Silicon dioxide hollow microsphere, preparation method thereof, application thereof to thermal insulating coating

A technology of silicon dioxide and thermal insulation coating, applied in the directions of silicon dioxide, silicon oxide, coating, etc., can solve the problem that the inner diameter of hollow microspheres cannot be effectively controlled, the particle morphology and size are not uniform, and the yield of hollow microspheres can not be effectively controlled. Low problems, to achieve good heat insulation effect, long drying cycle, small density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

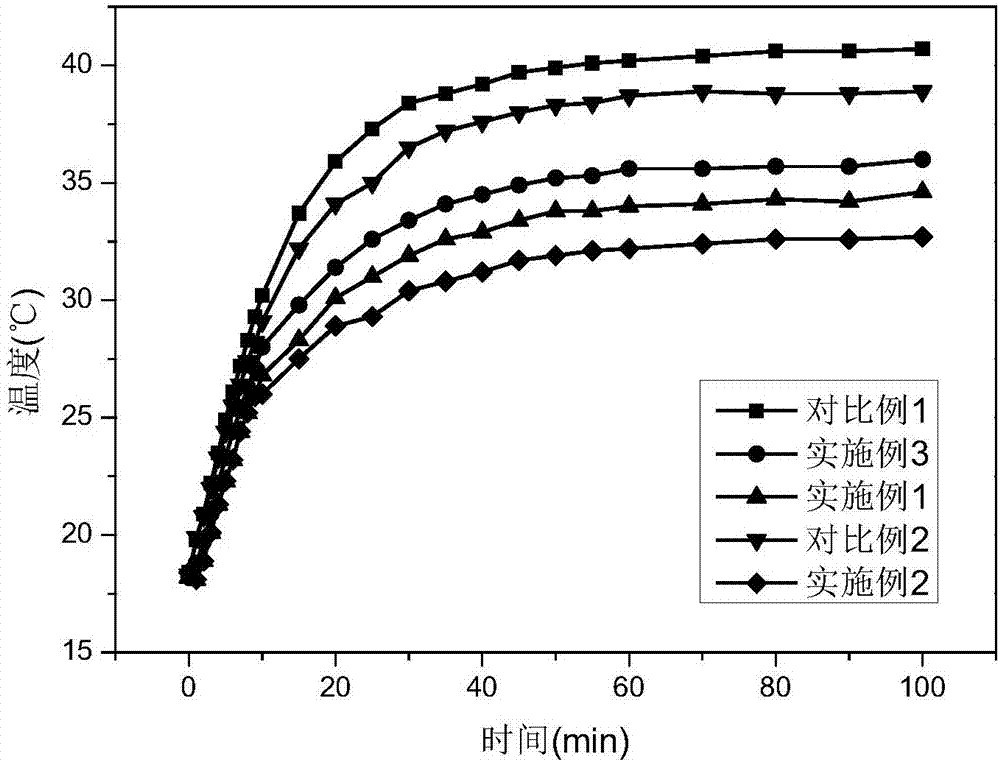

Embodiment 1

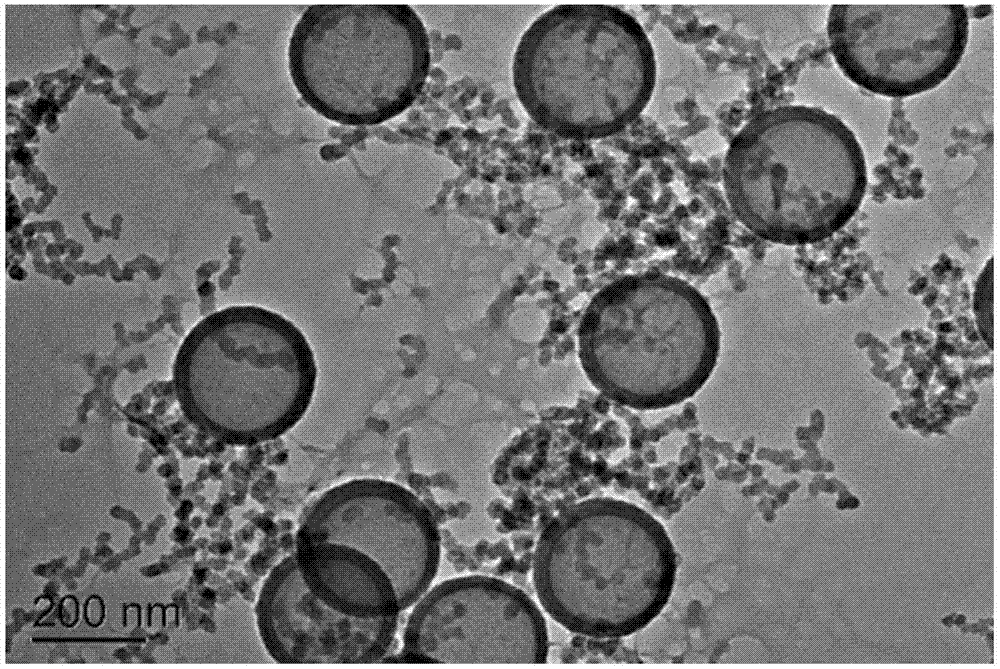

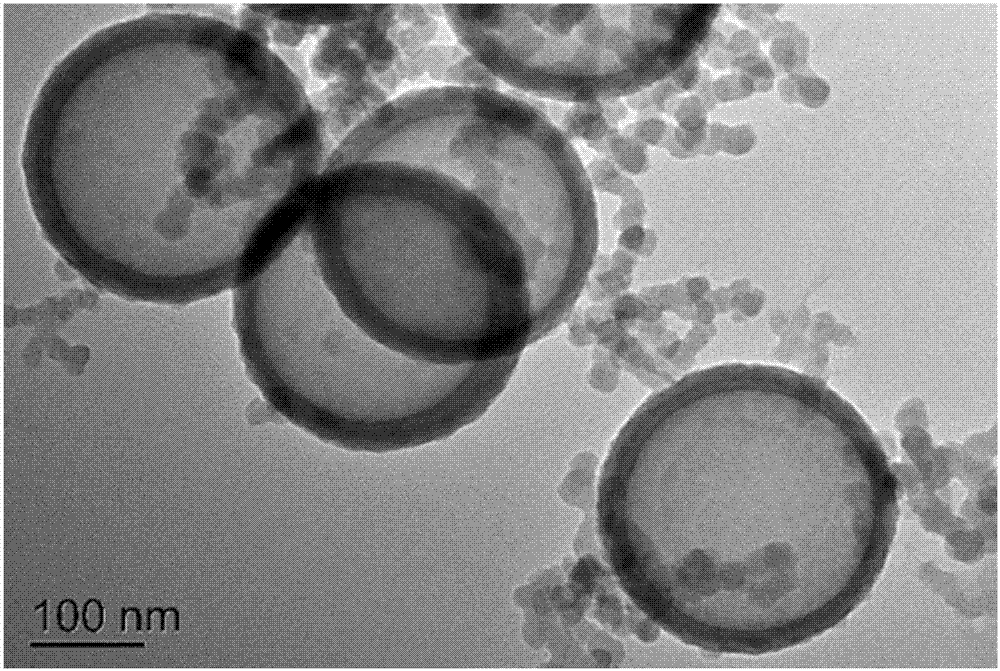

[0049] 1) Preparation of polystyrene microspheres:

[0050] Dissolve 20g of styrene and 4g of polyvinylpyrrolidone in 180ml of deionized water, stir at 350rpm for 15min, and heat up to 70°C to obtain a mixed solution; weigh 0.4g of azobisisobutylamidine hydrochloride with 20g of deionized Dissolve in water to obtain an initiator solution; add the initiator solution to the above mixed solution and react for 7 hours to obtain polystyrene microspheres

[0051] 2) Preparation of polystyrene / silica composite microspheres:

[0052] Take 12g of polystyrene as a template and 190g of absolute ethanol as a solvent in a four-neck flask and mix evenly, add 6ml of ammonia water with a mass fraction of 28% and stir at 200rpm for 15min, then slowly add 20ml of orthosilicic acid with a mass fraction of 25% Ethyl ester / ethanol solution, control the reaction temperature at 30°C, and react for 24 hours to obtain polystyrene / silica composite microspheres

[0053] 3) Preparation of silica hollow...

Embodiment 2

[0061] 1) Preparation of polystyrene microspheres:

[0062] Dissolve 20g of styrene and 2g of polyvinylpyrrolidone in 180ml of deionized water, stir at 400rpm for 15min, and heat up to 70°C;

