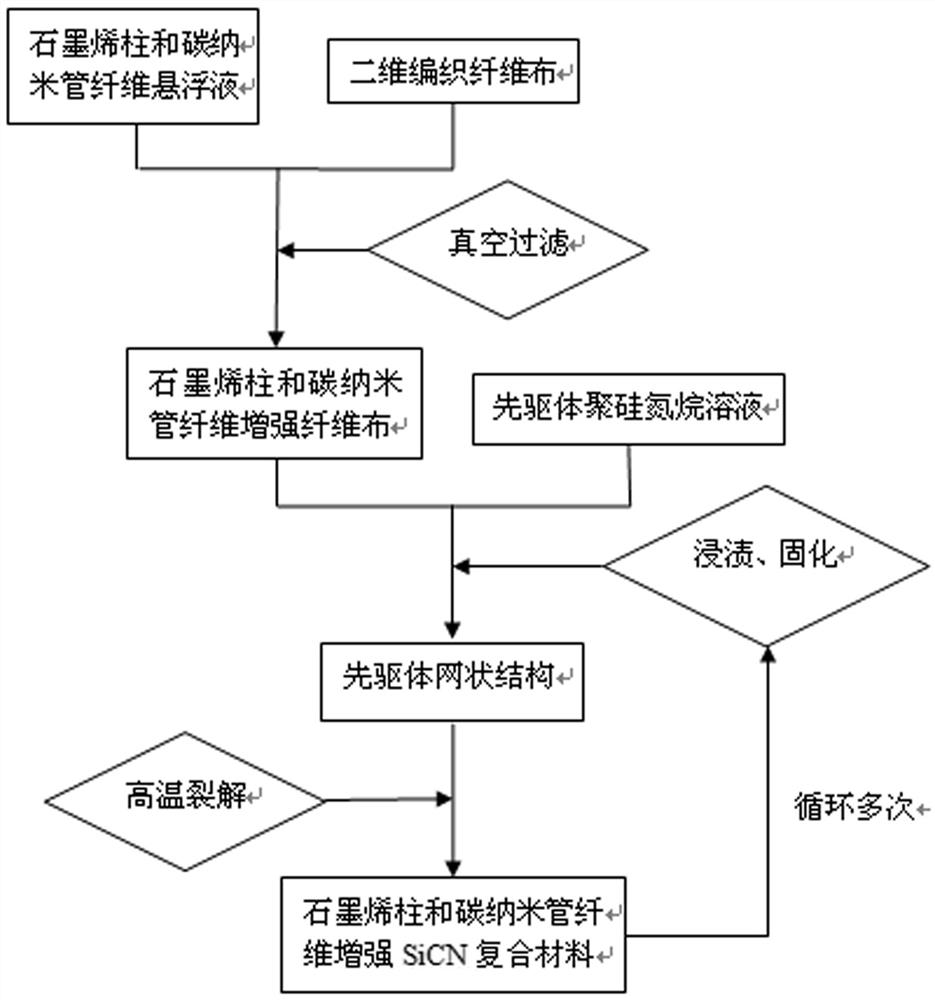

A kind of preparation method of graphene column and carbon nanotube fiber reinforced SiCN composite material

A technology of carbon nanotube fibers and composite materials, which is applied in the field of ceramic composite materials, can solve the problems of low mechanical properties and achieve the effect of improving mechanical properties and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first step, the preparation of three-dimensional graphene column: first place a copper foil with a thickness of 400nm on the SiO 2 on, the copper foil and SiO 2 Placed in the electron beam evaporation equipment, a layer of iron nanoparticles with a thickness of 3nm is evaporated on the surface of the copper foil, iron, copper foil and SiO 2 As the substrate, put the substrate into the chemical vapor deposition equipment, vacuum, and pass Ar (100sccm) and H 2 (80sccm), raise the temperature to 700°C, after the temperature stabilizes, pass into C 2 h 2 (20sccm), keep for 5min, grow three-dimensional graphene columns on the copper foil, and then put the copper foil and three-dimensional graphene columns into FeCl with a concentration of 1mol / L 3 The solution is etched, and then washed with HCl solution and deionized water to obtain a three-dimensional graphene column;

