Patents

Literature

107results about How to "Control diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

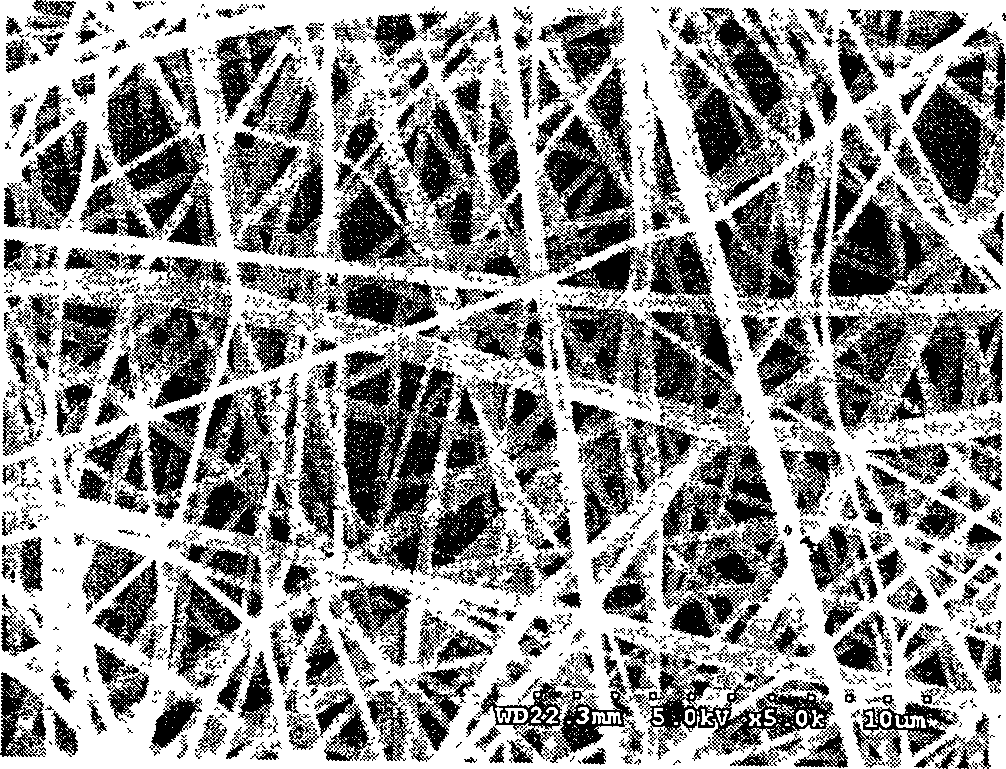

Degradable and absorbable polymer nano fibrous membrane materials and preparation process and use thereof

InactiveCN1837274AGood uniformityHigh porositySurgeryFilament/thread formingFilm materialDecomposition

The invention discloses a biological decomposable polymer nanometer fiber film material and preparing method and usage, which is characterized by the following: the material is made of several nanometer to several hundred nanometer fiber diameter nonwoven material, wherein the hyaluronic acid is more than 0 less than or equal to 100; other macromolecular material quantiy is more than 0 less than 100; the quantity of remedy medicine is 0-10 part. The invention possesses well biological compatity, biological decomposition and absorption property, which is applied in the medical tissue engineering rack material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

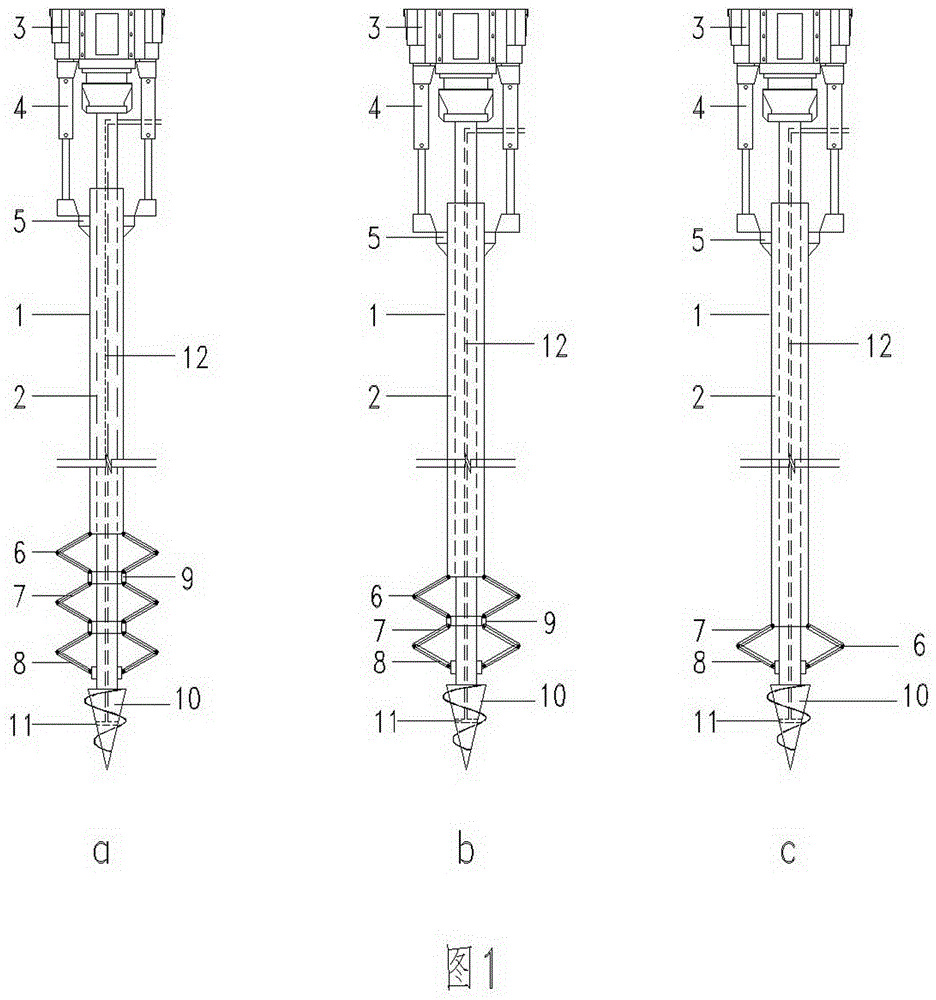

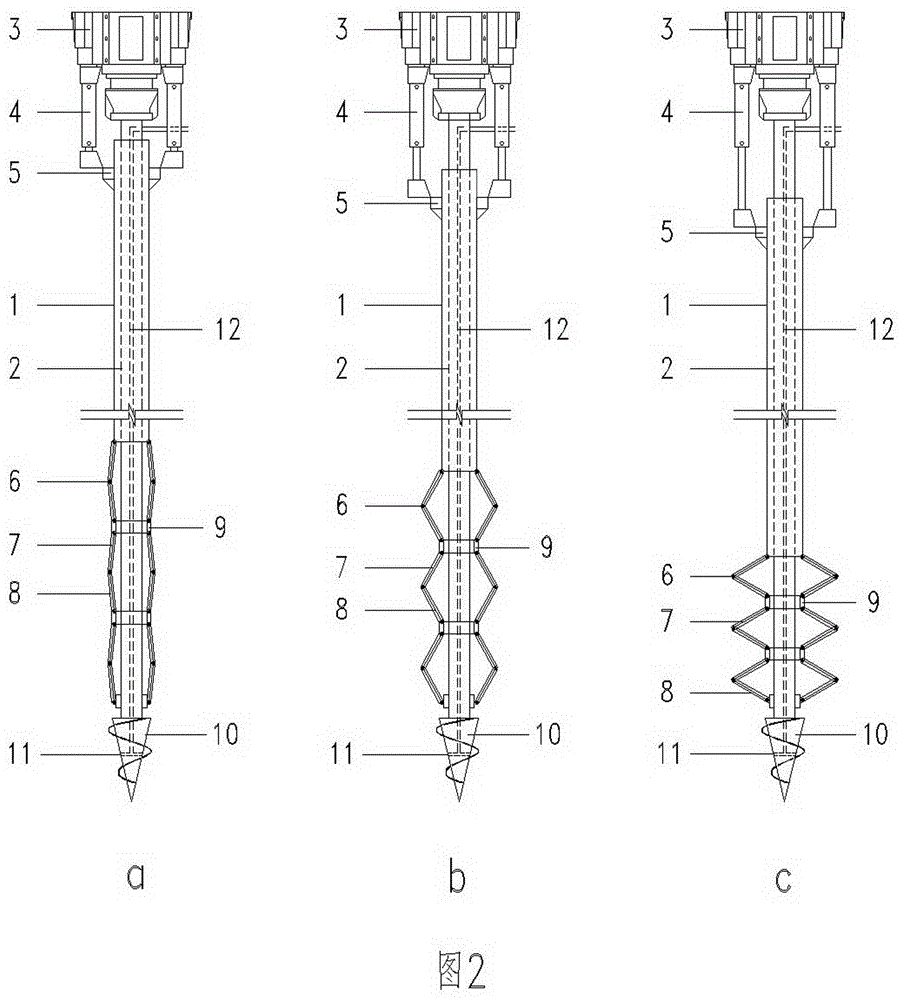

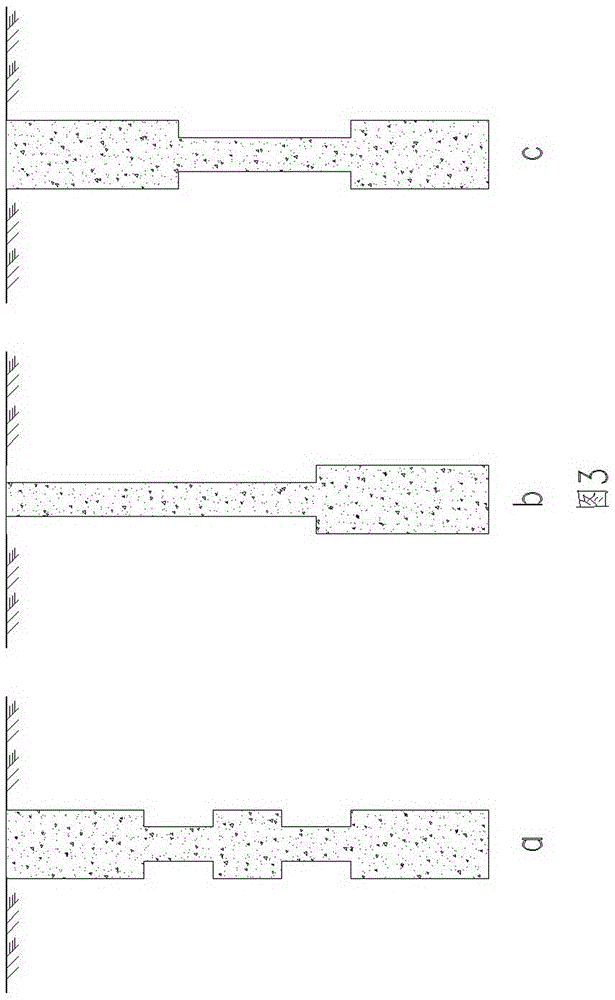

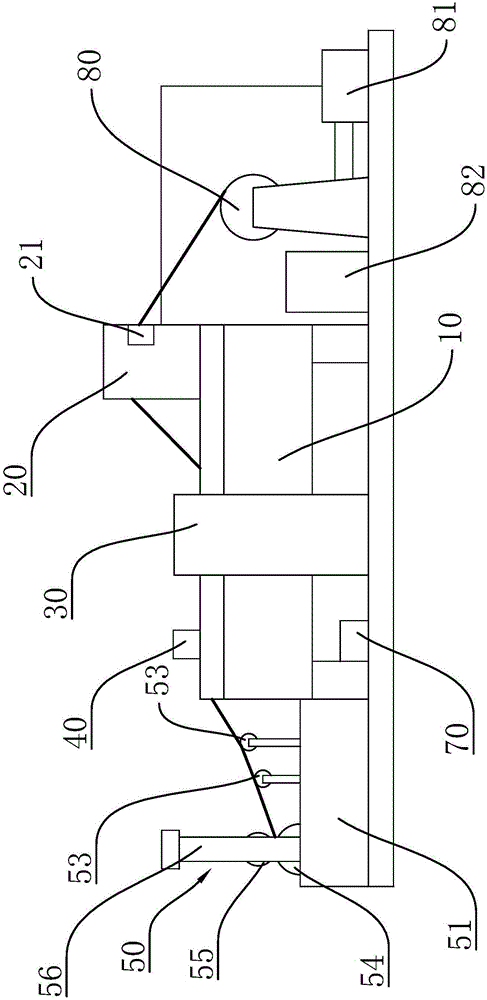

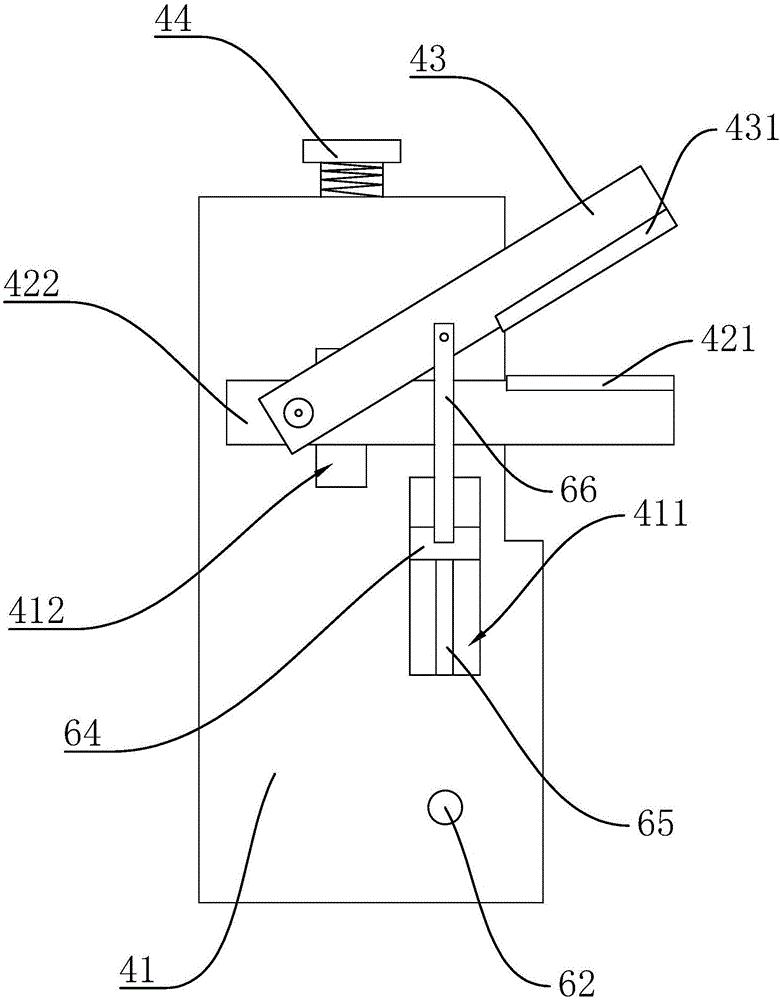

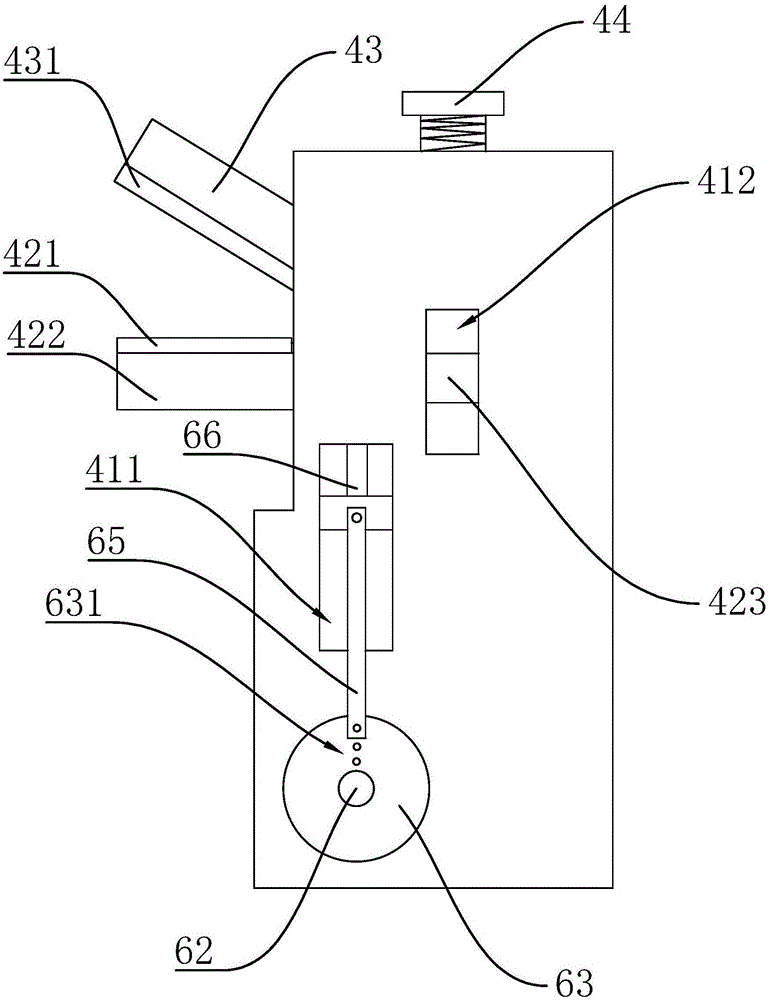

Construction device and construction method for stirring and spraying expanded reinforcement pile

ActiveCN106087999AIncrease resistance to horizontal thrustIncrease end resistanceBulkheads/pilesDrilling machines and methodsSpray nozzleHigh pressure

The invention provides a construction device and construction method for a stirring and spraying expanded reinforcement pile. The construction device is characterized in that a drill pipe is formed by coaxially overlapping an outer pipe body and an inner pipe body in a sleeving mode and provided with a rotary power mechanism, a lifting device and a variable-diameter telescopic stirring arm; the inner pipe body is provided with a spiral drill bit and a spraying nozzle, and high-pressure ejection, forced stirring, improvement on the drilling speed and adjustment of the specifications of a pile body and an expanded body are realized through the operations of arm folding, arm unfolding, rotating, high-pressure grouting and the like. The construction method is characterized in that the setting parameters and design scheme of the pile body and the expanded body of the reinforcement pile are designed in advance. The method includes the particular construction steps that (1) pile positions are aligned; (2) the expanded body and the pile body of the reinforcement pile are constructed in a mode A (from top to bottom) or mode B (from bottom to top) according to the advanced design; (3) the stirring and spraying expanded reinforcement pile which accords with the advanced design and is provided with the expanded body is formed; and (4) subsequent construction is carried out through multiple methods and includes manufacturing of a reinforcement body pile body and pile end carriers and laying of a cushion layer.

