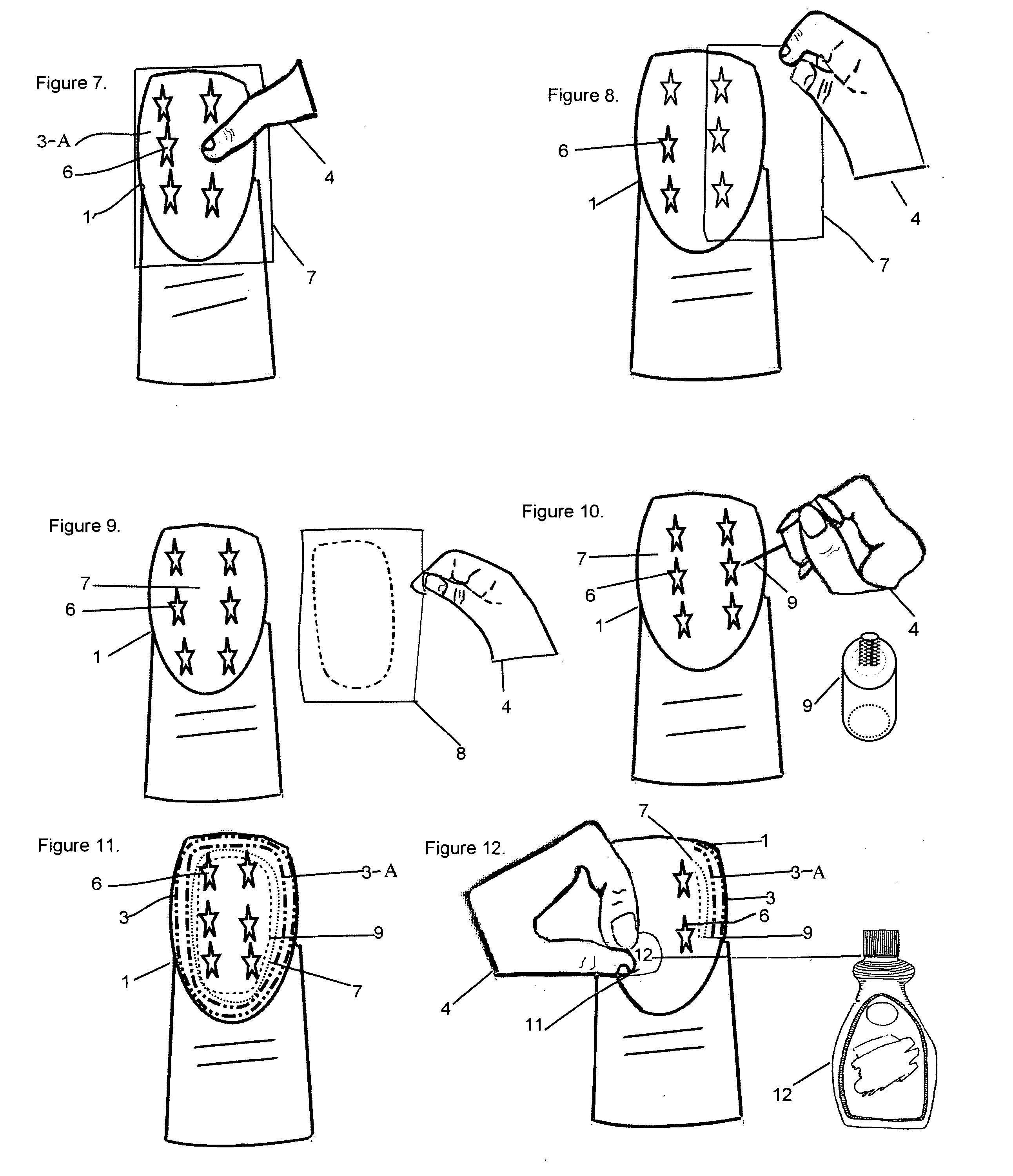

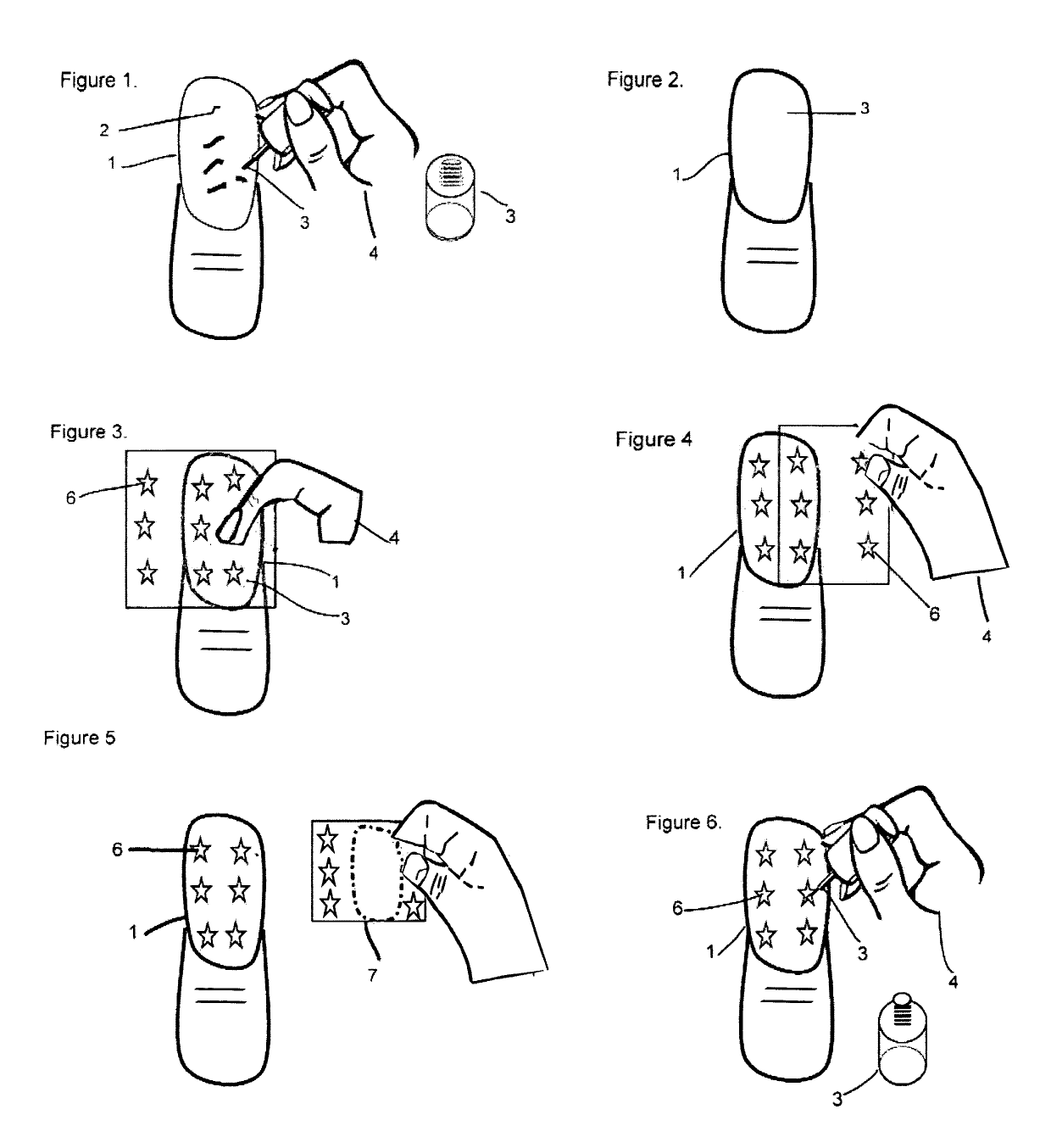

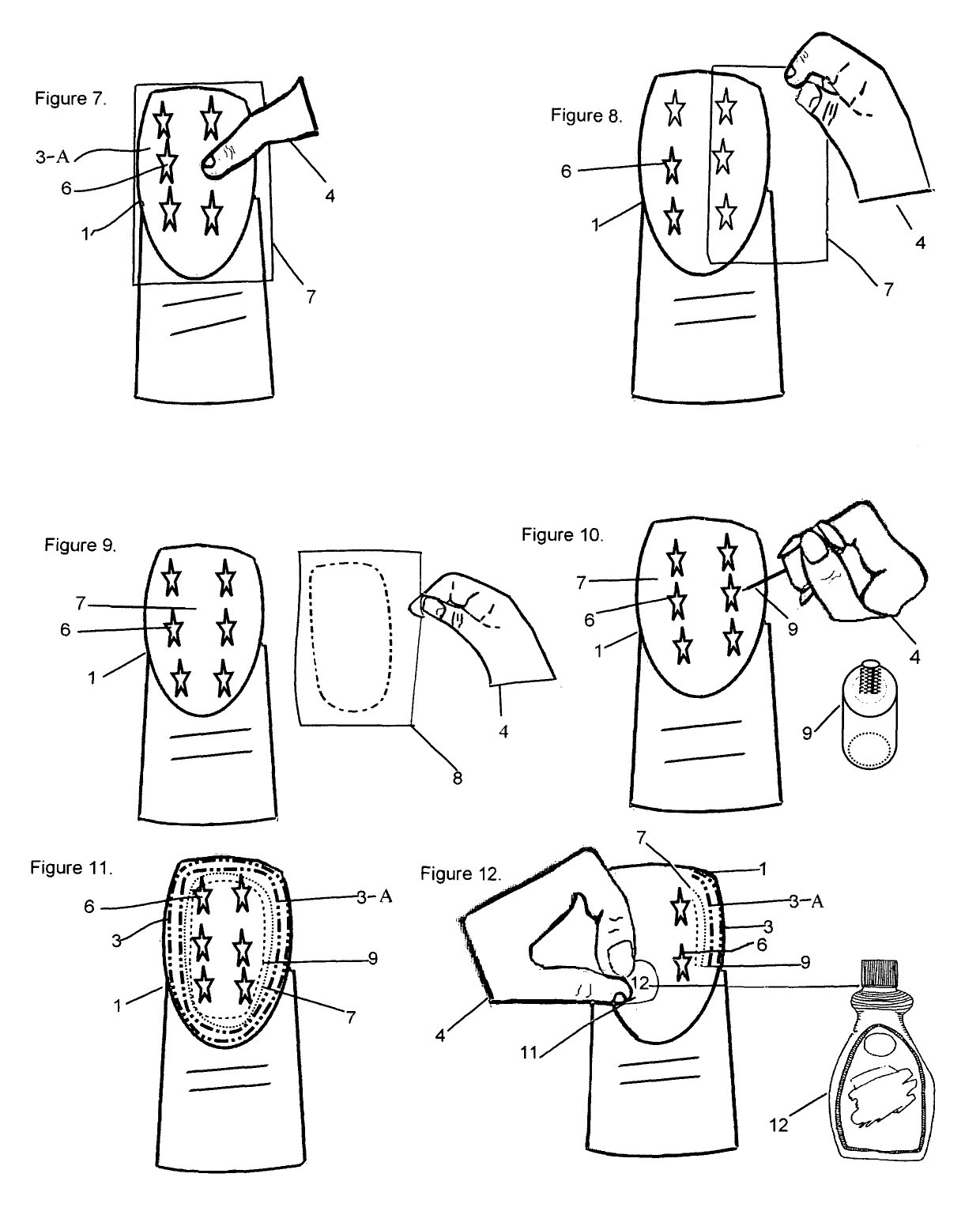

Method and apparatus for nail foil adornment, repair,protection and strengthening of the nails' plate of the finger or toe.

ActiveUS20160106193A1Improve protectionHigh incidenceCurling devicesManicure/pedicurePolyesterAdhesive

The invention provides a nail foil adornment method and apparatus which cosmetically strengthens, fills, protects and repairs imperfections on natural or artificial nail plates. The adornment apparatus is comprised of two non-thermal flexible adhesives, color or pattern polyester Mylar foil film, opaque polyester Mylar film and clear nail polish. The method is comprised of brushed on transfer adhesive to the bare nail plate which dries clear, level and tacky (sticky). The color or pattern polyester Mylar foil film is digitally pressure transferred onto the nail plates dry tacky (sticky) surface. The used clear film carrier is discarded. The second flexible adhesive is applied to the foiled nail. The adhesive dries clear, tacky (sticky). The opaque polyester Mylar film is digitally transferred onto the nail plate creating a protection layer. The film carrier is discarded. The foiled nail is sealed with clear nail polish to extend wear.

Owner:LAWRENCE IVY

Method and apparatus for nail foil adornment, repair, protection and strengthening of the nails' plate of the finger or toe

ActiveUS10264867B2Improve abilitiesImprove protectionManicure/pedicureHair equipmentsPolyesterAdhesive