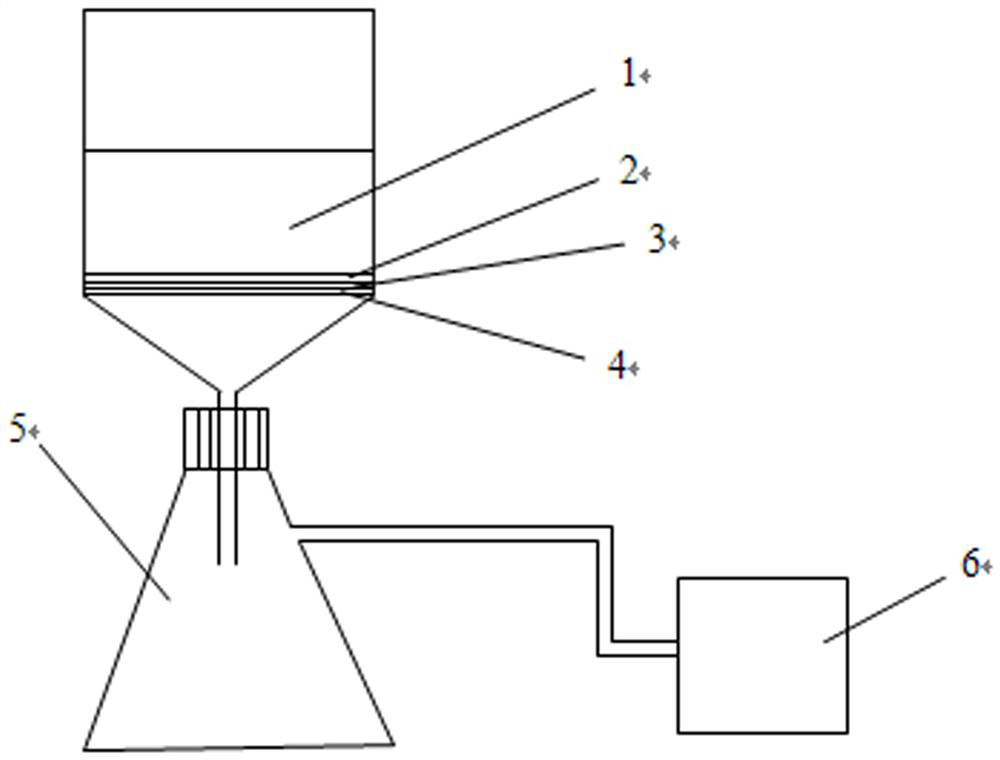

[0034] The second step, the preparation of carbon nanotube fibers: add carbon nanotubes to a fla...

Embodiment 2

[0045] In the first step, a copper foil with a thickness of 500nm is placed on the SiO 2 on, the copper foil and SiO 2 Placed in the electron beam evaporation equipment, a layer of iron nanoparticles with a thickness of 5nm is evaporated on the surface of the copper foil, iron, copper foil and SiO 2 As the substrate, put the substrate into the chemical vapor deposition equipment, vacuum, and pass Ar (100sccm) and H 2 (80sccm), raise the temperature to 750°C, after the temperature stabilizes, pass into C 2 h 2 (20sccm), keep for 15min, grow three-dimensional graphene columns on the copper foil, and then put the copper foil and three-dimensional graphene columns into FeCl with a concentration of 0.8mol / L 3 The solution is etched, and then washed with HCl solution and deionized water to obtain a three-dimensional graphene column;

[0046] In the second step, add carbon nanotubes into a flask containing a mixture of concentrated sulfuric acid and concentrated nitric acid (volu...

Embodiment 3

[0057] In the first step, a copper foil with a thickness of 600nm is placed on the SiO 2 on, the copper foil and SiO 2 Placed in the electron beam evaporation equipment, a layer of iron nanoparticles with a thickness of 10nm is evaporated on the surface of the copper foil, iron, copper foil and SiO 2 As the substrate, put the substrate into the chemical vapor deposition equipment, vacuum, and pass Ar (100sccm) and H 2 (80sccm), raise the temperature to 800°C, after the temperature stabilizes, pass C 2 h 2 (20sccm), keep for 30min, grow three-dimensional graphene columns on the copper foil, and then put the copper foil and three-dimensional graphene columns into FeCl with a concentration of 0.6mol / L 3 The solution is etched, and then washed with HCl solution and deionized water to obtain a three-dimensional graphene column;

[0058] In the second step, add carbon nanotubes into a flask containing a mixture of concentrated sulfuric acid and concentrated nitric acid (volume r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com