Owner:北京波森特岩土工程有限公司

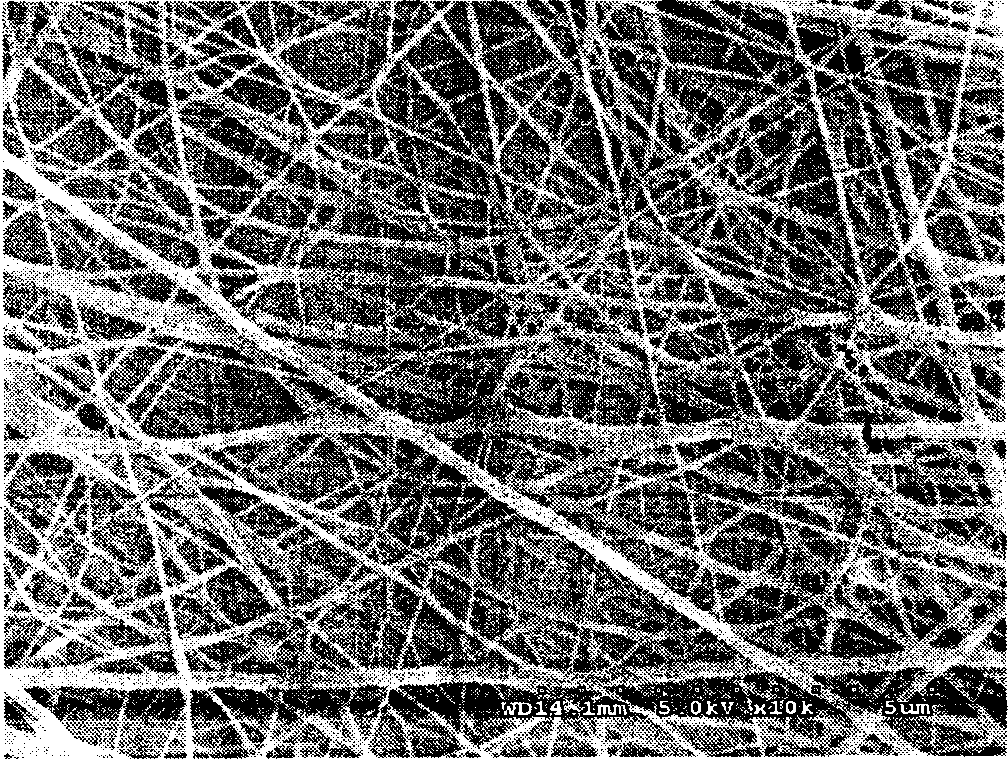

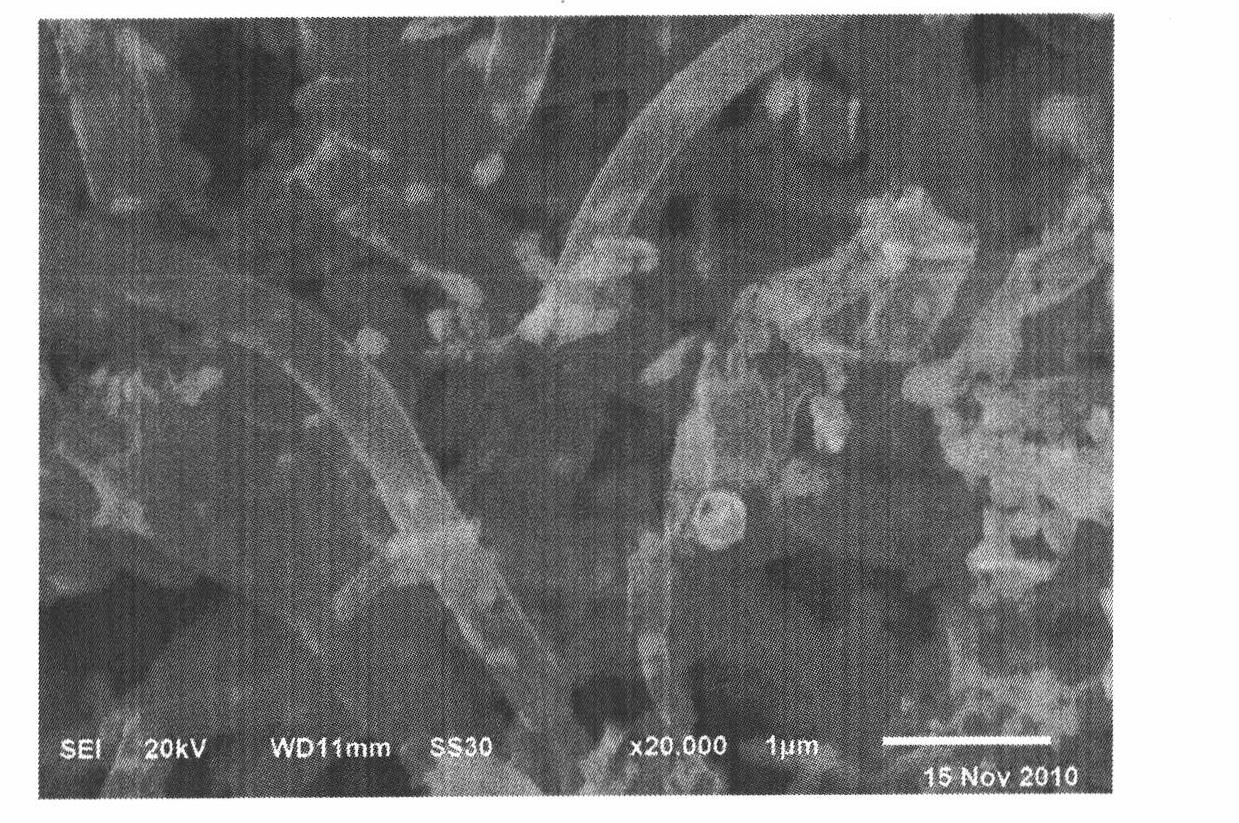

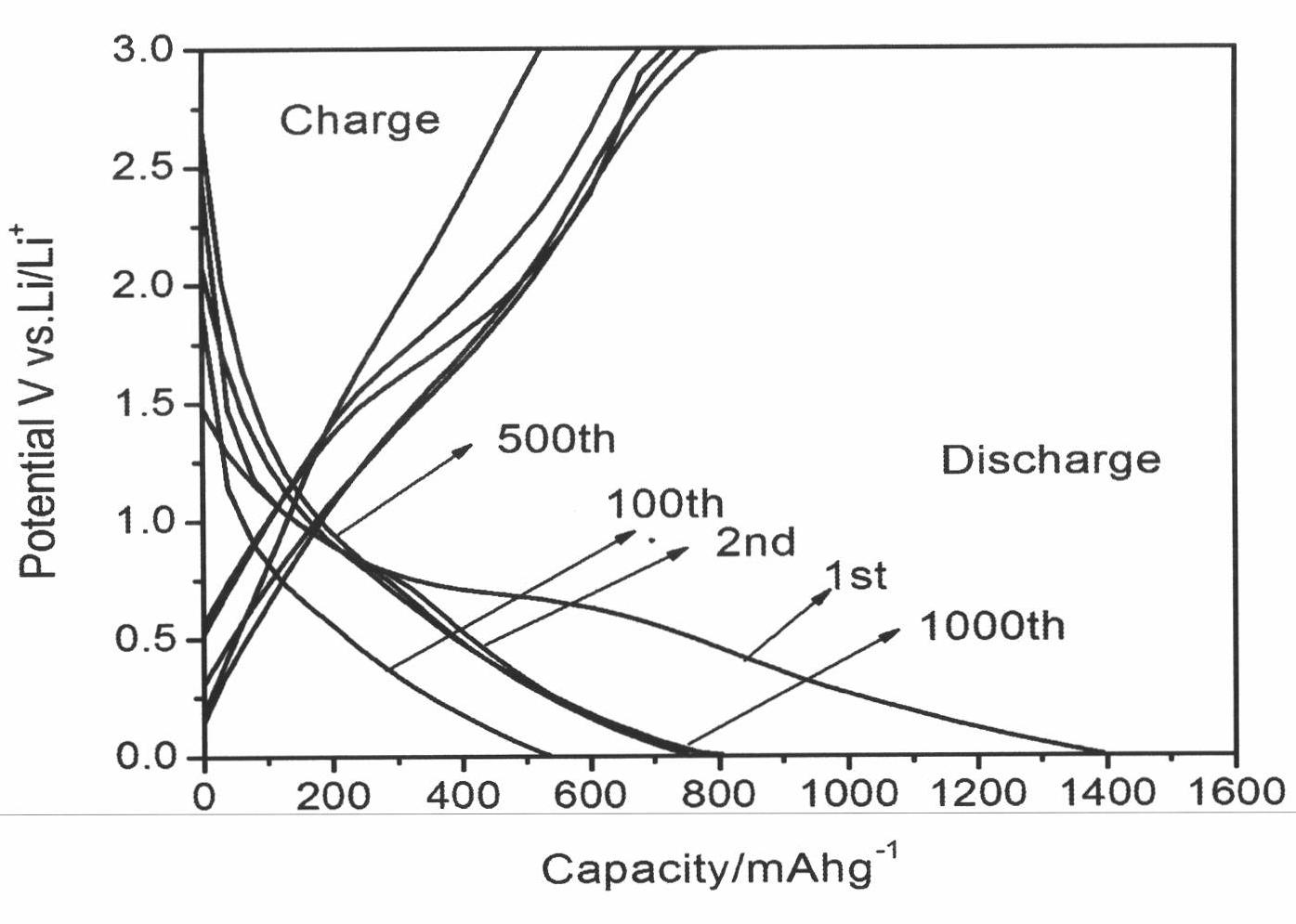

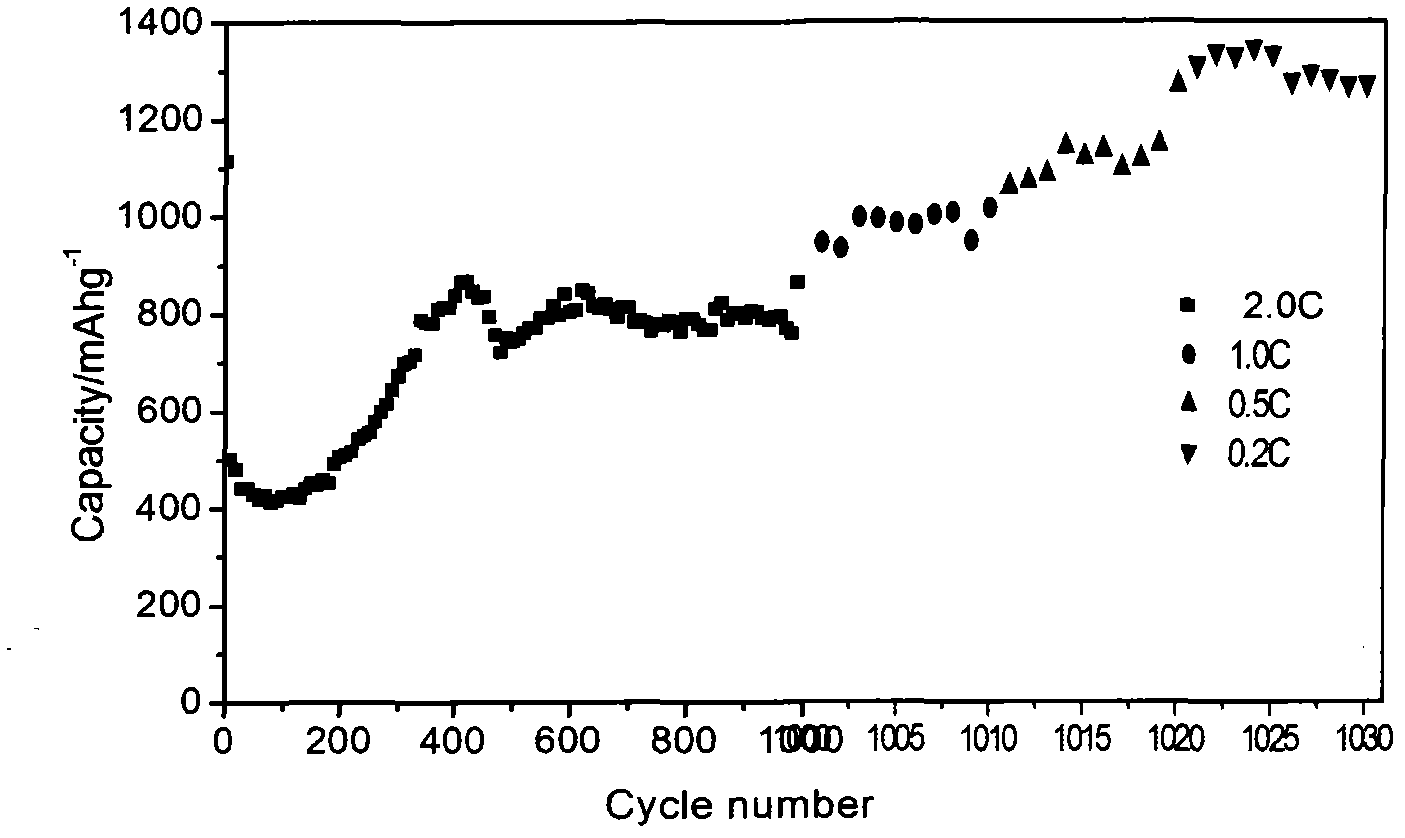

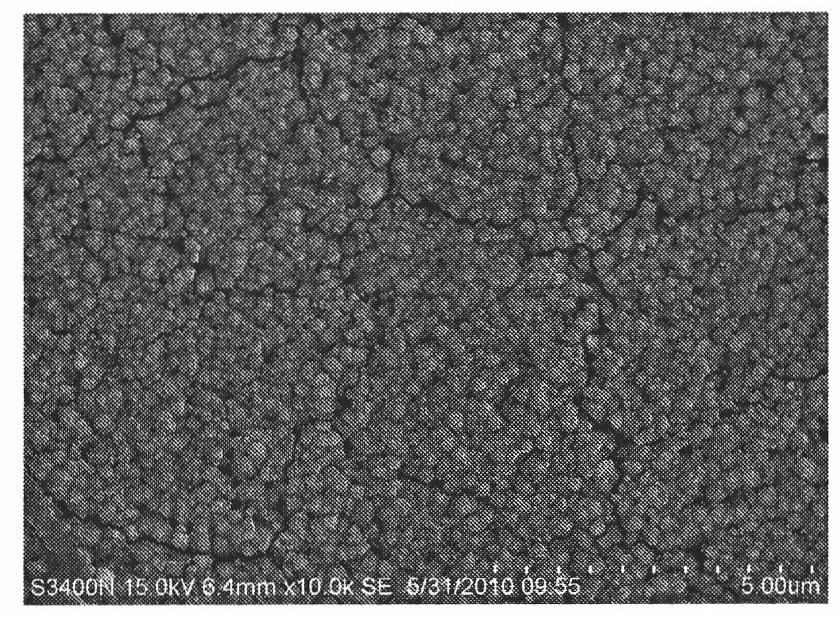

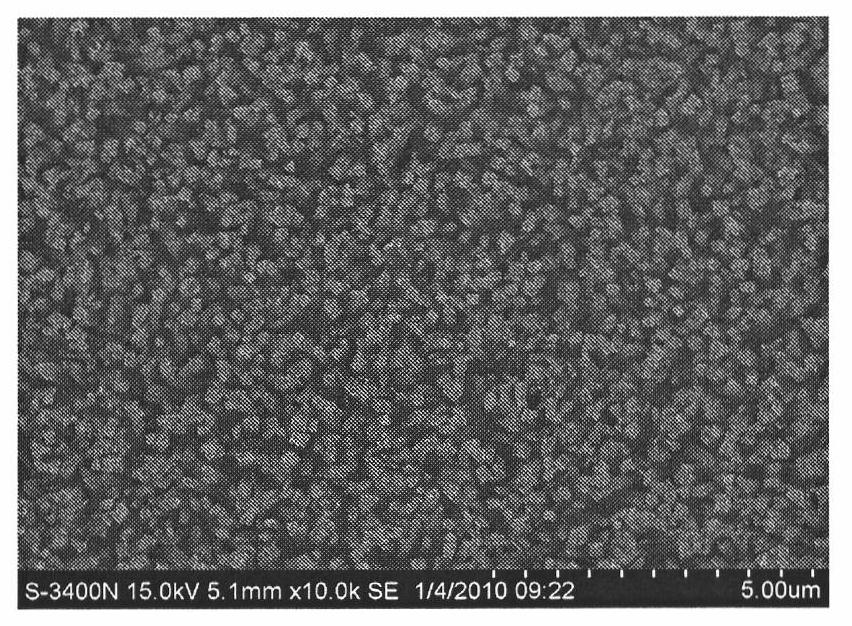

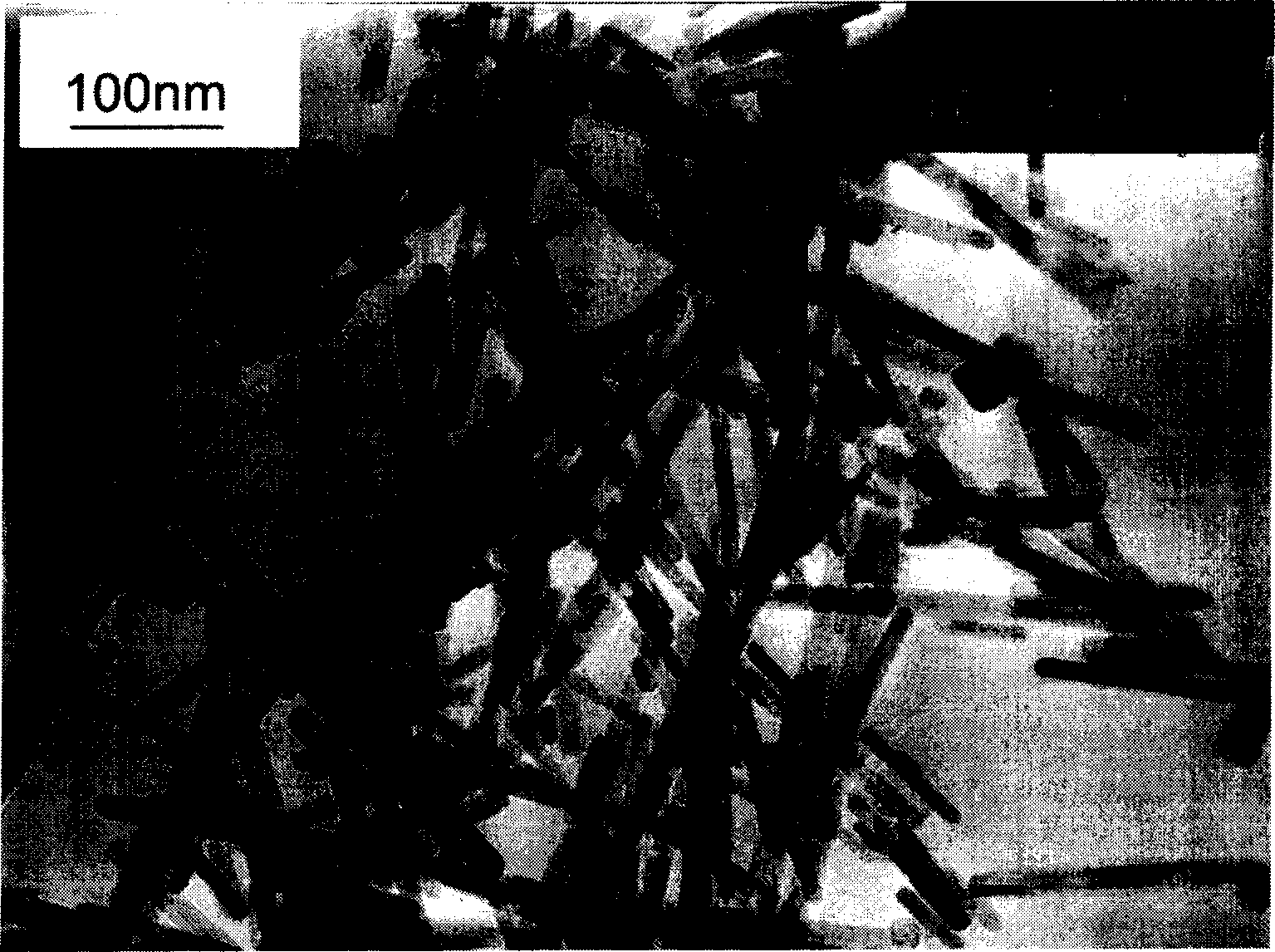

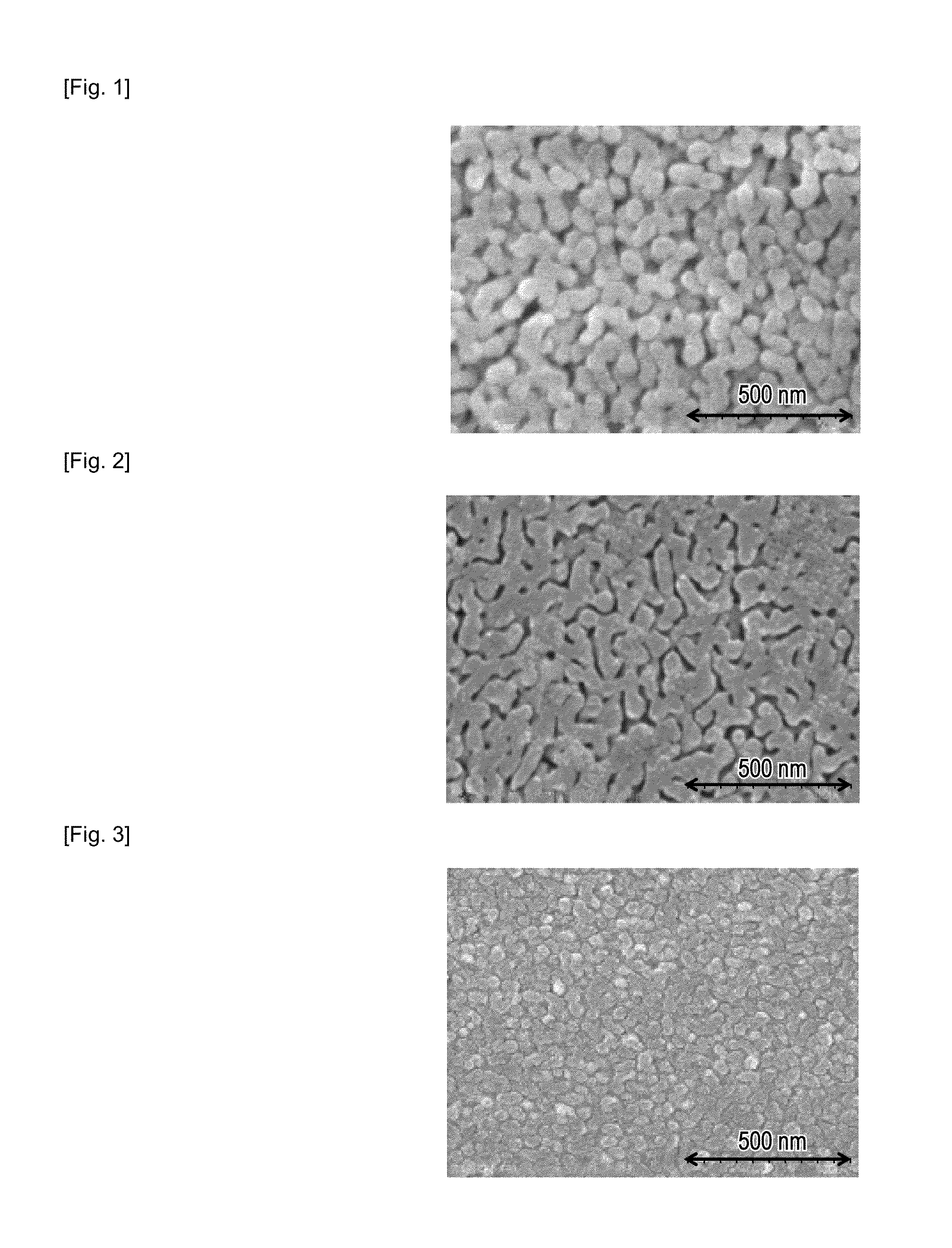

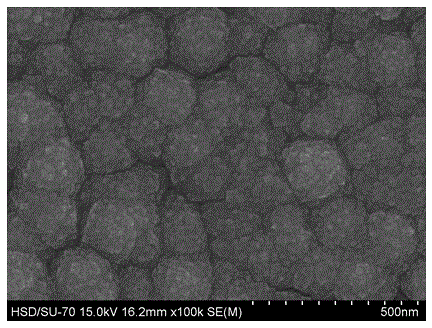

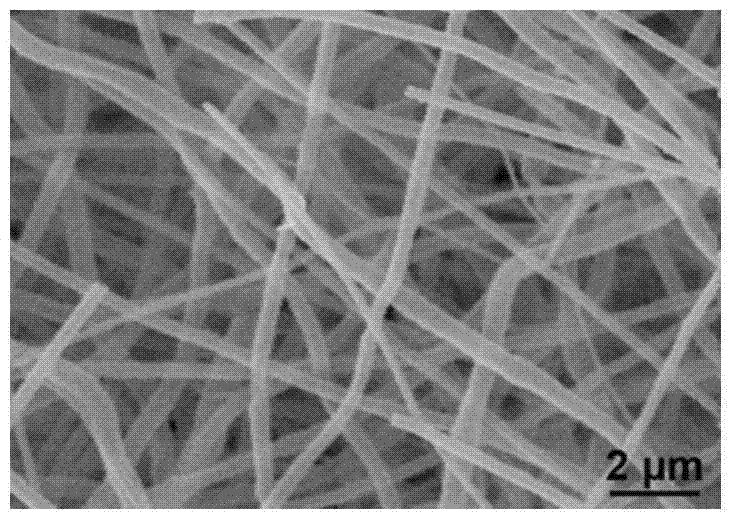

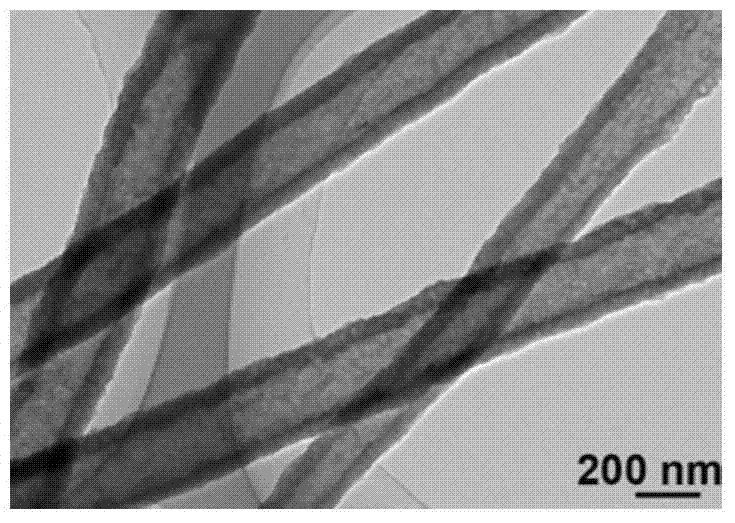

Method for preparing lithium ion battery cathode material ZnFe2O4/C nano fibers

InactiveCN102154739AControl diameterSolve reunionCell electrodesFilament/thread formingFiberCyclic process