Owner:LAWRENCE IVY

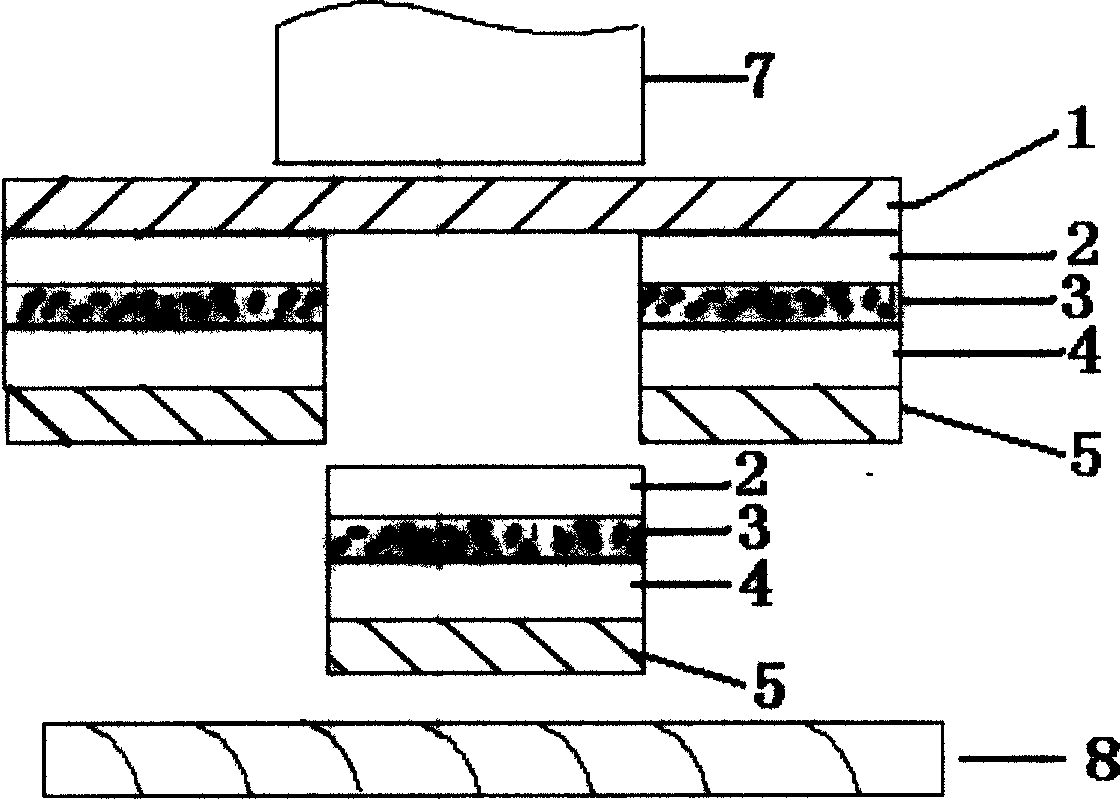

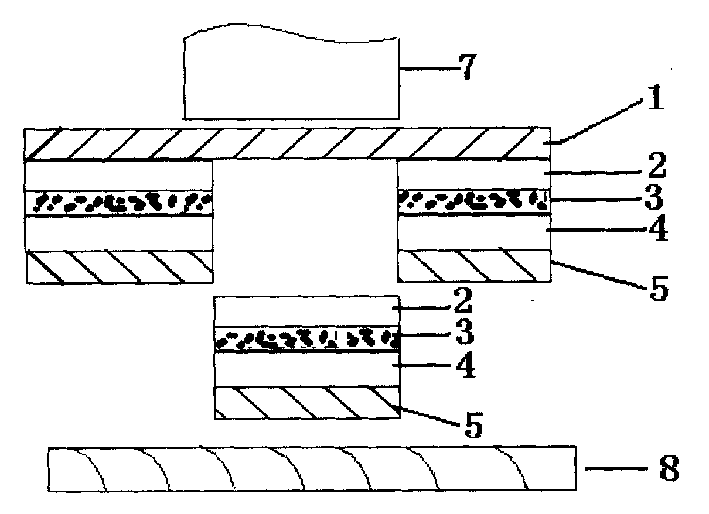

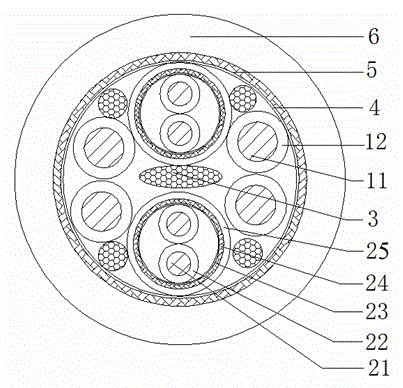

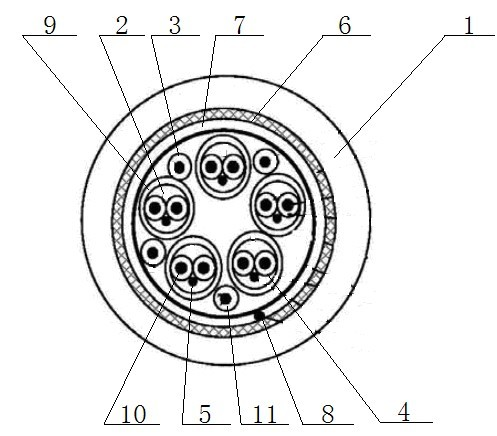

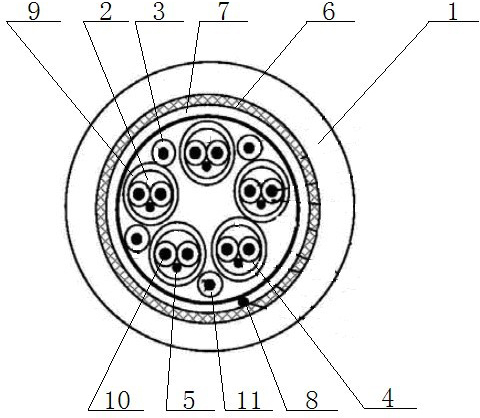

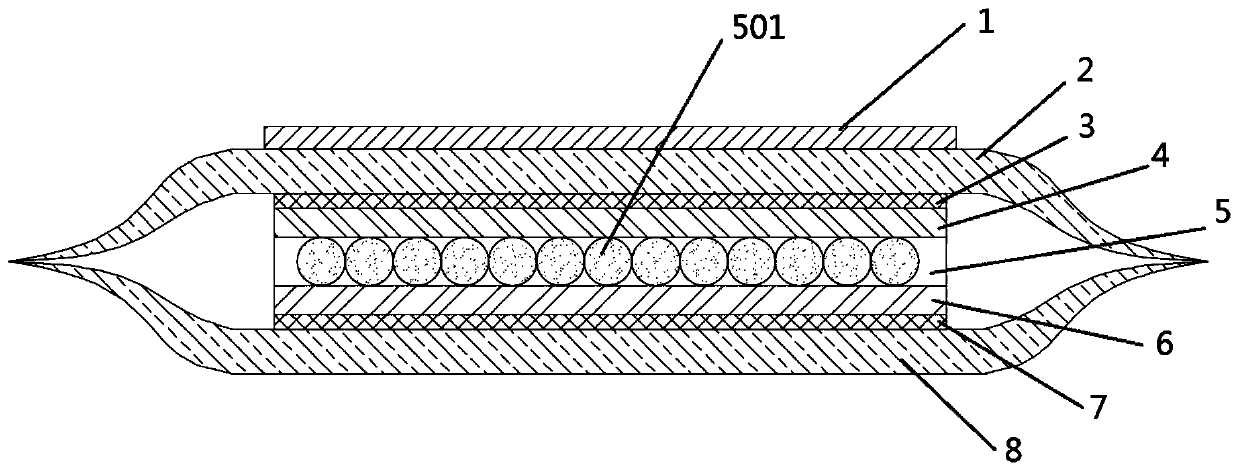

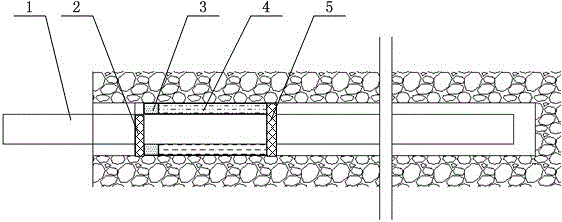

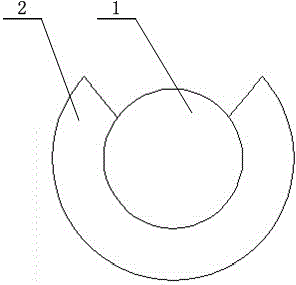

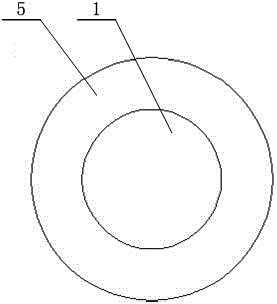

Cable for internal contracting brake of high-flexibility anti-torsion rotor

InactiveCN104835564ALow costEasy to installFlexible cablesFlexible conductorsElectrical conductorInsulation layer

The invention relates to a cable for an internal contracting brake of a high-flexibility anti-torsion rotor. The invention aims to solve technical problems of how to conveniently install the cable for an internal contracting brake of a rotor, how to improve the signal stability of the cable for the internal contracting brake of the rotor, how to enable a signal line to be more flexible, and how to prolong the service life of the cable. The invention adopts the technical scheme that a cable for the internal contracting brake of the high-flexibility anti-torsion rotor comprises a power line, a signal line, filler, non-woven fabric, a shielding layer and a sheath; the power line comprises conductors of the power line and insulation layers of the power line from inside to outside in sequence; and the signal line comprises multi-core conductors of the signal line, insulation layers of the signal line, mylar foil, shielding layers of the signal line and outer sheaths of the signal line from inside to outside in sequence. The beneficial effects are that the service life of the cable is prolonged and the shielding performance of the cable is improved.

Owner:奥林特电缆科技股份有限公司

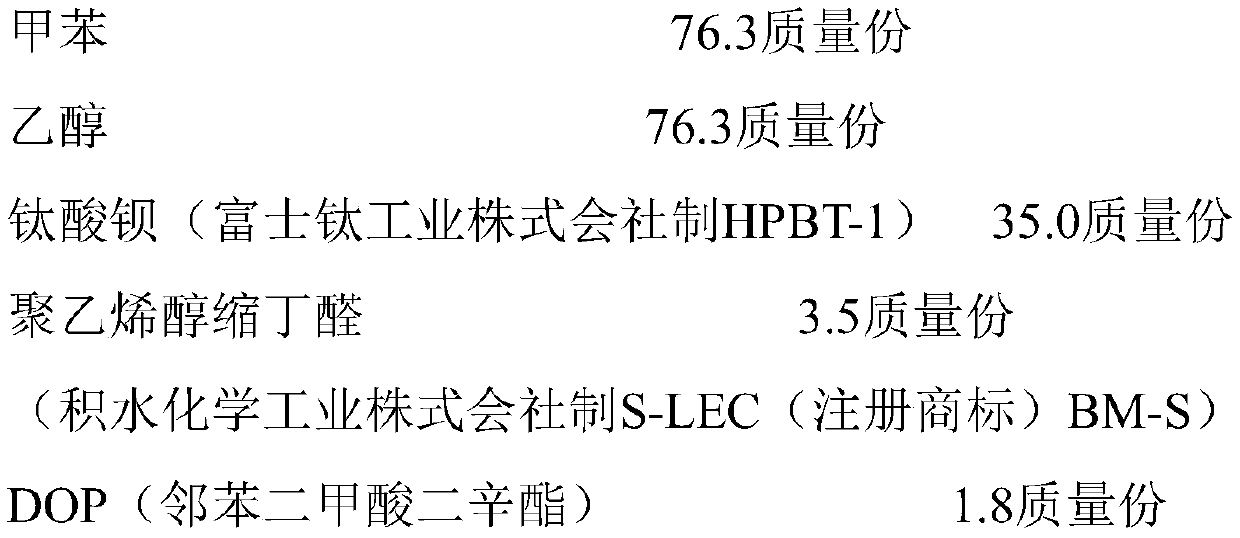

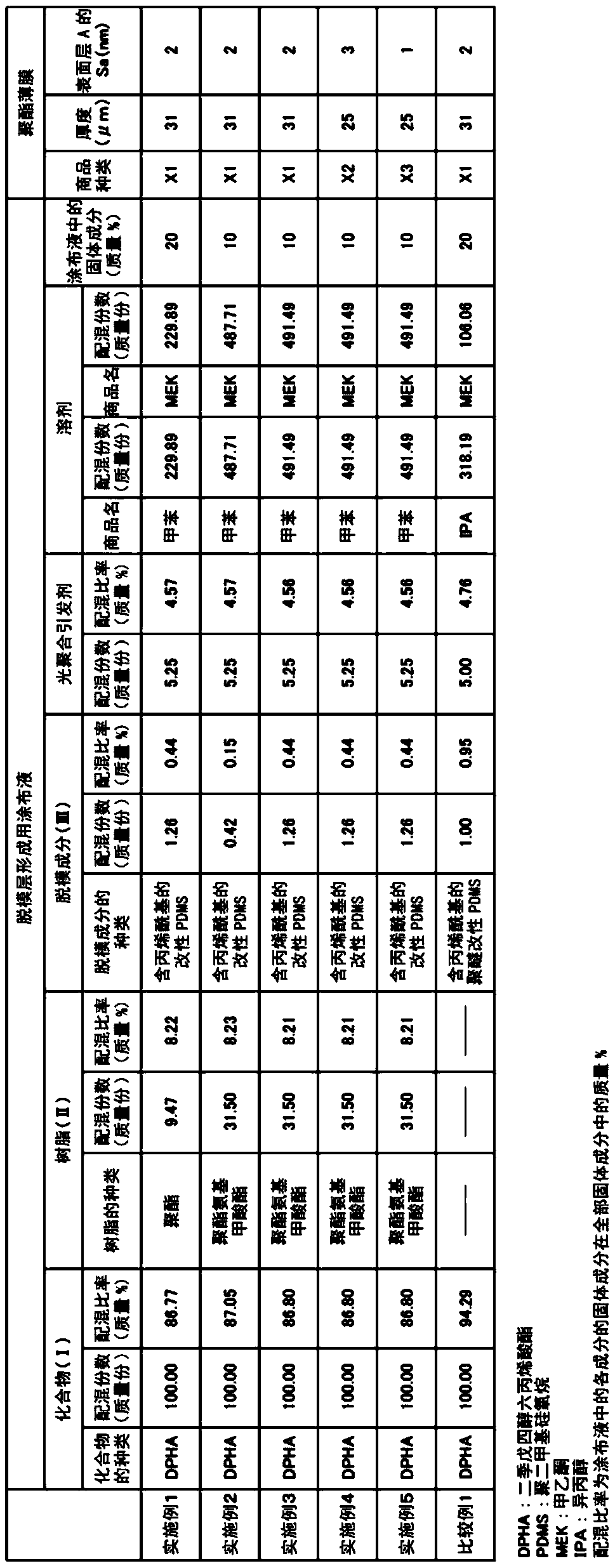

Mold release film for production of ceramic green sheet

ActiveCN111527136ANo protrusionNo big protrusionSynthetic resin layered productsCeramic shaping apparatusPolyesterSurface roughness

The invention provides a mold release film for molding of a ceramic green sheet, which has excellent releasability and is not likely to cause pin hole defects and damage such as cracks during releasing on an ultrathin ceramic green sheet that is molded with use of the mold release film. A mold release film for the production of a ceramic green sheet is obtained by superposing a mold release layerhaving a thickness of 0.2-3.5 [mu]m on at least one surface of a polyester film directly or with another layer being interposed therebetween, and is configured such that the surface of the mold release layer has a local surface roughness (Sa) of 5-40 nm and a maximum profile peak height (Rp) of 60 nm or less.

Owner:TOYOBO CO LTD

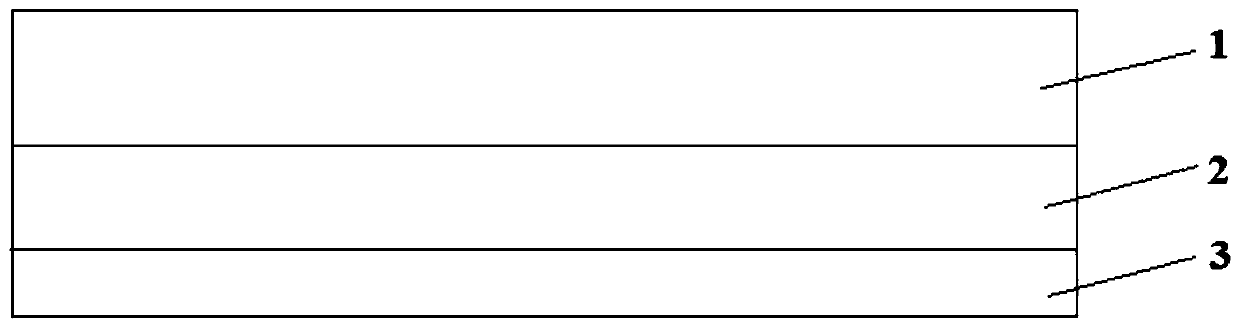

White laminated polyester film for reflecting sheet

InactiveUS20130222932A1Improve reflectivityHigh hiding powerMirrorsInorganic particleRefractive index

A white laminated polyester film for a reflecting sheet, includes a polyester layer (B) containing voids therein, and a polyester layer (A) laminated at least on one surface side of the layer (B), wherein: (1) the thickness of polyester layer (A) is from 5 to 15; (2) polyester layer (A) contains particles having a refractive index of 2.0 or more in an amount of 3 to 15% by weight; (3) the thickness of polyester layer (B) is 150 μm or more; (4) the amount of particles having a refractive index of 2.0 or more contained in polyester layer (B) is 2% or less by weight; and (5) polyester layer (B) contains therein a resin which is not soluble in polyester resin in an amount of 12 to 25% by weight and / or inorganic particles having a refractive index less than 2.0 in an amount of 30 to 50% by weight.

Owner:TORAY IND INC

High definition multimedia interface (HDMI) linear material

InactiveCN102024513ASmall outer diameterMeeting the needs of the miniaturization trendInsulated cablesMetal/alloy conductorsElectrical conductorElectromagnetic interference

The invention discloses a high definition multimedia interface (HDMI) linear material, comprising a core wire, at least one external paired core wire and a core wire jacket, wherein, the inner part of the core wire is provided with inlayer aluminum mylar foil, an internal paired core wire, inner cascading water earth wires and anti-electromagnetic interference earth wires, and the outer part of the core wire is coated with outer-layer aluminum mylar foil, anti-electromagnetic interference braided-layer core wires and the core wire jacket; the inner paired core wire and the external paired core wire are in a round layered structure which comprises a conductor layer and an insulating layer arranged outside the conductor layer; the specification of the manufacturing material of the conductor layer is 36AWG (American wire gauge) of tinned cooper wires; the core wire jacket is made of Teflon; and the external diameter of the core wire jacket is 3.6+ / -0.15 millimeters. The linear material provided by the invention not only has smaller wire material outer diameter, but also has better welding performance.

