Preparation method for ultra-long TiO2 nanowire array thin-film photo-anode

A nanowire array and photoanode technology, applied in the field of dye-sensitized solar cells, can solve the problem of high recombination loss of photogenerated carriers, achieve fast electron transfer rate, small recombination loss, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

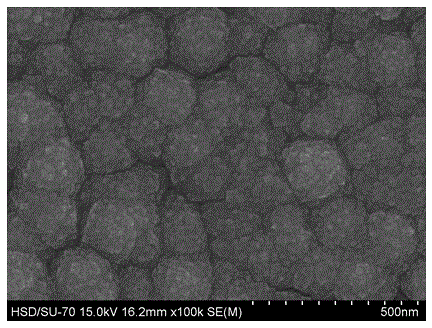

[0036] Specific implementation mode 1: In this implementation mode, one-dimensional rutile TiO is directly synthesized on FTO conductive glass by a solvothermal method. 2 A nanowire array, comprising the steps of:

[0037] Step 1. Treat the FTO glass substrate: Cut the FTO glass according to the size of 2.0×1.5 cm in length and width, put it in aqueous detergent solution, acetone and absolute ethanol for 10 minutes, and then use deionized Rinse with water and ethanol and dry.

[0038] Step 2. TiCl 4 Solution pre-treatment: Put the FTO glass with the conductive side facing up into the solution filled with 0.2 M TiCl 4 The solution was treated in a beaker at 70°C for 30 min, and after taking it out, it was rinsed with deionized water and ethanol in turn and dried. in:

[0039] TiCl used 4 The solution was prepared as follows: 250 mL of deionized water and 41.7 mL of concentrated hydrochloric acid were added to a 500 mL beaker. Slowly add 55 mL TiCl dropwise to the beaker w...

specific Embodiment approach 2

[0046] Specific implementation mode two: TiO 2 Controlled Growth of Nanowire Arrays:

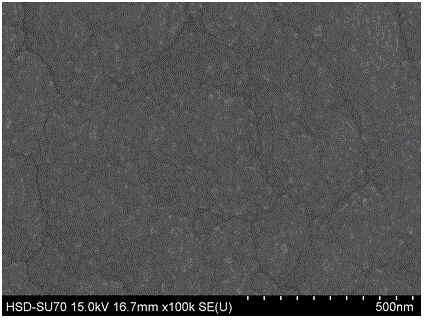

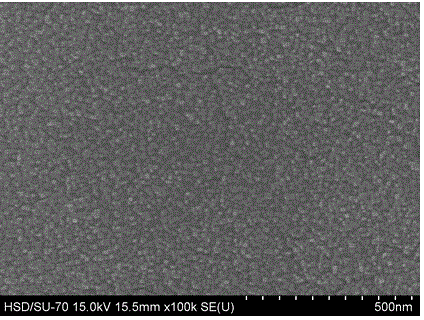

[0047] First, the length, density and regularity of nanowires can be controlled by changing the ratio of ethanol to hydrochloric acid by fixing the reaction time and the volume of titanium tetrachloride. In this embodiment, 3 mL of titanium tetrachloride solution is used, the reaction time is fixed at 12 h, and the reaction temperature is 150°C. and 40:20 ratio change process, TiO 2 The lengths of the nanowires were 23.3 μm, 39.5 μm, 51.4 μm, 30.3 μm, 17.4 μm, and 17.3 μm, showing a trend of first increasing and then decreasing; and with the increase of the proportion of ethanol, the nanowires gradually evolved from aggregation to cluster growth grow independently. When the volume ratio of ethanol: hydrochloric acid is 25:35, the diameter of the nanowires is uniform, the regularity of the shape is high, and the length is the longest. TiO synthesized under different volume ratios of ethan...

specific Embodiment approach 3

[0049] Specific implementation mode three: with TiO 2 Assembly of Dye-Sensitized Solar Cells with Nanowire Array Thin Film as Photoanode ( Figure 14 ):

[0050] Treat the synthesized nanowire film to obtain TiO with a diameter of 6 mm 2 Nanowire circular film.

[0051] TiCl 4 Solution post-treatment: the configured 1 M TiCl 4 Dilute the hydrochloric acid solution to 40 mM, and glue the edge of the FTO glass conductive surface with a waterproof tape of a certain size to avoid the deposition of nanocrystalline TiO 2 , affecting its conductivity. Then, put the FTO glass into 40 mM TiCl 4 In the aqueous solution, treat at 70 °C for 30 min, tear off the tape on the FTO glass, rinse with deionized water and ethanol in turn, and dry it, and set it aside.

[0052] TiO 2 Sensitization of nanowire thin film electrodes: Before sensitization, under the condition of air flow, TiO 2 The nanowire thin film electrode was heated to 500 °C for 30 min and cooled to 90 °C naturally, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com