Patents

Literature

105results about How to "Control wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

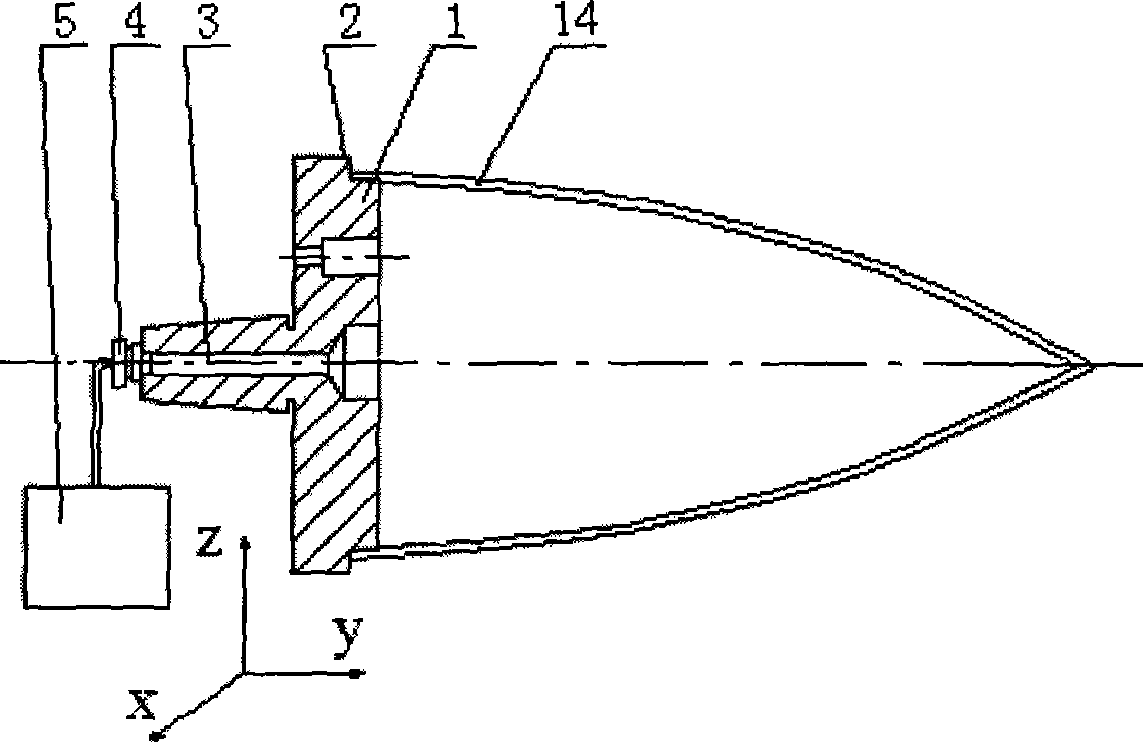

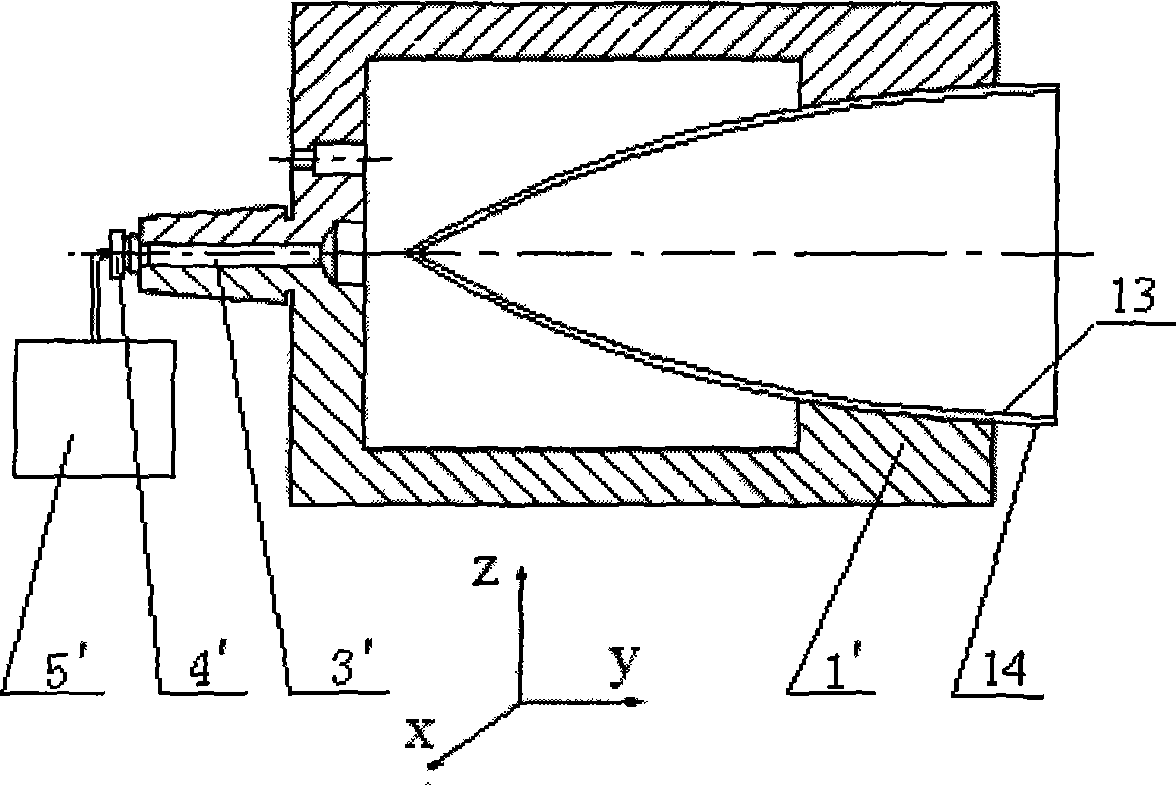

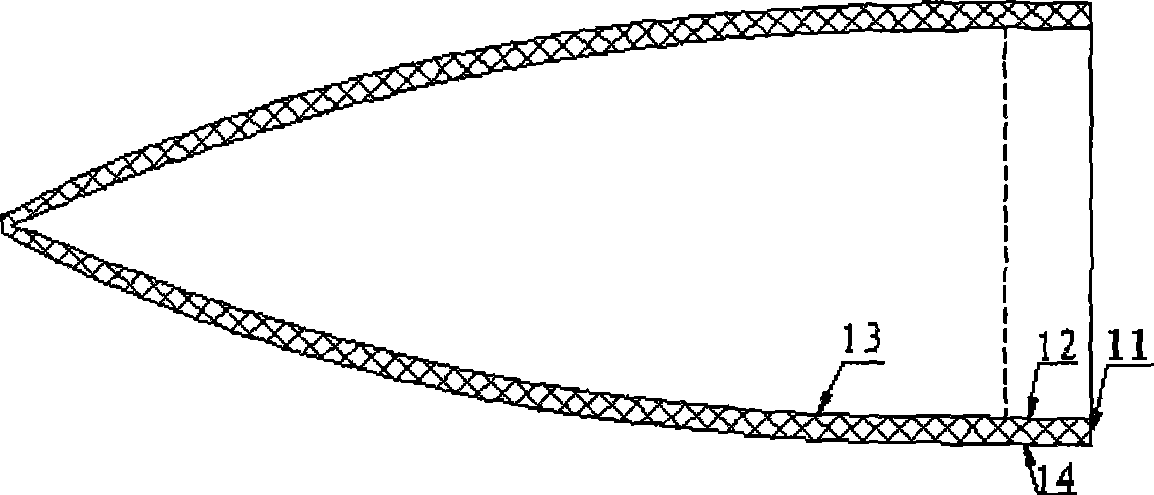

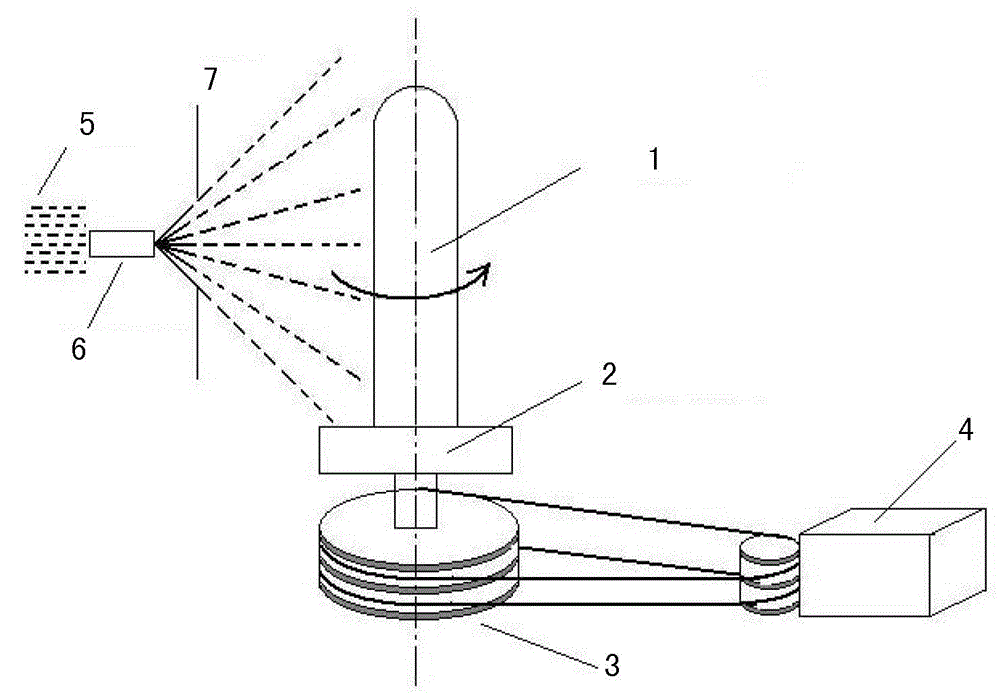

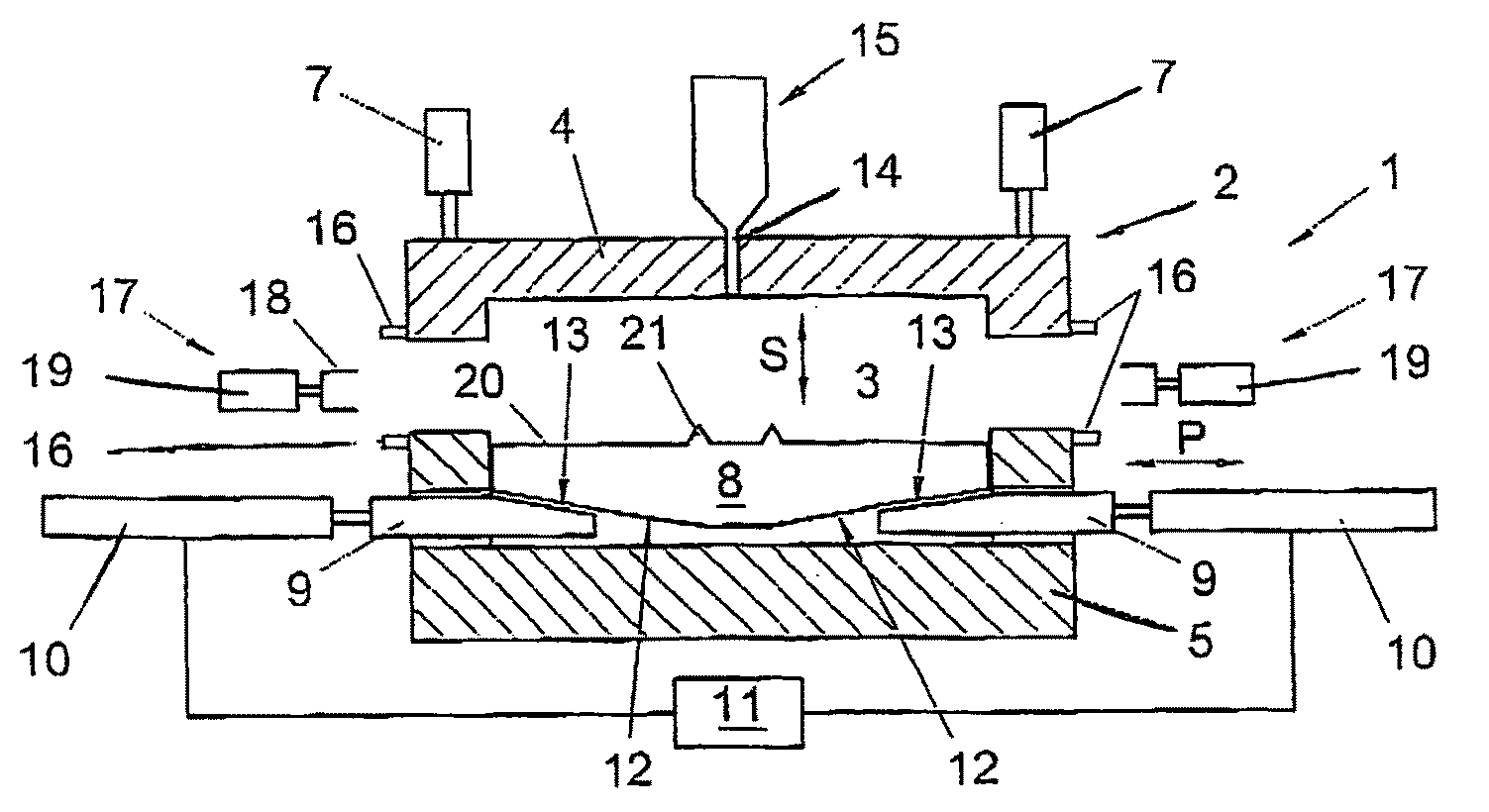

Inner and outer shaped surface precise machining process for antenna cover, active position searching method and processing apparatus

InactiveCN101478078AImprove yieldControl Concentricity and Wall ThicknessAntenna adaptation in movable bodiesRadiating element housingsProcessing accuracyEngineering