Owner:SUZHOU YIHUA COMMUNICATED CONNECTOR

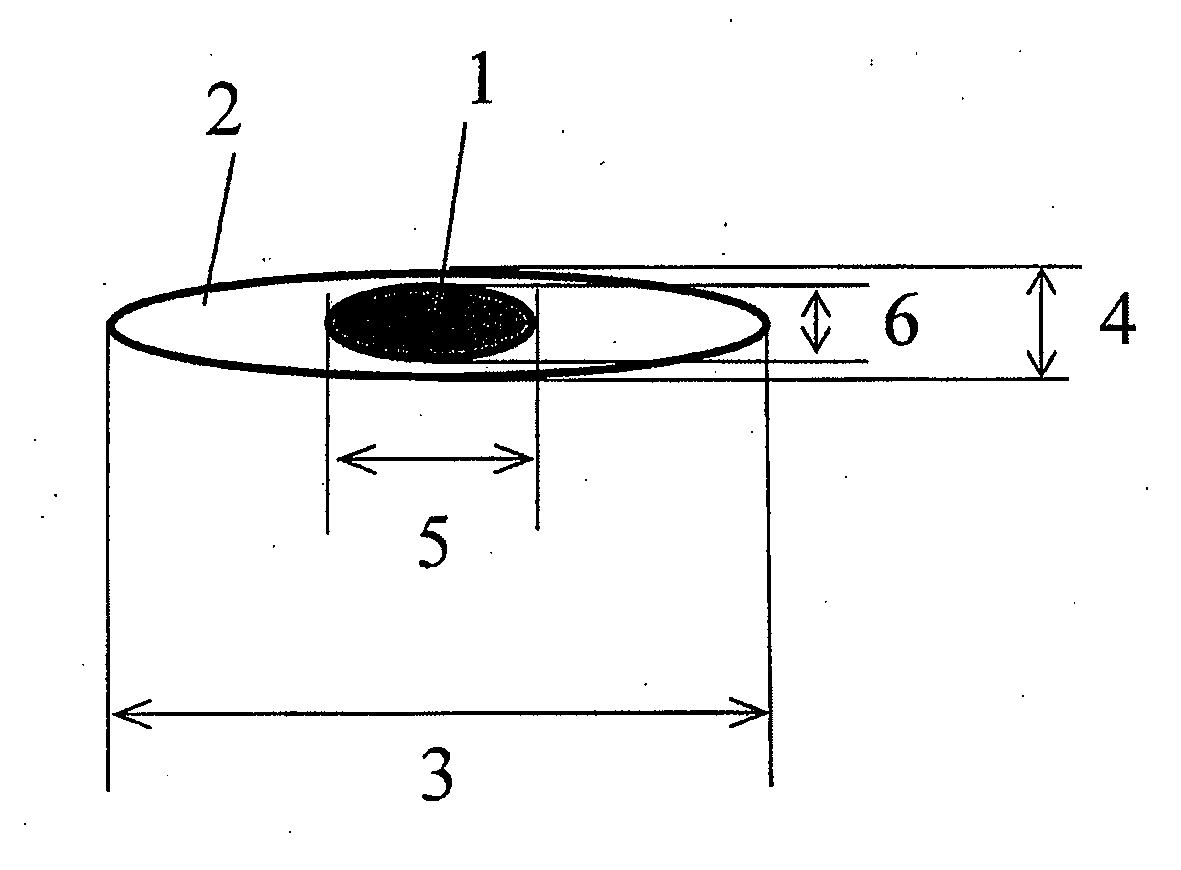

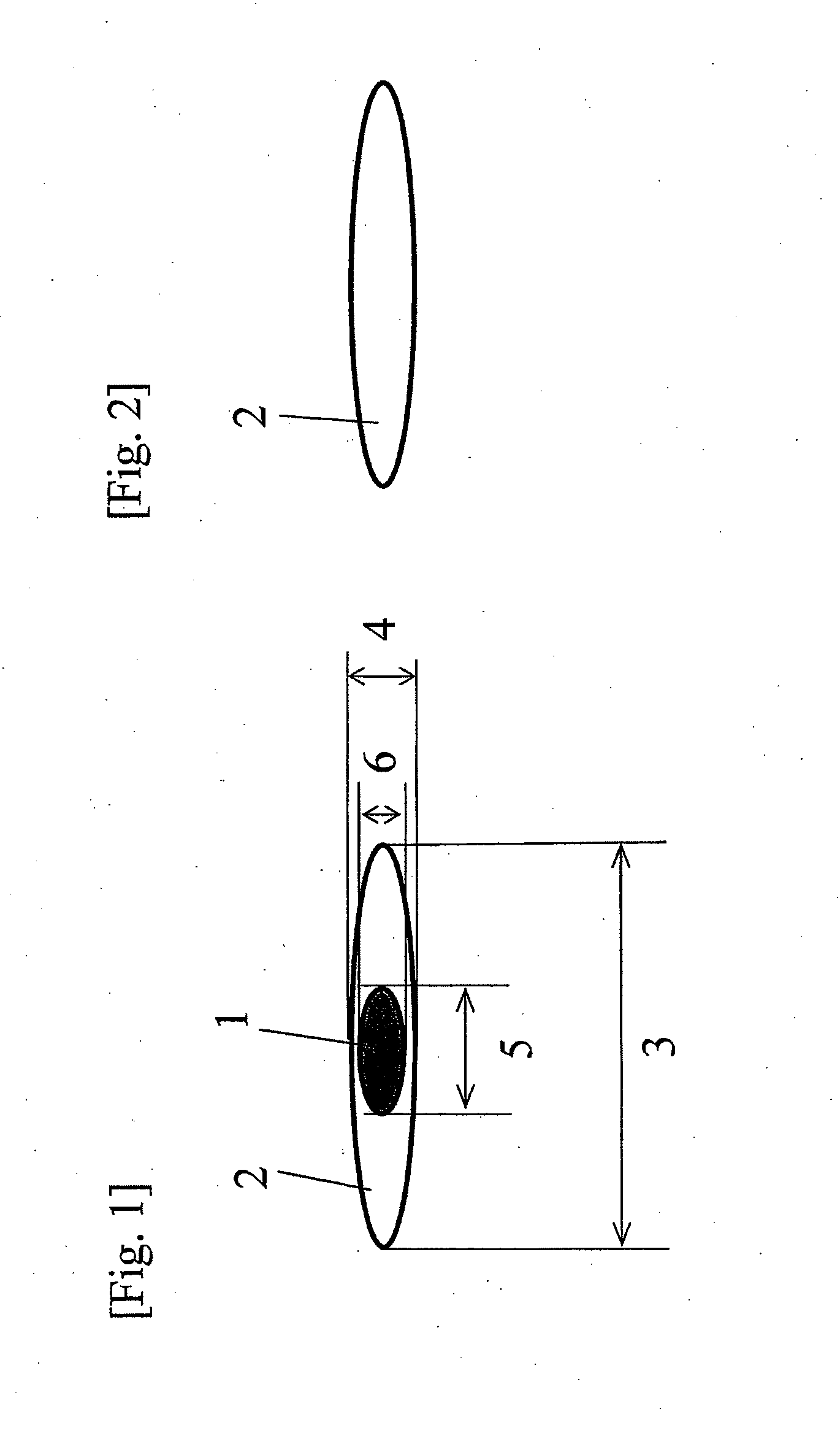

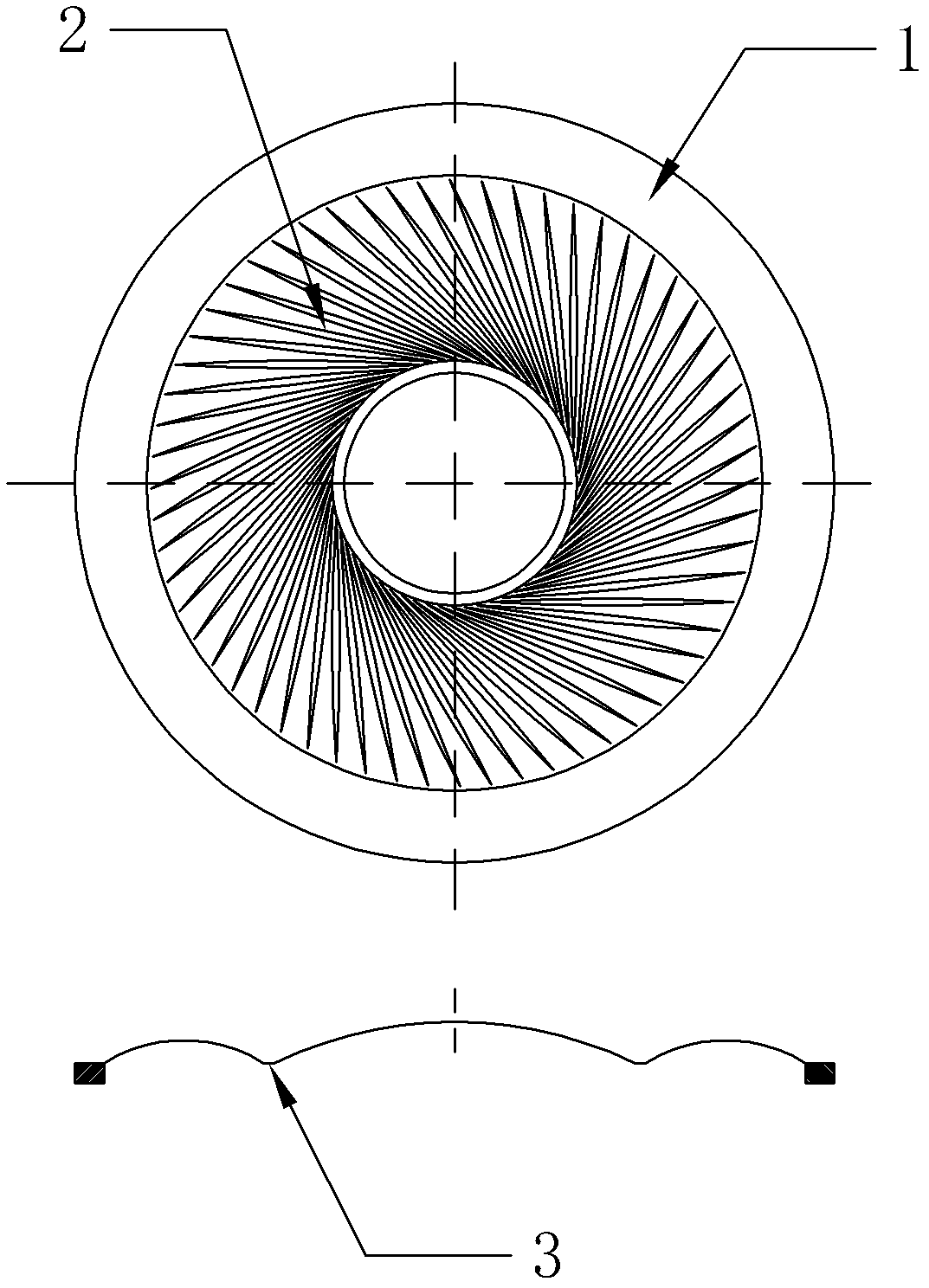

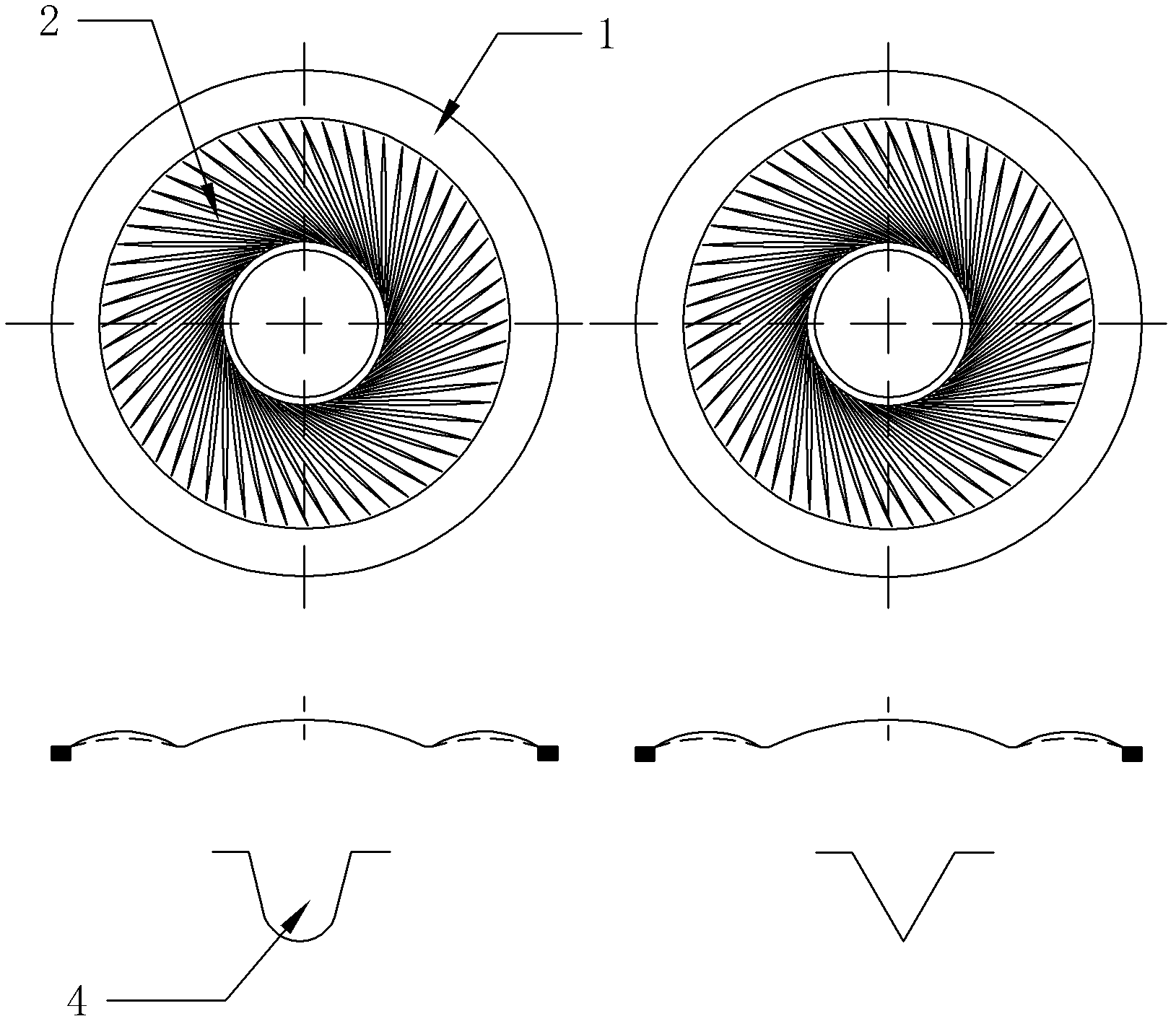

Collapse-free sound film

The invention belongs to the field of electric sound films and discloses a collapse-free sound film. An edge arc is arranged around the sound film and provided with a decorative pattern, and the section of the edge arc is a section of arc or formed by connection of a plurality of sections of arcs, and positions where arcs are connected are in fillet smooth connection. The section of the decorative pattern is U-shaped, the width of the decorative pattern is twice of the depth of the decorative pattern, the trend of the decorative pattern is basically the same with that of the edge arc, and a radian pattern is formed if the R value is large. The sound film is made of a polyester film, computer-based 3D drawing is adopted, the edge arc and the decorative pattern are designed reasonably according to electro-acoustic parameter requirements of clients, the design of an edge and a copper ring is adopted if the thickness of the raw material of polyester film is below 16 microns, reasonable molding techniques are adopted for different materials and thicknesses, the blow molding technique is adopted for the edge and the copper ring, and the clients use collapse-free vibrating films (sound films) to assemble micro speakers, so that poor acoustic characteristic variation caused by operations, carrying and reliability experiments can be reduced greatly, the production effectiveness can be improved, costs can be reduced, the quality can be guaranteed, and the product reliability can be improved.

