Patents

Literature

90results about How to "Less wrinkling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

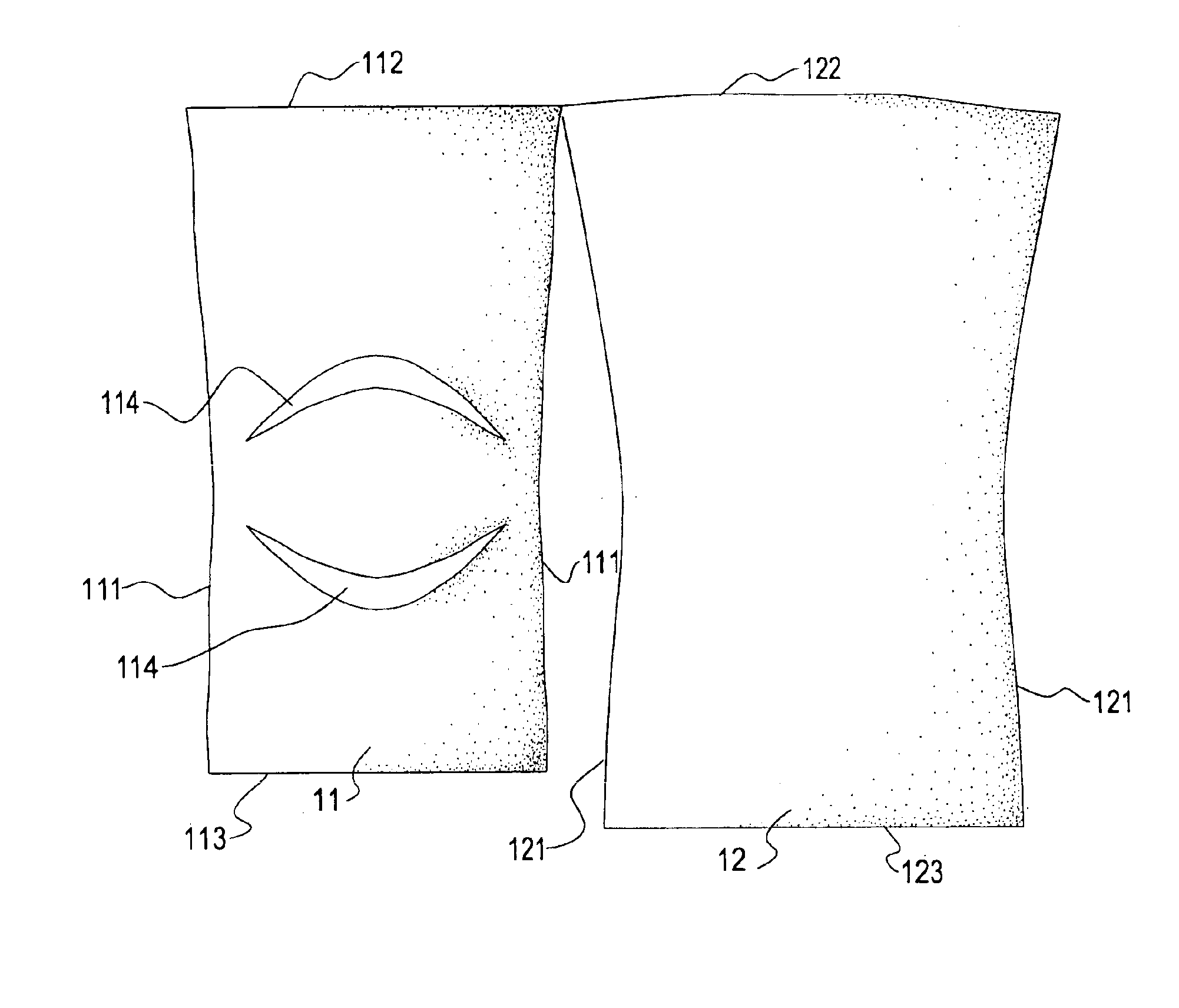

Systems and methods for forming openings in water soluble packets

InactiveUS20140228194A1Tightly packedLess wrinklingBox making operationsContainer making machineryWater solubleLaser

Systems and methods to form openings in water soluble packets are described. The system includes a packet forming assembly to form water soluble packets, and a laser to form one or more openings in the water soluble packets. The method includes forming openings in the water soluble packets with a laser. The openings permit air to escape from the packets. By allowing air to escape, the water soluble packets have improved packaging characteristics. The water soluble packets are packed more tightly with a product.

Owner:MULTI PACK CHICAGO LLC

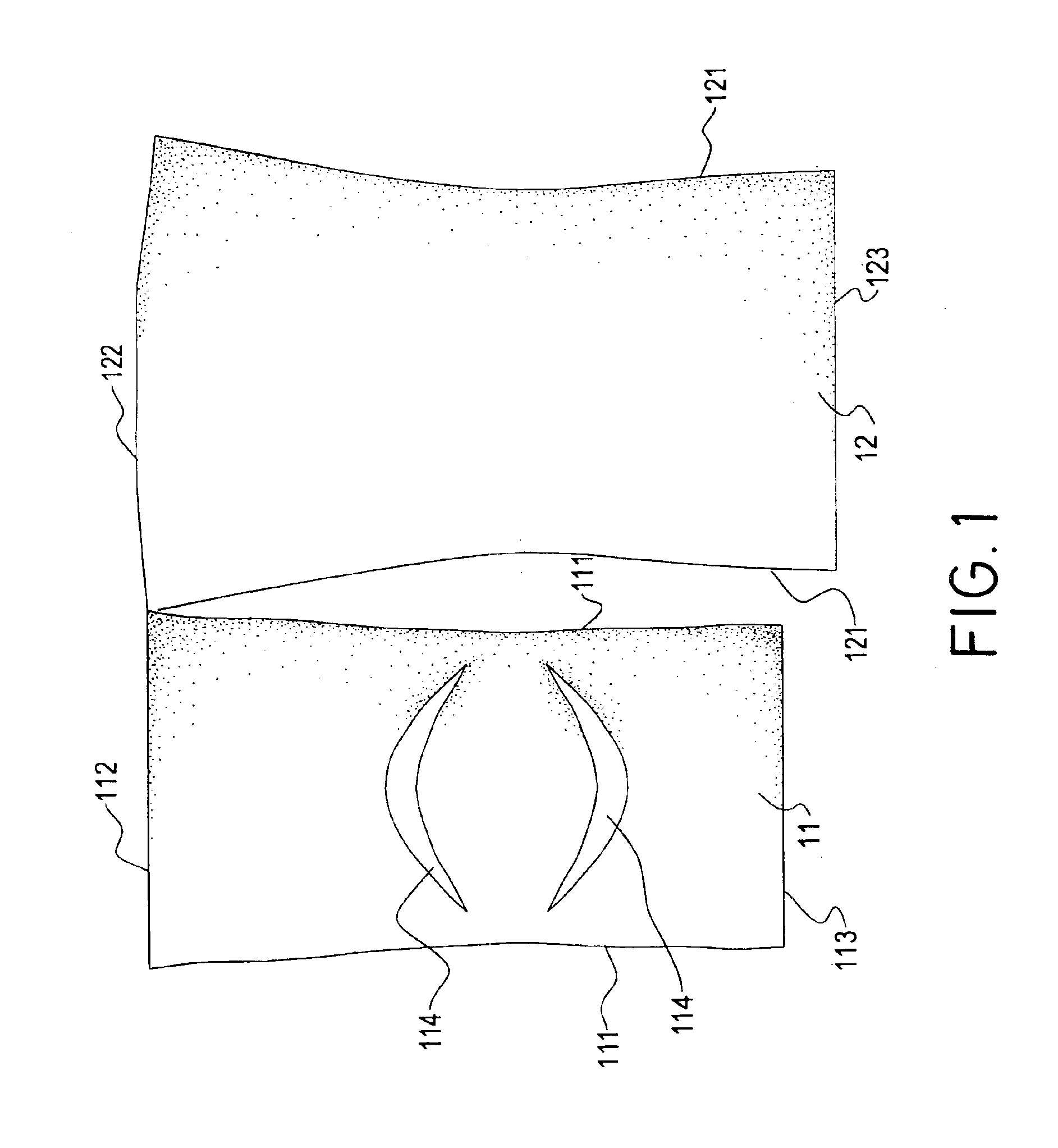

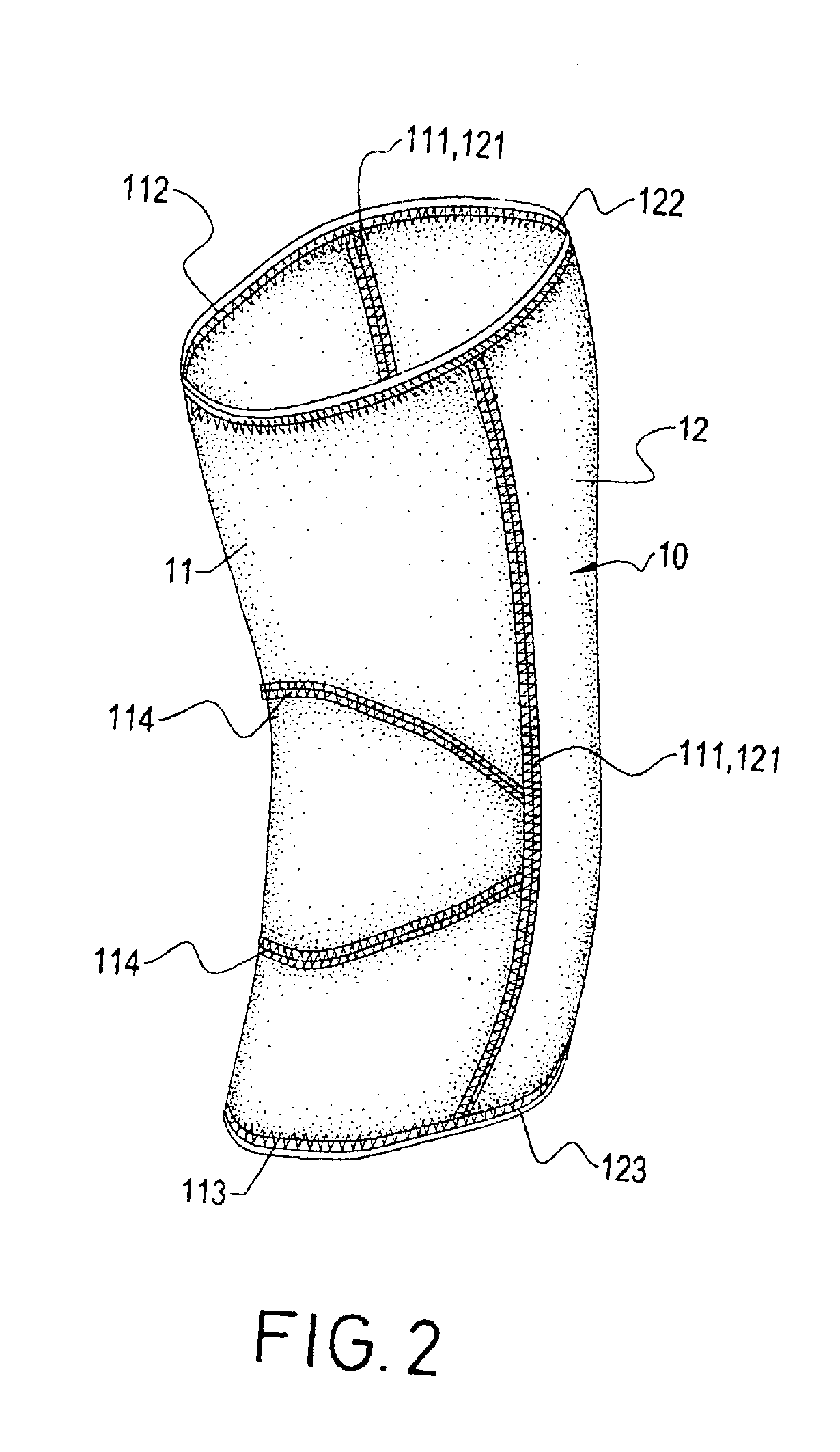

Support bandage for a joint between bones

A support bandage for a joint between bones includes a small fraction having two opposite first longitudinal sides sewn with two opposite second longitudinal sides of a large fraction. The small fraction is incurved towards the large fraction, and has two arcuate seams on the small fraction. The segment between the two arcuate seams is more incurved than two end segments outside the arcuate seams, and the two arcuate seams are away from a wearer 's joint. Whereby, the support bandage can be tightly abut a knee or an elbow yet have few wrinkles and will not uncomfortably press the wearer.

Owner:CHIANG PANG CHING

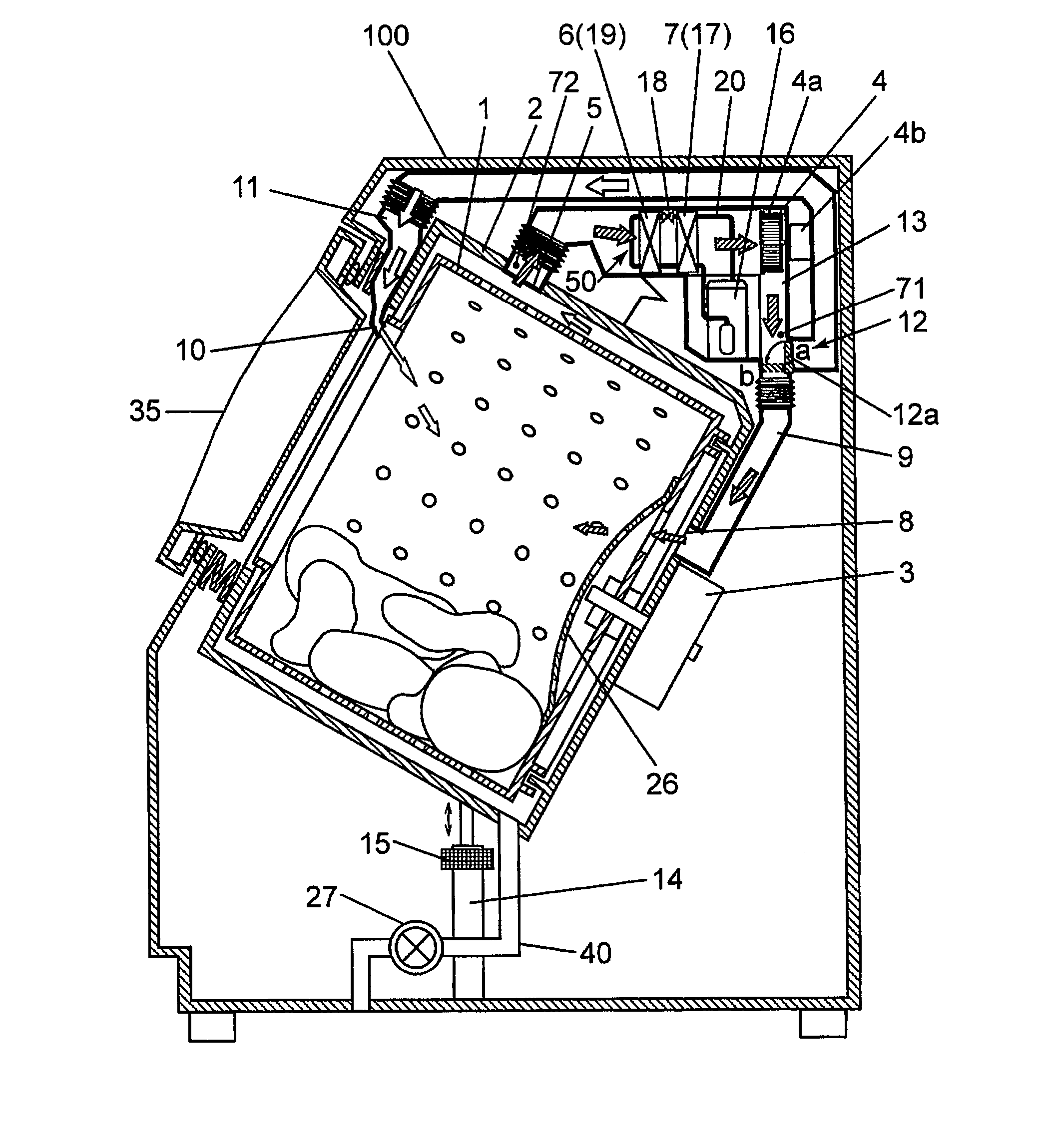

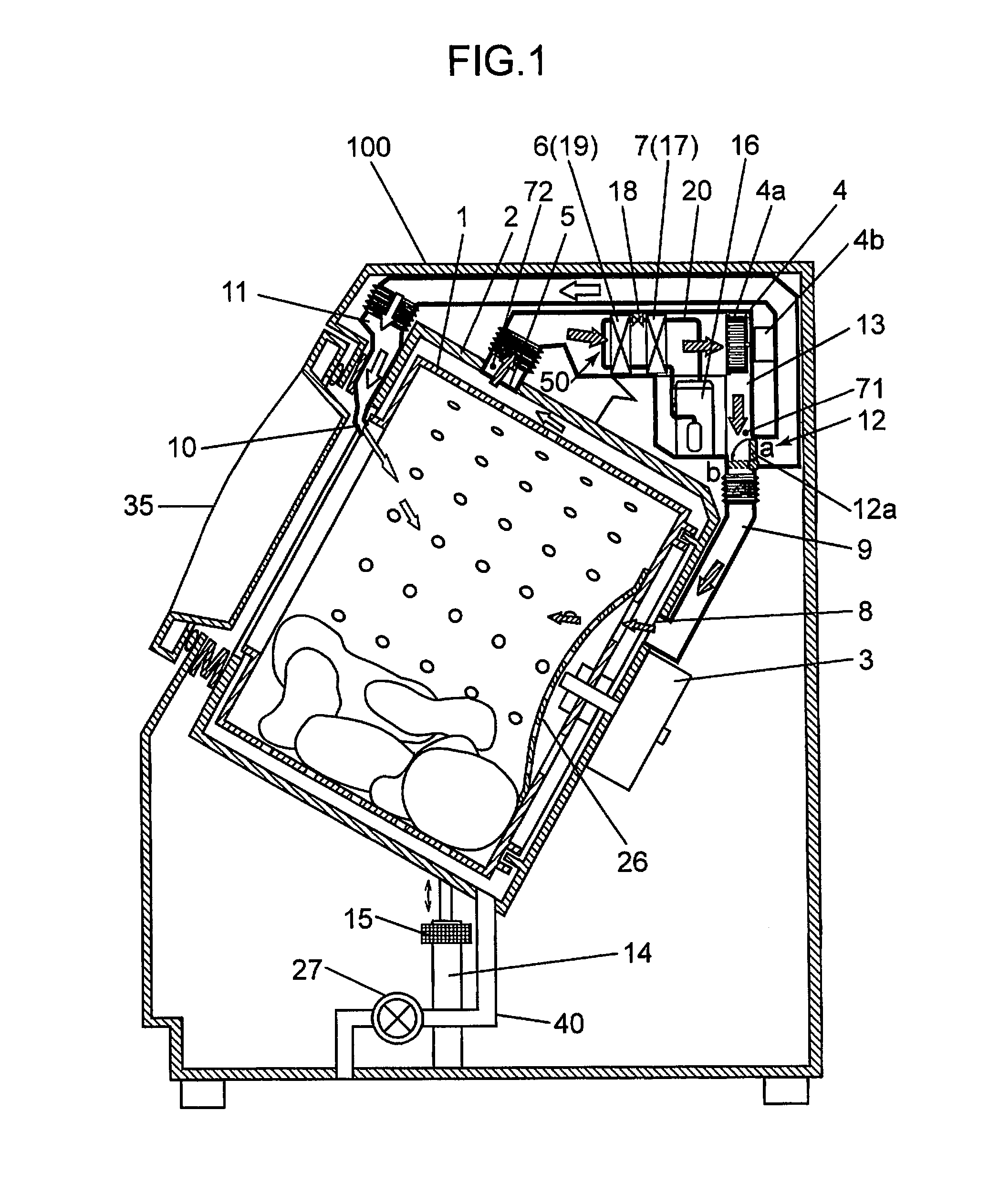

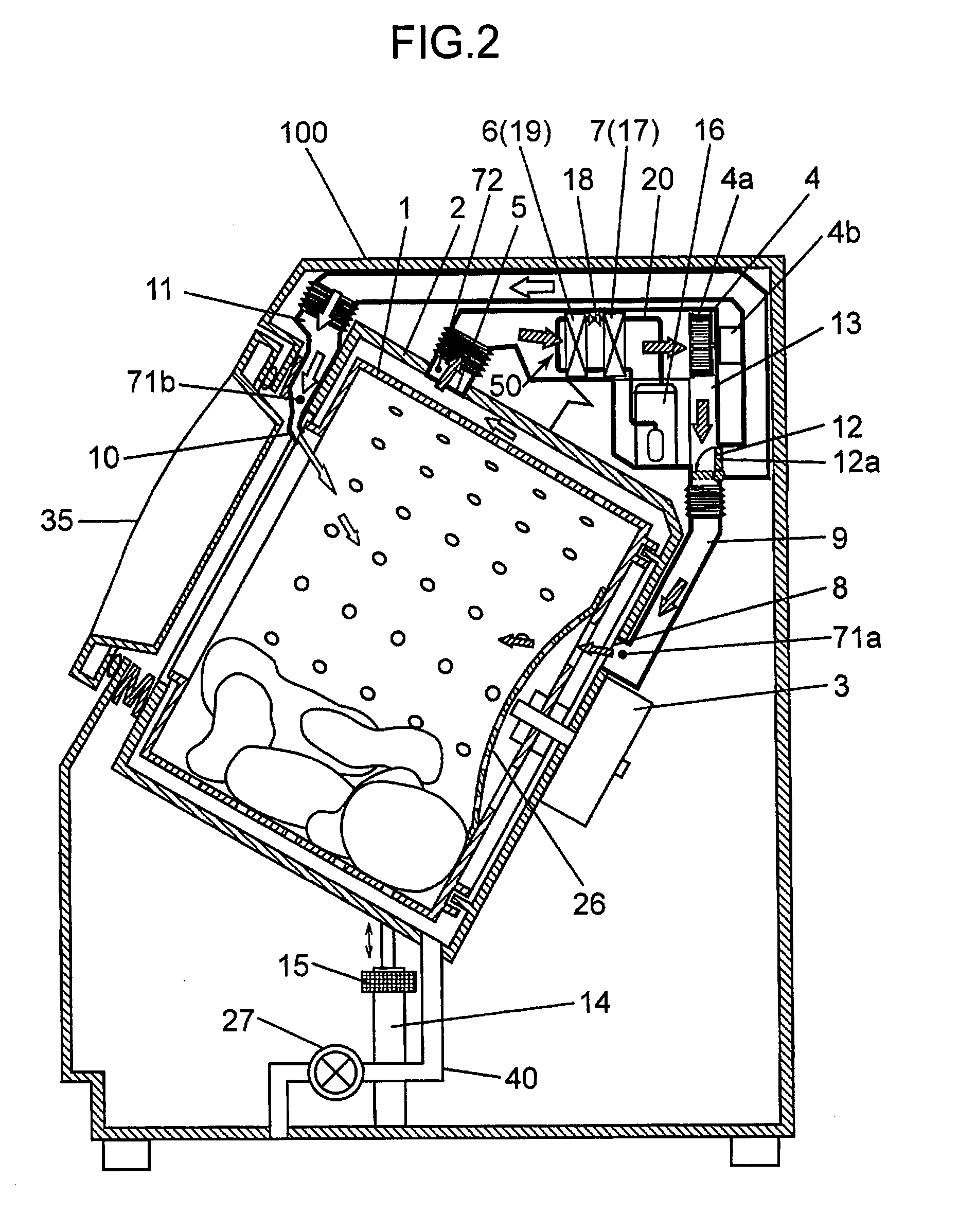

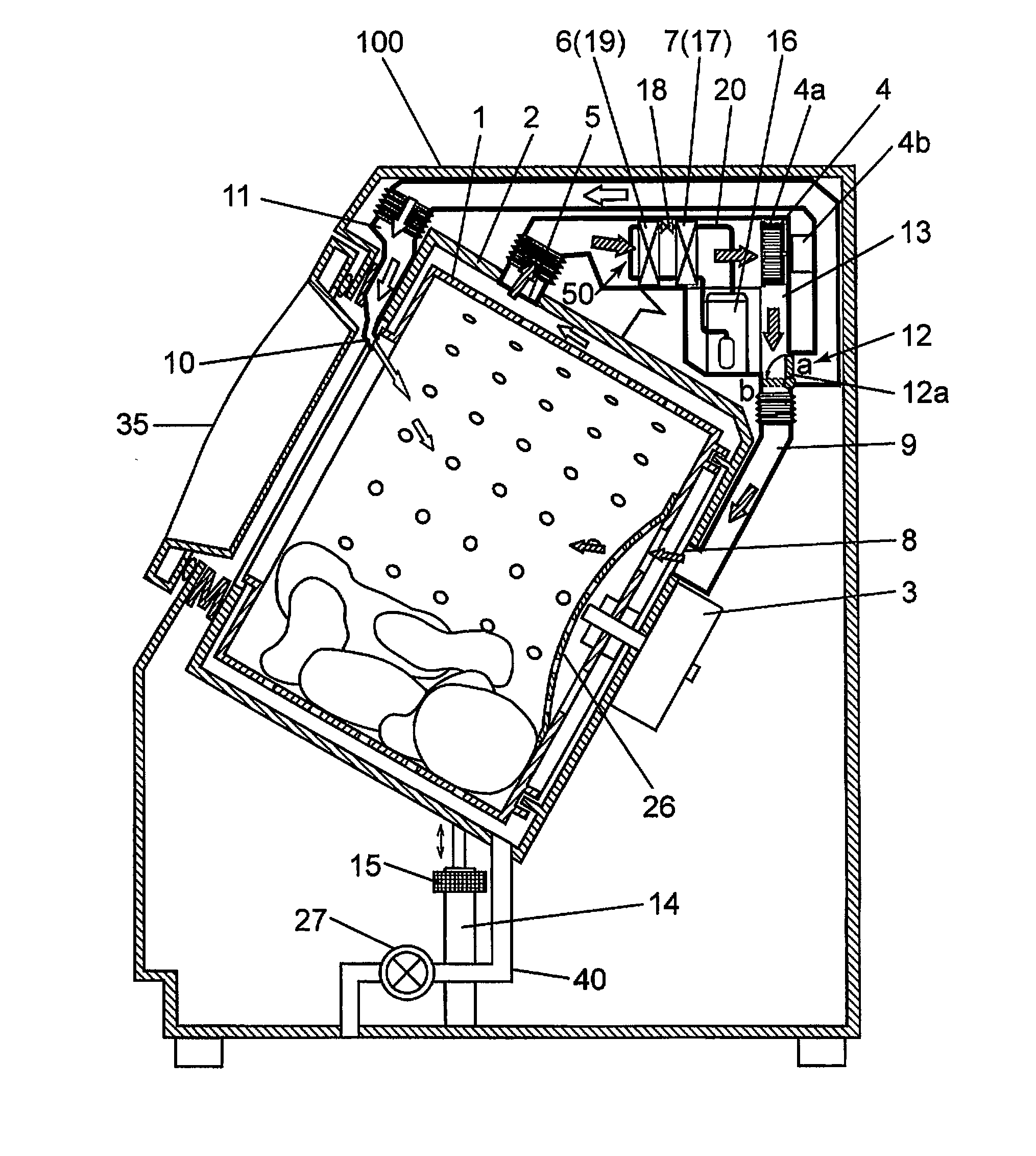

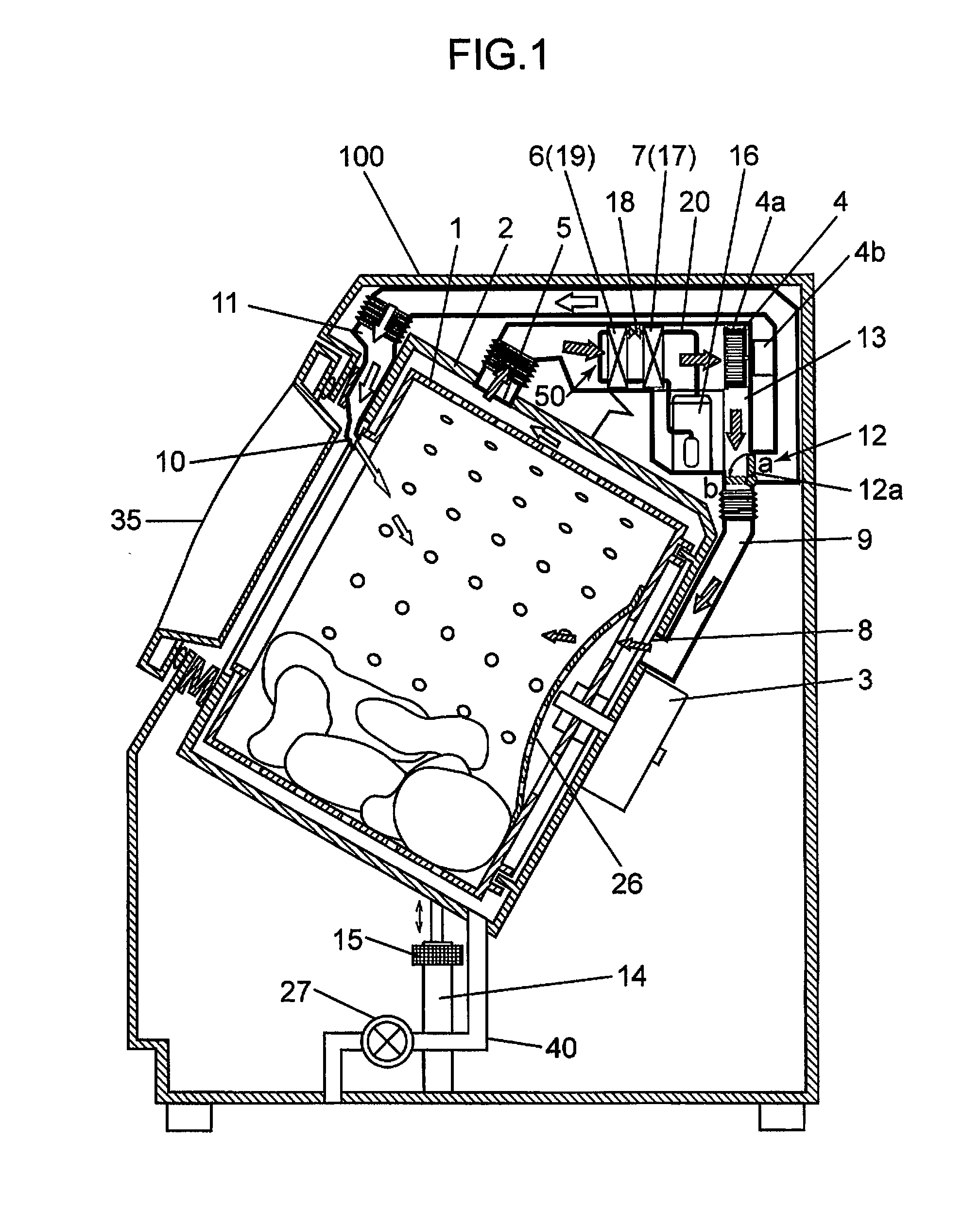

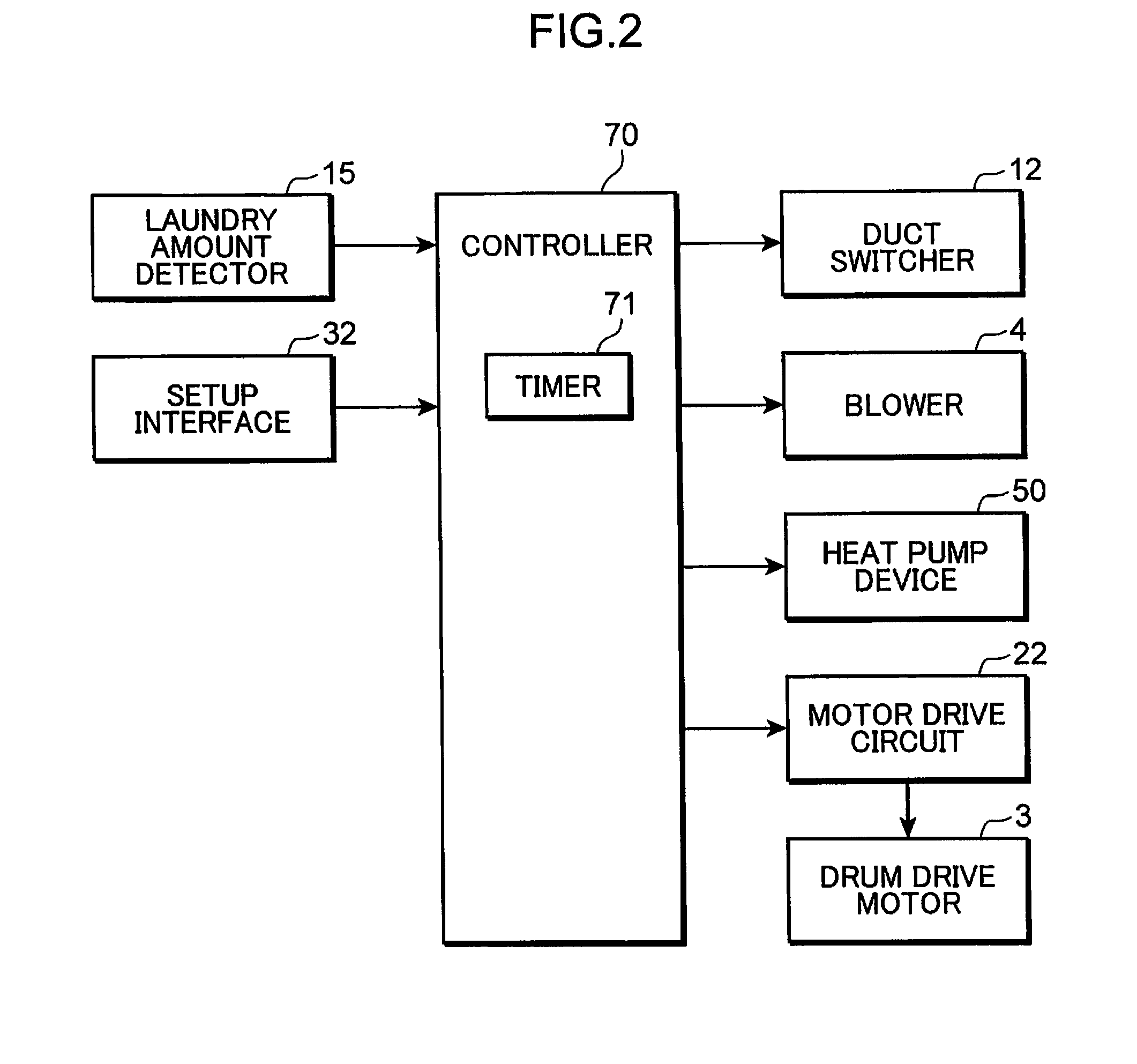

Laundry dryer and washer dryer

InactiveUS20120167636A1Reduce power consumptionReduce wrinklesOther washing machinesDrying machines with non-progressive movementsLaundryHigh pressure

Provided is a laundry dryer including a first duct having a first outlet opening at the rear of a drum storing laundry, and a second duct with a second outlet opening at the front of the drum. The second outlet has a smaller bore allowing air passage than the first outlet. The first and second ducts are selectively switched during the drying process in response to temperature detectors which detect the dry air temperature before and after contact between the air and the laundry. A larger volume of air is blown from the first outlet under selection of the first duct than the second duct whereas the dry air is blown from the second outlet at higher pressure and higher velocity under selection of the second duct than the first duct.