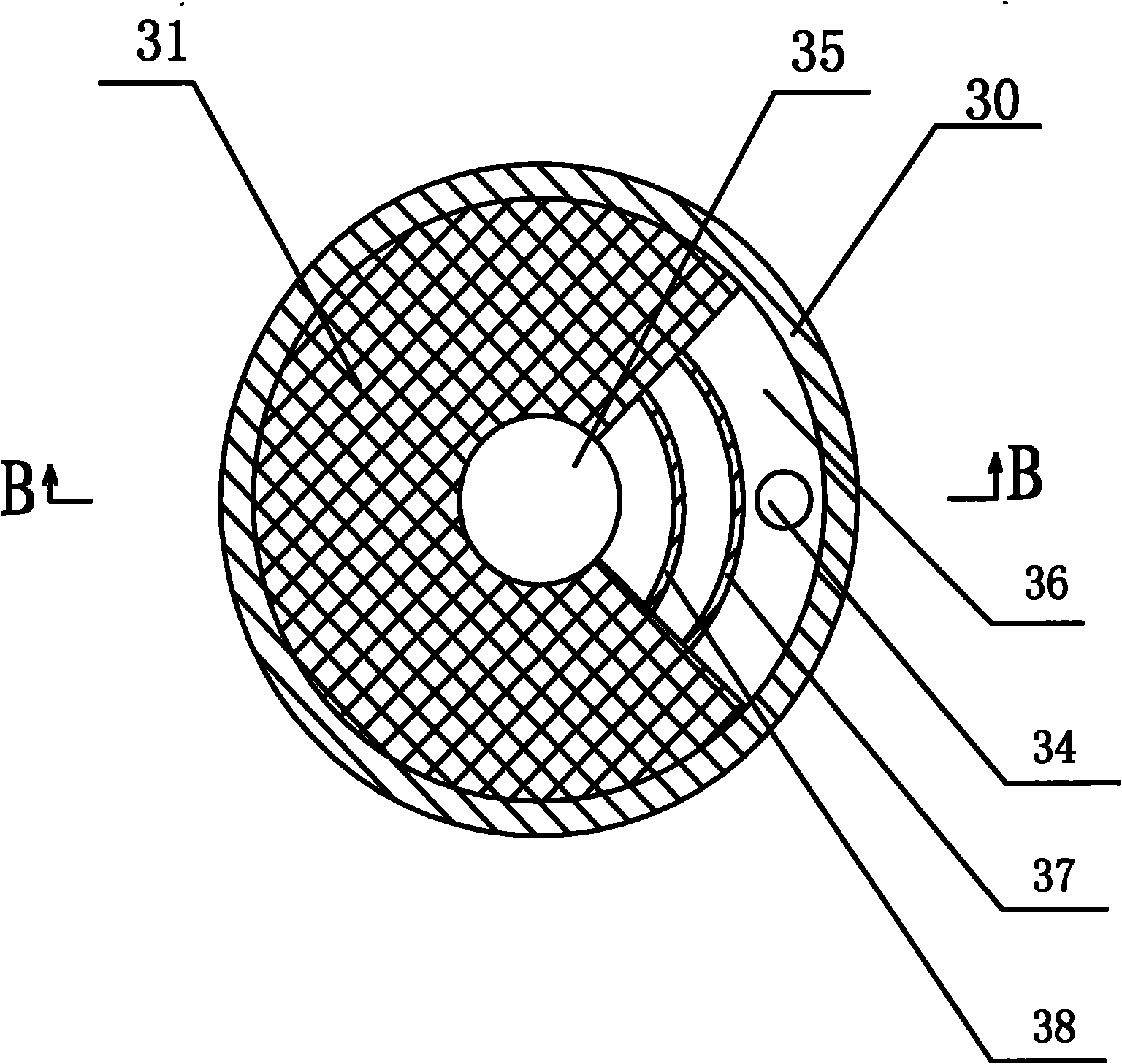

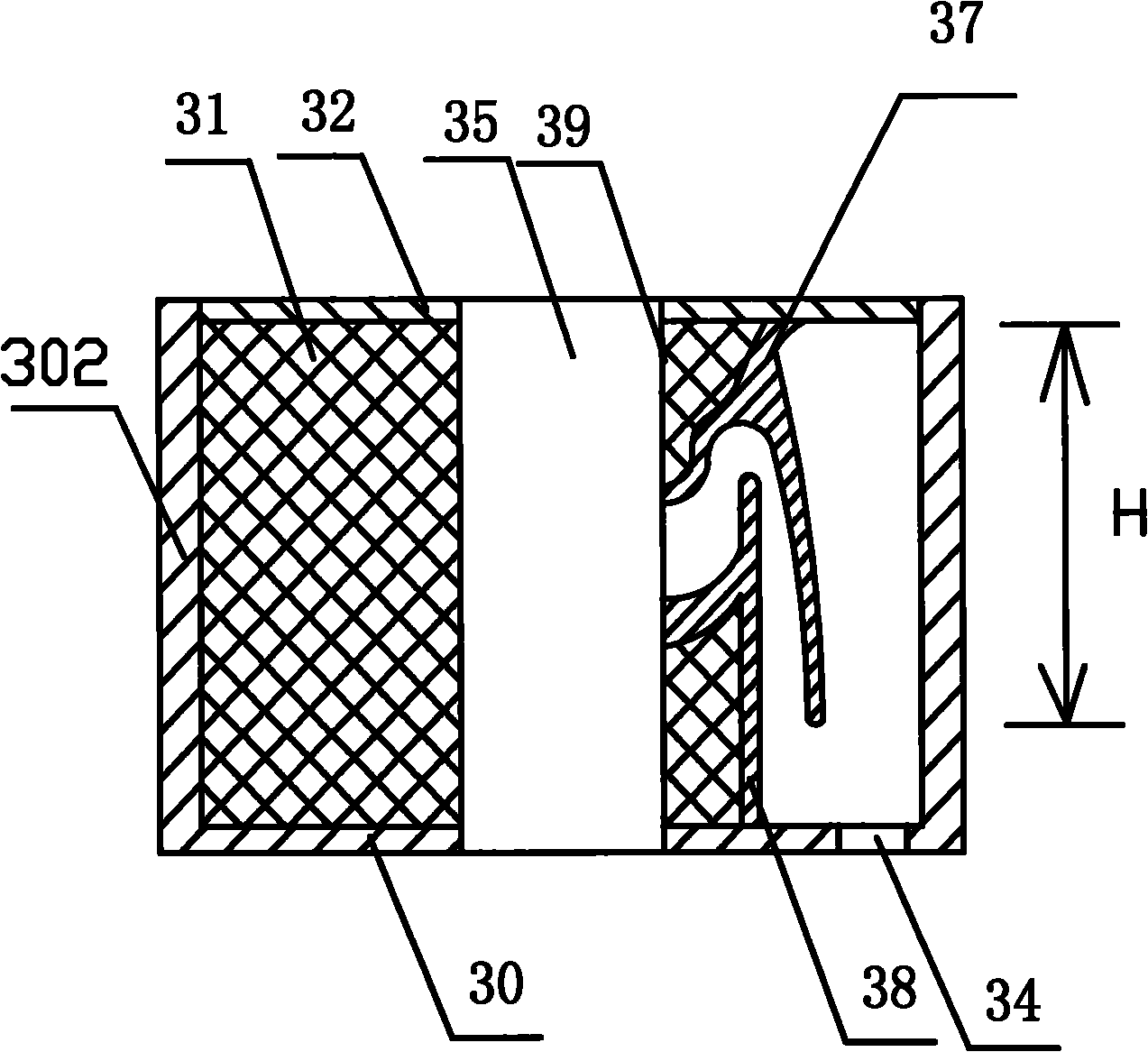

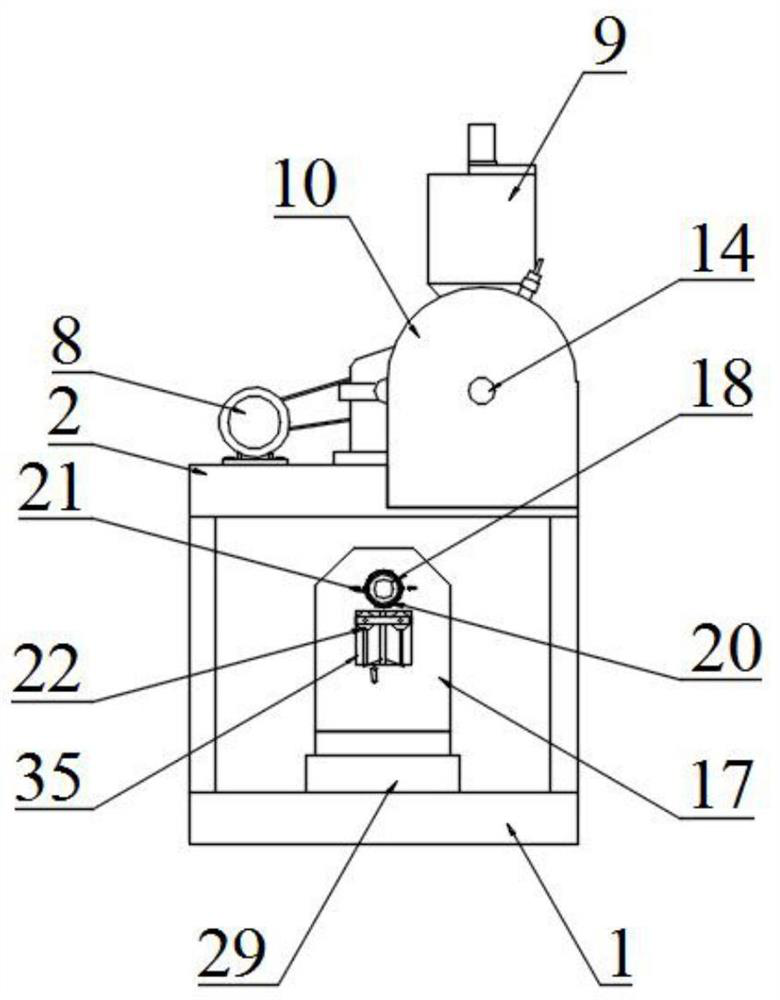

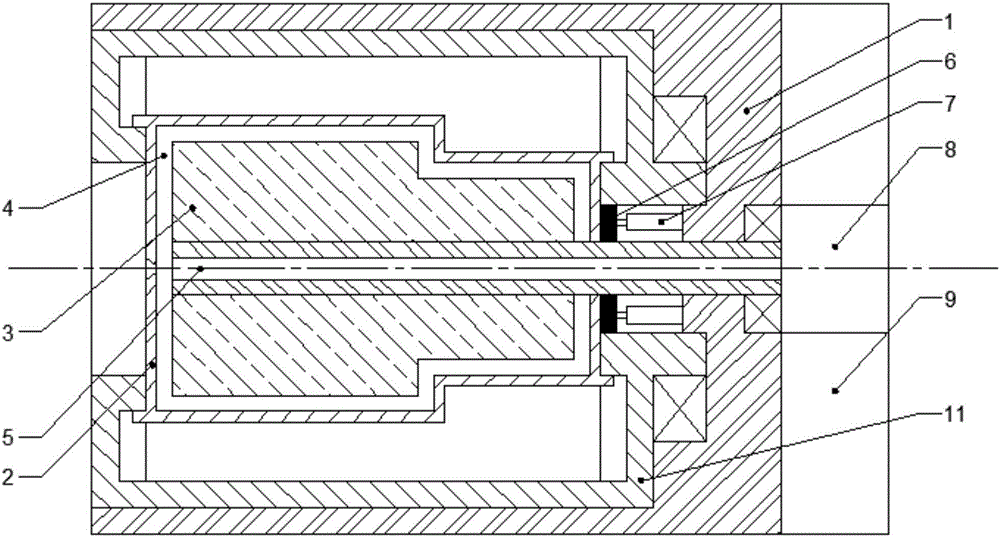

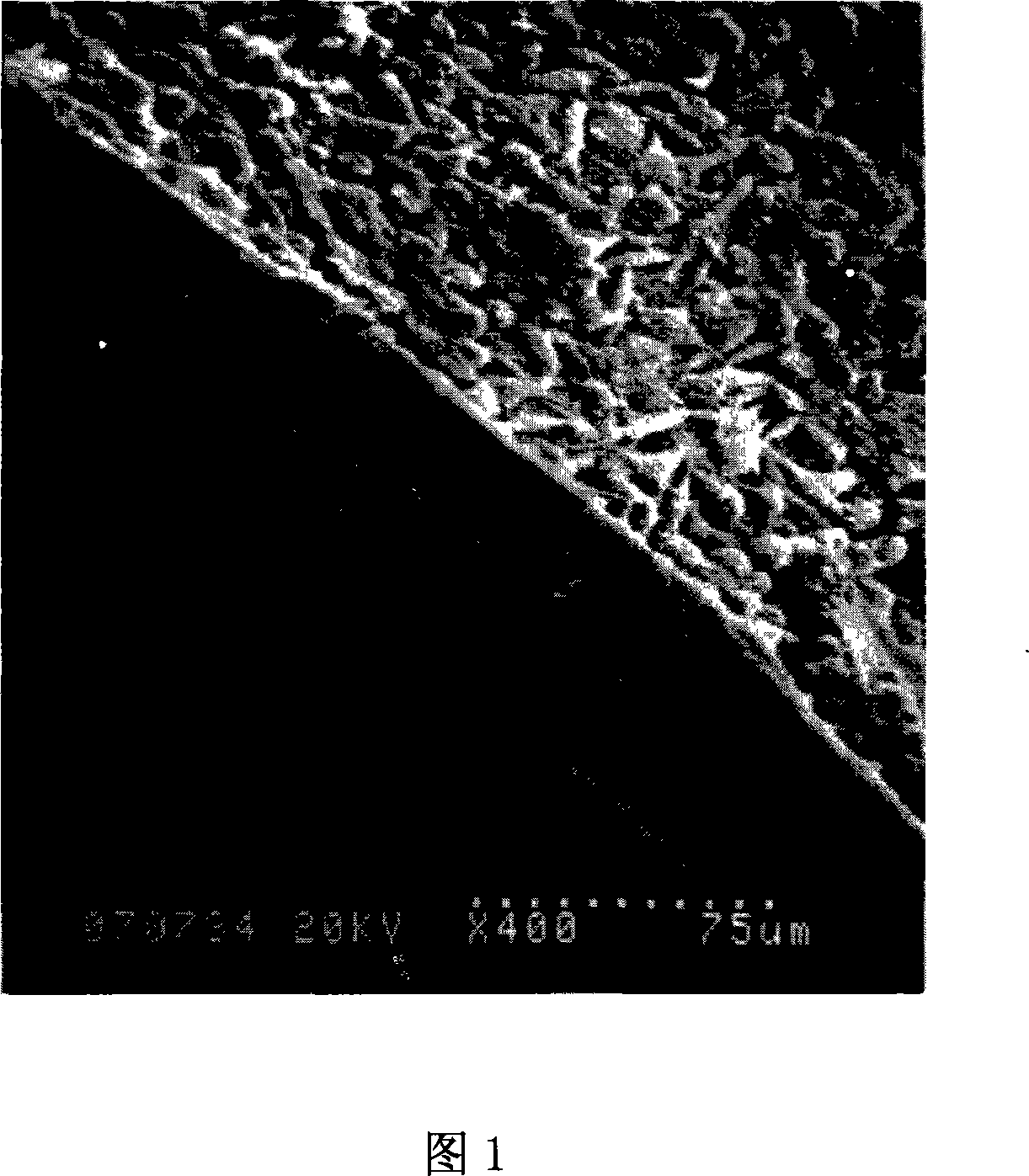

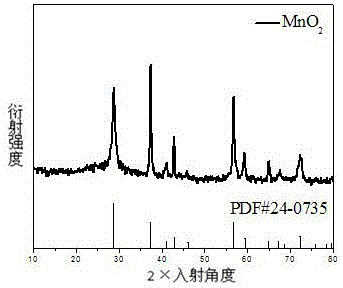

The invention relates to a precise process procedure for internal and external moulding surfaces of an antenna dome. The precise process procedure comprises the following main steps: (1) datum grinding process; (2) test process; (3) antenna dome installation process; (4) coarse and fine grinding process of external moulding surface of the antenna dome; (5) external moulding surface test process; (6) antenna dome installation and conversion process; (7) coarse and fine grinding process of internal moulding surface of the antenna dome; (8) test process; and (9) electrical thickness test process. The invention further relates to active position-finding technological equipment supporting installation of the antenna dome outside a machine, which consists of an external moulding surface special fixture (20), an internal moulding surface special fixture (30), a position finder (71) and a position finder (72), a position-finding workstation (40) and the like. The active position-finding technological equipment significantly improves the installation accuracy and the installation reliability of the antenna dome, significantly improves the working accuracy and the yield of the antenna dome, which in particular improves the coaxial accuracy by two grades or above two grades. By adopting the active position-finding technological equipment supporting installation of the antenna dome outside the machine, the debugging difficulty is significantly reduced; the installation and debugging time is reduced; the and utilization ratio of a numerical control grinder specially used for the antenna dome is effectively improved.

Owner:DONGHUA UNIV

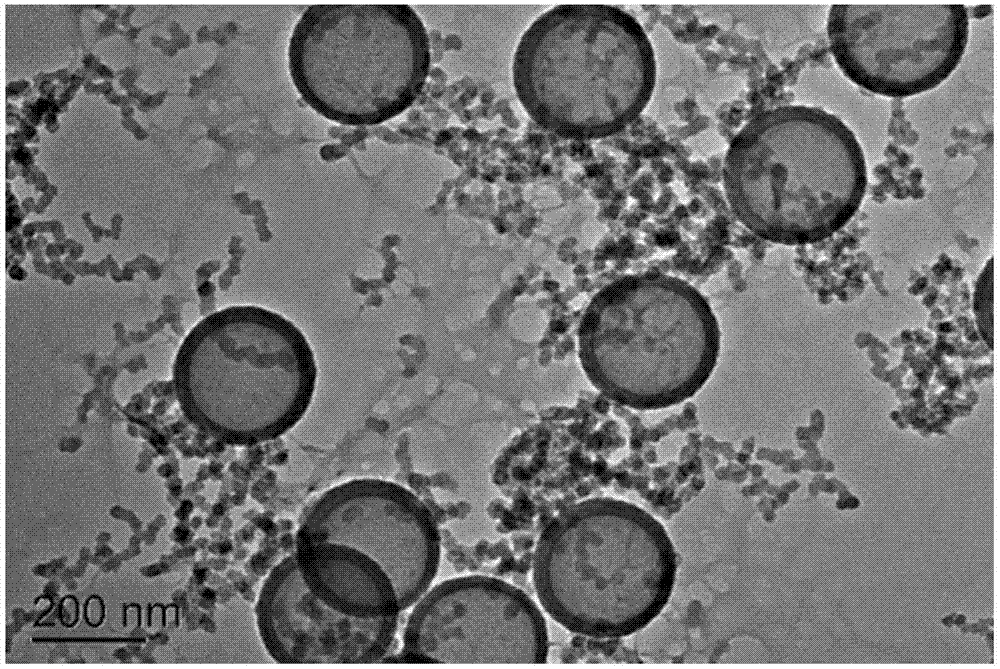

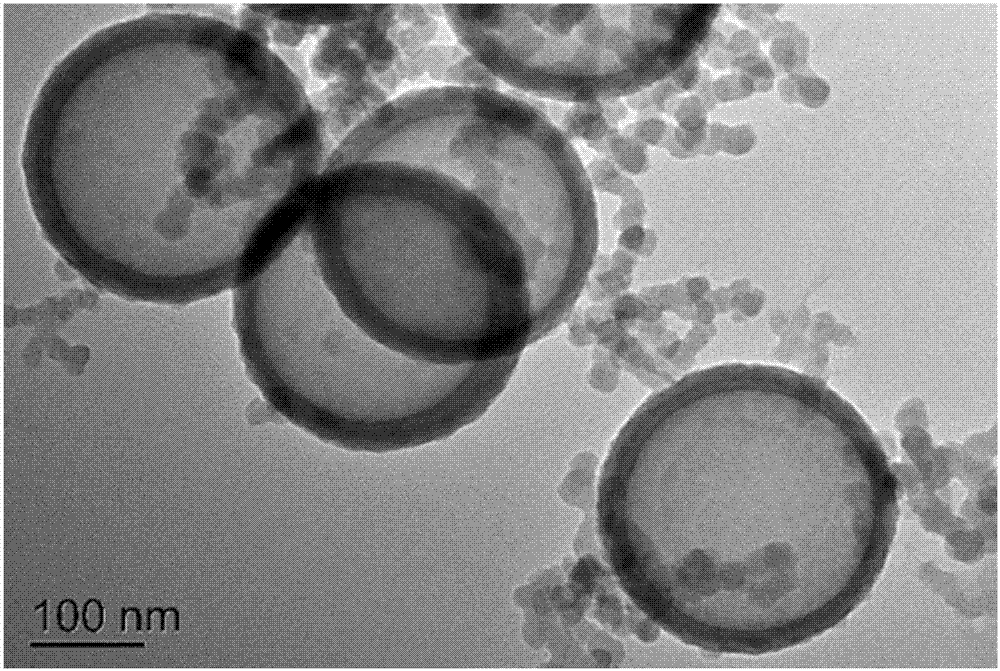

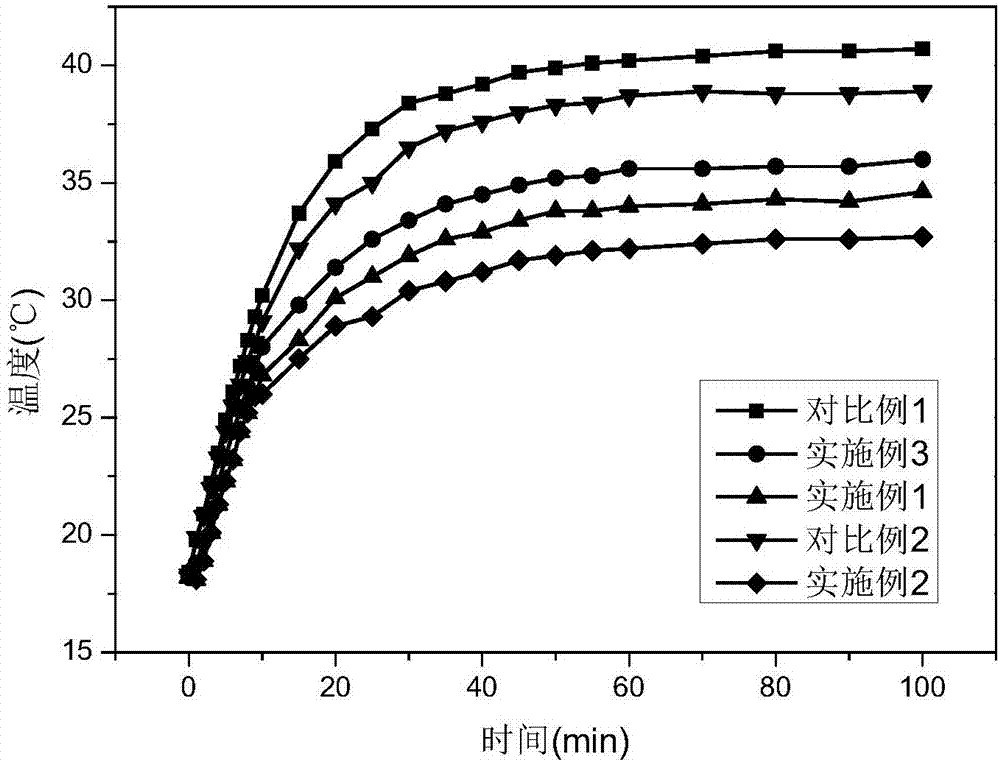

Silicon dioxide hollow microsphere, preparation method thereof, application thereof to thermal insulating coating

The invention discloses a silicon dioxide hollow microsphere, a preparation method thereof, application thereof to thermal insulating coating. The silicon dioxide hollow microsphere is prepared by taking polystyrene as the template and absolute ethyl alcohol as solvent, adding in tetraethoxysilane, hydrolyzing the mixture in alkaline conditions, controlling the reaction temperature at 28-32 DEG Cfor reaction for 22-26 h, performing centrifugal treatment, washing and drying to obtain solid powder and sintering the obtained solid powder at 540-560 DEG C for 7-8 h. The obtained silicon dioxide hollow microsphere is stable in structure, uniform in size and controllable in grain size; the thermal insulating coating obtained through the silicon dioxide hollow microsphere is good in film-formingproperty, easy to construct and good in thermal insulating effects and has a broad application prospect in development of the thermal insulating coating industry.

Owner:广东吉美帮新材料有限公司

Investment casting method capable of controlling wall thickness of aero-engine hollow blade

The invention discloses an investment casting method capable of controlling the wall thickness of an aero-engine hollow blade. In the provided method, a chaplet mould is used, and then a wax material that is used to prepare a hollow blade wax mould, is adopted to prepare a chaplet. Thus the crevice between the chaplet and the wax mould can be effectively avoided. Moreover, the repairing of the wax mould and the casting becomes easier. The free end and the fixed end can be controlled so as to effectively control the wall thickness of a hollow blade. Furthermore, reasonable casting technological parameters are adopted and the casting speed is controlled so as to avoid the phenomenon of deviation, leakage, and core breaking during the hollow blade casting process. The provided casting method can produce aero-engine hollow blades with a complicated internal structure, and the disqualified rate due to deviation, leakage, and core breaking is controlled below 5%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for synthesizing silicon dioxide hollow sphere with mesoporous channel controlled by dodecyl sulfonic acid sodium salt

InactiveCN101143724AFacilitate internal and external transmissionIncrease storage capacitySilicon oxidesCeramicwareMesoporous materialSilicon dioxide

The invention belongs to an inorganic mesoporous material area, in particular to a preparation method of a controllable silica hollow sphere material in a certain diameter range. The anionic surfactant sodium dodecyl sulfonate (SDS) controls the synthesis of spherical wall, which is provided with mesoporous channels and narrow distribution of diameter. The invention uses block copolymer and sodium dodecyl sulfonate as mixing template; with the addition of silicon source, the sol is formed after mixing; under the acid condition, through the agitating and aging treatment, after hydrothermal process, filtering and drying, the template is calcined to obtain silica hollow sphere with the mesoporous channel. Through changing the content of SDS, the synthesis of different size of silica hollow spheres with the mesoporous channel can be controlled. The invention has a simple process and a low cost; the mesoporous shell thickness and the pore diameter of the prepared silica hollow sphere with the mesoporous channel can be controlled in a large range; the invention is beneficial to the internal and external transmission of guest molecules; the invention also improves the reserves of guest molecules, which realizes the controlled release effectively.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of porous hollow carbon microsphere co-doped with oxygen and nitrogen

ActiveCN108511204ASimple processEnvironmentally friendlyHybrid capacitor electrodesIndustrial wasteControllability

The invention discloses a preparation method of a porous hollow carbon microsphere co-doped with oxygen and nitrogen. A spherical precursor (namely composite microsphere) is obtained by spray drying on a mixed solution of lignin and a metal compound, the crosslinking degree of the spherical precursor is improved by oxidizing the spherical precursor in air in advance, so that the spherical morphology during the subsequent carbonization process protected by inert atmosphere is maintained, and the porous hollow carbon microsphere co-doped with oxygen and nitrogen is finally obtained by oxidization of concentrated nitric acid. The preparation method is simple in process, production on a large scale is easily achieved, moreover, the main raw material lignin is industrial waste such as papermaking and is low in cost, and high utilization of the microsphere can be achieved; and the porous hollow carbon microsphere prepared by the method is uniform in grain size, high in size controllability and has relatively large specific area and developed hierarchical hole structure, and the electrochemical performance is excellent when the porous hollow carbon microsphere is used as a supercapacitorelectrode material.

Owner:张家港博威新能源材料研究所有限公司

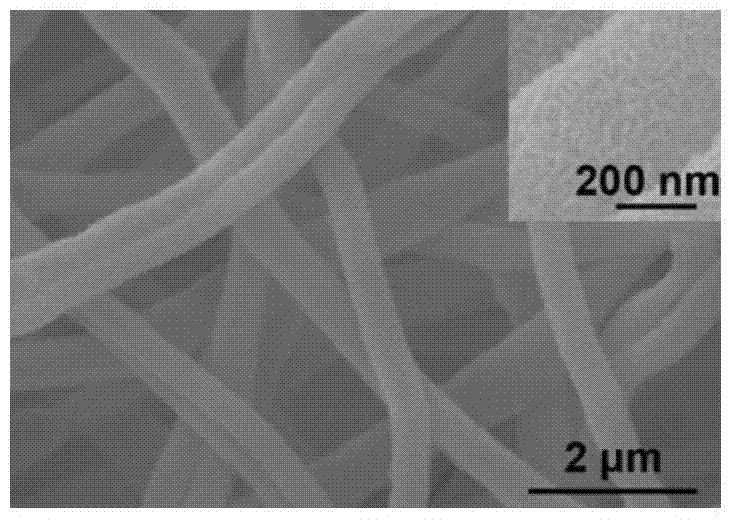

Silicon-carbon composite nano-tube preparation method

ActiveCN104979539AThe removal process is simple and thoroughGood lookingMaterial nanotechnologyCell electrodesCarbon compositesSolvent

