Patents

Literature

34results about How to "Control coaxiality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

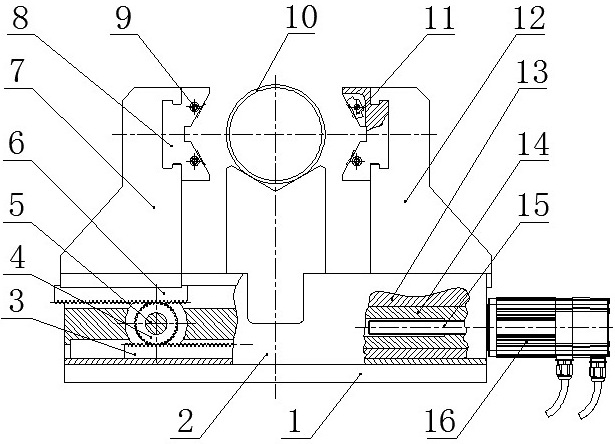

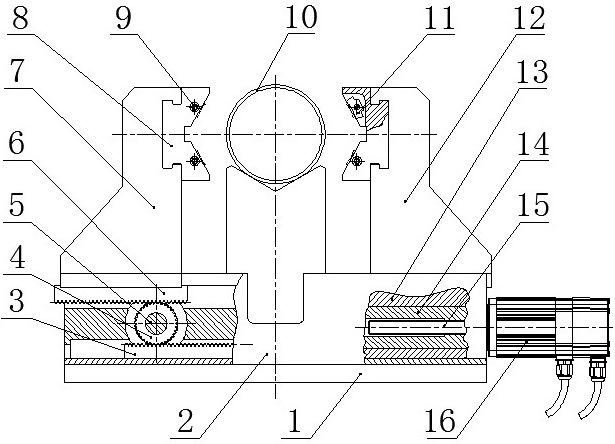

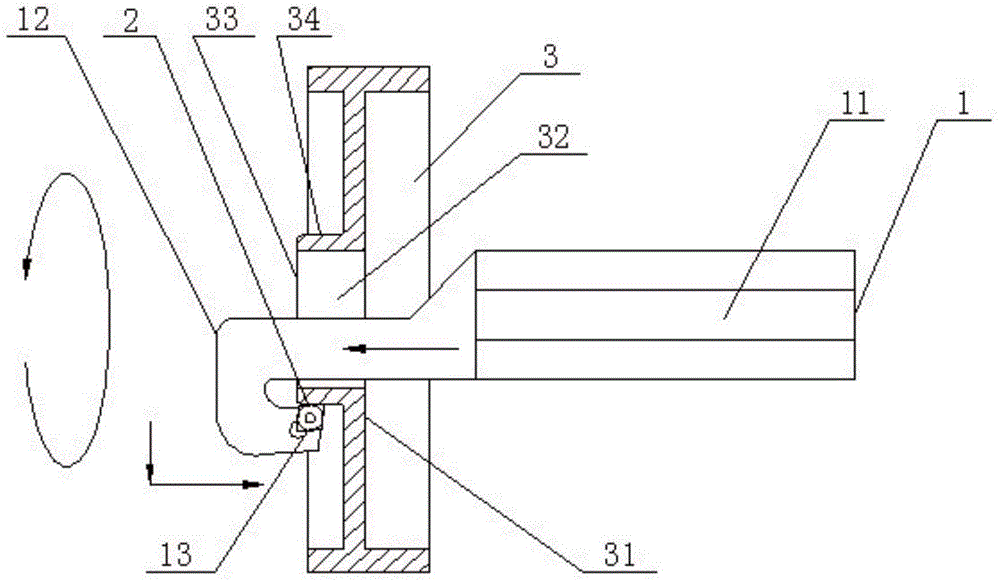

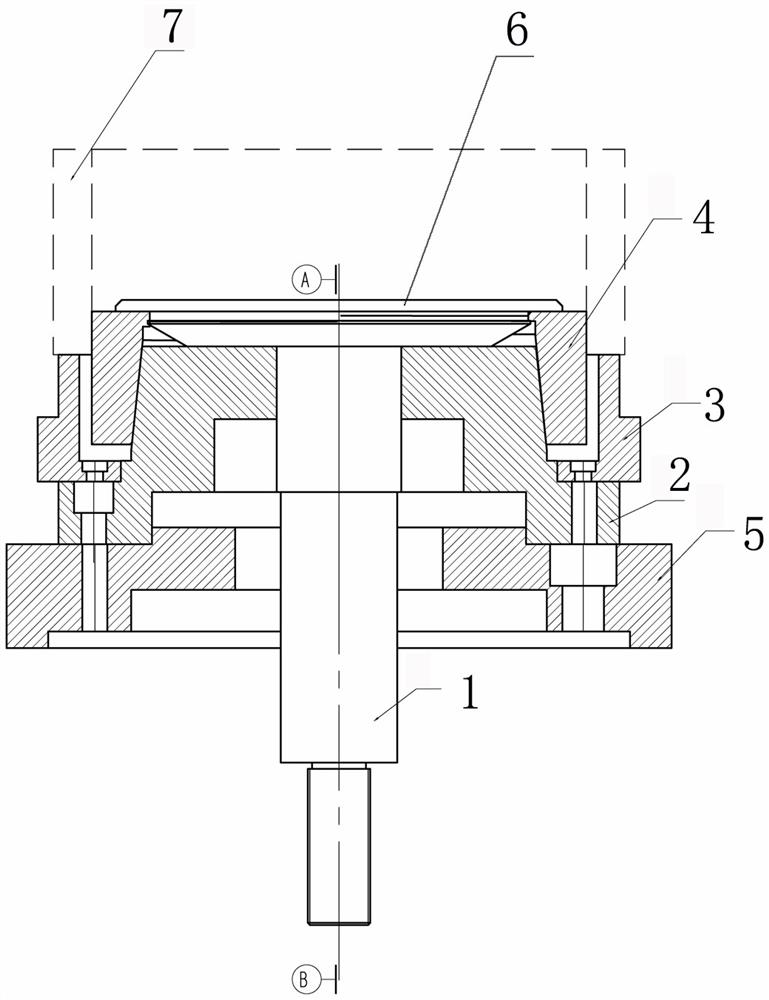

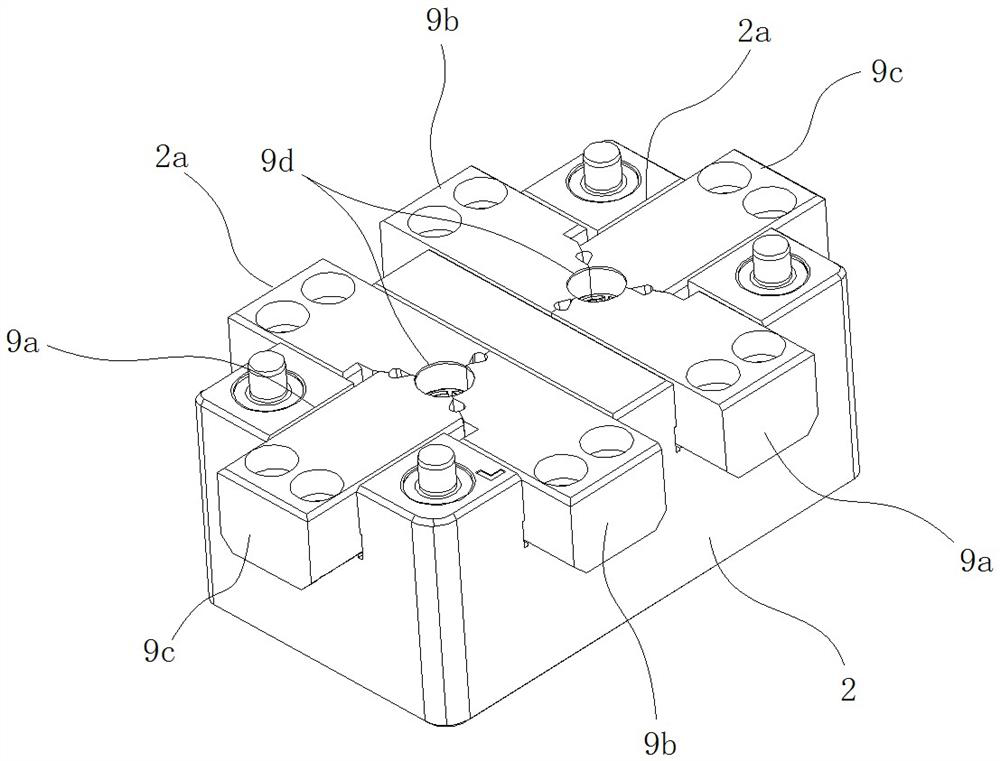

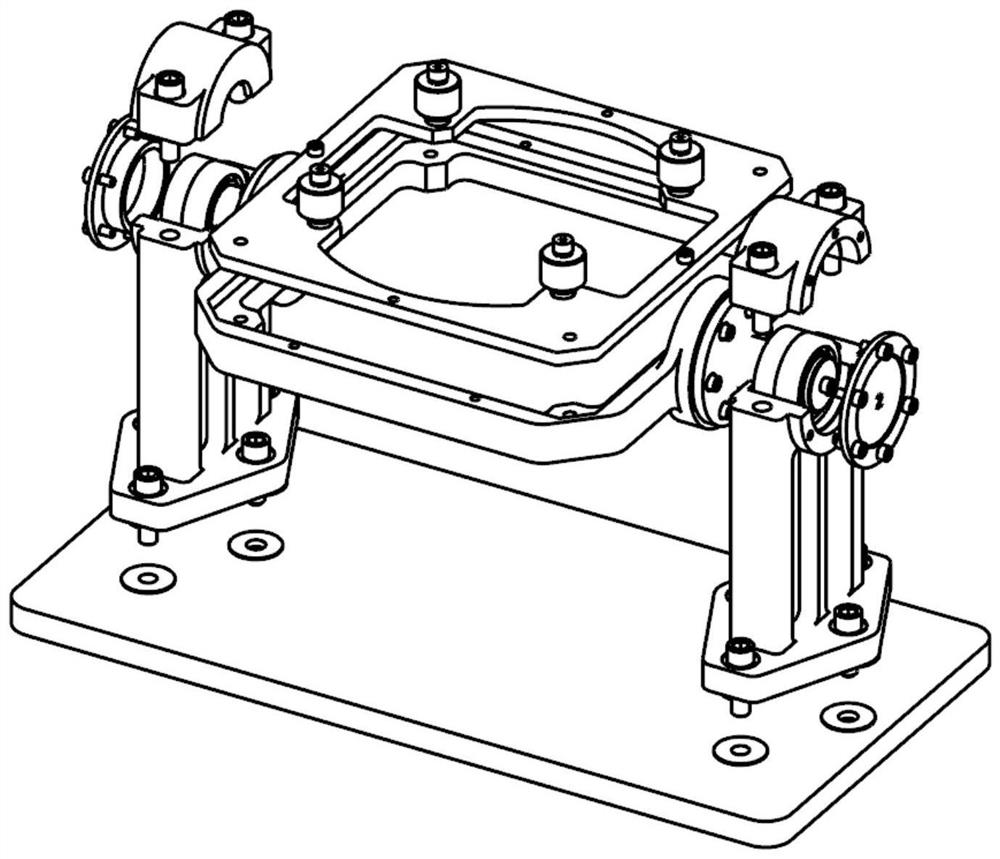

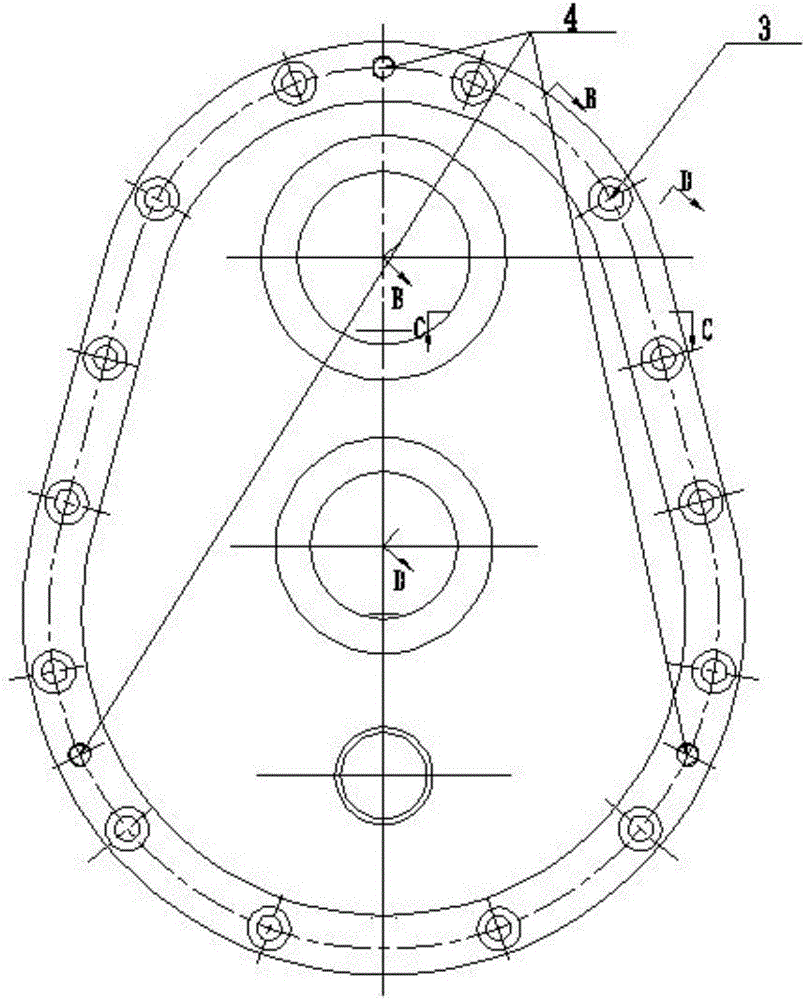

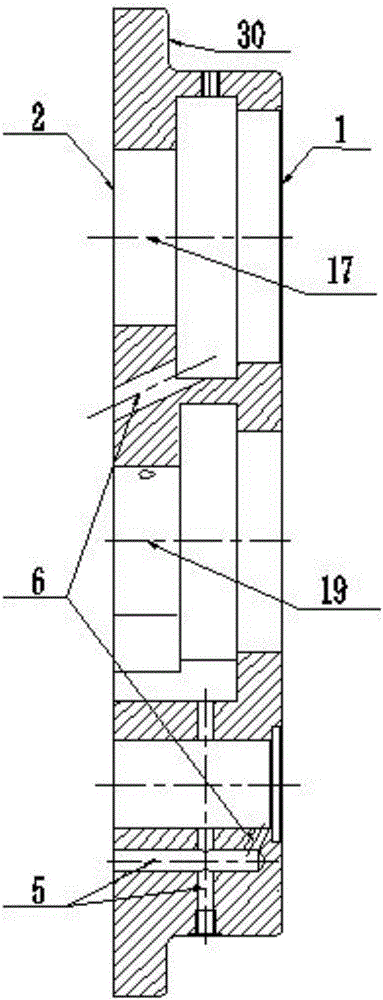

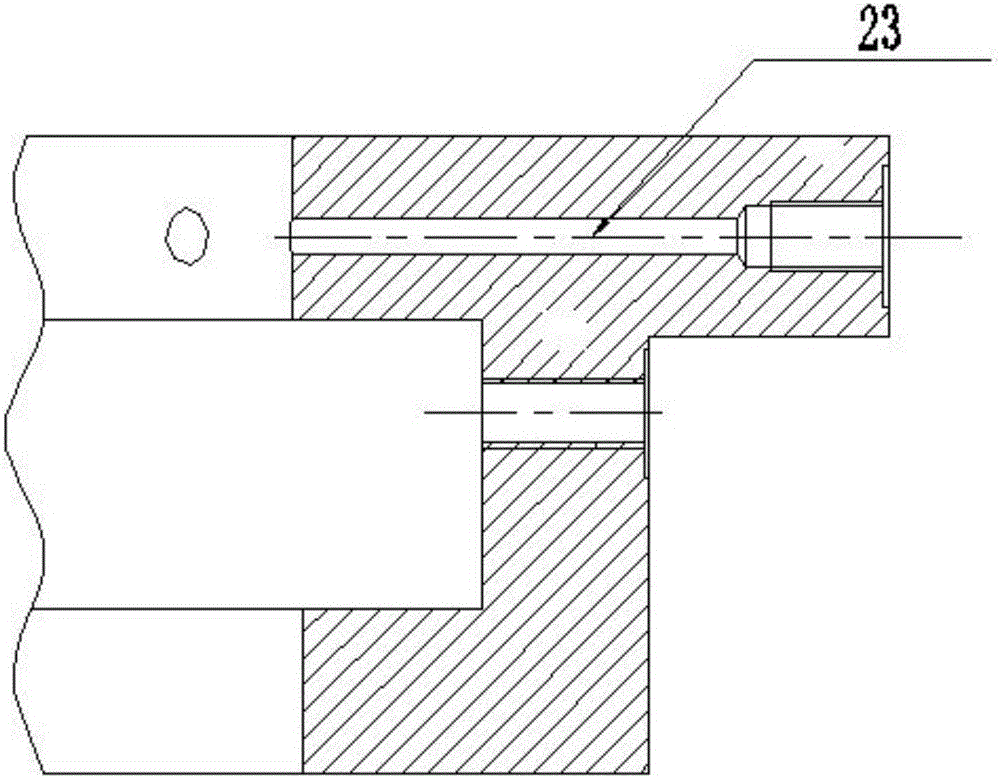

Center-aligning floating clamping fixture

InactiveCN102632404AAvoid deformationDecrease the jump valuePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a center-aligning floating clamping fixture used in a machine tool for two ends of a steel pipe. The structure of the center-aligning floating clamping fixture comprises a fixture supporting frame, a driving mechanism, a transmission mechanism, a clamping mechanism and a floating aligning mechanism, wherein the transmission mechanism and the clamping mechanism are connected with each other, the clamping mechanism is provided with two chuck uprights which are parallel to each other in opposite directions, the uprights are provided with V-shaped jaws and connected with a bracket, a V-shaped clamp is provided with two pairs of floating clamping blocks, clamping surfaces of the clamping blocks are multidentate clamping surfaces, and the multidentate clamping surfaces are positioned on a same cylindrical surface. The center-aligning floating clamping fixture can be used for special machine tool equipment for machining the two ends of the steel pipe of a DT II type roller of a belt conveyor, and the geometric axis center of the steel pipe to be automatically aligned with the axis center of the machine tool so as to control radial deformation of the steel pipe.