Owner:SHENZHEN WABONY ELECTRONICS

OCA (optical clear adhesive) wet coating specialized functional film

InactiveCN106433503AGuarantee the unfavorable phenomena that cannot be torn apart, and effectively guarantee product qualityThe bad phenomenon that the barrier cannot be torn apartFilm/foil adhesive primer layersElectrically-conductive paintsForeign matterPolyester

The invention discloses an OCA (optical clear adhesive) wet coating specialized functional film. The OCA wet coating specialized functional film comprises a releasing-type liquid coating, a PET (polyester) film body and an anti-static coating which are sequentially attached from top to bottom. The OCA wet coating specialized functional film is reasonable in structural design and specially suitable for the OCA wet coating process since the PET film body is ingeniously coated with the anti-static coating and the releasing-type liquid coating and components of the anti-static coating and the releasing-type liquid coating are reasonably optimized, good anti-static effect is achieved, the problem about static electricity easy to occur to coating and tearing of OCA products can be solved, bad situation generated from gathering of dust and foreign objects due to the static electricity is prevented, the situation that solvent can be effectively prevented from immersion corrosion to lead failure in tearing the OCA by the releasing-type layer in the OCA wet coating process is guaranteed, product quality is effectively guaranteed, product percent of pass is increased, convenience is brought to the OCA wet coating process, wide application is facilitated, and the OCA wet coating specialized functional film is specially suitable for the field of full lamination of smart phone screens.

