Patents

Literature

62results about How to "Reduce compound loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

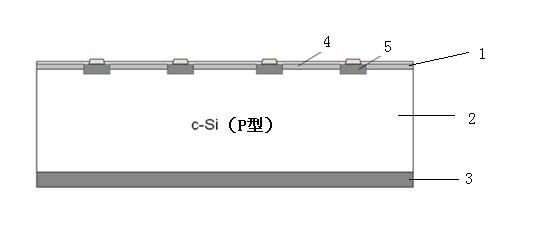

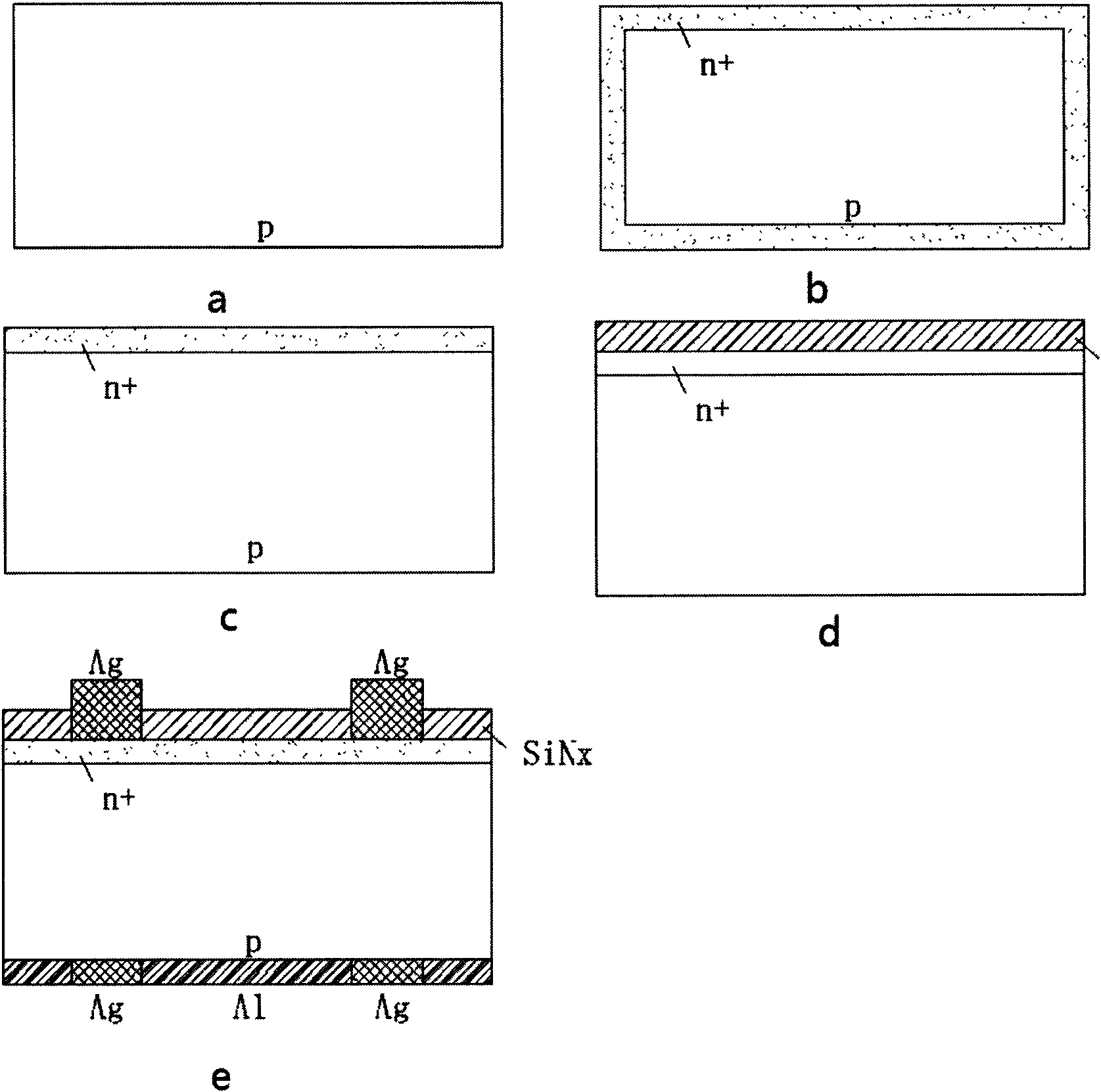

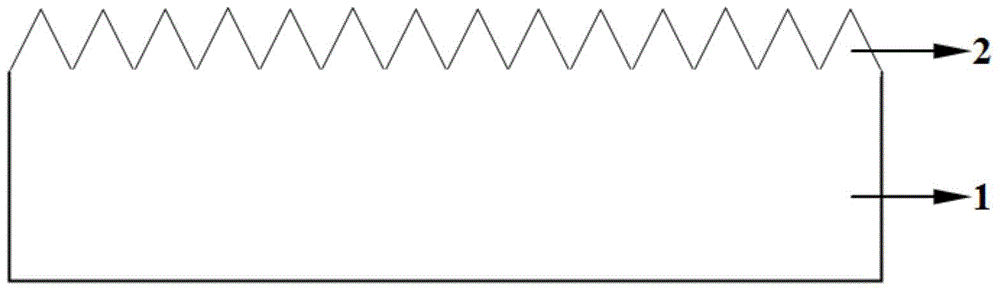

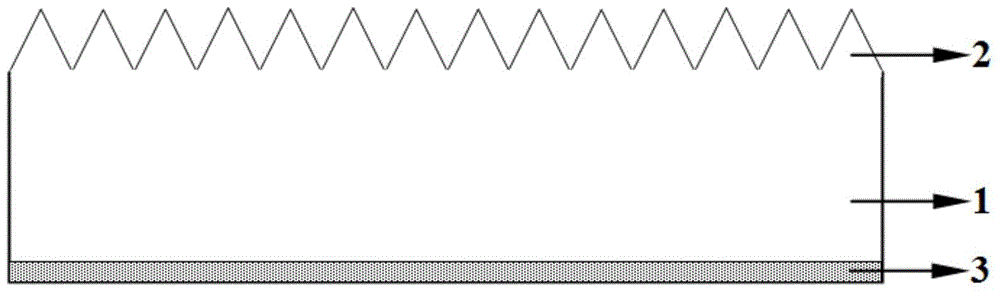

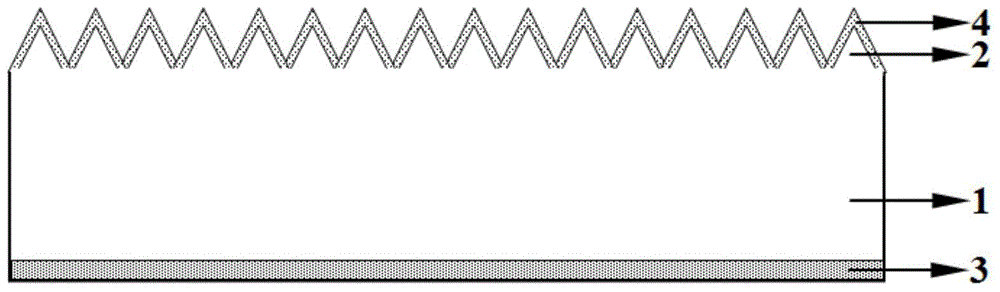

Novel crystalline silicon solar cell and manufacturing method thereof

InactiveCN102064216AImprove surface passivation effectReduce surface recombination rateFinal product manufacturePhotovoltaic energy generationHeterojunctionMaterials science

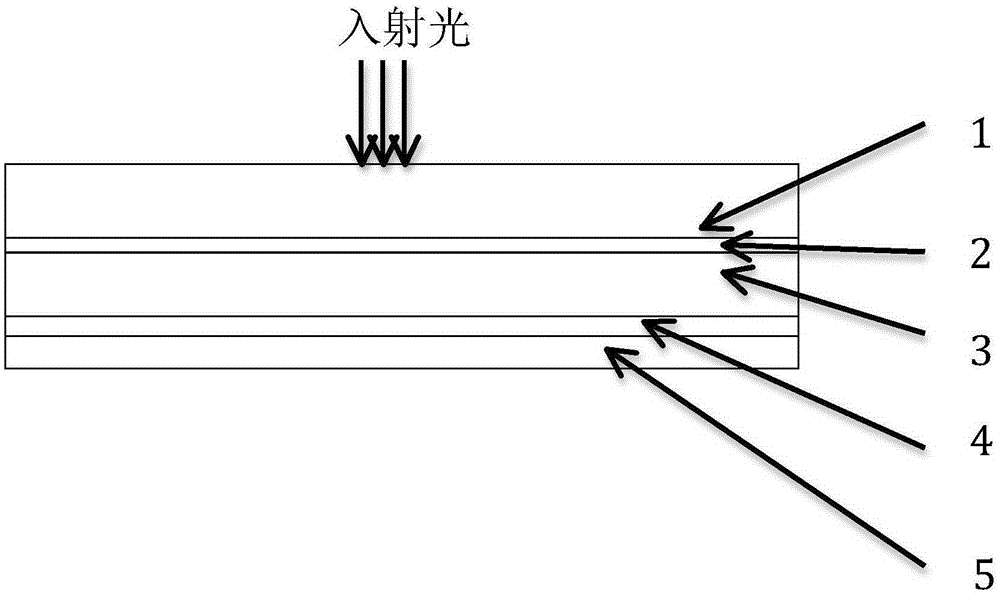

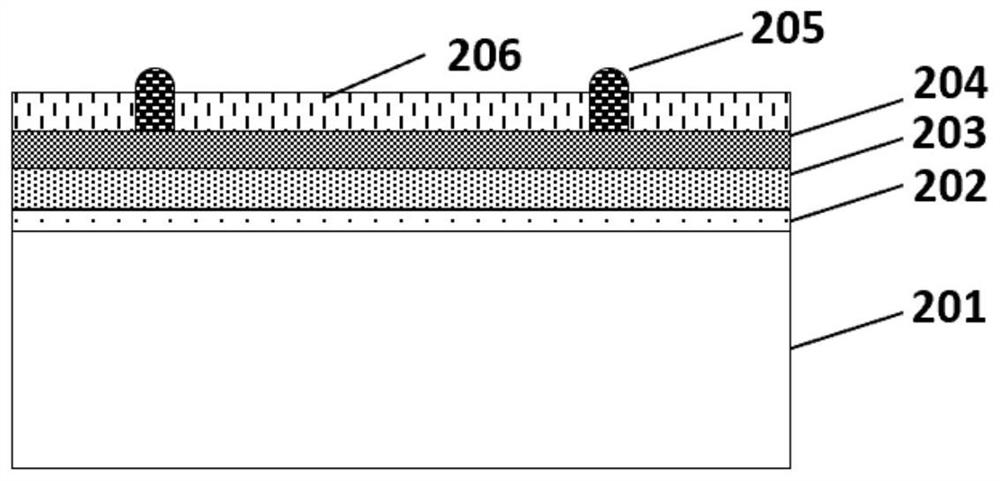

The invention discloses a novel crystalline silicon solar cell. The novel crystalline silicon solar cell comprises a crystalline silicon matrix, wherein the front surface of the crystalline silicon matrix has an emitter structure, and the back surface of the crystalline silicon matrix has a heterojunction structure; the heterojunction structure comprises an intrinsically hydrogenated amorphous silicon film, a hydrogenated amorphous silicon film, a transparent conductive oxide film and a metal conductive electrode in turn; the intrinsically hydrogenated amorphous silicon film covers the entire back surface of the crystalline silicon matrix; the hydrogenated amorphous silicon film is heavily doped by using a dopant which has the same conduction type as that of the matrix; and the metal conductive electrode passes through the transparent conductive oxide film and is in ohmic contact with a heavily doped layer. The invention also discloses a manufacturing method of the crystalline silicon solar cell. The crystalline silicon solar cell with the structure can reduce composite loss on the surface; meanwhile, the back surface of the solar cell forms a better light trap structure to improve open-circuit voltage of the solar cell, so that conversion efficiency of the solar cell is improved.

Owner:JA SOLAR TECH YANGZHOU

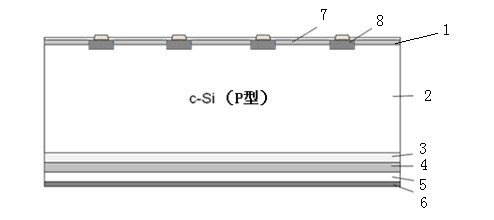

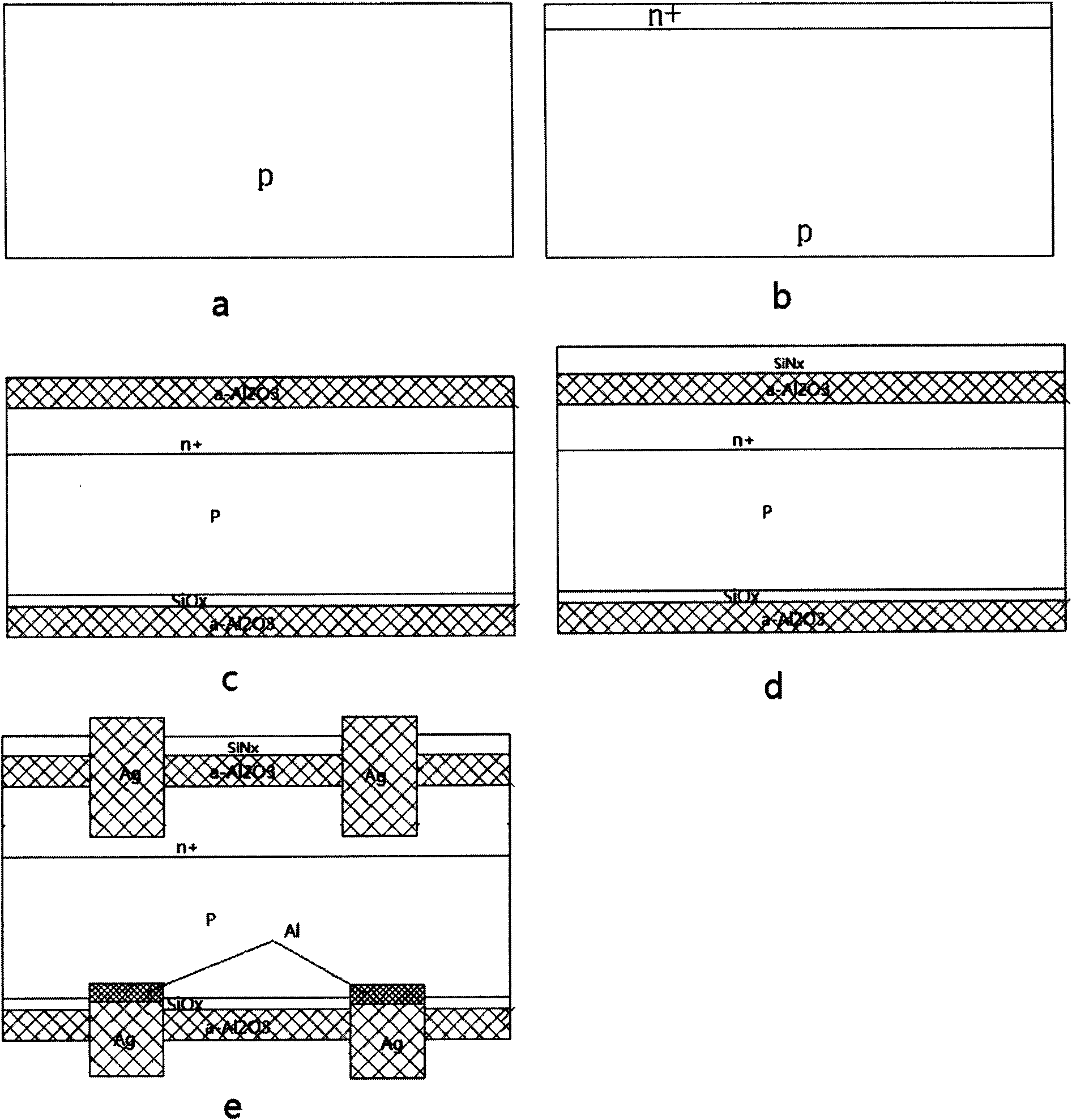

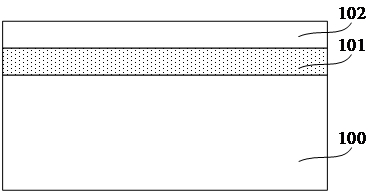

Crystalline silicon solar cell and preparation method thereof

ActiveCN102122674APromote passivationImprove anti-reflection abilityFinal product manufacturePhotovoltaic energy generationSilver electrodeSilicon oxide

The invention discloses a crystalline silicon solar cell and a preparation method thereof, and the crystalline silicon solar cell comprises a pn plus junction silicon substrate, wherein a first amorphous alumina layer and an amorphous silicon nitride layer are arranged on the surface of an n plus emitter, a silver electrode penetrates the amorphous silicon nitride layer and the first amorphous alumina layer and is connected with the n plus emitter, a composite passivation medium layer is arranged on the surface of a p type substrate, the p type substrate comprises a silicon oxide layer and a second amorphous alumina layer, and a p type substrate is in contact with a back electrode. The preparation method comprises the special preparation of the composite passivation medium layer, nitric acid and hydrogen peroxide solution are adopted for processing the surface of the p type substrate, the sol-gel process is adopted for preparing the second amorphous alumina layer, and the composite passivation medium layer (4) is formed after annealing. The crystalline silicon solar cell has the advantages of simple process, low equipment investment, good passivation and anti-reflection performances of the front surface, excellent passivation effect of the composite passivation medium layer on the back surface, capability of improving the utilization efficiency of long waves, and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

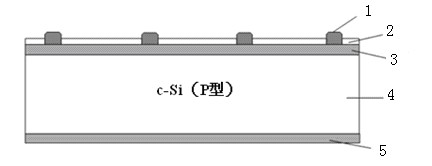

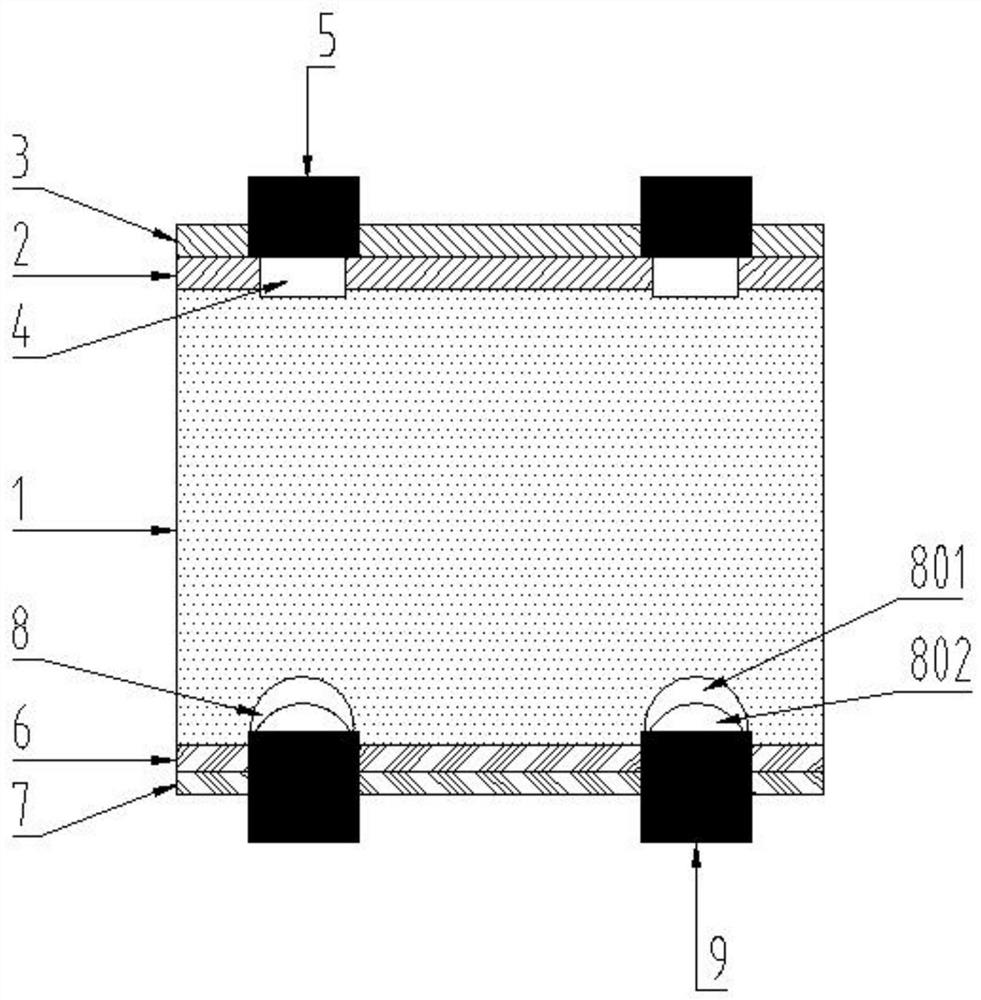

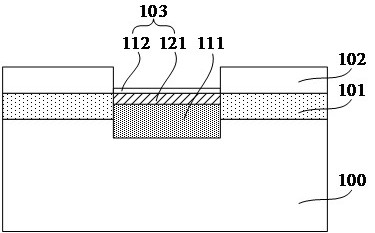

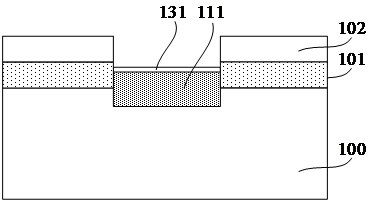

P-type tunneling oxide passivated contact solar cell and preparation method thereof