Owner:PANASONIC CORP

Dyeing process of cotton and linen blended fabric

InactiveCN104141247AQuality improvementStrong color fastness to lightDyeing processVegetal fibresDisperse dyeRoom temperature

The invention discloses a dyeing process of cotton and linen blended fabric. The dyeing process includes the following steps that (1) pre-finishing is carried out, wherein gray fabric of the cotton and linen blended fabric is prepared and then is placed into water for pre-wetting at a room temperature after singeing, light fastness reinforcing agents and anti-creasing agents are added, a pH value is adjusted, the grey fabric is soaked at a higher temperature, and then desizing, boiling-off and bleaching are carried out; (2) dyeing is carried out, wherein different kinds of active dye are selected according to different color requirements, the grey fabric pre-finished in the step (1) is put into water, dye leveling agents, buffer solutions, carrier auxiliaries and softening agents are added into the water, then disperse dye and the active dye are added, the temperature is raised and then dyeing is carried out in a differential dyeing method; (3) post finishing is carried out, wherein anti-shrinking finishing is carried out, the fabric is immersed in alkali liquor, the fabric is piled and shrunk, the fabric is washed to remove the alkali liquor, curing is carried out after the fabric is dried, then tentering, shaping and preshrinking are carried out, and finally the fabric is rolled. The dyed fabric is good in quality, light fastness is high, the fabric is not prone to fading under the combined action of light, oxygen and other chemical substances and wrinkling phenomena are effectively reduced.

Owner:WUXI XINDA DYEING MACHINE FACTORY

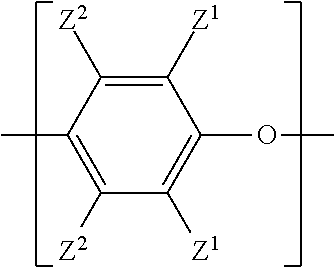

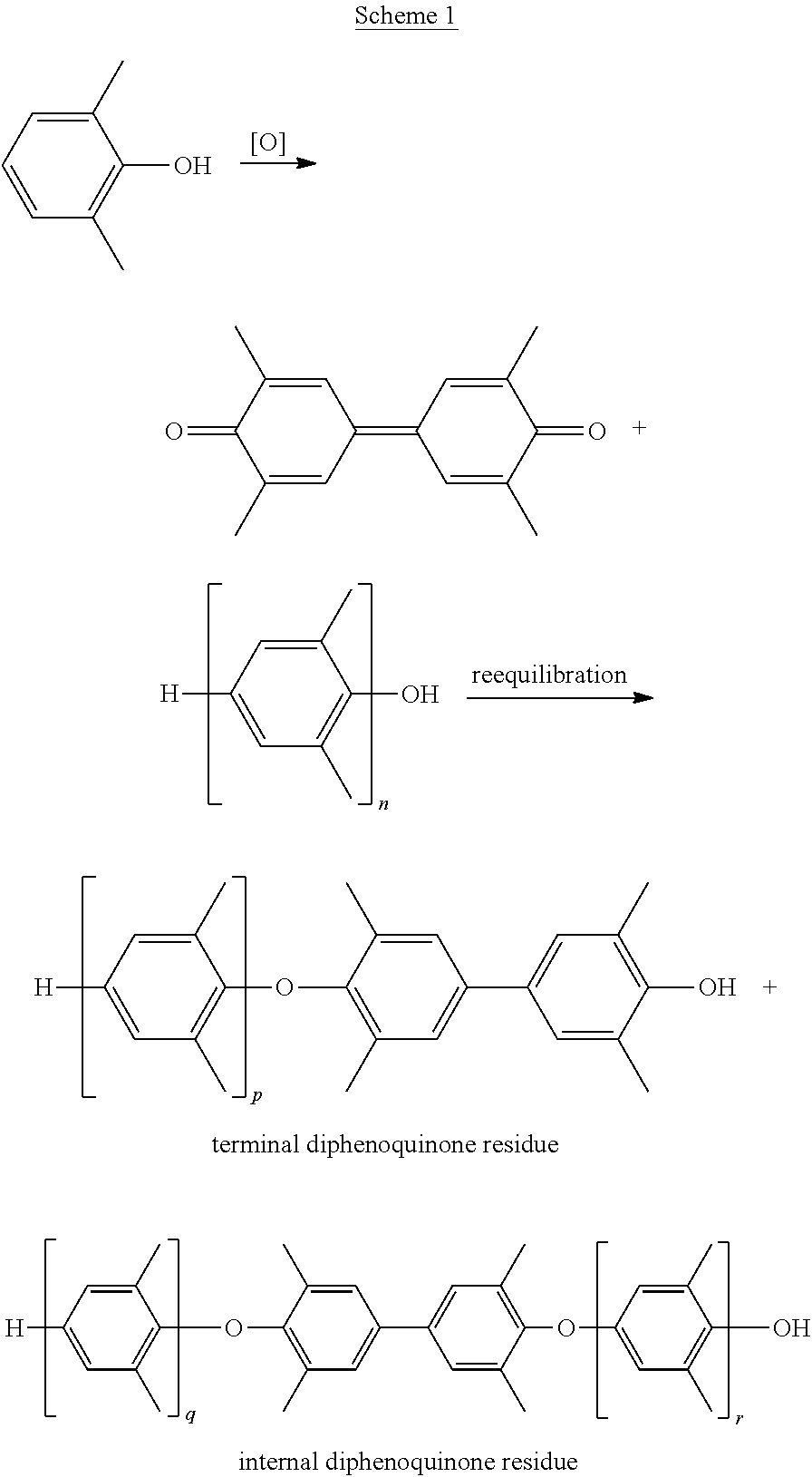

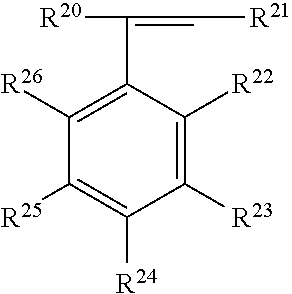

Flexible, wrinkle resistant poly (phenylene ether) cable jacketing composition

Disclosed is a flexible, wrinkle-resistant cable jacketing composition, comprising: cable jacketing compositions, comprising specific amounts of a poly(phenylene ether), a hydrogenated block copolymer of an alkenyl aromatic compound and a conjugated diene, an olefin homopolymer, a polybutene, and a flame retardant. Also disclosed are processes for making such compositions, as well as articles derived therefrom.