Owner:DONGGUAN DINGLI FILM TECH

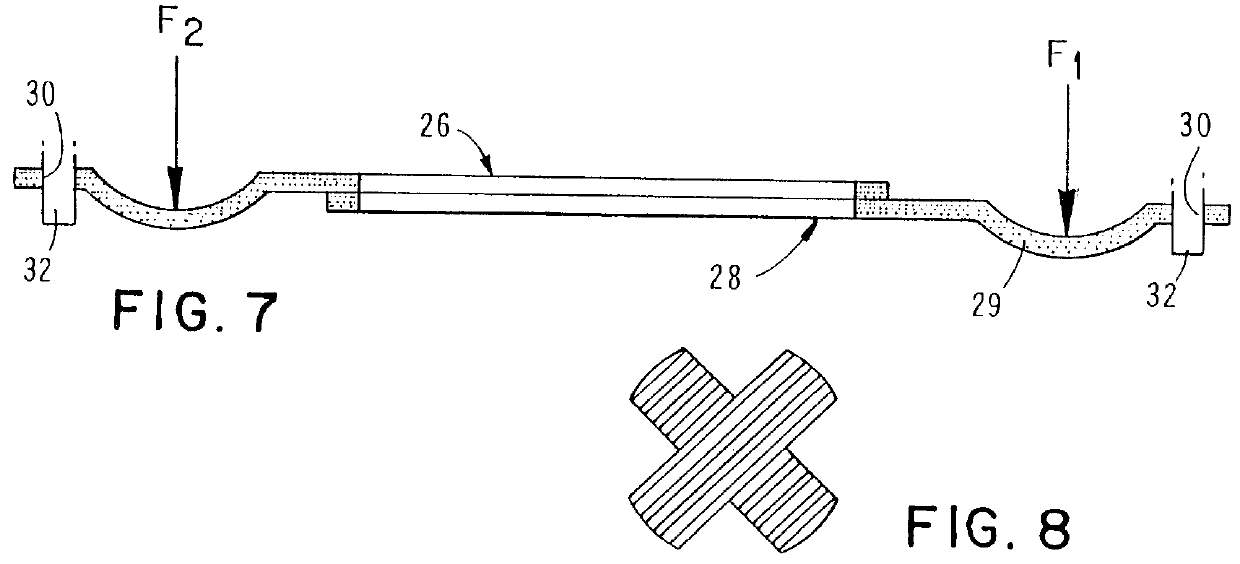

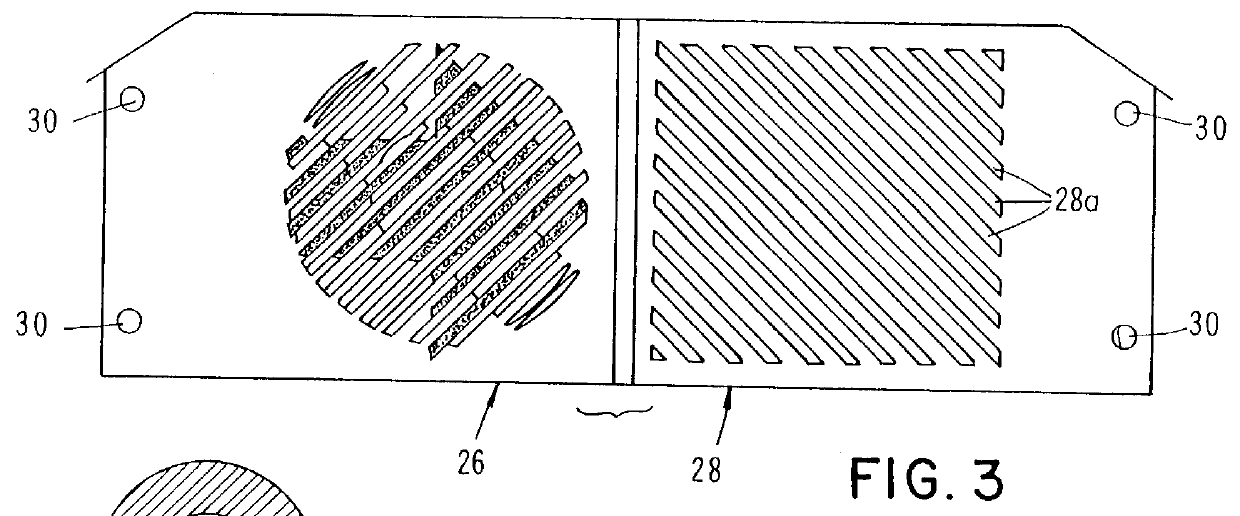

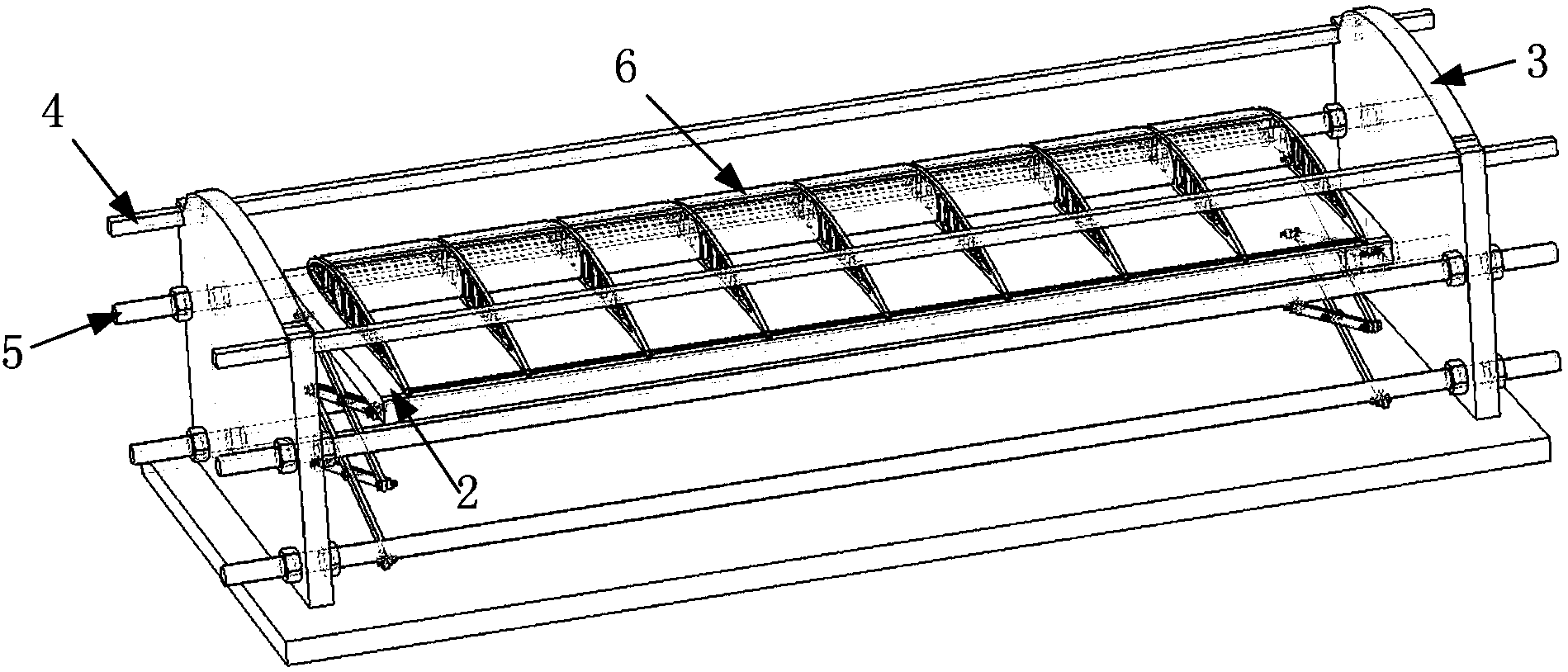

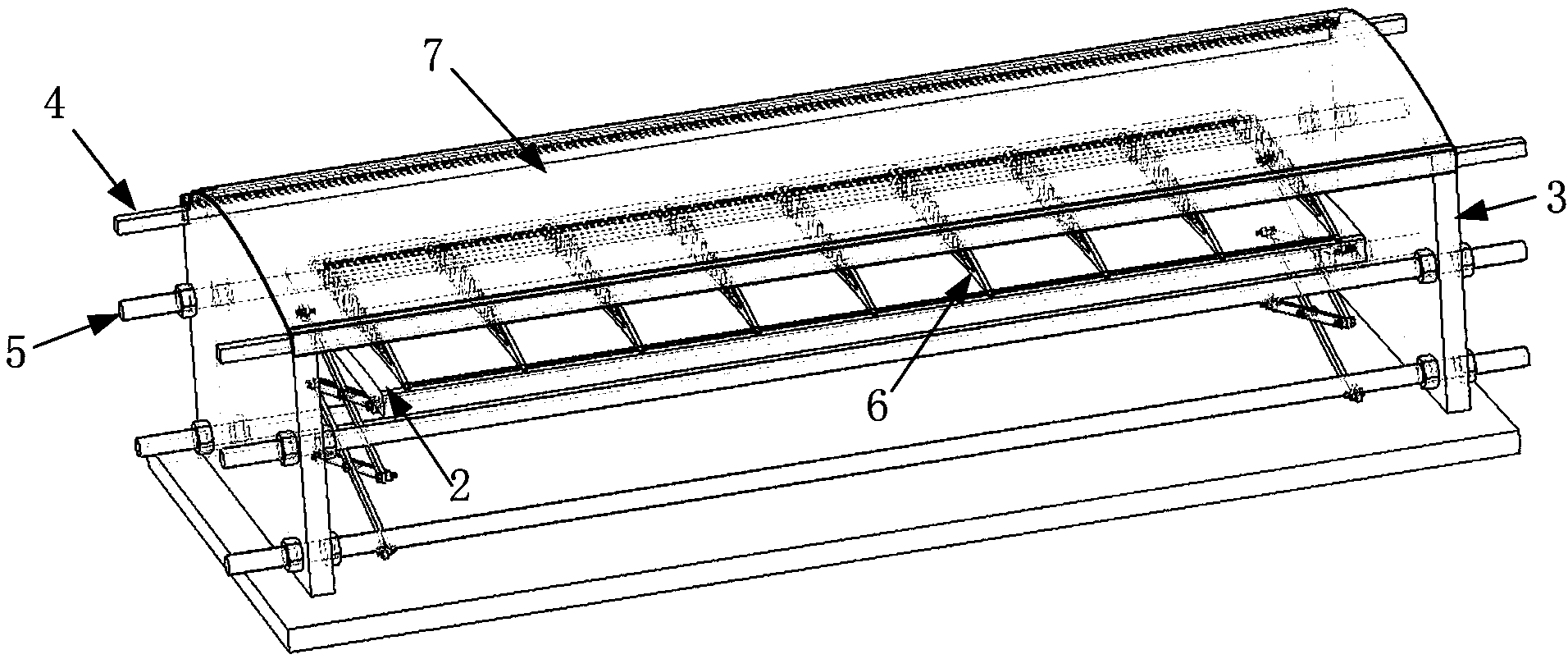

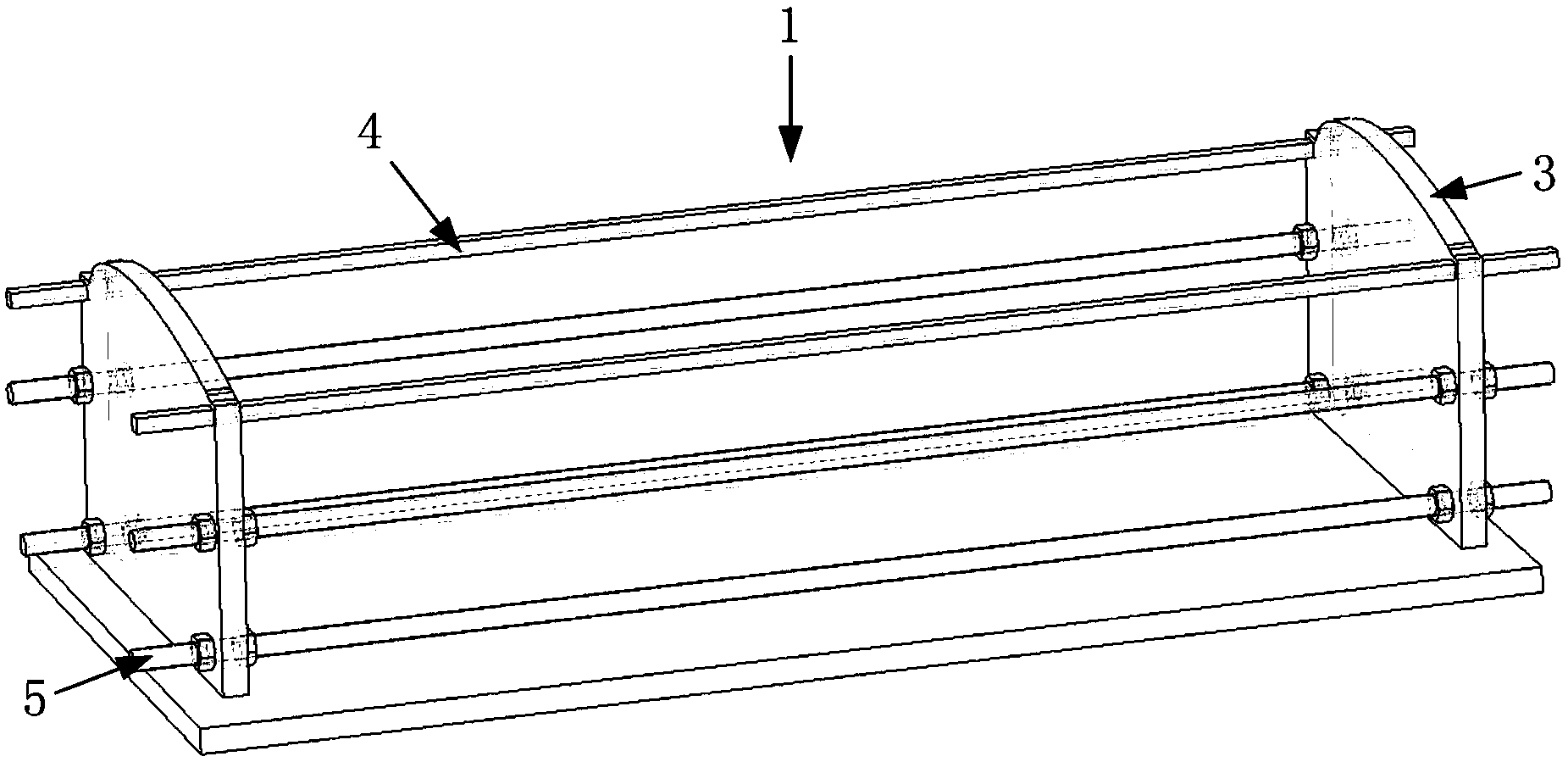

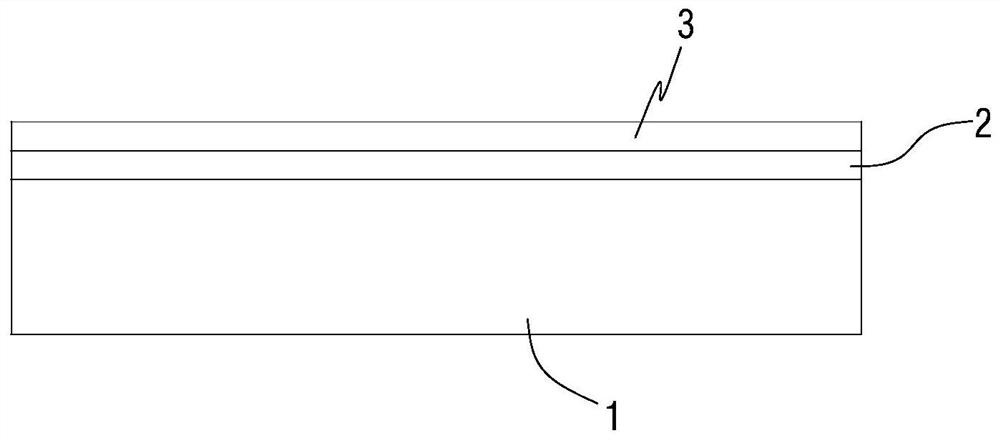

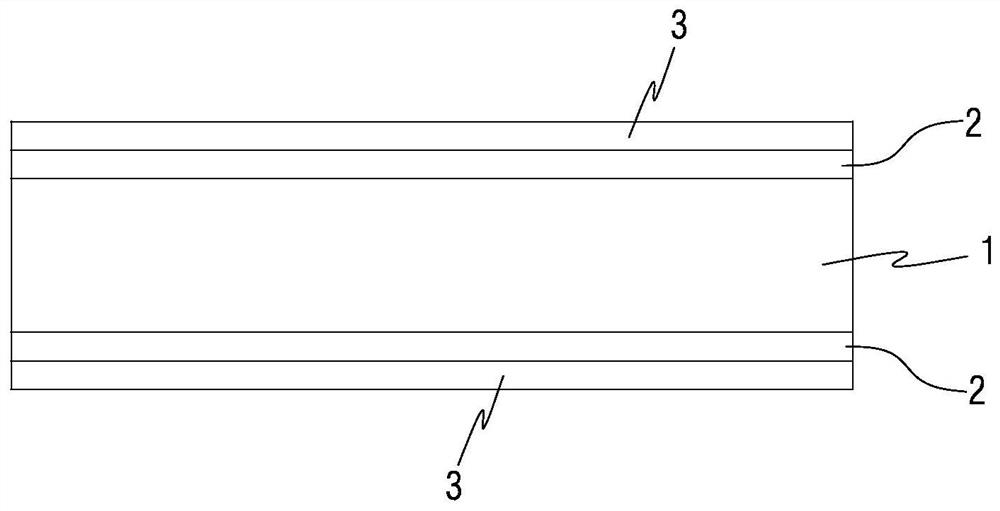

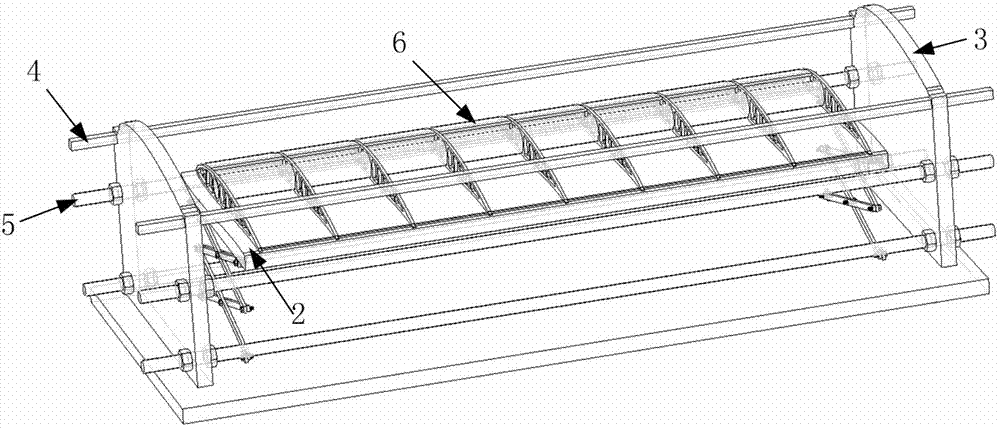

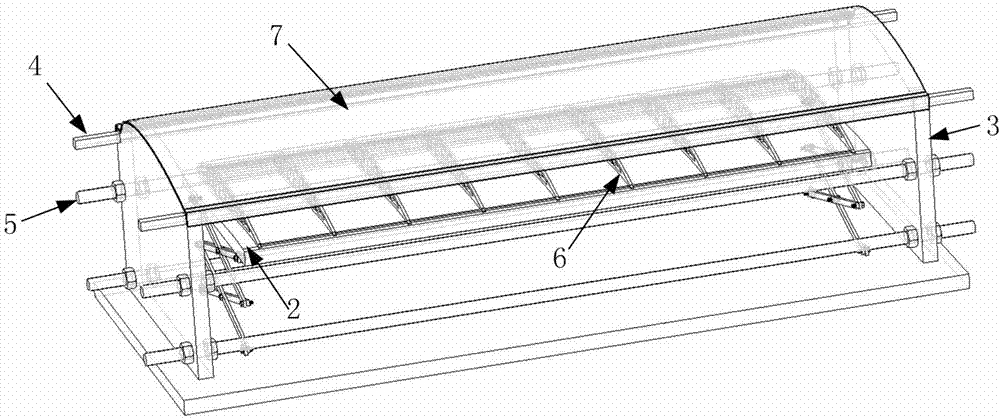

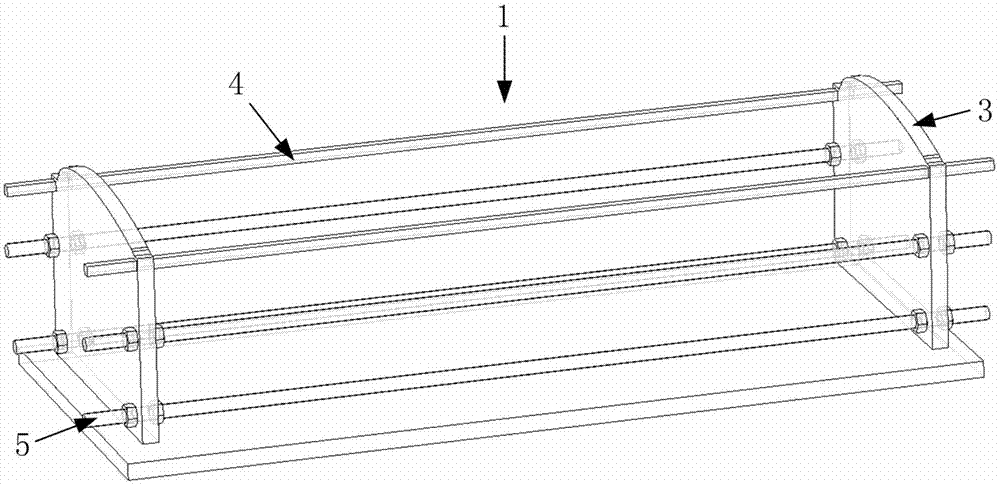

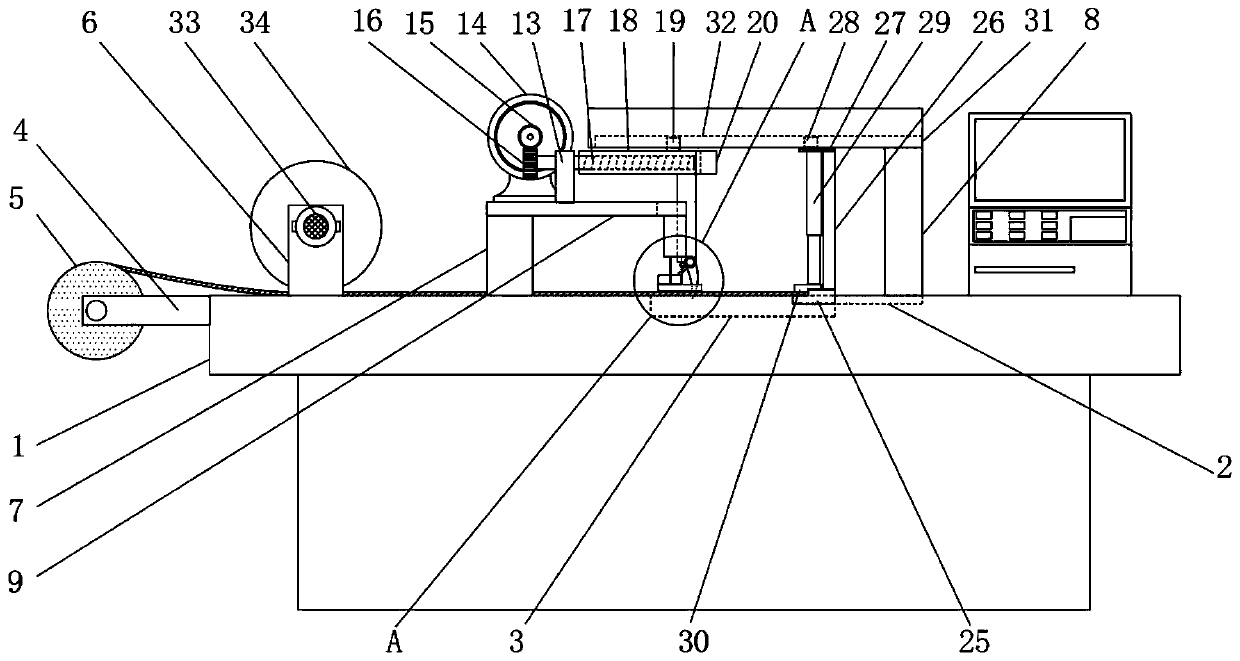

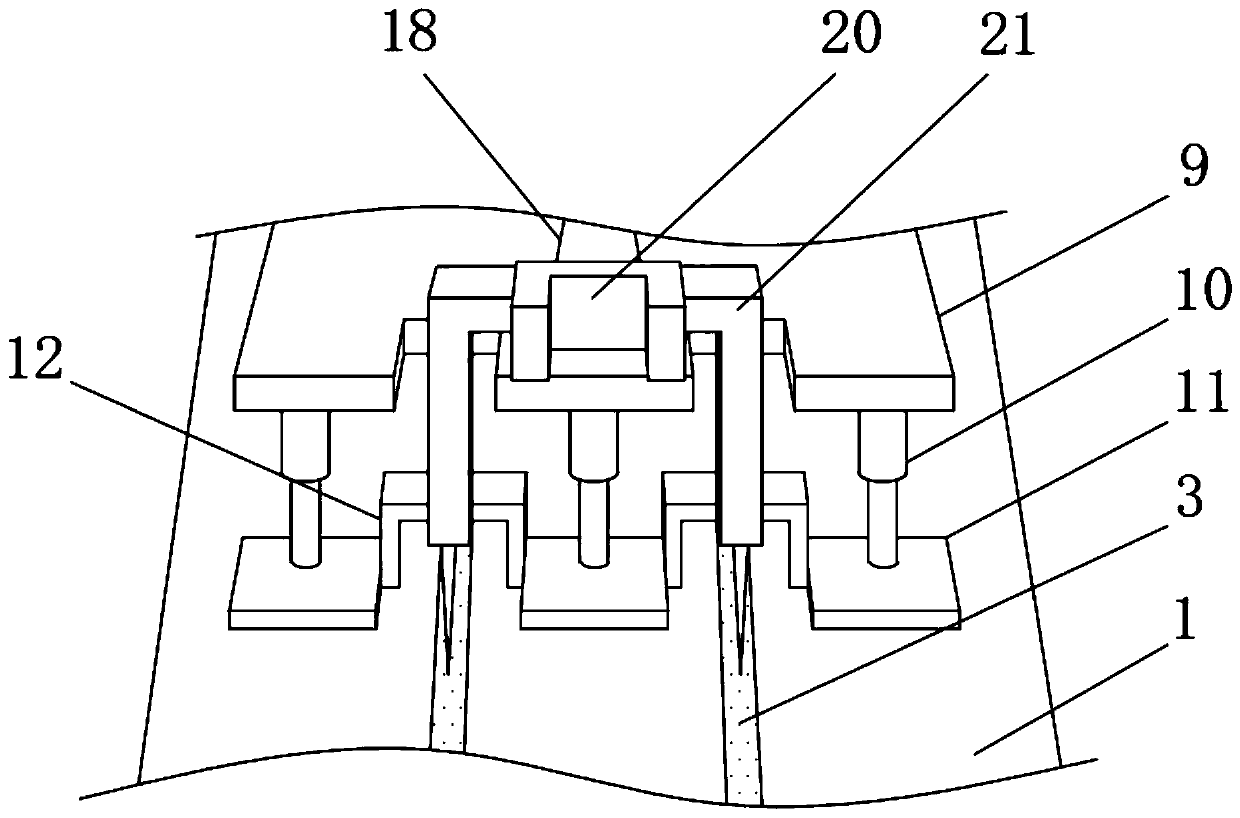

Film covering device and method of wing structure surface

The invention discloses a film covering device and a method of a wing structure surface. A film covering device comprises a film tension mechanism and a wing supporting device which is used for abutting a wing structure frame to a tensioned polyester film, distance is formed between a supporting face of the wing supporting device and a film fixing face of the film tension mechanism, and the supporting face and the film fixing face are constantly close to each other by opposite movement to achieve attachment of the wing structure frame to the tensioned polyester film. The film covering method comprises the following steps of assembling the covering device; fixedly arranging the polyester film on the film fixing face in a pasting mode; exerting pre-tension force on the film by adjusting span-dominated endplates in a separation mode; coating adhesives on the film portions to be pasted with the wing structure film, lifting a lifting platform until the wing structure frame is closely joint to the film and obtaining the wing structure covering with film on the surface after cutting edges and finishing. The film covering device and the method of the wing structure surface have the advantages of simple structure, convenience utilization, simple production, good film covering effect and the like.

Owner:NAT UNIV OF DEFENSE TECH

Base film for optical protective mask

The invention discloses a base film for an optical protective mask. The base film comprises a polyester film, wherein at least one side surface of the polyester film is coated with a hardened coating, and the outer side of the hardened coating is coated with an anti-fog coating. By means of an improved coating structure and an improved formula, the base film of the optical protective mask is suitable for disease control and epidemic prevention, the dental department, the stomatology department, instrument cleaning, decoration cleaning, chemical production and protection of employees needing to protect the face, and can effectively prevent pollutants from splashing to the face when medical workers conduct clinical reception, treatment and examination; and meanwhile, a good anti-fog function is achieved, and a clear view is provided for treatment.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

Aluminum foil mylar adhesive tape and preparation method thereof

InactiveCN110819251AImprove performanceExtended service lifeEster polymer adhesivesPressure sensitive film/foil adhesivesPolyesterPolymer science

The invention relates to the technical field of aluminum foil mylar adhesive tapes, particularly to an aluminum foil mylar adhesive tape and a preparation method thereof, wherein the prepared aluminumfoil mylar adhesive tape is good in weather resistance, cannot be denatured and broken under the condition of temperature change and humidity change, can avoid the separation of an aluminum foil froma polyester tape in a use process, and comprises a polyester film layer, an adhesion layer, an aluminum foil layer, an adhesion layer and an isolation layer, wherein the polyester film layer, the adhesion layer, the aluminum foil layer, the adhesion layer and the isolation layer are arranged from top to bottom, the adhesion layer comprises 5-15 parts of aqueous acrylic acid and 15-20 parts of cross-linked polyacrylic acid, and during the use, the aqueous acrylic acid and the cross-linked polyacrylic acid are mixed and added into a hot melting machine and are melted and stirred and mixed uniformly. The preparation method comprises: S1, base material preparing; S2, adhesive preparing; S3, polyester film layer treatment; S4, coating with an adhesive solution; Ss5, drying treatment; S6, laminating treatment; S7, curing treatment; S8, irradiation cross-linking modification treatment; S9, winding; and S10, slitting.

