Inner and outer shaped surface precise machining process for antenna cover

A technology of precision machining and radome, applied in the directions of antennas and radiation unit covers suitable for movable objects, can solve the problems of low machining accuracy and high rejection rate, and achieve energy saving and consumption reduction, improve yield, and improve machine quality. time utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

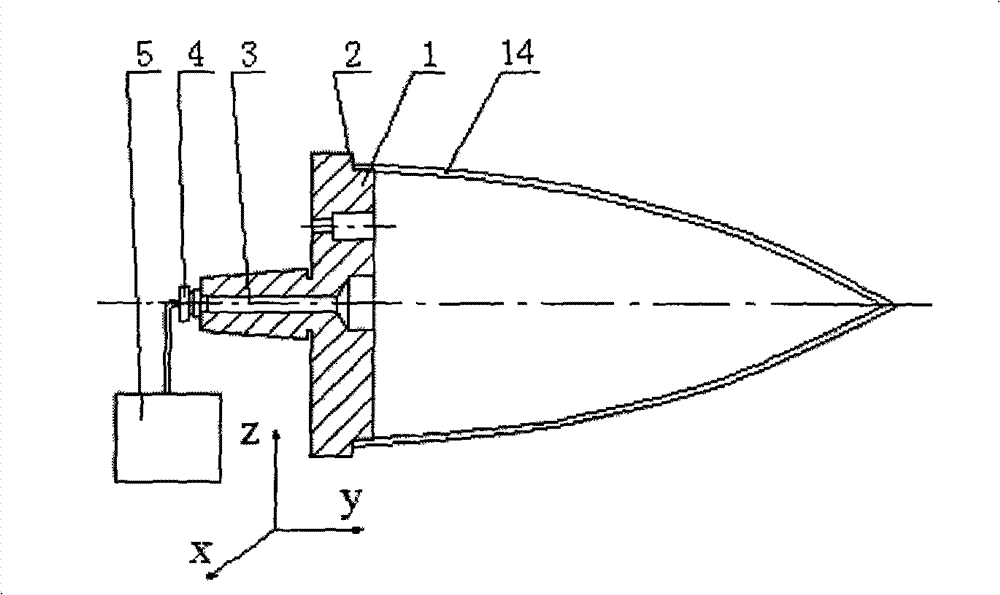

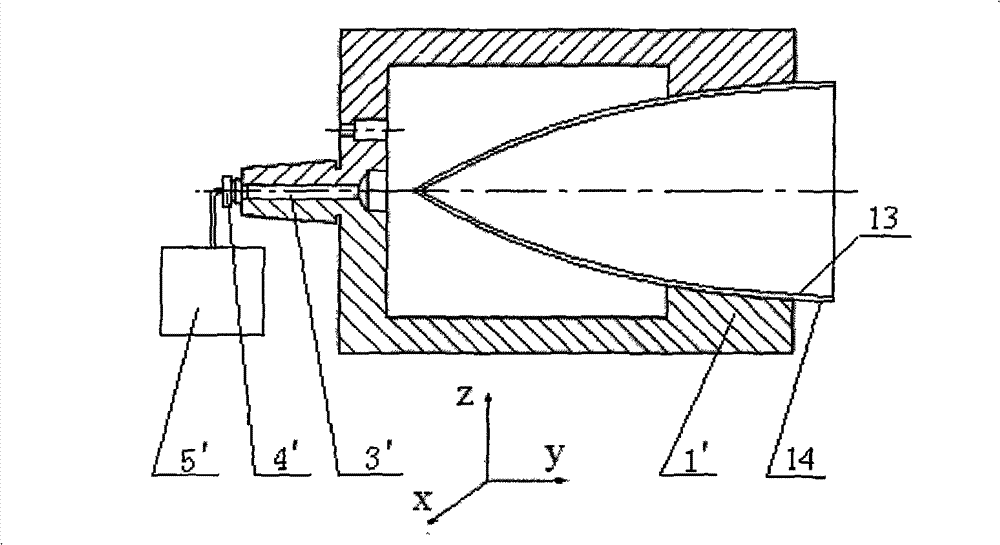

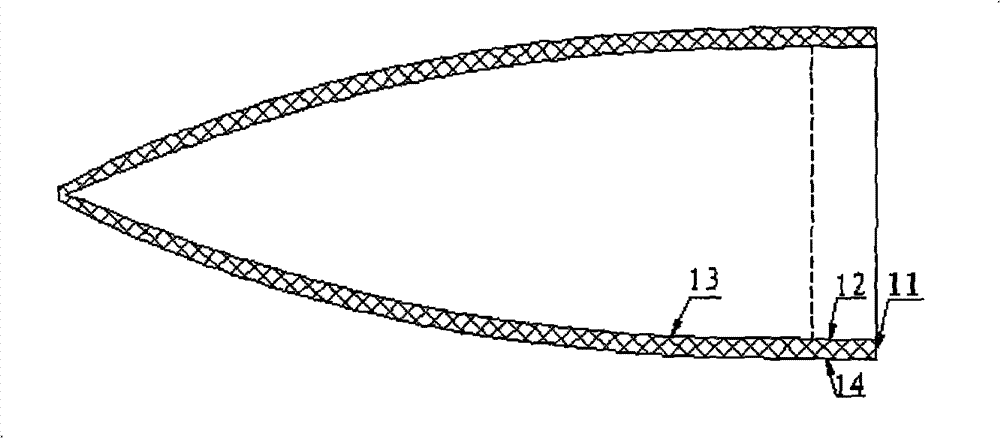

Embodiment 1

[0038]A special jig for precise machining of the inner and outer profiles of a radome, including two special jigs 20 for the outer profile and 30 for the inner profile. The special clamp 20 for the external surface includes a radome positioning element 21, a positioning support plate 22, and a special clamp base part 23 for external surface processing. The positioning surface of the positioning element 21 is conical, and the elastic ring 24 and The outer positioning base part 23 is connected, and there is a guide column on the positioning element 21 to match the guide hole of the special fixture base part 23 for external surface processing, and the positioning support plate 22 is connected with the special external surface processing fixture base part through positioning pins and bolts 23 is connected, and the special clamp base part 23 for exterior surface processing is connected with the air hole of the positioning element 21 with a flexible pipe 25, and the vacuum device is ...

Embodiment 2

[0061] An active location-finding method for the electrical thickness detection and precise grinding of the exterior surface of a radome, comprising the following steps:

[0062] 1) Install a special fixture 20 for the external profile on the positioning workstation 40, and the special fixture is positioned with the radome end face 11 and the tapered hole 12 after precision grinding;

[0063] 2) Place the radome after processing (or grinding) vertically on the special fixture 20 for the external surface, and actively seek the position, so that the center of the tapered hole 12 of the radome is consistent with the center of the special fixture 20 for the external surface, and at the end of the radome. Clamping mechanism 60 is used for external clamping;

[0064] 3) Make the support plate 22 and the clamping mechanism 60 of the radome 10 and the special clamp 20 for the external surface form a workpiece / clamp whole 53 ( Figure 8 , excluding 40, 71 and 81);

[0065] 4) Install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com