PendingCN109980022AImprove interface passivation effectReduce composite speedFinal product manufacturePhotovoltaic energy generationState of artSilicon thin film

The invention discloses a P-type tunneling oxide passivated contact solar cell and belongs to the technical field of crystalline silicon solar cells, aiming to solve the problem that the passivation effect of the back surface of the solar cell in the prior art is poor; the solar cell in the invention is characterized in that a silicon dioxide layer is formed on the front surface of a silicon wafer, and then an N-type heavily-doped polycrystalline silicon layer is formed on the silicon dioxide layer, so that the composite loss of a metal contact area is reduced; in addition, the tunneling oxideis combined with a heavily-doped silicon thin film to form a passivated contact structure, so that the original way of whole-face doping the back surface area is replaced, further, a high short-circuit current is kept, the open-circuit voltage is increased, the filling factor is improved, and the conversion efficiency of the battery is improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

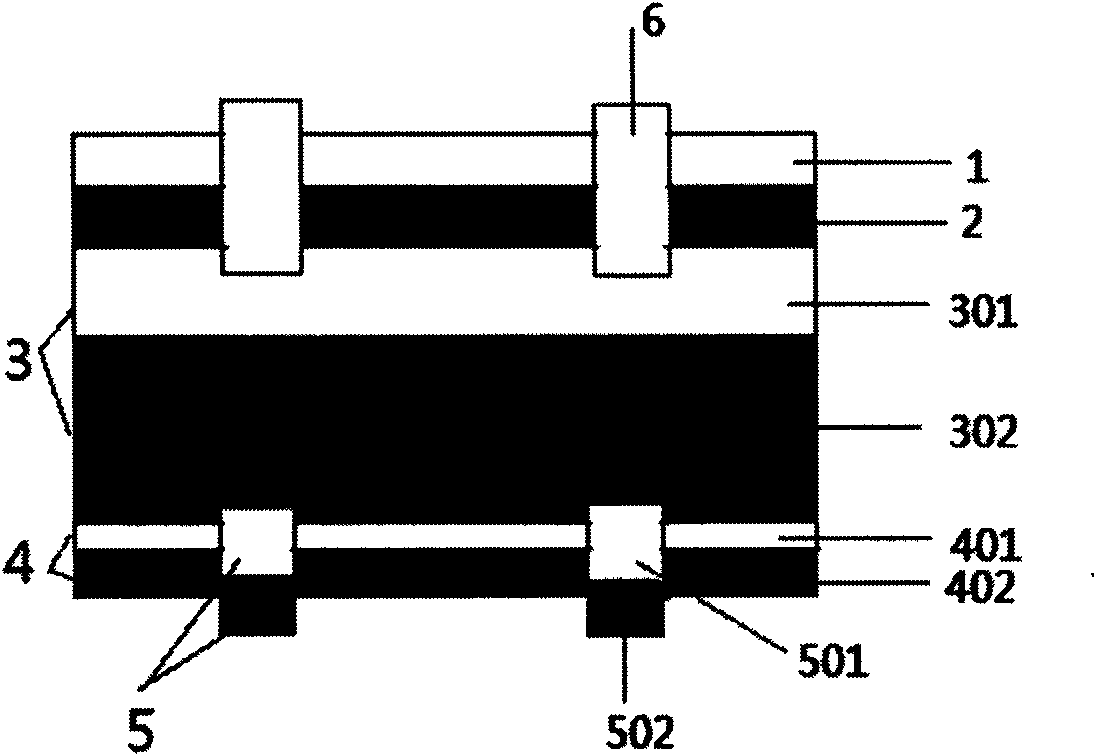

Preparing method of whole back electrode P type crystalline silicon heterojunction solar battery

ActiveCN104167471AImprove conversion efficiencyReduce manufacturing costFinal product manufacturePhotovoltaic energy generationHeterojunctionSlurry

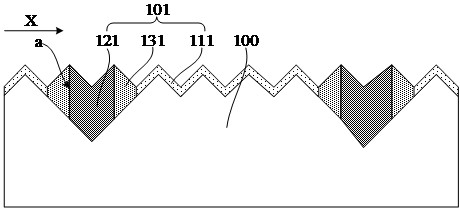

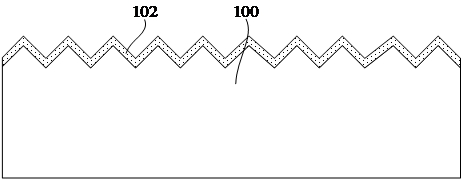

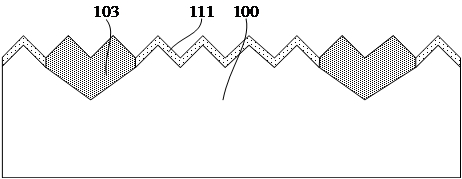

The invention discloses a preparing method of a whole back electrode P type crystalline silicon heterojunction solar battery. The method comprises the steps that nanometer suede, a P+ type boron shallow diffusion crystalline silicon layer and an SiOx passivation / SiNx anti-reflection layer are prepared on the front surface of a P type silicon substrate; a P++ type boron heavy diffusion crystalline silicon layer is prepared on the back face of the P type silicon substrate, then printing corrosion slurry is used for achieving local corrosion on the P++ type boron heavy diffusion crystalline silicon layer, an intrinsic amorphous silicon membrane layer and an n type amorphous silicon membrane layer are subjected to deposition in sequence, and intrinsic and n type amorphous silicon on the surface layer of a P++ type boron heavy diffusion crystalline silicon layer zone is removed; then a transparent conducting membrane layer is subjected to sputtering, a P zone and an N zone on the back face of the P type silicon substrate are separated through laser; and finally electrode printing is carried out, and low-temperature sintering is carried out. According to the method, all metal electrodes are moved to the back face of the battery, electrodes are not arranged on a light-borne face, component production cost is lowered, battery composite loss is lowered, accordingly, optical loss and resistance are obviously lowered, and efficiency is greatly improved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

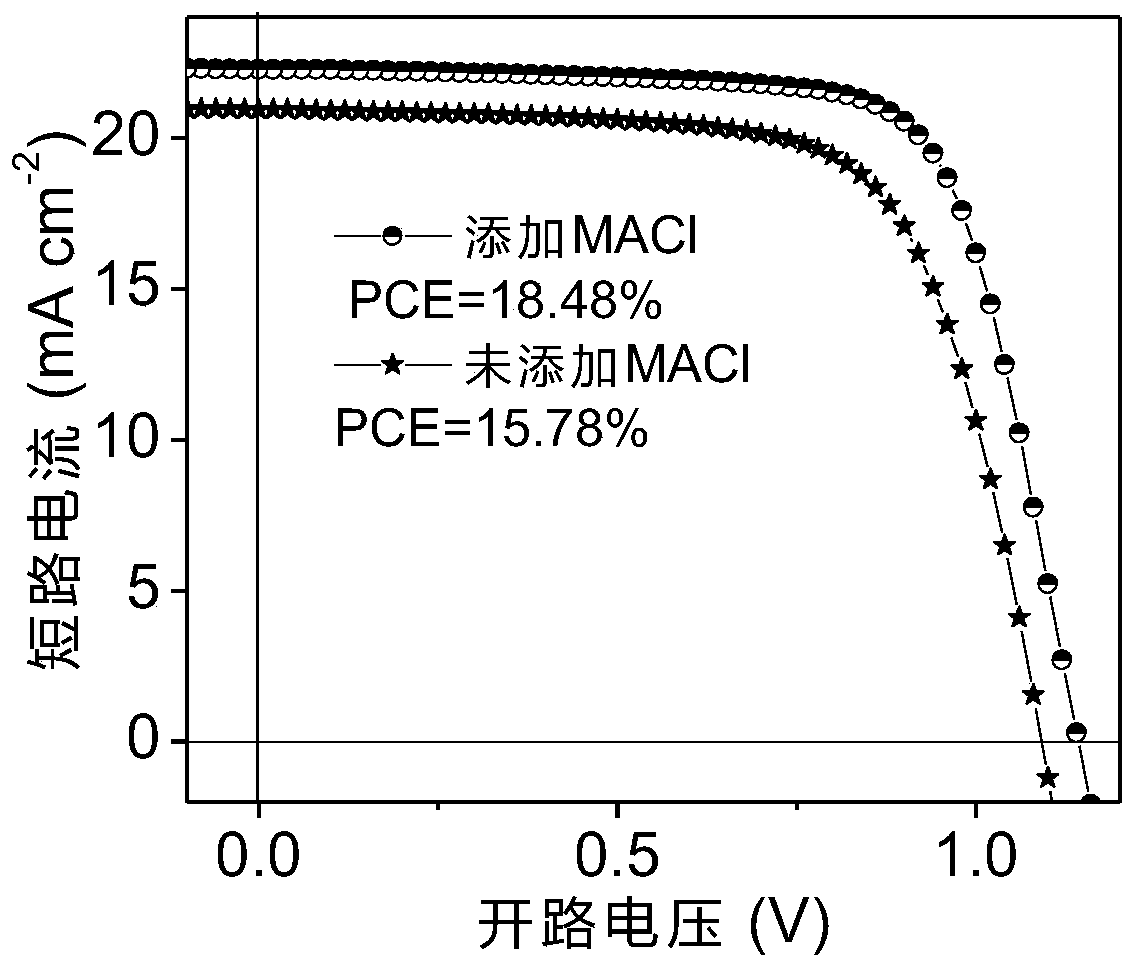

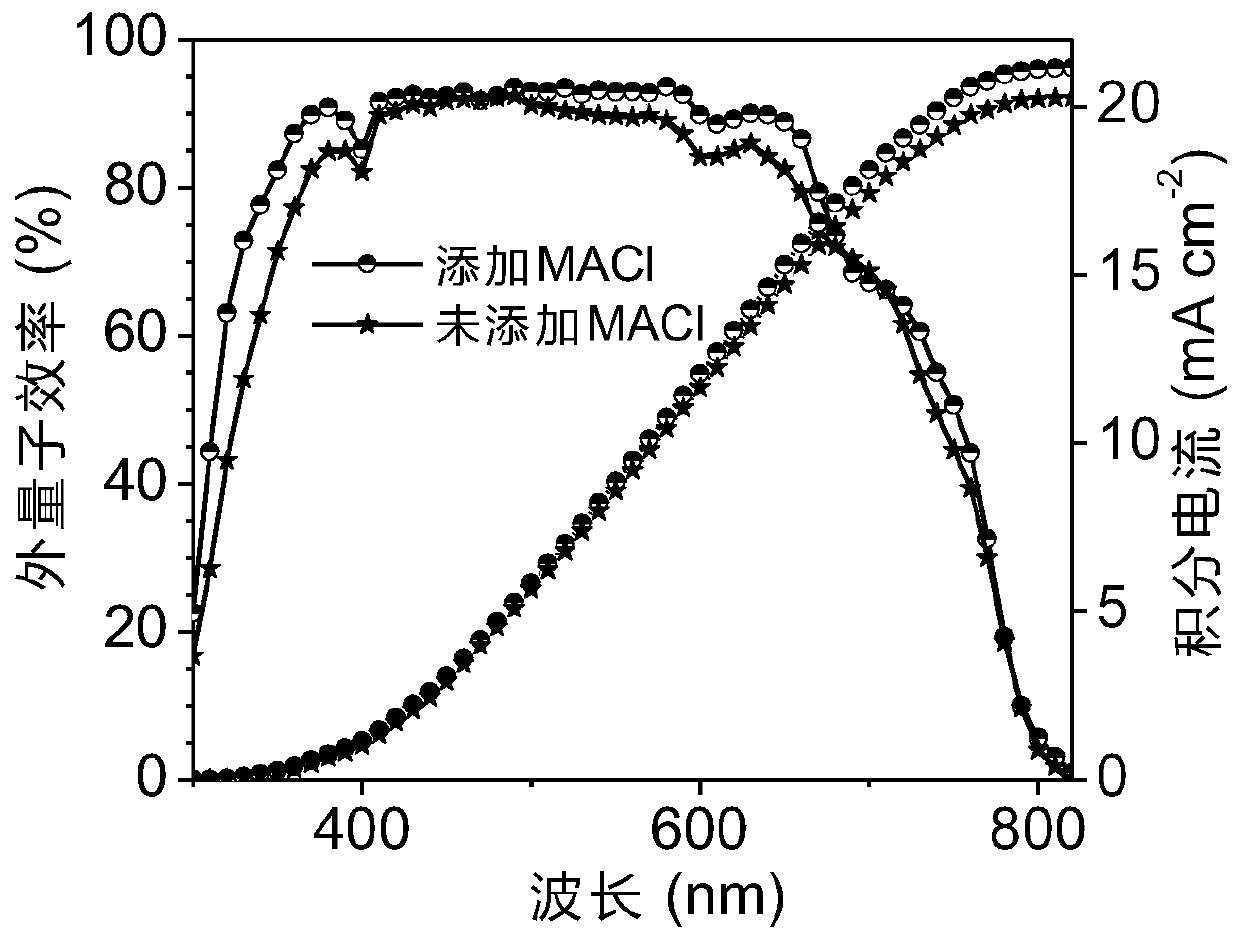

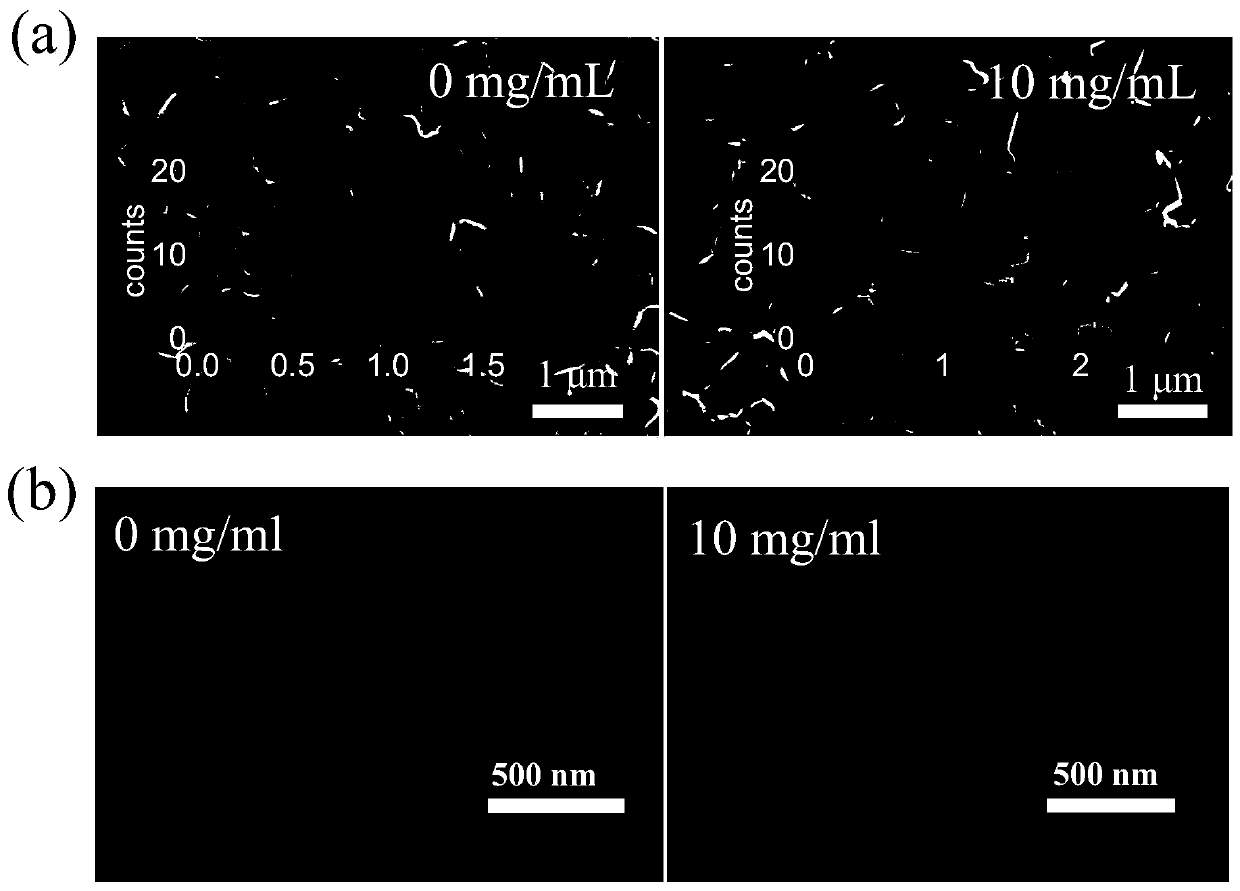

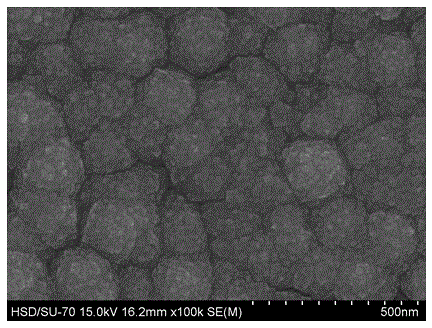

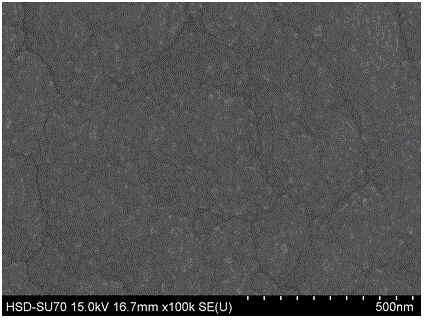

ACI type two-dimensional perovskite solar cell and preparation method thereof

ActiveCN110518128ASlow crystallization rateExtended crystallization timeFinal product manufactureSolid-state devicesPerovskite solar cellGrain boundary

The invention discloses an ACI type two-dimensional perovskite solar cell and a preparation method thereof. The perovskite absorption layer of the solar cell is a mixture of C(NH2)3I, CH3NH3I and PbI2. In the preparation process, CH3NH3Cl is added to serve as an additive. Compared with the conventional two-dimensional perovskite device, the addition of CH3NH3Cl greatly improves the crystallizationquality of the perovskite thin film, increases the grain size, reduces the carrier recombination loss caused by defects at the grain boundary, and prolongs the carrier service life. Meanwhile, effective gradient distribution of different n values is increased, the charge transmission efficiency is improved, the improvement of the photoelectric conversion efficiency of the perovskite battery device is finally directly determined, the series-parallel resistance of the device is improved, and the photoelectric conversion efficiency of 18.48% is finally obtained. The excellent photoelectric properties and device efficiency of the perovskite solar cell are helpful for promoting the commercial application of the perovskite solar cell.

Owner:SHAANXI NORMAL UNIV

Preparation method for ultra-long TiO2 nanowire array thin-film photo-anode

InactiveCN104576074AFast electron transportReduce compound lossMaterial nanotechnologyLight-sensitive devicesPhysicsElectron transmission

The invention relates to a preparation method for an ultra-long TiO2 nanowire array thin-film photo-anode, and belongs to the field of dye-sensitized solar cells. The problem that photon-generated carrier composite losses of an existing dye-sensitized solar cell TiO2 nanocrystalline photo-anode are large is solved. The preparation method comprises the steps that a solvothermal synthesis reaction is carried out at a time, an ethyl alcohol, hydrochloric acid and TiCl4 mixed solution is used as a precursor, and an ultra-long one-dimensional TiO2 nanowire array thin film is made to grow on a piece of FTO conductive glass. The TiO2 nanowire array thin film photo-anode is directly applied on the dye-sensitized solar cell; according to the one-dimensional structure, the electron transport speed is high, the photon-generated carrier composite losses are small, and the performance of the dye-sensitized solar cell is improved.