Owner:昆山恒永昌电子科技有限公司

Film covering device and method of wing structure surface

The invention discloses a film covering device and a method of a wing structure surface. A film covering device comprises a film tension mechanism and a wing supporting device which is used for abutting a wing structure frame to a tensioned polyester film, distance is formed between a supporting face of the wing supporting device and a film fixing face of the film tension mechanism, and the supporting face and the film fixing face are constantly close to each other by opposite movement to achieve attachment of the wing structure frame to the tensioned polyester film. The film covering method comprises the following steps of assembling the covering device; fixedly arranging the polyester film on the film fixing face in a pasting mode; exerting pre-tension force on the film by adjusting span-dominated endplates in a separation mode; coating adhesives on the film portions to be pasted with the wing structure film, lifting a lifting platform until the wing structure frame is closely joint to the film and obtaining the wing structure covering with film on the surface after cutting edges and finishing. The film covering device and the method of the wing structure surface have the advantages of simple structure, convenience utilization, simple production, good film covering effect and the like.

Owner:NAT UNIV OF DEFENSE TECH

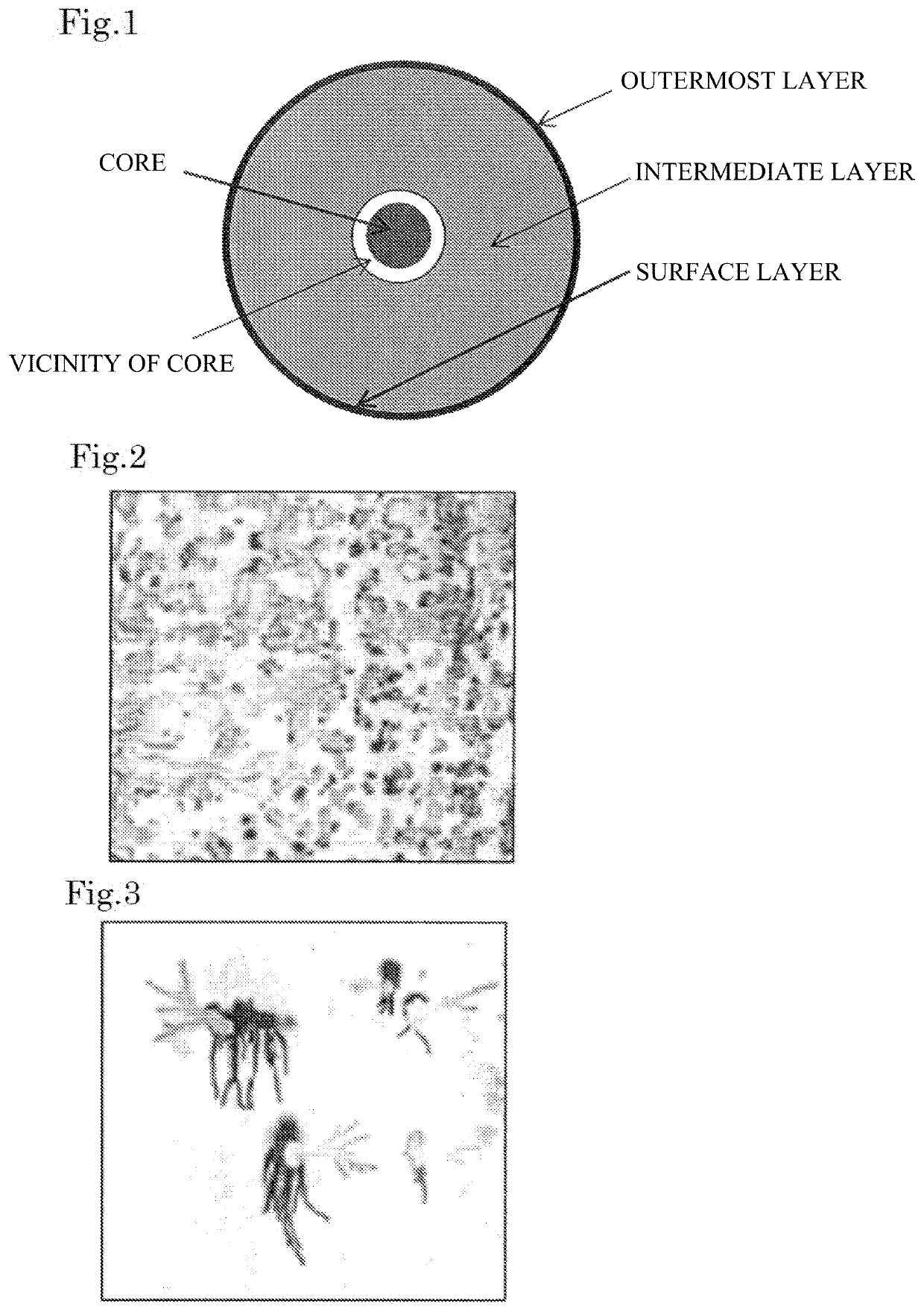

Polyester film, use thereof and metal laminated sheet made of said film, and metal can and metal lid made of the sheet

InactiveUS20050053796A1Improve mechanical propertiesReduce changesSynthetic resin layered productsThin material handlingGlass transition pointMechanical property

A polyester film made from two kinds of polyester resins and having a specific DSC (and a specific glass transition point) is provided, (i) which is superior in mechanical property, capable of thermocompression bonding with a metal sheet, despite a high degree of crystallization of the film, reduces quality change of plastic film laminated on the metal sheet even if faced with variation of conditions of thermocompression bonding with the metal sheet, and which is capable of thermocompression bonding even at a relatively low temperature, (ii) which is superior in formability, (iii) which is superior in flavoring property and impact resistance, and which obliterates occurrence of whitening or delamination of the film, or microcracks on the film, even if the film in the metal laminated sheet obtained by thermocompression bonding of the film on the metal sheet or on the surface of a metal can obtained by subjecting the metal laminated sheet to various form processings is crystallized, and (iv) which satisfies productivity at an industrial scale.

Owner:TOYO TOYOBO CO LTD

Flame-retardant, heat-insulating and sound-insulating material for aircraft

PendingCN111055562AImprove reflectivityFlame retardantSynthetic resin layered productsVehicle componentsPolyesterAviation

The invention discloses a flame-retardant, heat-insulating and sound-insulating material for an aircraft. The flame-retardant, heat-insulating and sound-insulating material sequentially comprises a mirror surface aluminum foil layer, a first polyvinyl fluoride film layer, a first nylon grid layer, a glass wool felt layer, a flame-retardant bubble layer, a polyester film layer, a second nylon gridlayer and a second polyvinyl fluoride film layer from outside to inside; the flame-retardant bubble layer comprises a plurality of closed-pore structure bubbles arranged in a matrix, and a flame retardant is arranged in the bubbles; and packaging is carried out between the first polyvinyl fluoride film layer and the second polyvinyl fluoride film layer. The mirror surface aluminum foil adopting anano-coating has extremely high reflectivity and can effectively reduce heat radiation. The reflecting layer and the flame-retardant bubble layer of the aluminum foil are utilized to realize multipleeffects of heat insulation, heat preservation, corrosion prevention and the like, and an aviation-grade glass wool felt is selected, so that the product has excellent heat insulation, sound absorptionand noise reduction performances. The flame-retardant, heat-insulating and sound-insulating material for the aircraft has the characteristics of flame retardance, light weight, thin layer, heat insulation, sound absorption, noise reduction, high efficiency, energy conservation, water resistance, outer protection and the like.

Owner:SUZHOU JUNYUE NEW MATERIAL TECH

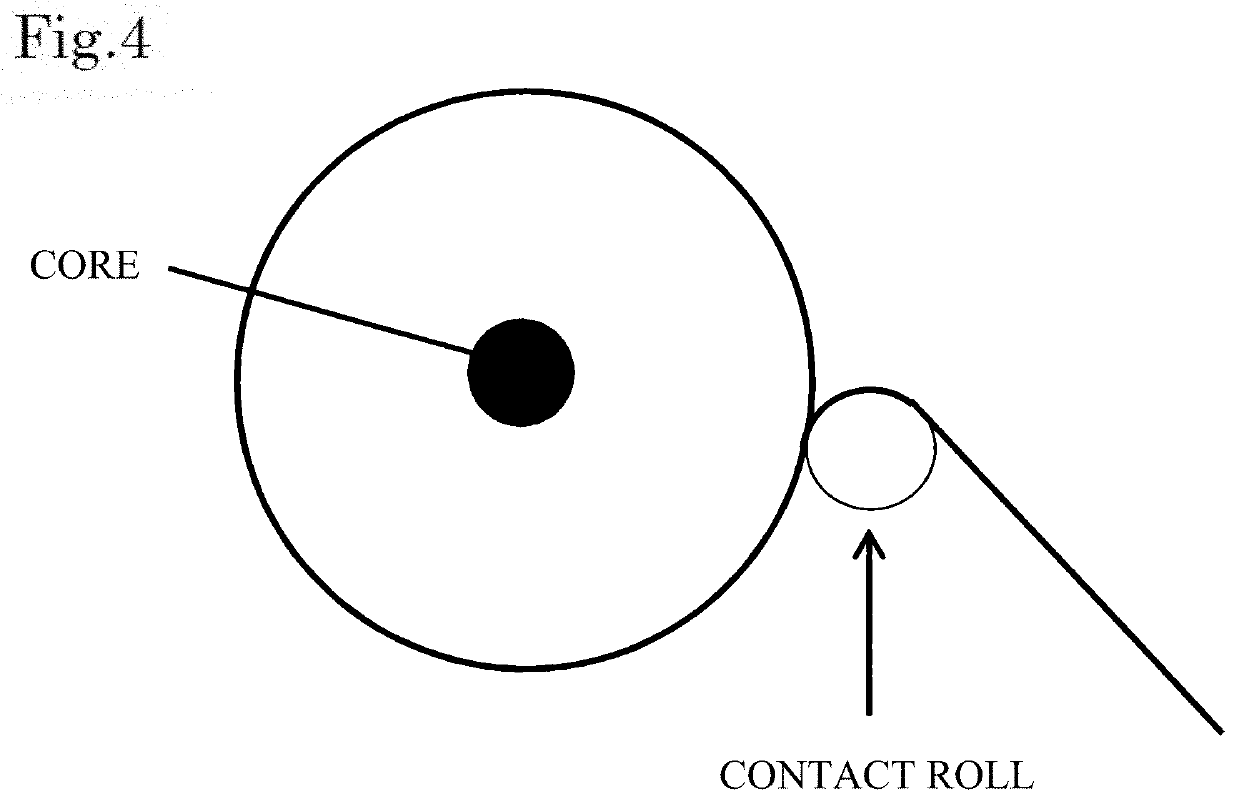

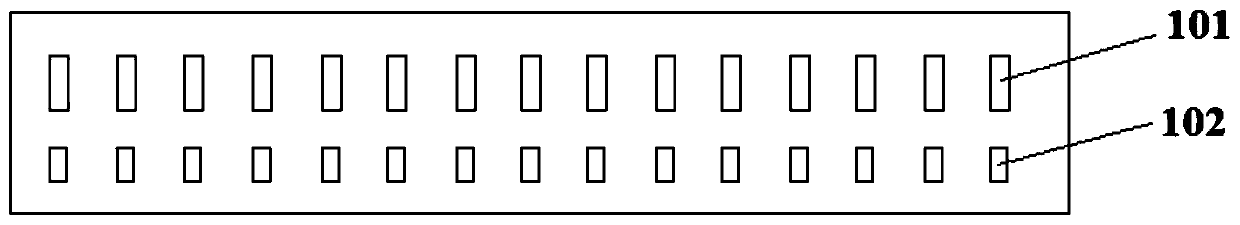

Biaxially oriented polyester film roll

Provided is a polyester film roll which has less wrinkles and film surface defects, exhibits no deviation of winding, and is suitable for secondary processing such as coating and vapor deposition. The polyester film roll is obtained by winding a biaxially oriented polyester film around a core, and is characterized by satisfying requirements (1)-(3) below: (1) the average winding hardness of the surface of the polyester film roll is in the range of 500-700; (2) the variation rate of the winding hardness of the surface of the polyester film roll in the film width direction is 1-5%; and (3) the variation rate of the average winding hardness from the surface of the polyester film roll to the core is 3-10%.