Owner:SHENZHEN CEMCN

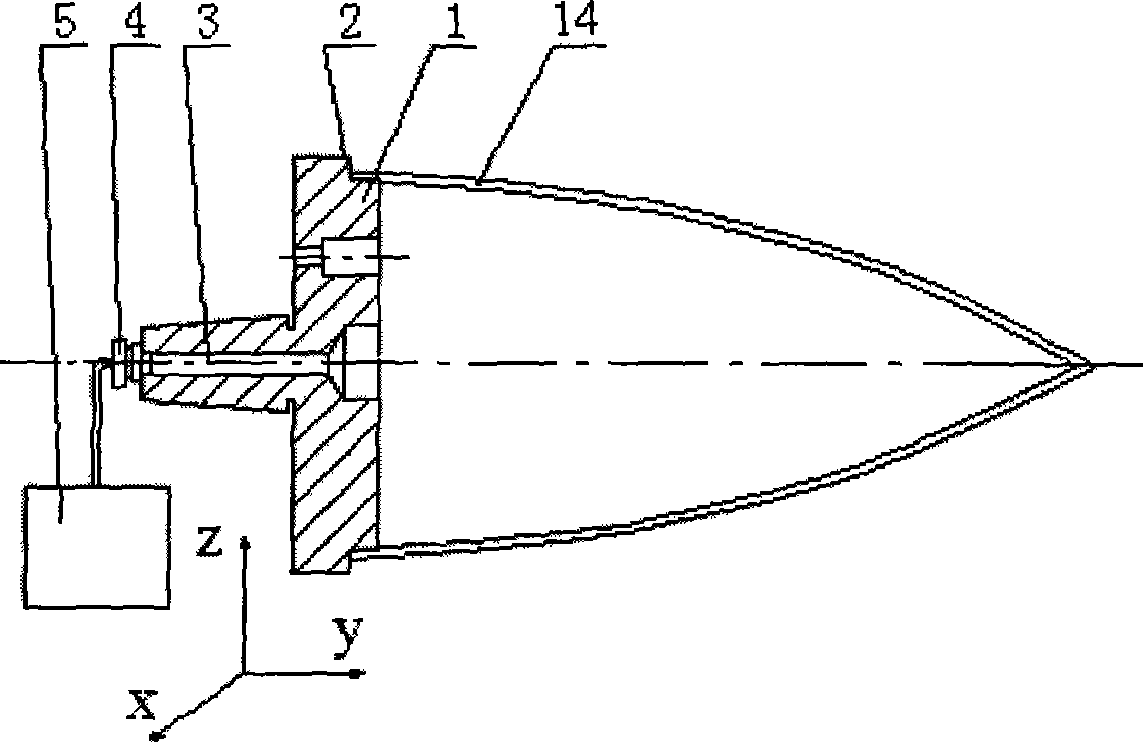

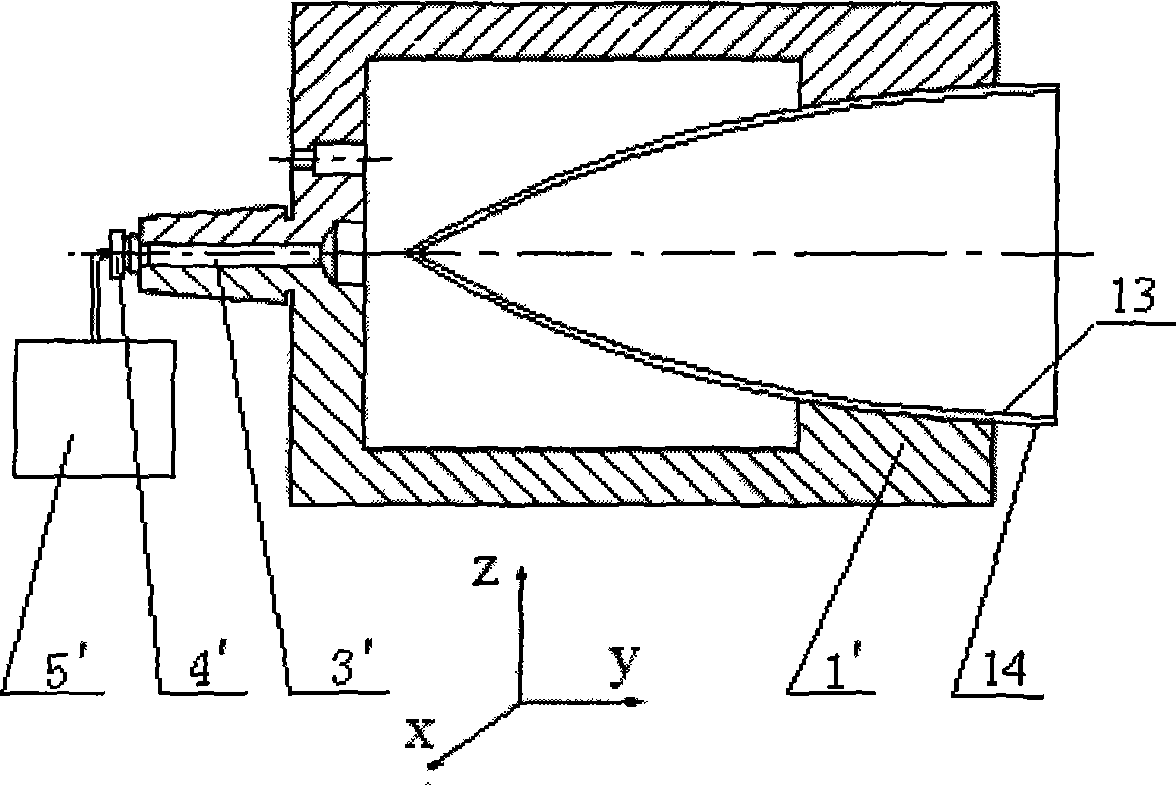

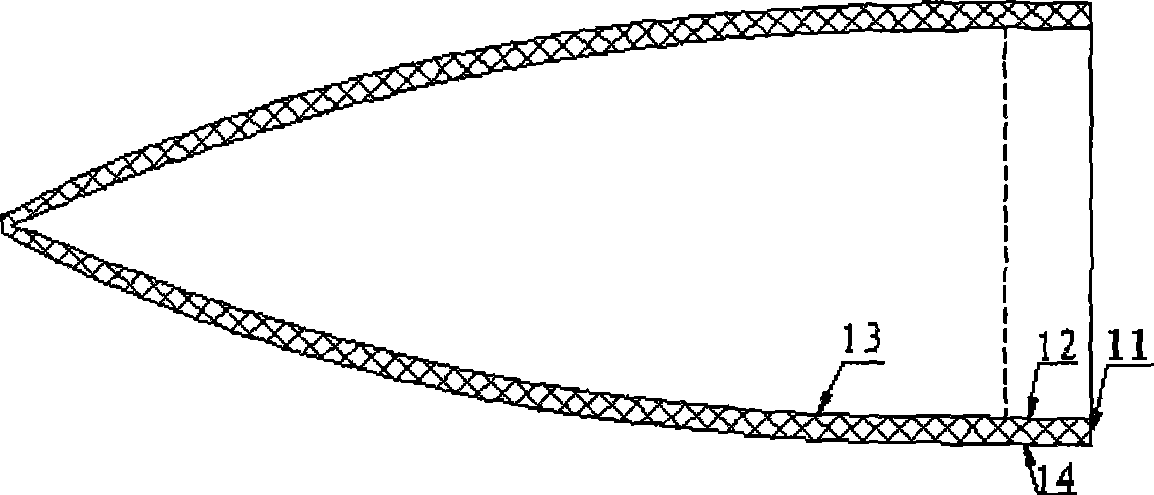

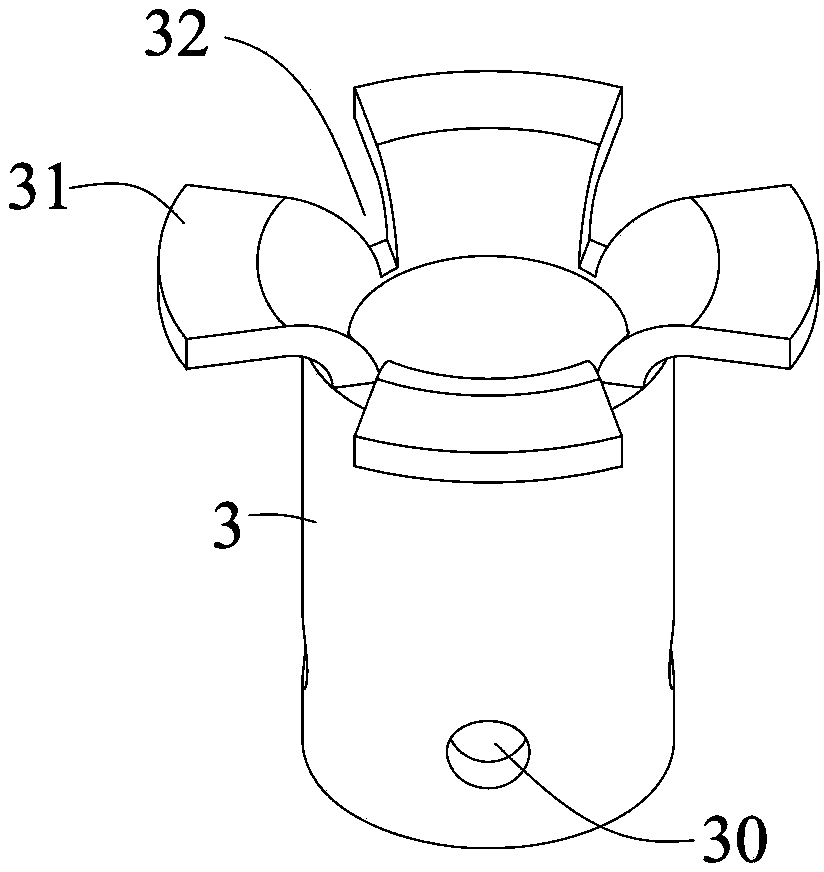

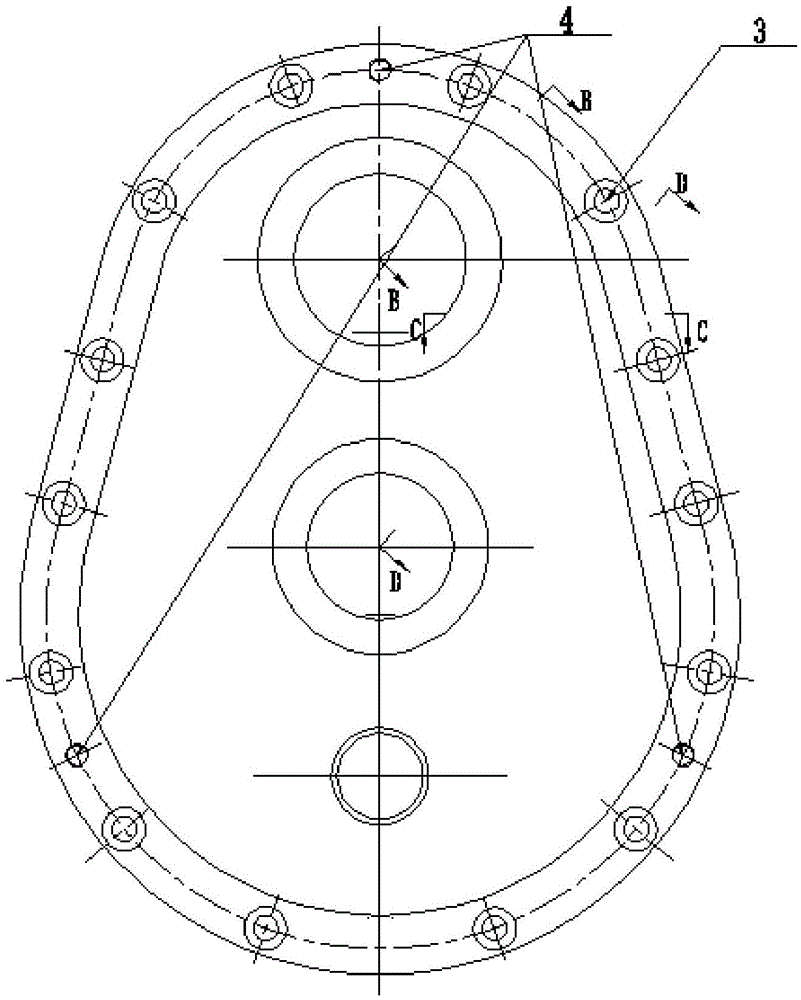

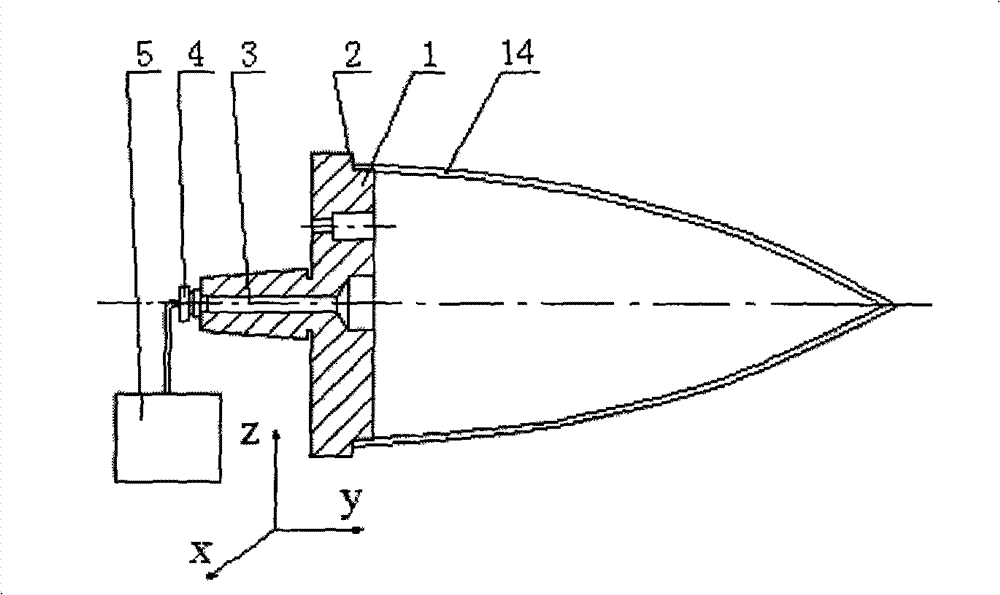

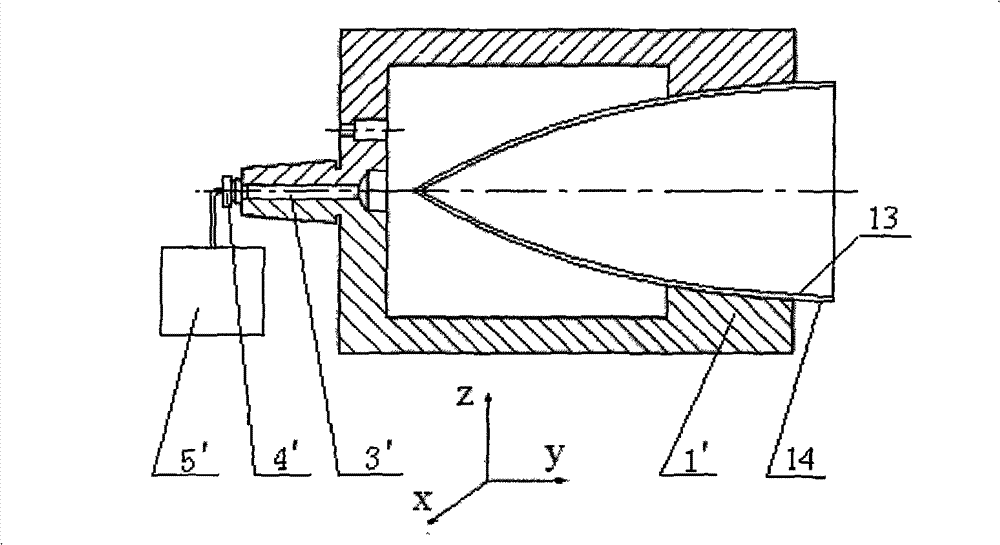

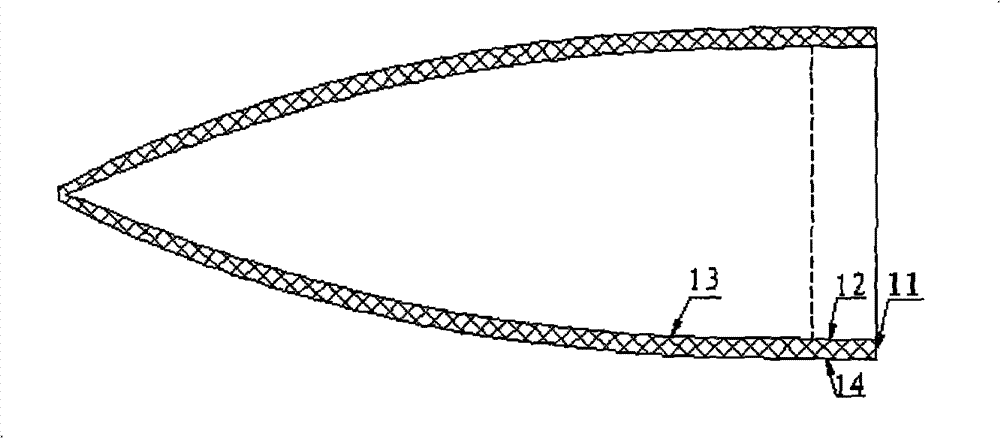

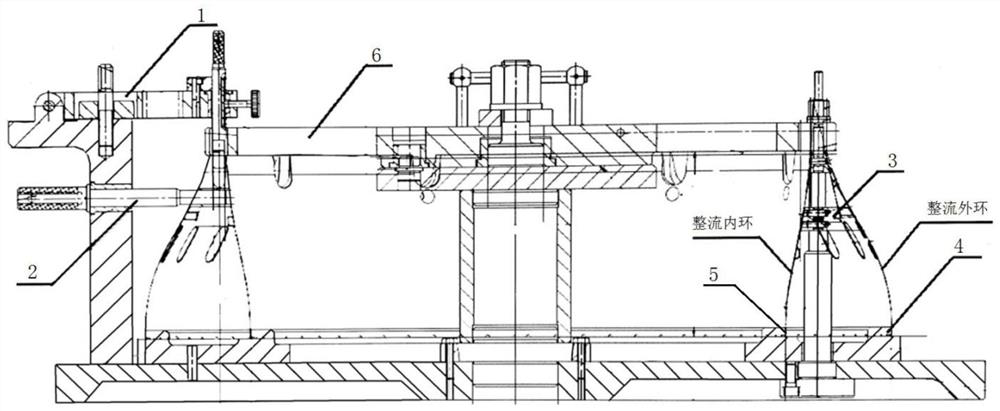

Inner and outer shaped surface precise machining process for antenna cover, active position searching method and processing apparatus

InactiveCN101478078AImprove yieldControl Concentricity and Wall ThicknessAntenna adaptation in movable bodiesRadiating element housingsProcessing accuracyEngineering

The invention relates to a precise process procedure for internal and external moulding surfaces of an antenna dome. The precise process procedure comprises the following main steps: (1) datum grinding process; (2) test process; (3) antenna dome installation process; (4) coarse and fine grinding process of external moulding surface of the antenna dome; (5) external moulding surface test process; (6) antenna dome installation and conversion process; (7) coarse and fine grinding process of internal moulding surface of the antenna dome; (8) test process; and (9) electrical thickness test process. The invention further relates to active position-finding technological equipment supporting installation of the antenna dome outside a machine, which consists of an external moulding surface special fixture (20), an internal moulding surface special fixture (30), a position finder (71) and a position finder (72), a position-finding workstation (40) and the like. The active position-finding technological equipment significantly improves the installation accuracy and the installation reliability of the antenna dome, significantly improves the working accuracy and the yield of the antenna dome, which in particular improves the coaxial accuracy by two grades or above two grades. By adopting the active position-finding technological equipment supporting installation of the antenna dome outside the machine, the debugging difficulty is significantly reduced; the installation and debugging time is reduced; the and utilization ratio of a numerical control grinder specially used for the antenna dome is effectively improved.

Owner:DONGHUA UNIV

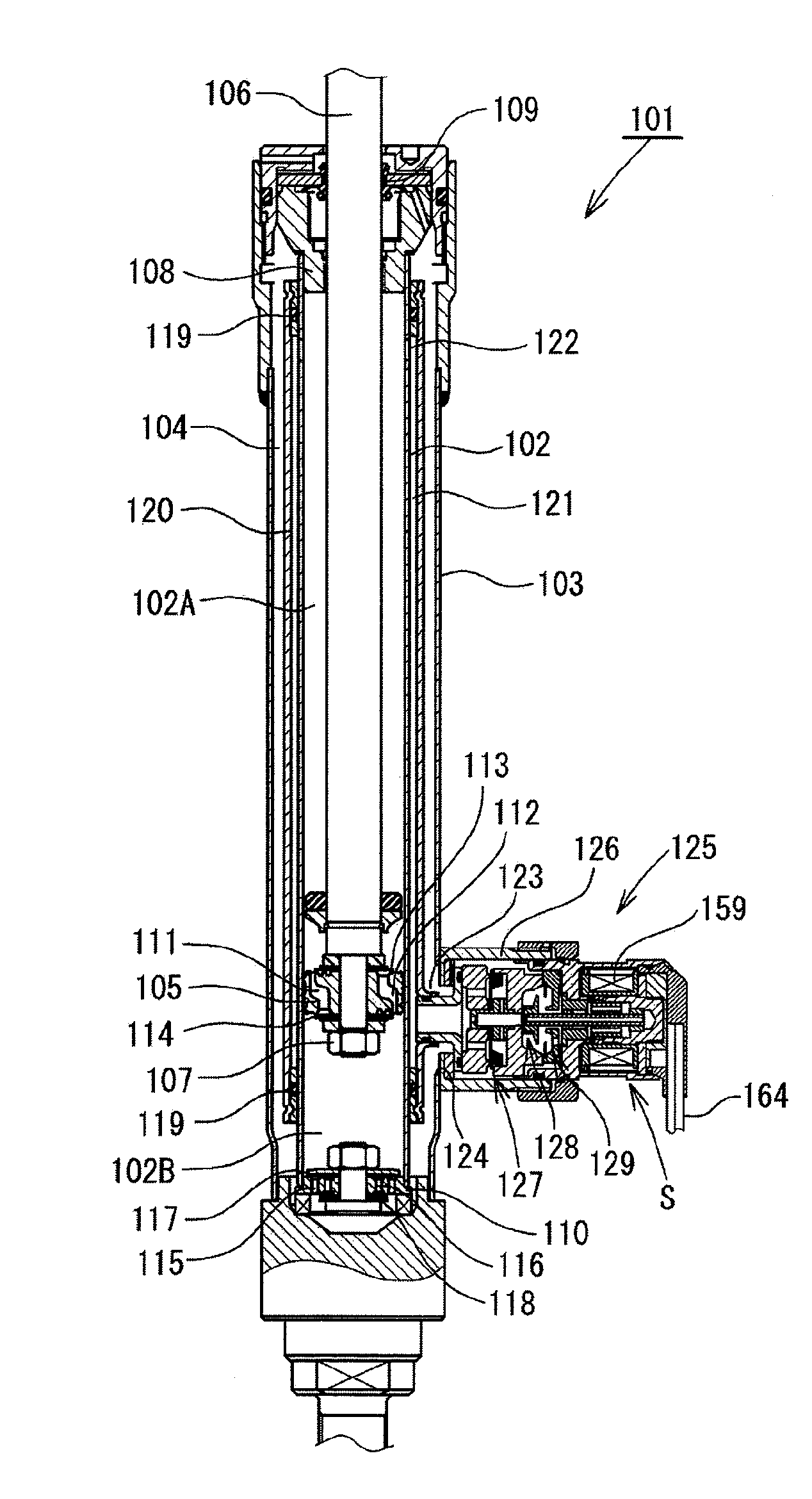

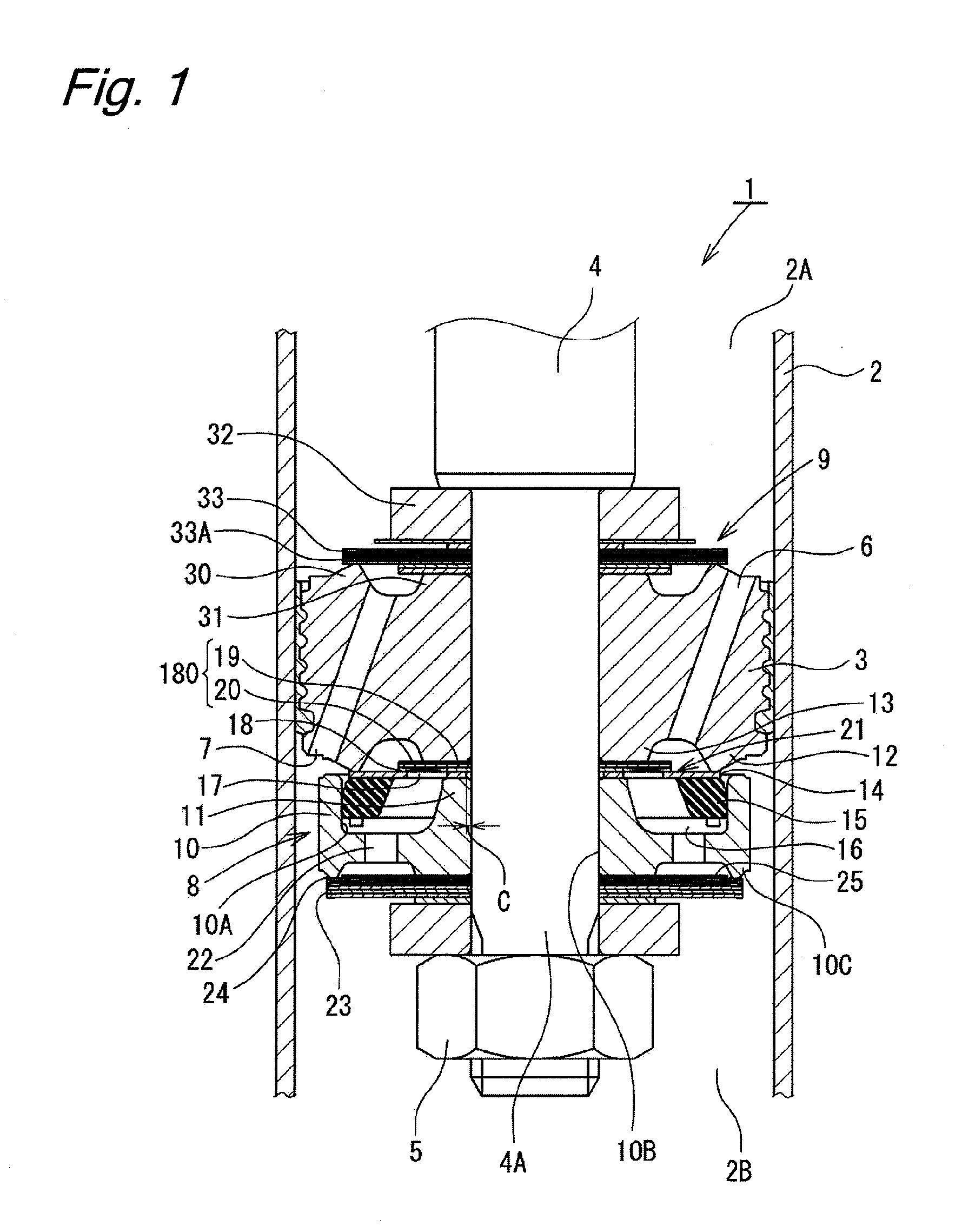

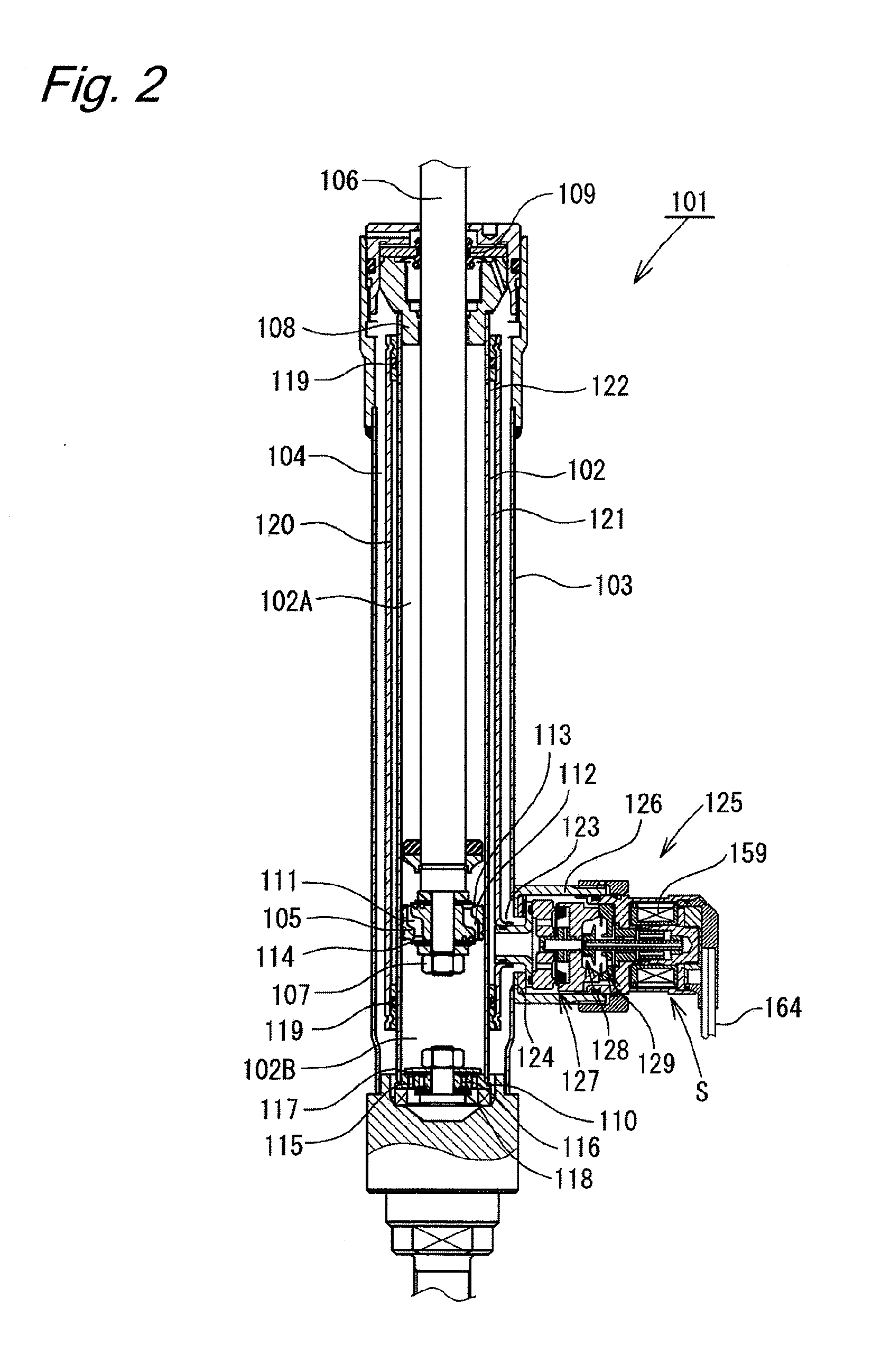

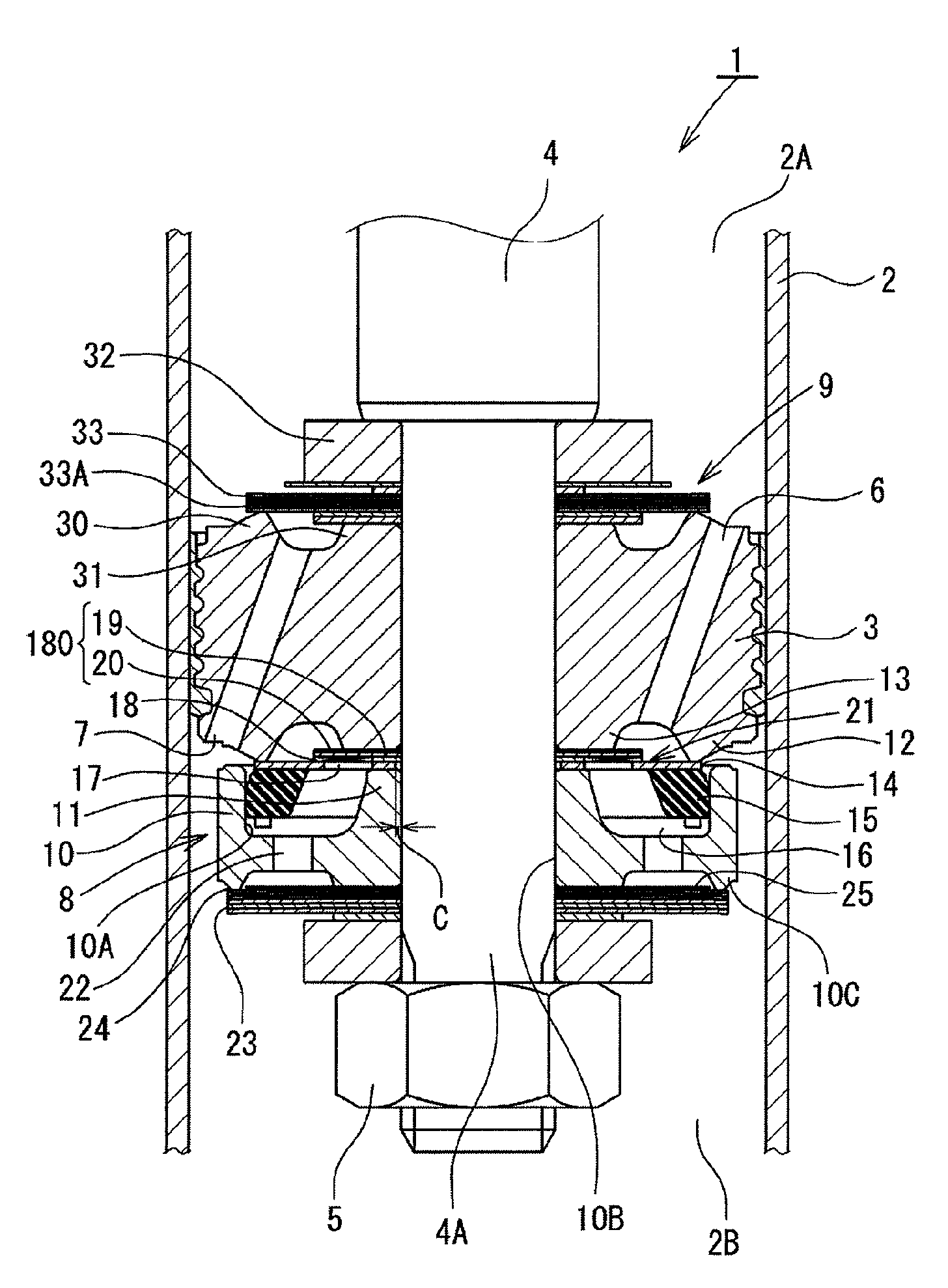

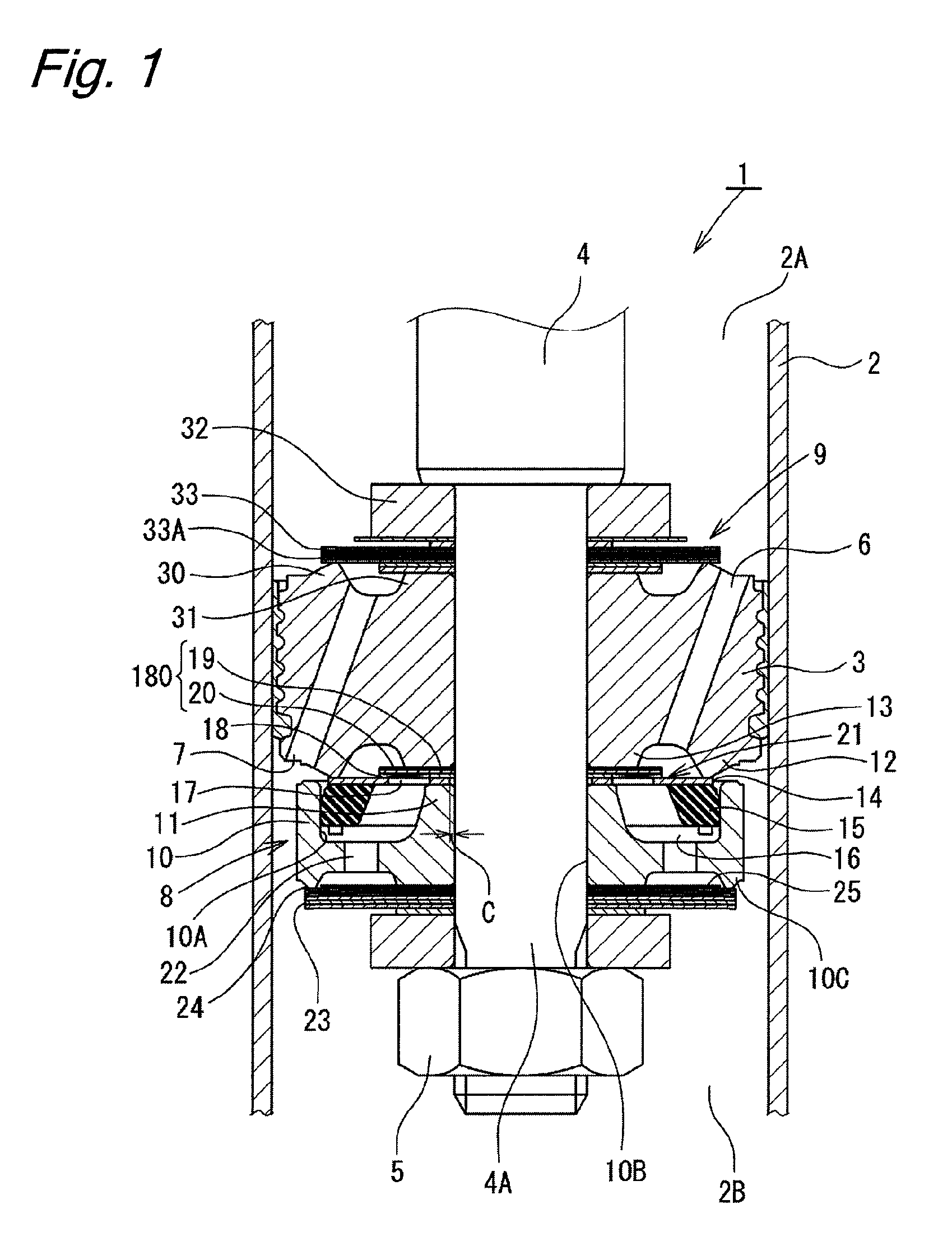

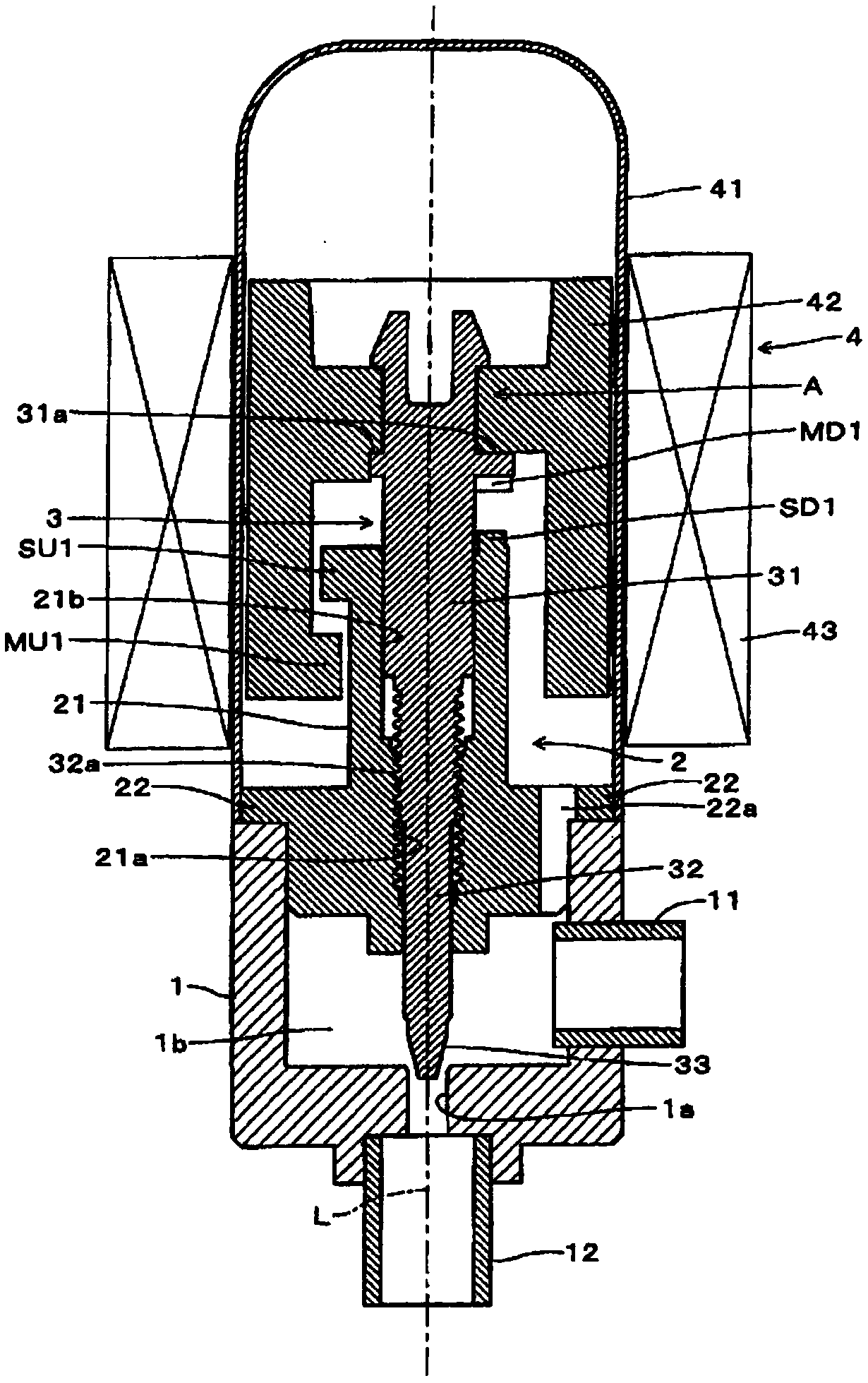

Shock absorber

ActiveUS20120048666A1Improve coaxialityDecrease productivitySpringsLiquid based dampersEngineeringSliding contact

A piston connected to a piston rod is fitted in a cylinder having a hydraulic oil sealed therein. Flows of hydraulic oil induced by sliding movement of the piston are controlled by extension and compression damping force generating mechanisms and to generate damping force. In the extension damping force generating mechanism, the valve-opening pressure of a disk valve is controlled by the pressure in a back pressure chamber. An elastic seal member fixed to the disk valve is brought into sliding contact with an inner peripheral surface of a cylindrical portion of a valve member to seal the back pressure chamber. The disk valve is self-aligned by fitting between the elastic seal member and the inner peripheral surface of the valve member and secured by being axially clamped at an inner peripheral portion thereof in a state where a clearance is formed between the inner peripheral portion of the disk valve and a shaft portion of the piston rod, thereby reducing the requirements for coaxiality.