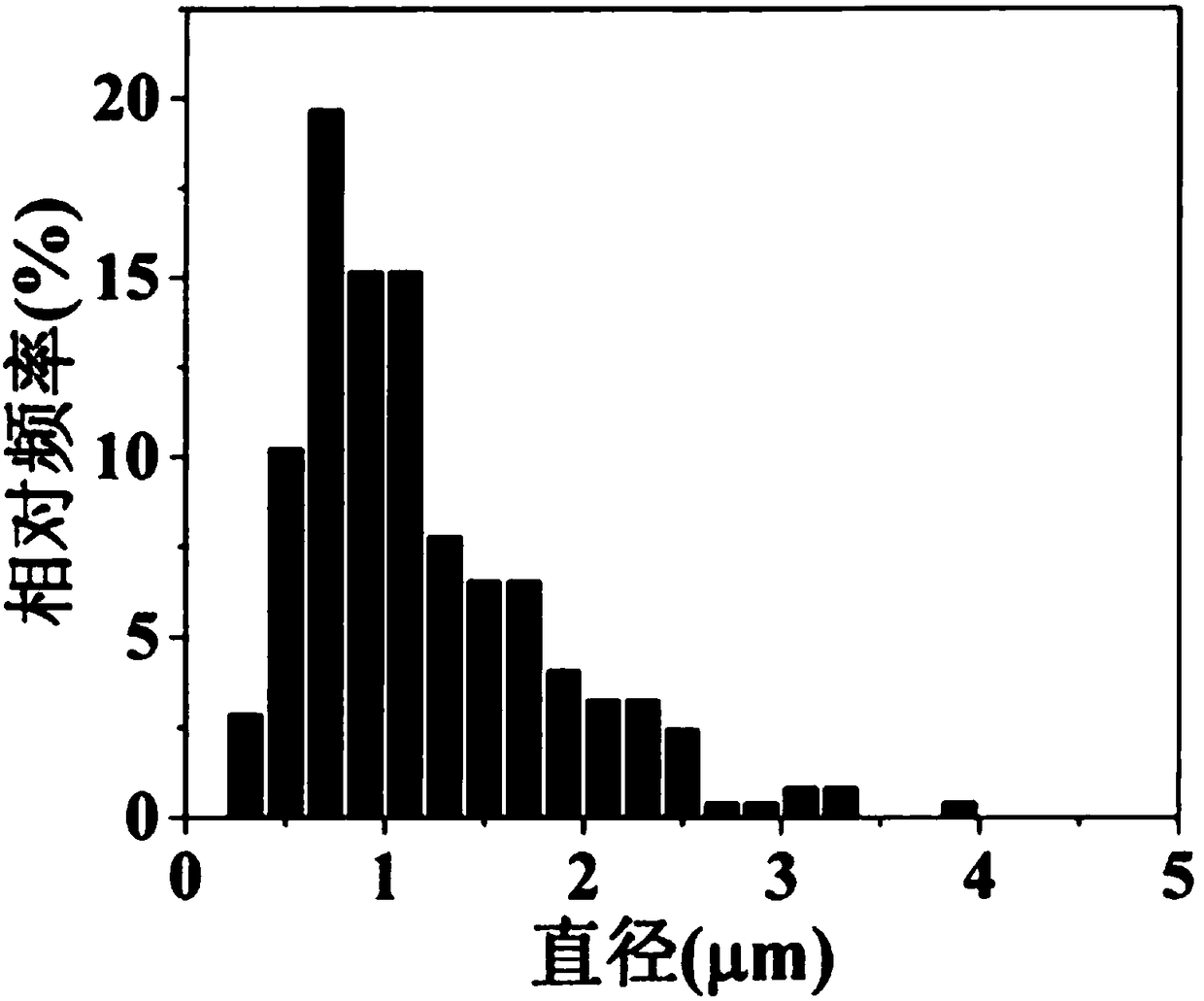

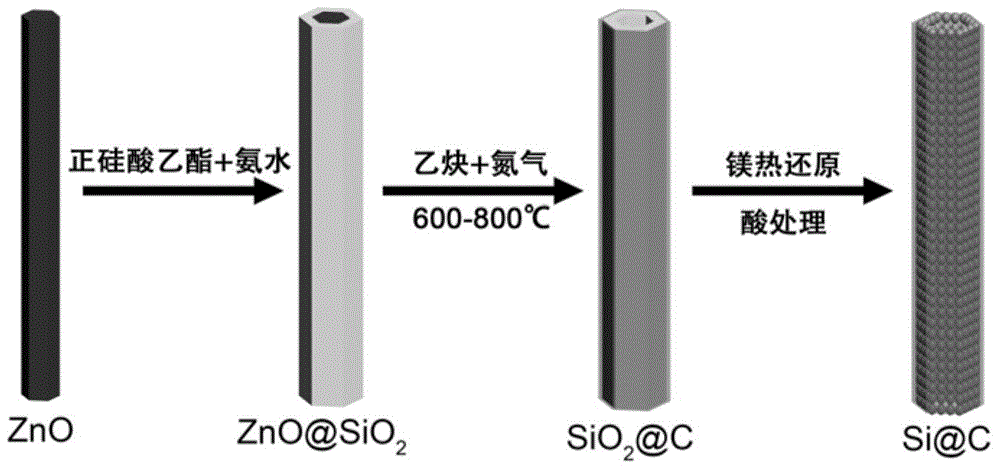

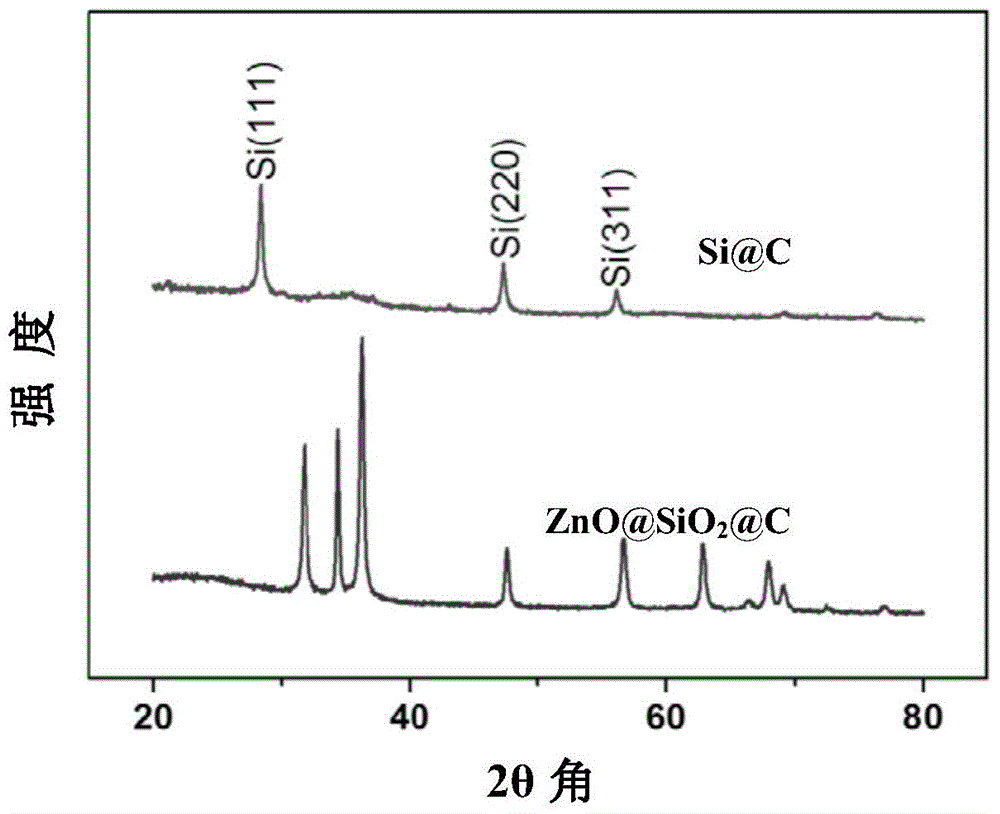

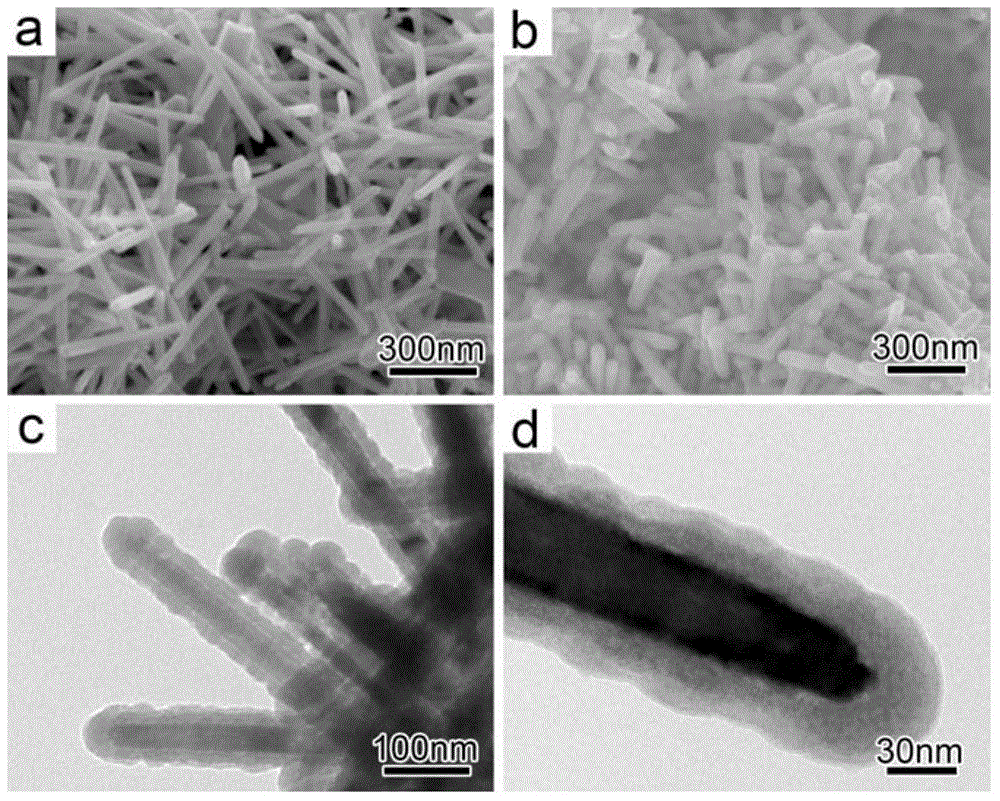

The present invention discloses a silicon-carbon composite nano-tube preparation method, which comprises: dissolving zinc oxide nano-rods in a solvent, adjusting to achieve an alkaline state, mixing with tetraethyl orthosilicate, reacting, carrying out centrifugation drying to obtain a silicon dioxide coated core-shell structure material, recording as ZnO@SiO2, adding the ZnO@SiO2 to a reactor, heating in the presence of an inert gas, introducing acetylene gas, reacting, depositing a carbon coating layer on the silicon dioxide coated core-shell structure material surface, recording as ZnO@SiO2@C, carrying out a magnesium thermal reduction reaction on the ZnO@SiO2@C, removing the zinc oxide nano-rod template, and carrying out a post-treatment to obtain the silicon-carbon composite nano-tubes. According to the present invention, the zinc oxide nano-rods are adopted as the template to prepare the silicon-carbon composite nano-tubes, the preparation process is simple, the template removing is convenient and complete, the large-scale industrial production is easily achieved, and the new approach for synthesizing other types of the nano-tubes is provided.

Owner:浙江锂宸新材料科技有限公司

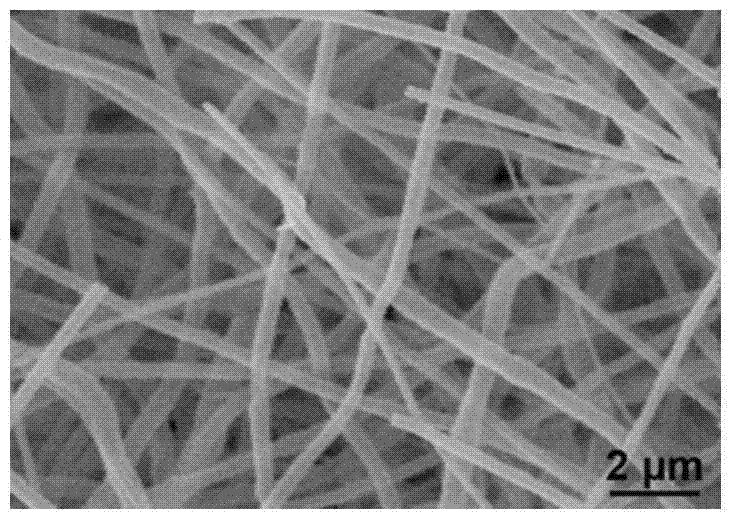

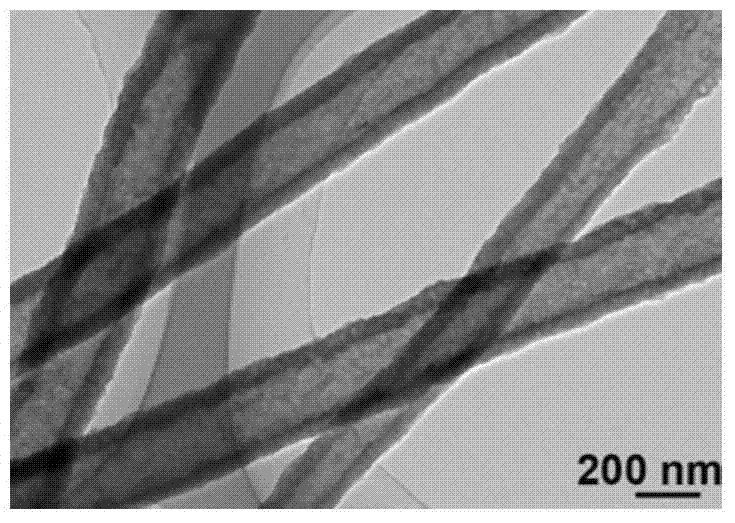

Preparation method of temperature-sensitive hollow nanofiber membrane

InactiveCN107604535AFlat surfaceUniform thicknessPhysical treatmentFibre typesSolventBiological substances

The invention relates to a preparation method of a temperature-sensitive hollow nanofiber membrane. The preparation method comprises the following steps: copolymerizing temperature-sensitive monomers,monomers capable of forming physical crossing points and monomers capable of forming chemical crossing points by heating by free radical solution polymerization to obtain a temperature-sensitive polymer; adding the temperature-sensitive polymer in a solvent and stirring to obtain a polymer solution as a shell spinning solution, taking viscous oil as a core layer spinning solution, and carrying out coaxial electro-spinning to obtain a nanofiber membrane with a core-shell structure; and carrying out heat treatment, and extracting the core layer viscous oil by an organic solvent to obtain the final product. By the coaxial electro-spinning method, the outer diameter, inner diameter and wall thickness of a product can be controlled effectively, a preparation process is environmentally friendly, and conditions are gentle. The obtained temperature-sensitive hollow nanofiber membrane can stably exist in water and cannot be dissolved, has rapid temperature sensitivity, and can be applied to atemperature sensor, a drug controlled release carrier, a cell culture substrate or a support, oil-water separation or biological substance purification film.

Owner:DONGHUA UNIV

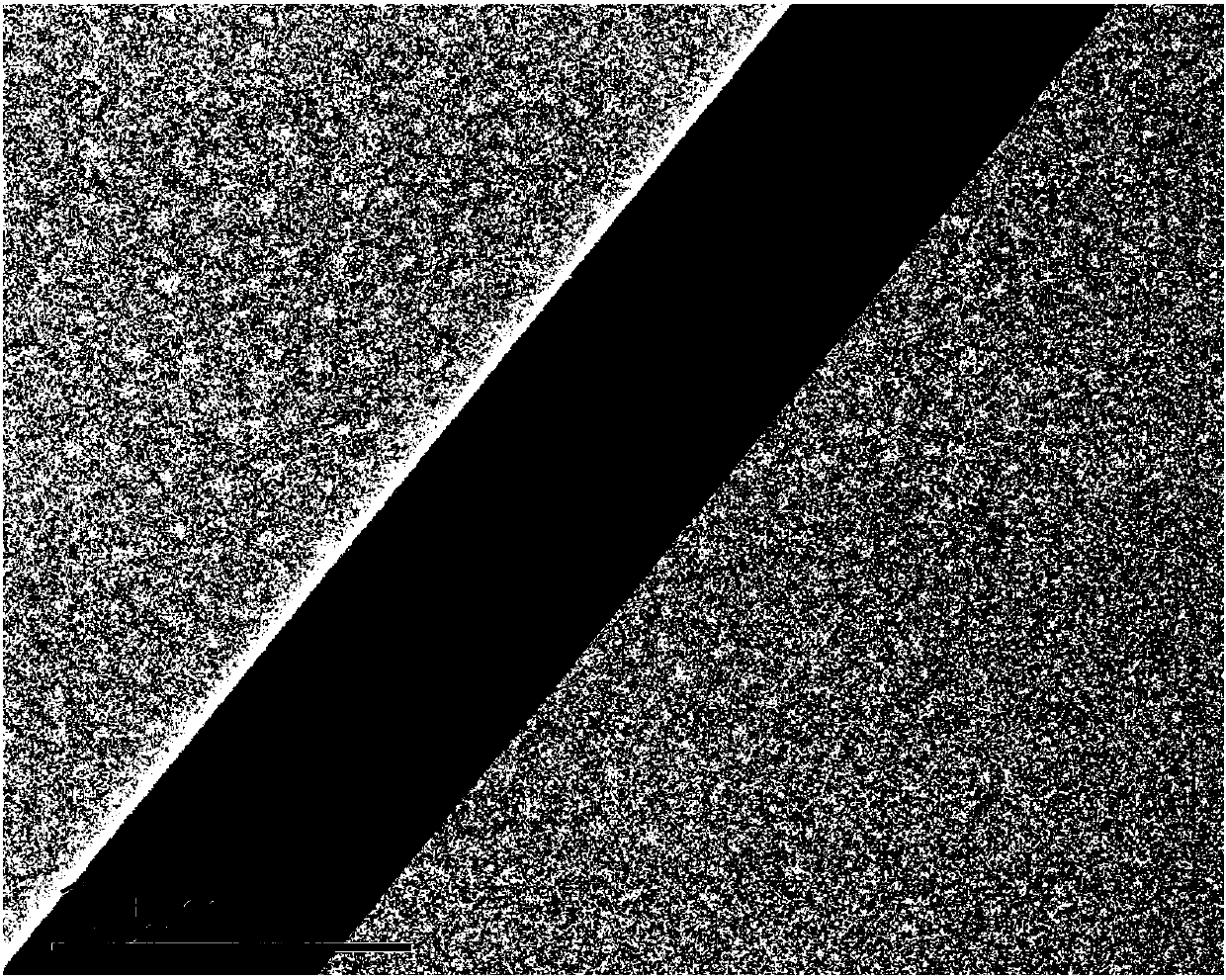

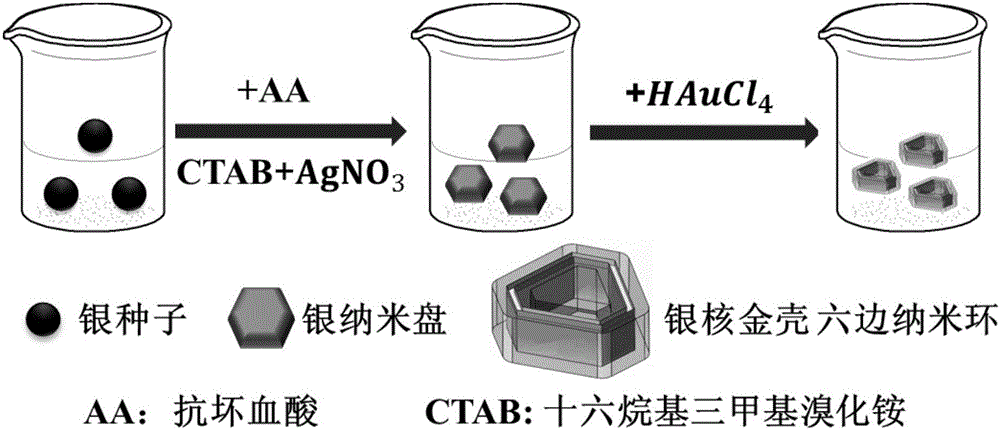

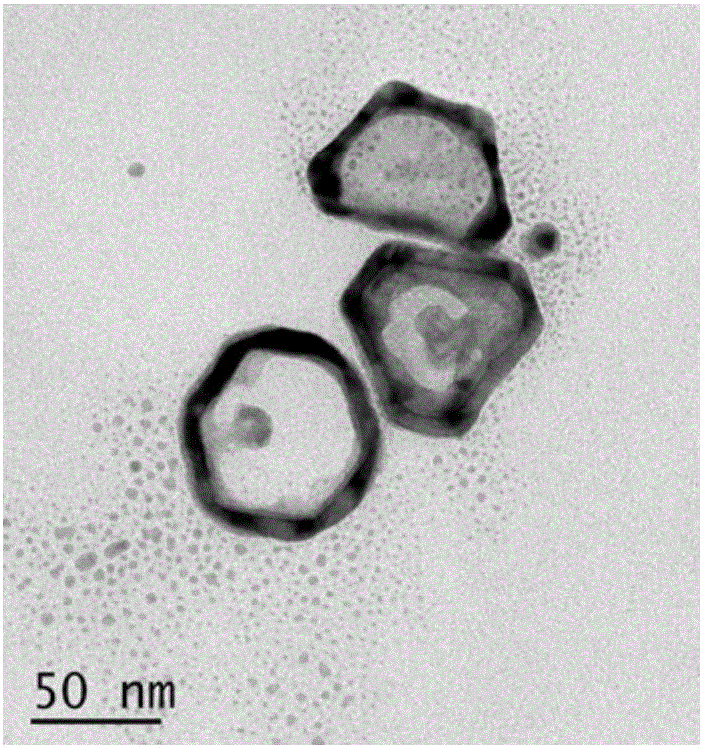

Preparation method of silver core-gold shell hexagonal nanometer ring

The invention discloses a preparation method of a silver core-gold shell hexagonal nanometer ring. Firstly, silver nanometer disc solution is prepared by a seed-medium growth method; then, the silver core-gold shell hexagonal nanometer ring is prepared by an electric replacement method; the process of preparing the silver nanometer disc solution is as follows: firstly, mixed solution of a precursor reagent and a protective agent is obtained; then, first reducing agent solution is taken and dripped in the mixed solution to obtain silver seed solution; then, growth solution is prepared; and finally, the silver seed solution and the growth solution are mixed to obtain the silver nanometer disc solution; the process of preparing the silver core-gold shell hexagonal nanometer ring is as follows: firstly, chloroauric acid solution and the silver nanometer disc solution are mixed to obtain purple solution; then, precipitates obtained by centrifugating the solution are renewedly dispersed in de-ionized water to obtain lavender solution; and nanometer particles in the lavender solution are the silver core-gold shell hexagonal nanometer rings. The preparation method has the advantages of simple preparation process, low preparation cost, high yield and uniform morphology of the prepared nanometer ring.

Owner:NINGBO UNIV

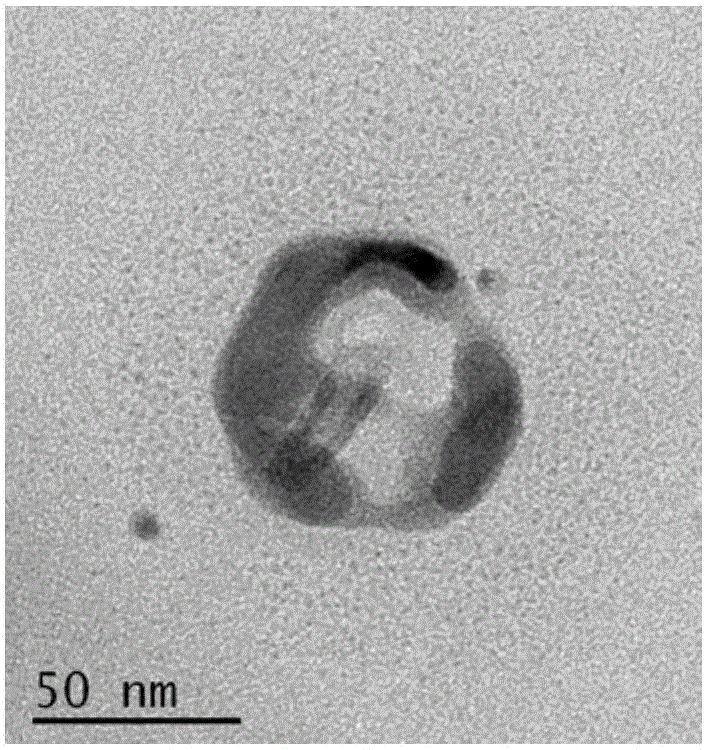

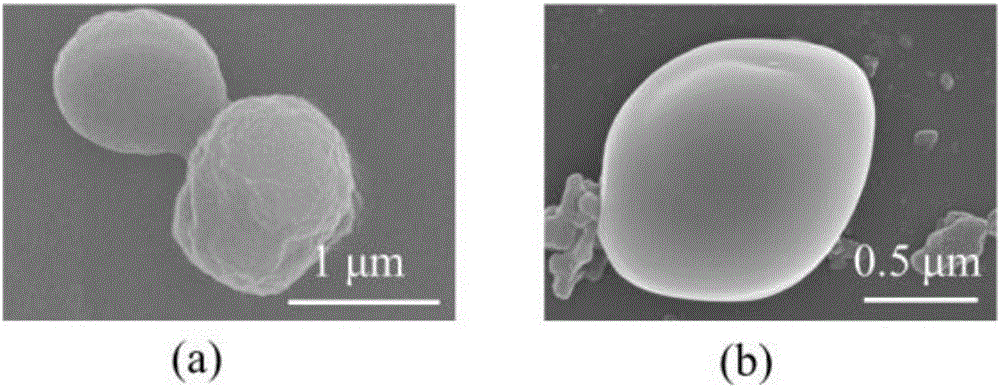

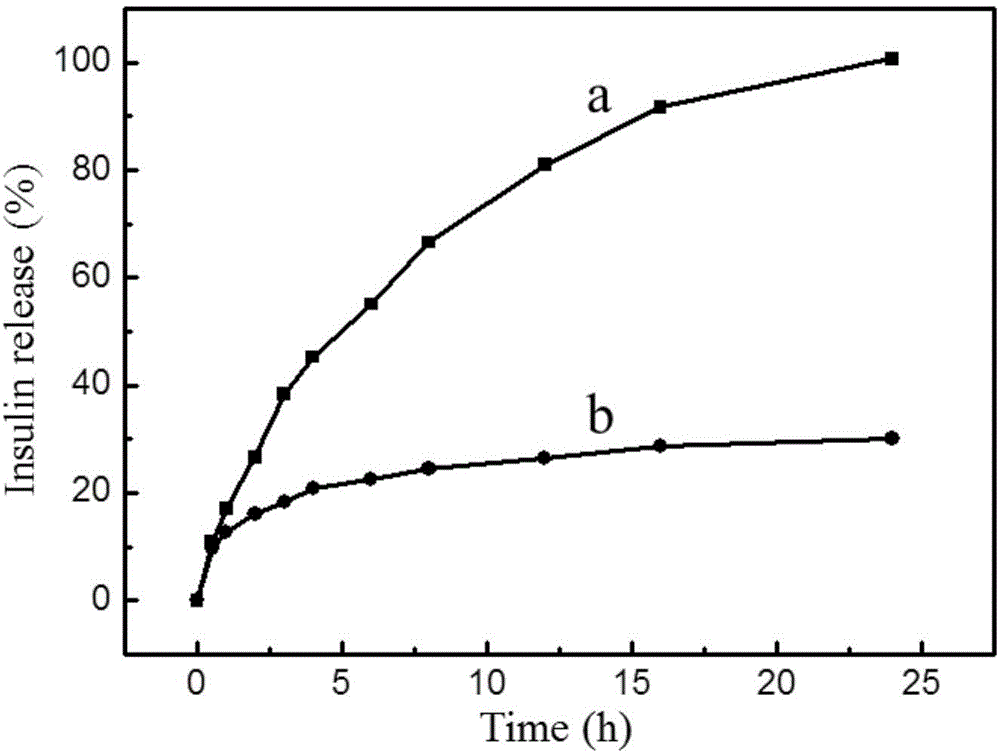

Preparation method of polydopamine microcapsule oral insulin administration carrier