Owner:HARBIN INST OF TECH

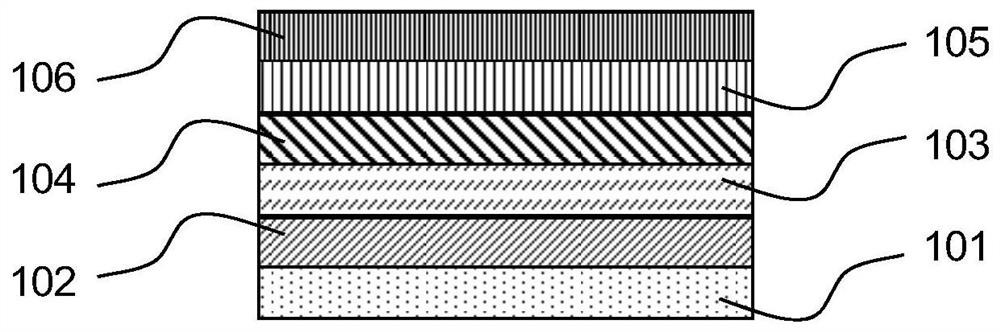

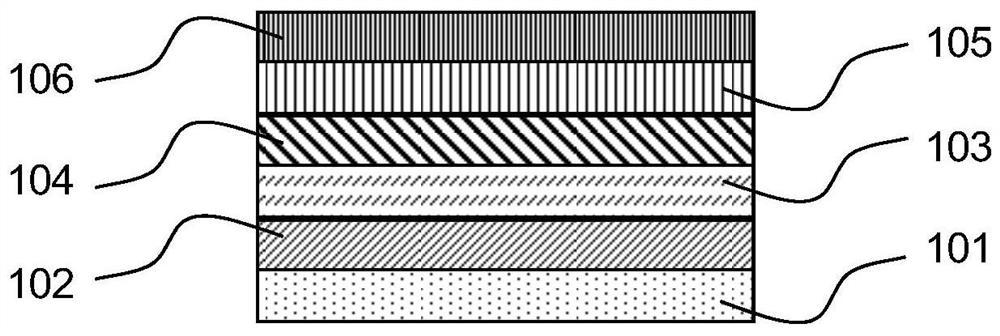

Thin film crystal silicon perovskite heterojunction solar cell manufacturing method

InactiveCN105244442AHighlight substantive featuresLow costFinal product manufactureSolid-state devicesHeterojunctionSolar cell

The invention discloses a thin film crystal silicon perovskite heterojunction solar cell manufacturing method, which relates to a semiconductor device manufacturing method particularly suitable for converting optical energy into electric energy, and is a manufacturing method based on an excimer laser crystallization method. The method of the invention comprises steps: the excimer laser crystallization method is used for manufacturing a P-type thin film crystal silicon layer on a transparent conductive substrate, spin coating of a perovskite light absorption layer is carried out on the P-type thin film crystal silicon layer, an electron transport layer formed by dense titanium dioxide is manufactured on the perovskite light absorption layer, a back electrode is manufactured on the electron transport layer formed by the dense titanium dioxide, and finally, a thin film crystal silicon perovskite heterojunction solar cell composed of the transparent conductive substrate, the P-type thin film crystal silicon layer, the perovskite light absorption layer, the electron transport layer formed by the dense titanium dioxide and the back electrode is manufactured. Defects that the layer transfer technique used in the prior art has multiple steps and is complicated, the obtained thin film crystal silicon has a small size, the finished product rate is low, and the thickness of the thin film crystal silicon can not be over thin can be overcome.

Owner:HEBEI UNIV OF TECH

Silicon thin film solar cell and preparation method thereof

InactiveCN101609852ALow costImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationDeposition temperatureAmorphous silicon

The invention discloses a silicon thin film solar cell and a preparation method thereof. A plurality of layers of an n-type amorphous silicon film, an i-type amorphous silicon film and a p-type si film are sequentially overlapped on a transparent conducting substrate from bottom to top. The i-type amorphous silicon film, the n-type amorphous silicon film and a transparent conducting film (TCO) are sequentially overlapped on the p-type si film to prepare a double-junction silicon film solar cell; or a layer of Al film is directly deposited on the p-type si film to prepare a single-junction silicon film solar cell. The substrate has wide selection range and low cost, the photoelectric conversion efficiency is high, the deposition temperature is low and the technique is simple.

Owner:HUNAN NORMAL UNIVERSITY

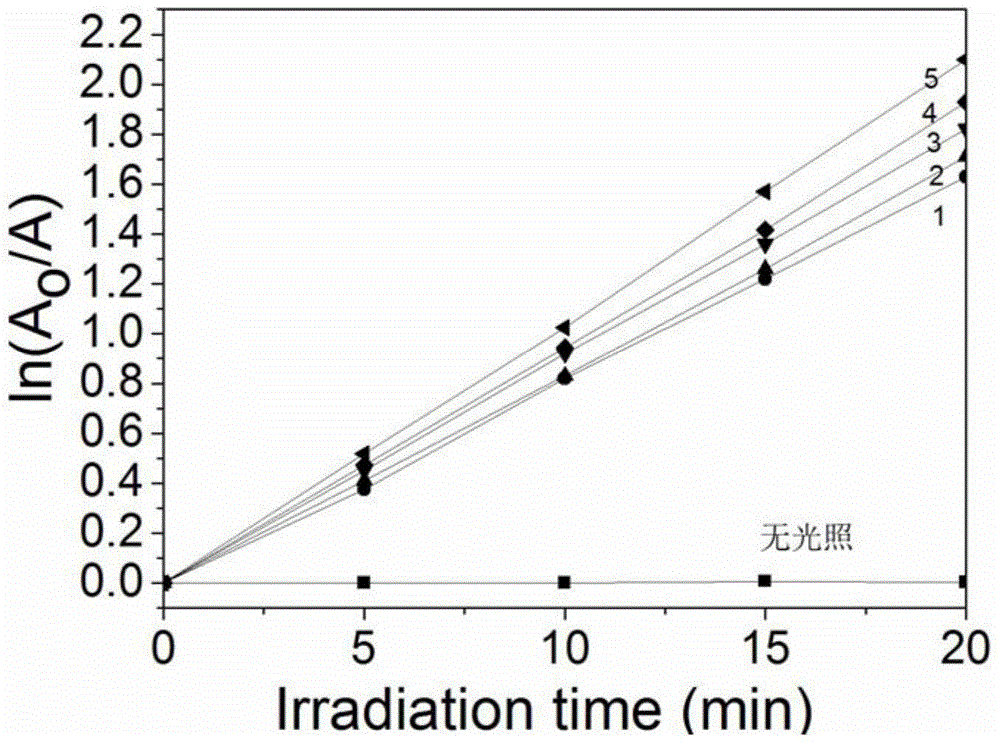

Apparatus and method for processing organic wastewater by using TiO2-based photocatalytic composite-electrode fuel cell

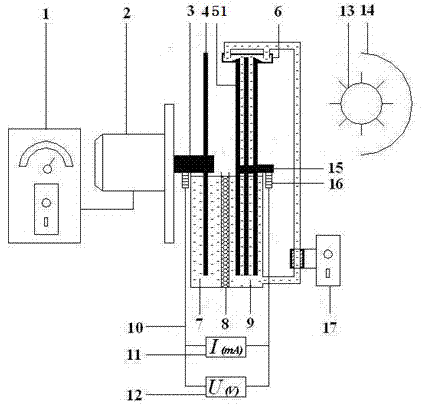

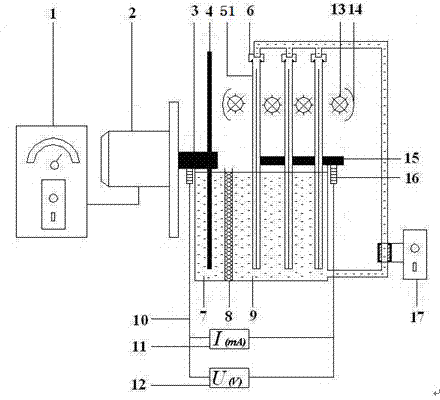

ActiveCN102403523AReduce compound lossIncrease profitWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsDrive motorLight source

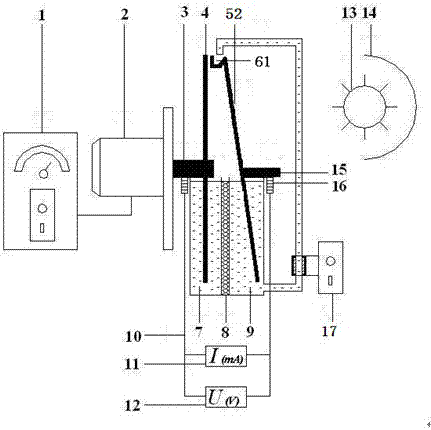

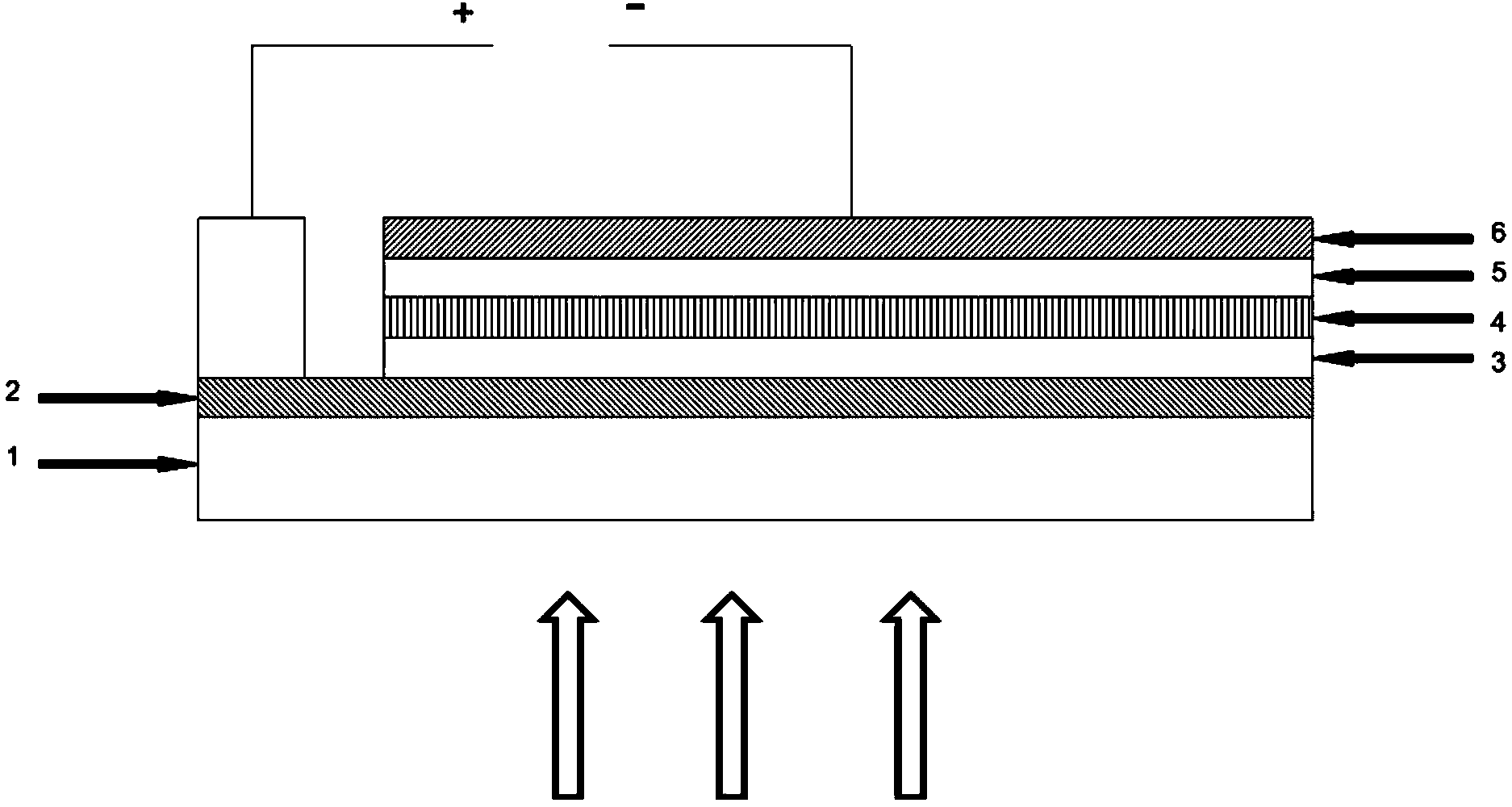

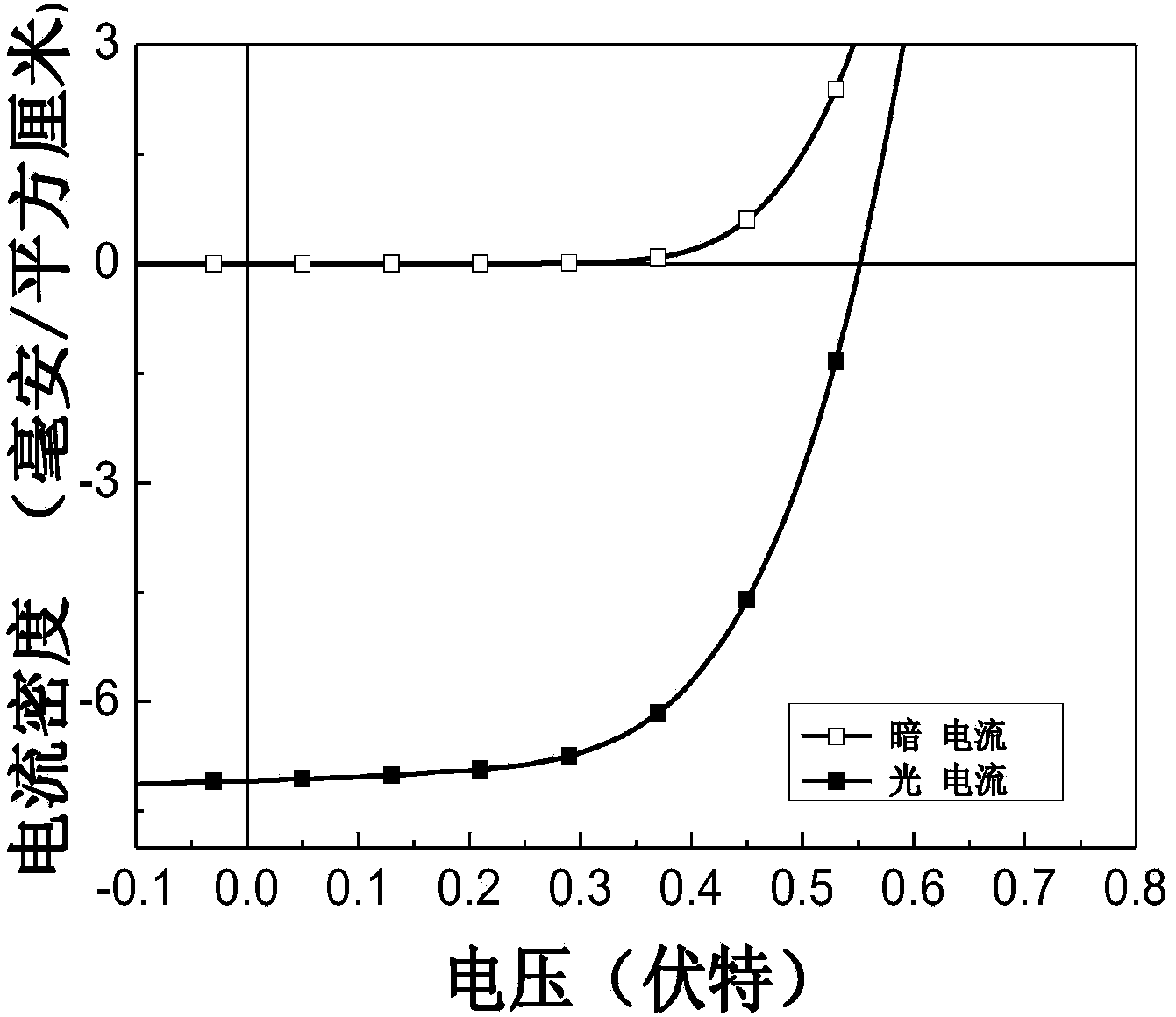

The invention provides two TiO2-based photocatalytic composite-electrode fuel cells with different structures, and an apparatus used for processing organic wastewater. The apparatus comprises a speed regulator, a driving motor, a photocathode shaft, a photocathode rotary table, plural sheets of photo-anodes, a fuel cell reaction tank, and an excitation light source. The apparatus is characterized in that: a draft-tube is arranged on the bottom of the fuel cell reaction tank; and a water pump is arranged on the draft-tube. The water pump is started; the organic wastewater is transferred from the draft-tube on the bottom of the photo-anode reaction tank to the top of the photo-anodes, and flows down, such that a liquid film is formed on the surfaces of the photo-anodes; meanwhile, the driving motor is started, the rotation speed of the photocathode rotary table is controlled by the speed regulator, such that the photocathode rotary table rotates, and a liquid film is also formed on the surface of the photocathode. Photo-anodes with different structures are adopted, such that the processing efficiency of the organic wastewater is improved. The photo-anodes are designed as rectangles, such that the liquid film formed by the water flow on the surfaces of the photo-anodes is more uniform, and the organic wastewater can be more effectively processed by using the TiO2-based photocatalytic composite-electrode fuel cell.

Owner:SHANGHAI JIAO TONG UNIV

Self-assembling type polymer solar cell negative electrode decorating material and decorating method thereof

InactiveCN103928615AReduce work function differenceEfficient injectionFinal product manufactureSolid-state devicesManufacturing technologyPolyvinylidene difluoride

The invention belongs to the technical field of solar cell negative electrode decorating, and particularly relates to a self-assembling type polymer solar cell negative electrode decorating material and a decorating method thereof. The polymer solar cell negative electrode decorating material is a polyvinylidene fluoride (PVDF) thin film formed in a self-assembling mode. The preparing method of the polymer solar cell negative electrode decorating material comprises the steps that a PVDF solution is directly dropped into an active layer solution, the mixed solution is stirred fully, and after one-time spinning coating, a self-separating negative electrode decorating layer is obtained through solvent annealing. Due to the introduction of the PVDF solution, the number of potential barriers collected by electrons in a polymer solar cell is reduced, and efficient collecting of the electrons is achieved. The self-separating PVDF thin film serves as a buffering layer, the recombination between holes and the electrons is effectively reduced, a leak current is reduced, and the photoelectric conversion efficiency of the polymer solar cell is improved. The polymer solar cell has the advantages that the manufacturing technology is simple, cost is low, the experiment repeatability is good and the polymer solar cell is suitable for large-scale industrial production.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Crystalline silicon solar cell and manufacture method thereof

InactiveCN105118874AImprove performanceReduce contact areaPhotovoltaic energy generationSemiconductor devicesCrystalline siliconN type silicon

The present invention relates to a crystalline silicon solar cell and a manufacture method thereof. The crystalline silicon solar cell includes a N type silicon wafer substrate; an antireflection film formed on any surface of the N type silicon wafer substrate; a plurality of first grid lines, wherein, one end of the first grid line is embedded in the N type silicon wafer substrate, and the other end of the first grid line extends and exceeds the antireflection film; a doping layer, wherein, the doping layer is correspondingly formed on the bottom of the first grid lines and integrates with the N type silicon wafer substrate; and a second grid line, wherein, the second grid line covers the first grid lines, is connected with the adjacent first grid line, and collects current. According to the above-mentioned method, a contact area of the grid lines and silicon is reduced, and a defect recombination due to contact is reduced, and furthermore, a recombination loss of heavy doping is reduced by the combination of silicon material partial doping, and a solar battery performance is increased.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