Owner:SABIC GLOBAL TECH BV

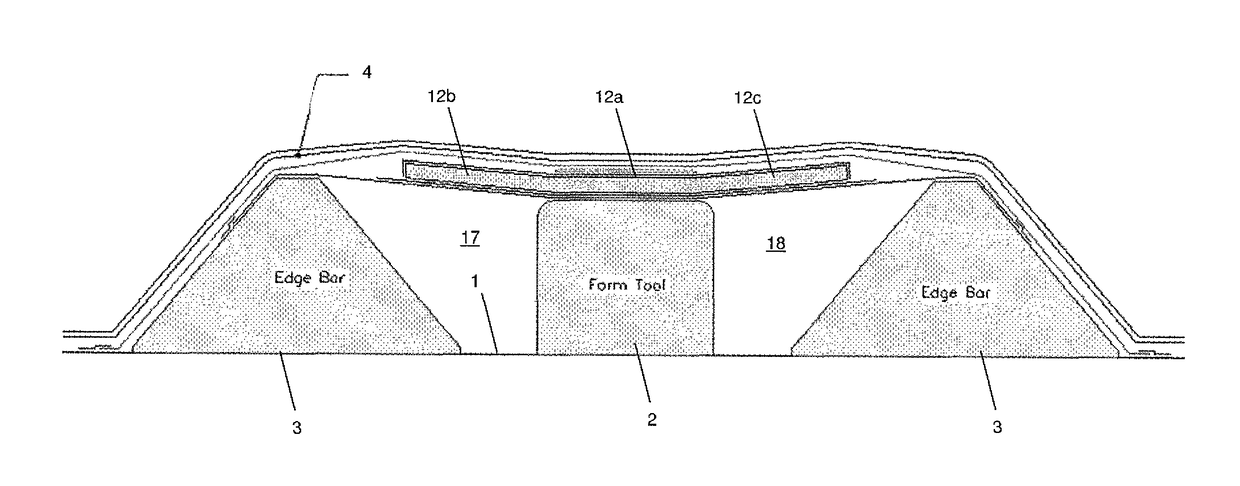

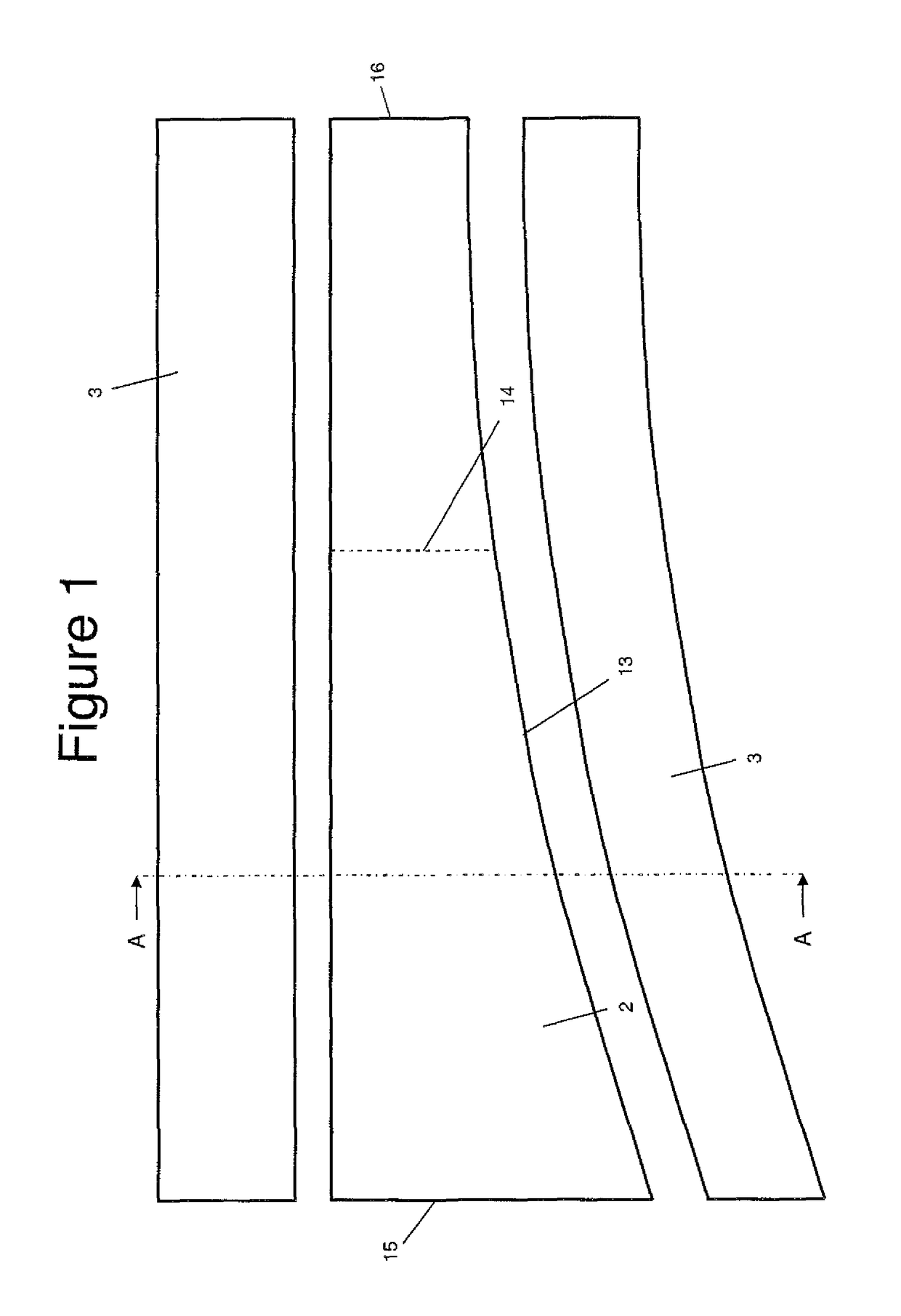

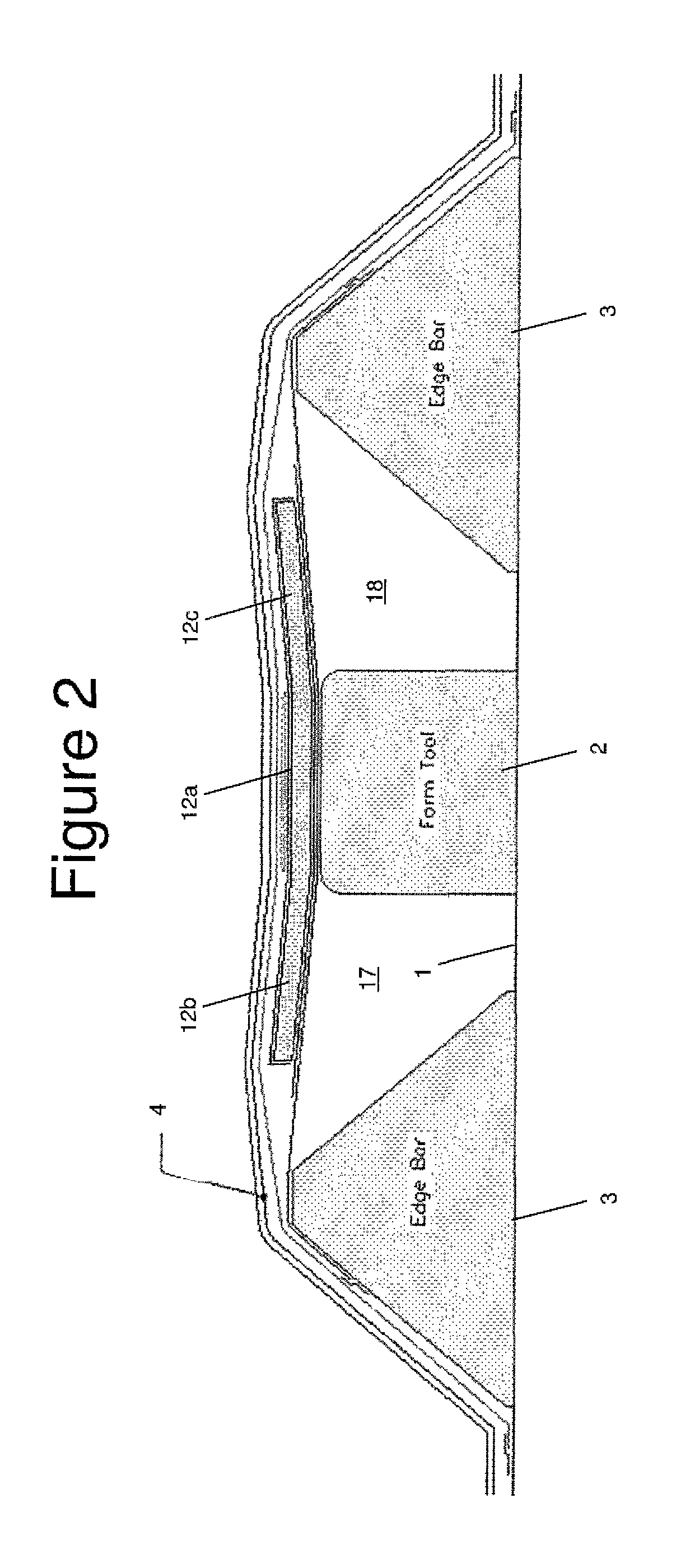

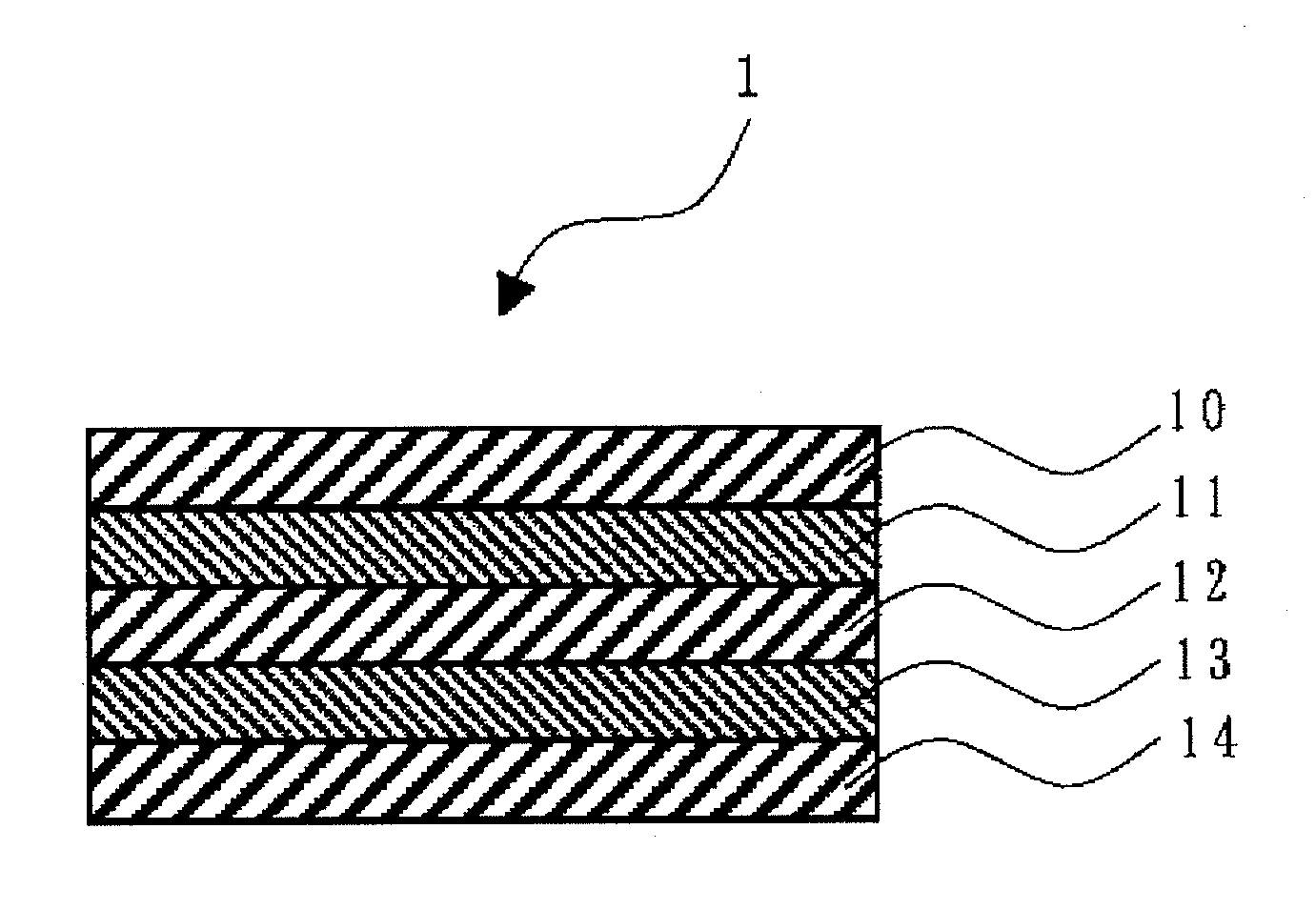

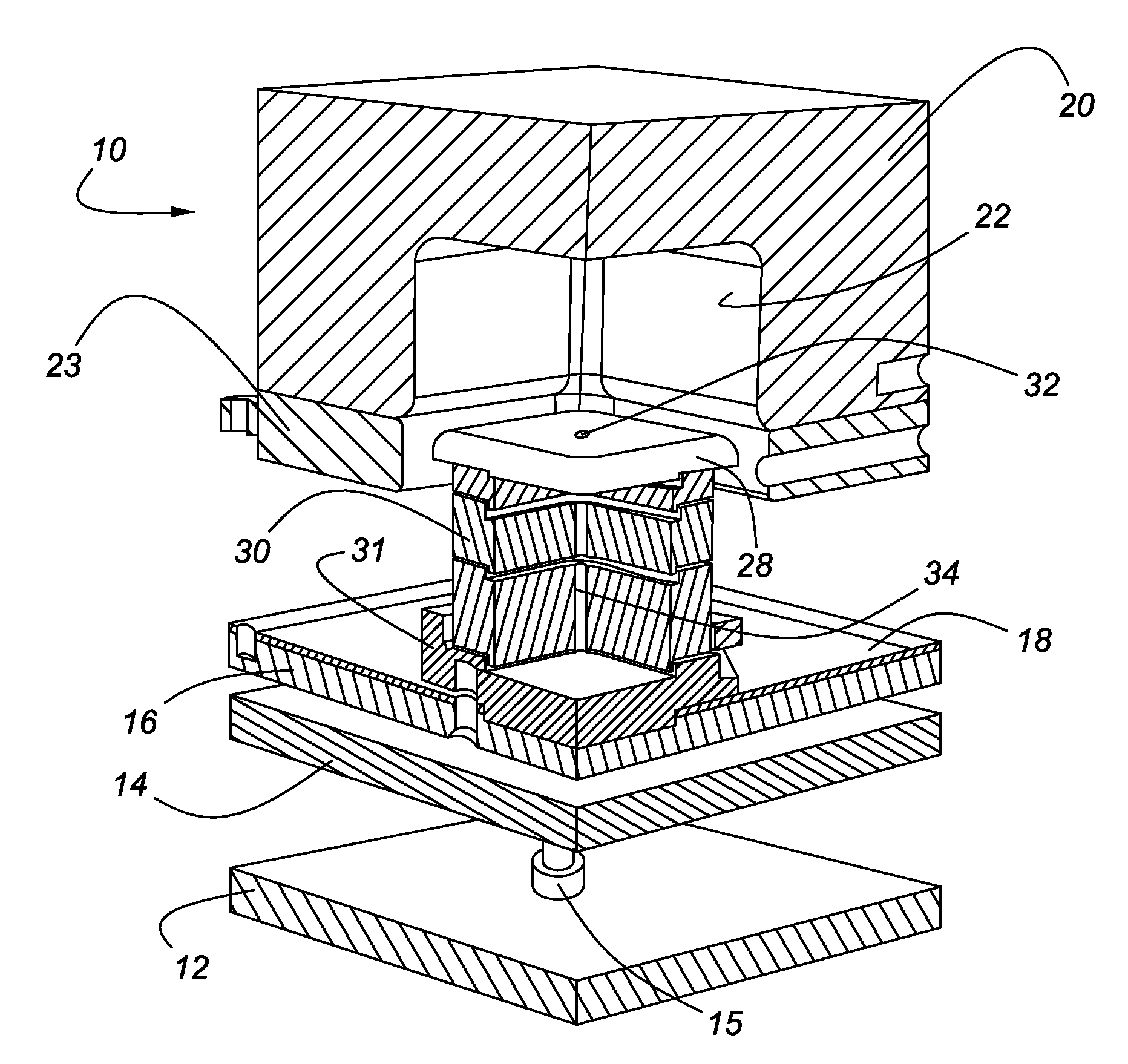

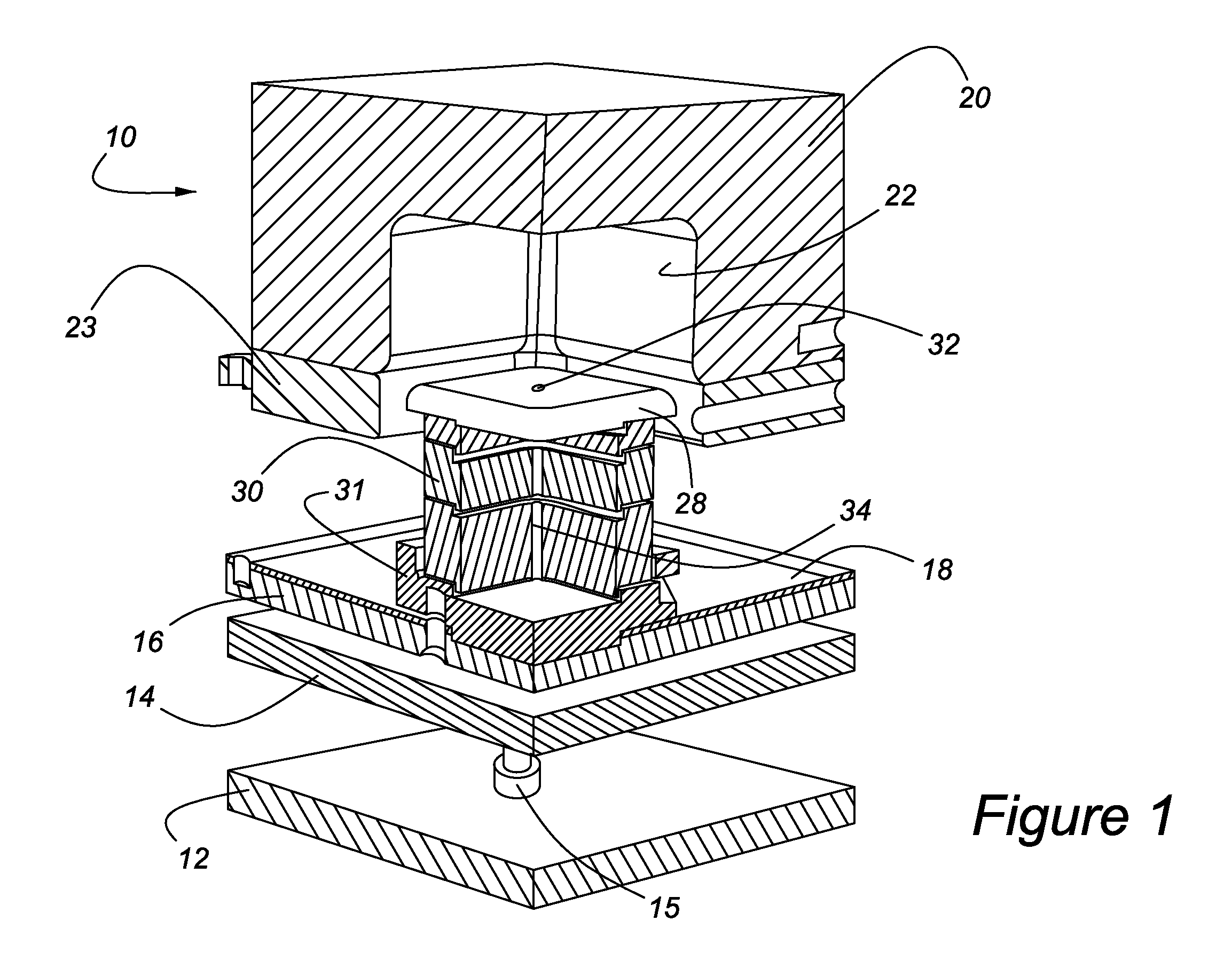

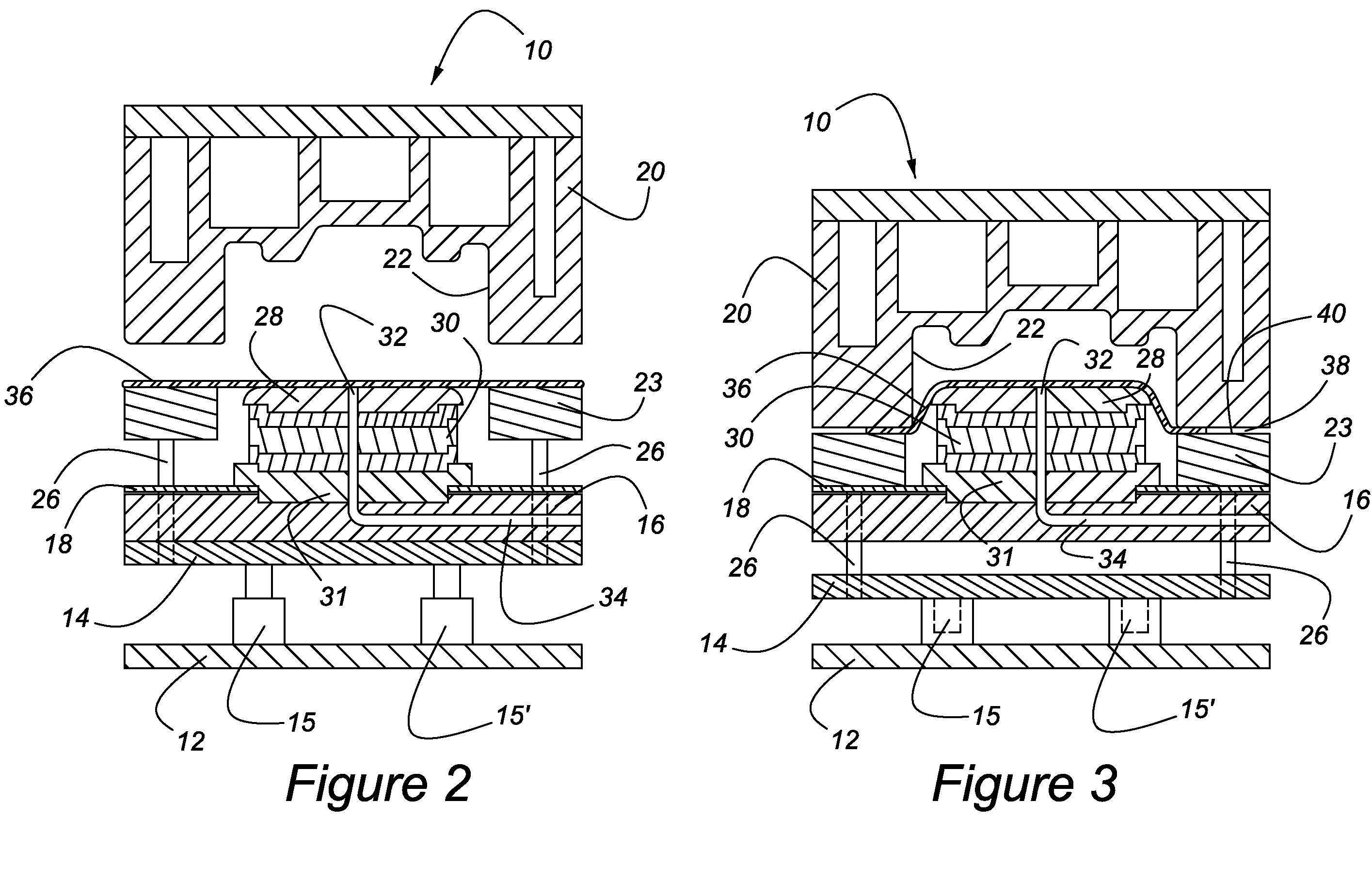

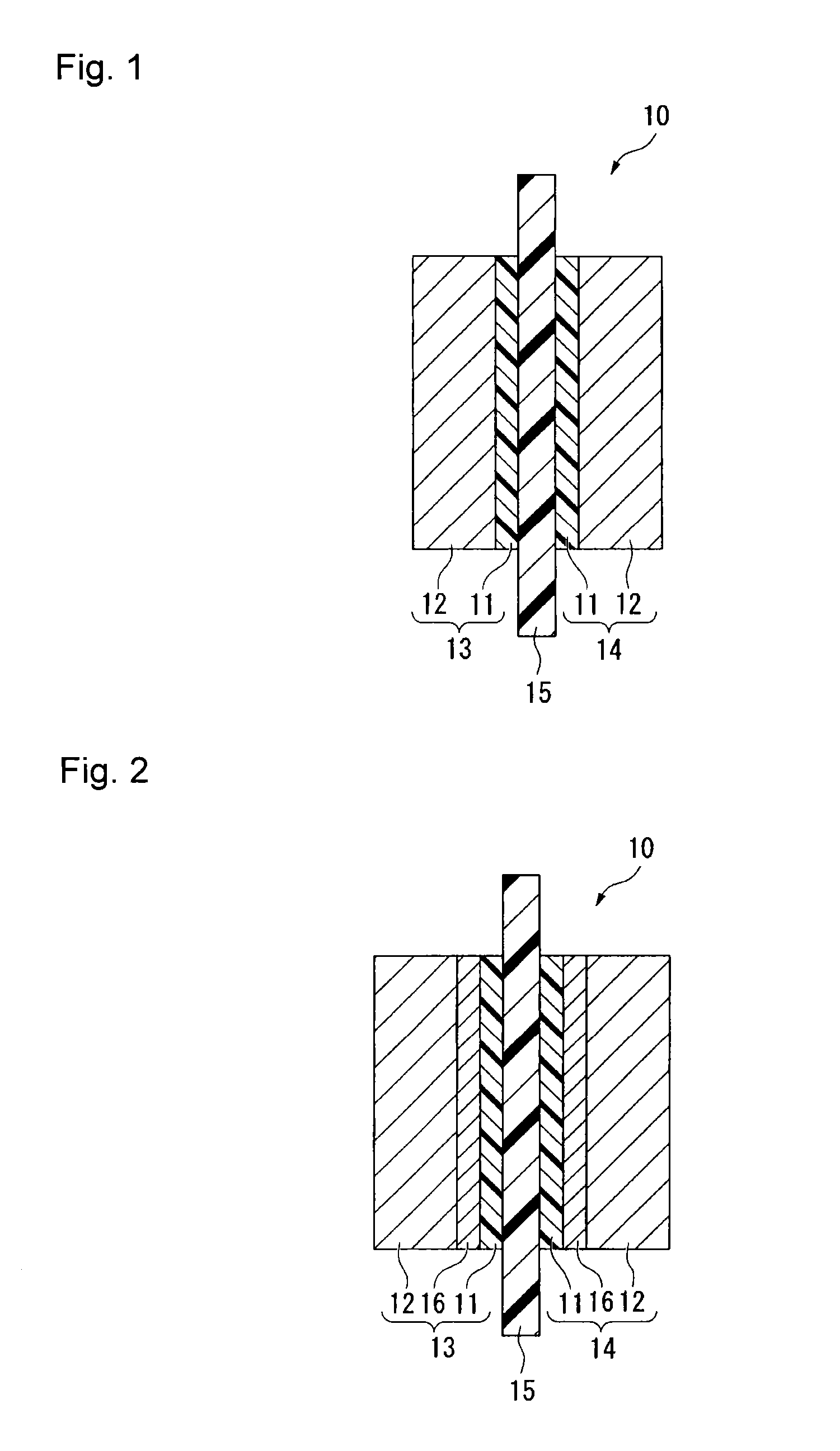

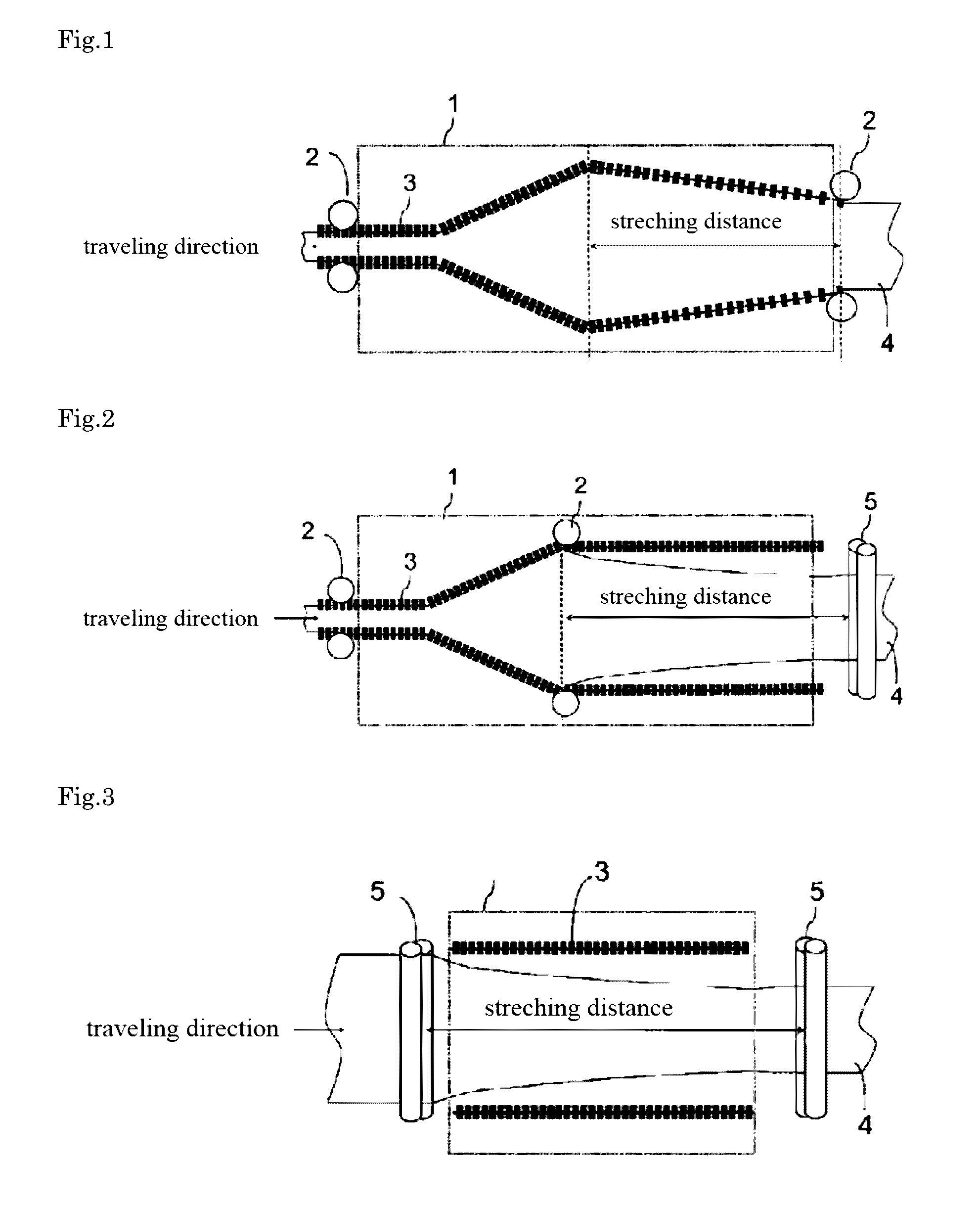

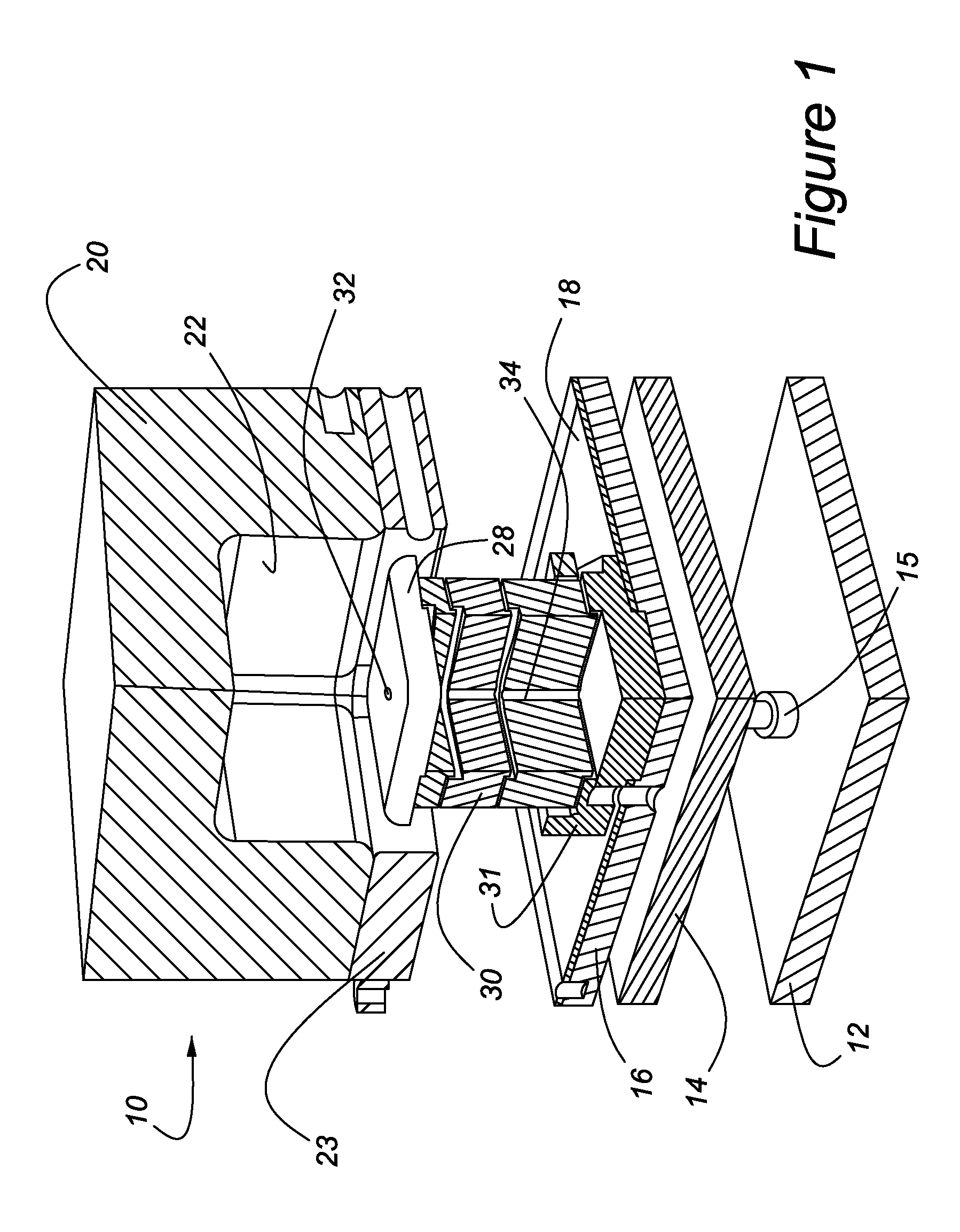

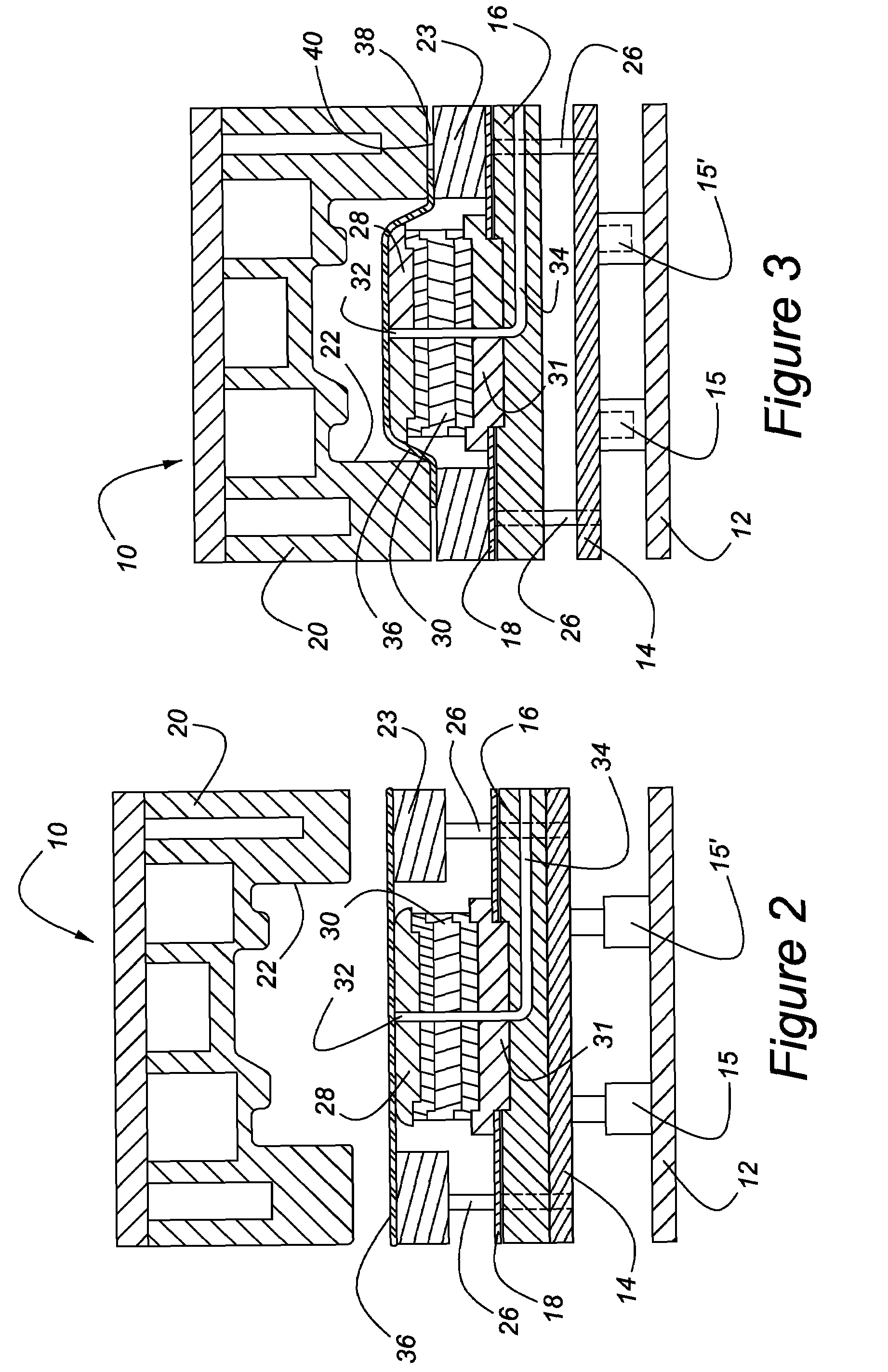

Method of moulding a charge

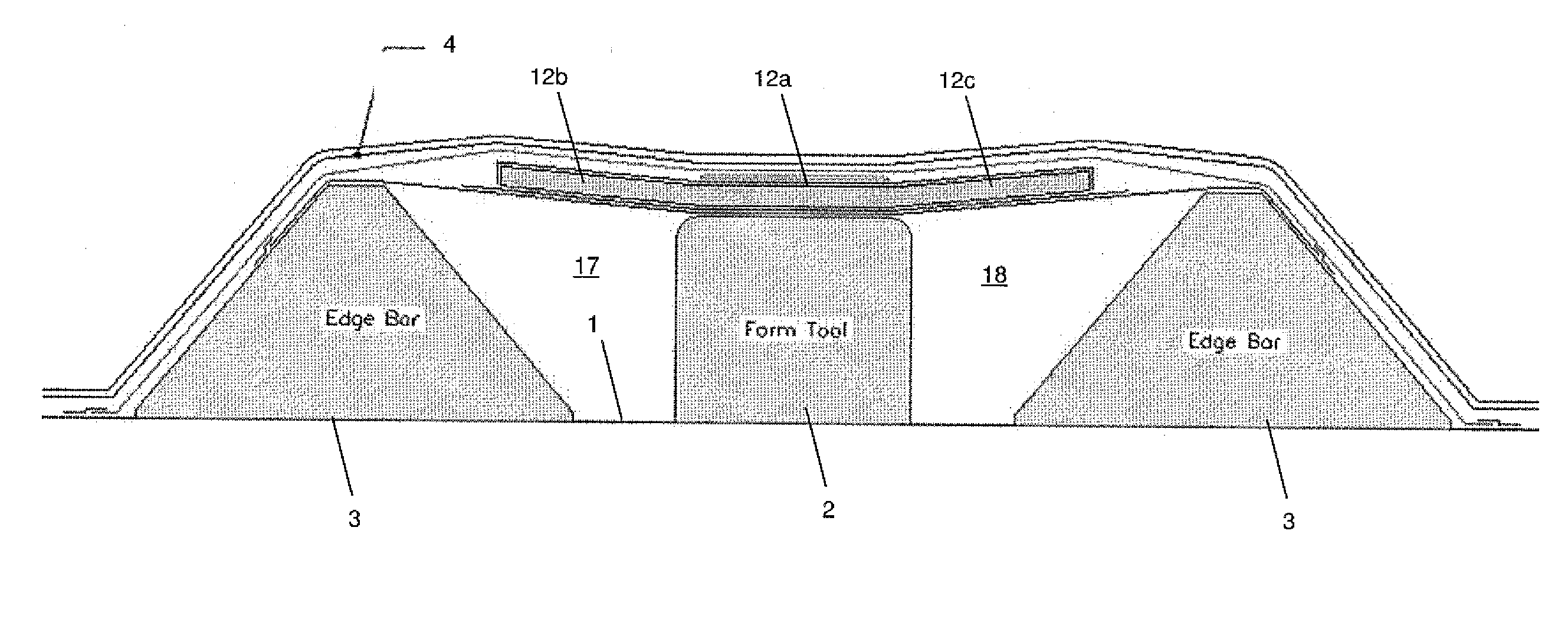

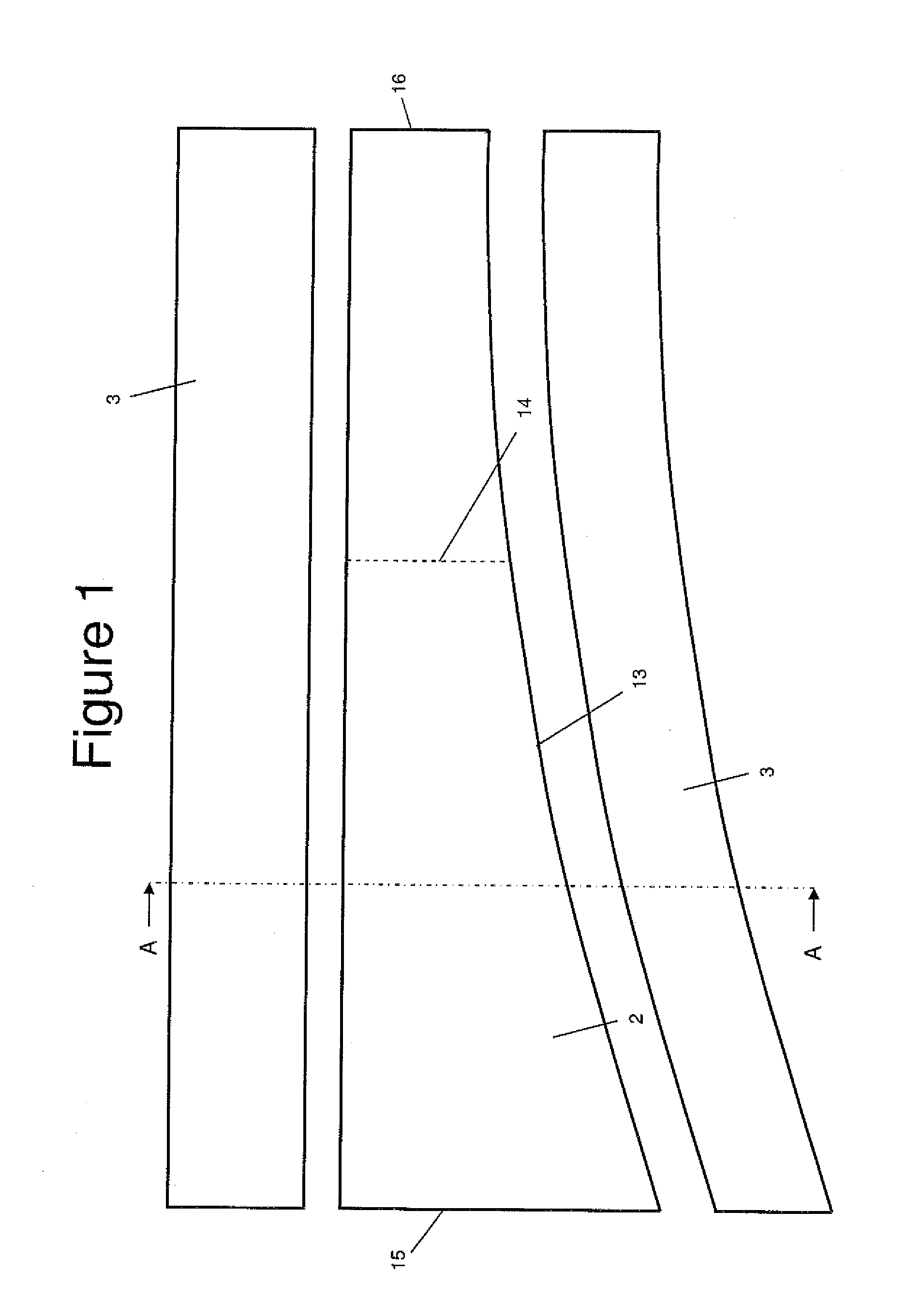

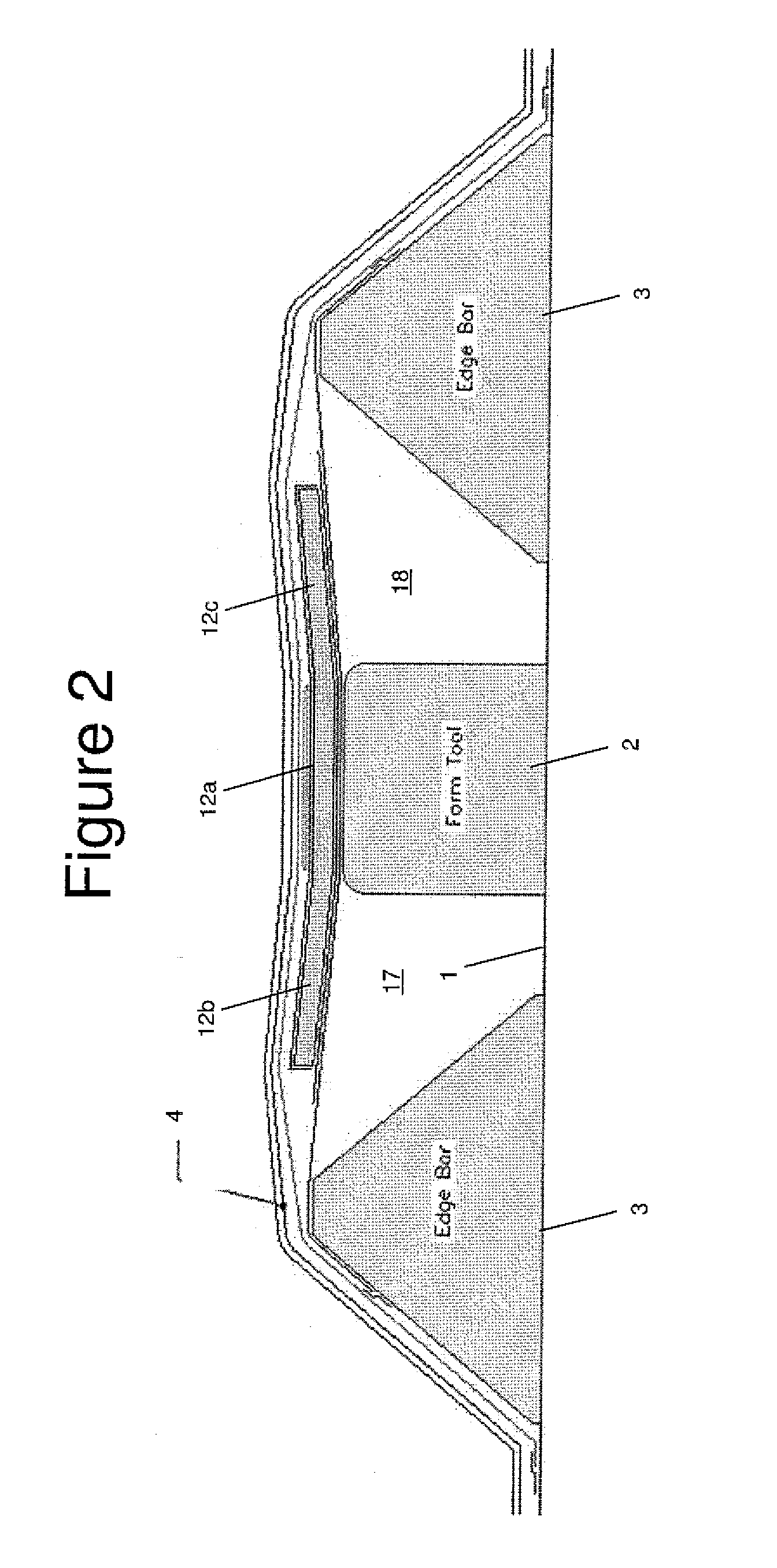

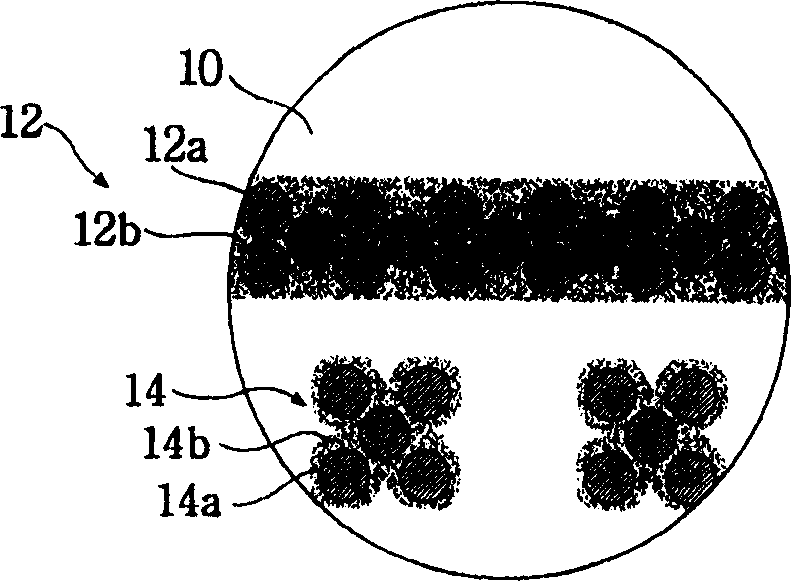

ActiveUS20100310818A1Promote resultsLess wrinklingLayered productsEfficient propulsion technologiesPressure differenceMechanical engineering

A method of moulding a charge (12) during the manufacture of a composite part. The method comprises: placing the charge and a diaphragm (4) on a male tool, the charge having a first part (12a) which is positioned above a top of the male tool (2) and a second part (12b, 12c) which projects to one side of the maletool; and progressively deforming the second part of the charge against a side of the male tool by applying a pressure difference across the diaphragm and stretching the diaphragm over the male tool as the pressure difference is applied. The diaphragm has a tensile modulus in the plane of the diaphragm which is greater than 5 MPa. Optionally a support membrane may be positioned on a opposite sides of the charge. In the case where a support membrane is used, then the diaphragm has a stiffness in the planeof the diaphragm which is higher than the stiffness of the support membrane in the plane of the support membrane.