Owner:HITACHI ASTEMO LTD

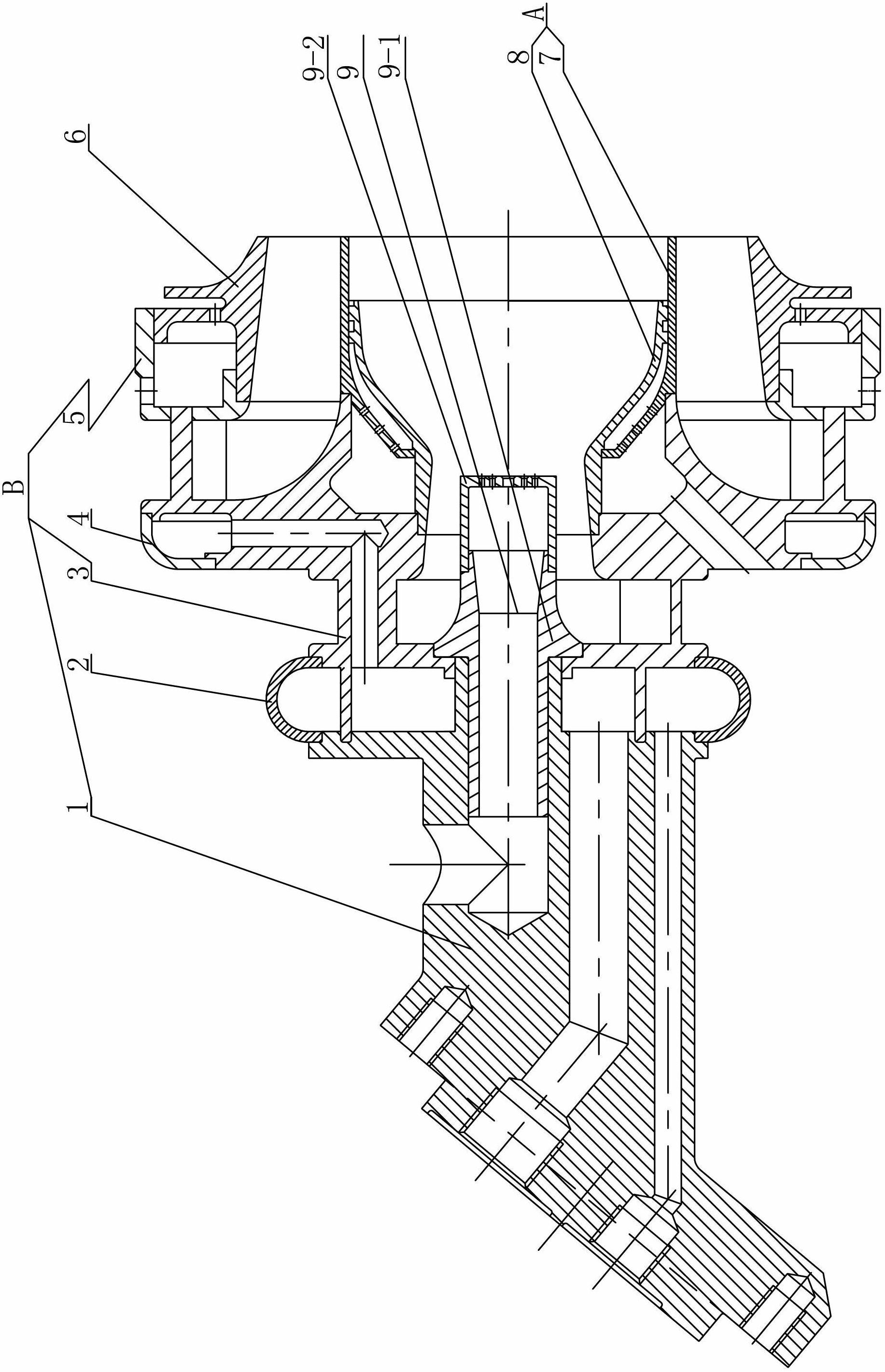

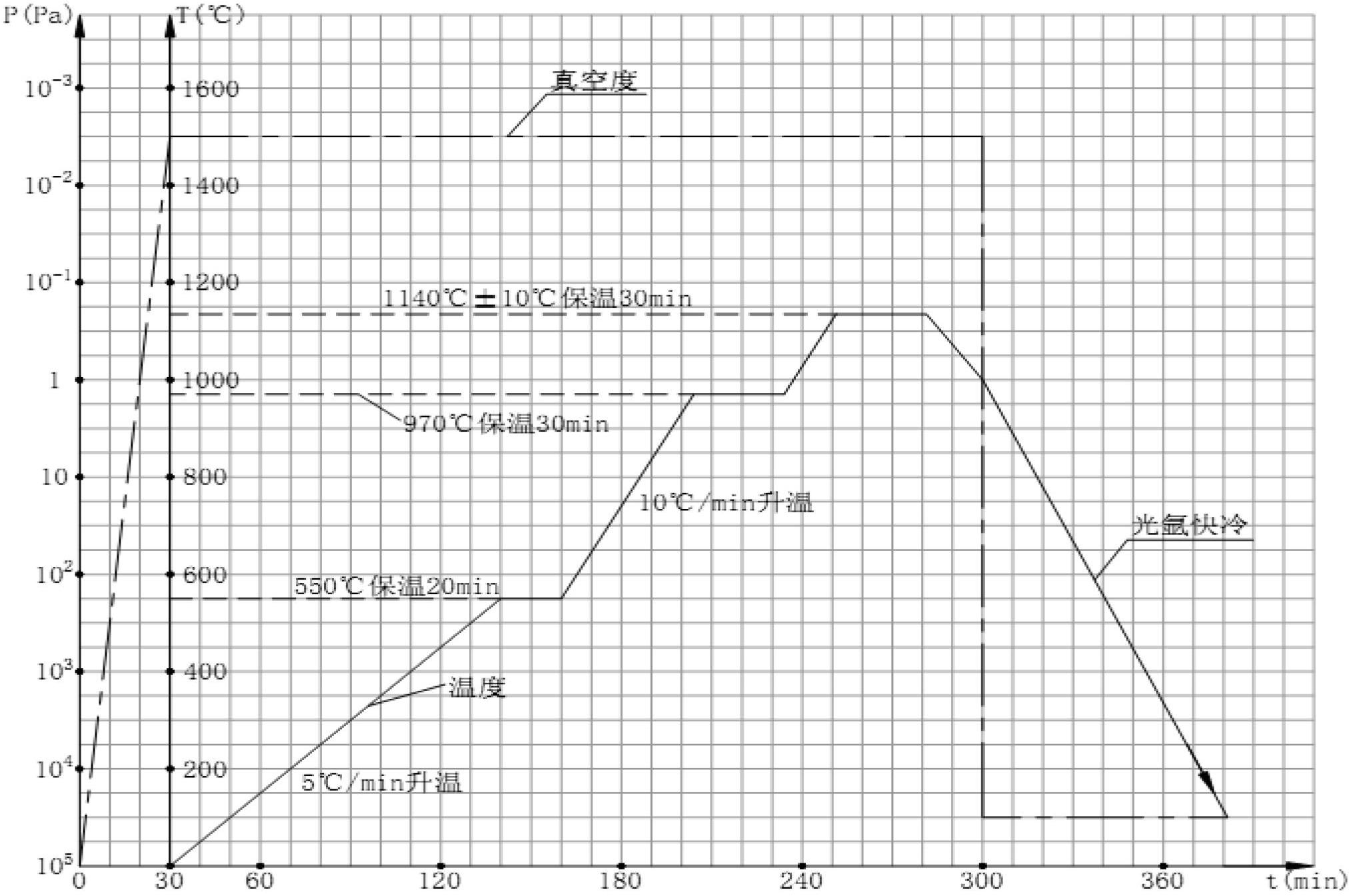

Vacuum brazing method of gas burner of combustion chamber of gas turbine

The invention discloses a vacuum brazing method of a gas burner of a combustion chamber of a gas turbine, which relates to a welding method of a gas burner, in particular to a vacuum brazing method of a gas burner of a combustion chamber of a gas turbine, and solves the problems that the welding quality is poor, the welding deformation is big, and the production period and the quality of the gas turbine are affected when the prior art is adopted for welding the gas burner. The method comprises the following main steps: firstly, cleaning all surfaces, operating platforms and jig surfaces of parts of a nozzle to be welded, secondly, performing primary welding, thirdly, performing primary brazing filler metal coating, fourthly, performing primary brazing, fifthly, performing secondary welding, sixthly, performing secondary brazing filler metal coating, and seventhly, performing secondary brazing. The method is used for welding the gas burner of the combustion chamber of the gas turbine.

Owner:HARBIN TURBINE +1

Shock absorber

ActiveUS8584818B2Improve coaxialityReduce distractionsSpringsShock absorbersSliding contactPiston rod

A piston connected to a piston rod is fitted in a cylinder having a hydraulic oil sealed therein. Flows of hydraulic oil induced by sliding movement of the piston are controlled by extension and compression damping force generating mechanisms and to generate damping force. In the extension damping force generating mechanism, the valve-opening pressure of a disk valve is controlled by the pressure in a back pressure chamber. An elastic seal member fixed to the disk valve is brought into sliding contact with an inner peripheral surface of a cylindrical portion of a valve member to seal the back pressure chamber. The disk valve is self-aligned by fitting between the elastic seal member and the inner peripheral surface of the valve member and secured by being axially clamped at an inner peripheral portion thereof in a state where a clearance is formed between the inner peripheral portion of the disk valve and a shaft portion of the piston rod, thereby reducing the requirements for coaxiality.

Owner:HITACHI ASTEMO LTD

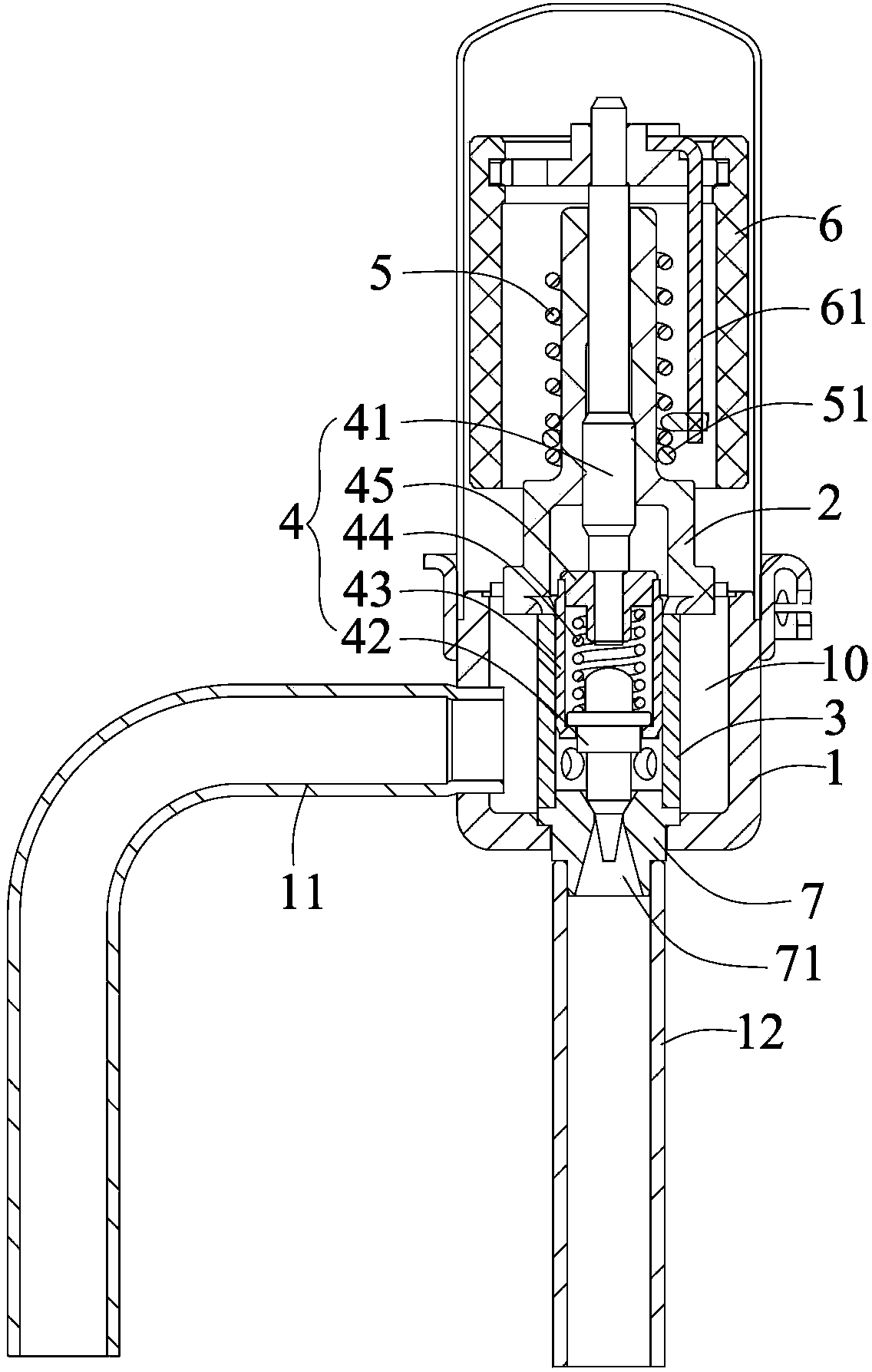

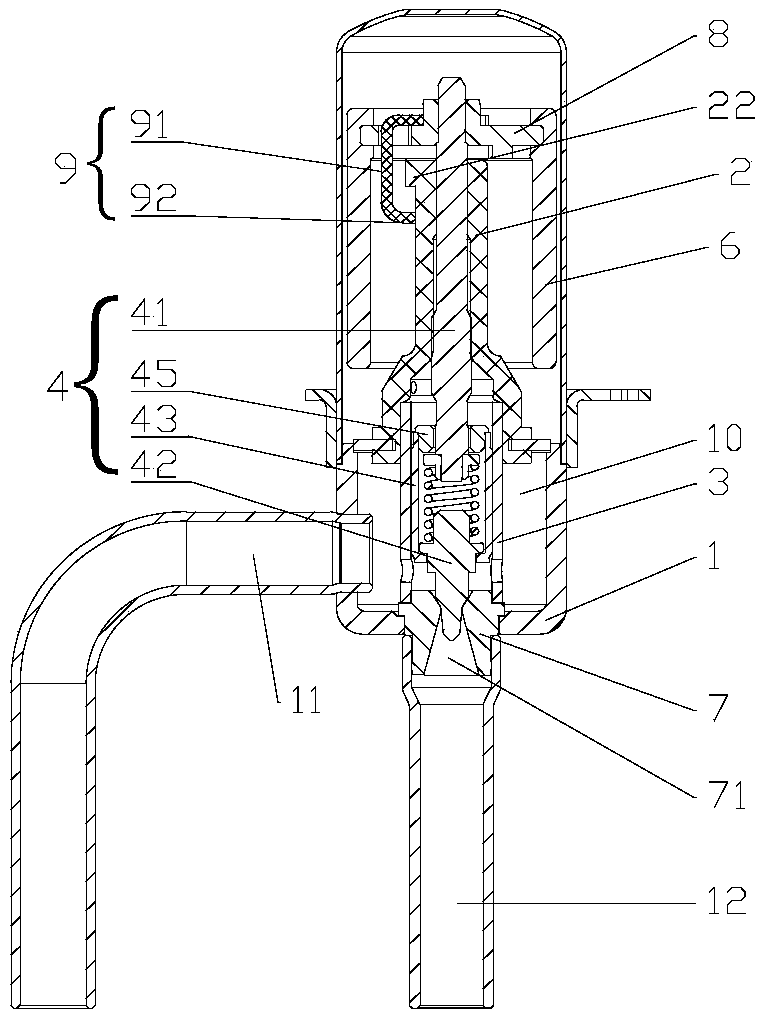

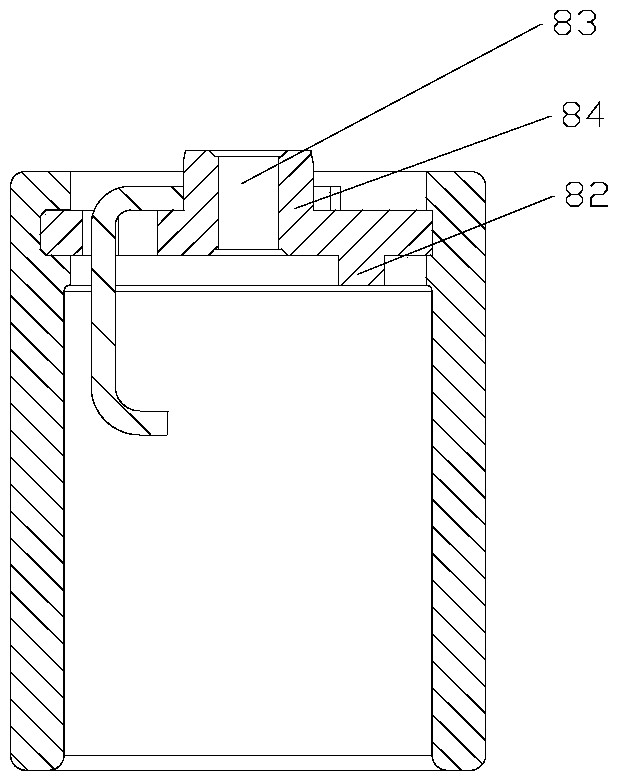

Electronic expansion valve

InactiveCN104279342AReduce wearImprove coaxialityEfficient regulation technologiesFluid circulation arrangementInjection mouldingRefrigeration

The invention discloses an electronic expansion valve, belongs to the technical field of refrigeration system control, and solves the technical problem of wear caused by the coaxiality difference between the existing electronic expansion valve nut and a valve needle assembly. The electronic expansion valve comprises a valve body, a nut, a valve needle assembly and a guide sleeve, wherein the nut and the guide sleeve are assembled on the valve body, and the valve needle is arranged on the nut; the nut and the guide sleeve are integrally molded by injection.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

High-speed gearbox processing method

ActiveCN104308468AControl coaxialityGuarantee the positioning accuracy of combined processingOffset distanceEngineering

The invention discloses a high-speed gearbox processing method, which is characterized in that when a body is roughly processed, a screw hole for matching a rear cover having roughly processed end faces in a processing body, coaxial bearing holes of the body and the rear cover, and a location pinhole for matching the body and the rear cover are adopted to guarantee the coaxiality of coaxial bearing holes of a gearbox and the position accuracy of the screw hole and the location pinhole; meanwhile after the end faces, various stages of bearing holes and gear pump holes are finely processed in gearbox combination processing, the high-speed bearing hole center of the gearbox and the rotation center of a machine tool are coincided by using a special spindle for equipment, then various inclined holes in the gearbox are drilled, a boring rod offset distance and an angle of the inclined hole shorter than the circle center offsetting the high-speed bearing hole center of the gearbox are calculated at the same time, and the position accuracy of the inclined holes in the gearbox is guaranteed.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

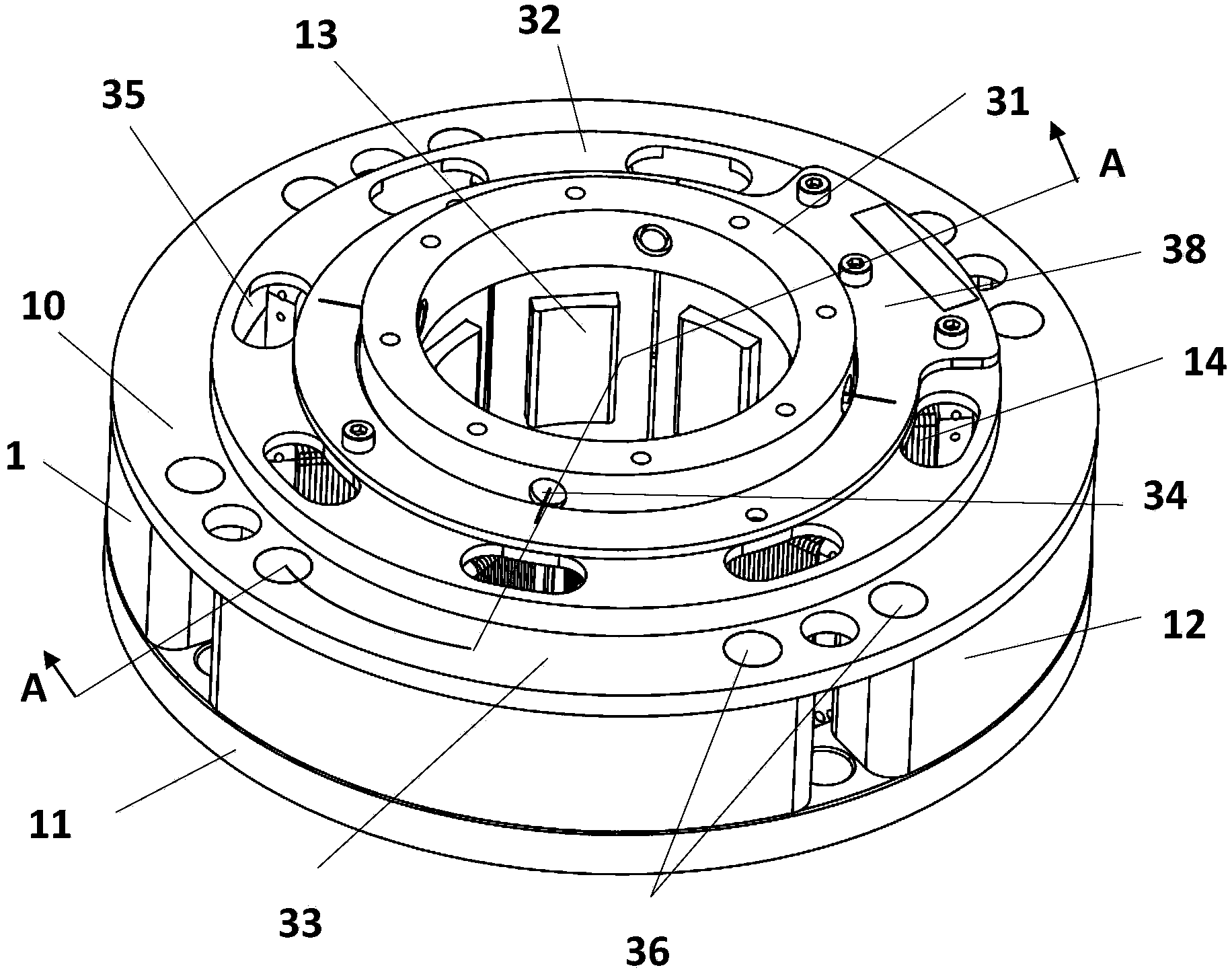

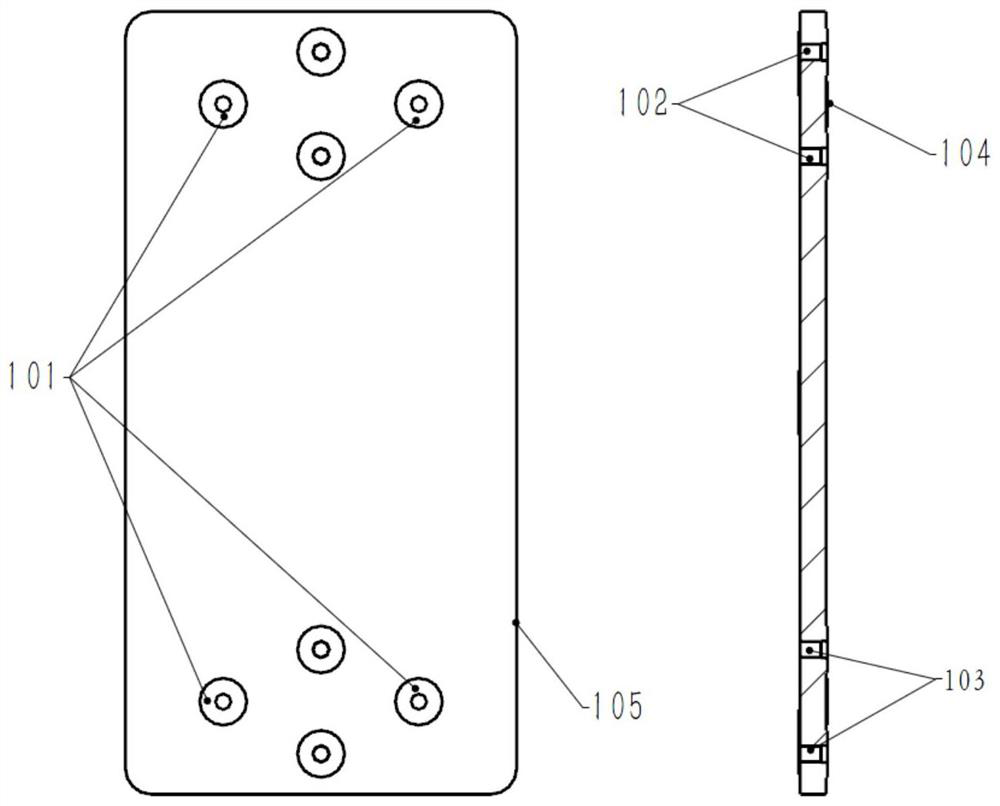

Installation structure and installation method of radial magnetic bearing and radial sensor

InactiveCN104343820ACoaxiality error is smallControl coaxialityBearing assemblyBearingsElectrical and Electronics engineeringMagnetic bearing

The invention discloses an installation structure of a radial magnetic bearing and a radial sensor and an installation method of the installation structure of the radial magnetic bearing and the radial sensor. The installation structure is characterized in that the radial magnetic bearing comprises an upper pressing plate, a lower pressing plate and silicon steel sheets, wherein coil frameworks are respectively installed on the inner side surfaces of the silicon steel sheets; coils are respectively intertwined on the coil frameworks; after the external circular arc surfaces of the silicon steel sheets are surrounded, the external cylindrical surface of the radial magnetic bearing is formed; after the inner side tail ends of the coil frameworks are surrounded, the internal cylindrical surface of the radial magnetic bearing is formed; the upper pressing plate comprises an upper step, a middle step and a lower step; a circular hole is formed in the middle of the upper pressing plate; a plurality of through holes are uniformly formed at intervals in the periphery of the round hole in the upper step; a plurality of groups of penetration holes are formed in the lower step; two outmost holes among the penetration holes are pin holes; the pin holes are also formed in the places, corresponding to the pin holes in the upper pressing plate, of the lower pressing plate; cylindrical pins are arranged in the pin holes in the lower pressing plate and the pin holes in the upper pressing plate in a penetrating mode; a magnetic bearing circuit board is arranged on the middle step; after the radial sensor is placed in the through holes, the tail end thereof is electrically connected onto the magnetic bearing circuit board.

Owner:NANJING CIGU TECH CORP LTD

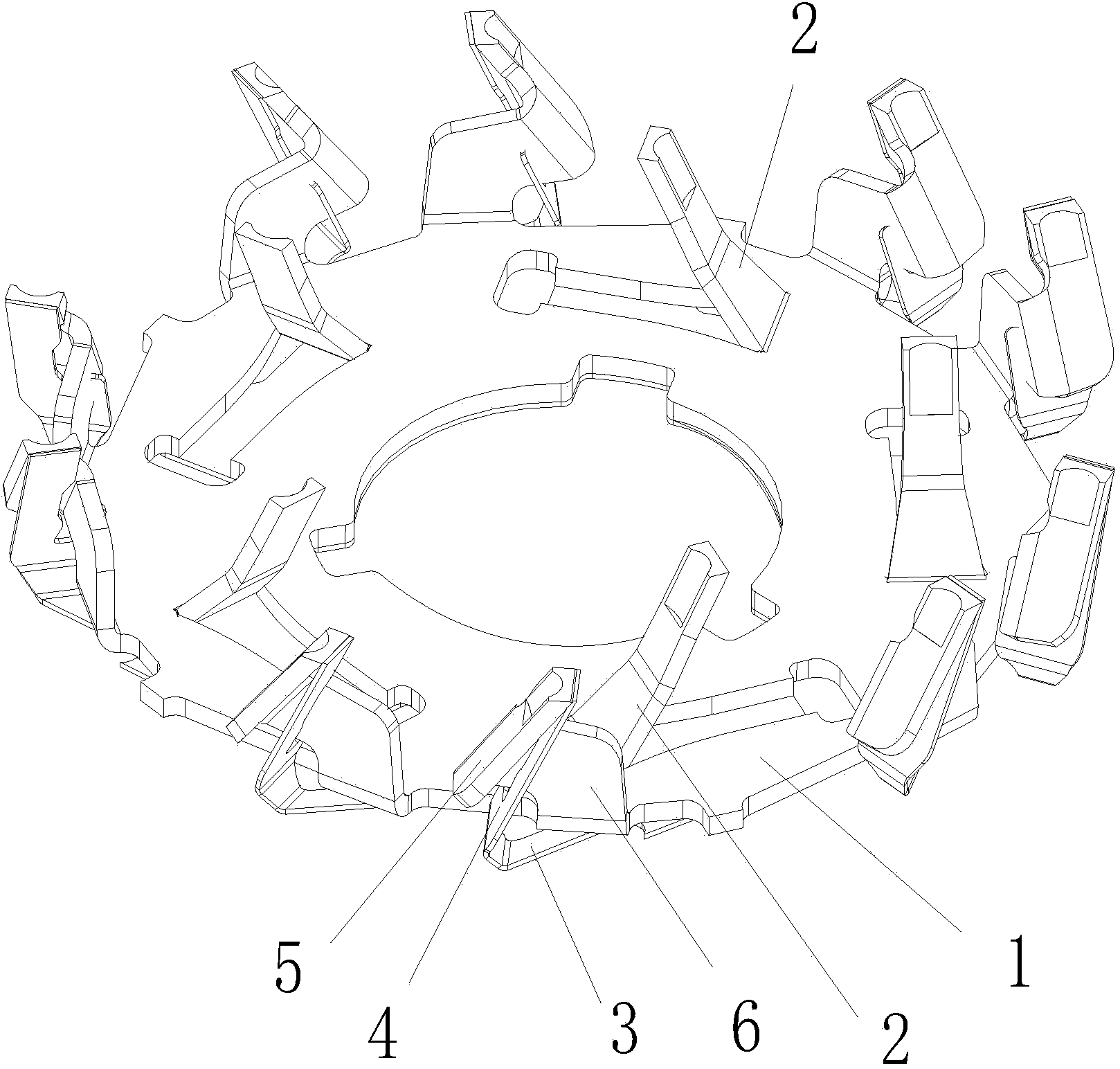

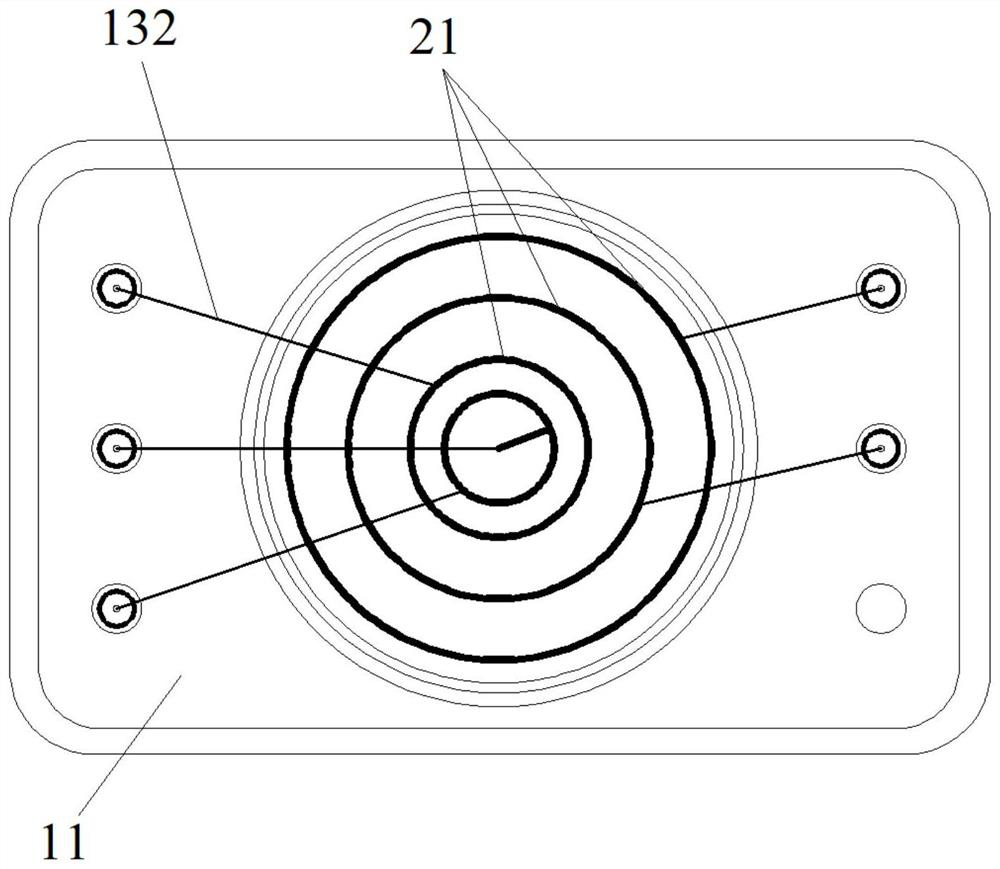

Shaving head device of rotary type electric shaver

ActiveCN103707332AImprove shaving effectImprove matrix strengthMetal working apparatusElectric razorsUltimate tensile strength

The invention relates to a shaving head device of a rotary type electric shaver. The shaving head device comprises a shaving head blade and a blade net, and is characterized in that the shaving head blade comprises inner circle knives and outer circle knives, the inner circle knives and the outer circle knives are concentrically arranged on a main blade base, auxiliary blades are arranged at the bottom of the main blade base, and elastic auxiliary knives are arranged on the peripheries of the auxiliary blades; the auxiliary knives are arranged at the front ends of the working portions of the outer circle knives of a main blade when the outer circle knives rotate, included angles are formed between the auxiliary knives and the outer circle knives of the main blade, and the auxiliary knives rebound after being in contact with beards to be then in contact with the outer circle knives to be lifted upwards. According to the structure of the shaving head device, the strength of a base body can be effectively improved through the inner circle knives, it is guaranteed that the coincidence of running tracks of the knives in working is high, the service life of the knives is prolonged, the matching degree of the blade and the blade net is improved, the sharpness is high, and the sound coincidence is high. The beards can conveniently enter the blade net at multiple angles through the design of the M-shaped blade net, and the shaving efficiency is improved.