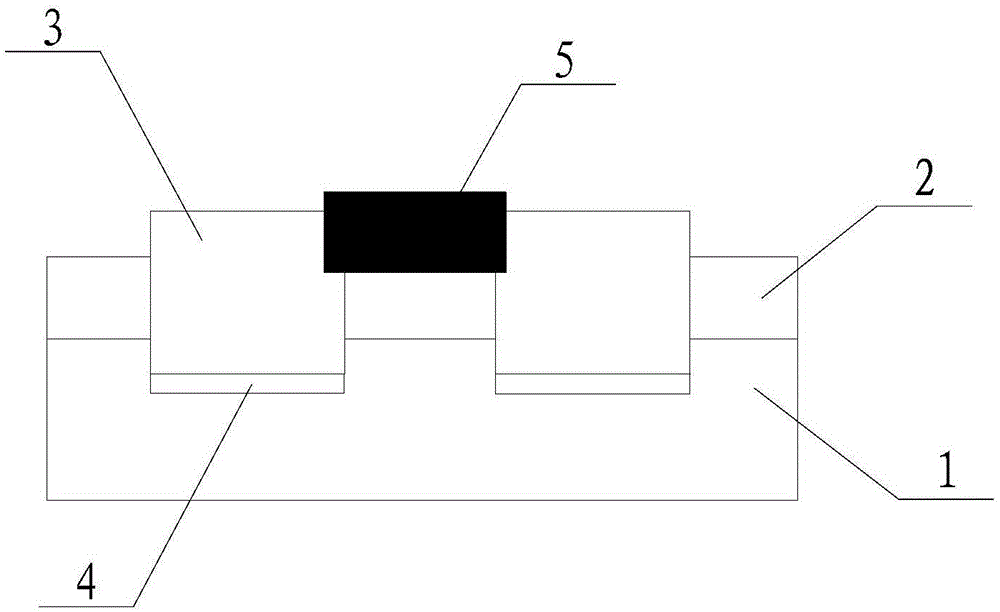

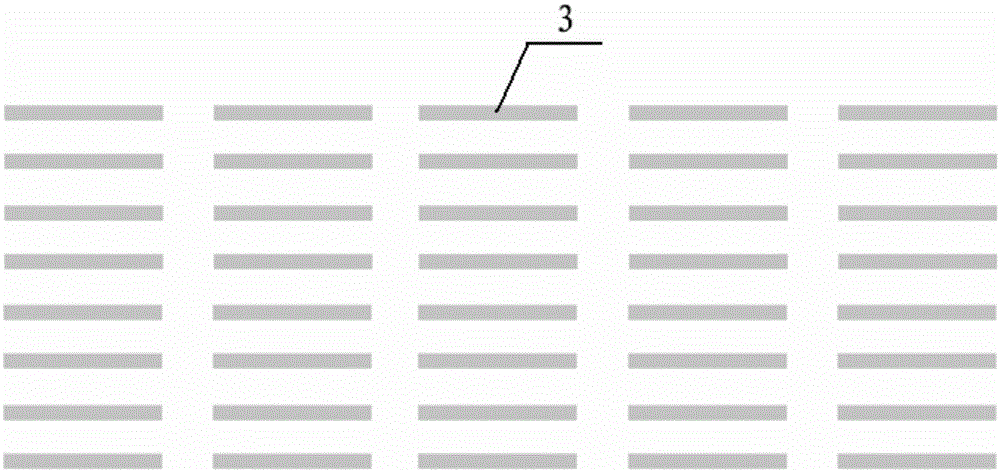

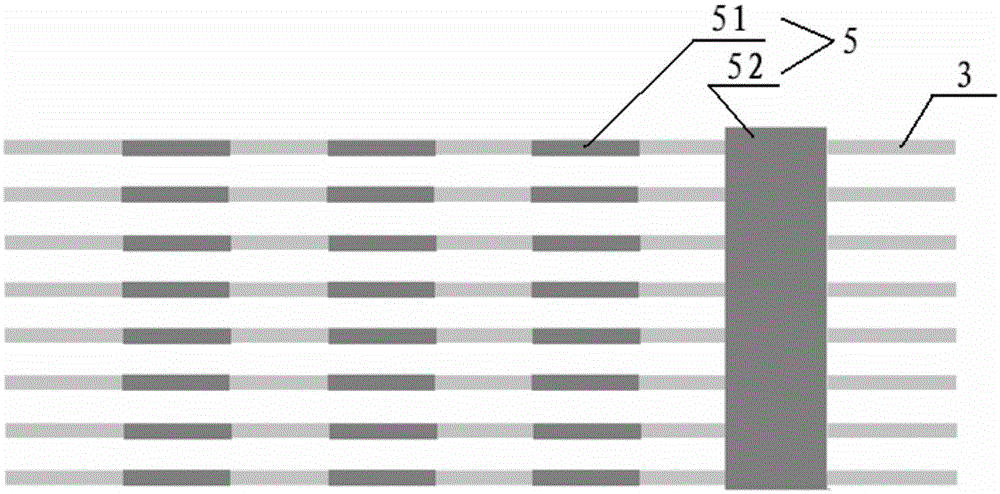

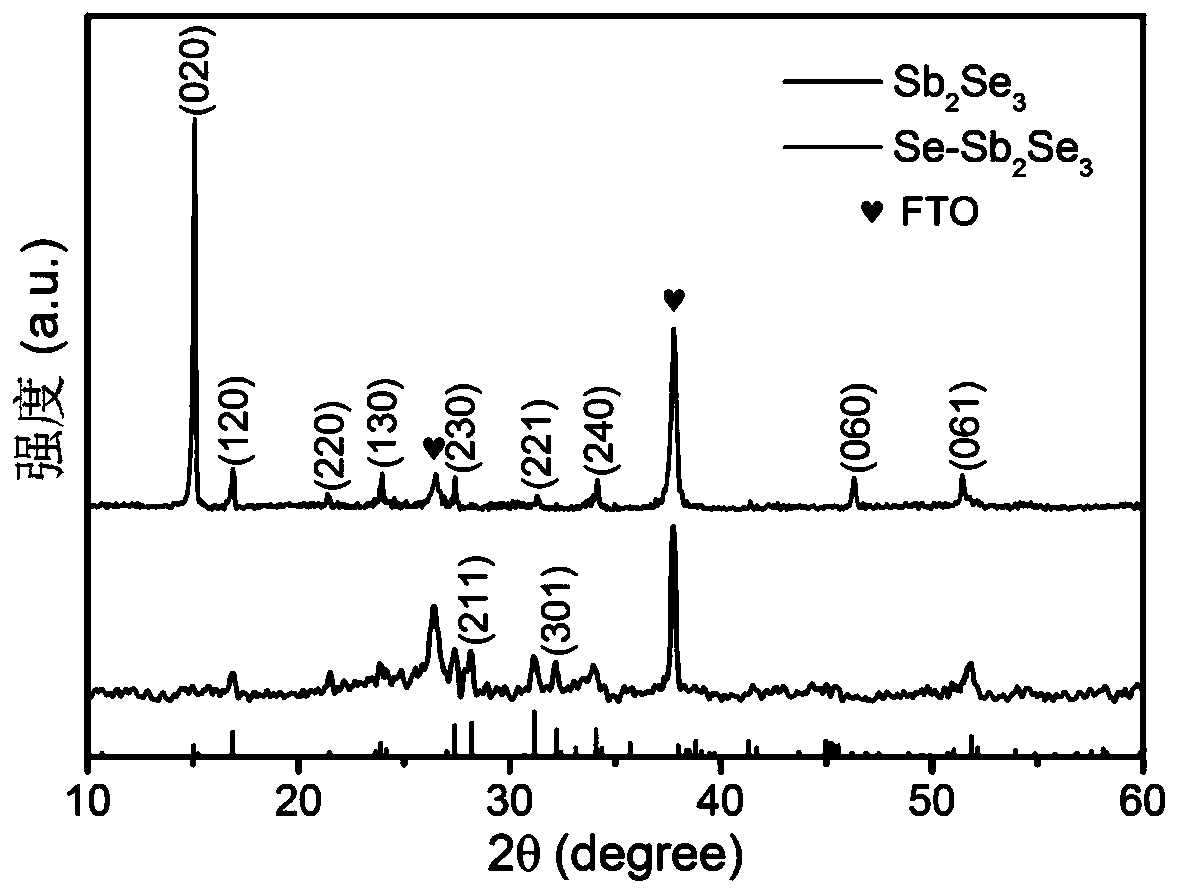

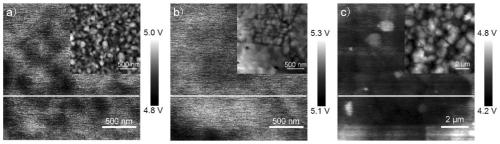

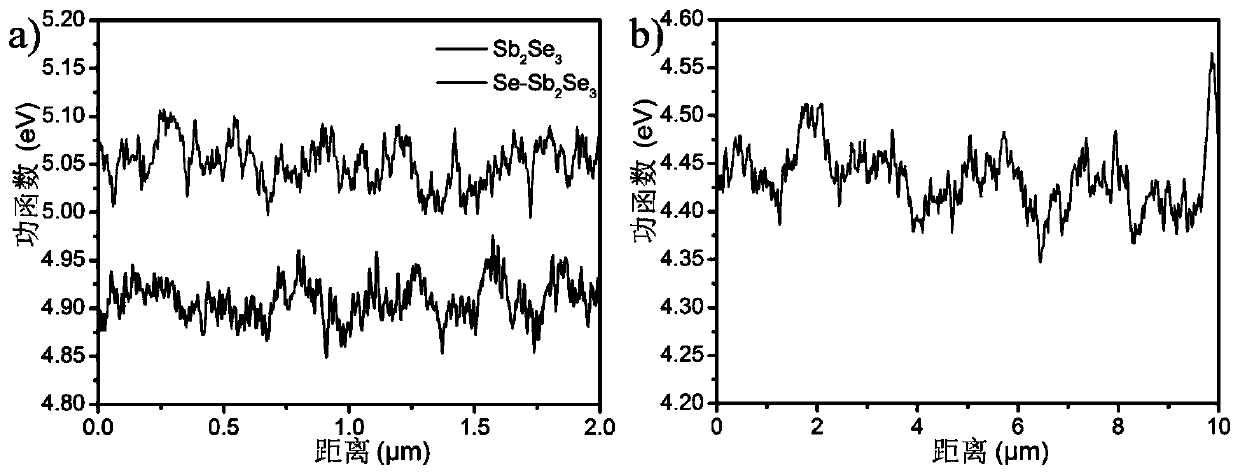

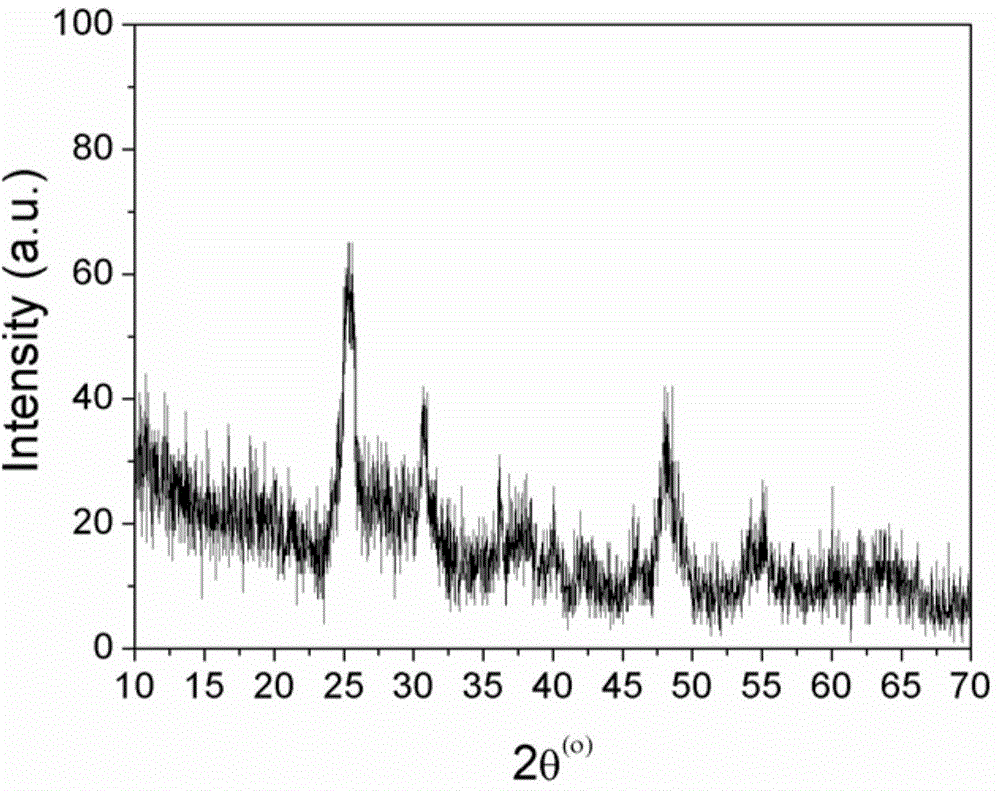

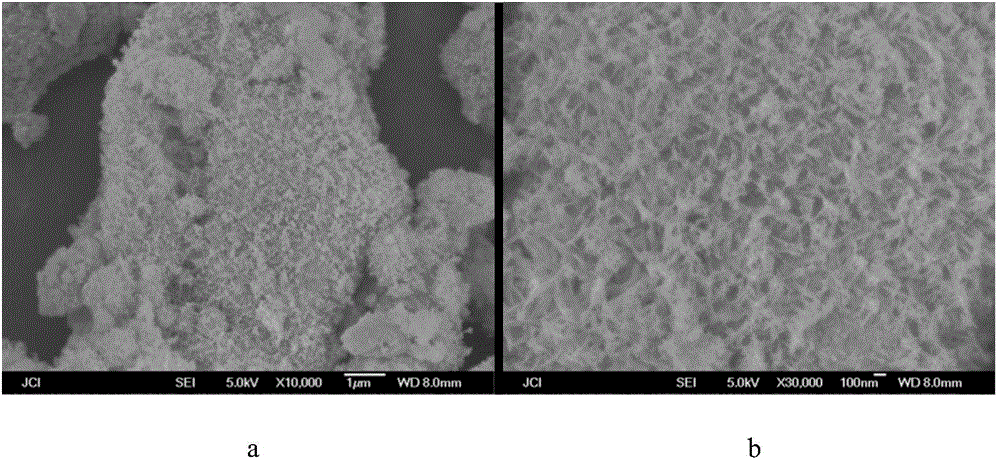

Full-inorganic P/N heterojunction antimony selenide/perovskite solar cell and preparation method thereof

ActiveCN111244220AEasy transferReduce compound lossFinal product manufacturePhotovoltaic energy generationHeterojunctionPerovskite solar cell

The invention provides a full-inorganic P / N heterojunction antimony selenide / perovskite solar cell and a preparation method thereof. The solar cell comprises an FTO conductive glass substrate, a titanium dioxide (TiO<2>) layer, an inorganic CsPbBrI<2> perovskite layer, a selenized Sb<2>Se<3> layer and a metal counter electrode layer which are sequentially arranged from bottom to top. According tothe invention, the Sb<2>Se<3> is selenized to prepare the selenized Sb<2>Se<3> layer, and the inorganic CsPbBrI<2> perovskite layer and the selenized Sb<2>Se<3> layer are compounded into the heterojunction to prepare the full-inorganic P / N heterojunction antimony selenide / perovskite solar cell. The photoelectric conversion efficiency of the prepared solar cell is greatly improved, and the solar cell has good long-term working stability.

Owner:SHANDONG UNIV

Preparation method of CaTi2O5tremella-like micro-nano structure photocatalyst and product prepared by method

ActiveCN104857944AReduce compound lossImprove photocatalytic performanceWater/sewage treatment by irradiationTitanium compoundsMicro nanoControllability

The invention discloses a preparation method of a CaTi2O5tremella-like micro-nano structure photocatalyst, which comprises the steps of dissolving a titanium compound in an organic solvent, adding distilled water to form powder A, dissolving calcium chloride dihydrate in the distilled water, adding an organic solvent, stirring uniformly to form liquid B, adding the liquid B into the powder A, regulating a pH (potential of hydrogen) value of a system to 2-4, stirring and mixing, putting in a hydrothermal kettle for hydrothermal reaction, and washing a reaction product with the distilled water to form the CaTi2O5tremella-like micro-nano structure photocatalyst. In addition, the invention further discloses a product prepared by the preparation method. The method has a simple process route and low production cost, does not require a special device; the pure CaTi2O5tremella-like micro-nano structure photocatalyst with outstanding photocatalysis performance is obtained without a surfactant or a template; the yield and controllability are high; the product still keeps a higher photocatalytic degradation rate after multiple reuse and is easy to recover; and the use value and economic benefits of the product in the industrial circle are effectively improved.