The invention discloses a method for preparing lithium ion battery cathode material ZnFe2O4 / C nano fibers. The method has the advantages that: 1, the preparation process flow is short, the diameter of the nano fibers can be controlled more effectively, nano fiber precursors with regular structure are obtained, and the lithium ion battery cathode material ZnFe2O4 / C nano fibers with uniform structure are prepared by combining different change of two polymers in the calcining process; and 2, the prepared lithium ion battery cathode material ZnFe2O4 / C nano fibers are apparently nano fibers, the diameter of the nano fibers is about 200 to 400 nanometers, ZnFe2O4 nano granules are distributed in the continuous phase of carbon in the internal structure, and meanwhile, because of the carbon, the volume change in the electrode circulating process is greatly relieved, the problem of granule agglomeration in the circulating process is solved and the electrochemical circulating stability is improved.

Owner:XIANGTAN UNIV

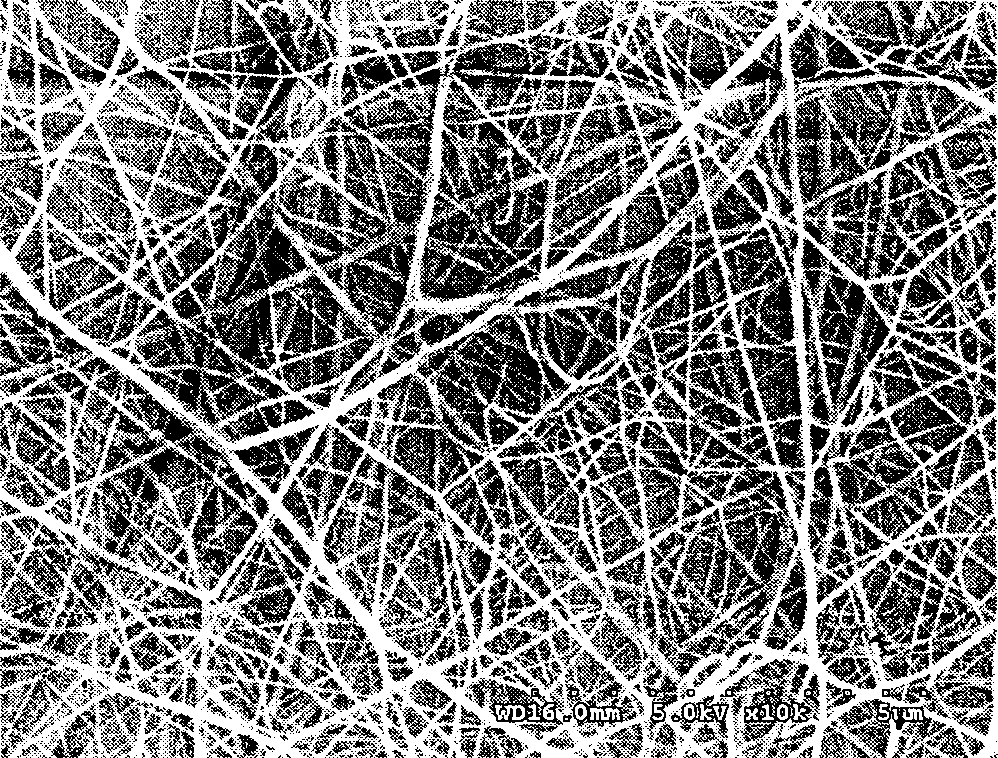

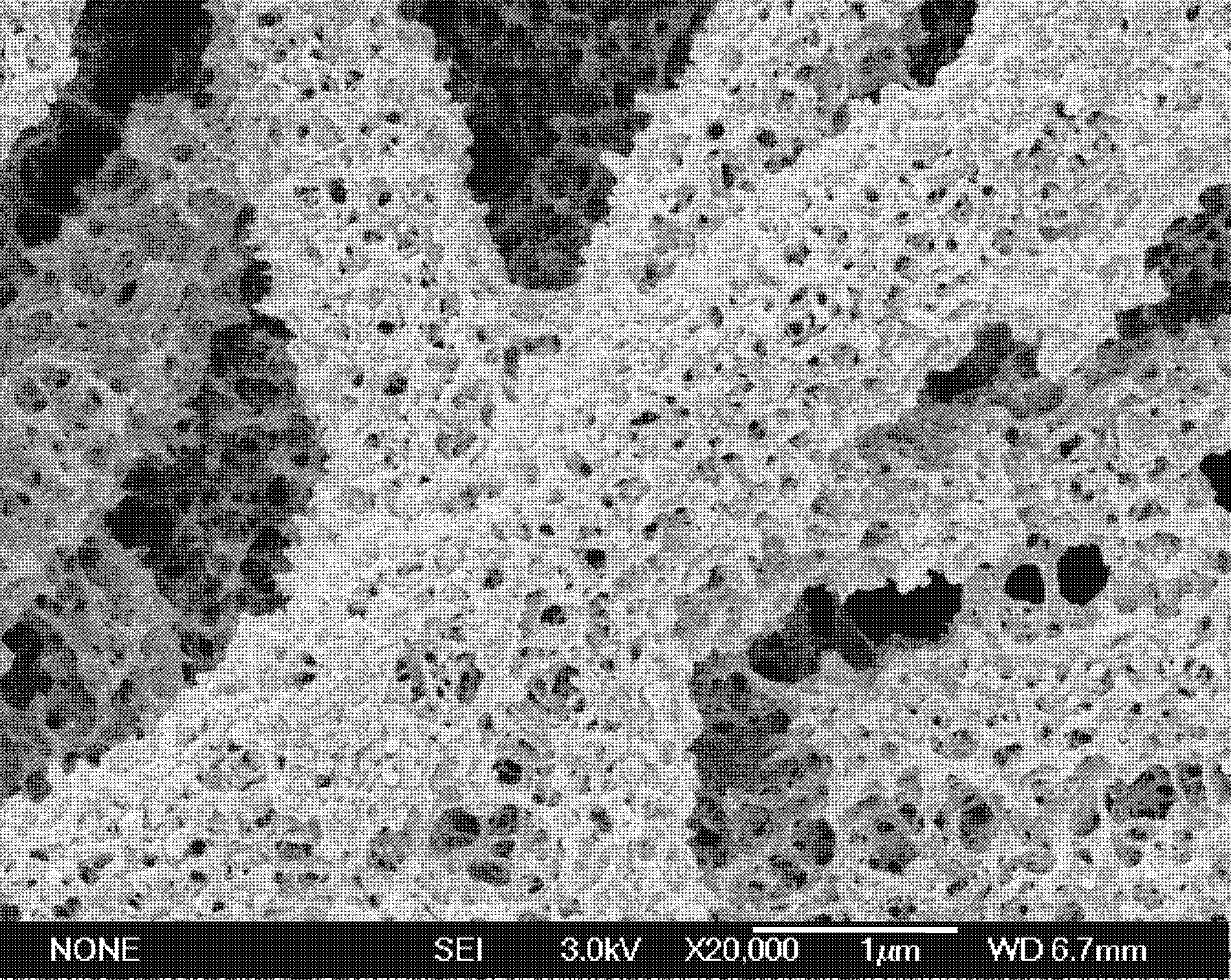

Preparation method of organic nano porous fiber film having controllable ultra-high specific area

InactiveCN101942704ASimple production methodLow costFilament/thread formingArtificial filaments from cellulose derivativesElectrospinningSolvent

The invention provides a preparation method of an organic nano porous fiber film having a controllable ultra-high specific area, which is characterized by comprising the following steps: 1. adding hydrophobic polymer to a closed vessel filled with a solvent at room temperature, placing onto a magnetic stirring apparatus, and stirring at a rotation speed of 10-200rpm to dissolve the polymer so as to obtain a macromolecular solution having uniform properties; and 2. putting the macromolecular solution prepared in Step 1 into a closed injector under the condition of room temperature and 25-75% in humidity, and spinning on electrostatic spinning equipment to obtain the organic nano porous fiber film having a controllable ultra-high specific area. By using the method, the organic nano porous fiber film having an ultra-high specific area can be obtained.

Owner:DONGHUA UNIV

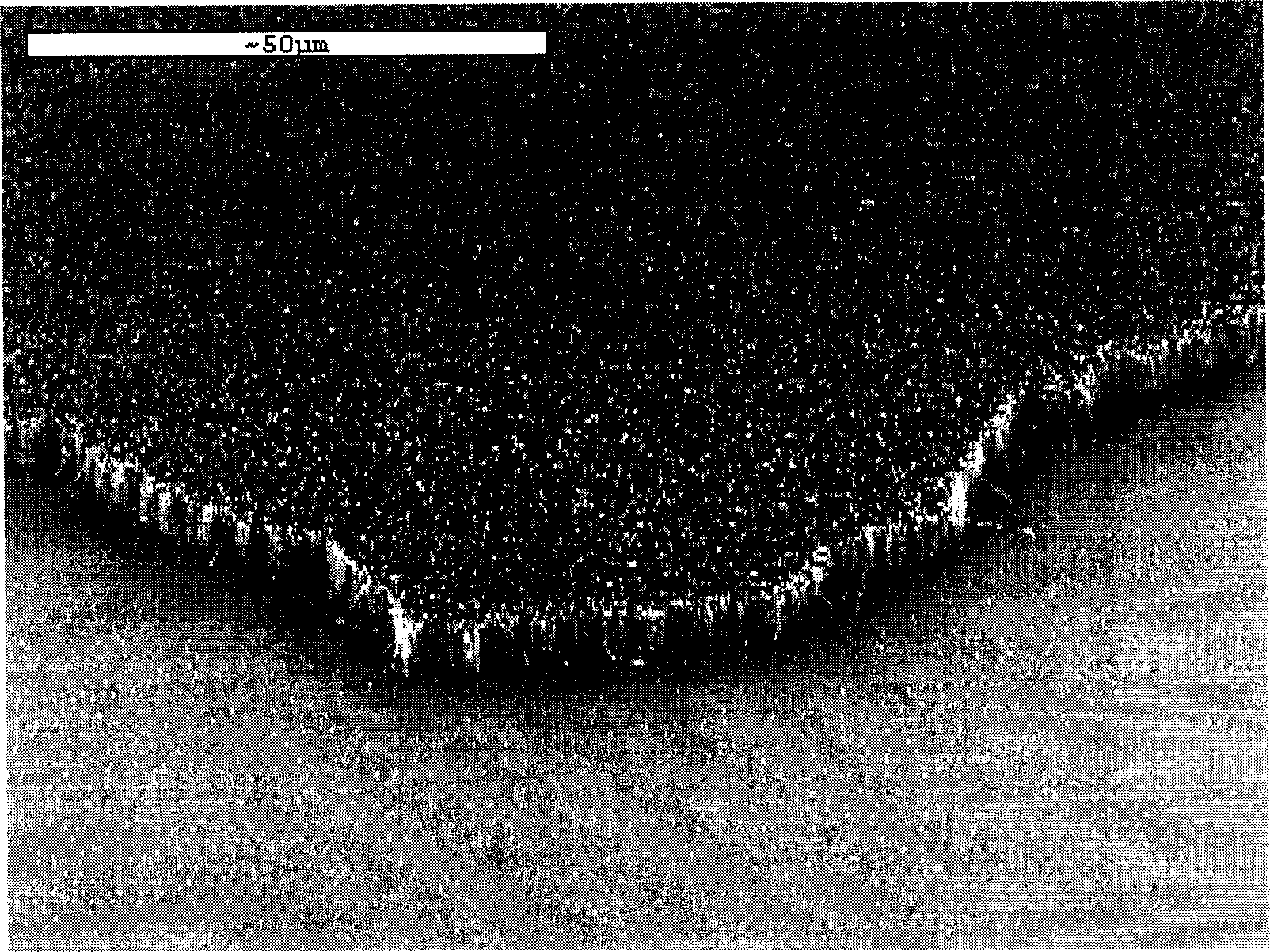

Array nanotube, mfg. method and use thereof

InactiveCN1401560ARegular arrayUniform structureSemiconductor/solid-state device manufacturingNitrogen and non-metal compoundsField emission deviceDisplay device

A carbon nitride nanotube array used for field emission device can be directly grown on the substrate. Its diameter is 20-200 nm. Its length is 1-100 microns. Its N content is 0.5-9%. Its initial emissino field is 1.5-5 V / micron.

Owner:INST OF CHEM CHINESE ACAD OF SCI

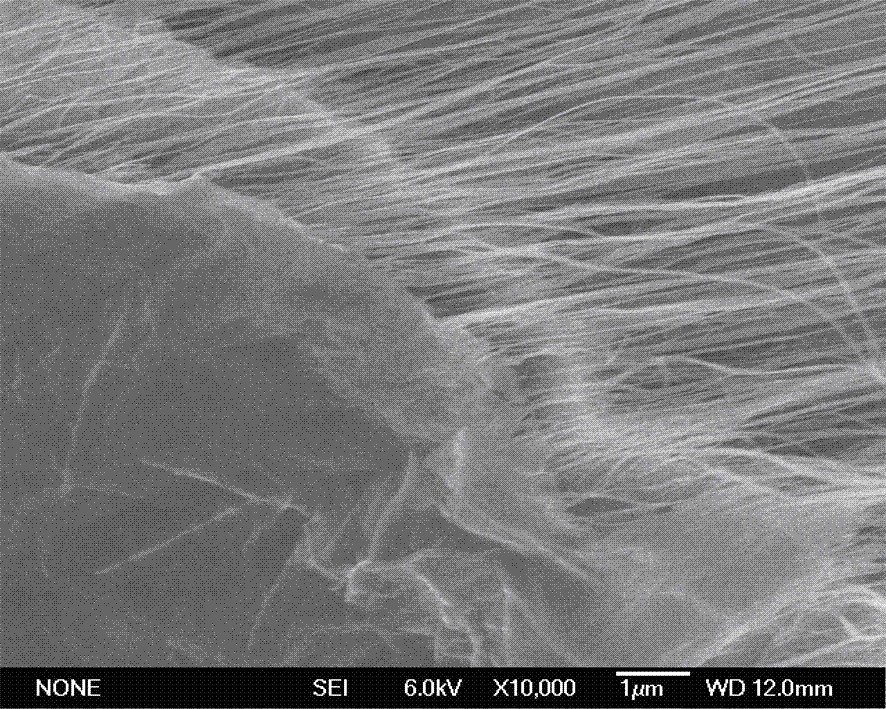

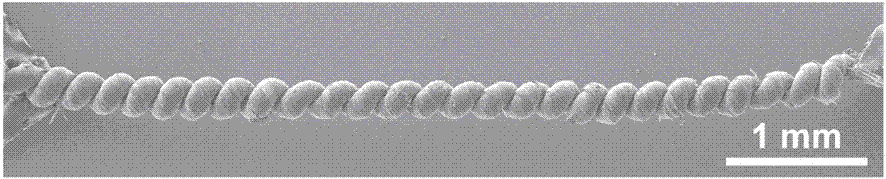

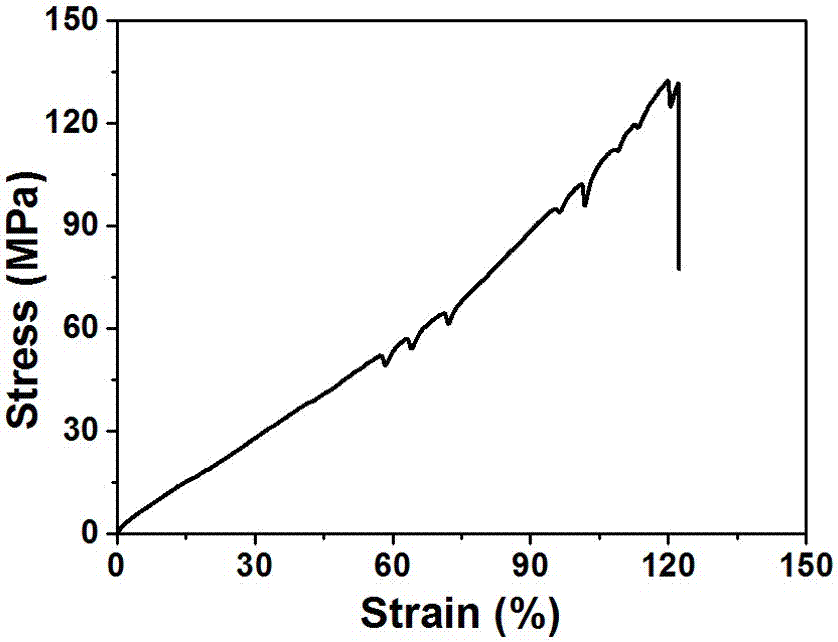

Preparation method of graphene-carbon nanotube composite fiber with helical structure

ActiveCN107043962AControl diameterContinuous and uniform shapeInorganic material artificial filamentsFiberCarbon nanotube

The invention provides a preparation method of a graphene-carbon nanotube composite fiber with a helical structure. The preparation method is used for solving problems in the prior art that mixing of traditional graphene-carbon nanotube composite fiber is not uniform, and large-size product is difficult to prepare. The preparation method comprises following steps: 1, an oxidized graphene aqueous solution is prepared; 2, carbon nanotube film is prepared; 3, a rotating wheel is used for collecting prepared carbon nanotube film, and is immersed in an oxidized graphene aqueous solution at the same time so as to obtain an oxidized graphene and carbon nanotube mixed film; and 4, the oxidized graphene and carbon nanotube mixed film is dried in the air, is collected from the rotating wheel via cutting, is subjected to twisting so as to achieve the helical structure, and then is subjected to chemical reduction so as to obtain the graphene-carbon nanotube composite fiber. The graphene-carbon nanotube composite fiber is unique in structure, and is stretchable; and the resistance changes regularly with deformation in a fiber elastic stretchable range.

