Film bubble diameter control system

A control system and film bubble technology, which is applied in the field of film bubble diameter control system, can solve the problems of film volume loss, film bubbles that cannot meet the film size requirements, and defective film bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

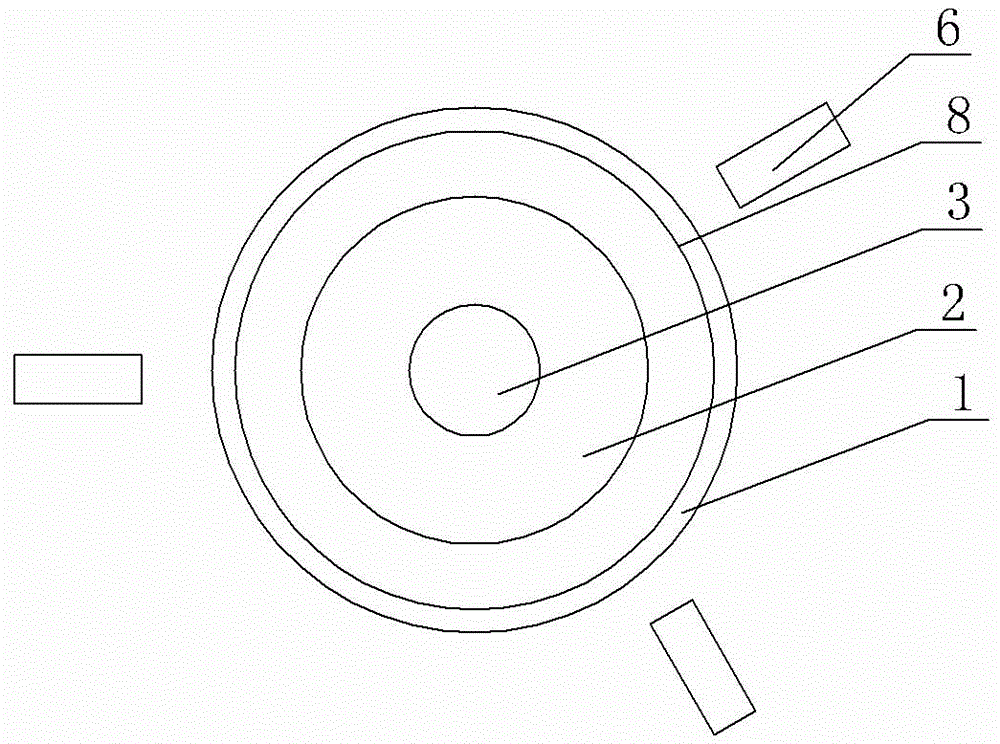

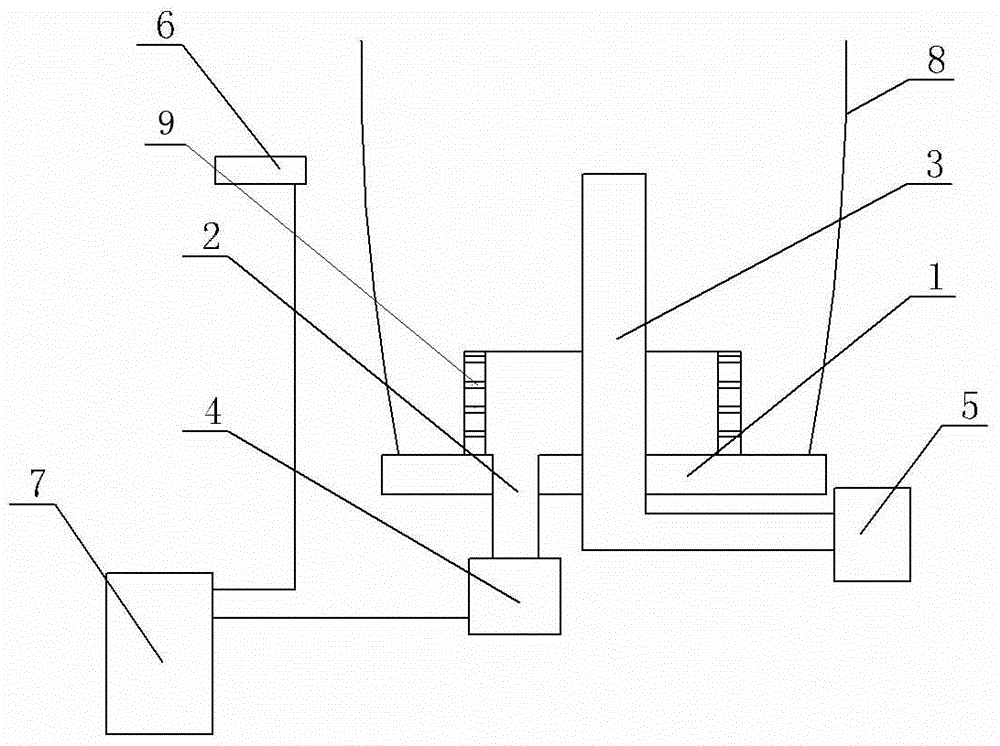

[0009] See figure 1 , figure 2 , a bubble diameter control system, which includes a bubble forming mold 1, the bubble forming mold 1 is connected to an air inlet pipe 2 and an air outlet pipe 3, the air inlet pipe 2 is connected to an air inlet fan 4, and the air outlet pipe 3 is connected to an air outlet The fan 5 forms a cycle of air inlet and outlet. The wind from the air inlet fan 4 enters the upper end of the bubble forming mold 1 through the air inlet duct 2 and the surrounding air inlet holes 9, so that the film blown out from the bubble forming mold 1 forms a film Bubble 8, three probes 6 are symmetrically arranged on the outer side of the bubble forming mold 1, and the three probes 6 are symmetrical with the center of the bubble forming mold as the symmetrical center, and the three probes are connected to form an equilateral triangle, and the probe 6 is connected to the air inlet fan 4 Control system 7, set the air volume at the air outlet to be constant, and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com