Owner:AIRBUS OPERATIONS LTD

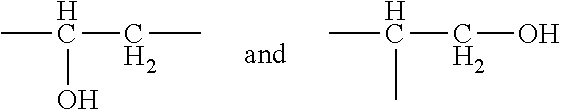

Hyrophilic ethylene oxide free emulsifier comprising dendrimeric polyhydroxylated ester moieties

ActiveUS20160102179A1Improve wettabilityDecrease solubilityBiocideCosmetic preparationsPersonal carePolyester

Owner:MOMENTIVE-PERFORMANCE MATERIALS GMBH

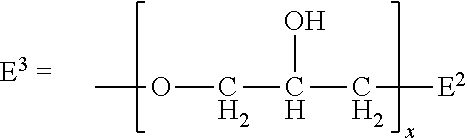

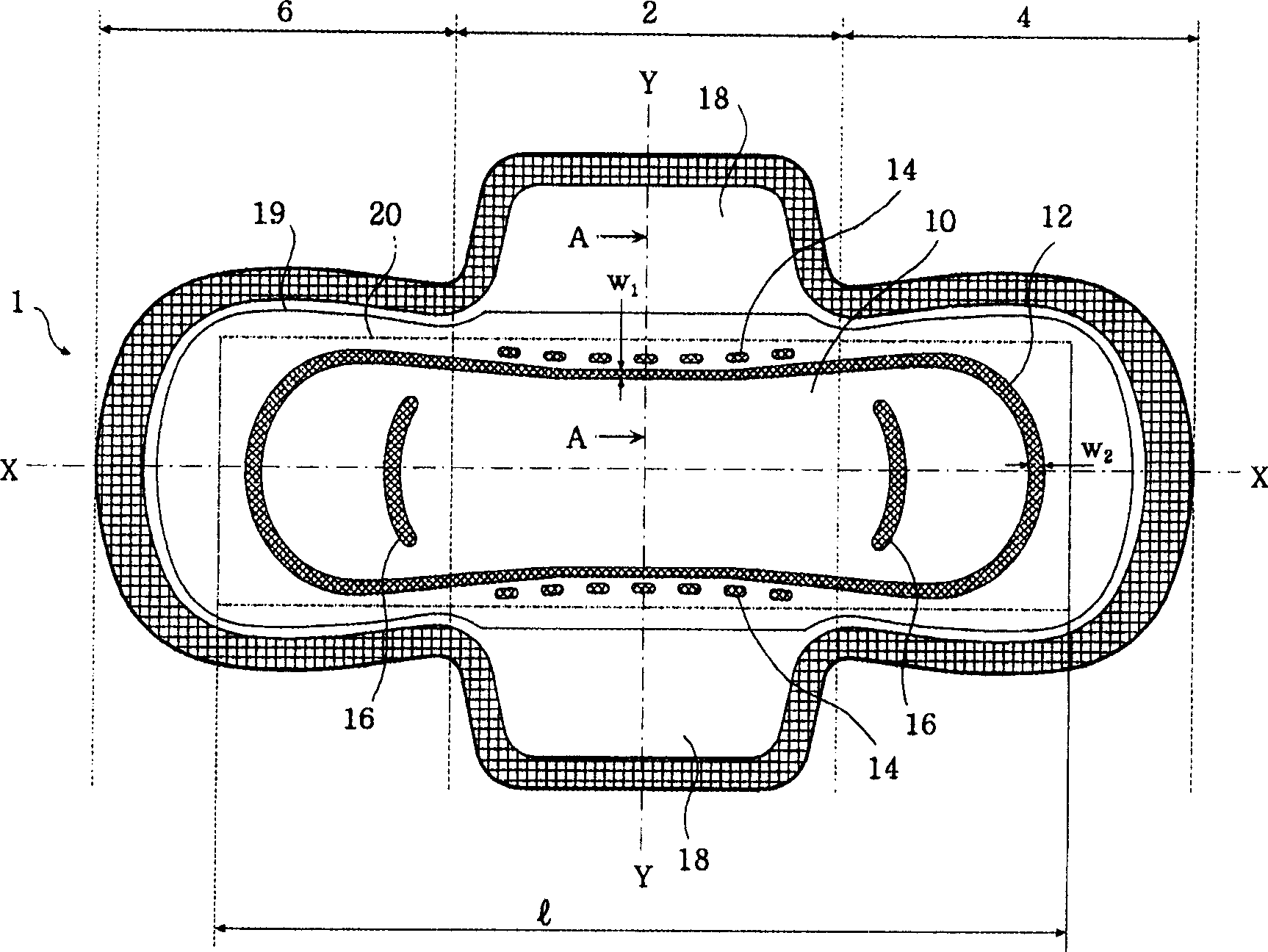

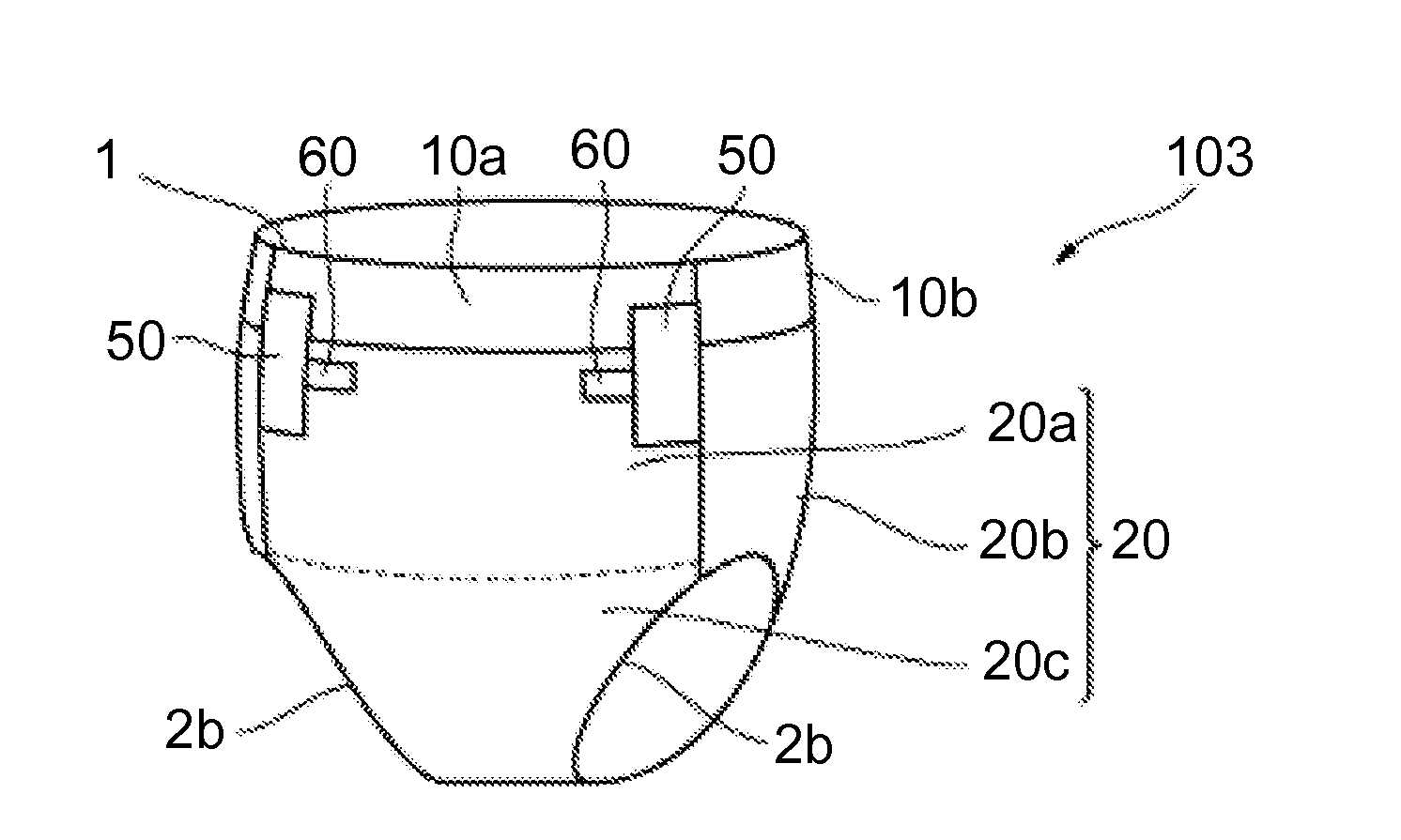

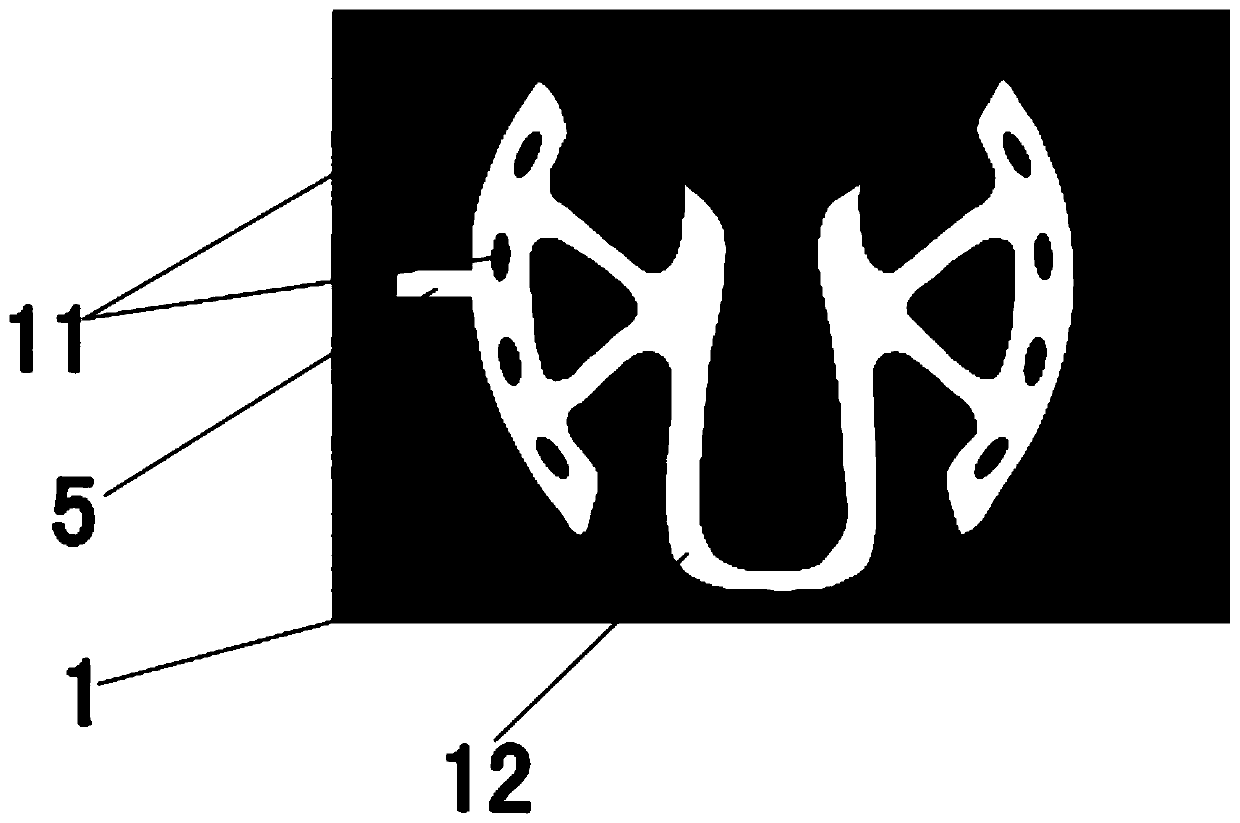

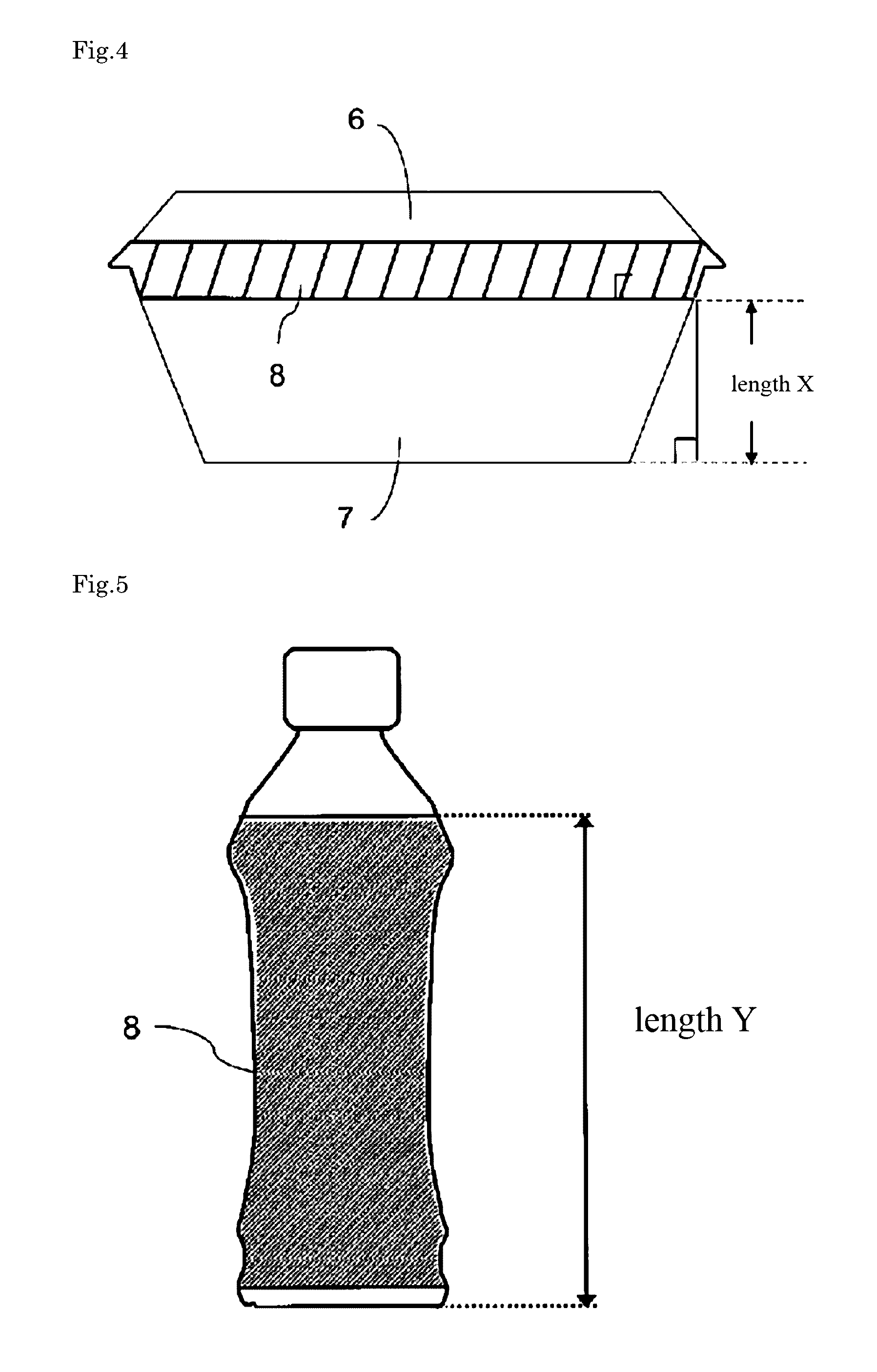

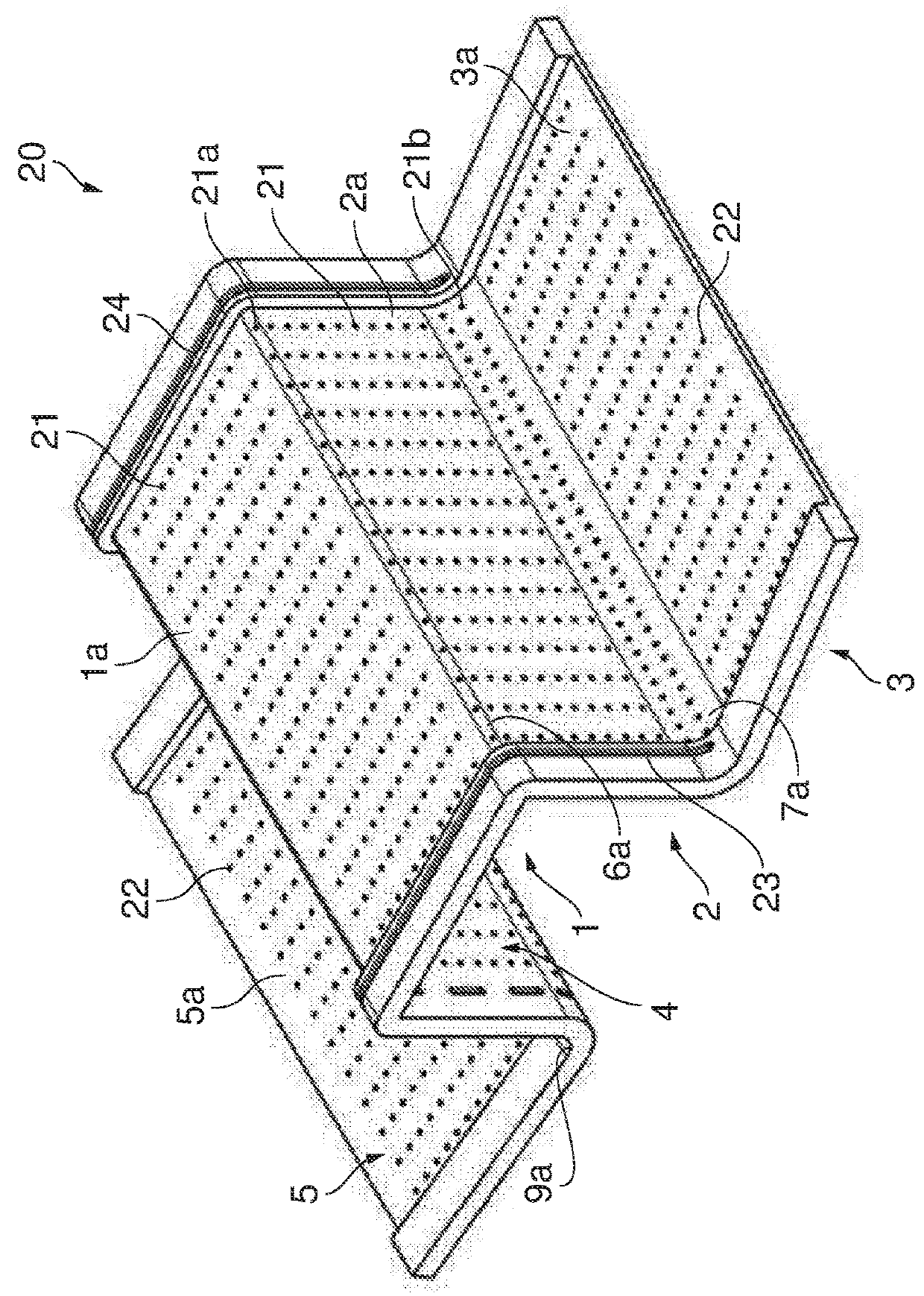

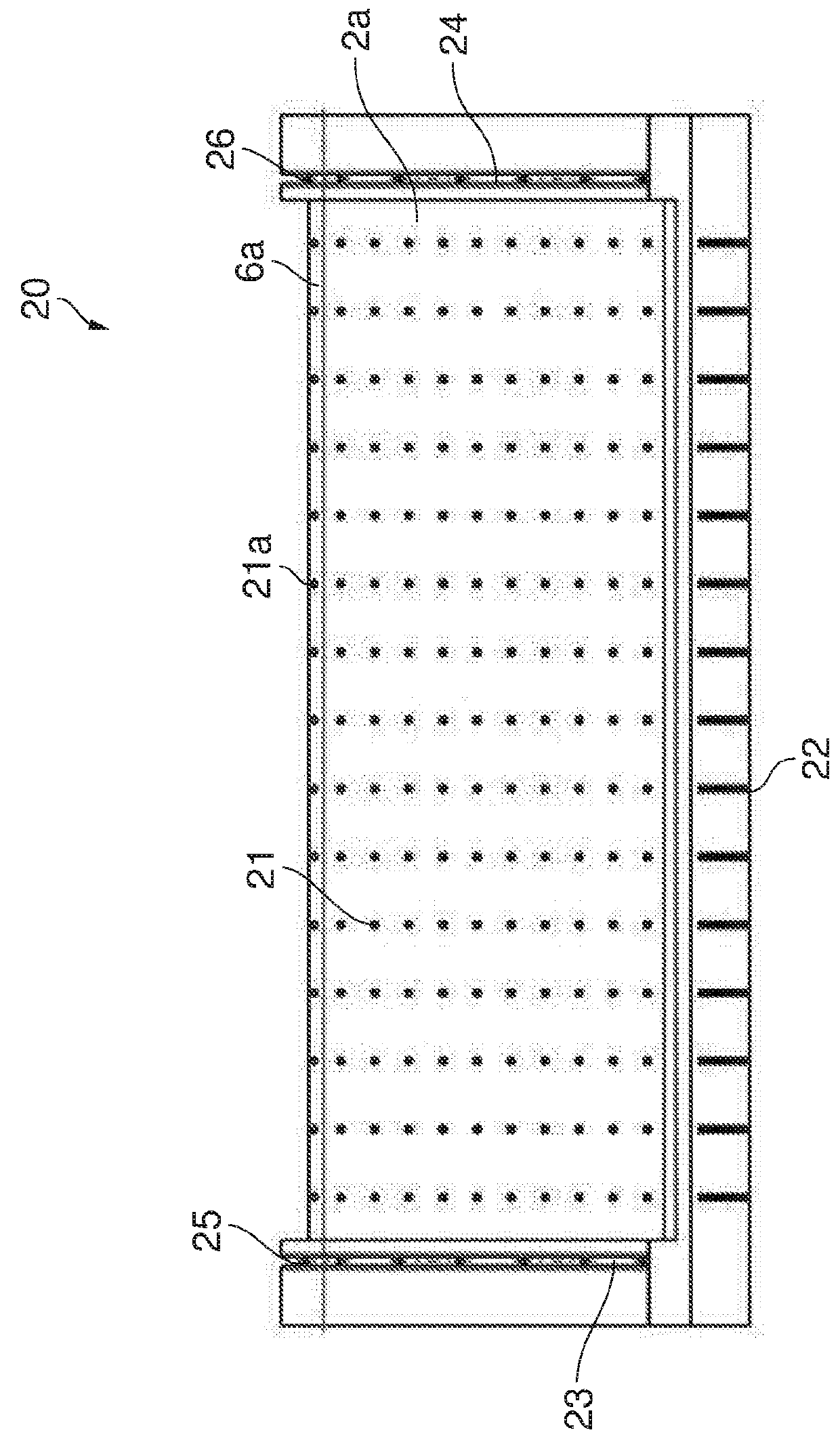

Absorbent product which is equipped with macro-embossing constituted of a plurality of micro-embossing and has increased function to prevent bunching and leakage and increased aesthetic effect

InactiveCN1911198ALess wrinklingImprove leakage prevention effectAbsorbent padsBandagesEngineeringAlong edge

The subject of the invention is to provides an absorbent product which is equipped with macro-embossing constituted of a plurality of micro-embossing and has an increased function to prevent bunching and leakage and increased aesthetic effects. The absorbent product is equipped with a first macro-embossing which extends adjacently along edge part of an absorbent region in the main body including a liquid-permeable upper sheet, a liquid-impermeable lower sheet, and a absorbent region located between the upper sheet and the lower sheet and is formed by performing pressure bonding on the upper sheet and the absorbent region, and a second macro-embossing which extends adjacently to the macro-embossing in the longitudinal direction of the main body and is formed by performing pressure bonding on the upper sheet and the absorbent region. The first macro-embossing and the second macro-embossing comprises a continuous linear pattern, a pattern of a series of discontinuous dots, a curved line, a straight line, or their combination. One of them comprises a plurality of micro-embossing and many sets of intermediate pressure bonding parts having a pressure bonding thickness different from the micro-embossing around the micro-embossing.

Owner:YUHAN KIMBERLY LTD

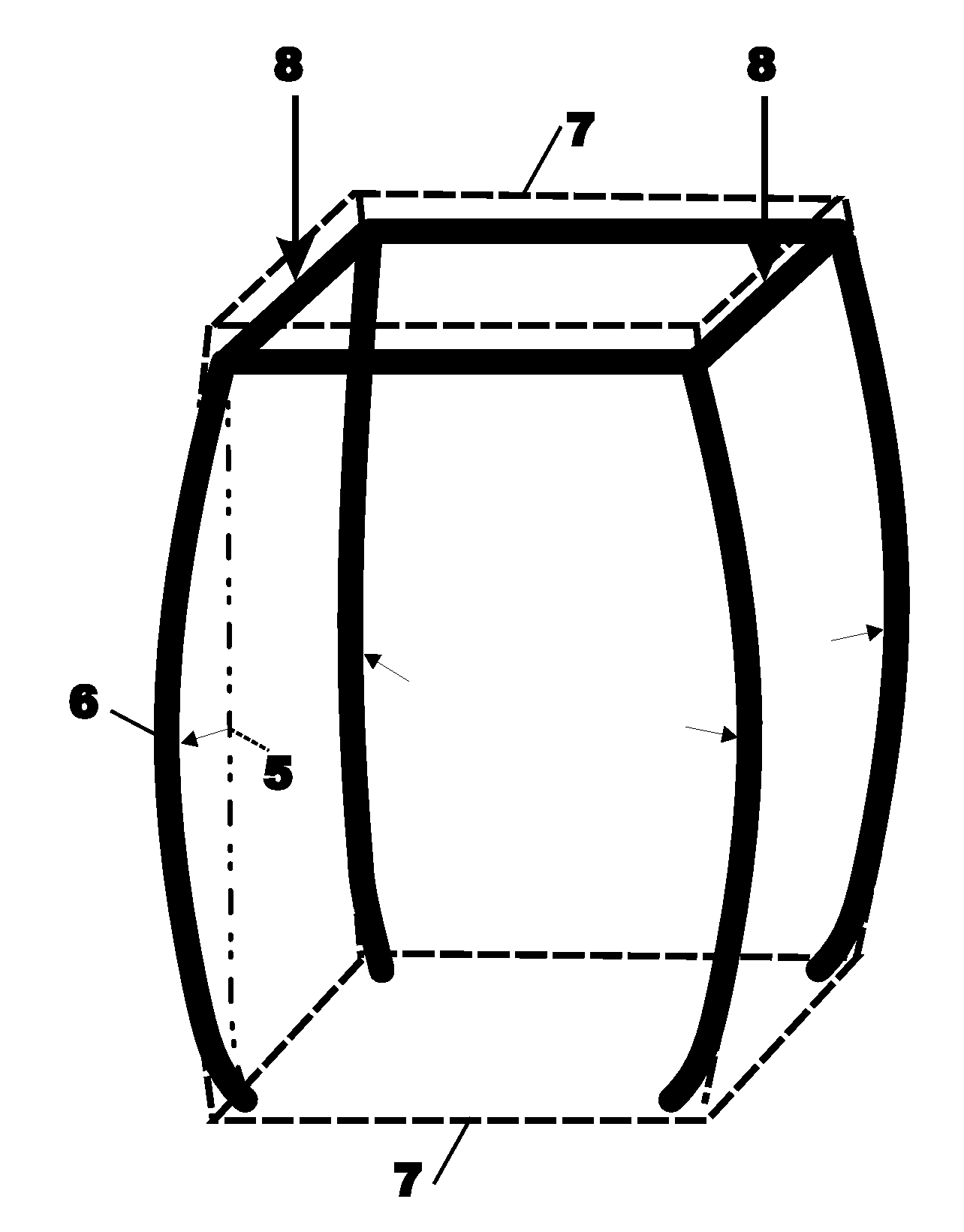

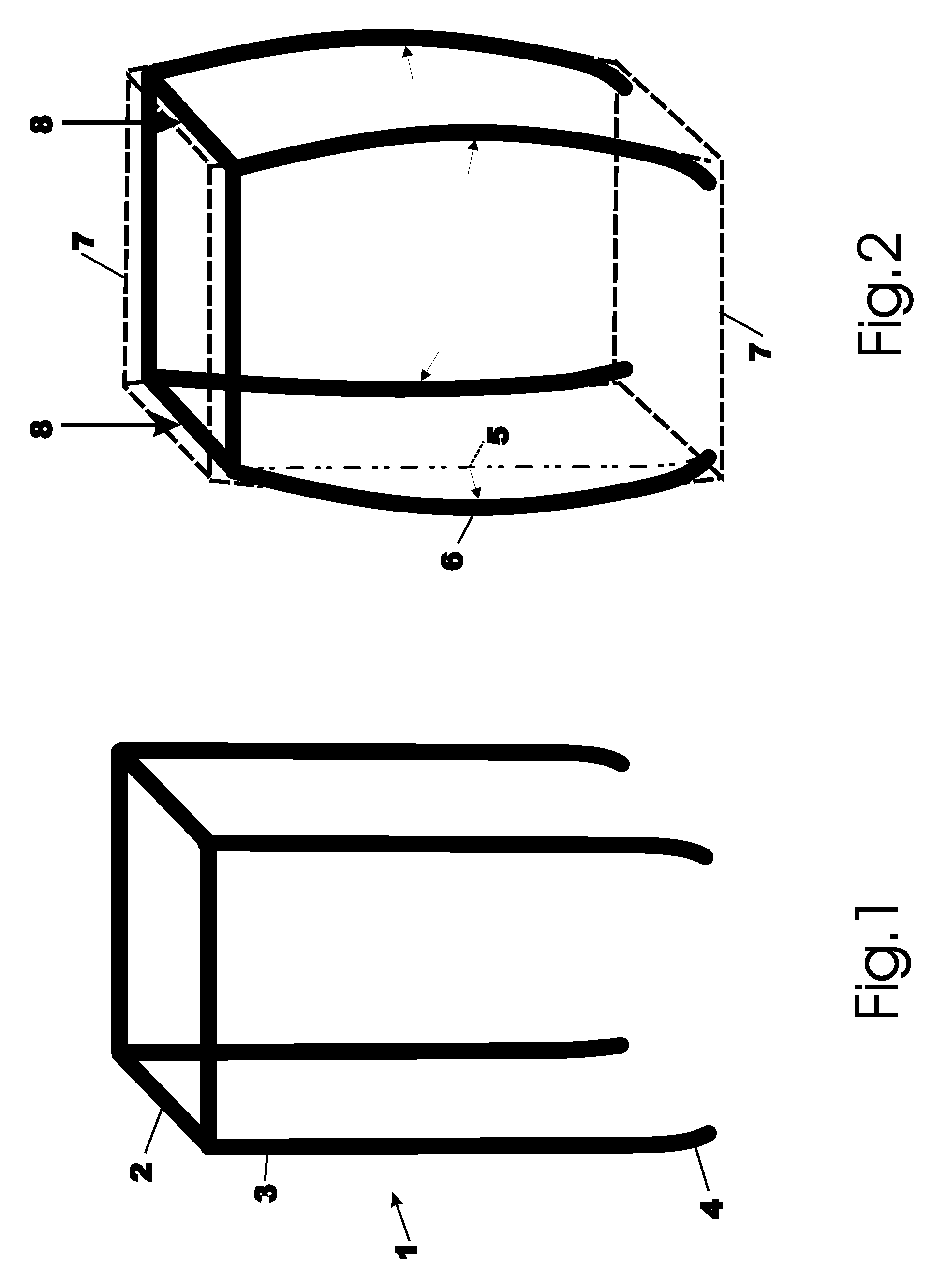

Bag holder

InactiveUS8322663B2Simple and improvedEasy constructionRefuse receptaclesStands/trestlesStable stateEngineering

A bag holder adapted to fit inside a flexible bag to support the bag comprising a rectangular frame having four vertical legs connected to and depending from the frame. Each of the legs has an inwardly bent portion at the lower end thereof to facilitate sliding entry into the bag. The legs are flexible such that upon pushing down on the frame the bend portion provides that the legs bow outwardly against the inside of the bag, shaping the bag into an unwrinkled and more rigid and stable state. With the frame reacting against the bag, the frame can resist a greater downwards vertical load which assists in the filling of the bag.