Owner:ZHENGZHOU UNIV

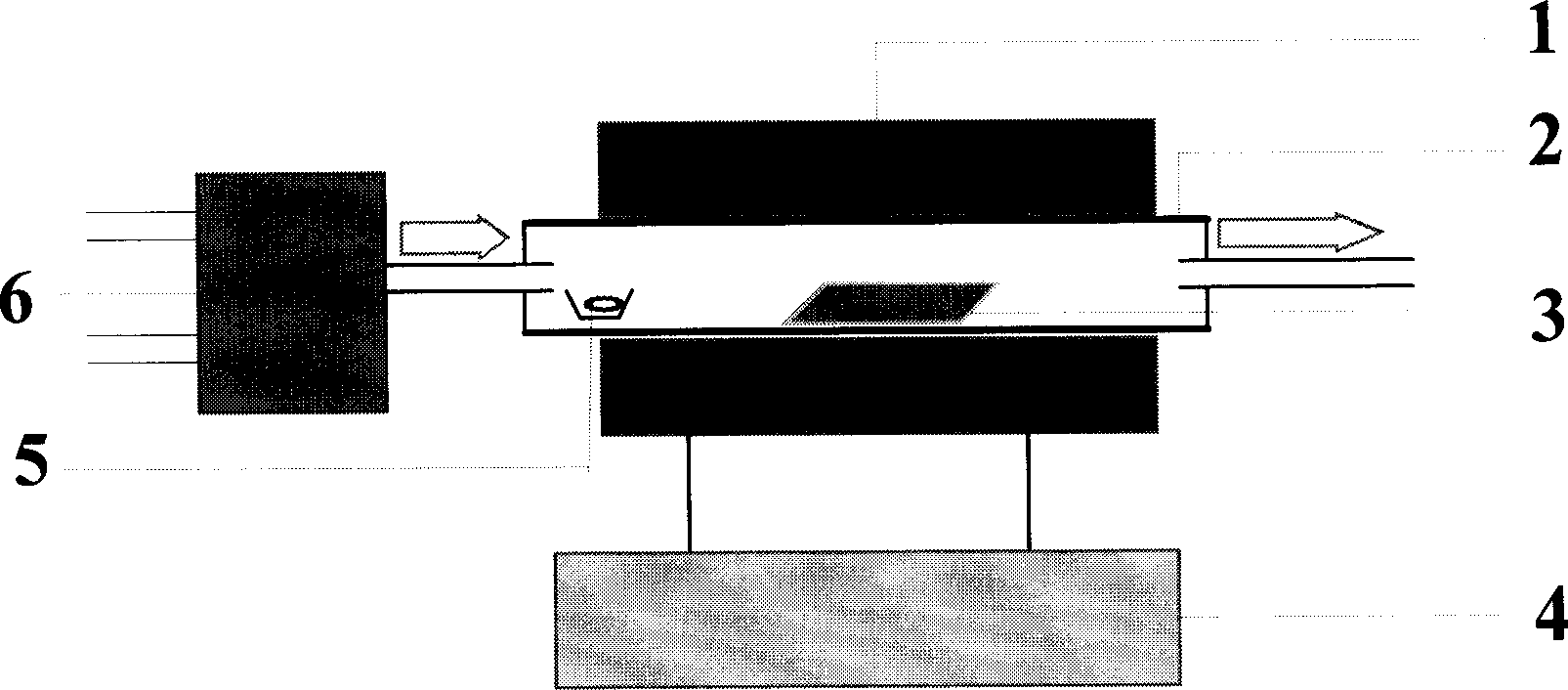

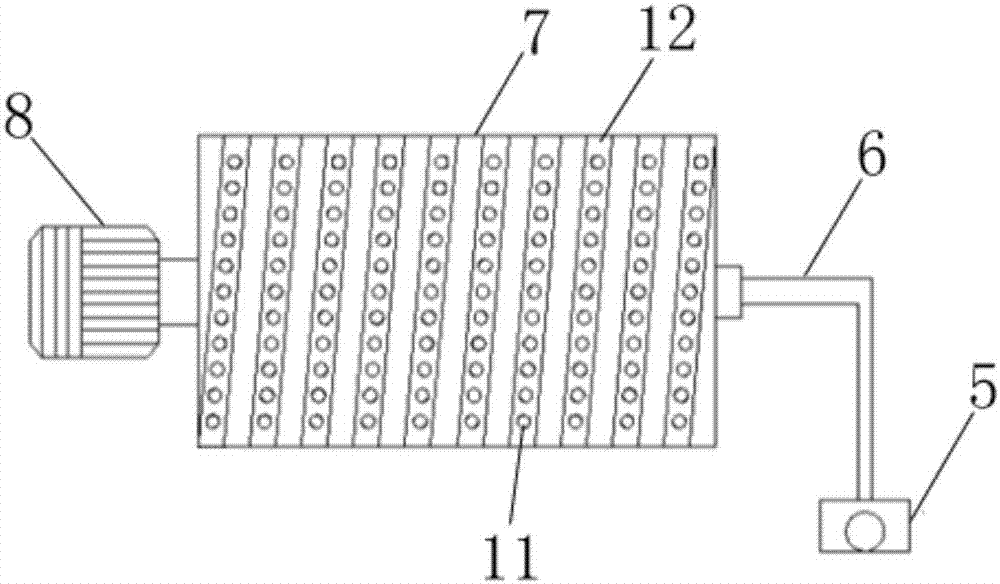

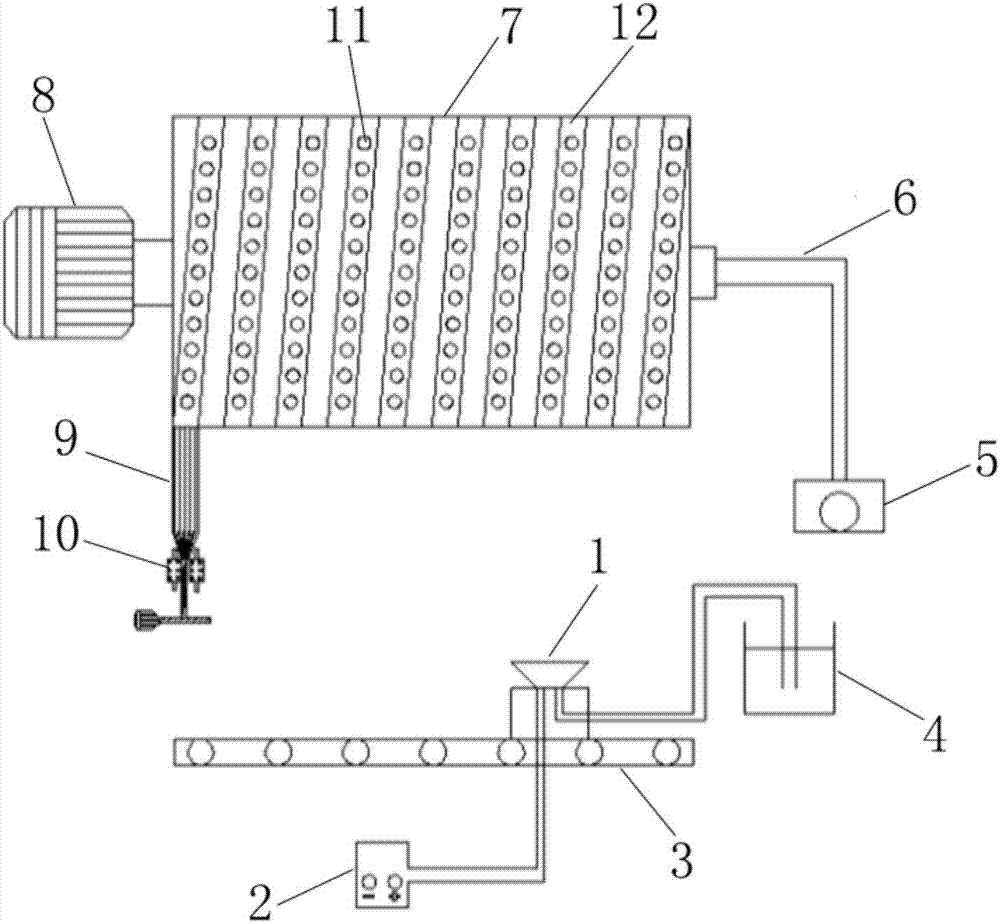

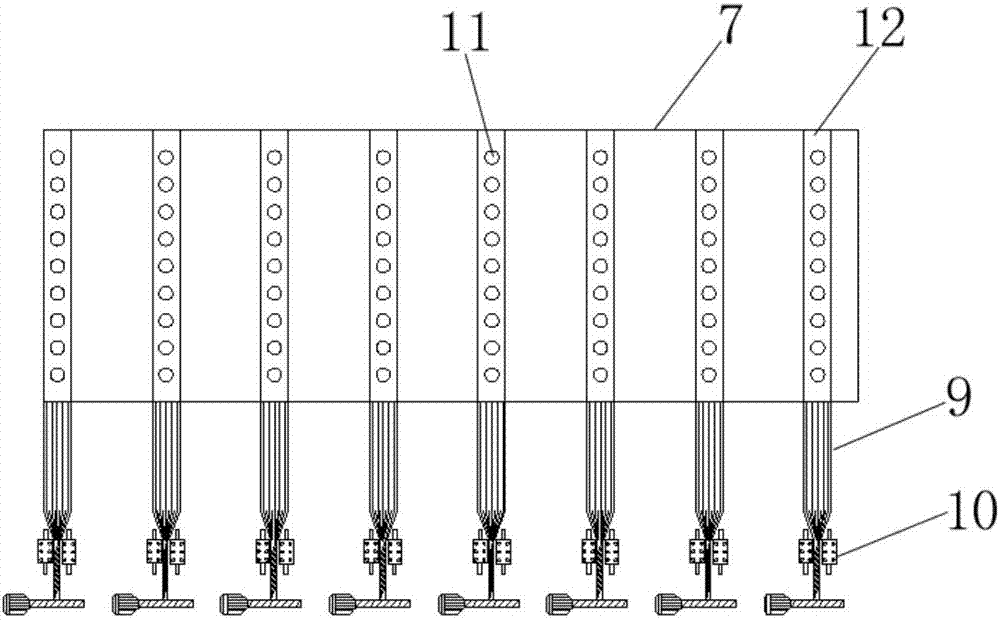

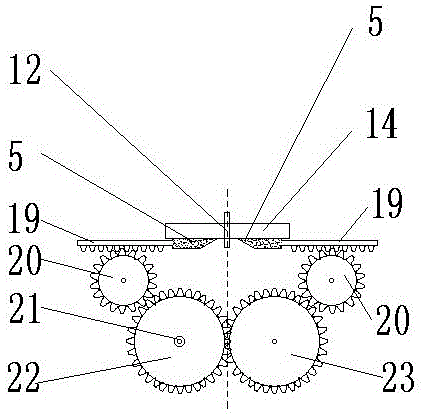

Orientation bundling device, electrostatic spinning device and nanofiber yarn preparation method

ActiveCN107366052AQuality improvementGood orientationFilament/thread formingDrafting machinesFiberYarn

The invention relates to an orientation bundling device, an electrostatic spinning device and a nanofiber yarn preparation method. The orientation bundling device comprises a negative pressure fiber collecting roller, a motor, a communicating device and an exhaust device. Air holes are formed in the surface of the negative pressure fiber collecting roller, the negative pressure fiber collecting roller is drive by the motor to rotate, air is exhausted through the exhaust device to form negative pressure, the electrostatic spinning device further comprises a spinning nozzle, a high pressure electrostatic generator, a sliding rail, an automatic liquid supply device and a twisting winding device, spinning solution jet generated by jetting of the spinning nozzle is received by the negative pressure fiber collecting roller, nanofiber is gathered under the dual effects of high-speed rotation of the negative pressure fiber collecting roller and the negative pressure airflow and achieves orientation in the air hole distribution direction, nanofiber bundles are pulled from the negative pressure fiber collecting roller to the twisting winding device to be twisted and wound to obtain continuous orientation nanofiber yarn. The influence of a twisting triangle region can be effectively weakened, basic parameters of the yarn can be stably controlled, the quality of the nanofiber yarn can be improved, and the yield of the nanofiber yarn can be increased.

Owner:SICHUAN SHENGSHAN BAIYULAN IND CO LTD

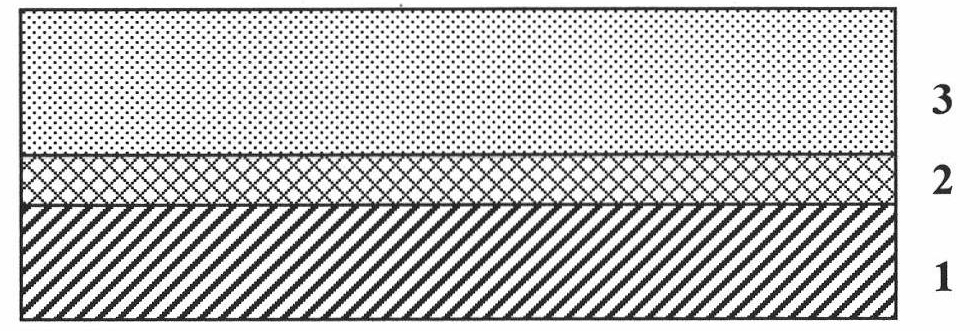

TiO2 nanowire array film light anode and preparation method thereof

InactiveCN101976611AControl diameterLow densityLight-sensitive devicesSolid-state devicesSolar batteryElectron transfer

The invention discloses a TiO2 nanowire array film light anode and a preparation method thereof. The structure of the light anode comprises common glass, an F-doped SnO2 transparent conducting film and a TiO2 nanowire array film. The preparation method comprises the following step of directly synthesizing the TiO2 nanowire array film which is used as a light anode of a dye-sensitization solar battery on a FTO (Tin Oxide) glass substrate by using the mixture of concentrated hydrochloric acid, deionized water and tetrabutyl titanate as a reaction precursor in a hydrothermal synthesis technique. The method controls the diameters and densities of nanowires by changing the ratio of the concentrated hydrochloric acid to the deionized water in the reaction precursor and the concentration of the tetrabutyl titanate, controls the lengths of the TiO2 nanowires by changing reaction time, and ensures that the electrode has higher light capturing efficiency, improves the transporting capacity of photon-generated carriers and reduces the compounding process of the photon-generated carrier by utilizing higher light utilization rate and favorable electron shifting properties of the TiO2 nanowires, thereby improving the photoelectric conversion efficiency of the dye-sensitization solar battery.

Owner:GUANGDONG UNIV OF TECH

Method for repairing nano stick of zinc oxide in even diameter

InactiveCN1686820ALow costSimple processZinc oxides/hydroxidesLithium hydroxideZinc Acetate Dihydrate

The method for preparing zinc oxide nano rod with uniform diameter includes the following steps: (1) dissolving zinc acetate in absolute ethanol or absolute methanol, fully stirring them at zero deg.C to obtain suspended liquor whose concentration is 0.5-30%, dissolving lithium hydroxide in absolute ehtanol or absolute methanol at room temperature to obtain lithium hydroxide solution whose molar concentration is twice that of zinc acetate; (2). under the temperature of zero deg.C drop-by-drop adding isopyknic lithium hydroxide solution to stirring zinc acetate solution to obtain white colloidal mixed solution; (3) placing said colloidal solution into a hydrothermal reactor, sealing said reactor, heat-insulating for 5-24 hr, at 80-200 deg.C, and taking out reaction solution; and (4). centrifugally-separating reaction solution, fully washing separated material by using absolute ethanol, drying at room temp. so as to obtain the invented product.

Owner:ZHEJIANG UNIV

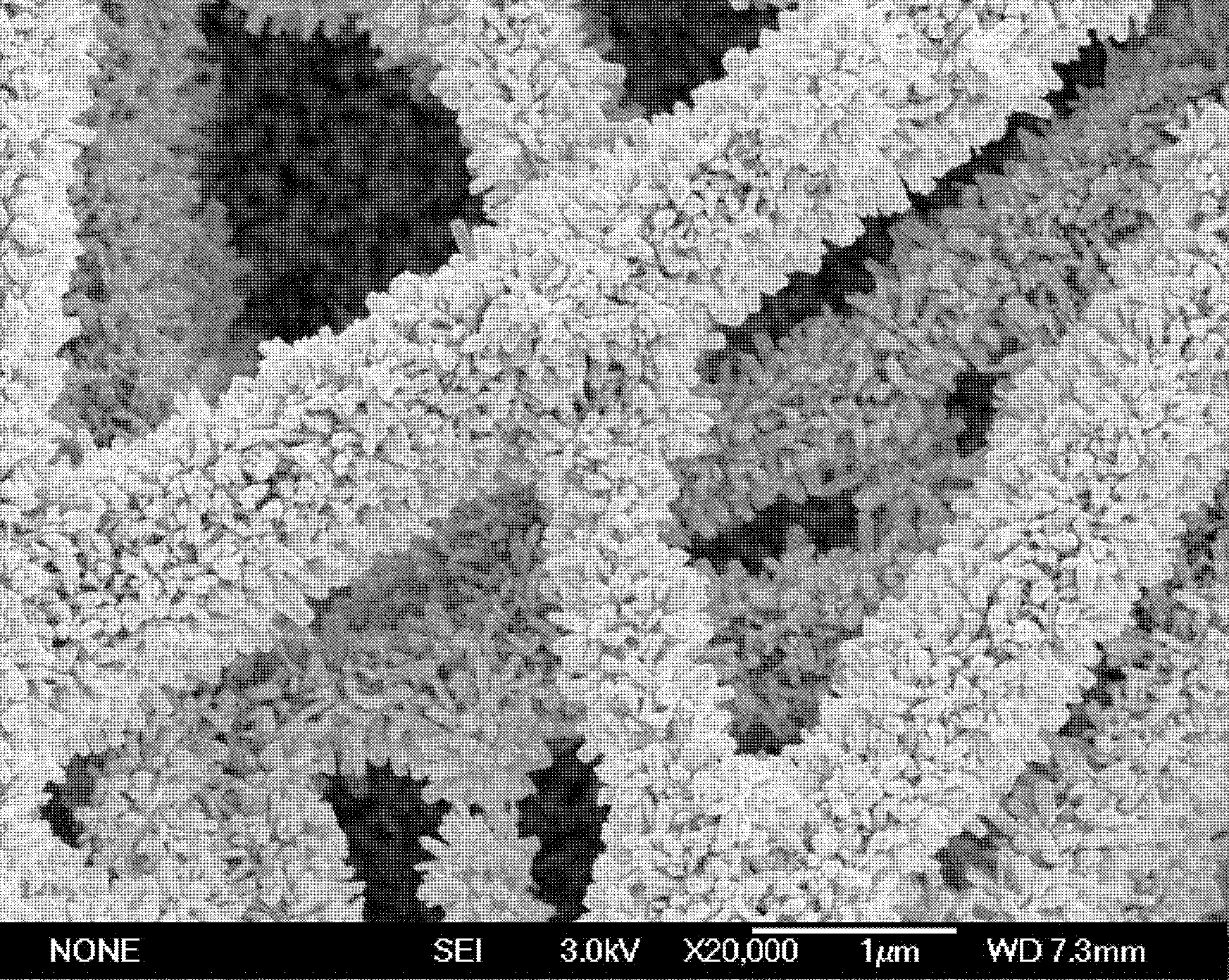

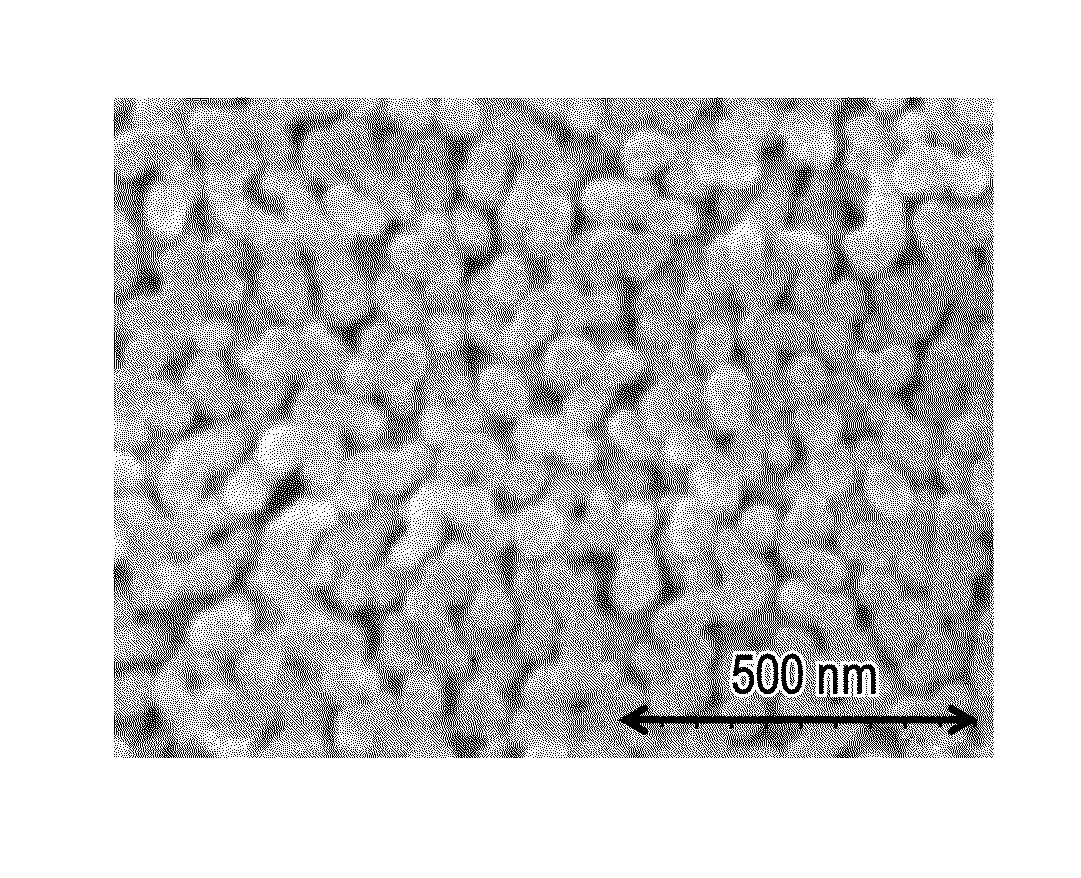

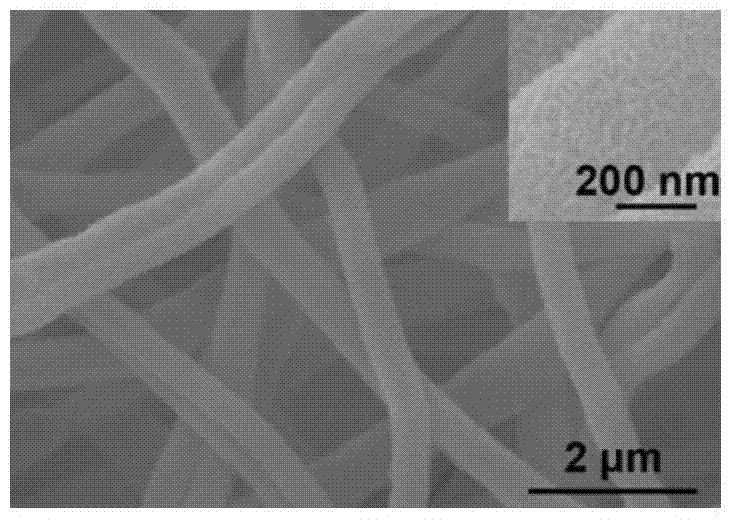

Underwater self-cleaning superoleophobic mineralized fibrous film and preparation method thereof

InactiveCN102758262AOvercome the disadvantage of being easy to wearStable oleophobic propertiesFilament/thread formingNon-woven fabricsFiberComposite film

The invention belongs to the field of self-cleaning organic / inorganic composite films, and particularly relates to an underwater self-cleaning superoleophobic mineralized fibrous film with a non-woven fabric structure and a preparation method of the underwater self-cleaning superoleophobic mineralized fibrous film. The underwater self-cleaning superoleophobic mineralized fibrous film with the non-woven fabric structure is produced by the following steps: a polymer fibrous film with the non-woven fabric structure and containing a mineralizing regulator is obtained by an electrostatic spinning method; the fiber surface of the polymer fibrous film is controllably mineralized by a biomineralization method so as to obtain the organic / inorganic composite underwater self-cleaning superoleophobic mineralized fibrous film with good stability. In air, the invasion of the film surface is hydrophilic; in water, the invasion of the surface is superoleophobic; and in water, the contact angle of the film surface to oil is more than 150 degrees.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for manufacturing porous glass, and method for manufacturing optical element

A method for manufacturing a porous glass includes: forming a phase-separated glass by heating at a temperature in a range of 300 to 500 degrees Celsius for 3 to 50 hours for phase separation of a glass body in which the concentration of SiO2 is 50 to 70 percent by weight, the concentration of B2O3 is 15 to 40 percent by weight, the concentration of Li2O is 1.0 to 8.0 percent by weight, the concentration of Na2O is 2.0 to 8.0 percent by weight, the concentration of K2O is 0.3 to 5.0 percent by weight, the total concentration of Li2O, Na2O, and K2O is 3.5 to 15 percent by weight, and the ratio of the concentration of K2O to the total concentration of Li2O, Na2O, and K2O is 0.10 to 0.30; and forming a porous glass by etching the phase-separated glass.

