Preparation method of silicate double-layer hollow nanometer fiber with multistage structure

A hollow nano- and composite nano-fiber technology, applied in the chemical characteristics of fibers, chemical instruments and methods, silicon oxide, etc., can solve the problems of difficult separation, recovery and reuse, and limit practical applications, and achieve easy separation, recovery and reuse. The effect of strong controllability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

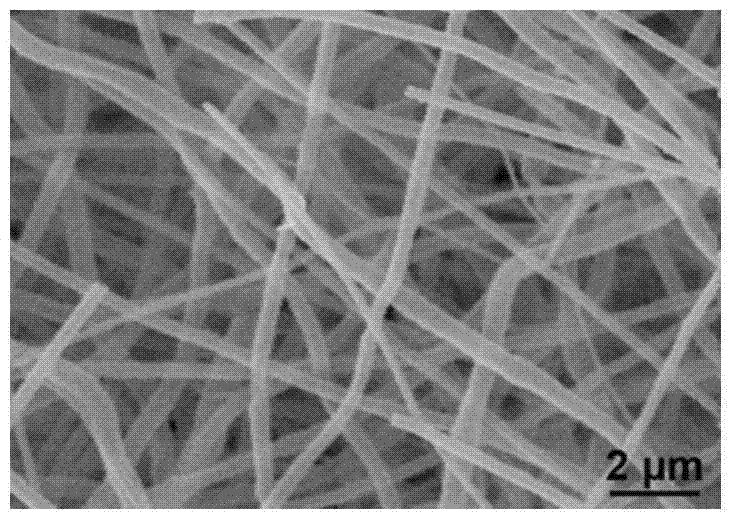

Embodiment 1

[0027] Magnetically stir 1.6ml of tetraethyl orthosilicate and 10ml of absolute ethanol for 10 minutes; add 0.95g of polyvinylpyrrolidone (molecular weight: 90,000) to the above solution, stir magnetically at room temperature for 4 hours, and stand still for 2 hours to form Spinning solution; add the prepared spinning solution into the liquid storage tube of the spinning device for electrospinning, the nozzle diameter is 0.6 mm, adjust the inclination angle between the nozzle and the horizontal plane to 15 degrees, apply a DC voltage of 9.5 kV, and the curing distance 20 cm, to obtain composite nanofibers of tetraethyl orthosilicate / PVP; put the composite nanofibers into a temperature-programmed furnace for heat treatment, the heating rate is 0.5°C / min, keep the temperature at 550°C for 2 hours, and then With the natural cooling of the furnace body, the target product can be obtained. The product was identified as amorphous silica by X-ray powder diffraction and energy dispers...

Embodiment 2

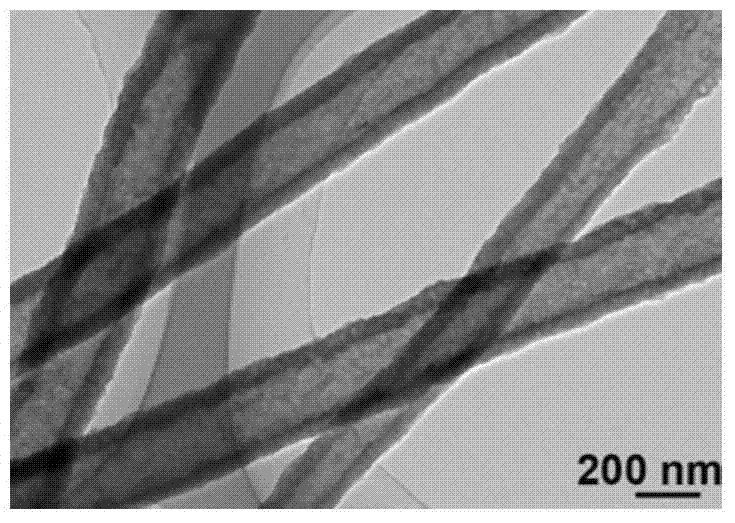

[0029] At room temperature, dissolve 0.0002 moles of nickel acetate tetrahydrate into 10 ml of deionized water, and stir thoroughly for 5 minutes; add 0.2 ml of concentrated ammonia water and 0.002 moles of ammonium chloride to the mixed solution in turn, and continue stirring for 5 minutes; mix the above The solution was transferred to a polytetrafluoroethylene-lined stainless steel reactor; then 0.02 g of silica hollow nanofibers were added to the reactor, and the reactor was sealed and placed in an oven for hydrothermal reaction at 100° C. for 10 hours. After naturally cooling to room temperature, it was alternately washed several times with deionized water and absolute ethanol, and the mixture was centrifuged to obtain the target product. The product is identified as nickel silicate by X-ray powder diffraction and energy dispersive X-ray spectroscopy. It can be proved by scanning electron microscopy that nickel silicate nanofibers have a multi-level structure. The fiber wal...

Embodiment 3

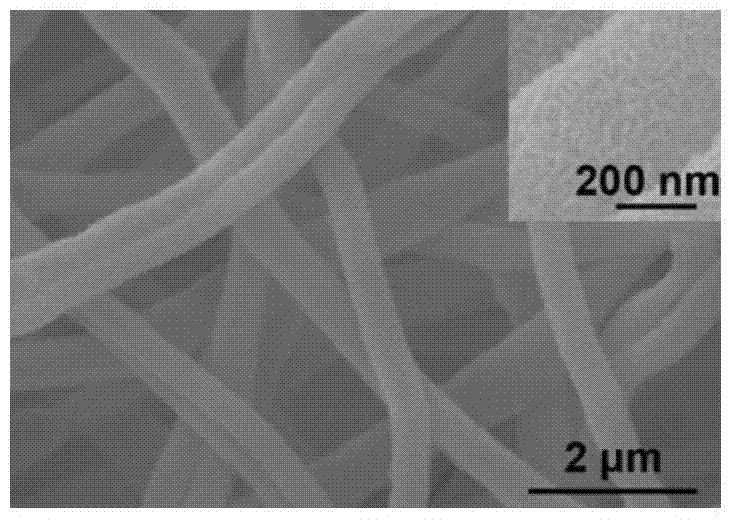

[0031] At room temperature, 0.0002 moles of copper acetate monohydrate were dissolved in 10 milliliters of deionized water and stirred for 5 minutes; 0.2 milliliters of concentrated ammonia water and 0.002 moles of ammonium chloride were added to the mixed solution successively and continued to stir for 5 minutes; The above mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel reaction kettle; then 0.02 grams of silica hollow nanofibers were added to the reaction kettle, and the reaction kettle was sealed and placed in an oven for hydrothermal reaction at 140°C for 10 Hour. After naturally cooling to room temperature, it was alternately washed several times with deionized water and absolute ethanol, and the mixture was centrifuged to obtain the target product. The product is identified as copper silicate by X-ray powder diffraction and energy dispersive X-ray spectroscopy. Scanning electron microscopy can prove that copper silicate nanofibers have a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com