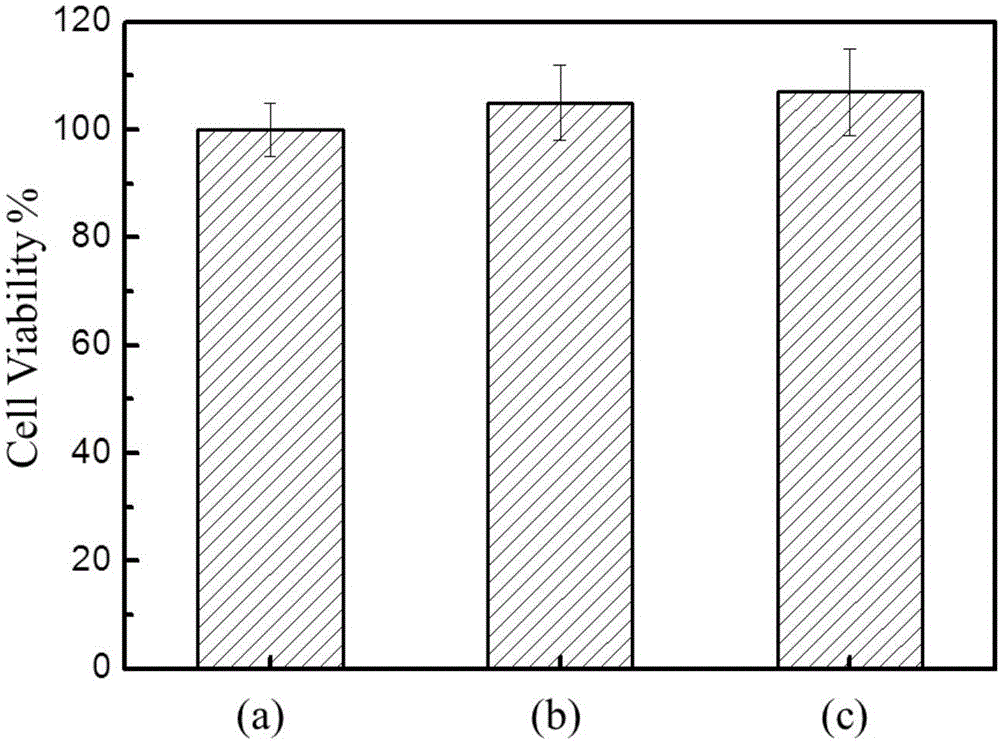

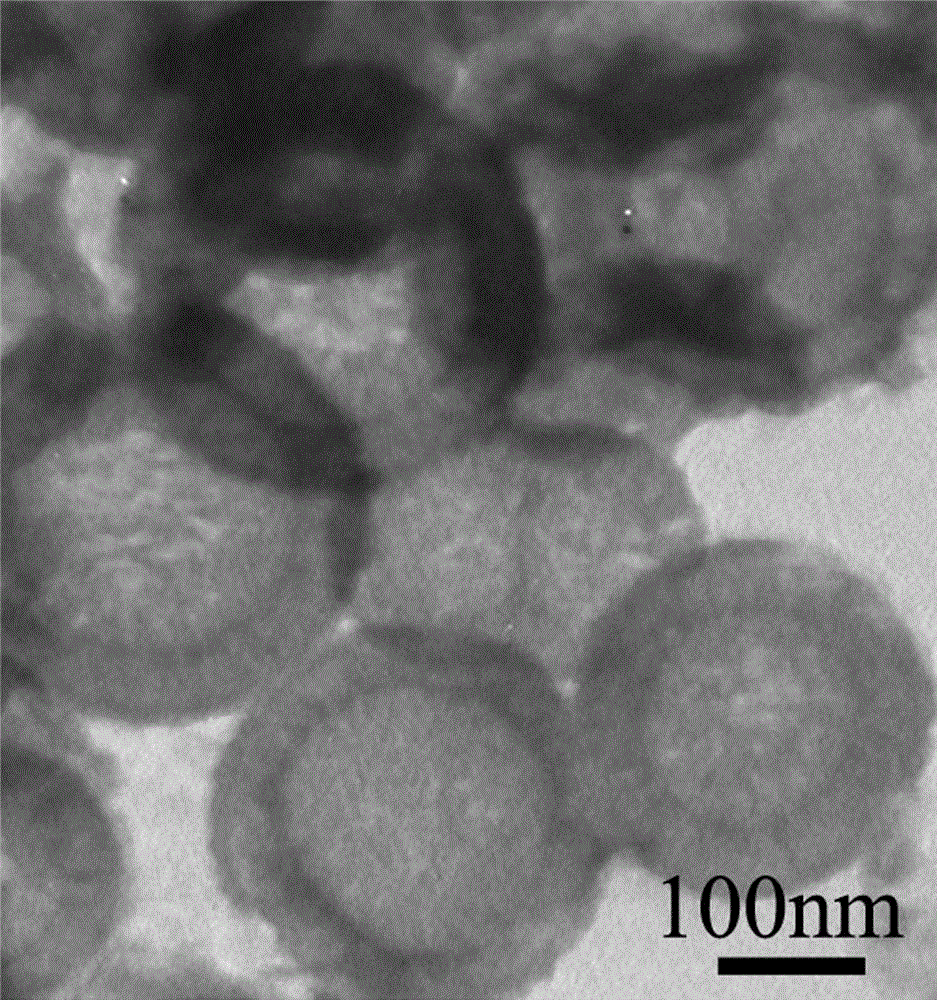

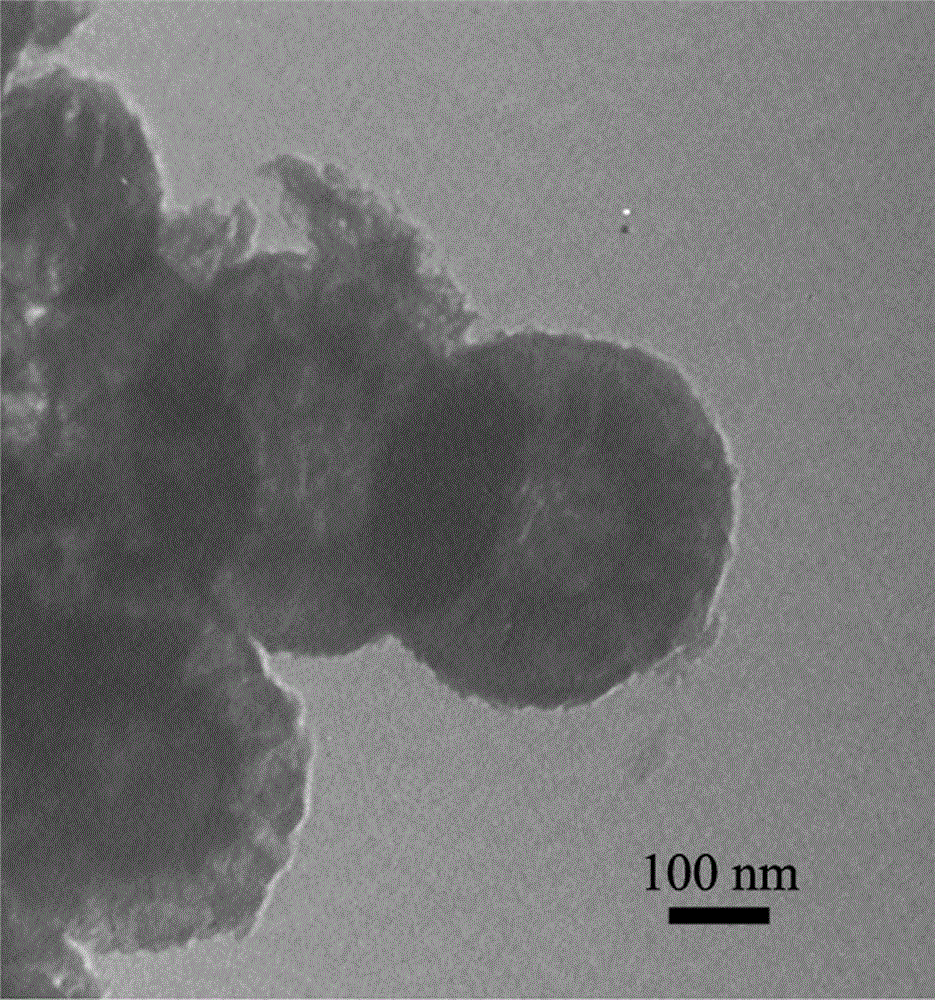

InactiveCN106729638AGood biocompatibilityControl wall thicknessPeptide/protein ingredientsMetabolism disorderDiabetes mellitusNanoparticle

The invention relates to a preparation method of a polydopamine microcapsule oral insulin administration carrier. The preparation method comprises the following steps: dissolving insulin powder in an acidic solution, adding sodium chloride, and preparing insulin micro / nano particles by a salting-out process; dispersing the insulin micro / nano particles in a dopamine weakly-alkaline solution, and reacting under oscillation conditions to obtain a polydopamine-coated insulin core-shell structure; and finally, dispersing the polydopamine-coated insulin core-shell structure in a functional molecule solution, and modifying functional molecules on the surface, thereby obtaining the biocompatible polydopamine microcapsule oral insulin administration carrier capable of overcoming the intestinal tract barrier. The polydopamine microcapsule oral insulin administration carrier has the p-responsive insulin release behavior, has the advantages of favorable cell compatibility and the like, can overcome the intestinal tract barrier, and can be used for treating diabetes.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for preparing pitch-based hollow carbon spheres

The invention provides a method for preparing pitch-based hollow carbon spheres. The preparation method mainly comprises the following steps: 1) preparing nano silicon dioxide spheres; 2) modifying the nano silicon dioxide spheres by use of hexadecyl trimethyl ammonium bromide and tetraethoxysilane; 3) taking petroleum pitch as a carbon source, preparing the hollow carbon spheres by use of a vapor deposition method. The carbon source used in the method is rich in source and low in price; the method is simple in preparation equipment, controllable in conditions and suitable for large-scale production; the obtained hollow carbon spheres are uniform in size, good in dispersity, controllable in diameter and wall thickness, and applicable to the fields of energy source materials, biocarriers and the like.

Owner:XINJIANG UNIVERSITY

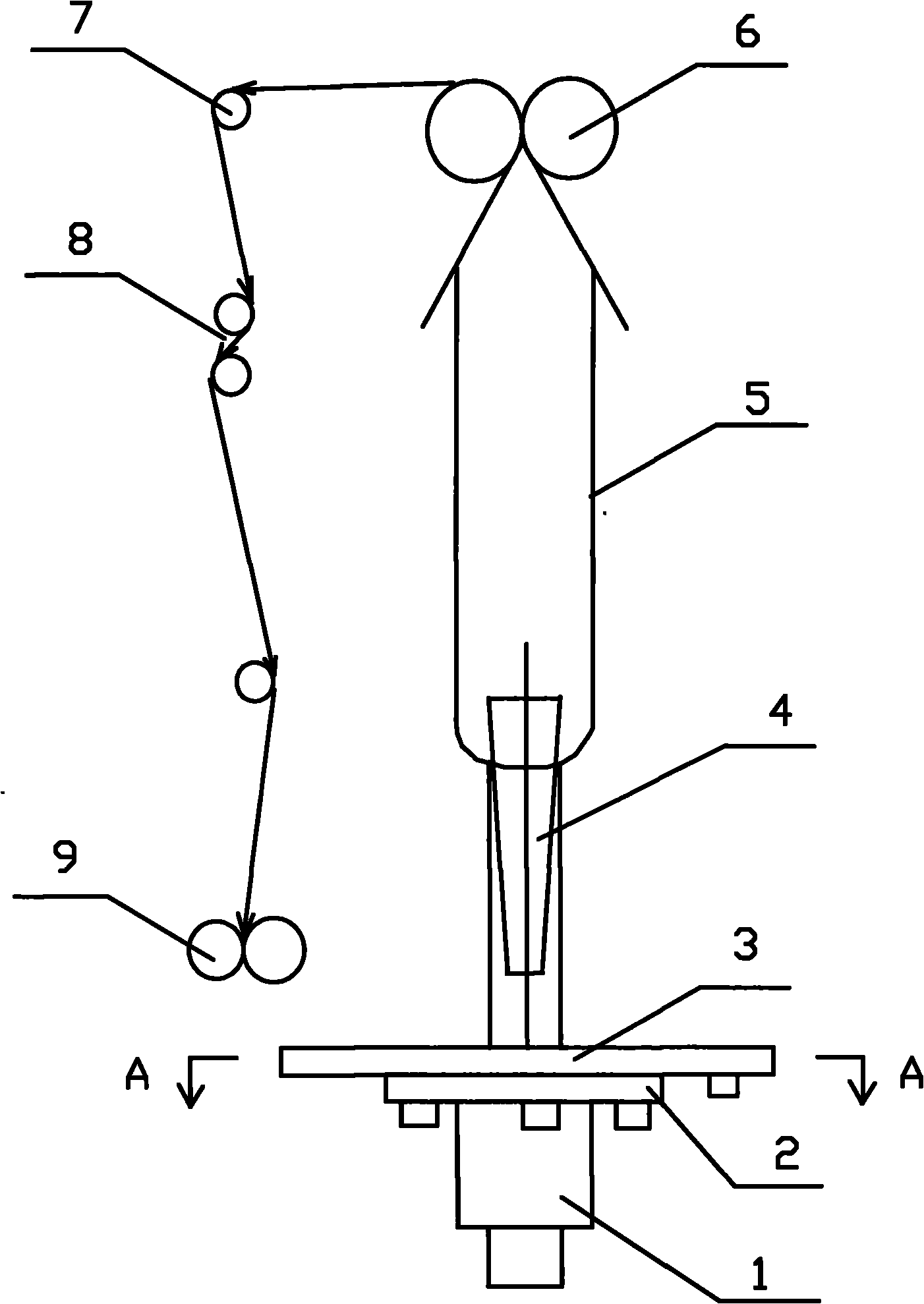

Thick and thin bag production device

The invention relates to a thick and thin bag production device which comprises an extruder, a die connected with a discharge port of the extruder, and a standard air ring and an upper traction roller arranged on the upper end of the die; the upper end of the standard air ring is provided with a mold air ring; a through hole for a film bubble crude embryo to pass through is arranged in the middle of the mold air ring; one side in the mold air ring is provided with a cavity communicated with the through hole; the upper end of the cavity is provided with an upper windshield which extends downwards, and the lower end thereof is provided with a lower windshield which extends upwards; a buffer air duct is formed between the upper and the lower windshields; the mold air ring is provided with an air inlet hole of a connecting air pipe; the air inlet hole and the cavity are communicated; and the gas enters the cavity through the air inlet hole, and is blown to the film bubble crude embryo in the through hole from the buffer air duct. The mold air ring is used to control the thickness of a side wall of a film bubble, the air outlet of the air pipe is not arranged directly to one side of the film bubble crude embryo but is blown to the film bubble crude embryo through the buffer air duct, so that the thickness of the thin side and the thick side of a produced thick and thin bag is uniform, and the strength is good.

Owner:NANTONG HUASHENG PLASTIC PRODS

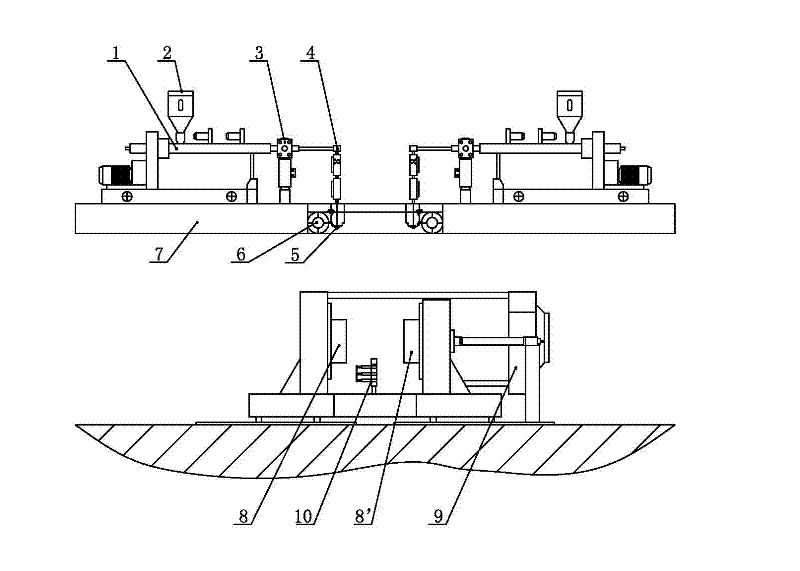

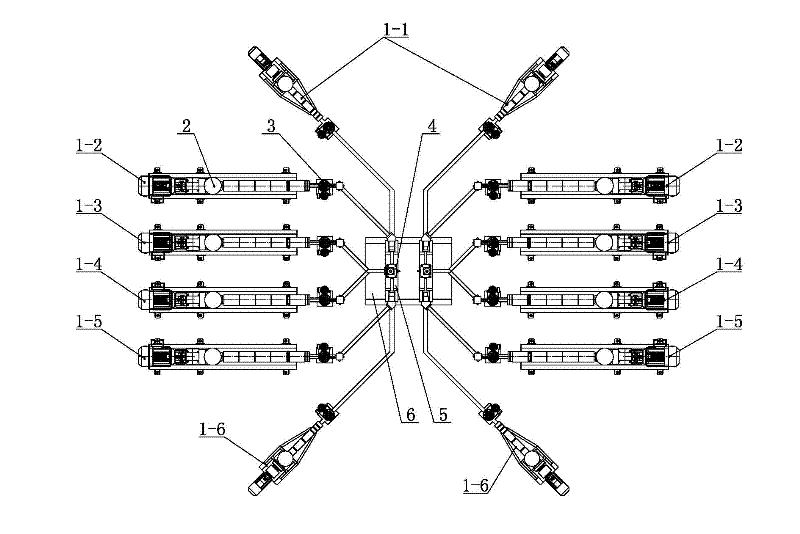

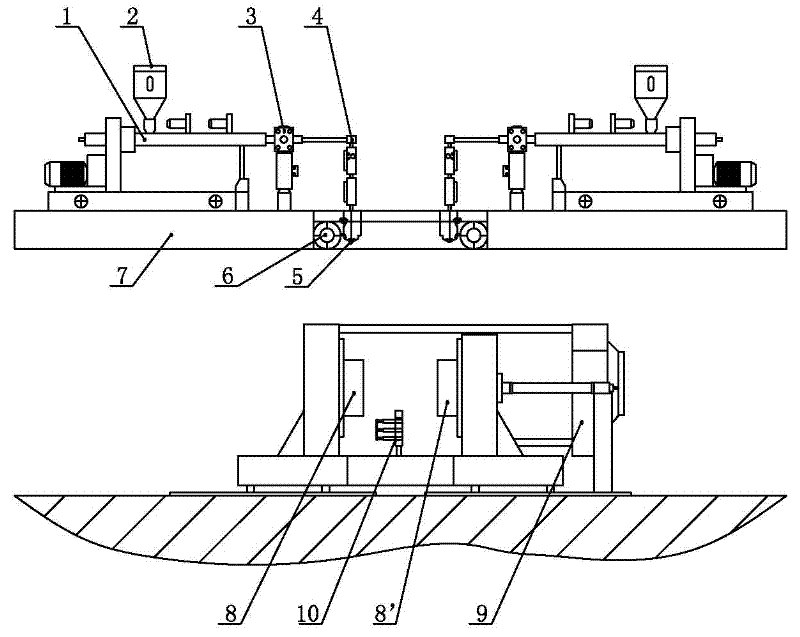

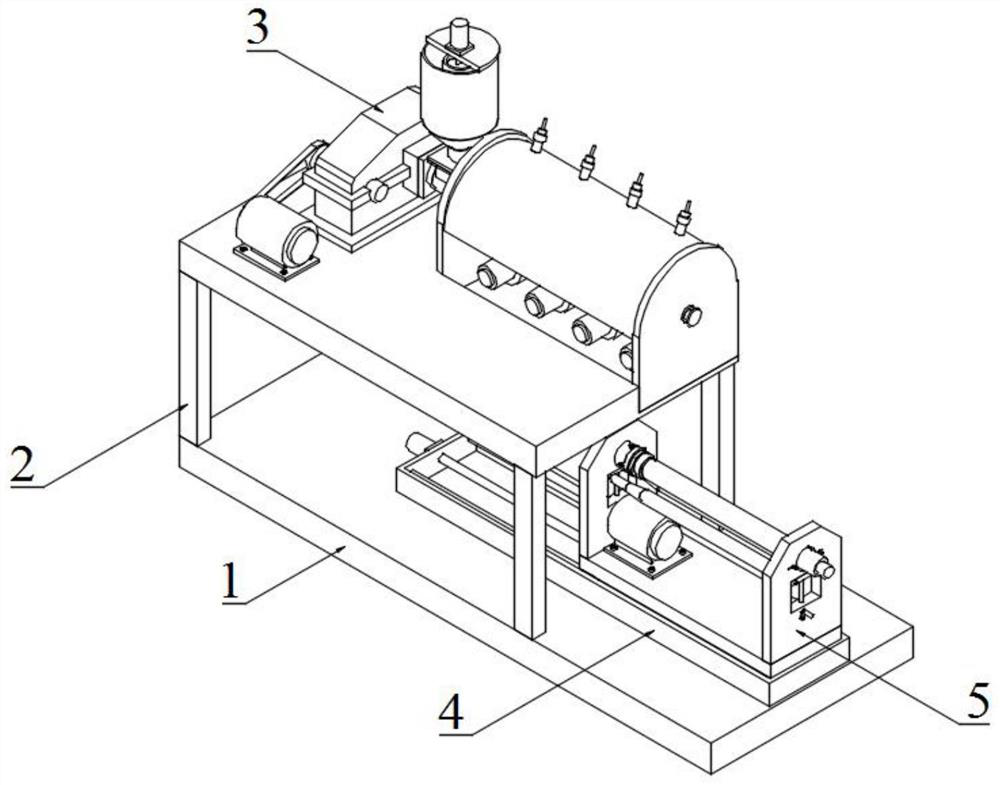

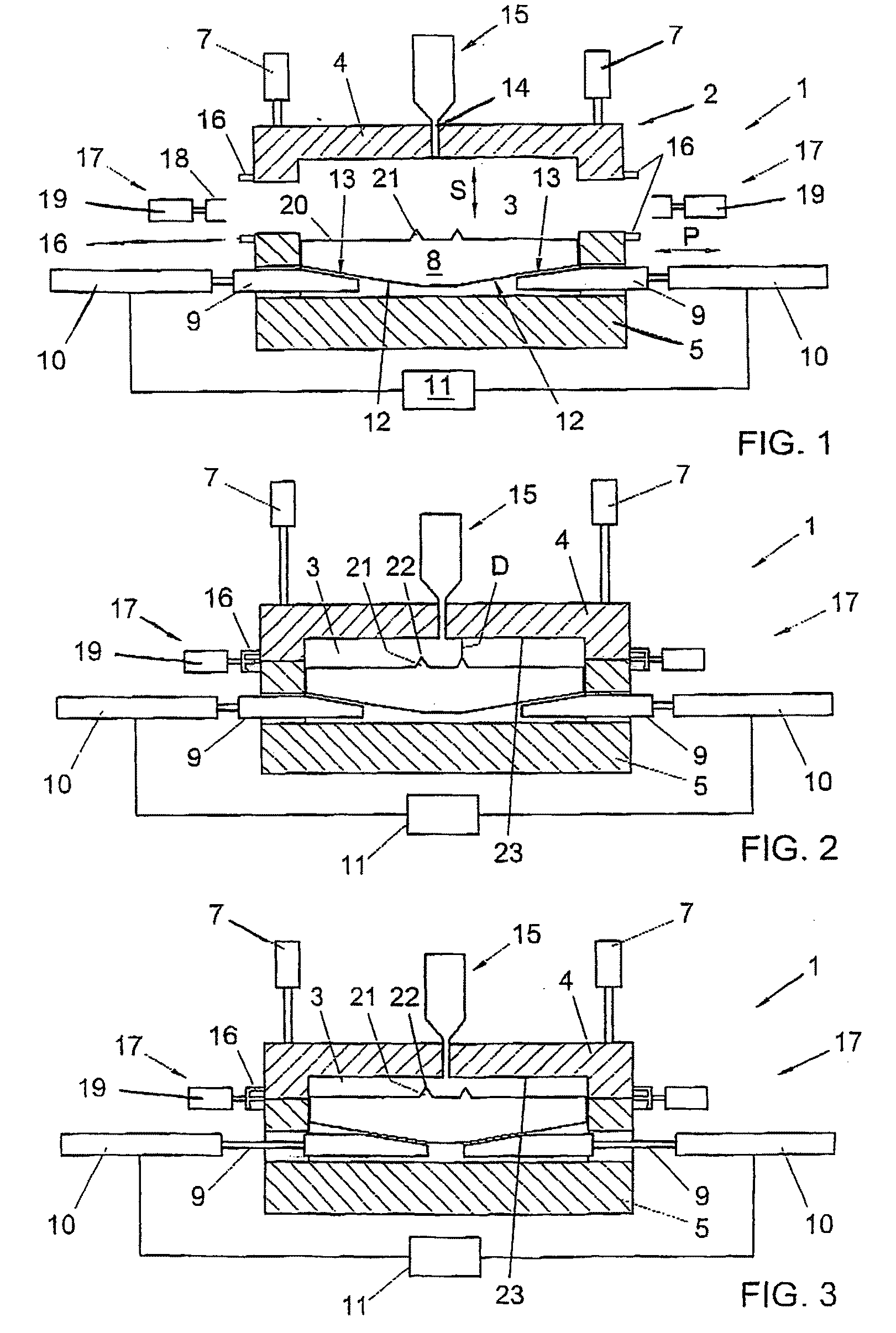

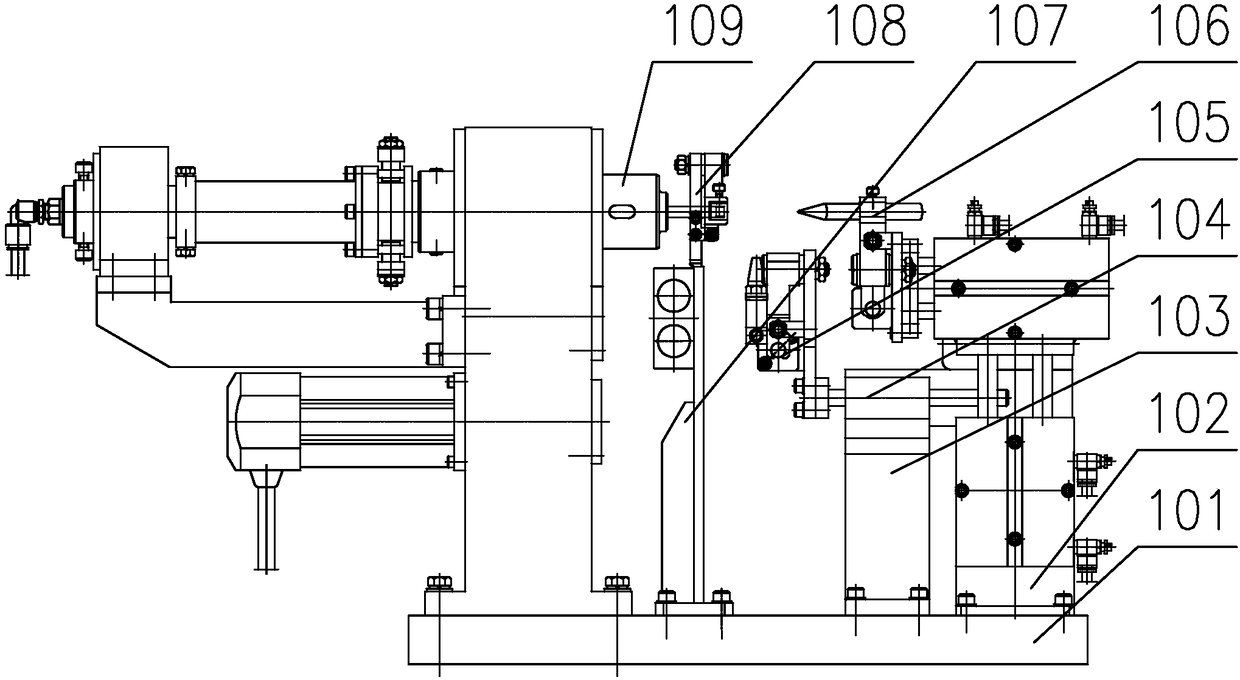

Blow molding device and blow molding method for plastic fuel tank

The invention relates to a blow molding device and a blow molding method for a plastic fuel tank. The blow molding device is symmetrically provided with two sets of profile blank extrusion devices; each set of profile blank extrusion device comprises six extruders, six hoppers, six melt metering pumps, a composite distributor and a servo plane die head; the melt metering pumps are respectively arranged at the outlets of the six extruders, the melts pumped by the melt metering pumps are fused together through the composite distributor, and the fused melt is fed into the servo plane die head and extruded into left and right plane profile blanks; the left and right plane profile blanks are respectively clamped by a right half die of a left oil tank to close, and a pre-formed shim plate is clamped in the middle; a blowing needle pierces the cavities of the profile blanks to perform pre-blowing, so that the profile blanks are outwards expanded and jointed to the inner wall of the die cavity; the right half die of the left oil tank is opened, the pre-formed shim plate is moved out, and a built-in component is stuck to the inner wall of the die cavity; and the right half die of the left oil tank is newly closed, the left and right profile blanks are stuck to form an oil tank, and the cavity of the oil tank is subjected to high-pressure blowing so that the oil tank is formed. The fueltank manufactured by the method has the advantages that: leakage is reduced, and efficiency and quality of the finished product are improved.

