Interdigitated back-contact photovoltaic cells with floating front-emitter regions

A technology for photovoltaic cells and emitter regions, which is applied in photovoltaic power generation, circuits, electrical components, etc., and can solve problems such as complex manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

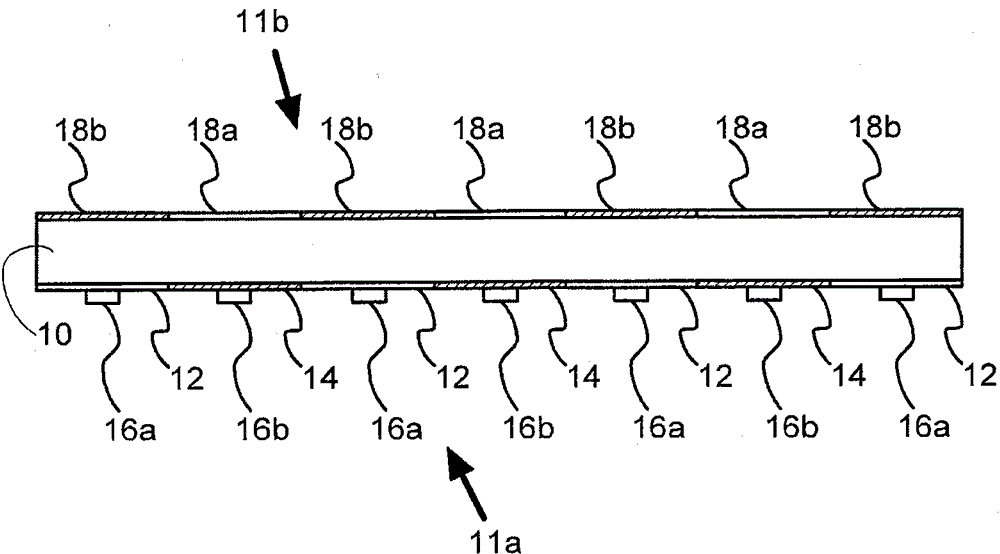

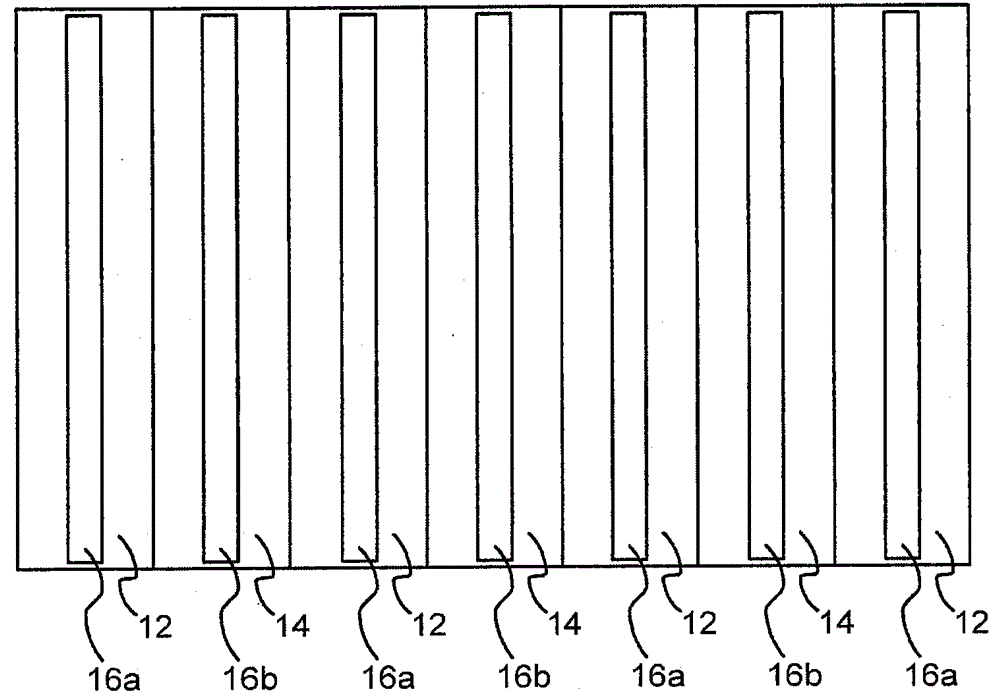

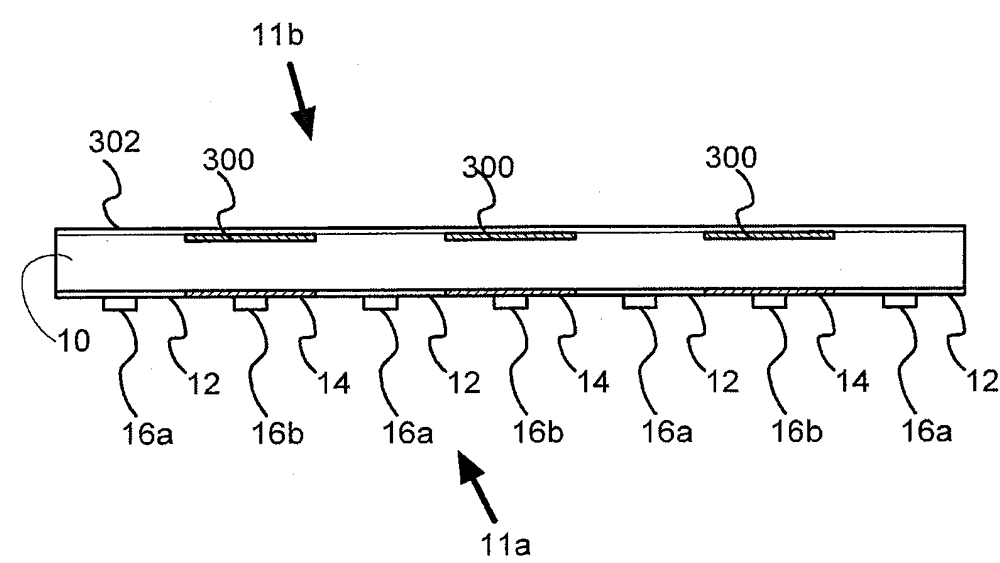

[0019] figure 1 Shown is a schematic cross-section of a photovoltaic cell comprising a semiconductor substrate 10 having a first surface and a second surface 11a, 11b, a base region 12 and an emitter region 14 on the first surface 11a , the first wire and the second wire 16a, 16b on the base region 12 and the emitter region 14 respectively, and other regions 18a, b of opposite conductivity types on the second surface 11b.

[0020] The semiconductor substrate 10 may be made of silicon, for example, silicon doped to have a first conductivity type (n-type or p-type) and have a thickness D in the range of 0.01-1000 microns, and more preferably 1-200 microns, This forms the distance between the first surface 11a and the second surface 11b. The first surface 11a and the second surface 11b of the semiconductor substrate 10 will be referred to as the back and the front, respectively, since the latter will face the sun or other source of light during operation, while the former will f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com