Owner:HAINING XINYI MACHINERY & ELECTRICAL

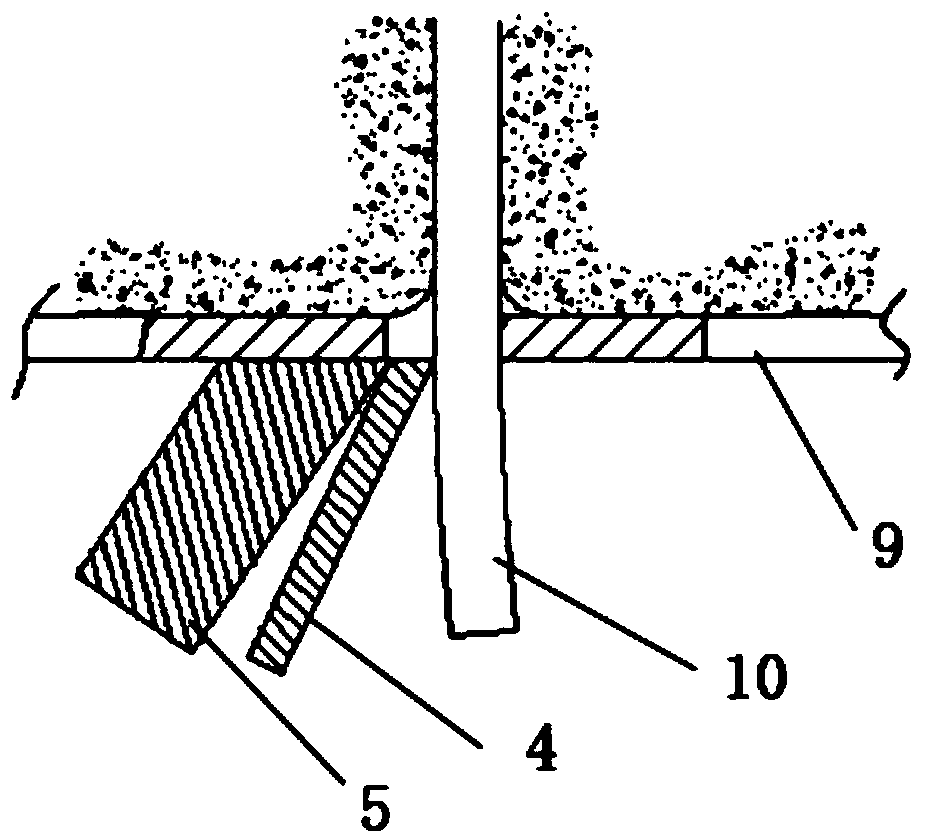

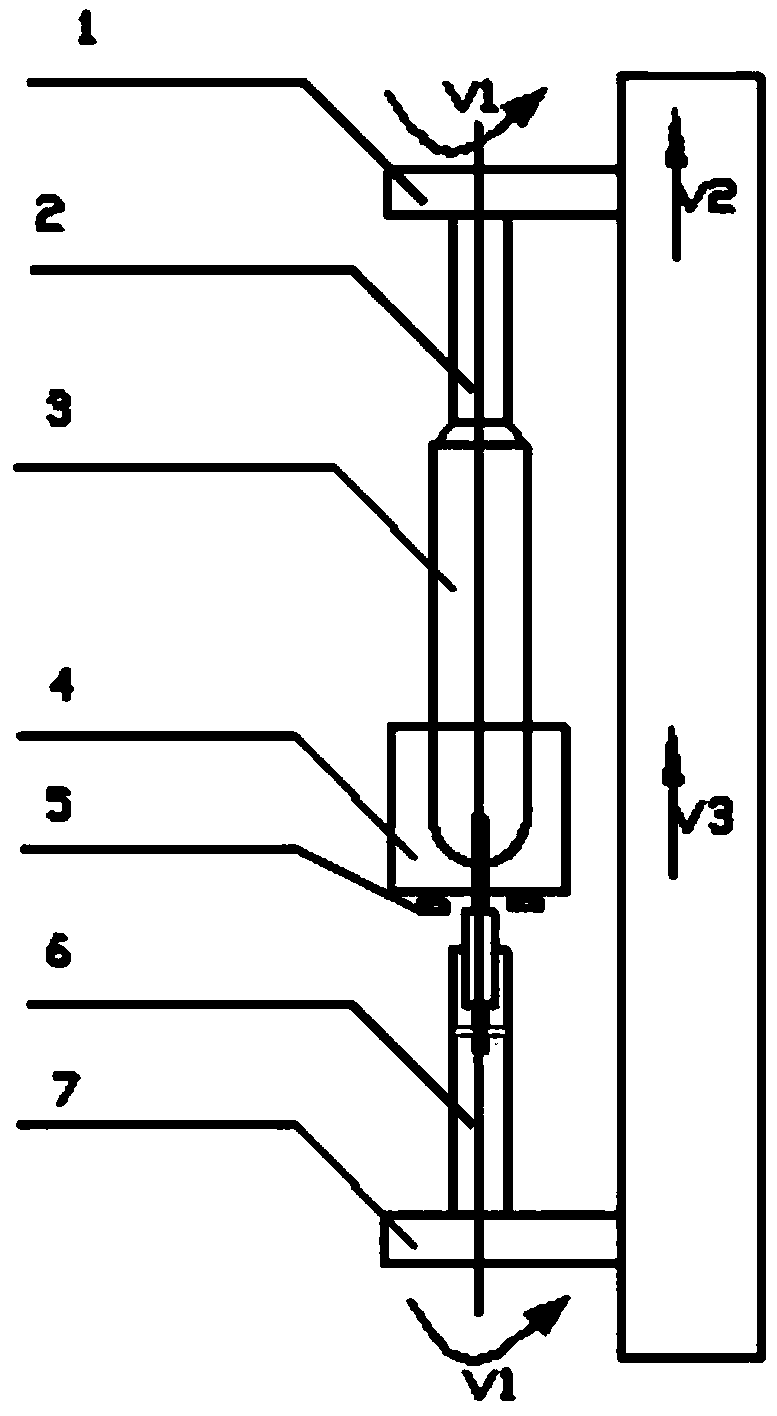

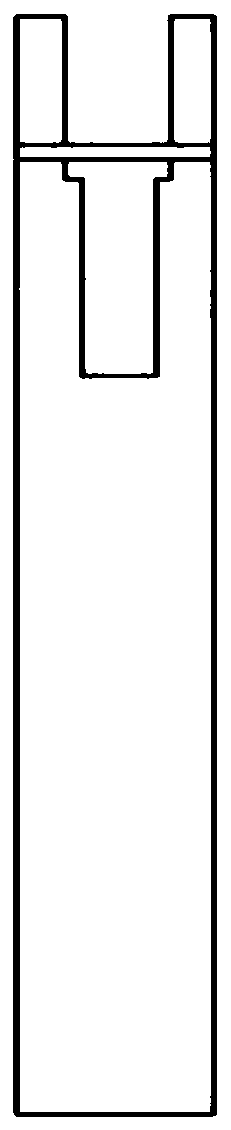

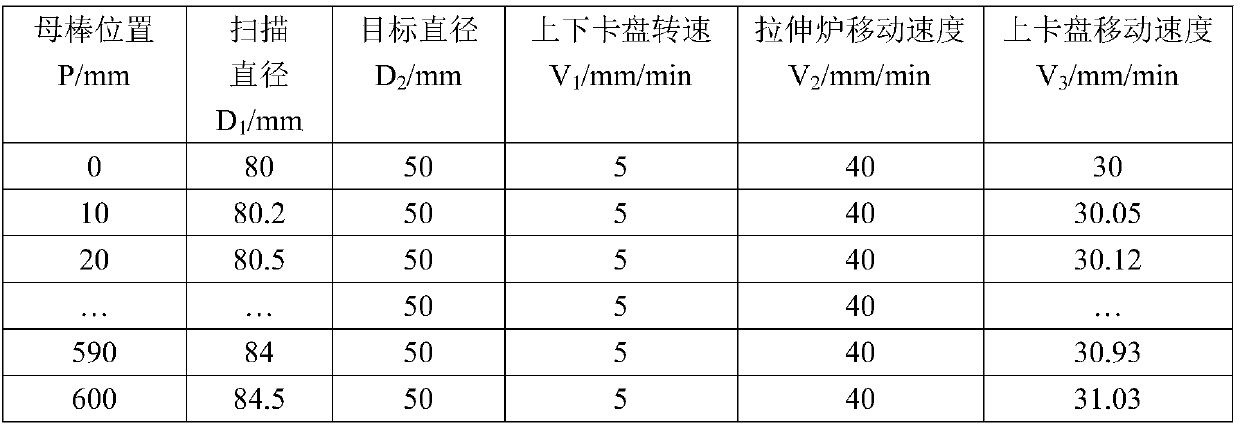

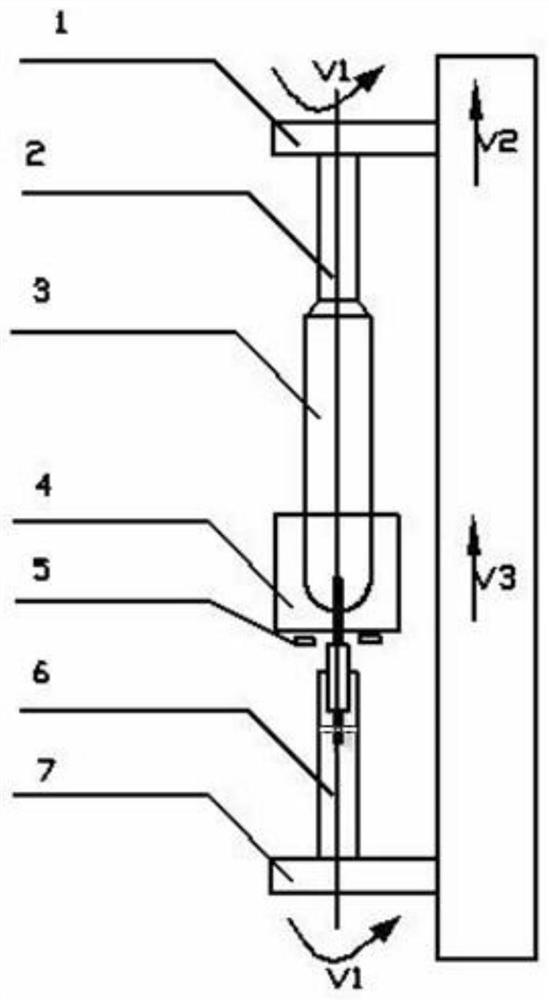

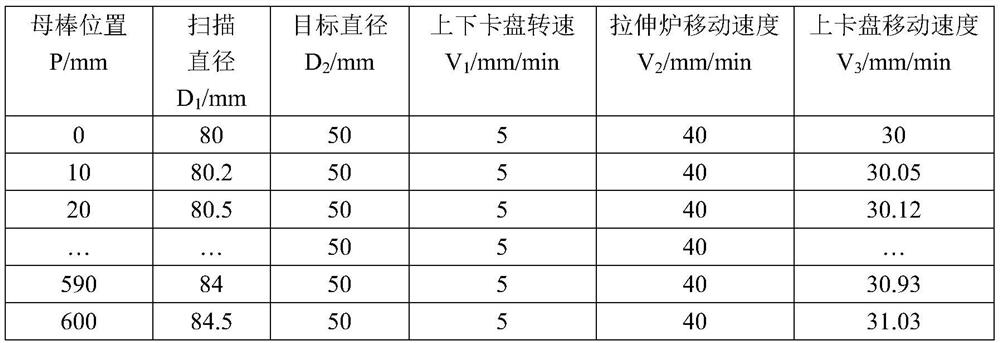

Stretching device and stretching method for VAD sintered optical fiber prefabricated base bar

The invention relates to a stretching device and a stretching method for a VAD sintered optical fiber prefabricated base bar. The stretching device comprises an upper chuck, a stretching furnace and alower chuck which are successively arranged along a vertical direction. The stretching method comprises the following steps: measuring and collecting diameter of the optical fiber prefabricated basebar on each position; calculating an upward moving rate of the upper chuck and confirming the upward moving rate of the upper chuck according to the required diameter of stretched core rod, the upwardmoving rate of the stretching furnace and the diameter of the stretched optical fiber prefabricated base bar; synchronously rotating the upper chuck and the lower chuck at a same rotation rate beforeheating and stretching, and then starting to heat the lower end of the optical fiber prefabricated base bar by starting the stretching furnace; controlling the upper chuck to calculate the upward moving rate and stretching the optical fiber prefabricated base bar, thereby forming a core rod. According to the invention, stretching quality and efficiency of optical fiber prefabricated base bar canbe guaranteed, dosage of guiding rod can be reduced and welding times of guiding rod can be reduced.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

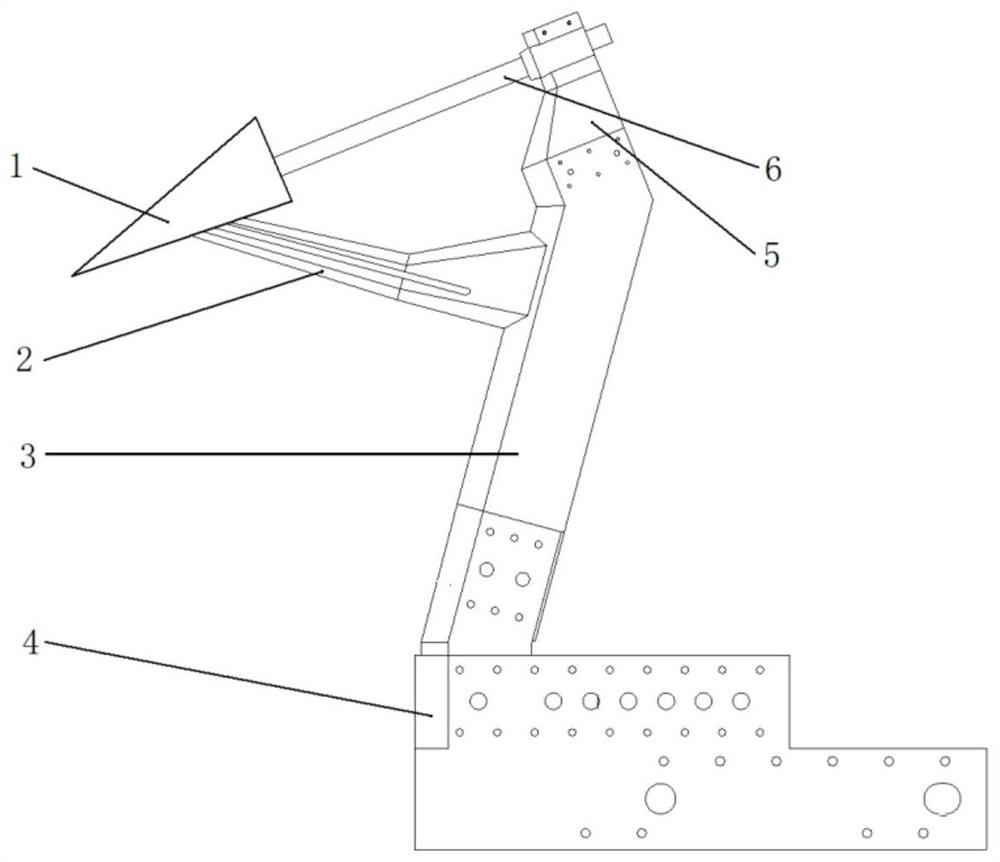

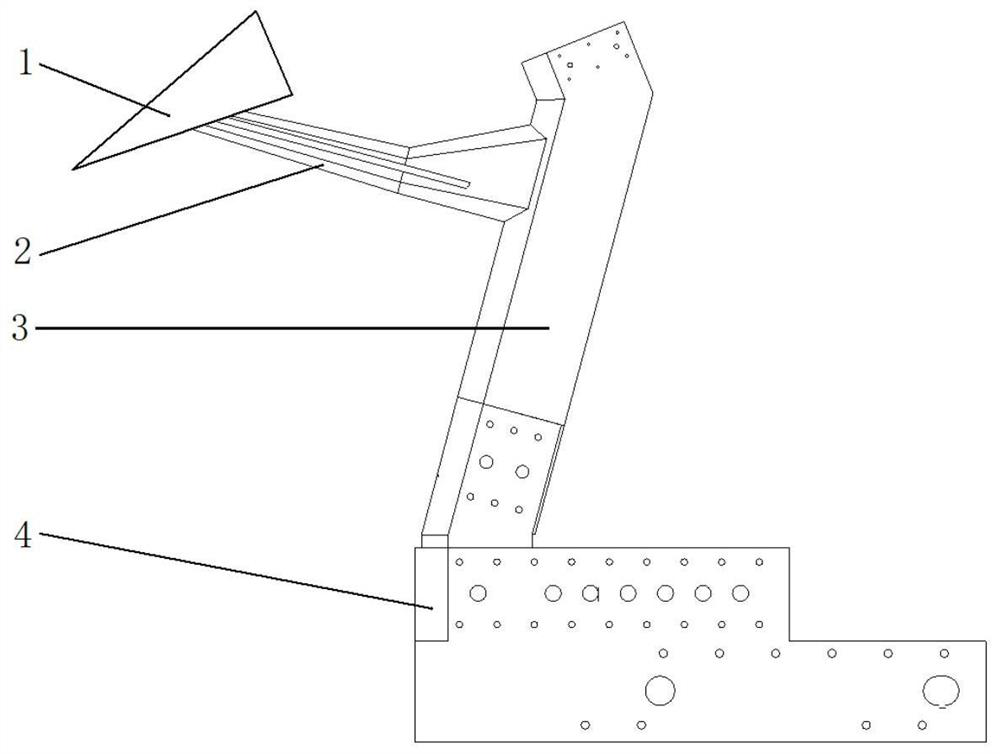

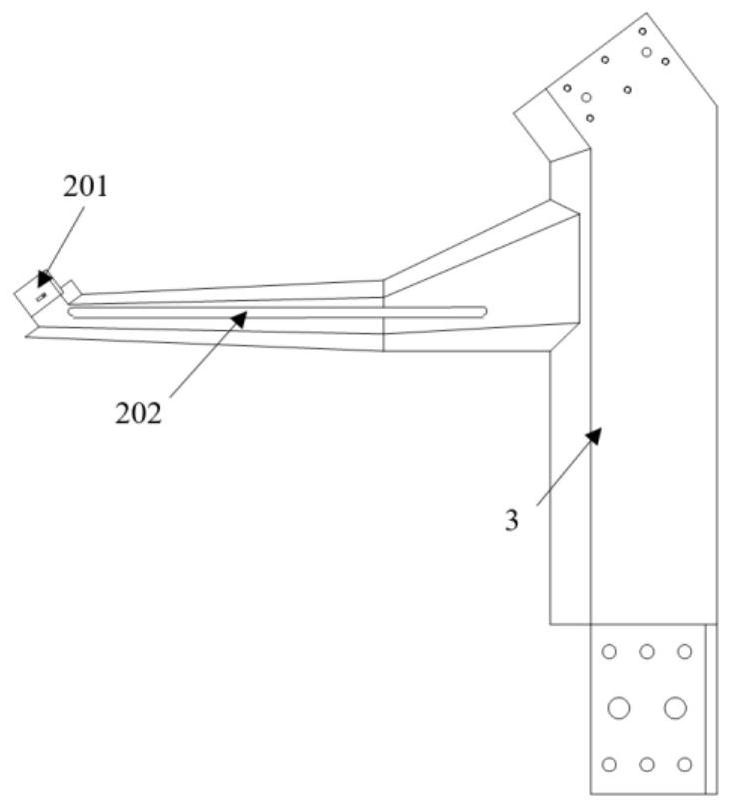

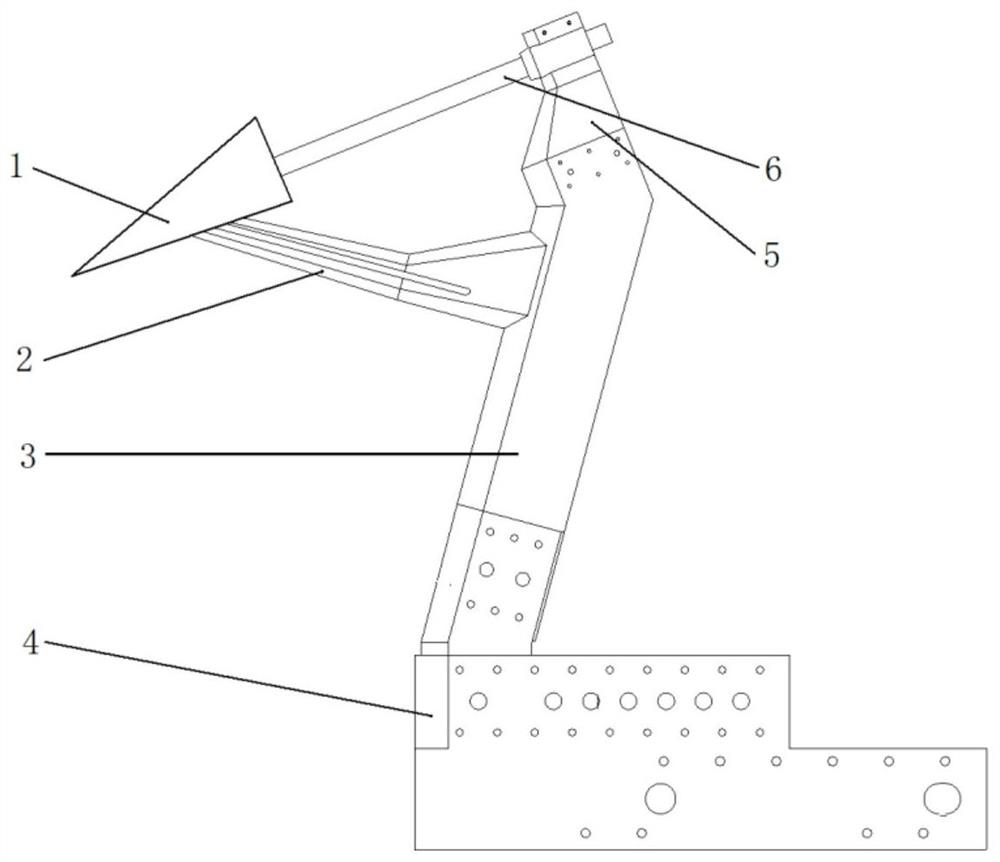

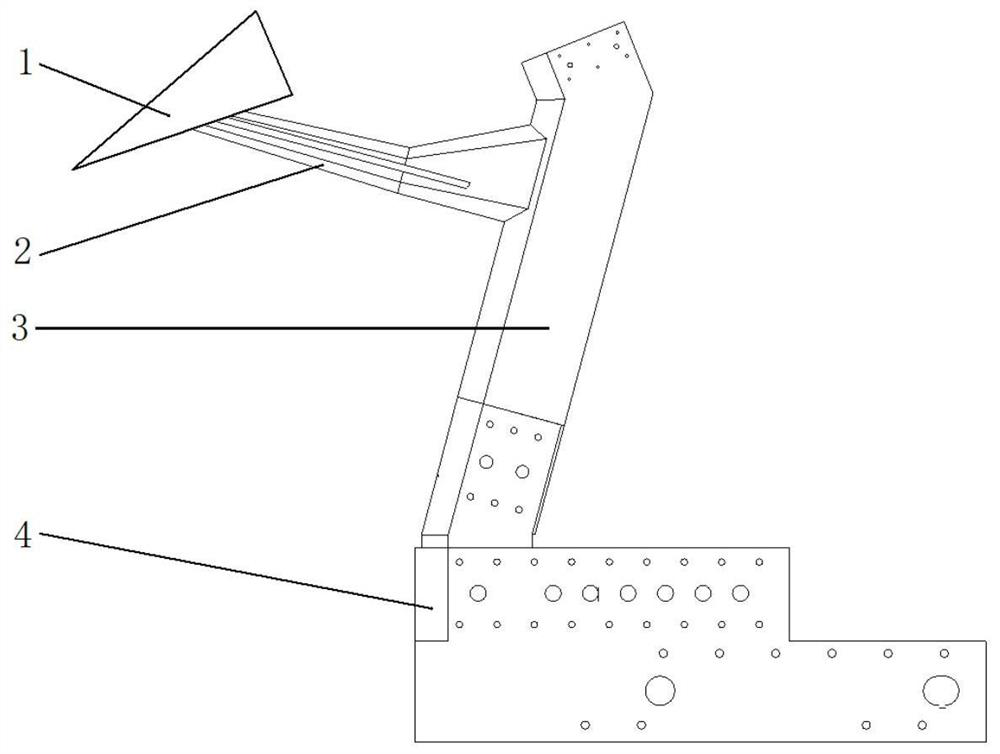

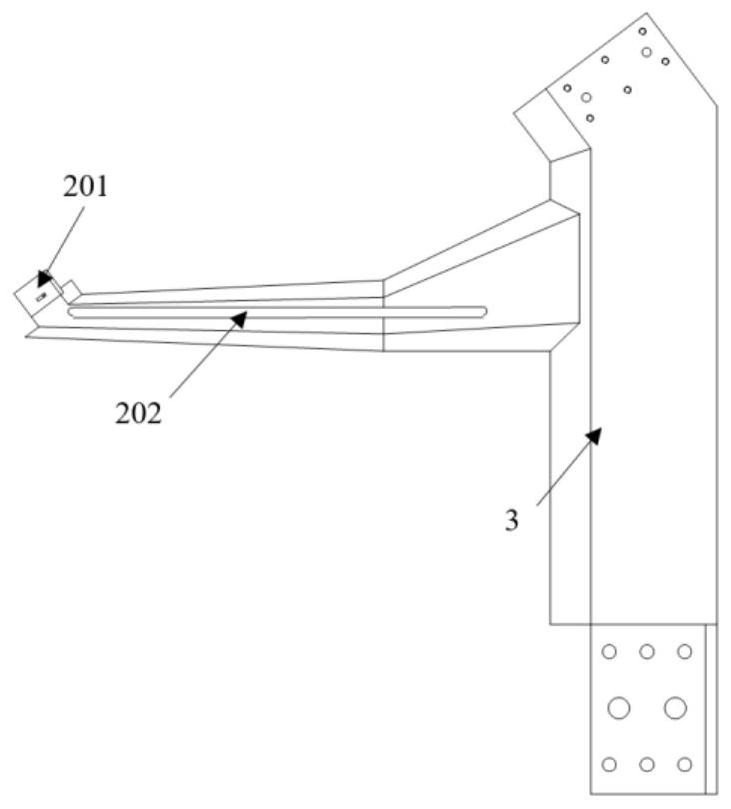

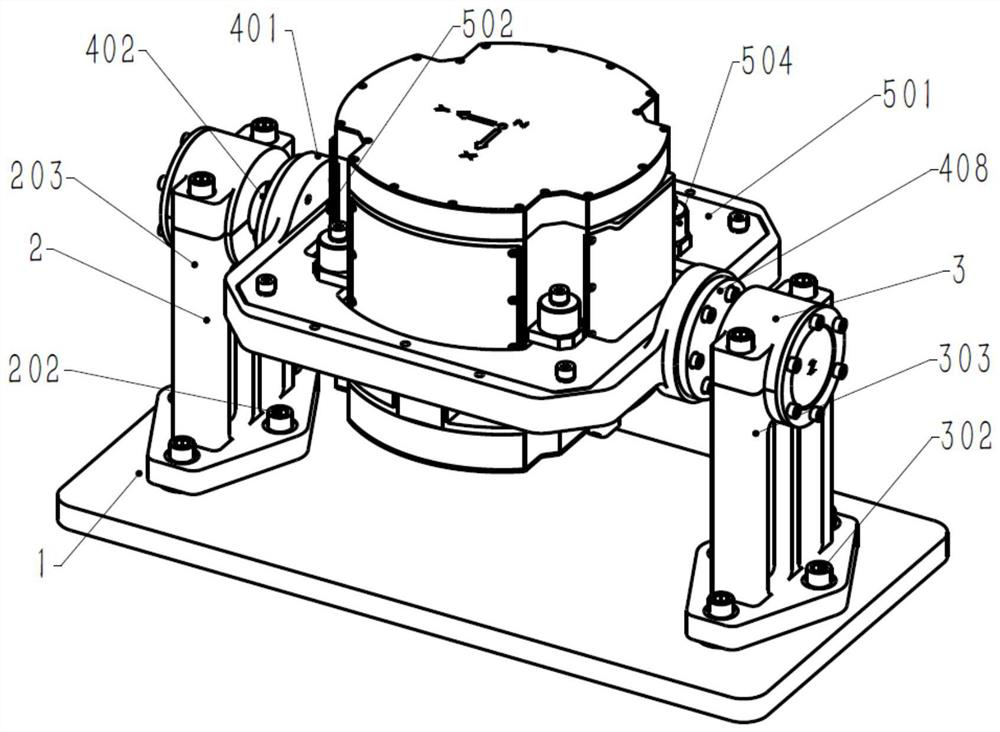

Model supporting device applied to wind tunnel test

ActiveCN112284676AInterference minimizationThe strength of the supporting structure is reasonableAerodynamic testingWall plateBack support