Owner:YAPP AUTOMOTIVE PARTS

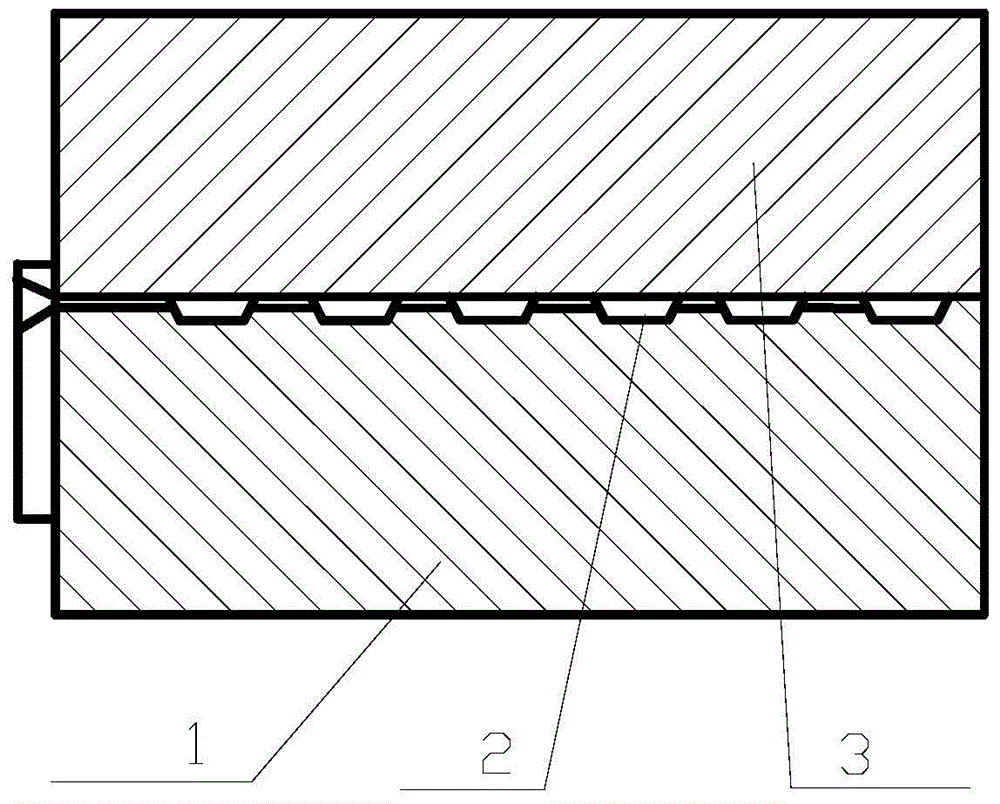

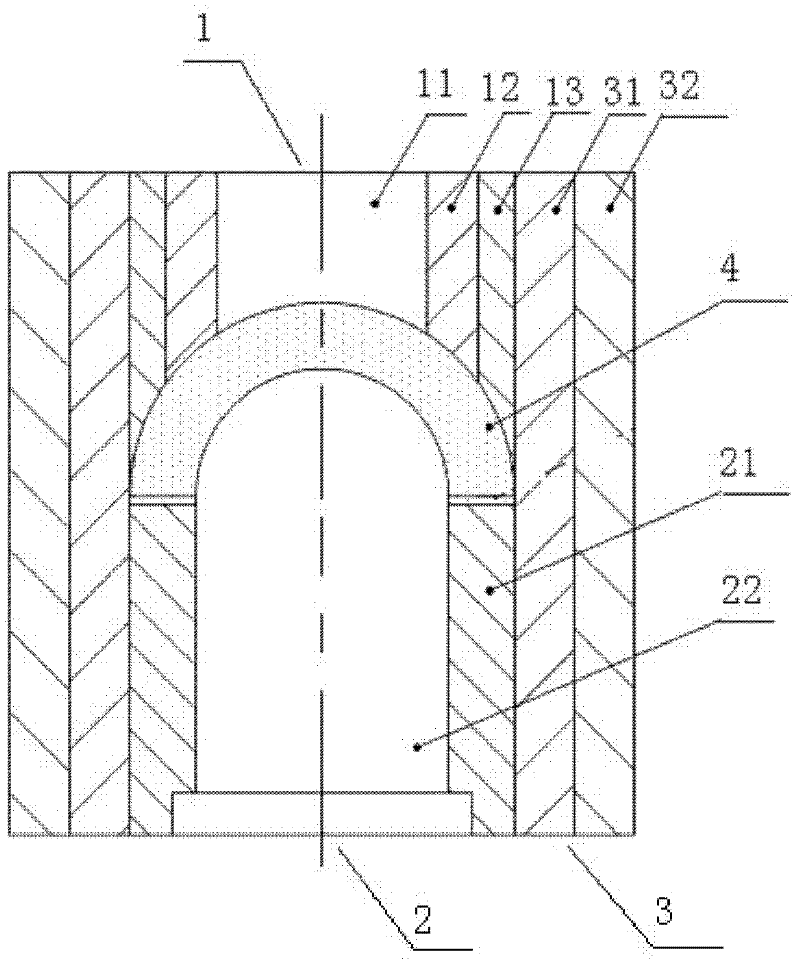

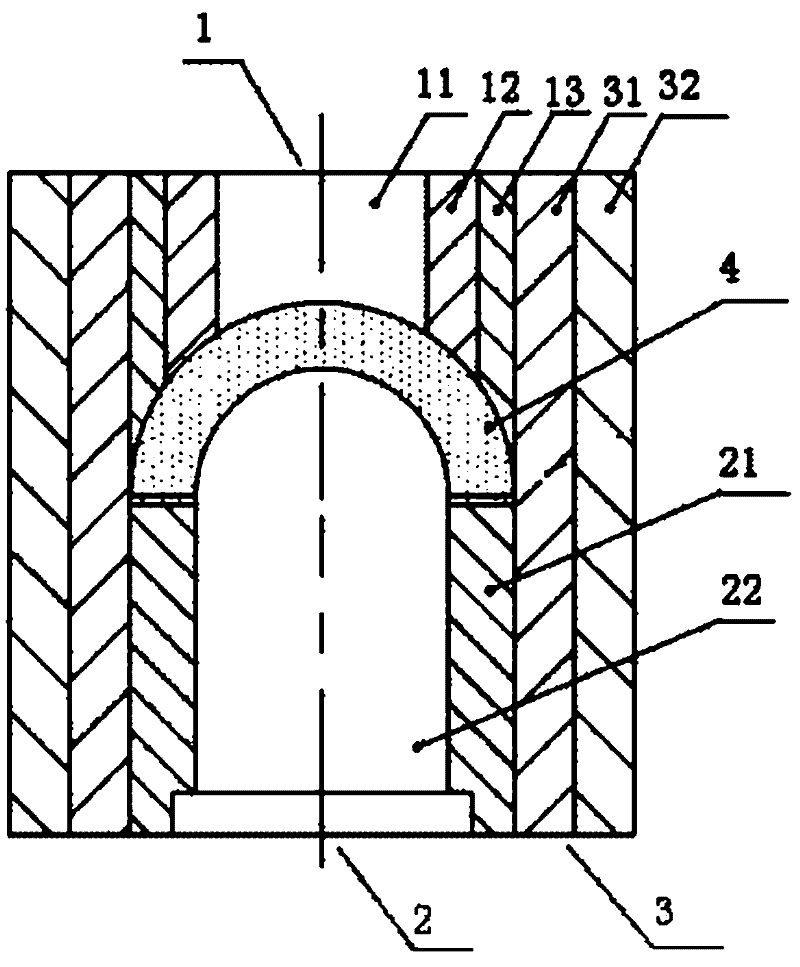

Mold and method for preparing hard alloy hollow sphere

The invention relates to a mold and a method for preparing a hard alloy hollow sphere. The mold consists of an upper mold, a lower mold and an outer sleeve for fixing the upper mold and the lower mold. The whole weight and density of the hollow sphere are controlled and changed in a large range, and raw materials are obviously saved; a high-accuracy steel forming mold and radial toothed end faces are adopted, so that the wall thickness of the hollow sphere can be accurately controlled, and weight eccentricity is avoided; the area and connection strength of a sintering and soldering surface are increased, so that the compression strength and impact strength of the hollow sphere are greatly improved; and the process is simple, high in yield, easy to popularize and suitable for industrial mass production, and economic benefits and social benefits are obvious.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing beta-Al2O3 ceramic electrolyte separator for sodium battery

ActiveCN104556980ALow matching accuracy requirementsReduce usageCeramic shaping apparatusCell component detailsSlurrySolvent

The invention provides a method for preparing a beta-Al2O3 ceramic electrolyte separator for a sodium battery. The method comprises steps as follows: Step (1), Na-Z powder and Li-Z powder which are used as precursor powder are synthesized respectively on the basis of an Al source and a Na source as well as on the basis of the Al source and an Li source; Step (2), the Na-Z powder and the Li-Z powder are mixed in the specified mole ratio and mixed with a binder and a solvent, and then slurry is prepared; Step (3), the slurry is atomized and then sprayed onto a rotating mandrel to be condensed and molded into a base body; Step (4), the condensed and molded base body is sleeved with a plastic film, and a beta-Al2O3 biscuit is obtained through demolding after isostatic pressing machining; Step (5), the beta-Al2O3 biscuit is subjected to plastic removal and then high-temperature sintering, and the beta-Al2O3 ceramic electrolyte separator is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of silicate double-layer hollow nanometer fiber with multistage structure

The invention relates to a preparation method of a silicate double-layer hollow nanometer fiber with a multistage structure. The preparation method belongs to an inorganic chemical synthesis method. The preparation method comprises that acetate as a raw material, ammonium hydroxide as a complexing agent, ammonium chloride as a mineralizer and silica hollow nanometer fibers as sacrifice templates undergo a hydro-thermal reaction at a certain temperature in an enclosed reactor to produce the silicate double-layer hollow nanometer fibers with multistage structures. The silicate double-layer hollow nanometer fiber has the diameter of 300-600 nanometers. The silicate double-layer hollow nanometer fiber has a large specific surface area, can be precipitated easily and is convenient for separation from a solution, recovery and recycle. The preparation method has simple and reliable processes, has high controllability, adopts cheap and easily available raw materials, has universality and lays the foundation of wide application of silicate.

Owner:NORTHEAST NORMAL UNIVERSITY

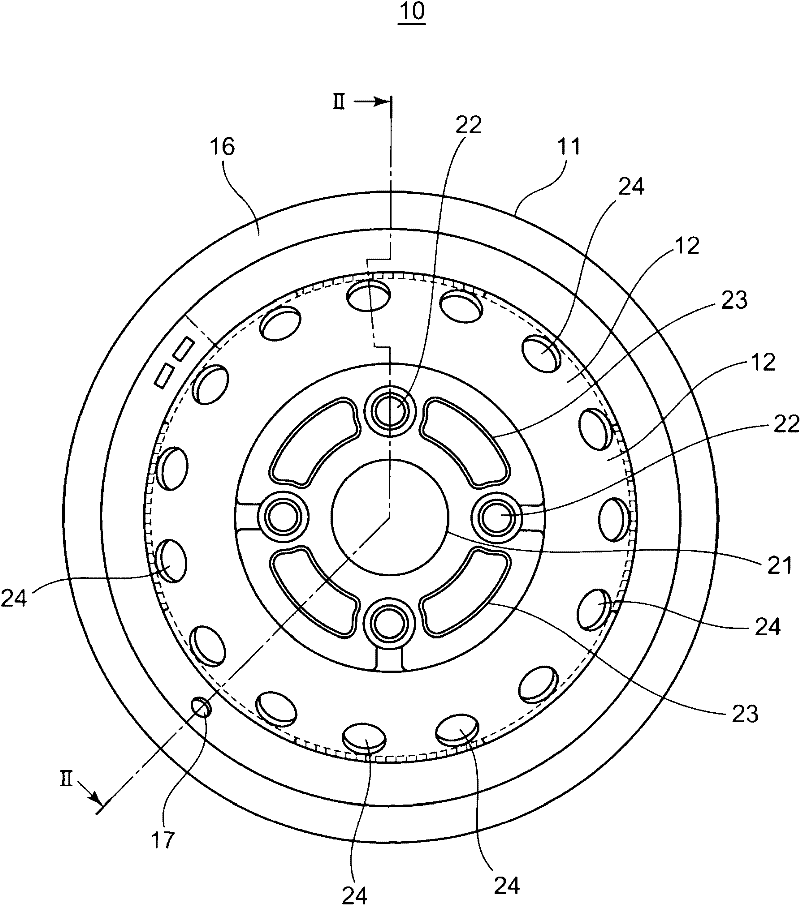

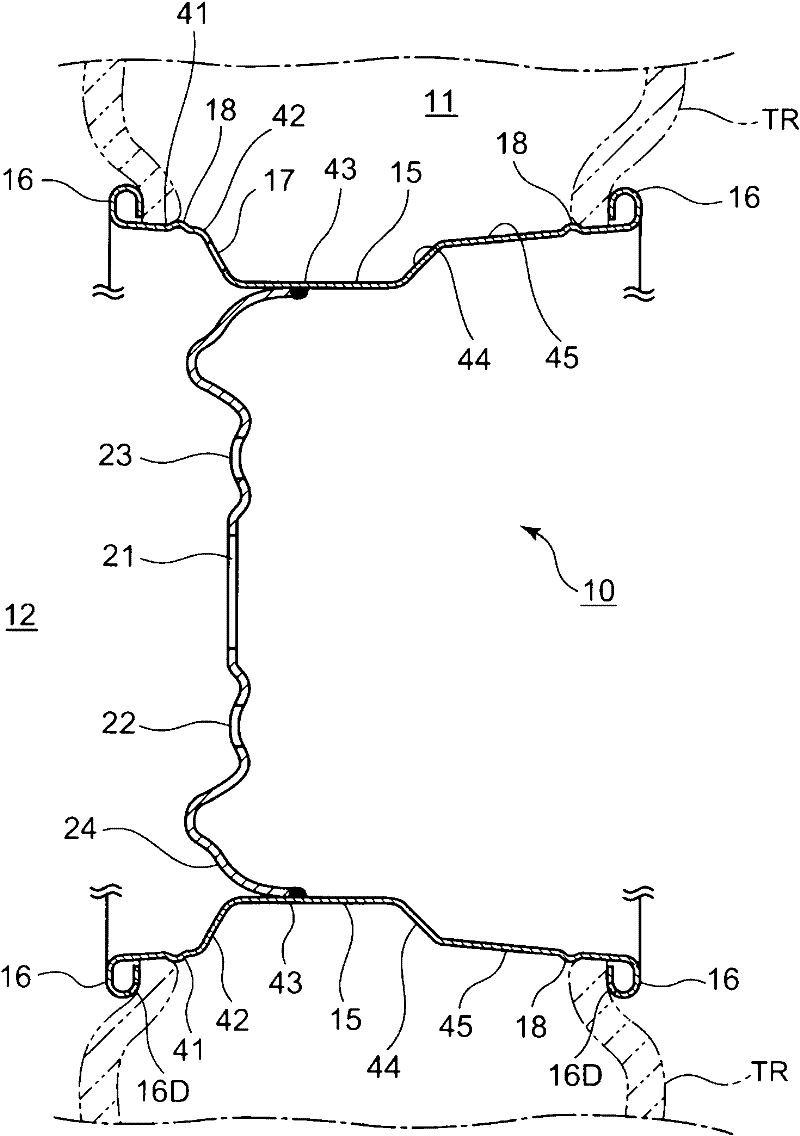

Vehicle wheel

Disclosed is a vehicle wheel which is excellent in appearance quality, is light, and has stiffness. The vehicle wheel (10) has a rim section (11) which has a substantially cylindrical shape and into which a tire (TR) is fit, and a disk section (12) having a substantially disk shape and bonded to the inside of the rim section (11), wherein the rim section (11) includes a rim body part (15) and a rim flange part (16), the rim body part (15) is formed such that the thickness of a part to which the disk section is bonded is thicker than the thicknesses of the other parts, and the rim flange part (16) is formed by bending both thin end parts of the rim body part (15) into a hollow shape.

Owner:HONDA MOTOR CO LTD

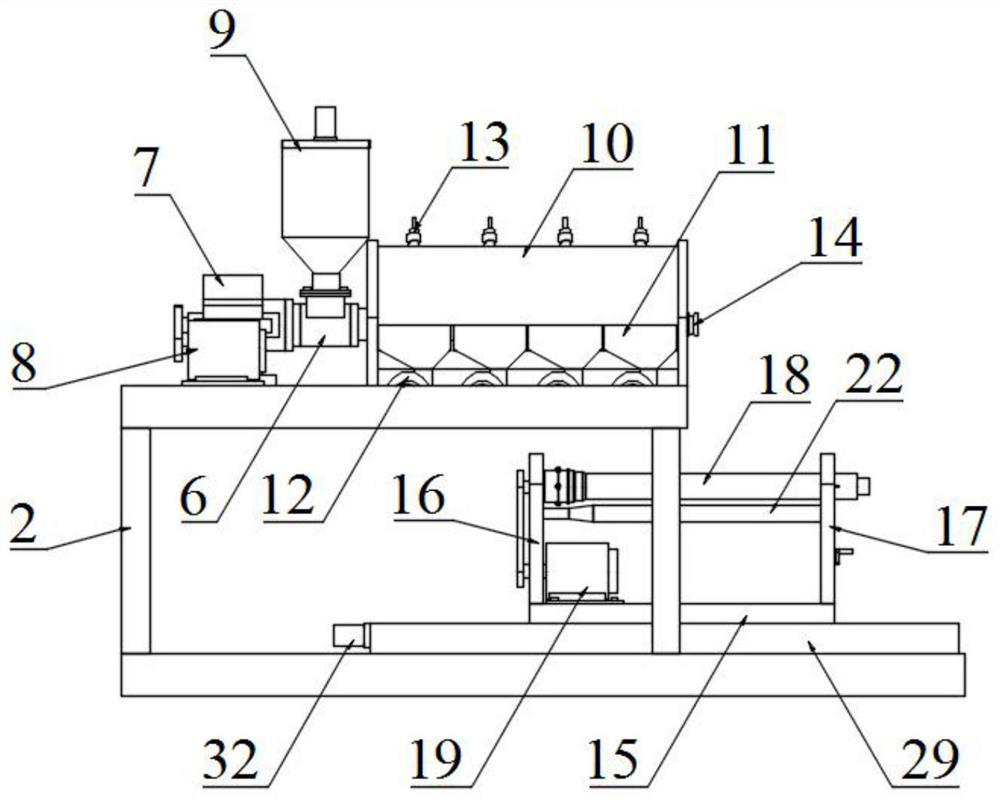

Pipe machining device and process for prefabricating embedded integrated rubber ring and pipe

InactiveCN113263705AStable structureGood sealingFlexible pipesHose connectionsMoulding deviceMachining process

The invention discloses a pipe machining device and process for prefabricating an embedded integrated rubber ring and a pipe. The pipe machining device comprises a base, a supporting frame is fixedly installed on the left side of the top of the base, an extrusion device is fixedly installed on the supporting frame, a movable seat is fixedly installed on the right side of the top of the base, and a forming device fixedly installed on the movable seat. The machining process comprises the following steps that firstly, the end of a core bearing opening is sleeved with the rubber ring; secondly, a mandrel is heated to the temperature required by the process; thirdly, a molten material belt is wound around the rolling mandrel, and after cooling, a winding pipe wound around the mandrel is formed; and fourthly, the tail of the rubber ring and a pipe socket hot melting material are mutually nested, and the pipe is cooled and demolded. The rubber ring embedded pipe is manufactured through the machining device and the machining process, manual operation factors such as neglected installation and wrong installation of the rubber ring in the engineering construction process can be avoided, and therefore the problem of leakage of an underground pipe network connector is solved.

Owner:海宁亚大塑料管道系统有限公司

Injection mold for molding of bottles

The invention relates to the field of injection molding equipment, in particular to an injection mold for molding of bottles. The injection mold for molding of the bottles comprises a mold body provided with a female mold and a male mold, wherein the female mold is slidably connected with the mold body and is detachably connected with the male mold; the female mold comprises two movable molds which are arranged oppositely; the two movable molds are detachably connected with each other and can slide on the mold body in the mold opening direction in a reciprocating manner; the male mold comprises a flexible mold bag and a filling device for controlling shrinkage and expansion of the mold bag; the filling device is arranged on the mold body; the mold bag is positioned between the two movable molds and is connected with the mold body; and a mold cavity is formed between the movable molds and the mold bag. According to the injection mold for molding of the bottles, the size of the mold bag is controlled by filling to control the wall thickness, the cooling time is shortened, and the production efficiency is improved.

Owner:红禾朗(重庆)工业制造有限公司

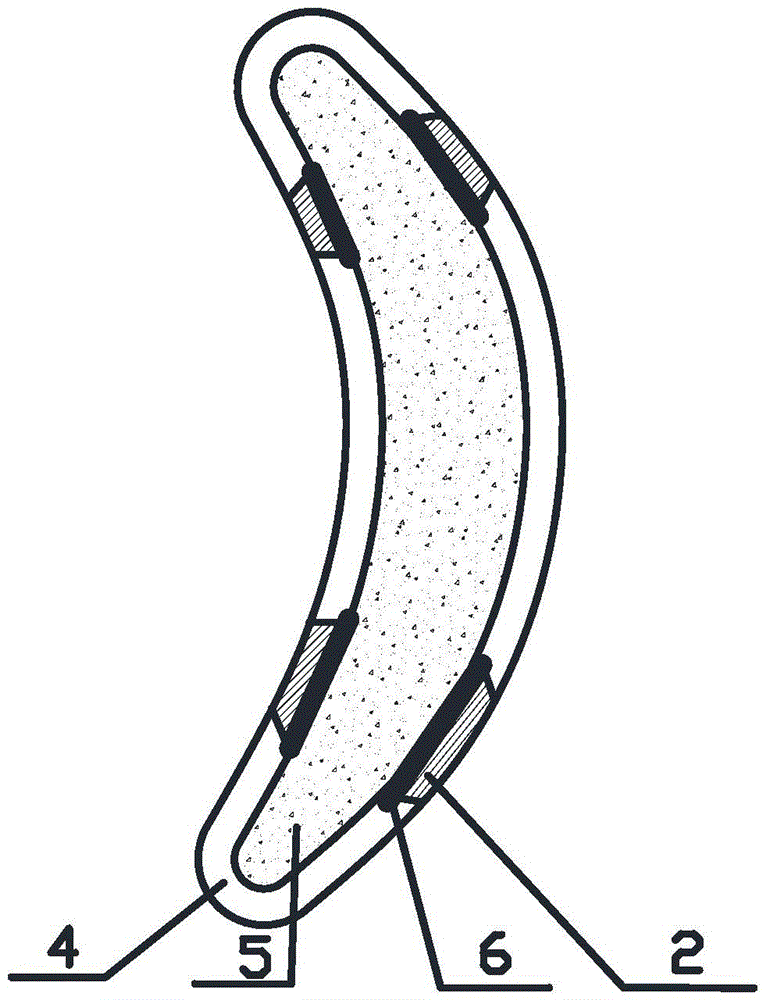

Nano fibrous tissue engineering blood vessel and preparation thereof

InactiveCN101214393BPromote endothelializationMeet the mechanical requirementsConjugated cellulose/protein artificial filamentsBlood vesselsFiberCross-link

The invention relates to a tissue engineering material and a preparation method thereof, in particular to a nano fiber tissue engineering blood vessel and a preparation method thereof. The invention consists of a three-dimensional reticular non-woven film formed by an inner layer of nano fiber and an outer layer of nano fiber; the inner layer of the blood vessel is natural polymer, wherein, calculated by weight, 40 percent to 80 percent is fibroin, 20 percent to 50 percent is gelatine, 0 percent to 20 percent is extracellular matrix protein; while the outer layer of the blood vessel is synthetic polymer. The preparation method is that the natural polymer is dissolved in trifluroroethyl and other solution, while the synthetic polymer is dissolved in hexafluoroisopropanol and other solution, which are respectively prepared into spinning solution; the static electricity spinning technique is adopted to subsequently form the inner and the outer layers on a gather roller; cross-linked treatment is conducted after the inner and the outer layers are taken down, to prepare the nano fiber tissue engineering vessel. The inner layer can simulate the structure of the extracellular matrix, provide good environment for endothelial cells to grow, support adhesion, proliferation and differentiation of the cells, and is good for endothelization of the blood vessel; and the outer layer has goodmechanical performance.

