Silicon-carbon composite nano-tube preparation method

A technology of silicon-carbon composites and nanotubes, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of unfavorable tubular structure lithium ion transport efficiency, anodized aluminum template is not easy to remove clean, silicon The long length of nanotubes and other problems can achieve the effect of simple and thorough template removal process, convenient template removal and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

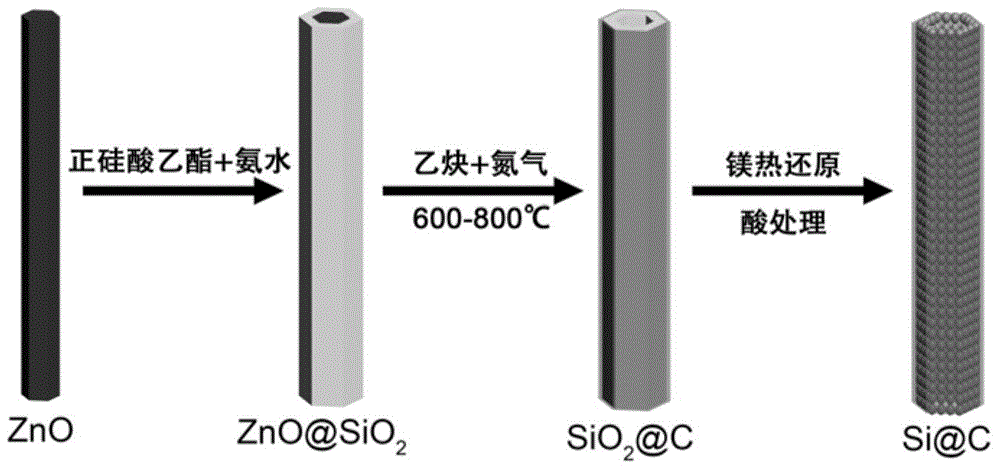

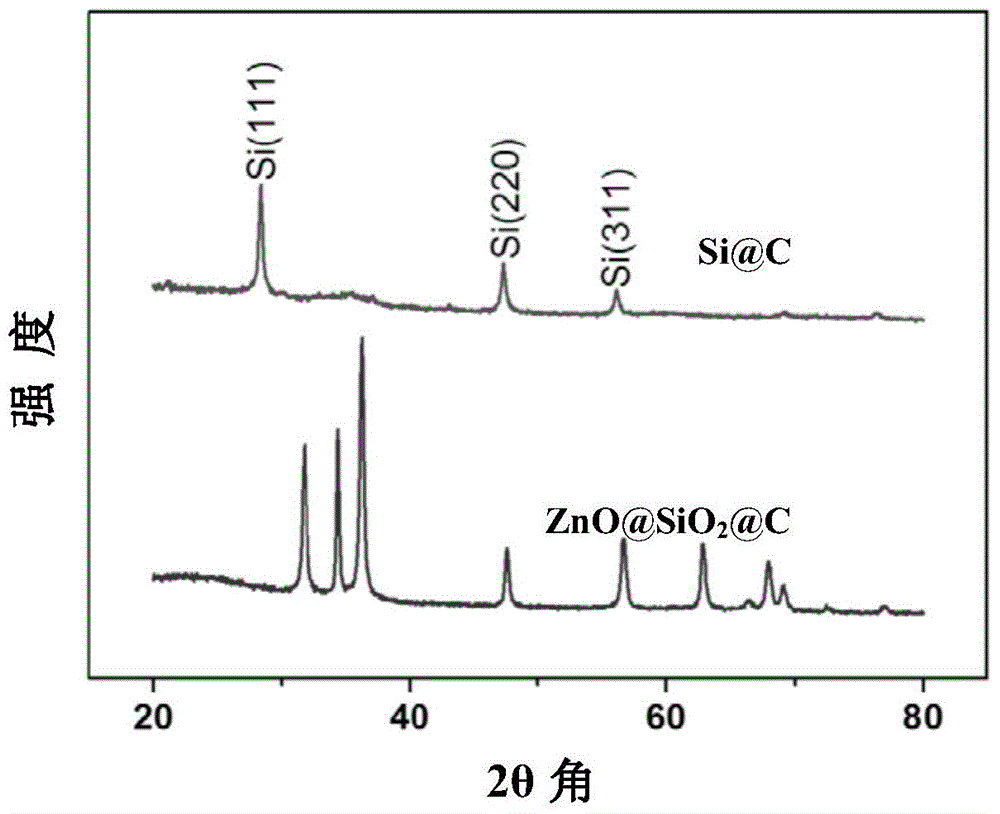

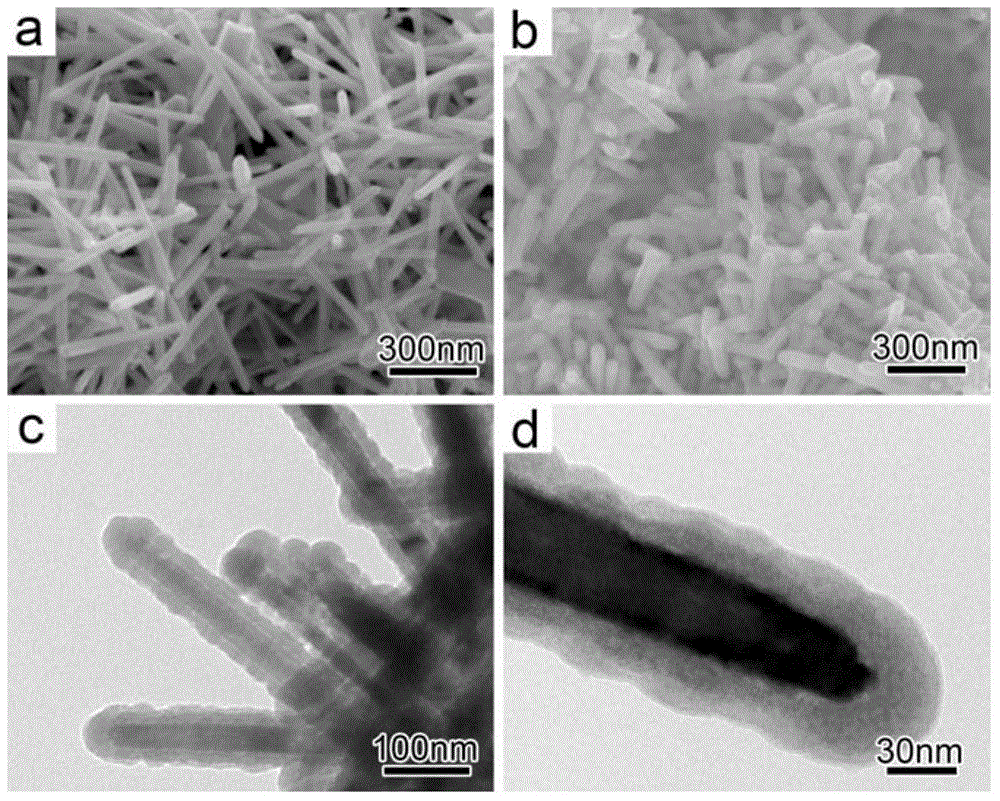

[0052] (1) Utilizing hydrothermal reaction to prepare zinc oxide nanorods (diameter is 50nm, length is 600nm);

[0053] (2) Stir and mix 0.1g zinc oxide nanorods with 30ml alcohol and 10ml water in a 100ml beaker, add ammonia water to adjust the pH to 10, add 6ml tetraethyl orthosilicate solution with a 2ml / h drop rate with a syringe pump, and react The time is 3 hours. After the reaction is completed, the product is centrifuged and dried;

[0054] (3) Place 0.2 g of the product obtained in step (2) in a corundum ark, put it into the heating zone of the tube furnace, feed nitrogen at a rate of 100 sccm, and heat up to 700 °C at a rate of 5 °C / min. Acetylene gas, the flow rate is 15 sccm, carry out the acetylene cracking chemical vapor deposition method to coat carbon, and keep it warm for 1h.

[0055] (4) the product obtained in step (3) is mixed with superfine magnesium powder (average particle diameter<100nm) and placed in the corundum ark, put into the heating zone in the ...

Embodiment 2

[0061] (1) Utilizing hydrothermal reaction to prepare zinc oxide nanorods (diameter is 50nm, length is 600nm);