Owner:CANON KK

Method for synthesizing superfine silver nanowires through light triggering conducted in aqueous solution

ActiveCN106563812ASmall sizeControl diameterMaterial nanotechnologyTransportation and packagingSeed crystalMaterials science

The invention discloses a method for synthesizing superfine silver nanowires through light triggering conducted in an aqueous solution. The method comprises the steps of heating a mixed solution of sodium citrate and polyvinylpyrrolidone, so that the mixed solution has reducibility; adding a silver nitrate solution, and meanwhile conducting illumination with blue light to trigger nucleation; then screening seed crystals with hydrogen peroxide as an etching agent, so that small silver nanowire seed crystals high in purity are obtained; and conducting three cycles of continuous growth, so that the superfine silver nanowires with the diameter ranging from 8 nm to 20 nm and the length ranging from 1 micron to 30 microns are obtained. By means of the method, the blank of silver nanowires with the diameter ranging from 10 nm to 20 nm is filled up; the superfine silver nanowires prepared through the method are quite suitable for being used for preparing transparent conducting thin films; and the haze situation caused by the large diameter of a nanowire can be effectively improved. Compared with a traditional polyhydric alcohol method, the method is easy to operate and short in experimental cycle.

Owner:SOUTHEAST UNIV

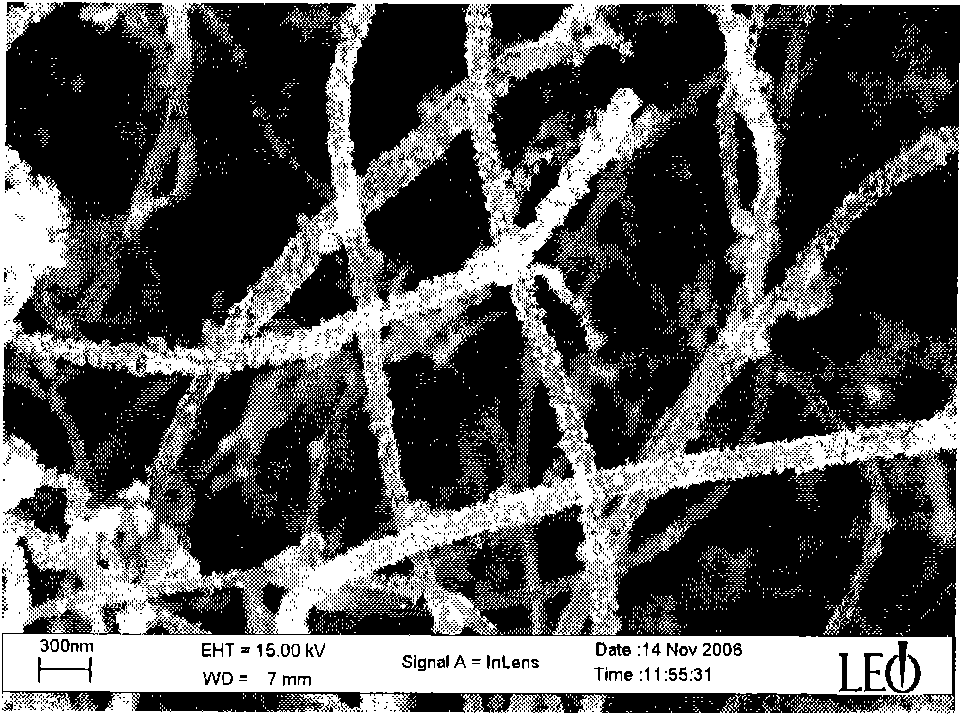

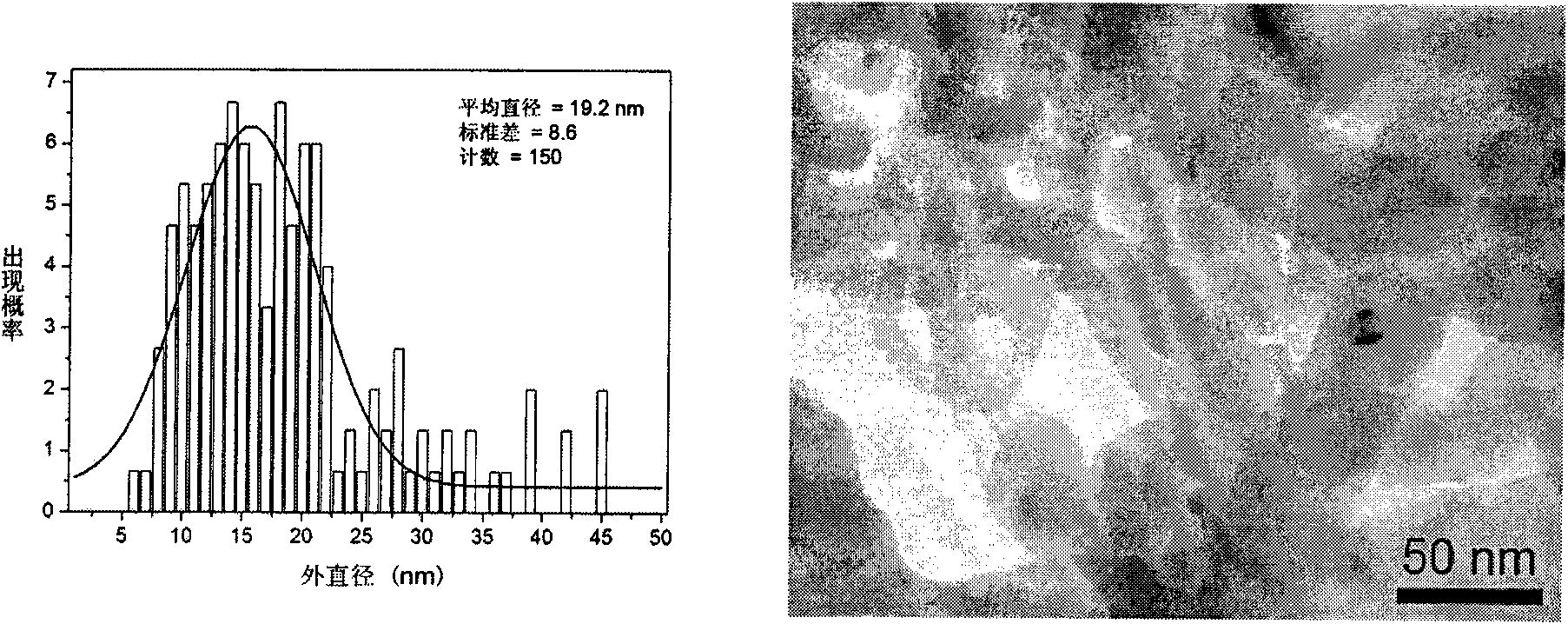

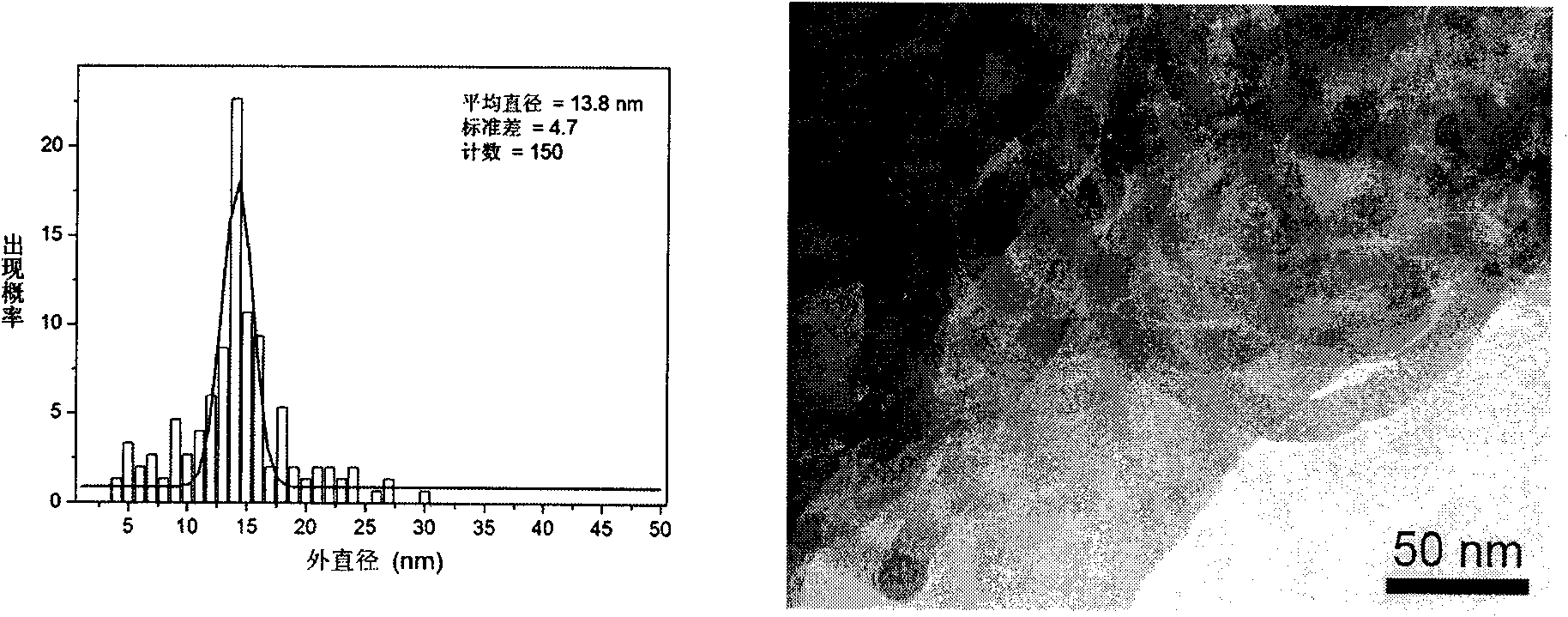

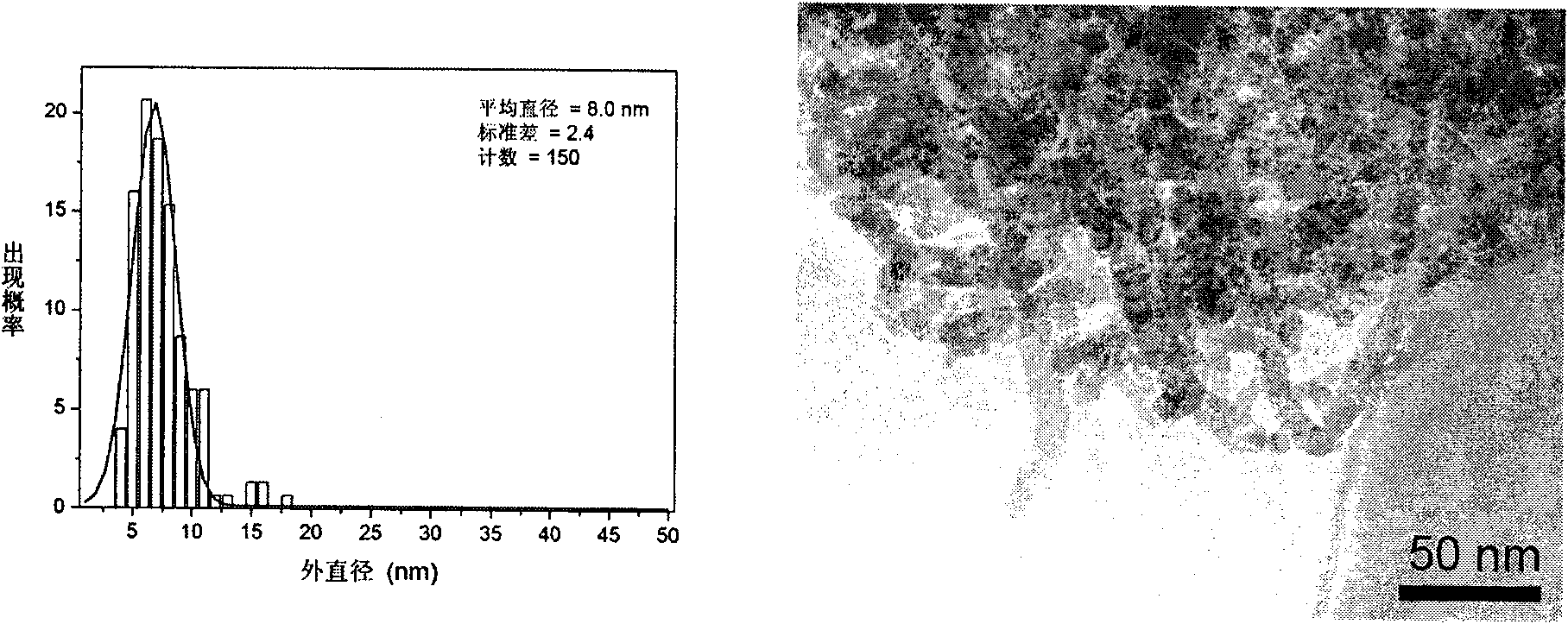

Method for preparing magnetic metal particle modified carbon nanotube

The invention relates to a carbon nanotube preparation technique, in particular to a method for preparing a magnetic metal (iron, cobalt or nickel) particle modified carbon nanotube. The method comprises the following steps: adopting organo-metallic compounds as a carbon source and a catalyst and simultaneously as precursors of the carbon source and the catalyst, wherein the organo-metallic compounds are compounds of organic iron, cobalt or nickel; sublimating the organo-metallic compound catalyst and sufficiently and evenly mixing the organo-metallic compound catalyst with a sulfur-bearing growth promoter in a gaseous state; and putting the mixture into a reaction area to generate the magnetic metal particle modified carbon nanotube under the entrainment of buffer gas, wherein the mol ratio of sulfur to the iron (cobalt or nickel) in the organo-metallic compound is between 0 and 1 / 4. By controlling the sublimation temperature of the organo-metallic compound and the concentration of sulfur atoms in the reaction area, the method achieves the growth of the magnetic metal particle modified carbon nanotube and can control the diameter of the magnetic metal (iron, cobalt or nickel) particle.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

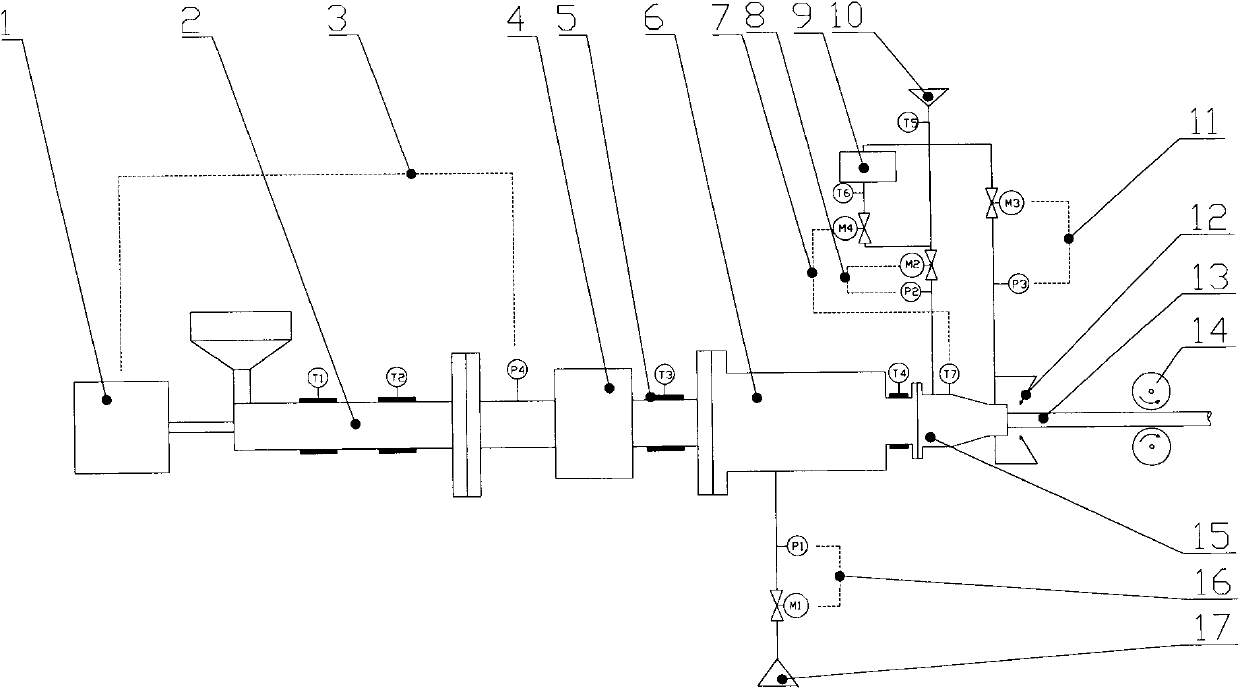

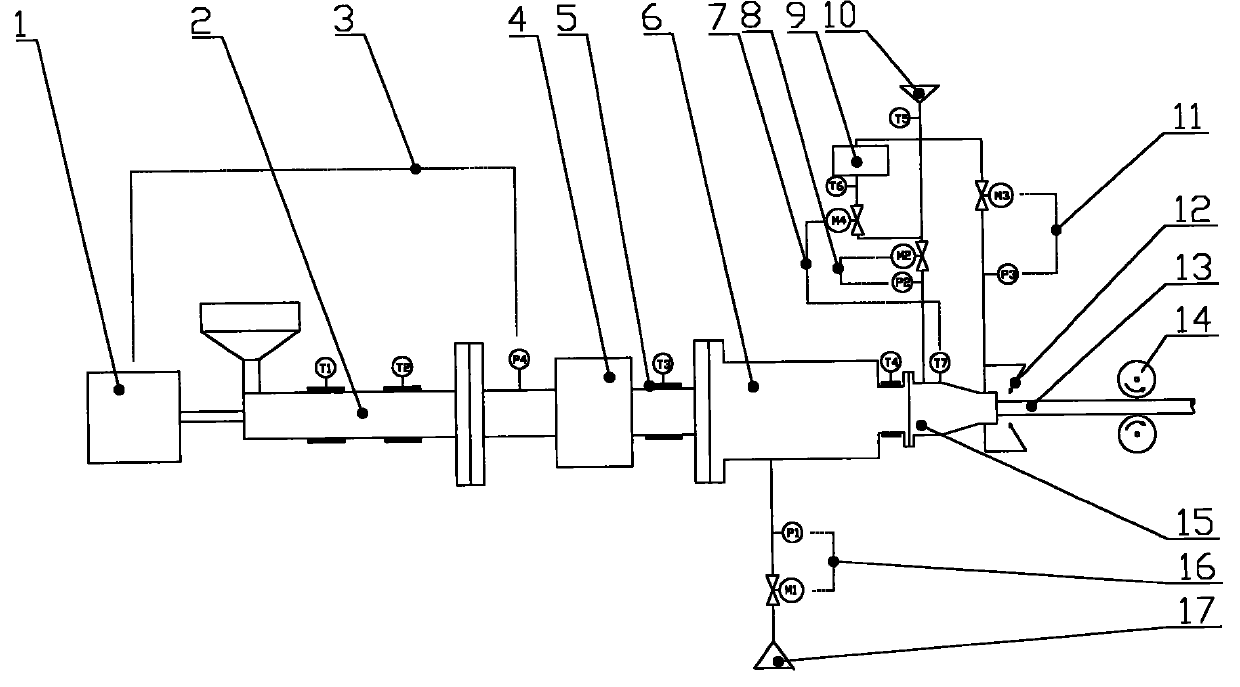

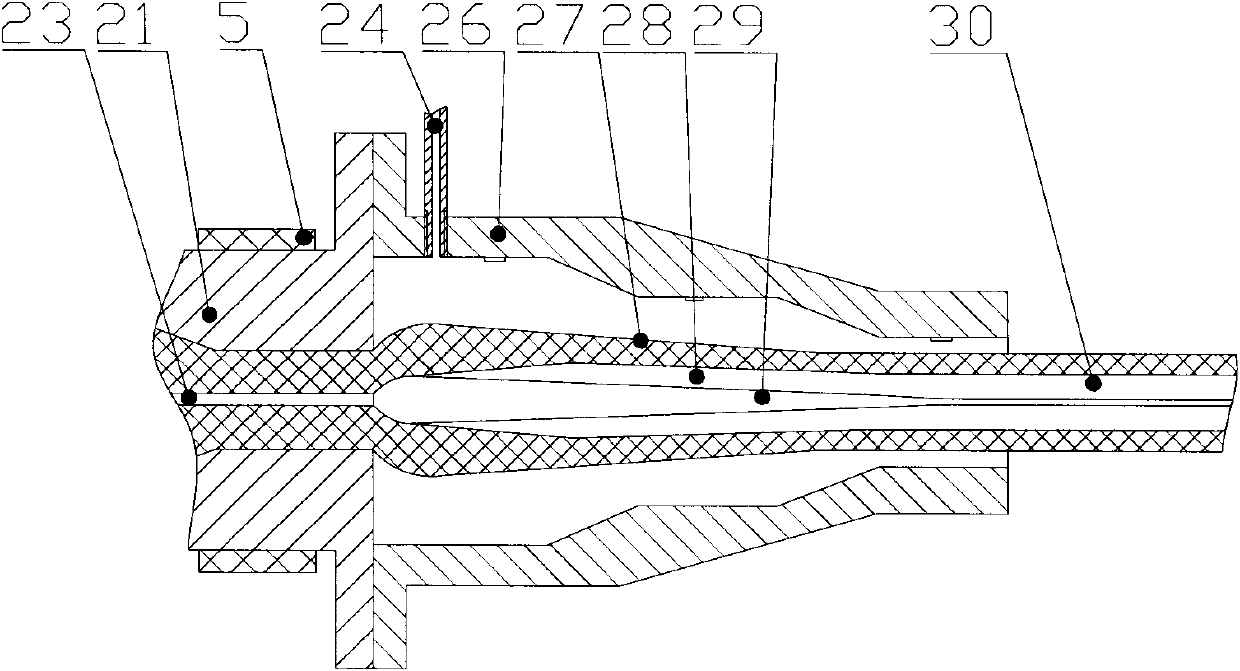

Physical foaming agent injected plastic extruded microchannel molding device and method

The invention discloses physical foaming agent injected plastic extruded microchannel molding device and method. The device comprises a motor, an extruder, a gear pump, a heating ring, a device head, an opening die, a heater, a compressed air supply system, a cooling gas nozzle, a cooling roll, a low-speed depressurization molding die, a foaming agent supply system, a pressure sensor, a temperature sensor and an electric valve. The new method for extruding and molding the high-roundness plastic microchannel has wide application range, high automation degree, simple operation and high molding quality of the plastic microchannel.