Owner:SUZHOU UNIV

Preparation method of oxide porous material

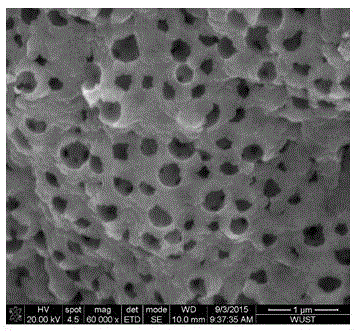

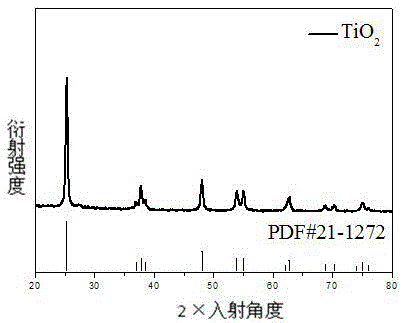

ActiveCN105480950ASuitable nanoporosityImprove sexual functionAlkali titanatesOxide/hydroxide preparationAir atmospherePorosity

The invention relates to a preparation method of an oxide porous material. According to the technical scheme, the method comprises the steps that an oxide precursor salt is dissolved in organic solvent according to the concentration ranging from 5 mol / L to 10 mol / L, stirring is conducted, and a solution I is obtained; a binder is added into the solution I according to the mass ratio of the oxide precursor salt to the binder of 1 to 0.01-0.1, stirring is conducted, and a solution II is obtained; a template agent is added into the solution II according to the mass ratio of the oxide precursor salt to the template agent of 1 to 0.1-0.35, stirring is conducted, and a solution III is obtained; liquid nitrogen freezing treatment is conducted on the solution III, drying is conducted in a vacuum freezing dryer, and a dried product is obtained; the product is put in a tube furnace, the temperature rapidly rises to 300-800 DEG C at the speed of 4-5 DEG C / min in an argon atmosphere or air atmosphere, heat preservation is conducted for 4-12 h, natural cooling is conducted along with the furnace, the template agent is removed, and the oxide porous material is obtained. The preparation method of the oxide porous material is convenient to operate and suitable for industrial production, and the hole size, the porosity and the wall thickness of the product can be regulated in a larger range.

Owner:WUHAN UNIV OF SCI & TECH

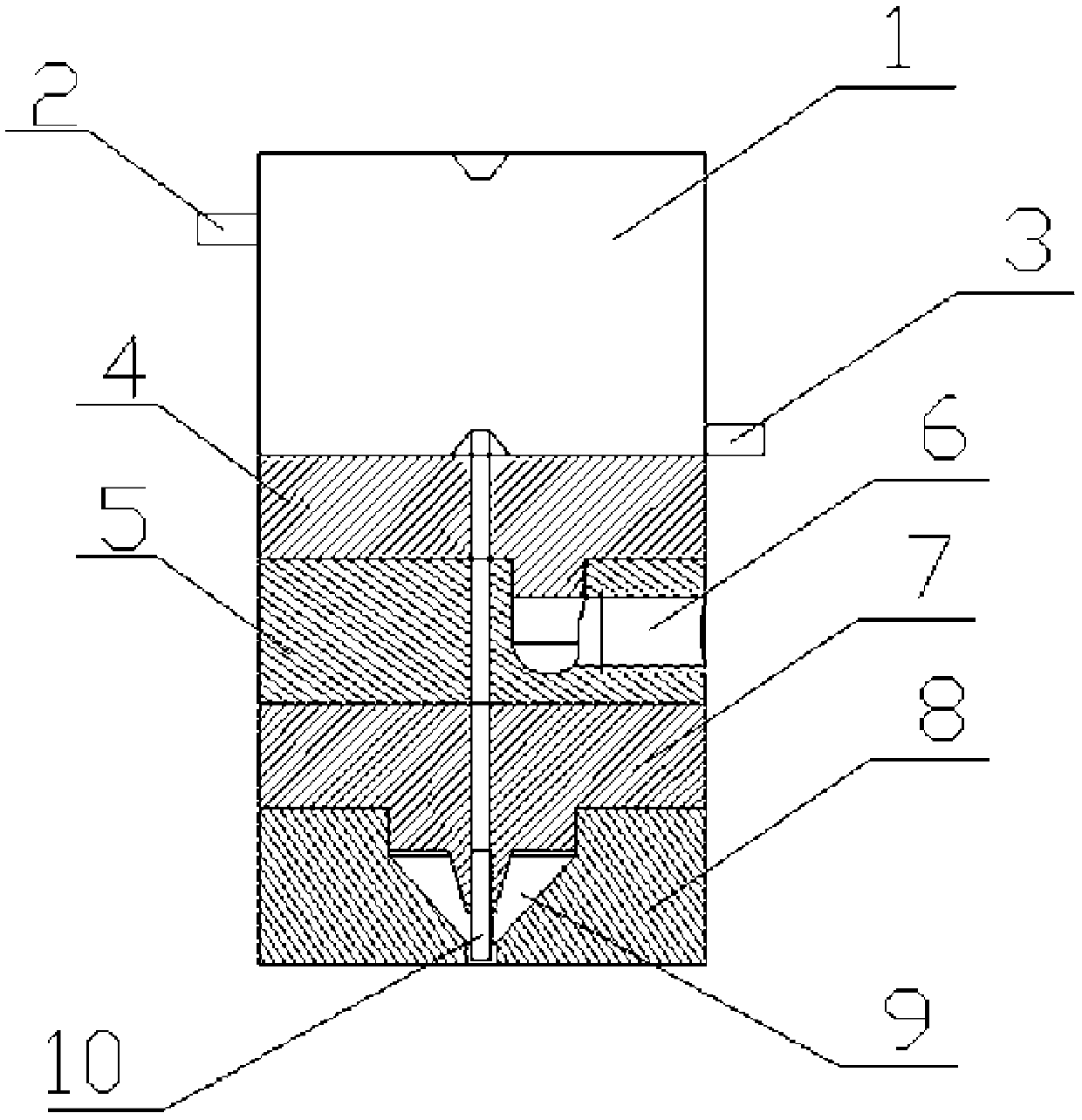

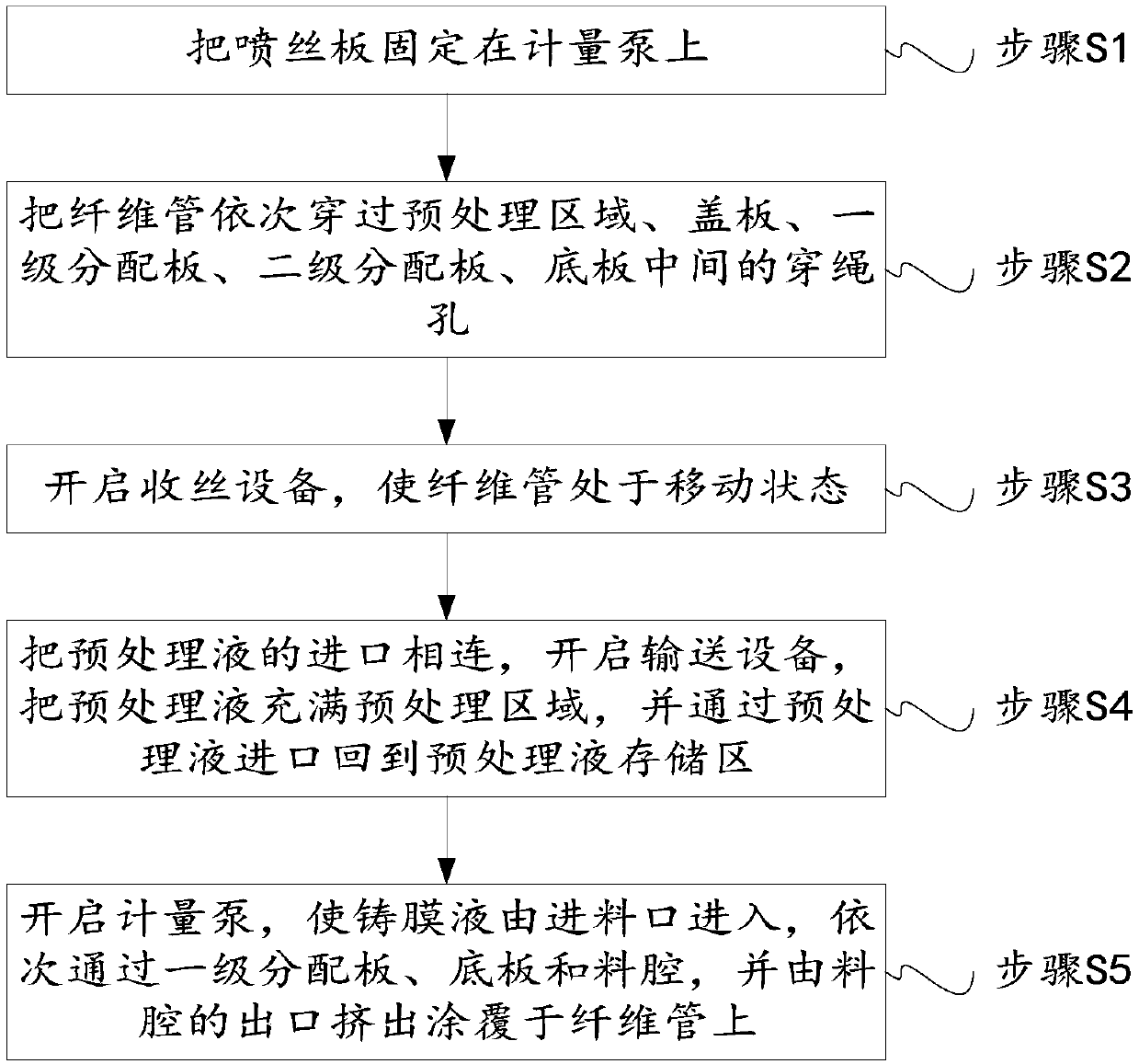

Integrated fiber pipe pretreatment enhanced hollow fiber membrane spinneret plate and use method thereof

ActiveCN108677261AControl wall thicknessControl UniformityHollow filament manufactureFilament manufactureEngineeringPre treatment

The invention discloses an integrated fiber pipe pretreatment enhanced hollow fiber membrane spinneret plate and a use method thereof, and relates to the technical field of hollow fiber membranes to solve the technical problems that osmosis and the wall thicknesses of the hollow fiber membranes cannot be effectively controlled, consequently, wall thickness uniformity is poor, and a device is complicated, high in cost and very difficult in operation in the prior art. The integrated fiber pipe pretreatment enhanced hollow fiber membrane spinneret plate comprises a pretreatment area, a cover plate, a primary distribution plate, a secondary distribution plate and a bottom plate which are sequentially communicated by a lacing hole. A pretreatment fluid inlet is formed in one side, far away fromthe cover plate, of the pretreatment area, a pretreatment fluid outlet is formed in one side, close to the cover plate, of the pretreatment area, particularly, a feeding port is formed in the primarydistribution plate, a material cavity is formed in the bottom plate, and a needle tube is arranged at the position of the material cavity.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

Homogeneous-tube pushing manufacturing method for pushed elbows

InactiveCN102310308AControl wall thicknessSave materialHigh volume manufacturingInternational standard

The invention relates to a homogeneous-tube pushing manufacturing method for pushed elbows. The invention is characterized in that: the homogeneous-tube pushing manufacturing method for pushed elbows has the specific requirements that: based on uncut homogeneous tubes, directly carrying out elbow pushing on tube ends; and then cutting the formed elbow sections. Compared with the prior art, the pushing method provided by the invention has the outstanding advantages that: over 5-20% of materials can be saved; and the caliber and the wall thickness at end parts can be effectively controlled, thereby facilitating forming. The pushed elbows manufactured by the method provided by the invention have an excellent technical effect; the physical and chemical properties, the dimensions and the structural shapes of the pushed elbows fully accord with the standards, such as the US standard ASMEB 16.9, the international standard GB / T 13401, the SH 3409 and the like; the pushed elbows have the advantages of high push-forming efficiency, stable performance, advanced technique and suitability for mass production. The method provided by the invention has foreseeable large economic and social values.

Owner:SHENYANG RUIHONG PIPE FITTINGS

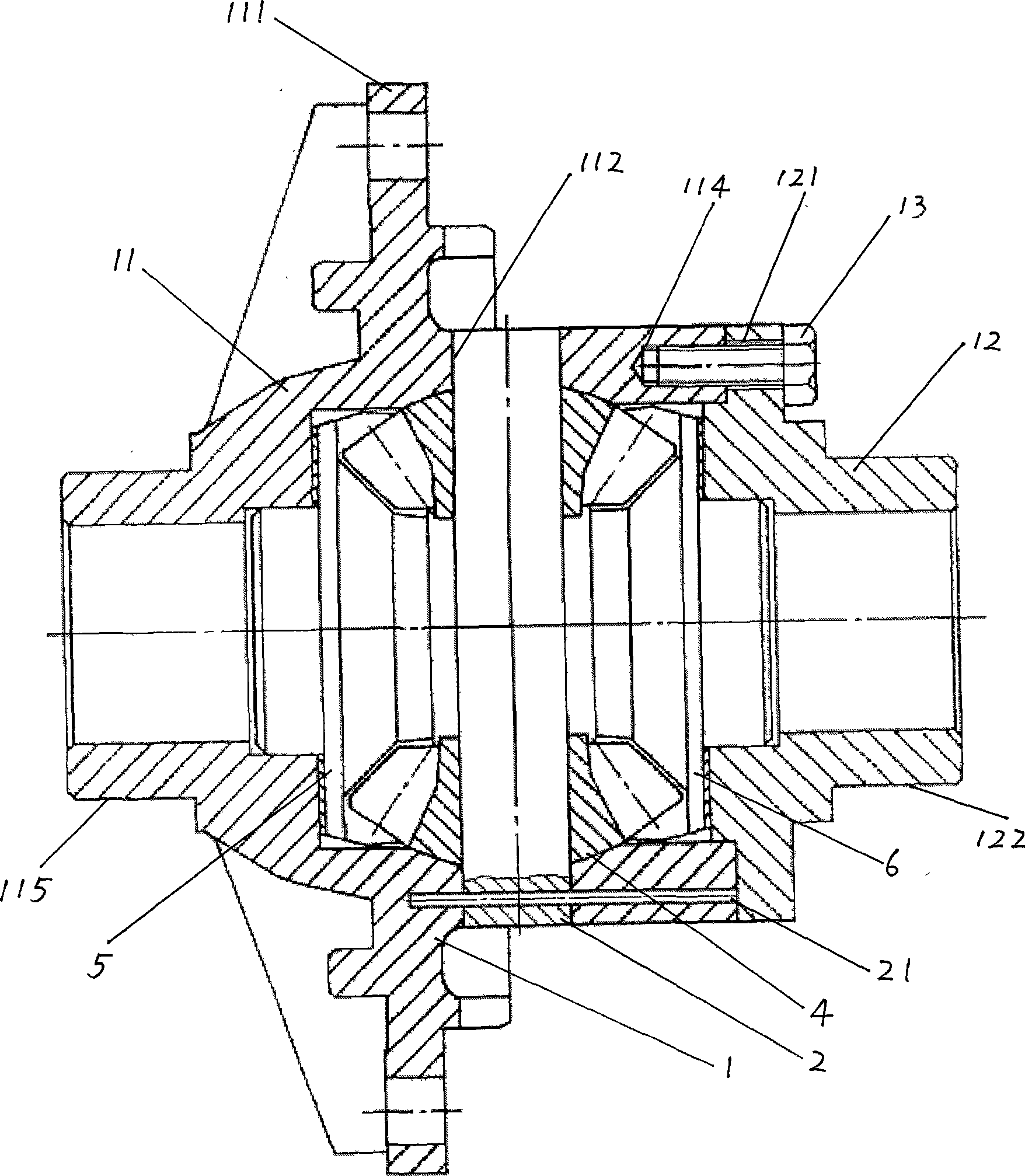

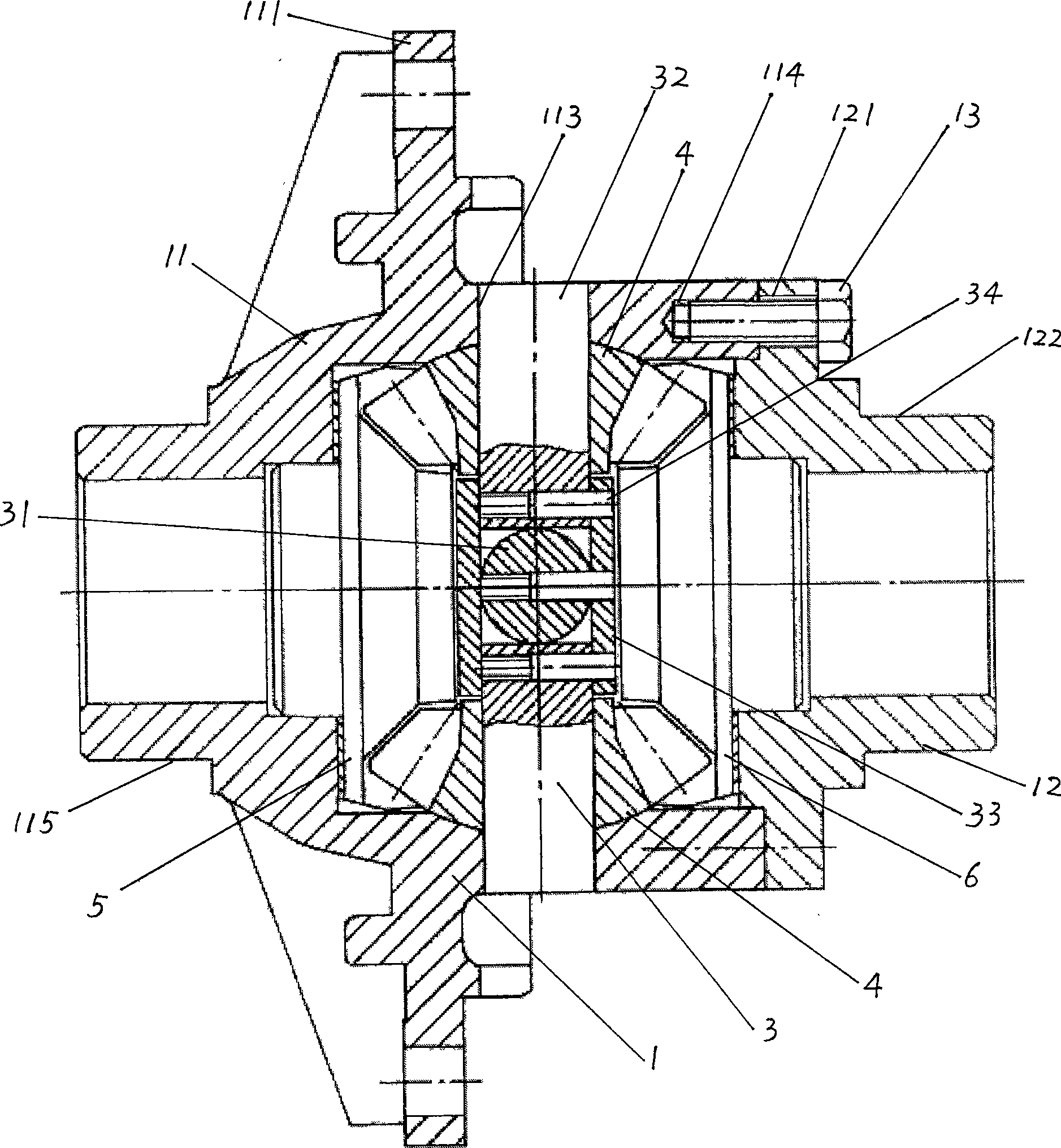

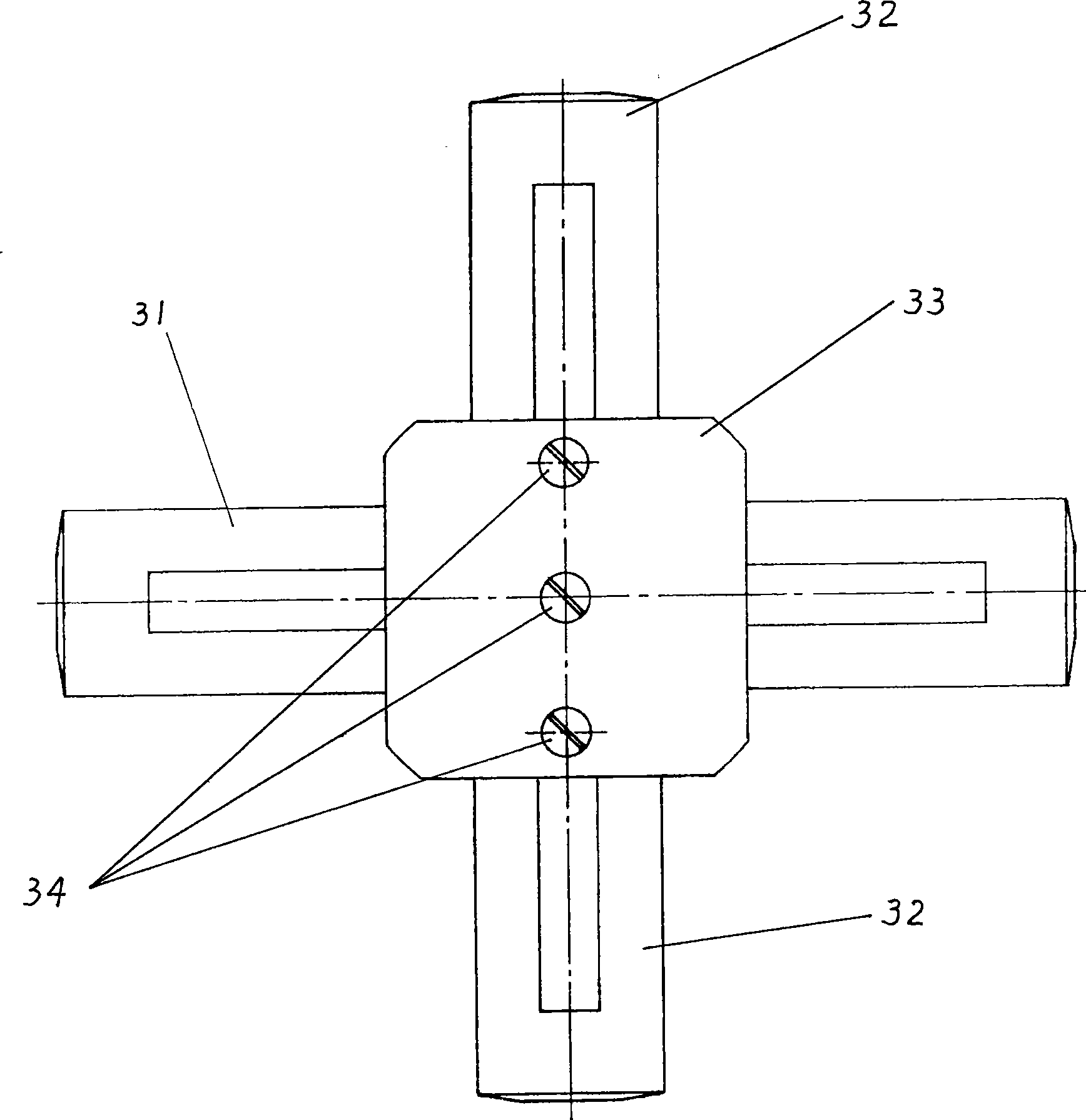

Differential gear with high bearing capacity

InactiveCN101482165ASolve assembly problemsSmall outer diameterGearboxesDifferential gearingsGear wheelControl theory

The invention relates to a conical gear differential mechanism structure with high bearing capacity. The differential mechanism comprises a differential shell and a horizontal straight shaft or a combined cross shaft, a satellite gear, and a bevel gear arranged in the differential shell; the dissection surface of the differential shell is arranged at the right side of the plane on which the horizontal straight shaft or the combined cross shaft is located; the combined cross shaft comprises a long pin, two short pins and a central bracket. The combined bolt and the bolt hole of the differential shell stop at the right side of the plane on which the horizontal straight shaft or the combined cross shaft is located; therefore, for a needed bearing capacity, the wall thickness of the differential shell can be thinned by about a half than conventional design, thus creating conditions for reducing the size of a driving axle; for the same volume, the bearing capacity thereof can be improved by increasing the modulus of the satellite gear, and the bevel gears in the differential mechanism.