Owner:BOSIK ANTHONY

Heat shrinkable polyolefin film and process for producing the same

ActiveUS20100093965A1Improve shrinkageExcellent perforated line openabilityMouldsSynthetic resin layered productsPolymer sciencePolyolefin

The inventive heat-shrinkable polyolefin film is high in shrinkability in the longitudinal direction that is its main shrinkage direction and excellent in finish properties after shrinkage, perforated line openability, and thermal blocking resistance. The heat-shrinkable polyolefin film is characterized by particular values with respect to hot-water heat shrinkage ratio in the longitudinal and width directions, right angle tear strength in the width direction, and heat-resistant peel strength.

Owner:TOYO TOYOBO CO LTD

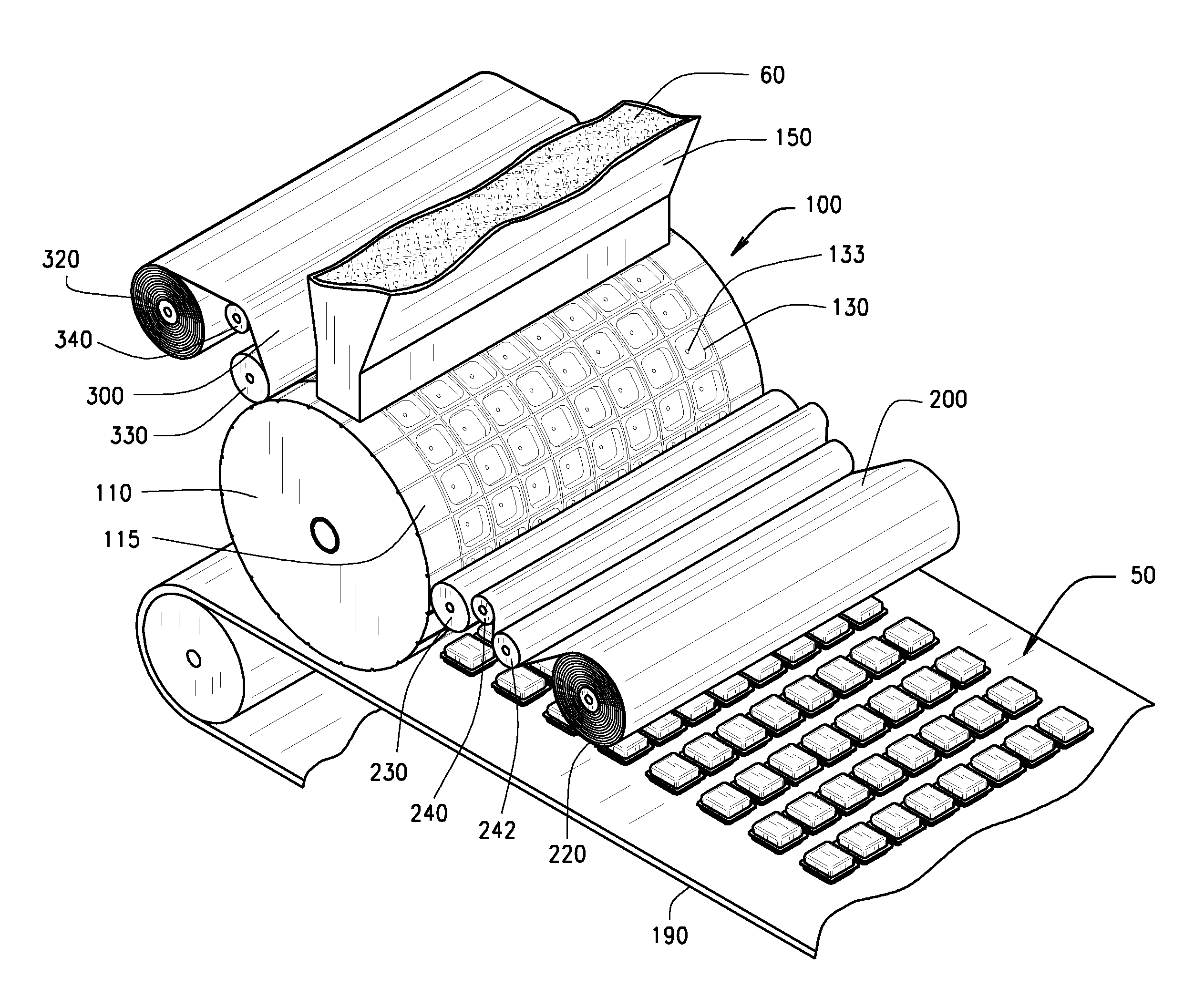

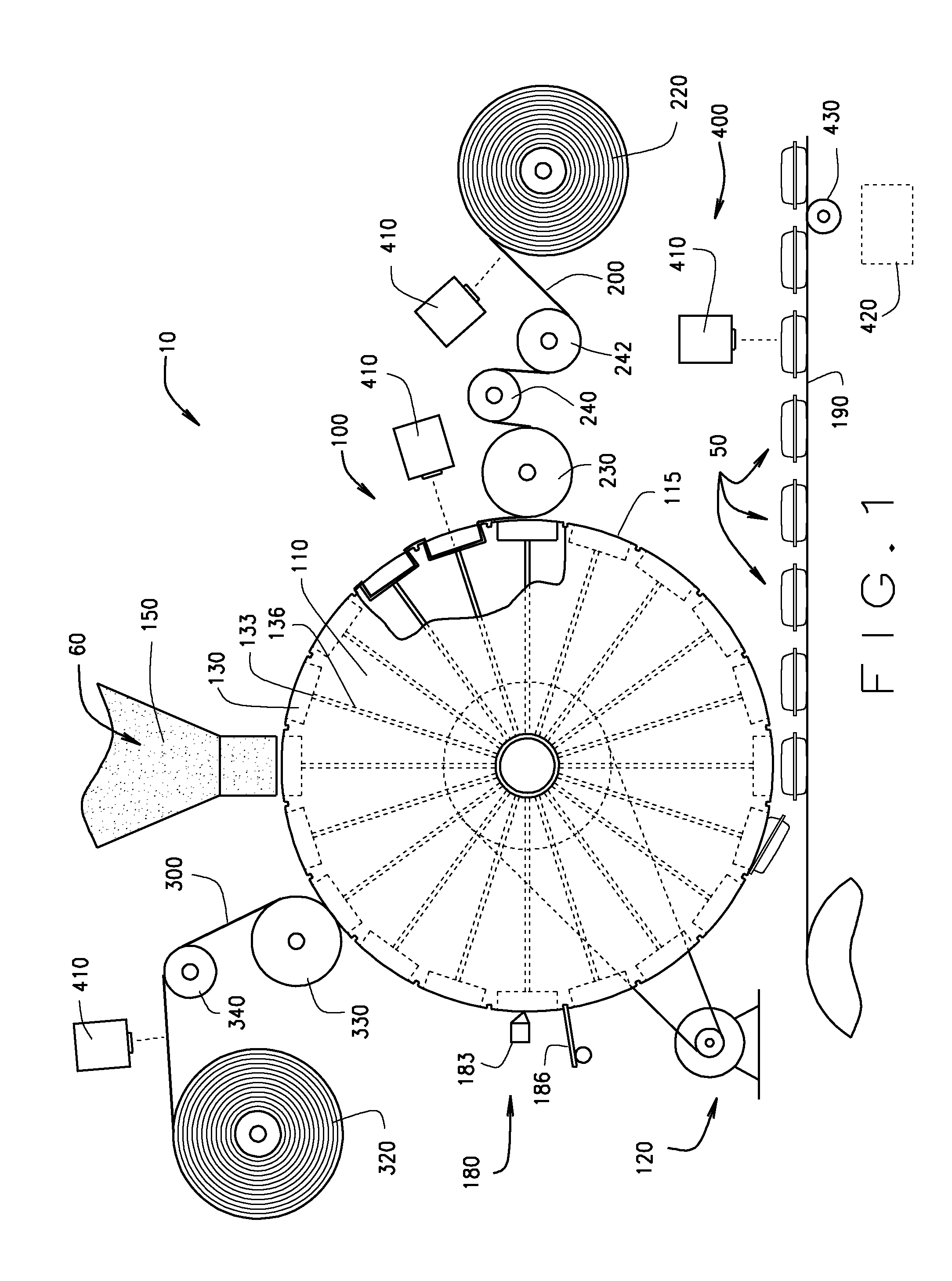

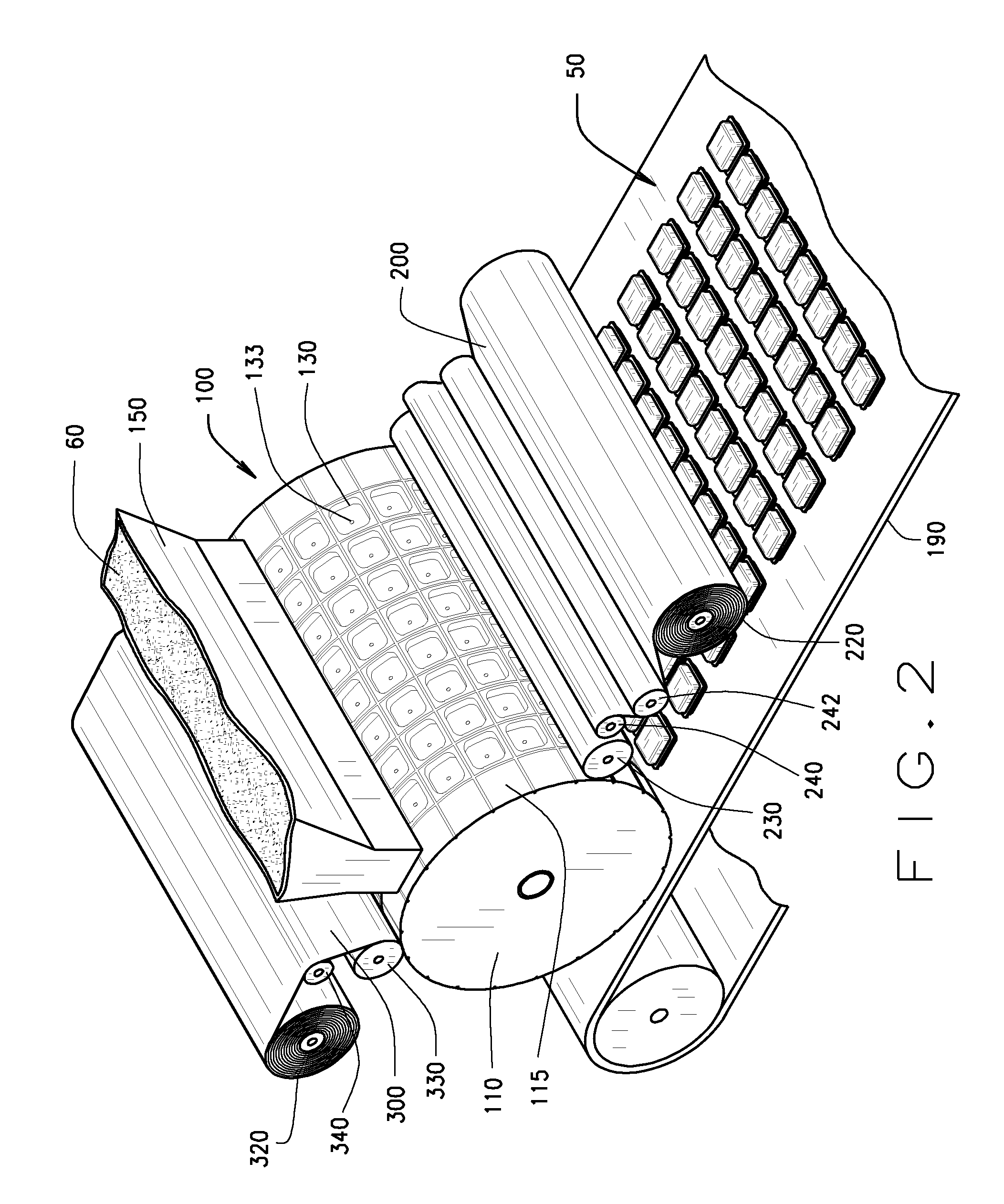

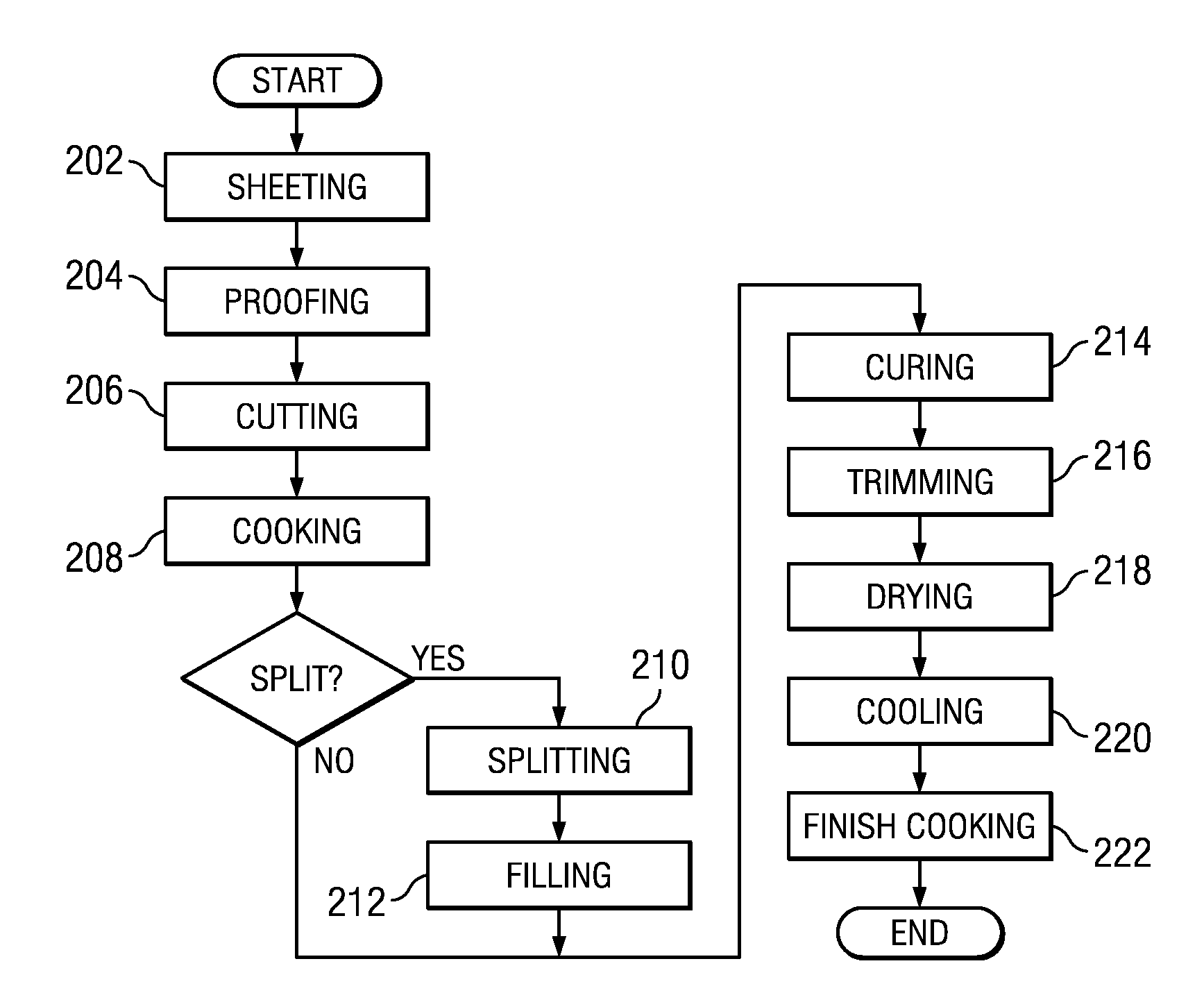

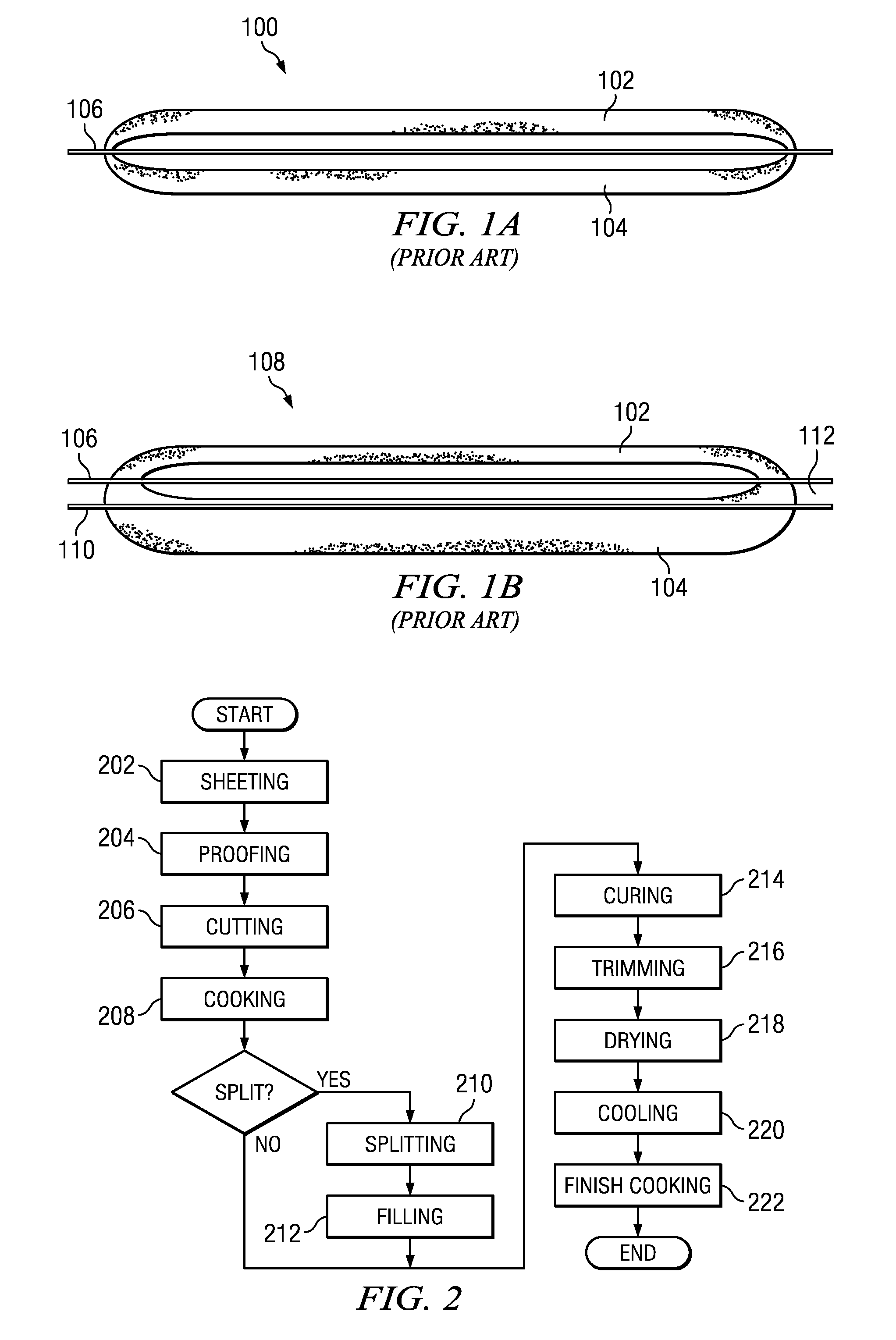

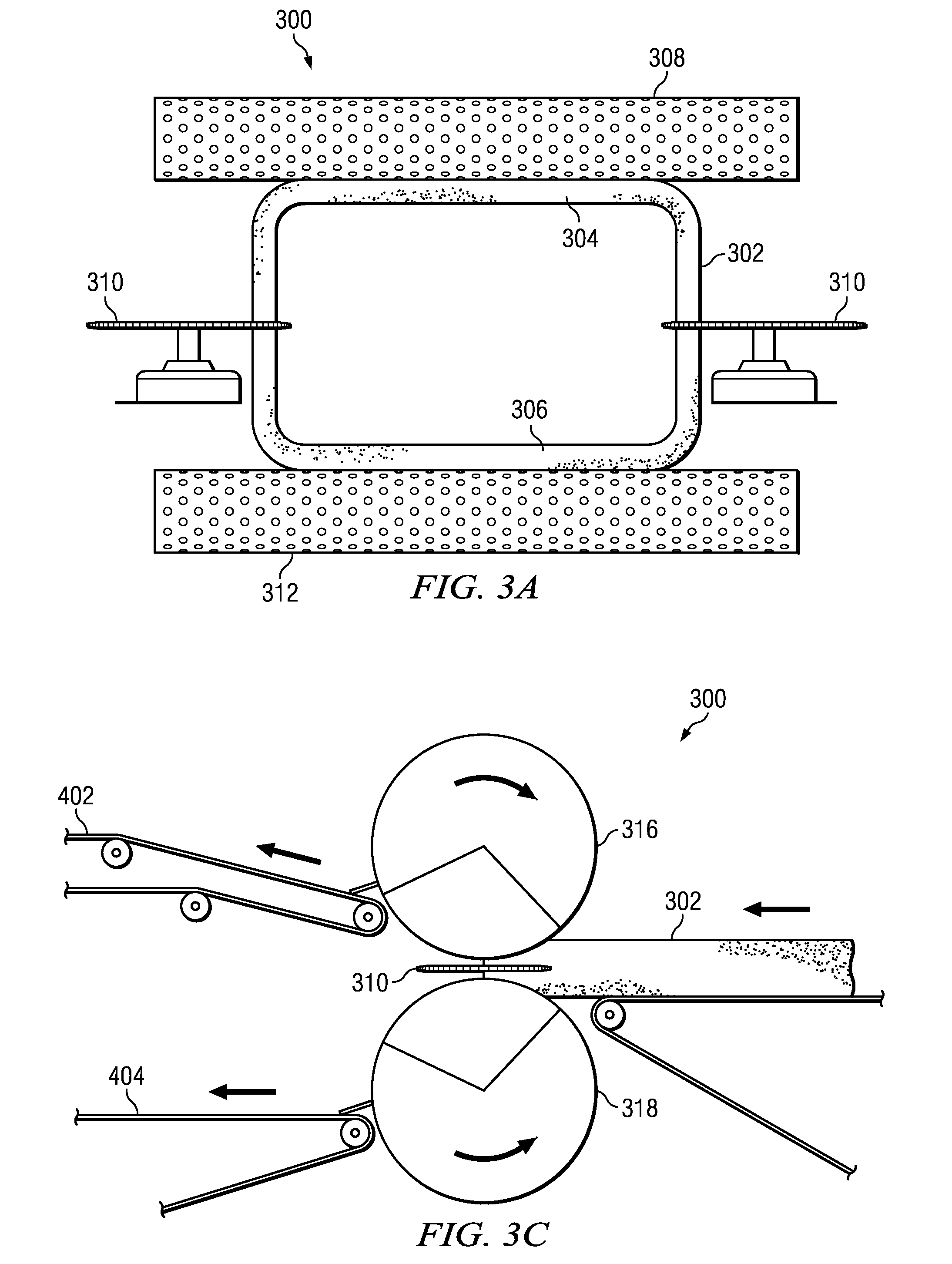

Continuous Process and Apparatus for Making a Pita Chip

InactiveUS20140037789A1Shorter coolingShort curing timeDough treatmentDrying solid materials with heatVacuum assistedMechanical engineering

A continuous process and the accompanying equipment for making a chip product, such as pita chips. The process involves cutting sheeted dough into continuous longitudinal strips, and cooking them to form hollow tubes. In some embodiments, these tubes are split longitudinally. Also disclosed is a vacuum-assisted splitter. These bread tubes or strips are cured in an accelerated process. The bread tube is trimmed into chip-sized pieces. In one embodiment, the pita bread strips are cut into chip-sized pieces using a continuous, low-pressure water jet cutting system. The resulting chip-sized pieces are nearly uniform in size, shape, and texture.

Owner:FRITO LAY NORTH AMERICA INC

Method of moulding a charge

ActiveUS10016949B2Promote resultsLess wrinklingLayered productsWeight reductionEngineeringPressure difference

Owner:AIRBUS OPERATIONS LTD

Stretched laminated film and bag

InactiveUS20100086711A1StructuredBeautifully conductedWrappers shrinkageFlexible coversSurface layerEngineering

A stretched laminated film and bag is provided, in which a packaging operation in thermal shrinkage packaging is effectively performed without the occurrence of fusion and the like between margins when sealing via heat-sealing with a margin portion of an adjacent bag in a layered state, and without of bag whitening in a thermal shrinkage process thereafter. Specifically, a stretched laminated film has at least four layers of: a surface layer (A), an adhesive layer (A), a barrier layer, and a surface layer (B) sequentially laminated in order thereof, in which the melting temperature of the surface layer (A) is only increased no less than 65° C. to no more than 150° C. higher than the melting temperature of the surface layer (B), and the barrier layer is composed of a vinylidene chloride copolymer, and the melting temperature of the barrier layer is no less than 130° C. to less than 160° C.