[0063] The potassium persulfate of 0.2g is dissolved with 20g deionized water to obtain initiator solution;

[0064] The initiator solution was added to the above mixed solution to react for 7h;

[0065] 2) Preparation of polystyrene / silica composite microspheres:

[0066] Take 12g of polystyrene as a template and 190g of absolute ethanol as a solvent in a four-neck flask and mix evenly, add 3ml of ammonia water with a mass fraction of 26%, stir at 250rpm for 15min, then slowly add 20ml of 50% tetraethyl orthosilicate / ethanol solution, control the reaction temperature at 30°C, and react for 20 hours;

[0067] 3) Preparation of silica hollow microspheres:

[0068] The mixed solution obtained from the above reaction was centrifuged at 8500 rpm for 15 minutes, washed and dried, and the ...

Embodiment 3

[0073] 1) Preparation of polystyrene microspheres:

[0074] Dissolve 15g of styrene and 4g of polyvinylpyrrolidone in 190ml of deionized water, stir at 400rpm for 15min, and heat up to 75°C;

[0075] The ammonium persulfate that takes 0.3g is dissolved with 10g deionized water, obtains initiator solution;

[0076] The initiator solution was added to the above mixed solution to react for 8h;

[0077] 2) Preparation of polystyrene / silica composite microspheres:

[0078] Take 10g polystyrene as a template and 190g absolute ethanol as a solvent in a four-necked flask and mix evenly, add 1.5ml of ammonia water with a mass fraction of 28%, stir at 200rpm for 15min, then slowly add 20ml of 20% tetraethyl orthosilicate / Ethanol solution, control the reaction temperature at 35°C, and react for 24 hours;

[0079] 3) Preparation of silica hollow microspheres:

[0080] The mixed solution obtained from the above reaction was centrifuged at 8500 rpm for 20 minutes, washed and dried, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com