Owner:ZHEJIANG UNIV +1

Method for preparing carbon nanofiber

ActiveCN101570329AEfficiently control the size of the diameterControl diameterNanostructure manufactureNumerical controlElectricity

The invention relates to a method for preparing carbon nanofibers (CNFs). The method is to control the diameter size of the carbon nanofiber by an external direct current electric field in a chemical vapor deposition system. The method comprises the following steps: firstly, plating a nickel nanocrystal film on the surface of a prepared substrate by numerical control double-pulsing electrodeposition technology; secondly, placing the electrodeposited substrate and an electrode in a uniform temperature zone of a furnace chamber of the chemical vapor deposition system, and sealing the furnace chamber; thirdly, introducing Ar gas; fourthly, heating the furnace chamber to 600 DEG C; and finally, preparing the carbon nanofibers with uniform diameter under the action of the external direct current electric field. The carbon nanofiber is synthesized by a common CVD system, and has strong practicality; the external electric field is a simple device, and can be operated and controlled easily. Furthermore, the method not only can effectively control the diameter size of the carbon nanofibers (CNFs), but also can lead the diameter size of the carbon nanofibers to be more uniform.

Owner:常熟紫金知识产权服务有限公司

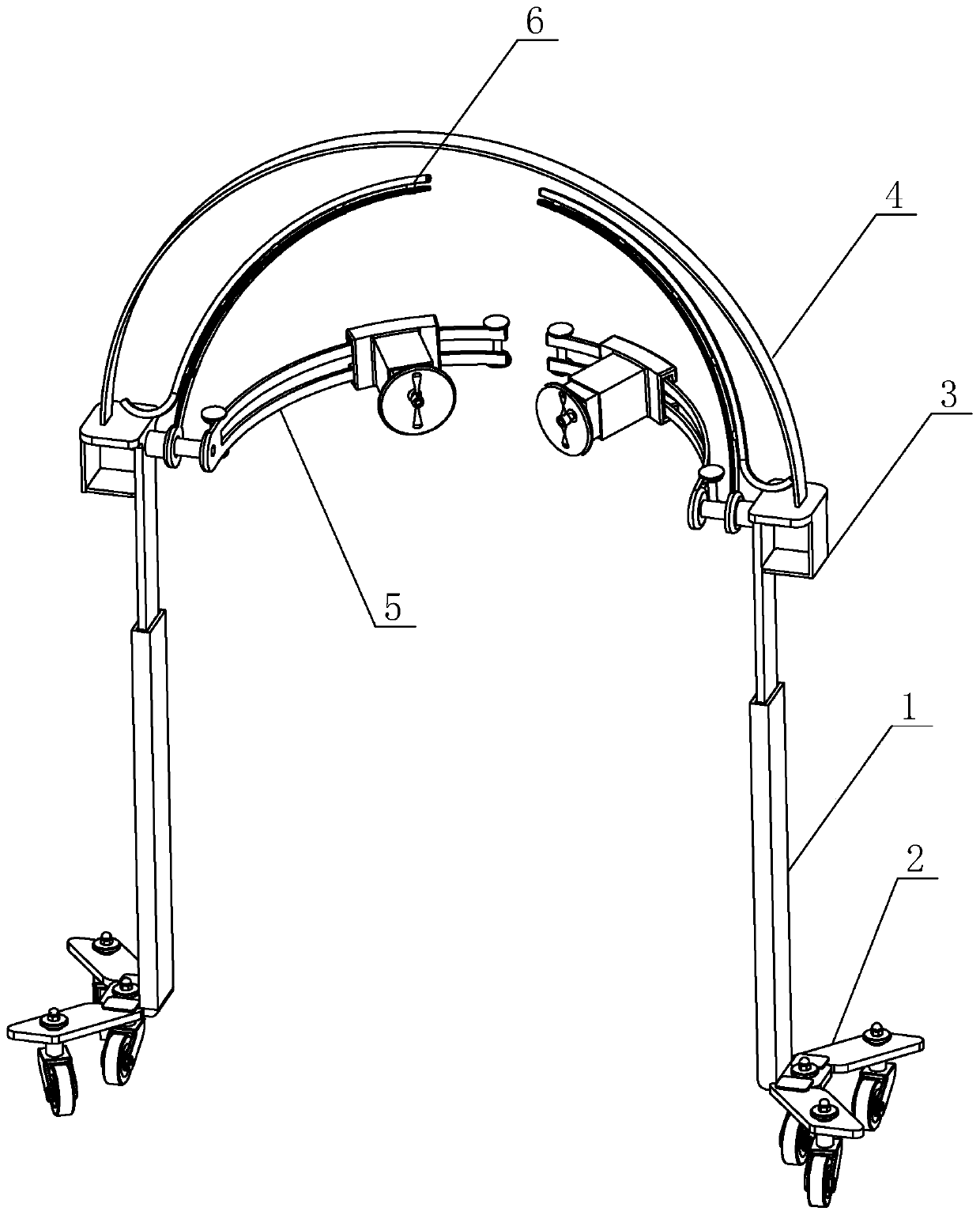

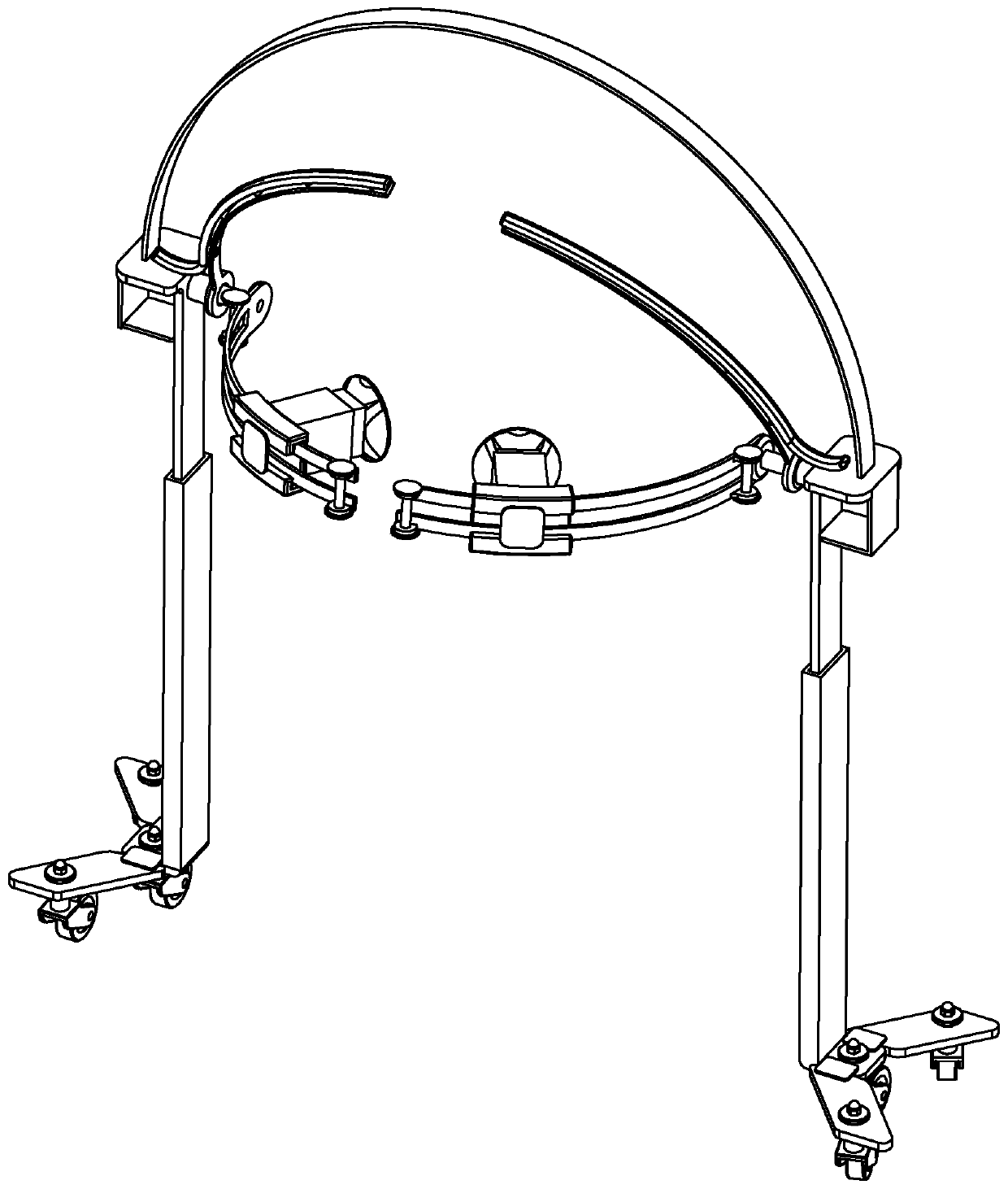

Road flower bed shrub pruning equipment and method

InactiveCN110622718ARegular shape standardControllable size and positionHedge trimming apparatusCuttersEngineeringMechanical engineering

The invention discloses road flower bed shrub pruning equipment and method and mainly relates to the technical field shrub pruning. The road flower bed shrub pruning equipment comprises a support module and a work module and is characterized in that the support module is used for supporting the equipment, and corner wheels are mounted at the bottom of the support module; the work module is fixed on the support module and comprises two oppositely arranged arc-shaped guide rails, a slide platform is slidably connected to each arc-shaped slide rail, the sliding, relative to the corresponding arc-shaped guide rail, of each slide platform is driven by electric power, two ends of each arc-shaped guide wheel are respectively provided with a drive belt wheel and a driven belt wheel, each drive belt wheel is driven through a motor, a mounting seat is arranged on each slide platform, each mounting seat is a structure which can telescope inwardly, the telescoping end of each mounting seat is provided with a rotary blade driven by electric power, an arc-shaped rack is arranged outside the arc-shaped guide rails, the arc-shaped rack is coaxial with the arc-shaped guide rails, and blowing pipesare fixed to the arc-shaped rack along the extension direction of the arc-shaped rack and provided with blowing air holes. The road flower bed shrub pruning equipment has the advantages that shrub balls can be fast and efficiently pruned, and standardized, precise and efficient pruning is achieved.

Owner:浙江宁围环境服务有限公司

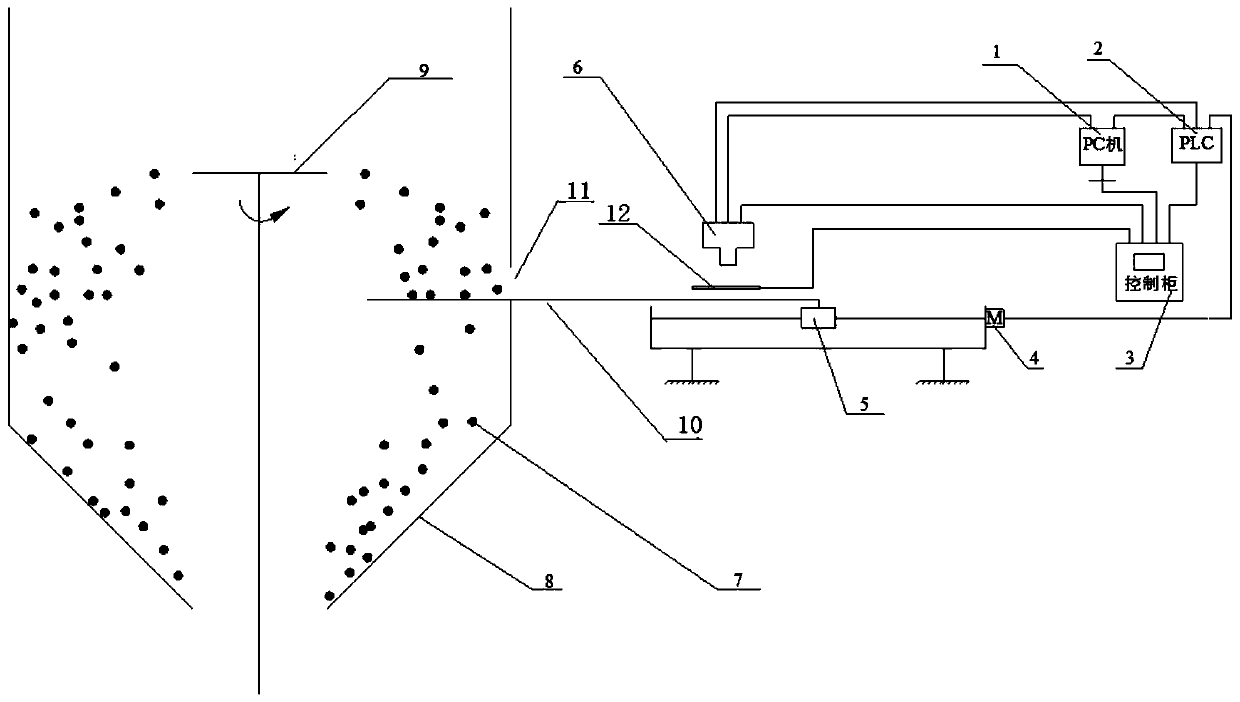

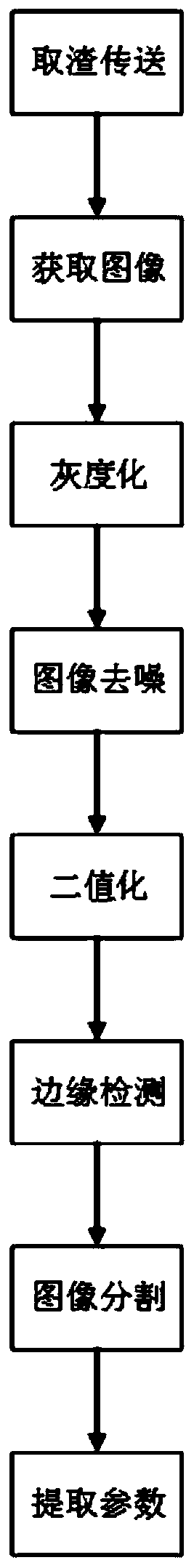

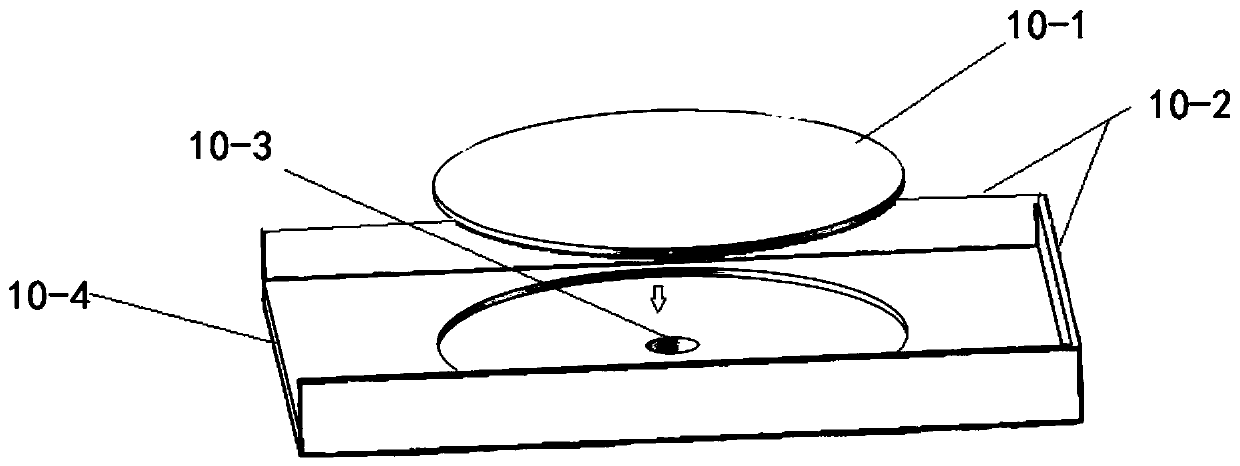

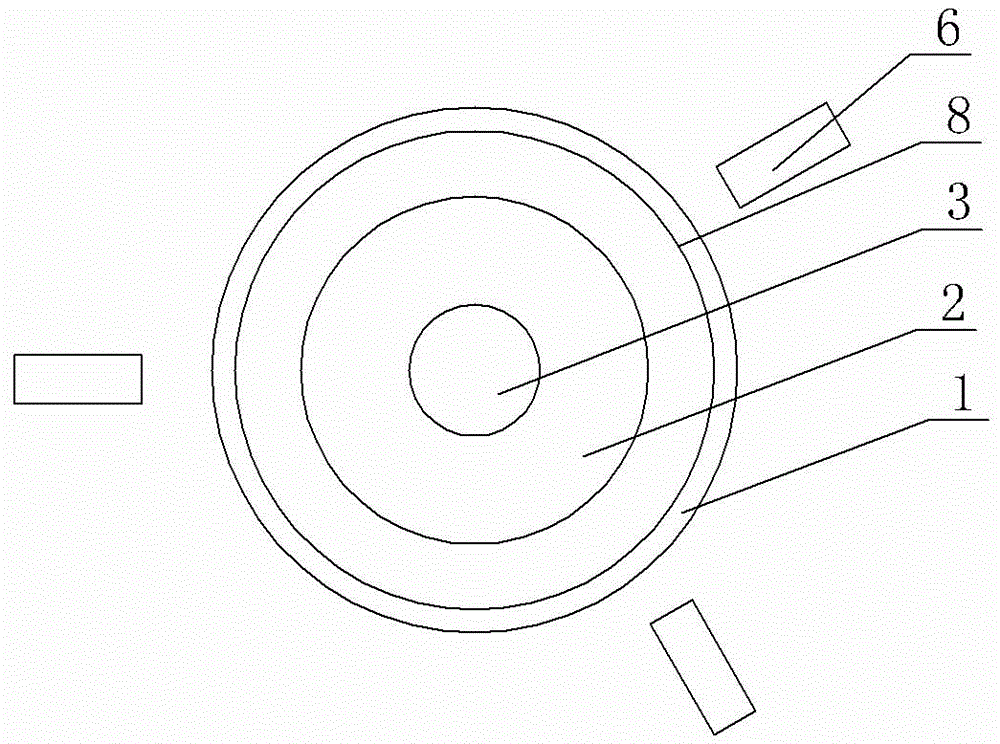

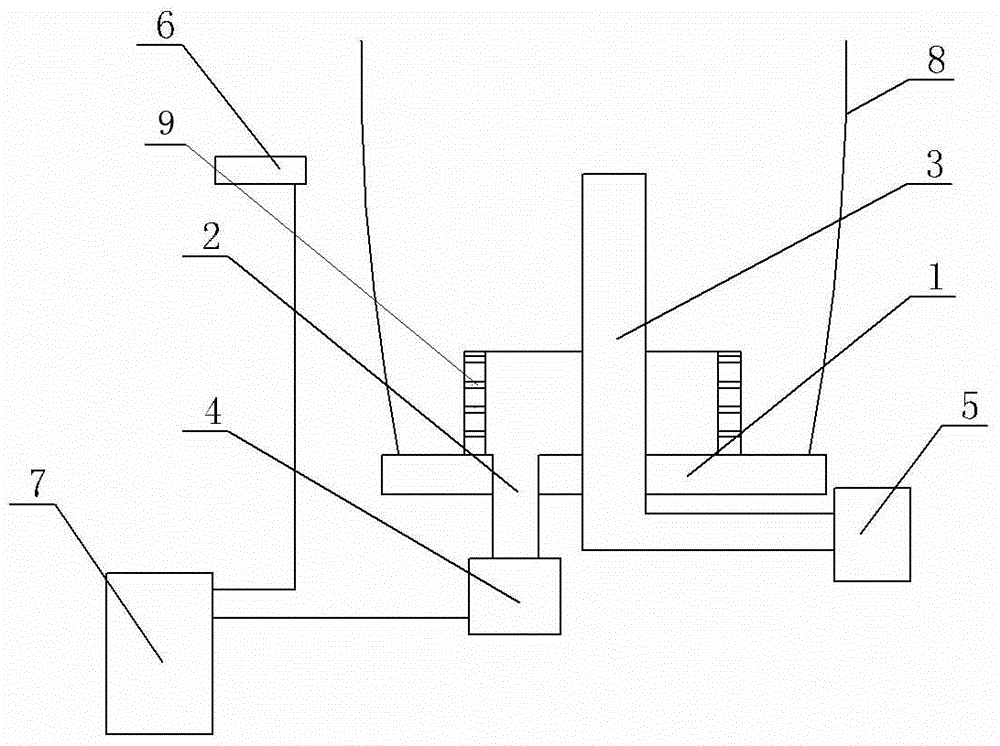

Blast furnace slag centrifuging and pelletizing particle size detecting system and method based on image recognition

InactiveCN110218824AControl diameterOvercome technical issues that cannot be measured in real timeCharacter and pattern recognitionParticle size analysisSlagParticle size measurement

The invention discloses a blast furnace slag centrifuging and pelletizing particle size detecting system and method based on image recognition. The detecting system comprises a control unit, a slag taking device and an image acquisition unit, wherein the slag taking device carries out sampling on slag particles obtained after the blast furnace slag is centrifuged and pelletized; the image acquisition unit collects the images of the slag particles; the control unit detects and analyzes the sizes of the slag particles according to the collected images to obtain the detecting data of the sizes ofthe slag particles; and the control unit is connected with the slag taking device and the image acquisition unit. According to the detecting system, the image acquisition unit is arranged to collectthe images of the slag particles, the data of the size of the slag particles is obtained after image analysis, the soft measurement method is adopted to solve the technical problem that the particlesof the blast furnace slag cannot be measured in real time due to high temperature, and the real-time performance and the precision of blast furnace slag centrifuging and pelletizing particle size measurement are improved. A blast furnace slag pelletizing device can be adjusted and controlled in real time according to the size data of the slag particles to control the particle diameter in real timeand ensure the heat recovery efficiency of mechanical centrifuging and pelletizing of liquid-state slag.