Owner:JINGDEZHEN CERAMIC INSTITUTE

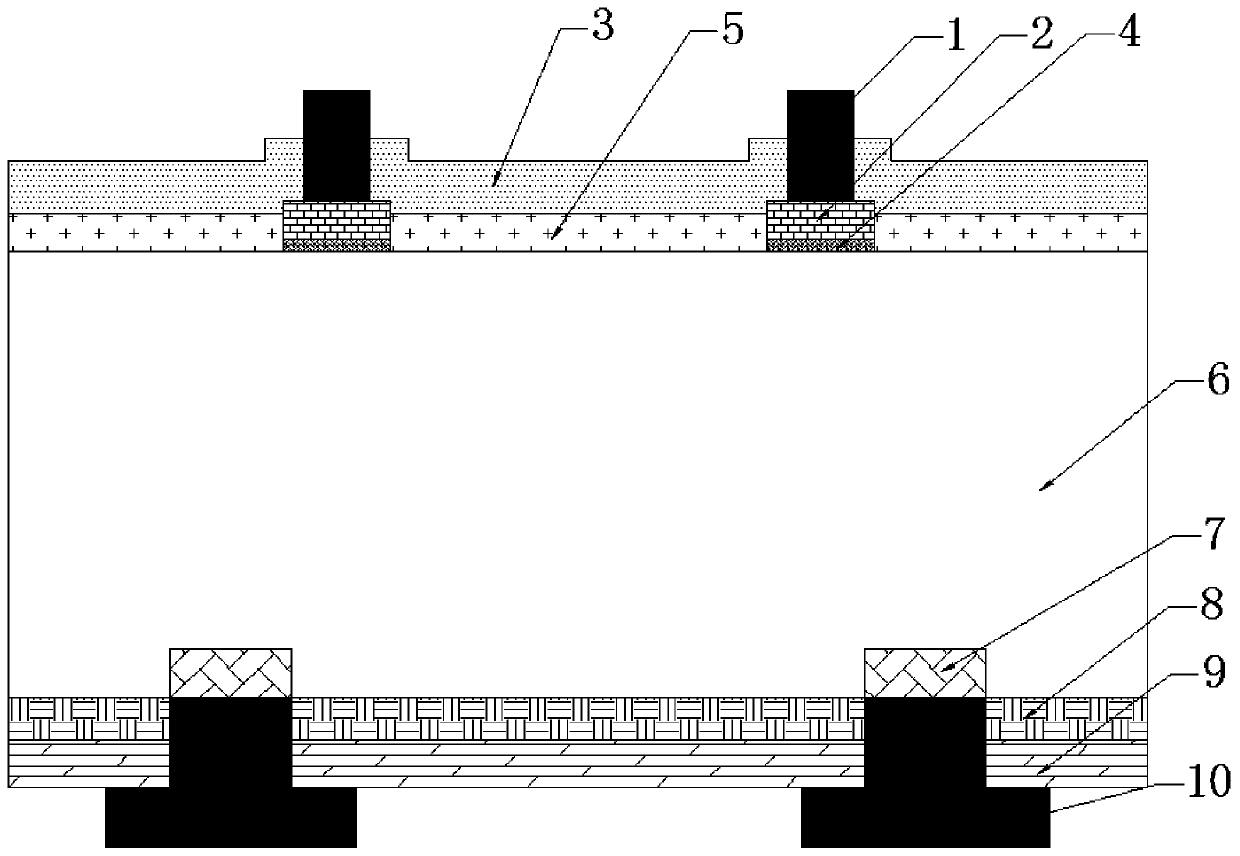

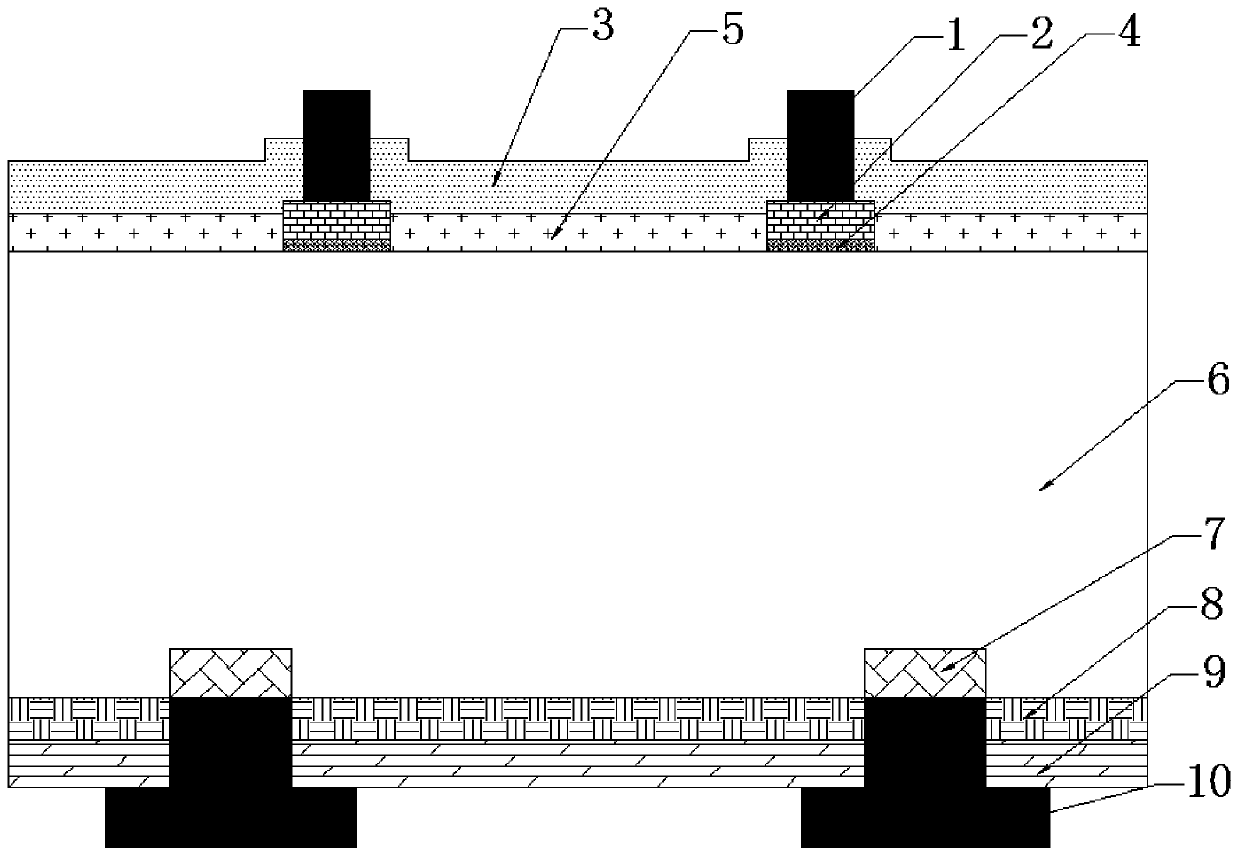

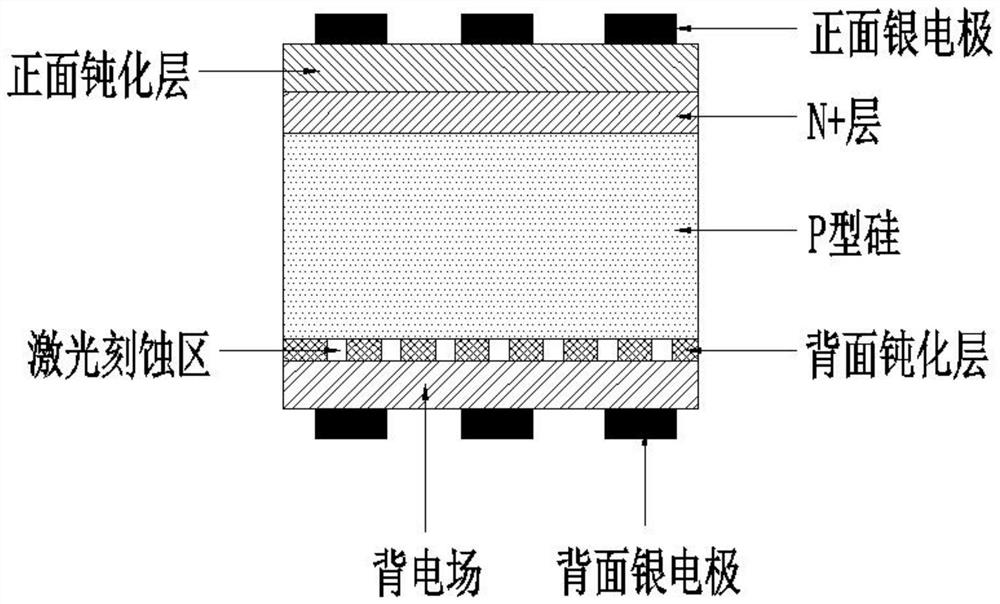

Laser boron-doped back passivation solar cell and preparation method thereof

PendingCN111816714AReduce compound lossIncrease hydrogen saturationFinal product manufacturePhotovoltaic energy generationElectrical batterySolar cell

The invention discloses a laser boron-doped back passivation solar cell and a preparation method thereof, aims at improving a back passivation structure of a solar cell in the prior art, and relates to the technical field of solar cells. The solar cell comprises P-type silicon; a phosphorus doping layer, a front passivation antireflection layer and an Ag gate finger electrode are sequentially arranged on the front surface of the P-type silicon upwards; a passivation layer, a back passivation antireflection layer and an Al gate finger electrode are sequentially arranged on the back surface of the P-type silicon downwards, a heavily doped region is further arranged on the back surface of the P-type silicon, the heavily doped region comprises a boron heavily doped layer and a local contact aluminum doped layer, and the Al gate finger electrode is connected with the lower surface of the P-type silicon through the heavily doped region; by forming the heavily doped region on the back surfaceof the cell, the composite loss of the metal contact region can be effectively reduced, the contact resistance can be reduced, the passivation capability can be enhanced, a relatively high short-circuit current can be maintained, the open-circuit voltage can be increased, and a filling factor can be improved, so that the solar cell with high conversion efficiency and high stability can be realized.

Owner:TONGWEI SOLAR ENERGY MEISHAN CO LTD

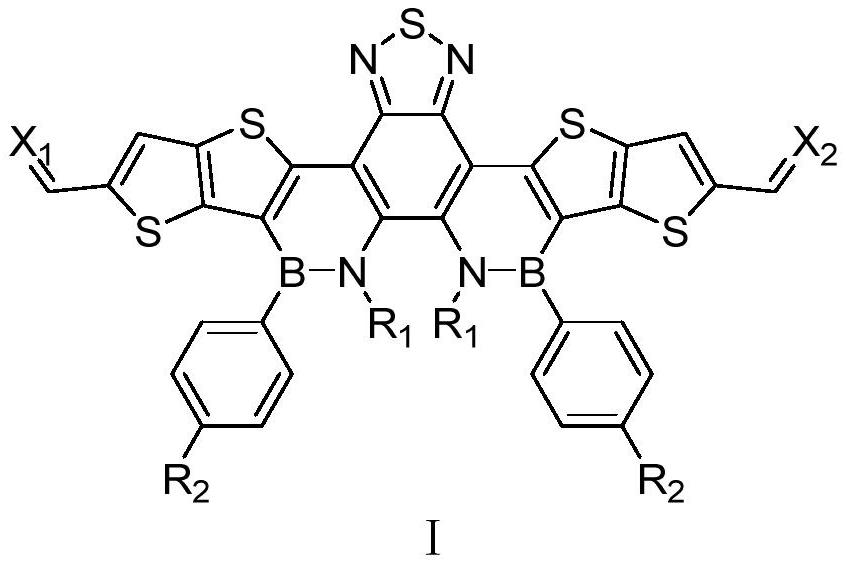

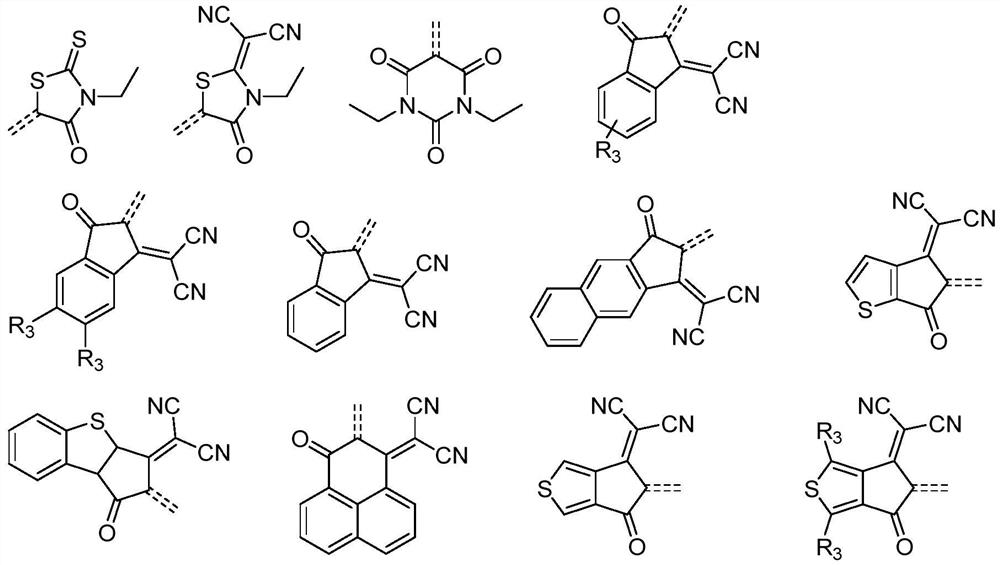

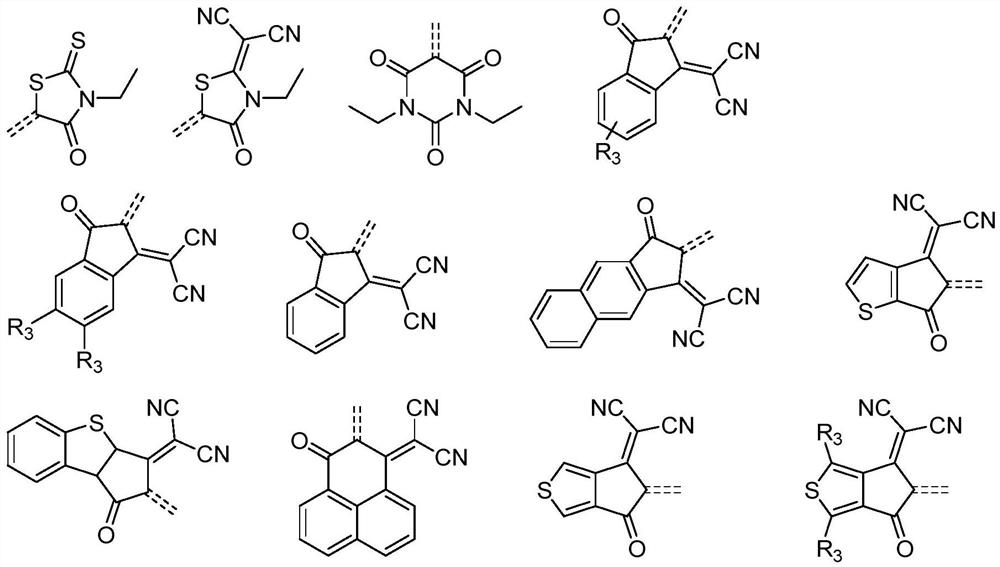

Benzothiadiazole boron-nitrogen derivative material and application thereof in organic electronic device

PendingCN113666953AImprove photoelectric conversion efficiencySolution to short lifeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellBromine

The invention discloses a benzothiadiazole boron nitrogen derivative material and application thereof in an organic electronic device, wherein R1 and R2 are independently selected from C6-C12 alkyl chains, and R3 is any one of hydrogen, fluorine, chlorine, bromine, iodine or methyl. The invention provides an application of the compound in an organic electronic device, wherein the organic electronic device comprises at least one compound as described above. According to the invention, the benzothiadiazole boron-nitrogen derivative has infrared absorption with an absorption wavelength at a long wavelength, the absorption spectrum of the benzothiadiazole boron-nitrogen derivative has a wide absorption range, and the benzothiadiazole boron-nitrogen derivative has high photoelectric conversion efficiency; an organic solar cell element prepared from the benzothiadiazole boron-nitrogen derivative has high photoelectric conversion efficiency and long device service life; and boron and nitrogen have opposite resonance effects, the corresponding boron-nitrogen fused ring compound can improve the triplet state energy level of molecules, but does not affect the accumulation and film formation of the molecules, the recombination loss is reduced, and the battery efficiency is effectively improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

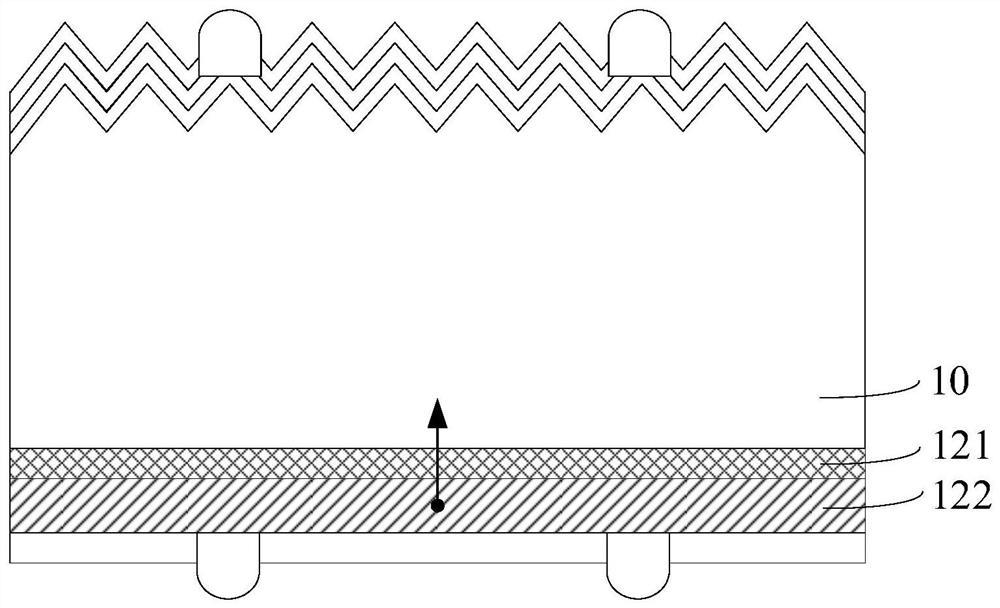

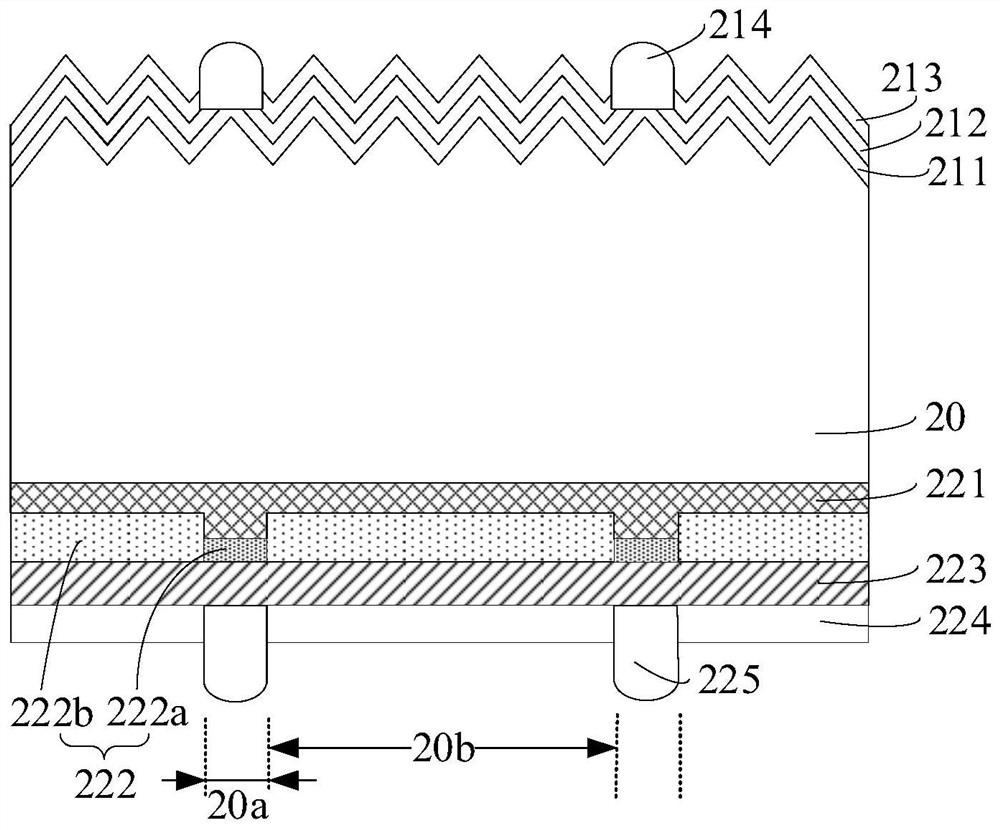

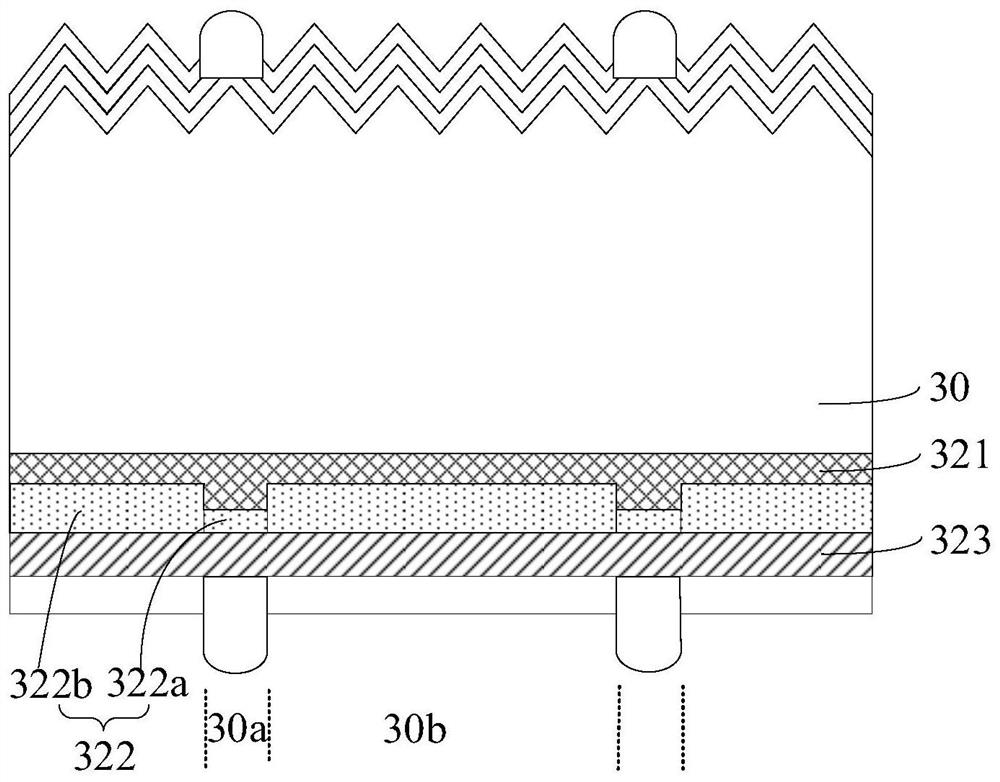

Solar cell

ActiveCN112289873AReduce compound lossImprove conversion efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSolar cell

The embodiment of the invention provides a solar cell. The solar cell comprises: a substrate; an emitting electrode, a first passivation film, an antireflection film and a first electrode which are sequentially stacked on the upper surface of the substrate; and a tunneling layer, a retarding layer, a field passivation layer, a second passivation film and a second electrode which are sequentially stacked on the lower surface of the substrate, wherein the retarding layer is used for retarding doped ions in the field passivation layer from migrating to the substrate, the retarding layer comprisesa first retarding layer body coinciding with the projection of the second electrode and a second retarding layer body with the projection staggered, and at least the second blocking layer is an intrinsic semiconductor. In the direction perpendicular to the surface of the substrate, the thickness of the first retarding layer is smaller than that of the second retarding layer, and the surface, awayfrom the substrate, of the first retarding layer is flush with the surface, away from the substrate, of the second retarding layer. The embodiment of the invention is beneficial to reducing the recombination loss of the solar cell and improving the conversion efficiency of the solar cell.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

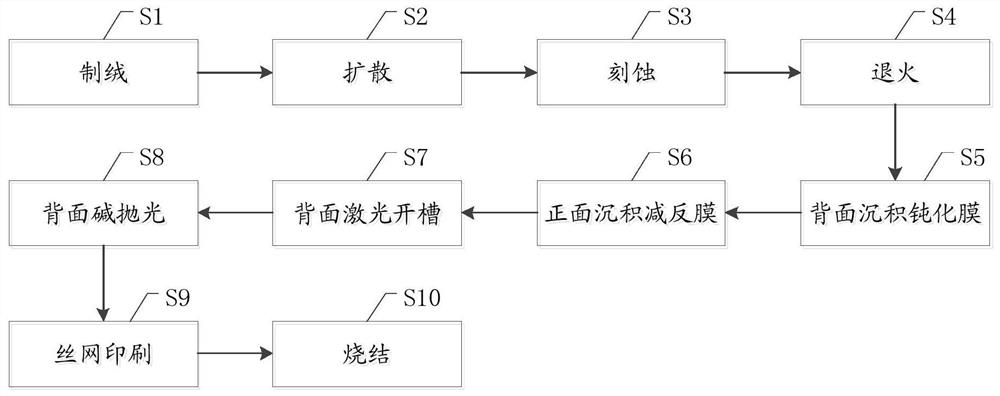

PERC cell processing technology capable of reducing back surface field recombination loss

InactiveCN113241391AReduce compoundingReduce back field compound lossFinal product manufacturePhotovoltaic energy generationPhysicsSilicon chip

The invention is suitable for the technical field of solar cell processing, and provides a PERC cell processing technology capable of reducing back field recombination loss. The technology comprises the steps of texturing, diffusion, etching, annealing, passive film deposition on the back surface, anti-reflection film deposition on the front surface, back surface laser grooving, silk-screen printing and sintering. Between the step of back surface laser grooving and the step of silk-screen printing, the method also comprises the following steps: back surface alkali polishing: polishing the back surface of the silicon wafer by using an alkali solution, and cleaning and drying the silicon wafer. According to the PERC cell processing technology capable of reducing the back field recombination loss provided by the invention, a back alkali polishing technology is added, a damaged layer formed by ablation during laser grooving on the back of the silicon wafer can be removed by using an alkali solution, and recombination of carriers by the damaged layer of the silicon wafer is reduced, so that the back field recombination loss of the PERC cell is reduced, the open-circuit voltage and the short-circuit current of the PERC battery can be improved, and the conversion efficiency of the PERC battery manufactured by the process can be improved by 0.03-0.06%.