Owner:TOYOBO CO LTD

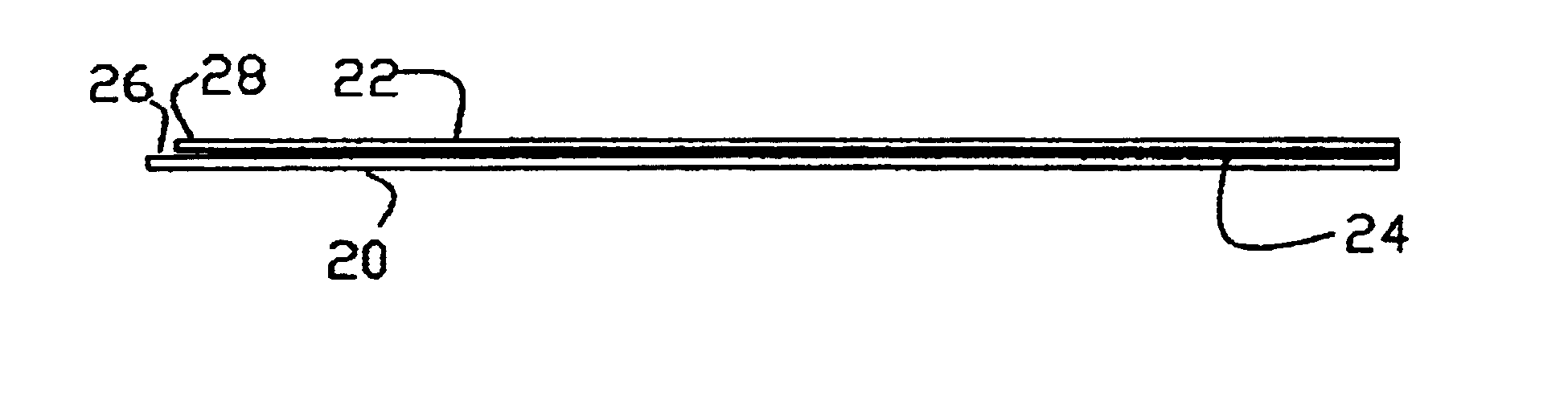

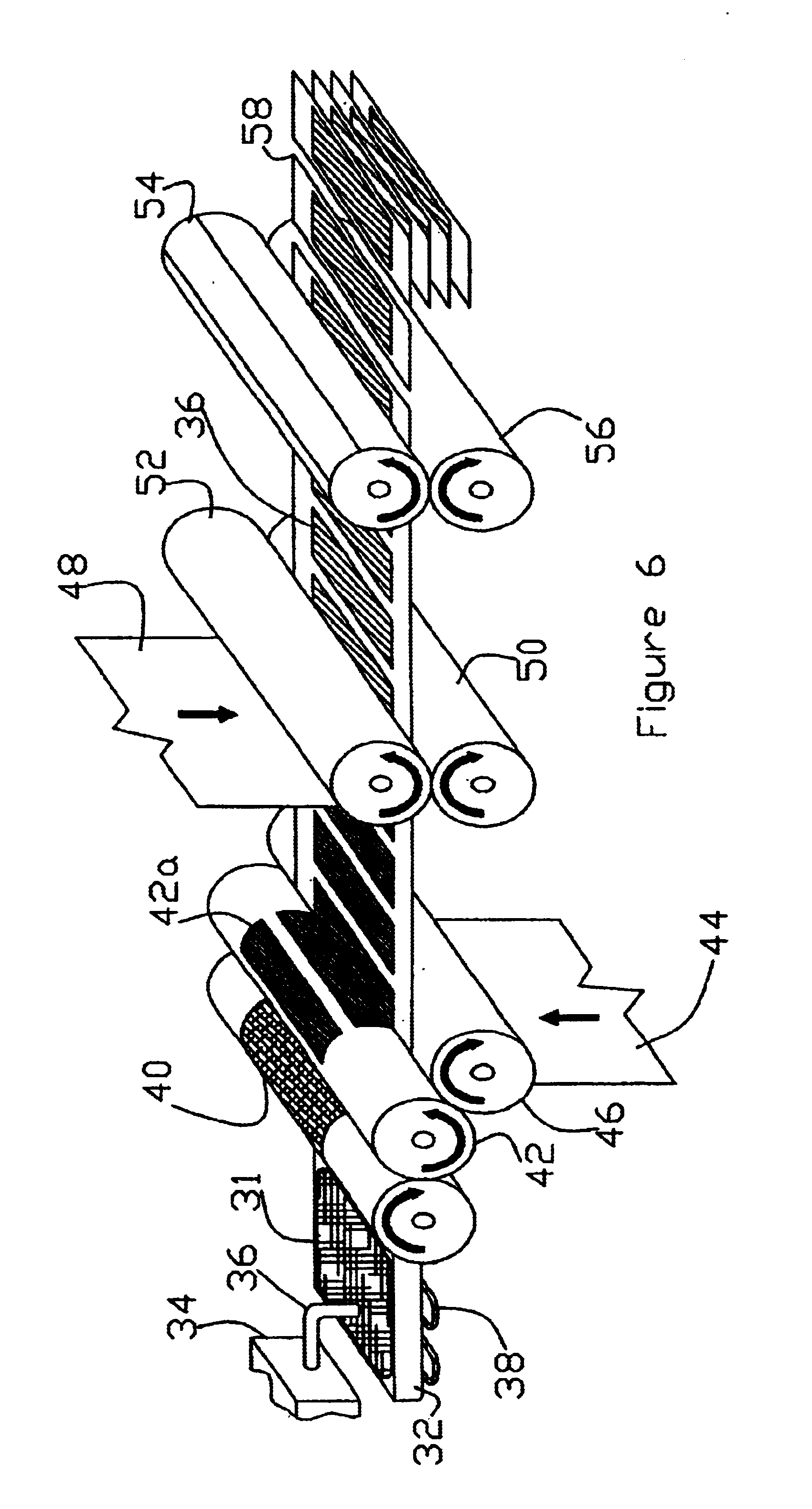

Resistance welding copper terminals through mylar

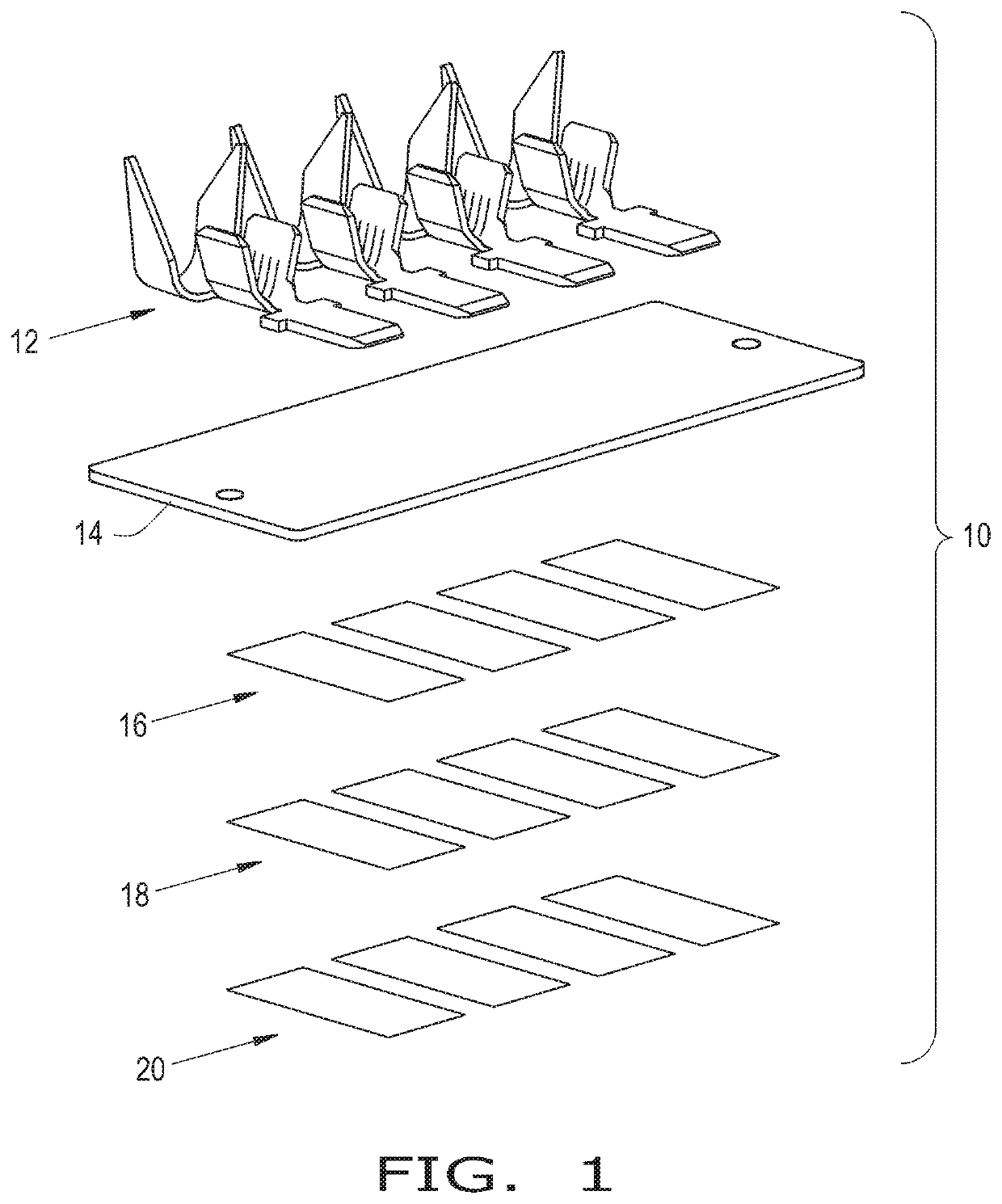

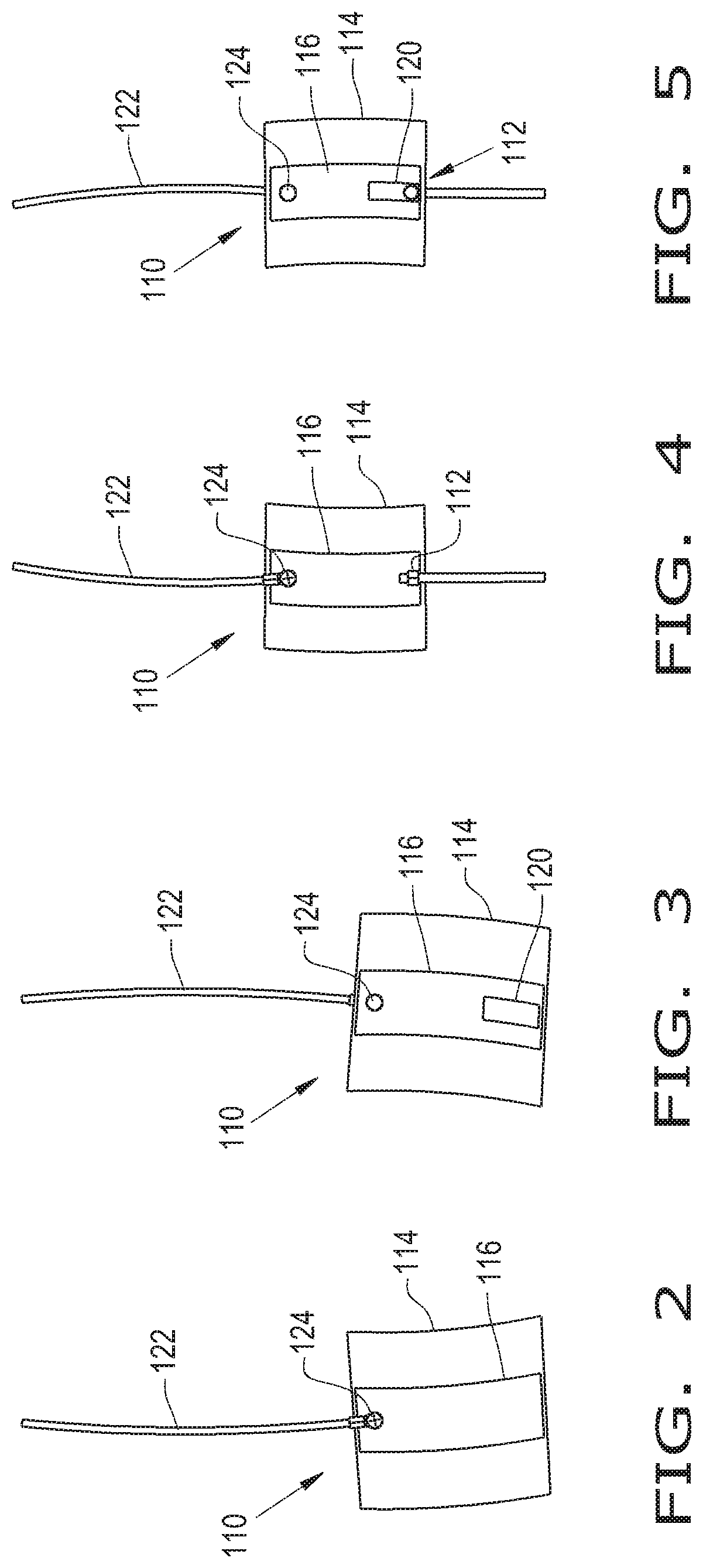

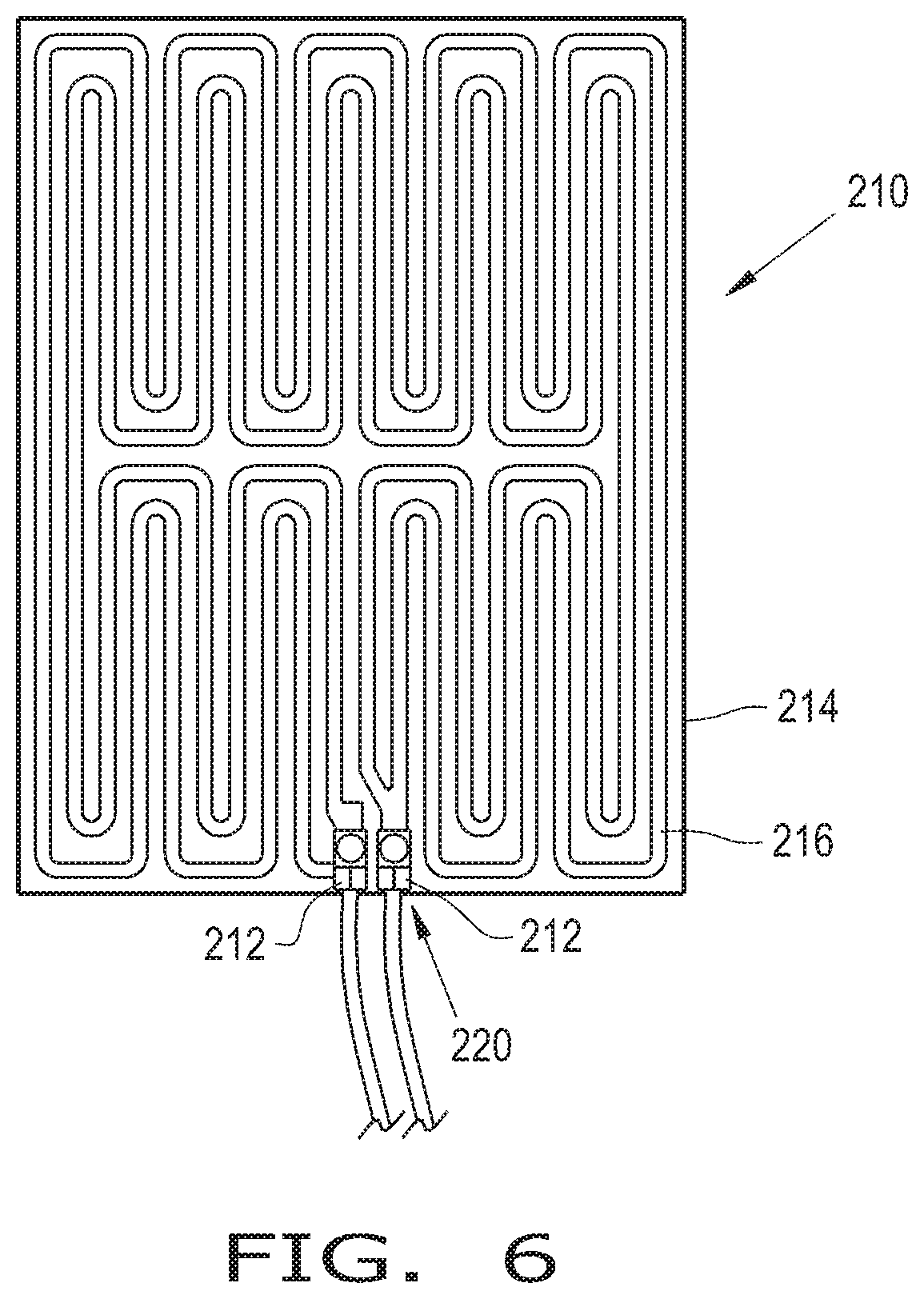

ActiveUS20200099188A1Ensure electrical connection reliabilityReliable electrical connectionLine/current collector detailsOhmic-resistance electrodesElectrical resistance and conductanceHemt circuits

A method for fusing an electrical conductor to a film pad circuit including the steps of: providing an electrically inert substrate having a first surface and an opposing second surface; applying an electrically conductive film to the second surface of the electrically inert substrate; applying an electrically conductive member to the electrically conductive film; placing an electrical conductor on the first surface of the electrically inert substrate; and fusing the electrical conductor to the conductive member.