Owner:QINGDAO UNIV

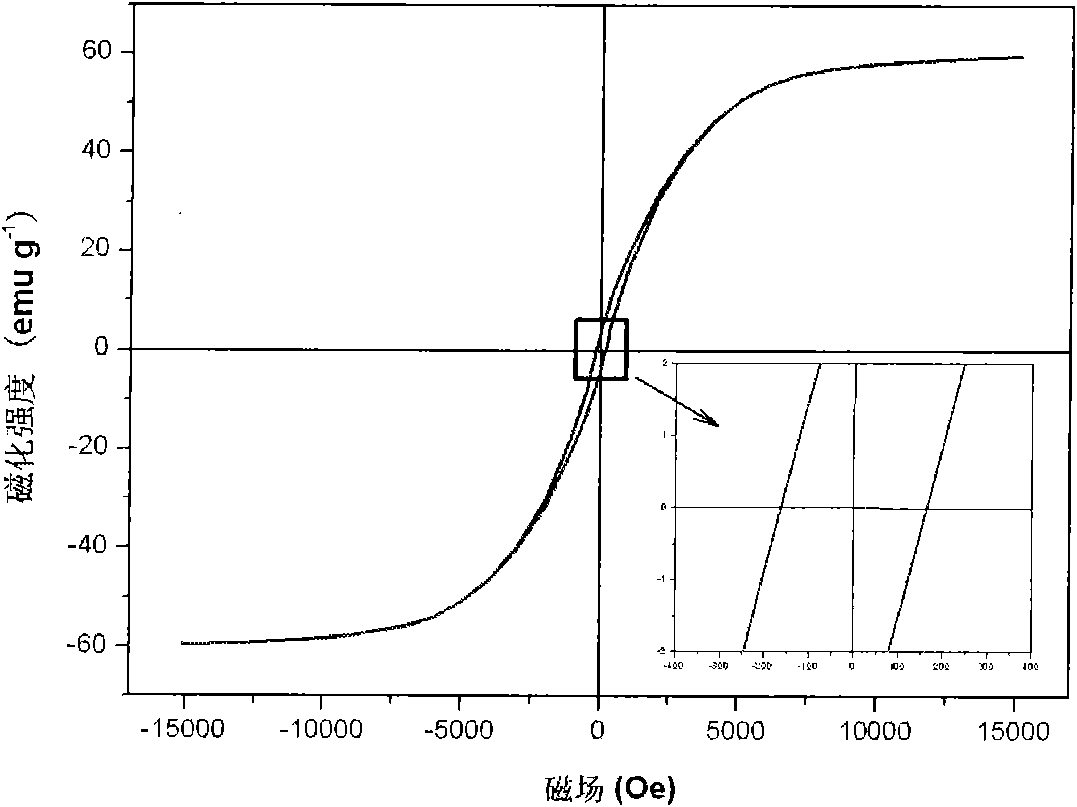

Method for synthesizing magnetic metallic oxide Nano wire in high length-diameter ratio

InactiveCN1761002AVersatilityControl diameterNanostructure manufactureInductances/transformers/magnets manufactureIonCoprecipitation

Through wet chemical method, the invention prepares one-dimensional Nano material of magnetic metallic oxide; especially, the invention is related to composite system of polyalcohol. In water solution of hydrophilic high polymer, using synthesis under metallic ion coprecipitation method obtains Nano wire of magnetic metallic oxide with high length-diameter ratio and even diameter. Adjusting scale among components of polyalcohol and speed for adding components can control length-diameter ratio of Nano wire of magnetic metallic oxide.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

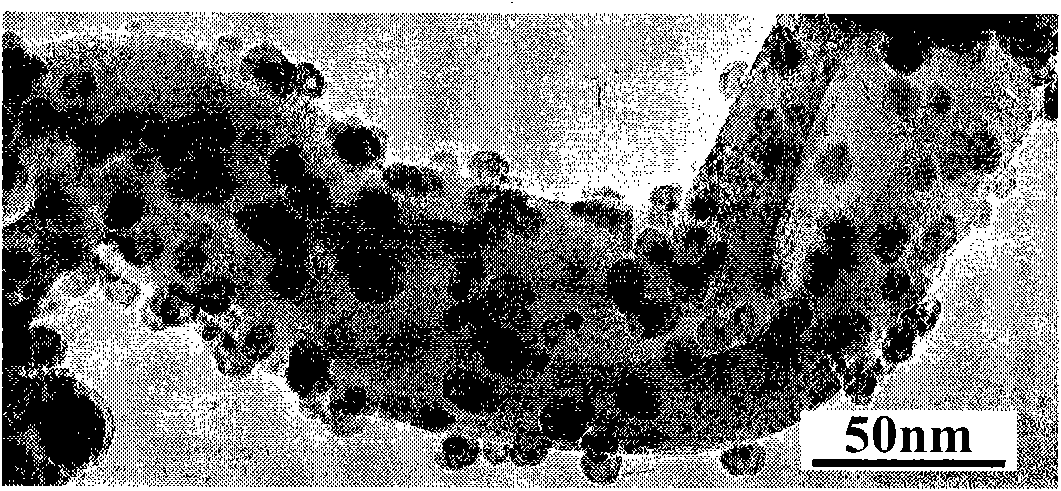

Preparation method of highly-dispersed nano-carbon particles

ActiveCN102910613ASimple processControl diameterMaterial nanotechnologyNano-carbonActive agentTube furnace

The invention discloses a preparation method of highly-dispersed nano-carbon particles, comprising the following steps of: dropwise adding a solution containing 5-10mmol of positive ion surface active agents into a suspension liquid containing 10g of bentonite in a water bath with the temperature of 60-65 DEG C, centrifugally separating, cleaning the obtained solid substance with deionized water, drying and grinding into powder; placing the powder into a tube furnace, introducing N2 for protection, carbonizing at the temperature of 500-800 DEG C for 4-6h, continuously introducing N2 again, cooling to the room temperature, placing 2-4g of the carbonized solid substance into a bottle, adding 10-15mL of hydrofluoric acid solution with the concentration of 20-40%, carrying out solid-liquid separation, and then, adding the hydrofluoric acid solution into 10-15mL of hydrochloric acid solution with the concentration of 20-40%; and carrying out solid-liquid separation, cleaning with deionized water and drying at the temperature of 60-70 DEG C for 5-6h to obtain the highly-dispersed nano-carbon particles. The preparation method is simple in process; and negative ion surface active agents and pollutants in waste water can be simultaneously removed by adding a small number of the highly-dispersed nano-carbon particles.

Owner:江阴智产汇知识产权运营有限公司

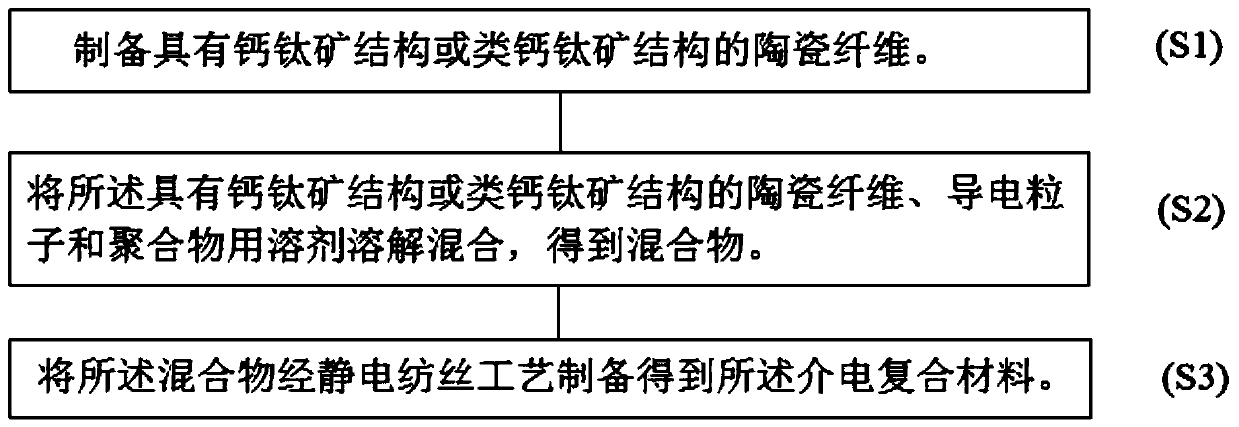

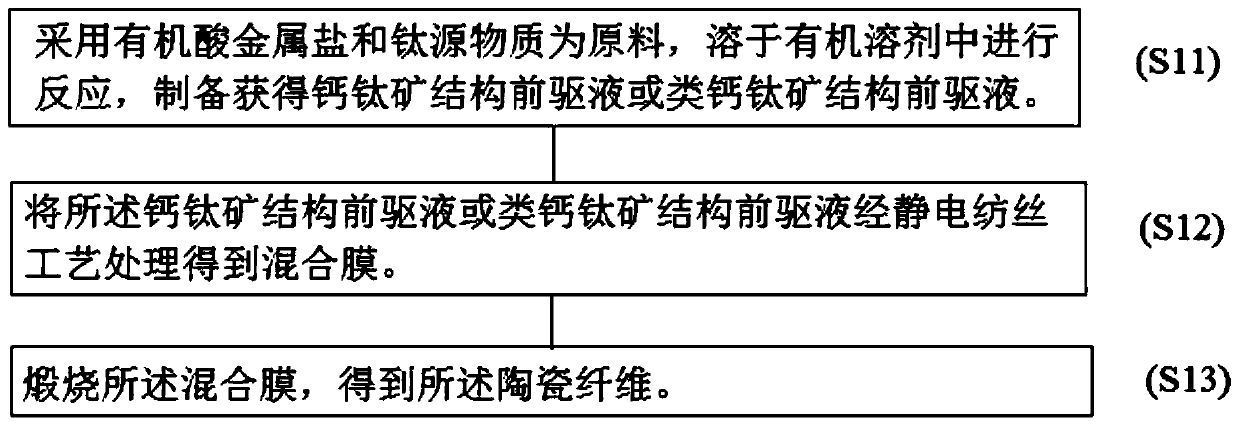

Dielectric composite material and preparation method thereof and flat-plate type capacitor

InactiveCN110016723ASimple preparation processLow costFixed capacitor dielectricElectro-spinningFiberElectrospinning

The invention discloses a dielectric composite material and a preparation method thereof and a flat-plate type capacitor. The preparation method of the dielectric composite material includes the following steps that S1, ceramic fiber having a perovskite structure or perovskite-like structure, conductive particles and polymers are dissolved with a solvent, and a mixture is obtained; S2, after the mixture is subjected to electrostatic spinning, the dielectric composite material is obtained. The invention further discloses the dielectric composite material. The dielectric composite material includes the polymers, the conductive particles and the ceramic fiber, wherein the polymers are filled with the conductive particles and ceramic fiber. The invention further discloses the flat-plate type capacitor based on the dielectric composite material, and the capacitor includes a metal electrode-dielectric composite material-metal electrode sandwich structure. The defects are overcome that in theprior art, the dielectric constant of a composite material is low, the dielectric loss is high, and the application of the composite material in field of intellectualization and miniaturization of electronic components is limited. The invention provides the composite material with a high dielectric constant and low dielectric loss, and the material can be applied to the flat-plate type capacitor.

Owner:SHENZHEN INST OF ADVANCED TECH

Vacuum molding box

The invention discloses a vacuum molding box and solves the problem that lots of spraying water exists in subsequent processing because water flow is retained on the wall of a pipe if molding is implemented after water cooling when a molding device adopts a spraying mode in use. The vacuum molding box comprises a long cylindrical box body and a sprayer which is arranged inside the box body; a conveying roller used for conveying a pipe body is arranged inside the box body; a wiping roller is arranged inside the box body; the axis of the wiping roller is parallel to the axial direction of the box body; the wiping roller leans against the outer wall of the pipe body positioned inside the box body; the wiping roller is fixedly provided with rotating blades; a pneumatic component used for blowing the rotating blades to rotate and driving the wiping roller to rotate toward a direction A is arranged inside the box body; the outer wall of the pipe body is wiped by a rotating shaft of the wiping roller; and thus the water flow on the surface of the pipe body is reduced.

Owner:杭州沃德塑胶有限公司

Preparation method for ultra-long TiO2 nanowire array thin-film photo-anode

InactiveCN104576074AFast electron transportReduce compound lossMaterial nanotechnologyLight-sensitive devicesPhysicsElectron transmission

The invention relates to a preparation method for an ultra-long TiO2 nanowire array thin-film photo-anode, and belongs to the field of dye-sensitized solar cells. The problem that photon-generated carrier composite losses of an existing dye-sensitized solar cell TiO2 nanocrystalline photo-anode are large is solved. The preparation method comprises the steps that a solvothermal synthesis reaction is carried out at a time, an ethyl alcohol, hydrochloric acid and TiCl4 mixed solution is used as a precursor, and an ultra-long one-dimensional TiO2 nanowire array thin film is made to grow on a piece of FTO conductive glass. The TiO2 nanowire array thin film photo-anode is directly applied on the dye-sensitized solar cell; according to the one-dimensional structure, the electron transport speed is high, the photon-generated carrier composite losses are small, and the performance of the dye-sensitized solar cell is improved.

Owner:HARBIN INST OF TECH

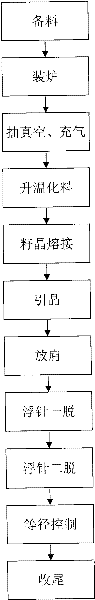

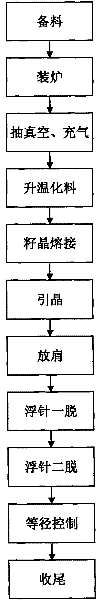

Method for growing gallium phosphide single crystals

InactiveCN102534771AReduce dislocation densityImprove single crystal yieldPolycrystalline material growthUnder a protective fluidChemistrySilicon nitride

The invention relates to a method for growing gallium phosphide single crystals. The method comprises the following steps of: preparing materials, charging, vacuumizing, filling gas, heating for dissolving, welding seed crystals, seeding, shouldering, removing a floating needle for the first time, removing the floating needle for the second time, performing equal-diameter control, and ending, wherein gallium phosphide polycrystals, a floating boat, a doping agent and boron oxide are put into a crucible in the material preparation process, the floating boat is made of silicon nitride and has the internal diameter of phi20 to 80mm, and pressure is controlled to be 1.0 to 5.0MPa (absolute pressure) after a hearth is filled with nitrogen. The method has the advantages that: the diameter of the crystals is controlled by the floating boat, the density of the floating boat is between the density of the boron oxide and the density of gallium phosphide, the floating boat can float on a melting surface of the gallium phosphide, and the diameter is slightly influenced by the ascending or descending of a solid liquid interface in the floating boat due to temperature change, so the diameter of the crystals can be well controlled by controlling the rotating speed of the floating boat, the gallium phosphide single crystals with the size of 1 to 3 inches are grown, the yield of the single crystals is improved, the crystallization quality of the single crystals is high, and a mobility index in electrical parameters can stably reach 130-140cm<2> / v.s.

Owner:GRINM ELECTRO OPTIC MATERIALS

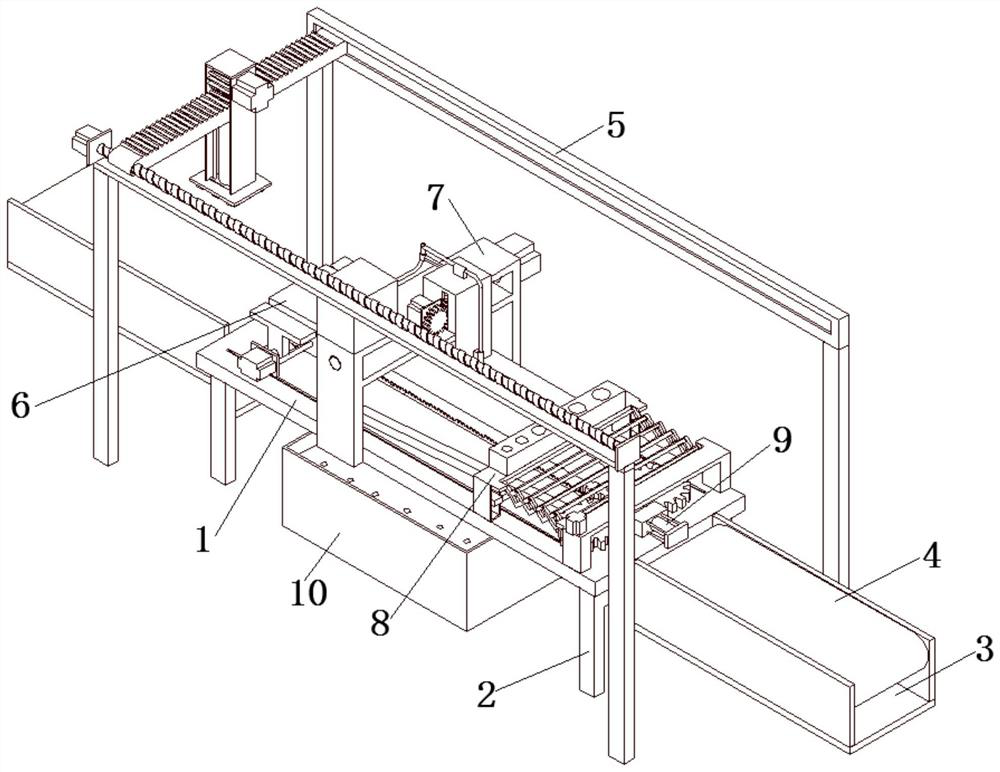

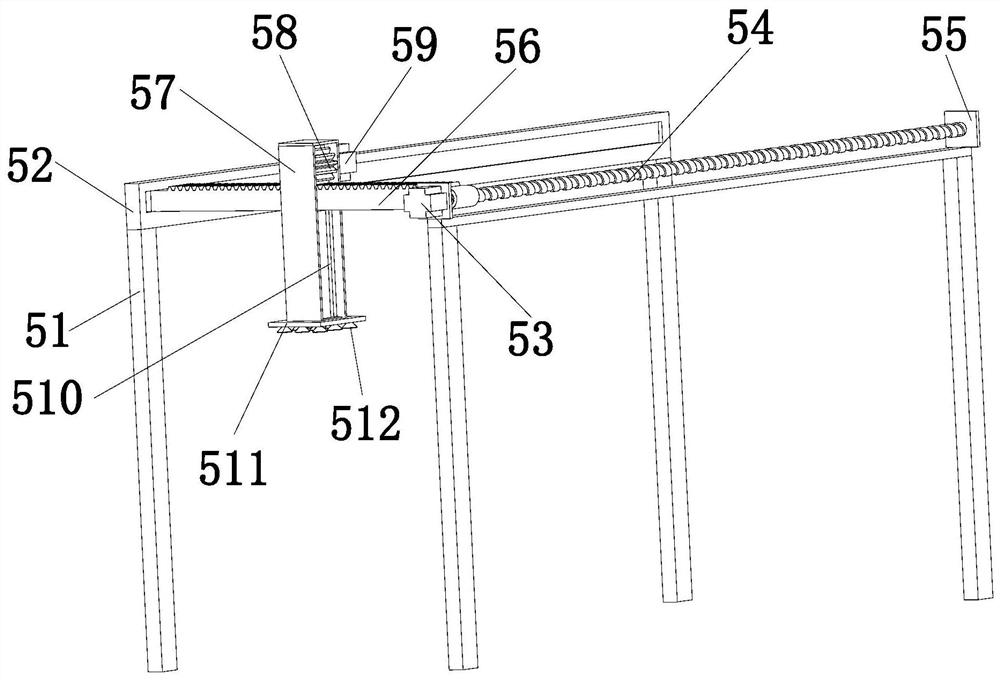

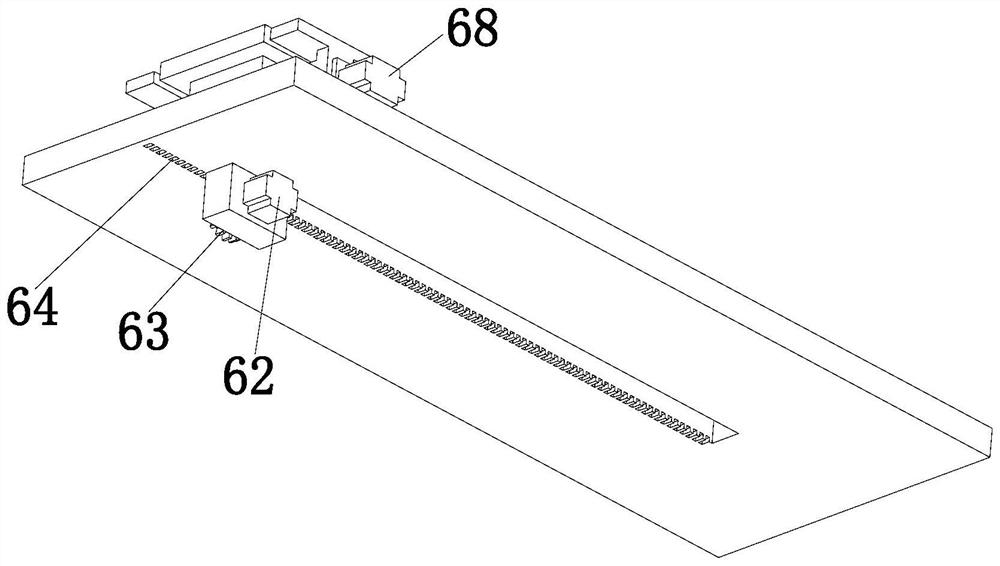

Gantry type multifunctional numerical control drilling machine

InactiveCN113369540AAvoid shakingControl diameterPositioning apparatusMetal working apparatusNumerical controlEngineering