Owner:TIANJIN AIKO SOLAR ENERGY TECH CO LTD +2

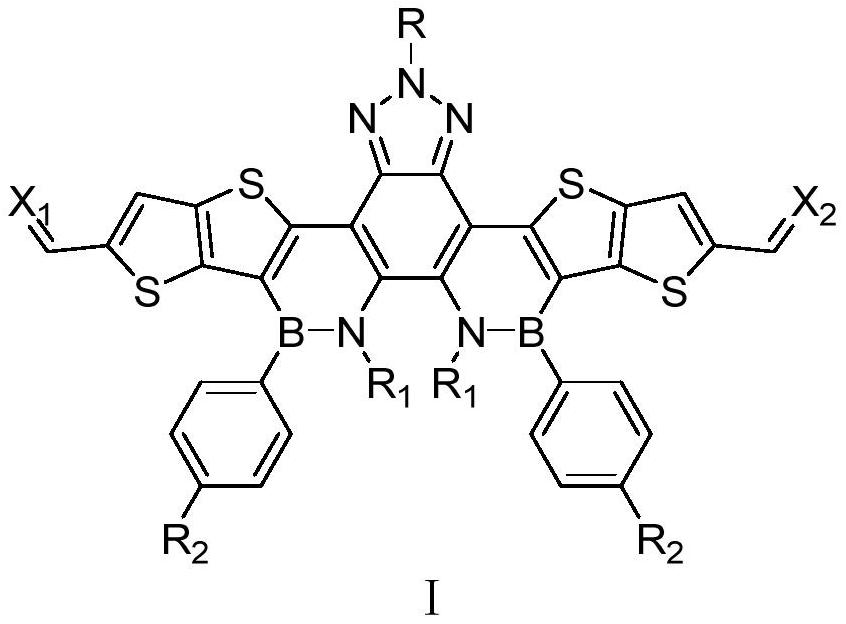

Benzotriazole boron nitrogen derivative small molecular material and application thereof in organic electronic device

PendingCN113549097AWide absorption rangeImprove photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellBenzotriazole

The invention discloses a benzotriazole boron nitrogen derivative small molecular material and application thereof in an organic electronic device. The compound is an n-type non-fullerene acceptor material taking benzotriazole with an alkyl chain as a central core. An organic electronic device comprises at least one compound as described above. The invention relates to a benzotriazole boron nitrogen derivative, which has infrared absorption with long absorption wavelength, and the absorption spectrum of the benzotriazole boron nitrogen derivative has a wide absorption range and high photoelectric conversion efficiency. An organic solar cell element prepared from the benzotriazole boron nitrogen derivative has high photoelectric conversion efficiency and long device service life; boron and nitrogen have opposite resonance effects, the corresponding boron-nitrogen fused ring compound can improve the triplet state energy level of molecules, but does not affect the accumulation and film formation of the molecules, the recombination loss is reduced, and the battery efficiency is effectively improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

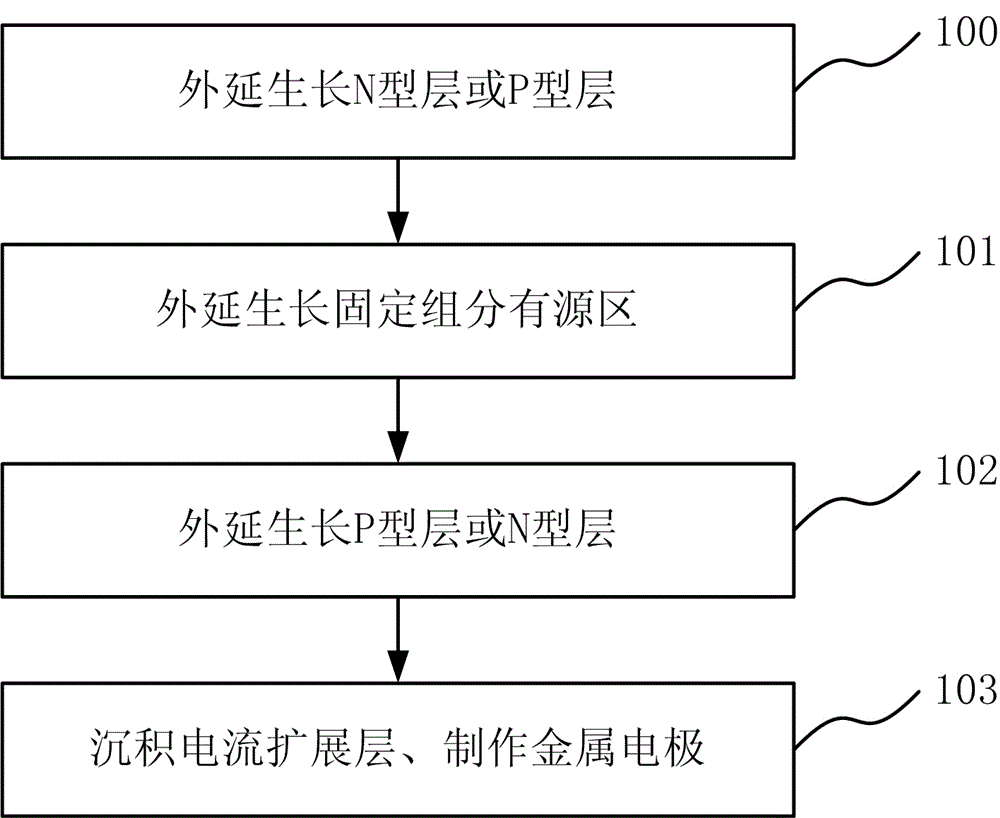

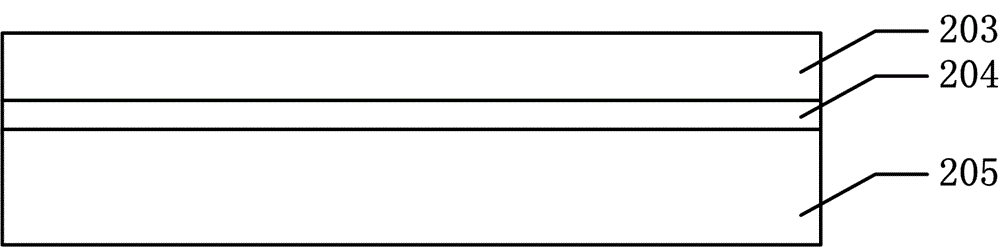

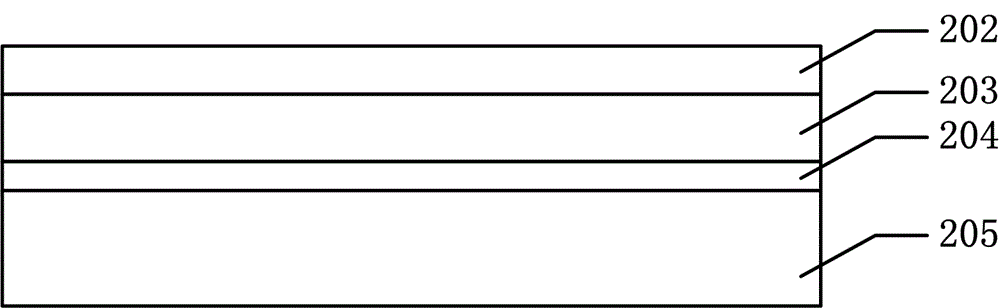

Heterojunction solar cell and preparation method thereof

InactiveCN102723397AReduce carrier recombination lossLower barrier heightFinal product manufacturePhotovoltaic energy generationSolar cellConduction type

The invention provides a heterojunction solar cell. The heterojunction solar cell comprises a first thin film provided with a first electric conduction type, an active area, and a second thin film provided with a second electric conduction type, wherein the active area and the second thin film are sequentially arranged on the surface of the first thin film; a first gradual change buffer layer which is heterogeneous with the first thin film is further arranged between the first thin film and the active area, and a second gradual change buffer layer which is heterogeneous with the second thin film is further arranged between the second thin film and the active area. The invention further provides a preparation method of the heterojunction solar cell, which comprises the following steps: 1), growing the first gradual change buffer layer heterogeneous with the first thin film on the exposed surface of the first thin film; 2), growing the active area epitaxially on the exposed surface of the first gradual change buffer layer; 3), growing the second gradual change buffer layer on the exposed surface of the active area; and 4), growing a second thin film layer heterogeneous with the second gradual change buffer layer on the exposed surface of the second gradual change buffer layer, and the electric conduction types of the first thin film and the second thin film are opposite.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

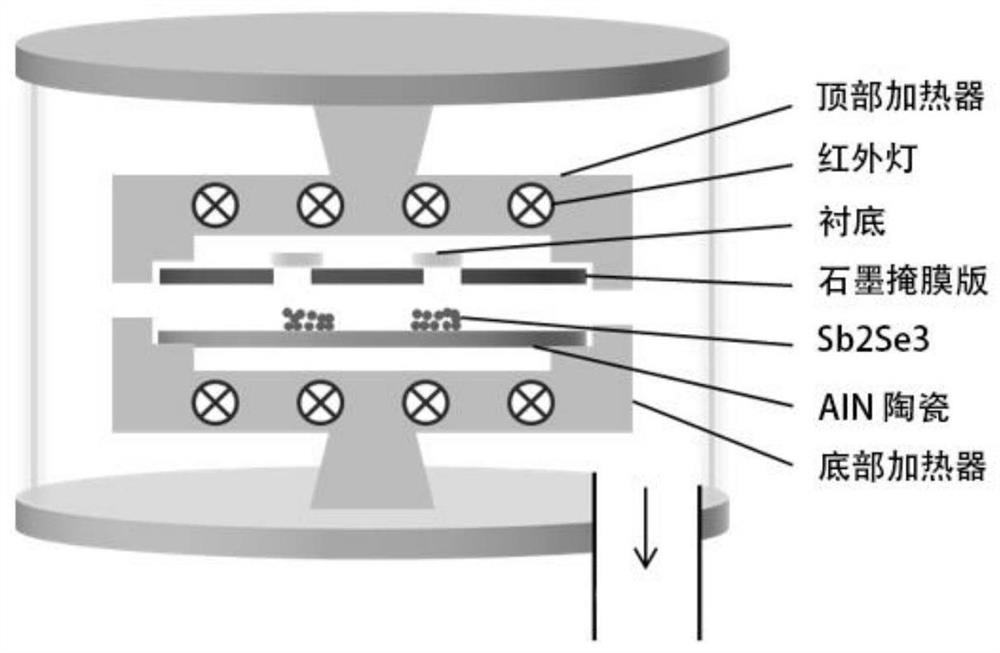

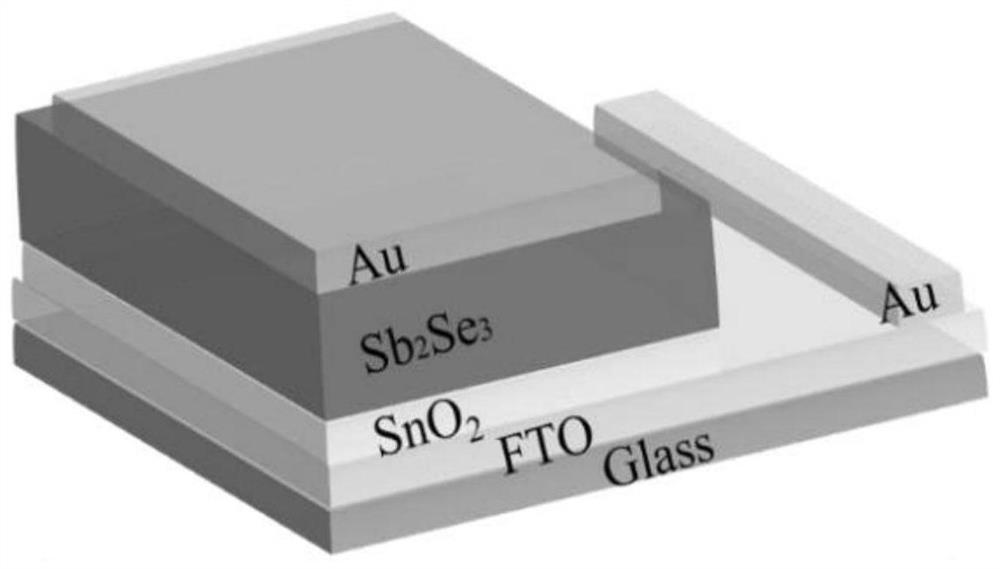

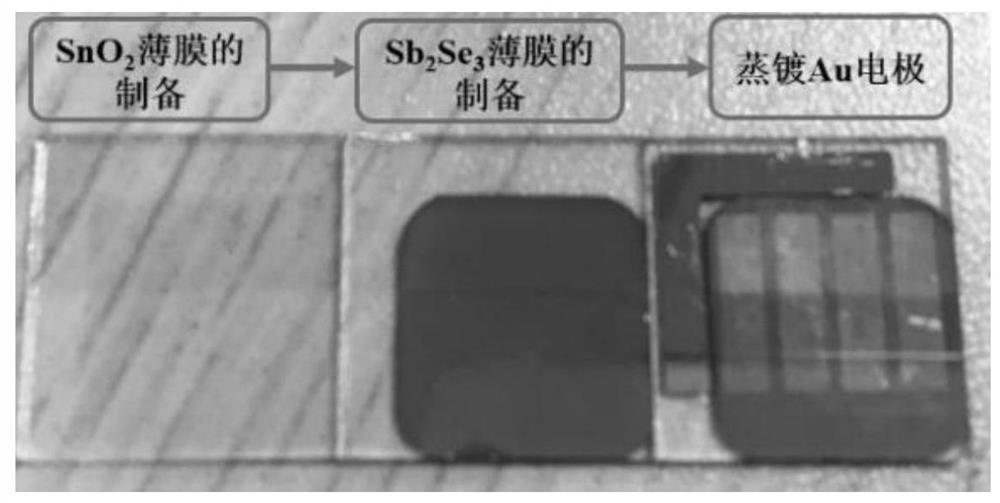

Preparation method of Sb2Se3 solar cell based on SnO2 buffer layer

PendingCN113506838AHigh purityGood repeatabilityFinal product manufactureVacuum evaporation coatingSource materialPhysical chemistry

The invention relates to a preparation method of a Sb2Se3 solar cell based on a SnO2 buffer layer, which comprises the following steps of: depositing a SnO2 thin film by using a magnetron sputtering method, depositing a Sb2Se3 thin film by using a near-space sublimation method CSS, respectively annealing and modifying the SnO2 thin film and the Sb2Se3 thin film, and finally preparing a thin film solar cell device with an FTO / SnO2 / Sb2Se3 / Au top lining structure. Compared with a spray pyrolysis method and a low-temperature pyrolysis method, the magnetron sputtering method has the advantages that the prepared SnO2 film is more compact, higher in purity, better in repeatability and controllable in thickness, introduction of impurities is effectively avoided through sputtering in a high-vacuum chamber, the prepared film is better in uniformity, and waste liquid and any harmful gas cannot be generated; and the CSS is a preparation method for heating a source material to quickly sublimate the source material and depositing the thin film on the substrate, and the CSS source is high in utilization rate, simple in process, good in repeatability and high in film layer purity, so that the Sb2Se3 thin film prepared by the CSS is more suitable for commercial production.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +2

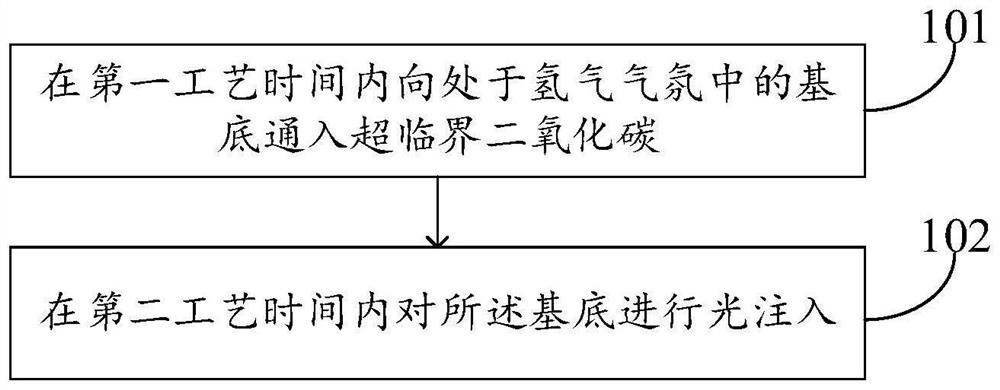

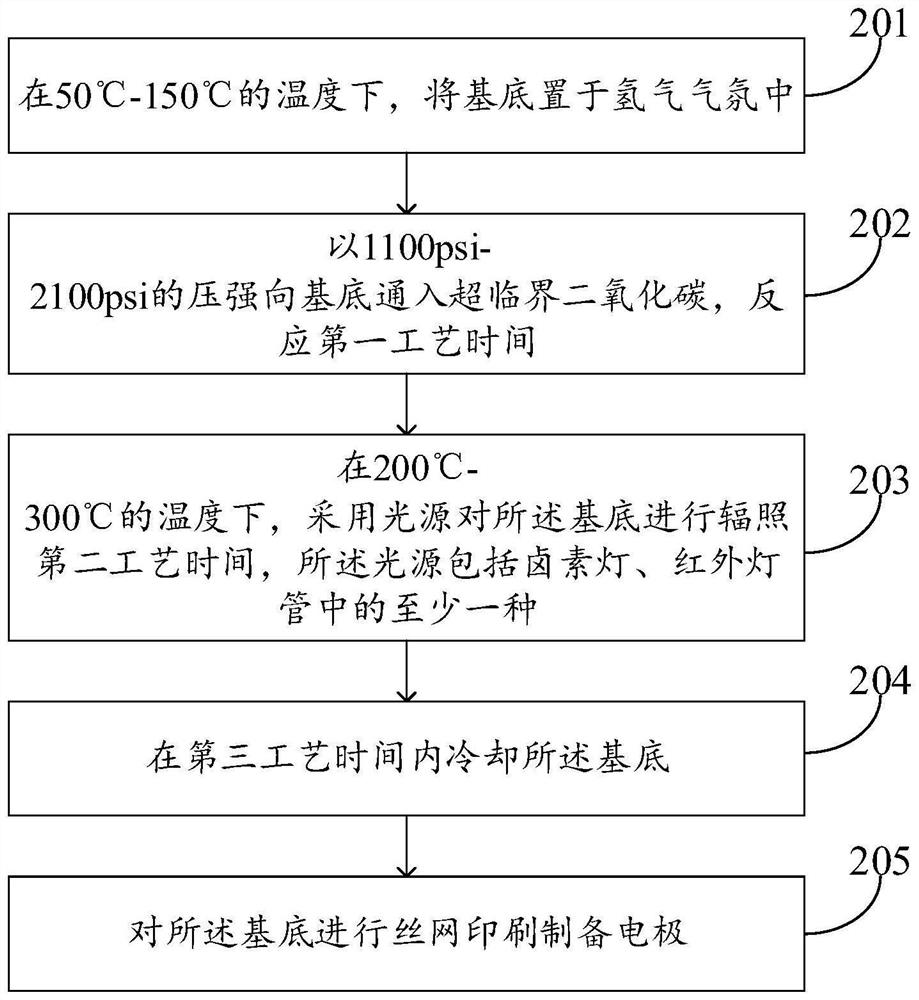

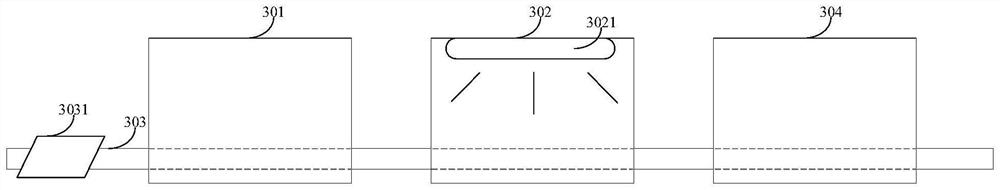

Solar cell annealing method and annealing equipment

PendingCN114420787AImprove conversion efficiencyImprove stabilitySemiconductor devicesHydrogen atmosphereSolar cell

The invention provides a solar cell annealing method and annealing equipment, and relates to the technical field of solar photovoltaics. Supercritical carbon dioxide is introduced into the substrate in the hydrogen atmosphere in the first process time, then light injection is carried out on the substrate in the second process time, the supercritical carbon dioxide is high in density and high in hydrogen solubility, and hydrogen can be better transmitted to the substrate, so that the problem of hydrogen overflow is avoided, and the hydrogen passivation effect is enhanced; after hydrogen excitation is carried out through light injection, the defects of the substrate can be fully saturated, and the recombination loss is reduced, so that the passivation effect is improved, and the conversion efficiency and stability of the cell are improved.