The invention discloses a model supporting device applied to a wind tunnel test. The device comprises a model back support, a false tail supporting rod and a middle support which form a triangular connecting structure, wherein the model back support and the middle support are integrally machined; a balance is installed in the model, the model back support is supported on the back of the model, thefalse tail support rod stretches into the tail of the model and is isolated from the model without making contact with the model, the false tail support rod is fixed to the false tail support rod support, and the model back support and the false tail support rod support are fixedly connected to the upper portion of the middle support; the lower end of the middle support extends downwards and is fixed to a bottom supporting platform, and the bottom supporting platform is fixed to a wind tunnel lower wall plate. The device is compact in structure, miniaturized, reasonable in layout and convenient to use, effectively reduces the interference of the size and shape of the support on the aerodynamic force of the model, and meets the requirements of a wind tunnel model support system.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

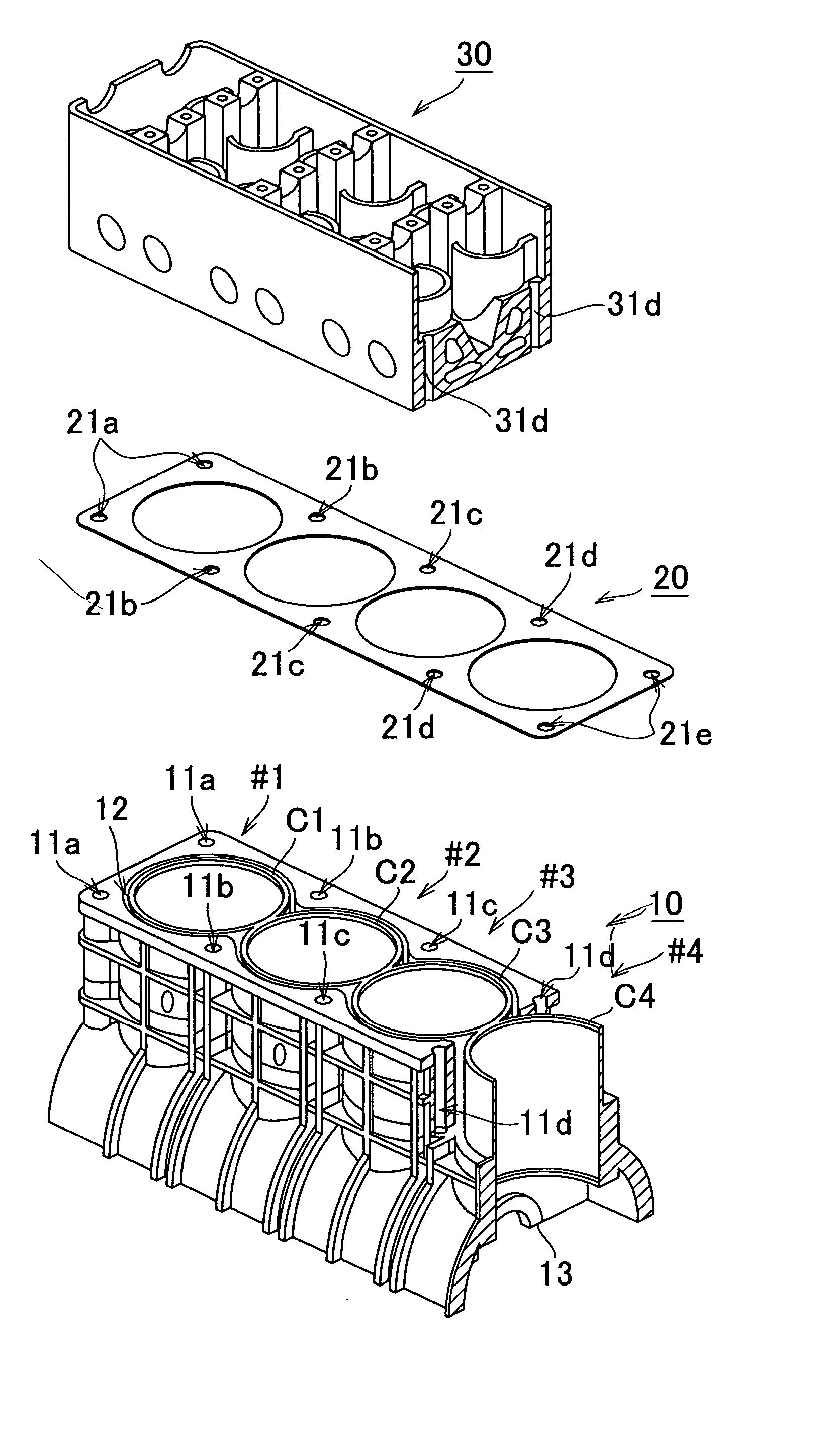

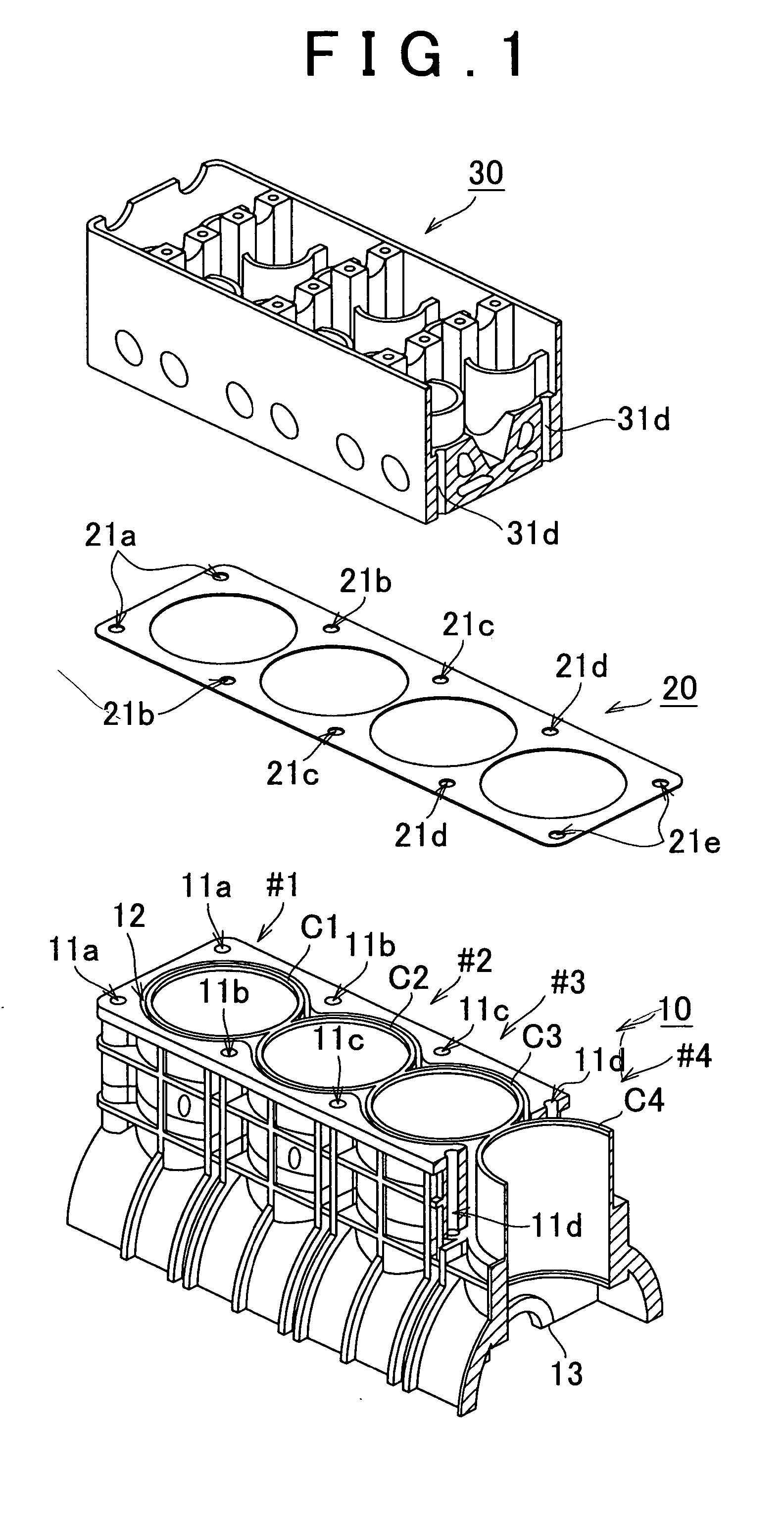

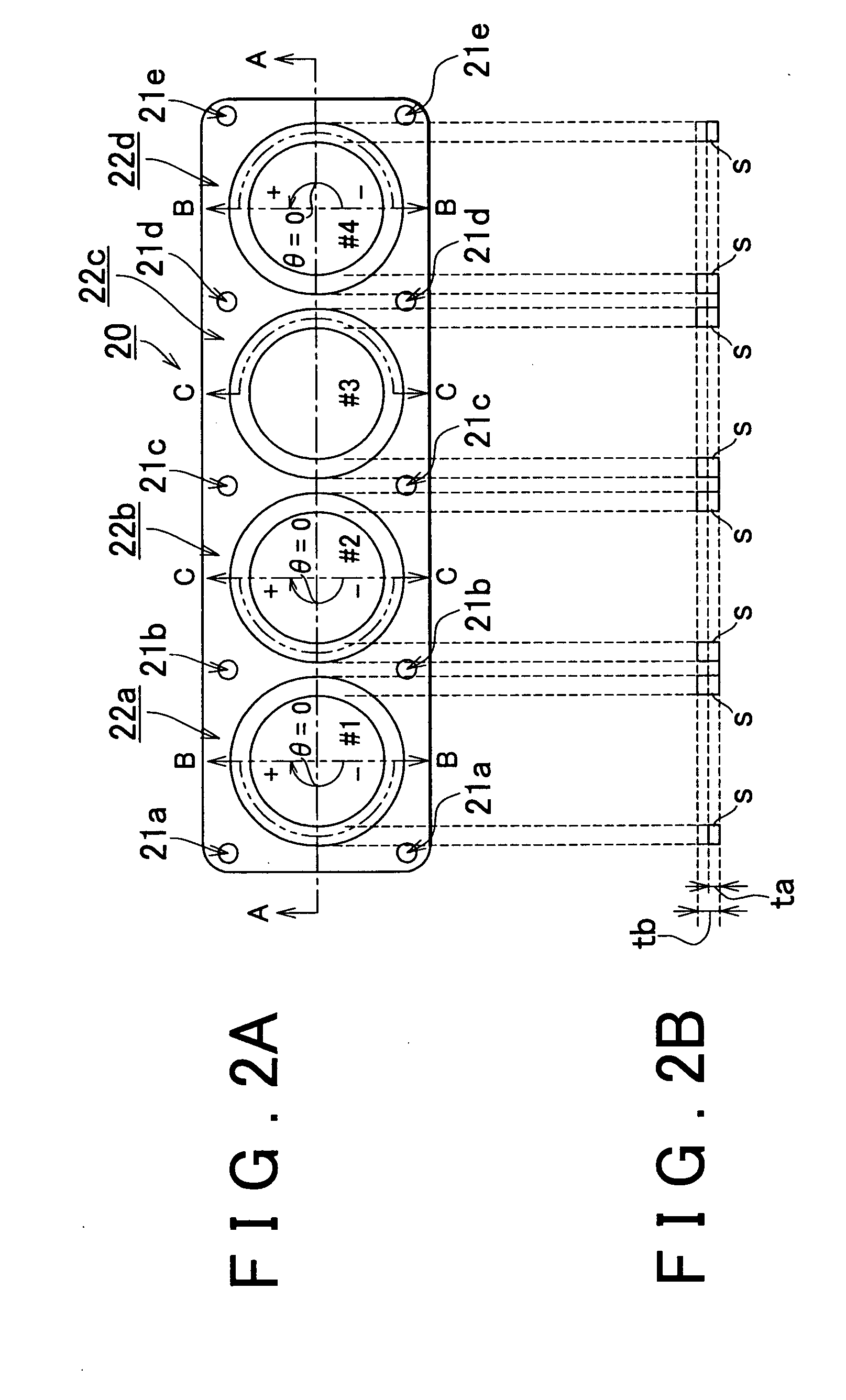

Seal structure for multi-cylinder internal combustion engine

InactiveUS20050046118A1Suppress mutationAppropriately appliedEngine sealsCylinder headsInternal combustion engineGasket

A gasket has seal portions at portions contacting peripheries of upper end portions of internal surfaces of cylinders, respectively. By being provided with a stopper, each of the seal portions is formed as a thick portion in the gasket. The stopper of each of the seal portions has a portion whose thickness is greater than a thickness of the stopper of each of the seal portions corresponding to cylinders at both ends of the cylinder alignment.

Owner:TOYOTA JIDOSHA KK

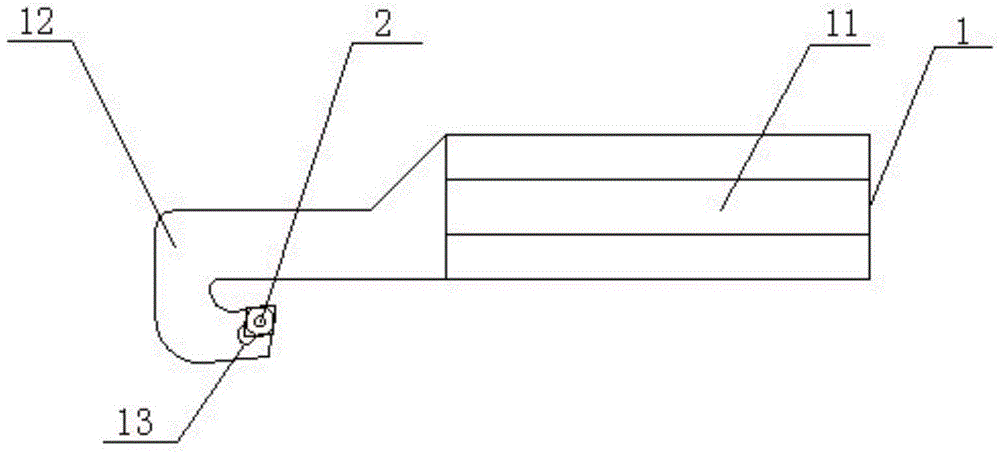

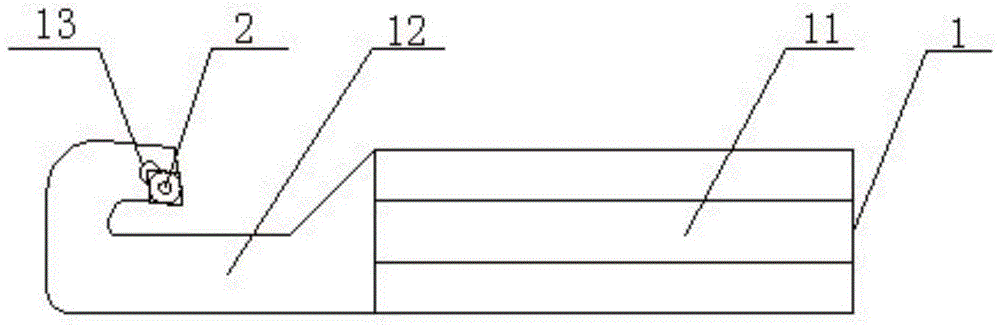

Machining tool and machining method for controlling coaxiality and parallelism of parts

InactiveCN104308205AImprove processing efficiencyReduce processing costsTurning toolsMetal working apparatusMachine partsEngineering

The invention provides a machining tool and a machining method for controlling the coaxiality and parallelism of parts. The machining tool comprises a turning tool rod and a machining blade, wherein the turning tool rod is shaped like an L, and comprises a turning tool rod clamping part and a turning tool rod machining part, and the machining blade is connected with one end, which is opposite to the turning tool rod clamping part on the turning tool rod, of the turning tool rod. The machining method for controlling the coaxiality and parallelism of the parts includes the following steps that firstly, the machining tool is chosen, and the machining tool and the part to be machined are mounted on a machine tool; secondly, a conventional turning tool is utilized to machine the front end surface and a bore of the part to be machined; finally, the tool is replaced, the feed direction of the turning tool rod is adjusted, and the rear end surface or excircle of the part to be machined is machined. The invention can be utilized to better control the parallelism between the front end surface and rear end surface of the part to be machined and the coaxiality between the excircle and bore of the part to be machined, the efficiency of machining is increased, and the cost of machining is reduced.

Owner:MIANYANG FULIN PRECISION MACHINING

Inner and outer shaped surface precise machining process for antenna cover

InactiveCN101478078BAvoid and reduce the impact of machining accuracyImprove Guidance AccuracyAntenna adaptation in movable bodiesRadiating element housingsNumerical controlEngineering

The invention relates to a precise process procedure for internal and external moulding surfaces of an antenna dome. The precise process procedure comprises the following main steps: (1) datum grinding process; (2) test process; (3) antenna dome installation process; (4) coarse and fine grinding process of external moulding surface of the antenna dome; (5) external moulding surface test process; (6) antenna dome installation and conversion process; (7) coarse and fine grinding process of internal moulding surface of the antenna dome; (8) test process; and (9) electrical thickness test process. The invention further relates to active position-finding technological equipment supporting installation of the antenna dome outside a machine, which consists of an external moulding surface special fixture (20), an internal moulding surface special fixture (30), a position finder (71) and a position finder (72), a position-finding workstation (40) and the like. The active position-finding technological equipment significantly improves the installation accuracy and the installation reliability of the antenna dome, significantly improves the working accuracy and the yield of the antenna dome, which in particular improves the coaxial accuracy by two grades or above two grades. By adopting the active position-finding technological equipment supporting installation of the antenna dome outside the machine, the debugging difficulty is significantly reduced; the installation and debugging time is reduced; the and utilization ratio of a numerical control grinder specially used for the antenna dome is effectively improved.