Owner:ASAHI KASEI CHEM CORP

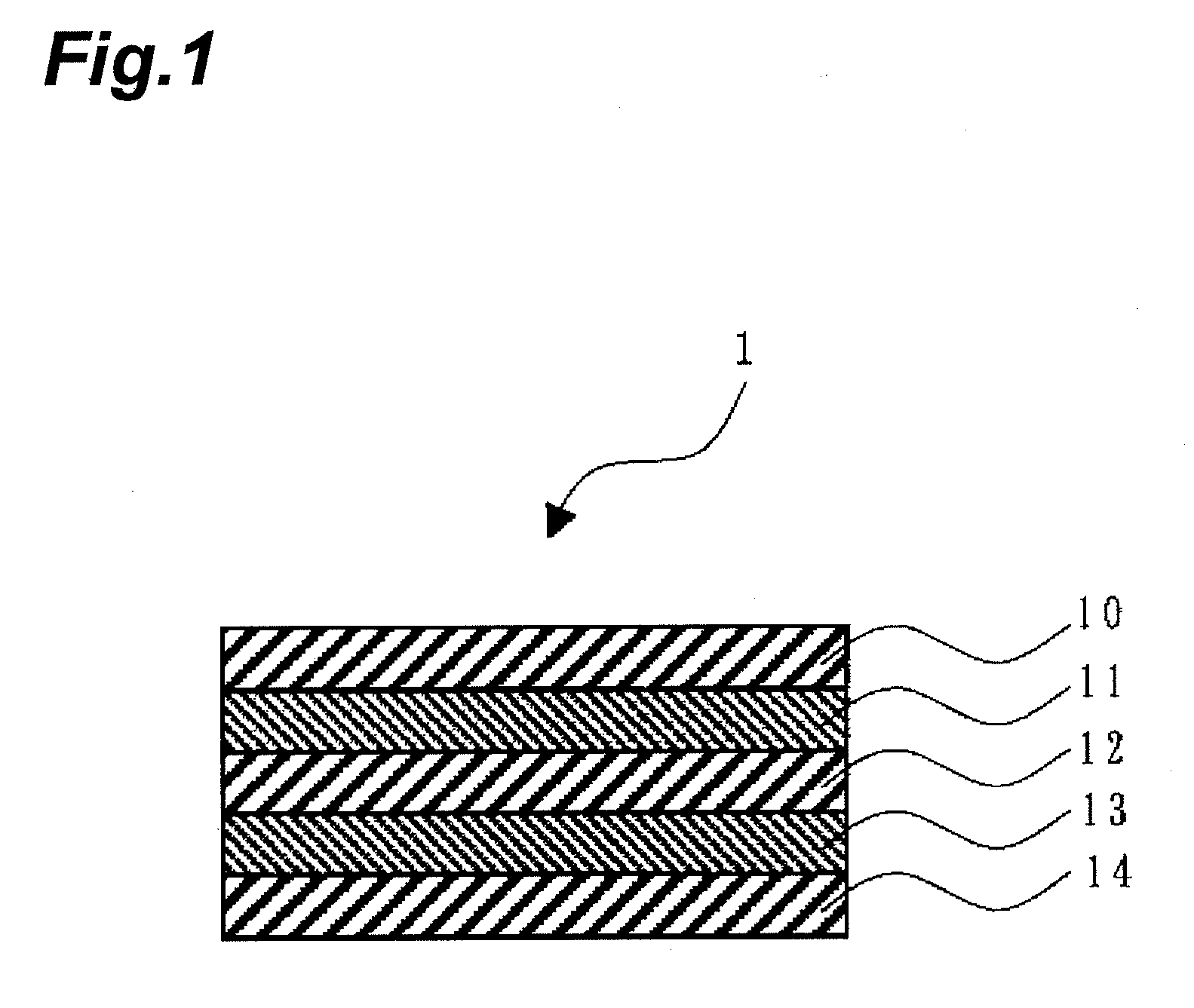

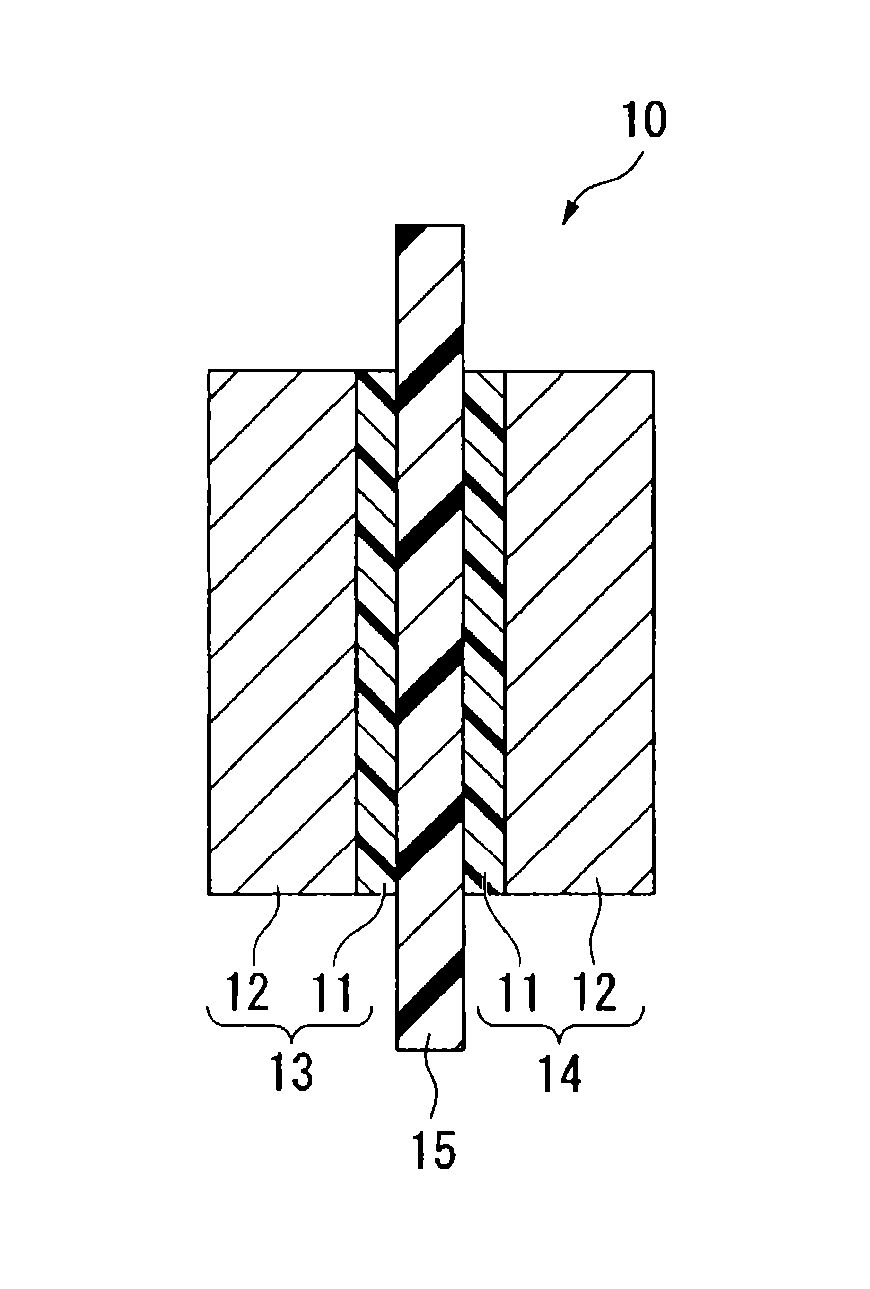

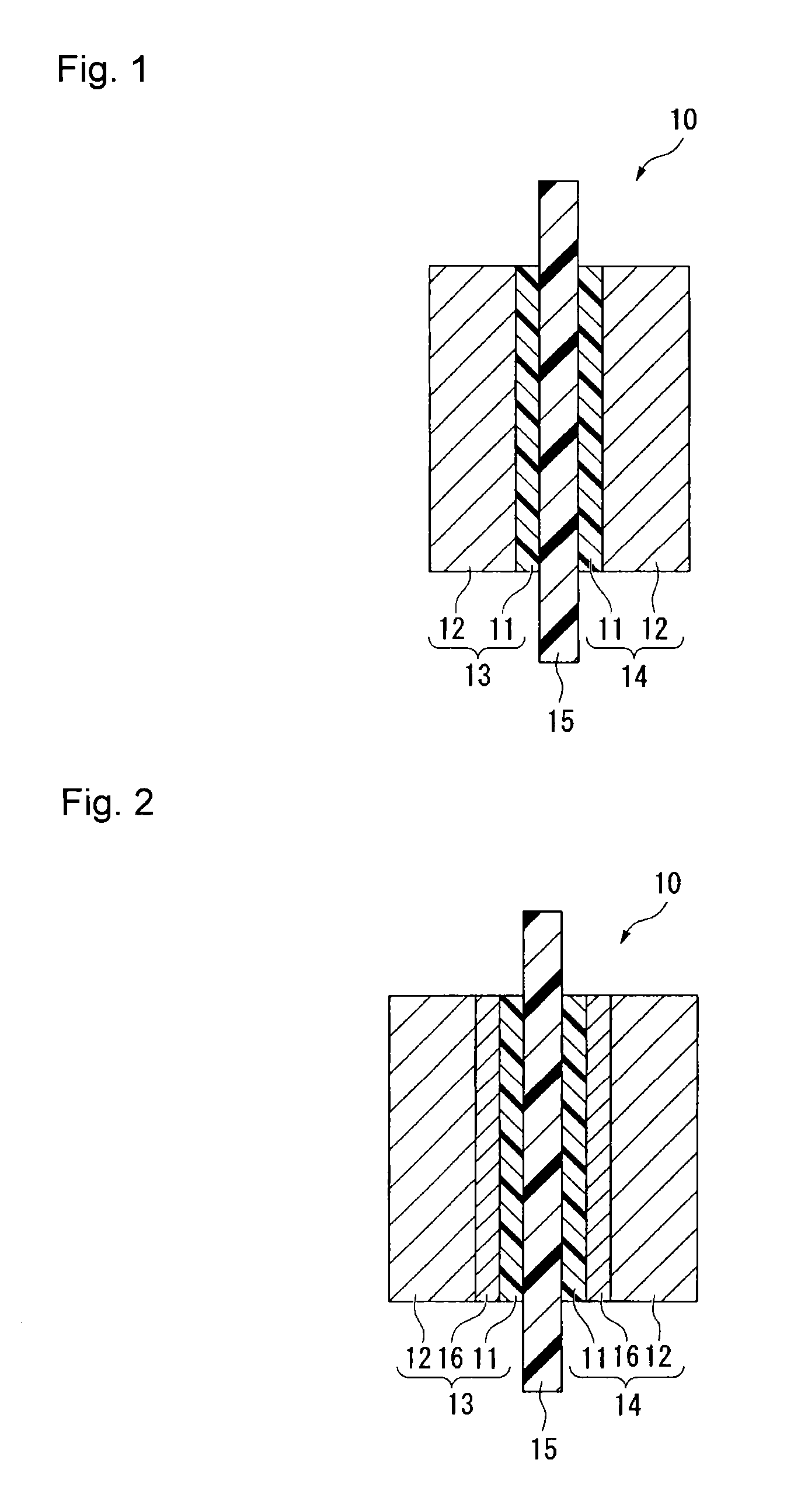

Non-woven fabric base material for lithium ion secondary battery separator and lithium ion secondary battery separator

ActiveUS20150372269A1Lower internal resistanceImprove productivityLi-accumulatorsCell component detailsLithiumFiber

A non-woven fabric base material for a lithium ion secondary battery separator composed mainly of a polyethylene terephthalate fiber, characterized in that the non-woven fabric base material comprises a polyethylene terephthalate binder fiber and a crystallized polyethylene terephthalate fiber, and the content of a polyethylene terephthalate binder fiber having a fiber length of 2.5 mm or less is 10 to 60 mass %.

Owner:MITSUBISHI PAPER MILLS LTD

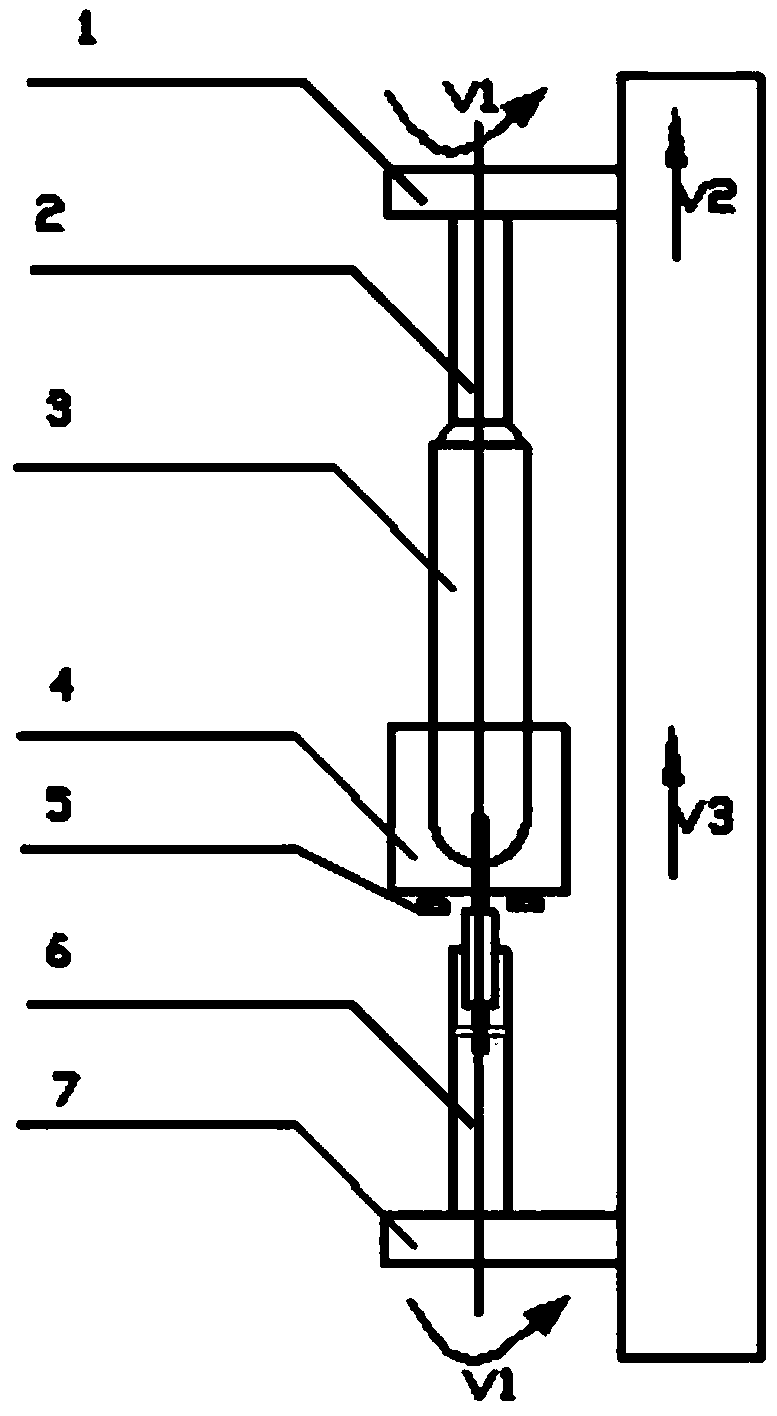

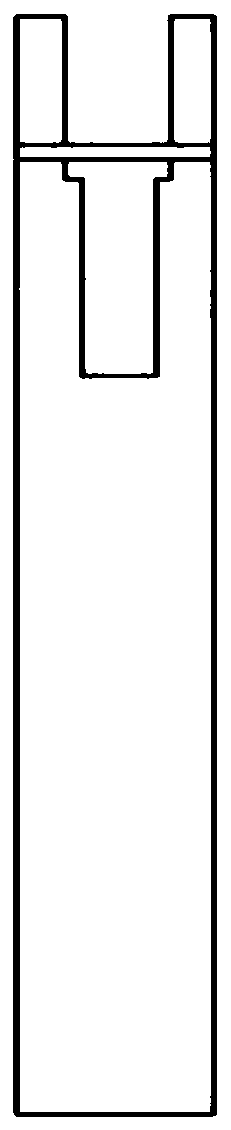

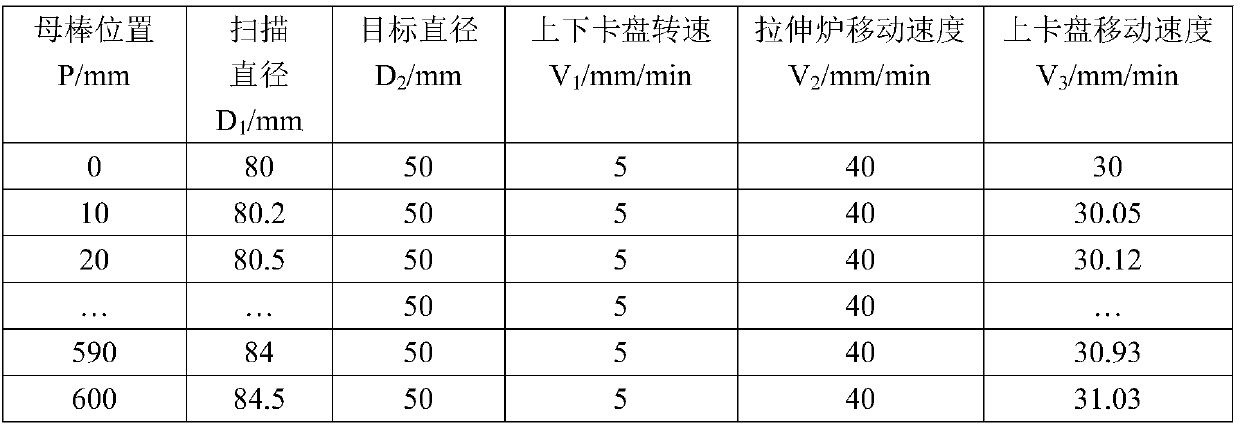

Stretching device and stretching method for VAD sintered optical fiber prefabricated base bar

The invention relates to a stretching device and a stretching method for a VAD sintered optical fiber prefabricated base bar. The stretching device comprises an upper chuck, a stretching furnace and alower chuck which are successively arranged along a vertical direction. The stretching method comprises the following steps: measuring and collecting diameter of the optical fiber prefabricated basebar on each position; calculating an upward moving rate of the upper chuck and confirming the upward moving rate of the upper chuck according to the required diameter of stretched core rod, the upwardmoving rate of the stretching furnace and the diameter of the stretched optical fiber prefabricated base bar; synchronously rotating the upper chuck and the lower chuck at a same rotation rate beforeheating and stretching, and then starting to heat the lower end of the optical fiber prefabricated base bar by starting the stretching furnace; controlling the upper chuck to calculate the upward moving rate and stretching the optical fiber prefabricated base bar, thereby forming a core rod. According to the invention, stretching quality and efficiency of optical fiber prefabricated base bar canbe guaranteed, dosage of guiding rod can be reduced and welding times of guiding rod can be reduced.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

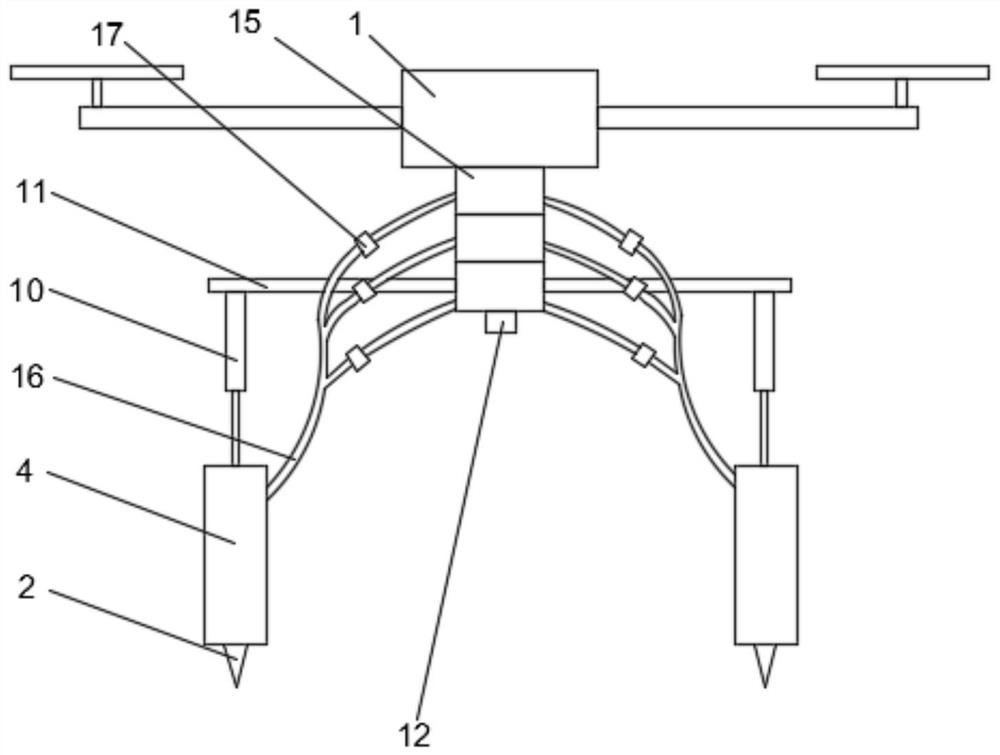

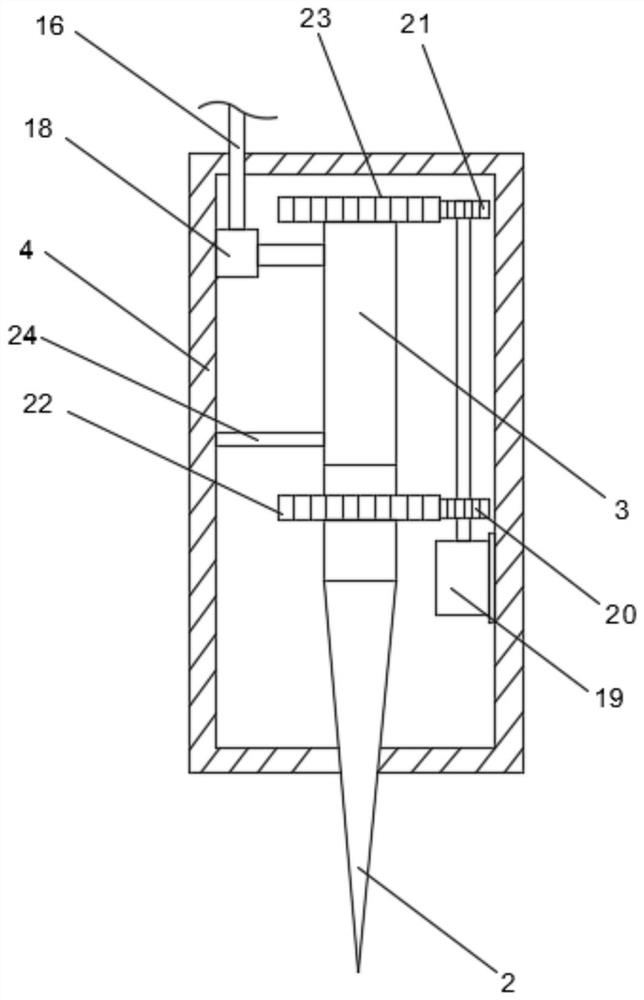

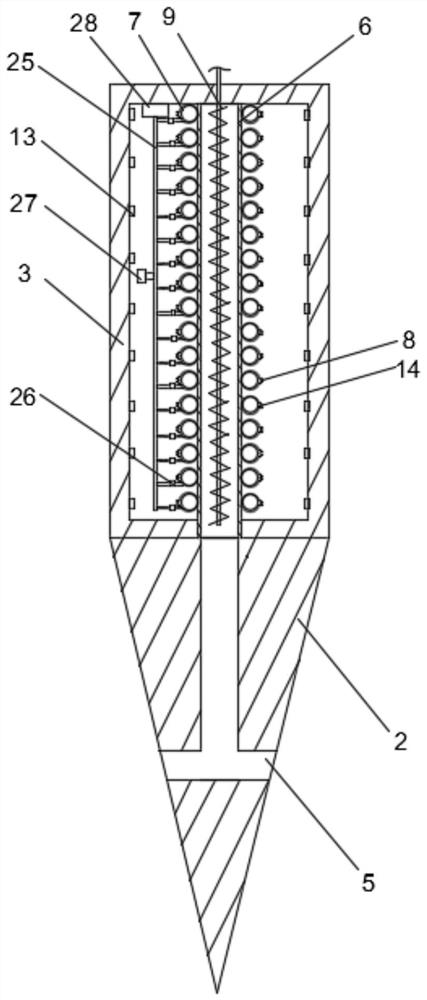

Unmanned aerial vehicle with forest heavy metal spectrum inversion and sample collection functions

ActiveCN112285033AReduce residualLess wrinklingWithdrawing sample devicesColor/spectral properties measurementsUncrewed vehicleStructural engineering

The invention discloses an unmanned aerial vehicle with forest heavy metal spectrum inversion and sample collection functions. The unmanned aerial vehicle comprises an unmanned aerial vehicle body, asample collection device and a plurality of sets of sampling mechanisms, wherein the sampling mechanisms are arranged on the sample collection device and communicate with the sample collection device;the sample collection device is arranged at the bottom part of the unmanned aerial vehicle body; each sampling mechanism comprises a drill bit, an inner cylinder and an outer cylinder, the bottom part of the inner barrel and the top part of the drill bit rotate relatively, the inner wall of the outer barrel abuts against the outer wall of the drill bit, a suction mechanism is arranged on the inner wall of the outer barrel, a cavity used for being communicated with the inner barrel is formed in the drill bit, the tail end of the cavity is flush with the outer wall of the drill bit, a first hose fixedly connected with the inner barrel is arranged in the inner barrel, the cavity is communicated with the first hose, the first hose is sleeved with a plurality of annular second hoses, and magnetic sheets are arranged on outer walls of second hoses. According to the unmanned aerial vehicle, accumulation of soil on the inner wall of the conveying pipeline can be reduced, the situation that the soil is difficult to remove due to wrinkles on the inner wall of the pipeline can be avoided, and the situation that data errors generated by subsequent detection work are too large is avoided.

Owner:海南省林业科学研究院

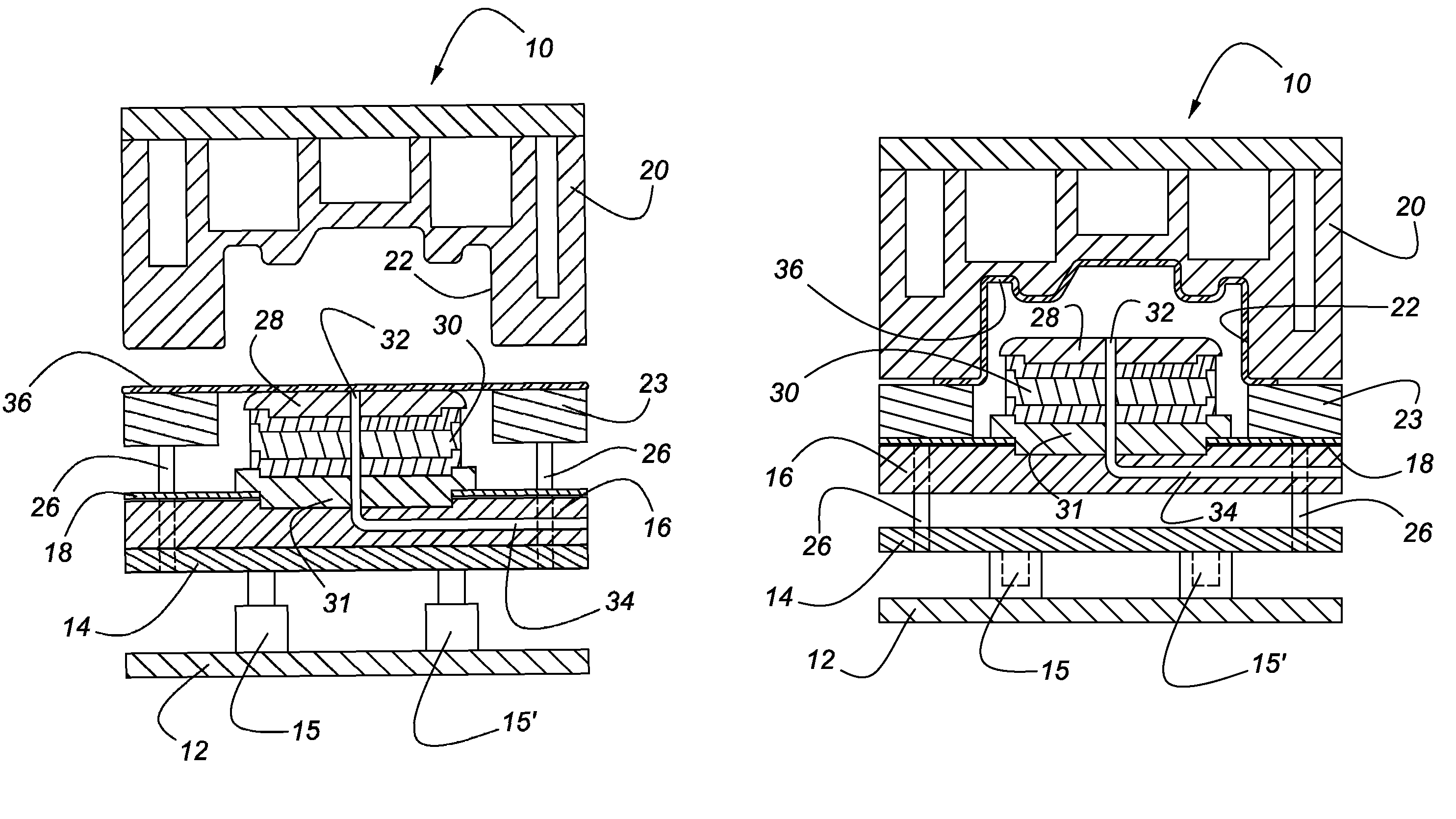

Method and apparatus for gas management in hot blow-forming dies

A method and apparatus for forming a sheet of ductile material by superplastic forming is disclosed. The method is directed to first creating a pre-form by mechanical forming in which the pre-form is created with a die and punch. Thereafter the pre-form is subjected to gas pressure in a forming cavity to complete formation of the part. A metallic gasket is provided to ensure that no pressurized gas escapes from the forming cavity.

Owner:FORD GLOBAL TECH LLC +1

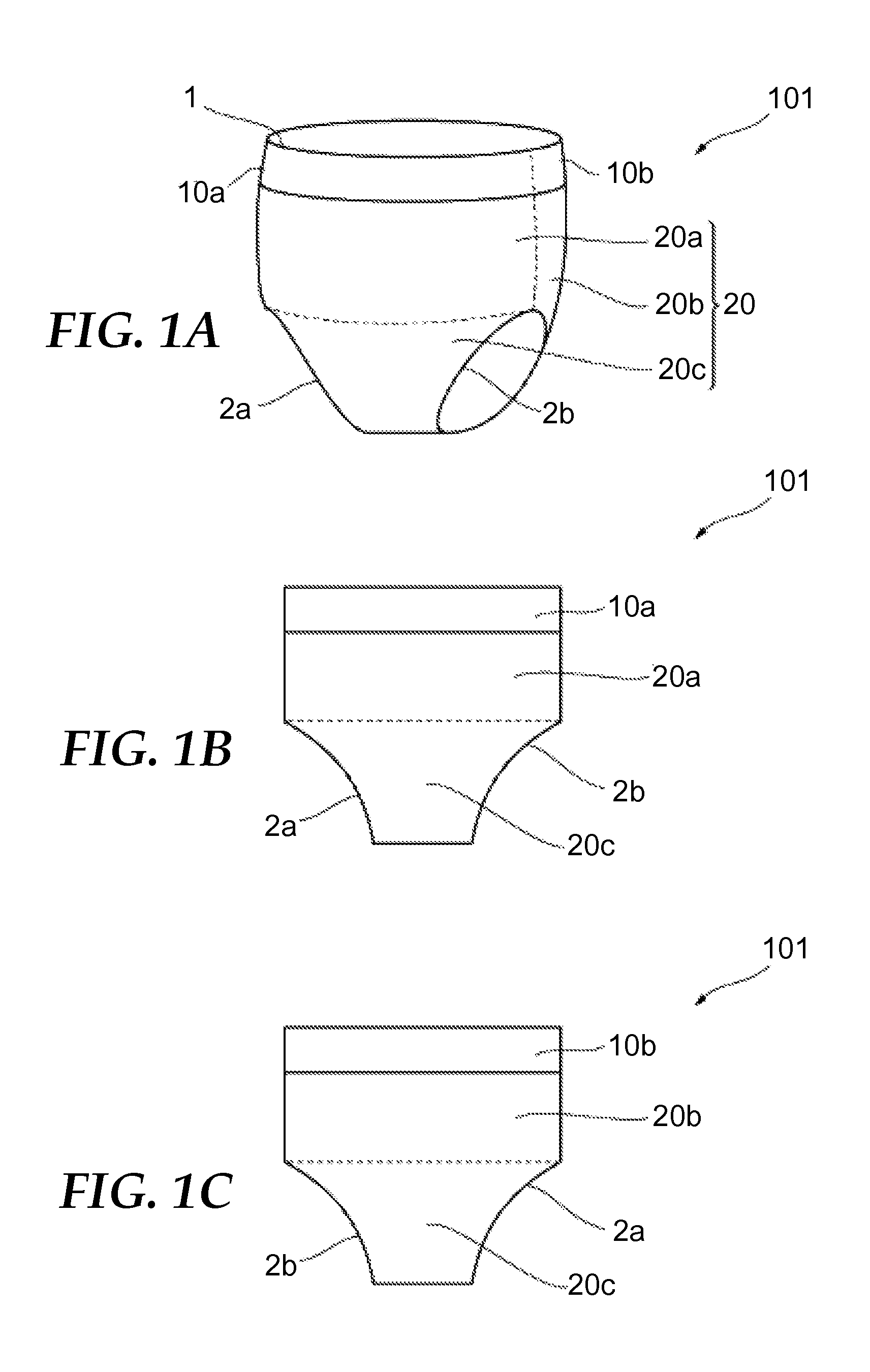

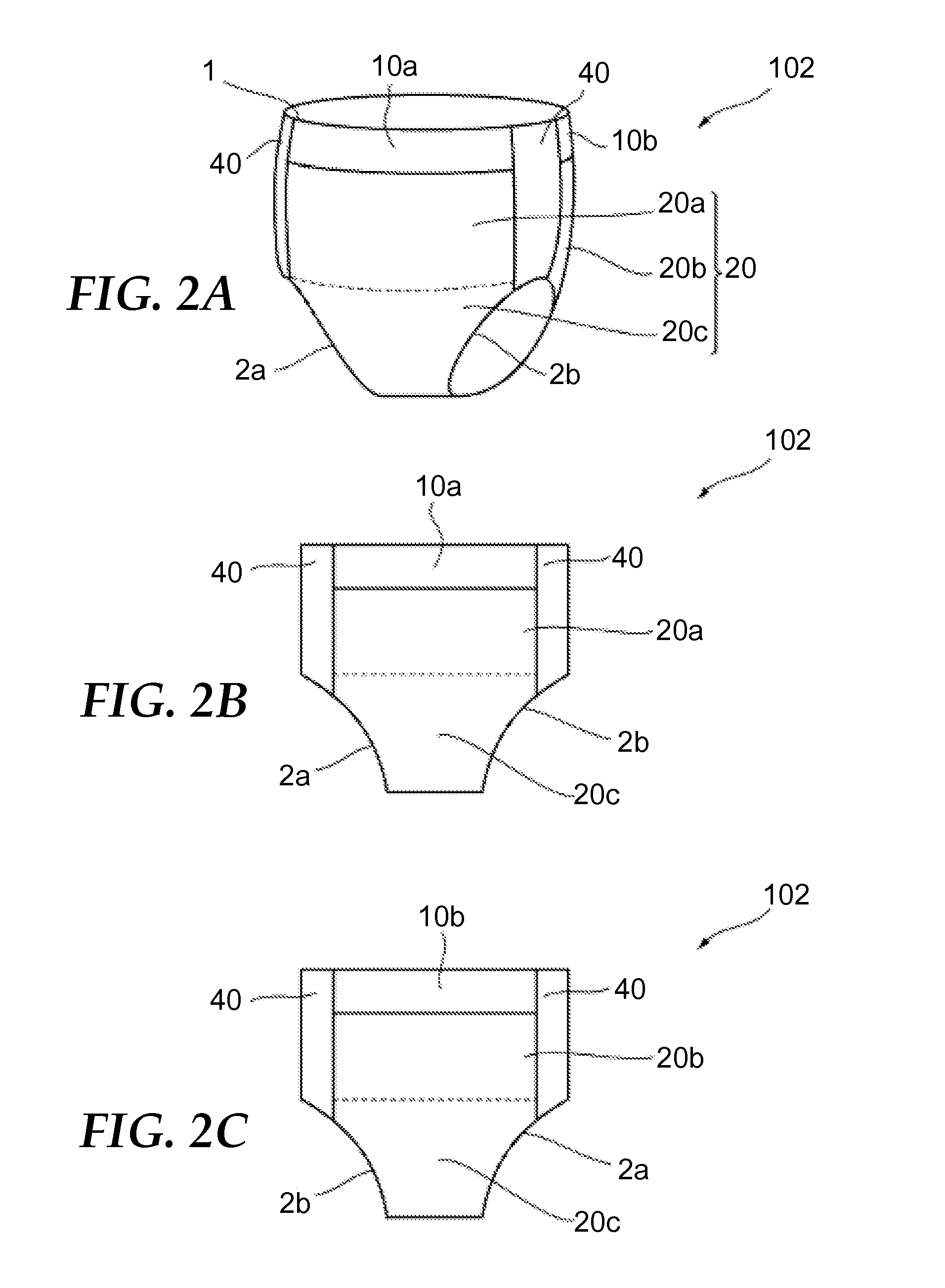

Diaper

InactiveUS20140343522A1Good lookingEliminate bulkinessBaby linensTamponsMechanical engineeringCrotch

A diaper includes an abdominal-side waist portion and a back-side waist portion forming at least a portion of a waist opening portion 1, as well as a body portion including an abdominal-side body portion, a back-side body portion, and a crotch portion forming at least a portion of a pair of leg opening portions. Any portion of the diaper except the crotch portion is constituted by a laminate including a plurality of elastomeric molded bodies arranged at intervals from an extensible fiber aggregate, and the elastomeric molded bodies have regions that are joined with the extensible fiber aggregate and regions that are separated from the extensible fiber aggregate.