[0062] (2) Stir and mix 0.2g zinc oxide nanorods with 60ml alcohol and 20ml water in a 100ml beaker, add ammonia water to adjust the pH to 10, add 12ml tetraethyl orthosilicate solution with a 2ml / h drop rate with a syringe pump, and react The time is 6 hours. After the reaction is completed, the product is centrifuged and dried;

[0063] (3) Place 0.3 g of the product obtained in step (2) in a corundum ark, put it into the heating zone of the tube furnace, feed nitrogen at a rate of 100 sccm, and heat up to 700 ° C at a rate of 5 ° C per minute. Acetylene gas, the flow rate is 15 sccm, carry out the acetylene cracking chemical vapor deposition method to coat carbon, and keep it warm for 1h.

[0064] (4) The product obtained in step (3) is mixed with ultrafine magnesium powder (average particle diameter<100nm) and placed in a corundum ark, and placed in the heating...

Embodiment 3

[0067] (1) Utilizing hydrothermal reaction to prepare zinc oxide nanorods (diameter is 50nm, length is 600nm);

[0068] (2) Stir and mix 0.1g zinc oxide nanorods with 30ml alcohol and 10ml water in a 100ml beaker, add ammonia water to adjust the pH to 10, add 6ml tetraethyl orthosilicate solution with a 2ml / h drop rate with a syringe pump, and react The time is 3 hours. After the reaction is completed, the product is centrifuged and dried;

[0069] (3) Place 0.2 g of the product obtained in step (2) in a corundum ark, put it into the heating zone of the tube furnace, feed nitrogen gas at a rate of 100 sccm, and heat up to 700 ° C at a rate of 5 ° C per minute. Acetylene gas, the flow rate is 15 sccm, carry out the acetylene cracking chemical vapor deposition method to coat carbon, and keep it warm for 2 hours.

[0070] (4) the product obtained in step (3) is mixed with superfine magnesium powder (average particle diameter<100nm) and placed in the corundum ark, put into the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com