Owner:DONGHUA UNIV

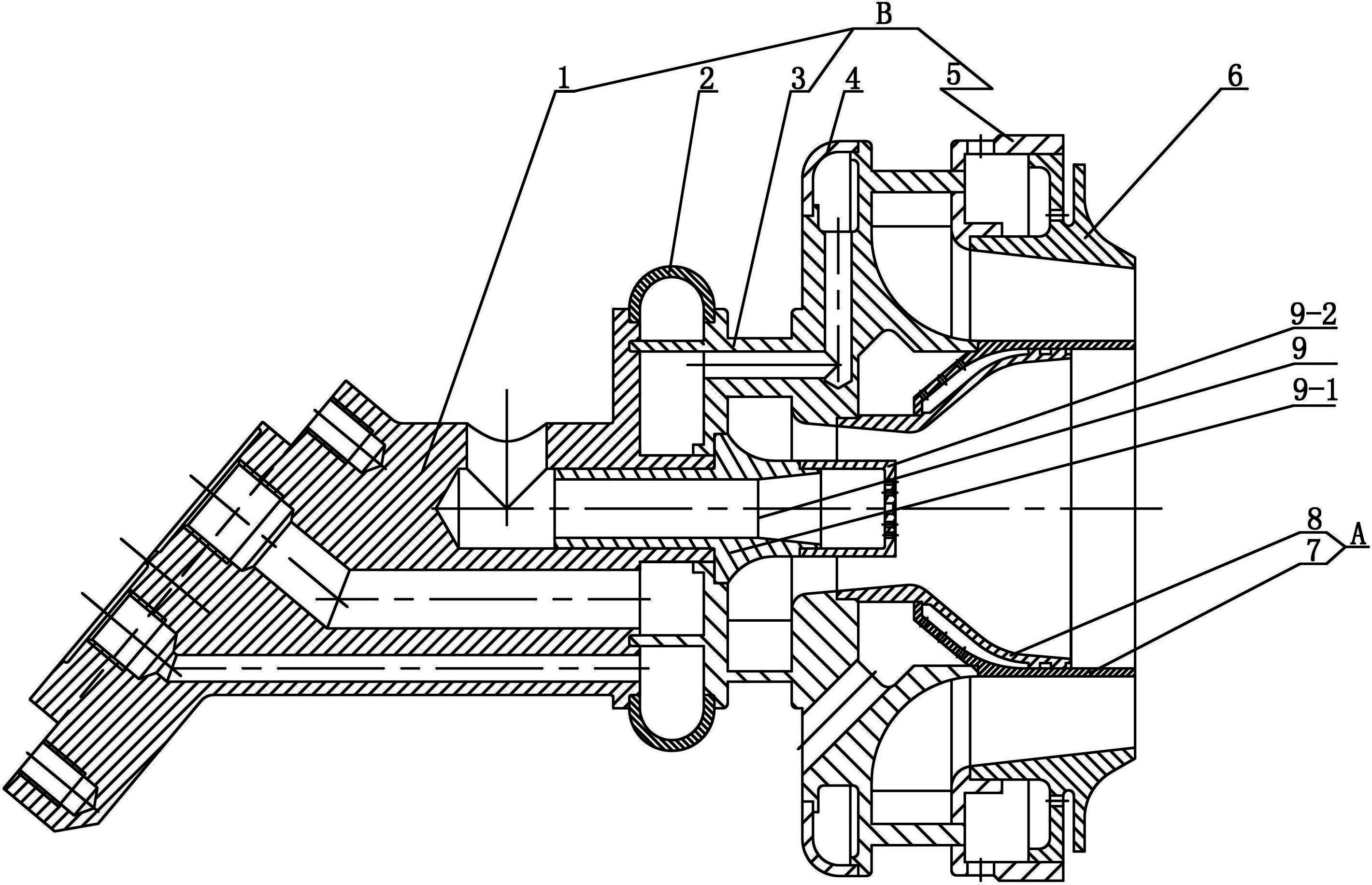

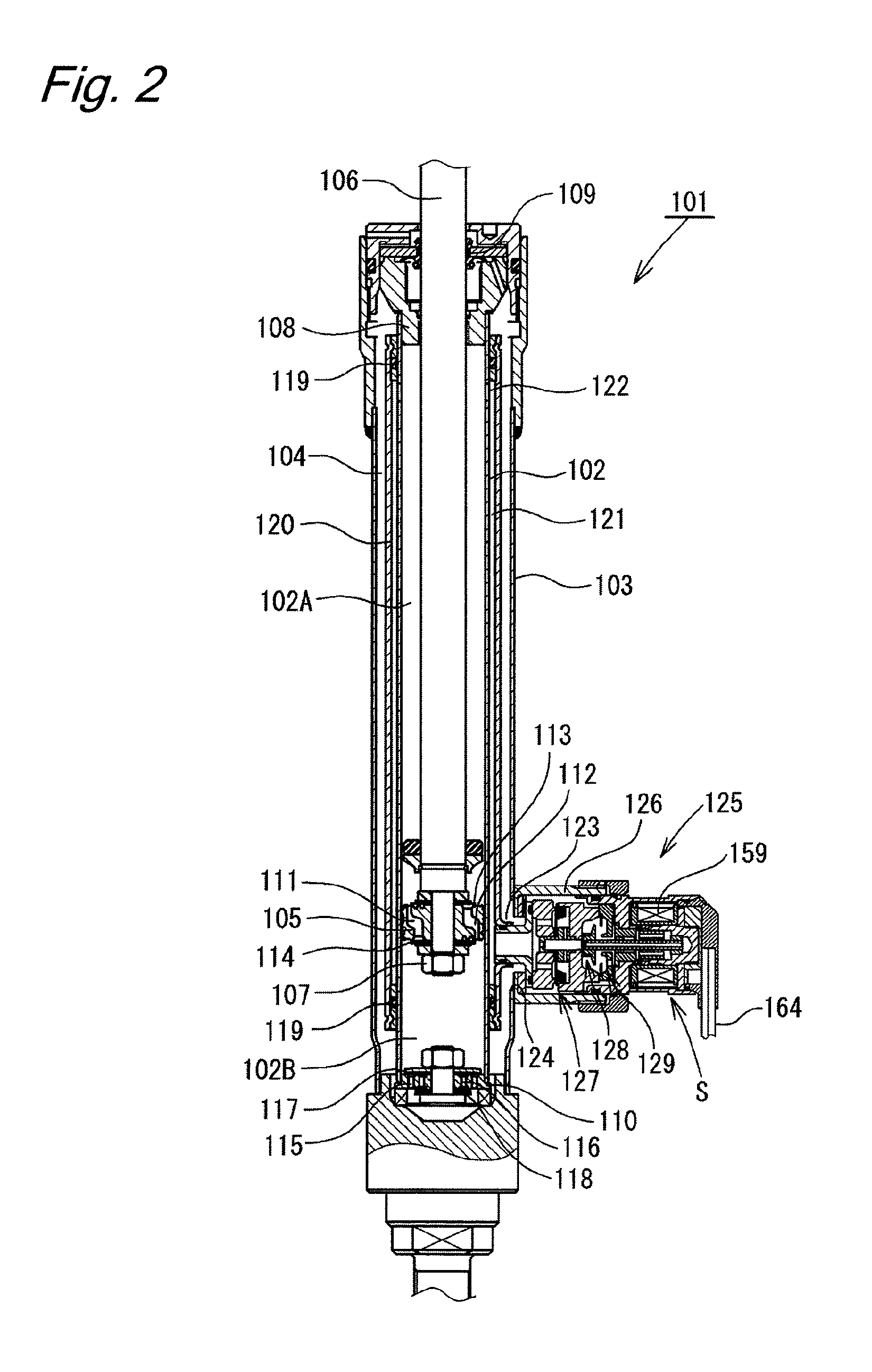

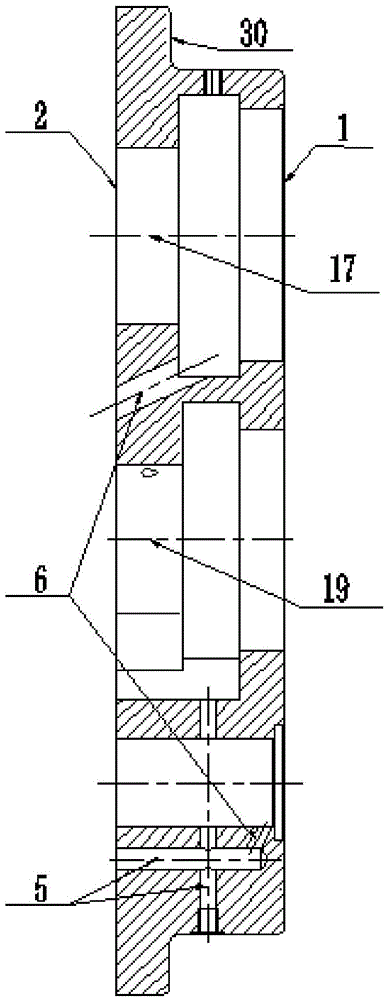

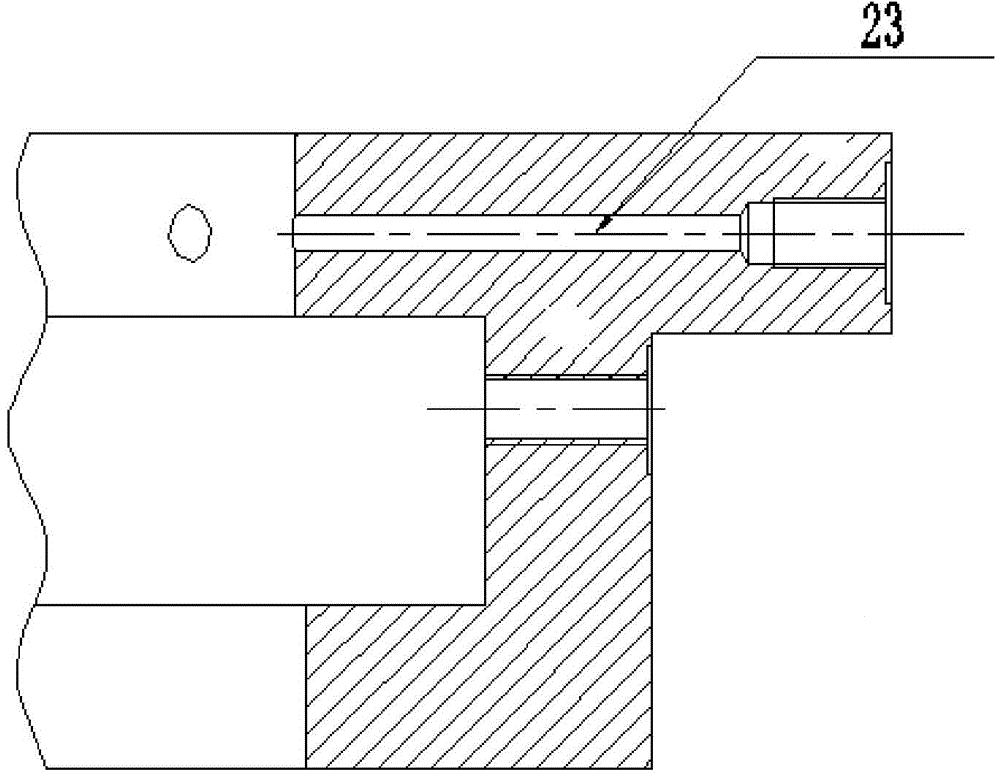

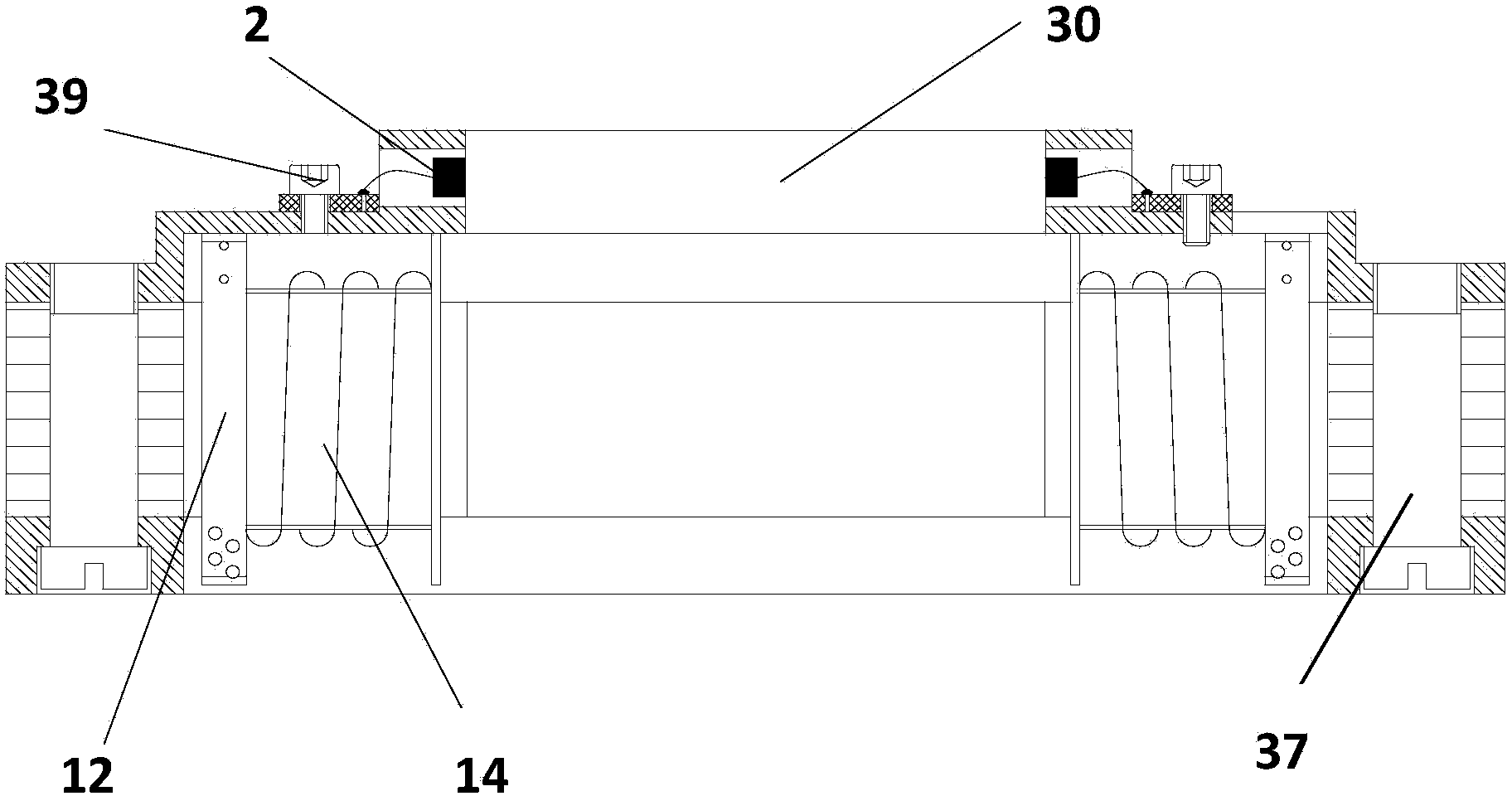

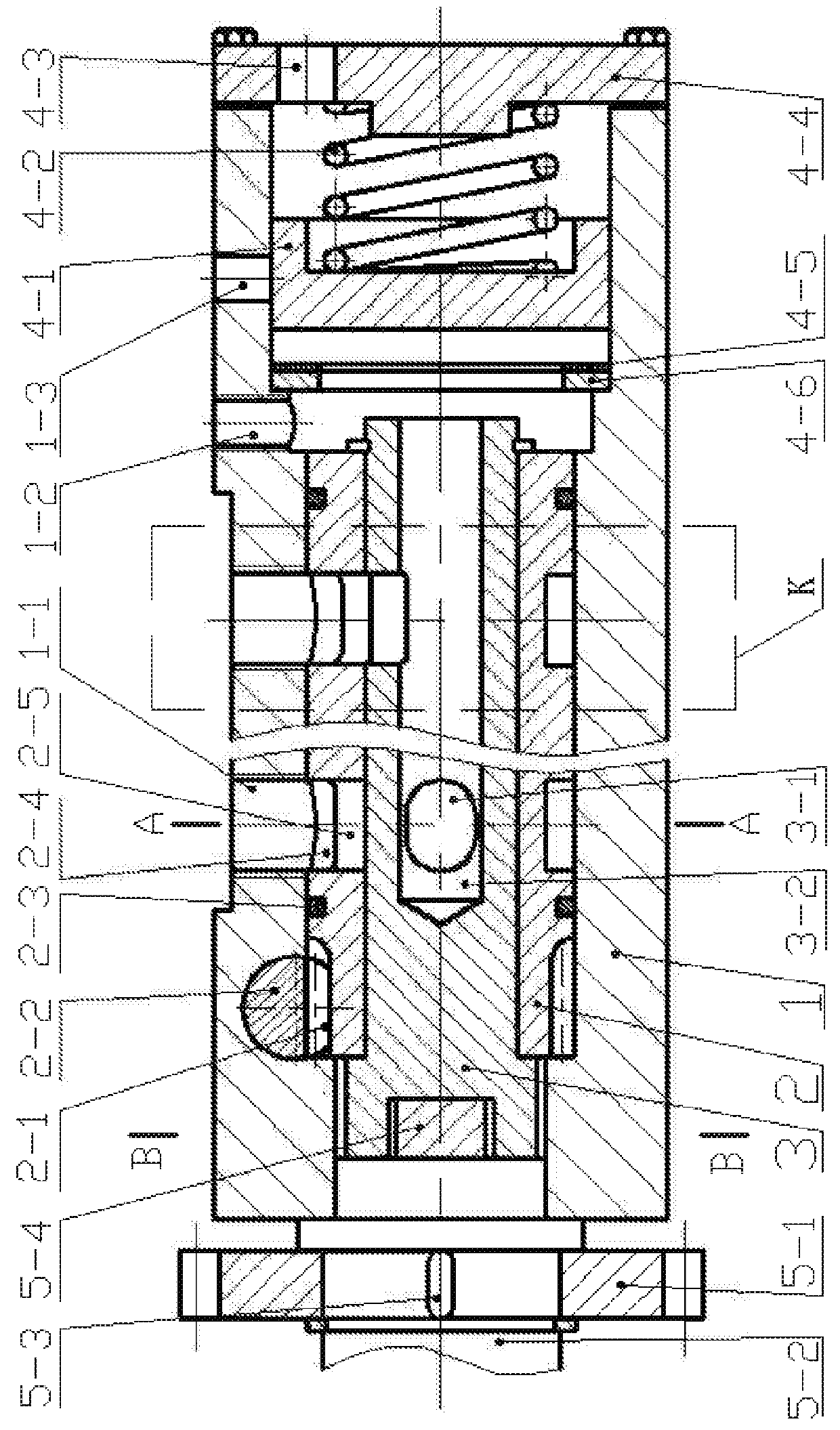

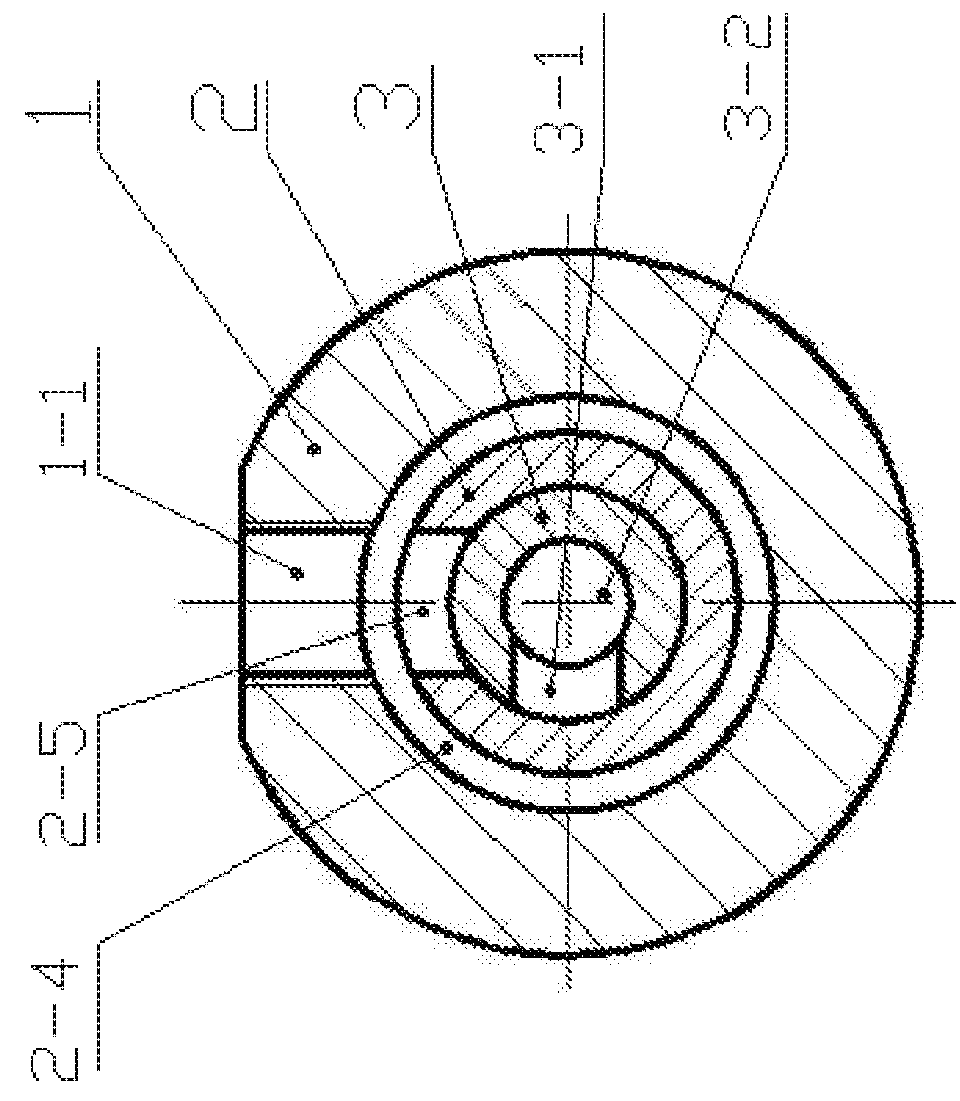

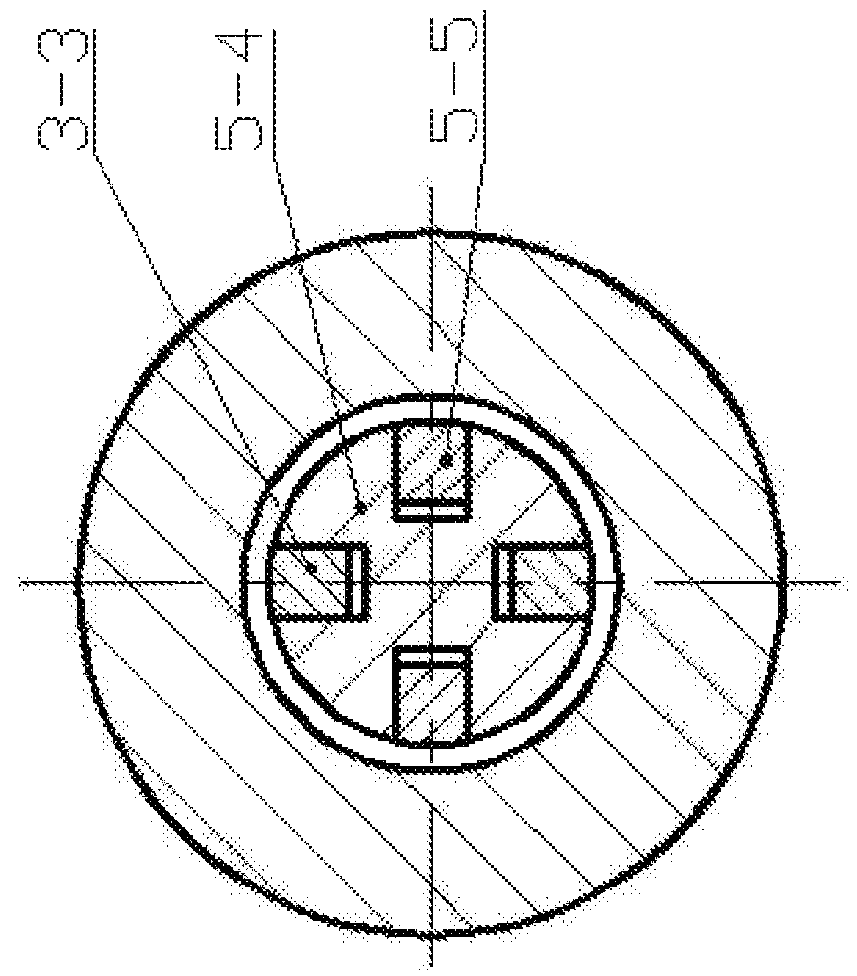

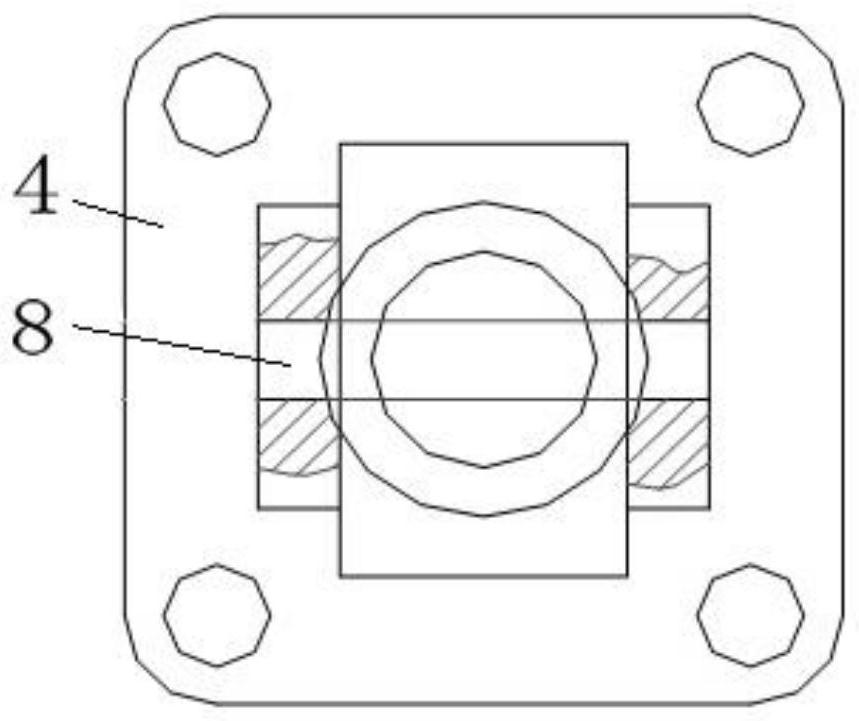

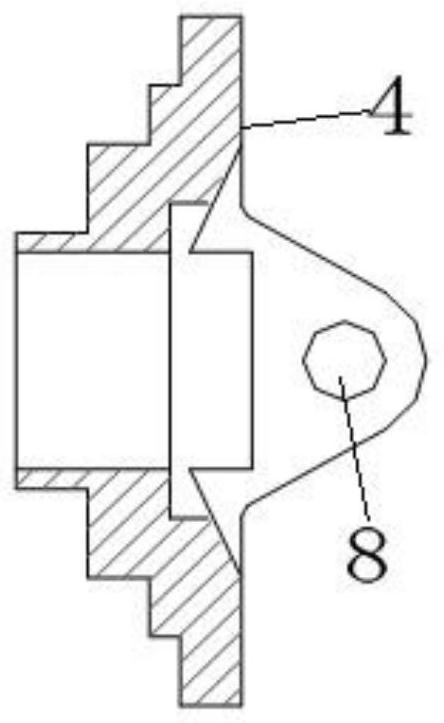

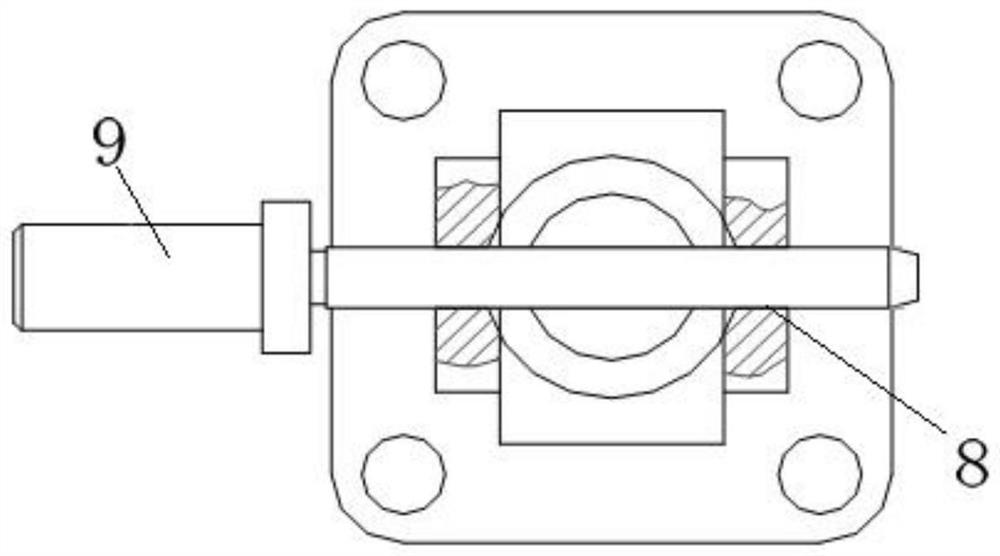

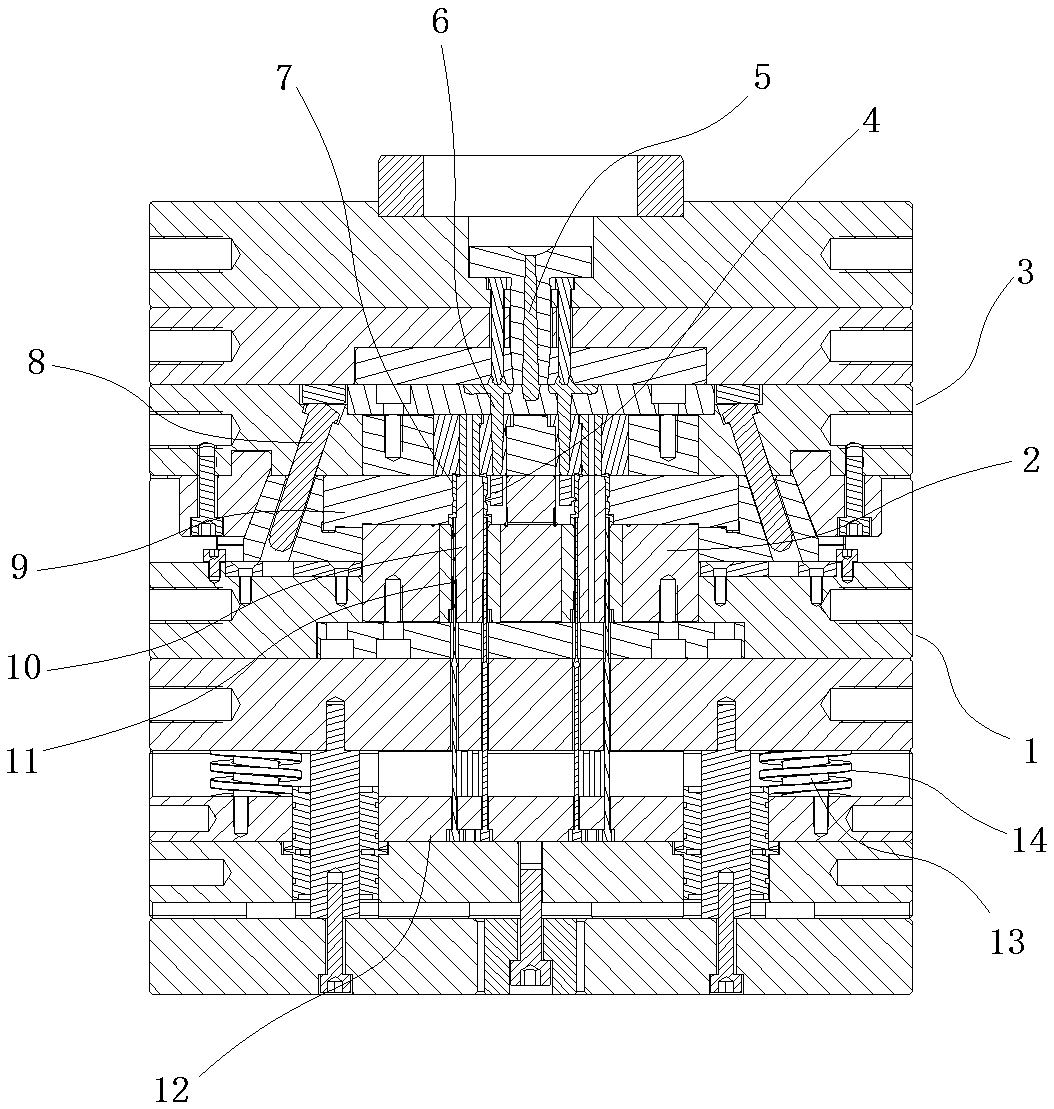

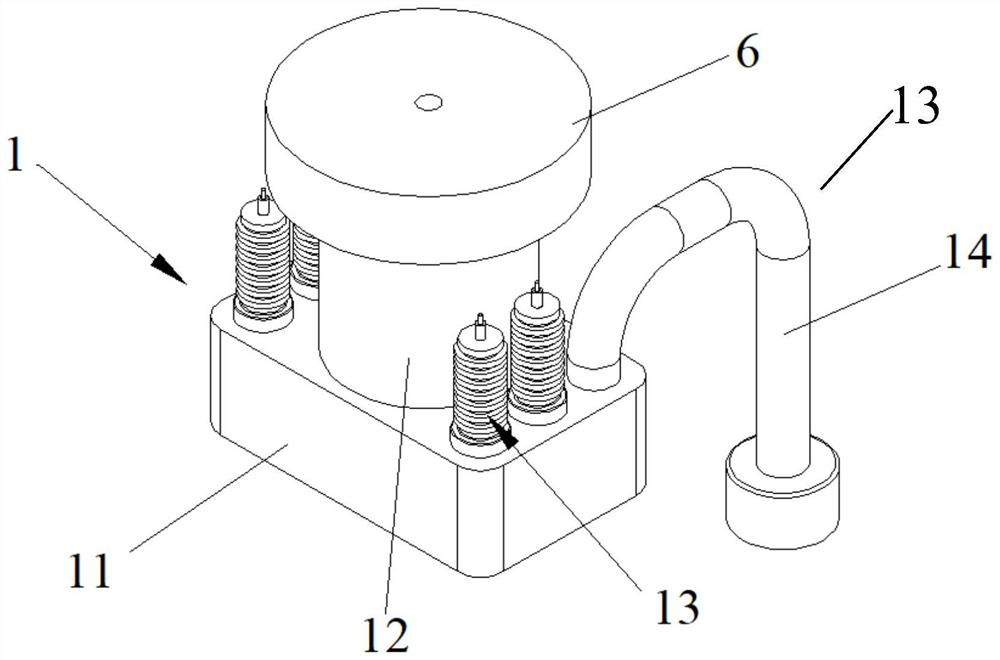

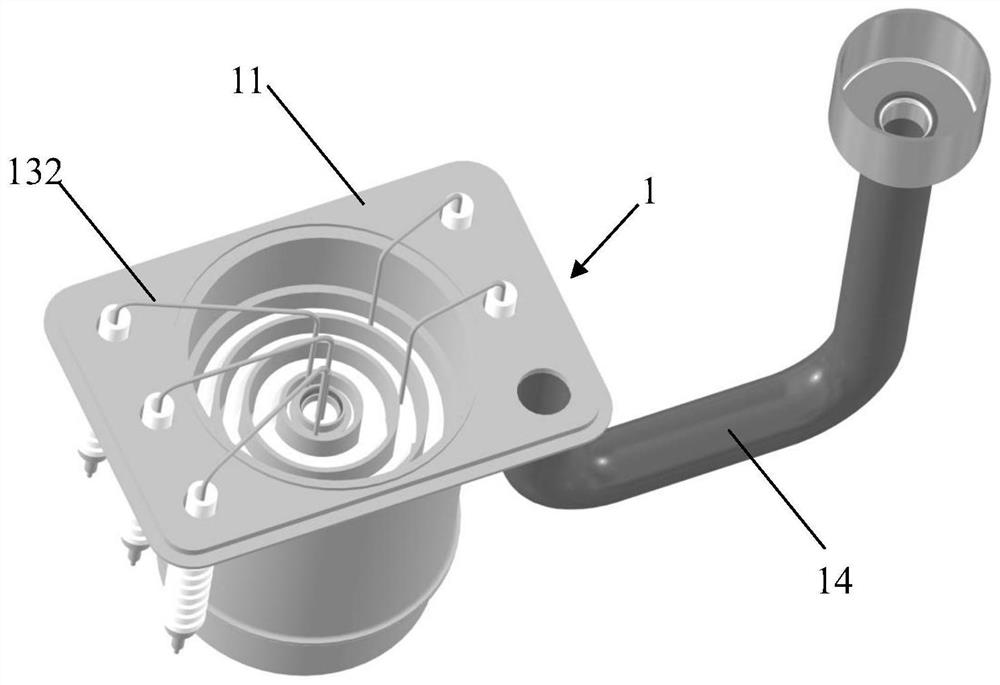

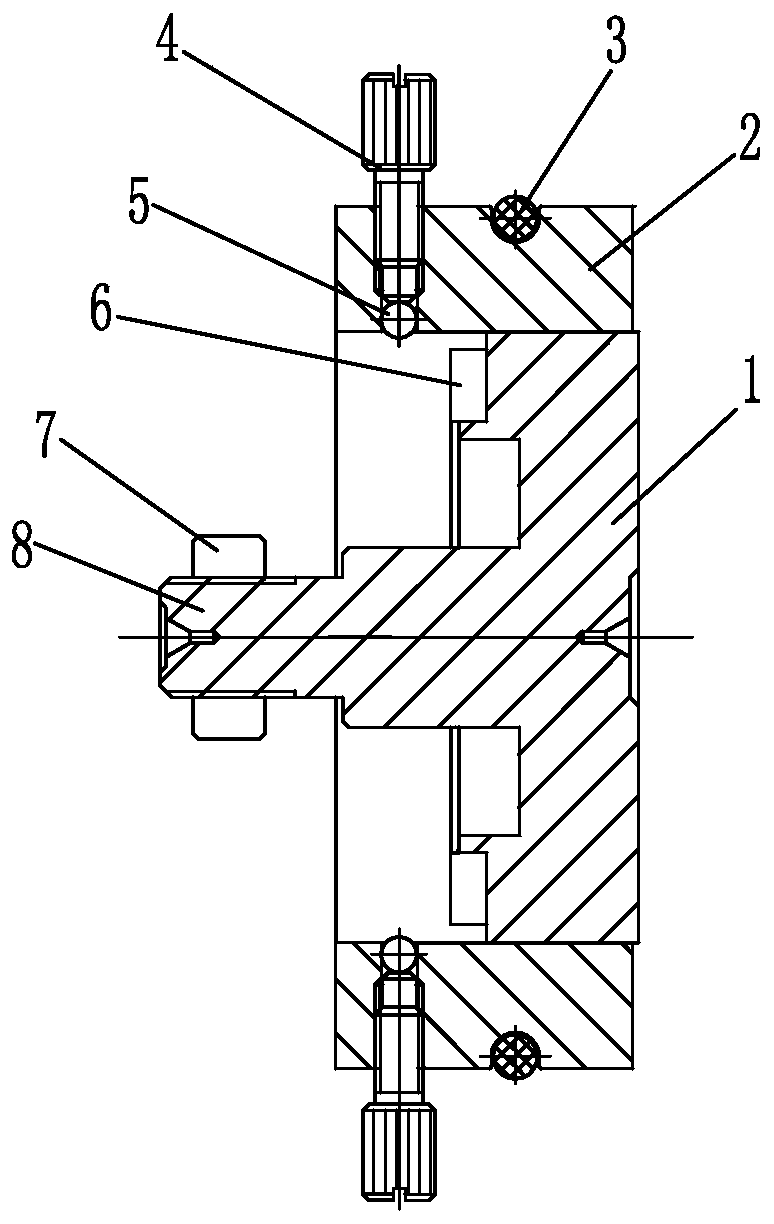

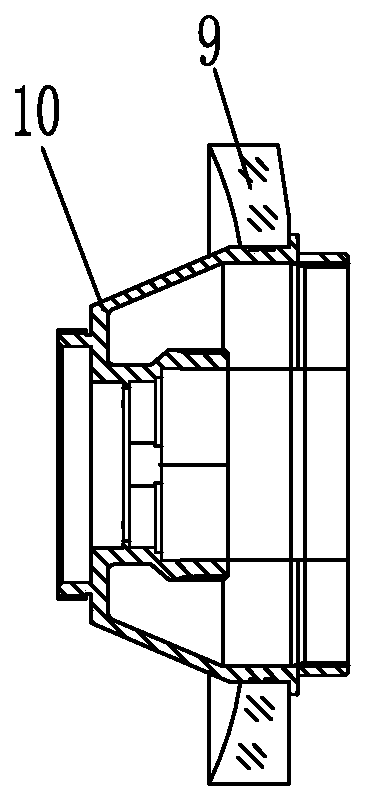

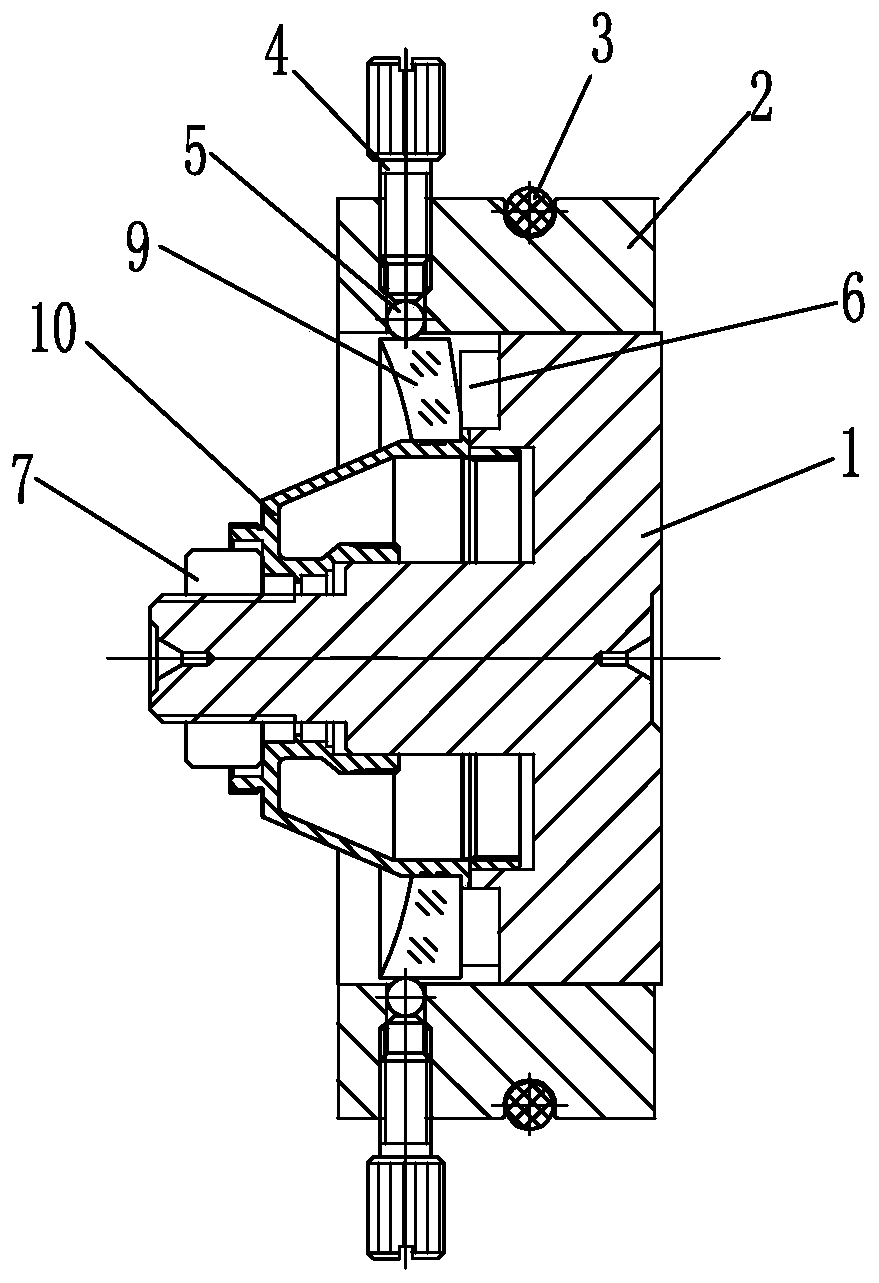

Oil control device for fully variable hydraulic valve system of internal combustion engine

ActiveUS9995188B2Guaranteed uptimeControl coaxialityMultiple way valvesMachines/enginesExternal combustion engineSolenoid valve

The present invention relates to a valve train mechanism and a fuel supply system of internal combustion engine, and particularly relates to an oil control device of a hydraulic fully variable valve system of the internal combustion engine. This device connected with the hydraulic valve system of internal combustion engine, the device consists of a housing, a rotary valve, a hydraulic accumulator and a transmission mechanism. The rotary valve, the hydraulic accumulator and the transmission mechanism are installed in the housing. The rotary valve consists of a rotary valve shaft and a rotary valve sleeve. The hydraulic accumulator consists of an accumulator piston, an accumulator spring, an end cover, a sealing seat ring and a rubber gasket and is installed in the cavity at one end of the housing. An accumulator chamber is provided between the rotary valve and the hydraulic accumulator. The transmission mechanism consists of a transmission gear, a gear shaft and a cross slide coupling. The transmission gear is installed on the gear shaft, while the gear shaft is connected with the rotary valve shaft through the cross slide coupling. The present invention can replace a high-frequency solenoid valve, it is applicable to use with hydraulic fully variable valve system of single-cylinder and multi-cylinder internal combustion engines. And the present invention has the advantages of simple structure, reliability, good manufacturability and low cost.