Owner:BEIJING JIAOTONG UNIV

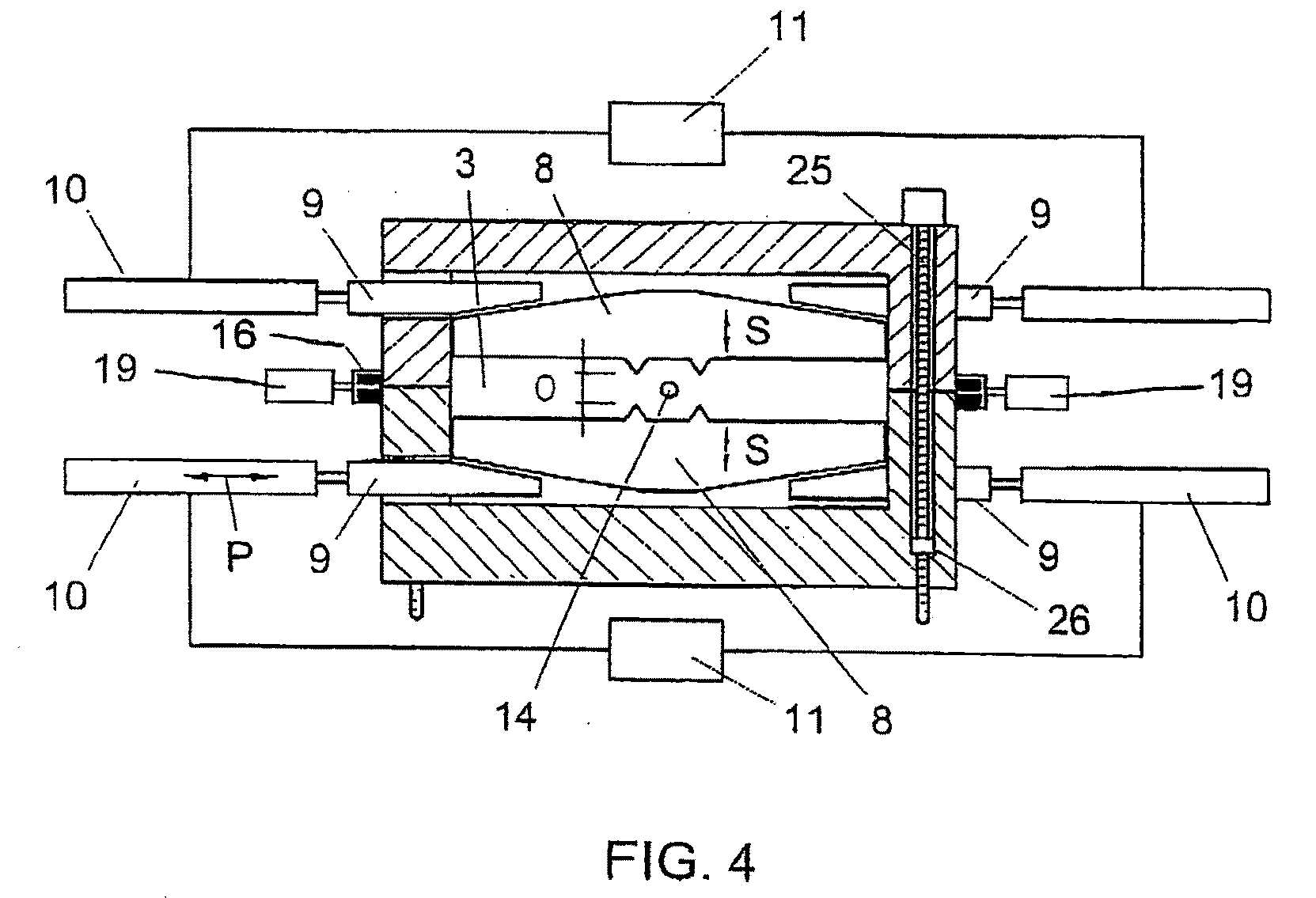

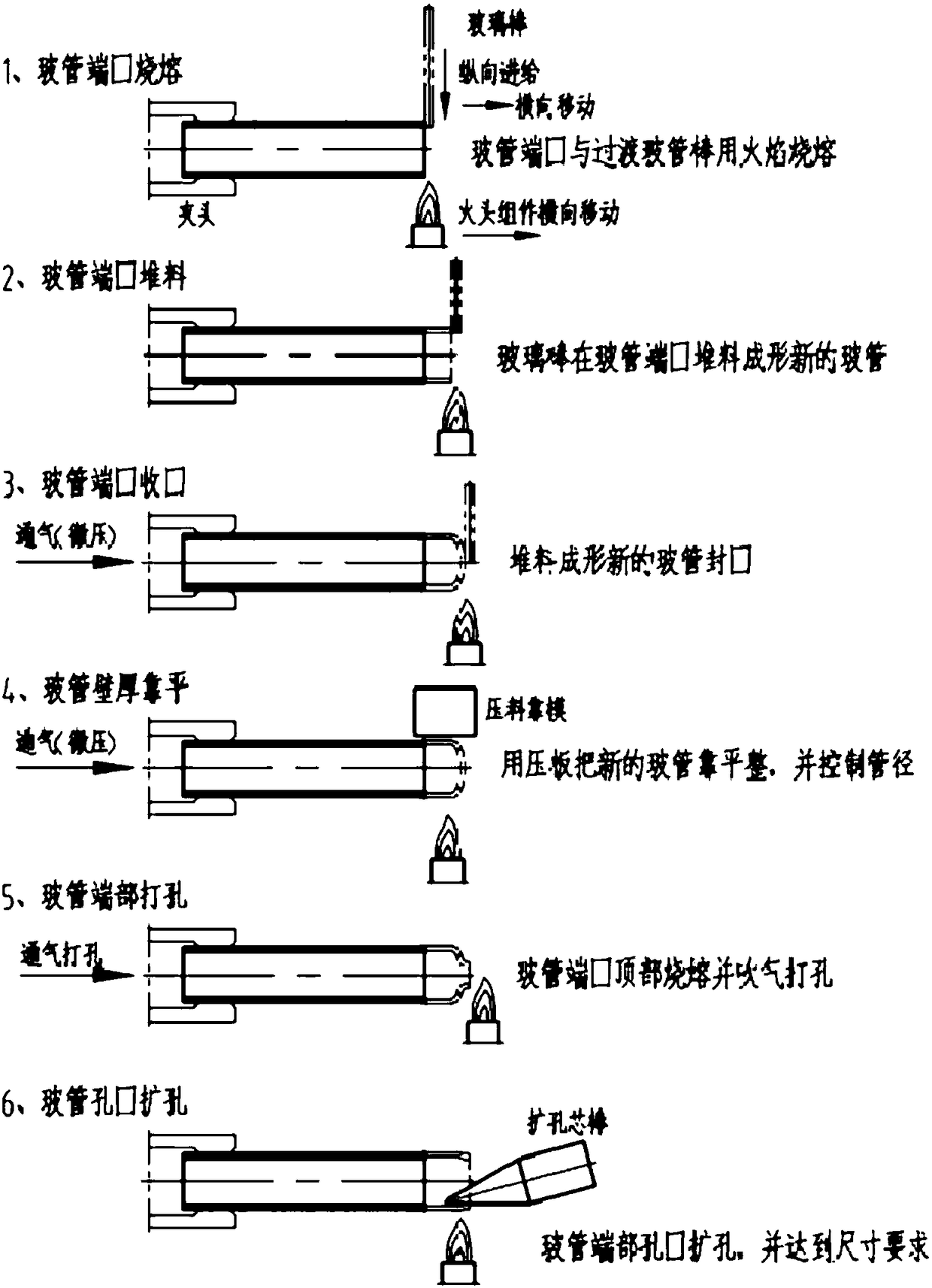

Method and equipment for automatically stacking glass to form glass tubes

InactiveCN108409116AUniform wall thicknessProduct quality consistency is goodGlass reforming apparatusGlass productionEngineeringGlass tube

The invention discloses a method and equipment for automatically stacking glass to form glass tubes. The method comprises the following steps: melting an end of a rotating glass tube with flame; aftera glass bar is melted with flame, sticking the glass bar to an end of the glass tube; and carrying out movement and feeding to form a spiral transitional glass tube at an end of the glass tube; sealing an end of the transitional glass tube, ventilating and bubbling; pressing a pressure plate against the outer wall of the transitional glass tube; controlling the diameter of the transitional glasstube; and perforating the closed end and carrying out pore broadening and forming so as to realize automatic forming of the transitional glass tube. The equipment comprises a glass tube clamping and ventilating mechanism, a glass tube outer wall pressing mechanism, a fire head device and a pore broadening mechanism. The transitional glass tube is formed automatically, the quality consistency of products is good, the labor intensity of workers is relieved, and the production efficiency is improved.

Owner:SOUTHEAST UNIV

Method for preparing aerogel through solvent plasticizing and foaming

InactiveCN111392716AReduce intermolecular forcesSolve the problem of foamingGrapheneAerogel preparationPolymer chemistryPolymer

The invention provides a method for preparing aerogel based on solvent plasticizing and foaming for the first time. An aerogel material is prepared through solvent plasticizing and in-situ bubble generation, the problem that a thermoplastic foaming process is difficult to realize for a non-polymer is solved, and the method has wide application universality. Besides, the scheme can select more foaming systems, is easy to implement, and does not need to utilize a special drying process, thereby greatly promoting the industrial development of the porous aerogel.

Owner:ZHEJIANG UNIV

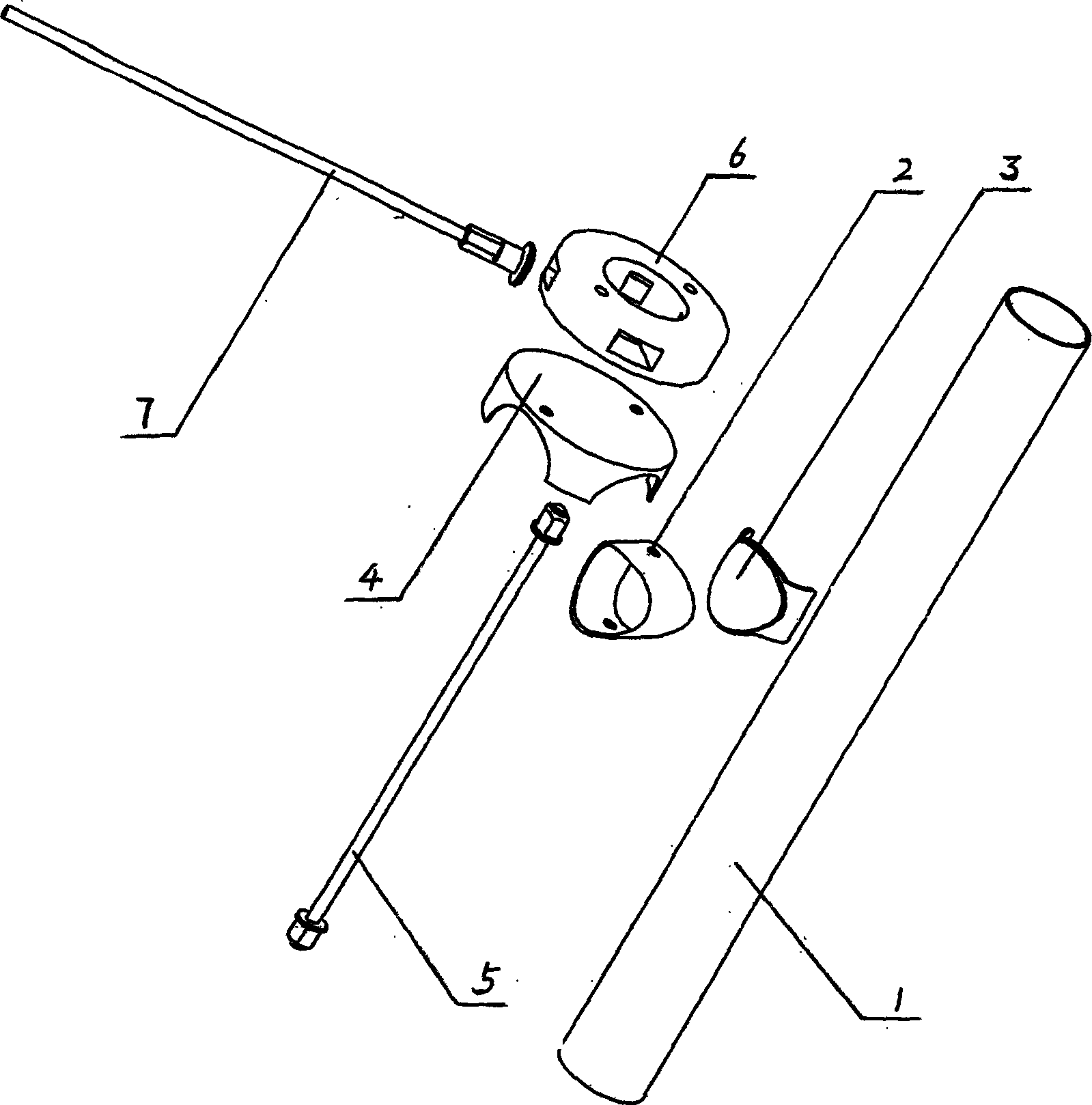

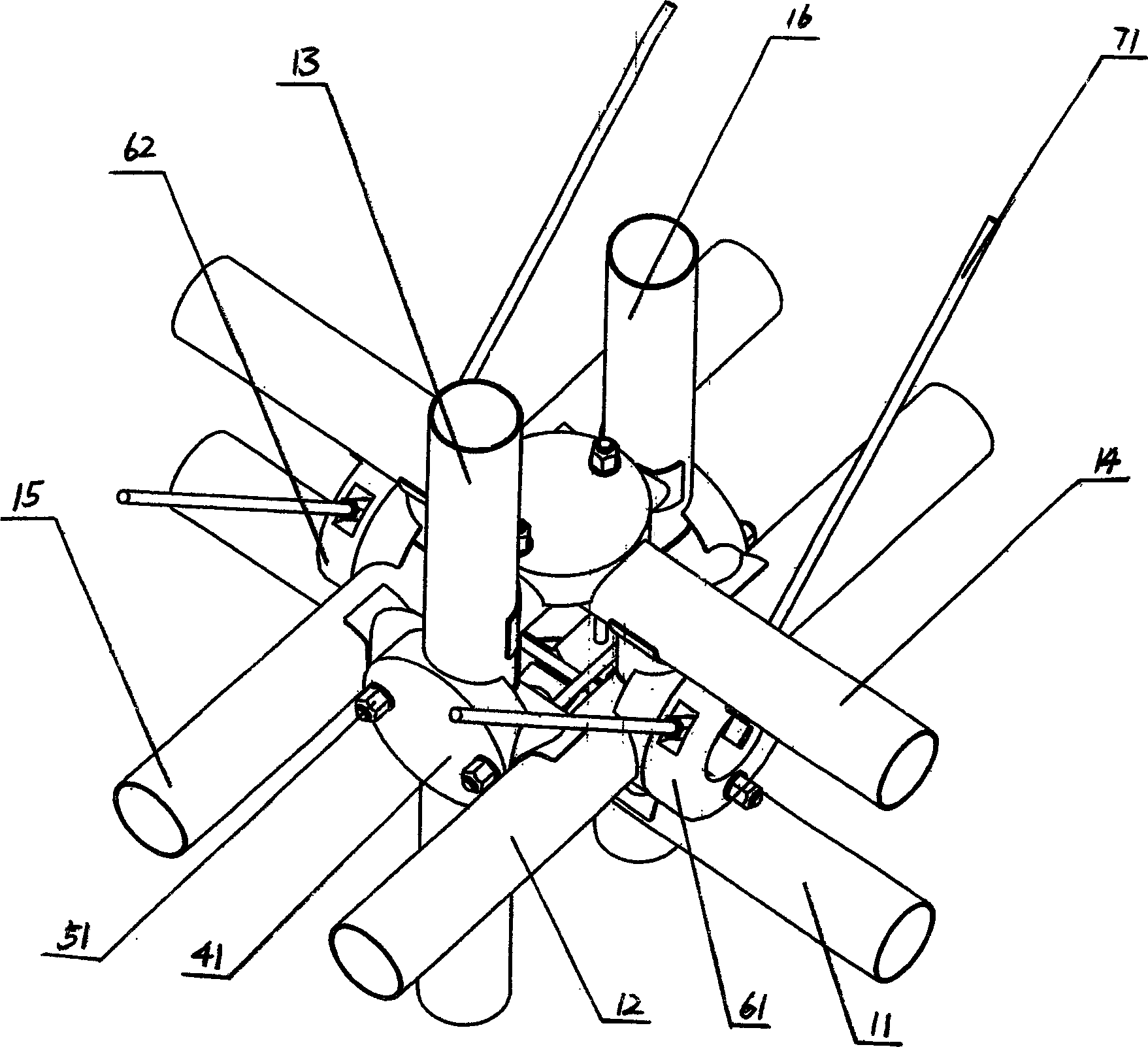

Erectable net rack nodes

InactiveCN1594770AReduce processing costsImprove reliabilityBuilding constructionsEngineeringMechanical engineering

The present invention discloses assemble net rack nodes capable of simplifying net rack nodes process, improving work efficiency, reducing cost. The net rack nodes, a first pole member, a second pole member, and a third pole member of the invention are separately arranged vertically each other in space via a first separation loop and a second separation loop, a fourth pole member, a fifth pole member, and a sixth pole member are separately arranged vertically each other in space via a third separation loop and a fourth separation loop, and are arranged in parallel with the first pole member, the second pole member, and the third pole member in space, two pole member in parallel are fixed with fastening bolt by travel cable installing frame, said travel cable installing frame has travel cable. The assemble net rack nodes of the invention establish a novel construction plat for future roof construction system, the constructed construction system adopts normalized production, which has high production efficiency and low cost.

Owner:远方

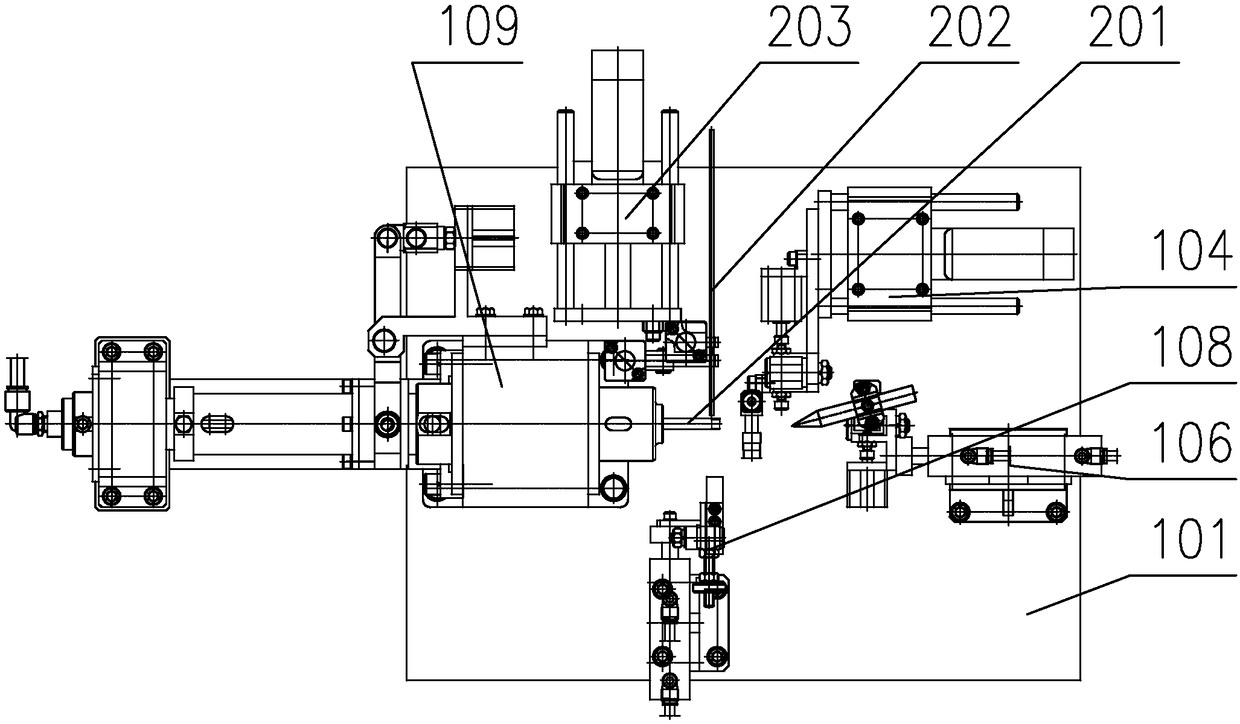

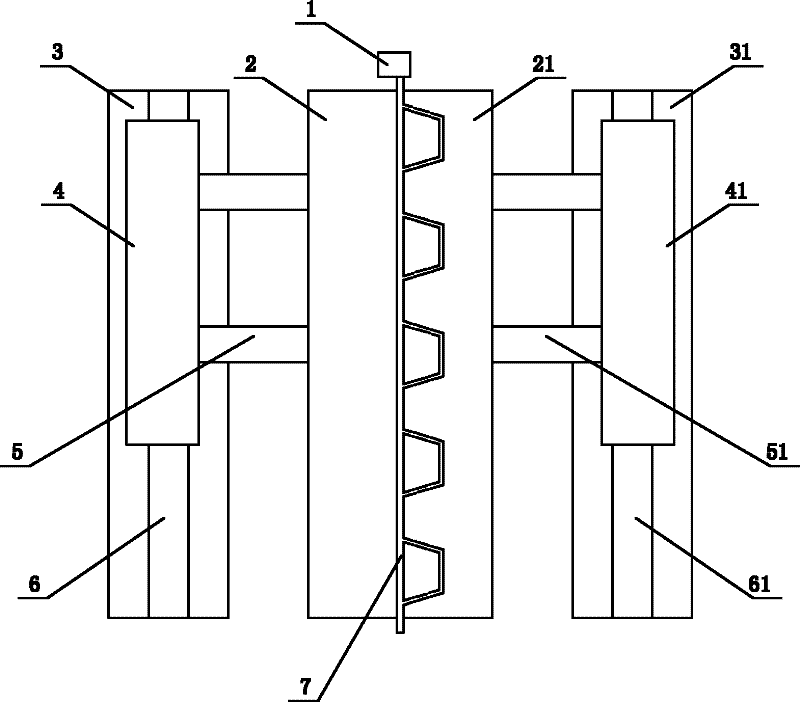

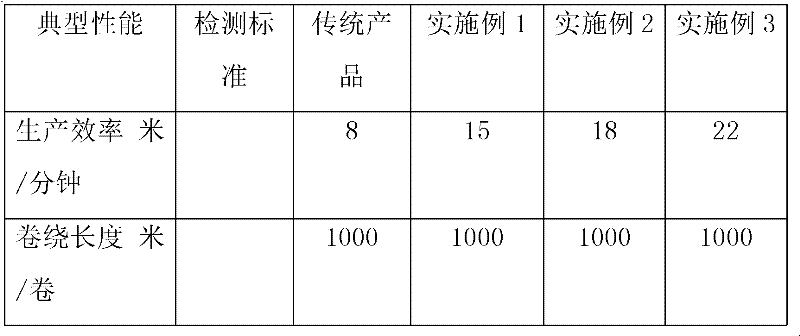

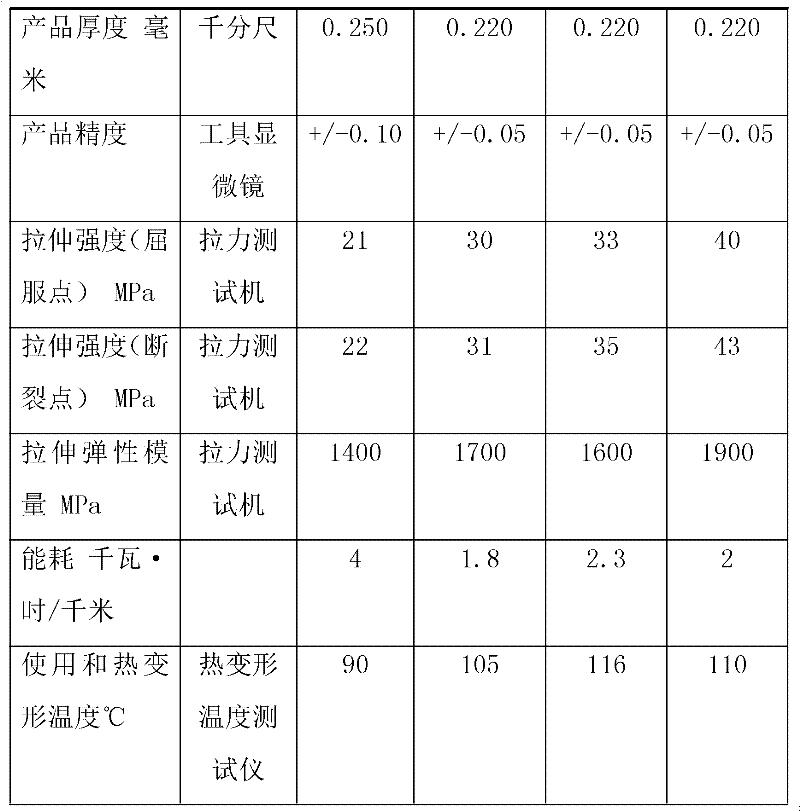

An electronic component carrying belt molding machine and its use method

The invention relates to a forming machine for integrally producing an electronic component bearing band. The forming machine of the electronic component bearing band comprises a film extruding die head, a convex die, a convex die horizontal movement mechanism, a convex die longitudinal movement table, a convex die base, a concave die, a concave die horizontal movement mechanism, a concave die longitudinal movement table and a concave die base, wherein the convex die and the concave die have corresponding shapes, and the positions of the convex die and the concave die are corresponding to thefilm extruding die head. The electronic component bearing band produced by the forming machine of the electronic component bearing band has the advantages of low production energy consumption, randomly adjustable length and thickness, high production efficiency and product quality, high tensile strength, and greatly increased use and heat distortion temperatures.