Owner:LONGI SOLAR TECH (XIAN) CO LTD

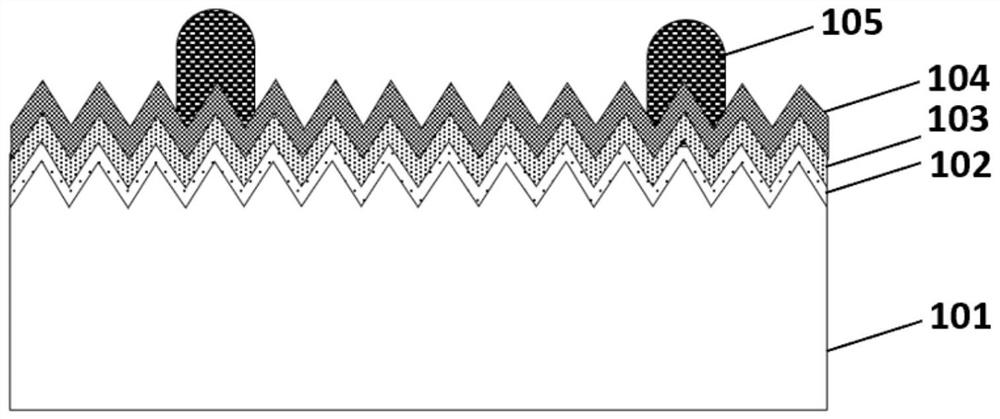

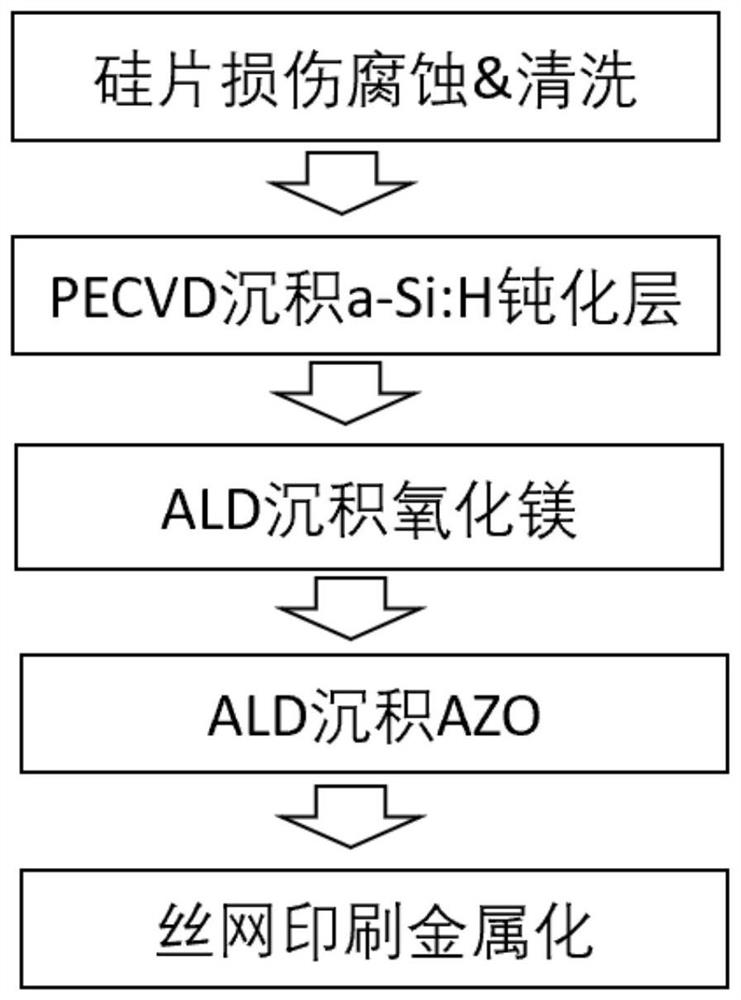

Electron selective passivation contact structure, solar cell and preparation method

ActiveCN114678430AReduce compound lossImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationMetallic electrodeCrystalline silicon

The invention discloses an electron selective passivation contact structure, a solar cell and a preparation method. The electron selective passivation contact structure comprises a crystalline silicon substrate; the tunneling passivation layer is deposited on the crystalline silicon substrate; the electron transport layer is deposited on the tunneling passivation layer, and the electron transport layer is a magnesium oxide film; the transparent electrode is deposited on the electron transport layer, and the transparent electrode is a zinc oxide transparent electrode; and the metal electrode is deposited on the zinc oxide transparent electrode. The crystalline silicon solar cell has high transparency and excellent passivation contact performance, carrier recombination loss at the metal-crystalline silicon contact position can be effectively reduced, parasitic optical absorption can be reduced, and the photoelectric conversion efficiency of the crystalline silicon solar cell is improved.

Owner:SUZHOU UNIV

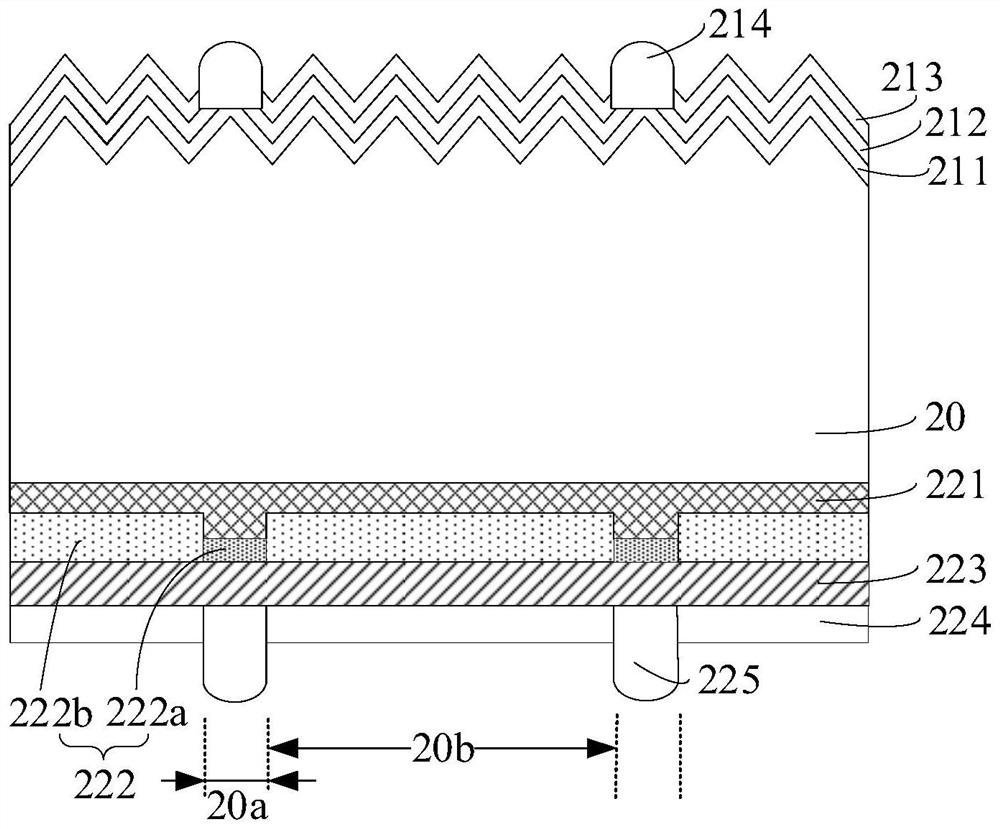

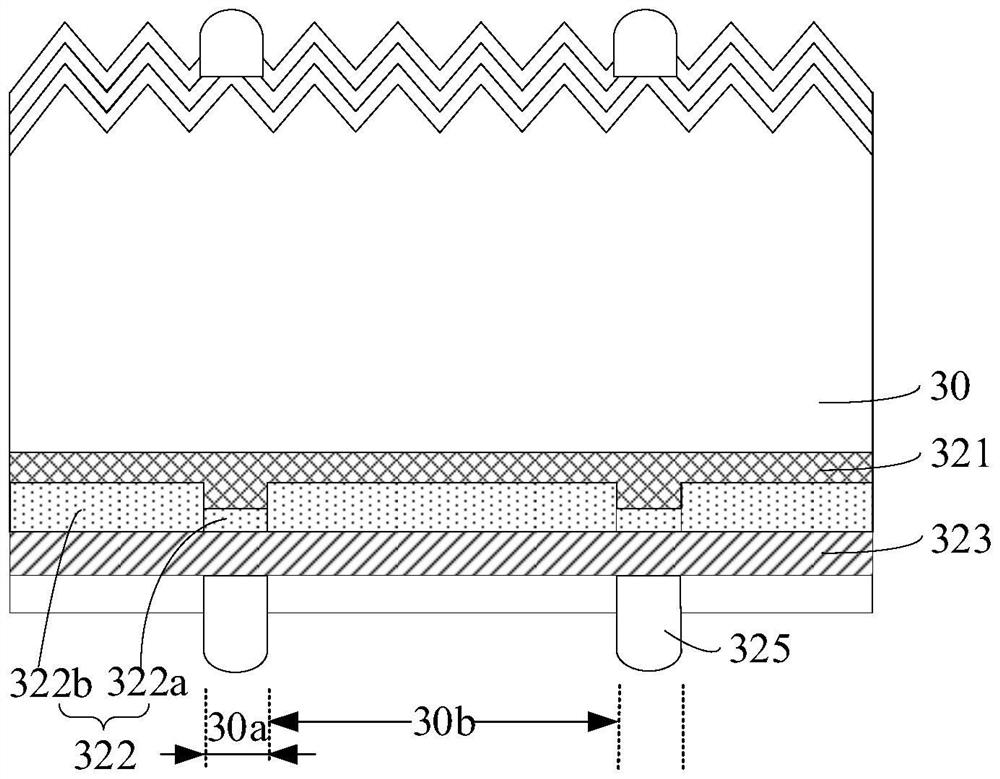

Photovoltaic cell and preparation method thereof, and photovoltaic module

ActiveCN113675289BImprove collection efficiencyImprove transmission efficiencyFinal product manufacturePhotovoltaic energy generationEngineeringCondensed matter physics

The embodiment of the present application relates to the field of solar energy, and provides a photovoltaic cell and its preparation method, and a photovoltaic module. The photovoltaic cell includes: a substrate; the emitter on one side of the substrate includes: at least two first doped regions spaced apart from each other; The second doped region is located between adjacent first doped regions, and there is a gap between the second doped region and two adjacent first doped regions; the transition region is located in the gap, and the first doped region, The transition region and the second doping region have the same doping element, and the concentration of the doping element in the first doping region is smaller than that in the second doping region; the transition region is in contact with the second doping region is the reference surface, the concentration of doping elements in the transition region increases with the decrease of the distance between the transition region and the reference surface, along the direction perpendicular to the reference surface, the width of the second doping region is the same as that of the transition region The ratio of width is 3:1~1:1. The embodiments of the present application are at least beneficial to improving the transport efficiency of carriers in the emitter.

Owner:ZHEJIANG JINKO SOLAR CO LTD

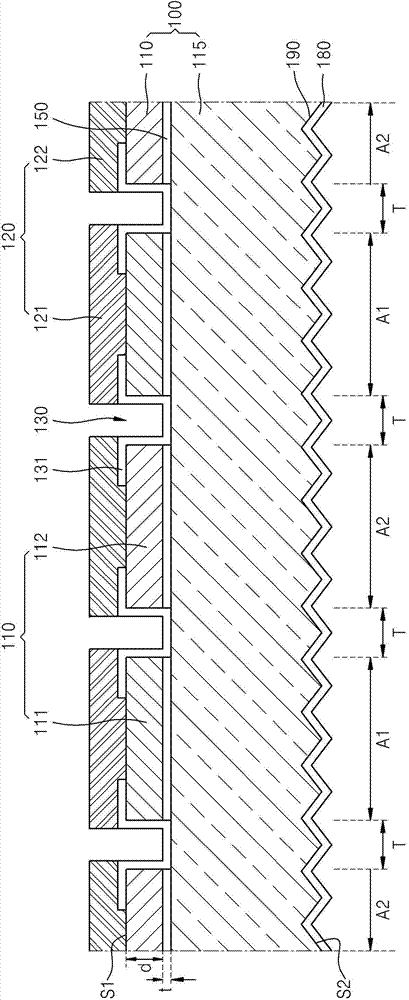

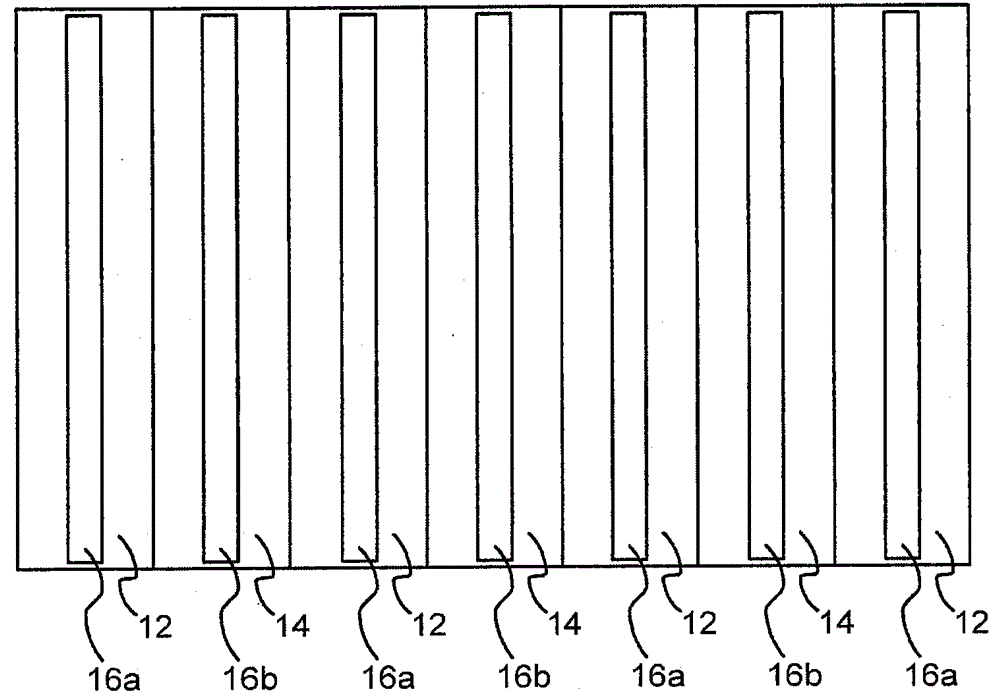

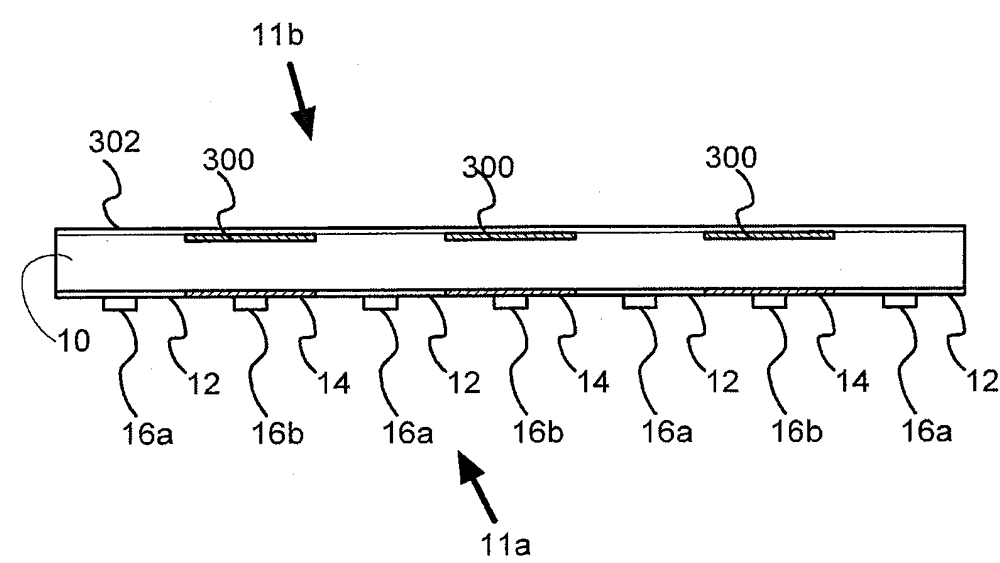

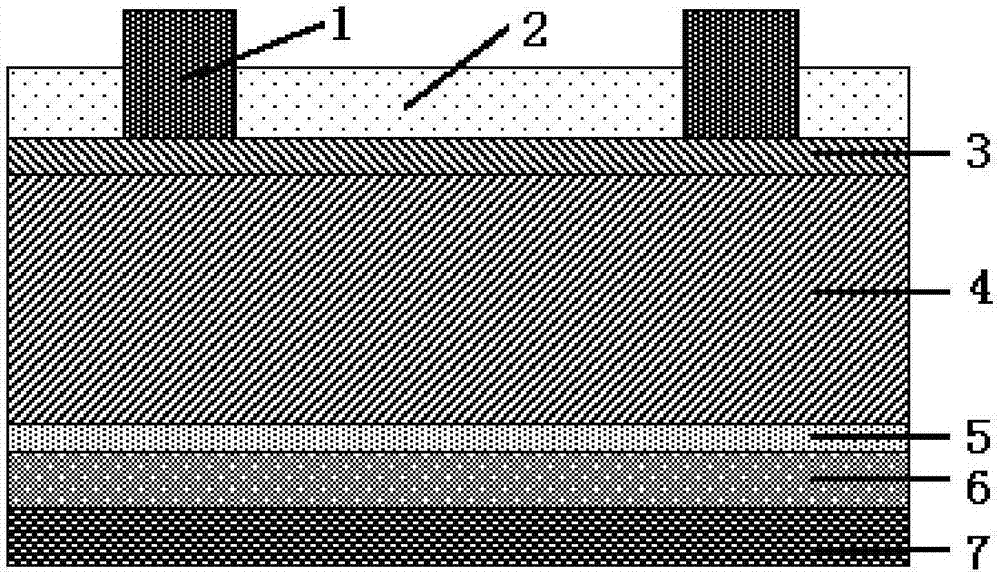

Photoelectric device and method of manufacturing same

ActiveCN103811572AReduce compound lossImprove collection efficiencyFinal product manufacturePhotovoltaic energy generationDopantElectrical conductor

Provided are a photoelectric device and a method of manufacturing the photoelectric device. The photoelectric device includes: a semiconductor substrate that is formed of monocrystalline silicon and has first and second surfaces that are opposite to each other; a doping unit formed in the first surface of the semiconductor substrate; and an insulating layer that is formed between the doping unit and the second surface of the semiconductor substrate, wherein the doping unit includes: a first semiconductor layer including a first dopant doped in the monocrystalline silicon; and a second semiconductor layer including a second dopant doped in the monocrystalline silicon.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Method for carrying out phosphorus diffusion on silicon wafer, product and solar cell

ActiveCN113130306AUniform resistance distributionReduce "dead layers"Final product manufactureSemiconductor/solid-state device manufacturingPhysical chemistryEngineering

The invention provides a method for carrying out phosphorus diffusion on a silicon wafer, a product and a solar cell. The method comprises the following steps of: 1) placing a silicon wafer in a container, placing the container in a reactor, introducing an oxidizing atmosphere, and heating the reactor; 2) introducing a gas containing a phosphorus source into the reactor for the first time, and then introducing the gas containing the phosphorus source into the reactor for the second time; 3) raising the temperature of the reactor, carrying out first propulsion, and then carrying out second propulsion; 4) cooling the reactor, introducing the gas containing the phosphorus source for the third time, then cooling again, and introducing the gas containing the phosphorus source for the fourth time; and 5) introducing an oxidizing atmosphere to obtain a silicon wafer with diffused phosphorus. According to the phosphorus diffusion method provided by the invention, the diffusion sheet resistance and uniformity are improved, so that the conversion efficiency of a large-size solar cell is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

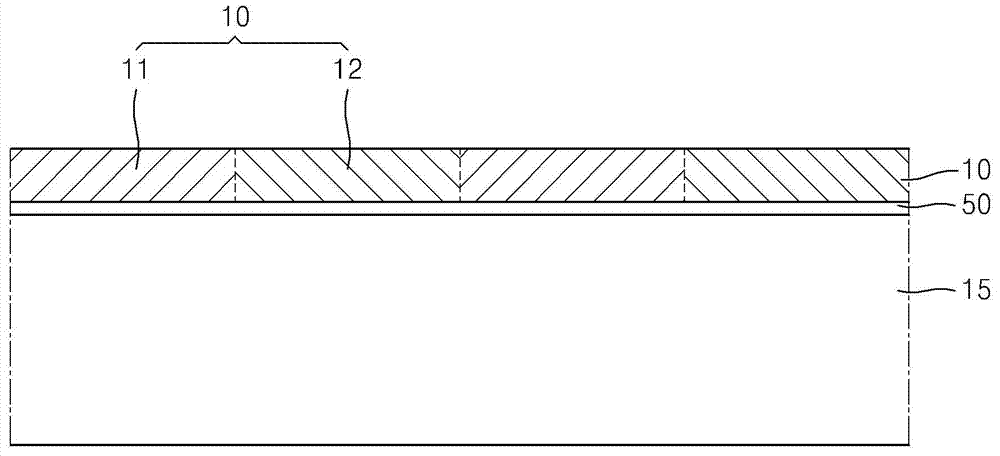

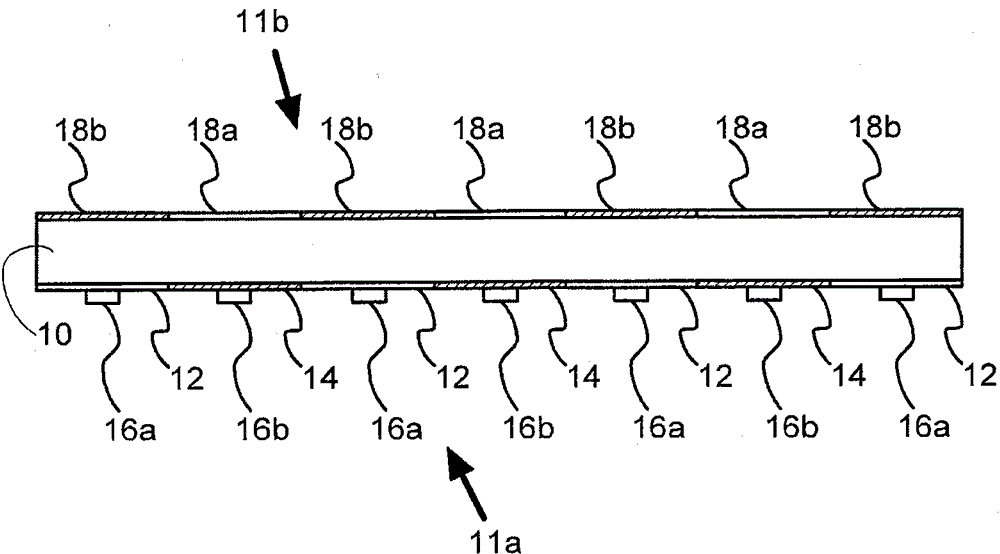

Interdigitated back-contact photovoltaic cells with floating front-emitter regions

InactiveCN103890961BReduce compound lossPhotovoltaic energy generationSemiconductor devicesEngineeringSemiconductor

A photovoltaic cell having a semiconductor substrate of a first conductivity type, the back surface of the semiconductor substrate having a base surface region and an emitter surface region of a first pattern, the base surface region and the emitter surface region being respectively coupled to a second One and the second output terminal. The first further surface area having the second pattern and the second further surface area on the front side are electrically floating with respect to the first and second output terminals. The first further surface region and the second further surface region have a first conductivity type and a second conductivity type, respectively. The first further surface region and the second further surface region at least partially overlap the emitter region and the base region, respectively, when viewed in projection in a direction perpendicular to the first surface.