Owner:SHANDONG UNIV

A Model Supporting Device Applied in Wind Tunnel Test

ActiveCN112284676BInterference minimizationControl coaxialityAerodynamic testingSupporting systemMarine engineering

The invention discloses a model support device applied to wind tunnel tests. The device includes a model back support, a false tail rod and a middle bracket to form a triangular connection structure. The model back support and the middle bracket are integrally processed; a balance is installed inside the model, the model back support is supported on the back of the model, and the fake tail rod extends into the model. The tail of the model is isolated from the model and does not touch each other. The dummy tail rod is fixed on the dummy tail rod support. Both the model back support and the dummy tail rod support are fixedly connected to the upper part of the middle bracket, and the lower end of the middle bracket extends downward and is fixed. On the bottom support platform, the bottom support platform is fixed on the lower wall plate of the wind tunnel. The device has compact structure, miniaturization, reasonable layout and convenient use, which effectively reduces the interference of the size and shape of the support on the aerodynamic force of the model, and meets the requirements of the wind tunnel model support system.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

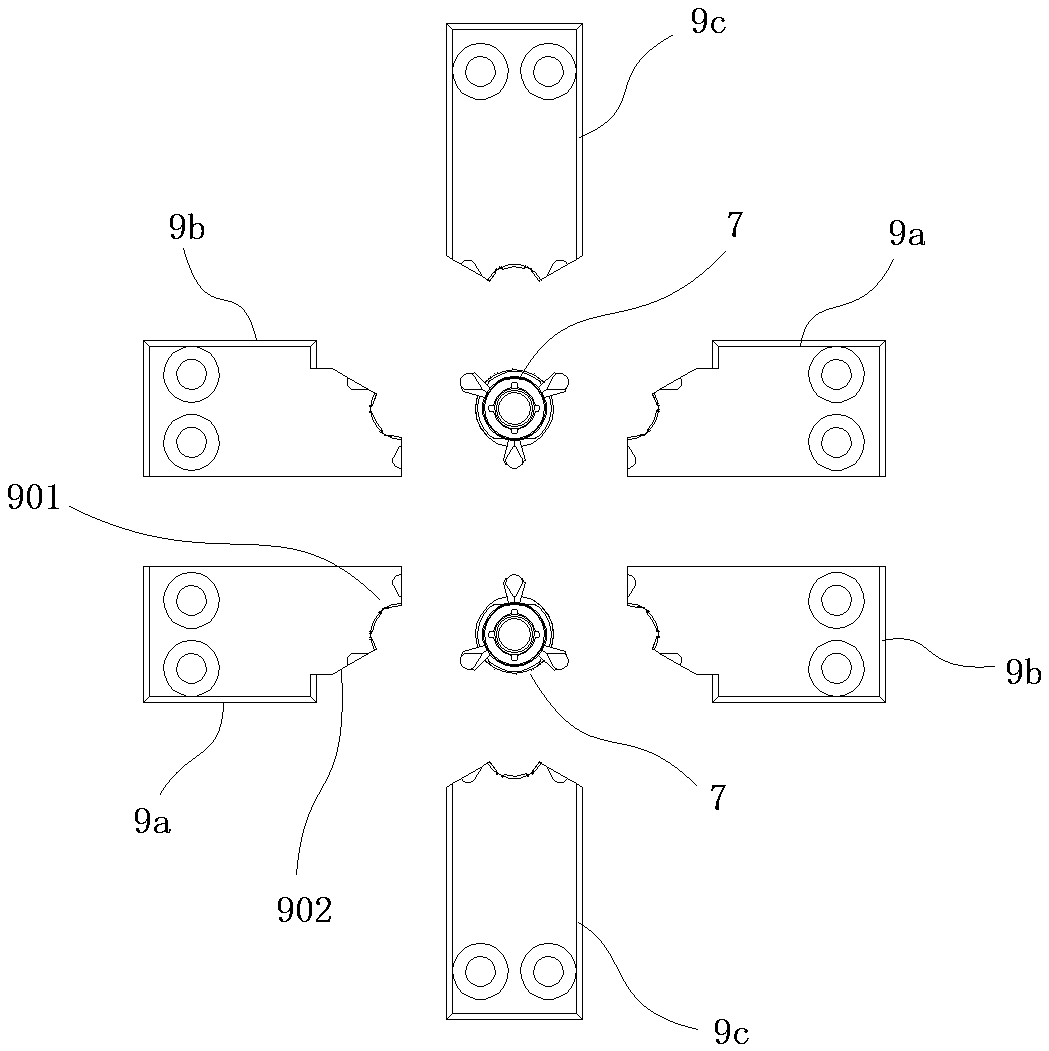

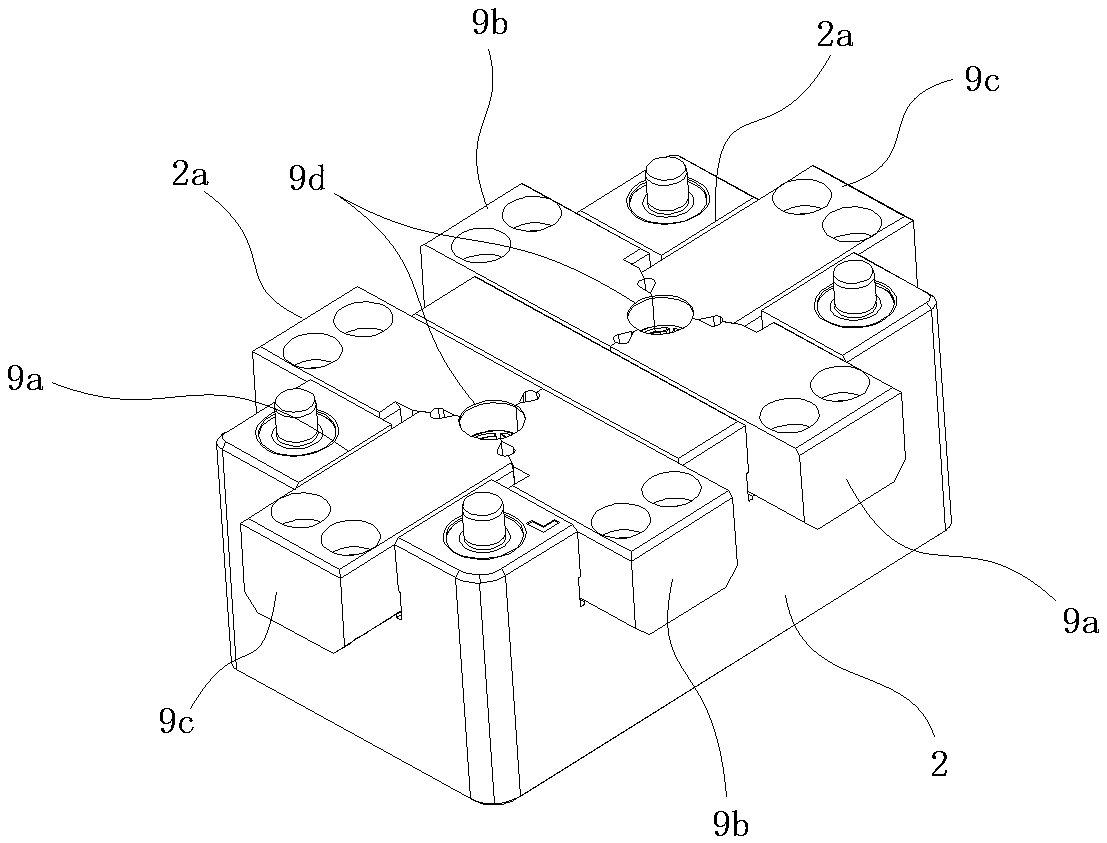

Method for controlling coaxiality between components

ActiveCN111761318AMeet the requirements of rotational flexibilityGood size consistencyDrive shaftEngineering

The invention discloses a method for controlling the coaxiality between components. The method comprises the following steps that (1) a machining process is carried out, specifically, 1.1, two fai A holes are reamed in a support by using a reamer; 1.2, two fai A holes in the support are subjected to finish machining; 1.3, the coaxiality between the two fai A holes in the support is measured by using a first coaxiality core rod; (2) a welding process is carried out, specifically, 2.1, a split washer and a bearing are assembled into a bearing hole of a rocker arm to form a rocker arm assembly; 2.2, a second coaxiality core rod is used for penetrating the rocker arm assembly formed in the step 2.1 and adjusting pieces into the support to be preassembled; and 2.3, the second coaxiality core rod penetrates into a left hole of a mounting hole in a clamp. The method for controlling the coaxiality between the components has the beneficial effects that the method has the advantages of being wide in adaptability and easy to operate, the coaxiality percent of pass can be increased, the production efficiency can be improved, and it can be guaranteed that the rotation flexibility is good when the components rotate with a transmission shaft as the center, so that the performance index of the whole products is improved.

Owner:GUIZHOU HONGLIN MACHINERY

A VAD sintered optical fiber preform master rod stretching device and stretching method

ActiveCN109516686BAffects the bowControl coaxialityGlass making apparatusCore (optical fiber)Composite material

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

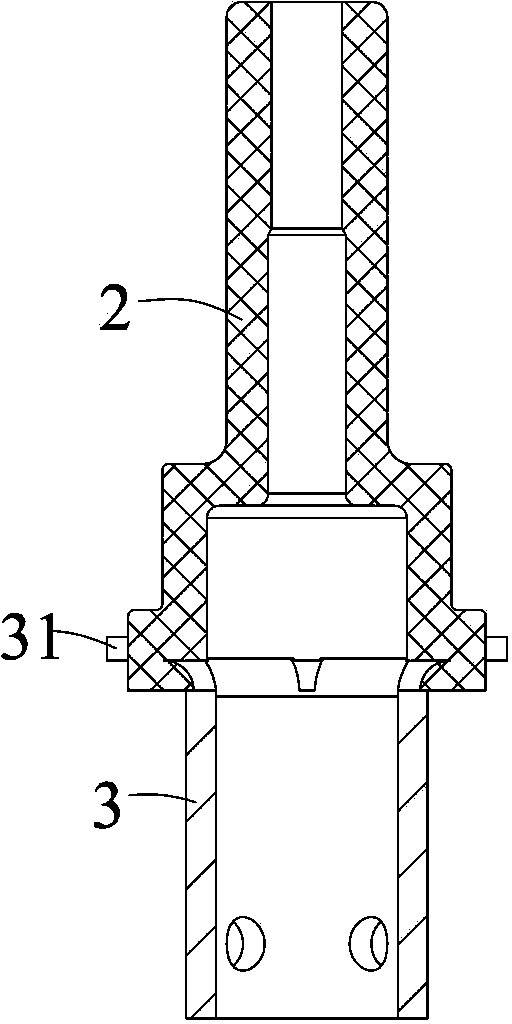

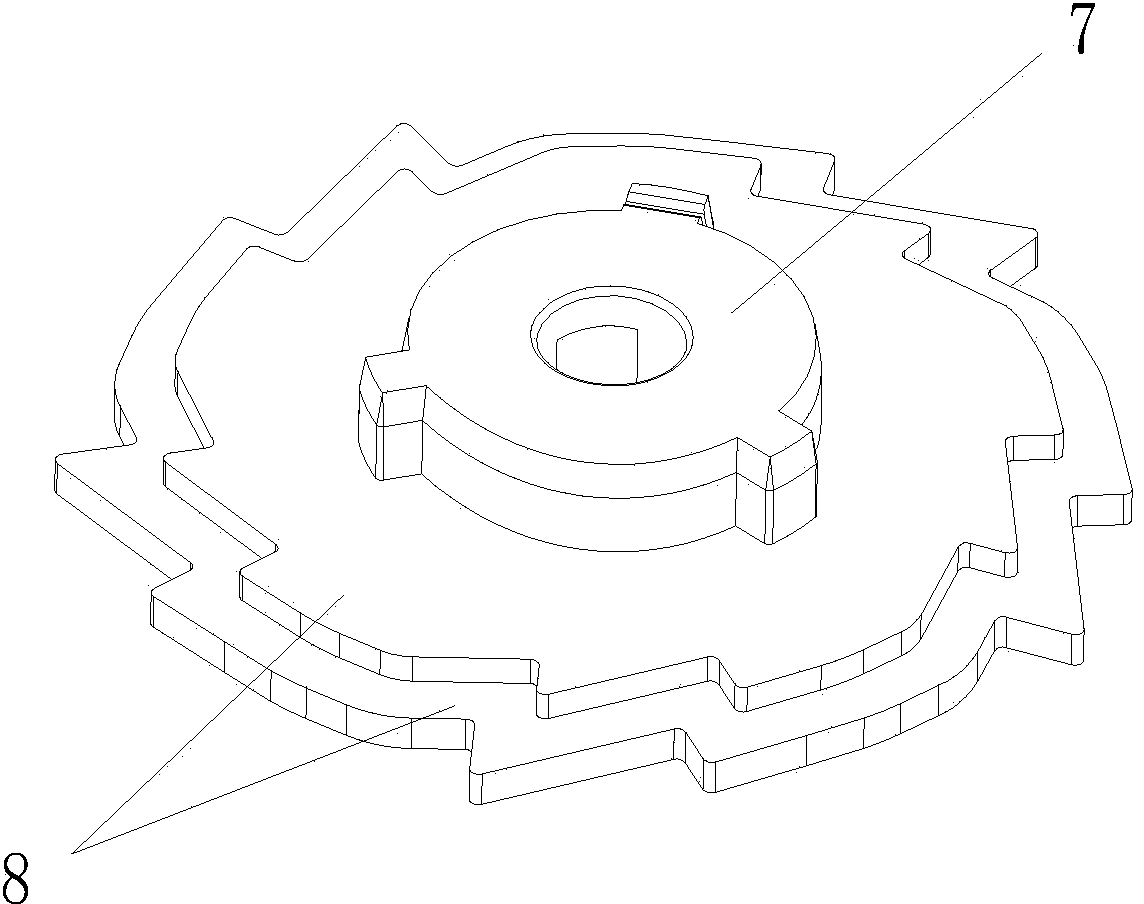

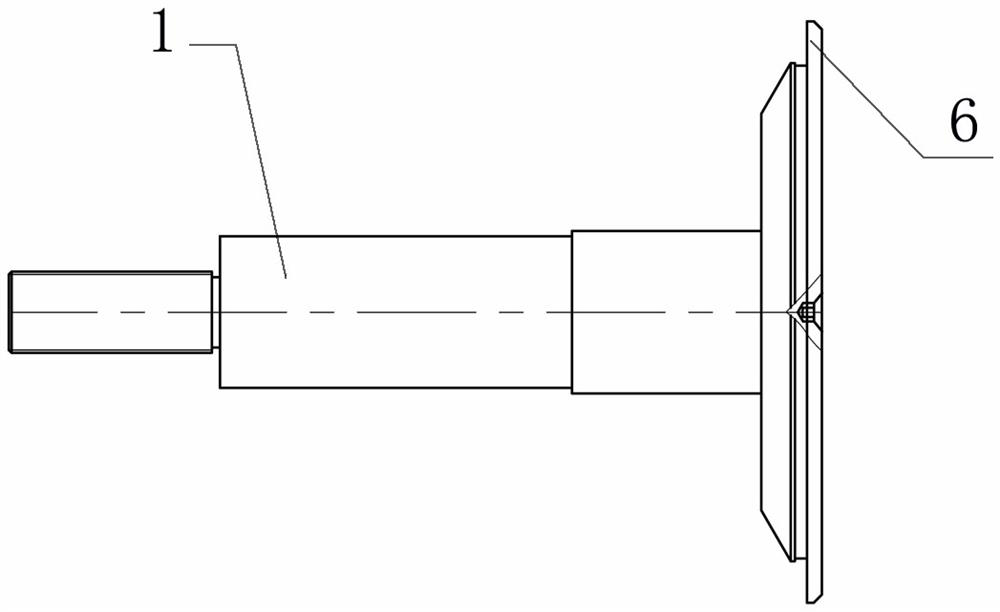

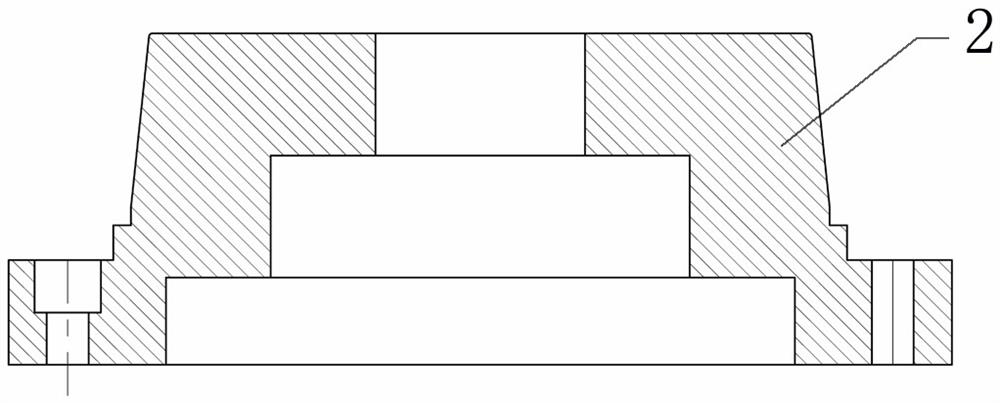

Machining method for gear ring type product

InactiveCN112276631AOvercoming weightOvercoming inertiaWork clamping meansPositioning apparatusNumerical controlStructural engineering

The invention discloses a machining method for a gear ring type product. In order to achieve machining of the gear ring type product, an auxiliary clamp is adopted, and the auxiliary clamp structurally comprises a pull rod, a transition disc, a positioning shaft, a positioning disc and a spring sleeve, wherein the spring sleeve is fixed to the upper end of the pull rod, the transition disc, the positioning shaft and the positioning disc are coaxially arranged from bottom to top, and the pull rod penetrates through the centers of the positioning disc, the positioning shaft and the transition disc. The method for machining the gear ring type product by adopting the auxiliary clamp comprises the following steps that an existing clamp with elastic core shaft positioning and end surface pressing is used for roughly turning an outer circle firstly; then, a vertical numerical control lathe is used, the used auxiliary clamp is installed on a spindle of the lathe to carry out finish turning onan outer circle and an inner hole of the gear ring type product, and the roundness of the outer circle subjected to finish turning treatment is controlled within 0.05 mm; and finally, a clamp spring groove and a step are cut to complete product machining. The clamp is simple in structure, low in manufacturing cost and convenient to use, ensures the quality of the machined product, and improves theproduction efficiency.