The invention discloses a gantry type multifunctional numerical control drilling machine, and relates to the field of numerical control drilling machines. The gantry type multifunctional numerical control drilling machine comprises a platform, four supporting rollers, a first supporting plate, a conveying belt, a material moving assembly, a conveying assembly, a drilling assembly, a cutter assembly, an extruding assembly and a filtering assembly, wherein the platform is horizontally arranged, and the four supporting rollers are arranged at the bottom of the platform in a matrix mode; the material moving assembly is erected above the platform; the conveying assembly, the drilling assembly and the cutter assembly are sequentially arranged at the top of the platform in the length direction of the platform; the extrusion assembly is located below the cutter assembly and the drilling assembly; the extrusion assembly is located at the top of the platform; and the filtering assembly is arranged below the platform. The gantry type multifunctional numerical control drilling machine provided by the invention has the advantages that by arranging the cutter assembly, the extrusion assembly and the filtering assembly, the function of the numerical control drilling machine is increased, manual work is replaced through a numerical control mode, and the labor cost is saved.

Owner:惠州市金越精密机械有限公司

Rapier loom

ActiveCN106048864AImprove surface qualityAccurate and fast resetLoomsAuxillary apparatusPush and pullMotor drive

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

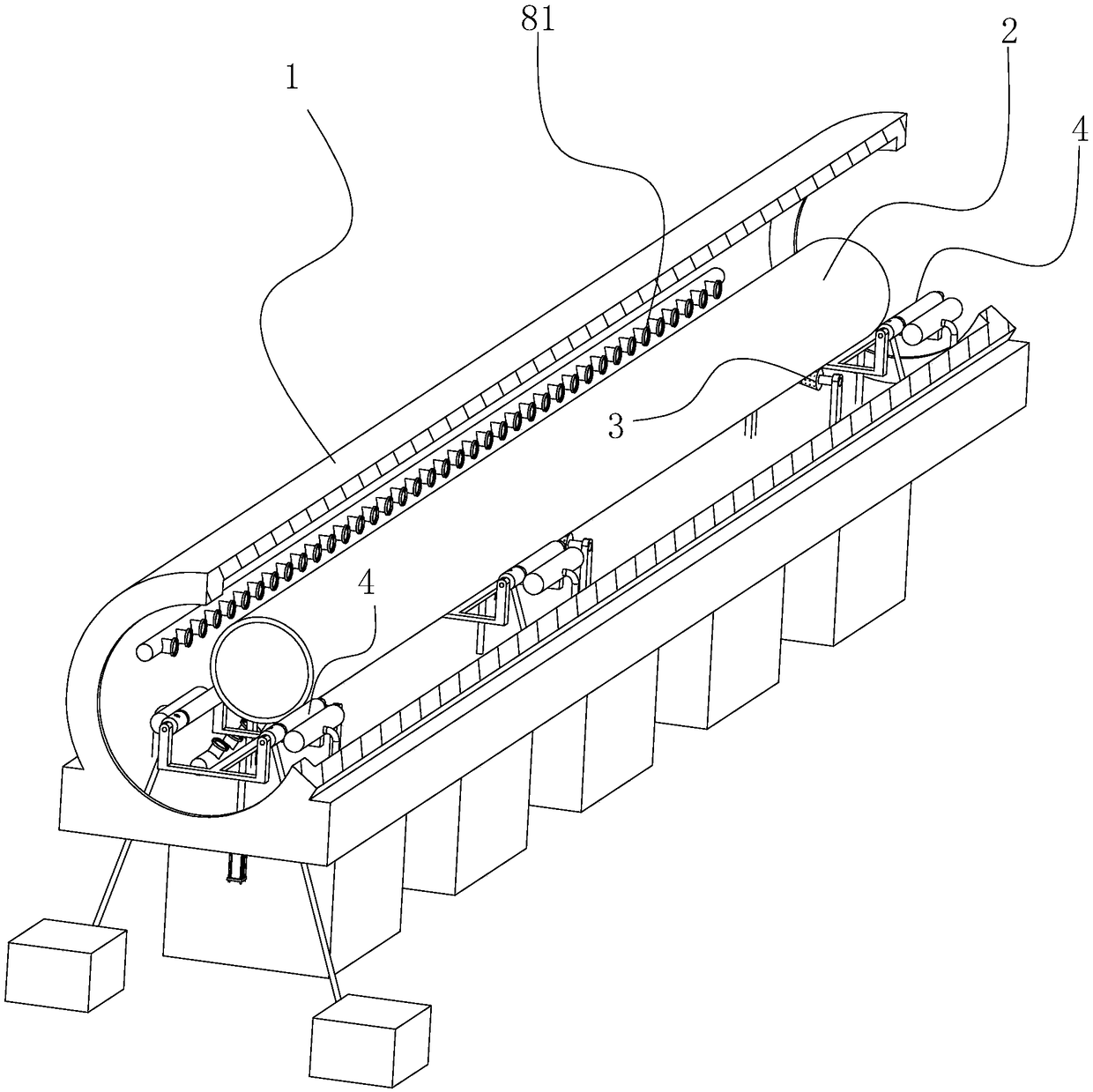

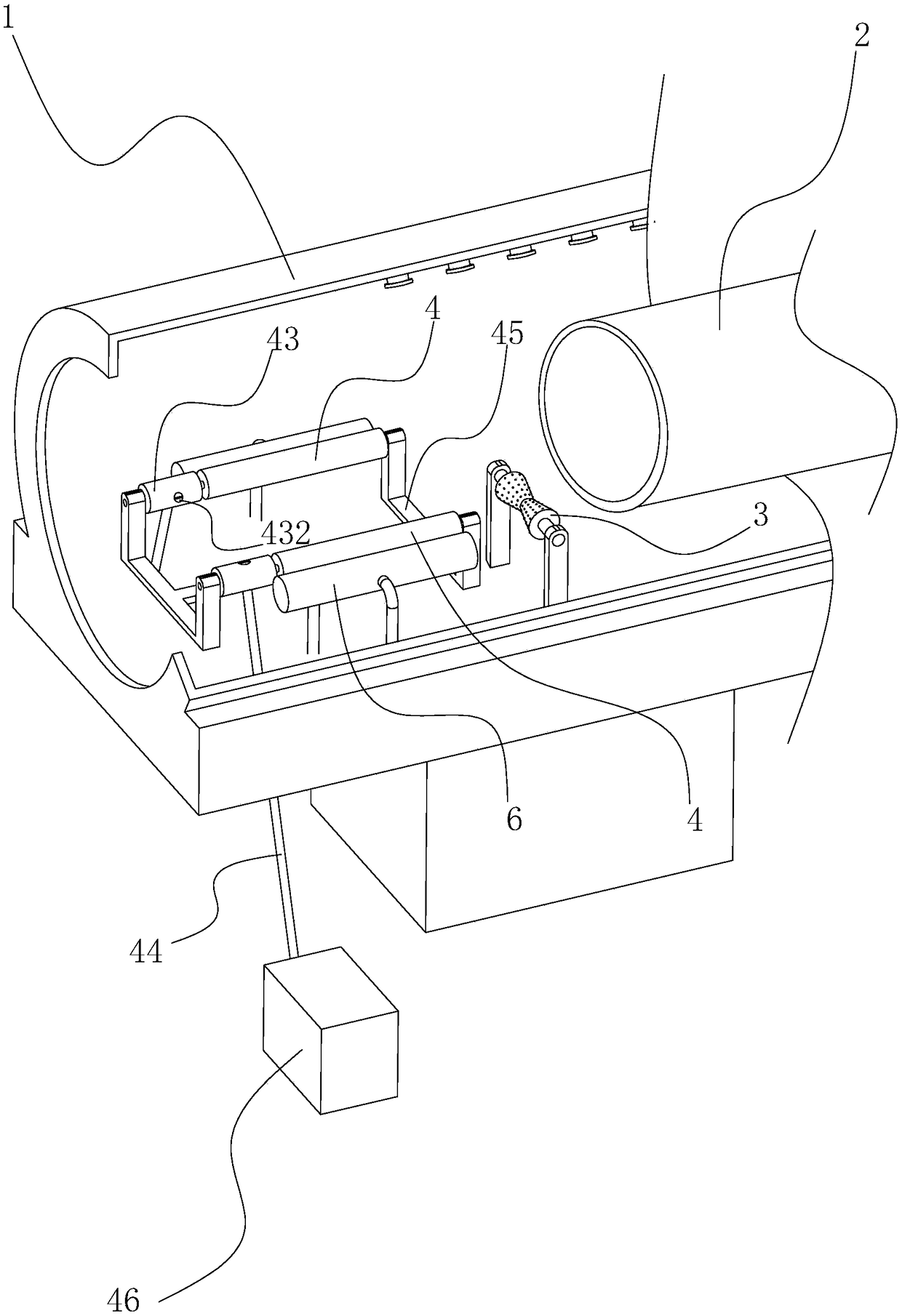

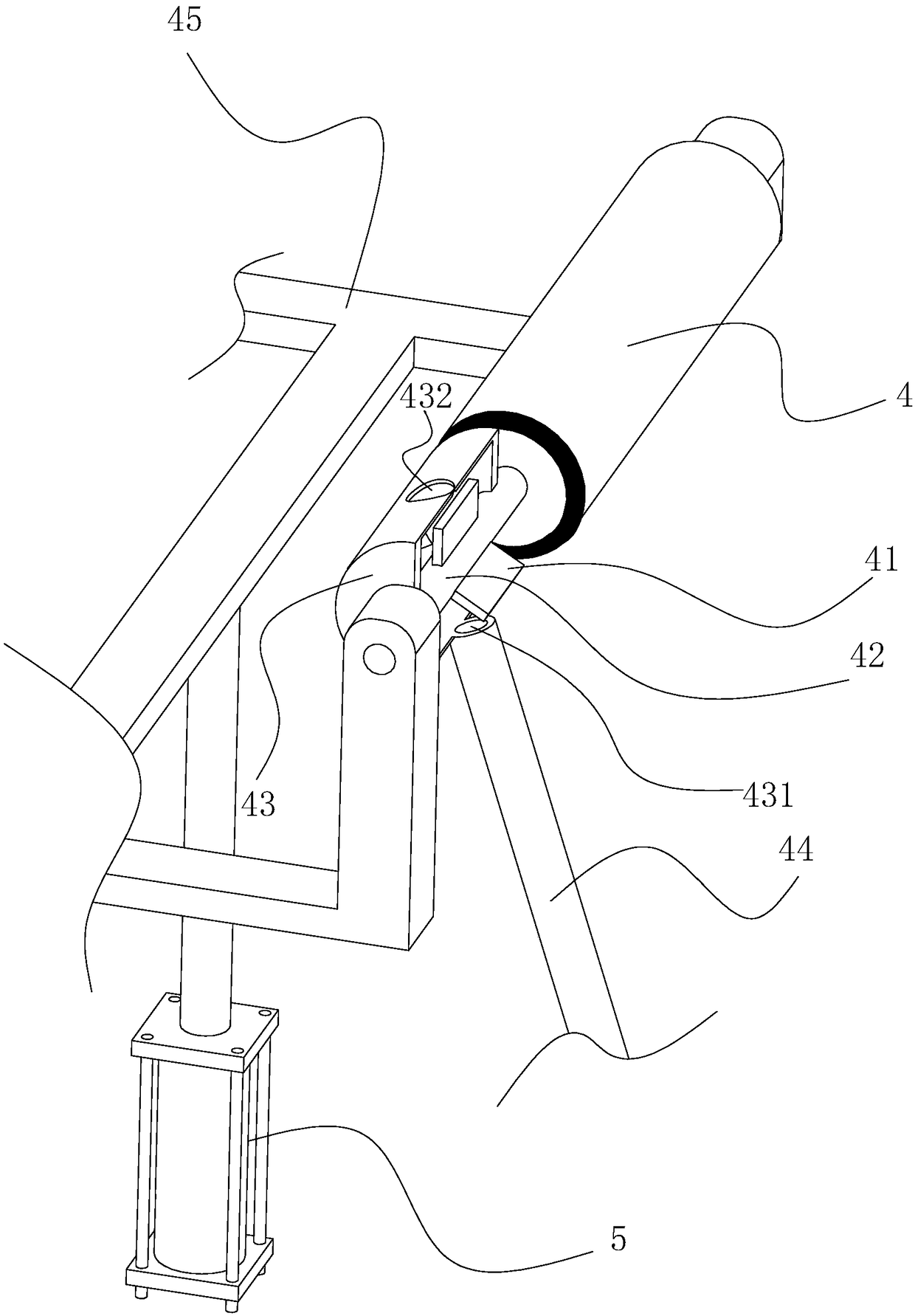

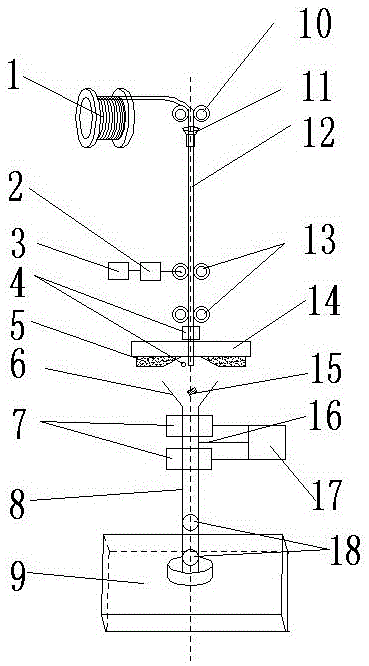

Brazing ball machining device enabling size of brazing balls to be controllable and machining method

InactiveCN105149808AControl lengthUniform lengthWelding/cutting media/materialsSoldering mediaHigh densityWire cutting

A brazing ball machining device enabling the size of brazing balls to be controllable comprises a wire feed device, a wire cutting device and a heating and cooling device, wherein the wire feed device, the wire cutting device and the heating and cooling device are sequentially arranged from top to bottom in the vertical direction. The wire feed device comprises a brazing wire scroll, a wire feed roller, a locating device and a brazing wire length control device. The wire cutting device comprises a blade and a liner plate, the liner plate is provided with a reciprocating drive mechanism, and the blade is installed on the reciprocating drive mechanism. The heating and cooling device comprises a heating and cooling pipe with a heating part and a cooling part. A method machining the brazing balls through the device comprises the steps of heating, wire feeding, wire cutting, balling, cleaning, drying, inspecting and the like. According to the invention, the brazing wire length control device measures the wire cutting length accurately and the wire cutting device cuts wires accurately to control the diameter of the brazing balls, and therefore the size of the machined brazing balls can be more uniform; the requirements of the high-density assembly technology can be met, the automation degree is higher and the machining efficiency is higher.

Owner:HENAN UNIV OF SCI & TECH

Method for preparing length and diameter controllable fibrous light calcium carbonate

ActiveCN1935657AReduce dosageReduce deforestationCalcium/strontium/barium carbonatesFiberGrowth control

The invention discloses a method for preparing fiber lightweight calcium carbonate with controllable length and diameter, comprising the steps of: (1) adding MgCl26H2O in Ca(OH)2 water slurry and simultaneously adding in lactic acid, charging the gas with the CO2 volumetric concentration of 10-100% and carbonizing, and collecting polygonal granular calcium carbonate crystal seeds in the resultant when pH is 6.5-7.5 ; (2) adding the obtained crystal seeds and crystal surface growth control agent in Ca(OH)2 water slurry, charging the gas with the CO2 volumetric concentration of 10-100% and carbonizing, and obtaining fiber lightweight calcium carbonate when pH is 6.5-7.5, where the fiber length and diameter can be perfectly controlled.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Preparation method of silicate double-layer hollow nanometer fiber with multistage structure

The invention relates to a preparation method of a silicate double-layer hollow nanometer fiber with a multistage structure. The preparation method belongs to an inorganic chemical synthesis method. The preparation method comprises that acetate as a raw material, ammonium hydroxide as a complexing agent, ammonium chloride as a mineralizer and silica hollow nanometer fibers as sacrifice templates undergo a hydro-thermal reaction at a certain temperature in an enclosed reactor to produce the silicate double-layer hollow nanometer fibers with multistage structures. The silicate double-layer hollow nanometer fiber has the diameter of 300-600 nanometers. The silicate double-layer hollow nanometer fiber has a large specific surface area, can be precipitated easily and is convenient for separation from a solution, recovery and recycle. The preparation method has simple and reliable processes, has high controllability, adopts cheap and easily available raw materials, has universality and lays the foundation of wide application of silicate.

Owner:NORTHEAST NORMAL UNIVERSITY

Film bubble diameter control system

The invention provides a film bubble diameter control system which controls the diameter of a film bubble effectively to effectively reduce the loss of a film roll and the waste of raw materials. The film bubble diameter control system comprises a film bubble forming mold. The film bubble forming mold is connected with an air inlet pipeline and an air outlet pipeline. The air inlet pipeline is connected with an air inlet fan, and the air outlet pipeline is connected with an air outlet fan, so as to form an air inlet and outlet circulation. The film bubble diameter control system is characterized in that at least three probes are symmetrically arranged on the outer sides of the film bubble forming mold, and the probes and the air inlet fan are connected with a control system.

Owner:WUXI PACIFIC NEW MATERIALS CO LTD

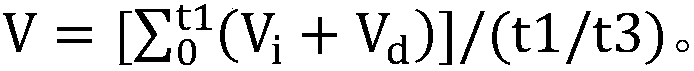

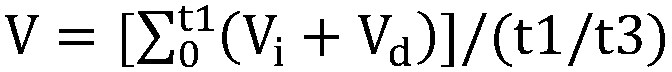

Temperature control method of Czochralski monocrystalline silicon

ActiveCN110528067AControl diameterImprove stabilityPolycrystalline material growthBy pulling from meltTemperature controlDelta-v

The invention discloses a temperature control method of Czochralski monocrystalline silicon and aims to automatically adjust temperatures in a silicon single crystal isometric growth process. The temperature control method comprises the following steps: confirming an average crystal growth speed V, and outputting the average crystal growth speed V; setting a target crystal growth speed VS, and calculating the deviation delta V of the average crystal growth speed V and the target crystal growth speed VS; and according to delta V, confirming a power set value Pr, outputting the power set value Pr, and furthermore performing temperature adjustment. Compared with a conventional SP closed-loop control mode, the temperature control method of the Czochralski monocrystalline silicon, which is disclosed by the invention, has the advantages that 1, SP control is canceled, unstable factors are eliminated, the stability of a temperature control system can be improved, furthermore, the diameter ofa crystal can be well controlled, the pass percentage can be increased, and the production cost can be lowered; 2, a thermocouple is eliminated, and the equipment cost can be lowered; and 3, the automation degree of a Czochralski monocrystalline silicon furnace can be increased.

Owner:LONGI GREEN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com