Owner:3M INNOVATIVE PROPERTIES CO

Laundry dryer and washer dryer

InactiveUS20120159808A1Few wrinkleLow powerDrying gas arrangementsDrying chambers/containersLaundryHigh pressure

Provided is a laundry dryer including: a first duct (9) having a first outlet (8) which opens at a rear side of a drum (1) for storing laundry, and a second duct (11) with a second outlet (10) which opens at a front side of the drum (1). The second outlet (10) has a narrower cross-sectional area, through which air passes, than the first outlet (8). The first or second duct (9, 10) is selectively switched during the drying process. A larger volume of dry air is blown from the first outlet (8) under selection of the first duct (9) than the second duct (11). The dry air is blown from the second outlet (10) at higher pressure and higher velocity under selection of the second duct (11) than the first duct (9).

Owner:PANASONIC CORP

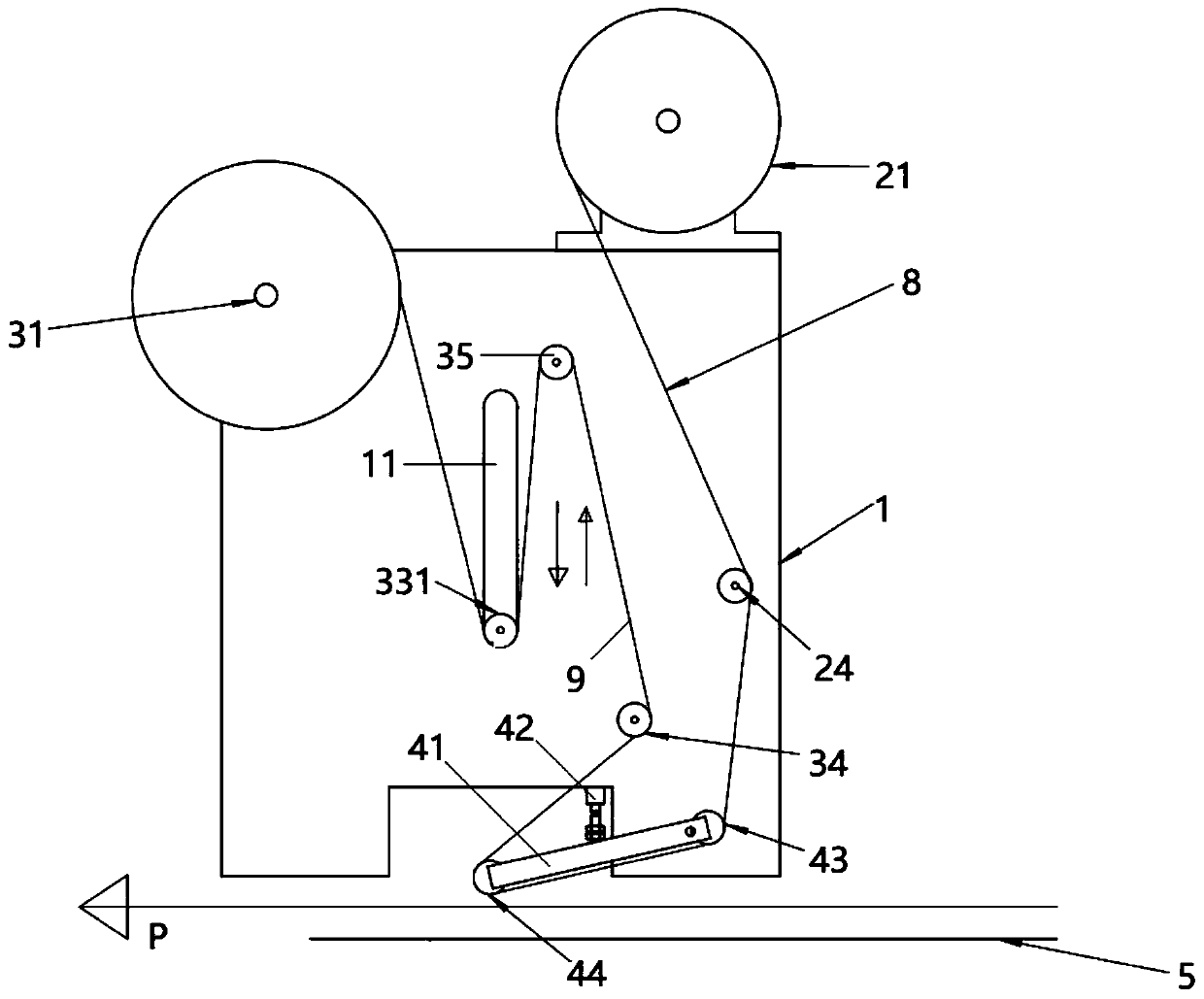

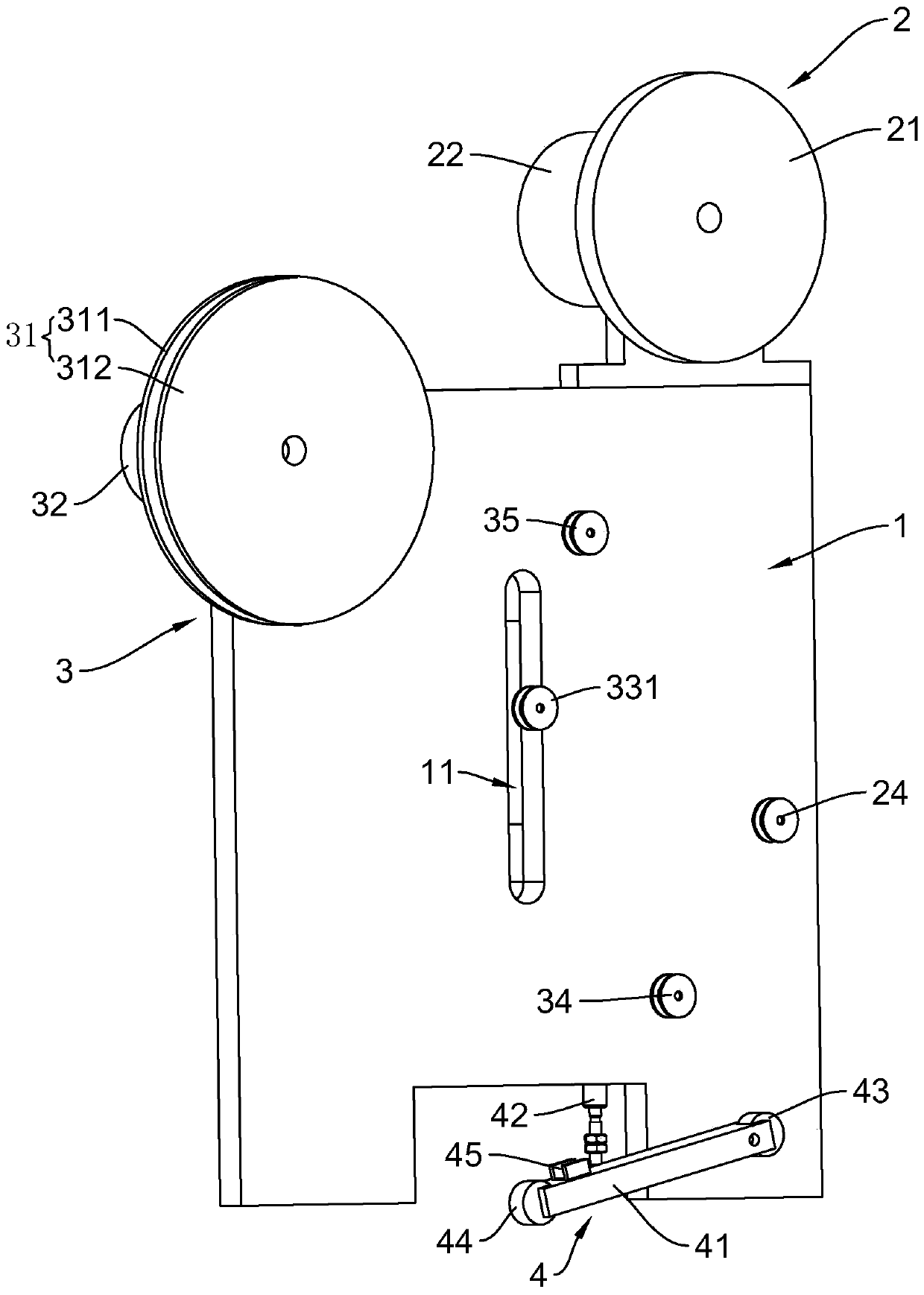

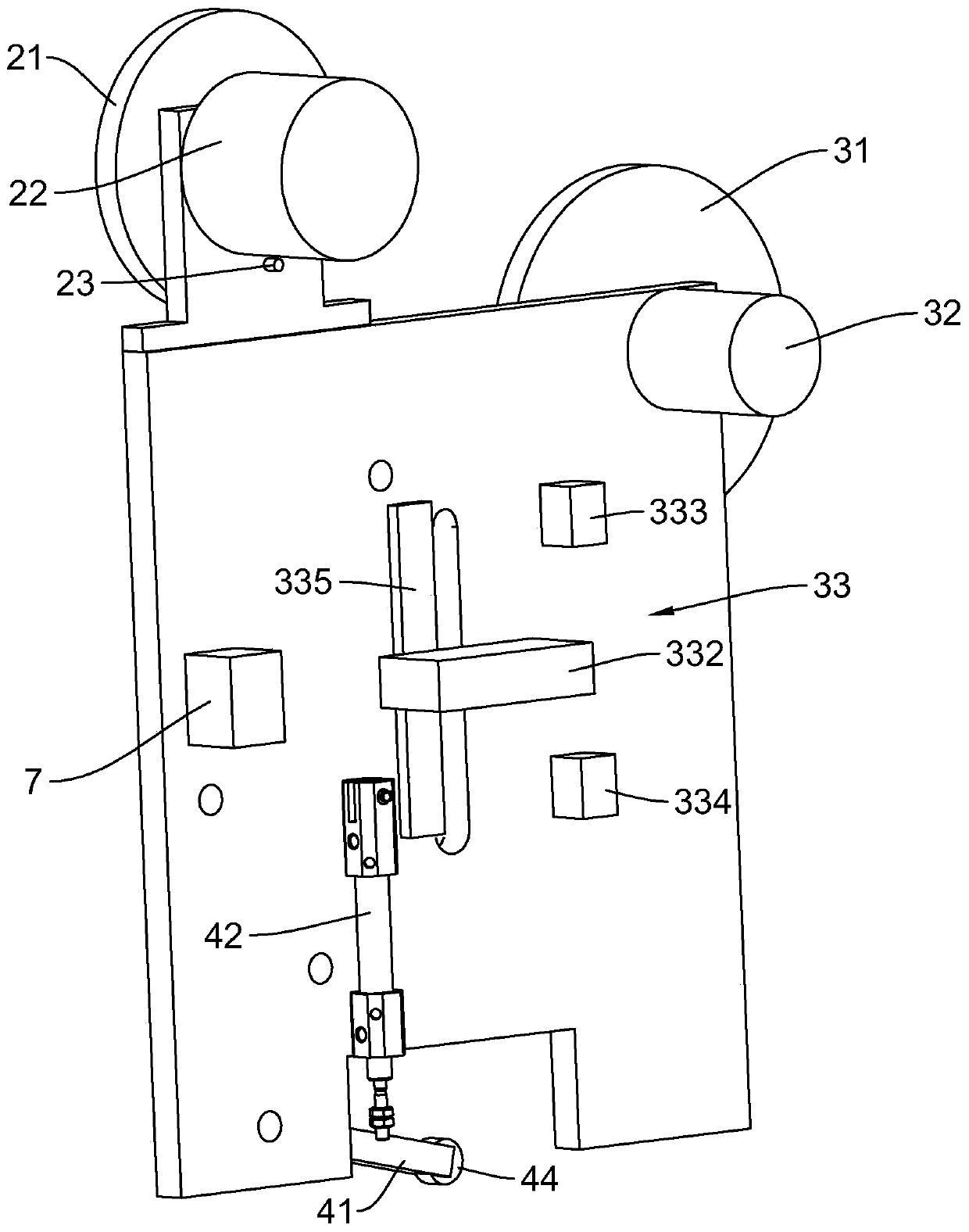

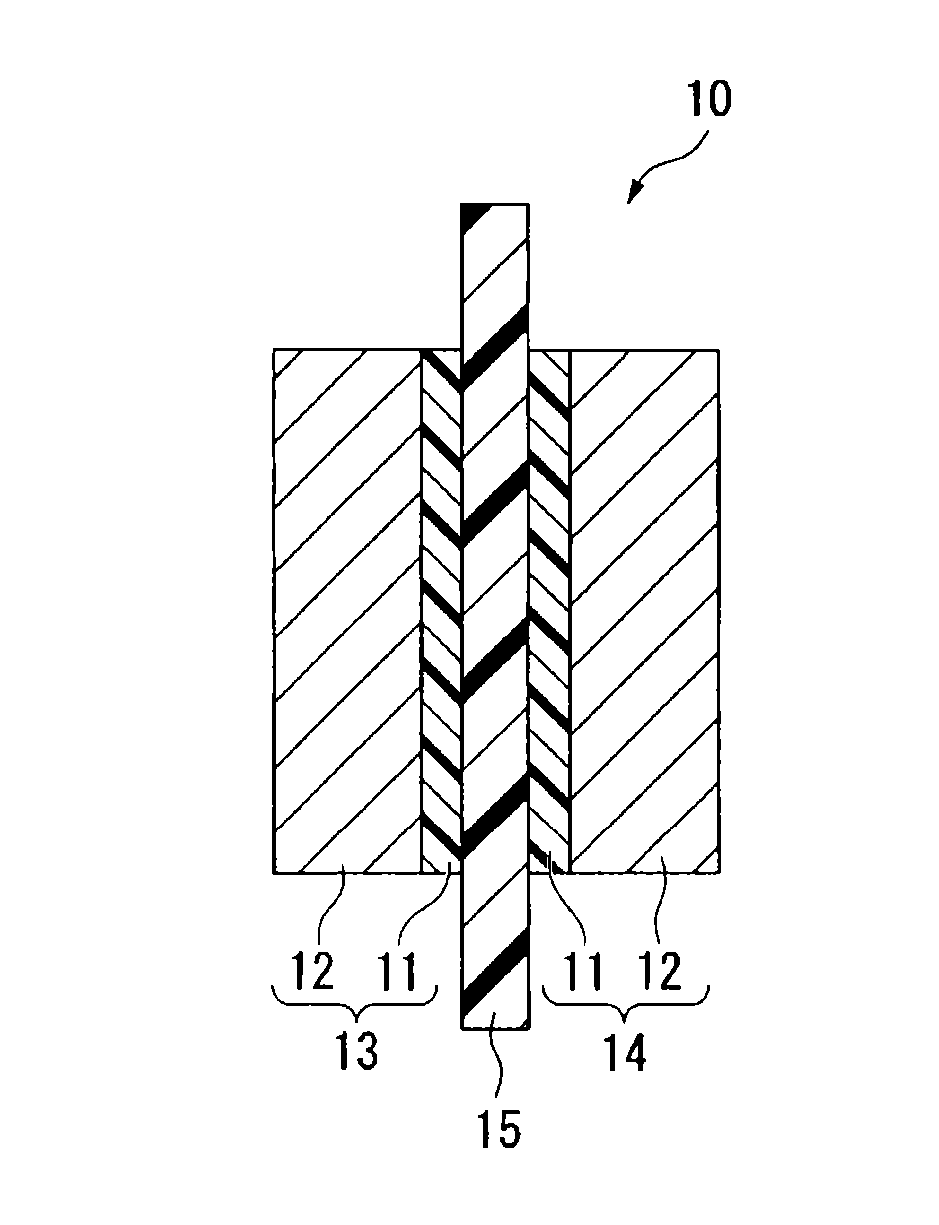

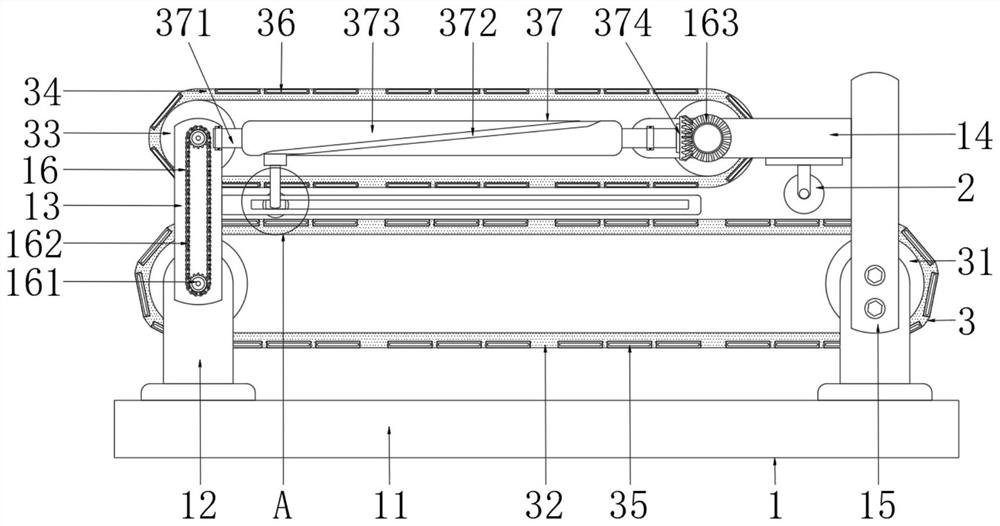

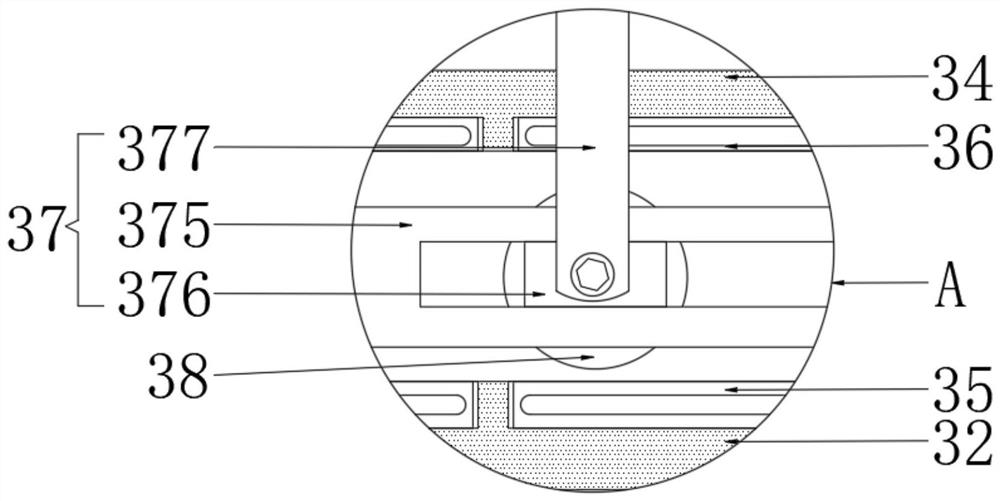

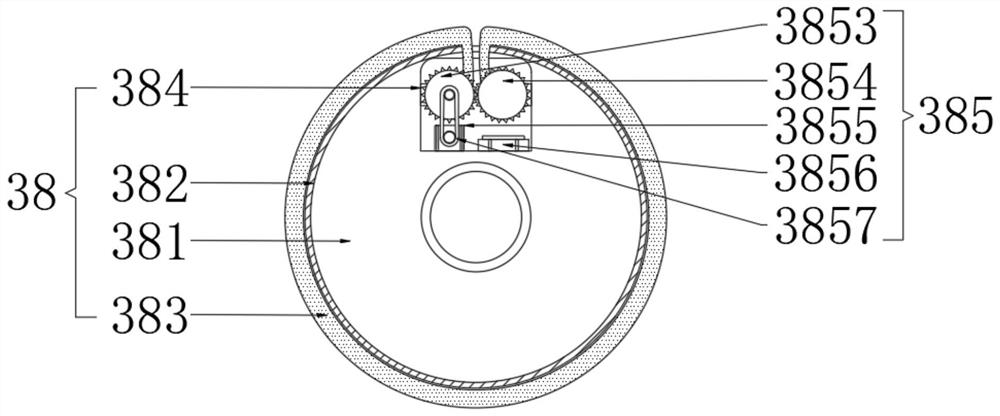

Narrow tape gluing device and full-automatic mirror cabinet edge gluing machine based on same

PendingCN110240000AAvoid breakingThe tension deviation range is smallArticle deliveryWebs handlingAdhesive beltElectric machinery

The invention relates to a narrow tape gluing device. The narrow tape gluing device comprises a mounting plate arranged on an assembly line, the mounting plate is provided with a discharging control mechanism, a receiving control mechanism and a gluing mechanism, the gluing mechanism is located below the discharging control mechanism and the receiving control mechanism, the receiving control mechanism is provided with a winding disc, a motor for controlling the winding disc in the winding of release paper, and a winding friction stabilizer for preventing the release paper from being broken, the winding friction stabilizer comprises a movable guide wheel capable of moving up and down, a balancing weight connected with the movable guide wheel, and an upper limit sensor and a lower limit sensor which are used for controlling the start or stop of the receiving control mechanism by sensing the upper limit and the lower limit of the balancing weight. The narrow tape gluing device is suitable for a narrow tape, can provide constant unwinding tension, can greatly reduce breakage times of a tape, and has good gluing effect; and the invention further provides a full-automatic mirror cabinet edge gluing machine based on the narrow tape gluing device.

Owner:中山科勒卫浴有限公司

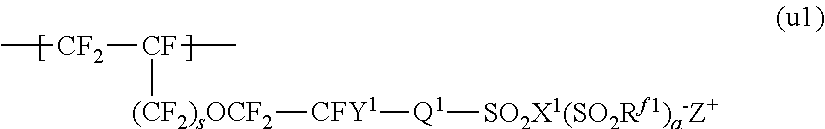

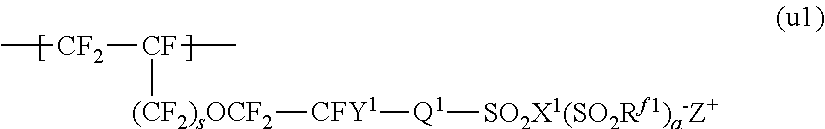

Process for producing fluorinated ion exchange resin fluid

ActiveUS20130209900A1Increased durabilityReduce wrinklesCell electrodesFinal product manufacturePolymer electrolytesFuel cells

To provide a process for forming a polymer electrolyte membrane having good durability and few wrinkles, a polymer electrolyte membrane capable of forming a catalyst layer, or a catalyst layer; a process for producing a fluorinated ion exchange resin fluid, or a paste for forming a catalyst layer, which can be used for such a forming process; and a process for producing a membrane / electrode assembly for a polymer electrolyte fuel cell having good durability and power generation properties. A fluorinated ion exchange resin fluid obtained by subjecting a powder or pellets of a fluorinated ion exchange resin having cation exchange groups to hydrogen peroxide treatment, followed by mixing with a solvent, is used.

Owner:ASAHI GLASS CO LTD

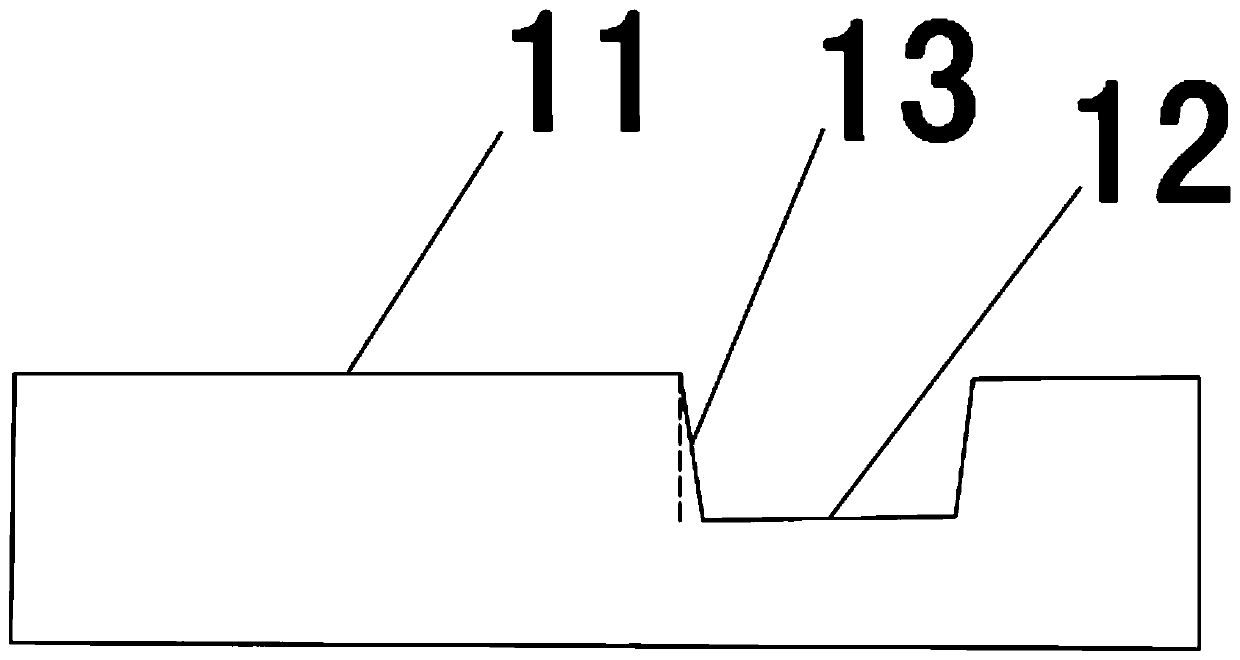

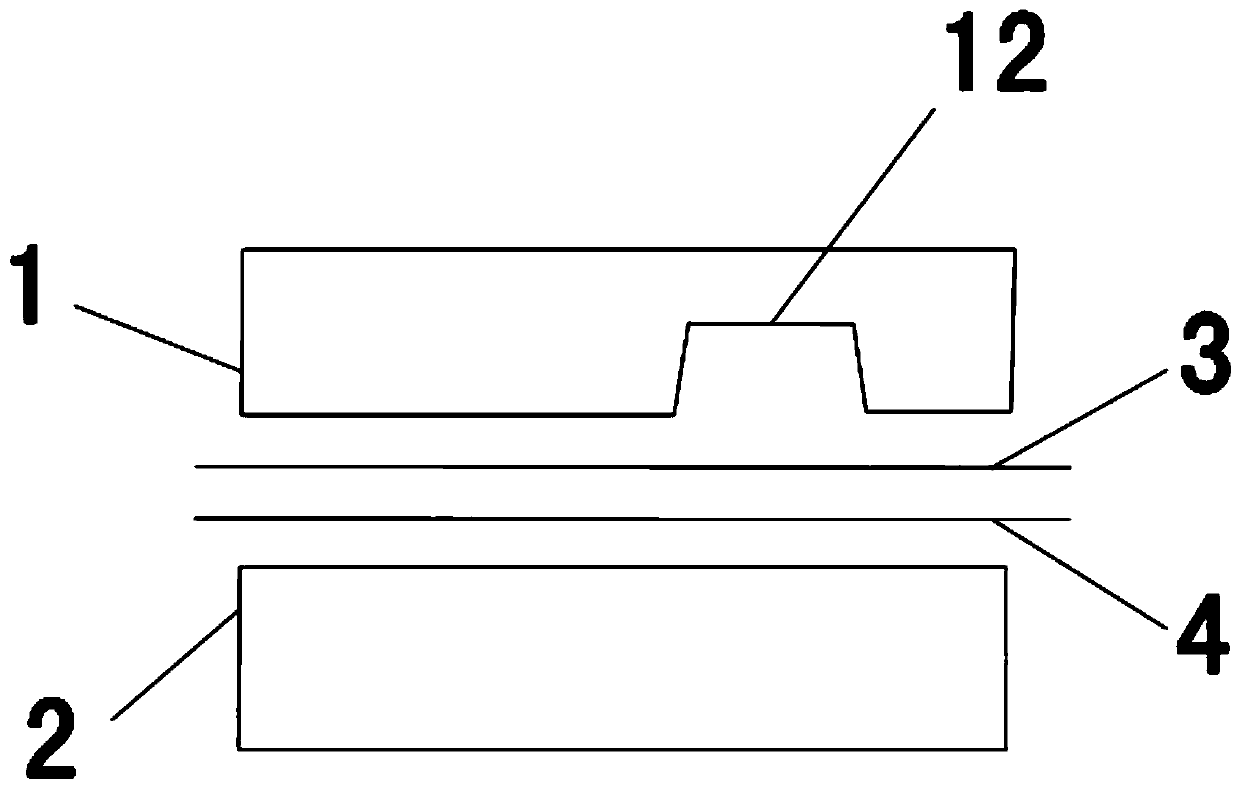

Air bag die and manufacturing method of air bag

The invention discloses an air bag die which comprises an upper air bag die and a lower air bag die. The upper air bag die comprises a convex part and a concave part, and a slow bevel is arranged between the convex part and the concave part. A manufacturing method of an air bag comprises the following steps: placing a lower film and an upper film successively on the upper surface of the lower airbag die and then placing the upper air bag die on the upper surface of the upper film; after placing the upper film and the lower film on the air bag die, hot melting and laminating the upper and lower TPU films by means of a high frequency fusion machine to manufacture a basic air bag with an air outlet pipe joint left; embracing a conduit by a hot melt adhesive in two turns, putting the conduitin the air outlet pipe joint of the basic air bag, and then putting the basic air bag and the conduct in the air bag die to be holt-melted and sealed, wherein the slow bevel is arranged between the convex layer and the concave layer of the upper die, so that a wrinkling condition after the upper film and the lower film are connected is reduced effectively.