Owner:十堰同创精密机械有限公司

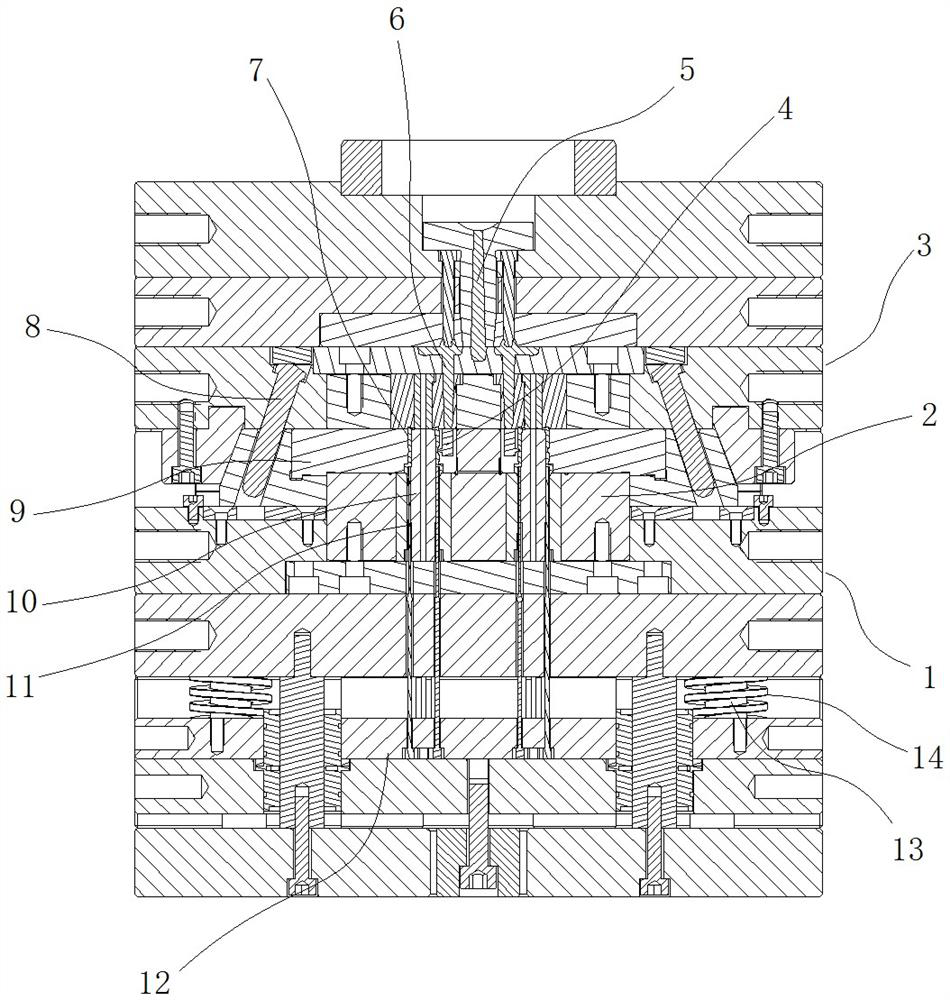

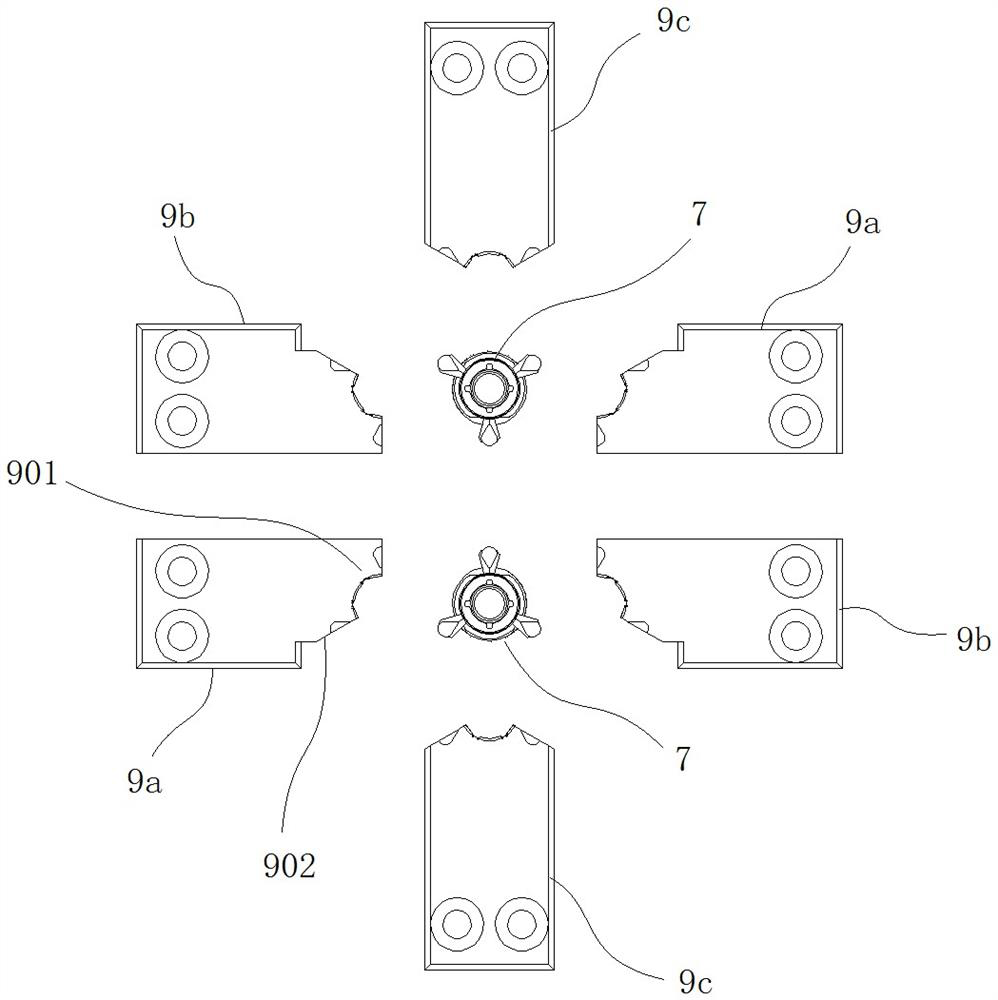

A side gate vertical runner and a plastic mold for the side gate

Owner:NINGBO BEILONG PRECISION MOLDING

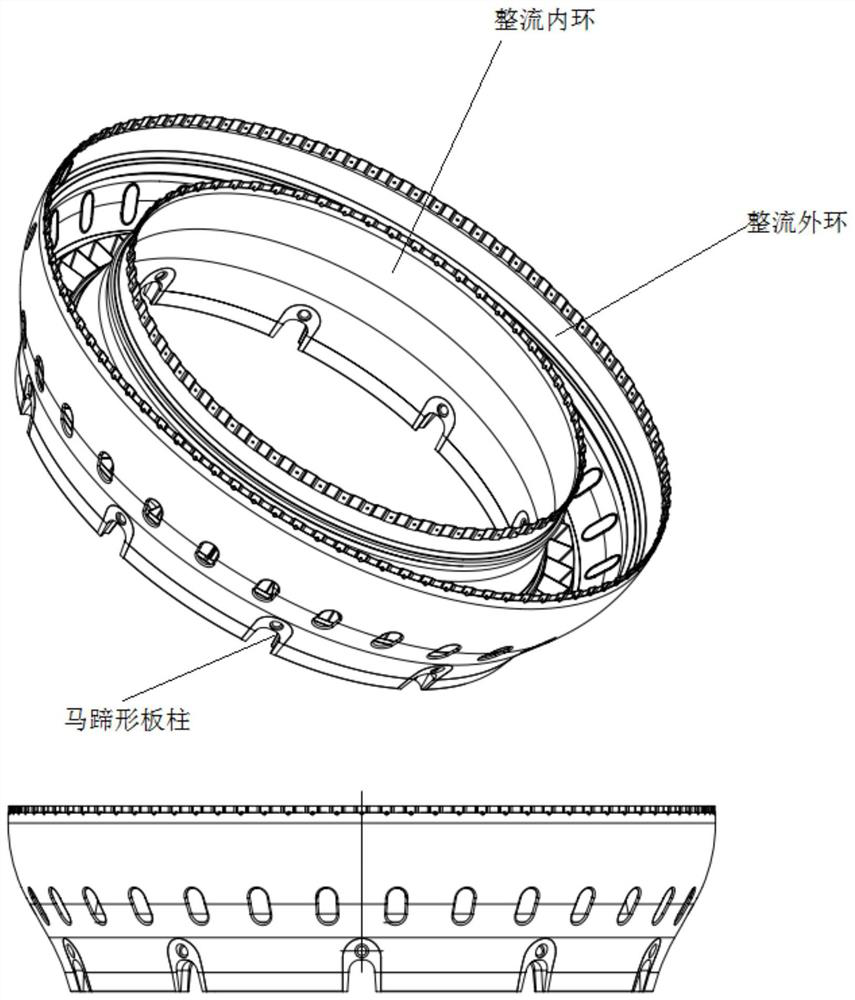

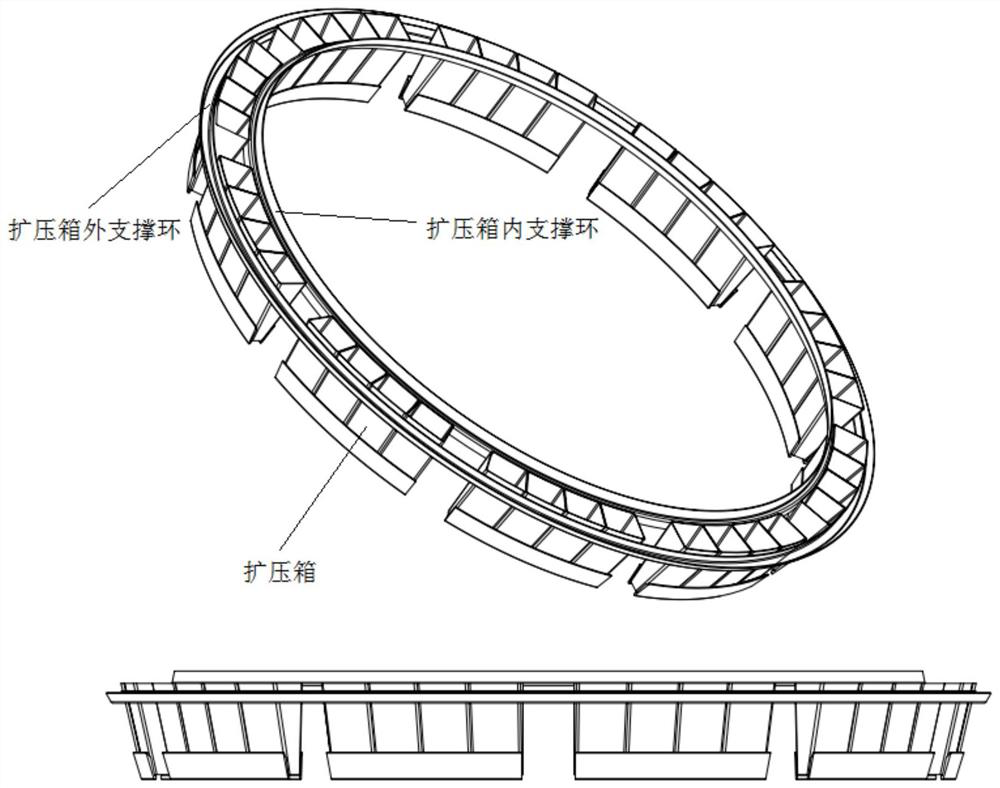

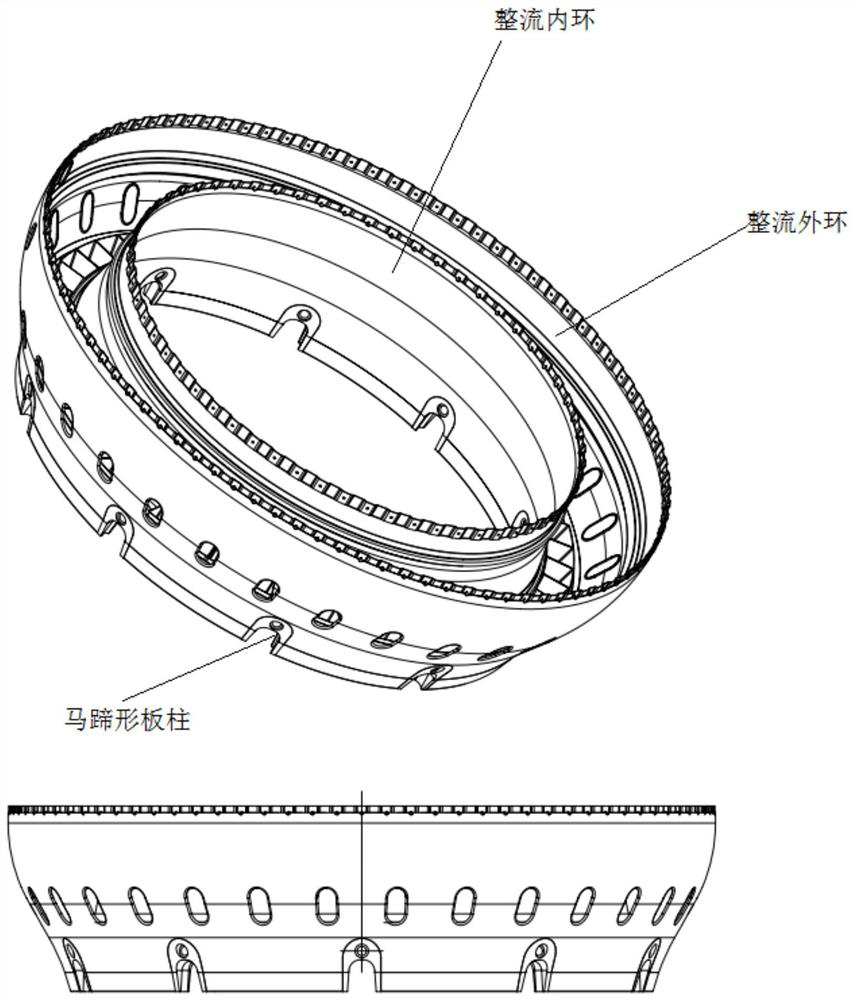

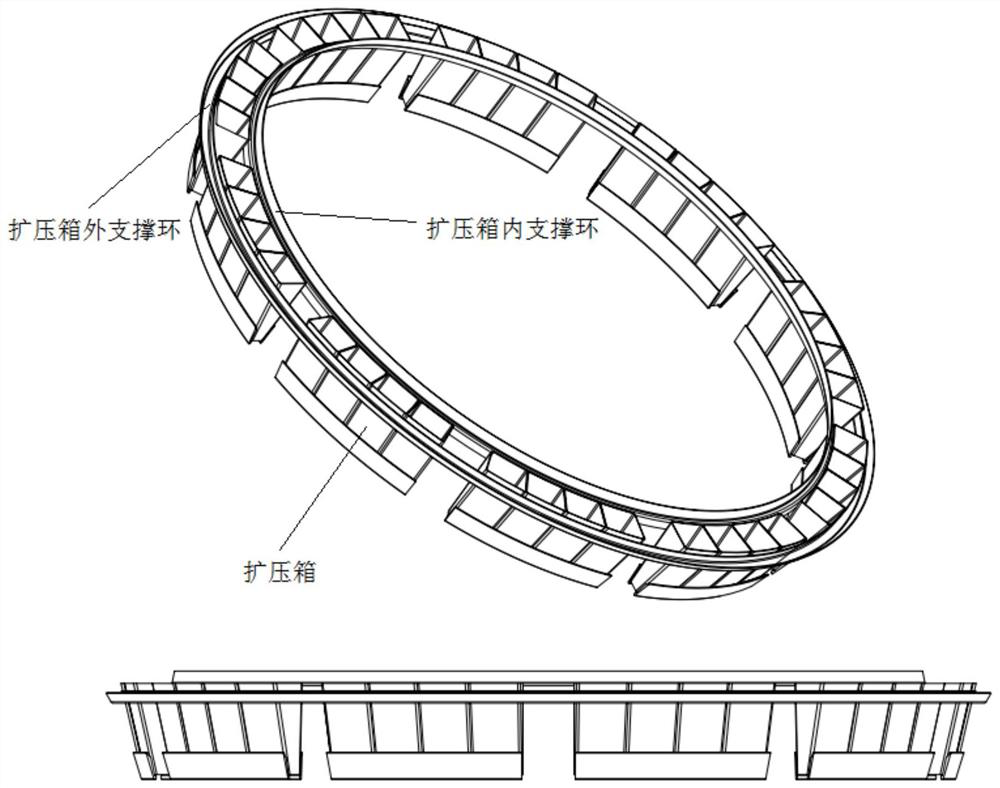

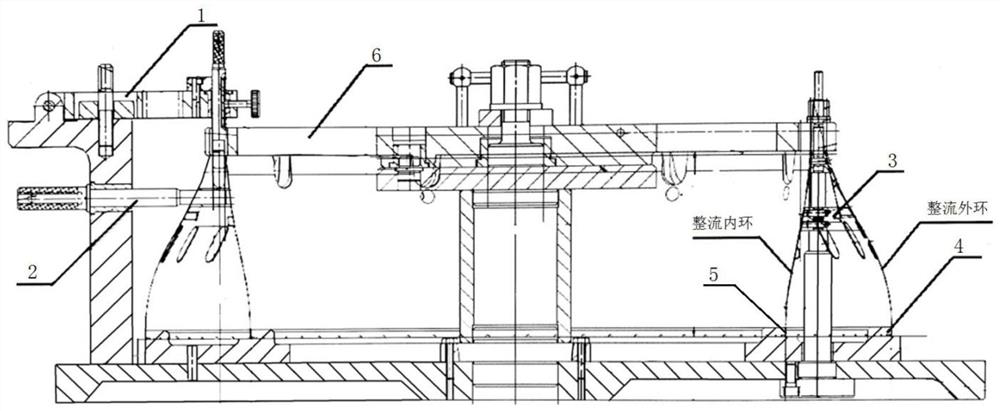

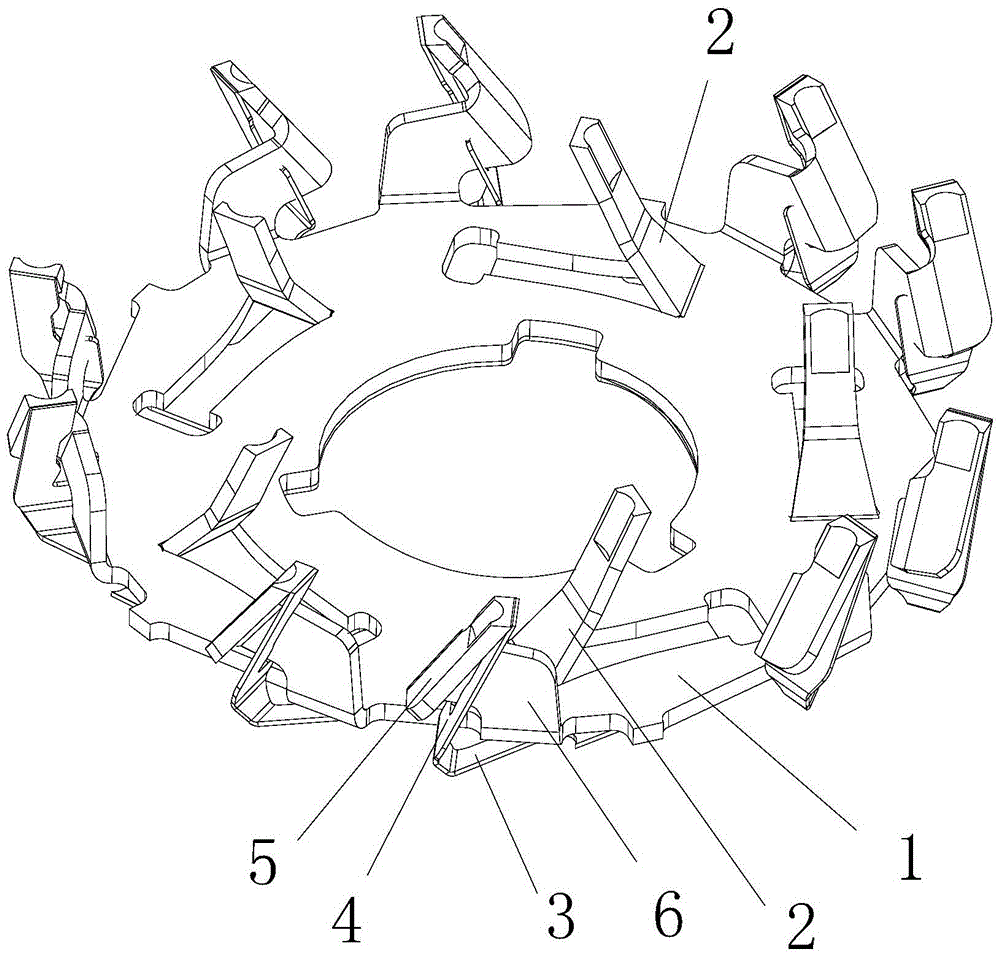

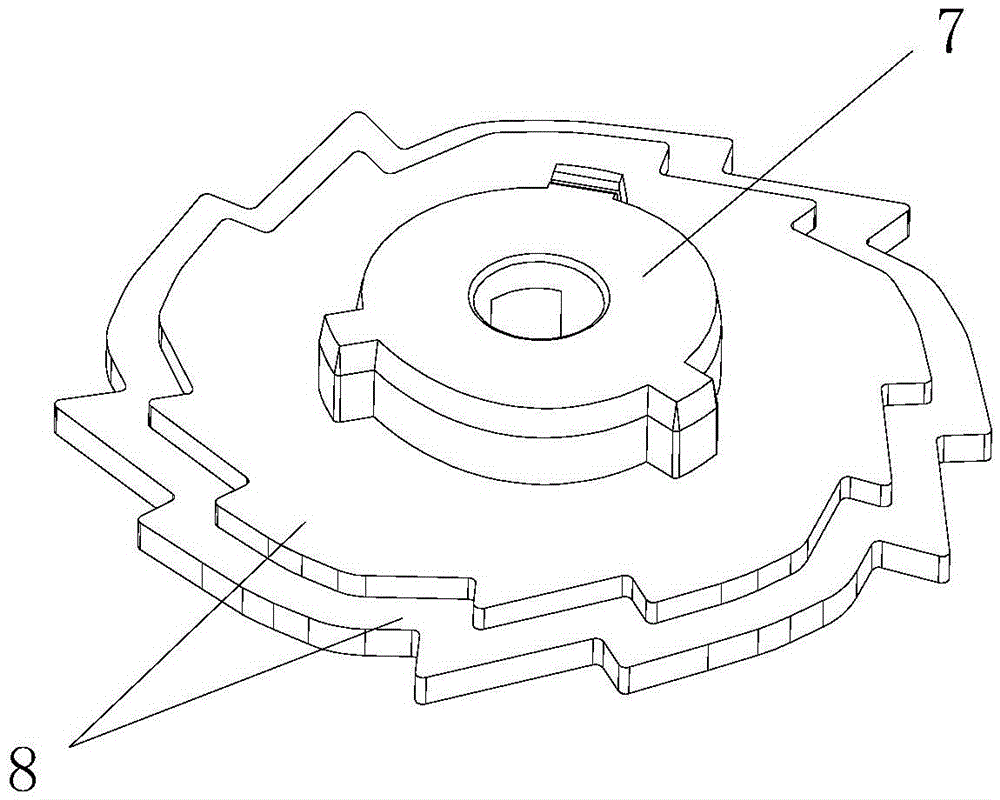

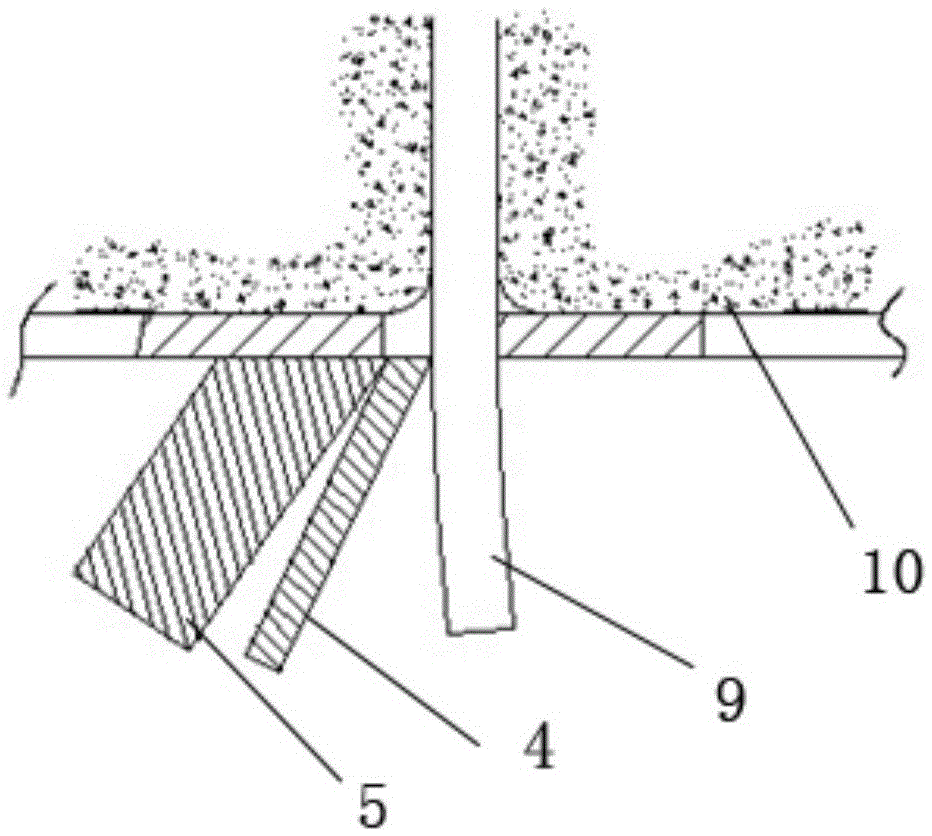

Method and device for controlling welding deformation of gas turbine flame tube rectifying ring assembly

ActiveCN112589302BControl coaxialityEasy to installWelding/cutting auxillary devicesArc welding apparatusEngineeringDeformation control

The invention discloses a method and device for controlling welding deformation of a gas turbine flame cylinder rectification ring assembly. The device includes a first pressing plate, a position degree positioning pin, a simulation block of a diffusion box, an outer ring positioning groove, an inner ring positioning groove and a second pressing plate . In the present invention, the rectification outer ring, the rectification inner ring and the connecting plate column are welded to form a first annular assembly, and the first annular assembly includes an annular flow channel cavity between the rectification outer ring and the rectification inner ring, and then multiple Diffusion boxes are grouped, and then respectively welded with the inner support ring of the diffuser box and the outer support ring of the diffuser box to form the second annular assembly, and finally the second annular assembly is integrally put into the annular flow channel cavity of the first annular assembly. , spot welding positioning, welding the first ring component and the second ring component.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

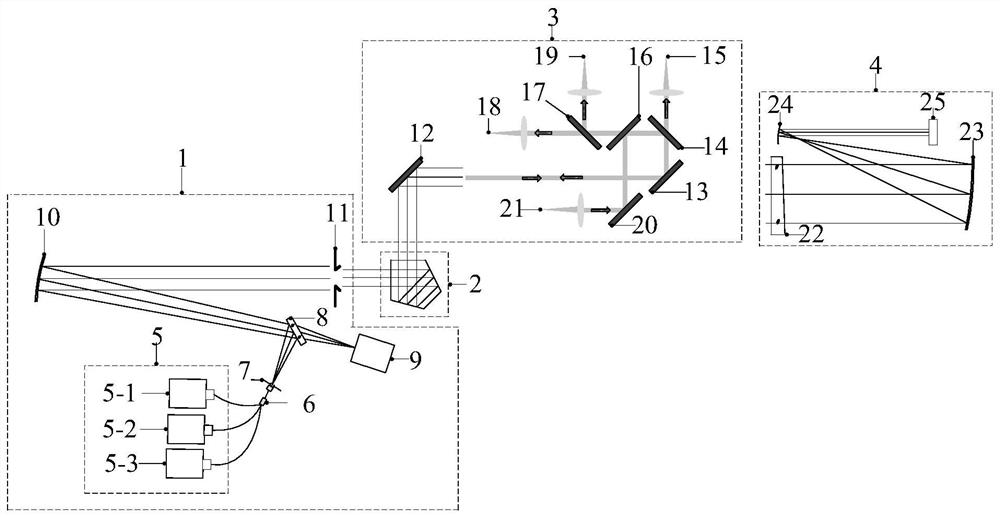

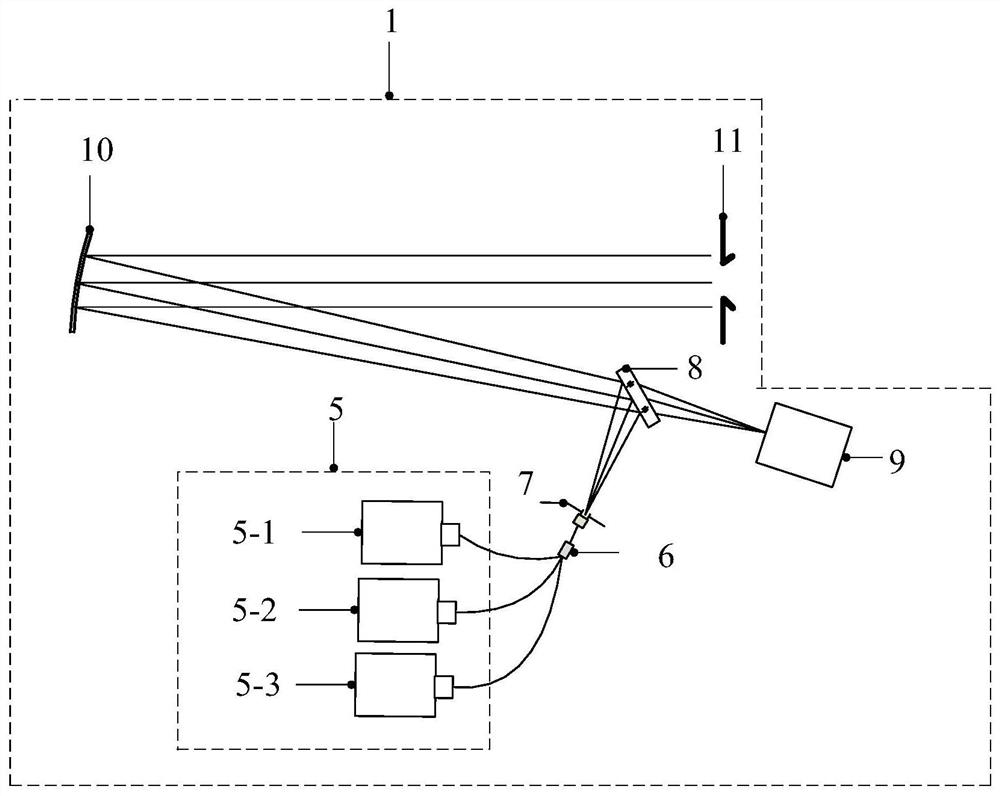

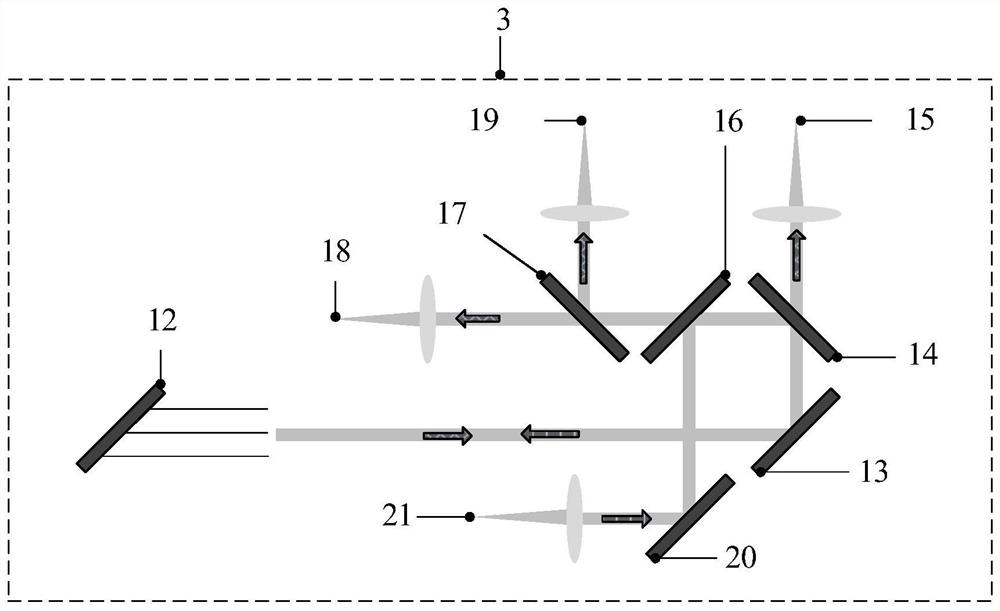

Assembly and inspection system for optical relay unit of laser communication terminal and detection method based on it

ActiveCN112713932BQuick SetupQuick checkFree-space transmissionOptical elementsTransceiverDivergence angle

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Injection mold for side gate vertical runners and side gates

Owner:NINGBO BEILONG PRECISION MOLDING

Welding deformation control method and device for gas turbine flame tube rectifying ring assembly

ActiveCN112589302AControl coaxialityEasy to installWelding/cutting auxillary devicesArc welding apparatusEngineeringStructural engineering

The invention discloses a welding deformation control method and device for a gas turbine flame tube rectifying ring assembly. The device comprises a first pressing plate, a positional tolerance positioning pin, diffusion box simulation blocks, an outer ring positioning groove, an inner ring positioning groove and a second pressing plate. According to the method, a rectifying outer ring, a rectifying inner ring and connecting plate columns are welded to form a first annular assembly which comprises an annular flow channel cavity located between the rectifying outer ring and the rectifying inner ring; then, multiple diffusion boxes are grouped and welded to a diffusion box inner supporting ring and a diffusion box outer supporting ring to form a second annular assembly; and finally, the second annular assembly is integrally arranged in the annular flow channel cavity of the first annular assembly, spot welding positioning is conducted, and the first annular assembly and the second annular assembly are welded.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

A rotary electric shaver shaving head device

ActiveCN103707332BClean shavedImprove shaving effectMetal working apparatusUltimate tensile strengthElectric razors

The invention relates to a shaving head device of a rotary type electric shaver. The shaving head device comprises a shaving head blade and a blade net, and is characterized in that the shaving head blade comprises inner circle knives and outer circle knives, the inner circle knives and the outer circle knives are concentrically arranged on a main blade base, auxiliary blades are arranged at the bottom of the main blade base, and elastic auxiliary knives are arranged on the peripheries of the auxiliary blades; the auxiliary knives are arranged at the front ends of the working portions of the outer circle knives of a main blade when the outer circle knives rotate, included angles are formed between the auxiliary knives and the outer circle knives of the main blade, and the auxiliary knives rebound after being in contact with beards to be then in contact with the outer circle knives to be lifted upwards. According to the structure of the shaving head device, the strength of a base body can be effectively improved through the inner circle knives, it is guaranteed that the coincidence of running tracks of the knives in working is high, the service life of the knives is prolonged, the matching degree of the blade and the blade net is improved, the sharpness is high, and the sound coincidence is high. The beards can conveniently enter the blade net at multiple angles through the design of the M-shaped blade net, and the shaving efficiency is improved.

Owner:HAINING XINYI MACHINERY & ELECTRICAL

Electronic expansion valve

InactiveCN108980378ASimple structureEasy to manufactureEfficient regulation technologiesFluid circulation arrangementInjection mouldingBiomedical engineering

The invention provides an electronic expansion valve, comprising a valve block, a nut, a valve needle component and a guide sleeve. The nut and the guide sleeve are fitted to the valve block. The valve needle component is mounted on the nut; the nut and the guide sleeve are formed by integral injection molding. The electronic expansion valve helps improve valve needle and nut coaxiality and reducenut abrasion, and can gain extended life.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

A device, adjustment method and application for adjusting the position of the center of mass of a product

ActiveCN110243392BImprove responseIntuitive centroid deviationMeasurement devicesRotational axisControl theory

The invention provides a device, adjustment method and application for adjusting the position of the center of mass of a product. The device includes a bottom plate, a base, a rotating system, and a connecting weight system; It is installed between two bases and has only one degree of freedom of rotation. The transfer weight system is installed on the rotation system, so that when the product is not clamped, the center of mass of the rotation system and the transfer weight system is on the rotation axis of the rotation system. Above; the product to be adjusted is clamped by the transfer counterweight system and fixedly connected with the transfer system. By adjusting the product, the elastic center of the product is guaranteed to be on the rotation axis of the rotation system. The standard of leveling is that the product can be stationary at any position around the rotation axis. , will not rotate due to center-of-mass deviation.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Emission device for emitting electrons, preparation method of emission device and electron gun

PendingCN114464512AReduce the difficulty of sealing and assemblyGood concentricityTransit-tube vessels/containersTransit-tube electron/ion gunsElectrically conductiveAnode

The invention discloses an emission device for emitting electrons, a preparation method thereof and an electron gun. An emission device used for emitting electrons comprises a main body part, at least four conductive electrode positioning rings, a first electrode positioning ring, a second electrode positioning ring, a third electrode positioning ring, a fourth electrode positioning ring and a fourth electrode positioning ring, the electrode positioning ring comprises a center positioning ring located in the center, an outer side positioning ring located on the outermost side and a plurality of middle positioning rings located between the center positioning ring and the outer side positioning ring. The at least three ceramic rings are respectively arranged between two adjacent electrode positioning rings; the cathode heat shield assembly is mounted in the central positioning ring; the control electrode is arranged on the central positioning ring; the at least one anode is arranged on the middle positioning ring; and the end cover is combined on the outer side positioning ring, and the control electrode and the anode extend into a containing groove, facing the main body part, of the end cover.

Owner:AEROSPACE INFORMATION RES INST CAS

A Debugging Method for Bonding of Annular Aspheric Mirror

ActiveCN107422452BGuaranteed parallelismGuaranteed coaxialityMountingsEngineeringMechanical engineering

The debugging method of the cementation of the annular aspheric reflector of the present invention relates to the debugging method of the reflector, comprising the following steps: (1) setting a stereotyped adjustment tool; Apply a layer of glue respectively, so that the mirror base and the annular aspheric mirror are initially bonded to form an annular aspheric mirror assembly; (3) Position the annular aspheric mirror assembly on the shaping adjustment tool; (4) Debug the annular The parallelism and coaxiality between the aspheric mirror and the mirror base; (5) Curing at room temperature; (6) Dismantling the shaping adjustment tooling outside the annular aspheric mirror assembly. The invention guarantees the parallelism and coaxiality of the annular aspheric reflector and the mirror base by the shaping adjustment tooling, and solves the problem that the parallelism between the annular aspheric reflector and the end surface of the mirror base increases due to the release of stress by the curing glue , effectively controlling the coaxiality of the annular aspheric mirror and the mirror base.

Owner:LIUZHOU CHANGHONG MACHINE MFG

A kind of high-speed gearbox processing method

ActiveCN104308468BControl coaxialityGuarantee the positioning accuracy of combined processingOffset distanceGear pump

The invention discloses a high-speed gearbox processing method, which is characterized in that when a body is roughly processed, a screw hole for matching a rear cover having roughly processed end faces in a processing body, coaxial bearing holes of the body and the rear cover, and a location pinhole for matching the body and the rear cover are adopted to guarantee the coaxiality of coaxial bearing holes of a gearbox and the position accuracy of the screw hole and the location pinhole; meanwhile after the end faces, various stages of bearing holes and gear pump holes are finely processed in gearbox combination processing, the high-speed bearing hole center of the gearbox and the rotation center of a machine tool are coincided by using a special spindle for equipment, then various inclined holes in the gearbox are drilled, a boring rod offset distance and an angle of the inclined hole shorter than the circle center offsetting the high-speed bearing hole center of the gearbox are calculated at the same time, and the position accuracy of the inclined holes in the gearbox is guaranteed.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com