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

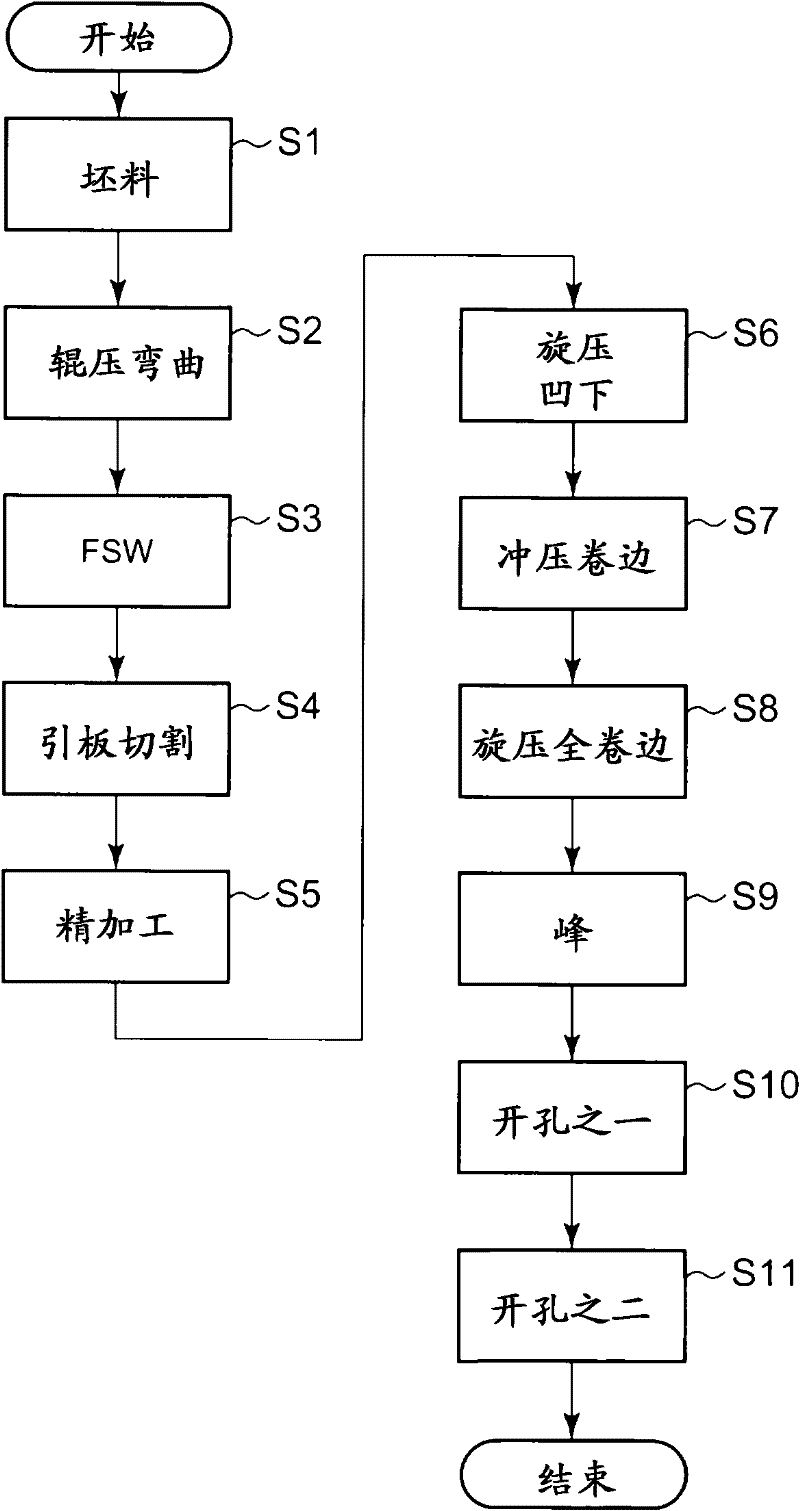

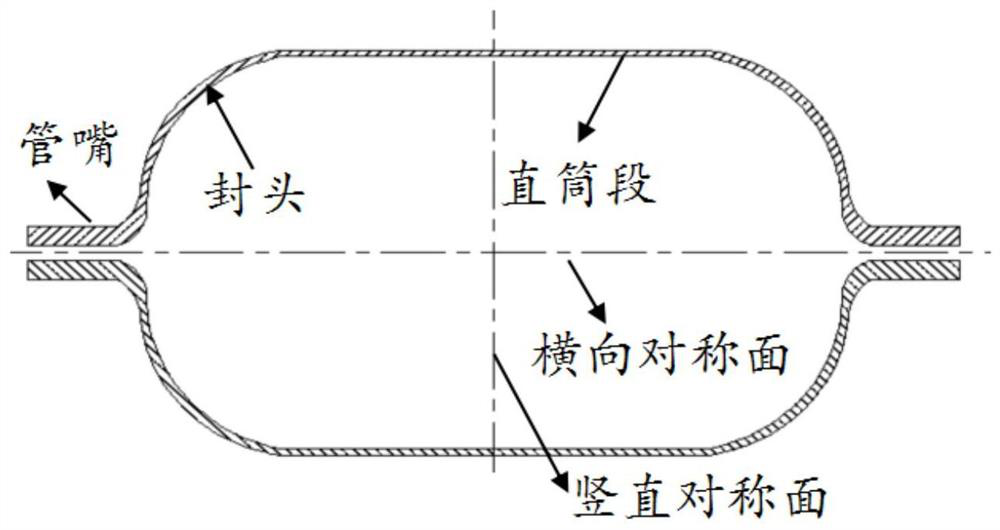

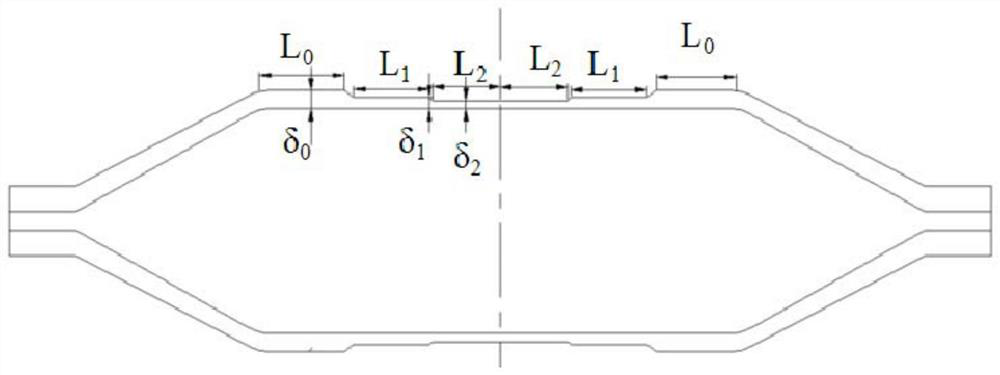

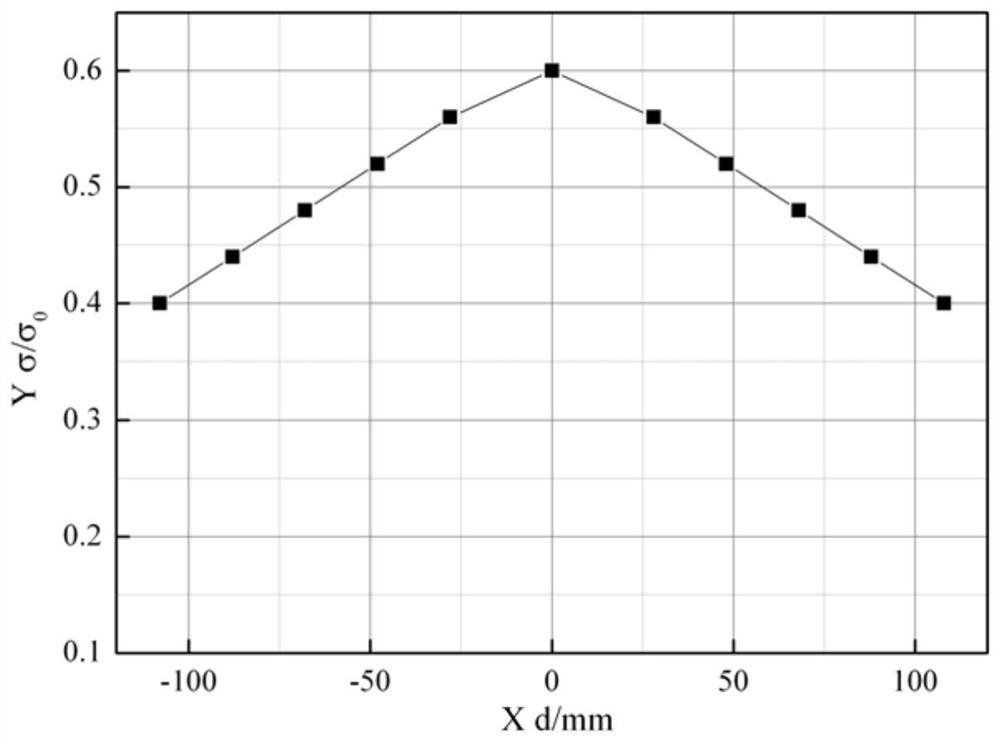

Titanium alloy thin-wall seamless lining straight cylinder section superplastic forming wall thickness uniformity control method

ActiveCN112974614AGuaranteed accuracyControl wall thicknessShaping toolsHydro energy generationSpinningTitanium alloy

The invention discloses a titanium alloy thin-wall seamless lining straight cylinder section superplastic forming wall thickness uniformity control method, and belongs to the technical field of plastic processing. According to the method, a small-caliber lining spinning part with the variable wall thickness is adopted for conducting superplastic bulging, firstly, a thinning area is machined on a straight cylinder section of the lining spinning part, an original equal-thickness straight cylinder section is machined into a variable-wall-thickness pipe with the same annular direction and axial gradient distribution, and then superplastic bulging is conducted. According to the method of the invention, through the special wall thickness gradient design, the wall thickness distribution of the straight cylinder section of the bulged titanium alloy lining can be adjusted, a large-diameter lining blank with the thickness of the straight cylinder section being evenly distributed is obtained, the requirement for subsequent machining thinning wall thickness tolerance is met, meanwhile, control measures are taken for cooling of the lining blank, and the dimensional stability of the formed titanium alloy lining is ensured. The method is suitable for titanium alloy thin-wall seamless linings with various diameters, which are integrally formed by spinning / superplastic.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

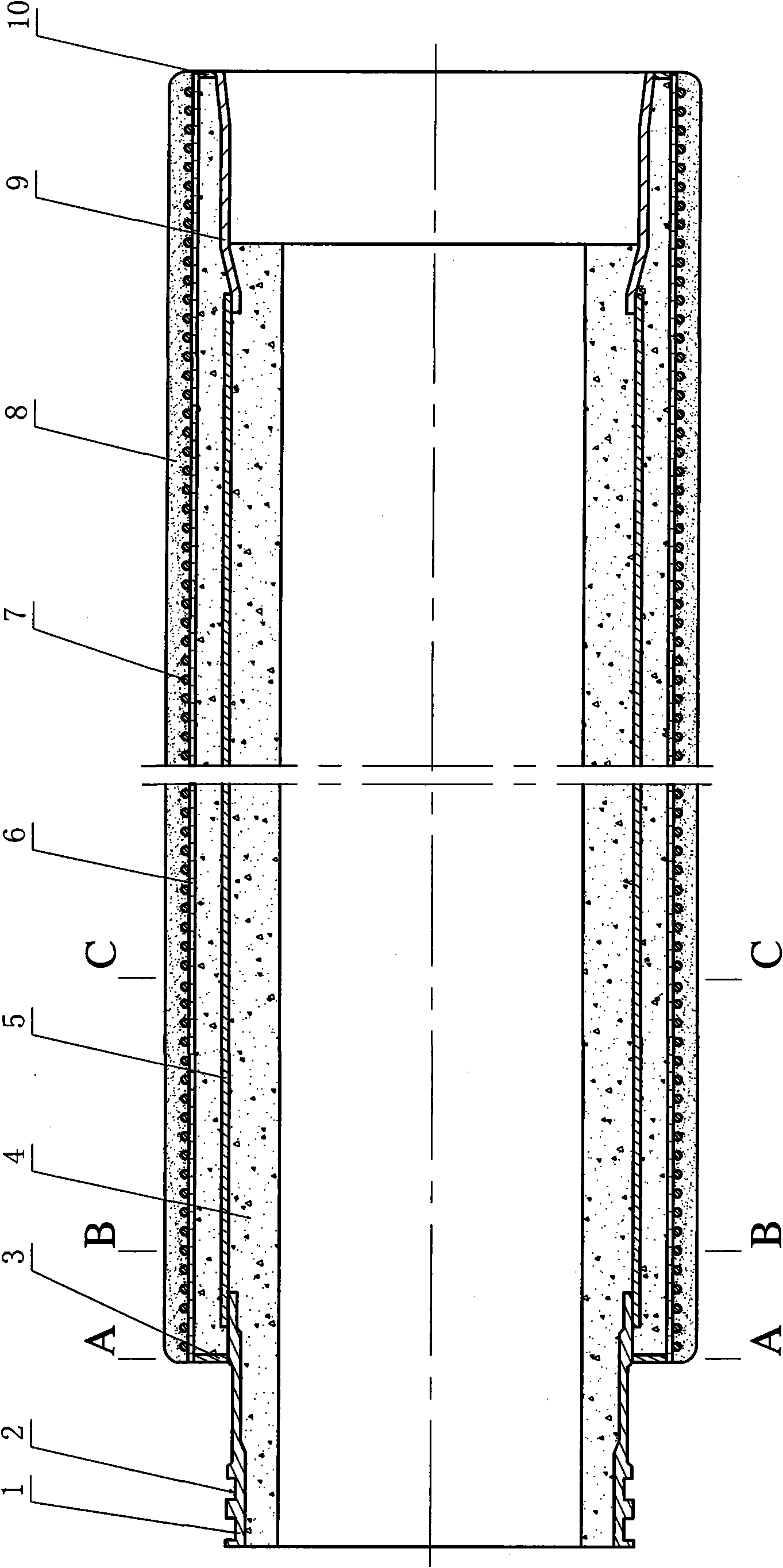

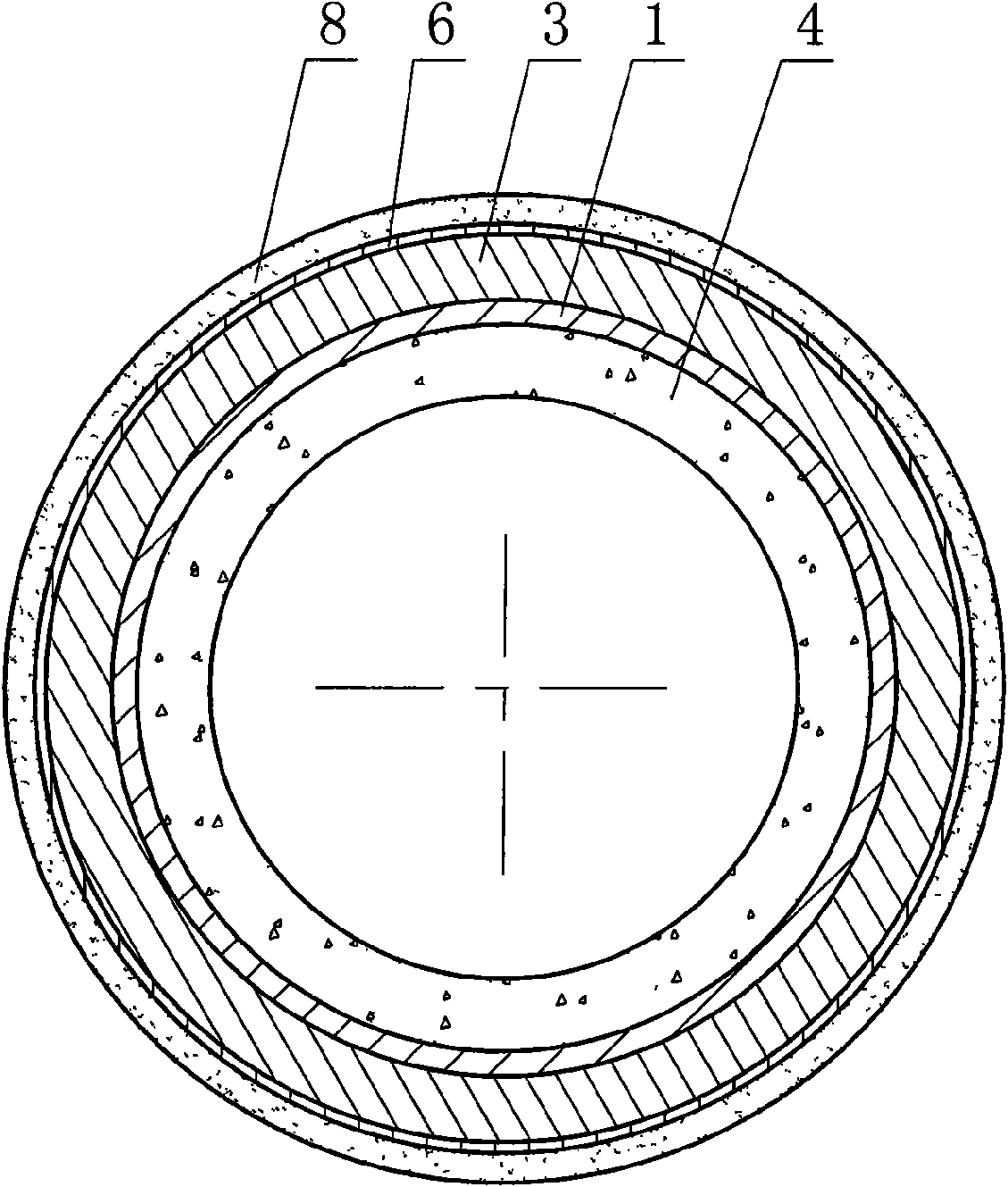

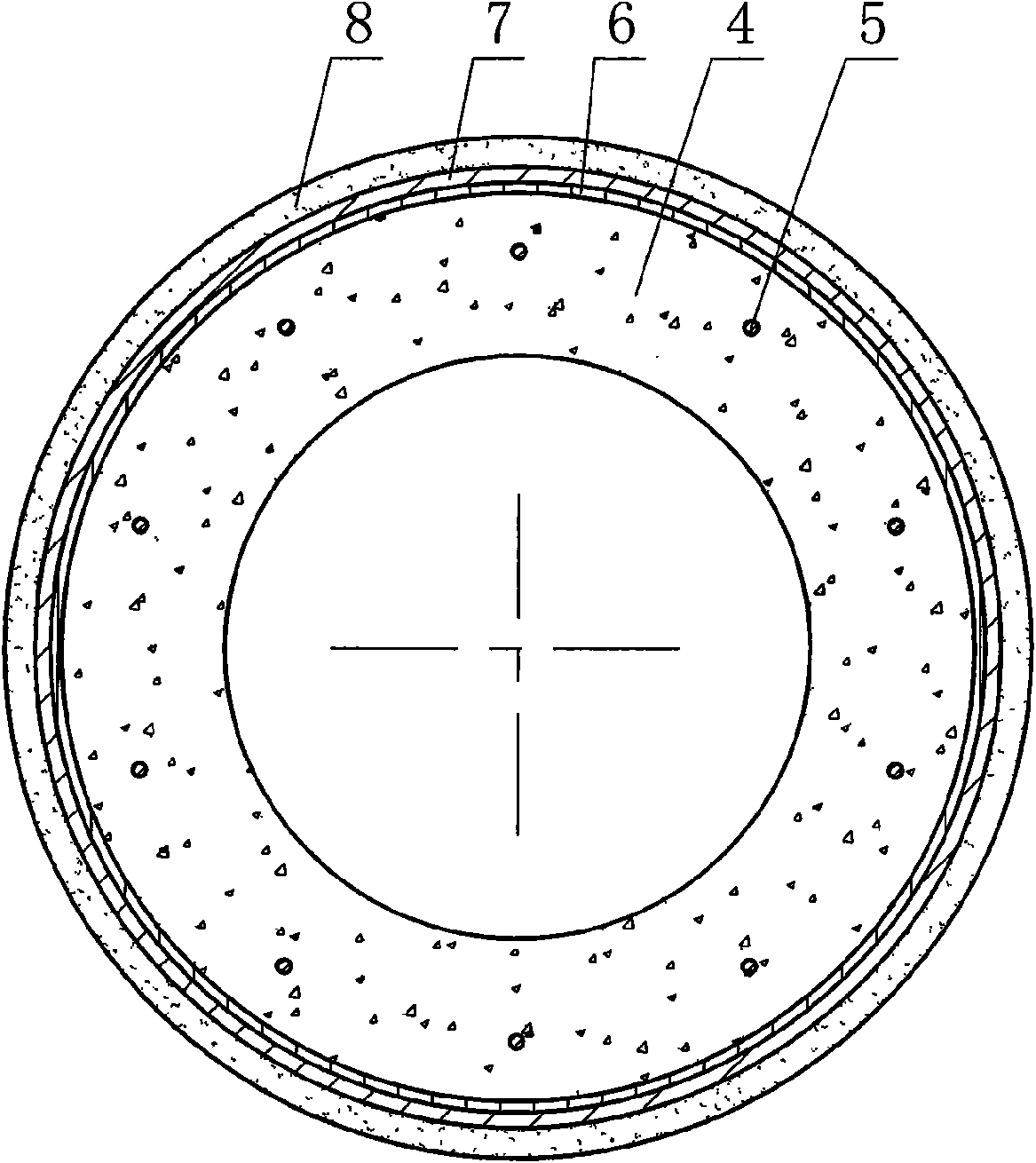

Prestressed steel cylinder reinforced concrete pipe with steel socket and spigot

The invention relates to a prestressed steel cylinder reinforced concrete pipe with a steel socket and a steel spigot, comprising a socket, a spigot, a concrete pipe core, a steel cylinder, a prestressed steel wire and a protecting layer, wherein the socket and the spigot in a concrete pipe core are fixedly installed with a longitudinal reinforced bar; and a connecting steel ring is respectively fixedly installed at two ends of the steel cylinder between the steel cylinder and the spigot and the socket in the radial direction. Through improvement, the invention still has excellent impermeability, corrosion resistance, prevention of non-uniform settlement, low cost of raw material and construction, simple construction process and convenient maintenance and can save external mould and control the wall thickness of the concrete pipe, thereby saving the production cost, reducing steps of forming concrete pipe core and improving the production efficiency.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com