Owner:SINCETECH FUJIAN TECH CO LTD +1

Heat-shrinkable polyester film

ActiveUS20160347920A1Sufficient heat shrinkage characteristicLow shrinkageSynthetic resin layered productsLaminationPolyester resinEthylene

A heat-shrinkable polyester film comprising ethylene terephthalate as a main component, containing not less than 0 mol % and not more than 5 mol % of a monomer component capable of serving as an amorphous component relative to the total of a polyester resin component, and having a main shrinkage direction in a lengthwise direction, wherein the heat-shrinkable polyester film satisfies heat shrinkage characteristics of the width direction and the lengthwise direction and the molecular orientation angle difference which is a difference between a molecular orientation angle of an edge of one end in the width direction and a molecular orientation angle of an edge of the other end.

Owner:TOYO TOYOBO CO LTD

Method and apparatus for gas management in hot blow-forming dies

A method and apparatus for forming a sheet of ductile material by superplastic forming is disclosed. The method is directed to first creating a pre-form by mechanical forming in which the pre-form is created with a die and punch. Thereafter the pre-form is subjected to gas pressure in a forming cavity to complete formation of the part. A metallic gasket is provided to ensure that no pressurized gas escapes from the forming cavity.

Owner:FORD GLOBAL TECH LLC +1

Paste and water-soluble glue adhesive and preparation method of adhesive

InactiveCN108003815AReduce the water content of the pasteLess wrinklingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionChemistry

The invention discloses paste and a water-soluble glue adhesive. When the paste is stirred with boiled water, water-soluble glue is blended with the mixture above, water contained in the paste can beeffectively reduced, the pulling force of the paste on Chinese art paper is reduced when the paste congeals, and since a water-soluble glue white emulsion congeals faster than the paste, when the paste dehydrates and the Chinese art paper is pulled and wrinkled, the water-soluble glue white emulsion already congeals, so that the pulling force of the paste can be resisted to a certain extent to reduce the wrinkling degree of the Chinese art paper. By adding a mildewproof agent into the adhesive, the adhesive can be prevented from mildewing after congealing.

Owner:YANGZHOU ANCIENT WIRE BOUND IND CO LTD

Process for producing fluorinated ion exchange resin fluid

ActiveUS9531026B2Increased durabilityLess wrinklingCell electrodesSolid electrolyte fuel cellsPolymer electrolytesPolymer science

To provide a process for forming a polymer electrolyte membrane having good durability and few wrinkles, a polymer electrolyte membrane capable of forming a catalyst layer, or a catalyst layer; a process for producing a fluorinated ion exchange resin fluid, or a paste for forming a catalyst layer, which can be used for such a forming process; and a process for producing a membrane / electrode assembly for a polymer electrolyte fuel cell having good durability and power generation properties. A fluorinated ion exchange resin fluid obtained by subjecting a powder or pellets of a fluorinated ion exchange resin having cation exchange groups to hydrogen peroxide treatment, followed by mixing with a solvent, is used.

Owner:ASAHI GLASS CO LTD

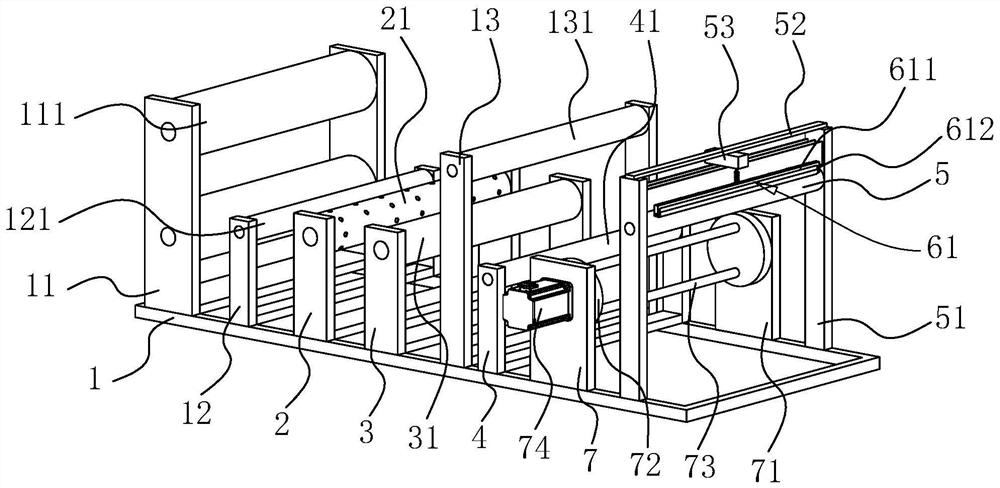

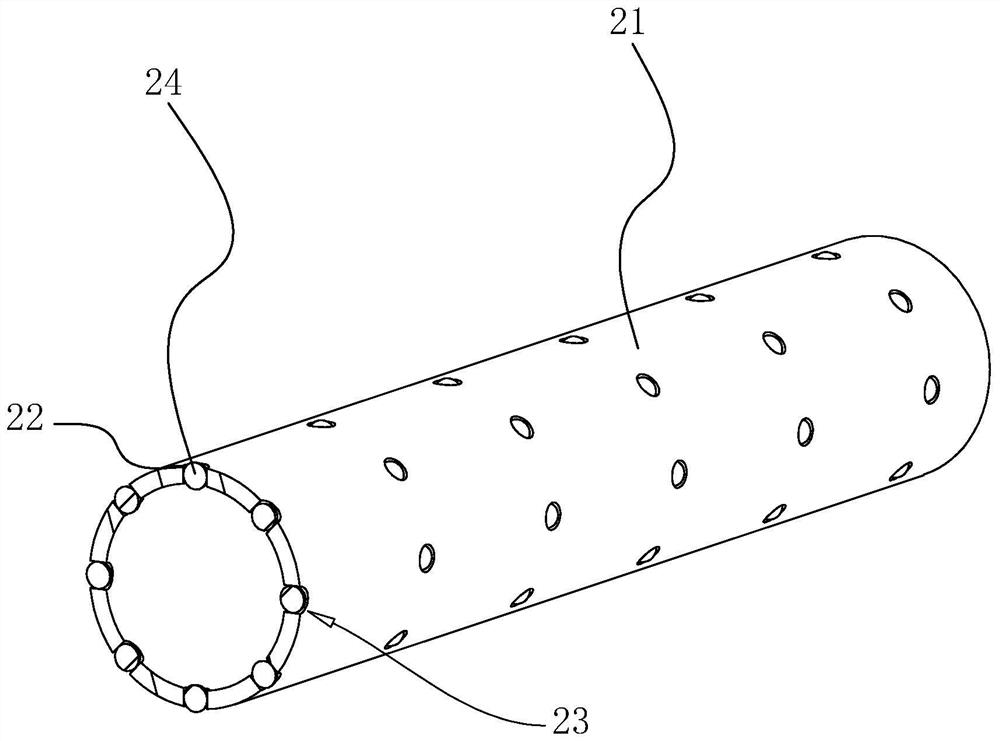

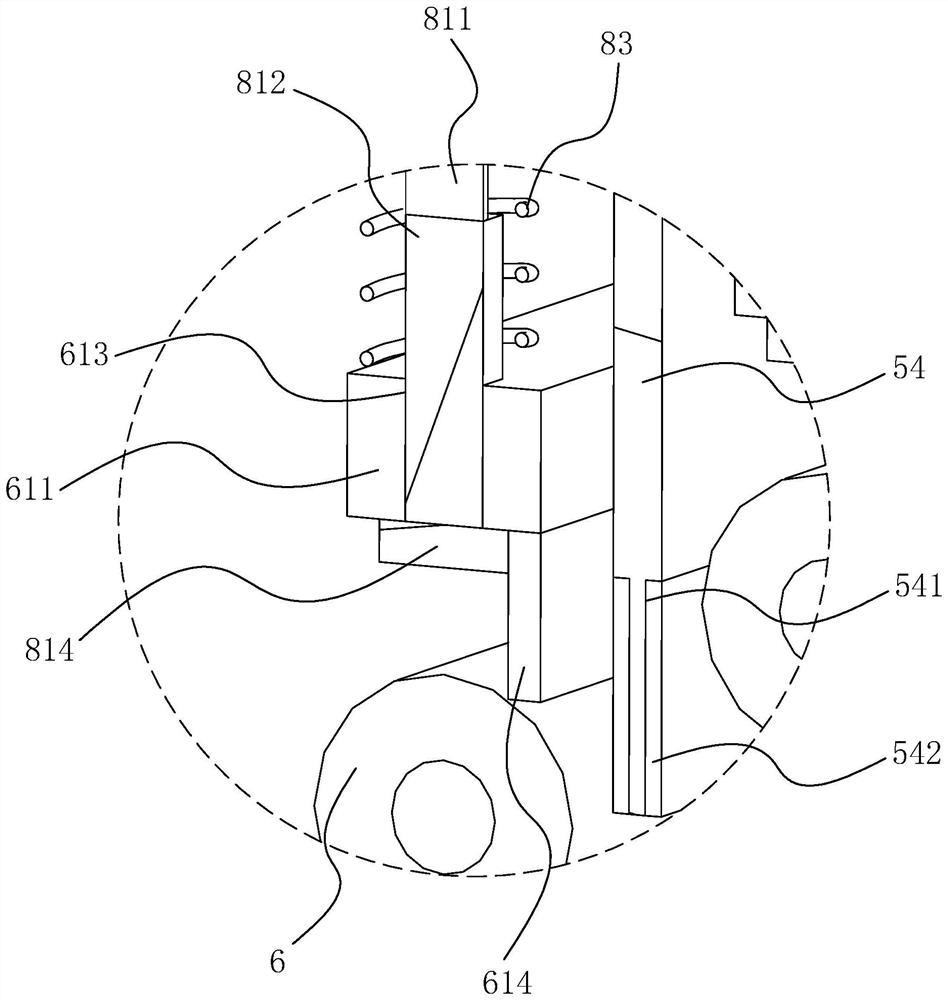

Anti-wrinkle compound machine

The invention relates to an anti-wrinkle compound machine which comprises a base frame, two material rollers are arranged at one end of the base frame, the base frame is provided with a glue spreading roller, a glue uniformizing roller and a combining roller, the base frame is connected with two compound supporting rods, and the two compound supporting rods are jointly and rotationally connected with a lower compound roller. The two composite supporting rods are jointly and fixedly connected with a transverse rod, the transverse rod is connected with a connecting rod, a plurality of supporting frames are arranged at the bottom of the connecting rod, each supporting frame is rotationally connected with an upper composite roller, the upper composite rollers and the lower composite rollers are arranged in parallel, each upper composite roller is provided with a cavity, and the cavities of the upper composite rollers are used for containing hot water. An abutting device used for enabling the upper composite roller to move towards the lower composite roller is arranged between each supporting frame and the corresponding connecting rod, and the effects that it is guaranteed that when the composite rollers extrude a thin film, the temperature of the thin film can be in a stable state, and a finished product is prevented from wrinkling are achieved.

Owner:青岛萱通工贸有限公司

Continuous feeding mechanism for printing machine for flexible paper and using method

InactiveCN112047148ALess wrinklingReduce use costElectrostatic cleaningArticle feedersEngineeringPrinting press

The invention discloses a continuous feeding mechanism for a printing machine for flexible paper in the technical field of printing machines. The continuous feeding mechanism comprises a feeding frameassembly and a conveying assembly, wherein the feeding frame assembly comprises a base, and U-shaped frames are fixedly arranged on the left side and the right side of the top of the base; and the conveying assembly comprises lower rollers movably arranged at the tops in the U-shaped frames through rotating shafts I, and upper rollers are movably arranged at the top between bearing frames on thefront side and the rear side and the left side between transverse frames on the front side and the rear side through rotating shafts II. According to the continuous feeding mechanism, the conveying assembly is arranged, a conveying belt drives the flexible paper to be conveyed to the right side, and a follow-up conveying belt and a main conveying belt are synchronously driven; and due to the factthat flexible magnetic strips I and flexible magnetic strips II are in one-to-one correspondence, under the action of the repulsion force of like poles of the flexible magnetic strips I and the flexible magnetic strips II, the flexible paper located at the top of the main conveying belt is stably attached to the top of the main conveying belt, on one hand, the situation that the flexible paper deviates or is separated from the main conveying belt during transmission is avoided, and on the other hand, the situation that the flexible paper is wrinkled during conveying and feeding is reduced.

Owner:钱建强

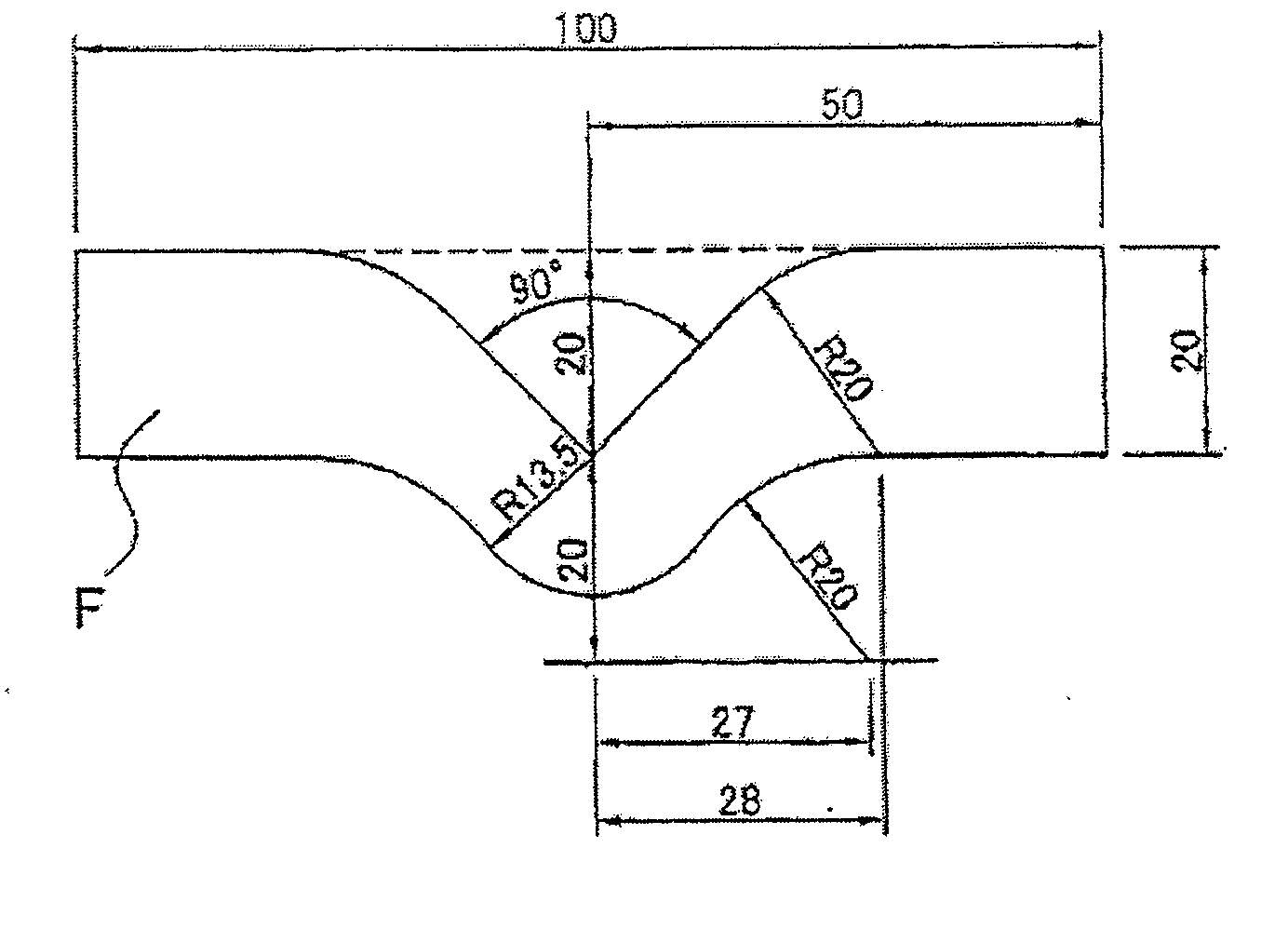

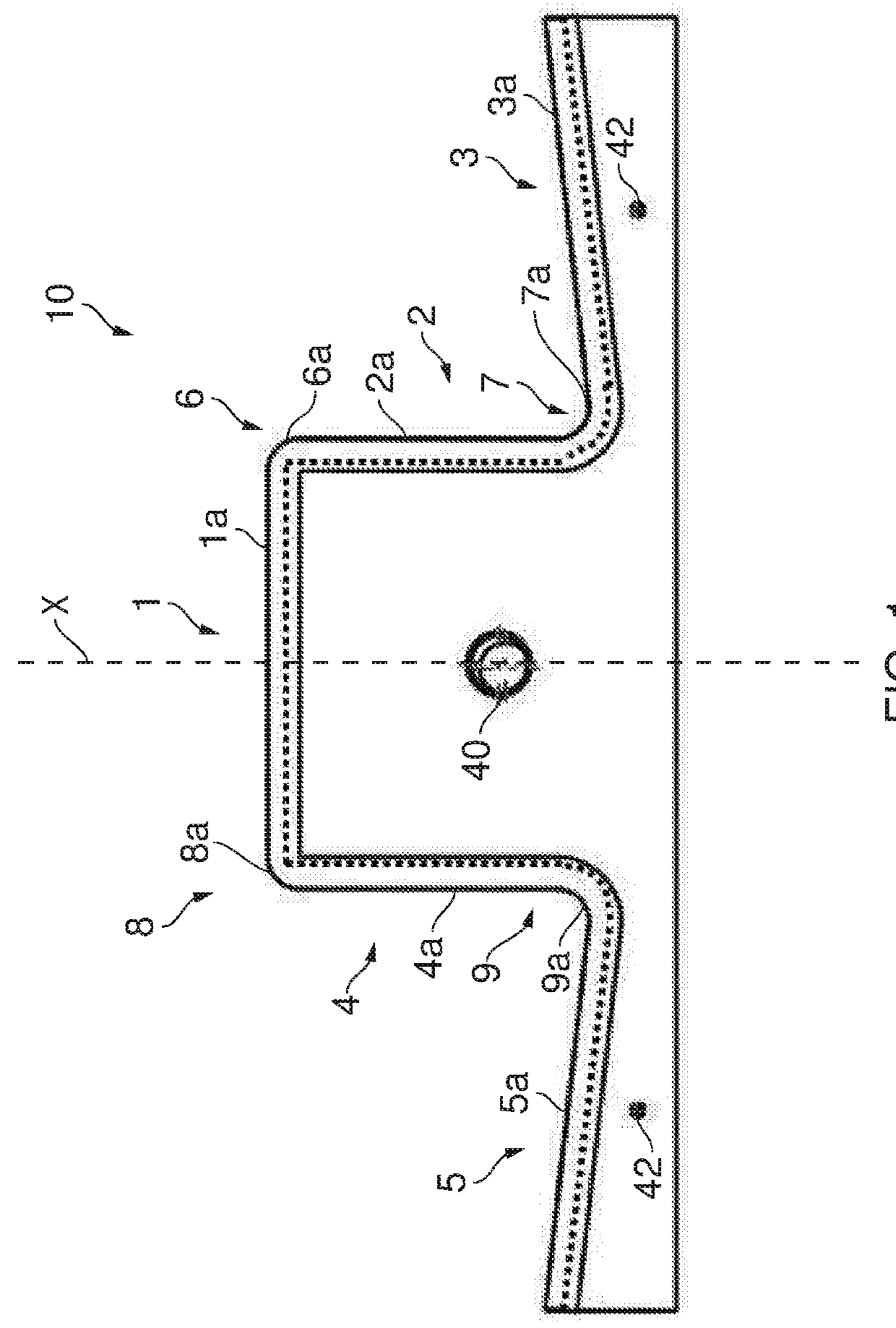

Vacuum forming a laminate charge

A method of forming a laminate charge, and a forming tool and apparatus for forming a laminate charge is disclosed. In a forming step, a suction force is generated between a forming tool and an impermeable sheet which causes the impermeable sheet to press the laminate charge against a male corner of the forming tool and into a female corner of the forming tool. The male corner of the forming tool is positioned between first and second parts of the laminate charge, and the female corner of the forming tool is positioned between second and third parts of the laminate charge. During the forming step, gas is injected between the forming tool and part of the laminate charge to create a gas cushion between the forming tool and the third part of the laminate charge. This gas cushion inhibits the third part of the laminate charge from becoming clamped against the forming tool as the laminate charge is pressed into the female corner of the forming tool.

Owner:AIRBUS OPERATIONS LTD

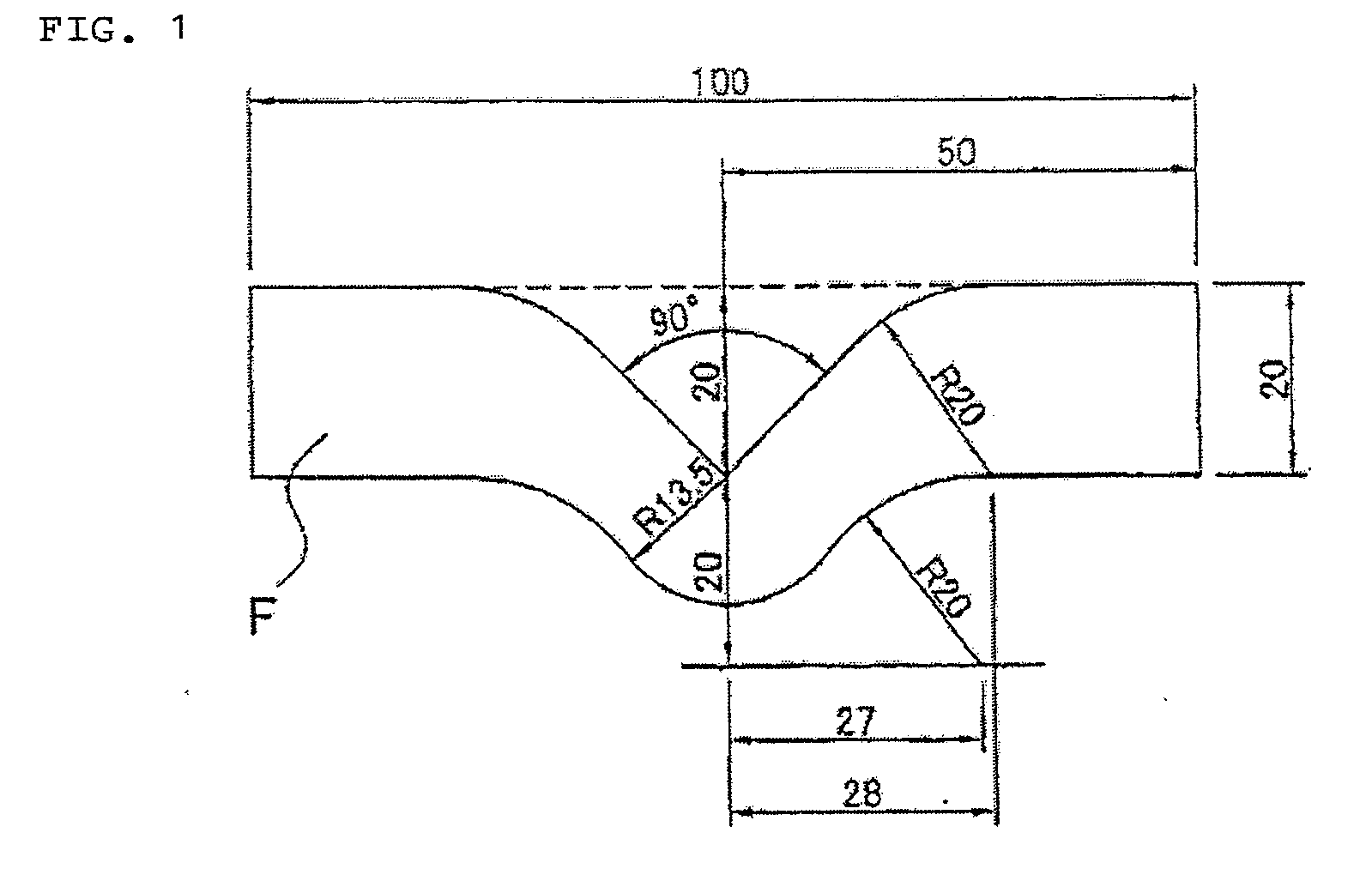

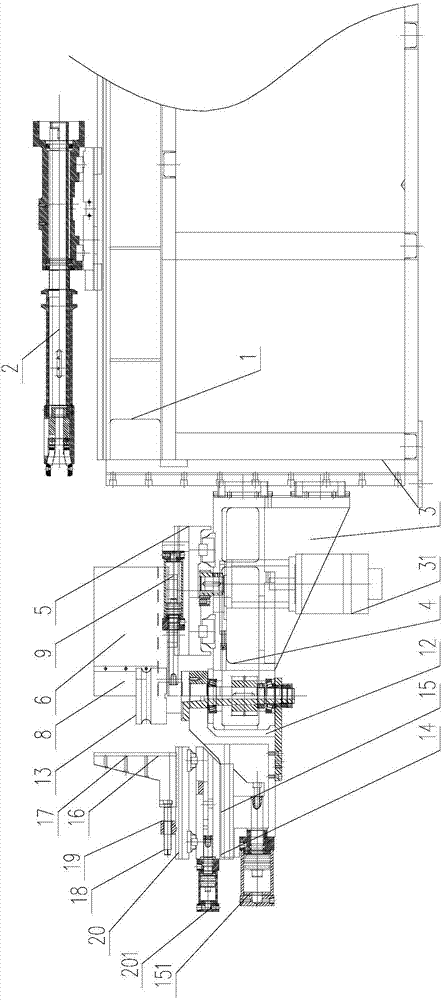

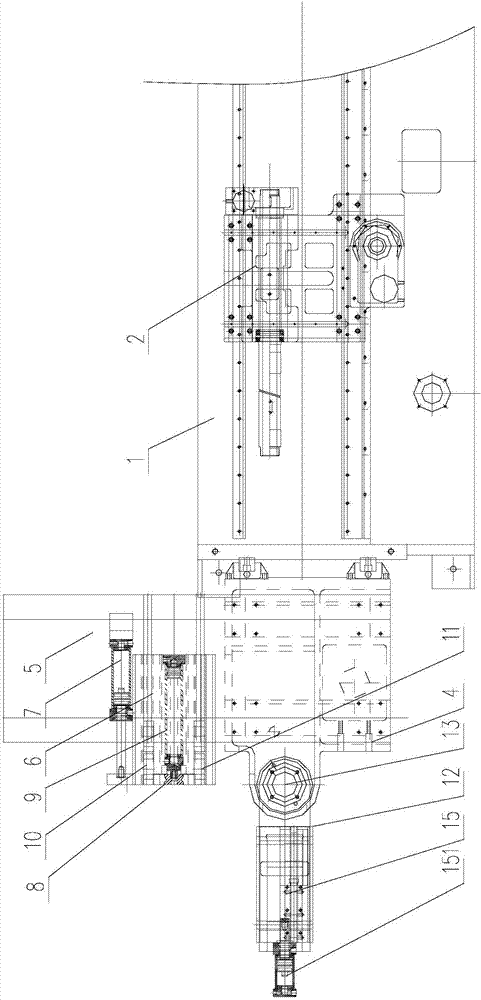

Two-way pipe bending machine

ActiveCN107030154AEasy to processSolve the situation that there is interference in the operation and cannot be processedMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a two-way pipe bending machine. The machine comprises a stand; a pipe feeding device is movably arranged on the stand; a lifting base and a lifting power device are arranged at the end part of the stand; the lifting base is provided with a lower slide base and a lower driving device; the lower slide base is provided with an upper slide base and an upper driving device; the upper slide base is provided with an auxiliary push basic table and a positioning oil cylinder; the auxiliary push basic table is provided with an auxiliary push mold base and an auxiliary push oil cylinder; a left auxiliary push module and a right auxiliary push module are respectively arranged on two sides of the auxiliary push mold base; the lower slide base is provided with a rotating table and a rotating power device; the rotating table is provided with a pipe bending wheel mold module in the rotating center; the rotating table is provided with an end slide base aligned to the direction of a pipe bending wheel mold; a pipe bending movable mold module is arranged on the end slide base; the rotating table is provided with a slide oil cylinder for driving the end slide base to slide; the end slide base is provided with an adjusting base for sliding in a pipe feeding direction when the end slide base leans against the upper slide base; and the end slide base is further provided with a deviation oil cylinder for driving the adjusting base on the end slide base to slide.

Owner:张家港和升数控机床制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com