Owner:CALIENTE LLC

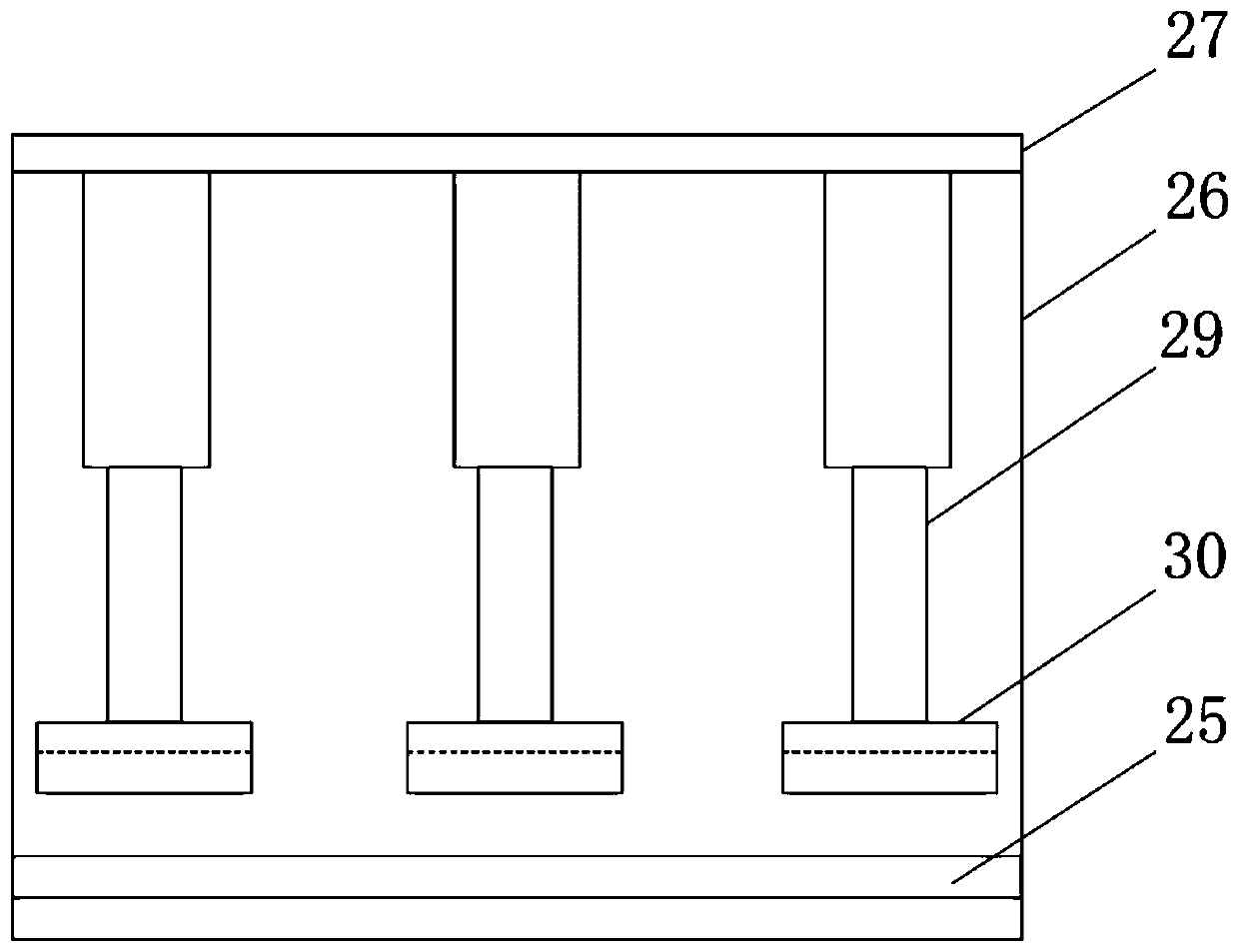

Quality inspection device in polyester film production

ActiveCN111015759ASave the trouble of manually cutting the filmAvoid manual fasteningMaterial strength using tensile/compressive forcesMetal working apparatusPolyesterThin membrane

The invention relates to the technical field of polyester film production and discloses a quality inspection device in polyester film production. The quality inspection device comprises a table top. Agroove and two symmetrically distributed thin grooves are formed in the top surface of the table top. The two thin grooves are located in the left side of the groove and one ends of the thin groovesextend into the groove. Two symmetrically distributed supports are fixedly arranged on the left side of the table top. A thin film roll is arranged between the two supports. A first strut, a second strut and a third strut are fixedly arranged at the top of the table top. The first strut is located on the left side of the second strut. According to the quality inspection device in polyester film production, a first motor operates to finally drive two cutting knives to move to cut a film into three sections of thin films with the same size, the trouble of manually cutting the film is omitted, the two ends of each cut film can be compressed through first electric push rods and second electric push rods, manual fastening is avoided, the time and manpower are saved, meanwhile, three samples arestretched and detected, and the detection efficiency is improved.

Owner:绍兴日月新材料有限公司

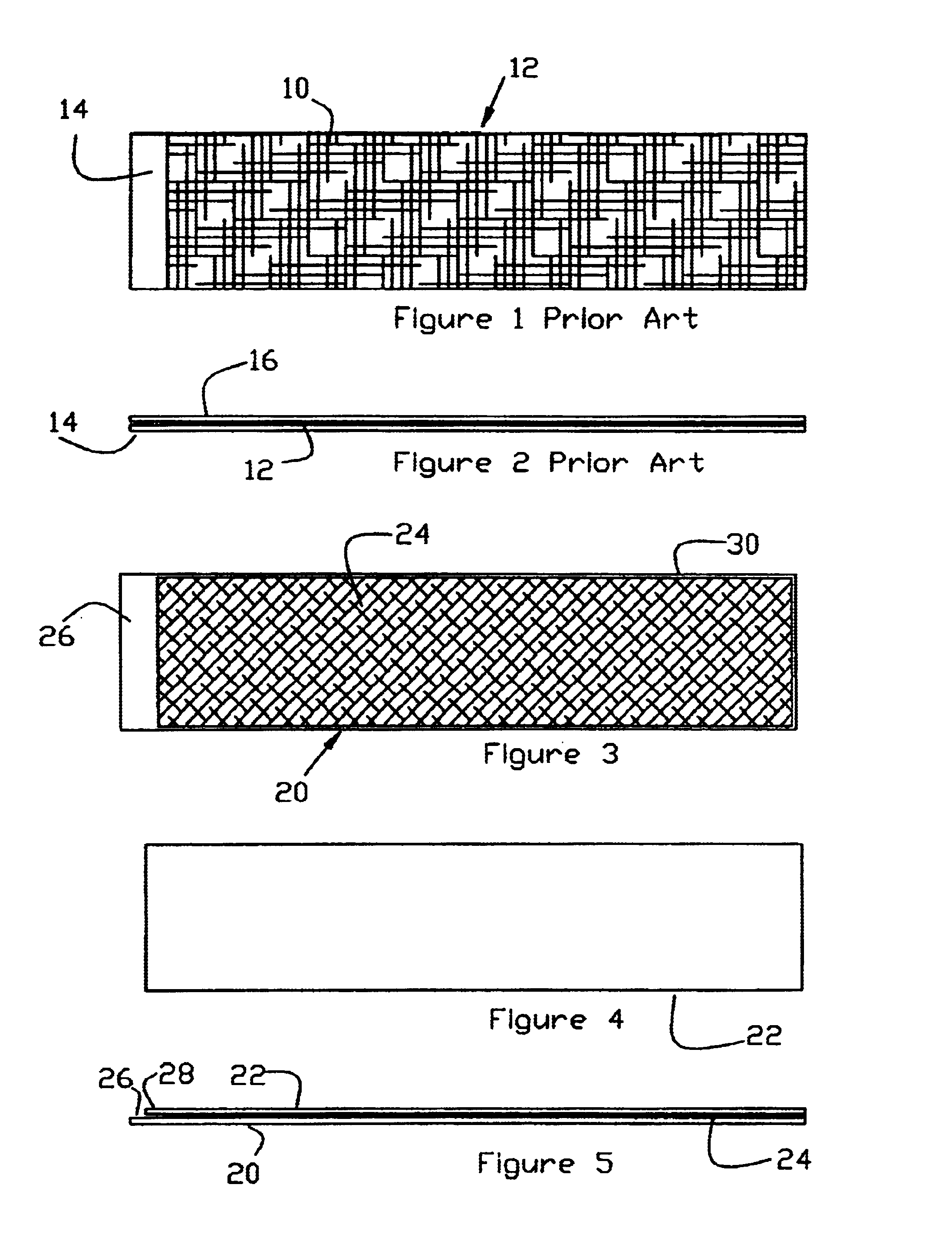

Inkless fingerprint composition and applicator therefor

A nonstaining ink (or inkless) fingerprint composition and applicator comprises two nonpermeable foil strips, made of Mylar, for example, having the same width with one strip being slightly longer than the other. A thin layer or coating of an inkless (or nonstaining) fingerprint composition is sandwiched between the superimposed foil strips leaving a small border including a small area at the end of the strips free of the composition. The inkless composition which includes a color former and may or may not include a developer is in a semisolid state and room temperature and in a liquid state at about 110° F. and above.

Owner:SAFARILAND

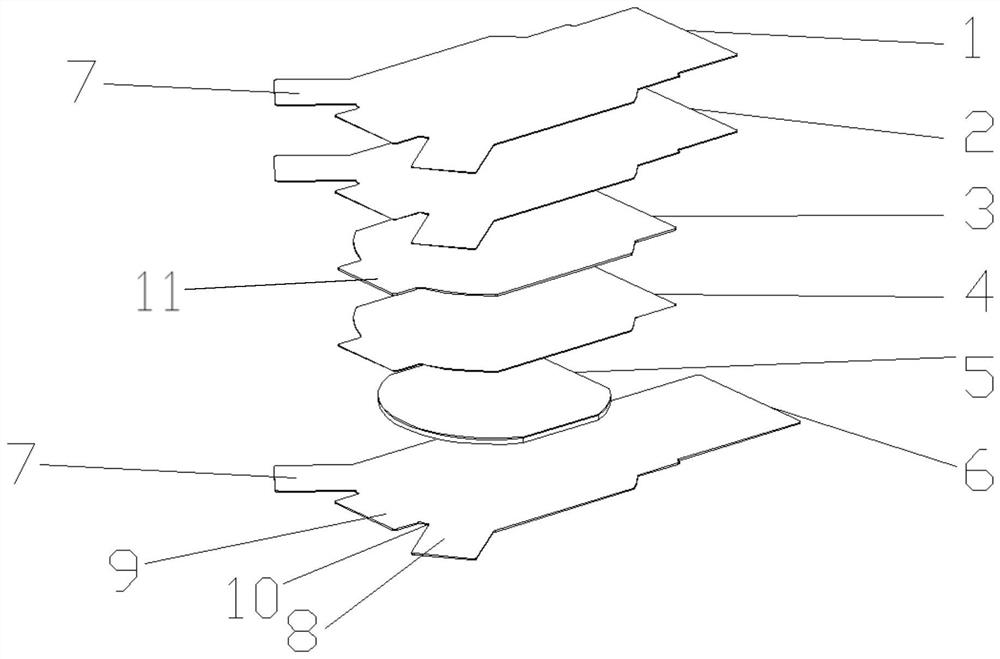

Button cell protective film convenient to mount

The invention discloses a button cell protective film convenient to mount. W-like grooves are formed in a matte black polyester film layer, a first 3M adhesive layer and a PET release film layer, the sizes of the matte black polyester film layer, the first 3M adhesive layer, a black polyester film layer, a second 3M adhesive layer and self-contained adhesive are all not larger than the size of the PET release film layer, and the size of the self-contained adhesive is not larger than the second 3M adhesive layer. According to the button cell protective film convenient to mount, the matte black polyester film layer, the 3M adhesive layers, the black polyester film layer and the self-contained adhesive are bonded together through the two 3M adhesive layers and the self-contained adhesive, and the button cell protective film can be efficiently mounted on a button cell through the two 3M adhesive layers after the PET release film layer is quickly torn off. The protective film has good shading performance, electrical insulation performance, heat resistance, waterproofness and the like, is good in adhesion performance and adhesiveness, plays a good role in protecting the button cell, and is simple in overall structure, attractive and elegant.

Owner:SUZHOU YIBANG ELECTRONICS MATERIAL CO LTD

Polyester Mylar tape and production process thereof

InactiveCN109207081AGood dielectric insulation propertiesNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterMaterials science

The invention discloses a polyester Mylar tape comprising a base material and a coating; the base material is made of a polyester thin film; the coating is prepared by mixing acrylic glue, halogen-free flame-retardant powder, a toner, titanium dioxide and a curing agent according to the weight percentage. The coating is filtered and then evenly coated on the base material made of the polyester thin film. The coating is prepared by mixing the acrylic glue, halogen-free flame-retardant powder, the toner, titanium dioxide and the curing agent according to the weight percentage. The coating is evenly coated on the base material made of the polyester thin film, so the polyester Mylar tape has good dielectric insulation performance and flame-retardant, environmental-protection and halogen-free characteristics.

Owner:龙运贴

A kind of preparation method of discontinuous shielding tape

ActiveCN109859897BIncrease diversityEasy to stretchLamination ancillary operationsSynthetic resin layered productsPolyesterEngineering

The invention provides a discontinuous shielding tape and a preparation method thereof. The discontinuous shielding tape comprises a metal layer, a first polyester film layer and a second polyester film layer which are arranged sequentially from top to bottom, wherein the metal layer is provided with a first notch and a second notch; and the first notch and the second notch have different slit widths. The discontinuous shielding tape has a metal / film / film structure, and in comparison with the conventional discontinuous shielding tape with a metal / film structure, the damage of the laser energyto the film can be reduced in the case of metal cutting by the laser, the stretching performance of the shielding tape is improved, and as the first notch and the second notch with different slit widths are arranged, one-time processing is achieved, the diversity of discontinuous shielding tapes is enhanced, and signal crosstalk is reduced.

Owner:JIANGSU KEMAITE TECH DEV CO LTD

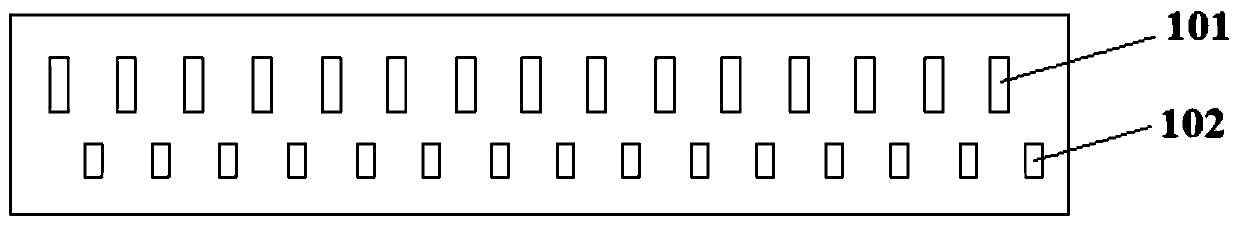

Heat-shrinkable polyester-based film roll

PendingCN111655450ACore wrinkle lessReduce troubleFlat articlesWebs handlingPolyesterPolymer science

The issue is to provide a heat-shrinkable polyester-based film roll that exhibits good winding properties, and in particular, good resistance to winding core wrinkling and end face displacement. The heat-shrinkable polyester-based film roll is characterized by being prepared by winding a heat-shrinkable polyester-based film on a paper tube, the film having a shrinkage rate in a primary film shrinkage direction of 40% or more following treatment in hot water at 90 DEG C for 10 seconds. The heat-shrinkable polyester-based film roll satisfies requirements (1) to (6): (1) the film winding length is 2000-20,000 m; (2) the film width is 400-2500 mm; (3) the film thickness is 5-30 [mu]m; (4) the thickness irregularity at a surface layer part of the film roll in the film width direction is 12% orless; (5) the paper tube has an internal diameter of 3 inches, the difference in clearance of the paper tube in the width direction is 0.5 mm or less after the film is removed from the film roll, andthe flat pressure resistance of the paper tube is 1700 N / 100 mm or more after the film is removed; (6) the average winding hardness of a surface layer part of the film roll in the width direction is 500-850.

Owner:TOYOBO CO LTD

Hole sealing device and method for grouting anchor

The invention relates to a hole sealing device and method for a grouting anchor. The hole sealing device for the grouting anchor includes an annular baffle with a circular hole, Ma Lisan, water and an annular baffle without holes; the sealing steps are as follows: , mark the position of the grouting anchor, use the anchor trolley or the air gun to drill the hole, the Marysan wrapped in the annular polyester film and the water wrapped in the annular polyester film are set near the tail of the grouting anchor in turn, Then fix the annular baffle with circular holes and the annular baffle without holes, insert the grouting anchor rod and exhaust pipe into the hole at the same time, and use a thin iron wire to pass through the annular polyester film wrapped with Marysan and water. If it is broken, plug the gap of the circular baffle with a circular hole with a sealer, use a BW250 mortar pump to inject grout, and remove the grouting hose and anchor joint after completion. The hole sealing device of the grouting anchor has simple structure, convenient processing, quick and accurate installation during grouting, convenient operation, good hole sealing effect, effective prevention of grout leakage, and is suitable for large-scale production and market promotion.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com