Owner:STICHTING ENERGIEONDERZOEK CENT NEDERLAND

Solar cell

ActiveCN114843349ARaise the barrierImprove flexibilityFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellBlocking layer

The embodiment of the invention provides a solar cell. The solar cell comprises a substrate; the emitting electrode, the first passivation film, the anti-reflection film and the first electrode are sequentially stacked on the upper surface of the substrate; the tunneling layer, the blocking layer, the field passivation layer, the second passivation film and the second electrode are sequentially stacked on the lower surface of the substrate, the blocking layer is used for blocking doping ions in the field passivation layer from migrating to the substrate, the blocking layer comprises a first blocking layer coinciding with the projection of the second electrode and a second blocking layer with the projection staggered, and at least the second blocking layer is an intrinsic semiconductor; in the direction perpendicular to the surface of the substrate, the thickness of the first blocking layer is smaller than that of the second blocking layer, the surface, away from the substrate, of the first blocking layer is flush with the surface, away from the substrate, of the second blocking layer, and the thickness of the tunneling layer coinciding with the projection of the second electrode is larger than that of the tunneling layer staggered with the projection of the second electrode. The embodiment of the invention is beneficial to reducing the recombination loss of the solar cell and improving the conversion efficiency of the solar cell.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

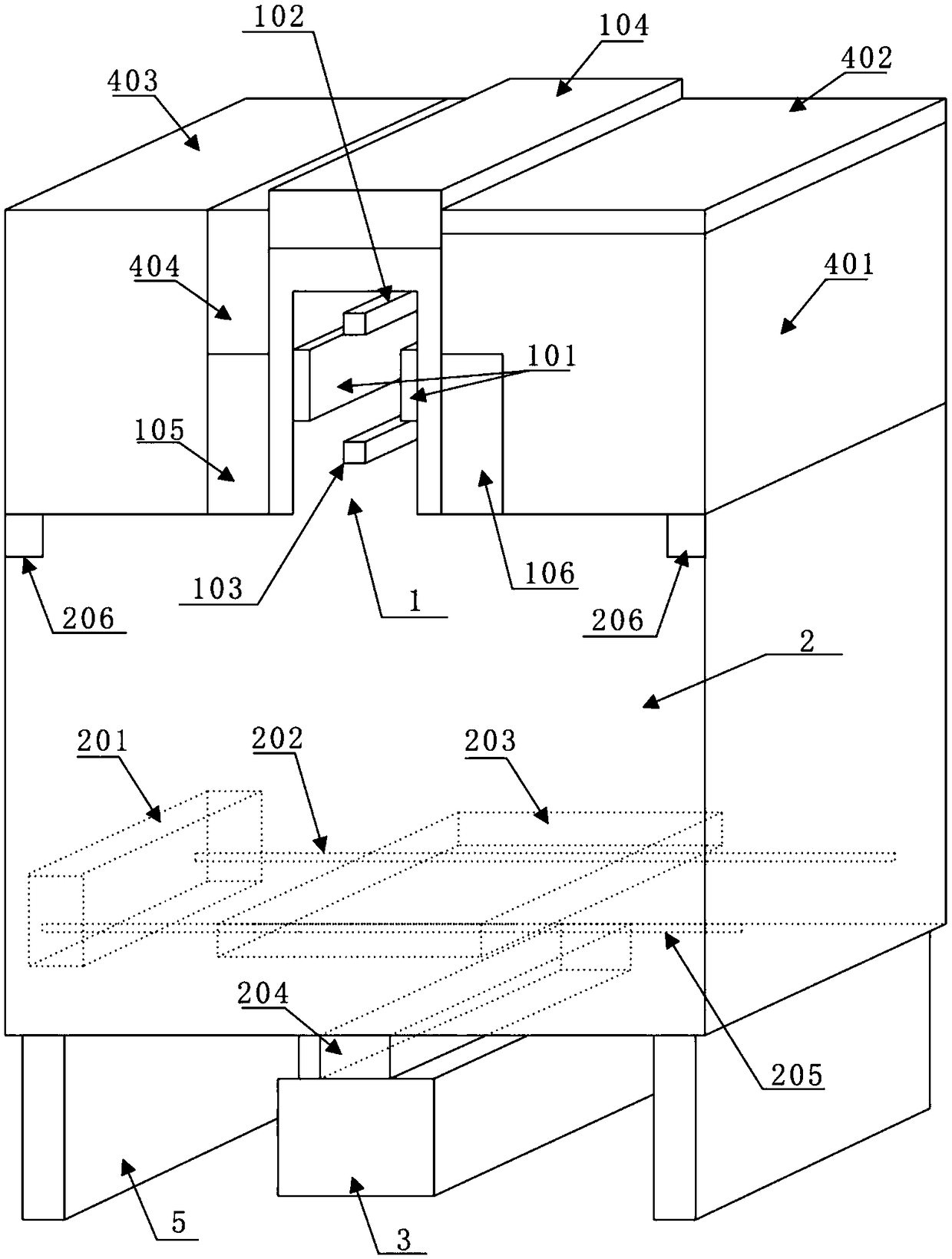

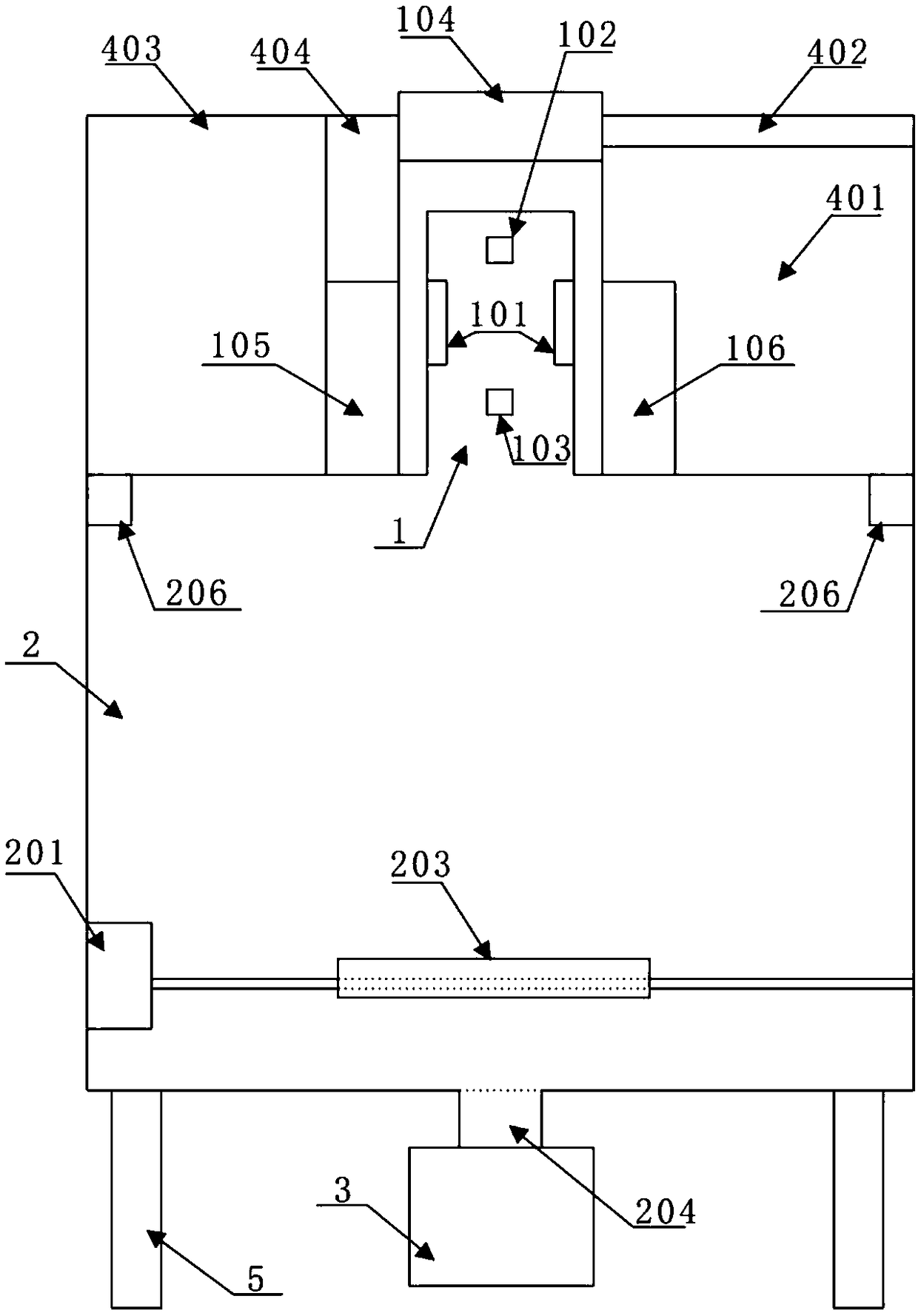

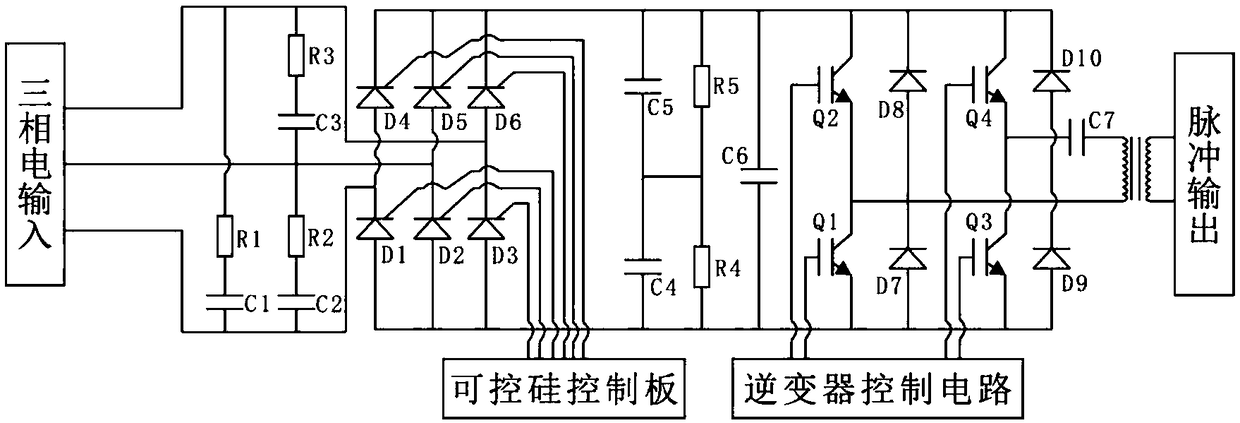

A plasma modified ultrafiltration membrane treatment system

ActiveCN107301942BHigh densityImprove uniformityElectric discharge tubesUltrafiltrationEngineeringModified ultrafiltration

The invention discloses a plasma modified ultrafiltration membrane processing system which comprises a working room which is provided with a discharge chamber. One side of the discharge chamber is provided with a master control box which is internally provided with a control unit and a plasma power supply module. The master control box is provided with a control panel connected to the control unit. The discharge chamber is internally provided with electrodes which just face the plasma power supply module and are connected to the plasma power supply module. The working room is internally provided with an ultrafiltration membrane loading component. The bottom of the working room is provided with an extraction opening which is connected to a vacuum machine set. The vacuum machine set is connected to the control unit. The ultrafiltration membrane loading component comprises a stepping device connected to the control unit, and the stepping device is movably connected to a substrate holder for storing an ultrafiltration membrane through at least one threaded rod. According to the system, the thickness of a film formed on the ultrafiltration membrane is uniform, the output of the plasma power supply module is stable, the accidental tripping protection can be carried out, and the safety of the system is effectively improved.

Owner:四川恒创博联科技有限责任公司

Photovoltaic cell and its preparation method, photovoltaic module

ActiveCN113571604BImprove collection efficiencyImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryMaterials science

The embodiment of the present application relates to the field of solar energy, and provides a photovoltaic cell and its preparation method, and a photovoltaic module. The method includes: providing a substrate; sequentially forming an emitter and a doping source layer on the surface of the substrate. Doping elements: using a laser to process a local region of the doping source layer to sequentially form a first doping region and a damaged region in the emitter corresponding to the local region and the substrate, the first doping region has a doping element; removing the doped source layer and the damaged region; forming a passivation layer on the surface of the first doped region and the emitter; forming a doped electrode with doping elements on the side of the passivation layer away from the emitter; sintering the doped electrode to form The electrode of the passivation layer is penetrated, and a second doping region is formed between the electrode and the first doping region, and the concentration of doping elements in the second doping region is higher than that in the first doping region. The embodiments of the present application are at least beneficial to improving the photoelectric conversion efficiency of the photovoltaic cell.

Owner:ZHEJIANG JINKO SOLAR CO LTD

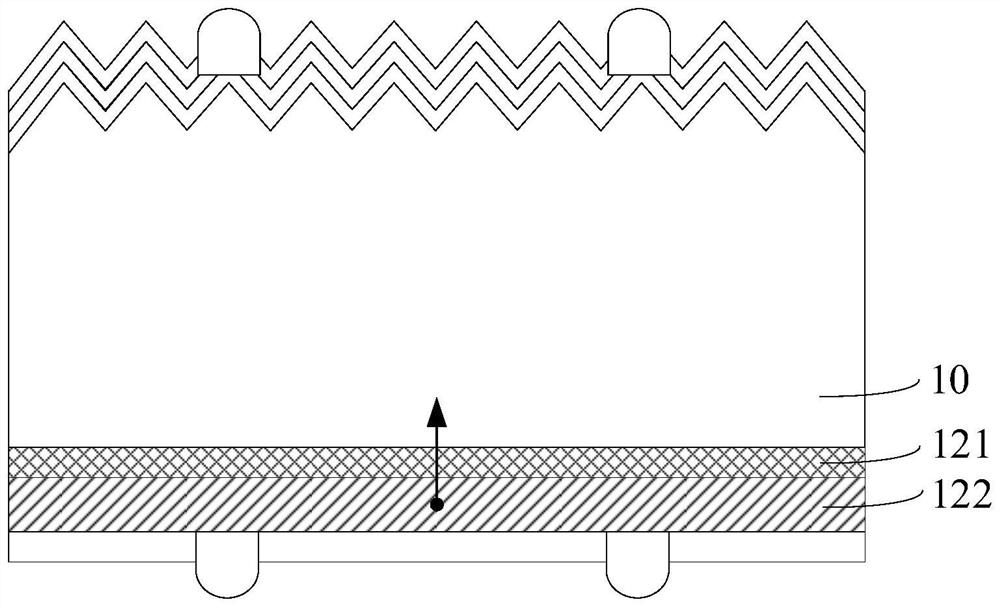

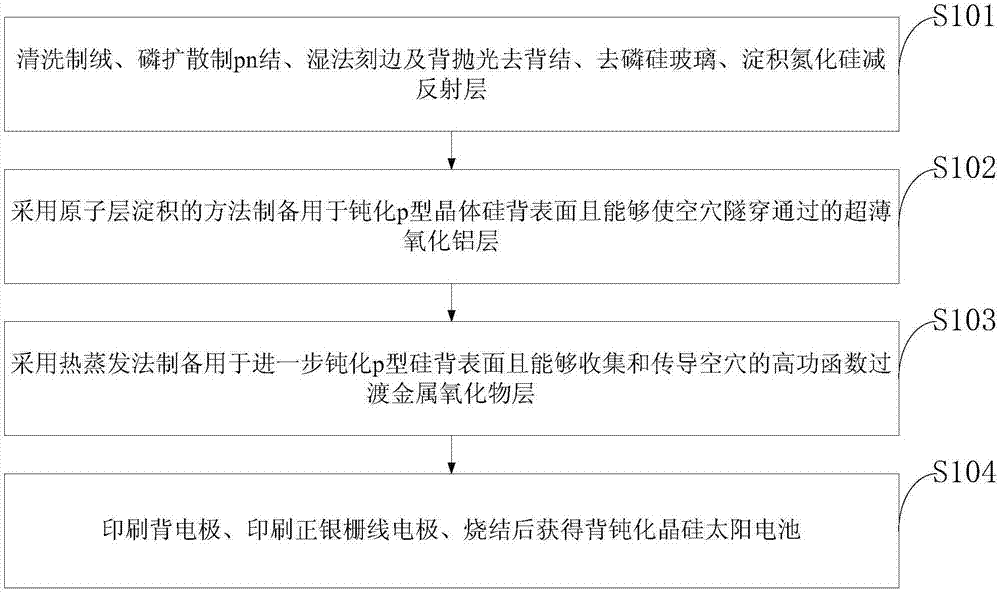

A kind of rear passivation crystalline silicon solar cell and preparation method thereof

InactiveCN106449813BImprove photoelectric conversion efficiencyReduce compound lossFinal product manufacturePhotovoltaic energy generationElectron holeEvaporation

The invention discloses a back passivation crystal silicon solar battery and a preparation method thereof. An ultra-thin aluminum oxide and high-power function transition metal oxide laminated passivation film is formed on the back surface of the solar battery back passivation crystal silicon solar battery, and is arranged between p type crystal silicon and a back electrode; ultra-thin aluminum oxide and high-power function transition metal oxide laminated films are used for passivating and contacting the back surface of the p type crystal silicon. The preparation method comprises the following steps that an atom layer deposition method is used for preparing an ultra-thin aluminum oxide layer; a metal oxide layer is prepared by a heat evaporation method or a plasma enhanced atom layer deposition method. The back passivation crystal silicon solar battery and the preparation method have the advantages that the back surface light loss and the current carrier composite loss can be reduced, so that the photoelectric conversion efficiency of the battery can be improved; meanwhile, the electron hole collection and transmission can be realized through ultra-thin aluminum oxide and high-power function transition metal oxide lamination; the preparation obtianign can be realized only through atom layer deposition and heat evaporation film plating process; the further use of laser hole forming process with high process difficulty and high required equipment cost can be avoided.

Owner:王行柱 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com